Method for cultivating micro alga and photo-biologic reactor system utilized

A photobioreactor and microalgae technology, applied in photobioreactors, biochemical equipment and methods, biochemical instruments, etc., can solve the problems of medium pollution, increase of cultivation cost, temperature change, etc., and save manpower and material resources , Conducive to adding and exporting, avoiding the effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

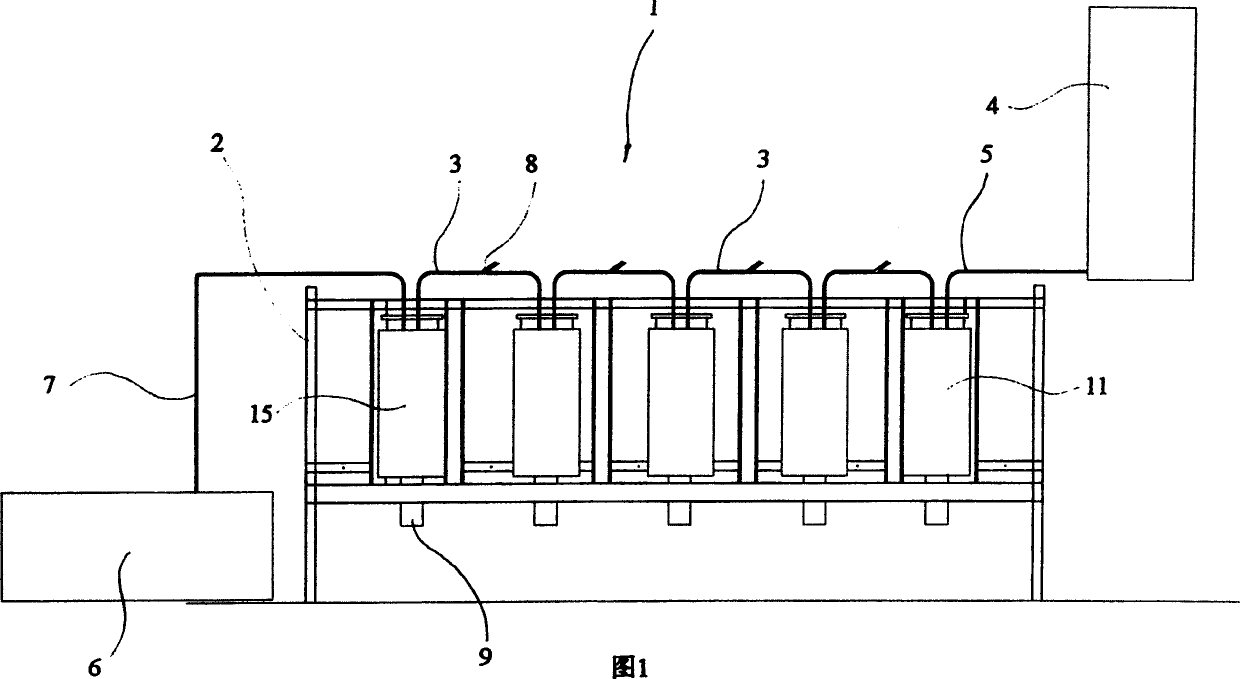

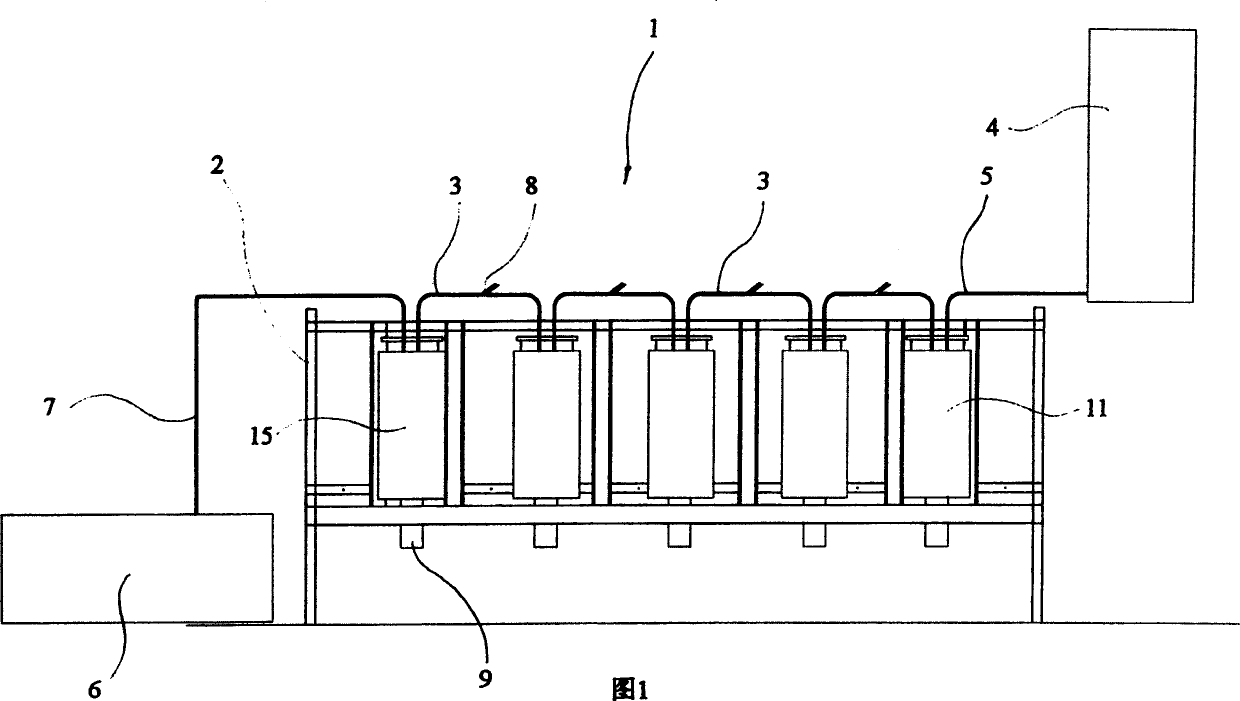

[0024] Embodiment 1: A method for cultivating microalgae is carried out in a five-stage photobioreactor system 1, comprising the following steps: 1. through a high-level water storage container 4 containing a medium and a connection high-level water storage container 4 and the filling guide tube 5 of the first-stage closed photobioreactor 11 adds culture medium to the first-stage closed photobioreactor 11 in a self-flowing manner; 2. in each stage of closed photobioreactor Inflate CO through gas tube 9 2 gas and carry out the circulation culture of the culture medium, ③transfer the culture medium in the closed photobioreactor of the upper level to the closed type photobioreactor of the next level In the photobioreactor, ④ pass through a low-level water storage container 6 and a collection guide pipe 7 connecting the fifth-level closed photobioreactor 15 and the low-level water storage container 6 from the fifth-level closed type in a self-flowing manner. Microalgae products a...

Embodiment 2

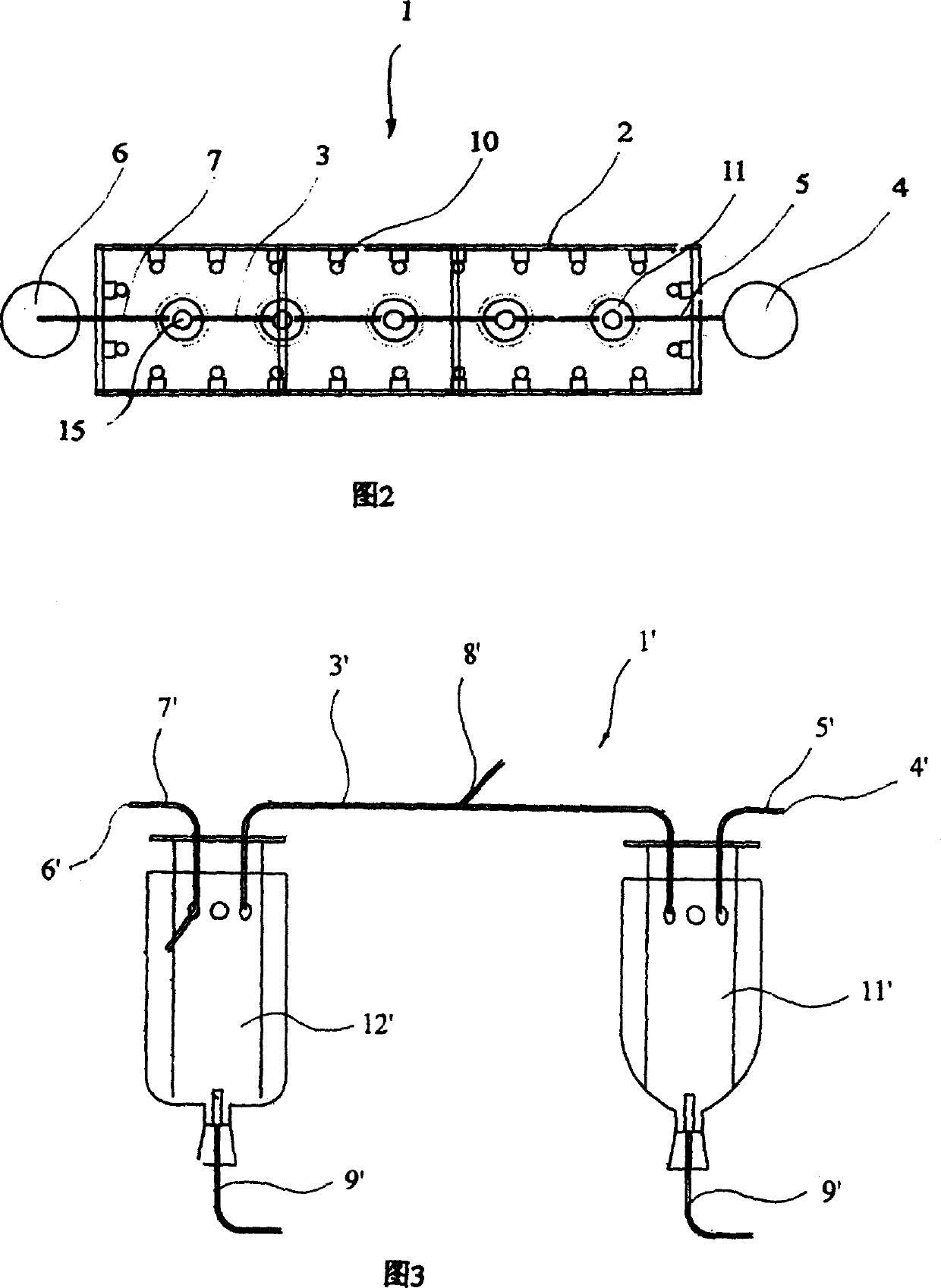

[0028] Embodiment 2: A method for cultivating microalgae is carried out in a secondary photobioreactor system 1', comprising the following steps: ① through a high-level water storage container 4' containing a medium and a connection high-level storage The water container 4' and the filling guide tube 5' of the first-stage closed photobioreactor 11' add culture medium to the first-stage closed photobioreactor 11' in a self-flowing manner; ② at each stage The closed photobioreactor is filled with CO through the gas tube 9' 2 gas and carry out the circulation culture of the culture solution, ③ transport the culture solution in the first-stage closed photobioreactor 11' to the second-stage closed photobioreactor 12' by connecting the guide tube 3', ④ pass A low-level water storage container 6' and a collection guide pipe 7' that connects the second-stage closed photobioreactor 12' and the low-position water storage container 6' flow from the second-stage closed photobioreactor in ...

Embodiment 3

[0029] Embodiment 3: A kind of photobioreactor system is a five-level closed photobioreactor system 1 composed of five closed photobioreactors, five closed photobioreactors are arranged on the support 2, each The closed photobioreactors are connected to each other through the connecting guide tube 3, and a high-level water storage container 4 is connected to the first-stage closed photobioreactor 11 through the filling guide tube 5, and the high-level water storage container 4 is connected to each other through the filling guide tube 5. Injection guide tube 5 delivers culture medium to first-stage closed photobioreactor 11, and a low-level water storage container 6 is connected with fifth-level closed-type photobioreactor 15 through collection guide tube 7, and low-position water storage container 6 Collect the culture product from the fifth stage closed photobioreactor 15 by collecting the draft tube 7; the connecting draft tube 5 is provided with a glass tee 8, and the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com