Patents

Literature

193results about How to "Uniform fineness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

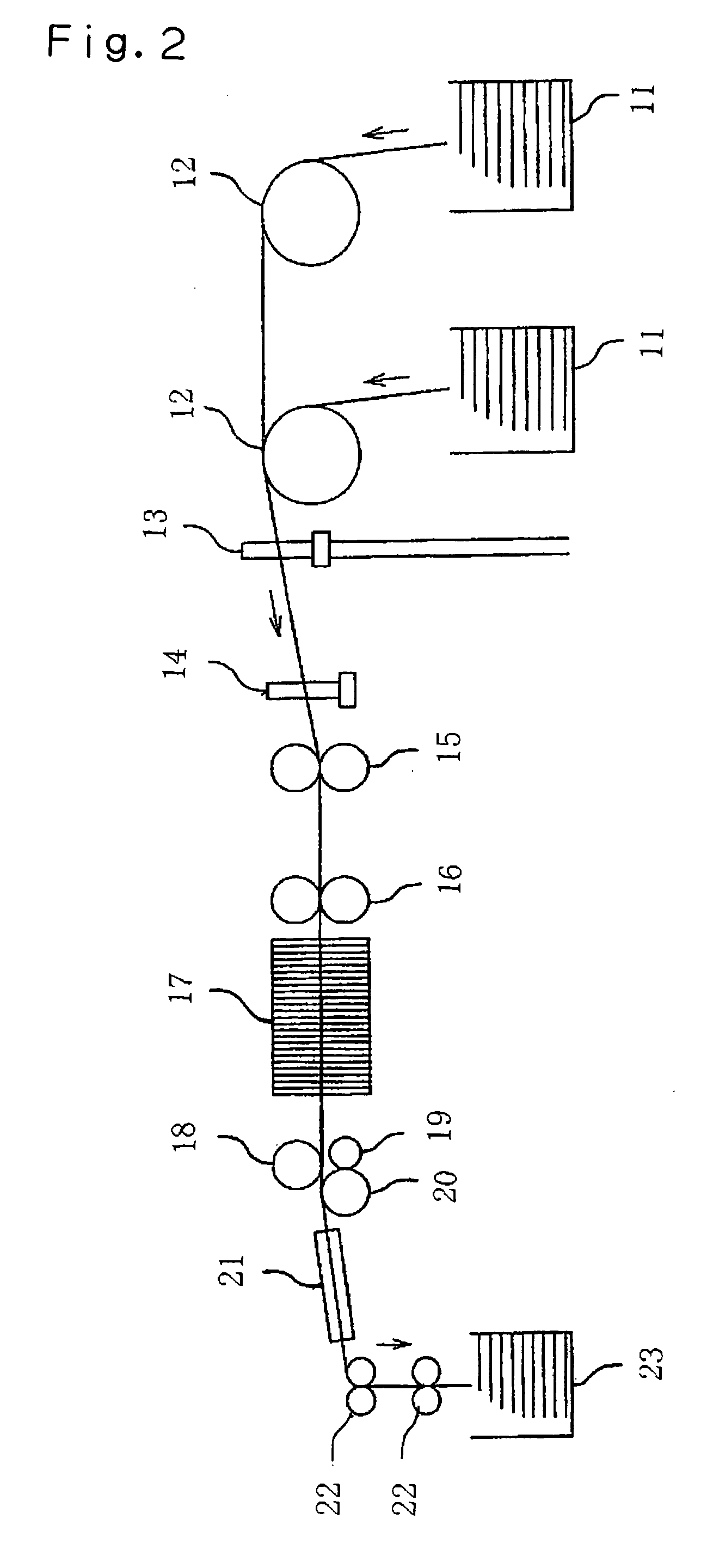

Polytetrafluoroethylene fiber and method for manufacturing the same

ActiveUS7108912B2Small finenessUniform finenessOther chemical processesSynthetic resin layered productsNetwork structureEngineering

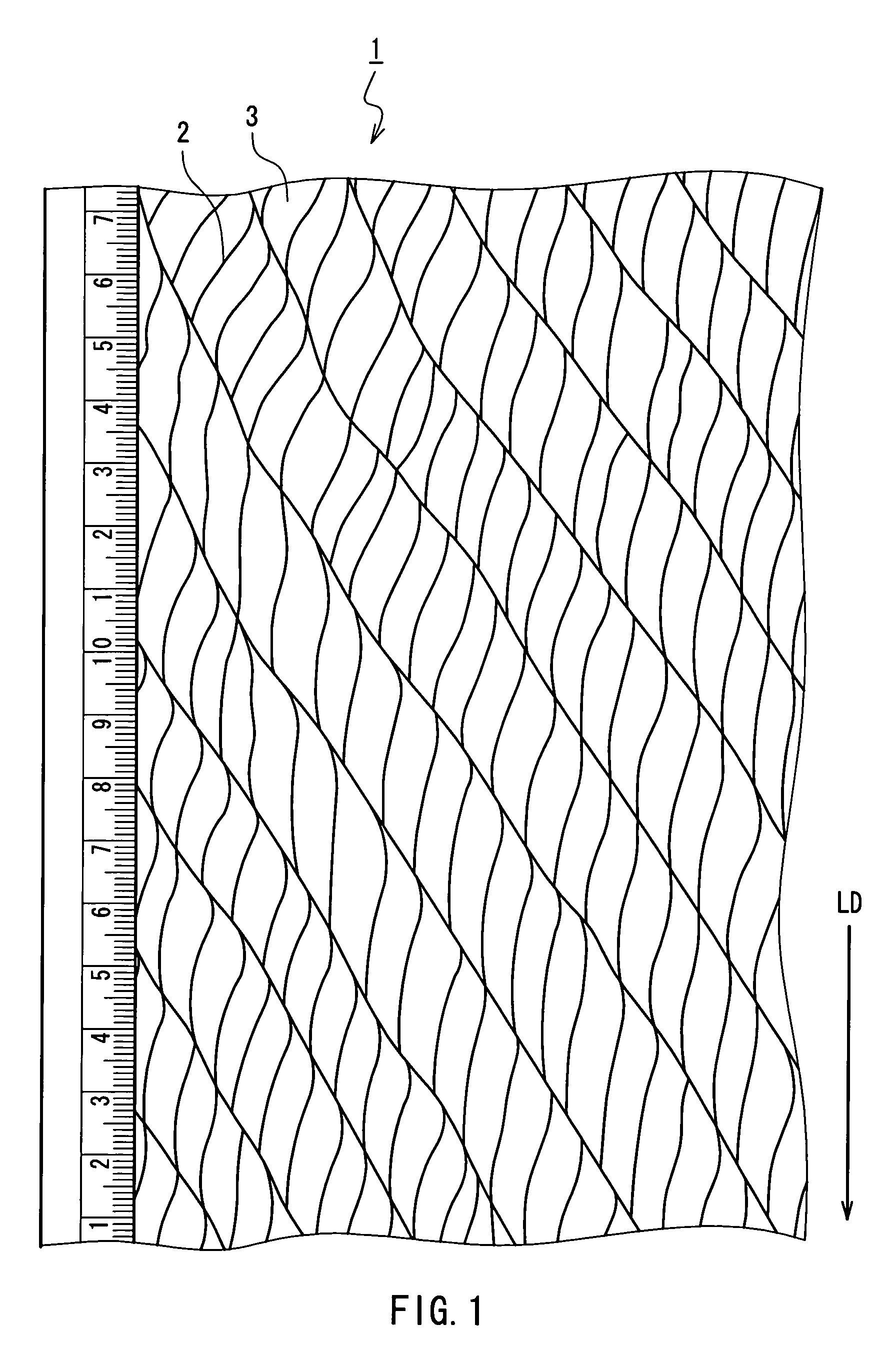

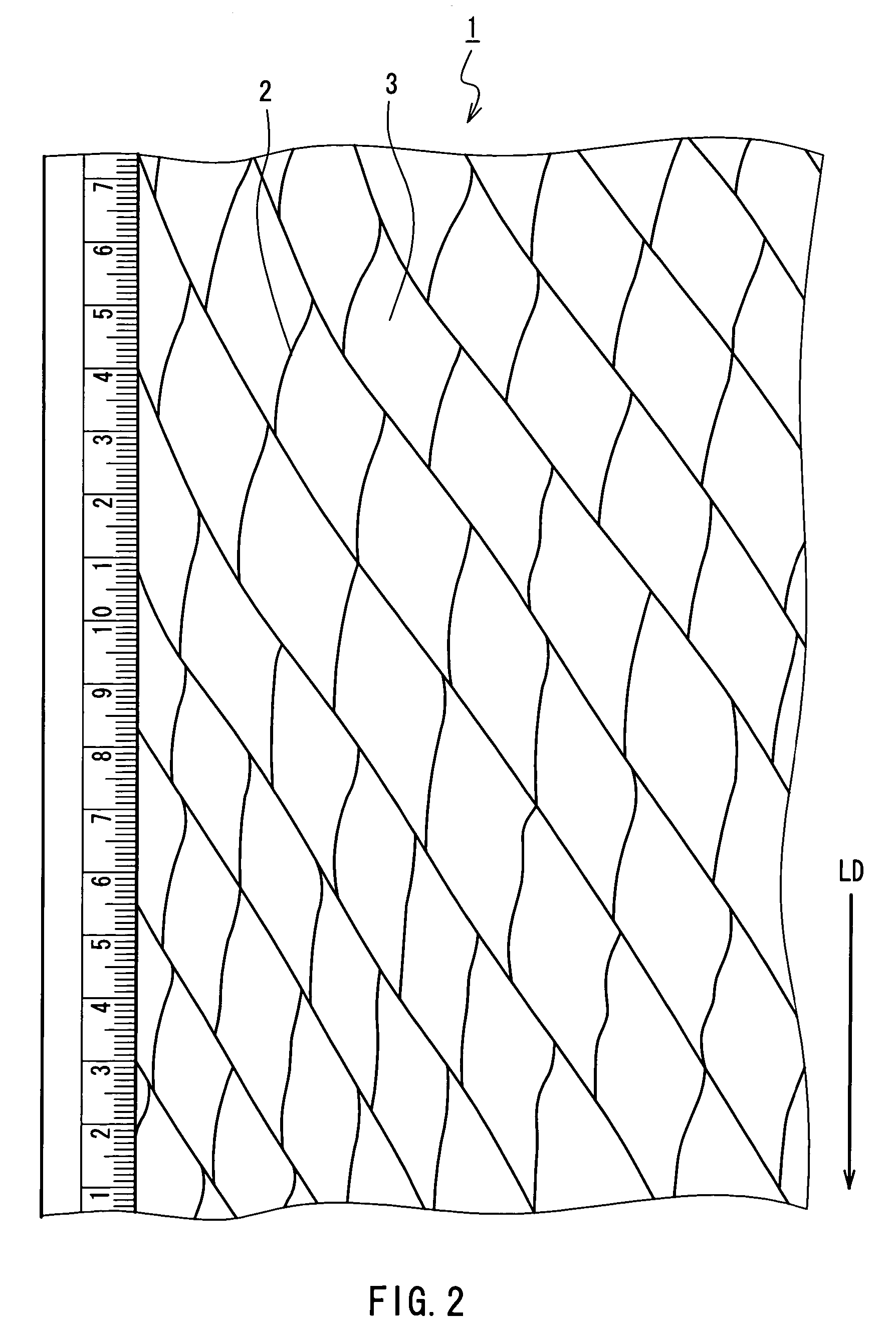

A polytetrafluoroethylene (PTFE) fiber includes a filament obtained by partially slitting an oriented PTFE film in a lengthwise direction of the film. Emboss processing is conducted linearly along the lengthwise direction of the film and like a zigzag shape or a convexo-concave shape in a width direction of the film, followed by slitting, whereby the filament includes a network structure in which single fibrils that are opened partially are arranged regularly. A PTFE short fiber is obtained by cutting the above filament and includes a branch structure. Thereby, a PTFE fiber with a small average fineness of single fibrils, a uniform fineness and a single-peak distribution with the peak at a center of fineness and with a high production yield and uniform and stable branch structure can be provided and a method for manufacturing the PTFE fiber can be provided.

Owner:YEU MING TAI CHEM INDAL

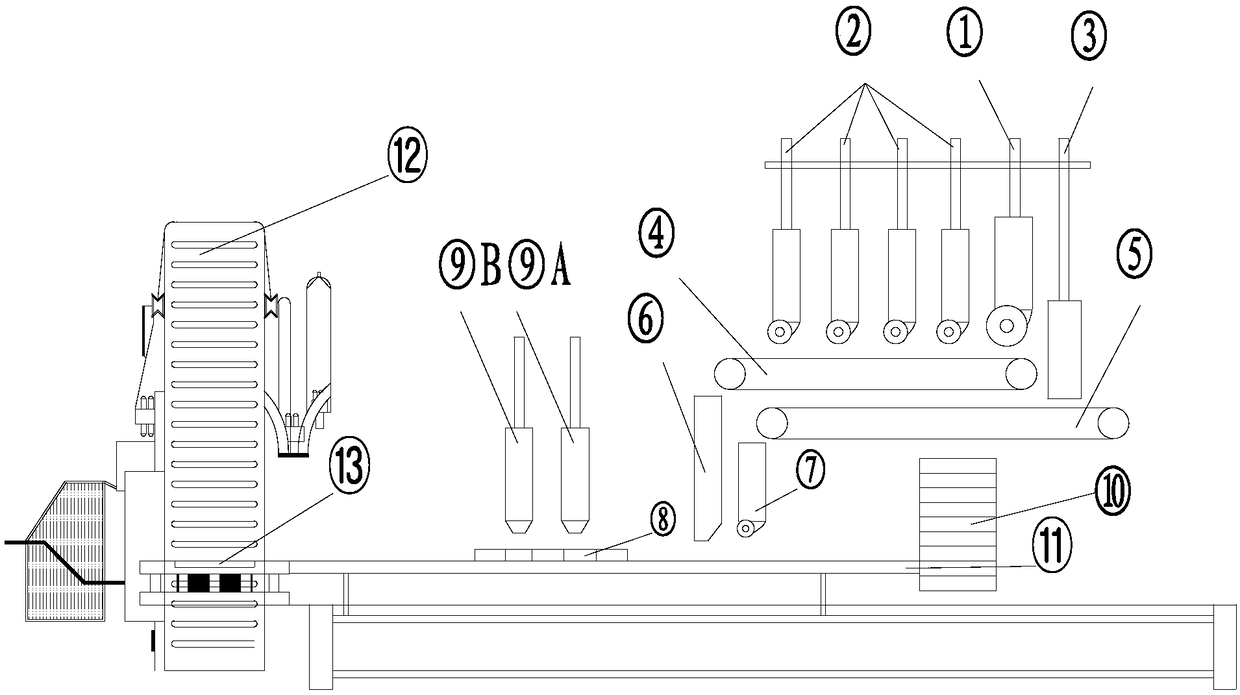

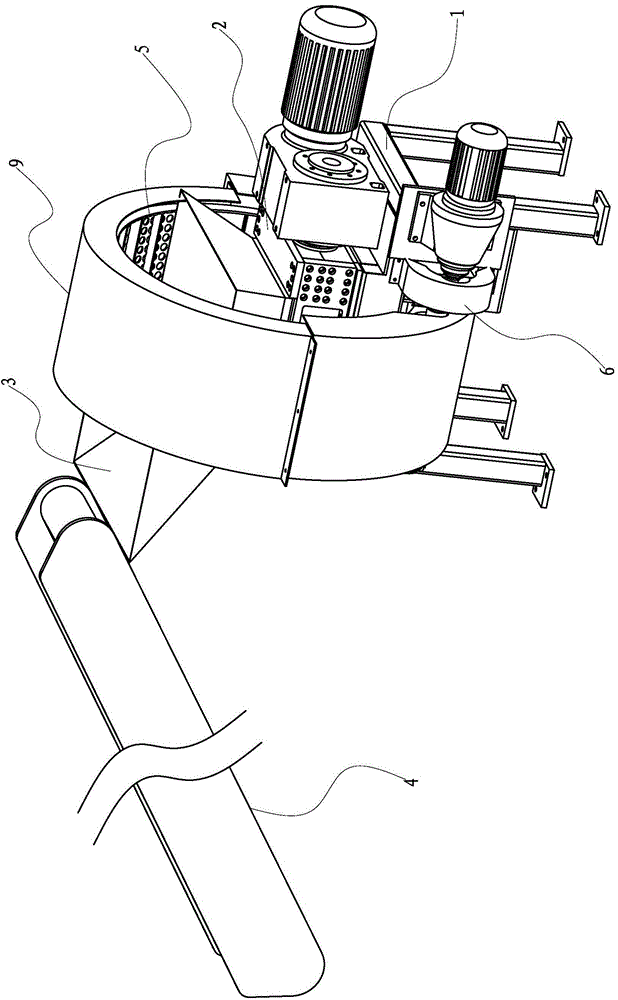

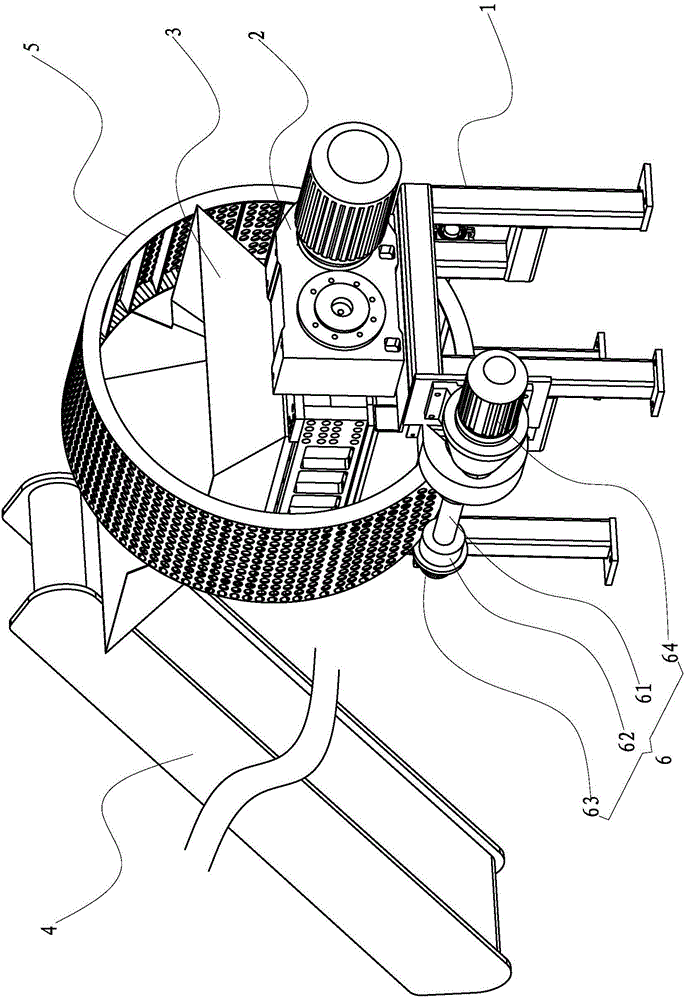

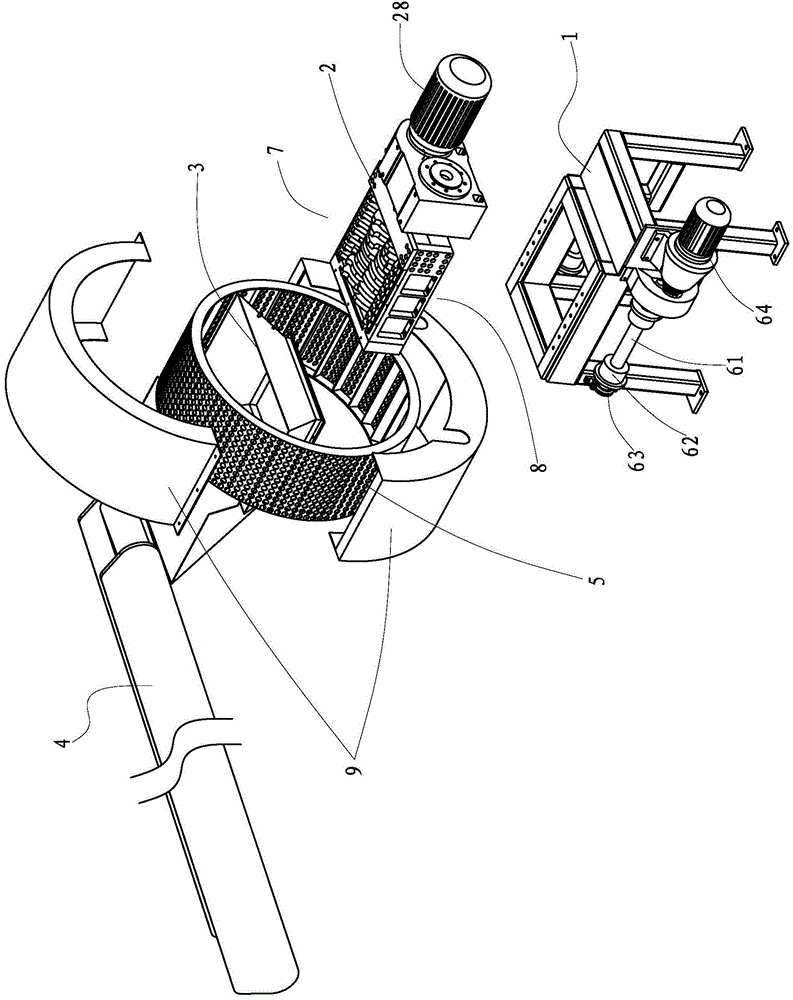

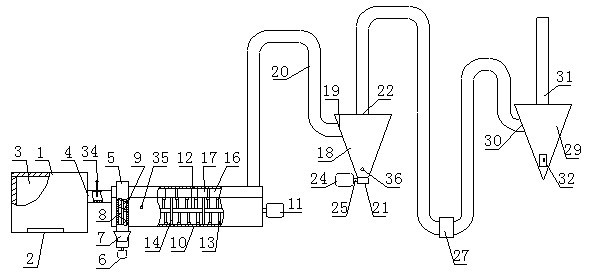

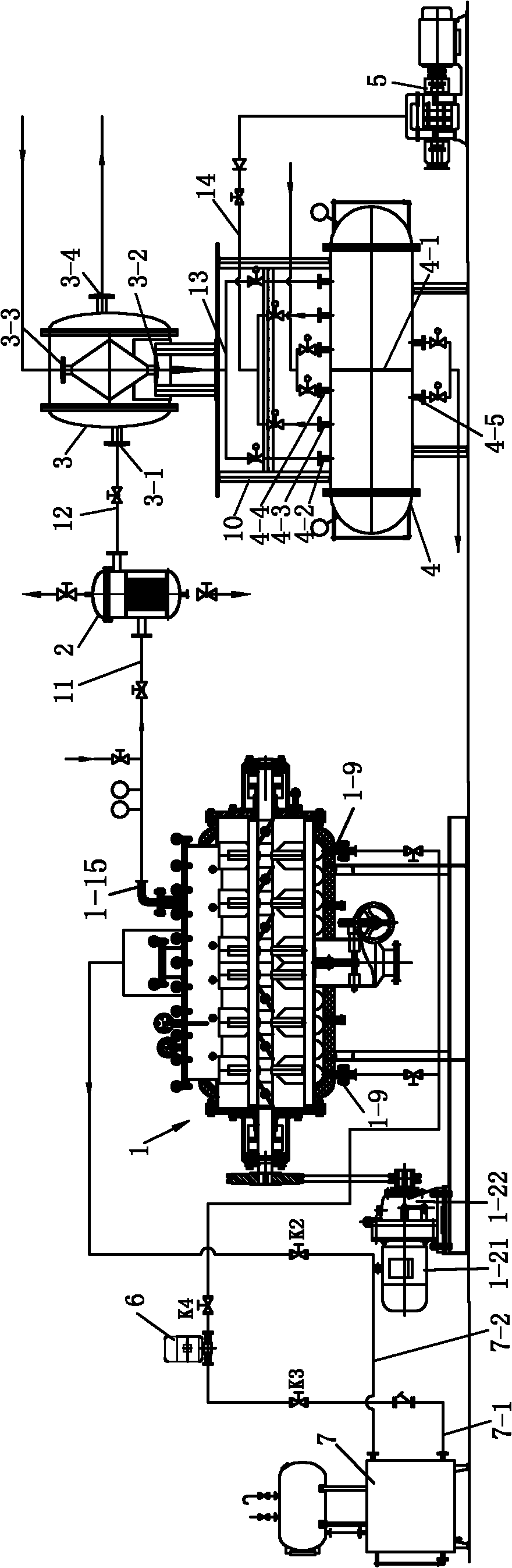

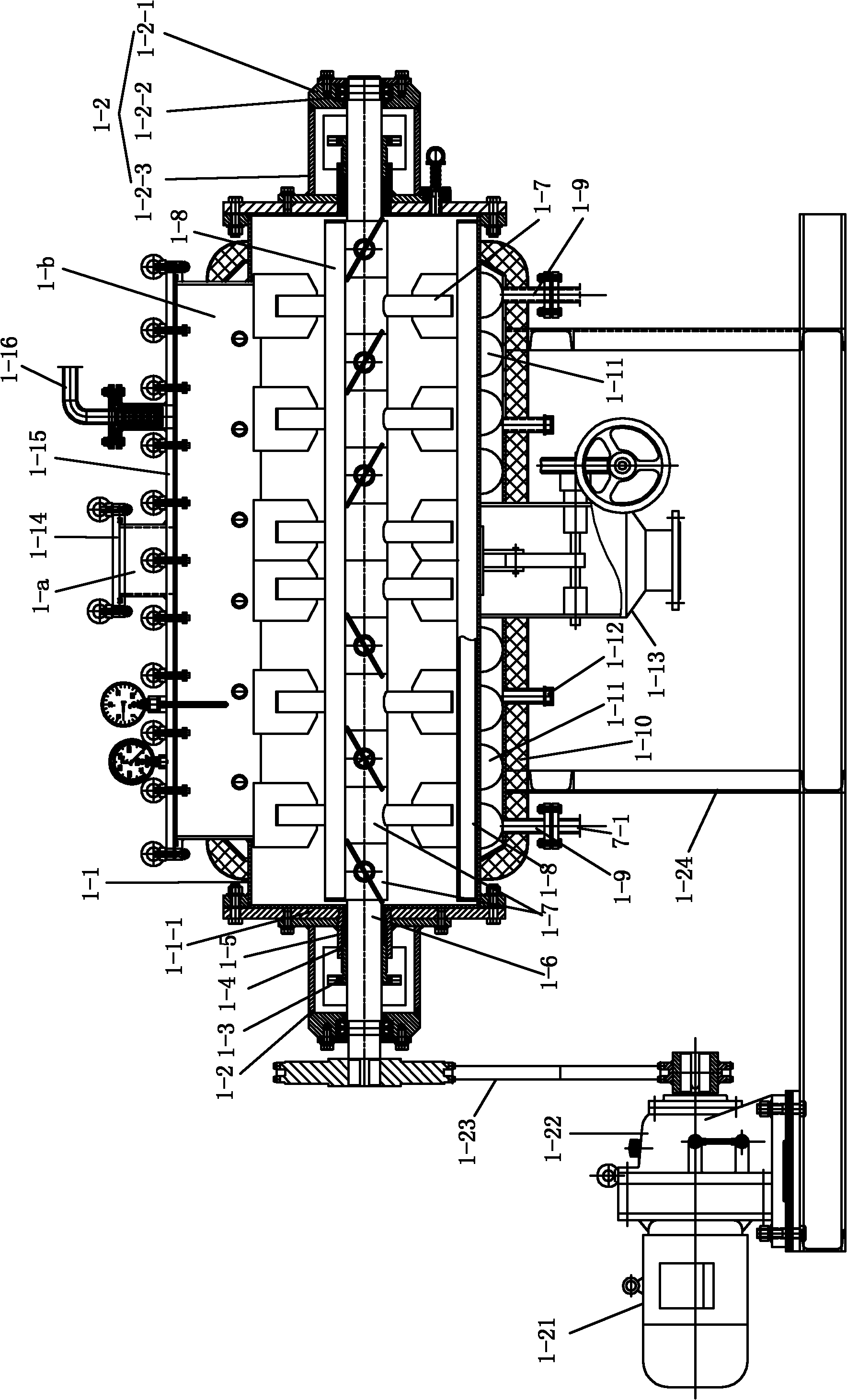

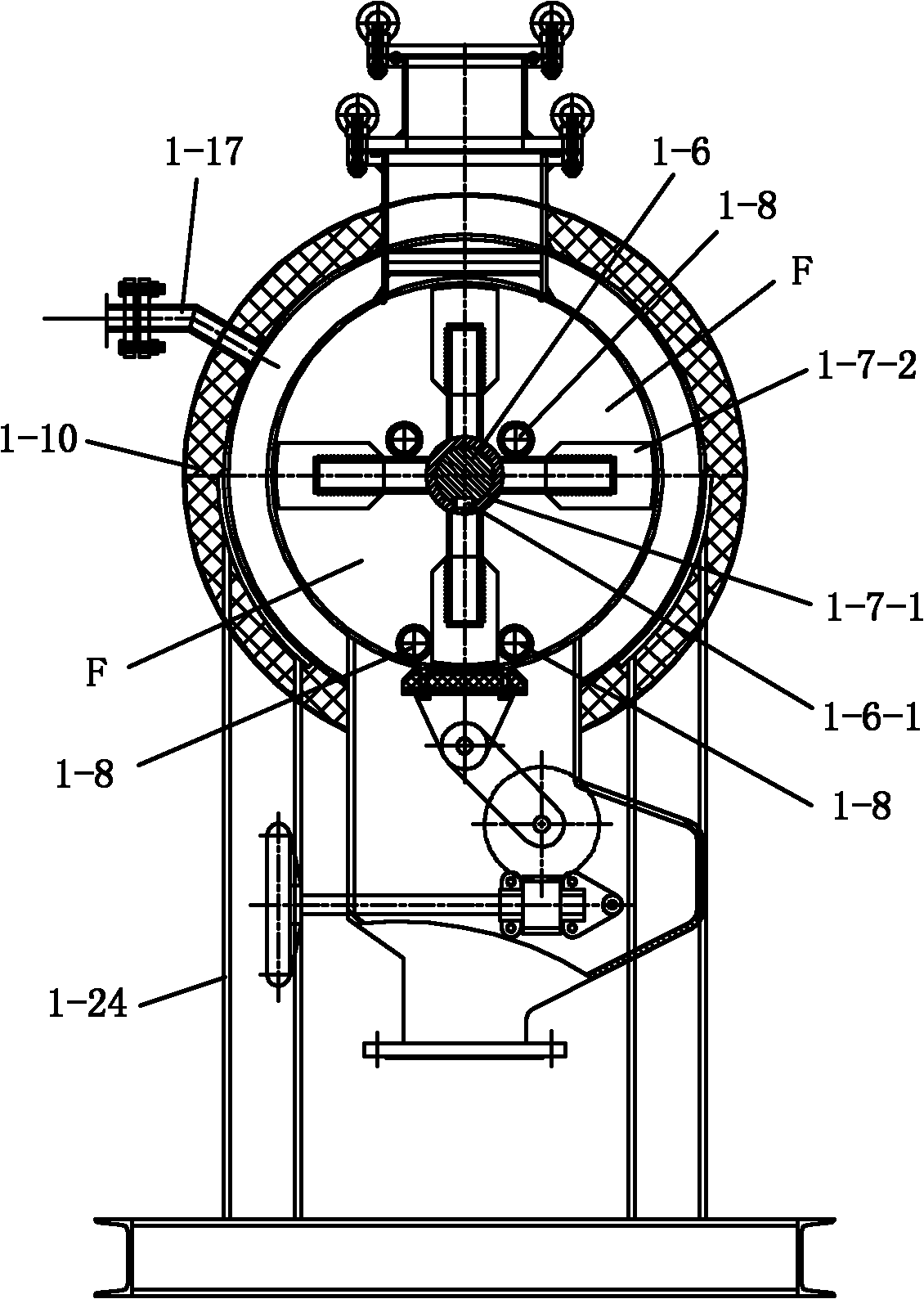

Production equipment for extracting cotton protein from cottonseed meal

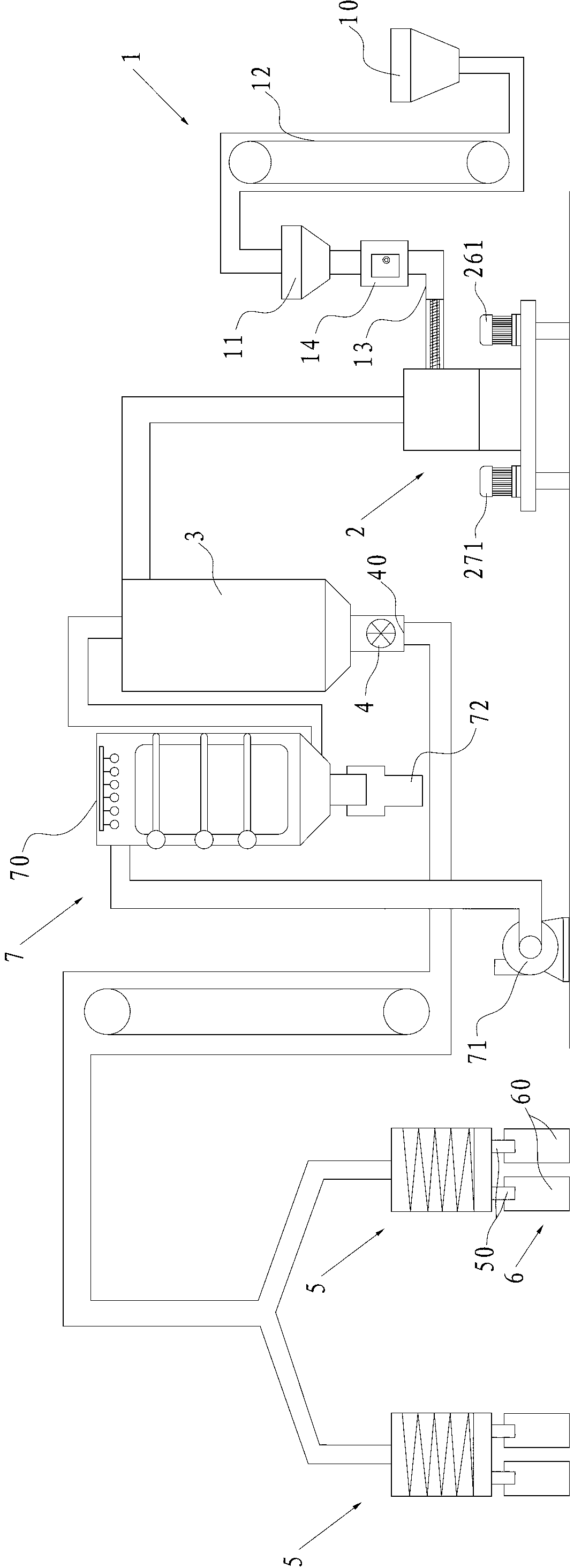

The invention relates to production equipment for extracting cotton protein from cottonseed meal. The production equipment comprises a feeding mechanism, a particle crashing mechanism, a midway feed bin, an airlock, a sieving mechanism and a material receiving mechanism, wherein an air outlet of the airlock is communicated with the sieving mechanism; the particle crashing mechanism is an airflow scroll type crashing mechanism, and is provided with an air inlet chamber, a crashing chamber and a grading chamber which are communicated with each another; and the airflow scroll type crashing mechanism comprises a feeding device communicated with the crashing chamber, a crashing device arranged inside the crashing chamber, a grading device arranged inside the grading chamber, as well as a first driving device and a second driving device which respectively drive the crashing device and the grading device. According to the production equipment, cottonseed meal particles with different sizes can be crashed, and the finenesses of the cottonseed meal particles after being crashed are uniform, so that the phenomenon that the compositions of the cotton protein are damaged is reduced, the working requirement of the sieving mechanism is reduced at the same time, and the equipment cost is saved.

Owner:张家港市华丰油脂有限公司

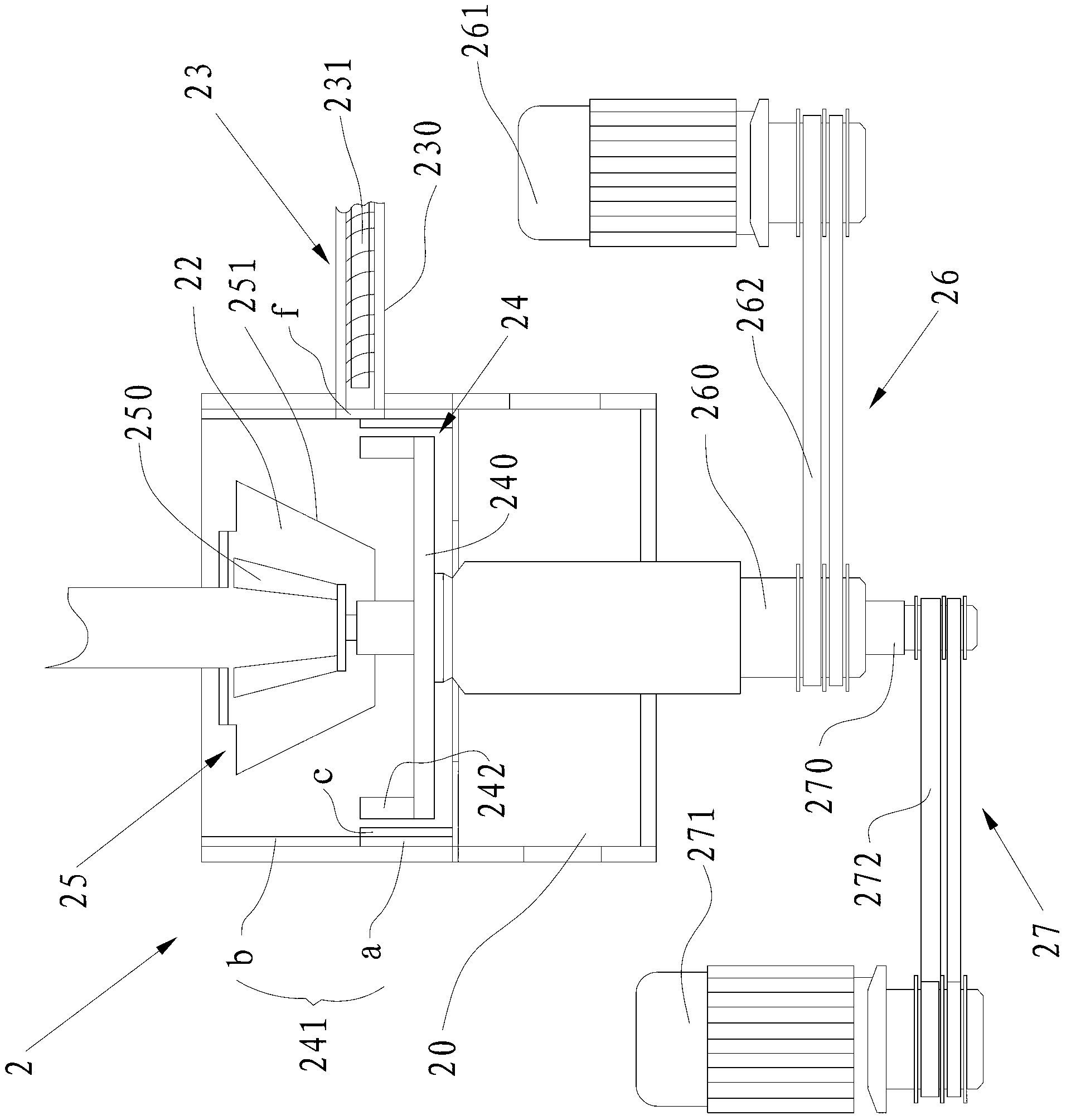

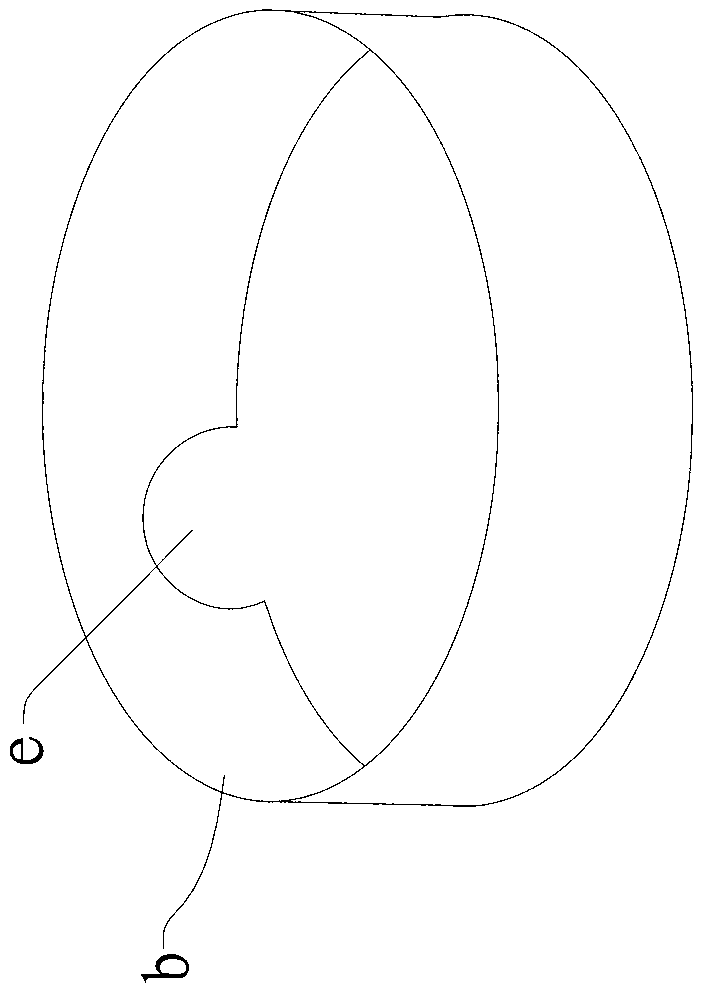

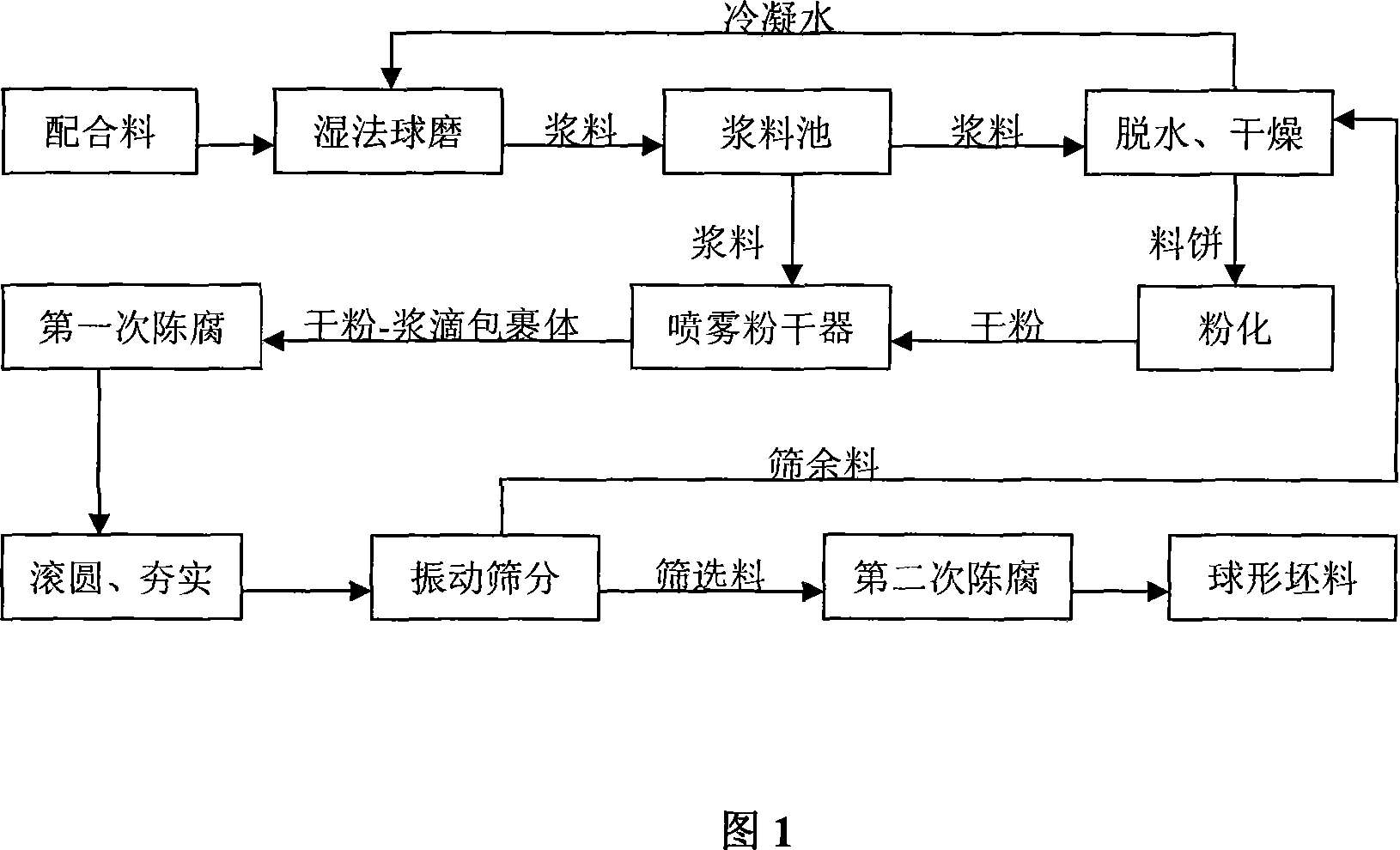

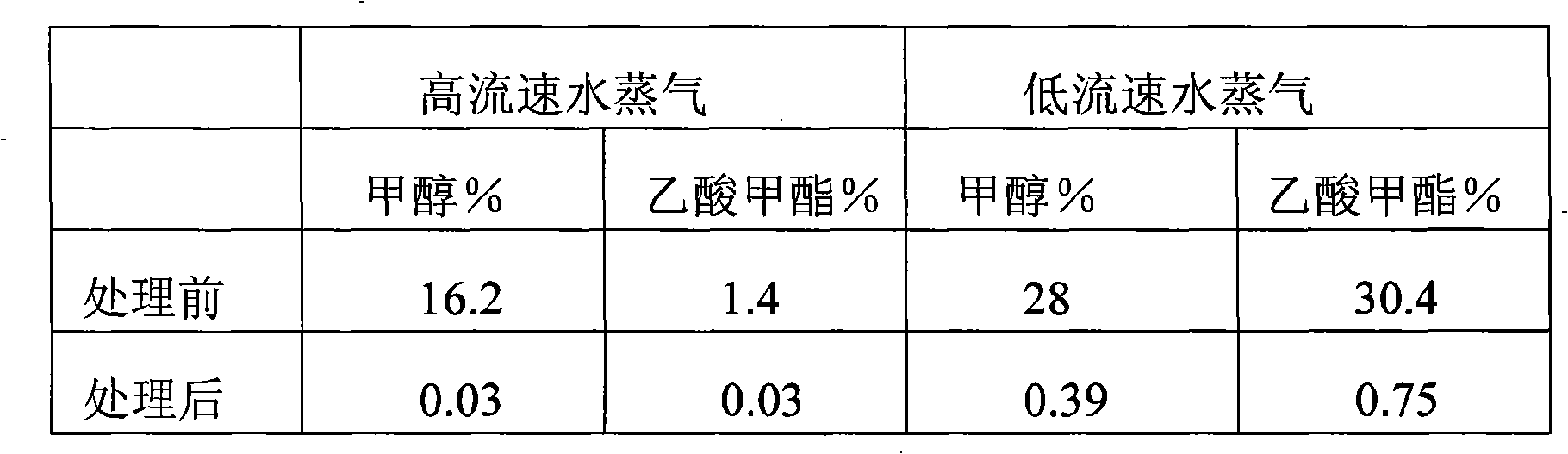

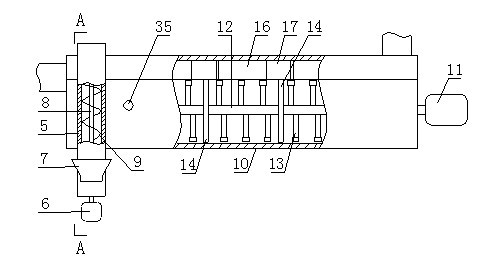

Technology for preparing blank for constructive ceramic with semi-drying method

ActiveCN101121282AReduce energy consumptionHigh energy consumptionClay processing apparatusLight pollutionRegular Production

The present invention relates to a technology for manufacturing the blank of architectural ceramics. The technology is a semi-dry one for manufacturing the blank of architectural ceramics; the technology is characterized in that the technology comprises the following steps: materials batching that materials are quantified according to regular production materials proportion of architectural ceramics and the materials is put into a ball grinder; wet ball grinding; the iron material is sifted out; the dry powder is manufactured: a part of the pulp manufactured through the process (3) is made into dry powder; spraying powder dry grain manufacturing: one share of the pulp made through the process (3) is sprayed into a spraying powder drier to form pulp fogdrop, i.e. wet core; 4 to 7.5 shares of dry powder are sprayed into the spraying powder drier made through the process (4) to form a dispersed distribution state; the wet core contacts and fully absorbs the dispersed dry powder to from grains of dry powder-pulp drop inclusion which is wet inside and dry outside; rolling and solidifying of the grains to form ball blank; vibrating and sifting out; water content is modulated and fossilized to form the blank used for architectural ceramics. The present invention boasts of low energy consumption, light pollution, material evenness and no iron pollution.

Owner:浙江中地大科技有限公司

Superfine ground calcium carbonate powder production method

ActiveCN104845411AImprove grinding efficiencyReduce energy consumptionPigment treatment with macromolecular organic compoundsPigment physical treatmentPowder mixtureGranularity

The invention belongs to the field of nonmetallic mineral processing and specifically relates to a superfine ground calcium carbonate powder production method. The method comprises the following steps: crushing the marble raw material into coarse calcium carbonate having the diameter of less than or equal to 1cm; grinding the coarse calcium carbonate by use of a dry grinding mill to obtain a calcium carbonate powder mixture; performing grading treatment on the calcium carbonate powder mixture to obtain a first-stage powder having the granularity greater than j, a second-stage powder having the granularity within the range of j-k, and the third-stage powder having the granularity less than k, next, returning the first-stage powder to the dry grinding mill for grinding, performing wet grinding on the second-stage powder, directly feeding the third-stage powder to a product homogenization silo for homogenization or wet grinding, wherein k is smaller than j; and after the all wet-ground calcium carbonate slurry is dried and crushed, homogenizing and packaging. The superfine ground calcium carbonate powder production method is capable of effectively saving the energy under the premise of guaranteeing the product quality and the production efficiency.

Owner:SICHUAN SHIMIAN JUFENG POWDER

Preparation method of activated adsorbent and application of prepared activated adsorbent

ActiveCN104587954AImprove adsorption capacityLight weightOther chemical processesWaste water treatment from metallurgical processSorbentStrong acids

The invention relates to the technical field of activated adsorbents and application thereof and in particular relates to a preparation method of an activated adsorbent and application of the prepared activated adsorbent. The preparation method of the activated adsorbent comprises the following steps: 1) carrying out hydrothermal reaction; and 2) carrying out activation treatment. The preparation method of the activated adsorbent has the advantages that diatomite and coal ash are mainly adopted as basic materials, and roasting is carried out, so that the specific area is greatly increased, and the adsorption property is greatly improved; a surfactant is added, so that the adsorption property is further improved; a heavy metal adsorption principle adopts ion exchange, heavy metal can be recycled, the adsorbent can be regenerated, and the activated adsorbent can be widely applied to severe environments such as deeply polluted and strong acid and strong alkali waste water or can be applied to remediation of heavy metal polluted soil; and compared with the prior art, the activated adsorbent has the advantages that the capability of adsorbing heavy metals in electroplating wastewater is greatly improved, the investment is low, the cost is low, copper, chromium and nickel can be recycled, and the adsorbent can be regenerated, so that a huge economic benefit is produced, and a soil remediation effect is also significant.

Owner:INNER MONGOLIA PURUIFEN ENVIRONMENTAL SCI ANDTECH

Purification method of polyvinyl alcohol resin

ActiveCN101357956ALoose structureUniform finenessPharmaceutical non-active ingredientsPurification methodsSolvent

The invention provides a method for purifying polyvinyl alcohol resins. The method comprises the steps as follows: polyvinyl alcohol resins are added to the mixed solvent of ethanol and water and are beaten; ethanol is added so that the polyvinyl alcohol resins are separated out; the polyvinyl alcohol resins separated out are dried. The remaining content in the polyvinyl alcohol resins acquired by using the method meets the requirement of medicinal auxiliary materials.

Owner:TIANJIN BOKELIN MEDICINE PACKAGING TECH

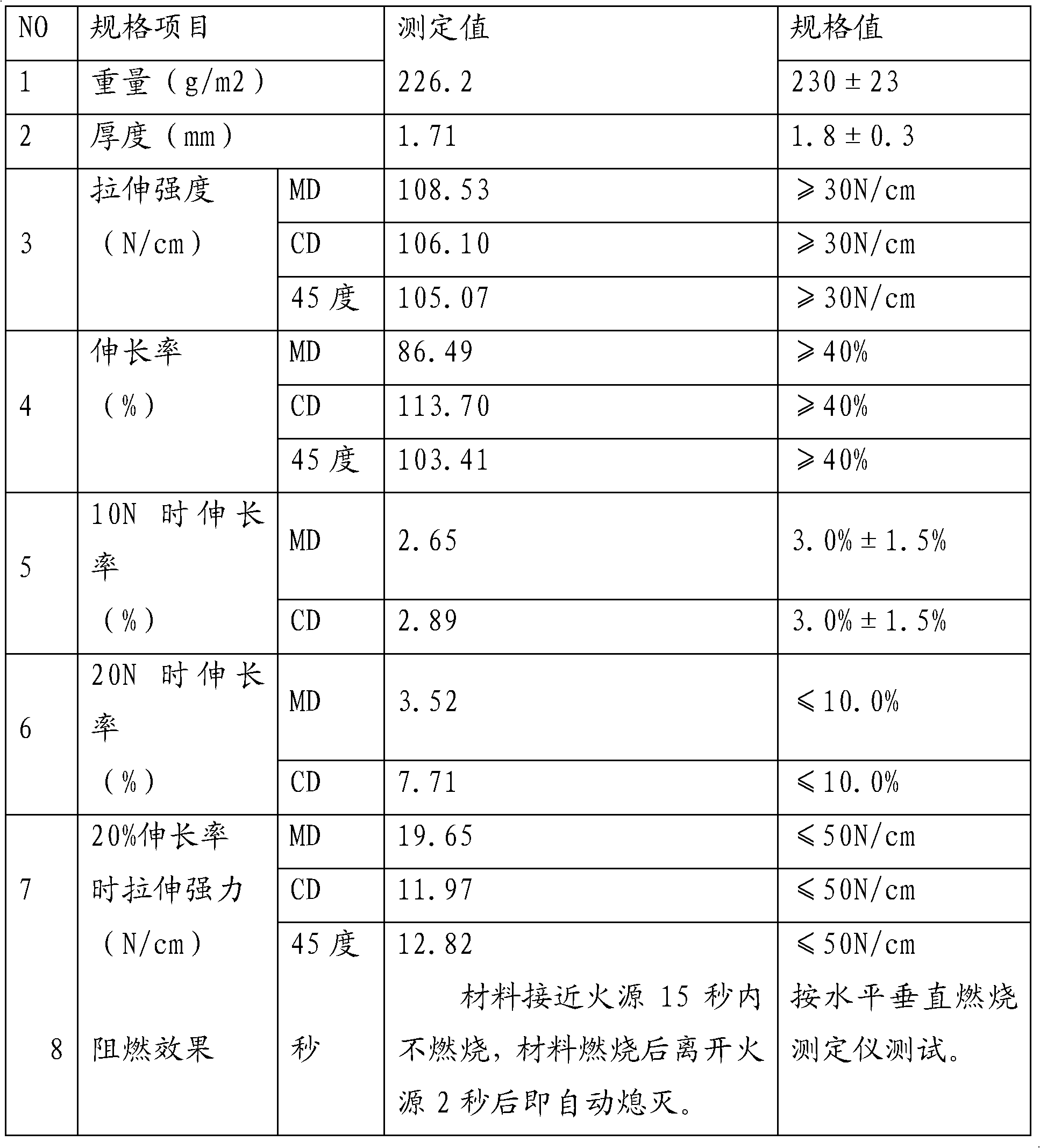

Environmentally friendly differential fiber non-woven automotive interior trim material and preparation method thereof

ActiveCN101851863AImprove spinnabilityAvoid it happening againFibre typesNeedling machinesFoam rubberEngineering

The invention belongs to automotive non-woven textiles, in particular to an environmentally friendly differential fiber non-woven automotive interior trim material and a preparation method thereof. The preparation method comprises the following steps of: preparing needle-punched grey cloth through feeding fibers, roughly opening, mixing fibers, fine opening, carding the fibers into a net, crosswise spreading the net and needling by using environmentally friendly colored flame retardant terylene short fibers as a raw material; and then carrying out foam gum dipping in flame retardant polyacrylate foaming rubber latex to obtain the differential fiber non-woven automotive interior trim material, wherein the adhesion quantity of the rubber latex is controlled to be 12-18g / m<2>. The environmentally friendly differential fiber non-woven automotive interior trim material has good property, high quality, environmental protection and high safety; and the preparation method provided by the invention has low energy consumption, no pollution and low cost.

Owner:福建福能南纺卫生材料有限公司

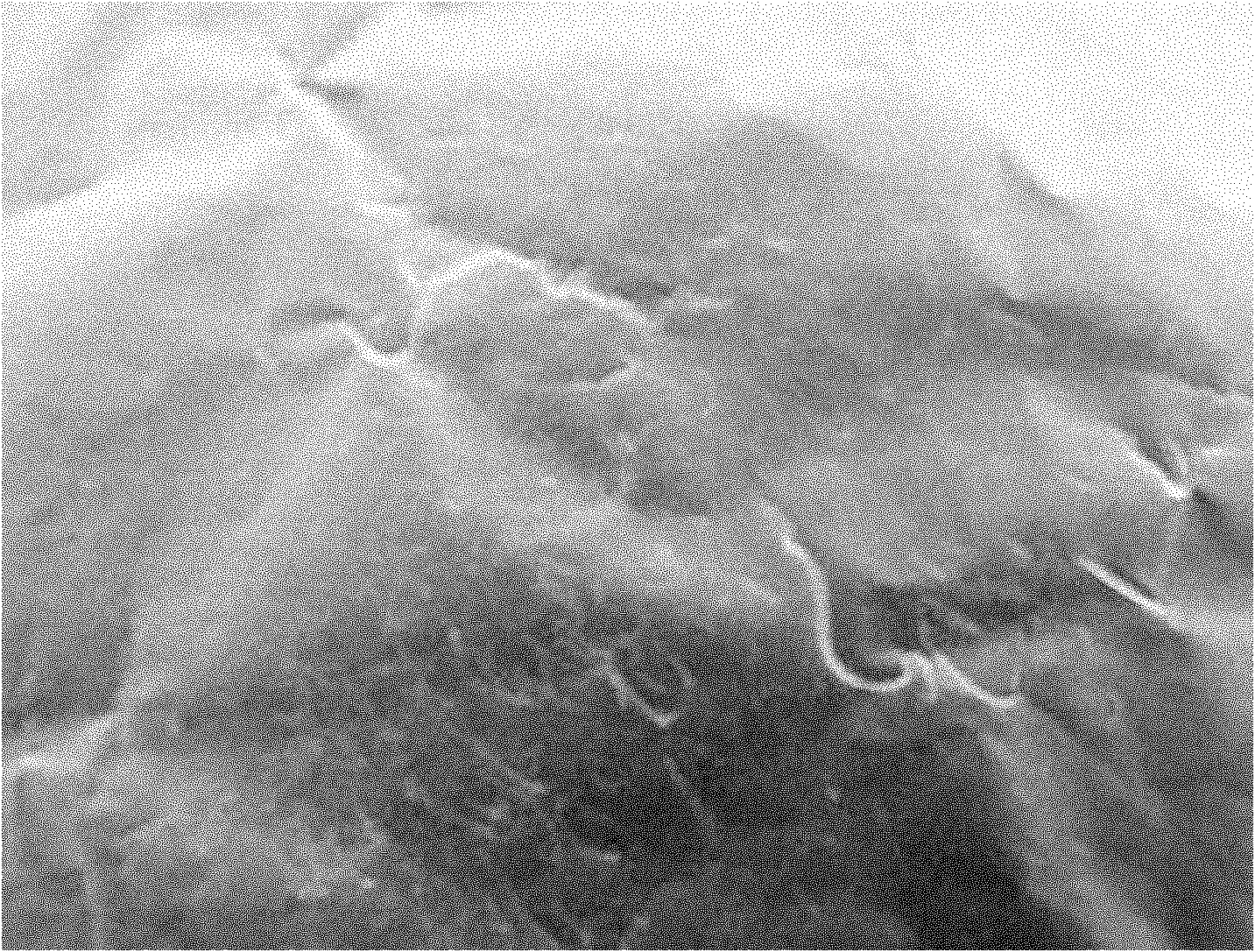

Diacetate electrostatic spinning solution based spinning method

InactiveCN101949068ALarge specific surface areaSmall diameterFilament/thread formingArtificial filaments from cellulose derivativesFiberElectrospinning

The invention relates to a diacetate electrostatic spinning solution based spinning method. The method comprises the following steps: (1) dissolving diaceate CA in acetone and DMAC to obtain diacetate electrostatic spinning solution with concentration of between 4 and 12 weight percent, wherein the volume ratio of the acetone to the DMAC is 1-3:1; and (2) electrostatically spinning the electrostatic spinning solution at voltage of between 10 and 25KV, receiving distance of between 10 and 30cm and solution flowing speed of 3ml / h. The method is used for preparing nano-fibers at normal temperature without heating or pressurizing, so that the production step is simplified, production cost is saved, no pollution is caused to the environment, and a new state of the diacetate is opened for electrostatic spinning technology with excellent market prospect.

Owner:DONGHUA UNIV +1

Ceramic ball mill with discharging classifying screen

InactiveCN104741174AImprove grinding efficiencyUniform finenessSievingScreeningScreening effectUltimate tensile strength

The invention discloses a ceramic ball mill with a discharging classifying screen. The ceramic ball mill comprises a hopper, a roller, a transmission mechanism and the like, wherein a first screening plate, a secondary screening plate, a first oversize material hole, a secondary oversize material hole, a first vibrating arm and a secondary vibrating arm are arranged in a classifying screen device at different heights, the first screening plate is arranged on the first vibrating arm by a connecting thread of the first vibrating arm, and a secondary buffer device is also arranged between the upside of the secondary screening plate and the classifying screen device. A ground material is accelerated to be screened through vibration of the classifying screen device, the fineness uniformity, the screening efficiency and the screening effect of a ground product are improved, the action of a vibrating mechanism on the classifying screen device replaces the manual screening operation, the labor intensity is alleviated, impact force of the vibration on the classifying screen device is alleviated due to a first buffer device and the second buffer device, production equipment cannot be damaged easily, and the service life of the production equipment is prolonged.

Owner:广西北流市红日紫砂陶瓷厂

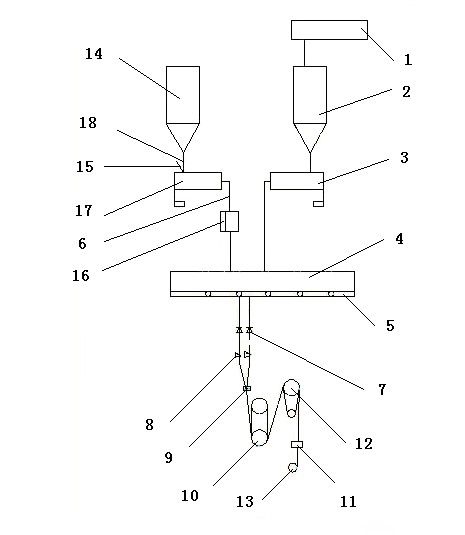

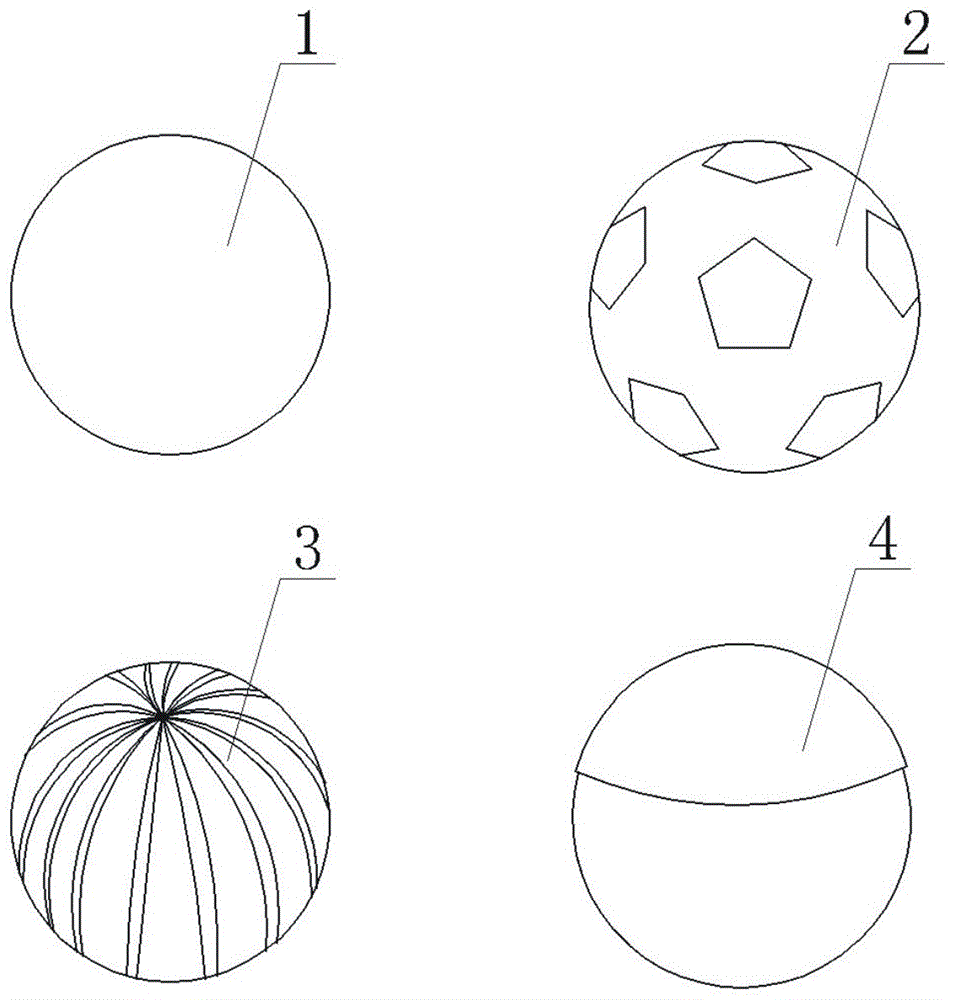

Sea-island fibre and preparation method thereof

ActiveCN102418169AWith memory functionLodging resistanceMelt spinning methodsConjugated synthetic polymer artificial filamentsColour fastnessPolymer science

The invention discloses a sea-island fibre and a preparation method thereof. A PTT (polytrimethylene terephthalate) slice is taken as an island component, a COPET (copolyester) slice is taken as a sea component, the two raw materials are respectively dried, extruded and molten, then the melts are fed into a spinning box and then are extruded out after being accurately metered by a metering pump, the island component is uniformly distributed into the sea component, the island component and the sea component are sprayed out from a same spinneret orifice, then cooling, moulding, oiling, drawing based on a silk guiding roller, winding and silk doubling are carried out to obtain a PTT sea-island fibre, the breaking strength of the fibre is 2.8-3.7cN / dtex, the breaking elongation is 57-62%, and the evenness uster value is less than 1.3%; and the filament number of the island component PTT is 0.05-0.20DPF. The sea-island fibre product not only has the characteristics of a common sea-island fibre but also has the characteristics of high elasticity, lodging resistance, high dyeing degree, high colour fastness, bright finished product colour, no wrinkling, easy care and memory function, thus the sea-island fibre is an ideal fibre used for a top-grade garment material and has great market potential.

Owner:SUZHOU LONGJIE SPECIAL FIBER

White glaze, boundary-free ceramic tile containing white glaze and production method of boundary-free ceramic tile

The invention relates to a white glaze, a boundary-free ceramic tile containing the white glaze and a production method of the boundary-free ceramic tile. The white glaze comprises, by weight percentage, 60-75% of opacifier, 15-28% of opacifying frit and 4-15% of clay. The boundary-free ceramic tile comprises a green body decoration layer, a white glaze layer, a comprehensive decoration layer anda transparent glaze or protecting glaze layer. The production method includes: using a sponge material to polish the surface of a green body; drying, and using a rubber roller to print the surface ofthe green body with the white glaze, and subjecting the white glaze to sintering of 1100-1200 DEG C to obtain the white glaze layer of the boundary-free ceramic tile, wherein the white glaze is weighed according to the formula, 45wt% of printing oil is added, ball milling is performed until the fineness of glaze slurry is smaller than 40 micrometers, the viscosity of the glaze slurry is regulatedto Engler viscosity 18-23 seconds, and glaze slurry proportion is 1.53-1.62.

Owner:JIANGXI HEMEI CERAMICS +3

High-efficiency crushing machine

ActiveCN104624320AUniform finenessMeet the process requirementsGrain treatmentsCrusherLabor operations

The invention discloses a high-efficiency crushing machine. A crushing device is arranged on a rack; a crushing feeding hole and a crushing discharge hole are respectively formed in the upper part and the lower part of the crushing device; a rolling screen which can rotate relative to the rack and is of a cylindrical structure, and a rolling screen driving device for driving the rolling screen to rotate are arranged on the rack; the crushing discharge hole is positioned in the inner side of the rolling screen; crushed garbage falls on the continuously rotating rolling screen through the garbage discharge hole; when the fineness of the crushed garbage meets provided requirements, the garbage can be screened off from the rolling screen, the garbage which does not meet the fineness requirements rotates along with the rolling screen, falls into the crushing feeding hole when rotating to a highest point, and is further crushed. Therefore, the uniform fineness of the garbage screened off from the rolling screen is effectively ensured, the process requirements can be met, and garbage which does not meet the fineness requirements can be automatically crushed for the second time or multiple times, so that the labor operation cost can be lowered, and the crushing efficiency can be improved.

Owner:OMS MASCH CO LTD

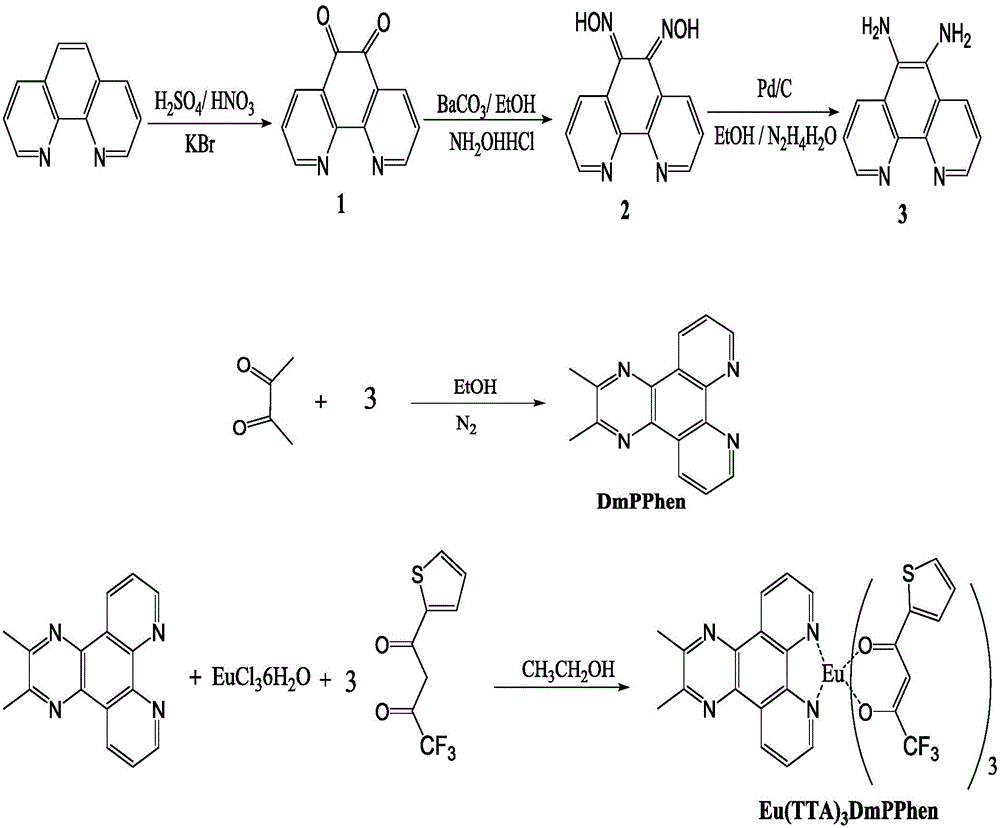

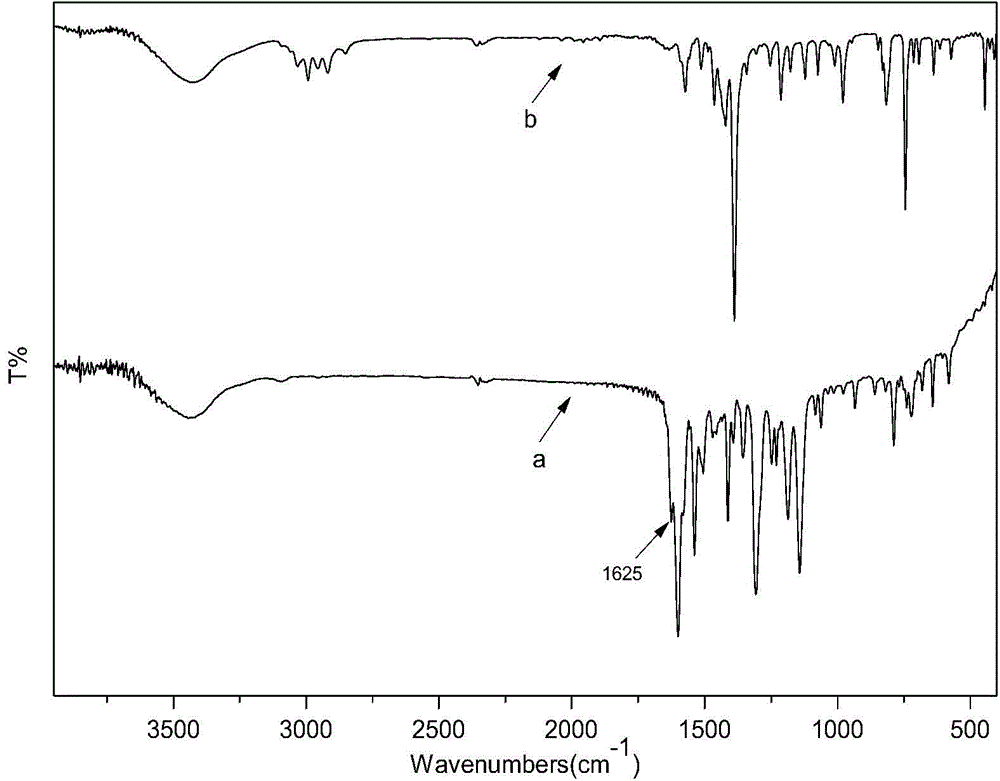

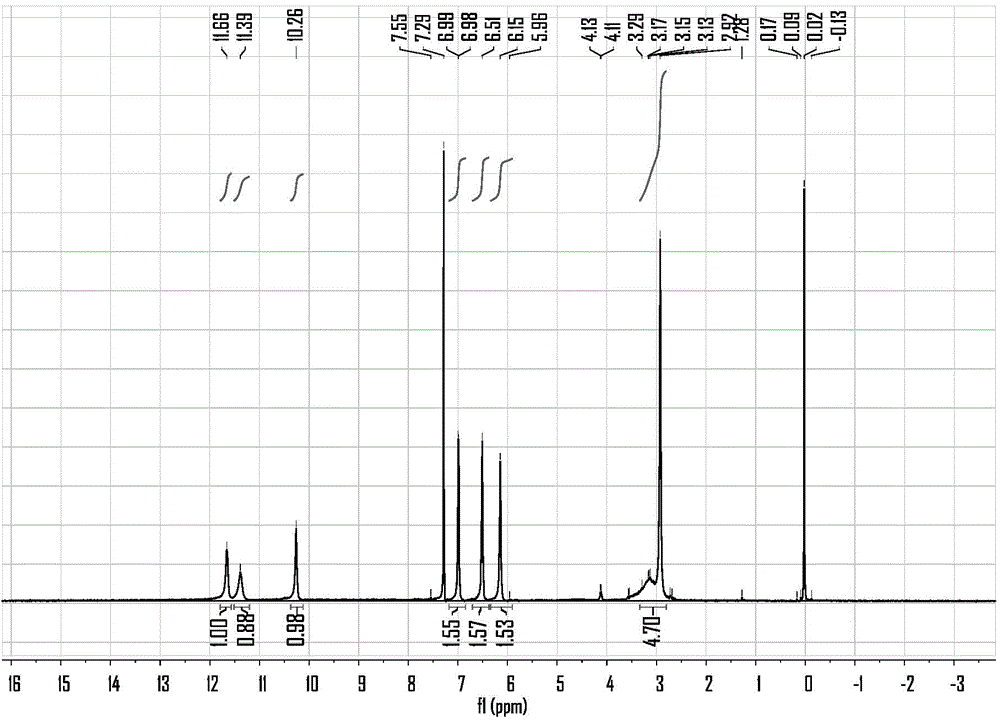

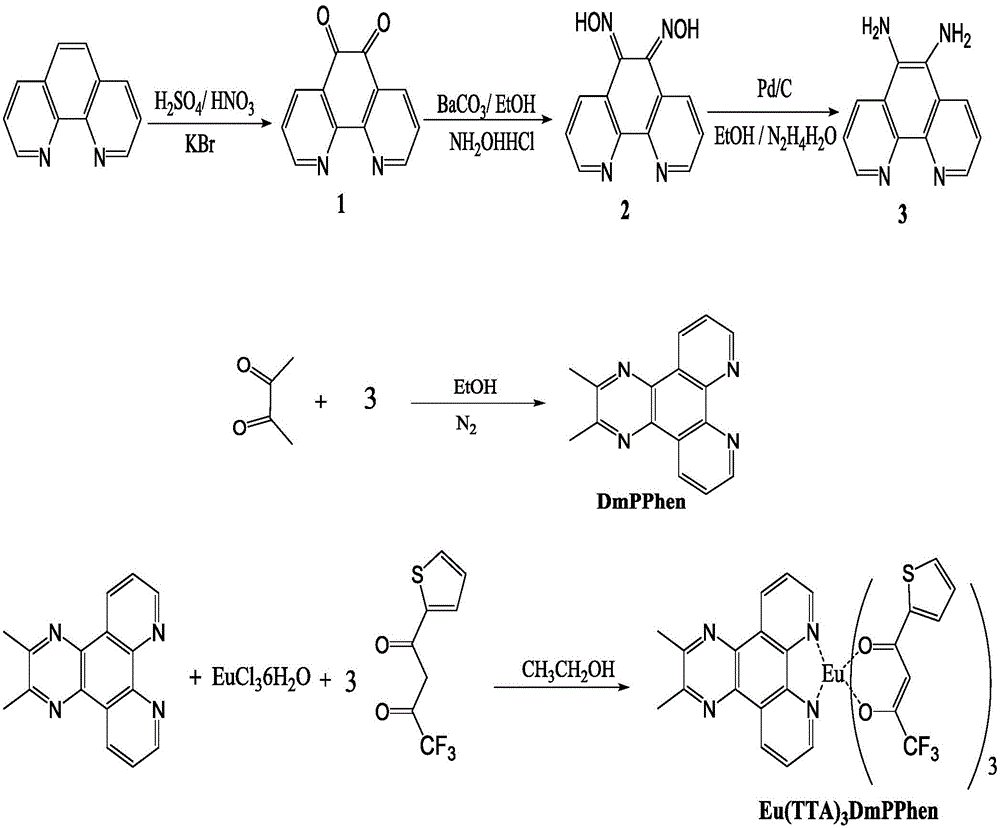

Organic rare earth europium light-emitting dacron and preparation method thereof

ActiveCN104610957AImprove luminous efficiencyHigh luminous intensityGroup 3/13 element organic compoundsLuminescent compositionsPolyethylene terephthalate glycolRare earth

The invention discloses an organic rare earth europium light-emitting dacron and a preparation method thereof. The preparation method comprises the following steps: firstly preparing an o-phenanthroline neutral ligand which is combined with alpha-thenoyltrifluoroacetone and rare earth Eu (III) for coordination and preparing a rare earth europium coordination compound Eu(TTA)3DMPaPhen light-emitting material having a close nanoscale by virtue of an atmospheric titration and high-pressure reaction method. The material emits very strong pure red light in a 10<-5>mol / L CH2Cl2 solution at 615nm. A light-emitting fiber is prepared from the coordination compound as a light-emitting material and polyethylene terephthalate (PET) through composite melt spinning. When the content of the rare earth light-emitting material in the fiber is 0.05%, the rare earth light-emitting material emits very strong pure red light in a 10<-5>mol / L CH2Cl2 solution at a light-emitting position of 615nm. The light-emitting fiber has the advantages of high color purity and good spinnability.

Owner:湖州信倍连网络科技有限公司

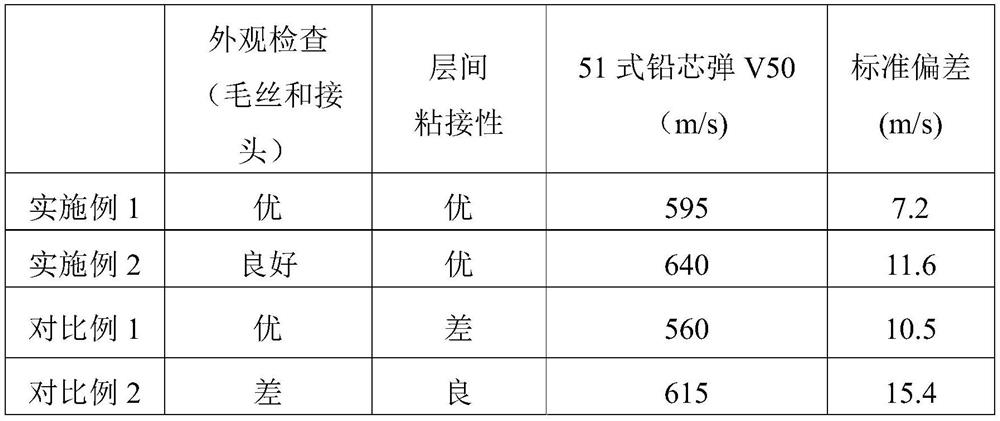

Polyethylene fiber composite cloth with high protection performance and preparation and application thereof

ActiveCN112848569AReduce joint defectsReduce fuzzLamination ancillary operationsProtective equipmentPolymer sciencePolymer chemistry

The invention relates to a polyethylene fiber composite cloth with high protection performance and preparation and application thereof, a preparation method comprises the following steps: 1) high-fineness ultra-high molecular weight polyethylene fibers are sequentially subjected to unwinding and tiling, heating and drafting, gluing and drying to obtain unidirectional polyethylene fiber cloth; (2) carrying out cross lamination and compounding on multiple layers of unidirectional polyethylene fiber cloth, rolling together with an isolating layer, and then carrying out vacuum hot-pressing shaping treatment, so as to obtain polyethylene fiber composite cloth; wherein the activation temperature of the glue is 50-150 DEG C, and the glue content is 5-30wt%; and the polyethylene fiber composite cloth is used in a soft bulletproof armor or a hard bulletproof armor. Compared with the prior art, the preparation method has the advantages that conventional high-denier monofilament and bunched ultra-high molecular weight polyethylene fibers are adopted, heating and drafting are carried out after unwinding and tiling, the activation temperature and the gluing amount of glue are controlled, and vacuum hot-pressing shaping treatment is carried out after compounding, so that the prepared polyethylene fiber composite cloth is good in appearance quality, high in bulletproof performance and small in discreteness.

Owner:SHANGHAI RES INST OF CHEM IND

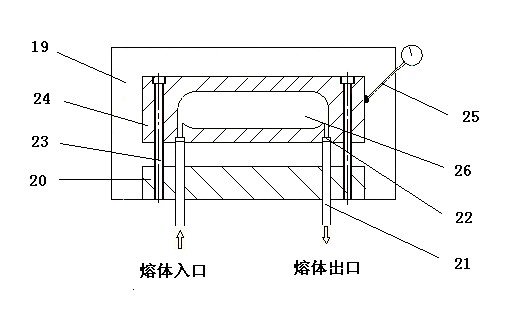

Water cooling method in polyester fiber melt-spinning

InactiveCN1544719AReduced skin-core structureUniform finenessFilament/thread formingPolyesterEngineering

The invention relates to a water cooling method in polyester fiber melt spinning, additionally installing spray generator at the air intake of the original side blower or around the spinning window, and able to generate water spray, water foam, and water bubble or water film according to the needs; the melt streamlet extruded from spinning components passes through swelling area into deformation area, then blows the water spray, water foam, and water bubble or water film in the spinning window by a breeze at a speed of 0.05-0.1 m / s to make them fill up the whole window to cool threads, and after heat exchange, the produced water drops and surplus water are collected by water collector. Its advantage: accelerating cooling, reducing skin-core structure of threads and avoiding swing of threads caused by wind cooling. It makes fiber size uniform, breaking tenacity high and product quality good.

Owner:黄忠

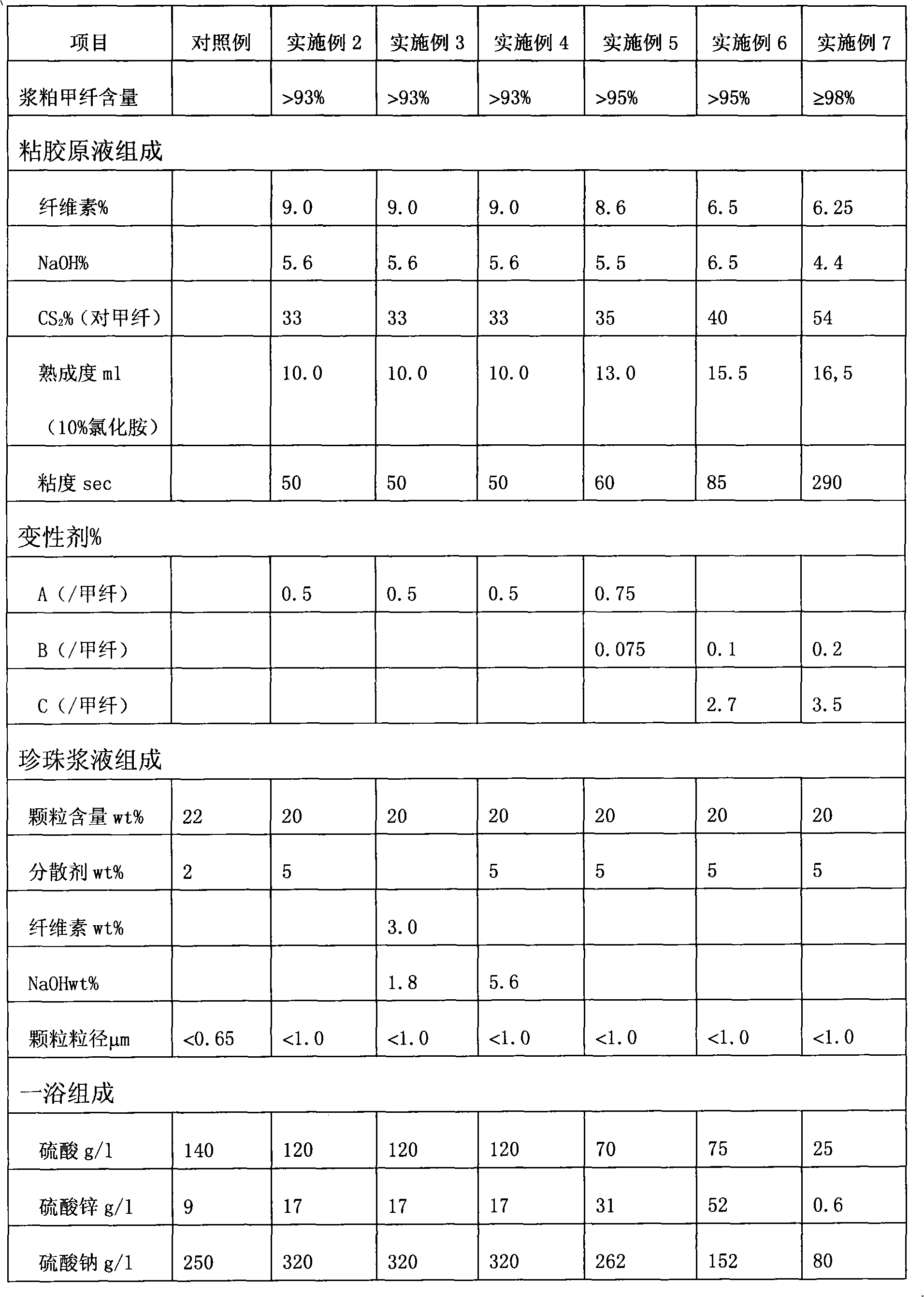

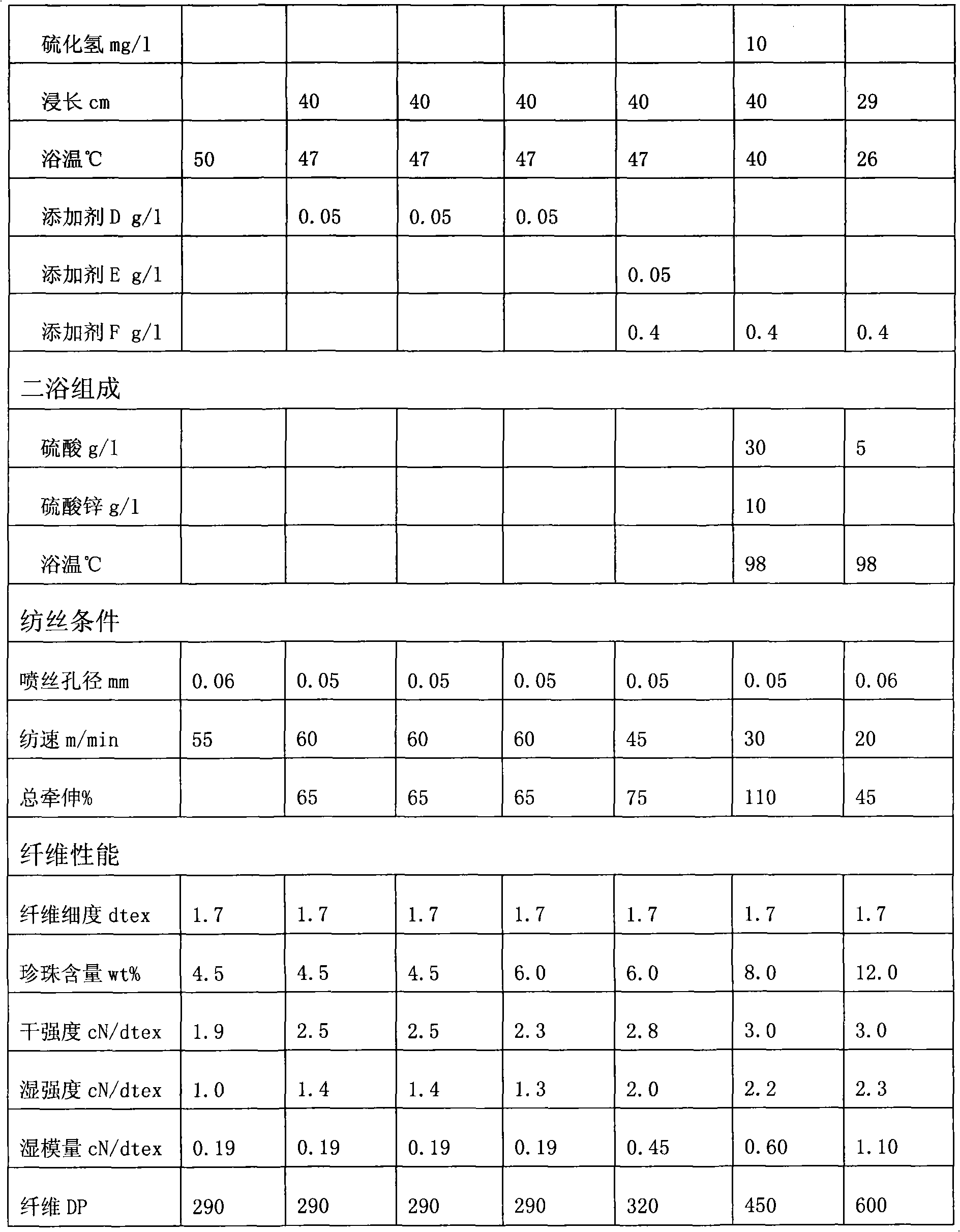

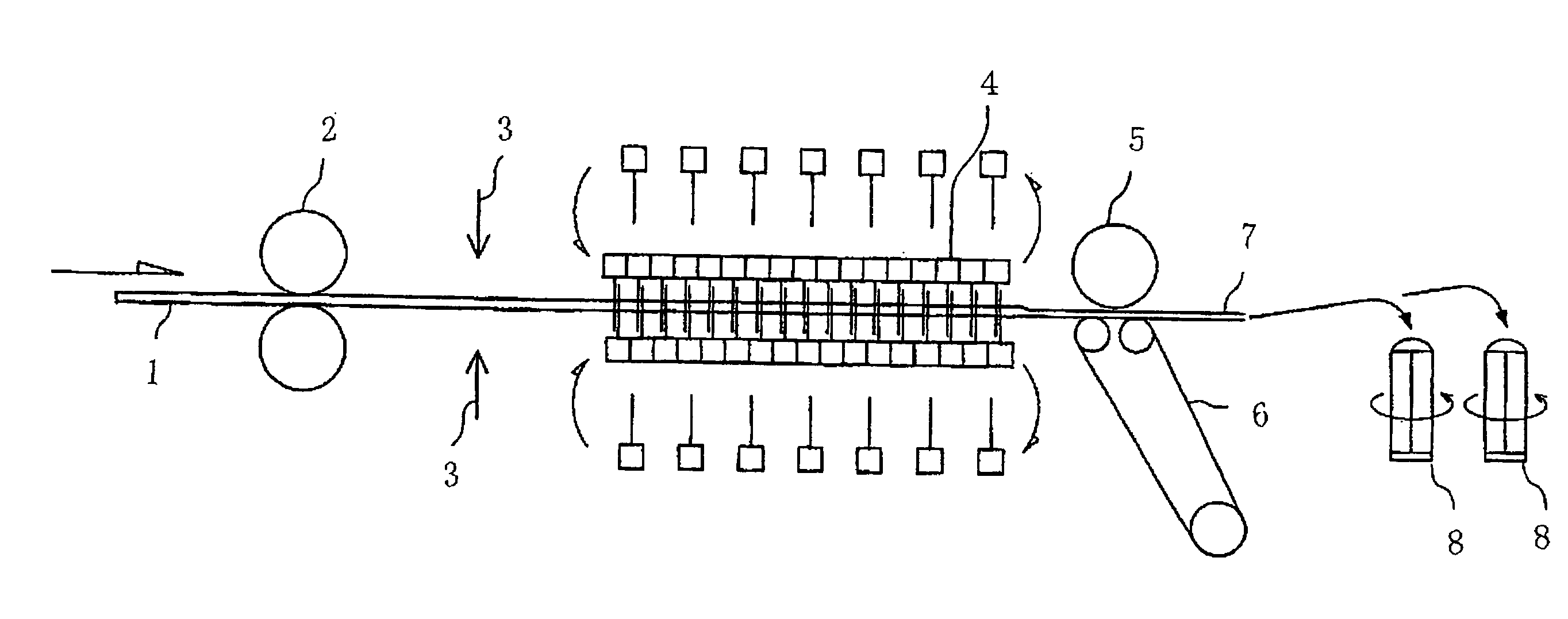

Improved viscose fiber containing pearl particles and manufacturing method thereof

InactiveCN101514496ASolve washing deformationSolve wrinkleMonocomponent cellulose artificial filamentSpinning solutions preparationCellulosePolymer science

The invention relates to improved viscose fiber containing pearl particles and a manufacturing method thereof. The fiber is reinforced, high-wet-modulus or rich and strong viscose fiber, the total amount of the fiber comprises 0.1 to 15.0 weight percents of the pearl particles, 0.2 to 6.0 weight percent of denaturant, and 79.0 to 99.7 weight percents of cellulose, the dry rupture strength of the fiber is more than or equal to 2.2 cN / dtex, and the wet rupture strength of the fiber is more than or equal to 1.2 cN / dtex. The mixture of one or more components selected from the copolymer of fatty amines, polyamines compounds, alcohol amine, polyoxyethylene and the aliphatic amine thereof, fatty acid, fatty alcohol, amide condensation compounds, ethylene oxide and propylene oxide, quaternary ammonium, pyrrolidine dithiocarbamate, dithioglycol, imidazole and derivatives thereof, is adopted as the denaturant. The manufacturing method for the fiber comprises the steps of: (1) the preparation of a viscose stock solution; (2) the preparation of slurry of the pearl particles; (3) the injection mixing of the slurry of the pearl particles and the viscose stock solution through a pre-spinning injection system; (4) spinning; and (5) post-treatment.

Owner:上海士林纤维材料有限公司

Hybrid Carbon Fiber Spun Yarn and Hybrid Carbon Fiber Spun Yarn Fabric Using the Same

ActiveUS20080152906A1High tensile strengthReduce adhesionFinal product manufactureLayered productsYarnCarbon fibers

A hybrid carbon fiber spun yarn comprising a core region which comprises carbon fibers as a main component, and a surrounding region which comprises carbon fibers as a main component and covers an outer peripheral surface of the core region;wherein 20% by mass or more of fibers forming the core region are long carbon fibers having a fiber length of 500 mm or longer,80% by mass ormore of fibers forming the surrounding region are short carbon fibers having a fiber length of less than 500 mm, anda mass ratio between the long carbon fibers and the short carbon fibers (long carbon fibers:short carbon fibers) is in a range of 20:80 to 80:20.

Owner:KUREHA KAGAKU KOGYO KK

Long afterglow solar energy storage luminescence target

InactiveCN101251357AStrong absorption capacityPhysical stabilityAntifouling/underwater paintsPaints with biocidesLight equipmentEffect light

The invention relates to a long afterglow solar energy storage light-emitting shooting target. To solve the problem that the prior night lighting equipment of the shooting target has high cost, a target surface or a piece of target paper is orderly coated with a transparent coating layer provided with long afterglow solar energy storage light-emitting material and a transparent water-proof coating layer, the target surface comprises an overland gun target, an aviation target and a navigation target. The coating is produced by transparent crylic acid varnish added with 20 to 65 weight percent of rare earth aluminate noctilucent powder. The target surface is firstly coated with a layer of white or light primer and then is coated with the transparent coating layer added with the long afterglow solar energy storage light-emitting material. No lighting is needed during the night use, the target can meet the requirement of the shooting training only through the light emission of the self energy storage, the brightness of the light emission is closer to the natural environment with low visibility at night and more meets the practical need, the target has low cost, short target arrangement time and less expense.

Owner:SHANGHAI ZHONGHAILONG NEW ENERGY

Ceramic grinding ball for cement ball mill, and preparation method thereof

The invention discloses a ceramic grinding ball for a cement ball mill, and a preparation method thereof. The ceramic grinding ball for the cement ball mill comprises the following raw materials in weight percentage: 92-95% of alumina, 0.5%-2% of ferric oxide, 0.8-3% of kaolin, 0.2-2% of silicon carbide, 1.5-2% of titanium dioxide, 0.8-1% of titanium carbide, and 0.3-2% of molybdenum disulfide. According to the technical scheme of the invention, the grinding ball is prepared through the compression moulding and high-temperature sintering process. The preparation method comprises the steps of burdening, ball-milling, spray granulation, ageing in a stock bin, compression processing, high-temperature sintering, powder removing, polishing, finished product drying, and the like. The ceramic grinding ball for the cement ball mill has the advantages of high hardness, high temperature resistance, corrosion resistance, low operation energy consumption, low material consumption, good bonding force, strong impact resistance, shock resistance and detonation resistance. The produced cement is uniform in fineness, reasonable in particle morphology and high in later strength.

Owner:SHANDONG TIANHUI GRINDING WEAR TECH DEV CO LTD

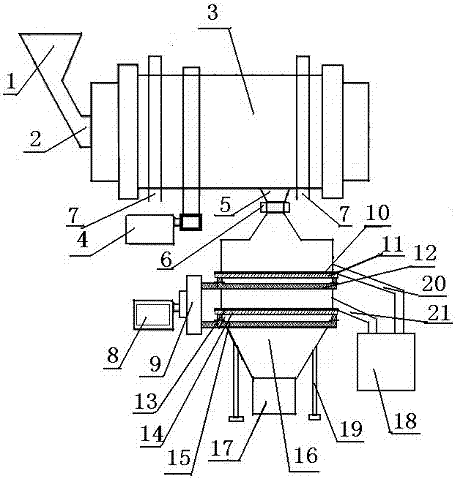

Poultry excrement drying device

ActiveCN101900479AModerate moisture contentSuitable for productionDrying solid materials with heatDrying machines with non-progressive movementsEngineeringFodder

The invention discloses a poultry excrement drying device. The device comprises a hot-blast stove, a feeding mechanism, a stirring and grinding device, a separating column, a discharging mechanism, a fan and a dust recovery device, wherein the hot-blast stove is used to provide hot blast; the feeding mechanism is used to feed poultry excrement; the stirring and grinding device can scatter and grind the poultry excrement entering the shell of the device; the separating column is used to separate the poultry excrement from air flow; the discharging mechanism is arranged at a discharge hole on the lower end of the separating column and used for discharging; the fan is arranged in a pipe between the separating column and the dust recovery device and used to generate air flow along the hot-blast stove, the stirring and grinding device, the separating column and the dust recovery device; and the dust recovery device is used for air-out and dust recovery. The poultry excrement drying device has the advantages of fast processing speed, good dewatering effect and deodorizing effect, high nutrient retention capacity, good sterilizing effect, high degree of grinding, uniform fineness, no environmental pollution and the like. The technology is especially suitable for the pretreatment of poultry excrement feed preparation and is especially suitable to be used in the poultry farm.

Owner:重庆福纳斯生物技术有限公司

High-strength and wear-resisting liteglow glass product and preparation method thereof

The invention discloses a high-strength and wear-resisting liteglow glass product and a preparation method thereof. The glass product is prepared from the following components: silicon dioxide, aluminum oxide, calcium oxide, magnesium oxide, graphene, titanium dioxide, diboron trioxide, sodium silicate, potassium oxide, antimony oxide, arsenic oxide and noctilucent powder. The preparation method comprises the following steps: firstly, carrying out mixed melting on all the components to obtain a molten mass; secondly, raising the temperature of the molten mass to 1400 to 1500DEG C and performing thermal insulation for 12 to 14 hours; thirdly, feeding a glass molten mass into a forming machine to obtain glass products with different shapes and sizes; fourthly, carrying out annealing treatment on the glass products to obtain a finished product. The glass product prepared by the preparation method disclosed by the invention has better strength and wear resistance; the fragile degree of the product can be greatly reduced, the service life of the product is prolonged, and the use cost of the product is reduced.

Owner:HEFEI LIYUTAI GLASS PROD CO LTD

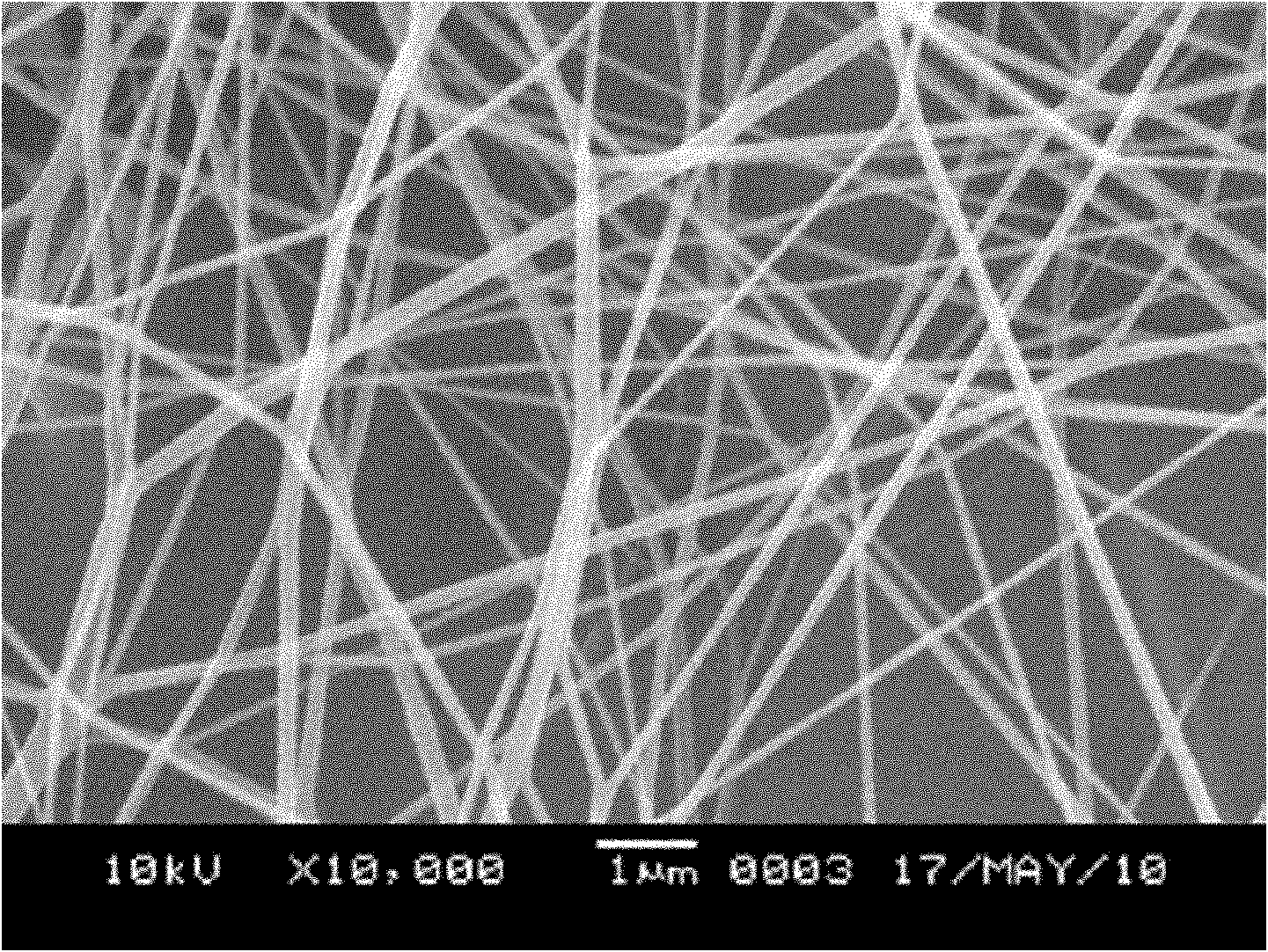

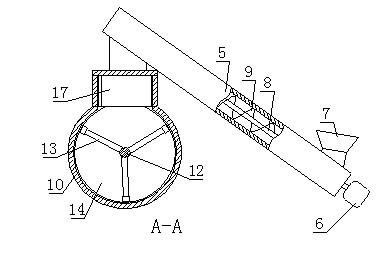

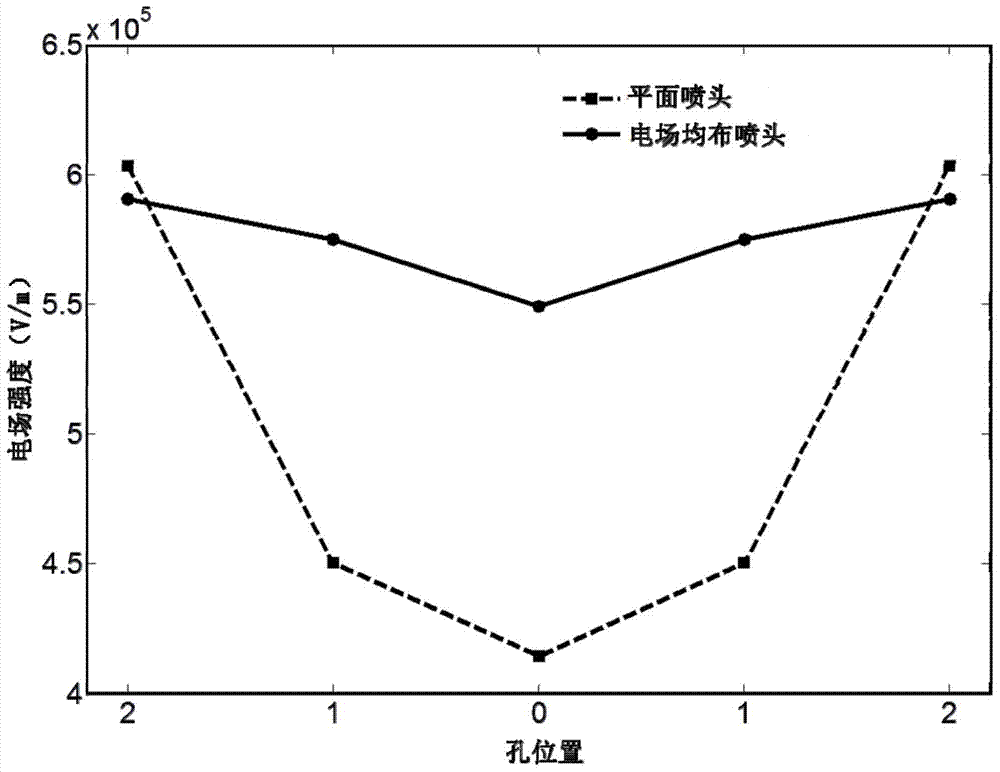

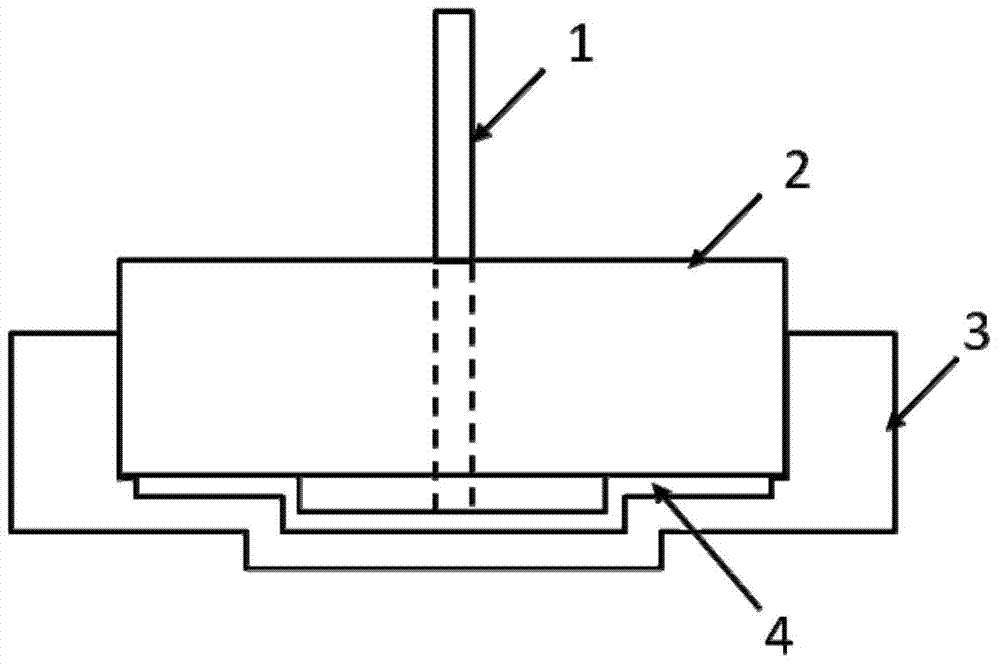

Multi-jet-flow electrostatic spinning sprayer with uniformly distributed electric fields

InactiveCN103668482AEliminate electric field repulsionGood for collectionSpinnerette packsElectric fieldMultiple stages

The invention relates to a multi-jet-flow electrostatic spinning sprayer with uniformly distributed electric fields. The multi-jet-flow electrostatic spinning sprayer with the uniformly distributed electric fields comprises a solution injection tube, a spinneret plate and an electrode. The spinneret plate is a step-shaped spinneret plate formed by overlaying small circular truncated cones on multiple stages of hollow circular truncated cones, and the upper bottom surface of each stage of circular truncated cone is provided with spinneret orifices. The electrode is consistent with a hollow cavity of the spinneret plate in shape, and a gap is reserved between the electrode and the hollow cavity of the spinneret plate to form a solution cavity. The spinneret plate is made of hydrophobic insulation materials. According to the multi-jet-flow electrostatic spinning sprayer with the uniformly distributed electric fields, holes are formed in the hydrophobic insulation materials so that traditional metal needles can be replaced, electric field rejection between the needles is avoided, the rejection effect of jet flow sprayed out from the spinneret plate is weakened, and therefore nanofibers can be collected conveniently; in addition, the electric fields at the position of a center hole are effectively increased by the utilization of the step-shaped electrode and the spinneret plate matched with the step-shaped electrode, therefore, stable jet flow can be formed at the position of the center hole, and the nanofibers with even fineness can be obtained.

Owner:DONGHUA UNIV

Organic rare earth europium luminescent polypropylene (PP) fiber and preparation method thereof

ActiveCN104674363AImprove luminous efficiencyHigh luminous intensityGroup 3/13 element organic compoundsMonocomponent polyolefin artificial filamentPhenanthrolineRare earth

The invention discloses an organic rare earth europium luminescent polypropylene (PP) fiber and a preparation method thereof. The rare earth europium complex Eu(TTA)3DmPPhen luminescent material close to nanoscale is prepared by firstly preparing a phenanthroline neutral ligand and carrying out coordination on the phenanthroline neutral ligand and rare earth Eu (III) in combination with alpha-thenoyltrifluoroacetone and adopting a method of firstly carrying out titration under atmospheric pressure and secondly carrying out reaction under high pressure. The material emits strong pure red light at 615nm in a 10-5mol / L CH2Cl2 solution. The luminescent fiber is prepared by adopting the complex as a luminescent material and carrying out compound melt spinning on the complex and PP. When the content of the rare earth luminescent material in the fiber is 0.05%, the fiber emits stronger pure red light in a 10-5mol / L dimethyl formamide (DMF) solution and the luminescent position is still at 615nm. The luminescent fiber has the advantages of high color purity and better spinnability.

Owner:济南市佳新纤维有限公司

Preparation method and application of daily chemical organosilicone elastomer gel

InactiveCN107446145ARefreshing skinNon-greasy skin feelCosmetic preparationsToilet preparationsSolventOrganosilicon

The invention belongs to the field of daily chemical organosilicone materials and discloses a preparation method and application of daily chemical organosilicone elastomer gel. The preparation method comprises the following steps: adding anorganic solvent, hydrogen-containing silicone oil, and a compound containing at least two aliphatic unsaturated groups in molecules into a reactor, and carrying out a precipitation polymerization reaction in the presence of a catalyst at the temperature of 50-90 DEG C for 2-9 hours; cooling and filtering after reaction completion, drying the obtained solid powder so as to obtain organosilicone elastomer powder; swelling the organosilicone elastomer powder with a diluents, thereby obtaining the daily chemical organosilicone elastomer gel, wherein the organic solvent refers to a volatile organic solvent which is soluble in reactive raw materials while insoluble in polymerization reaction products. According to the method disclosed by the invention, the organosilicone elastomer powder is prepared by the precipitation polymerization method by adopting a specific organic solvent, the requirement on equipment is low, and the obtained organosilicone elastomer gel is fresh and cool but not greasy in skin feeling and good in matte sense and can be directly added into daily cosmetics.

Owner:GUANGZHOU TINCI MATERIALS TECH

Calcium carbonate powder production technology

ActiveCN105536963AWeight increaseEasy to suspendGrain treatmentsAlkyl dimethyl benzyl ammonium chlorideWet grinding

The invention discloses a calcium carbonate powder production technology. The production technology comprises crushing, homogenizing, grinding, grading, wet grinding and drying. Through use of sodium carbonate and dodecyl dimethyl benzyl ammonium chloride in homogenizing, after grinding efficiency is improved and grinding time is reduced. A water spraying device is arranged in a grinder and the sprayed atomized water improves powder weight so that the powder does not easily suspend and a grinding disc material layer is stable. The atomized water, sodium carbonate and dodecyl dimethyl benzyl ammonium chloride produce synergism to promote grinding effects. According to the technology, coarse powder subjected to dry grinding is graded and the graded secondary coarse powder is subjected to wet grinding so that wet grinding efficiency is improved and production unit energy consumption is reduced, the product particle size distribution is narrow and product fineness is uniform. The technology has the advantages of good product quality, high efficiency, simple processes, preparation convenience and low cost and is suitable for industrial large-scale production.

Owner:SICHUAN YIXIN NEW MATERIAL CO LTD

Grind grading technique for aluminum oxide raw material - monohydrallite

The invention relates to a grading process technology containing two procedures of grinding ore and grading in processing monohydrallite. Grinding equipment adopts two-bin overflow ball mill and grading equipment adopts hydraulic cyclone group, which cooperate with each other to form closed-circuit grading flow process. Two-bin overflow ball mill equips compartment board that can be adjusted to separate mill into two bins. The invention simplifies procedure and makes the operation convenient.

Owner:GUIYANG AL-MG DESIGN & RES INST

Rake type vacuum drying system

ActiveCN102183126ASpeed up crushingLarge specific surface areaDrying machines with non-progressive movementsDrying solid materialsVapor–liquid separatorLithium iron phosphate

The invention provides a rake type vacuum drying system, which comprises a rake type vacuum drying host machine, a bag type filter, a condenser, a gas-liquid separator, a vacuum pump, an oil pump and a hot oil tank, wherein a main shaft of the rake type vacuum drying host machine is a solid main shaft; a plurality of rake tooth components are arranged on the main shaft; each rake tooth component comprises a sleeve shaft and four solid rake teeth uniformly distributed on the sleeve shaft in a fixed manner, and is connected on the main shaft through a sleeve shaft key; the rake teeth of the respective rake tooth components face towards the same direction, so that four passageways are formed in a tank body; and striking rods are respectively arranged in respective passageways or in spaced passageways. In the invention, materials inside the tank body of the drying host machine are struck continuously by using the striking rods, so that the crushing of the materials is accelerated, the materials can obtain larger specific surface areas, the drying process is accelerated, and finished products have uniform fineness and low water content; thus, the rake type vacuum drying system is suitable for drying lithium iron phosphate materials, and the product quality and drying efficiency are improved; moreover, the system is used for recovering solvents through the condenser and the gas-liquid separator, and is beneficial to reduction of the cost.

Owner:JIANGSU XIANFENG DRYING ENG

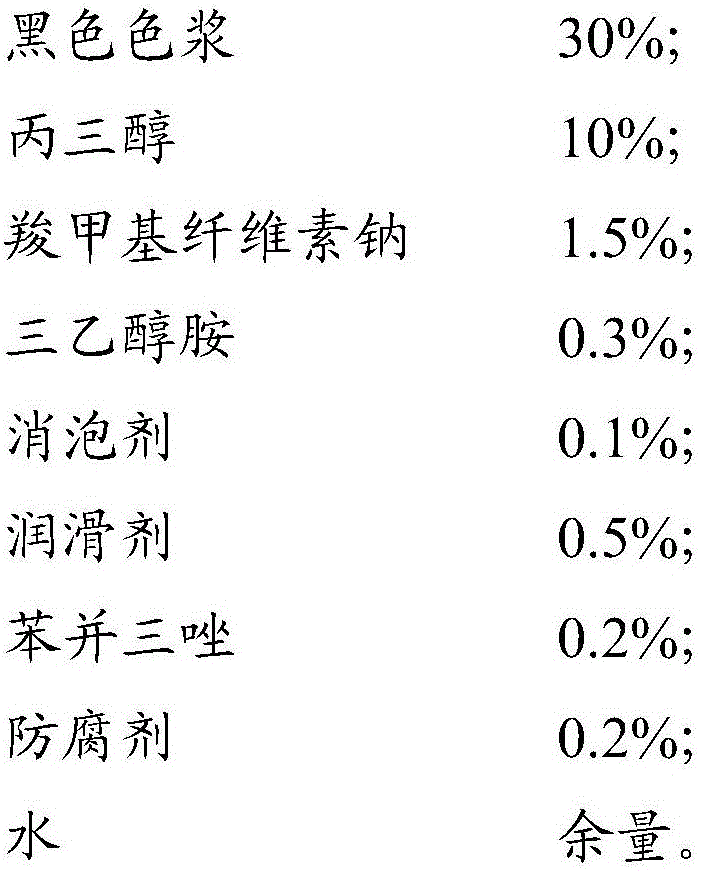

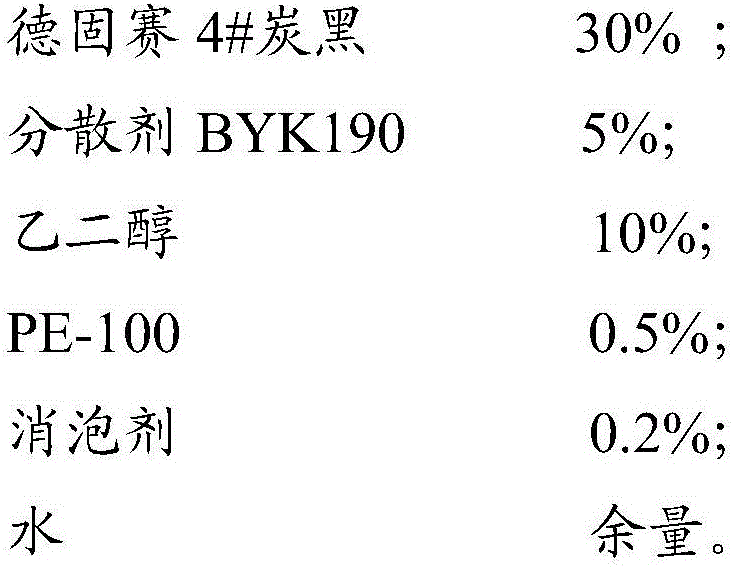

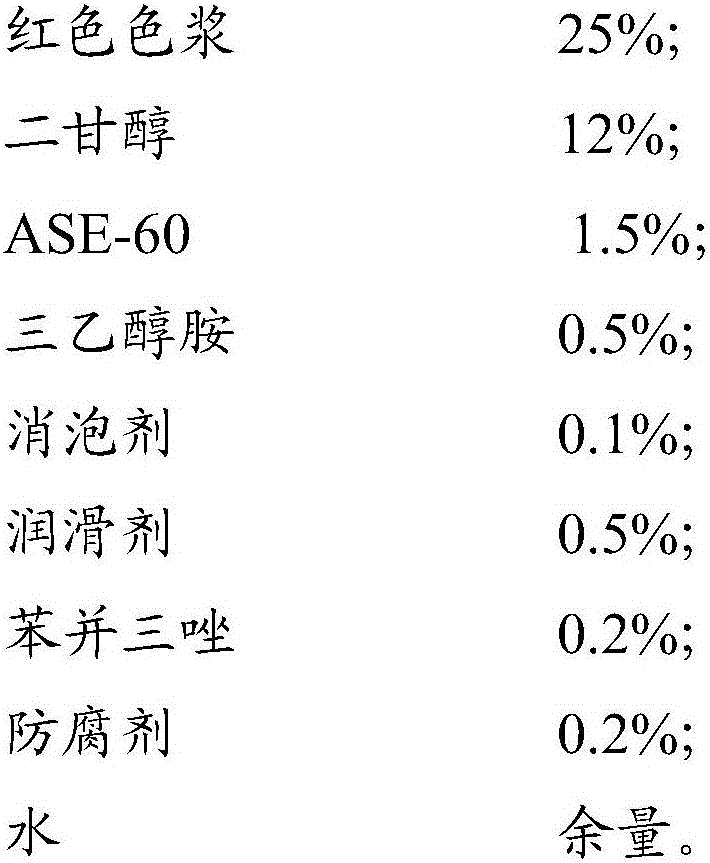

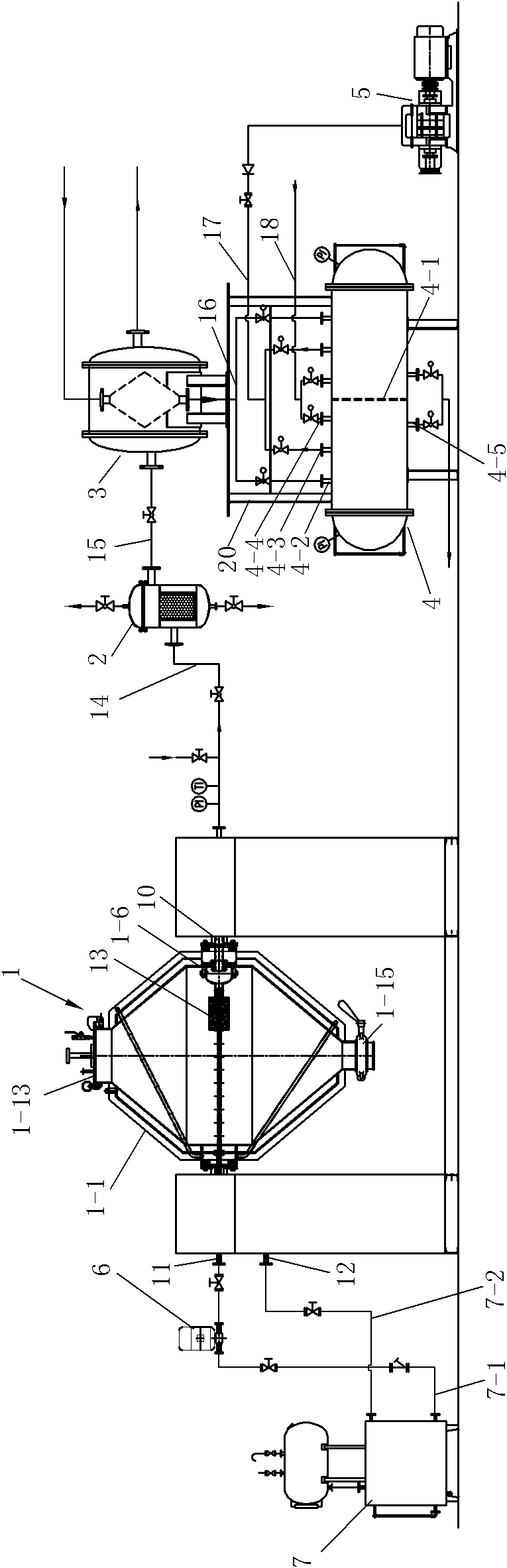

Water-based nano pigment-type gel pen ink and preparation method thereof

The invention relates to a water-based nano pigment-type gel pen ink and a preparation method thereof. The water-based nano pigment-type gel pen ink comprises the following components in percentage by weight: 20-40% of resin-free nano color paste, 10-30% of humectant, 0.1-3% of thickener, 0.2-3% of pH regulator, 0.05-0.5% of defoaming agent, 0.1-3% of lubricant, 0.2-2% of rust inhibitor, 0.2-2% of preservative and the balance of deionized water. The average particle size of the resin-free nano color paste is 100-250nm. The preparation method comprises the following steps: sufficiently stirring and uniformly mixing the components, and defoaming. By using the resin-free nano color paste, the ink has the advantages of favorable stability, proper viscosity, uniform particle fineness, smooth writing and uniform ink release without floating. The ink has the characteristics of bright color, light fastness, high water resistance and high stable quality after long-term storage, and can not have the phenomenon of stratification, precipitating deterioration or the like. The sand mill is used for grinding, so that the particle size of the pigment particles reaches nano scale. The preparation method is simple to operate and reasonable in technique.

Owner:SHANTOU WANHUI IND CO LTD

Nano-level pigment-type ink-jet ink stock, and its manufacturing method

The invention relates to nanometer dye type jet ink raw liquor and the manufacture method. It contains 16-20 portions dye, 5-25 portions auxiliary agent, 5-10 portions dispersing agent, 2-5 portions emulsifier, 5-15 portions wetting agent, 0.03 portions antiseptic and 30-40 portions deionized water. The method includes the following steps: adding deionized water into pre-dispersing boiler, whisking and adding antiseptic, mixing; adding auxiliary, dispersing agent, emulsifier, wetting agent, and whisking; adding dye, taking fully whisking and mixing; taking unltramicro grinding until the diameter of particle in nanometer grade, stopping grinding and discharging. The invention has the advantages of light fastness, water proof, acid resistant, non toxicity, etc.

Owner:苏州三威纳米科技有限公司

Biconical rotary vacuum drying system

ActiveCN102168909AGuaranteed uniformityUniform finenessDrying solid materials without heatDrying machines with non-progressive movementsSolventBicone

The invention relates to a biconical rotary vacuum drying system, which comprises a biconical rotary vacuum drying main machine, a condenser, a gas-liquid separator, a vacuum pump, an oil pump, a hot oil tank, a vacuumizing pipe, an oil supply pipe and an oil return pipe, wherein the vacuumizing pipe extends into a cylinder body of the biconical rotary vacuum drying main machine from the inner cavity of a driving half shaft and the pipe hole of a driving shaft base; the oil supply pipe extends into an oil inlet cavity from the inner cavity of a driven half shaft and a pipe hole on a baffle; and two built-in oil supply branch pipes which are arranged horizontally on front and back sides are arranged on the middle part of a clamp sleeve of the cylinder body and are communicated with an oil inlet cavity of a driven shaft base. By the biconical rotary vacuum drying system, heat conducting oil can be distributed to integral clamp sleeve space uniformly to ensure the uniformity of clamp sleeve heating, the problem that biconical rotary vacuum drying is 'semi-hot and semi-cold' for a long term is solved, the quality of products and the work efficiency are improved, and energy is saved. In the biconical rotary vacuum drying system, solvents are recovered by a gas condenser and a liquid separator.

Owner:JIANGSU XIANFENG DRYING ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com