Improved viscose fiber containing pearl particles and manufacturing method thereof

A pearl particle and viscose fiber technology, applied in the direction of single-component cellulose artificial filament, fiber chemical characteristics, spinning solution preparation, etc., to solve washing deformation and wrinkling, good textile processing performance, and good product performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Match the pre-spinning injection system with the improved viscose fiber production line with a daily output of 25 tons of pearl particles. The metering pump for the viscose collagen solution uses a 14,000 liter / hour NEMO single-screw pump, the pearl particle slurry uses a 1,000 liter / hour diaphragm metering pump, the primary mixer uses a 24,000L / h static mixer, and the secondary mixer uses a 24,000L / h rotor / stator high shear mixer, the fiber production capacity of the corresponding spinning machine is 25 tons / day.

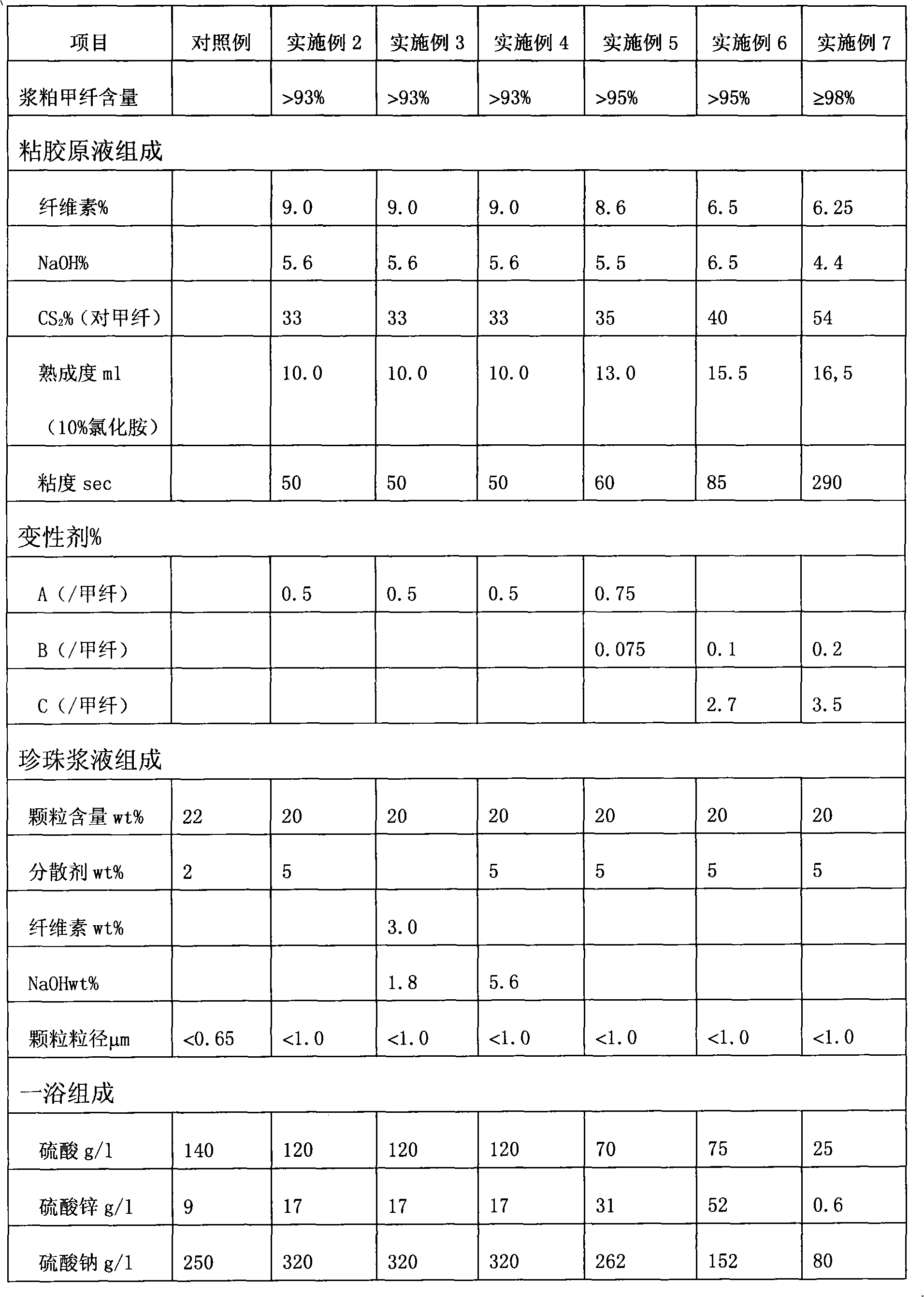

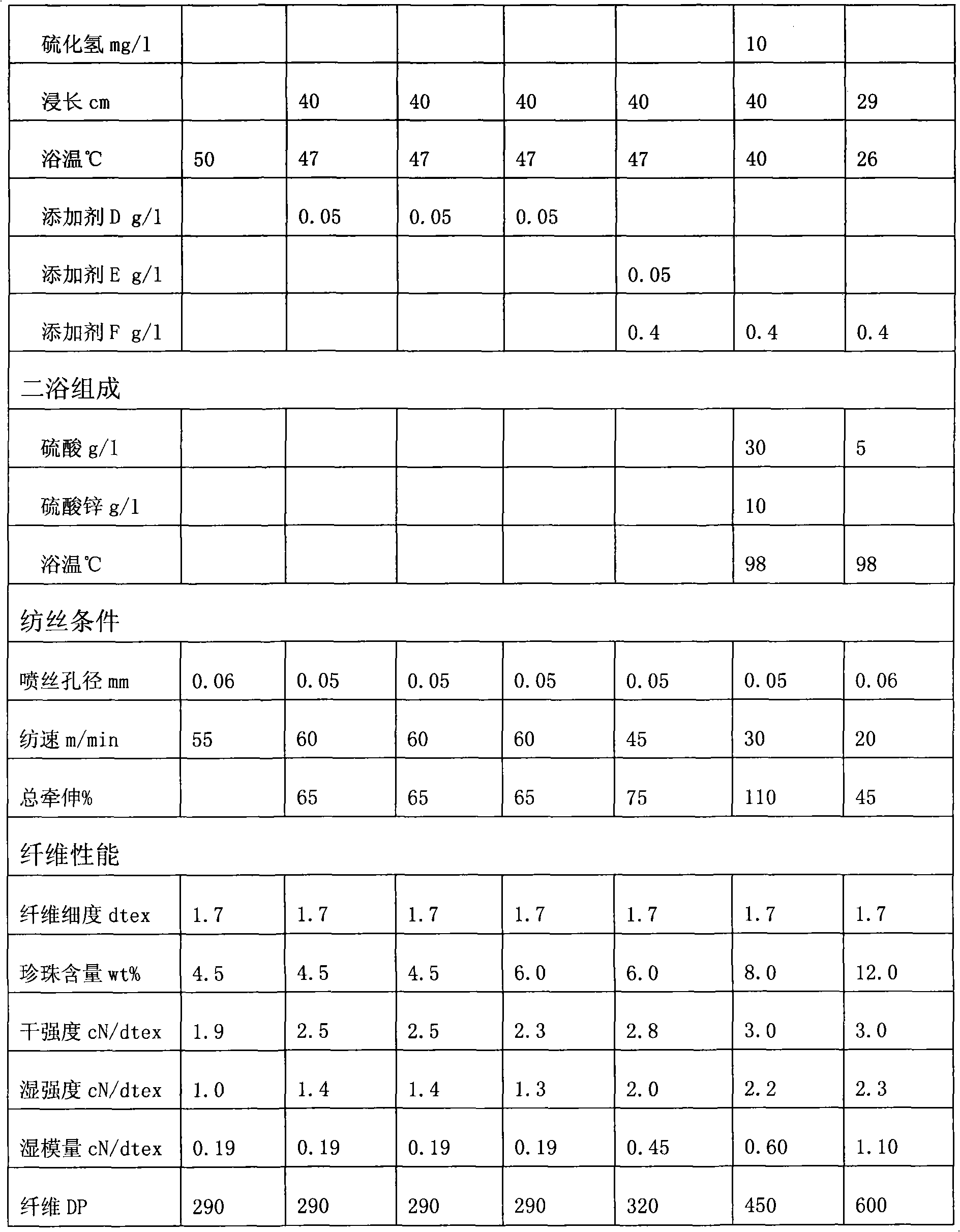

Embodiment 2

[0050] To prepare reinforced viscose fiber containing pearl particles, the content of methylcellulose in the raw material pulp is not less than 93%.

[0051] Viscose collagen composition: cellulose 9.0%, NaOH 5.6%, CS 2 (p-methylcellulose) 33%, denaturant A 0.5%, maturity 10ml (10% ammonium chloride), falling ball viscosity 50sec.

[0052] The composition of the pearl particle slurry: the pearl particle content is 20wt%, the dispersant is 5wt%, the rest is water, and the pearl particle is less than 1 μm.

[0053] The pre-spinning injection system of Example 1 was used to adjust the flow rate of the stock solution and the slurry metering pump to ensure that the proportion of pearl particles in the fiber was 4.5 wt%, and the above-mentioned blended stock solution was subjected to viscose wet spinning and post-treatment.

[0054] Spinning bath composition: sulfuric acid 120g / l, zinc sulfate 17g / l, sodium sulfate 320g / l, additive D 0.05g / l, immersion length 40cm, bath temperature...

Embodiment 3

[0056] To prepare reinforced viscose fiber containing pearl particles, the content of methylcellulose in the raw material pulp is not less than 93%.

[0057] Viscose collagen composition: cellulose 9.0%, NaOH 5.6%, CS 2 (p-methylcellulose) 33%, denaturant A 0.5%, maturity 10ml (10% ammonium chloride), falling ball viscosity 50sec.

[0058] The composition of the mother liquor of pearl particle viscose: pearl particle content 20wt%, cellulose 3wt%, NaOH 1.8wt%, the rest is water, and the pearl particle is less than 1 μm.

[0059] Adopt the pre-spinning injection system of Example 1, adjust the flow rate of the stock solution and the slurry metering pump to ensure that the proportion of pearl particles in the fiber is 4.5wt%, and carry out the above-mentioned blended stock solution for viscose wet spinning and post-treatment, and the composition of the spinning bath: sulfuric acid 120g / l, zinc sulfate 17g / l, sodium sulfate 320g / l, additive D 0.05g / l, immersion length 40cm, bath...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com