Patents

Literature

78 results about "High-shear mixer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A high-shear mixer disperses, or transports, one phase or ingredient (liquid, solid, gas) into a main continuous phase (liquid), with which it would normally be immiscible. A rotor or impeller, together with a stationary component known as a stator, or an array of rotors and stators, is used either in a tank containing the solution to be mixed, or in a pipe through which the solution passes, to create shear. A high-shear mixer can be used to create emulsions, suspensions, lyosols (gas dispersed in liquid), and granular products. It is used in the adhesives, chemical, cosmetic, food, pharmaceutical, and plastics industries for emulsification, homogenization, particle size reduction, and dispersion.

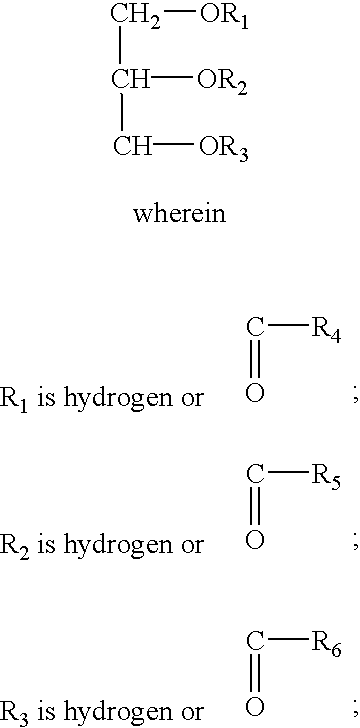

Control release formulation containing a hydrophobic material as the sustained release agent

The present invention is directed to a sustained release pharmaceutical composition in oral dosage form consisting essentially of a pharmaceutically effective amount of a medicament and a hydrophobic material in the absence of a lactose or hydrophobic carbohydrate polymer, said medicament being present in an amount greater than about 25% of the pharmaceutical composition and having a water solubility greater than about 1 gram per 10 mL of water at 25° C., said hydrophobic material having a melting point ranging from at least about 40° C. to about 100° C. at 1 atm pressure, and being present in an amount ranging from about 3% to about 20% by weight of the pharmaceutical composition and in an amount less than the of the medicament, and said hydrophobic material not being present in coating of said pharmaceutical composition; said pharmaceutical composition being prepared by direct compression in the absence of or melting the hydrophobic material or the use of high shear mixer. The present invention is also directed to a method of preparing said pharmaceutical composition.

Owner:NOSTRUM PHARMA INC

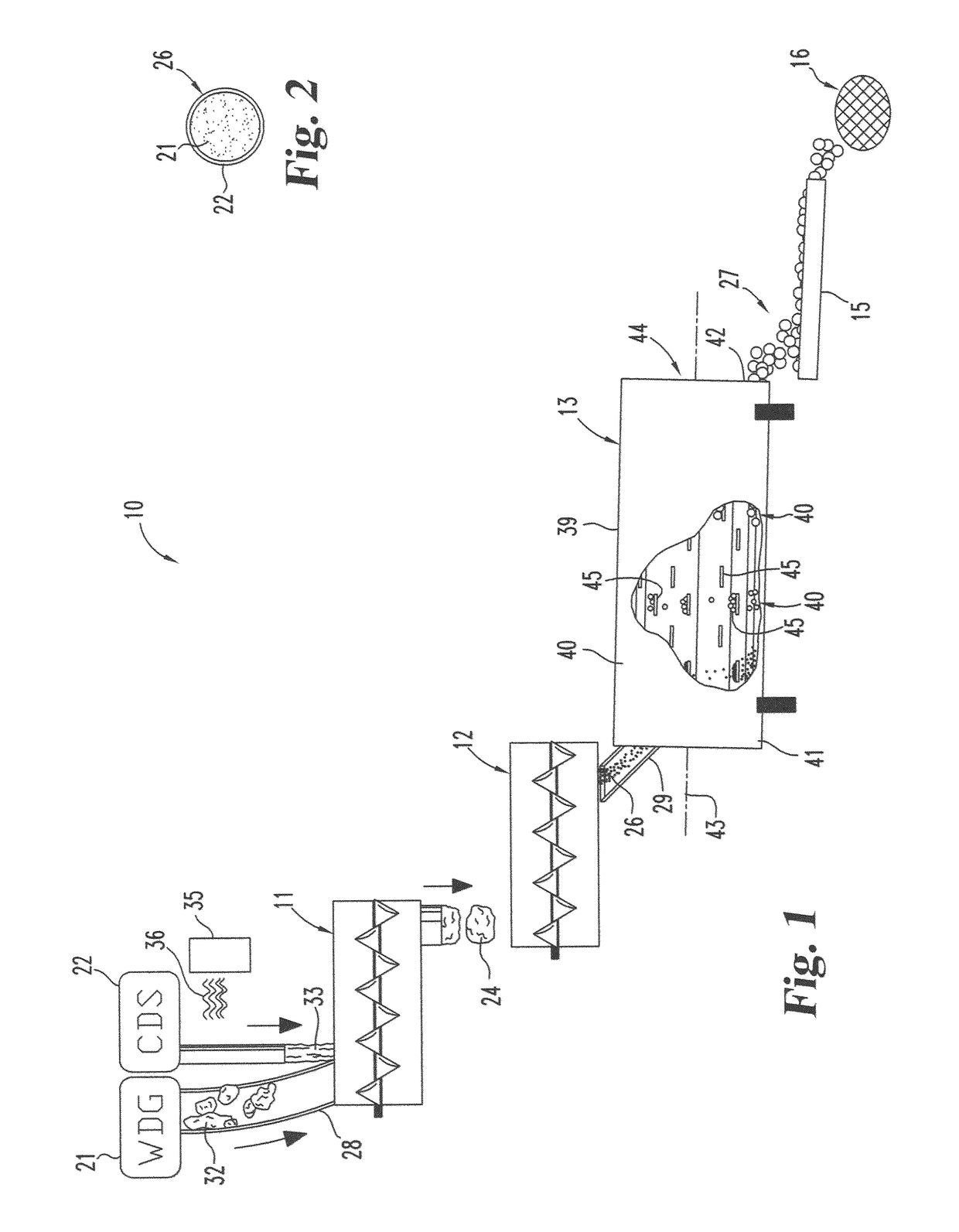

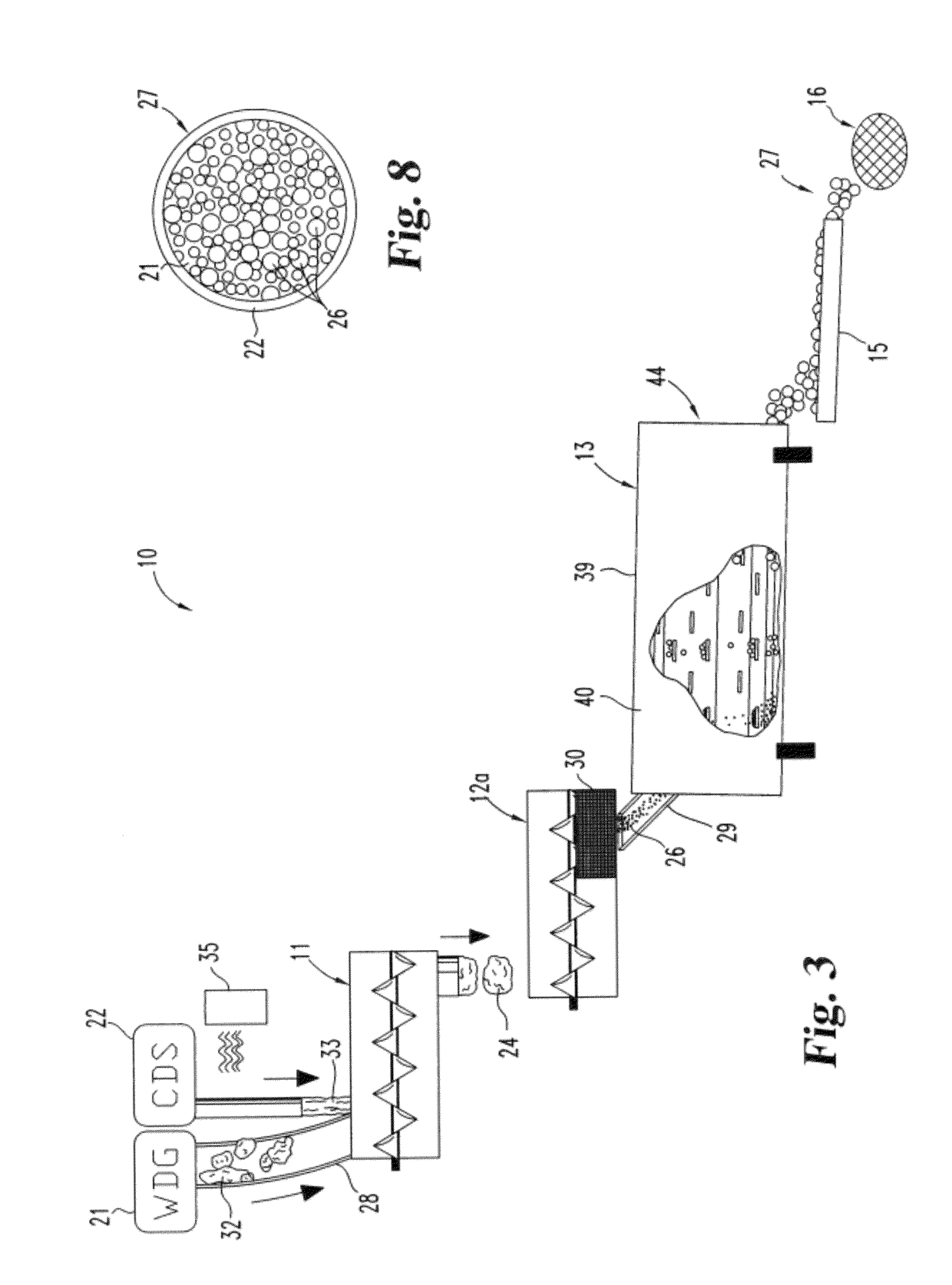

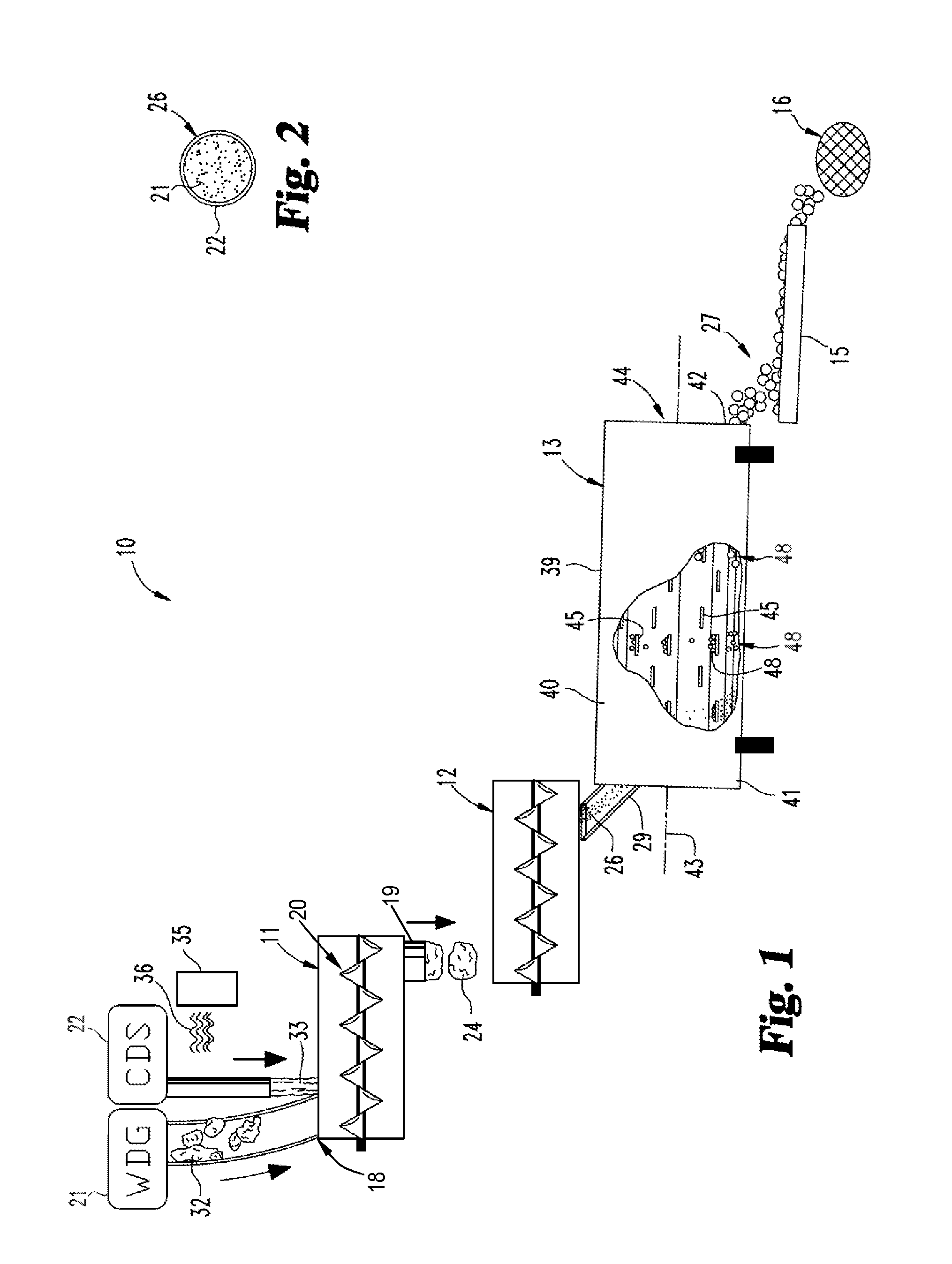

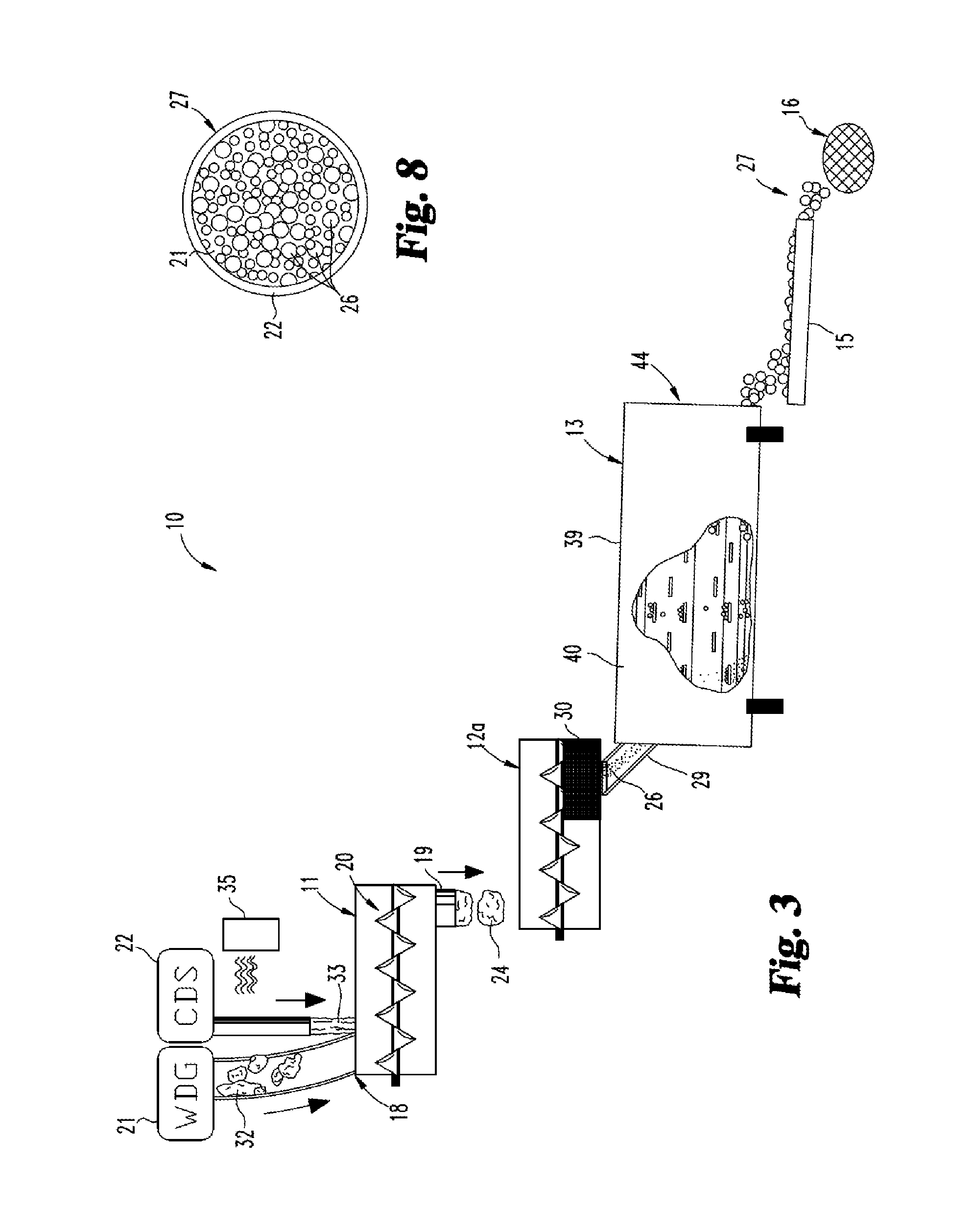

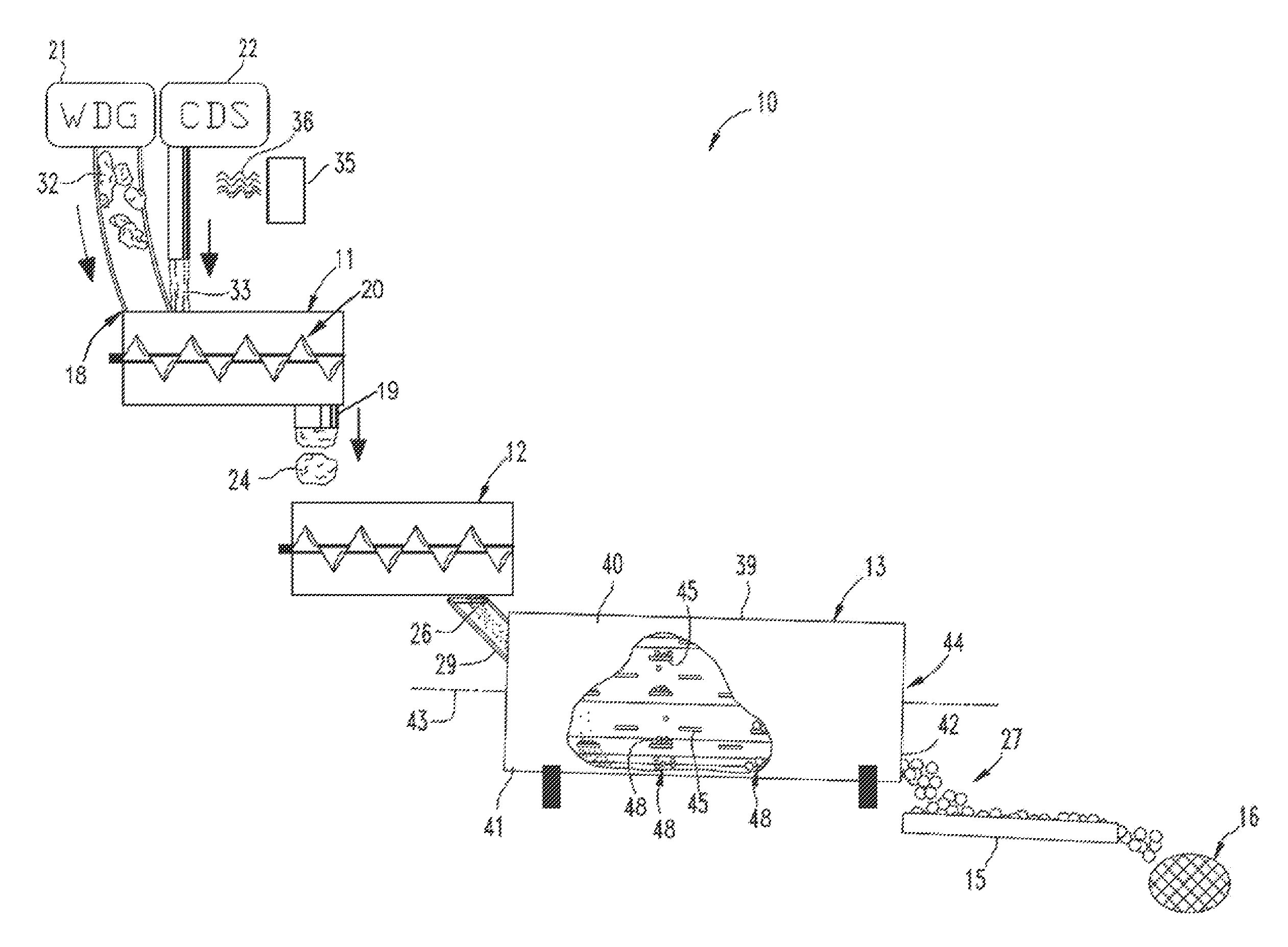

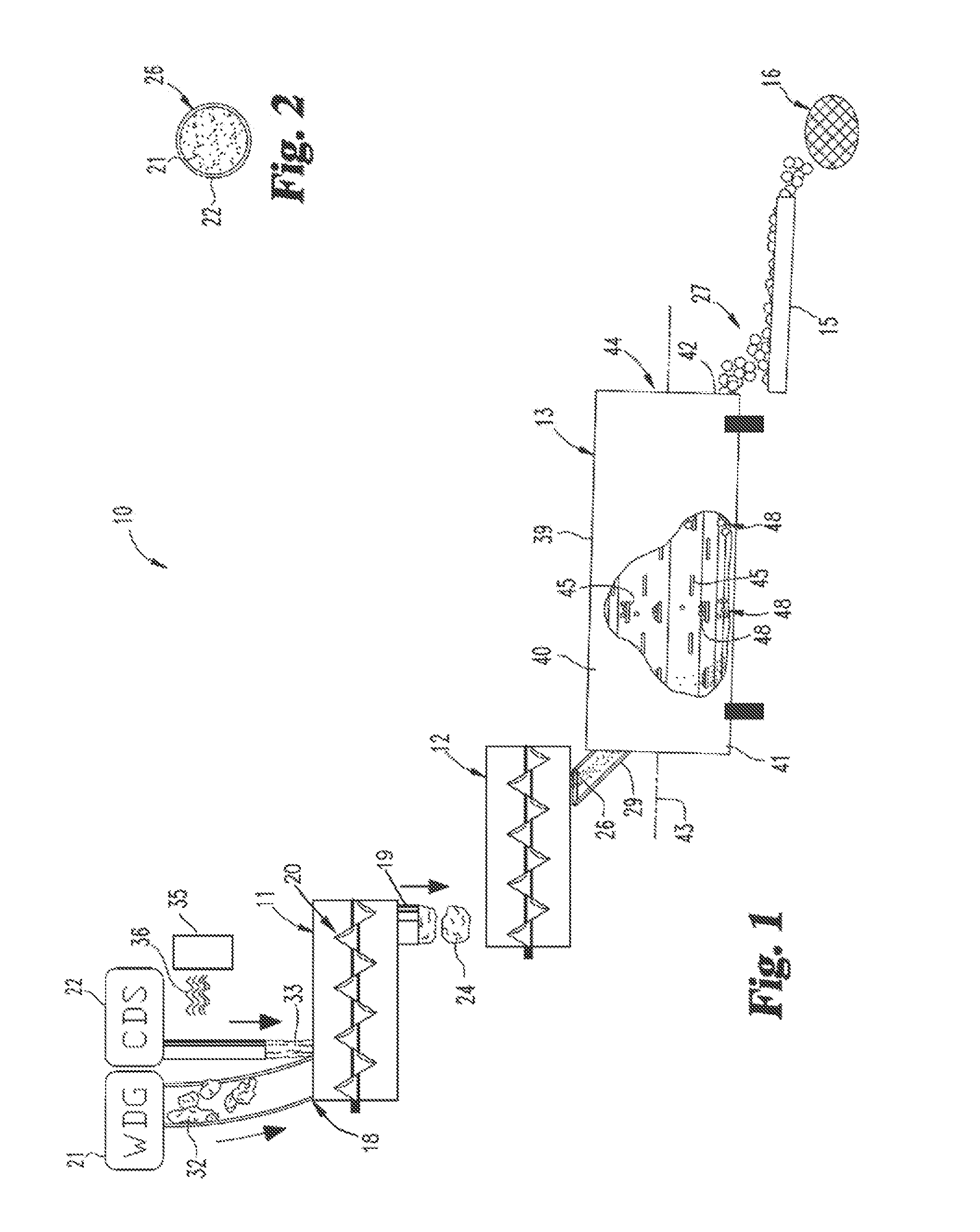

Method and apparatus for producing biobased carriers from byproducts of biomass processing

An apparatus for producing biobased carriers for dispersal of biological and chemical molecules includes a premixer having a cavity for receiving a coproduct of a wet biomass process and a binder and being operable to premix the coproduct and binder to produce a substantially homogeneous DDGS mixture; a high shear mixer having a receptacle for receiving the DDGS mixture and being operable to shear mix the mixture and produce very small DDGS particles; and, an agglomerator having an interior chamber sized and configured to receive and transform the DDGS particles into substantially spherical DDGS pellets.

Owner:PURDUE RES FOUND INC

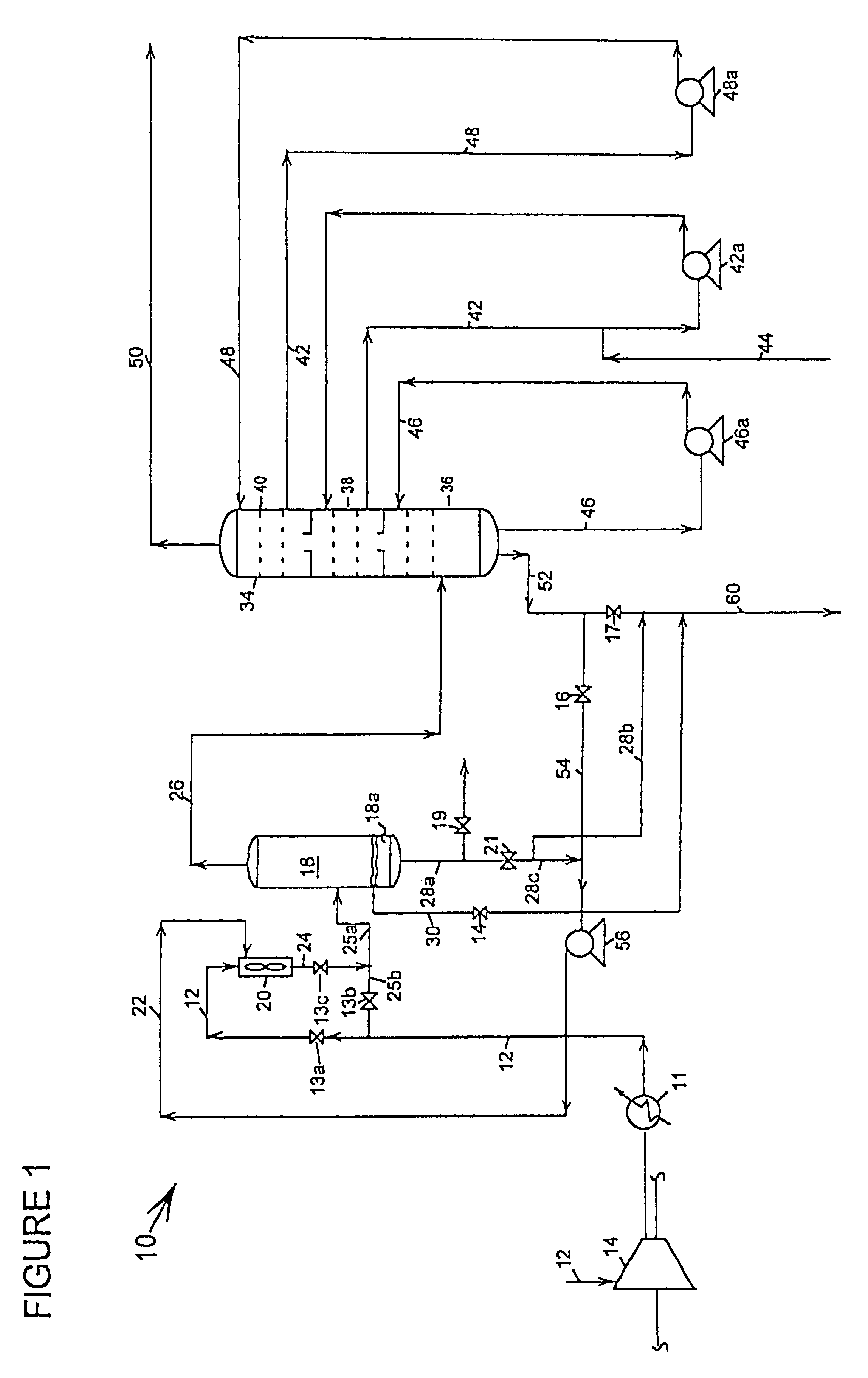

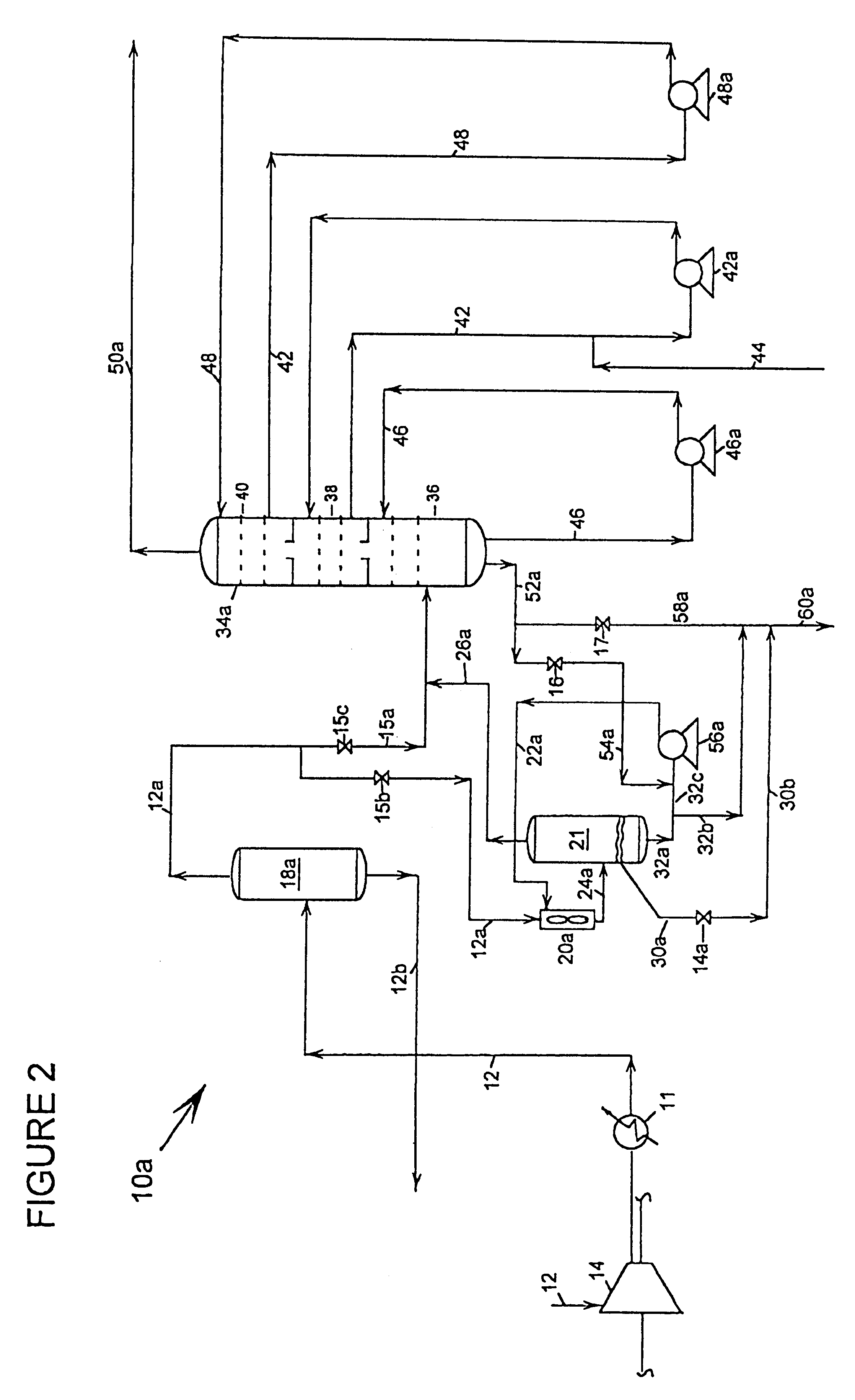

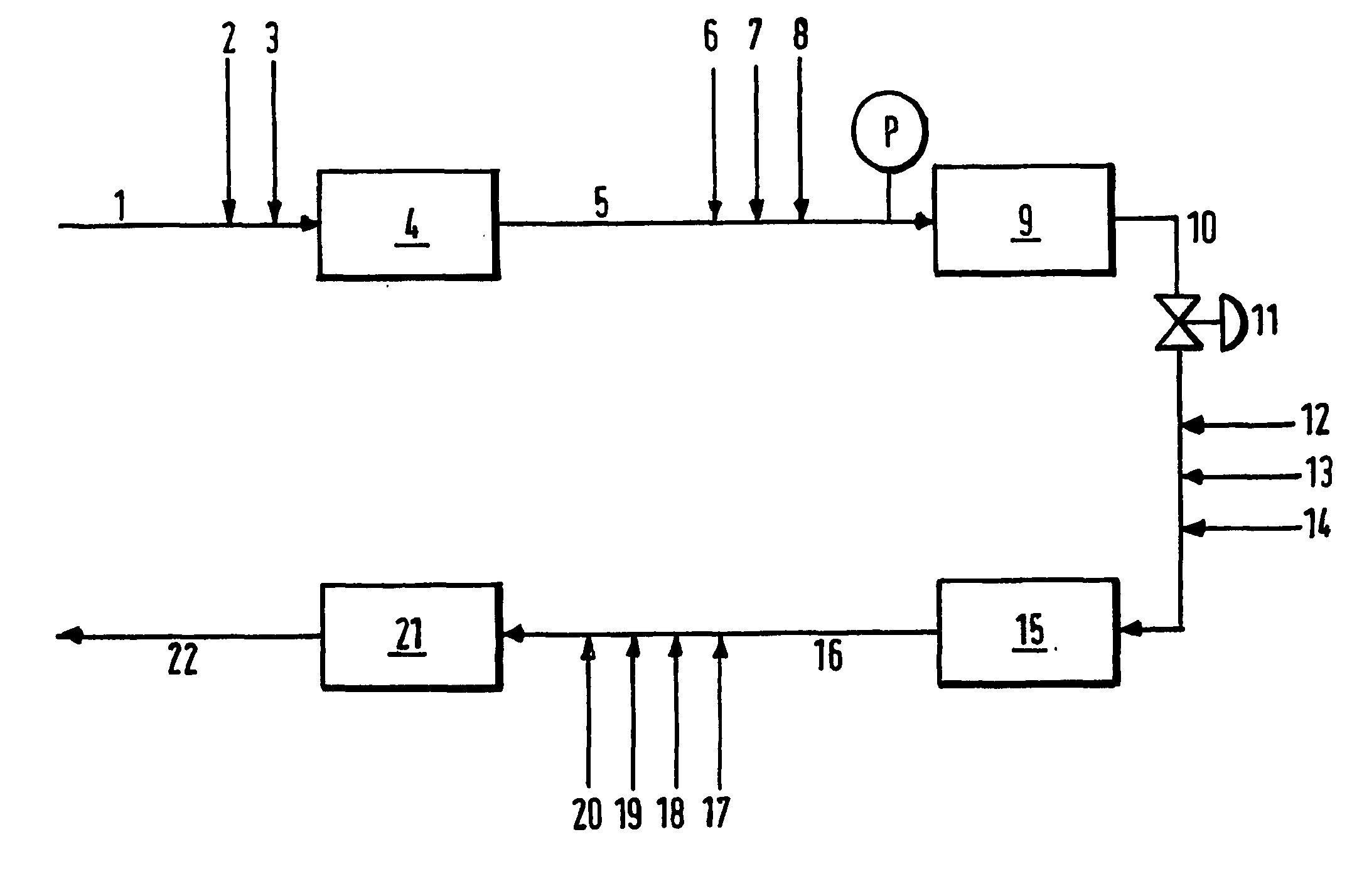

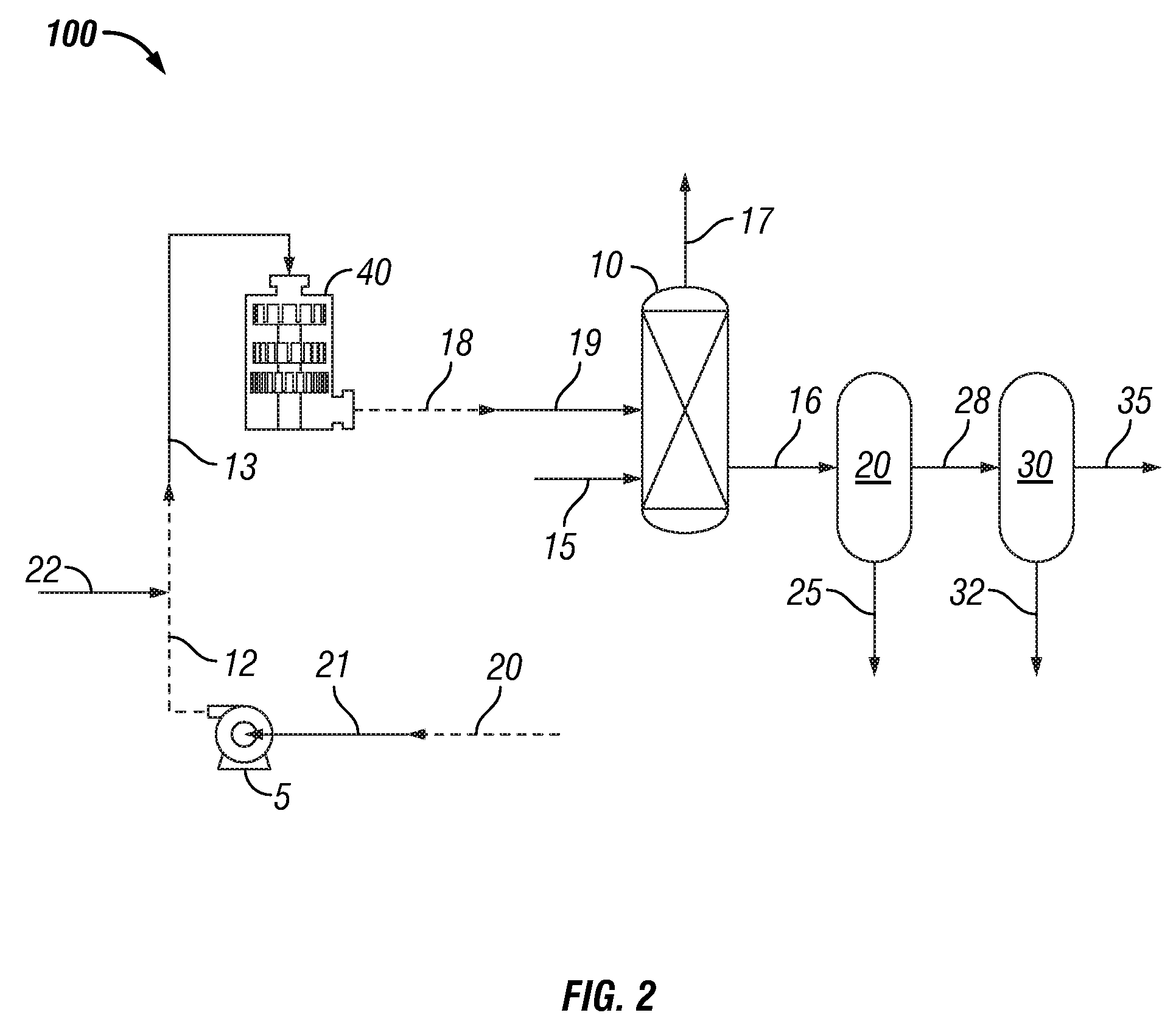

Process for pretreating cracked gas before caustic tower treatment in ehtylene plants

InactiveUS6235961B1Improve efficiencyIncrease capacityThermal non-catalytic crackingCatalytic crackingProduct gasTower

An inline, high-shear mixer is provided in a cracked gas stream upstream of a caustic tower in an ethylene production unit. Spent caustic is withdrawn from the bottom of the caustic tower and pumped to the mixer, where the spent caustic mixes with and absorbs acid gas components from the cracked gas stream. The spent caustic is separated from the cracked gas, forming a partially treated cracked gas stream. The partially treated cracked gas stream is then fed to the caustic tower. Polymer deposition in the caustic tower is reduced because polymeric material is formed when the cracked gas stream is mixed with the spent caustic and is removed before the cracked gas stream is fed to the caustic tower.

Owner:STONE & WEBSTER PROCESS TECH

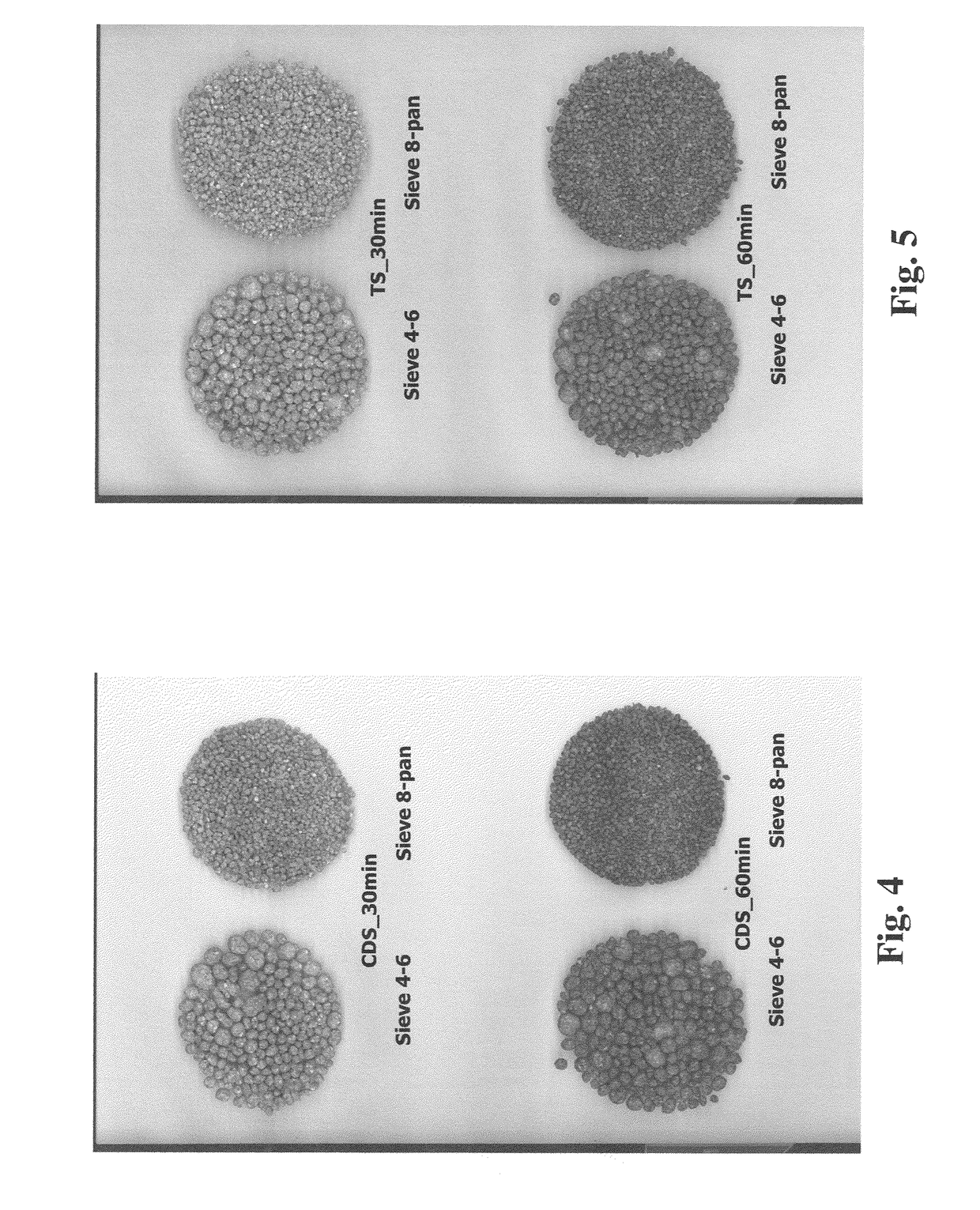

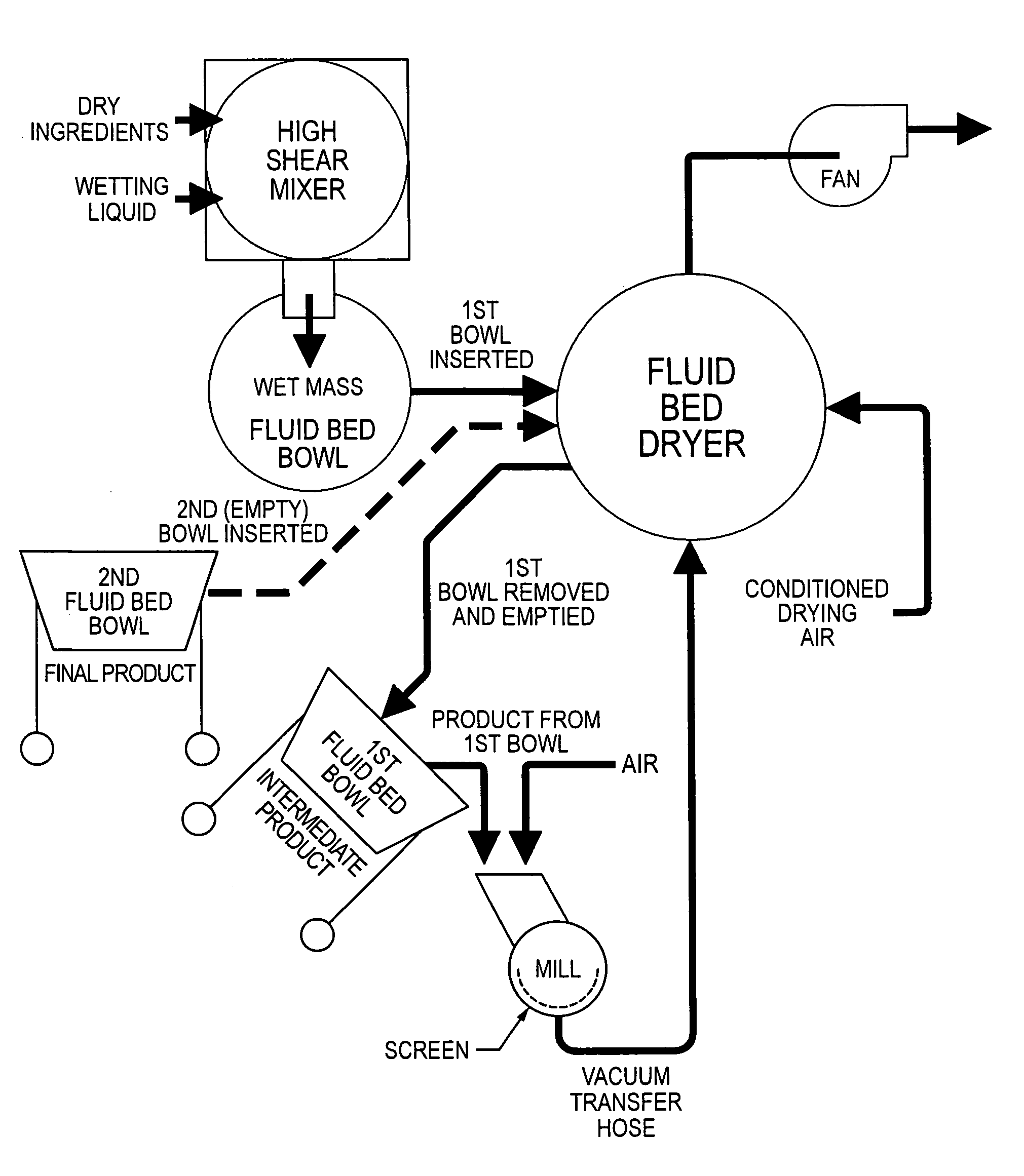

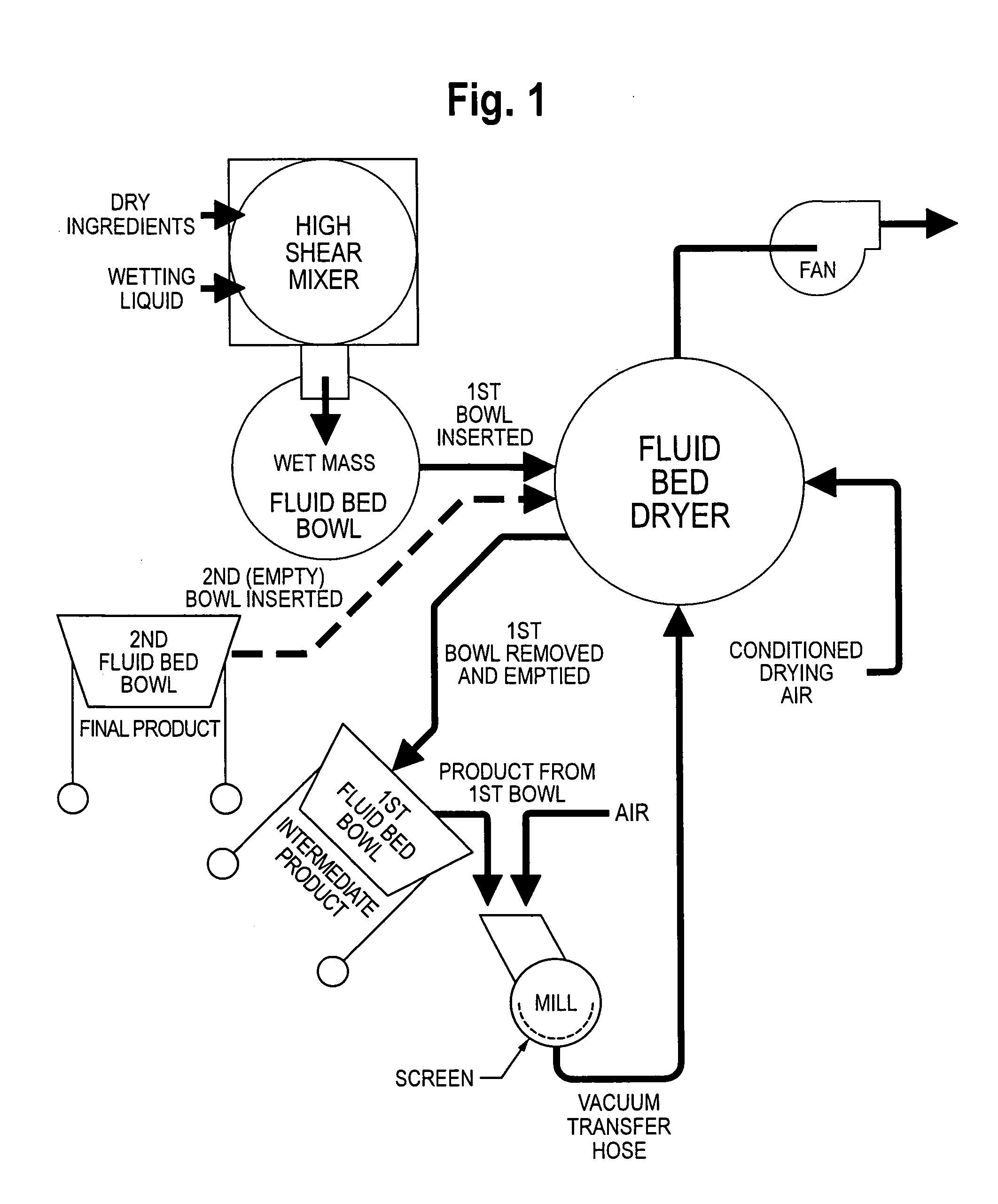

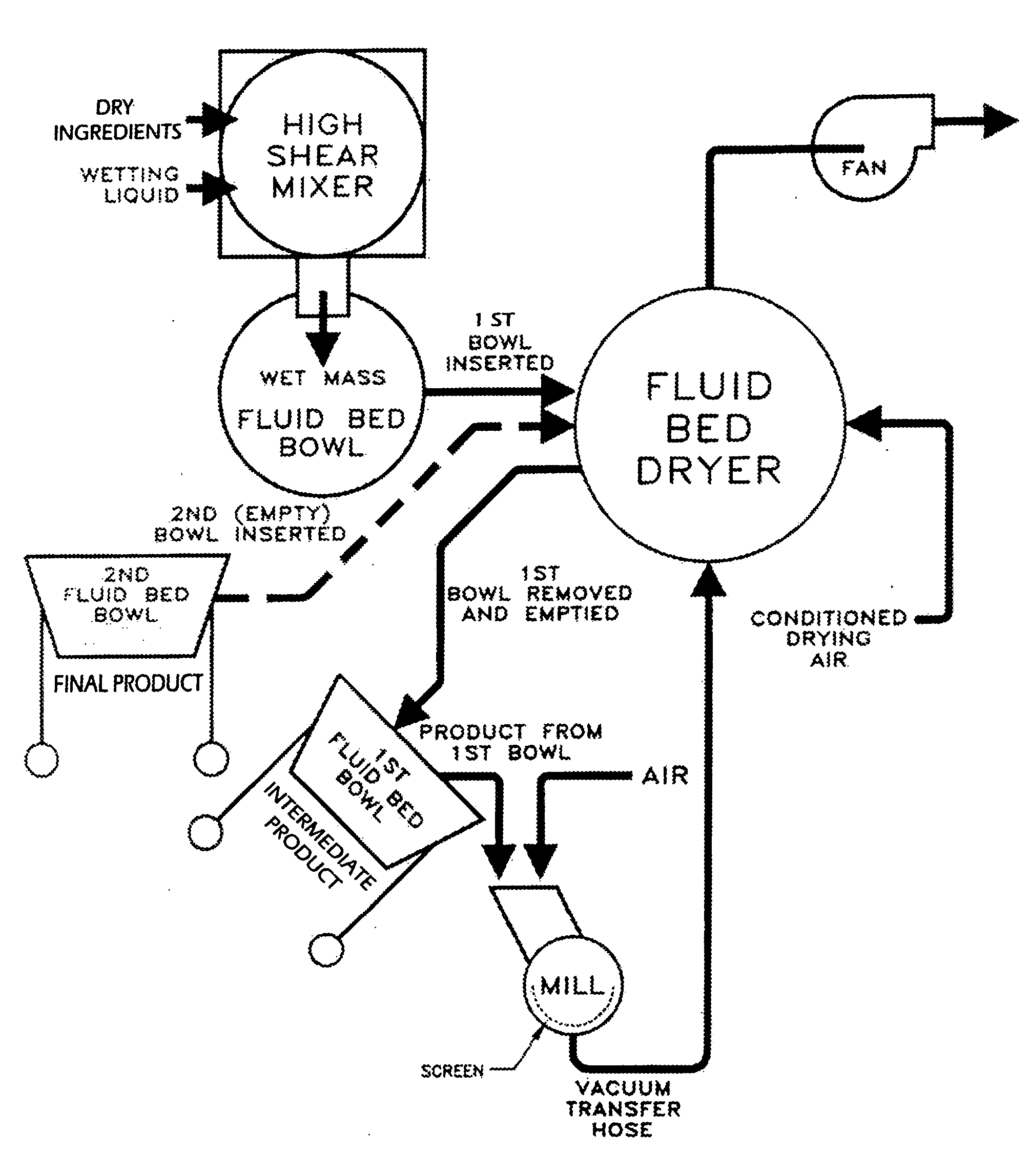

Method for producing small granules

InactiveUS7207505B2Efficient formationIncrease food productionGranular deliveryGranulation by powder suspensionProcess equipmentHigh-shear mixer

A method for quickly forming a high value powdered feed materials, particularly pharmaceuticals, into small, durable granules using known elements of process equipment, comprising the steps of mixing the feed materials with a wetting solution in a high shear mixer or granulator, partially drying the granulated mixture in a first drying means to a state of intermediate dryness, milling the partially dried granulated product in a stream of air to create small partially dried granules of the desired physical size, and drying the product in the second drying means to the desired final Loss On Drying (LOD) percentage of wetting solution. The milled product may be conveyed by vacuum from the milling step to the second drying means through a relatively long cylindrical transfer hose to create uniformly rounded granules.

Owner:FFP LLC

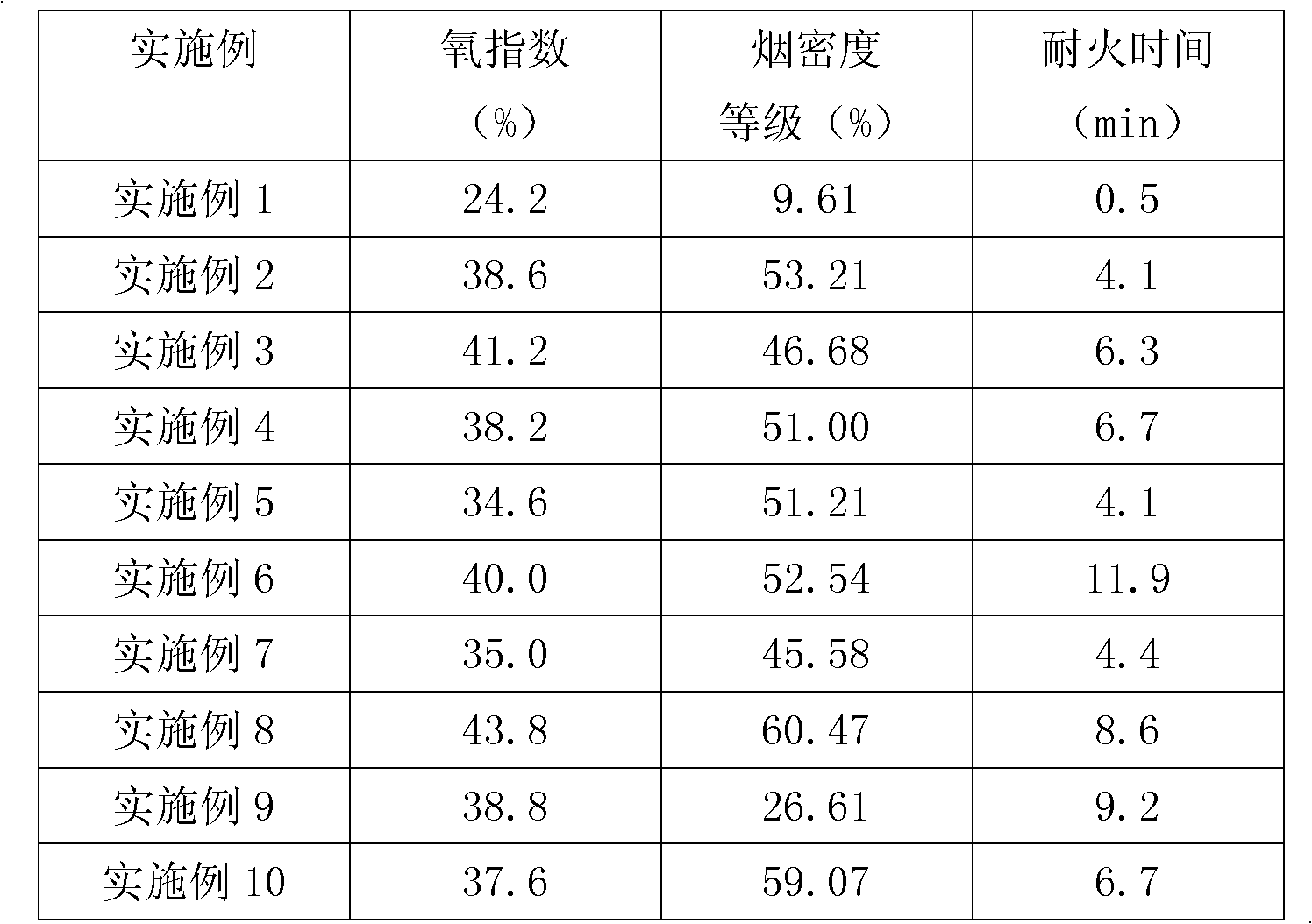

A kind of high-efficiency environment-friendly flame retardant for coating flame retardant and preparation method thereof

InactiveCN102277030AHigh synergistic flame retardant performanceImprove performancePolyester coatingsSodium BentoniteSilanes

The invention relates to a flame retardant of an environment-friendly expansion type flame retardant coating and a preparation method thereof. In the present invention, tea saponin is used as gas source, acid source and carbon source to form a new type of flame retardant in a certain proportion. Alkyd resin varnish is used as base material, and auxiliary agents such as coupling agent and dispersant are added to form a high-efficiency flame retardant. burn paint. In terms of the weight percentage of the solid content of the coating, its important components are: alkyd resin varnish 40-60%; ammonium polyphosphate 25-35%; pentaerythritol 12-18%; tea saponin 2-5%; silane coupling agent 1 -3%; organic bentonite 1-3%. The preparation method is as follows: mix tea saponin, ammonium polyphosphate and pentaerythritol in proportion, grind them sufficiently to obtain superfine powder, then add them to alkyd resin varnish in a certain proportion, stir and mix well, add silane coupling The joint agent and organic bentonite are fully stirred and dispersed in a high-speed shear mixer to obtain a finished product. The invention does not contain a halogen flame retardant, has the advantages of low volatility, excellent flame retardancy, good coating film performance, high efficiency and environmental protection, and the like.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY +1

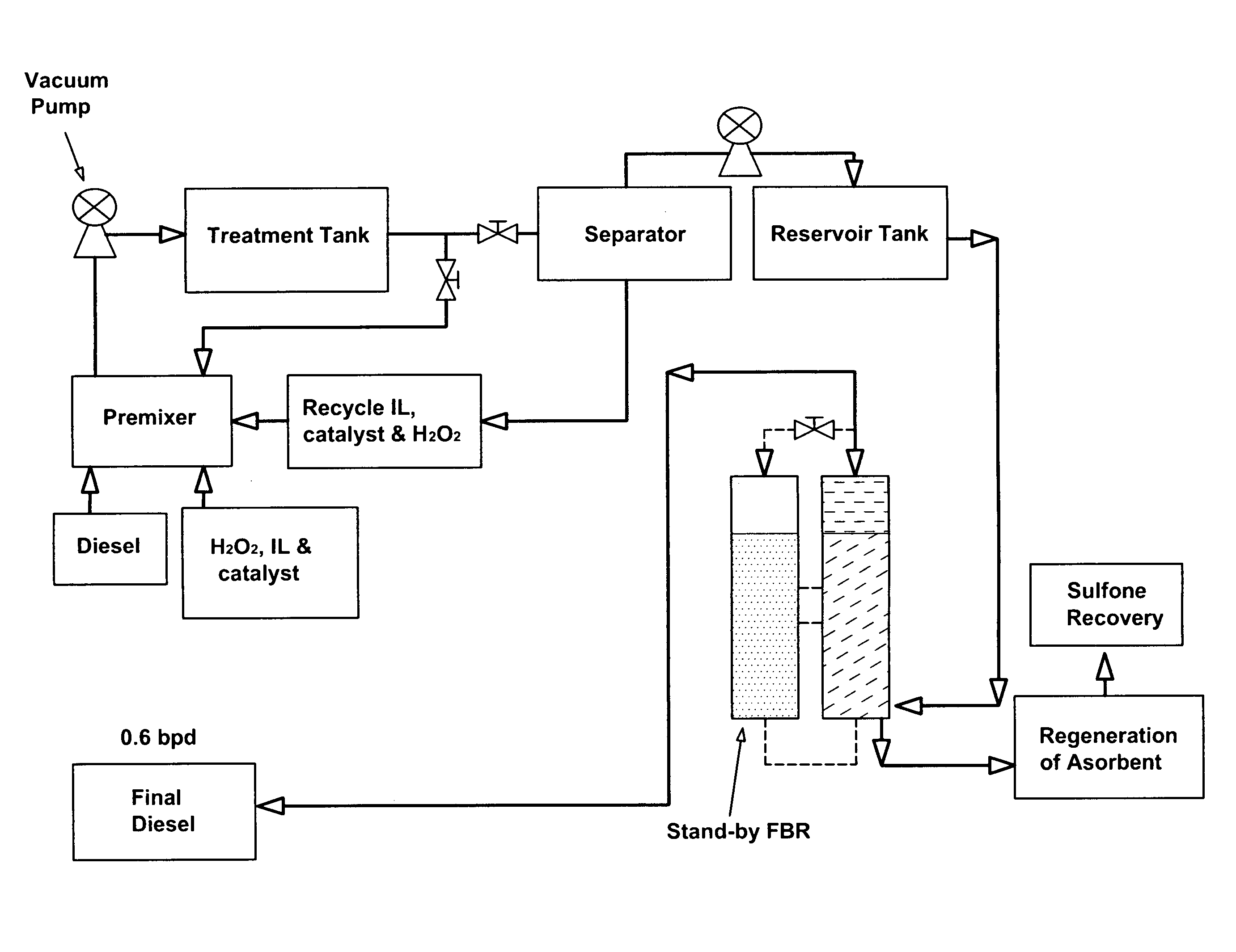

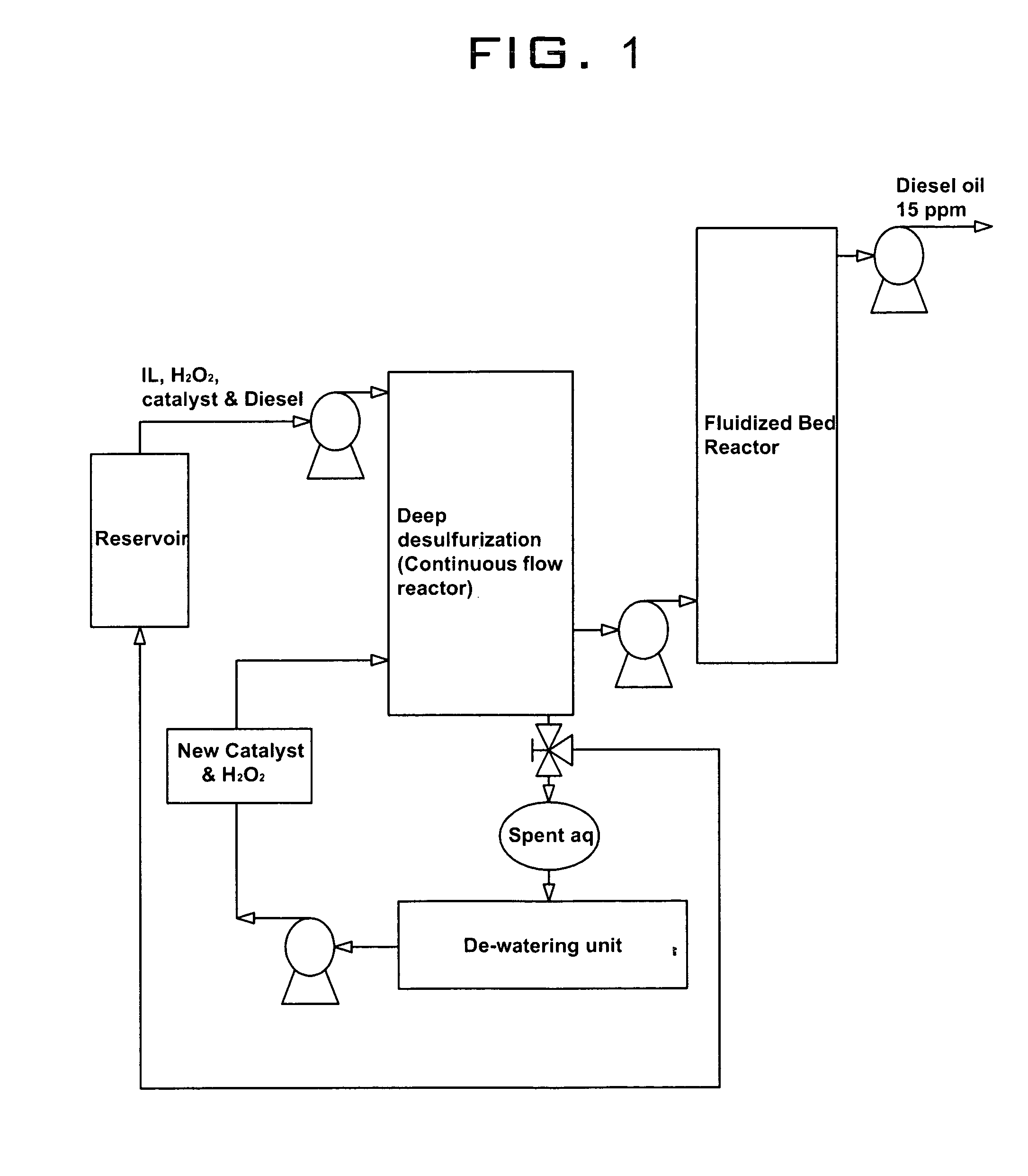

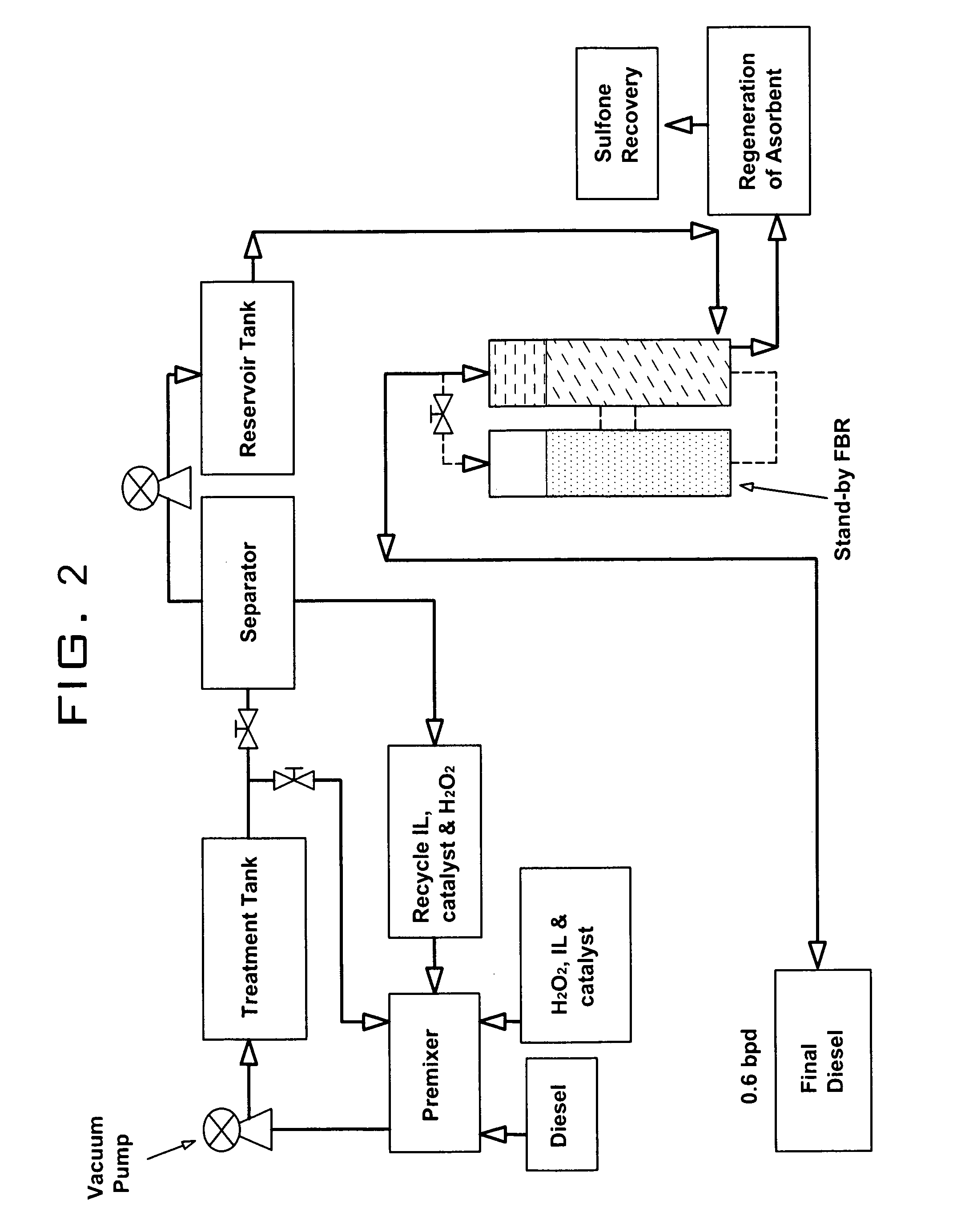

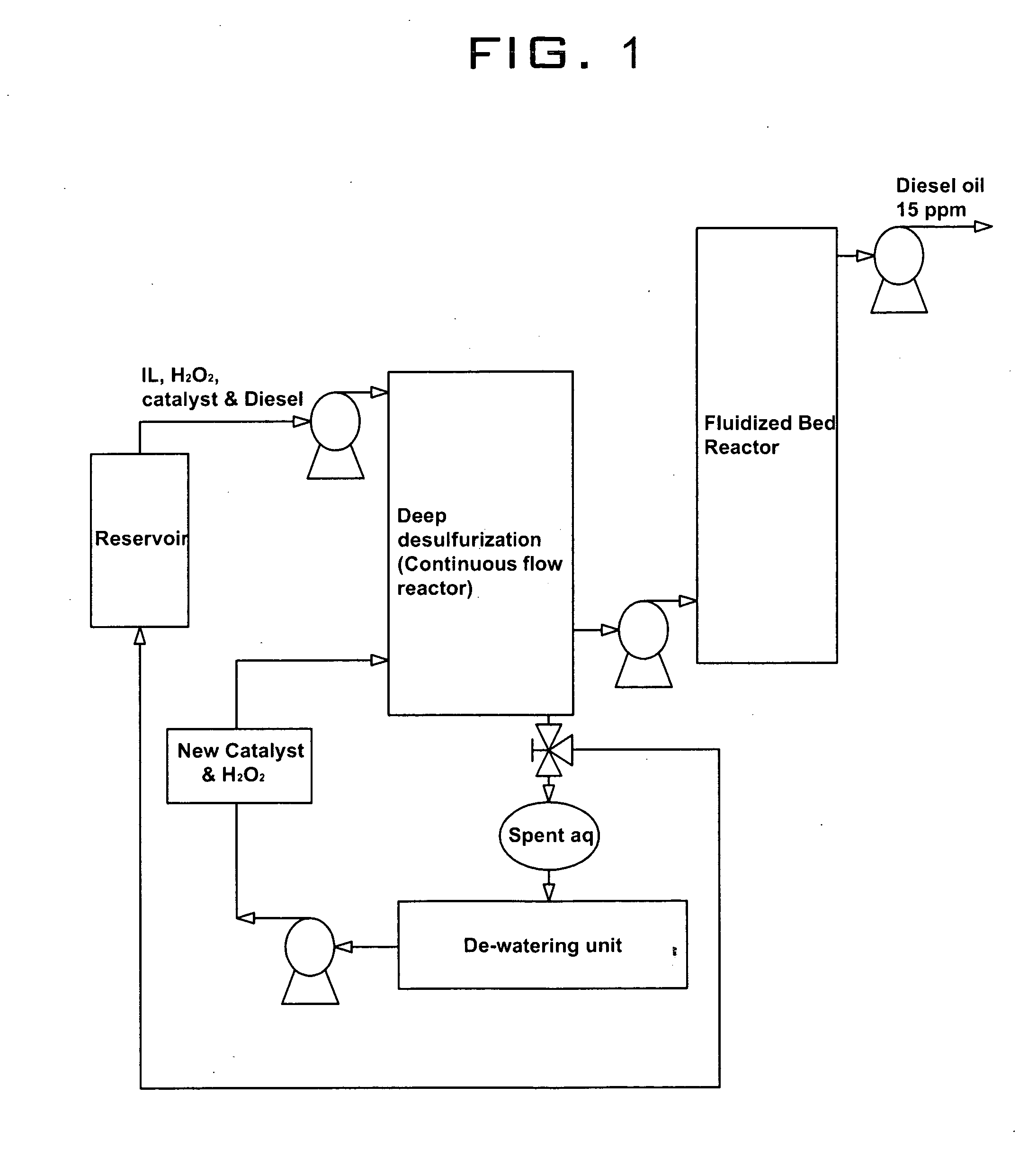

Diesel desulfurization method

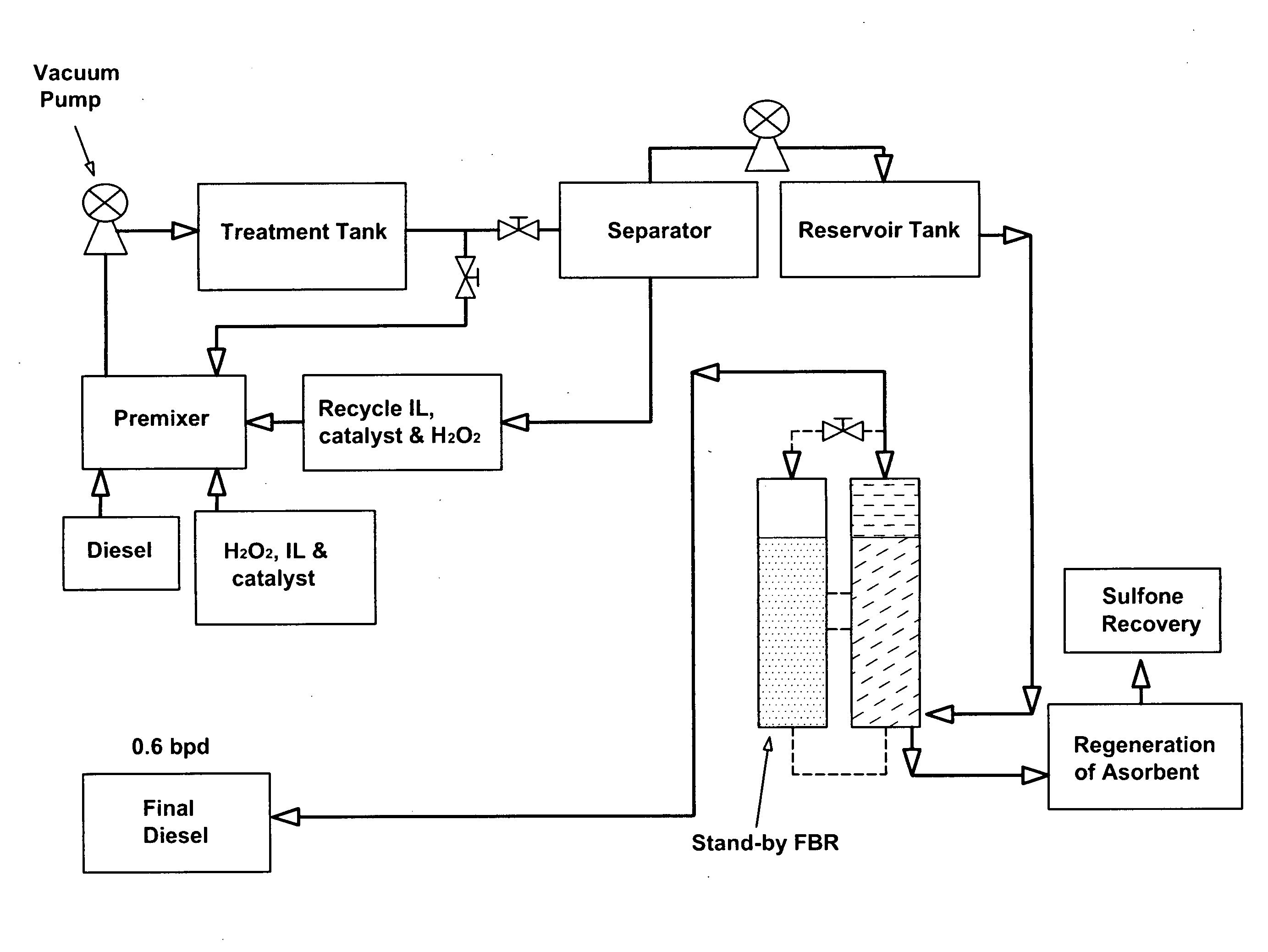

InactiveUS7758745B2Efficient removalRefining with oxygen compoundsRefining with acid-containing liquidsAcetic acidFluidized bed

A diesel desulfurization method has various steps including: implementing a modified oxidative desulfurization (UAOD) process. The UAOD has the steps of: mixing diesel fuel with room temperature ionic liquid, oxidant, phase transfer catalyst, and acid catalyst in a tank in a mix; recycling the ionic liquid and recycling the acid catalyst in aqueous phase. A step is to move the sulfur from the diesel fuel in a fluidized bed reactor (FBR) having bed reactor material. The process can be improved with ultrasound during mixing, or a high shear mixer. The bed reactor is preferably acidic alumina for adsorbing oxidized sulfur. The oxidant is preferably hydrogen peroxide (H2O2). The acid catalyst is preferably a mixture of Acetic acid and Tri-fluoro acetic acid.

Owner:GREENTECH REFINING

Storage stabilized devulcanized tire rubber modified asphalt composition and the process for its preparation

ActiveUS20160096960A1Good miscibilityImprove solubilityIn situ pavingsBituminous material adhesivesSynthetic rubberAsphalt

This invention relates to a storage stabilized recycled and devulcanized tire rubber modified asphalt composition, which comprises: 65.0 to 90.0% by weight of a neat asphalt, 3.0-50.0% by weight of a recycled and devulcanized rubber from used tires and / or other scrap rubbers, 0.01-15.0% by weight of a compatibilizer / stabilizer derived from Natural or Synthetic Rubbers, which composition passes the “cigar tube” softening point test difference of less than 5° C. between the top and bottom layers; and, the process for the said asphalt composition comprises mixing 65.0% to 90.0% by weight of a neat asphalt, 3.0 to 50.0% by weight of a recycled and devulcanized rubber from used tires, 0.01-10.0% by weight of a compatibilizer / stabilizer derived from Natural or Synthetic Rubbers, using high shear mixers at elevated temperatures of between 120° C. and 175° C. for between 15 minutes to 6 hours, to obtain storage stabilized asphalt composition that is stable in hot storage and transportation conditions.

Owner:PILLAI CHANDRASEKARAN RAMAYYA +1

Efficient mixing process for producing thermoplastic elastomer composition

Owner:EXXONMOBIL CHEM PAT INC +1

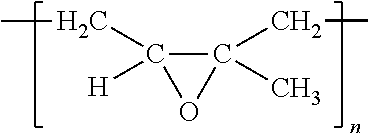

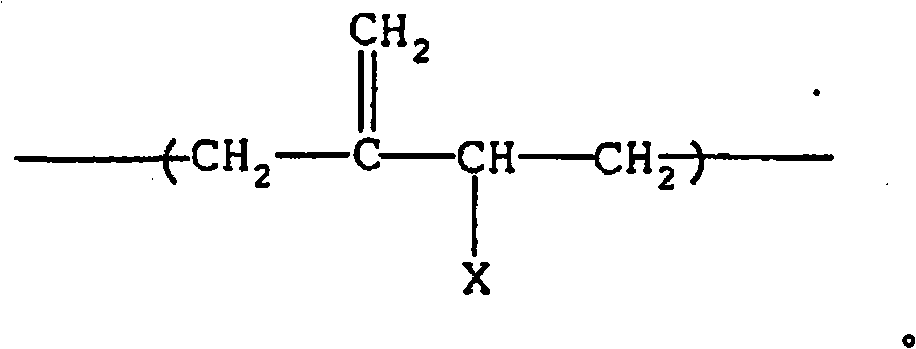

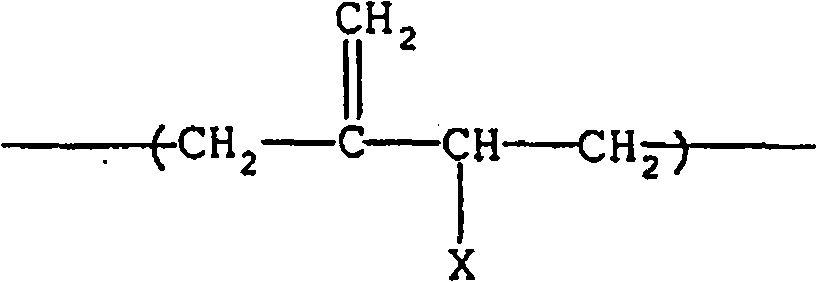

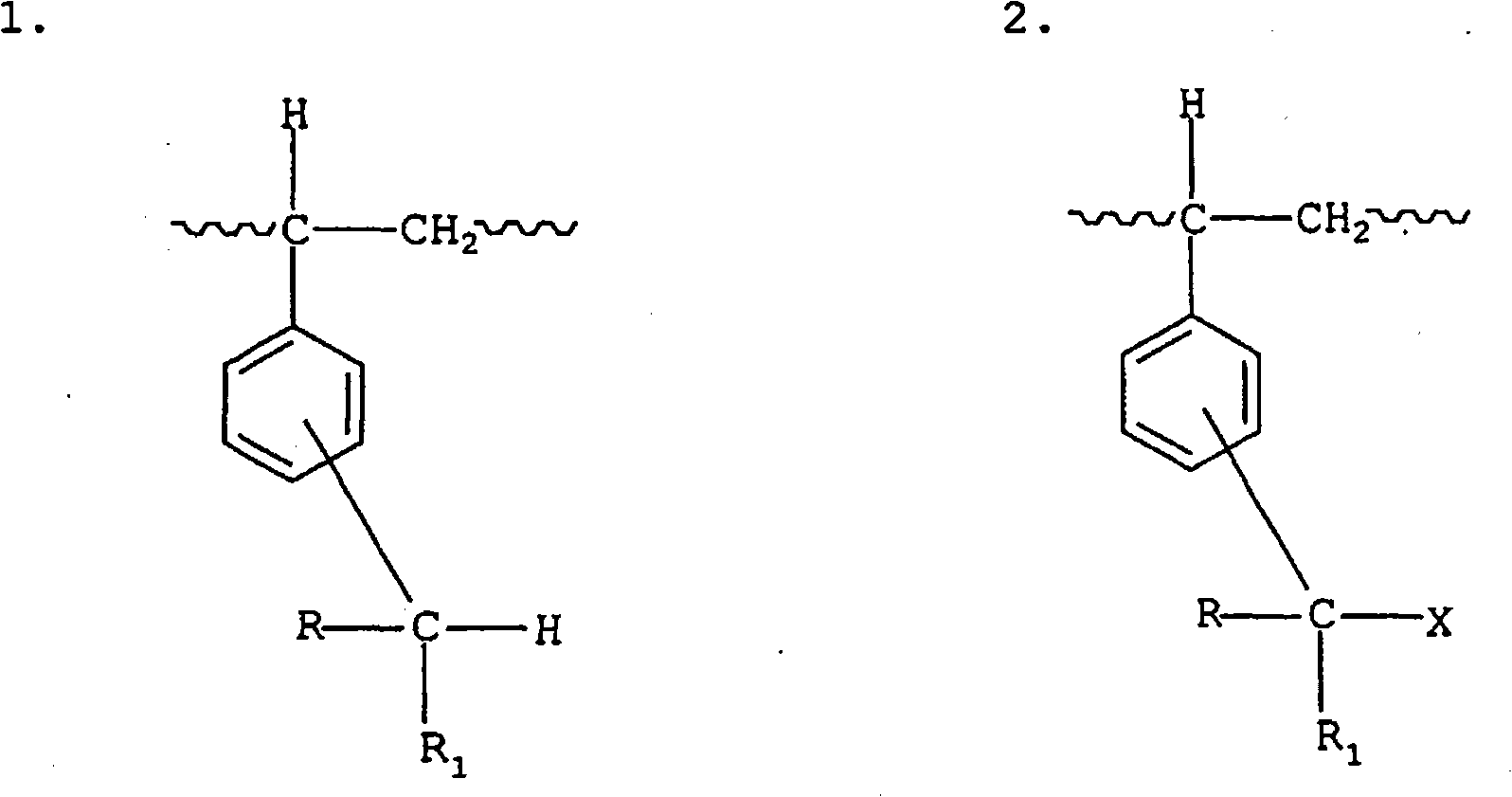

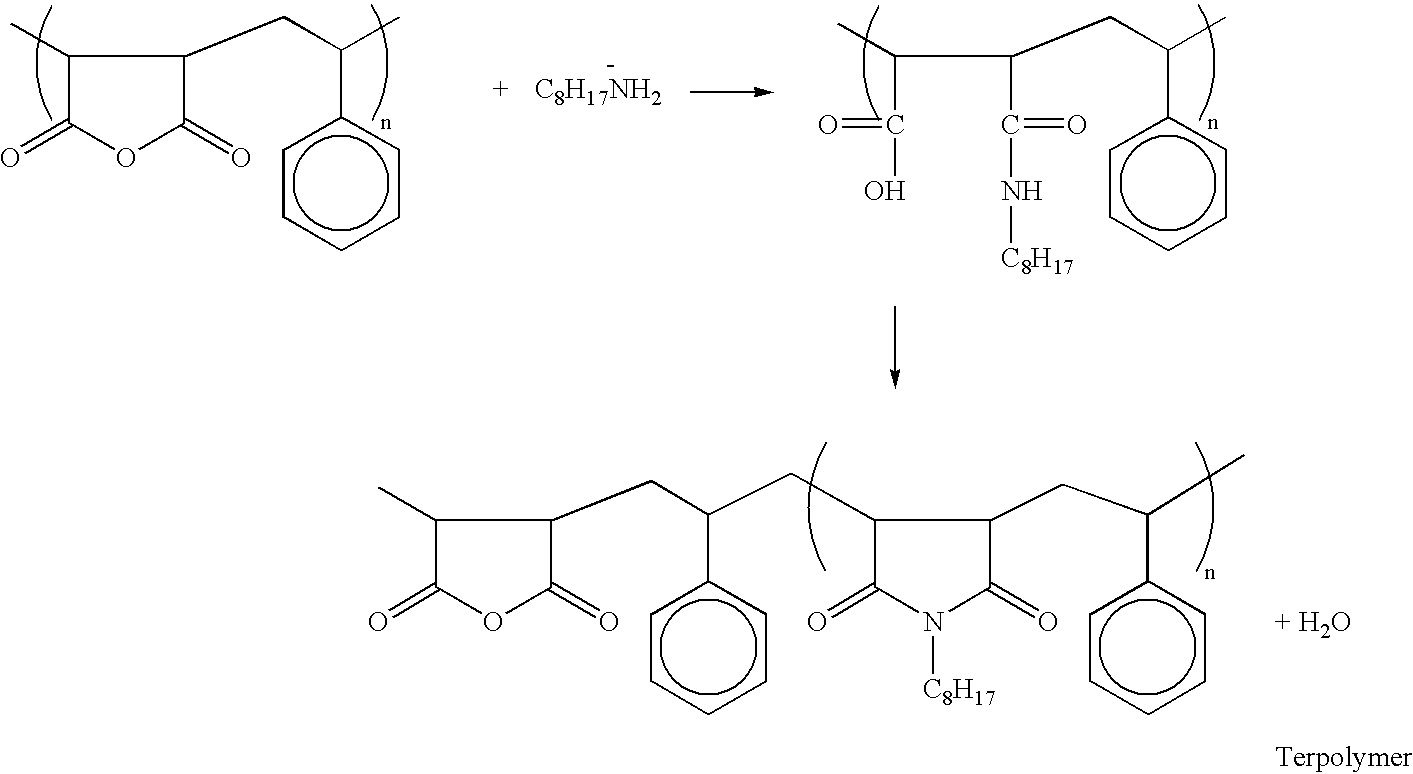

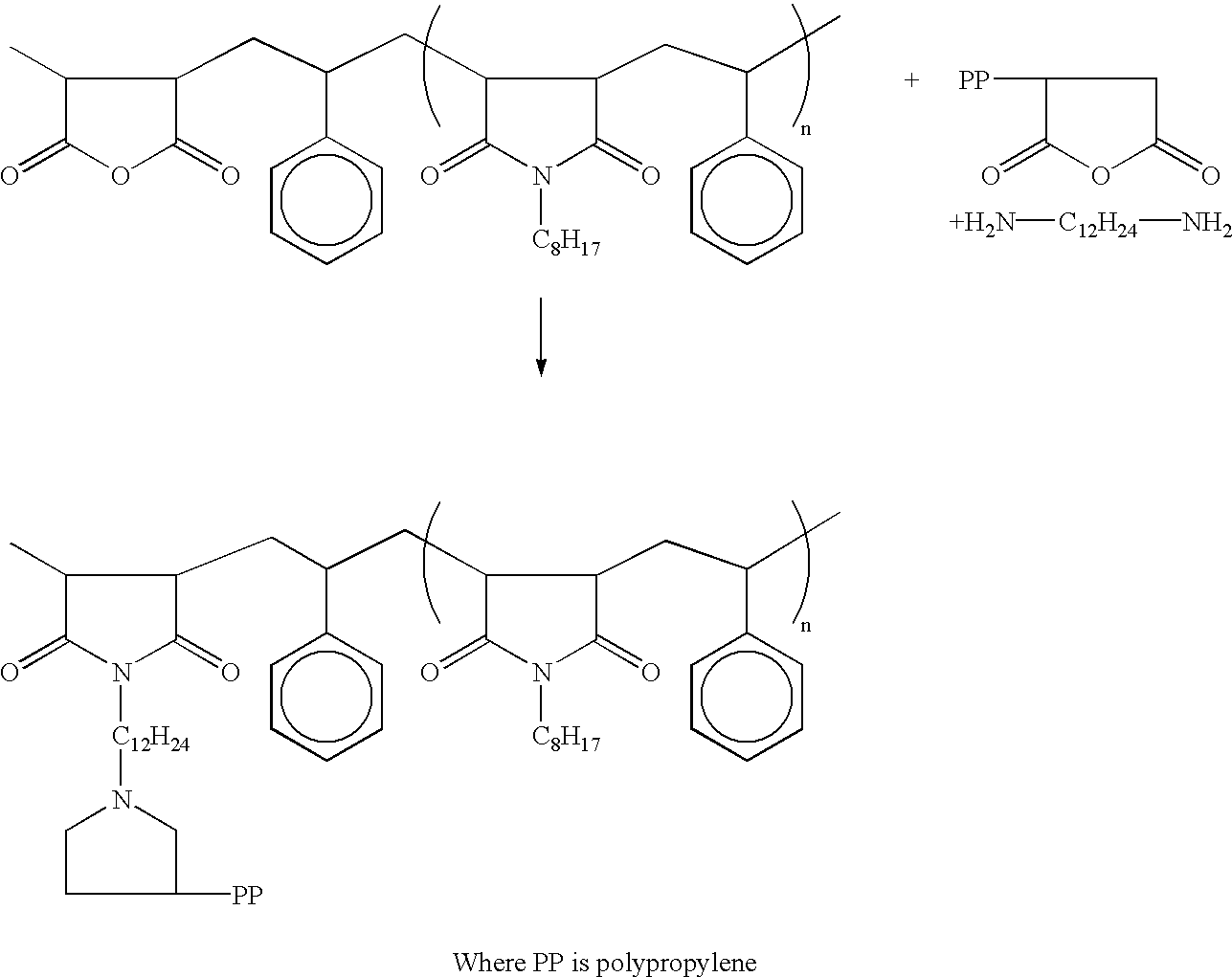

Process for forming centipede polymer gels

InactiveUS7429393B2Increase dampingImprove damping performancePowder deliveryCosmetic preparationsPolymer scienceCopolymer

A process that enables the formation of a high damping, soft polymer gel includes reacting a maleimide copolymer with a maleated polyalkylene and an alkyl diamine under substantially dry conditions sufficient to form a polyalkylene-grafted maleimide copolymer product which then is dispersed with an extender sufficient to form the gel. The steps can be carried out sequentially in a high shear mixer without the need for intermediate steps of cooling and grinding the reaction product of one step before proceeding to the next.

Owner:BRIDGESTONE CORP

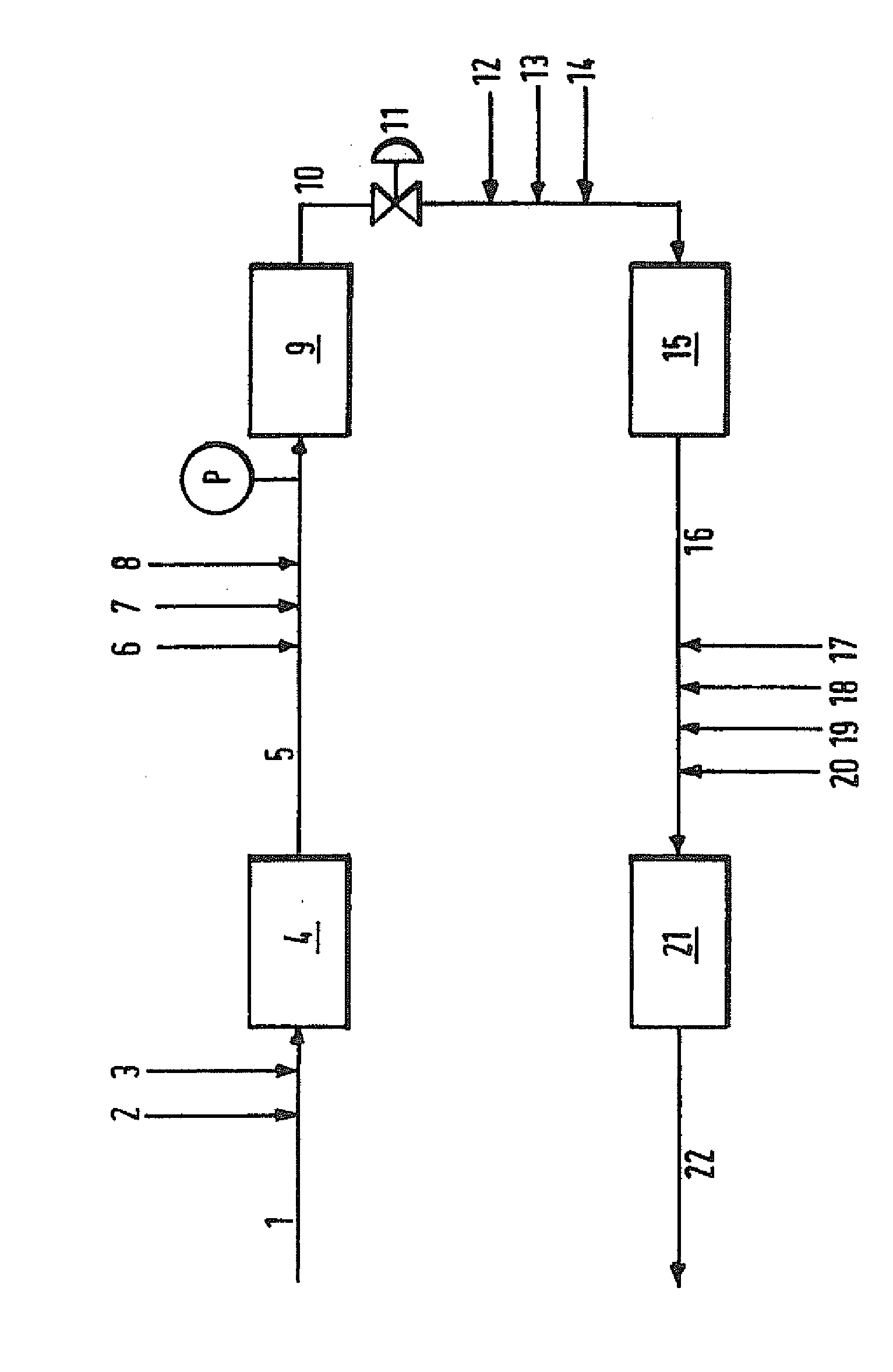

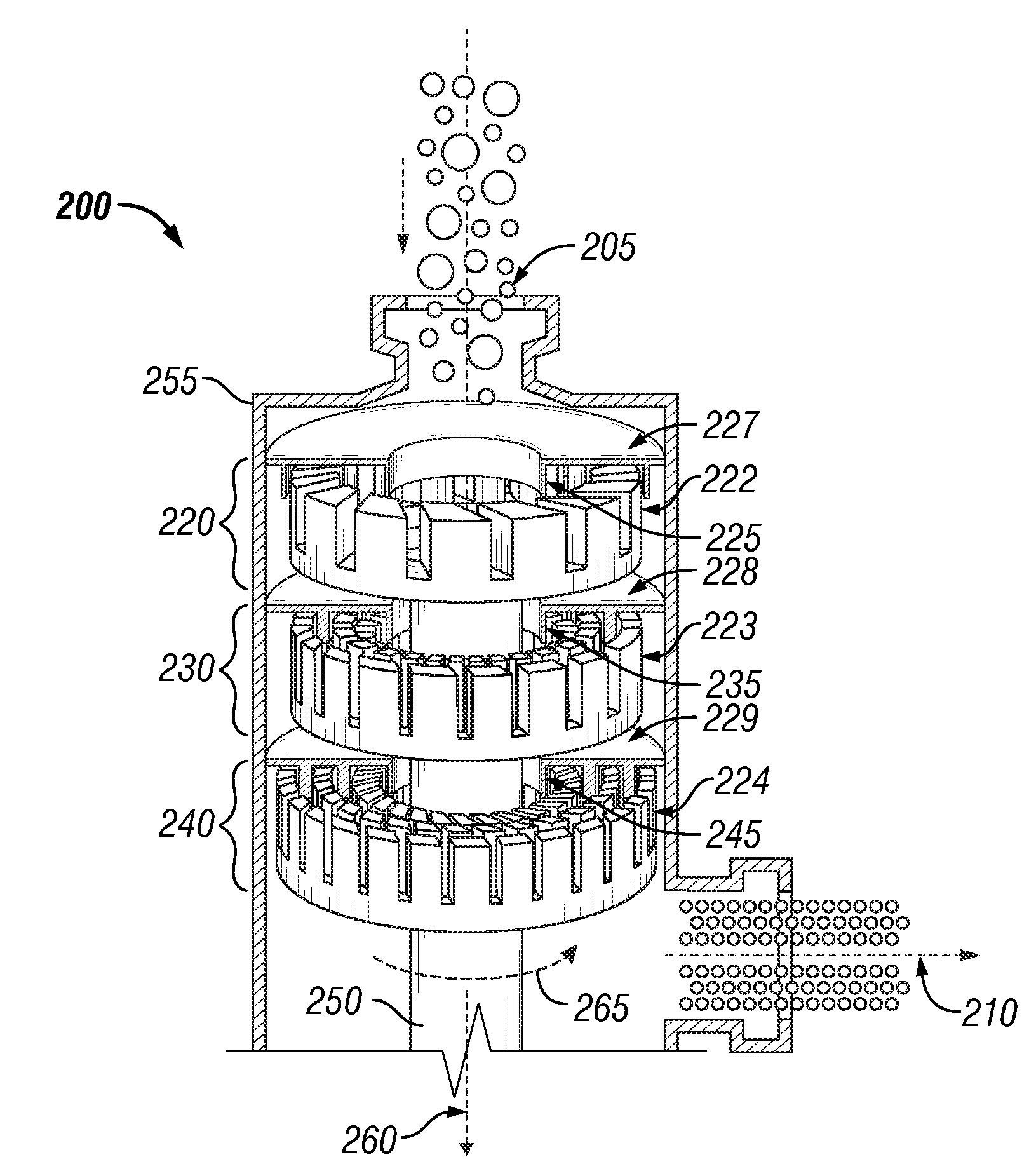

Continuous high shear mixing process

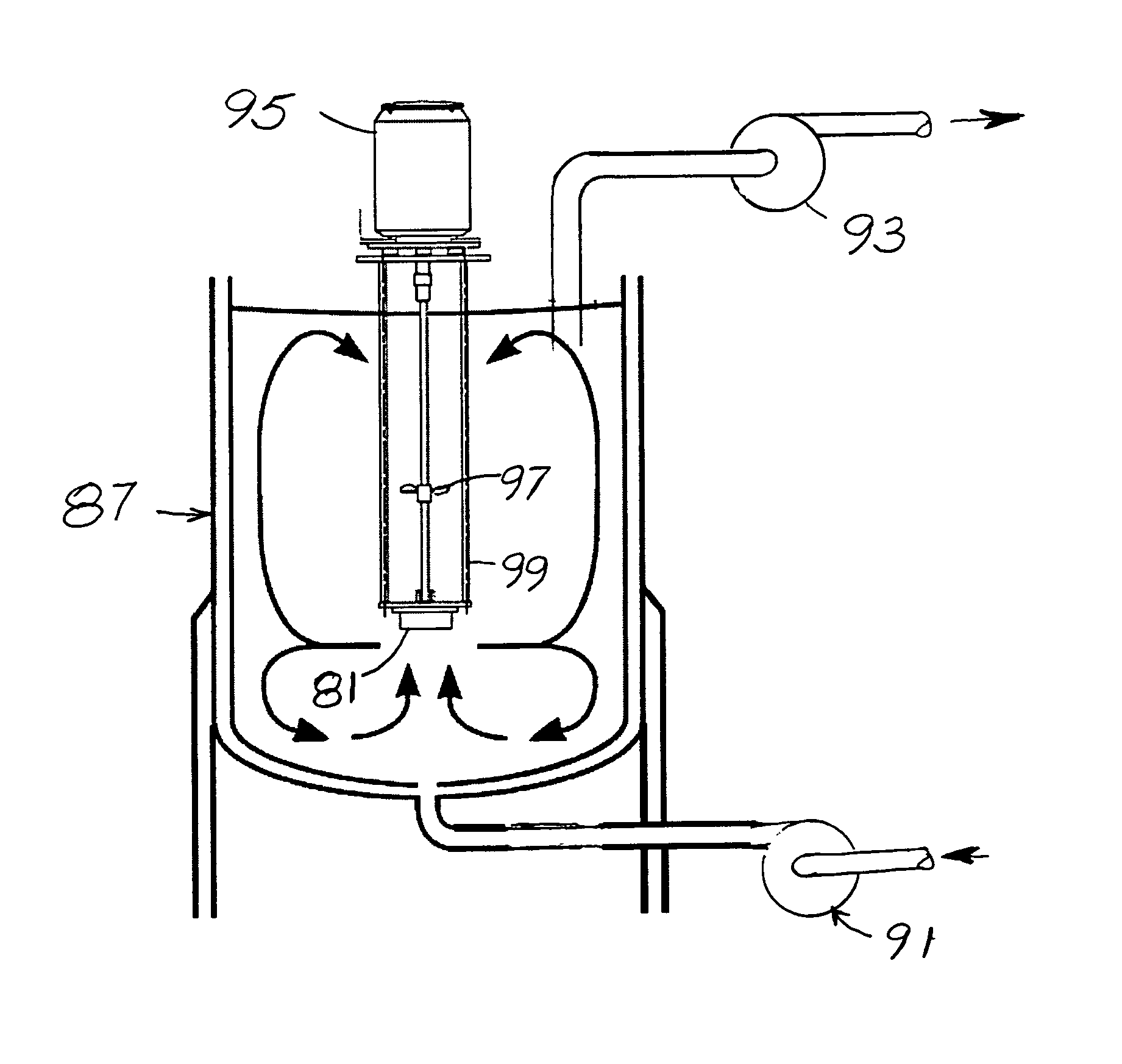

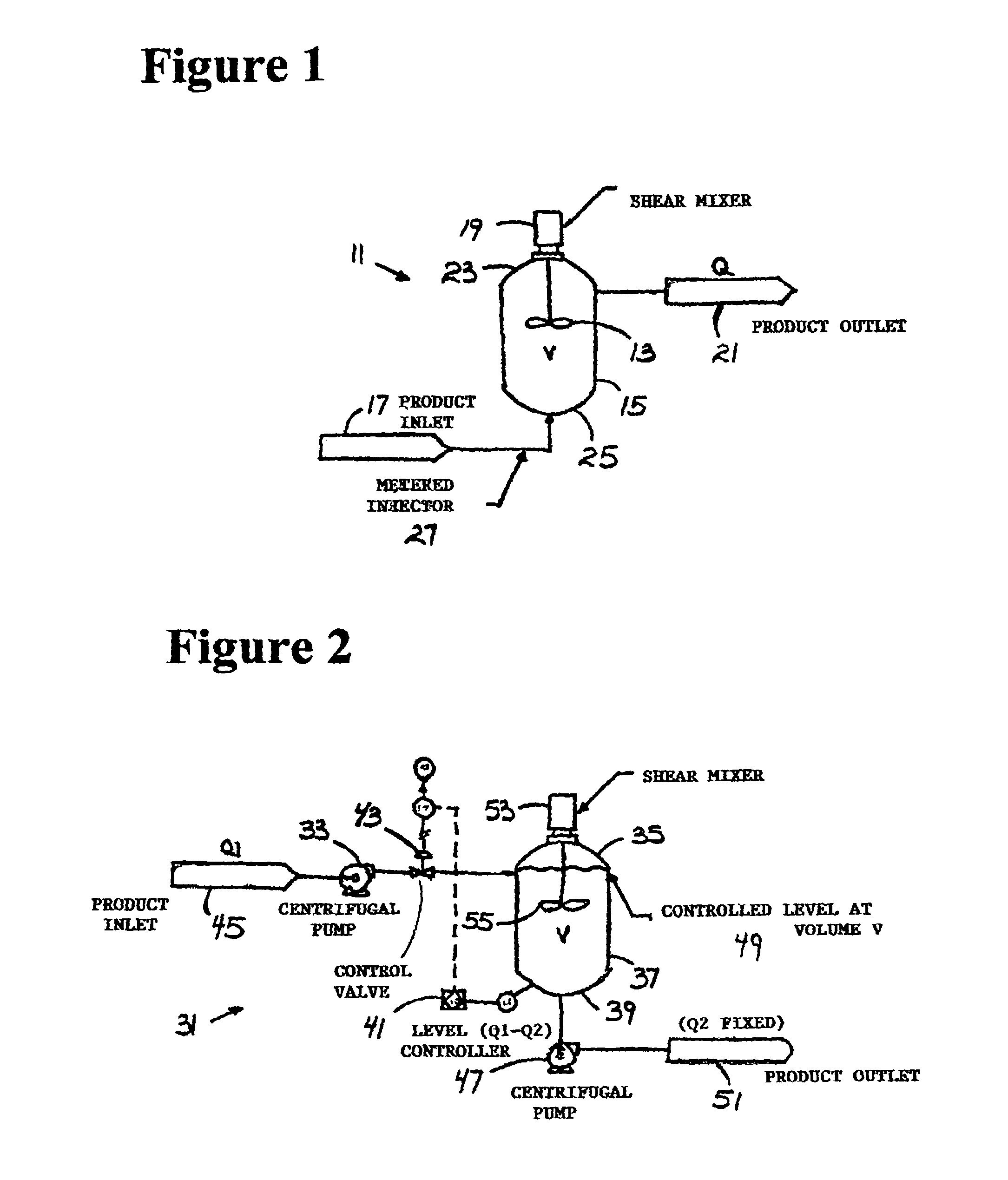

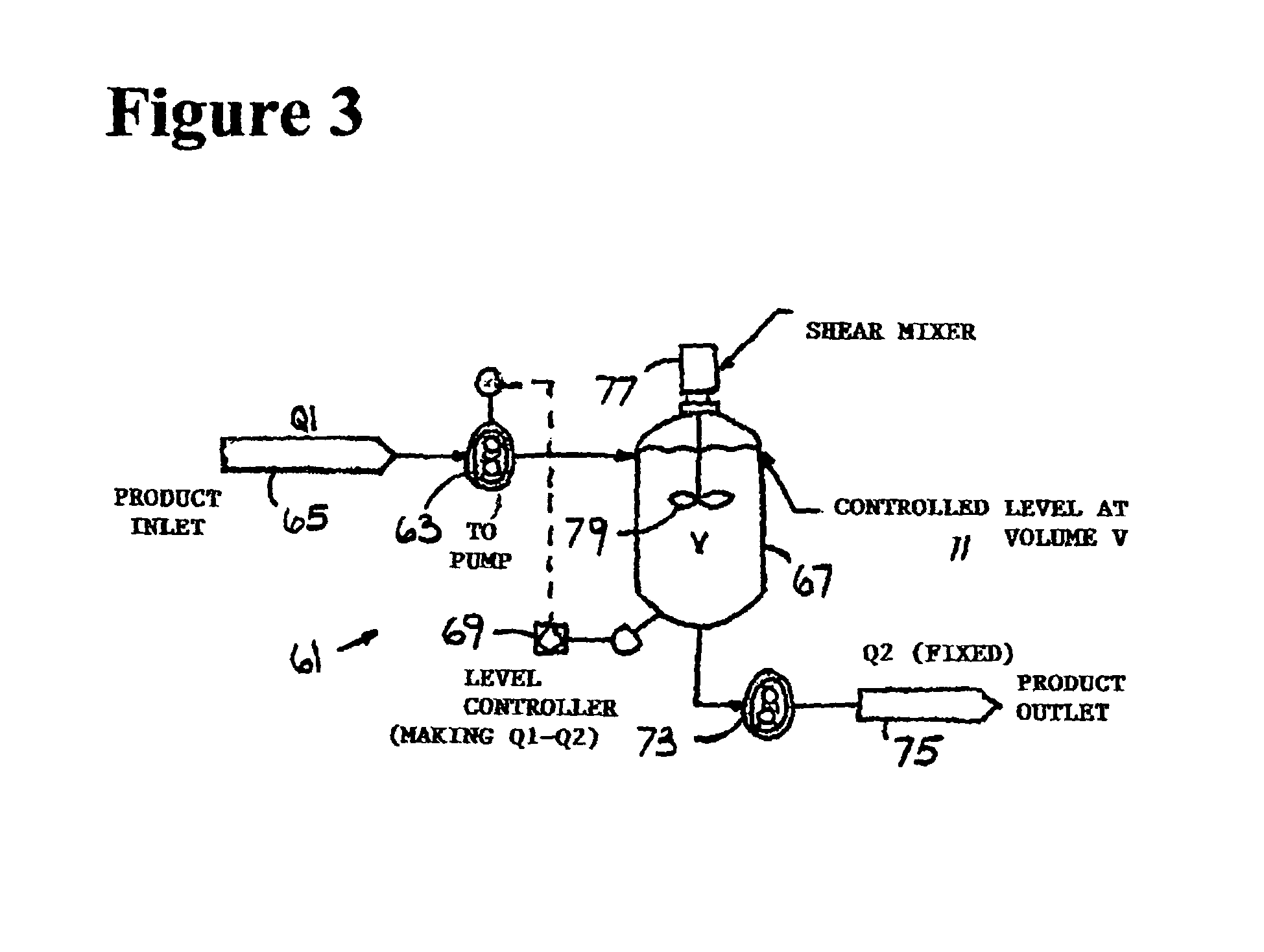

ActiveUS8047702B1Lower cost of capitalSave energyControlling ratio of multiple fluid flowsRotary stirring mixersContinuous flowEngineering

A high shear mixer in a holding tank is used in a continuous flow process. Flow rate of material into and out of the holding tank establishes residence time in contact with shearing elements. A batch shear mixer is used in a tank that has continuous flow into the bottom and out of the top. A level controller controls a valve or a positive displacement pump at the inlet. The mixing chamber is sized for the maximum needed residence time, slowing the flow increases the residence time. In an open tank lower inlet pump and upper outlet pump are coordinated. Incoming flow rate matches outgoing flow for continuous processing.

Owner:LOPRESTI WILLIAM J

Processes for producing nanocellulose-lignin composite materials, and compositions obtained therefrom

InactiveUS20160168272A1Maintain good propertiesMaterial nanotechnologyPulp properties modificationCellulose fiberVortex mixer

This invention provides a process for producing a nanocellulose-lignin material, comprising: providing a starting material comprising lignin and discrete cellulose fiber fines, chemically and physically separate from the lignin; and mechanically refining the starting material to form a nanocellulose-lignin material comprising cellulose nanofibrils and / or cellulose nanocrystals chemically or physically associated with the lignin. In certain embodiments, the starting material contains about 60 wt % lignin and about 40 wt % cellulose fiber fines on a dry basis. The starting material may be obtained from an AVAP® process. The refining may utilize single disk refiners, double disk refiners, conical refiners, cylindrical refiners, beaters, grinders, homogenizers, microfluidizers, vortex mixers, rotor-stator mixers, and / or high-shear mixers, for example. A novel nanocellulose-lignin composite material is obtained.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

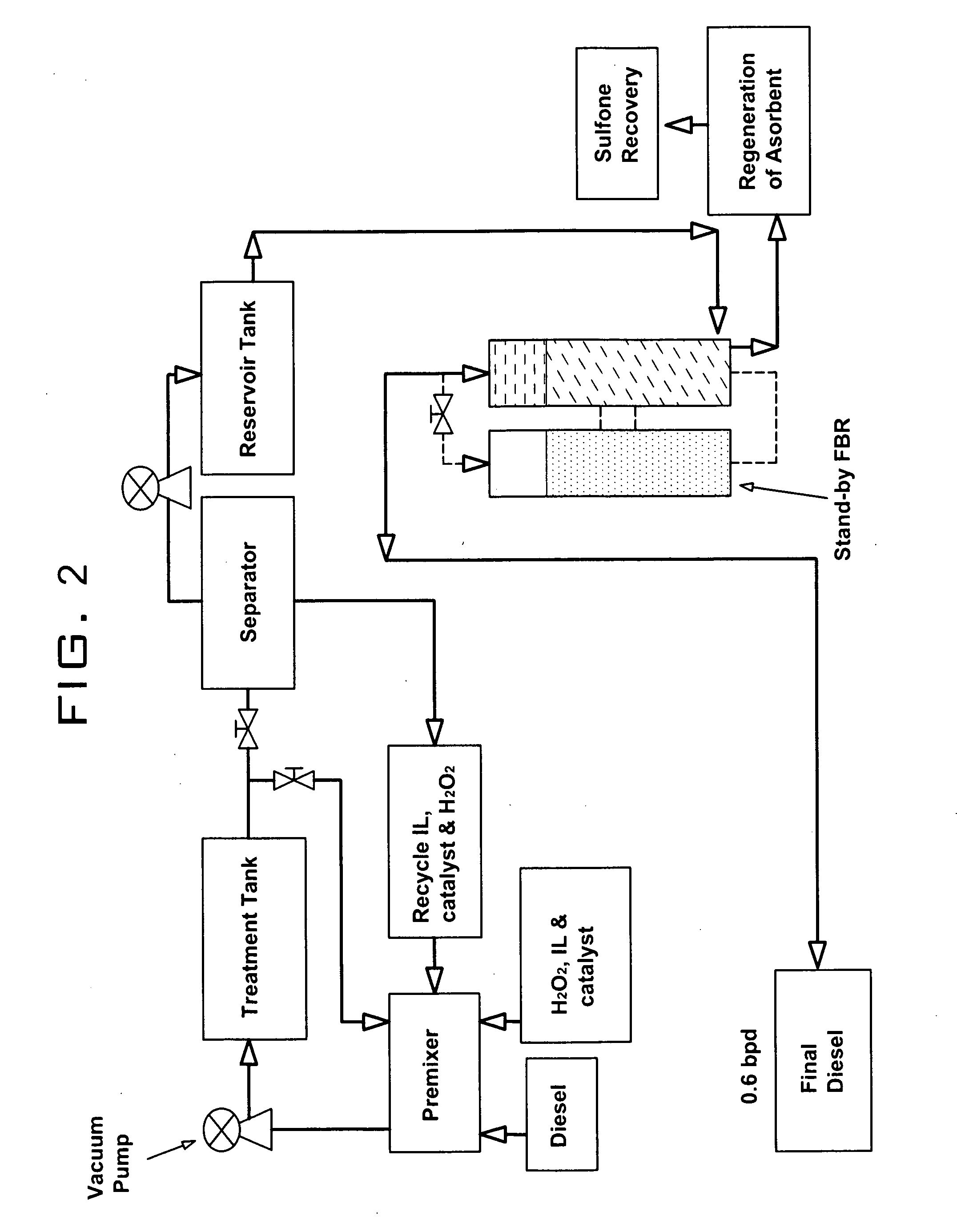

Diesel desulfurization method

InactiveUS20090236266A1Efficient removalRefining with oxygen compoundsRefining with acid-containing liquidsAcetic acidTrifluoroacetic acid

A diesel desulfurization method has various steps including: implementing a modified oxidative desulfurization (UAOD) process. The UAOD has the steps of: mixing diesel fuel with room temperature ionic liquid, oxidant, phase transfer catalyst, and acid catalyst in a tank in a mix; recycling the ionic liquid and recycling the acid catalyst in aqueous phase. A step is to move the sulfur from the diesel fuel in a fluidized bed reactor (FBR) having bed reactor material. The process can be improved with ultrasound during mixing, or a high shear mixer. The bed reactor is preferably acidic alumina for adsorbing oxidized sulfur. The oxidant is preferably hydrogen peroxide (H2O2). The acid catalyst is preferably a mixture of Acetic acid and Tri-fluoro acetic acid.

Owner:GREENTECH REFINING

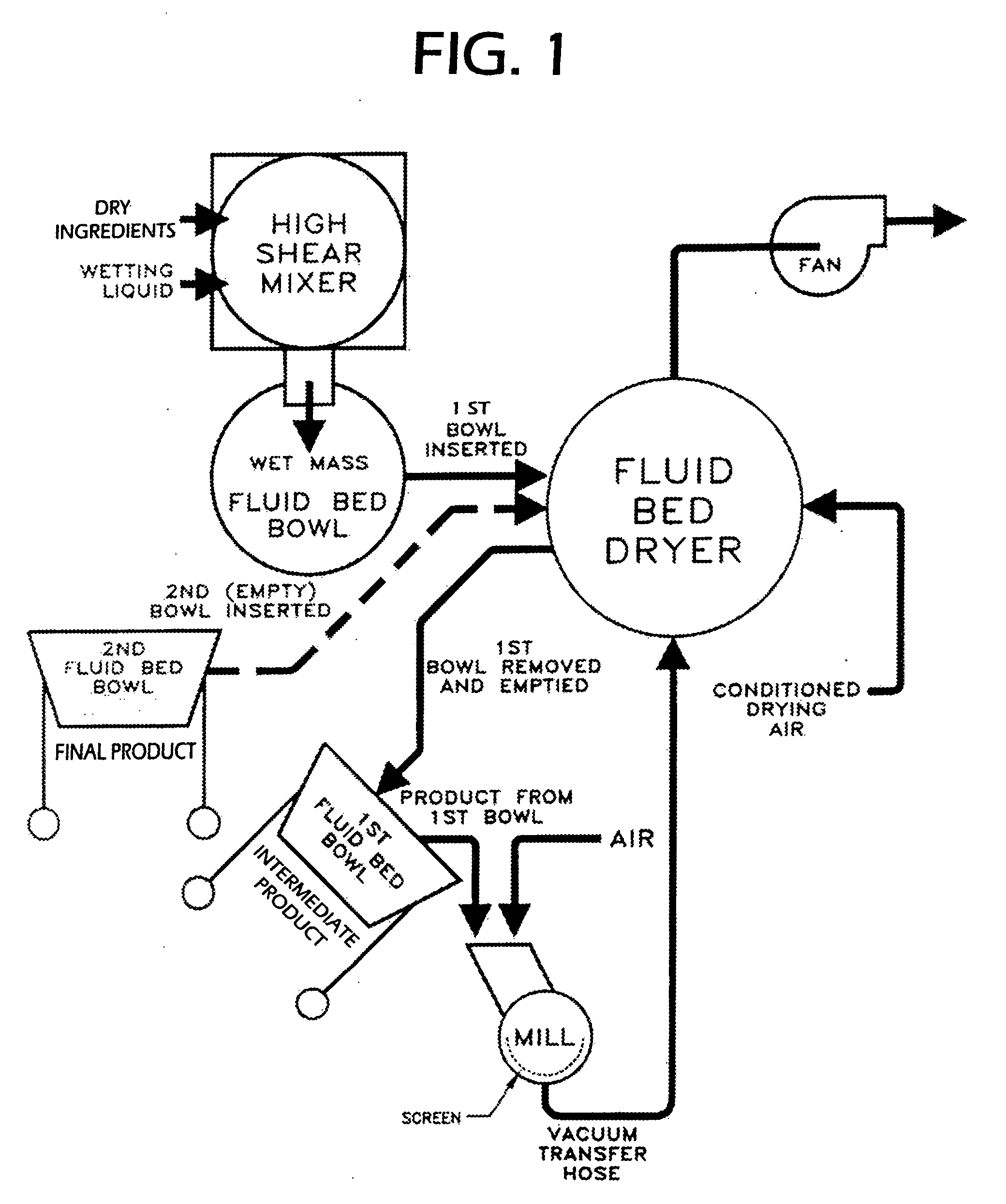

Method for producing small granules

InactiveUS20050269433A1Efficient formationIncrease food productionGranular deliveryGranulation by powder suspensionProcess equipmentProcess engineering

A method for quickly forming a high value powdered feed materials, particularly pharmaceuticals, into small, durable granules using known elements of process equipment, comprising the steps of mixing the feed materials with a wetting solution in a high shear mixer or granulator, partially drying the granulated mixture in a first drying means to a state of intermediate dryness, milling the partially dried granulated product in a stream of air to create small partially dried granules of the desired physical size, and drying the product in the second drying means to the desired final Loss On Drying (LOD) percentage of wetting solution. The milled product may be conveyed by vacuum from the milling step to the second drying means through a relatively long cylindrical transfer hose to create uniformly rounded granules.

Owner:FFP LLC

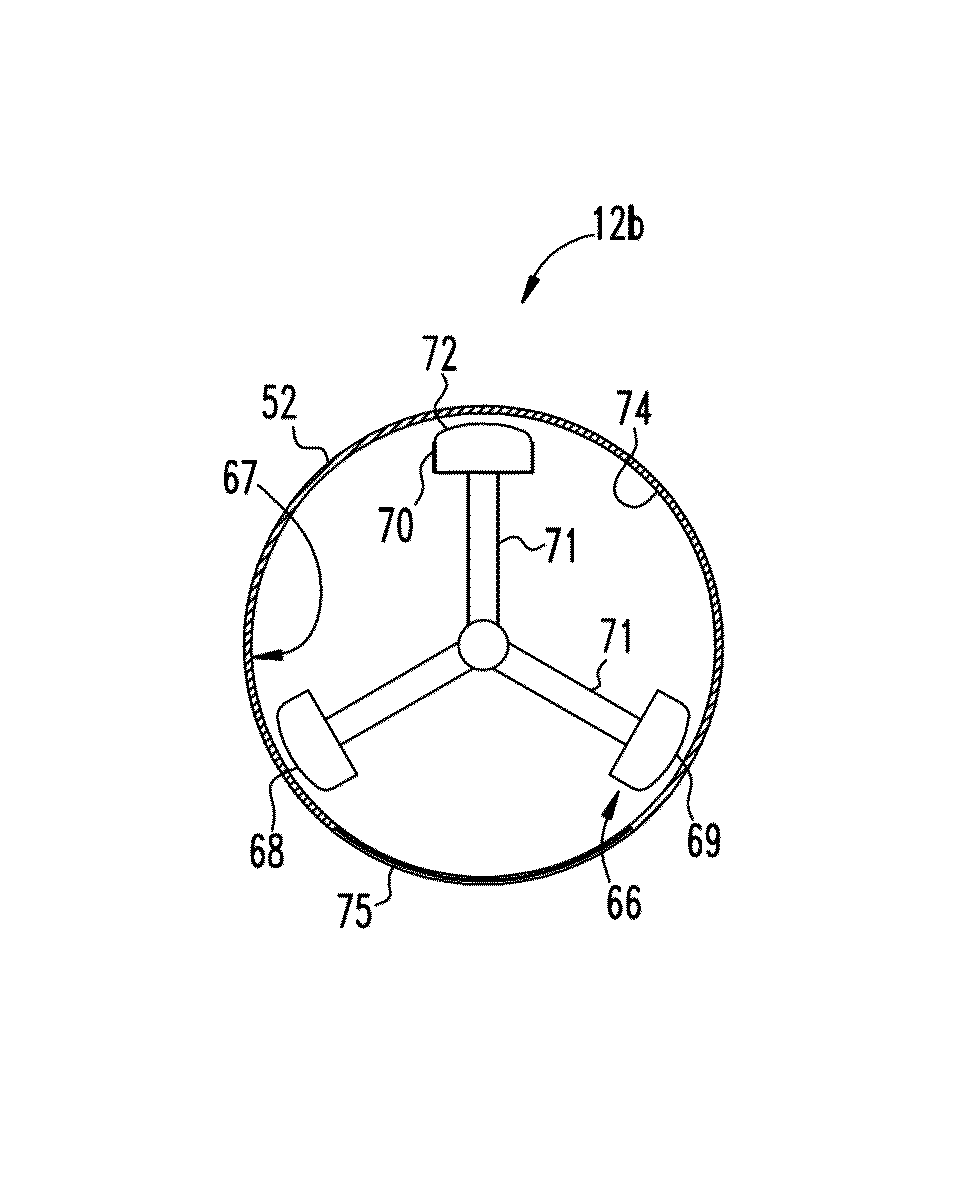

Apparatus and method for producing biobased carriers from byproducts of biomass processing

An apparatus for producing biobased carriers for dispersal of biological and chemical molecules includes a premixer having a first inlet, a first outlet, a cavity configured for receiving a wet coproduct and a binder through the first inlet, and a stirring apparatus within the cavity for premixing the wet coproduct and binder into a substantially homogeneous mixture; a high shear mixer having a housing, a drive apparatus and a high shear apparatus, the housing defining an opening, the drive apparatus being within the housing and for forcing the substantially homogeneous mixture from the premixer into the high shear apparatus, and the high shear apparatus including a rotor, a stator and a screen covering the opening and being for shear mixing the mixture including forcing the mixture through the screen and out of the housing in the form of nucleation enhanced particles; and an agglomerator having an interior chamber sized and configured to receive the nucleation enhanced particles from the high shear mixer and for transforming the nucleation enhanced particles into substantially spherical biomass pellets.

Owner:PURDUE RES FOUND INC

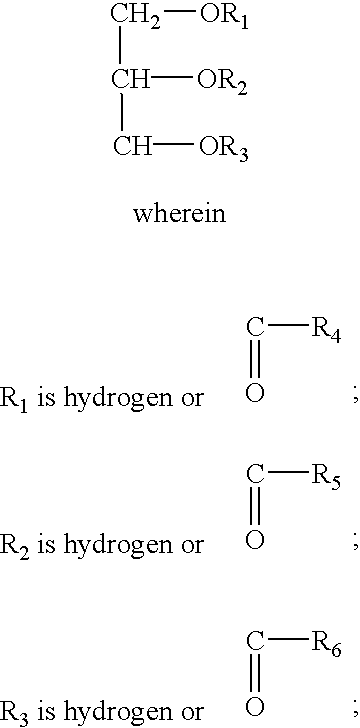

Pesticide for insect control

A method for the control of insects breeding on water surfaces and particularly mosquitoes, comprising blending in a high shear mixer water, the ester of a fatty acid of 10 to 25 carbon atoms and a low molecular weight alcohol, such as methanol or ethanol, an emulsifying agent and a thickener until an emulsion containing the ester with droplet sizes ranging from 1 to 20 microns in diameter is obtained and applying such to the surface of insect infested water in sufficiently diluted form, to break the emulsion and form a thin continuous film.

Owner:REMEDIATION & NATURAL ATTENUATION SERVICES

Apparatus and method for producing biobased carriers from byproducts of biomass processing

An apparatus for producing biobased carriers for dispersal of biological and chemical molecules includes a premixer having a first inlet, a first outlet, a cavity configured for receiving a wet coproduct and a binder through the first inlet, and a stirring apparatus within the cavity for premixing the wet coproduct and binder into a substantially homogeneous mixture; a high shear mixer having a housing, a drive apparatus and a high shear apparatus, the housing defining an opening, the drive apparatus being within the housing and for forcing the substantially homogeneous mixture from the premixer into the high shear apparatus, and the high shear apparatus including a rotor, a stator and a screen covering the opening and being for shear mixing the mixture including forcing the mixture through the screen and out of the housing in the form of nucleation enhanced particles; and an agglomerator having an interior chamber sized and configured to receive the nucleation enhanced particles from the high shear mixer and for transforming the nucleation enhanced particles into substantially spherical biomass pellets.

Owner:PURDUE RES FOUND INC

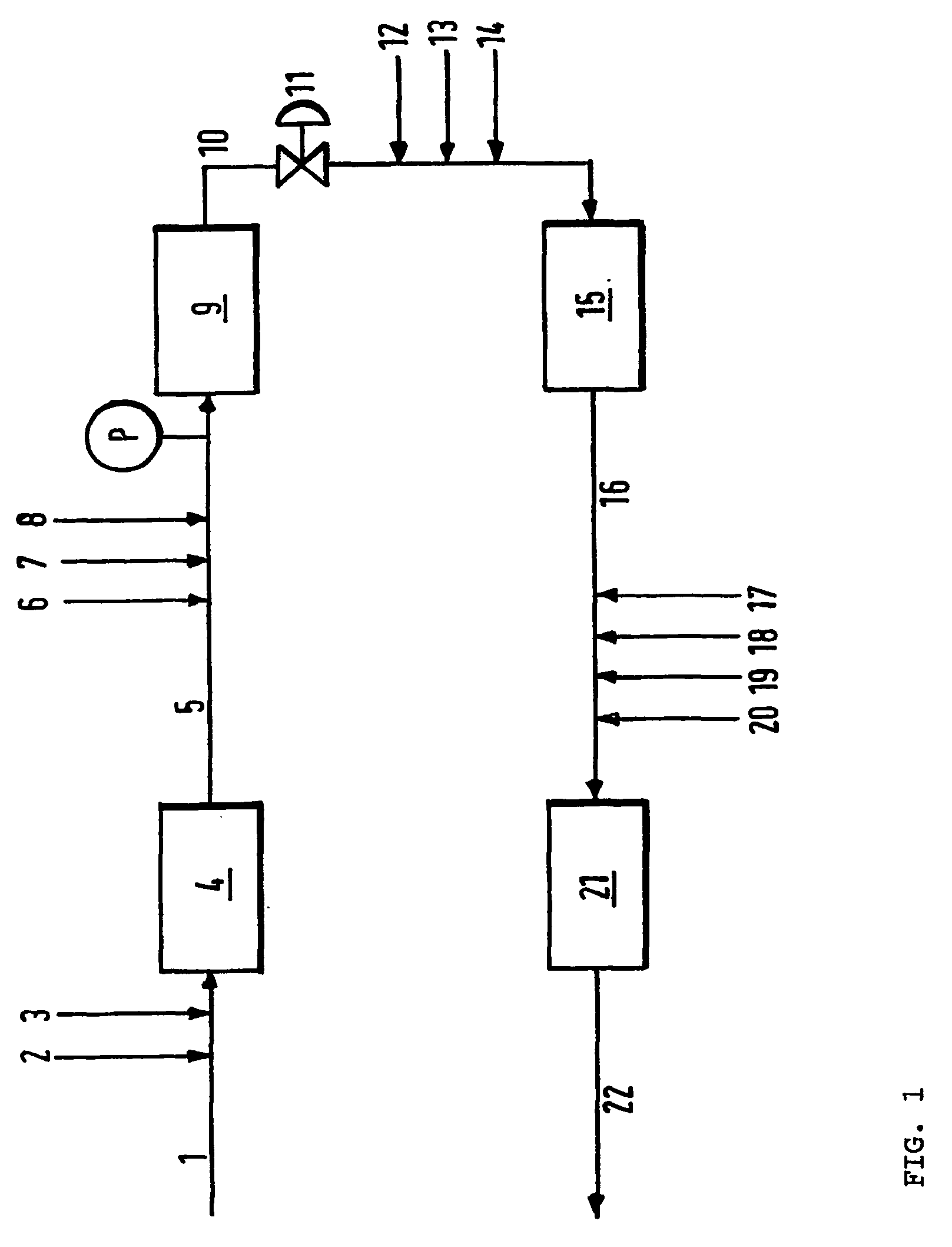

Process for making silicone emulsions

In a process for the production of a silicone in water emulsion in which a polysiloxane fluid, at least one surfactant and water are continuously fed to a high shear mixer in such proportions as to form a viscous oil in water emulsion which is continuously withdrawn from the mixer. The polysiloxane fluid may be a non-reactive fluid or may have reactive groups capable of taking part in a chain extension reaction. A desired emulsion particle size can be maintained by monitoring the pressure in the supply line at the inlet to the high shear mixer.

Owner:DOW CORNING CORP

Control release formulation containing a hydrophobic material as the sustained release agent

InactiveUS7052706B2Effectively controlling releaseControl releaseCosmetic preparationsImpression capsSolubilityGram

The present invention is directed to a sustained release pharmaceutical composition in oral dosage form consisting essentially of a pharmaceutically effective amount of a medicament and a hydrophobic material in the absence of a lactose or hydrophobic carbohydrate polymer, said medicament being present in an amount greater than about 25% of the pharmaceutical composition and having a water solubility greater than about 1 gram per 10 mL of water at 25° C., said hydrophobic material having a melting point ranging from at least about 40° C. to about 100° C. at 1 atm pressure, and being present in an amount ranging from about 3% to about 20% by weight of the pharmaceutical composition and in an amount less than the of the medicament, and said hydrophobic material not being present in coating of said pharmaceutical composition; said pharmaceutical composition being prepared by direct compression in the absence of or melting the hydrophobic material or the use of high shear mixer. The present invention is also directed to a method of preparing said pharmaceutical composition.

Owner:NOSTRUM PHARMA INC

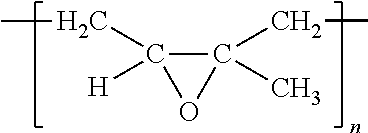

Continuous Production Of Poly(vinyl butyral)

InactiveUS20100267921A1Weaken energyRecuperation of energy more straightforwardEngineeringHeating cycle

The present invention provides a method for continuously producing poly(vinyl butyral) in which the acetalization of poly(vinyl butyral) is carried out using a poly(vinyl alcohol) varnish provided to a mixing region of a high shear mixer at an elevated temperature, which reduces the amount of energy required compared to conventional processing because at least one cooling and heating cycle is eliminated, or makes the recuperation of energy more straightforward.

Owner:SOLUTIA INC

Emulsifier-free bio mineral structured emulsion

ActiveUS20170105908A1Simple and efficient to createLong period of timeCosmetic preparationsHair cosmeticsPickering emulsionOil phase

A process for creating cold emulsions for cosmetic use involves creating a gel component by exfoliating silicate compounds with catalysts and organic materials under pressure and mixing the resulting components with water, mixing an oil phase with additional powdered components as desired, and mixing the gel component with the oil phase in a high shear mixer until a Pickering emulsion is created. The resulting emulsion is simple to manufacture, stable for long periods of time, and has a desirable texture for cosmetic use.

Owner:ARCLAY NATURAL TECH INC

Pesticide for insect control

A method for the control of insects breeding on water surfaces and particularly mosquitoes, comprising blending in a high shear mixer water, the ester of a fatty acid of 10 to 25 carbon atoms and a low molecular weight alcohol, such as methanol or ethanol, an emulsifying agent and a thickener until an emulsion containing the ester with droplet sizes ranging from 1 to 20 microns in diameter is obtained and applying such to the surface of insect infested water in sufficiently diluted form, to break the emulsion and form a thin continuous film.

Owner:REMEDIATION & NATURAL ATTENUATION SERVICES

Process For Making Silicone Emulsions

InactiveUS20100204398A1Minimization requirementsCatalytic activity can be suppressedCosmetic preparationsHair cosmeticsPolymer scienceEmulsion

In a process for the production of a silicone in water emulsion in which a polysiloxane fluid, at least one surfactant and water are continuously fed to a high shear mixer in such proportions as to form a viscous oil in water emulsion which is continuously withdrawn from the mixer. The polysiloxane fluid may be a non-reactive fluid or may have reactive groups capable of taking part in a chain extension reaction. A desired emulsion particle size can be maintained by monitoring the pressure in the supply line at the inlet to the high shear mixer.

Owner:DOW CORNING CORP

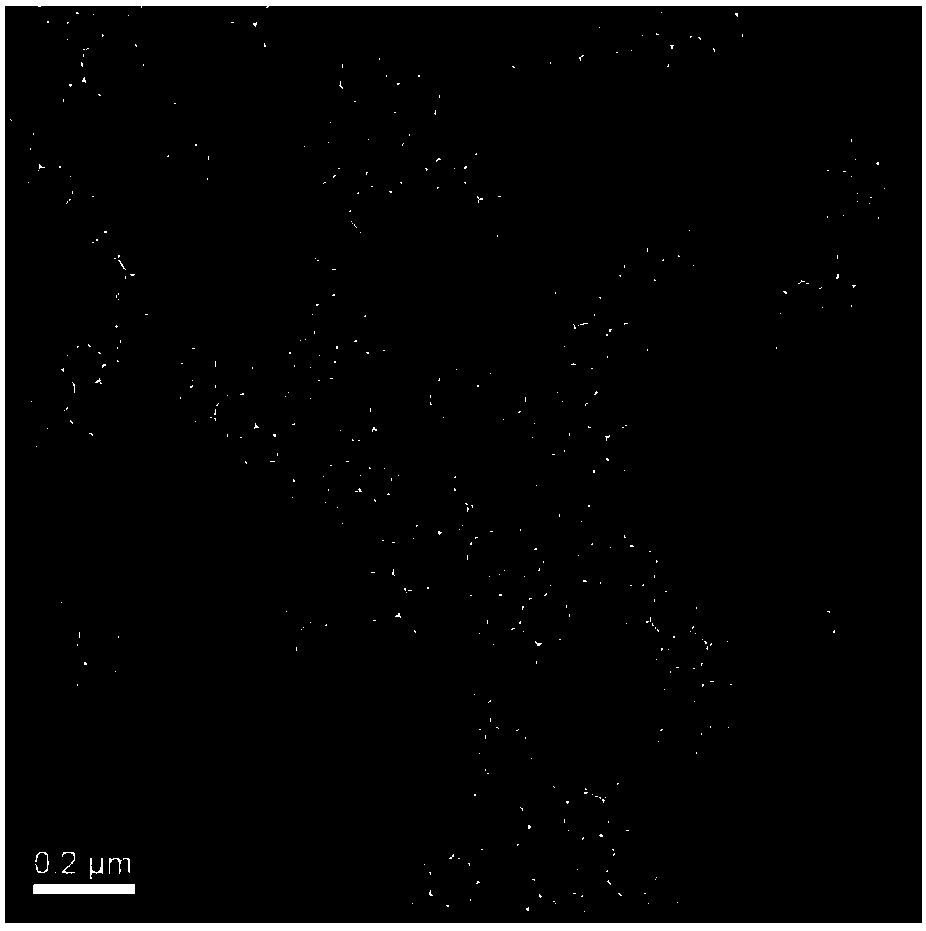

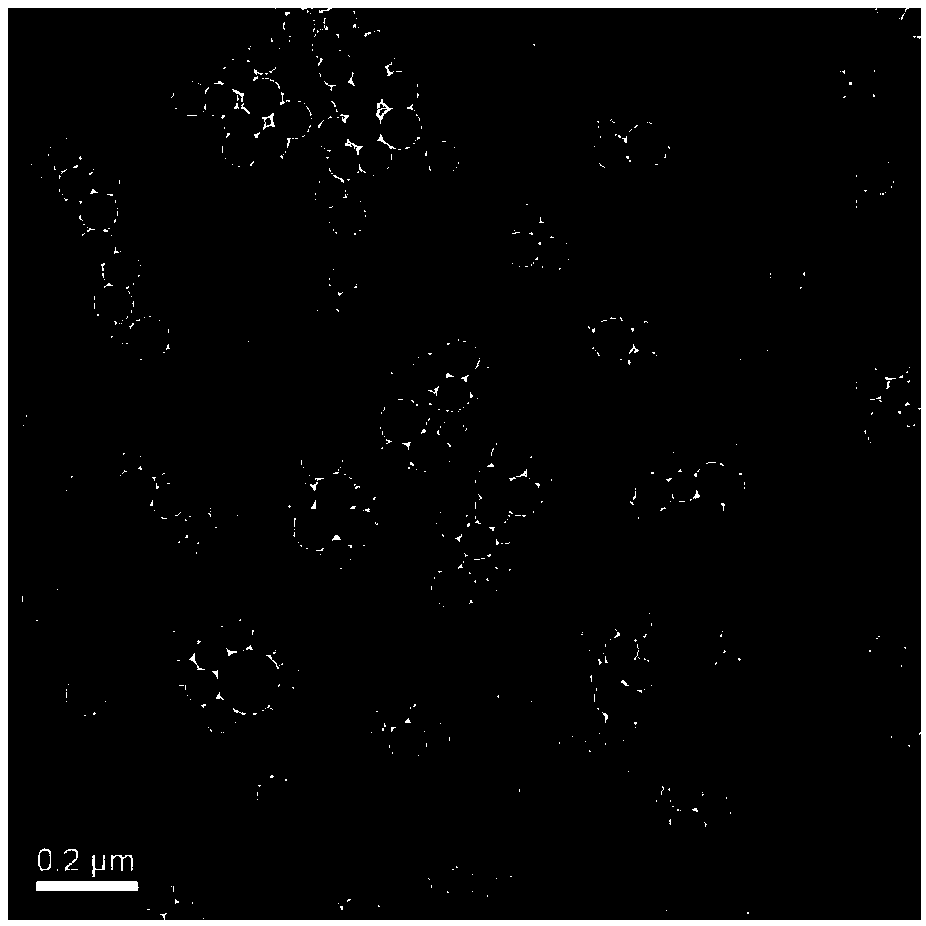

Preparation method of nano-silica spheres

InactiveCN108545754ASimple methodShort preparation timeSilicaNanotechnologyNano sio2Ammonium hydroxide

The invention discloses a preparation method of nano-silica spheres. The preparation method of the nano-silica spheres comprises the following steps: (1) preparing a nano-silica sphere suspension: mixing ammonium hydroxide, tetraethyl orthosilicate and an alcoholic solution with a high-shear mixer at the revolving speed of 10,000 to 22,000r / min to obtain the nano-silica sphere suspension; (2) separating the nano-silica spheres: centrifuging and washing the nano-silica sphere suspension, and drying a precipitate to obtain the nano-silica spheres. The preparation method of the nano-silica spheres disclosed by the invention has relative short preparation time, and nano-SiO2 spheres prepared by hydrolysis can be obtained by stirring for 10 to 20 minutes. Moreover, a template agent is not required, the preparation process is simplified, the template agent does not need to be removed by high-temperature calcining, and the cost is lowered; moreover, the particle sizes of the nano-SiO2 spherescan be controlled by controlling the different conditions of revolving speed, temperature and the like in order to meet the requirement on the particle sizes of the nano-SiO2 spheres. The preparationmethod can be applied to the fields of catalysis, stabilizing agents, enhancers, additives, biology and the like.

Owner:SHIHEZI UNIVERSITY

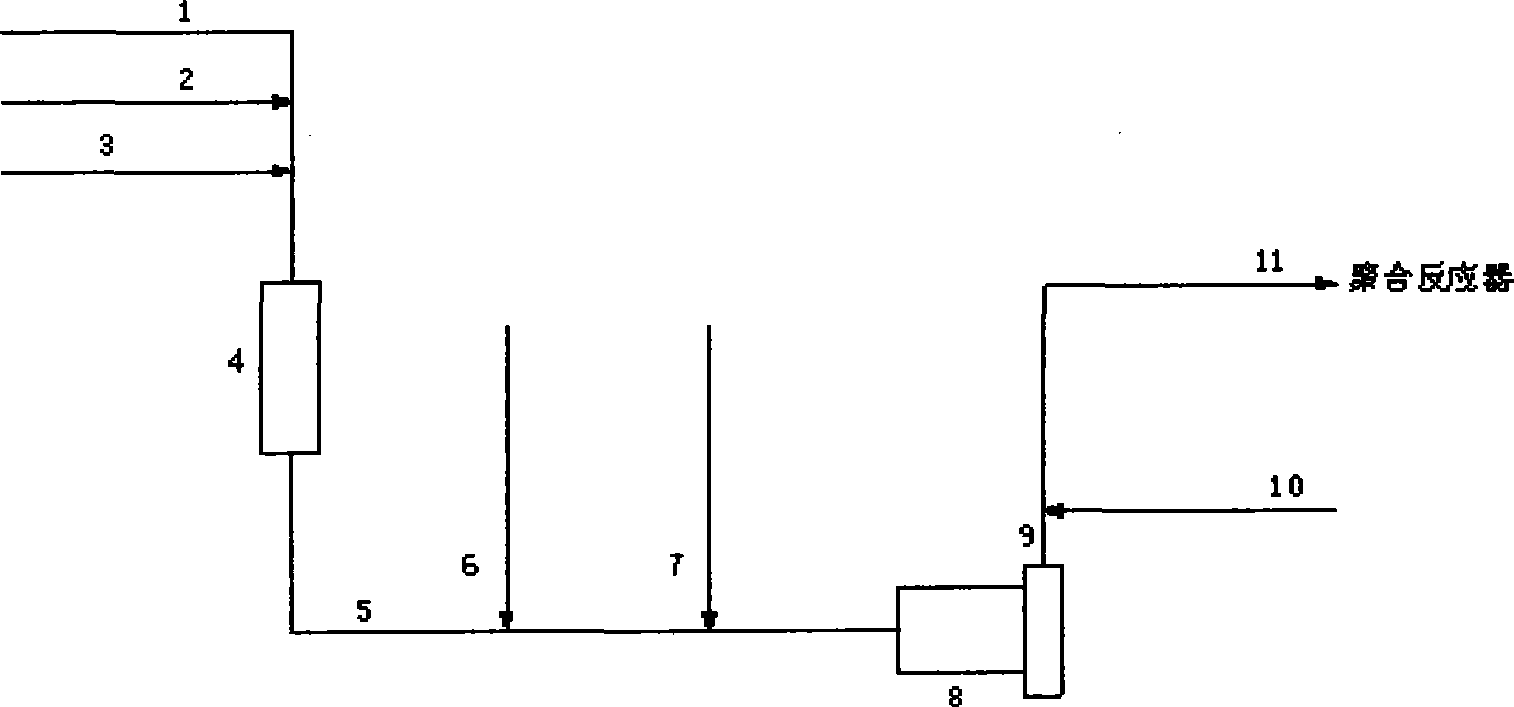

Continuous preparation of high hydroscopicity resin polymerization single polymerization monomer solution

Owner:SHANGHAI HUAYI NEW MATERIAL

High shear process for the production of butadiene sulfone

InactiveUS20090005578A1Reduce the total massImprove reaction speedOrganic chemistryTransportation and packagingSulfoneSulfolene

Use of a high shear mechanical device incorporated into a process for the production of sulfolene as a reactor device is capable of decreasing mass transfer limitations, thereby enhancing the sulfolene production process. A system for the production of sulfolene from butadiene and sulfur dioxide, the system comprising a reactor and an external high shear mixer the outlet of which is fluidly connected to the inlet of the reactor; the high shear mixer capable of providing a dispersion of sulfur dioxide gas bubbles within a liquid, the bubbles having an average bubble diameter of less than about 100 μm.

Owner:HRD CORP

Continuous production of poly(vinyl butyral)

The present invention provides a method for continuously producing poly(vinyl butyral) in which the acetalization of poly(vinyl butyral) is carried out using a poly(vinyl alcohol) varnish provided to a mixing region of a high shear mixer at an elevated temperature, which reduces the amount of energy required compared to conventional processing because at least one cooling and heating cycle is eliminated, or makes the recuperation of energy more straightforward.

Owner:SOLUTIA INC

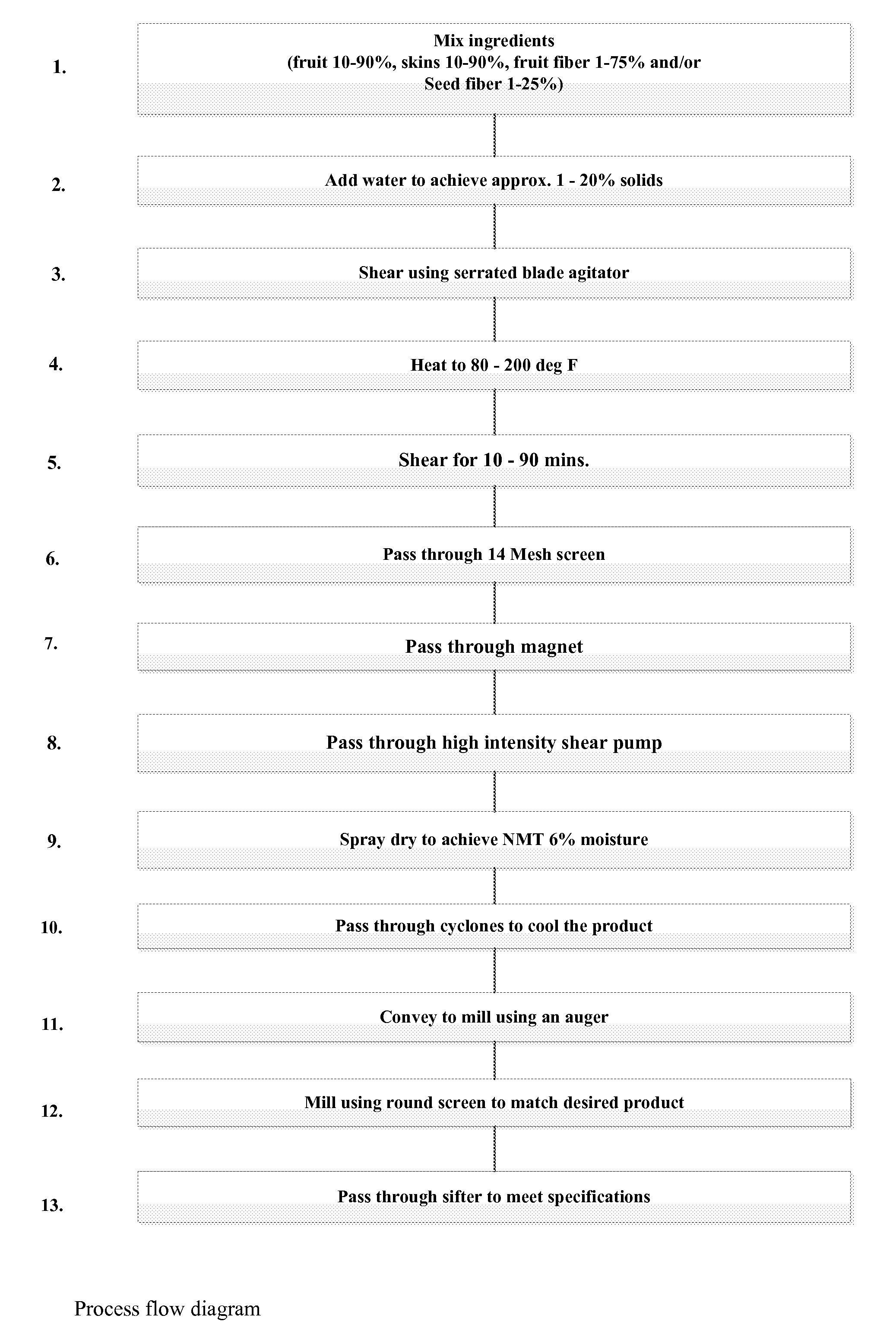

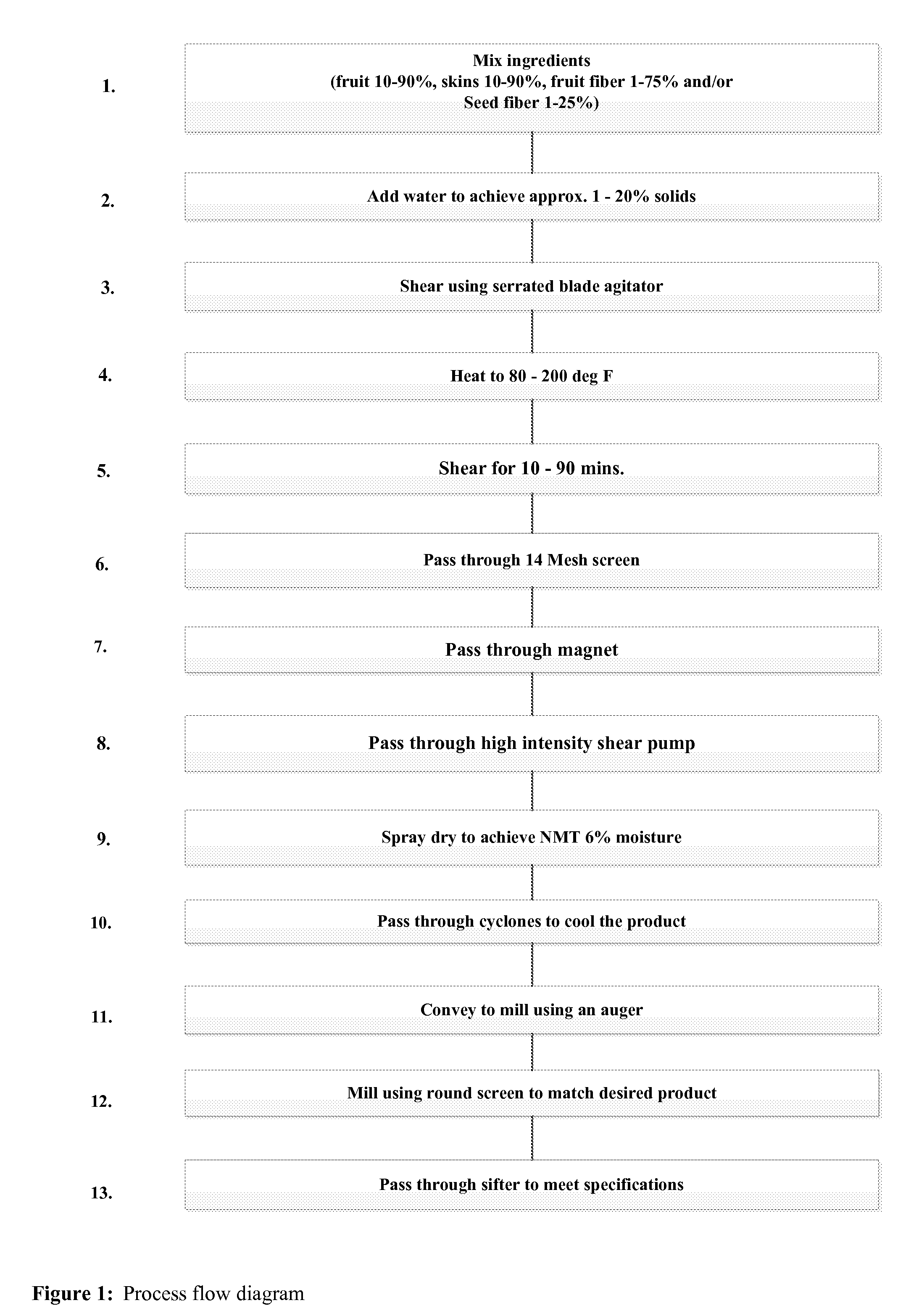

Process for Spray Drying Botanical Food

In some embodiments, the invention provides processes for making a spray-dried whole botanical food powder from a whole botanical food. The processes comprise combining components of a whole botanical food to create a whole botanical food slurry, the components comprising 0-80% whole botanical food, 0-75% skin, 20-80% pomace, and 0-75% seed fiber; adding water to the whole botanical food slurry to produce a mixture with a solids content of about 1-20%; heating the mixture to a temperature between approximately 80 and 200 degrees Fahrenheit; shearing the mixture with a high shear mixer for 10 to 90 minutes to create a uniform slurry; pumping the uniform slurry through a high intensity shear pump to achieve a uniform particle slurry; atomizing the uniform particle slurry; and spray drying the uniform particle slurry to form a spray-dried whole botanical food product. Also provided are compositions made using the disclosed processes.

Owner:DECAS BOTANICAL SYNERGIES

Polypropylene fiber containing composite nitrogen phosphorus flame retardant used for periwig and its production method

ActiveCN102199804AHigh glossGood drapabilityWigsFlame-proof filament manufactureMasterbatchNon toxicity

The present invention belongs to the chemical technology field, particularly relates to polypropylene fiber containing a composite nitrogen phosphorus flame retardant used for periwig and its production method. The invention is characterized in that the components comprise by mass: 100 parts of polypropylene, 5 to 20 parts of dehydrating agent, 5 to 20 parts of charring agent, 5 to 20 parts of foaming agent, 1 to 5 parts of coupling agent, 1.5 to 2.5 parts of heat stabilizer and 1.0 to 2.0 parts of polypropylene heat degradation masterbatch. Polypropylene, the heat stabilizer and polypropylene heat degradation masterbatch are added into a high-shear mixer in proportion, the dehydrating agent, the charring agent, the foaming agent and the coupling agent are orderly added for improving the continuously stirring mixing rotating speed, color masterbatch is added and the rotating speed is kept, the material is discharged after continuously stirring, the discharged material is extruded by adouble screw extruder, melt spinning is performed after drying, the extruded nascent fiber is cooled and reeled by crosswind and a filament is obtained after drawing-off. The present invention has the advantages of non-toxicity, smoke suppression, friendly environment and the like.

Owner:HENAN REBECCA HAIR PRODS TNC

Storage stabilized devulcanized tire rubber modified asphalt composition and the process for its preparation

ActiveUS10000638B2Good miscibilityImprove solubilityBituminous material adhesivesBuilding insulationsSynthetic rubberAsphalt

This invention relates to a storage stabilized recycled and devulcanized tire rubber modified asphalt composition, which comprises: 65.0 to 90.0% by weight of a neat asphalt, 3.0-50.0% by weight of a recycled and devulcanized rubber from used tires and / or other scrap rubbers, 0.01-15.0% by weight of a compatibilizer / stabilizer derived from Natural or Synthetic Rubbers, which composition passes the “cigar tube” softening point test difference of less than 5° C. between the top and bottom layers; and, the process for the said asphalt composition comprises mixing 65.0% to 90.0% by weight of a neat asphalt, 3.0 to 50.0% by weight of a recycled and devulcanized rubber from used tires, 0.01-10.0% by weight of a compatibilizer / stabilizer derived from Natural or Synthetic Rubbers, using high shear mixers at elevated temperatures of between 120° C. and 175° C. for between 15 minutes to 6 hours, to obtain storage stabilized asphalt composition that is stable in hot storage and transportation conditions.

Owner:PILLAI CHANDRASEKARAN RAMAYYA +1

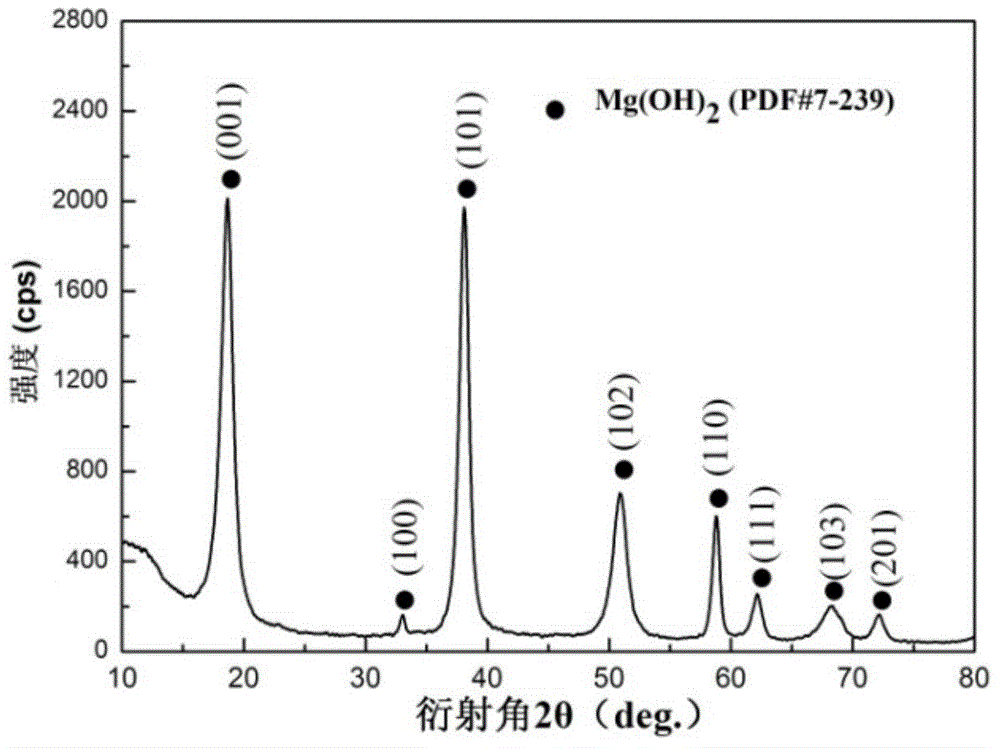

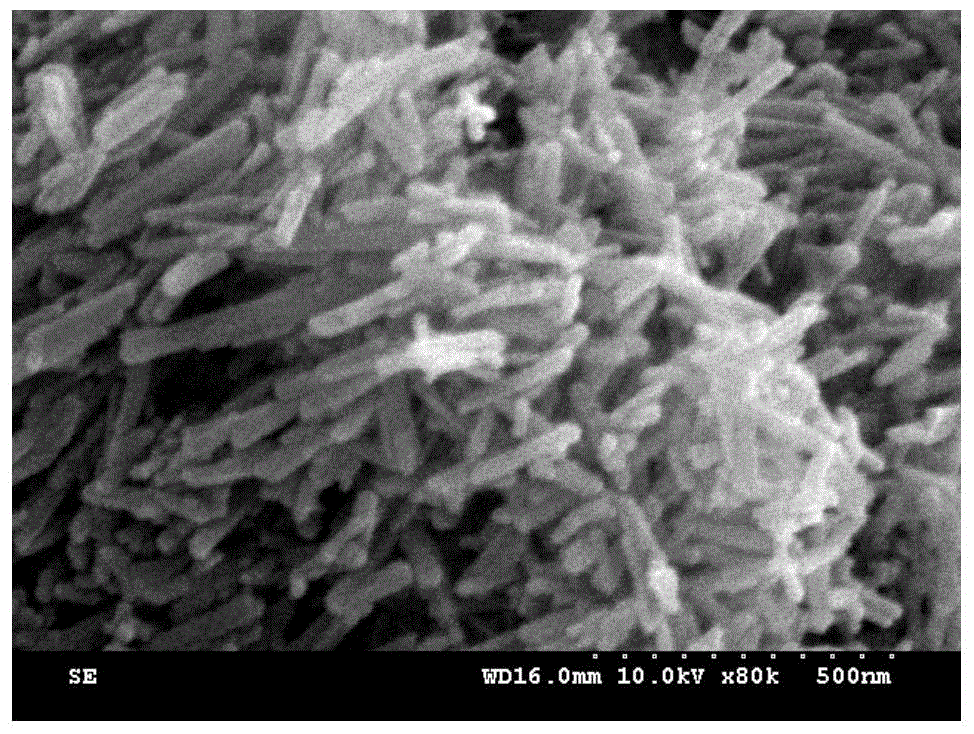

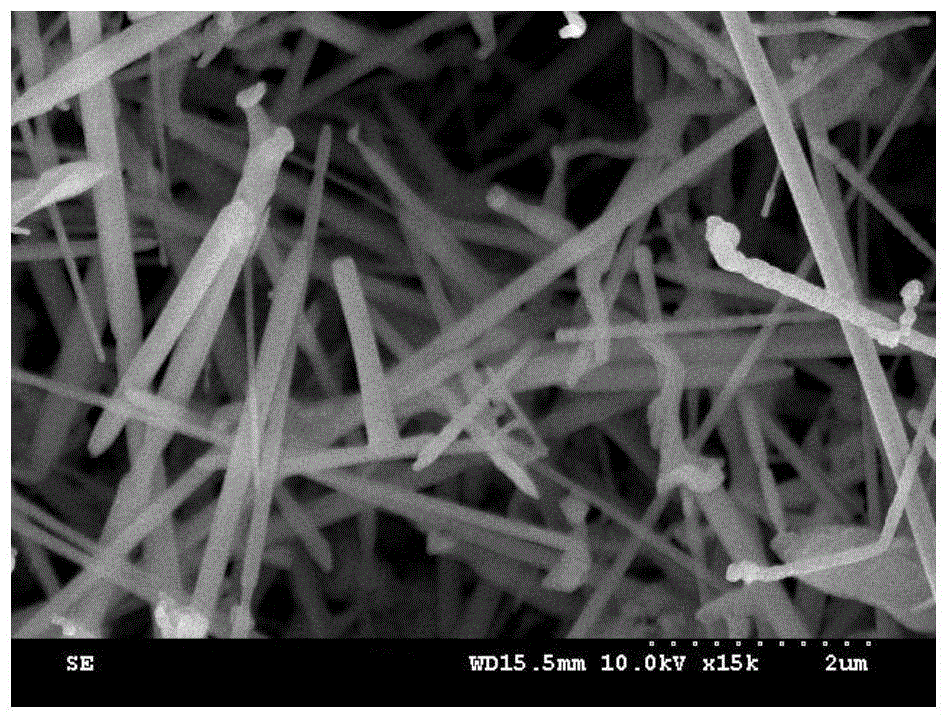

Preparation method of nano magnesium hydroxide material

InactiveCN104528779AReduce corrosionExtended service lifeMaterial nanotechnologyMagnesium hydroxideMaterials preparationMagnesium salt

The invention discloses a preparation method of a nano magnesium hydroxide material, relates to the technical field of preparation of nano materials, and solves the problems that the existing nano magnesium hydroxide material preparation method causes severe corrosion to reaction equipment, has strict requirements for instruments and equipment and is high in equipment cost. The main technical scheme of the invention is as follows: the preparation method of a nano magnesium hydroxide material comprises the following steps: 1. preparing a precursor liquid: dissolving magnesium salt and surfactant in solvent, and homogenizing the obtained mixture through a pipeline type high-shear mixer to obtain the precursor solution; 2. preparing a precursor: introducing ammonia gas into the precursor solution obtained in the step 1, adding crystal form control agent into the precursor solution while stirring, and reacting to obtain the precursor; and 3. heating the precursor obtained in the step 2 at 60-300 DEG C to obtain the nano magnesium hydroxide material.

Owner:SHIHEZI UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com