Continuous preparation of high hydroscopicity resin polymerization single polymerization monomer solution

A technology of super absorbent resin and polymerized monomer, which is applied in the field of continuous preparation of super absorbent resin polymerized monomer liquid, can solve problems such as product performance decline, low production efficiency, blockage of feeding pipeline, etc. Production process, the effect of improving production efficiency

Active Publication Date: 2009-07-08

SHANGHAI HUAYI NEW MATERIAL

View PDF2 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This way, on the one hand, the heat of neutralization reaction is not effectively utilized, on the other hand, it causes low production efficiency

In another Chinese patent CN1690086, although the preparation of polymerized monomer liquid also adopts the mode of continuous preparation, because the concentration of its monomer liquid is as high as more than 45%, when acid and alkali are neutralized, on the one hand, due to the high concentration

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

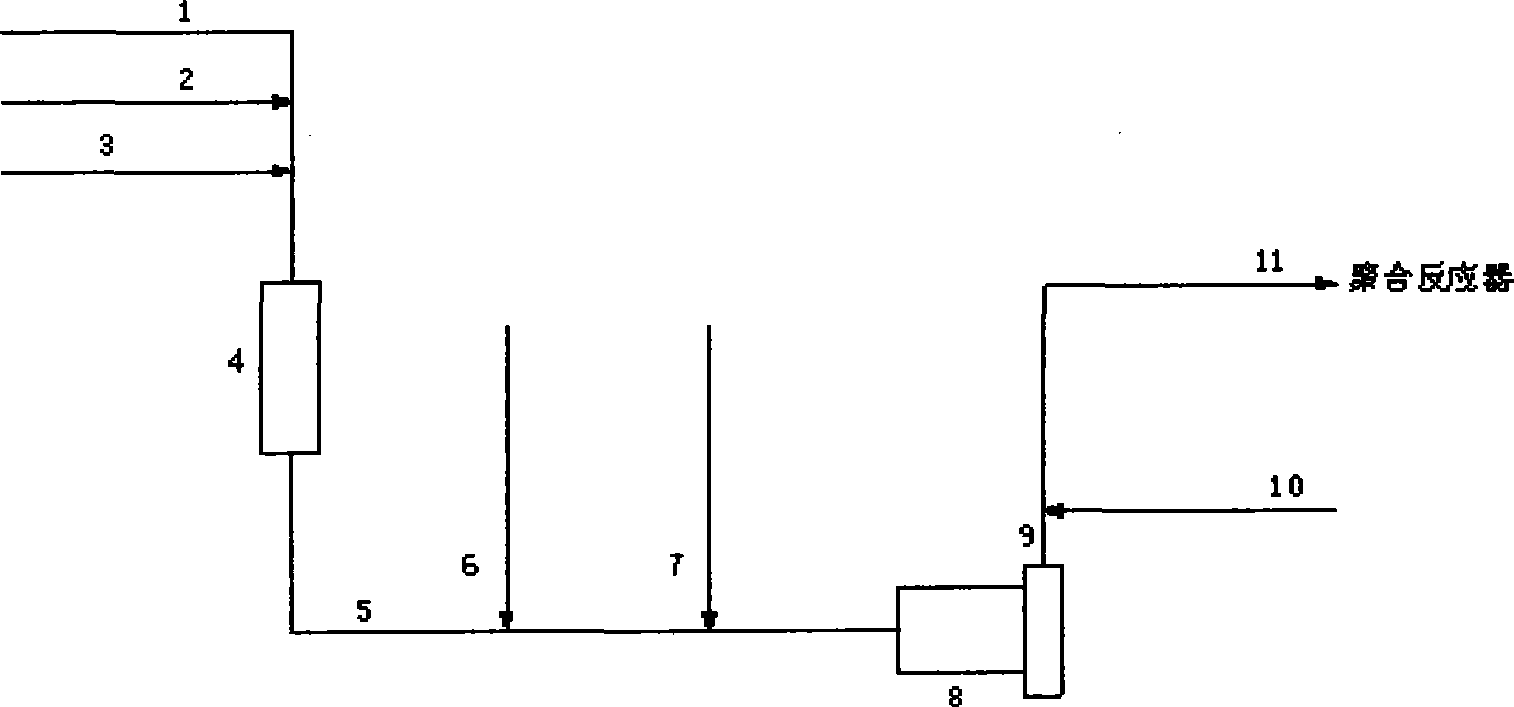

The invention relates to a continuous preparation method for high hydroscopicity resin polymerized monomer liquid. Acrylic acid is taken as the main raw material. The preparation method is characterized by comprising the following steps: placing deionized water, sodium hydroxide or potassium hydroxide and ice crystal-shaped acrylic acid needed by a polymerization reaction process recipe in a pipe mixer for the continuous neutralization reaction, then making the obtained neutralizer and a cross-linking agent aqueous solution and an oxidation initiator aqueous solution pass through an on-line high shear mixer for intensive mixing, then making the mixed liquid and the reduction initiator aqueous solution be mixed evenly and quickly at the outlet of the mixer, and finally carrying out the continuous supply to a polymerization reactor through a pipe. The method can reasonable utilizes the acid alkali neutralization reaction heat to improve the temperature of the neutralizer to the reaction temperature needed by the polymerization process and realize the continuous preparation of the polymerized monomer liquid during the continuous production of the high hydroscopicity resin without adding other additional cooling devices, and can also simplify the production technological process.

Description

technical field [0001] The invention relates to the specialty of polymer material synthesis in the field of chemical industry, in particular to a link in the resin manufacturing process, that is, to a continuous preparation method of superabsorbent resin polymerization monomer liquid. Background technique [0002] As we all know, cross-linked polyacrylic acid (salt), as a main variety of superabsorbent resin, is widely used in sanitary products such as disposable diapers, sanitary napkins, and adult incontinence products. Its preparation method generally adopts production techniques such as inverse phase suspension polymerization method, inverse phase emulsion polymerization method, and aqueous solution polymerization method. Among them, the aqueous solution polymerization method includes a batch method and a continuous method. Of course, the production efficiency of the latter is higher. At this time, the use of conveyor belt production technology is an important method f...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08F220/06C08F2/00

Inventor 周柳茵连旭罡王月珍张伟民褚小东

Owner SHANGHAI HUAYI NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com