Patents

Literature

962results about How to "Good drapability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

One-way moisture guiding and absorbing and heating knitted fabric and manufacturing method thereof

ActiveCN106192177AGood hygroscopicityStrong discomfortWeft knittingHeating/cooling textile fabricsFiberYarn

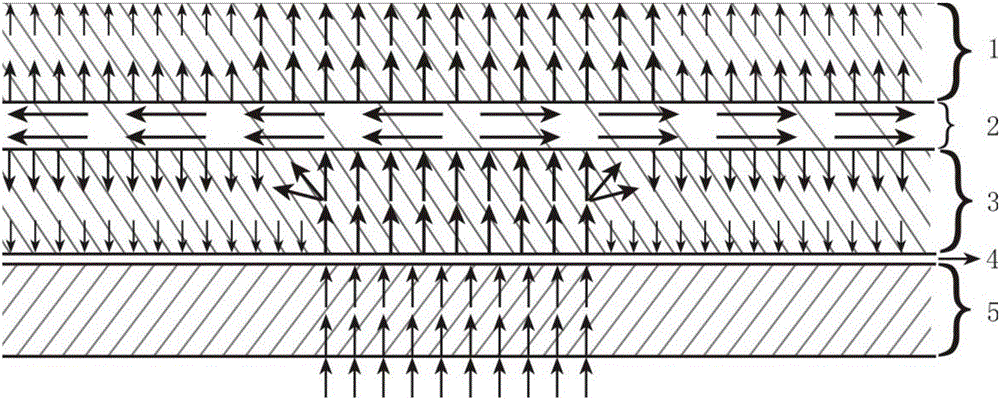

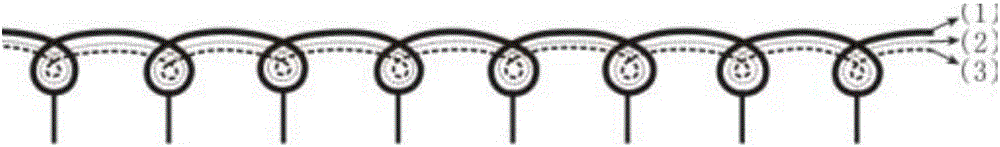

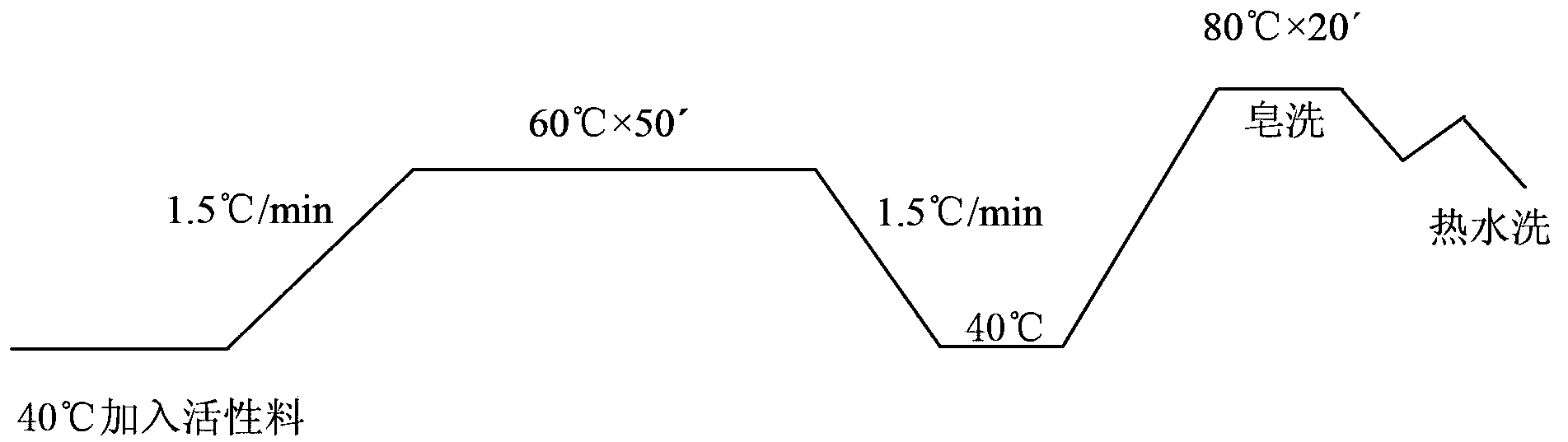

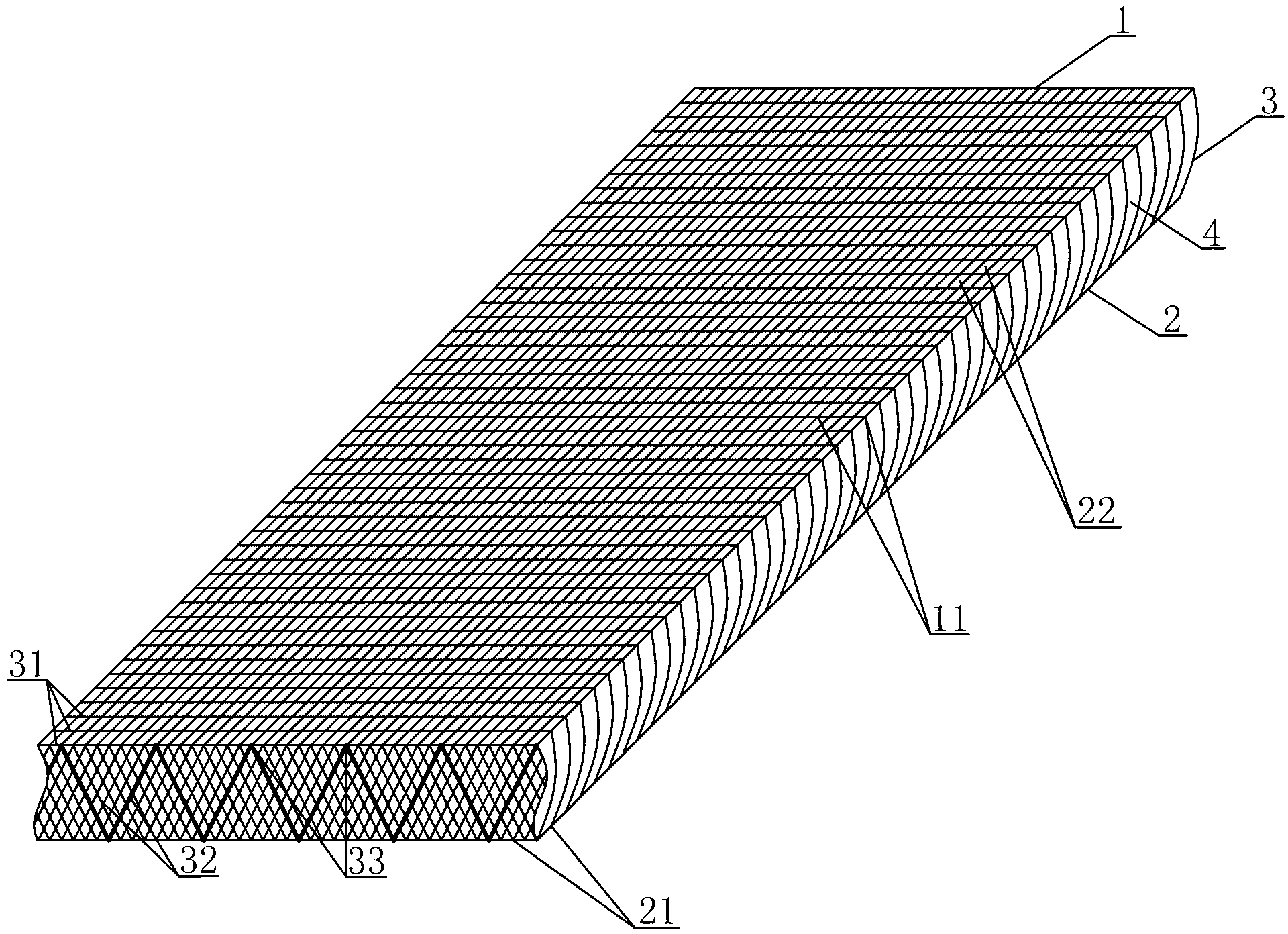

The invention discloses a one-way moisture guiding and absorbing and heating knitted fabric and a manufacturing method thereof. The fabric is knitted from first yarn, second yarn and third yarn, the first yarn is covering yarn, the second yarn is polyurethane elastic fiber yarn or polyolefin elastic fiber yarn, and the third yarn is cotton fiber blended yarn or all cotton yarn. The fabric is of a three-layer structure composed of an outer layer, a middle layer and an inner layer, the outer layer is knitted from the first yarn, the middle layer is knitted from the second yarn, and the inner layer is knitted from the third yarn. The manufacturing method of the fabric sequentially comprises the following steps of 1, yarn preparation; 2, weaving on a machine; 3, blank inspection; 4, loose fabric cylinder matching; 5, pre-sizing; 6, pretreatment; 7, dyeing; 8, soaping; 9, acid pickling; 10, in-cylinder softening; 11, dehydrating and drying; 12, re-sizing; 13, polished blank inspection. The fabric has a one-way moisture guiding function and achieves moisture absorbing and heating functions.

Owner:WUHAN LOVE GOD HIGH LEVEL DRESS & ADORNMENTS

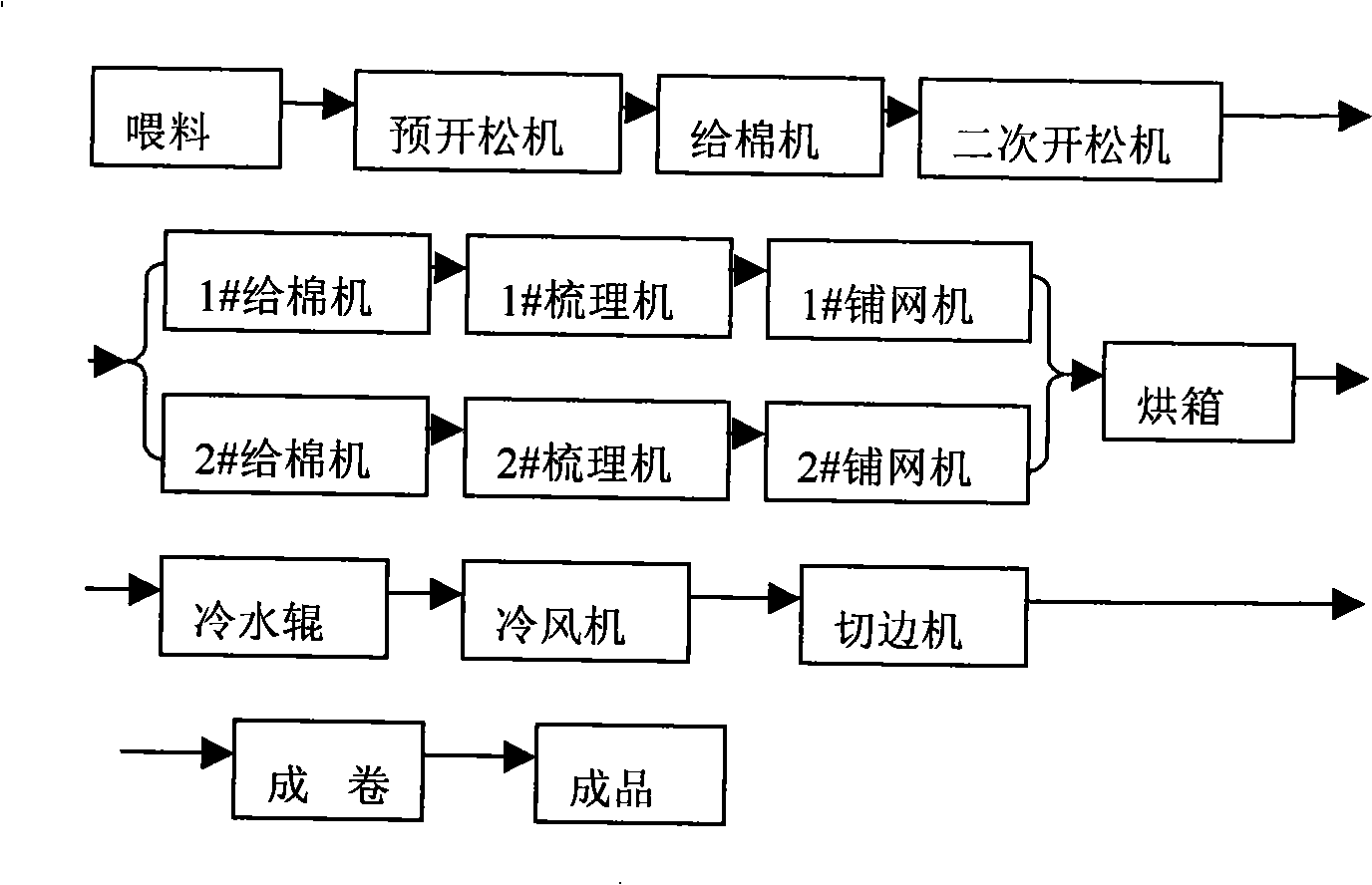

Fire retardant cotton nonwoven fabrics and manufacture method thereof

InactiveCN101307528AImprove flame retardant performanceGood anti-melting effectHeating/cooling textile fabricsNon-woven fabricsCardingPolymer science

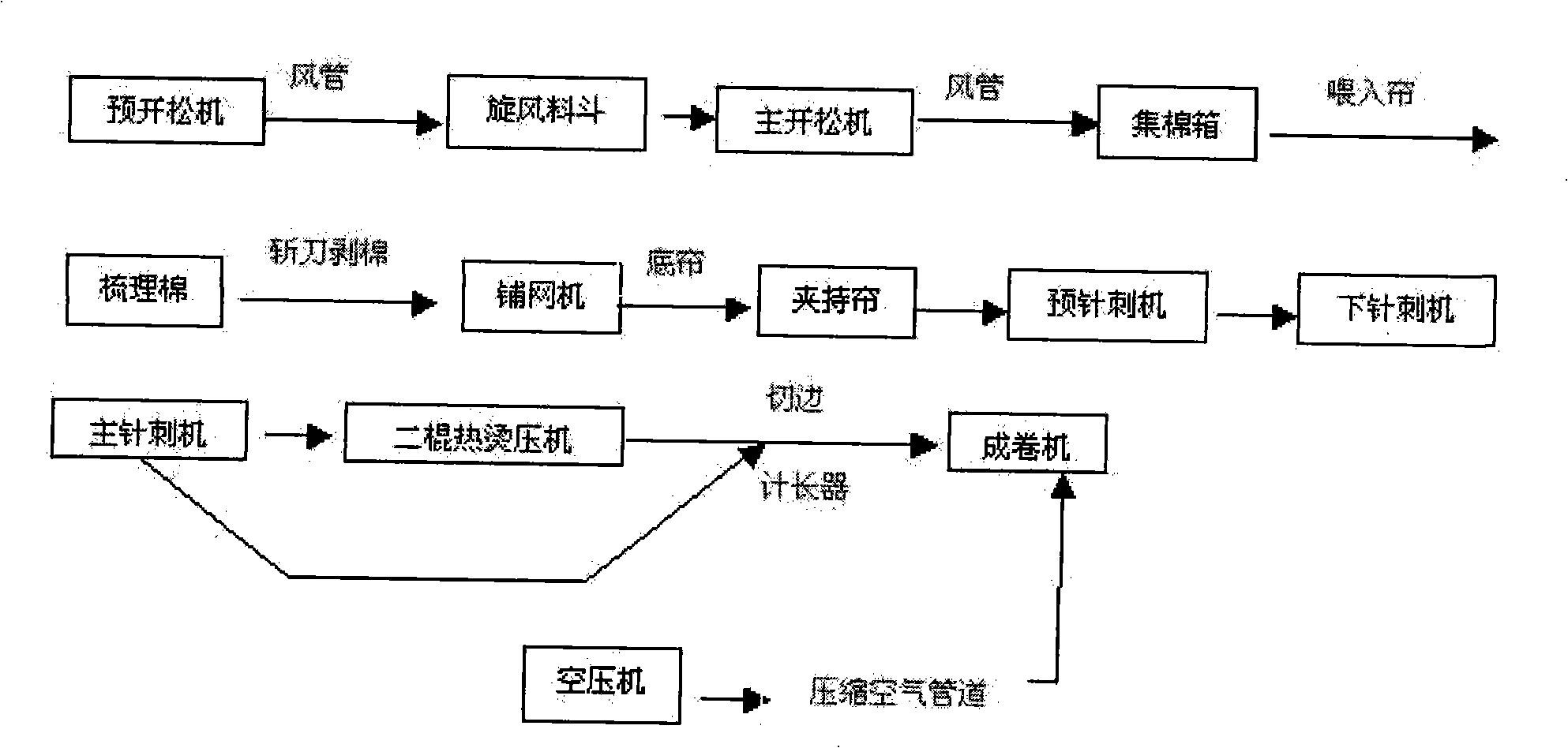

The invention discloses an flame retardant non-woven cotton fabric, comprising anti-fcell flame retardant fiber and washing / washing composite hot melting short fiber, wherein, the weight percentage of the anti-fcell flame retardant fiber is between 70 and 90 percent, the balance is the washing / washing composite hot melting short fiber; the two fibers are stuck into an integrated whole by the hot wind heating and / or are penetrated together by prickling fibers to combine into the non-woven fabric. The method for producing the non-woven cotton fabric comprises the processes of mixing, opening, carding, mesh placing, moulding processing, etc. The moulding processing method has the needle point method and the through-air method. The flame retardant non-woven cotton fabric adopts the prescription of mainly taking the anti-fcell flame retardant fiber and solves the problems of the flammability of the terylene, dropping of the fusion and the flammability of the viscose. The washing / washing composite hot melting short fiber is added to increase the caking coefficient so that the fibers are conglutinated evenly. The unique processing flow ensures that the inflaming retarding non-woven cotton fabric has high tension intensity and anti-breakage intensity as well as certain elasticity and bulkiness.

Owner:DONGGUAN LIANYING NONWOVEN TECH

Foamed aqueous composition

ActiveUS9469738B1Minimize exposureEliminates sewingCurtain accessoriesRadiation-absorbing paintsPorous substrateFluorescence

Foamable aqueous compositions can be used to form light-blocking and light-colored foamed, opacifying elements with one or more dry foamed layers. The compositions contain: (a) 0.05 to 20 weight % of porous particles comprising a continuous polymeric phase and a first set of discrete pores, the porous particles having a mode particle size of 2 to 50 μm; (b) at least 20 weight % of a binder material (that can be curable); (c) 0.1 to 30 weight % of one or more additives including dispersants, plasticizers, inorganic or organic pigments or dyes, thickeners, flame retardants, biocides, fungicides, optical brighteners, tinting colorants, metal flakes, and inorganic or organic fillers; (d) water; and (e) at least 0.001 weight % of an opacifying colorant different from (c), which opacifying colorant absorbs electromagnetic radiation. The foamable aqueous composition can be aerated, disposed on a porous substrate, dried, and crushed on that porous substrate.

Owner:EASTMAN KODAK CO

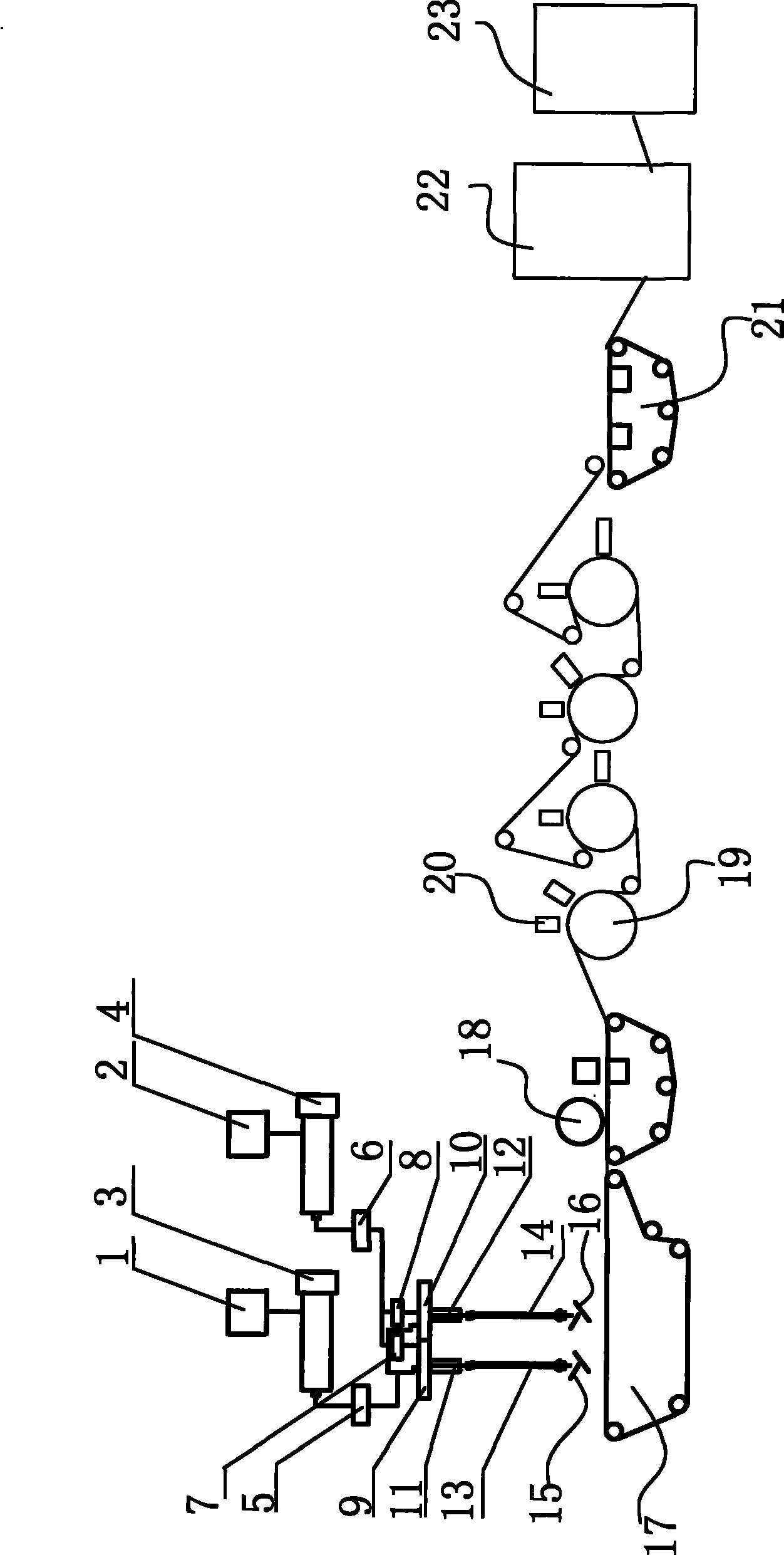

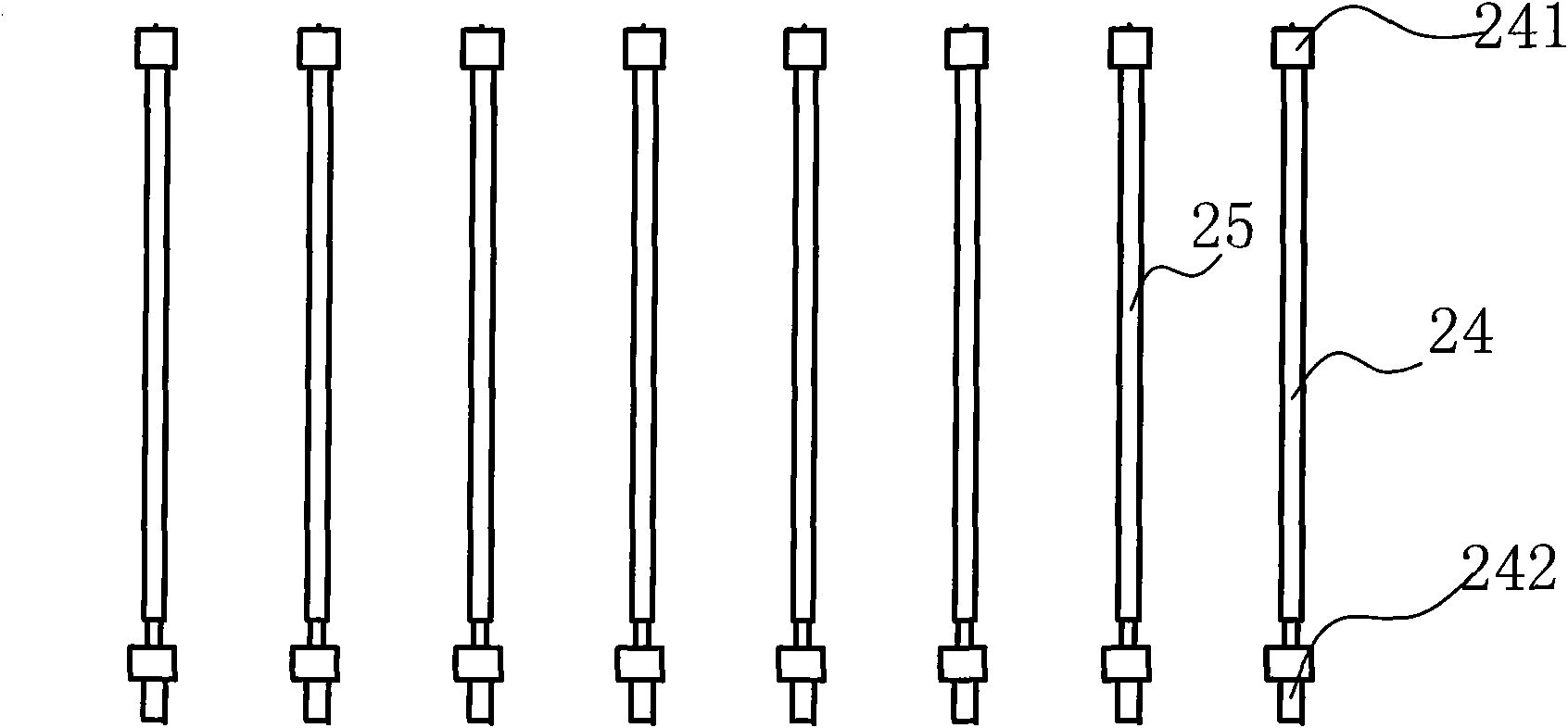

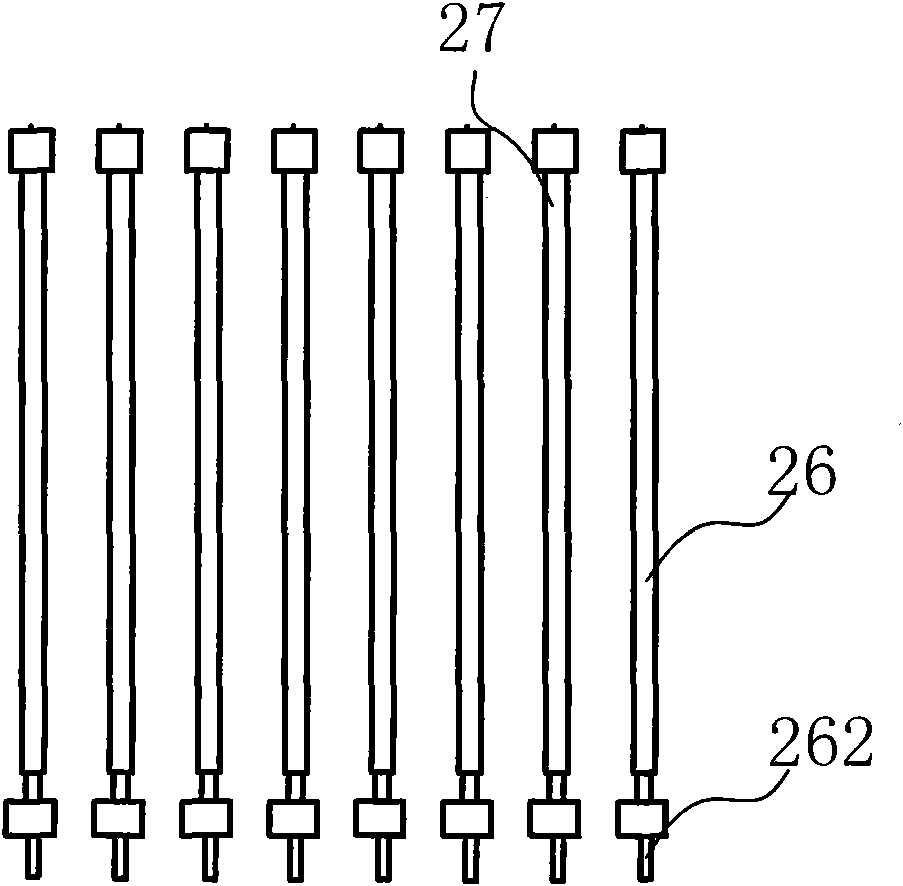

Manufacturing method and device for two-component hollow spun-bonded spunlace non-woven fabrics

InactiveCN101818413ASoft touchGood drapabilityHollow filament manufactureFilament/thread formingWoven fabricYarn

The invention belongs to the technical field of spun-bonded nonwovens manufacturing. The manufacturing method comprises the following steps: a. respectively drying, extruding, melting and filtering the two slices made of different materials according to a ratio; b. precisely measuring the two melts with a metric pump to enter into a main box for conjugate composition, spinning the composite melts at the condition of air cooling to obtain hollow as-spun fibers; c. air-drafting and spinning the as-spun fibers; d. spreading and lapping the obtained spinning; e. carrying out spunlace solidifying and splitting on the fiber nets obtained by spreading and lapping; and f. drying and shaping to form clothes. The device comprises a slice device, a conjugate composition device, a spinning device, an air drafting device, a swaying yarn and web forming device, a spunlace device and a sari forming device which are arranged in turn, and also comprises a central control desk which can manipulate the devices. The invention has the advantages of less labor room buildings, short processing flow, high production efficiency and the like. And the produced non-woven fabrics have better hand feeling, better softness and thinner single fiber fineness, have improved filtering property and developed application of the non-woven fabrics in health care.

Owner:JIAN CITY SANJIANG SUPERFINE FIBER NONWOVEN

Epoxy Resin Composition for Fiber-Reinforced Composite Material, Prepreg, and Fiber-Reinforced Composite Material

InactiveUS20080160860A1Good drapabilityGood tackinessSynthetic resin layered productsVehicle componentsChemistryOxazolidone

The invention provides epoxy resin composition containing, as epoxy resin, the following epoxy resin (a) and epoxy resin (b), solid rubber at a ratio of 1 to 20 parts by weight to 100 parts by weight of the entire epoxy resins, and an aromatic amine as a curing agent and having a glass transition temperature of 160 to 220° C. in form of a cured material after heat curing at 180° C. for 2 hours:(a) an epoxy resin having oxazolidone rings and(b) a glycidylamine type epoxy resin.

Owner:TORAY IND INC

Preparation process for fine denier and superfine denier polypropylene fibers

InactiveCN101736416AReduce consumptionSave dyeing energyMonocomponent polypropylene artificial filamentMelt spinning methodsPolymer scienceAbnormal shaped

The invention mainly discloses a preparation process for fine denier and superfine denier polypropylene fibers, which comprises the following steps of: adopting a spinning special material of which the melting point is between 165 and 175 DEG C; in a spinning device, extruding and melting the spinning special material by a single screw extruder, wherein a melt flows evenly; performing spinning through a round or abnormal spinneret orifice of a spinneret plate of a spinning box, wherein the spinning speed is 2,200 miters per minute; cooling and oiling tows; and then performing hot drawing and winding to finally obtain the fine denier and superfine denier polypropylene fibers of 0.5 to 2 deniers, wherein the hot drawing temperature is between 45 and 105 DEG C, the drawing multiple is 1.5 to 4 times, and the winding speed is 80 meters per minute for overfeeding. The preparation process is a nuisanceless, environment-friendly, energy-saving and innovative process, and the finally obtained product has the advantages of light in texture, high strength, good abrasion resistance and elastic resilience, small static electricity, small coefficient of heat conductivity and good electrical insulating property.

Owner:绍兴前瞻化纤有限公司

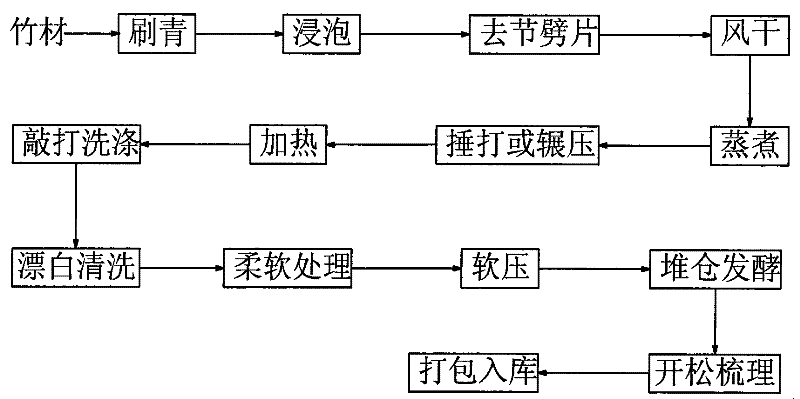

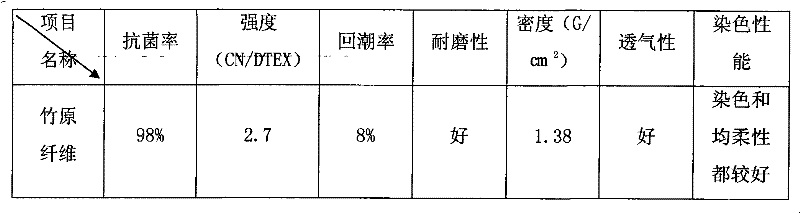

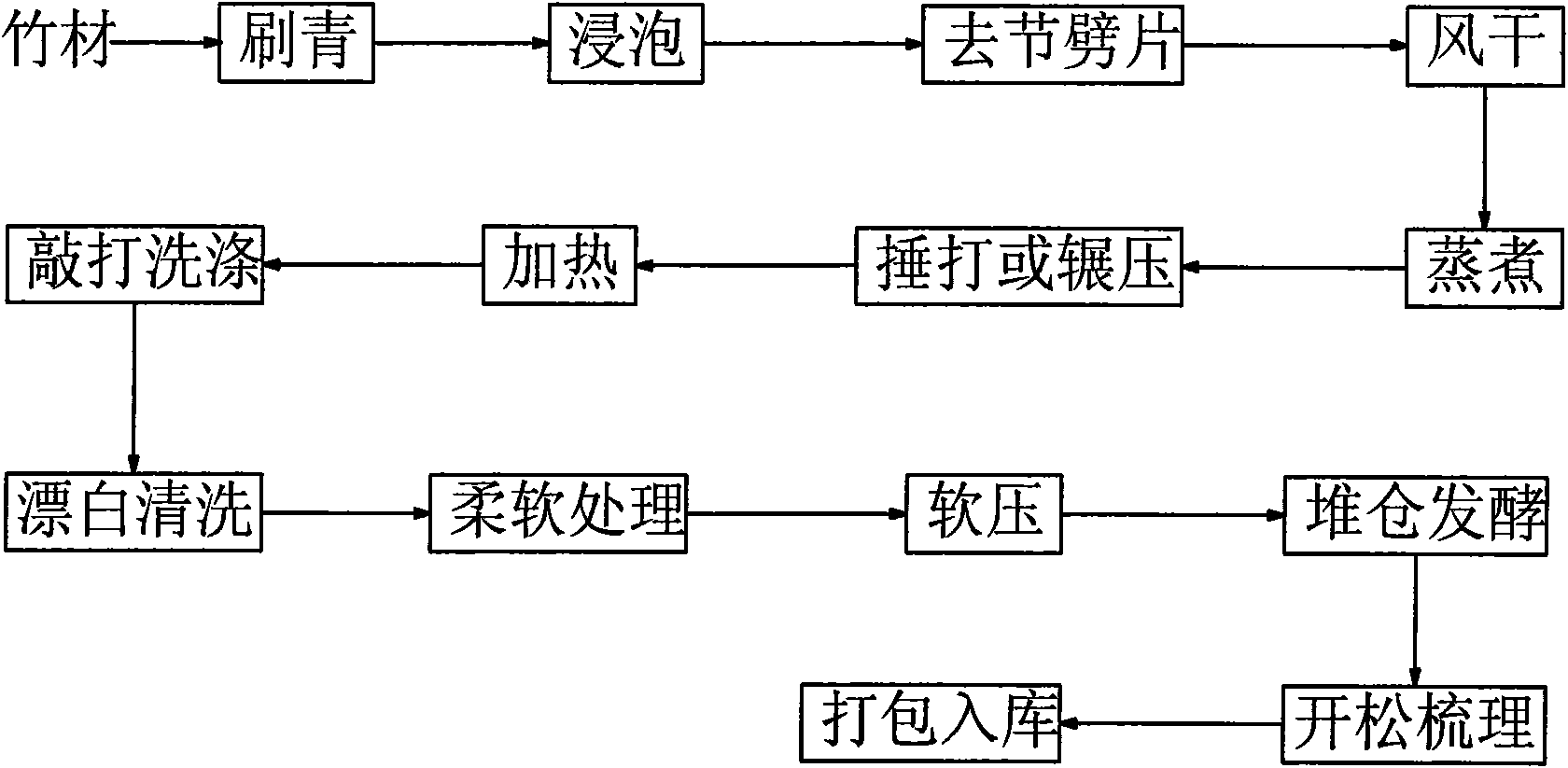

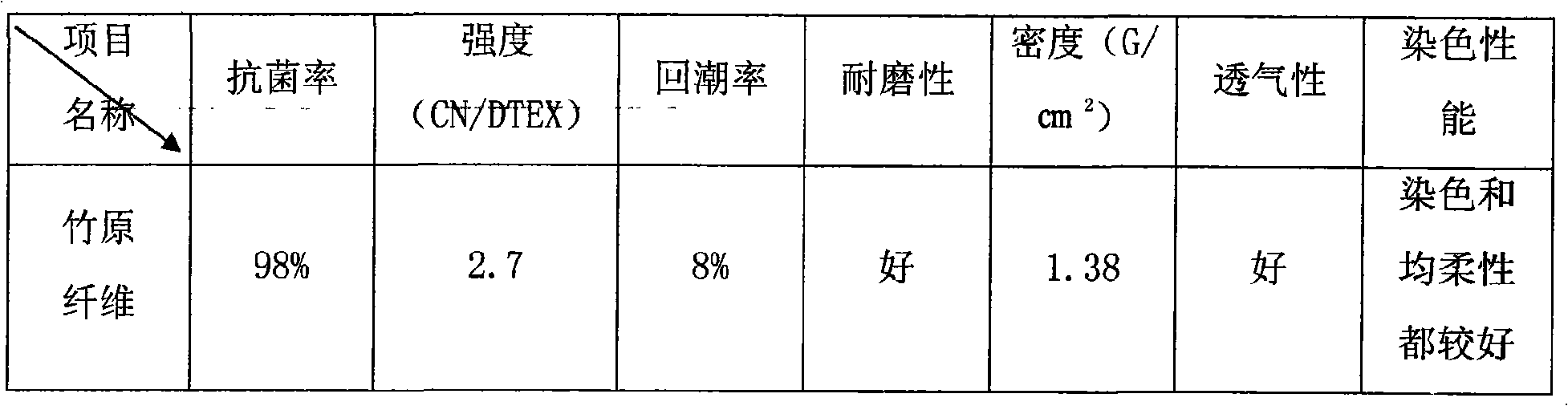

Solvent method for biologically preparing bamboo fiber

ActiveCN101538743BHigh antibacterial rateHigh strengthWood working apparatusMechanical fibre separationCardingBlack liquor

The invention provides a technology for preparing bamboo fiber by 1, 4-butanediol in a solvent method, which comprises the steps of preparing bamboo into bamboo filaments; soaking the bamboo filaments in the solvent and heating to remove lignin, hemicellulose and other impurities on the surface of the cellulose; preparing into coarse bamboo fibre; beating the coarse bamboo fibre, washing with water simultaneously, and then spin-drying through a centrifuge; bleaching and cleaning; conducting mellowing to the bamboo fiber; soft-impressing the bamboo fiber; stowing fermentation and curing, and finally obtaining the bamboo fiber with spinnability after opening and carding. The solvent adopted by the invention has high boiling point and stable chemical property and can be recycled; the whole technological process does not generate black liquor and seriously pollute the environment, and belongs to clean techniques; the obtained natural bamboo fiber has the remarkable advantages of moisture absorption, quick dry, coolness, comfort, antibacterium, deodorization and the like; and the method has low cost and good economic benefit and environmental protection benefit.

Owner:FUJIAN HAIBOSI CHMEICAL TECH

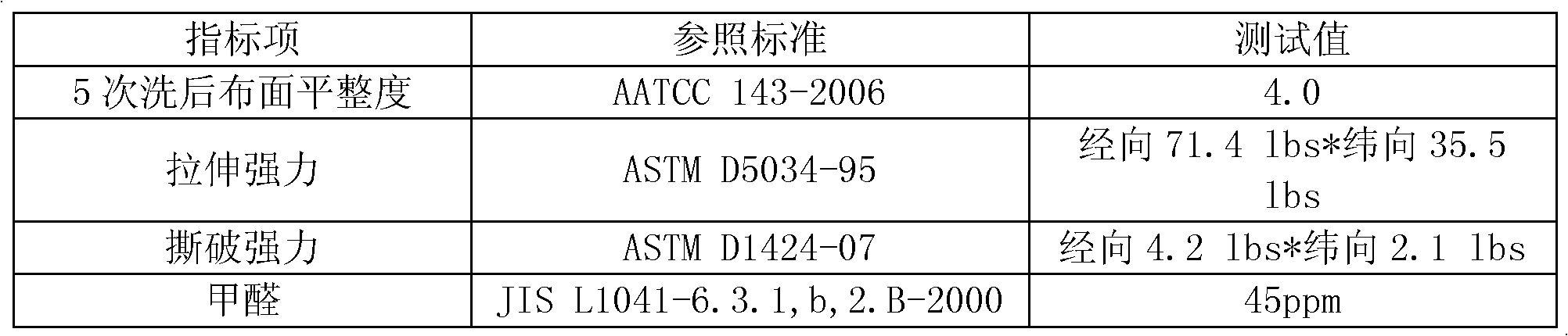

Finishing agent composition for cotton silk fabrics and production method of wash and wear cotton silk shirts

InactiveCN102634984AImprove breathabilityGood hygroscopicityVegetal fibresAnimal fibresEthylene ureaGlyoxal

The invention discloses a finishing agent composition for cotton silk fabrics and a production method of wash and wear cotton silk shirts. The finishing agent composition contains a finishing agent selected from dihydroxyl ethylene urea resin, butanetetracarboxylic acid, propanetricarboxylic acid, citric acid, polymaleic acid, glyoxal and glutaraldehyde, a polyurethane finishing agent and a catalyst. The wash and wear cotton silk shirts produced by the method can simultaneously have such advantages of cotton as good air permeability and strong moisture absorbability and such advantages of silk as good drapability, gloss and outstanding handfeel and can have excellent wash and wear effect while maintaining the peculiar handfeel of the cotton silk fabrics.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

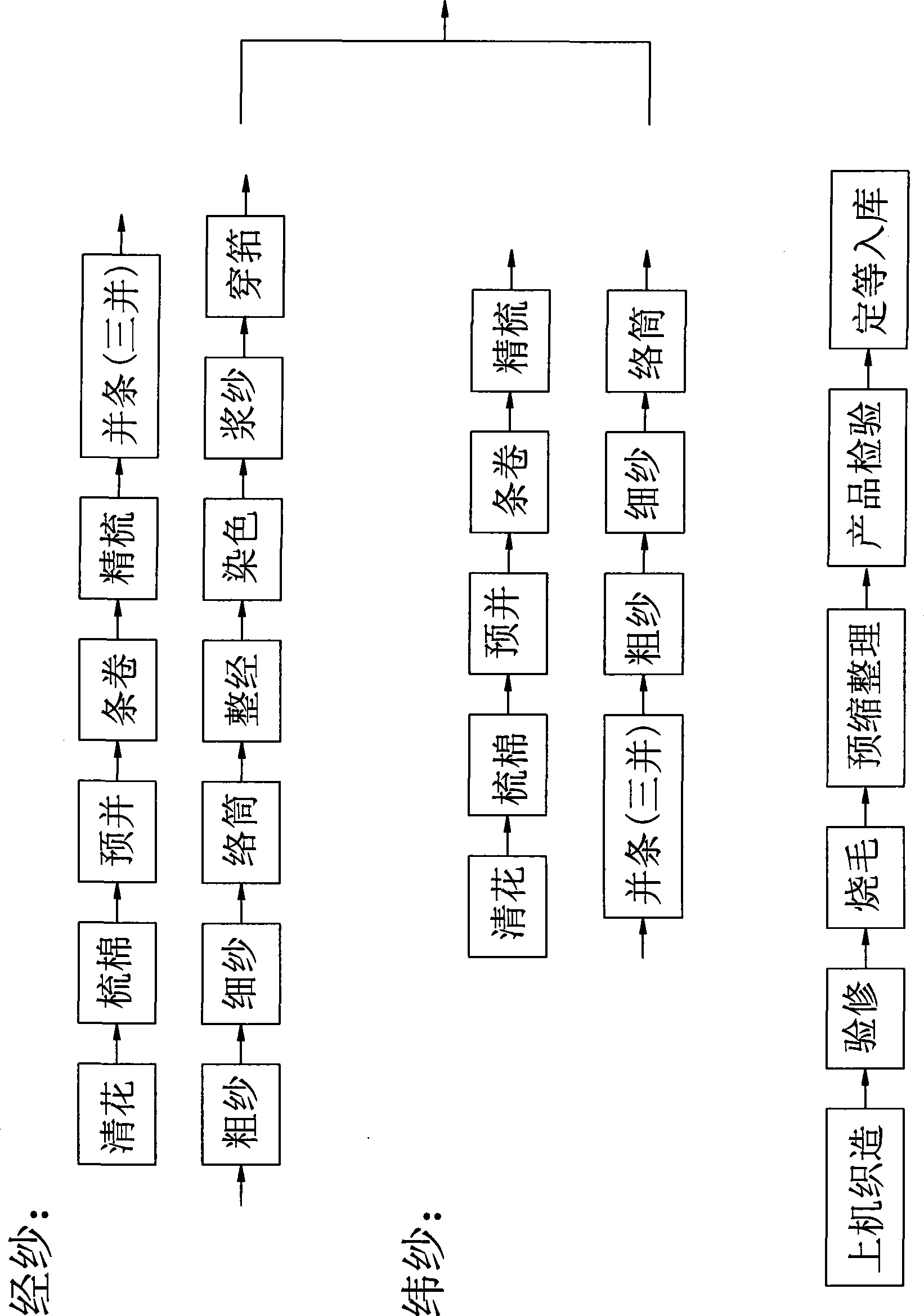

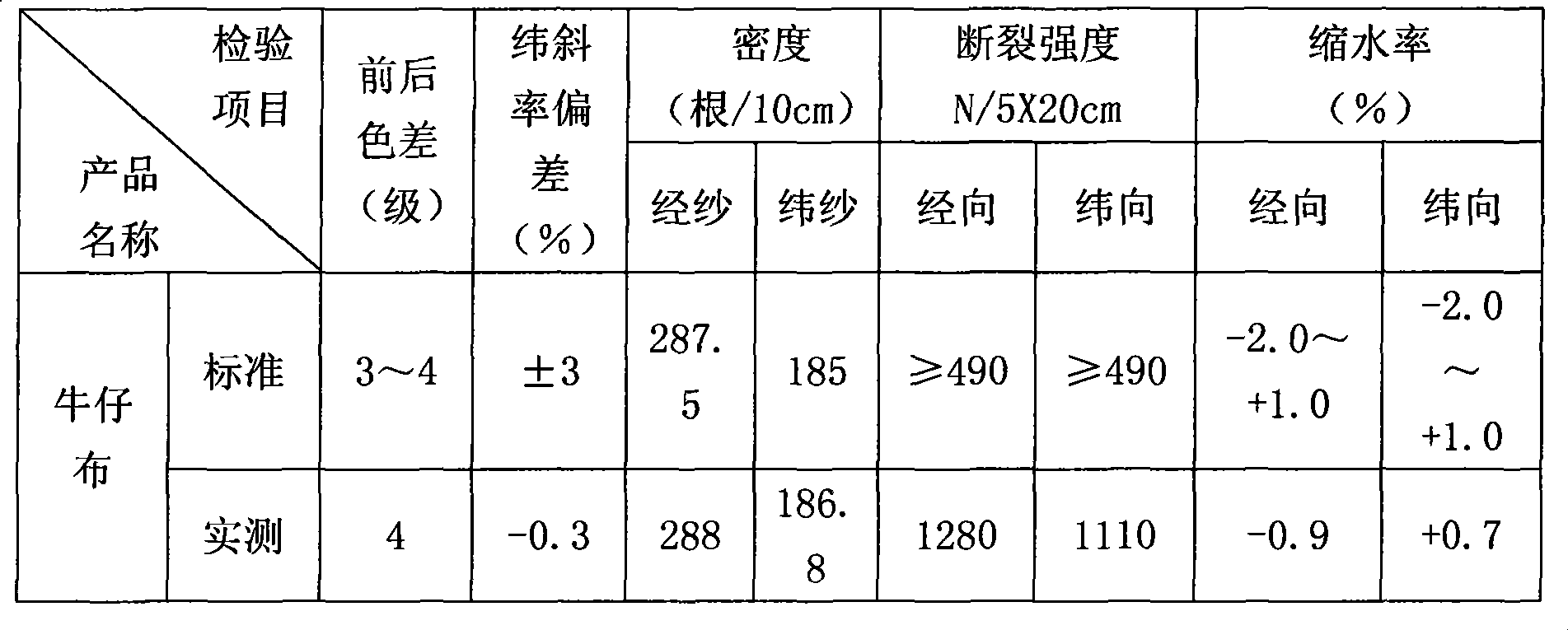

Viloft shengma smooth edge denim and production technology thereof

The invention relates to VILOFT sunn crotataria plain edge jean which comprises the following components by weight percentage: 20-40% of VILOFT fiber, 20-40% of sunn crotataria, 20-40% of one or multiple of cotton fiber, color cotton fiber, prolivon, cashmere, milk fiber, soybean fiber, tencel yarn, flax, silk, etc. In the picking process, the lap pressure is weighted, multi-combing and little beating, combing instead of beating are adopted, the speed of each beater is reduced, and the gauge of the beater and grid bars is enlarged. In the carding process, the lap is fully carded and the card sliver quota is increased; in the drawing process, the clockwise drawing process is adopted, the gauge is enlarged; the pressurizing quantity is improved and the vehicle speed is reduced, the combination process and the three blending combination process are adopted, and the first tension drawing multiple is grasped in a slightly large way; in the spinning process, large postzone roller gauge, small postzone draft multiple and small nip gauge are required, the vehicle speed is reduced, and the pressure is increased. The fabric of the jean has the advantages of environment protection, moderate elastic, soft texture, good luster and drapability, and obviously bamboo joint effect.

Owner:山东万泰创业投资有限公司

Shield tail seal grease of shield excavating machine

The invention discloses a shield tail seal grease of a shield excavating machine, which is used for passing through sand soil, rivers and lakes in the process of excavating construction of an underground project. The shield tail seal grease is combined by the following raw materials in parts by weight: 15-25 parts of plant oil, 15-25 parts of viscosity index modifying agents, 50-60 parts of stuffing, 5-10 parts of thickening agent, 0.8-1.2 parts of mildewproof agents, 0.5-1.0 part of wet dispersing agents and 2-6 parts of bamboo fibres. The seal grease has good seal performance and pumping ability and no pollution to the environment, can particularly play a favorable seal role in the sand soil or a deeper soil layer with more water content and solve the problem of easy slurry leakage or large dosage in the sand soil, which commonly exists in the grease in the current market.

Owner:SHANGHAI CIFU NEW BUILDING MATERIALS CO LTD

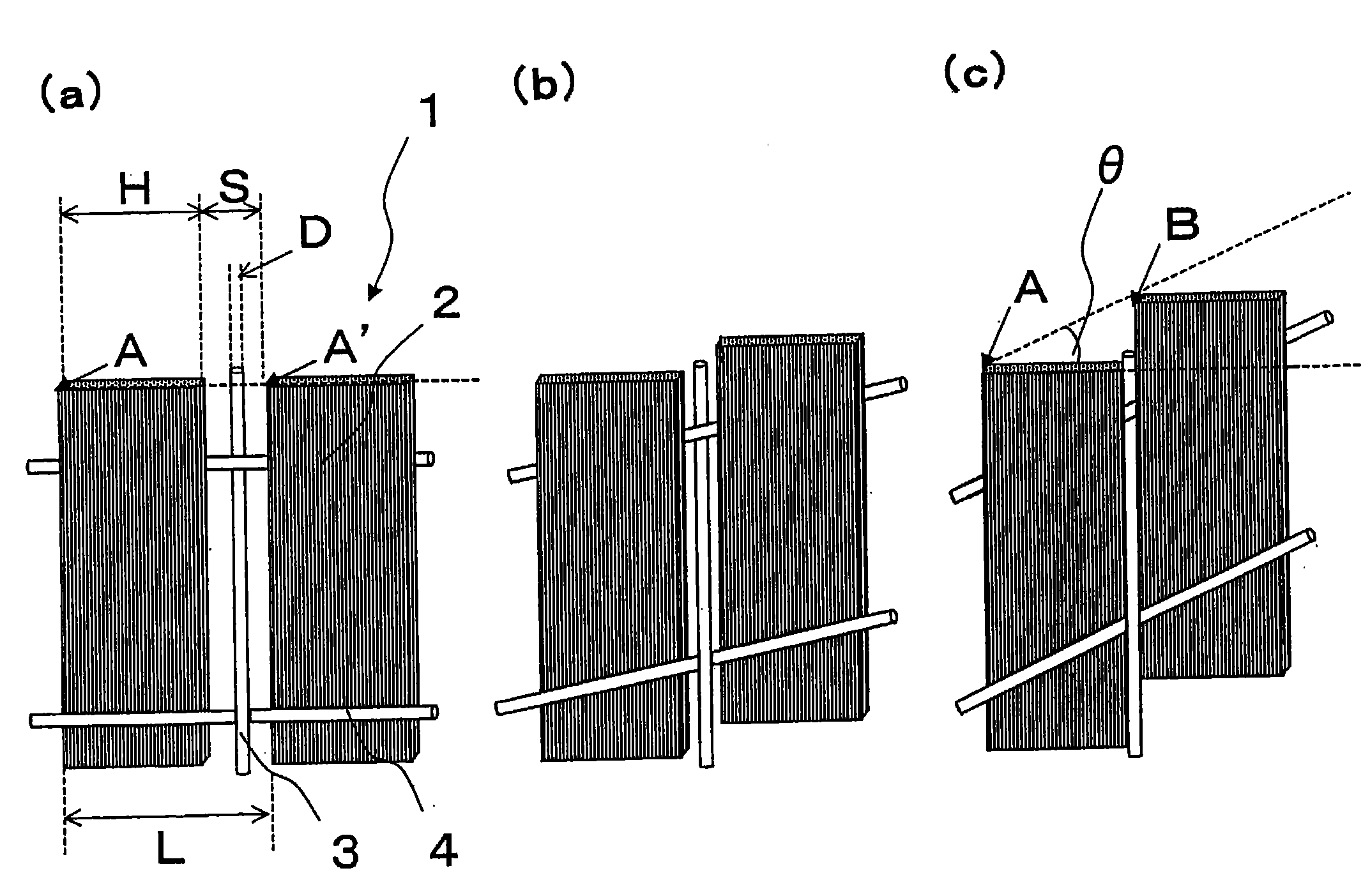

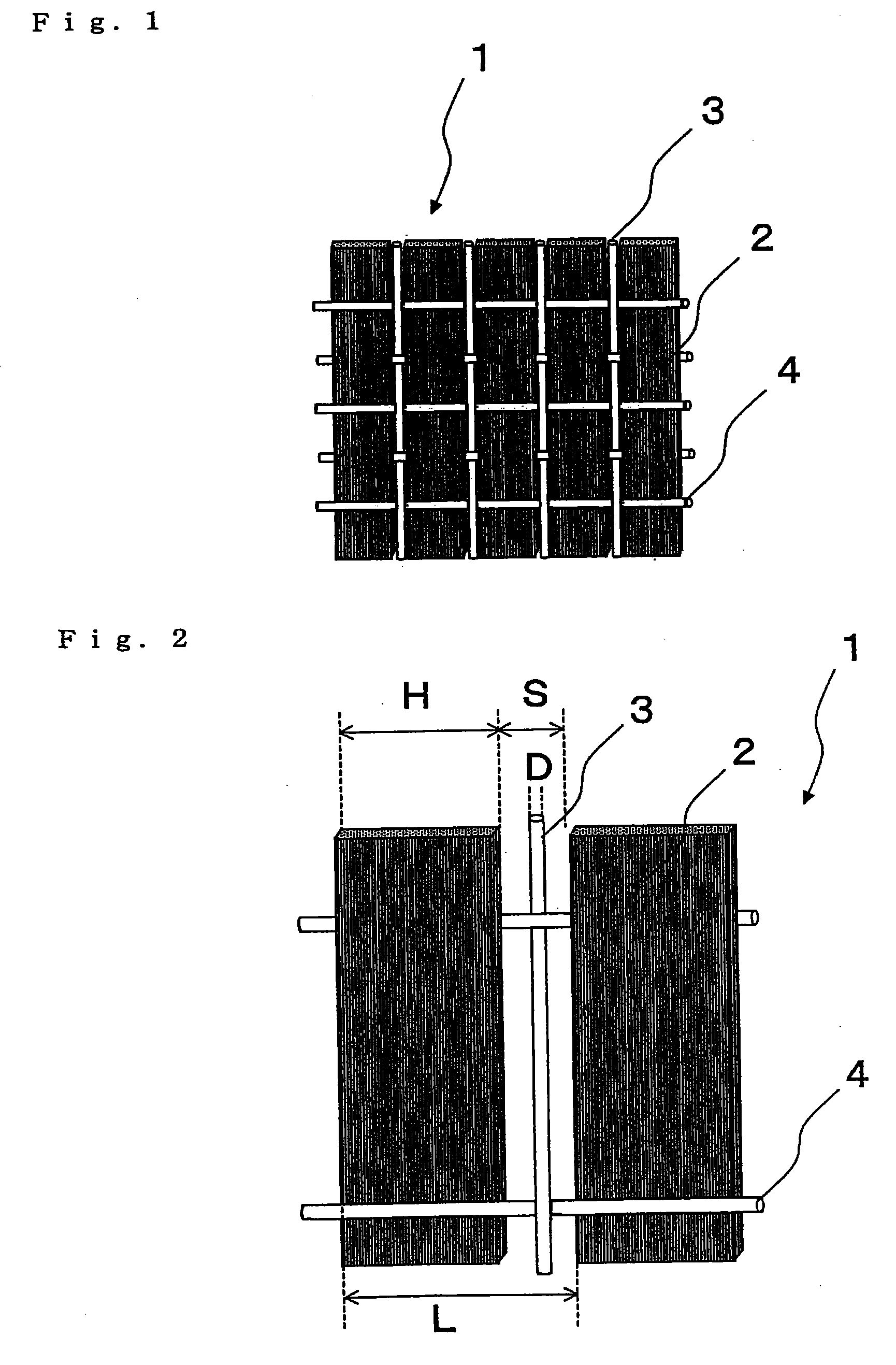

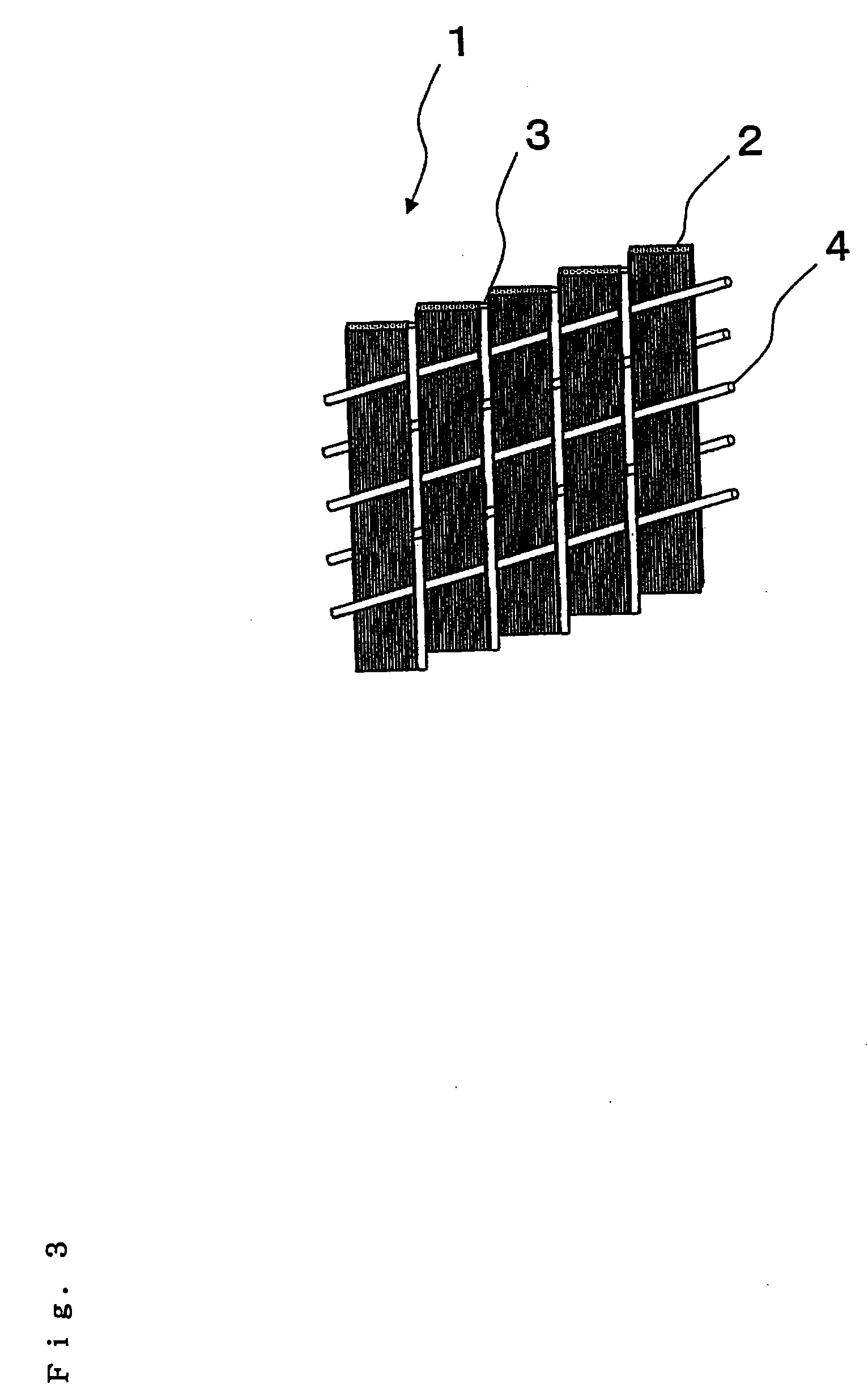

Reinforcing fiber base material for preforms, process for the production of laminates thereof, and so on

ActiveUS20090068428A1Excellent characteristicsGood drapabilityPaper/cardboard layered productsNon-woven fabricsVitrificationYarn

The invention provides (1) a reinforcing fiber base material having a weave constituted of both reinforcing fiber filaments arranged in one direction in parallel with each other and auxiliary yarns arranged in another direction, which satisfies the relationship: L=H / cos θ (wherein L is the length of auxiliary yarn covering one reinforcing fiber filament and H is the width of the filament as determined in such a state where the reinforcing fiber filaments are unified only with the auxiliary yarns; and 3°≦θ (in-plane shear strain)≦30°) and wherein 2 g / m2 to 40 g / m2 of an adhesive resin having a glass transition temperature between 0° C. and 95° C. is adhesed to at least one side thereof in spots, lines, or discontinuous lines; (2) a laminate obtained by laminating layers of the above reinforcing fiber base material, wherein the adhesive resin adhesed to each layer of base material partially bonds to a facing layer of base material over the whole surface thereof, with the maximum length of each bonding joint being not less than 1 mm and not more than the width H of a reinforcing fiber filament; and (3) a preform, obtained by shaping the laminate, having a reinforcing fiber volume fraction (Vpf) of 45% to 62%.

Owner:TORAY IND INC

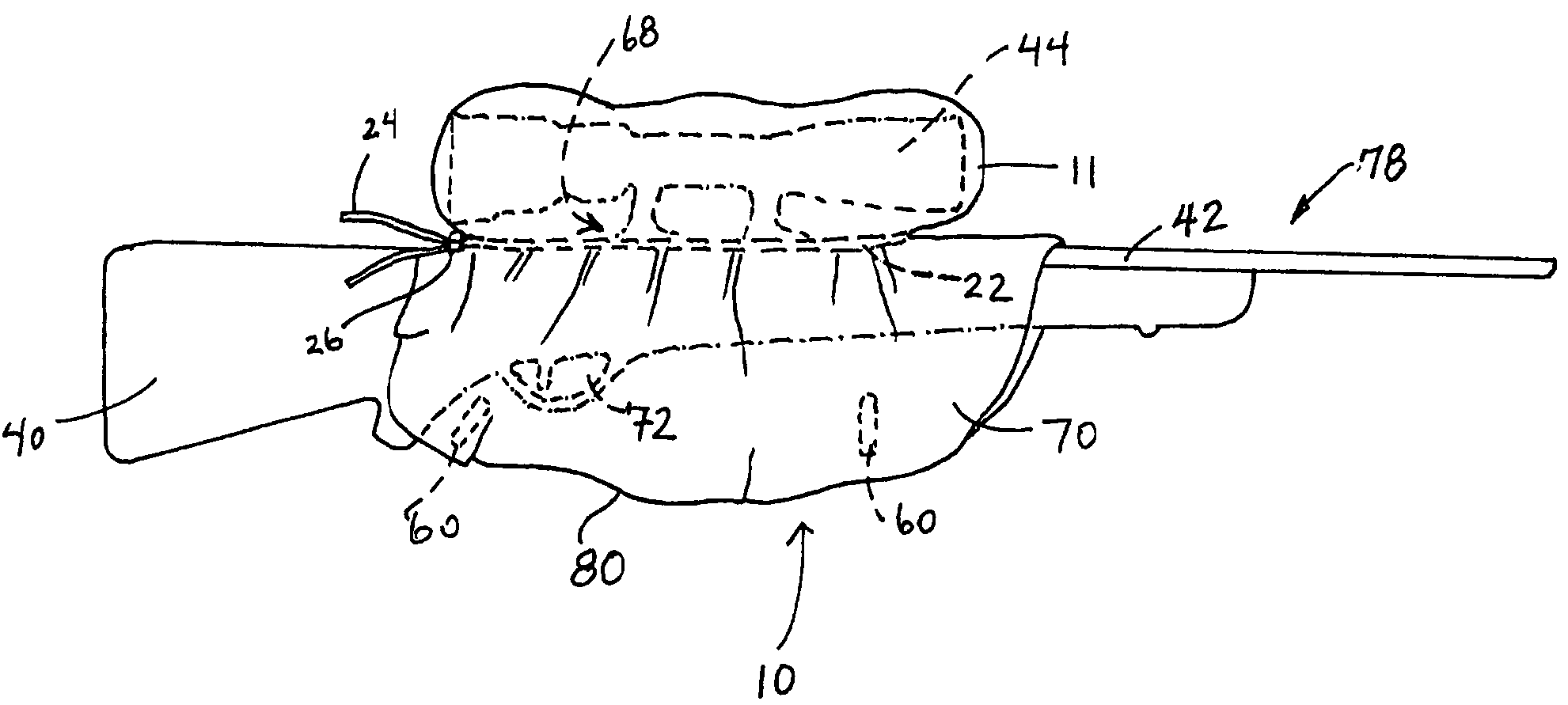

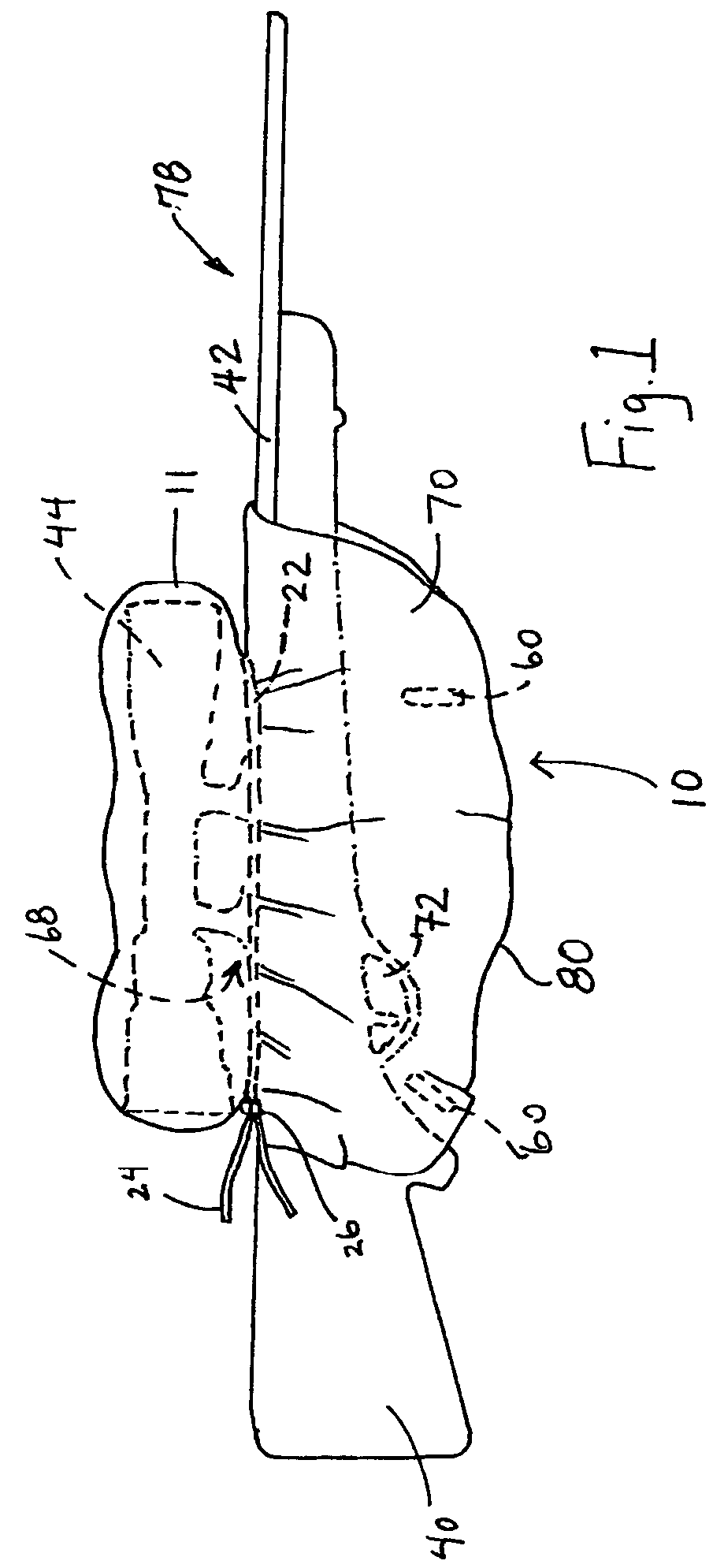

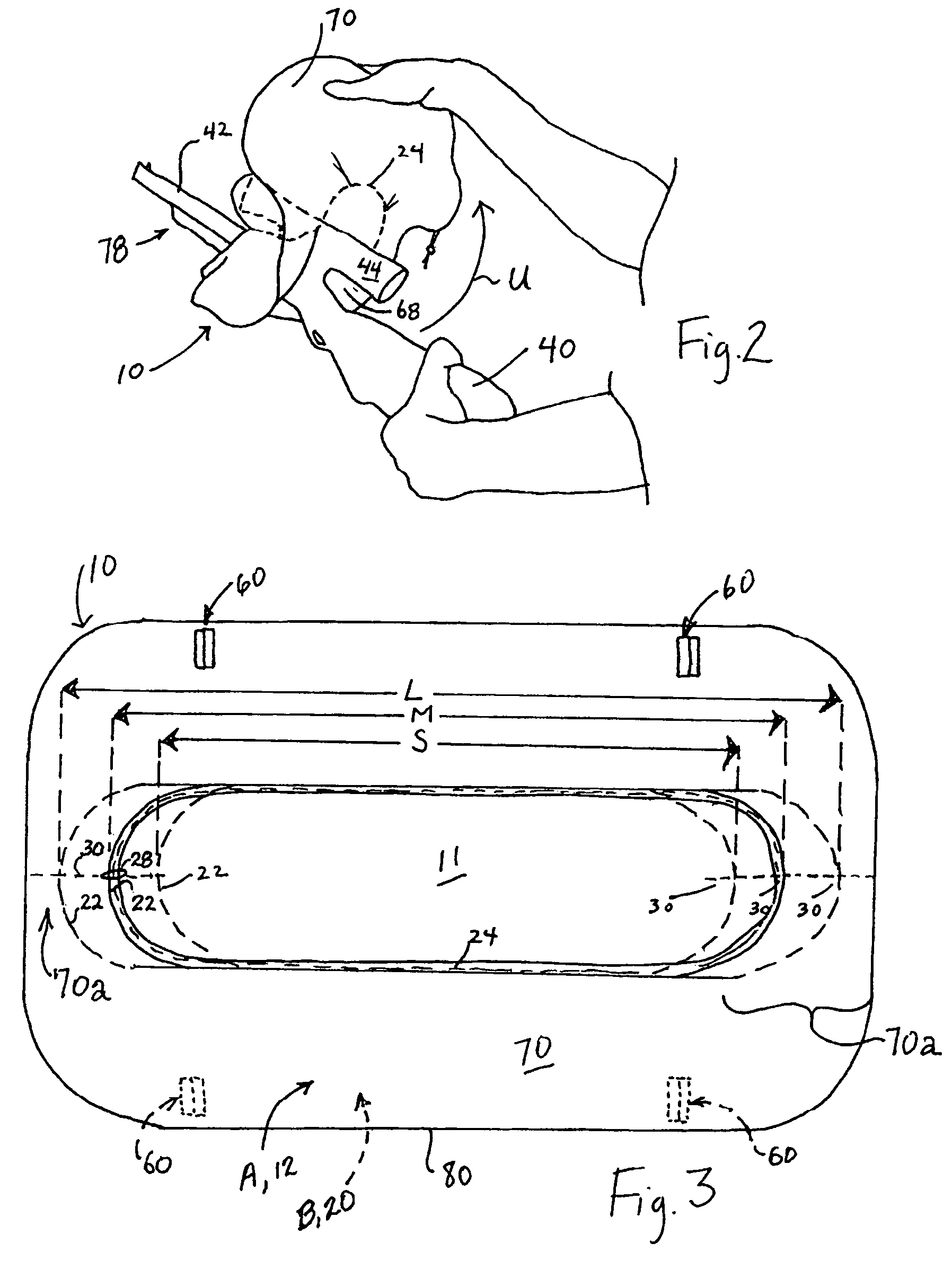

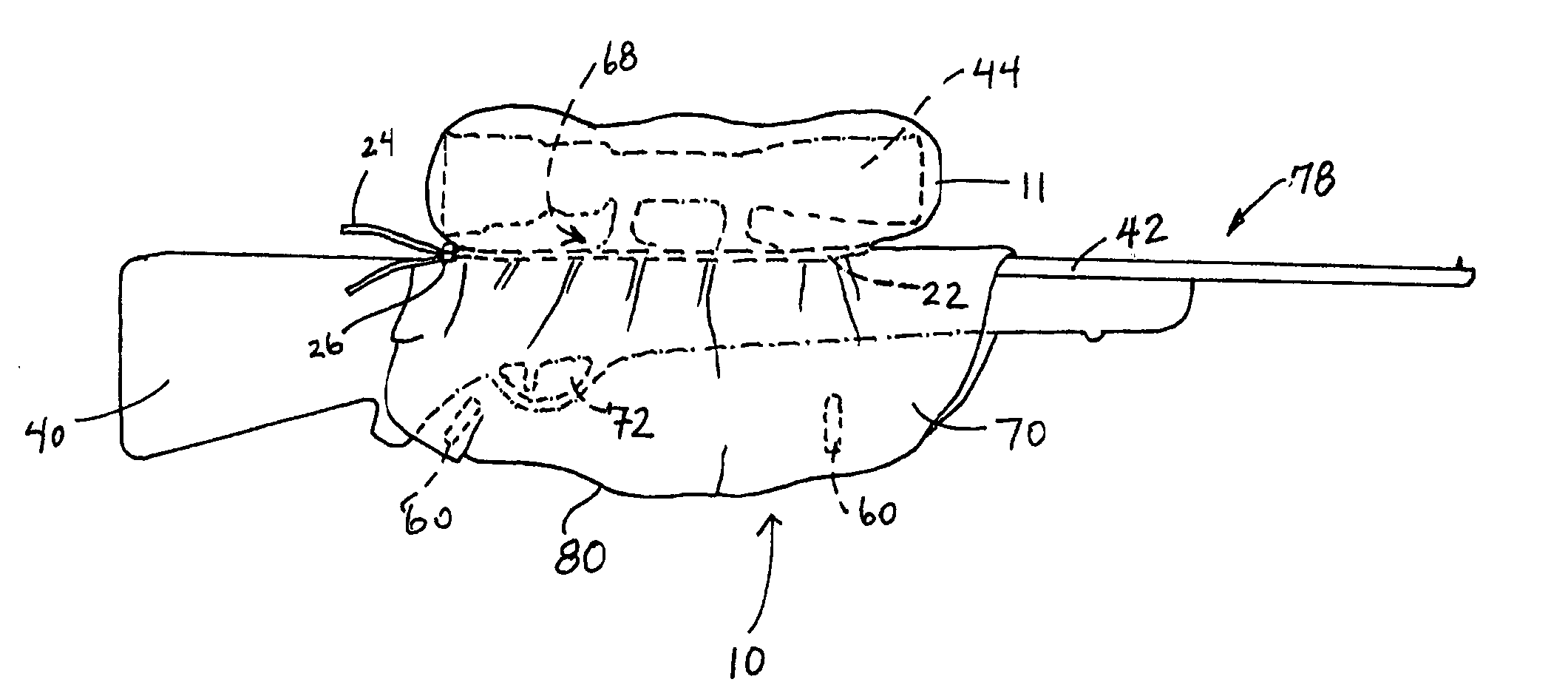

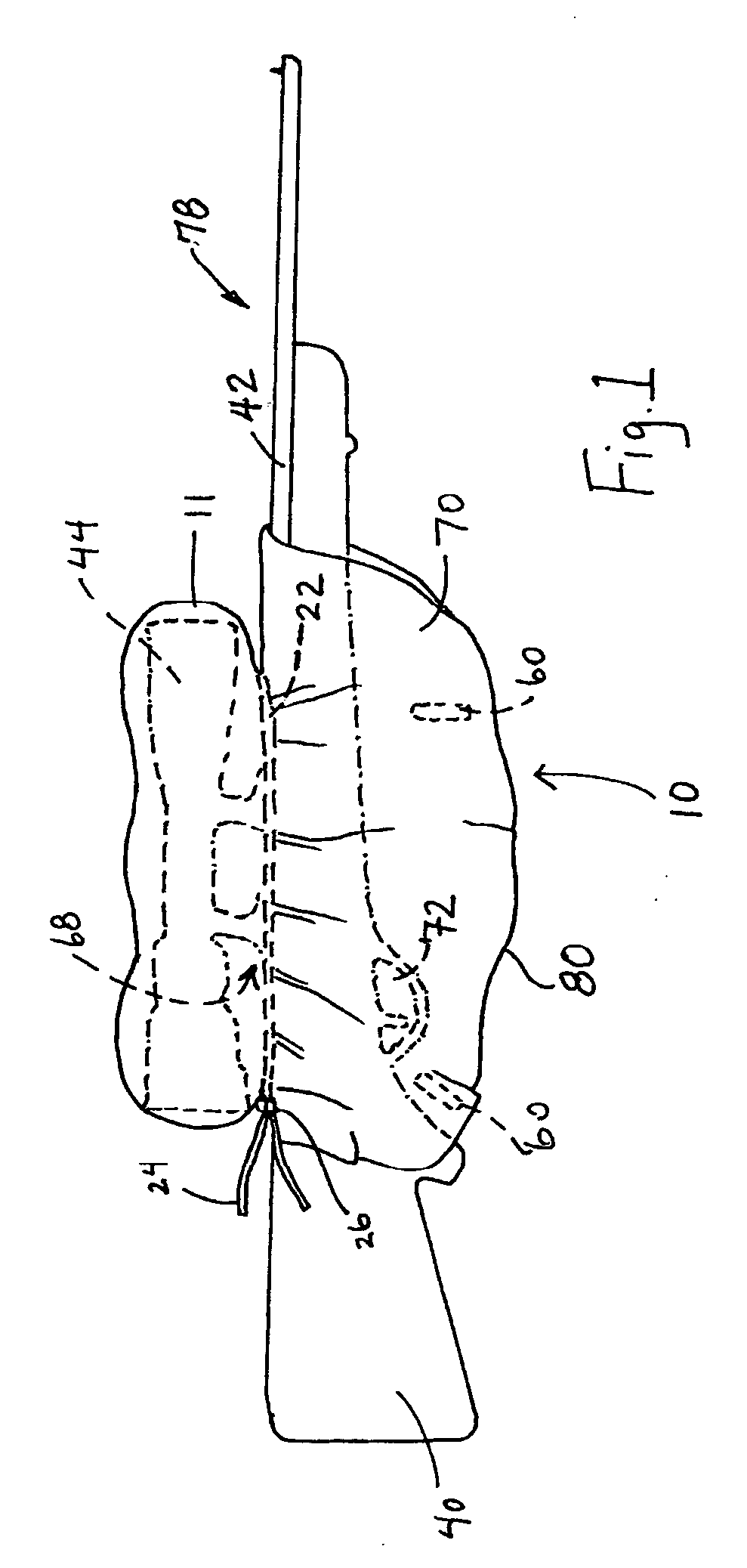

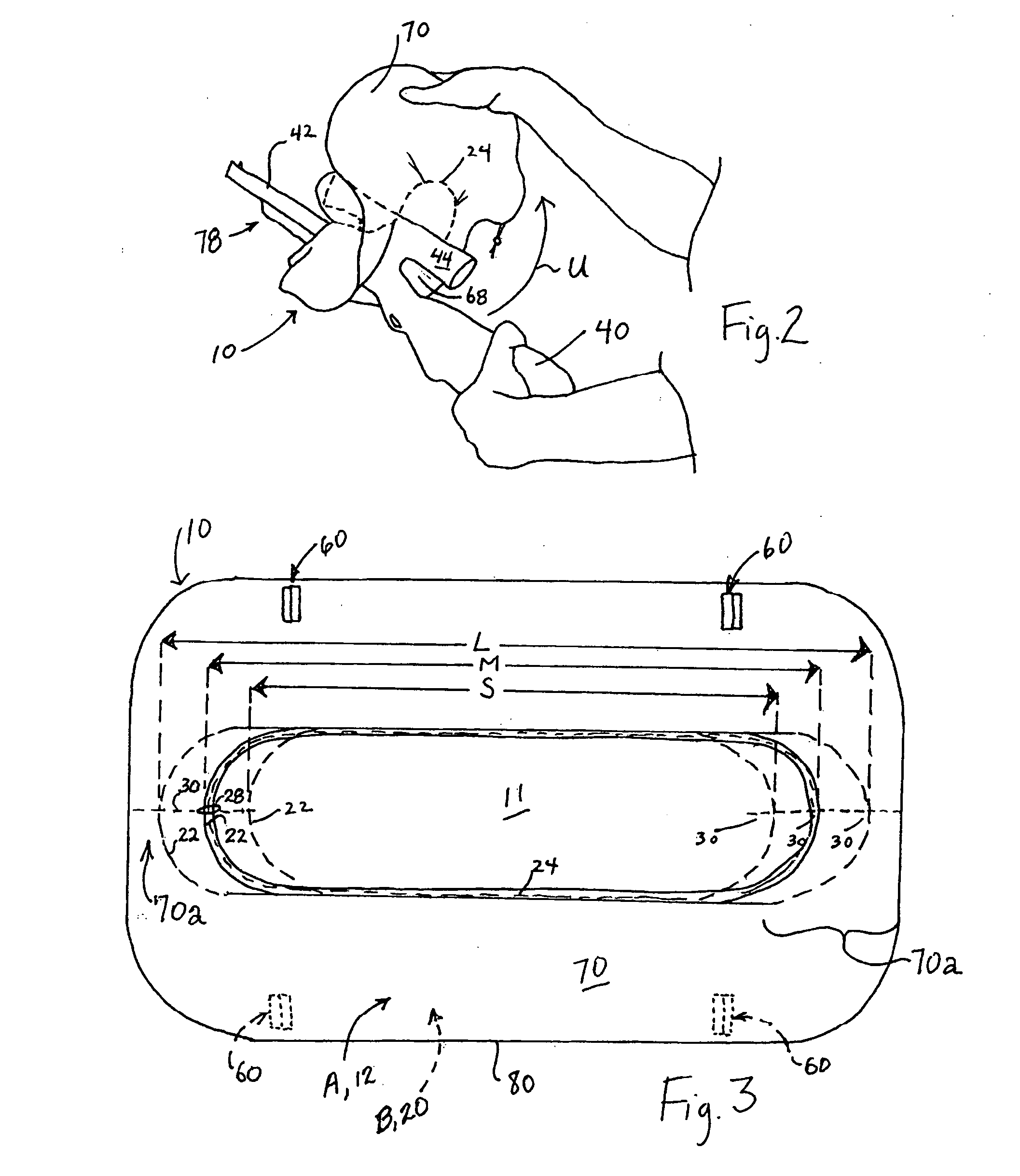

Scope and action cover for hand guns and rifles

InactiveUS7559168B2Use quietEasy to put inFlexible coversDead plant preservationStructural engineeringRifle

Gun scope and action cover comprises a water-proof, breathable / air-permeable, reversible, light-weight, highly-flexible fabric pouch formed by an enclosed, cinchable elastic cord that fits over the optical scope of a rifle or hand gun, and that is universal in size, quiet in use, easy to put on and take off, and easy to store. The pouch area, formed by cinching and locking the cord, is bounded with an extended skirt that drapes down over the mechanical action of the gun. 2-ply waterproof / breathable fabric is preferred. Additional features include a securing cord for adding camouflaging ghillie strips, hook and loop fastener silencer(s) that prevent accidental adhesion to clothing, the release of which causes game-spooking sound, and a pocket for a warmer unit. The cover employs a variety of camouflage patterns on one or both sides, or one side may be a dark, a light, or a safety color, such as neon orange.

Owner:MIDDLEPOINT TRADING

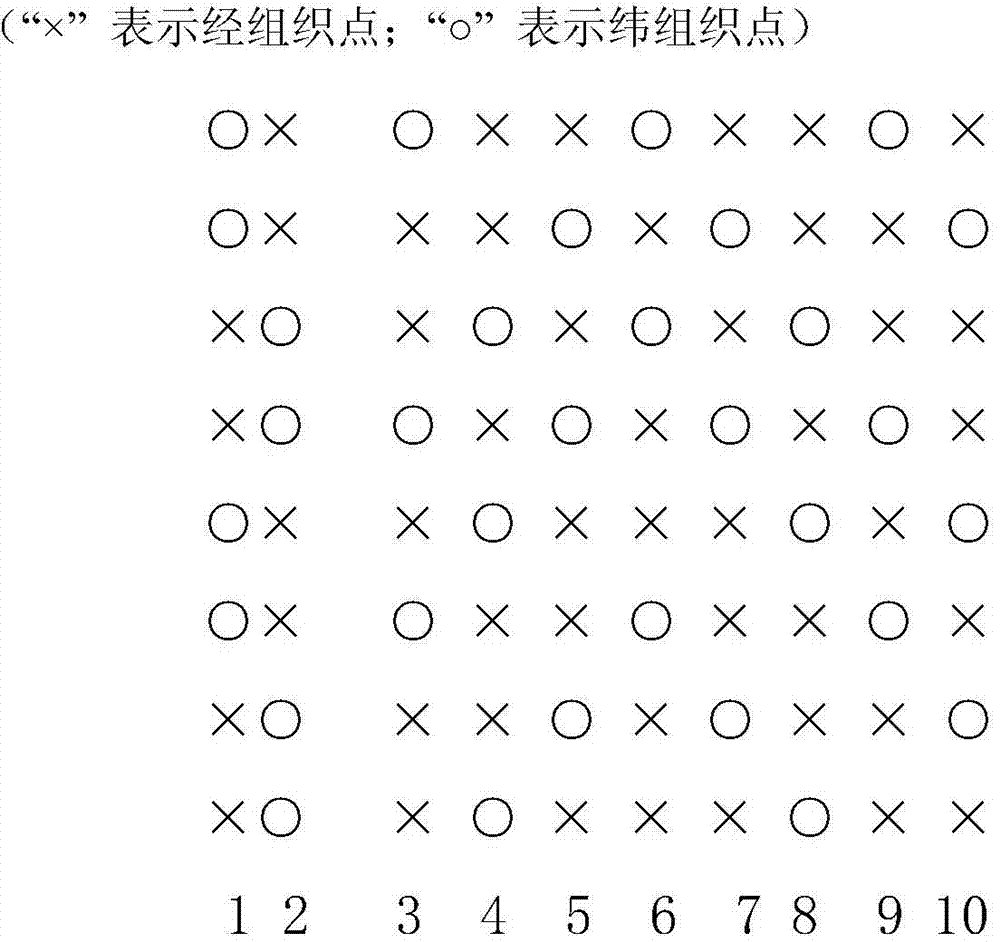

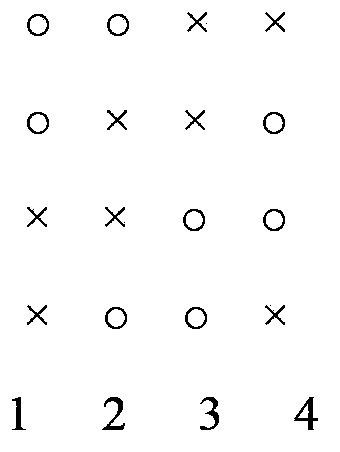

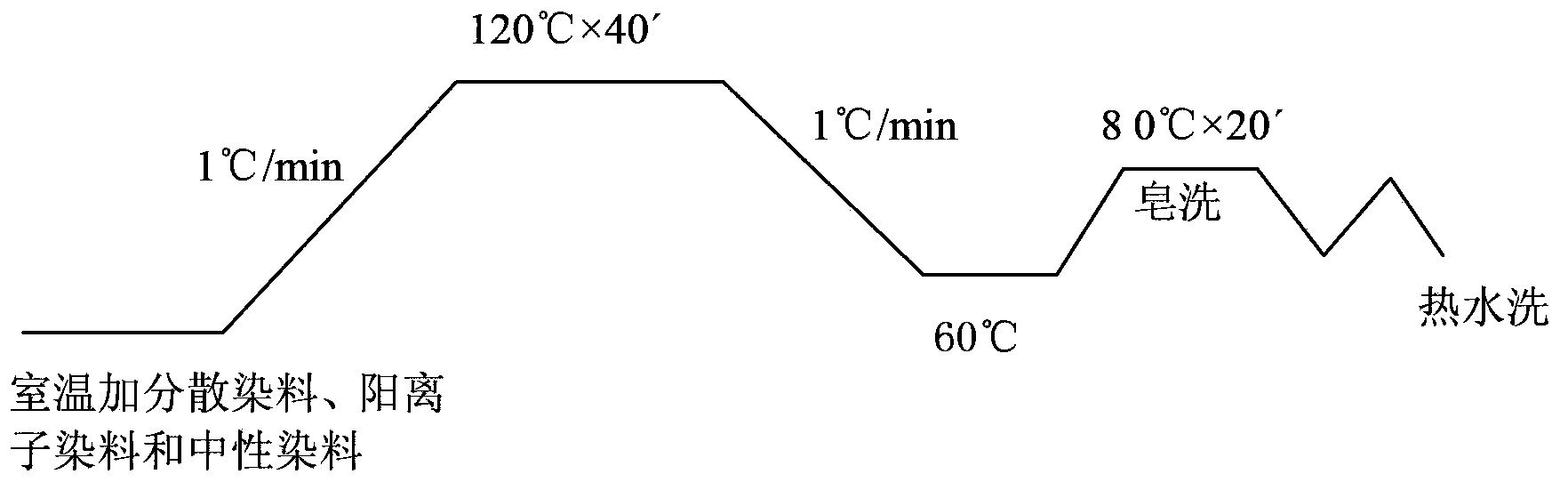

Coffee carbon multi-component fiber weaving fabric and preparation method thereof

The invention belongs to the field of spinning, dyeing and finishing, and particularly relates to coffee carbon multi-component fiber weaving fabric and a preparation method of the coffee carbon multi-component fiber weaving fabric. The coffee carbon multi-component fiber weaving fabric is made of the following raw materials of warp direction yarns and weft direction filaments, wherein the warp direction yarns are formed by blending the following raw materials, by weight, 25-45% of coffee carbon fibers, 25-40% of bamboo fibers, 20-30% of cationic modified polyester fibers and 0.5-0.8% of conductive fibers, and the weft direction filaments are formed by alternately ranking 150D-160D coffee carbon fiber filaments and 100D-120D PTP fiber filaments at the ratio of 1 to 1. The coffee carbon multi-component fiber weaving fabric has the advantages that different characteristics of the coffee carbon fibers and the other fibers are exerted, comfort of the apparel fabric and the uvioresistant function and other protection functions are integrated, physicochemical indexes are good, dyefastness is high, and cost performance of the fabric is high. The preparation method is provided, the process is reasonable, and a new path is opened up for improving high performance and comfort of the coffee carbon multi-component fiber weaving fabric.

Owner:SHANDONG WOYUAN NEWFASHIONED FABRIC

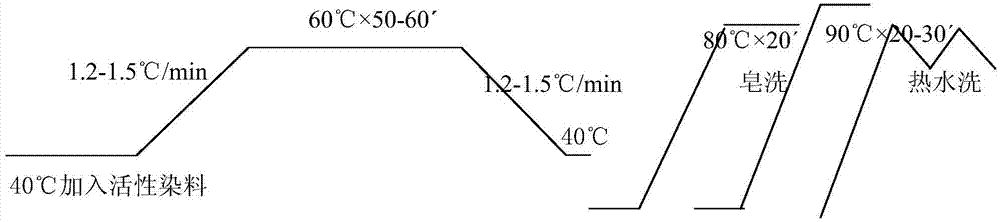

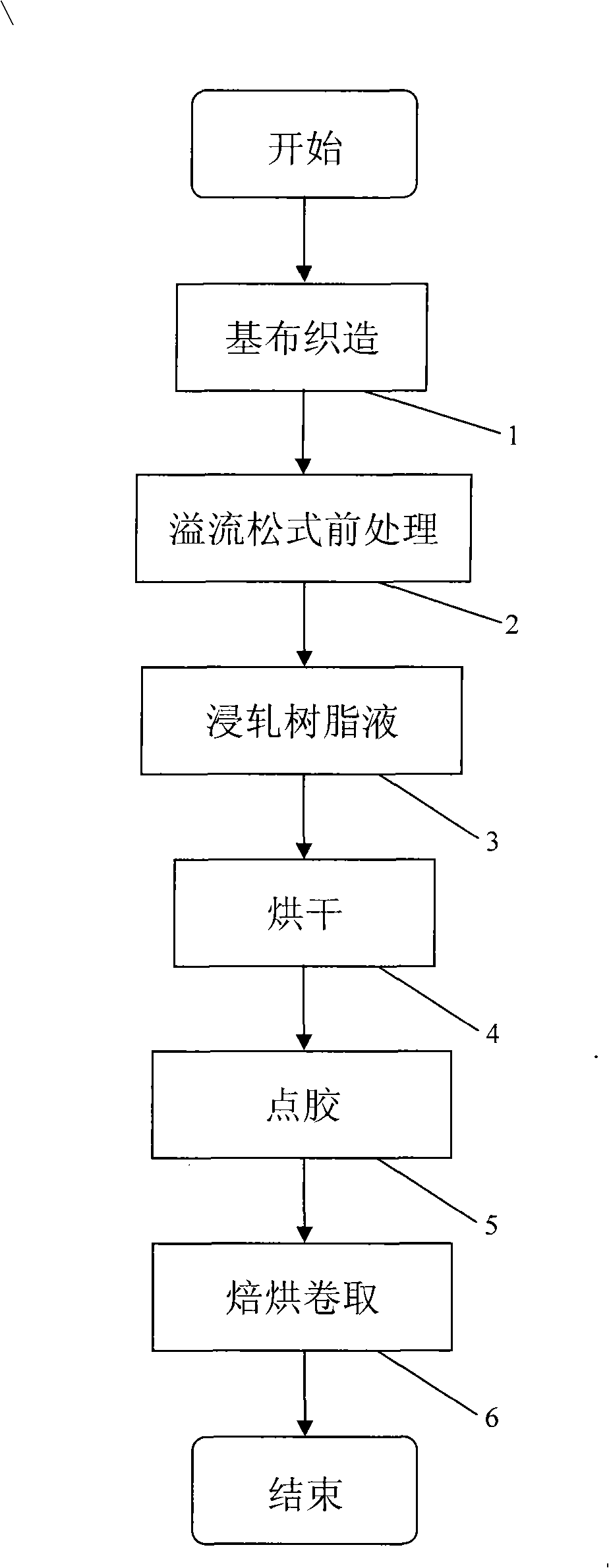

Manufacturing technique of crease-shedding uniforms lining

InactiveCN101288507AImprove deformation recovery performanceImproves wrinkle recoveryGarmentsVegetal fibresFiberPolyamide

The invention discloses a technique for manufacturing anti-wrinkle liner of suits. The technique comprises the processes of weaving base fabric, overflow and loose pre-treatment, immersing in resin liquid and rolling, drying, gluing, baking, coiling and so on. The technique adopts environment-friendly resin liquid with high quality for twice-immersing and twice-rolling treatment which causes the resin liquid to sufficiently permeate into fibers and to become uniformly cross-linking, leads the treated fabric to obtain good anti-wrinkle recoverability and solid hand feeling. Nylon polyamine hotmelt adhesive is used for double-dot coating, which is characterized by strong adhesion fastness, having good drapability after being bonded with the fabric and excellent anti-wrinkle property when in use. The lining cloth has soft hand feeling and good anti-wrinkle property. Suits made from the lining cloth have the advantages of fullness and being docile. The anti-wrinkle property and sizing property after washing are better than any other ordinary adhesive lining cloth. The lining cloth is mainly used for wash-and-wear suits and career wears.

Owner:严华荣

Epoxy resin composition for fiber-reinforced composite material, prepreg and fiber-reinforced composite material

The present invention provides an epoxy resin composition, which contains at least (a) an epoxy resin having an oxazolidone ring and (b) a glycidylamine type epoxy resin, containing 100 parts by weight of the total epoxy resin 1 to 20 parts by weight of the hard rubber contains an aromatic amine as a curing agent, and the glass transition temperature of the cured product after heating and curing at 180°C for 2 hours is 160 to 220°C.

Owner:TORAY IND INC

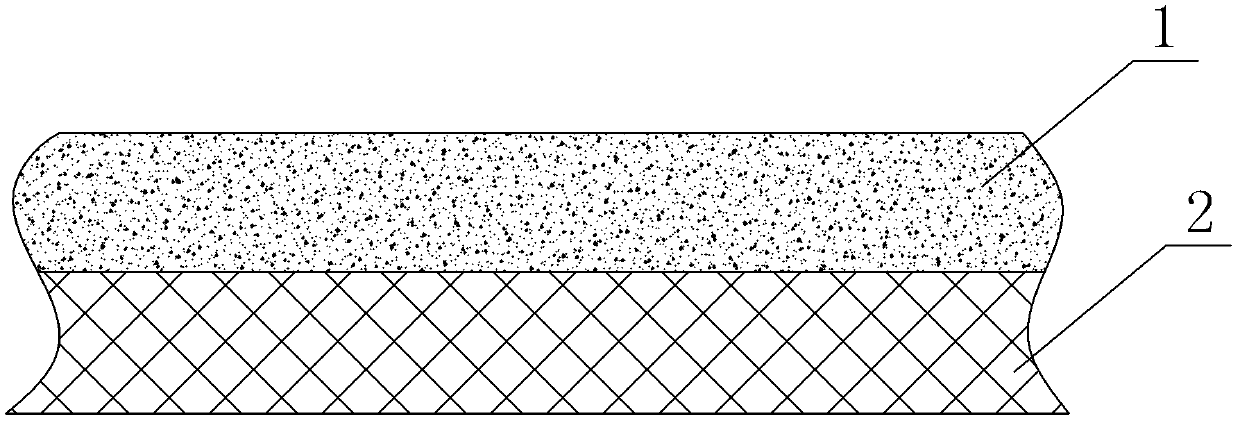

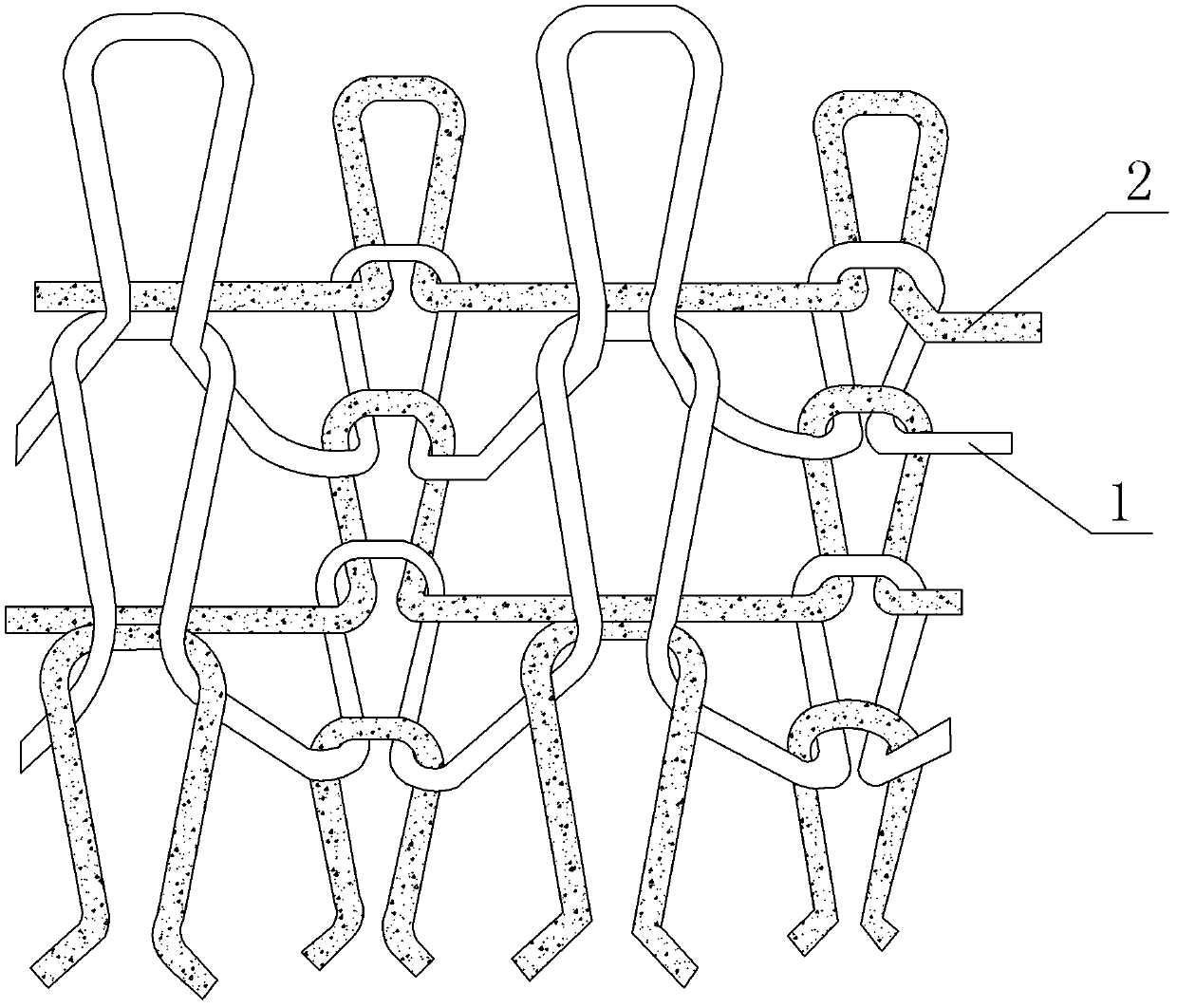

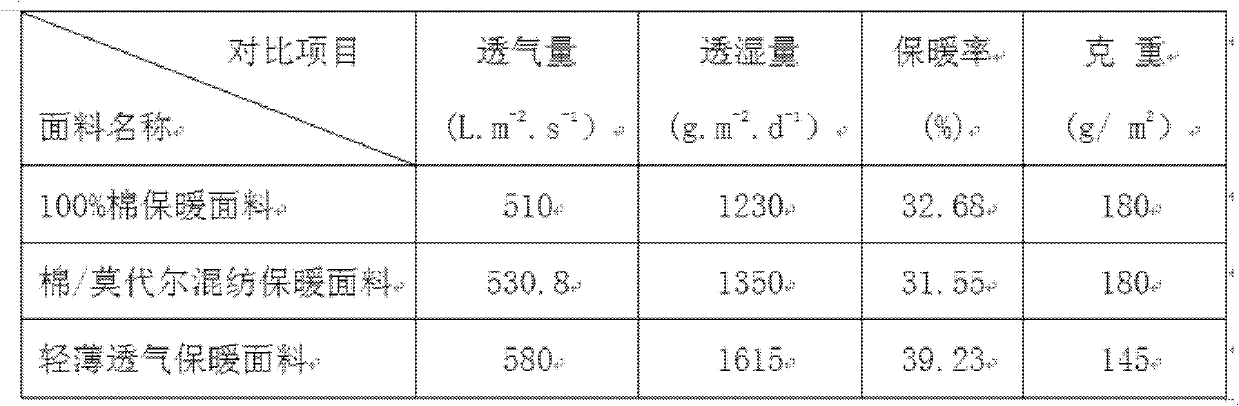

Thin breathable warm fabric and manufacture method thereof

InactiveCN102605523AHigh standardFullnessWeft knittingLiquid/gas/vapor treatment of propelled fabricsYarnMoisture absorption

The invention relates to a thin breathable warm fabric, comprising a surface fabric and an inner layer fabric, wherein the inner layer fabric is a moisture absorption and heating layer; the surface fabric is a warm breathable and moisture-leading layer; the moisture absorption and heating layer is formed by blending 30-60% of moisture absorption and heating EKS fibers and 40-70% of ordinary acrylic fibers; the warm breathable and moisture-leading layer is formed by blending 15-40% of bulk acrylic fibers, 20-60% of superfine acrylic fibers and 0-65% of modal fibers. The invention further relates to a manufacture method of thin breathable warm fabrics, comprising the steps of preparing yarns, weaving, sanding, dyeing, finishing softly and shaping; and the thin breathable warm fabric provided by the invention has the advantages of high wearing comfort, good thin and breathable performance as well as good anti-dropping, anti-static and warmth retention performances.

Owner:SHENZHEN HUIJIE GROUP

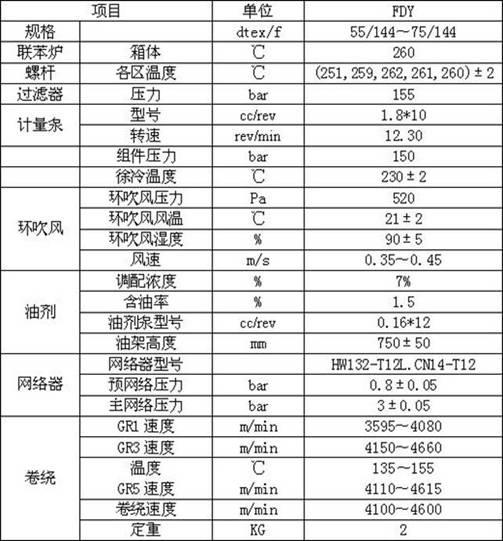

Porous superfine polyamide 6 fully-drawn yarn, preparation method thereof, and equipment thereof

InactiveCN102493016AImprove mixing uniformityImproved pressure stabilityFilament forming substance formingArtificial thread manufacturing machinesYarnAir velocity

The invention relates to a porous superfine polyamide 6 fully-drawn yarn, a preparation method thereof, and equipment thereof. According to the invention, existing FDY production equipment is adopted. A raw material polyamide 6 is sliced and dried; an additive is added on line; the material is subject to screw extrusion and melt extrusion; the material is then cured with a gradually cooling manner and a circular air blow cooling manner; with a reasonably selected spinning temperature of 259-262 DEG C, an air temperature in the circular air blowing process of 19-23 DEG C, a humidity of 85-95%, an air velocity of 0.35-0.45m / s, an oiling and clustering position of 700-800mm, and a winding speed of 4100-4600m / min, the porous superfine polyamide 6 fully-drawn yarn product with a specification of 55dtex / 144f-75dtex / 144f is prepared. Flexible operation is adopted in the preparation method. The preparation method is advantaged in simple technology and low production cost. The product is advantaged in stable performance, good yarn evenness, and good coloration property.

Owner:SUZHOU UNIV

A kind of functional modified acrylic fiber for hair and preparation method thereof

ActiveCN102286800AImprove performanceIncrease elasticityWigsArtificial filament heat treatmentPolymer scienceUltraviolet

The invention relates to a functional modified acrylic fiber for hair and a preparation method thereof. The technical problems of low fire resistance and poor antibacterial, deodorant and ultraviolet-resistant functions of the conventional products are solved. The functional modified acrylic fiber for hair is prepared by copolymerizing four monomers of acrylonitrile, vinylidene chloride, sulfonicacid group-containing olefin and olefin acid ester. The fiber for hair also contains antibacterial powder, an anti-ultraviolet agent, a composite fire retardant and a pigment whose composition comprising carbon black pigment and cation black X-RL dye and a dye composite colorant. The fiber can serve as a precursor and a raw material for manufacturing fashionable hair products and noble artificial fur and has functionality of super natural hair.

Owner:SHANGHAI REBECCA FIBER MATERIAL TECH

Spunlace nonwoven fabric and manufacture method

InactiveCN105220357AHas anti-inflammatory propertiesGood hygroscopicityLiquid/gas/vapor removal by squeezing rollersLiquid/gas/vapor removal by suctionEngineeringMoisture absorption

The invention discloses spunlace nonwoven fabric and a manufacture method. Aloe is adopted by raw material and the spunlace nonwoven fabric is manufactured by a spunlacing method. The manufacture method comprises following steps of: (1) extraction of raw material; (2) opening and mixing; (3) combing; (4) cross lapping; (5) drafting; (6) pre-wetting; (7) afterfinish; (8) drying; (9) winding into finished products. The spunlace nonwoven fabric and the manufacture method have following beneficial effects: the spunlace nonwoven fabric adopts aloe as raw material and manufactured by the manufacture method and has the anti-inflammatory function of the human skin and is also characterized by being high in moisture absorption and strength, low in fuzzing performance, good in breathability, soft in handfeel and fine in drapability.

Owner:徐波

Solvent method for biologically preparing bamboo fiber

ActiveCN101538743AHigh antibacterial rateHigh strengthWood working apparatusMechanical fibre separationCardingBlack liquor

The invention provides a technology for preparing bamboo fiber by 1, 4-butanediol in a solvent method, which comprises the steps of preparing bamboo into bamboo filaments; soaking the bamboo filaments in the solvent and heating to remove lignin, hemicellulose and other impurities on the surface of the cellulose; preparing into coarse bamboo fibre; beating the coarse bamboo fibre, washing with water simultaneously, and then spin-drying through a centrifuge; bleaching and cleaning; conducting mellowing to the bamboo fiber; soft-impressing the bamboo fiber; stowing fermentation and curing, and finally obtaining the bamboo fiber with spinnability after opening and carding. The solvent adopted by the invention has high boiling point and stable chemical property and can be recycled; the whole technological process does not generate black liquor and seriously pollute the environment, and belongs to clean techniques; the obtained natural bamboo fiber has the remarkable advantages of moisture absorption, quick dry, coolness, comfort, antibacterium, deodorization and the like; and the method has low cost and good economic benefit and environmental protection benefit.

Owner:FUJIAN HAIBOSI CHMEICAL TECH

Low-wool-content multi-component chemical fiber blended fabric and preparing method thereof

ActiveCN103835048AImprove perceptionEasy to takeSucessive textile treatmentsWoven fabricsPolyesterPolymer science

The invention provides a low-wool-content multi-component chemical fiber blended fabric and a preparing method of the low-wool-content multi-component chemical fiber blended fabric and belongs to the field of spinning dyeing and finishing. Wool is added to multi-component chemical fibers and the low-wool-content multi-component chemical fiber blended fabric comprises, by weight, 30% to 40% of polyester staple fibers, 20% to 30% of modified polyester fibers, 10% to 20% of mucilage glue, 5% to 15% of Tencel, 8% to 30% of the wool and 0.1% to 0.6% of conductive fibers. The wool content of a traditional product is changed, wool fibers with the content smaller than 30% are blended with the polyester staple fibers, the modified polyester fibers, the mucilage glue, the Tencel and the conductive fibers in the chemical fibers in a combined mode, so that mutual advantage complement of the various fibers is achieved, and multiple colors, the high comfort degree and the easy-maintenance performance of the fabric are achieved with the low wool content. The technology is reasonable, the technical purpose of one bath dyeing of the wool and the multi-component chemical fibers is effectively achieved, and a new path is created for upgrading orientation and the comfort of chemical fiber fabric.

Owner:SHANDONG WOYUAN NEWFASHIONED FABRIC

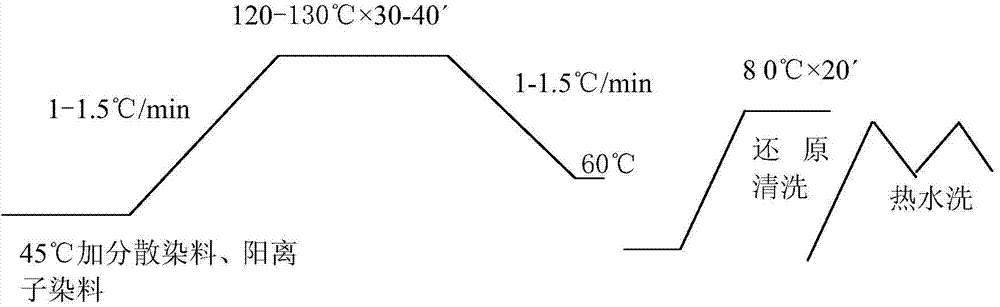

Preparation process of artificial leather shell material

A rpeparation process of imitation real leather shell fabric with excellent elasticity, air permeability, heat insulating ability, crease-resistance and buckskin effect includes the procedures of warp knitting, grey fabric, pretreatment, drying, raising, opening, dyeing, carding, shearing, grinding and foring, and is characterized by that its raw material is of "islands-in-sea" type fibre, and the technological condition of pretreatment is as follows: adding adjuvant at 120-130 deg.C, treatment time is 30-50 min., the technological condition of raising process is as follows: number of pin-rollers of raising machine is 24, model of card clothing is RA-91, and frame needling for three times; and the condition of opening treatment is that adding sodium hydroxide 10-15 g / l at 100-150 deg.C, heating time is 60-90 min., and the condition of grinding process is that grinding roller speed is 1200 rpm, pressing distance is 3mm and abrasive paper specification is 140-180 meshes.

Owner:JIANGSU HONGDA TEXTILE

Multifunctional composite carpet and ditch construction technology thereof

The invention discloses a multifunctional composite carpet comprising three-dimensional warp knitting fabric composed of a top layer, a bottom layer and a connecting layer connecting the top layer and the bottom layer. The top layer, the bottom layer and the connecting layer enclose to form a cavity. The multifunctional composite carpet is characterized in that composite which can be solidified is filled in the cavity, the top layer is made of mesh fiber fabric, the bore diameter of each mesh of the mesh fiber fabric ranges from 0.02mm to 60mm, and the meshes in the top layer are in regular or irregular shapes. The multifunctional composite carpet and the ditch construction technology thereof have the advantages of good overall performance, environment friendliness, flexibility in application, convenience in using, mounting, demounting and transporting; the solidified composite can form special materials of mesh composite concrete layer with serialized functions and having certain thickness and hardness; the ditch construction technology is simple in technology, convenient to construct, high in efficiency, good in overall performance and attractive in appearance.

Owner:蔡晓民 +1

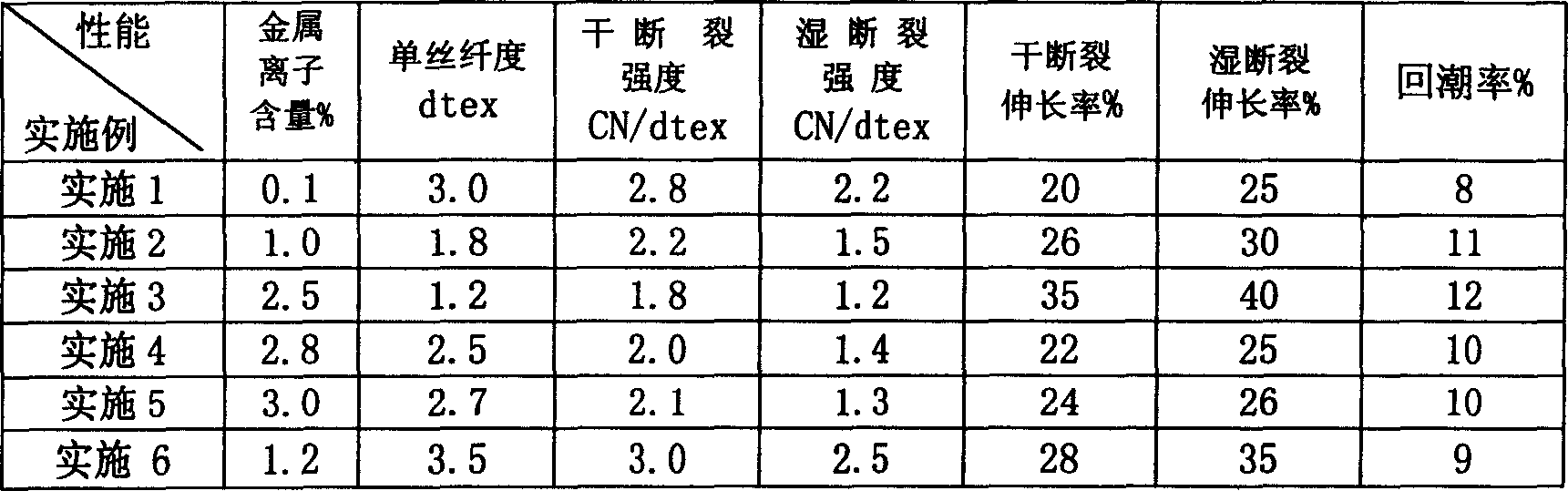

Collagen-polyvinyl alcohol composite fiber modified by metallic ion, and preparation method

InactiveCN1696362AImprove stabilityHigh strengthConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsFiberPolyvinyl alcohol

The invention relates to a metal ion modified collagen protein-polyvinyl alcohol composite fibre. On the basis containing collagen protein and polyvinyl alcohol it also contains metal ions capable of producing chelation crosslinking action. Said invention also relates the preparation method of said composite fibre, and said method includes the following steps: adding metal salt into the collagen protein-polyvinyl alcohol mixed solution to make chelation crosslinking modification to obtain spinning solution, and adopting a series of after processes so as to obtain the new type collagen protein-polyvinyl alcohol composite fibre.

Owner:SICHUAN UNIV

Ecological warm-keeping cotton and manufacturing process thereof

InactiveCN105603634AImprove the bactericidal effectNot easy to passNon-woven fabricsCardingEngineering

The invention provides ecological warm-keeping cotton and a manufacturing process thereof. The ecological warm-keeping cotton has good wind-resistant water-repellent effects, also has a certain sterilization function and is better in warm-keeping effect, lots of raw materials are renewable raw materials, and an environmental protection effect is good. The ecological warm-keeping cotton comprises a warm-keeping layer and a waterproof breathable sterilization layer adhered to one side of the warm-keeping layer, wherein the thickness of the waterproof breathable sterilization layer is 10%-15% of the thickness of the warm-keeping layer, the warm-keeping layer is manufactured from, by weight, 30% of Sorona polymer fiber, 30% of superfine warm-keeping fiber, 30% of three-dimensional hollow warm-keeping fiber and 10% of native cotton fiber through mixing, the waterproof breathable sterilization layer is manufactured from, by weight, 40% of collagen fiber, 20% of bamboo fiber, 20% of seaweed carbon fiber and 20% of nanoscale antibacterial silver ion masterbatch native fiber through mixing, the surfaces of the two sides of the waterproof breathable sterilization layer are coated with treatment layers formed by blending silicon nanoparticles and nano titanium dioxide, and the surfaces of the treatment layers are coated with hydrophobic fluorine quaternary amine silane coupling agent coatings. The manufacturing process of the ecological warm-keeping cotton comprises the steps of automatic material preparation and mixing through a machine, opening, carding, web laying, adhesive spraying, heat setting and rolling.

Owner:FUJIAN JINJIANG HENGFENG SPEWING WEAVING

Scope and action cover for hand guns and rifles

Gun scope and action cover comprises a water-proof, breathable / air-permeable, reversible, light-weight, highly-flexible fabric pouch formed by an enclosed, cinchable elastic cord that fits over the optical scope of a rifle or hand gun, and that is universal in size, quiet in use, easy to put on and take off, and easy to store. The pouch area, formed by cinching and locking the cord, is bounded with an extended skirt that drapes down over the mechanical action of the gun. 2-ply waterproof / breathable fabric is preferred. Additional features include a securing cord for adding camouflaging ghillie strips, hook and loop fastener silencer(s) that prevent accidental adhesion to clothing, the release of which causes game-spooking sound, and a pocket for a warmer unit. The cover employs a variety of camouflage patterns on one or both sides, or one side may be a dark, a light, or a safety color, such as neon orange.

Owner:MIDDLEPOINT TRADING

Bamboo fibre knop cloth and its production method

A bamboo fibre frieze boucle features that its warp and / or weft are partially or all made of the bamboo fibre yarn. It is made up through weaving, boiling up, dyeing, softening, and post-treating. Its advantages are cold, comfortable, antibacterial action, and good hydroscopicity.

Owner:青岛美好巾被股份有限公司

Semi-finished textile product, particularly prepreg, manufactured from non-woven fiber fabric

InactiveUS20120077402A1Simple and inexpensive to manufactureImprove abilitiesSynthetic resin layered productsLaminationElastomerThermoplastic

A method for manufacturing a semi-finished textile product, particularly a prepreg, from carbon fibers preimpregnated with a matrix material, includes the steps of manufacturing non-woven fabric having at least 10% carbon fibers and / or a fleece having at least 10% carbon fibers. At least a portion of the fibers used for manufacturing the fabric and / or the fleece are waste fibers and / or recycling fibers. The non-woven fabric and / or fleece is impregnated with a matrix material selected from the group thermoplastic, thermoset, elastomers and any chosen mixtures of two or more of the aforementioned materials.

Owner:BENTELER SGL

Method for dissolving and processing wood/cotton bamboo hemp fibre by employing ionic liquid

InactiveCN101225552ANon-volatileEasy to recycleConjugated cellulose/protein artificial filamentsWet spinning methodsCelluloseTotal solid content

The invention relates to a dissolving and processing method for wood, cotton, bamboo and hemp fiber with ionic liquid, which is characterized in that: (1) the pulverized wood or the pulverized cotton, the pulverized bamboo and the pulverized bast pulp are uniformly mixed with the ionic liquid; the spinning solution of the total solid content of 3 to 40% is formed through dissolving and deaerating for 1 to 120 hours at 35 to 160 degrees centigrade; wherein the weight ratio of the wood or the cotton, the bamboo and the bast is 30 to 80% : 7 to 60% : 10 to 60% ; (2) the spinning and the concreting bathing solidification are carried out after being filtered and deaerated; (3) the oiling and the drying process are carried out after being pulled, rinsed and bleached, so as to obtain a composite fiber. The dissolving and processing method for wood, cotton, bamboo and hemp fiber with ionic liquid has the advantages that: due to use the ionic liquid, the productivity is high, the recovery is easy, the requirement of the green production is satisfied and the prepared composite fiber has good mechanical strength; simultaneously the different fiber characteristics of a plurality of materials such as the wood or the cotton, the bamboo and the bast are synthesized; the source of the material is wide; the cost is low; and the advantages of various natural celluloses can be synthesized according to the requirement.

Owner:DONGHUA UNIV

Bamboo fiber and combed cotton compact siro spinning technology

The invention discloses bamboo fiber and combed cotton compact siro spinning technology, which solves the problem that the fabric made from yarns is susceptible to pilling, has insufficient toughness and strength and the like in the prior art. The technology is characterized in that: by adopting the process of drawing and mixing the bamboo fibers and combed cotton, bamboo fiber and cotton fiber card sliver is produced and is mixed on a drawing frame, and the compact siro spinning yarns are produced by three drawing processes and by a roving frame, spinning frame and an automatic winder. The bamboo fibers and cotton fibers are organically combined, and the processed blended yarns have good moisture absorption, air permeability, drapability and antibiotic property, the fabric is an uncommon natural and cool fabric and is suitable for making high-grade dress, underwear, home textiles, sportswear and socks, and the development of the series of products has a promising market prospect.

Owner:黄冈三泰纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com