Solvent method for biologically preparing bamboo fiber

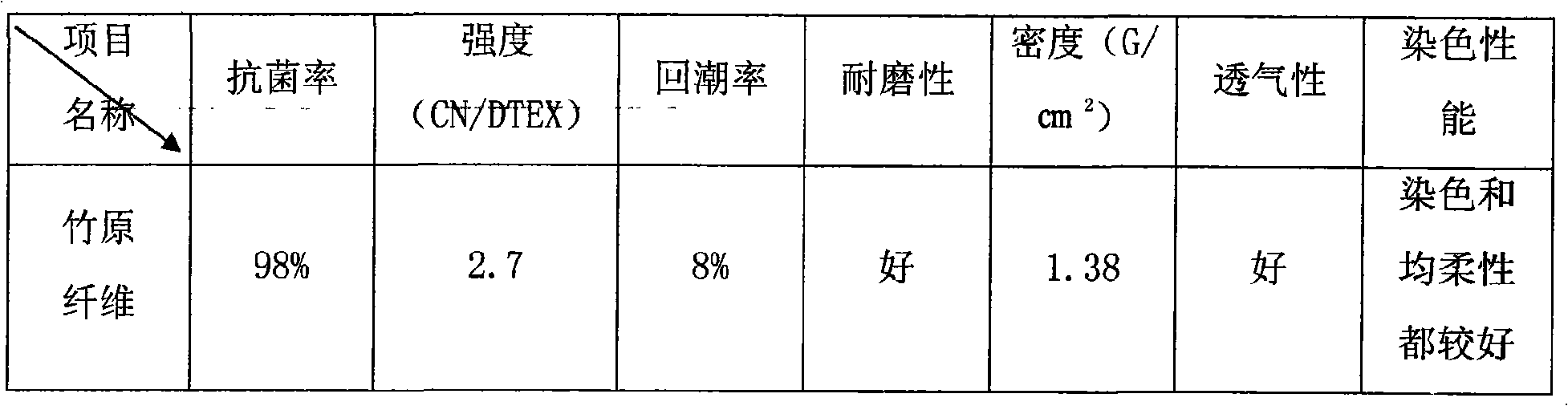

A bamboo fiber and bio-preparation technology, applied in the direction of chemical production of bast fiber, fiber treatment, fiber mechanical separation, etc., can solve environmental pollution, reduce environmental protection, black liquor is difficult to treat, etc., and achieve stable chemical properties and antibacterial rate The effect of high and excellent dyeing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

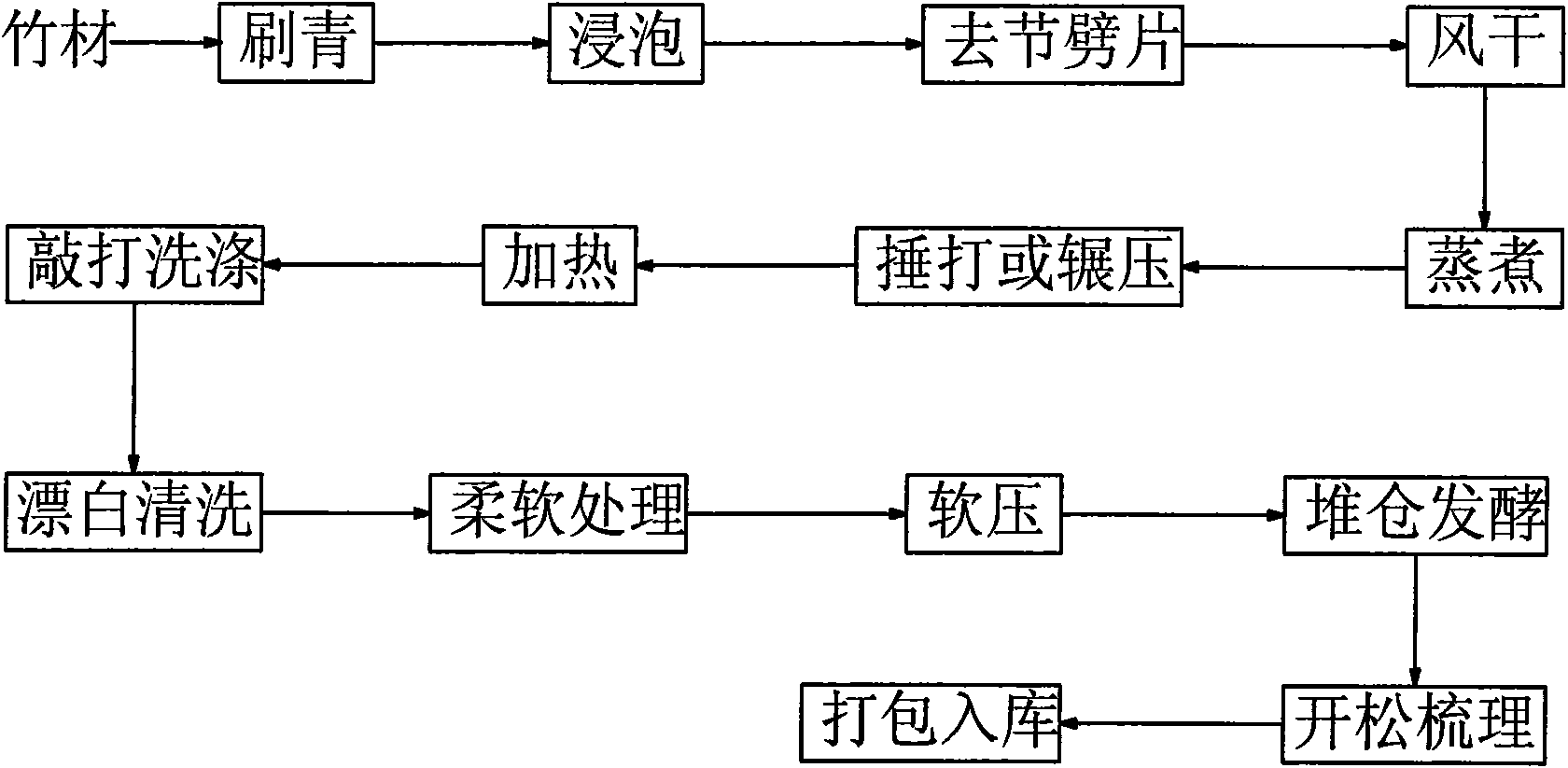

[0014] The preparation process of the method is:

[0015] (1) Bamboo is prepared into bamboo shreds; after removing the green bamboo on the surface of the bamboo, 1 ton of the freshly felled bamboo is placed in the soaking pool and soaked at room temperature for 1 month, and then the bamboo is removed from the bamboo joints and split into 10 pieces along the fiber direction. Bamboo slices ~20mm wide are air-dried, put the bamboo slices into a pressure-heatable container for heating and pressure cooking, and the steamed bamboo slices are hammered or multi-stage rolled into bamboo filaments, which are heated and pressurized. The temperature of the cooking treatment is about 190°C, and the time is 6 to 8 hours; the cooking medium used is water or an organic solvent; the cooking medium used during the cooking treatment is water or an organic solvent; the organic solvent is a weight concentration of 80 % 1,4-butanediol solution, the consumption of the organic solvent and the bamboo...

Embodiment 1

[0025] Brush the freshly cut moso bamboo green, soak it in a normal temperature pool for one month, remove the knots and split the bamboo slices, then put the bamboo slices in a high-pressure cooking pot, add 5 tons of bamboo with a weight concentration of 80% to 1 ton of dry bamboo 1. 4-butanediol aqueous solution, heating up to 190°C and cooking at constant temperature for 8 hours, let the solvent dissolve and remove impurities such as lignin and hemicellulose in bamboo, separate solid and liquid after cooking, and extract lignin with the used solvent With hemicellulose, the solvent is recovered and recycled. The bamboo chips are mechanically beaten into bamboo threads, and the bamboo threads are shaken with a hemp shaker to remove bamboo powder and bamboo yellow. The shaken bamboo powder is in powder form, and the bamboo yellow is in the form of Small blocks, the fluffed bamboo filaments become loose and clean, soaked in 1,4-butanediol aqueous solution with a weight concentr...

Embodiment 2

[0027] Green the freshly cut green bamboo, soak it in a pool at normal temperature for a month, remove the knots and split the bamboo slices, and then put the bamboo slices in a high-pressure cooking pot, add 5 tons of dry bamboo to 1 ton of bamboo with a weight concentration of 80% 1, 4-butanediol aqueous solution, heating up to 180°C and cooking at a constant temperature for 6 hours, allowing the solvent to dissolve and remove impurities such as lignin and hemicellulose in the bamboo, separating the solid and liquid after cooking, and extracting the wood with the used solvent Vegetables and hemicellulose are recycled and reused. Bamboo slices are mechanically beaten into bamboo threads, and the bamboo threads are loosened with a hemp shaking machine to remove bamboo powder and bamboo yellow. The loose bamboo powder is in powder form. The yellow is in the form of small blocks, and the fluffed bamboo filaments become loose and clean, soaked in 1,4-butanediol aqueous solution wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com