Antiseptic biological active titanium coating and its production

A biologically active, titanium coating technology, applied in coating, metal material coating process, fusion spraying, etc., can solve the problem of increasing infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

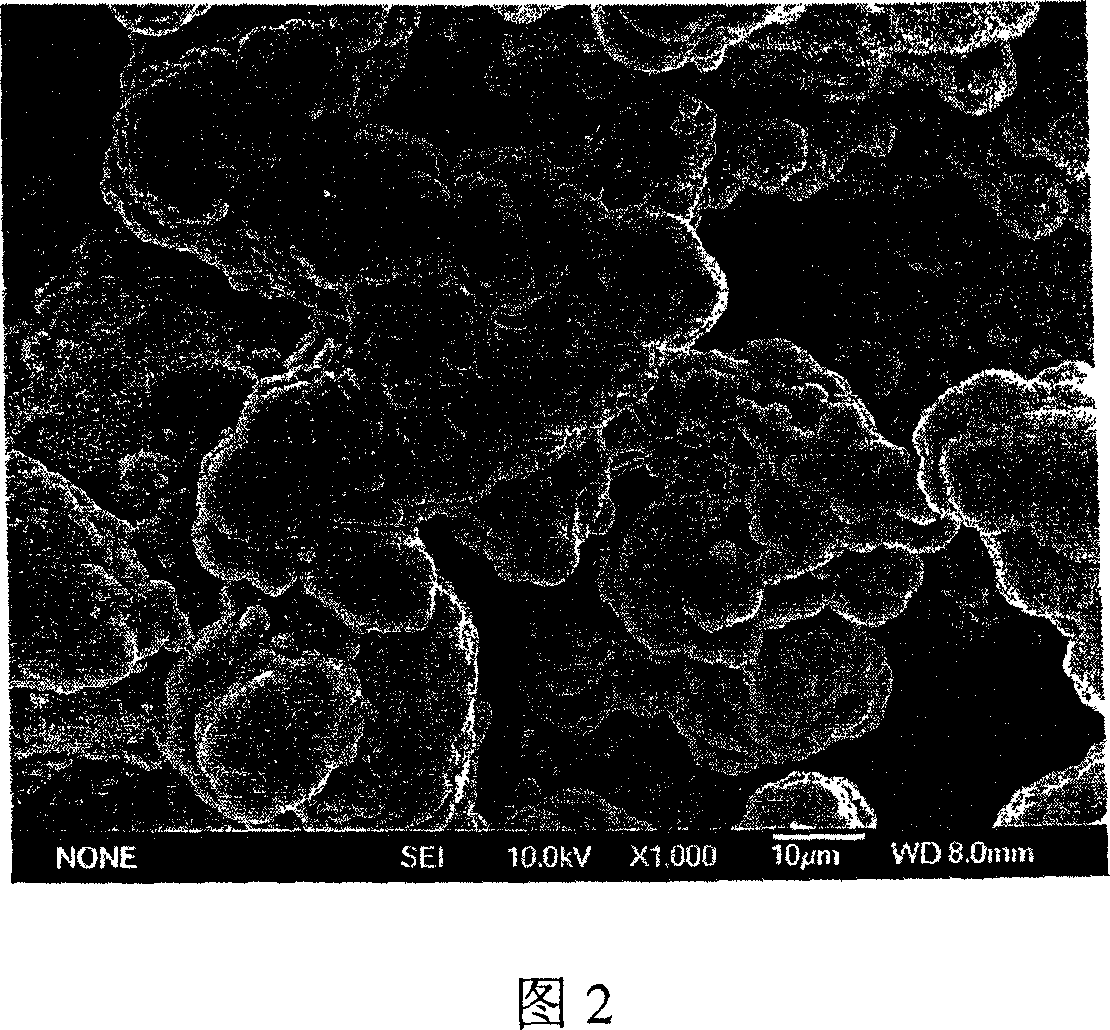

[0019] The titanium coating was prepared by vacuum plasma spraying method, immersed in 5M NaOH solution, kept at 60°C for 24h, taken out, ultrasonically cleaned with deionized water for 3 times, each time for 5 minutes, and then dried at 40°C for 24h. Formulated with Ag + Ion 0.02mM supersaturated calcium phosphate solution: Weigh 12.0700g NaNO in turn 3 , 0.8856g Ca(NO 3 ) 2 4H 2 O, 0.3423g K 2 HPO 4 ·3H 2 O, 0.0034gAgNO 3 , into 1000ml deionized water, at 25°C with HNO 3 And 6.0600g tris hydroxy aminomethane adjusts the pH value of solution to 7.42. The alkali-treated titanium coating was immersed in a supersaturated calcium phosphate solution, kept at 25°C for 48h, and then dried at 120°C for 2h. The sample number is CA0.02.

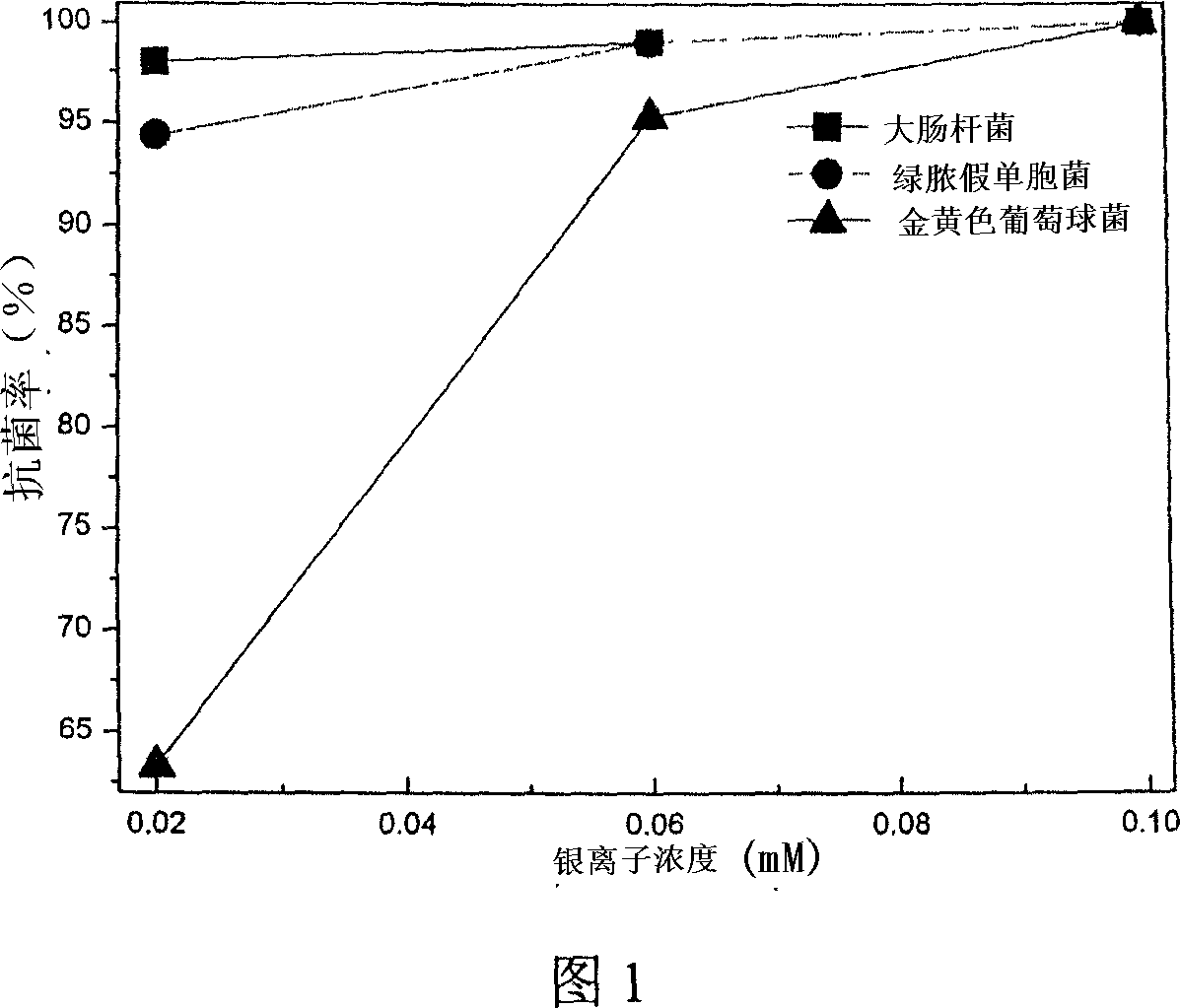

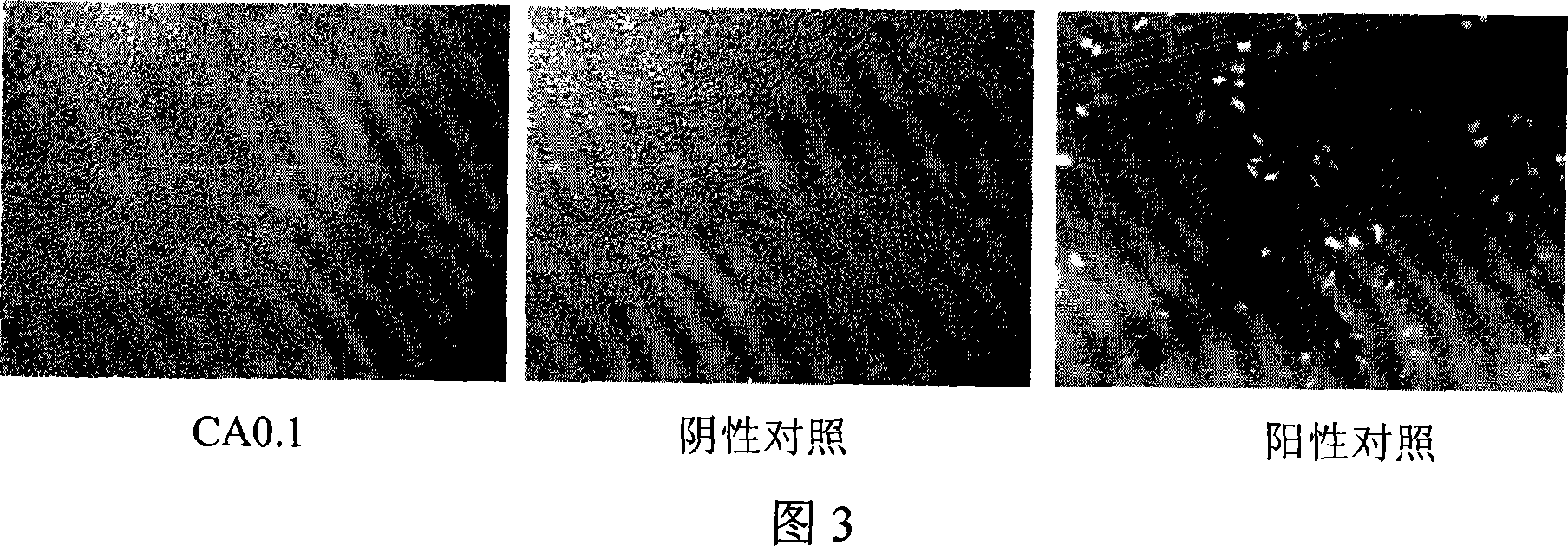

[0020] After Ag + The antibacterial rates of the modified titanium coating CA0.02 against Escherichia coli, Pseudomonas aeruginosa and Staphylococcus aureus were 98%, 94% and 63%, respectively. See Figure 4 for the photos of colonies after...

Embodiment 2

[0022] Using the same method as above to prepare the formulation containing Ag + 0.06mM supersaturated calcium phosphate solution. Then adopt the same steps as in Example 1 to prepare Ag-containing + Modified titanium coating CA0.06. The antibacterial rates of CA0.06 coating against Escherichia coli, Pseudomonas aeruginosa and Staphylococcus aureus were 99%, 99% and 95%, respectively. See Figure 4 for the photos of colonies after 24 hours of bacterial culture on the surface of the specimen. The results showed that the CA0.06 coating had a good antibacterial effect on Gram-negative bacteria such as Escherichia coli and Pseudomonas aeruginosa and positive bacteria such as Staphylococcus aureus. The in vitro cytotoxicity grade of CA0.06 detected by MTT colorimetry was 0, indicating no obvious cytotoxicity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com