Manufacturing method and device for two-component hollow spun-bonded spunlace non-woven fabrics

A manufacturing method and technology of non-woven fabrics, applied in the manufacture of hollow filaments, non-woven fabrics, rayon, etc., can solve the lack of production process and equipment for hollow orange segment ultra-fine fiber spunbond spunlace non-woven fabrics, etc. problems, to achieve the effect of improving poor filtration performance, high strength, and improving the stiffness of the cloth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further elaborated below in conjunction with the accompanying drawings.

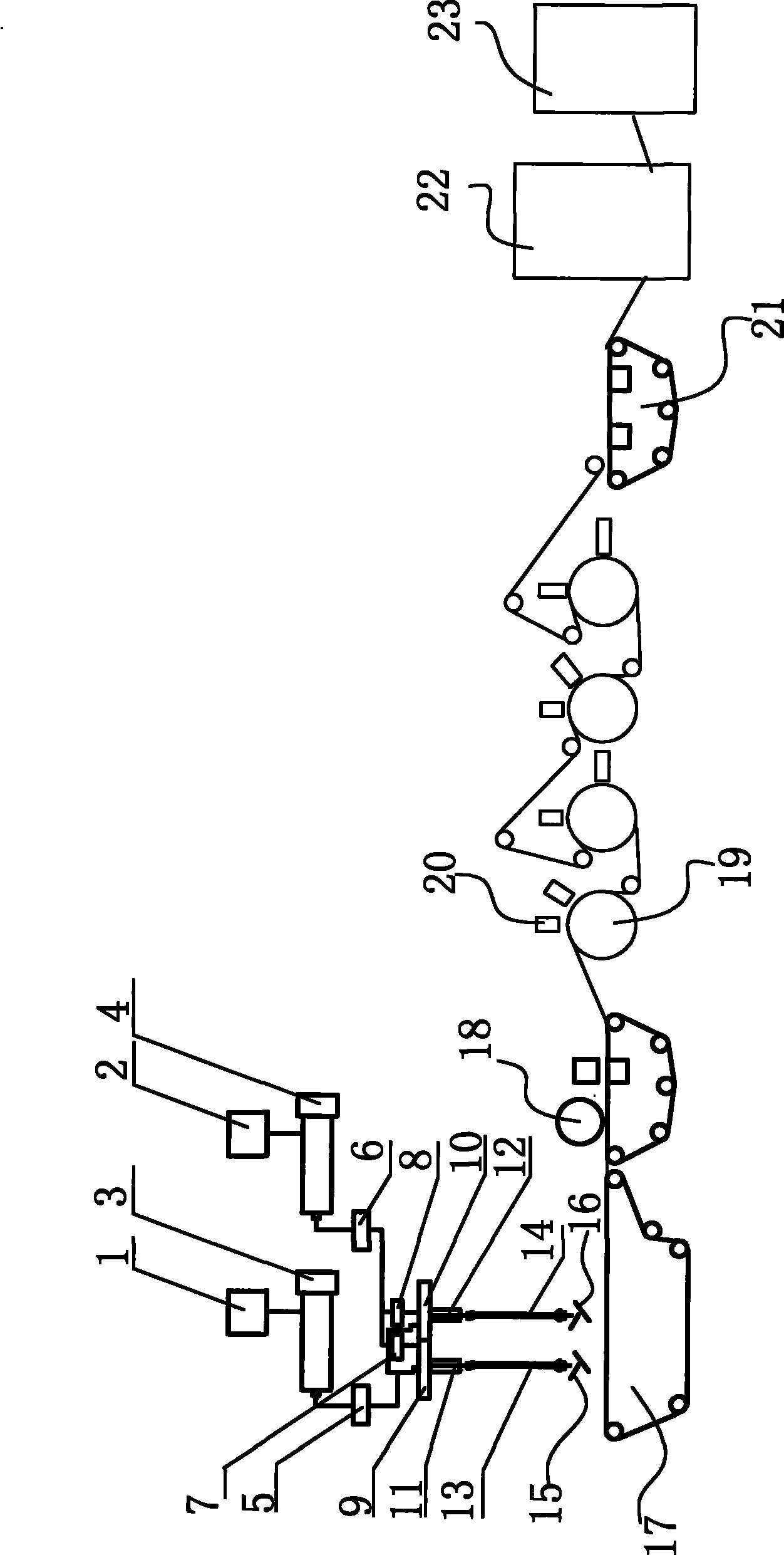

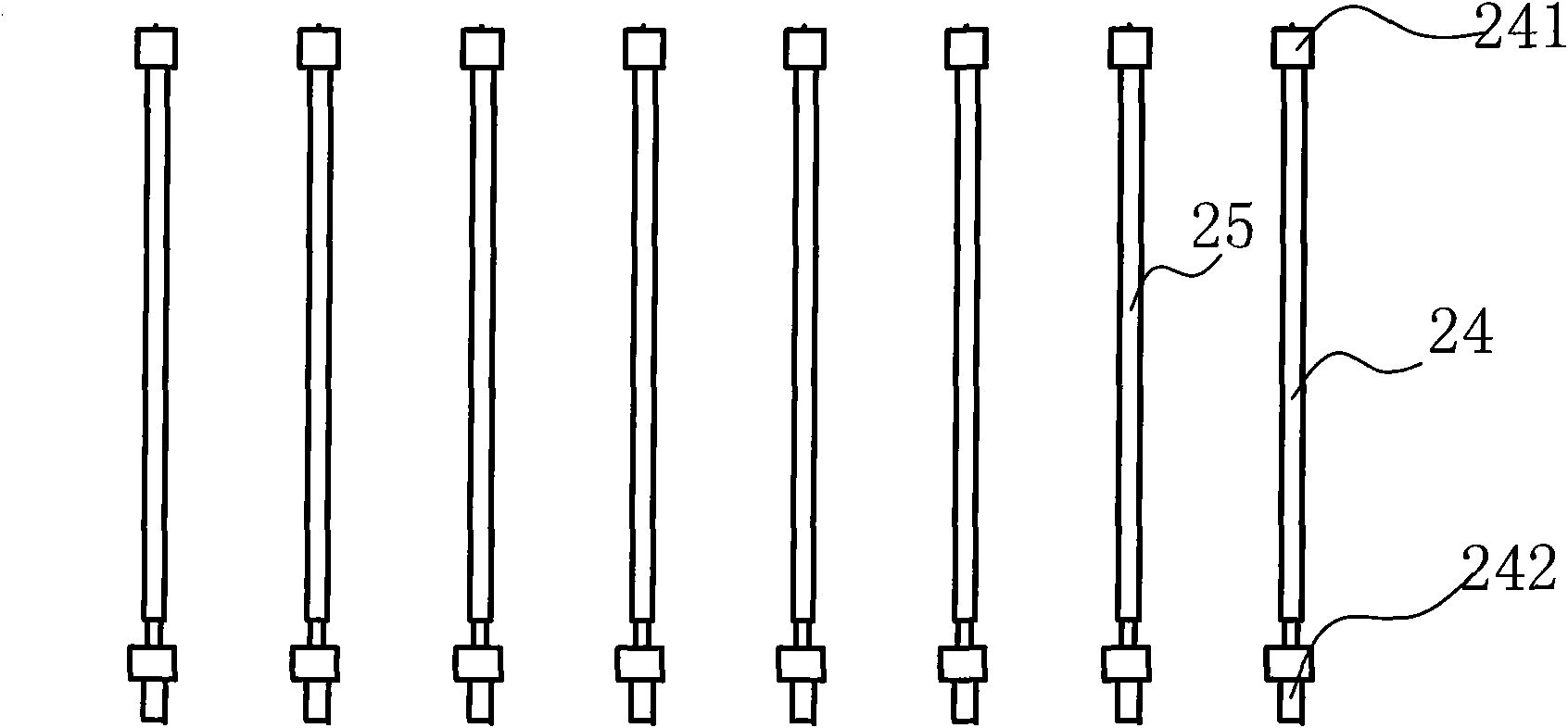

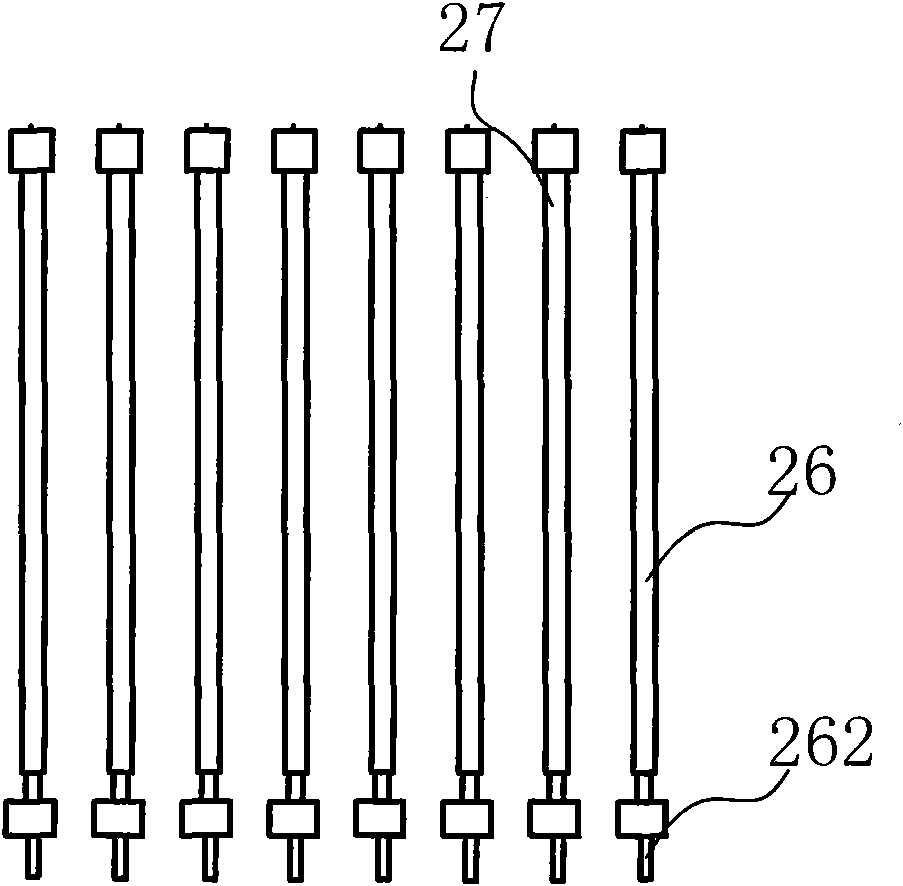

[0060] Such as figure 1 , figure 2 with image 3 As shown, PET and PA-6 slices are delivered to respective dryer 1 and dryer 2, and after drying, they are sent to screw extruder 1 and screw extruder 2 for melting, and the obtained melt is filtered and measured by filter 5 and filter 6 , PA-6 first enters the sub-box 8, and then the melt pipe of the sub-box 8 is introduced into the main box 10 and the main box 9, and PET directly enters the main box 10 and the main box 9, or according to The production requirements first enter the auxiliary box 7, and then enter the main box 10 and the main box 9; after the melt is compounded by the spinning assembly, it is sprayed out from the spinneret hole, and the sprayed melt flows through the side wind air-cooled The device 11 and the air cooler 12 are rapidly cooled into as-spun yarns, the conjugate compounding temperature i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting temperature | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com