Patents

Literature

1354results about "Needling machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

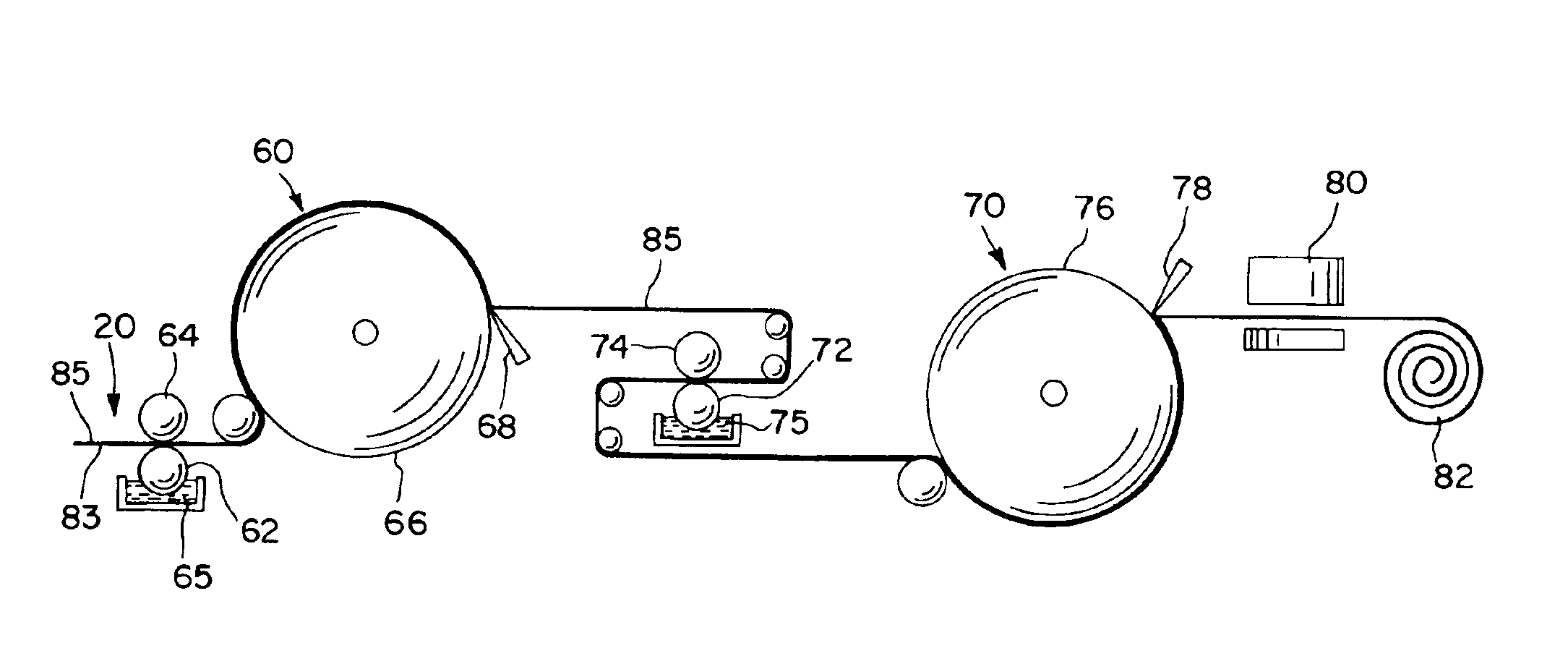

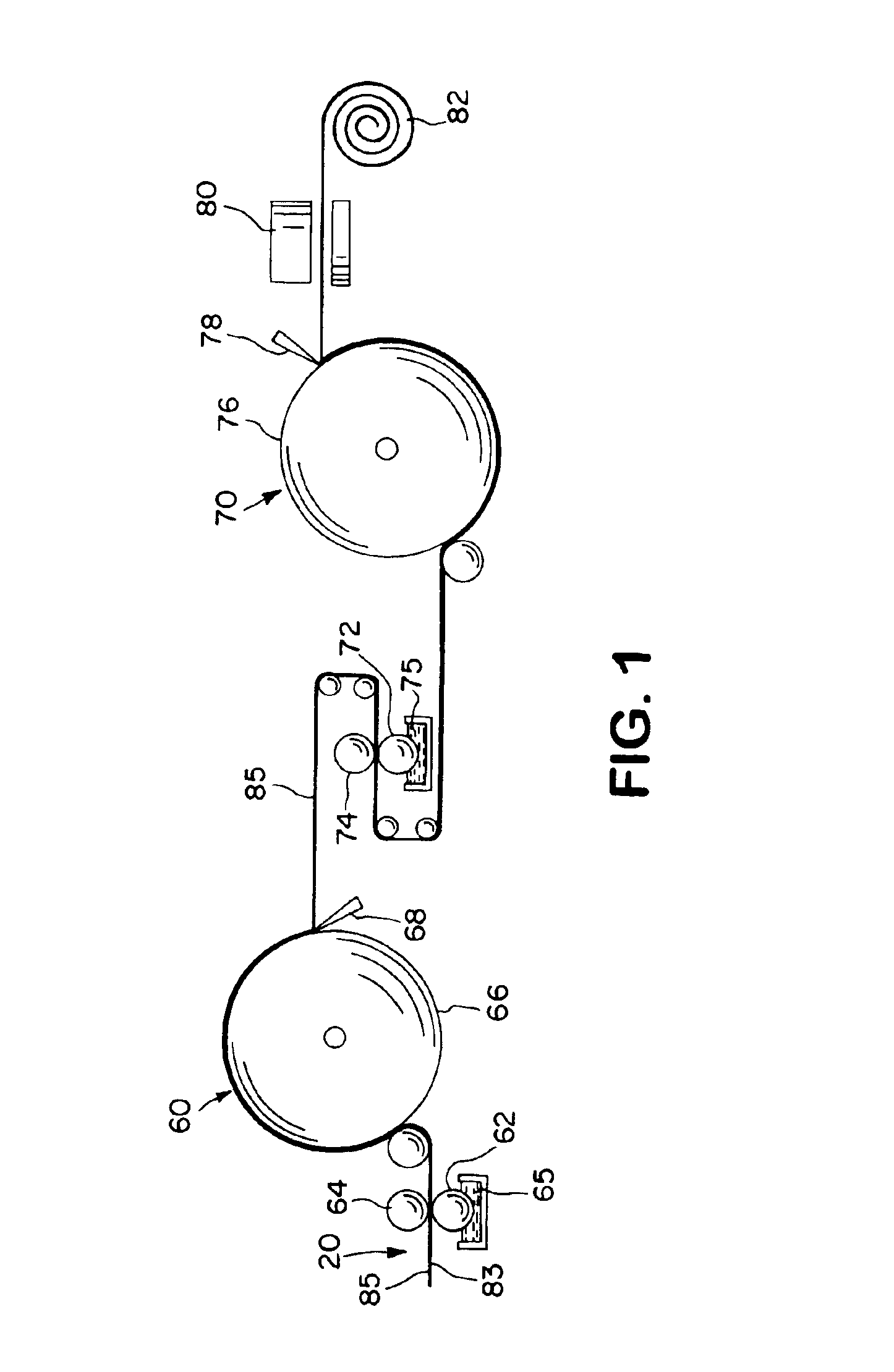

Method and apparatus for producing high efficiency fibrous media incorporating discontinuous sub-micron diameter fibers, and web media formed thereby

InactiveUS6315806B1Increase distanceReduce resistanceFilament/thread formingLoose filtering material filtersMean diameterFiber

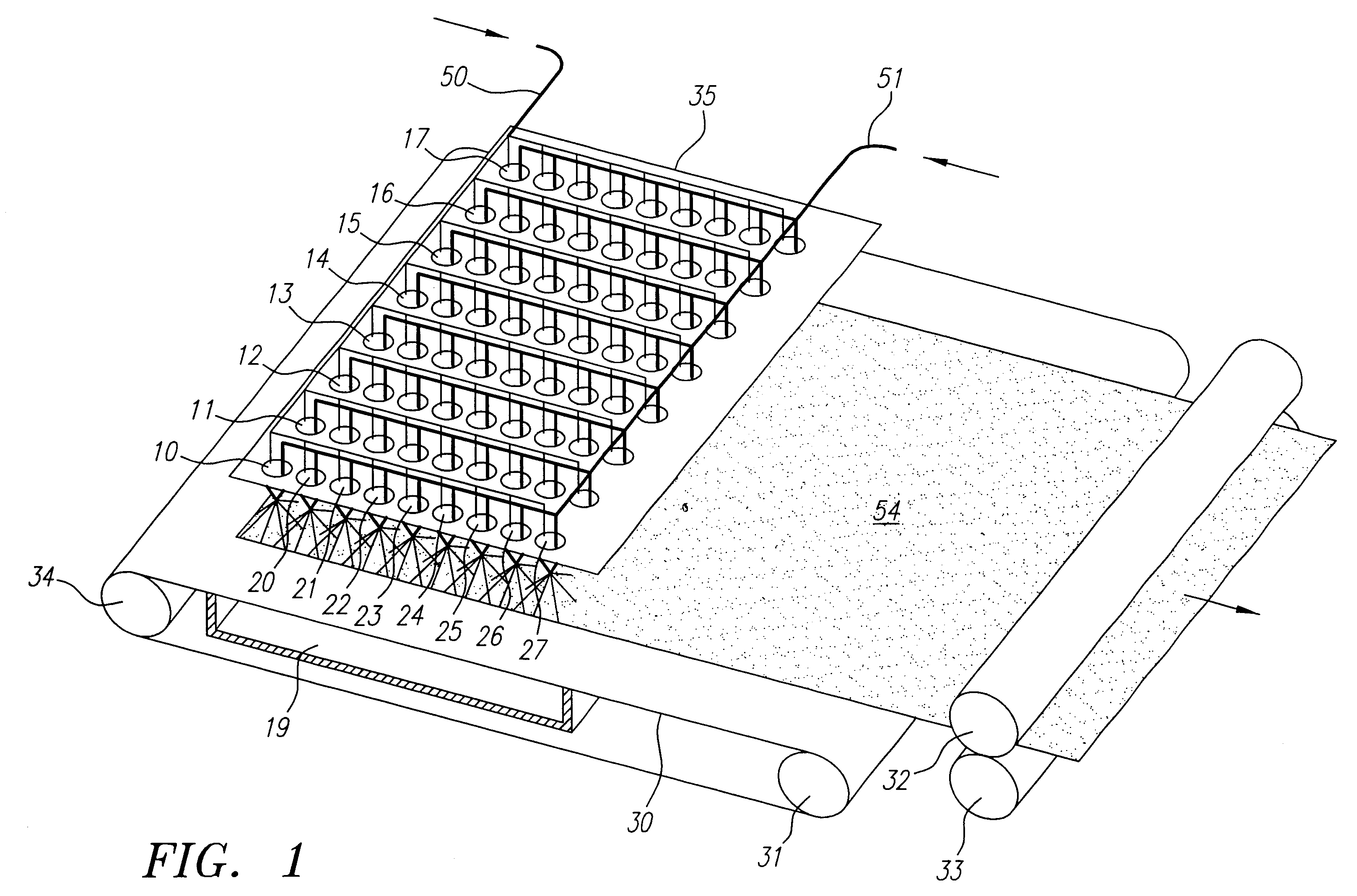

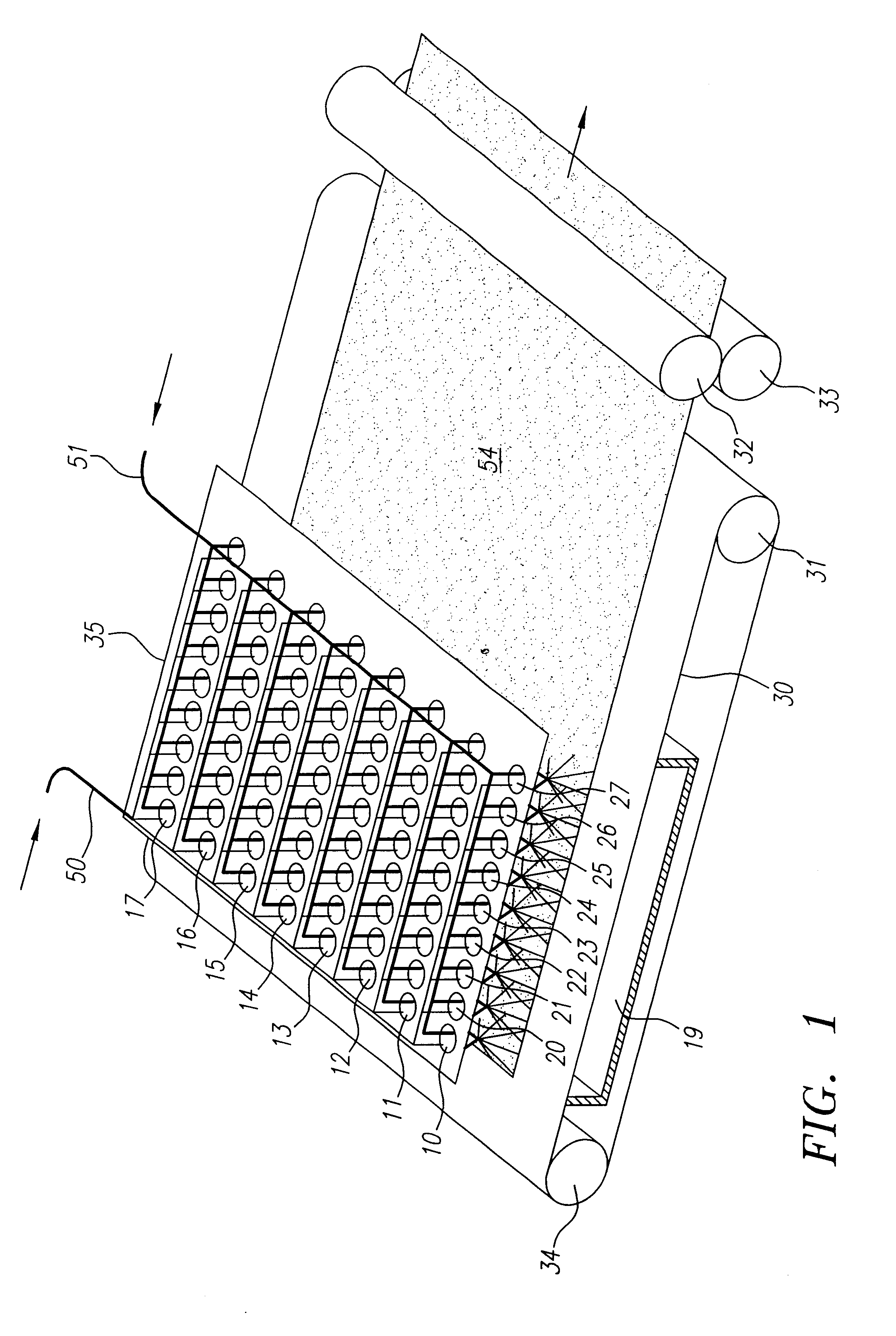

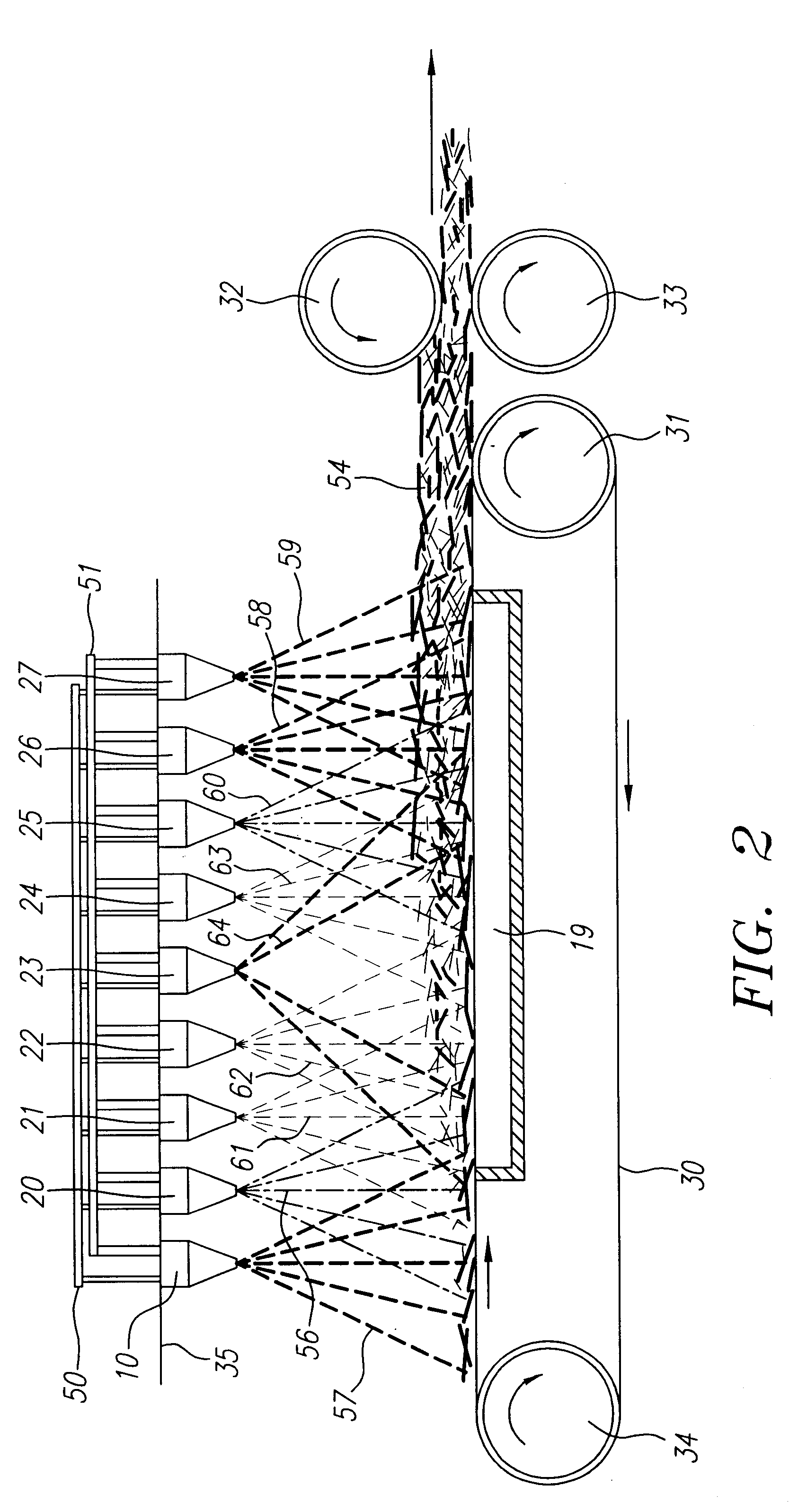

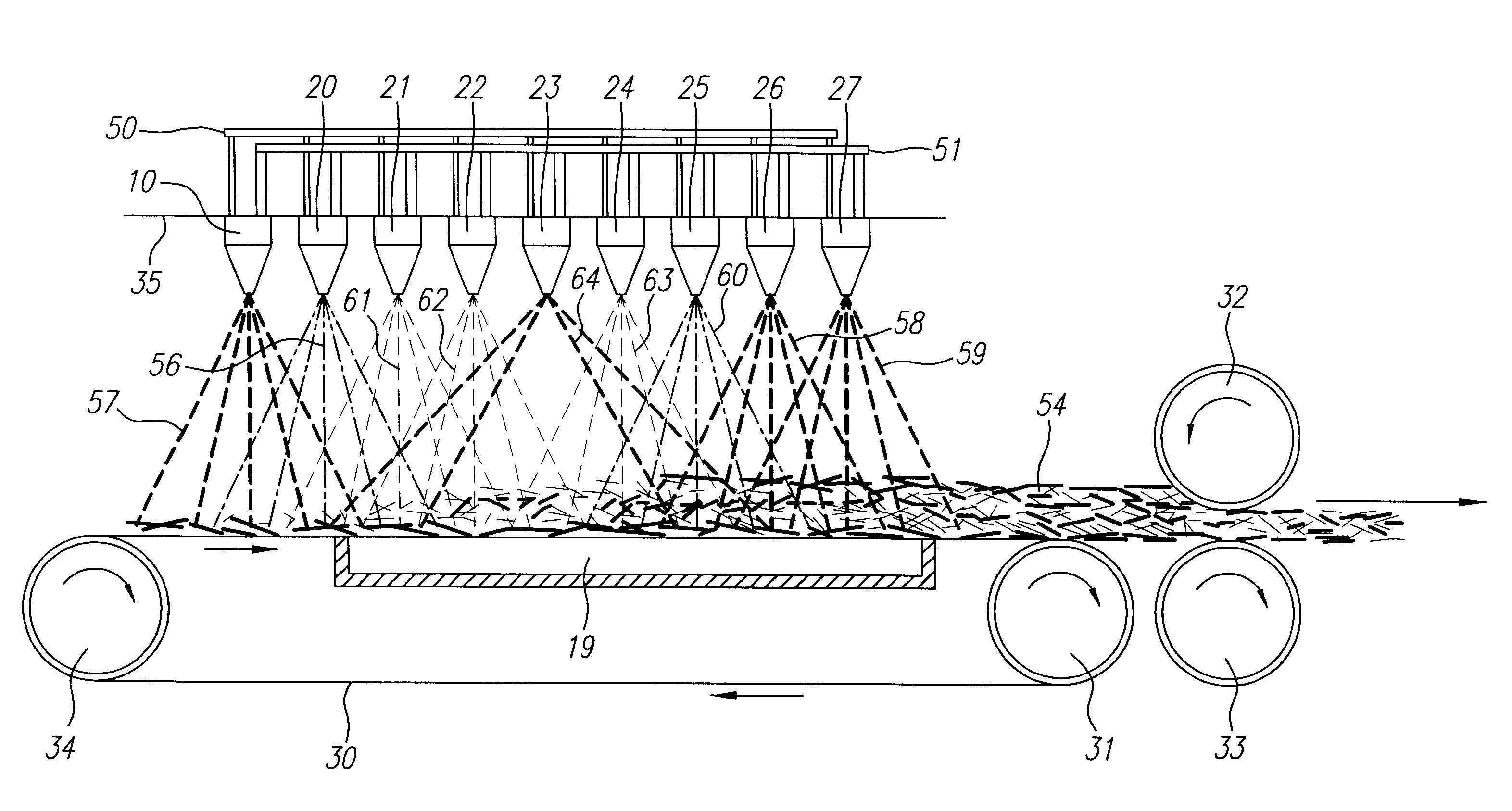

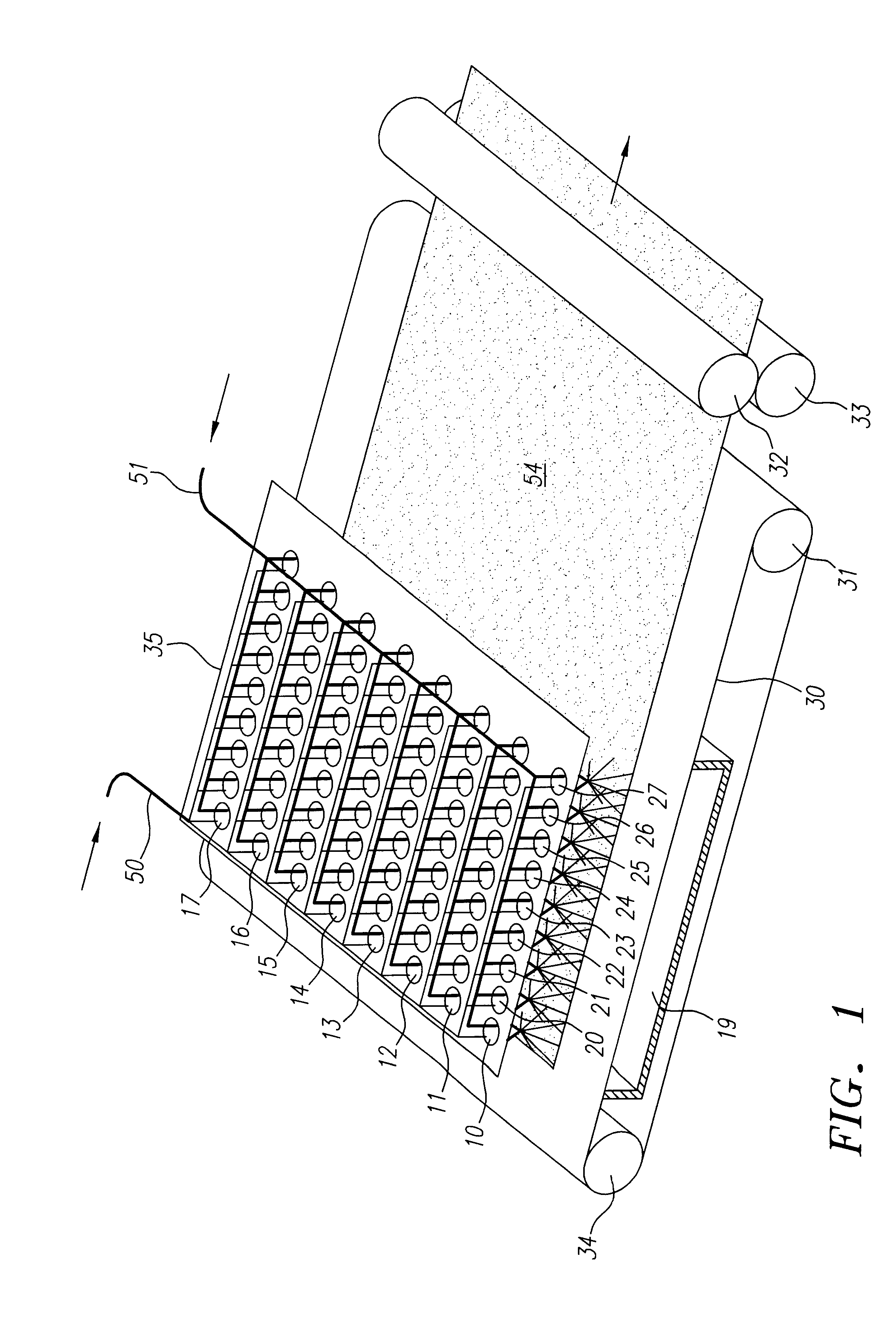

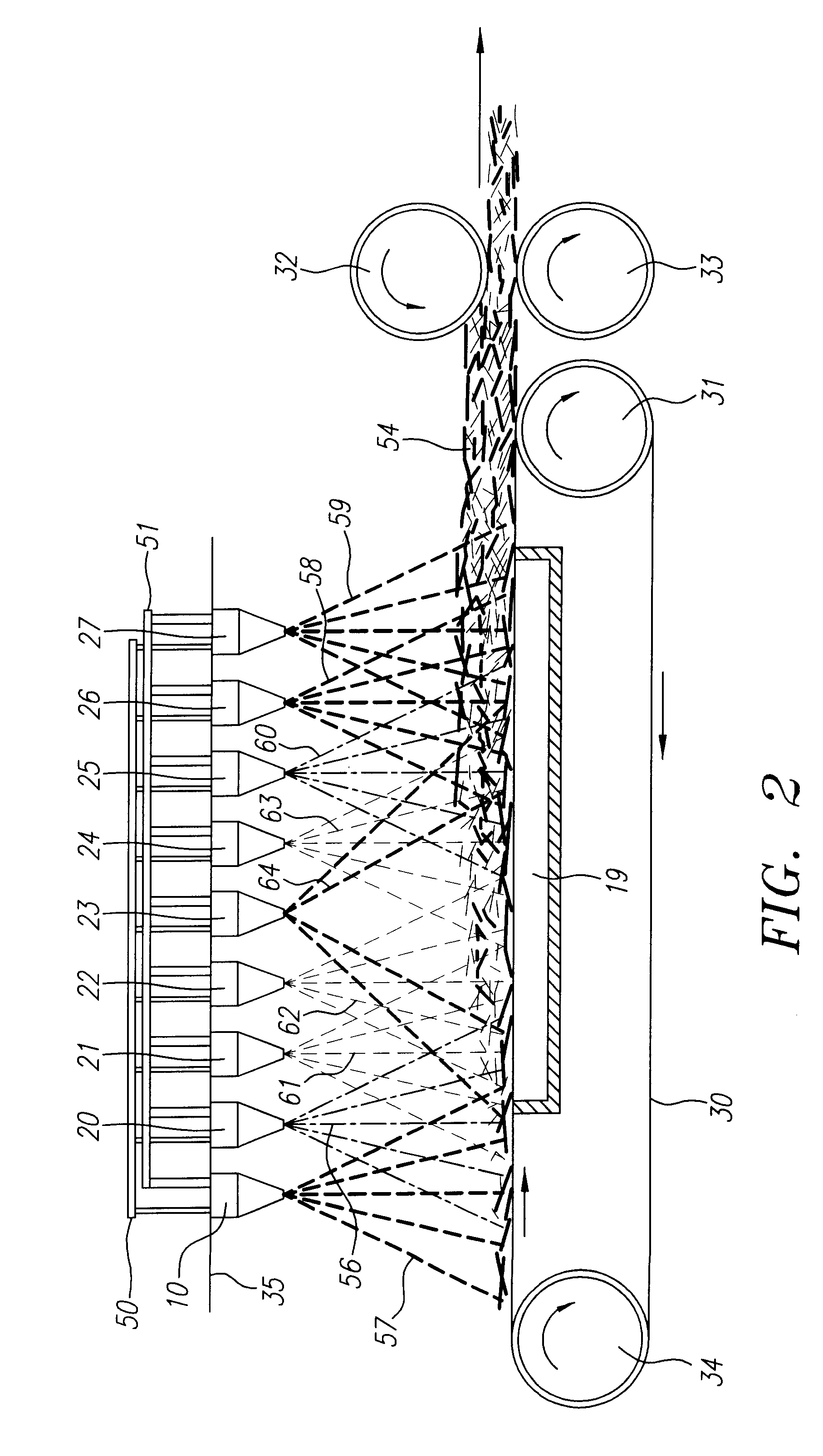

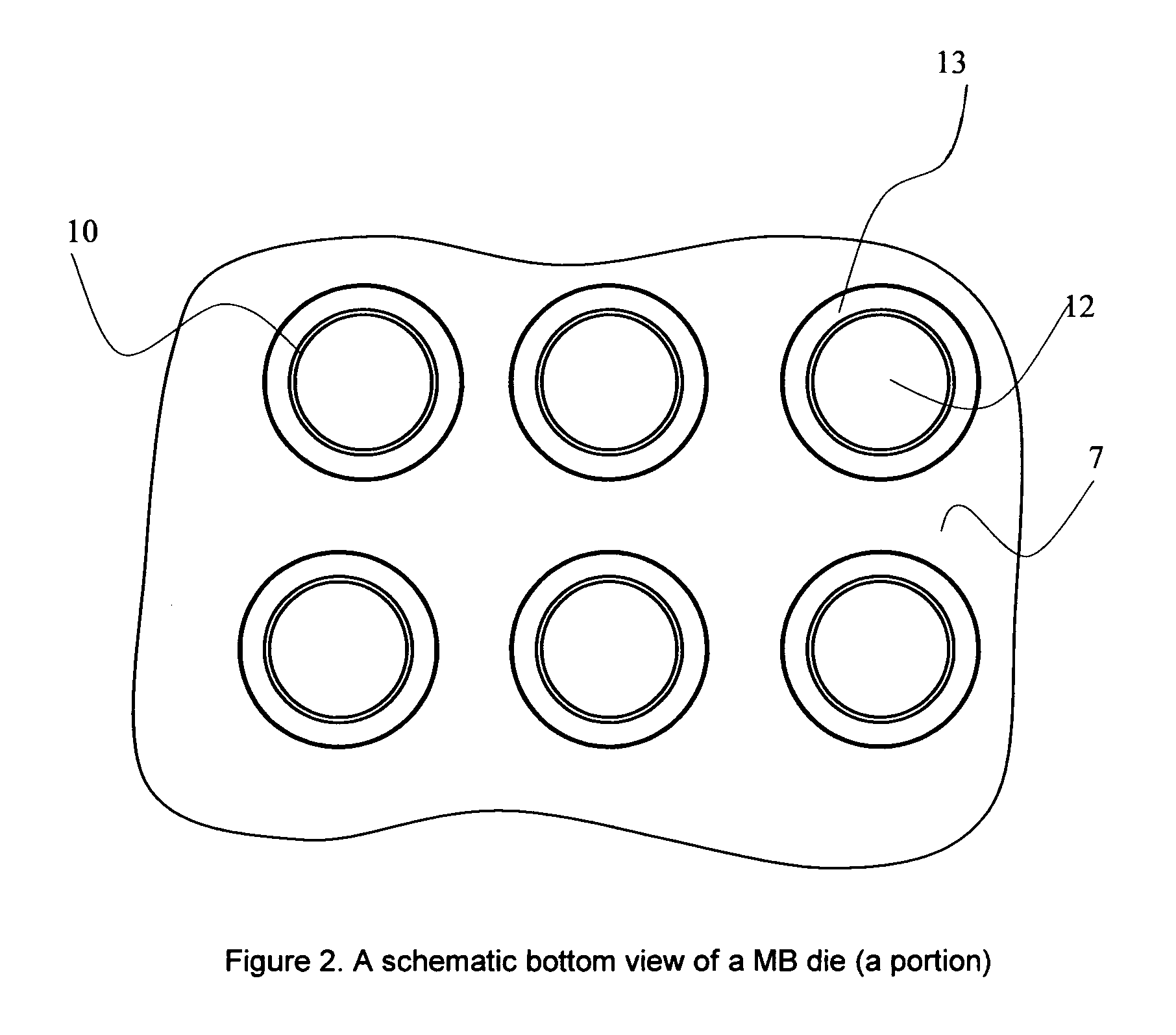

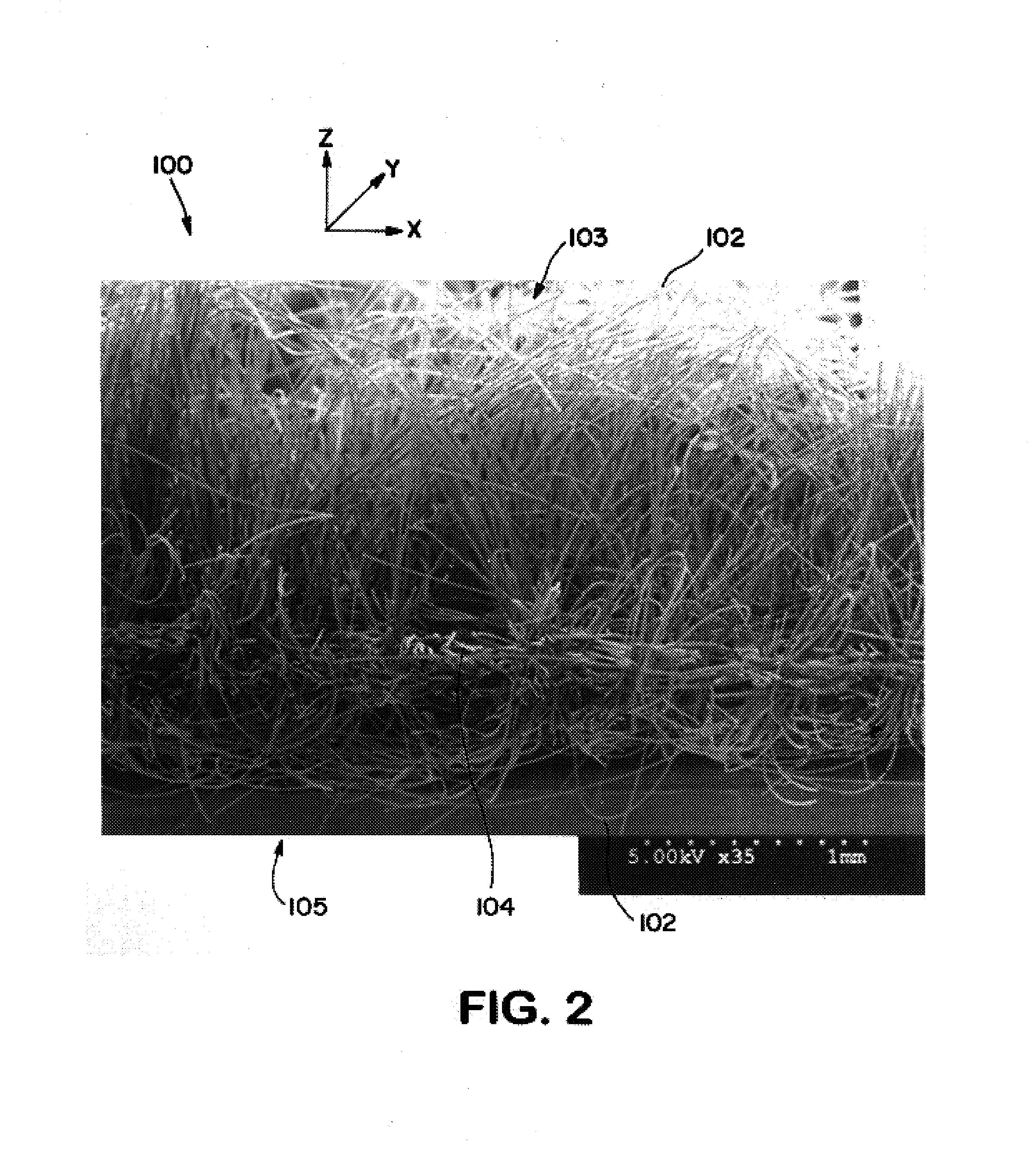

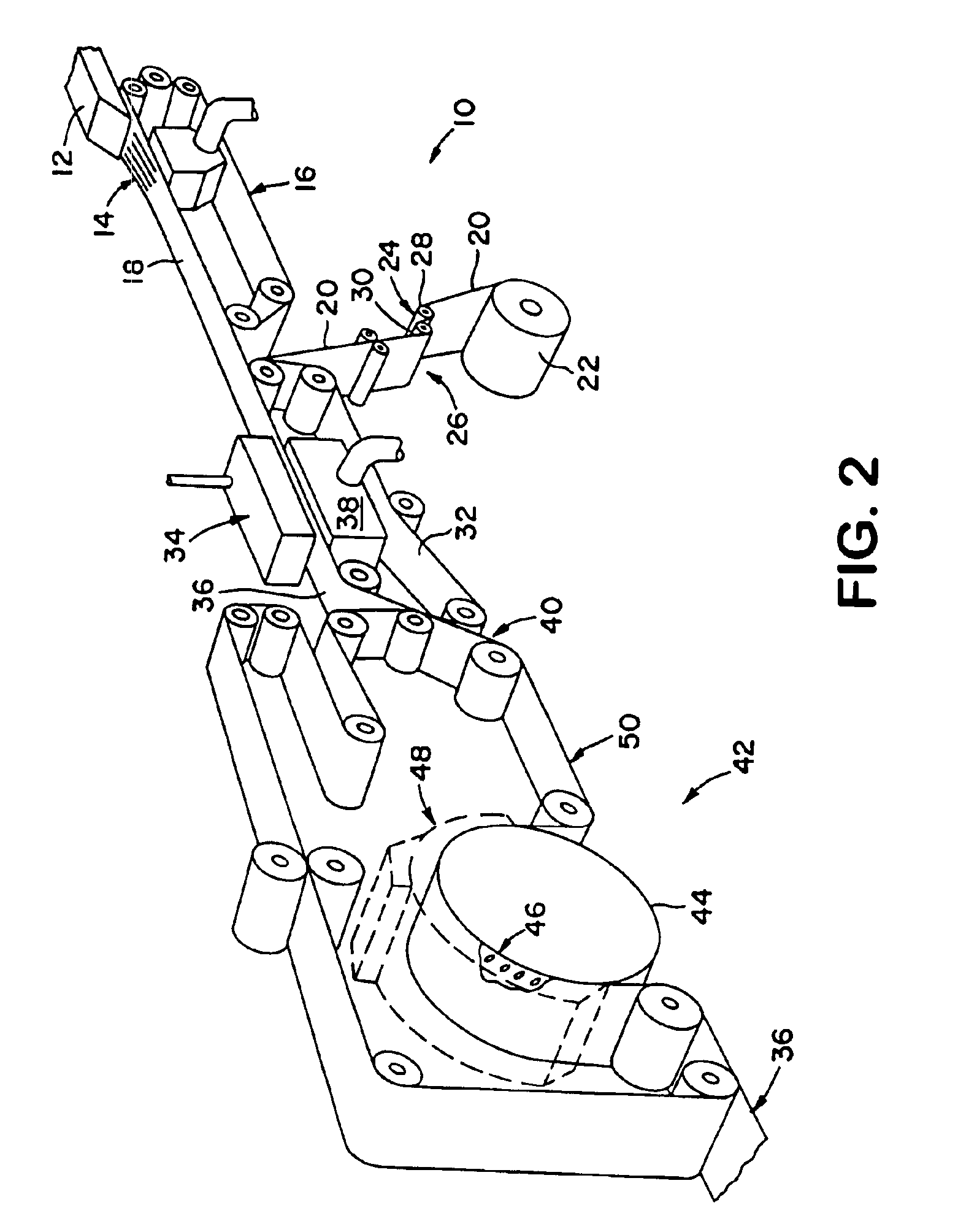

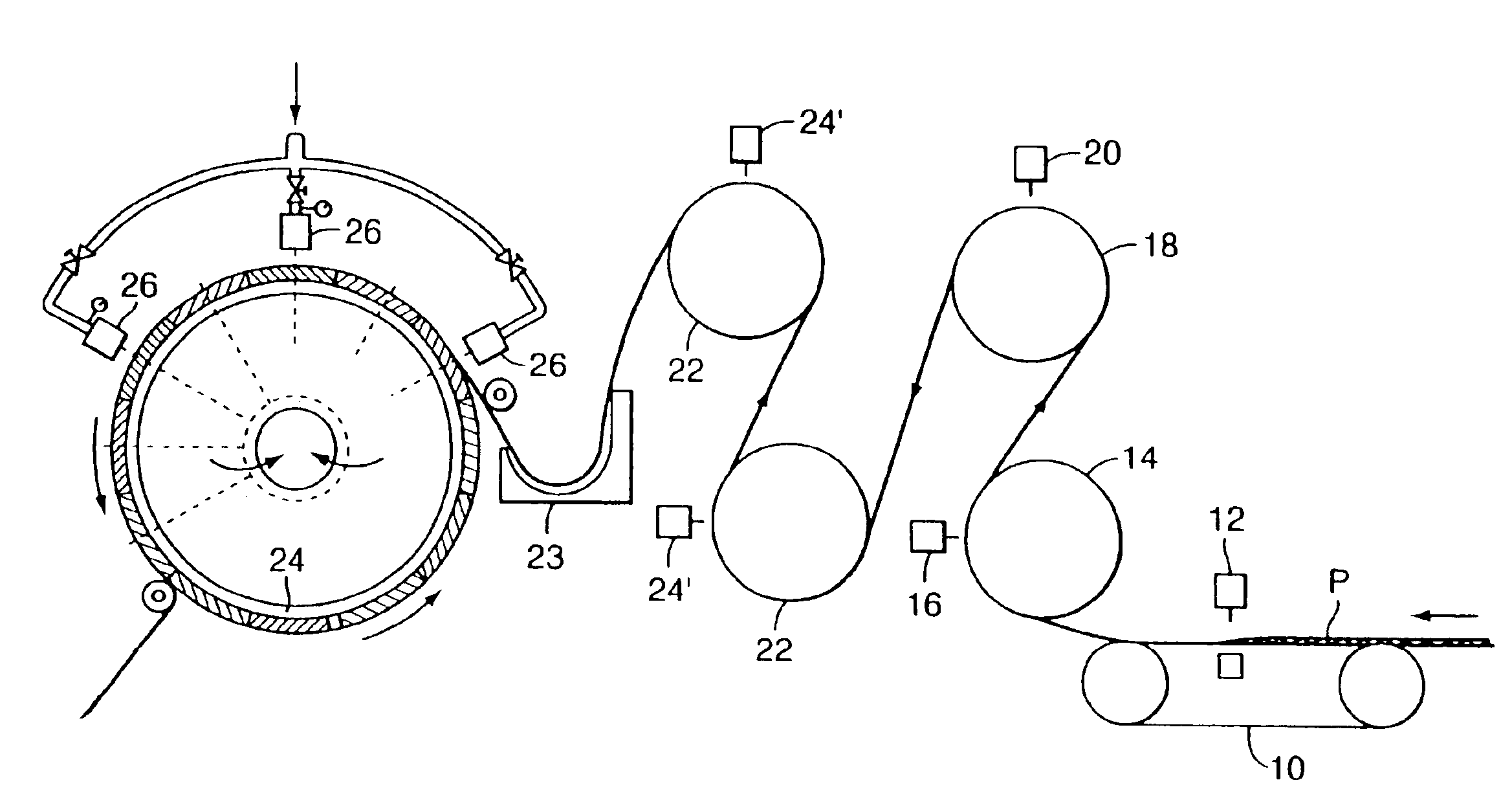

A composite filtration medium web of fibers containing a controlled dispersion of a mixture of sub-micron and greater than sub-micron diameter polymeric fibers is described. The filtration medium is made by a two dimensional array of cells, each of which produces a single high velocity two-phase solids-gas jet of discontinuous fibers entrained in air. The cells are arranged so that the individual jets are induced to collide in flight with neighboring jets in their region of fiber formation, to cause the individual nascent fibers of adjacent jets to deform and become entangled with and partially wrap around each other at high velocity and in a localized fine scale manner before they have had an opportunity to cool to a relatively rigid state. The cells are individually adjusted to control the mean diameters, lengths and trajectories of the fibers they produce. Certain cells are adjusted to generate a significant percentage of fibers having diameters less than one micron diameter, and which are relatively shorter in length and certain other cells are adjusted to generate a significant percentage of structure-forming reinforcing fibers having diameters greater than one micron diameter which are relatively longer in length. By employing appropriate close positioning and orientation of the cells in the array, the sub-micron fibers are caused to promptly entangle with and partially wrap around the larger reinforcing fibers. The larger fibers thereby trap and immobilize the sub-micron diameter fibers in the region of formation, to minimize the tendency of sub-micron diameter fibers to clump, agglomerate, or rope together in flight. Also, the larger fibers in flight are made to form a protective curtain to prevent the sub-micron fibers from being carried off by stray air currents.

Owner:THE PROCTER & GAMBLE COMPANY

Method and apparatus for producing high efficiency fibrous media incorporating discontinuous sub-micron diameter fibers, and web media formed thereby

InactiveUS6183670B1Increase collisionImprove compactionFilament/thread formingAuxillary shaping apparatusMean diameterFiber

A composite filtration medium web of fibers containing a controlled dispersion of a mixture of sub-micron and greater than sub-micron diameter polymeric fibers is described. The filtration medium is made by a two dimensional array of cells, each of which produces a single high velocity two-phase solids-gas jet of discontinuous fibers entrained in air. The cells are arranged so that the individual jets are induced to collide in flight with neighboring jets in their region of fiber formation, to cause the individual nascent fibers of adjacent jets to deform and become entangled with and partially wrap around each other at high velocity and in a localized fine scale manner before they have had an opportunity to cool to a relatively rigid state. The cells are individually adjusted to control the mean diameters, lengths and trajectories of the fibers they produce. Certain cells are adjusted to generate a significant percentage of fibers having diameters less than one micron diameter, and which are relatively shorter in length and certain other cells are adjusted to generate a significant percentage of structure-forming reinforcing fibers having diameters greater than one micron diameter which are relatively longer in length. By employing appropriate close positioning and orientation of the cells in the array, the sub-micron fibers are caused to promptly entangle with and partially wrap around the larger reinforcing fibers. The larger fibers thereby trap and immobilize the sub-micron diameter fibers in the region of formation, to minimize the tendency of sub-micron diameter fibers to clump, agglomerate, or rope together in flight. Also, the larger fibers in flight are made to form a protective curtain to prevent the sub-micron fibers from being carried off by stray air currents.

Owner:THE PROCTER & GAMBLE COMPANY

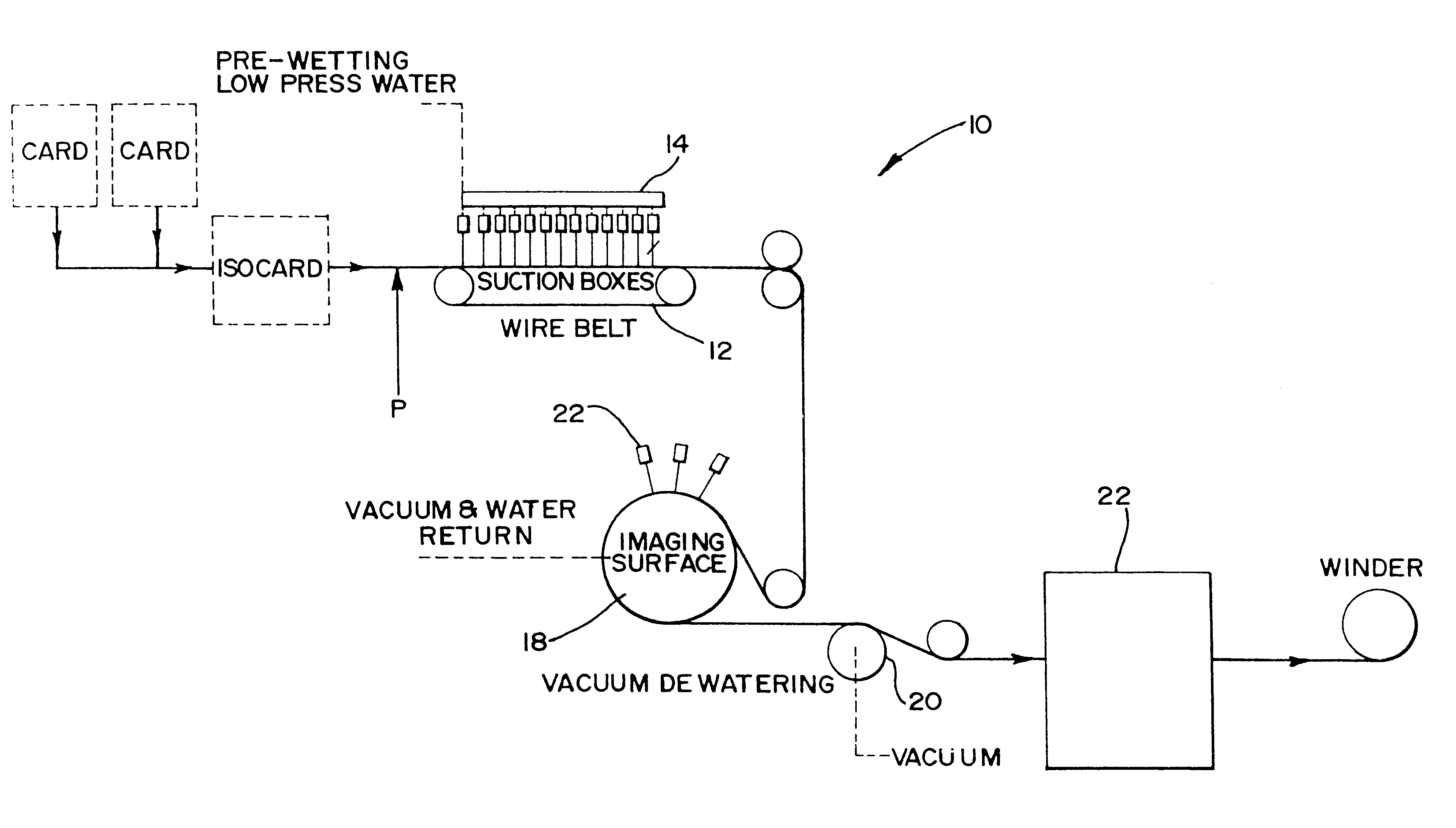

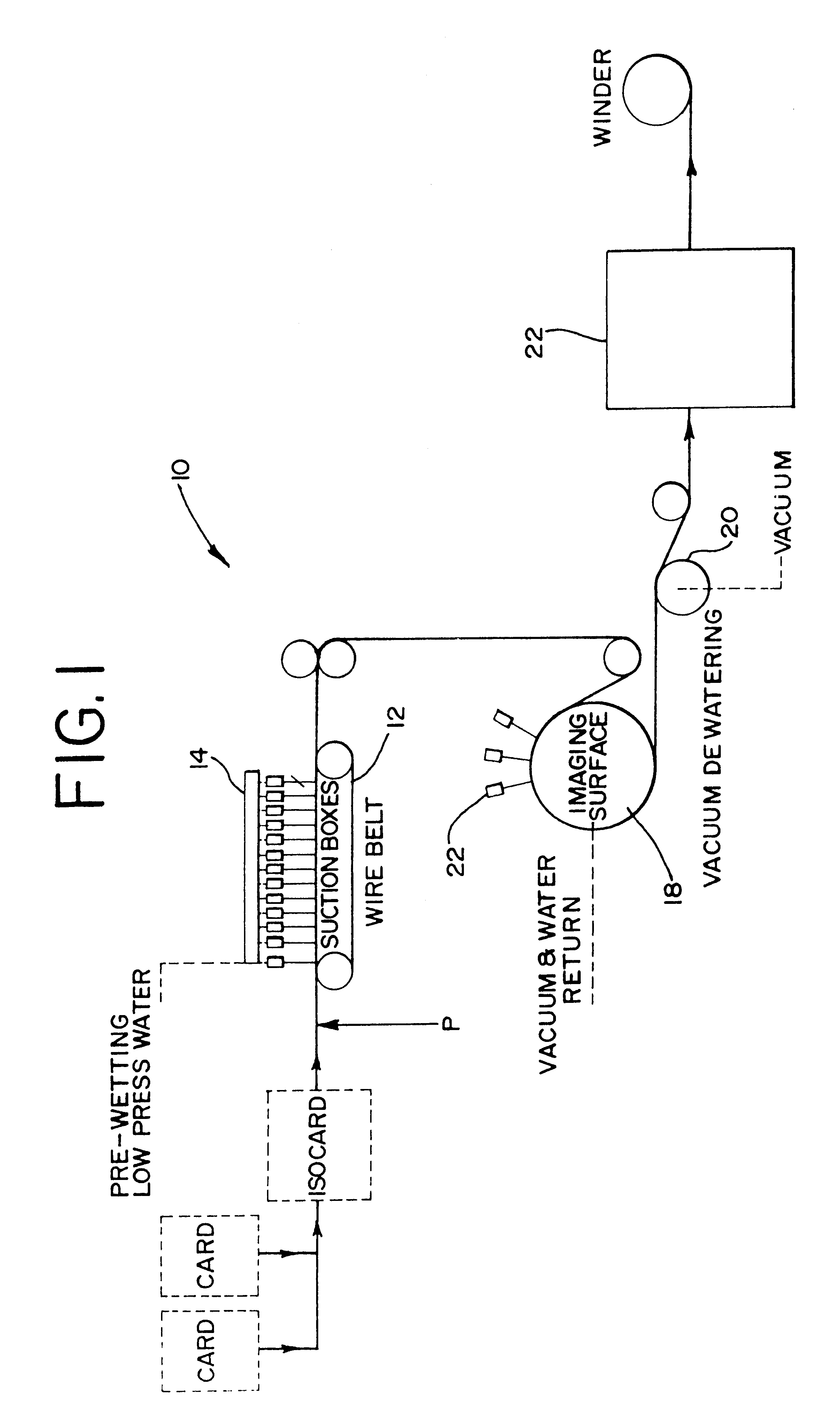

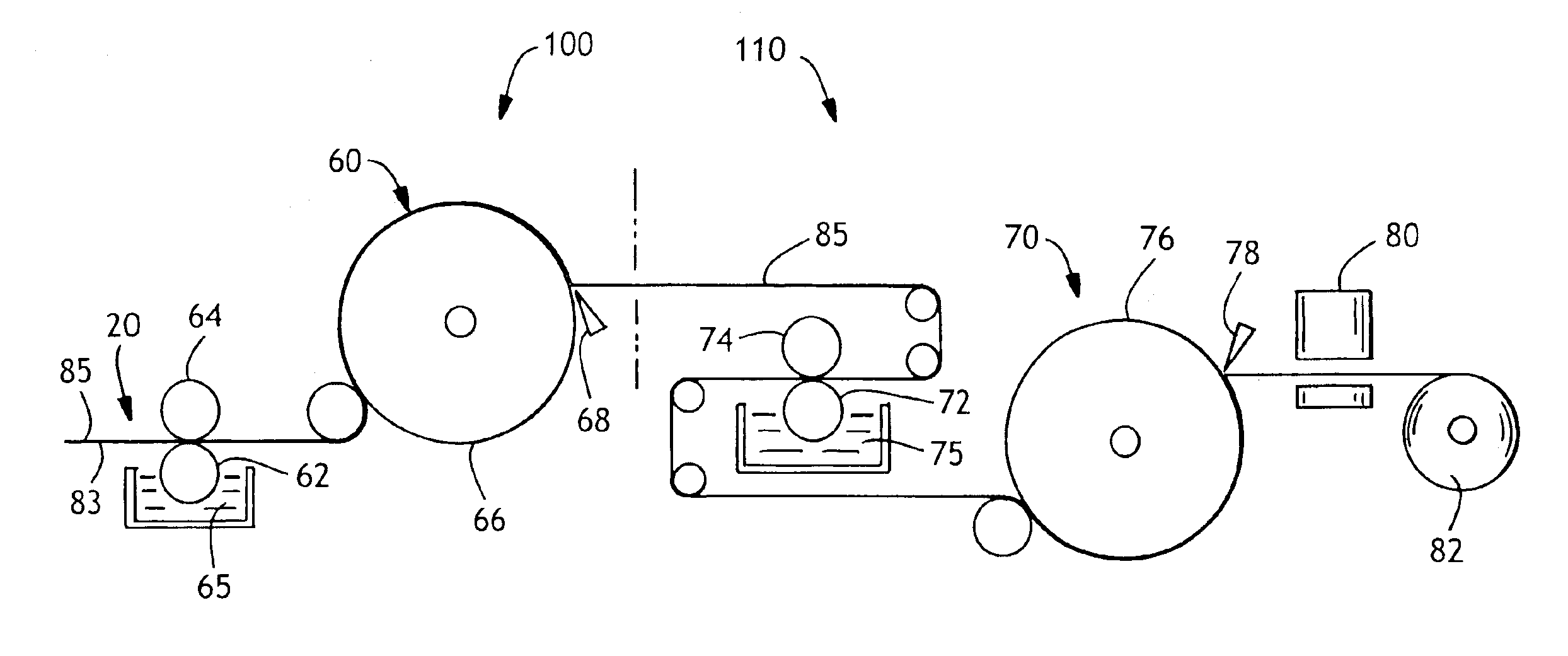

Process for forming micro-fiber cellulosic nonwoven webs from a cellulose solution by melt blown technology and the products made thereby

InactiveUS20050056956A1Artificial filament washing/dryingLoose filtering material filtersNon solventEngineering

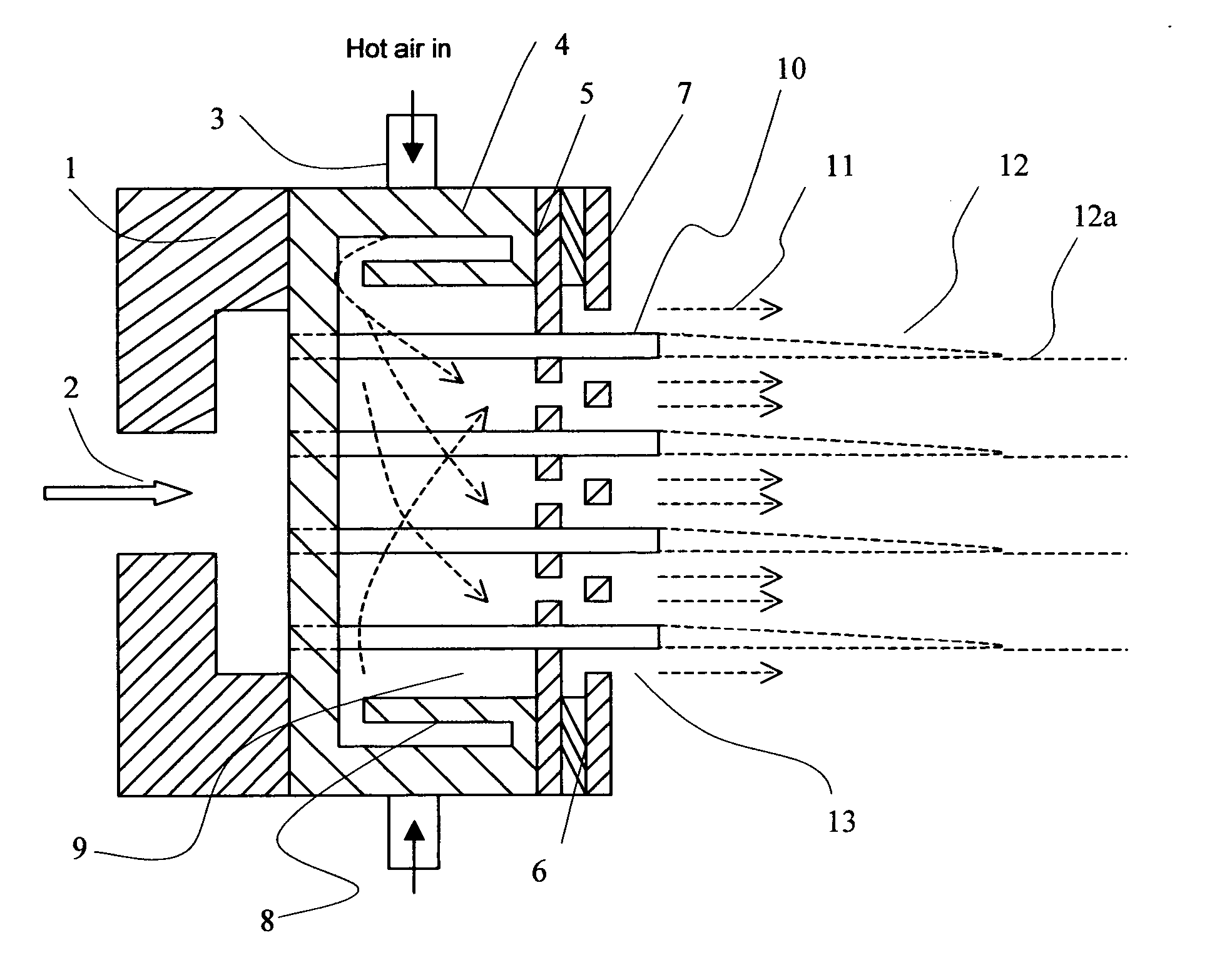

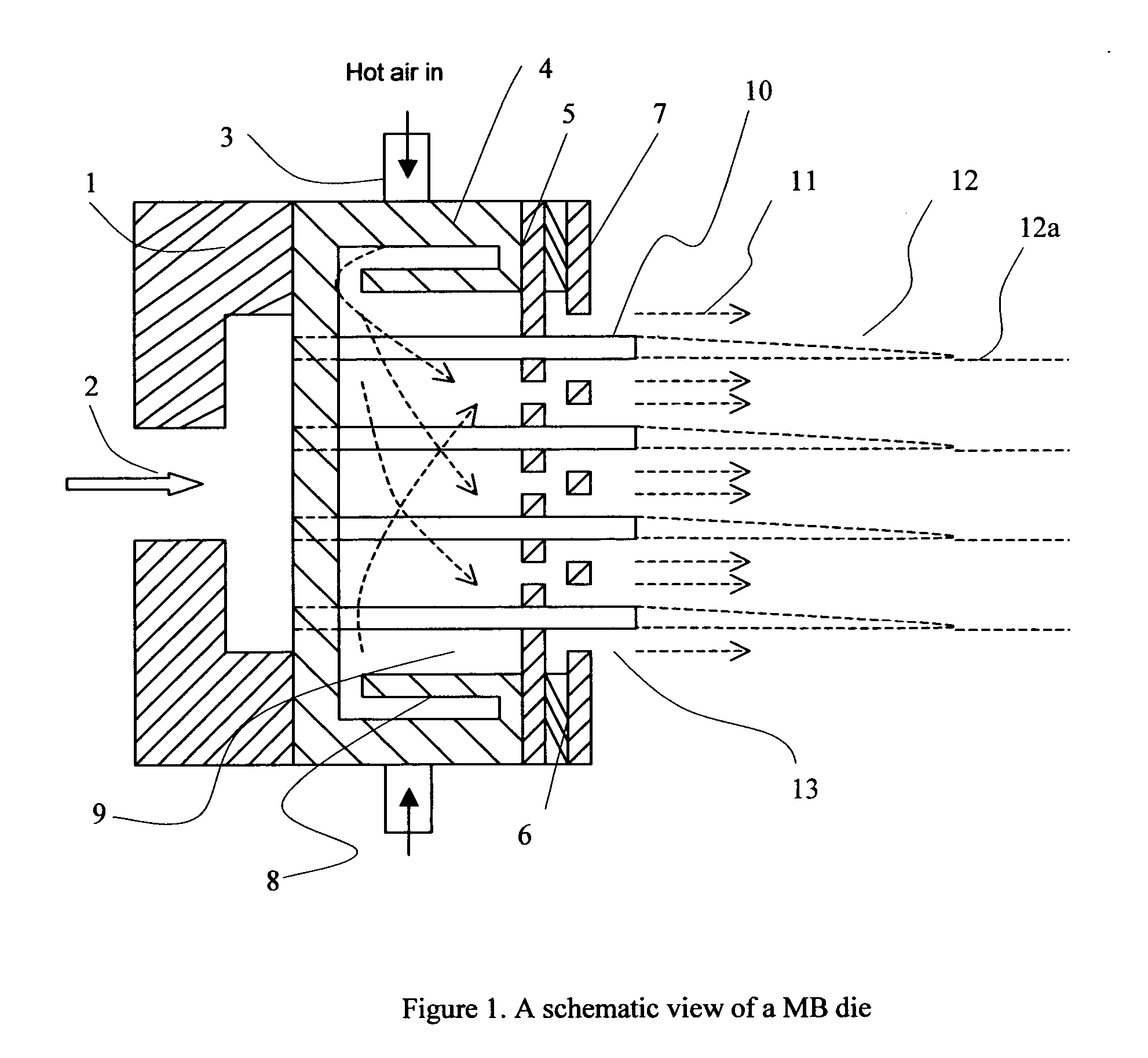

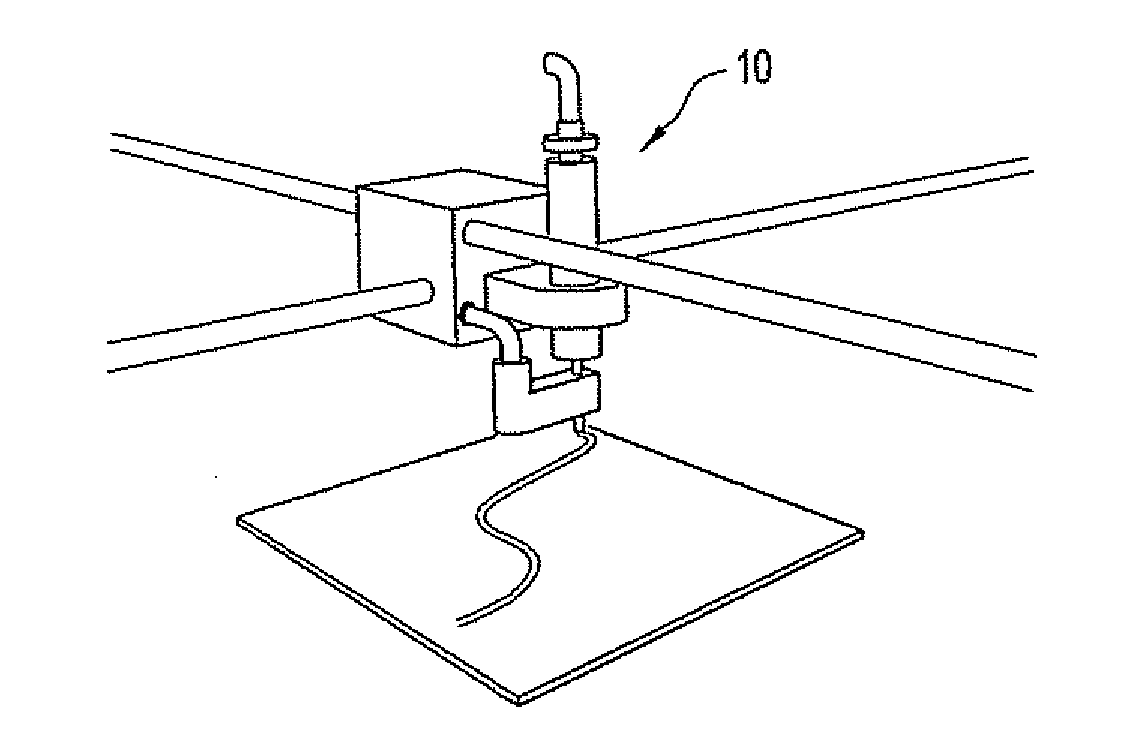

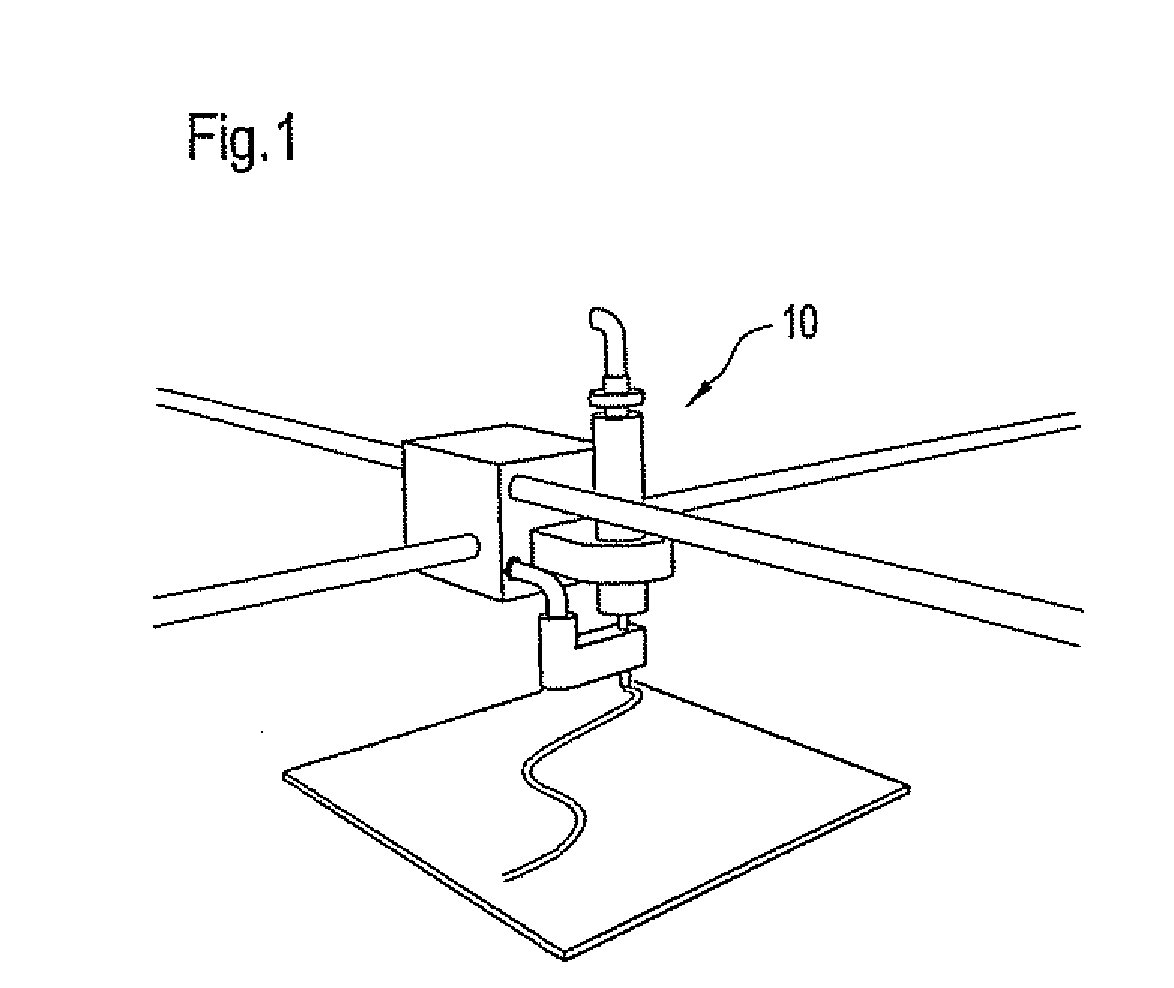

This invention relates to a process of melt blowing a cellulose solution through a concentric melt blown die with multiple rows of spinning nozzles to form cellulosic microfiber webs with different web structures. The process comprises the steps of (a) extruding a cellulose solution (dope) through a melt blown spinneret with multiple rows of spinning nozzles; (b) drawing each individual extrudate filament to fine fiber diameter by its own air jet; (c) coagulating and entangling the fine fibers with a series of pressured hydro needling jets of recycling solution of the mixture of cellulose solvent and non-solvent in the spin-line; (d) collecting the stream of microfibers, air and needling jets on a moving collecting surface to form cellulosic fiber web; (e) hydro-entangling the said pre-bonded web downstream with at least one set of hydro needling jets of recycling solvent / non-solvent solution for forming well bonded nonwoven web; (f) regenerating the fine fibers in at least one bath for at least 5 seconds; (g) further regenerating and washing the fine fibers in another bath for at least 5 seconds; (h) pinching the well bonded melt blown cellulosic nonwoven with pressure rollers to remove major portions of the non-solvent; (i) drying the nonwoven web by heat, or vacuum or both, and (j) winding the nonwoven web into rolls.

Owner:BIAX FIBERFILM CORP

Method for the production of patterned designs

InactiveUS20070170610A1Easy to separateRestricts distributionConfectionerySweetmeatsPerpendicular directionBiomedical engineering

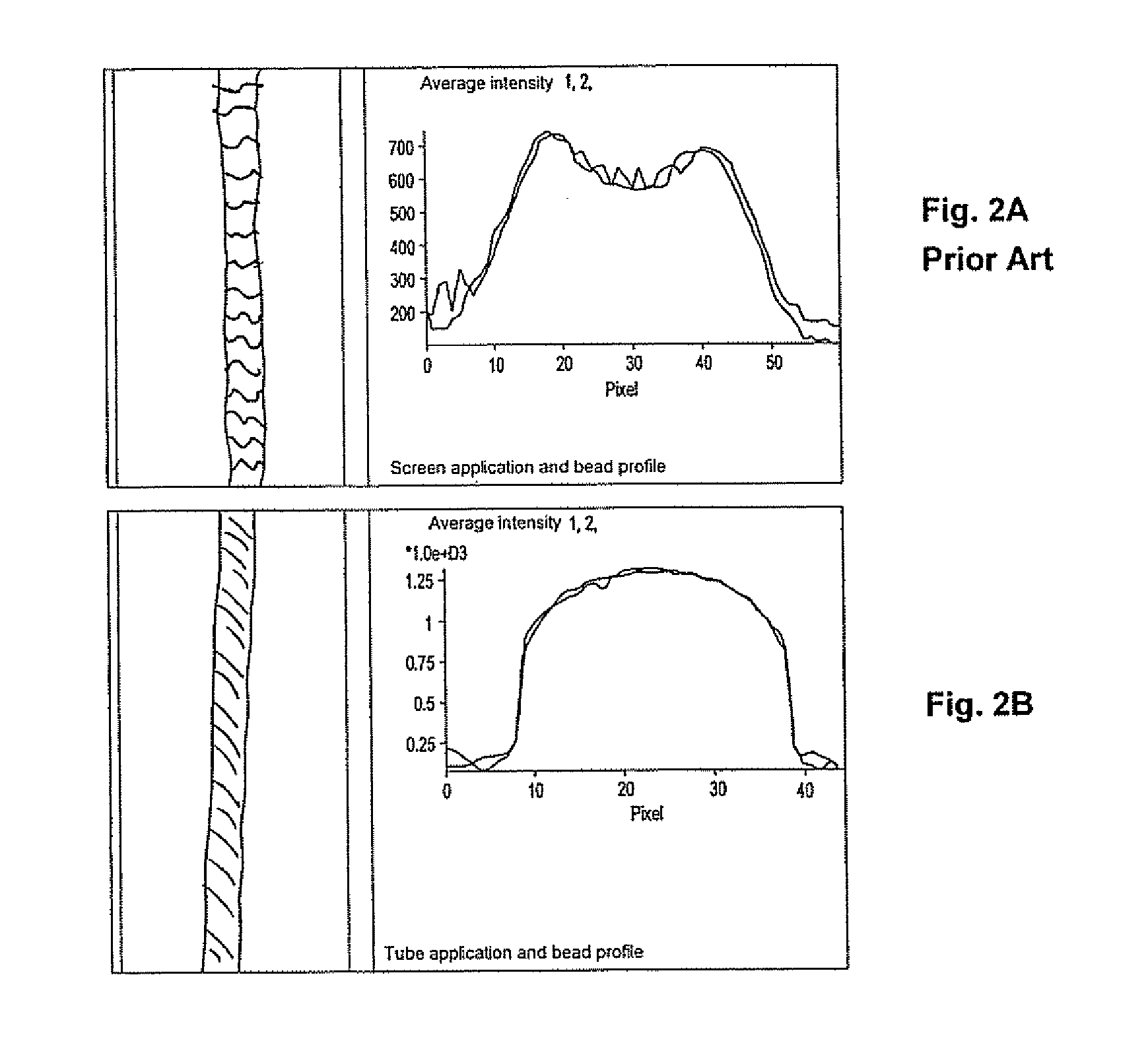

A method for the production of a fabric for industrial use comprising extruding polymer material onto a carrier structure to produce a patterned design on the carrier structure, wherein a cross-sectional profile of the extruded polymer material is substantially convex. An apparatus for carrying out the method comprising a polymer extrusion apparatus structured and arranged to move in three mutually perpendicular directions. A fabric comprising a carrier structure and a patterned design comprising extruded polymer material arranged on the carrier structure, wherein the extruded polymer material is arranged to form a substantially convex cross section on the carrier structure. The instant abstract is neither intended to define the invention disclosed in this specification nor intended to limit the scope of the invention in any way.

Owner:VOITH PATENT GMBH

Melt-blown nonwoven fabric, process for producing same and the uses thereof

InactiveUS6207601B1Avoid undesirable oxidative processEliminate useLayered productsTobacco smoke filtersMean diameterPolymer science

The disclosure relates to a melt-blown non-woven fabric based on cellulose esters, with fibers of mean diameter less than about 10 microns. The fabric contains 0-10 wt. % extractable softener, has a reflection factor determined according to DIN 53 145 Part I (1992) of more than 60% and the cellulose ester has a degree of substitution DS of about 1.5-3.0. The softener is preferably water-extractable. A melt-blown non-woven fabric is produced with the cellulose ester as follows: a cellulose ester, cellulose acetate, with a DS of about 1.5-3.0, in particular 1.7-2.7, is mixed with softener in a weight ratio of about 2:1 to 1:4 and simultaneously heated and melted. The mixture of softener and cellulose ester has a melting index MFI (210 / 2.16) according to DIN 53 735 of about 400 to 5 g / 10 min., in particular 300 to 50 g / 10 min. The melt is worked in a melt-blown spinning device into a melt-blown non-woven fabric and the softener is then extracted with a softener solvent to leave a proportion of 0-10 wt. %. The melt-blown non-woven fabric is especially suitable as a filter material.

Owner:RHODIA ACETOW AG

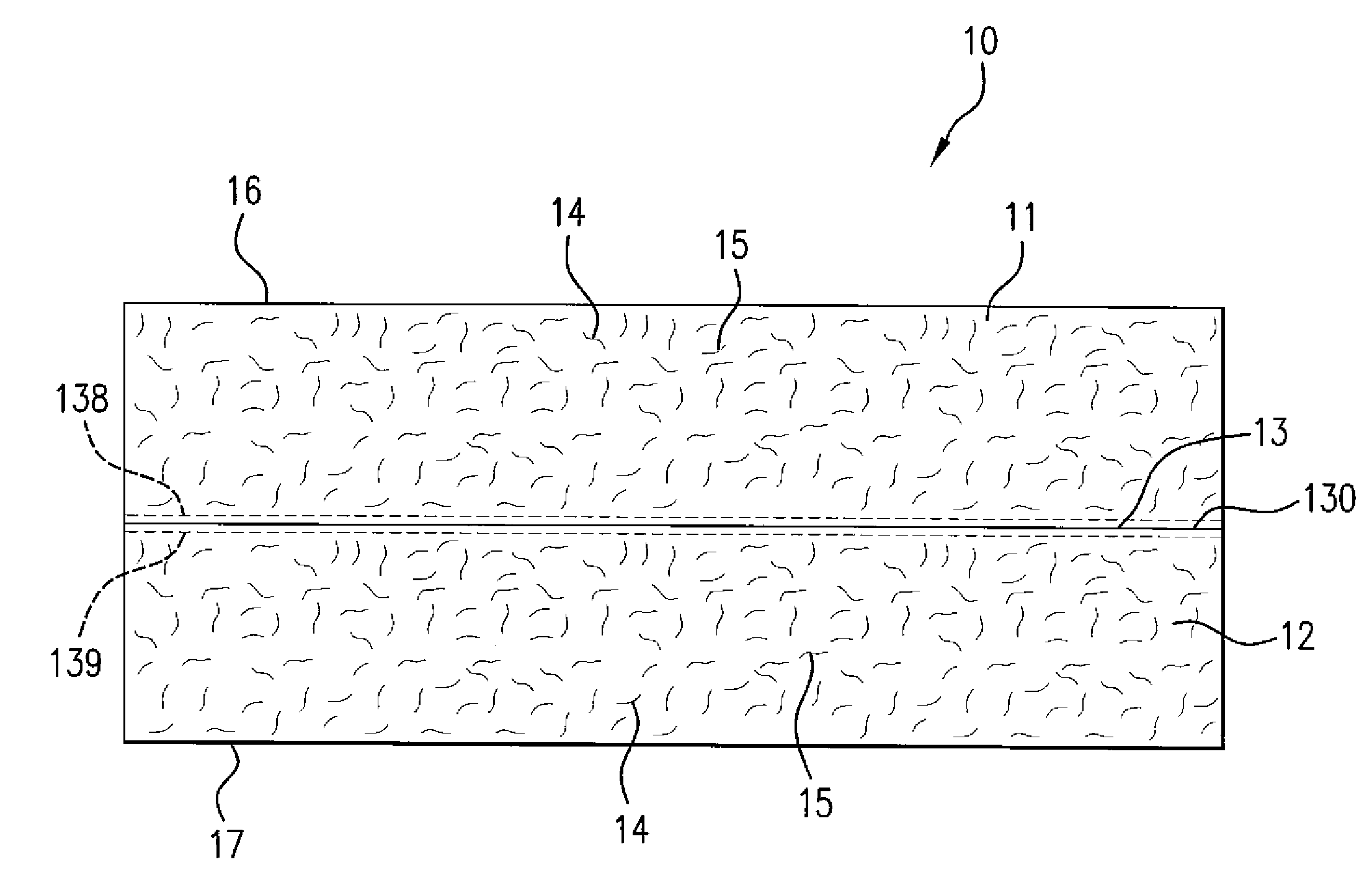

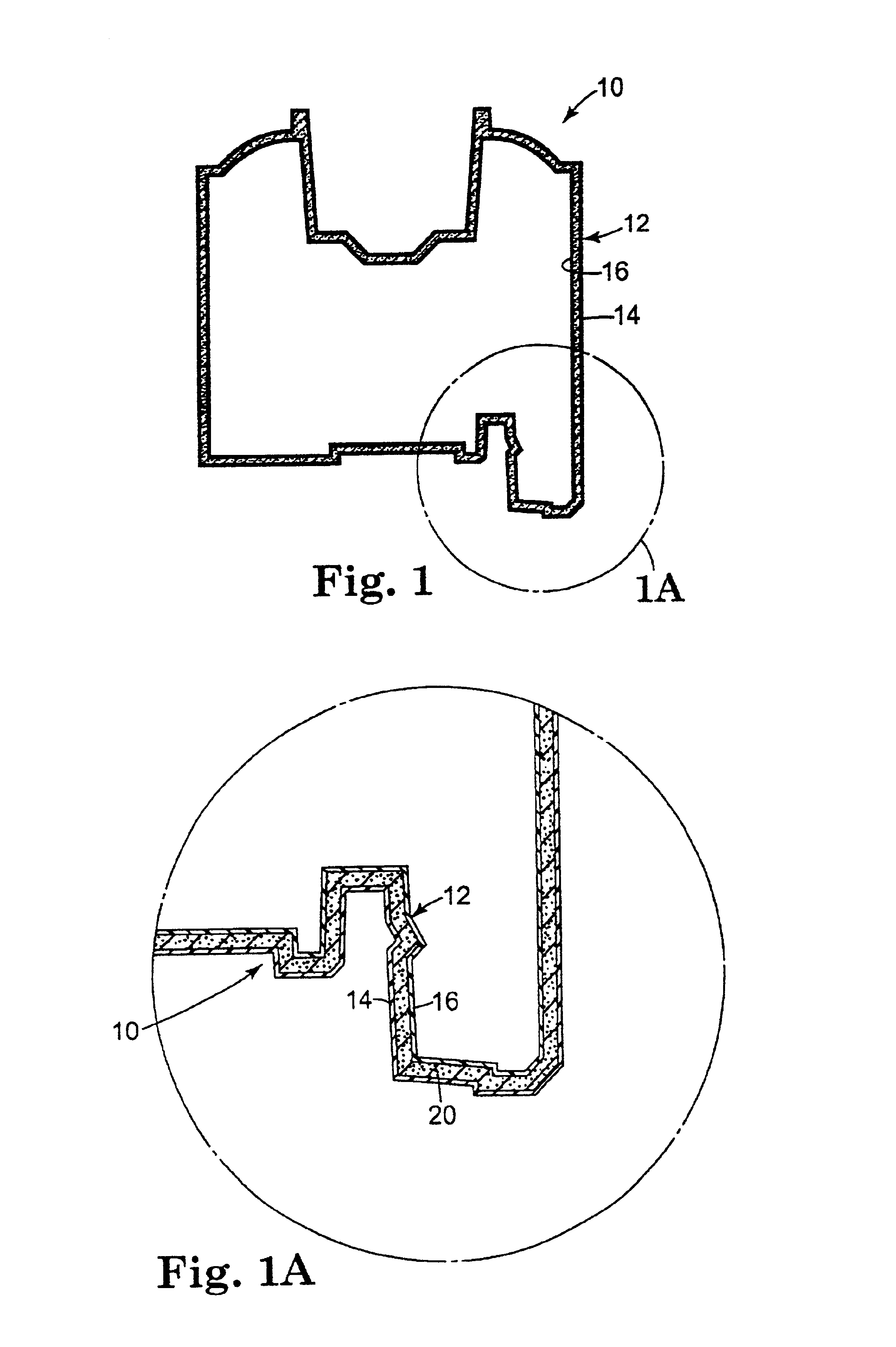

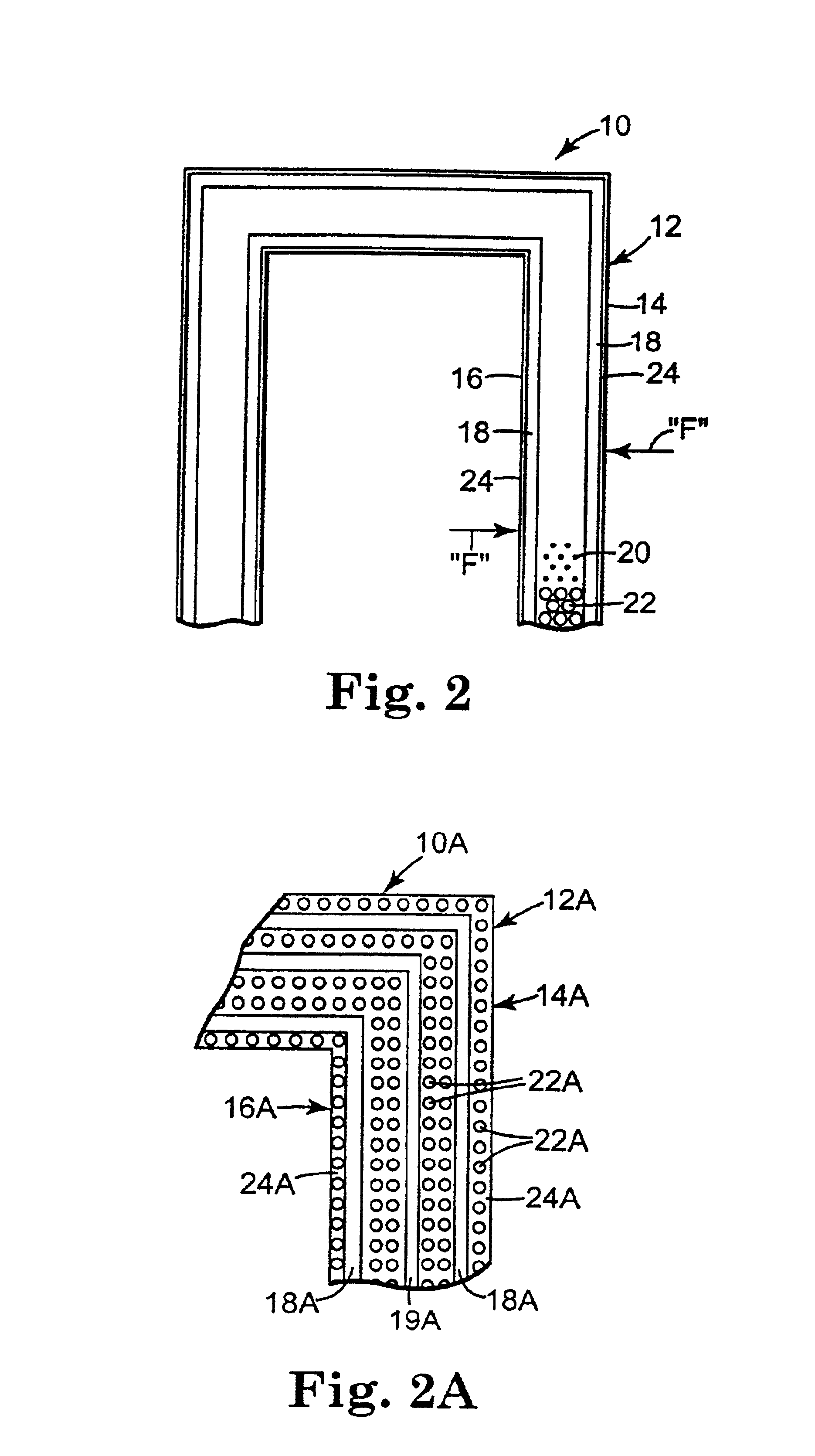

Absorbent structure

InactiveUS20130226120A1Excellent fluid managementInhibit migrationLiquid surface applicatorsPattern makingEngineeringFluid management

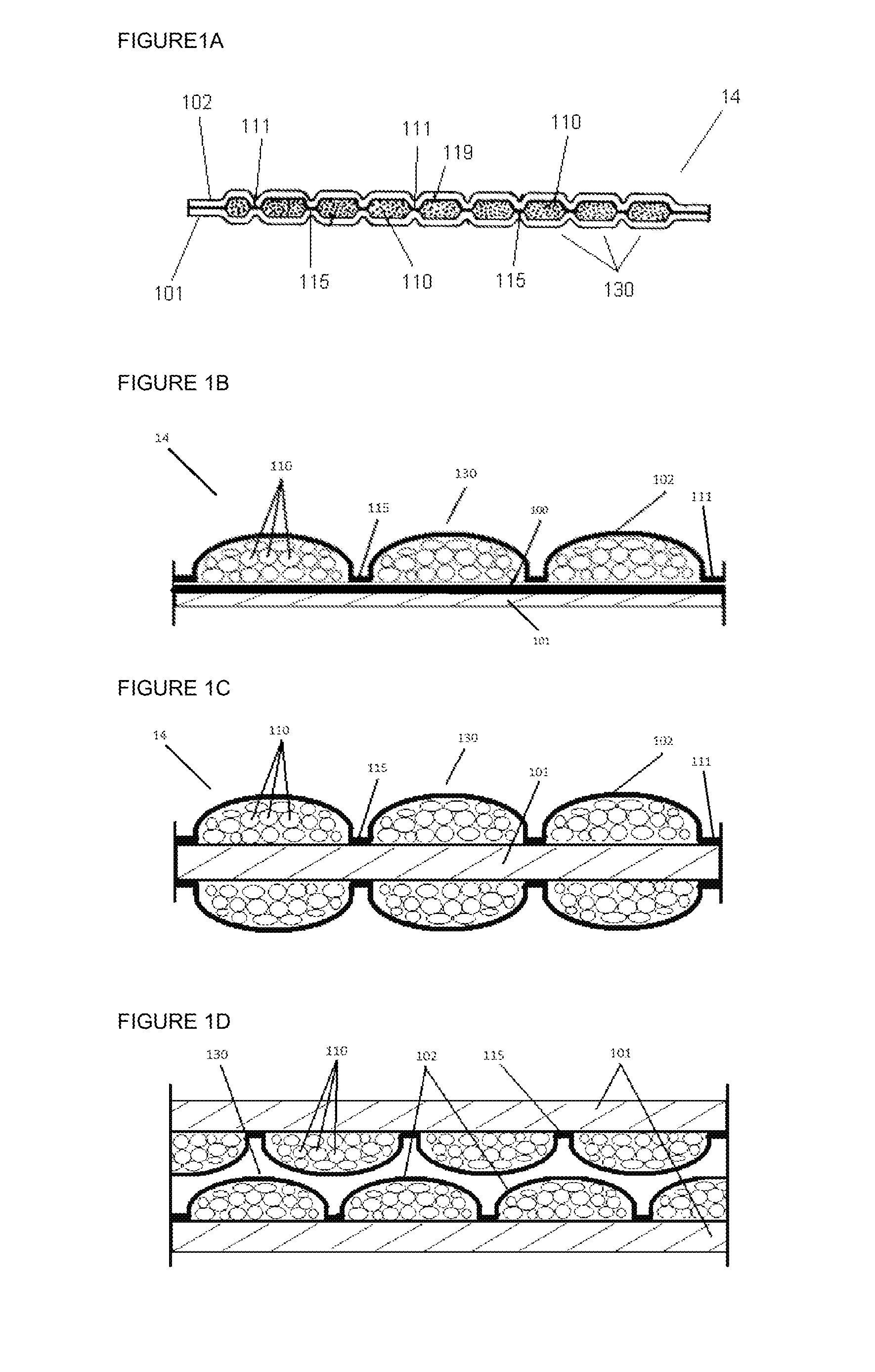

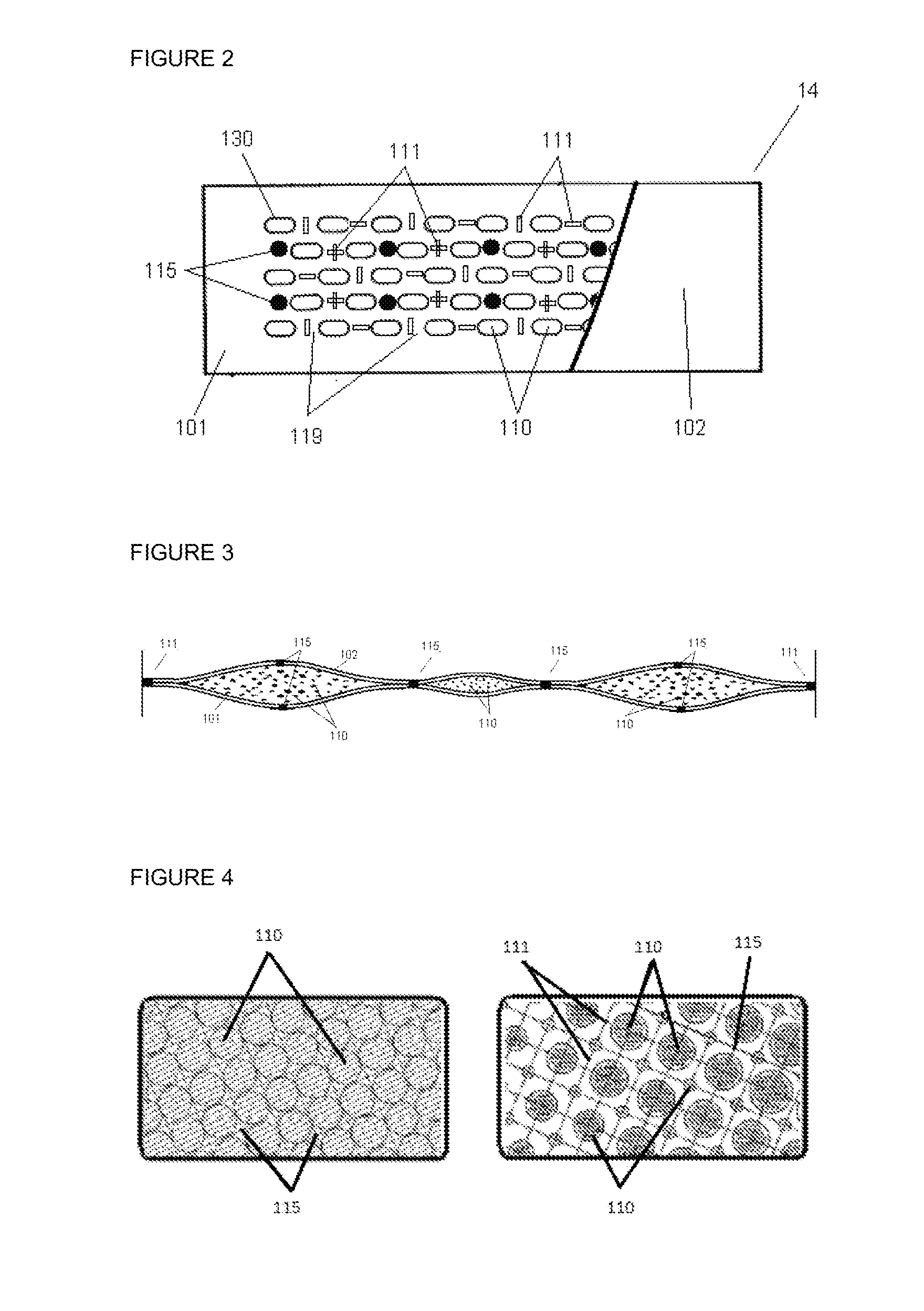

The present invention relates to an absorbent structure, preferably for use in absorbent products, such as used in the food, consumer, household, building and construction, beauty and medical industry, and as used in the personal hygiene industry. The substantially cellulose free absorbent structures continuously immobilise absorbent polymer material via initial smaller pockets and subsequently larger compartments allowing excellent fluid management of the absorbent polymer material in dry, partially and fully liquid loaded state. Preferably such absorbent structure volume increases are result of temporary secondary attachment patterns made in combination with substantially permanent primary attachment grids allowing the release of bigger volumes from the initial smaller volumes by detachment of the secondary attachments. Furthermore the absorbent structure according to an embodiment of the invention non-homogeneously swells to form a liquid-managing surface structure as a result of exposing the absorbent structure to liquid. The present invention foresees in the need for improved flexible, thin, lightweight absorbent structures which overcome the absorbency problems of the prior art during absorption, distribution and retention of liquids with optimal fit.

Owner:DRYLOCK TECHNILOGIES NV

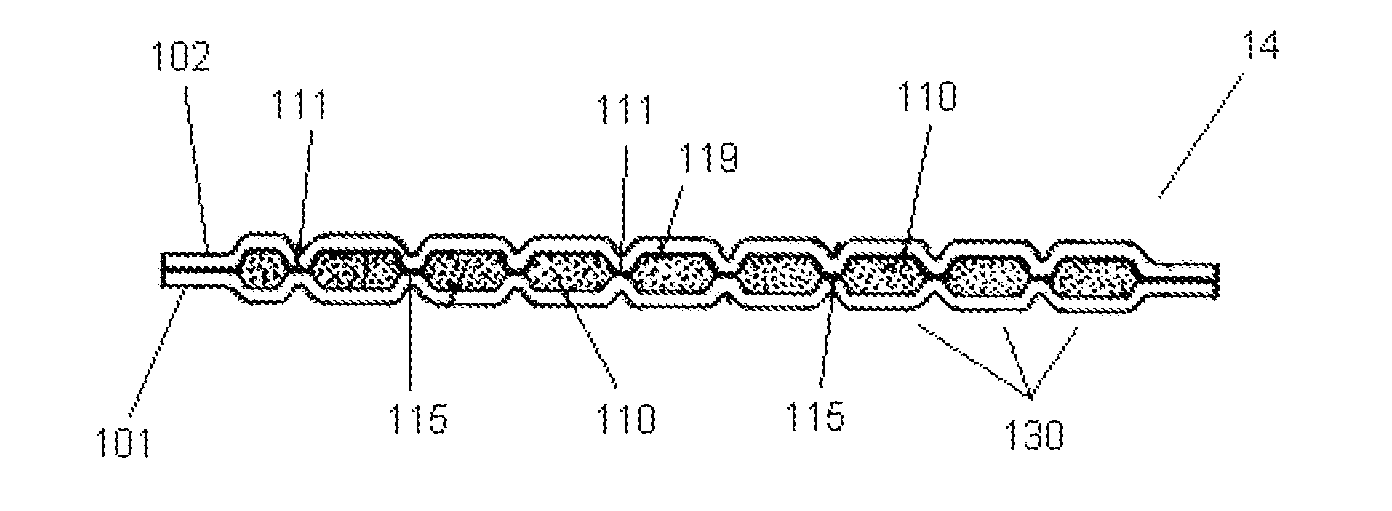

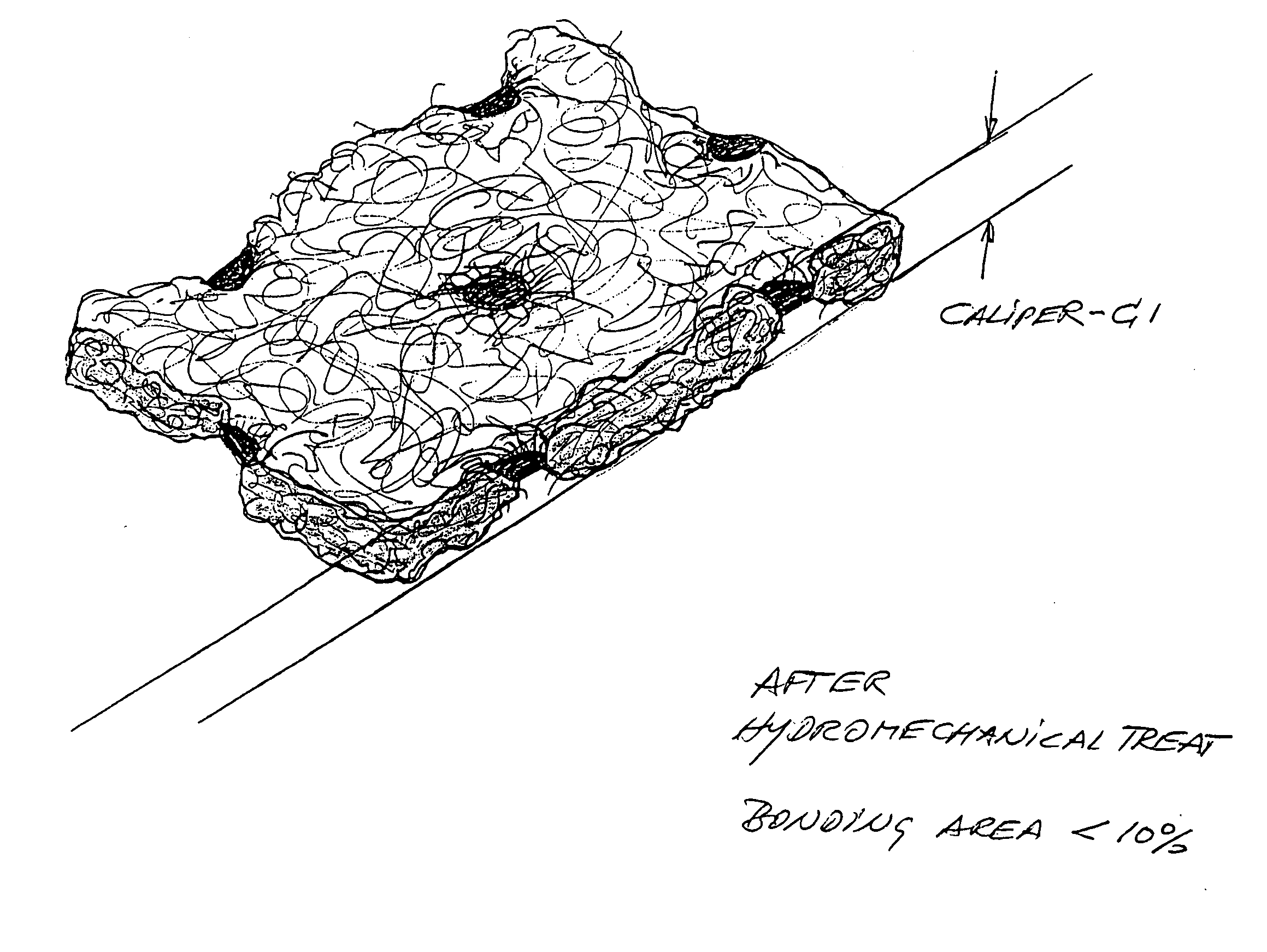

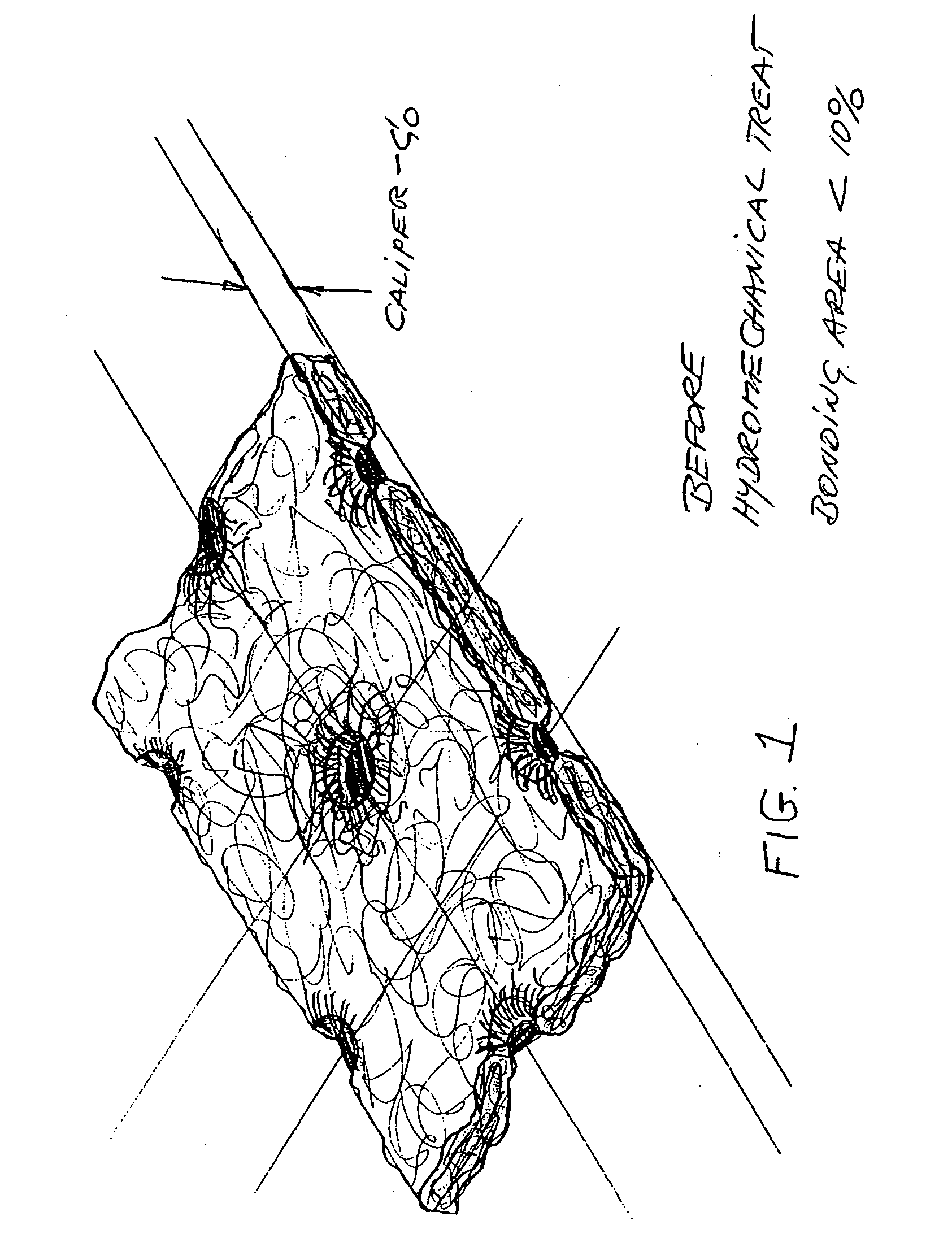

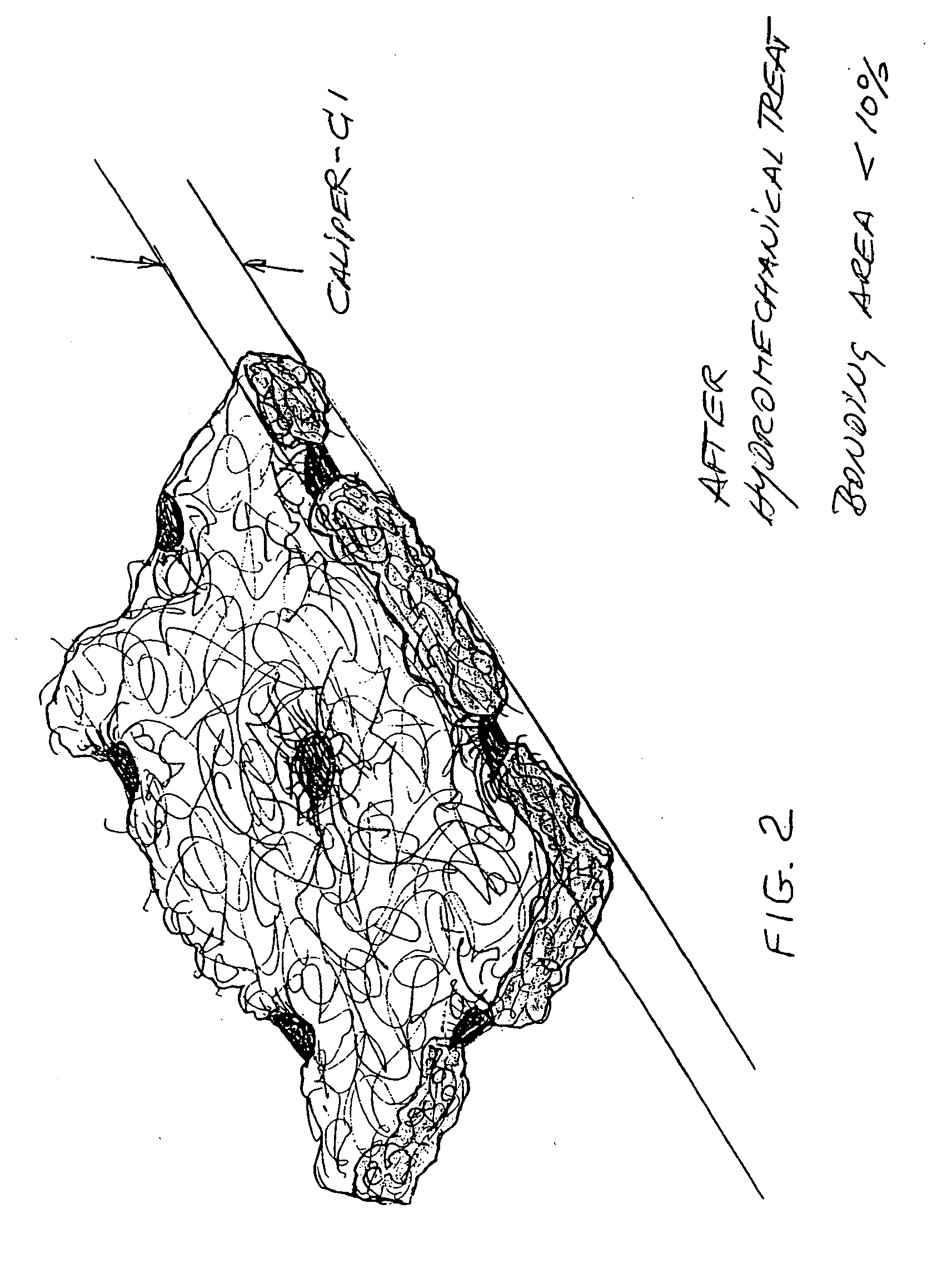

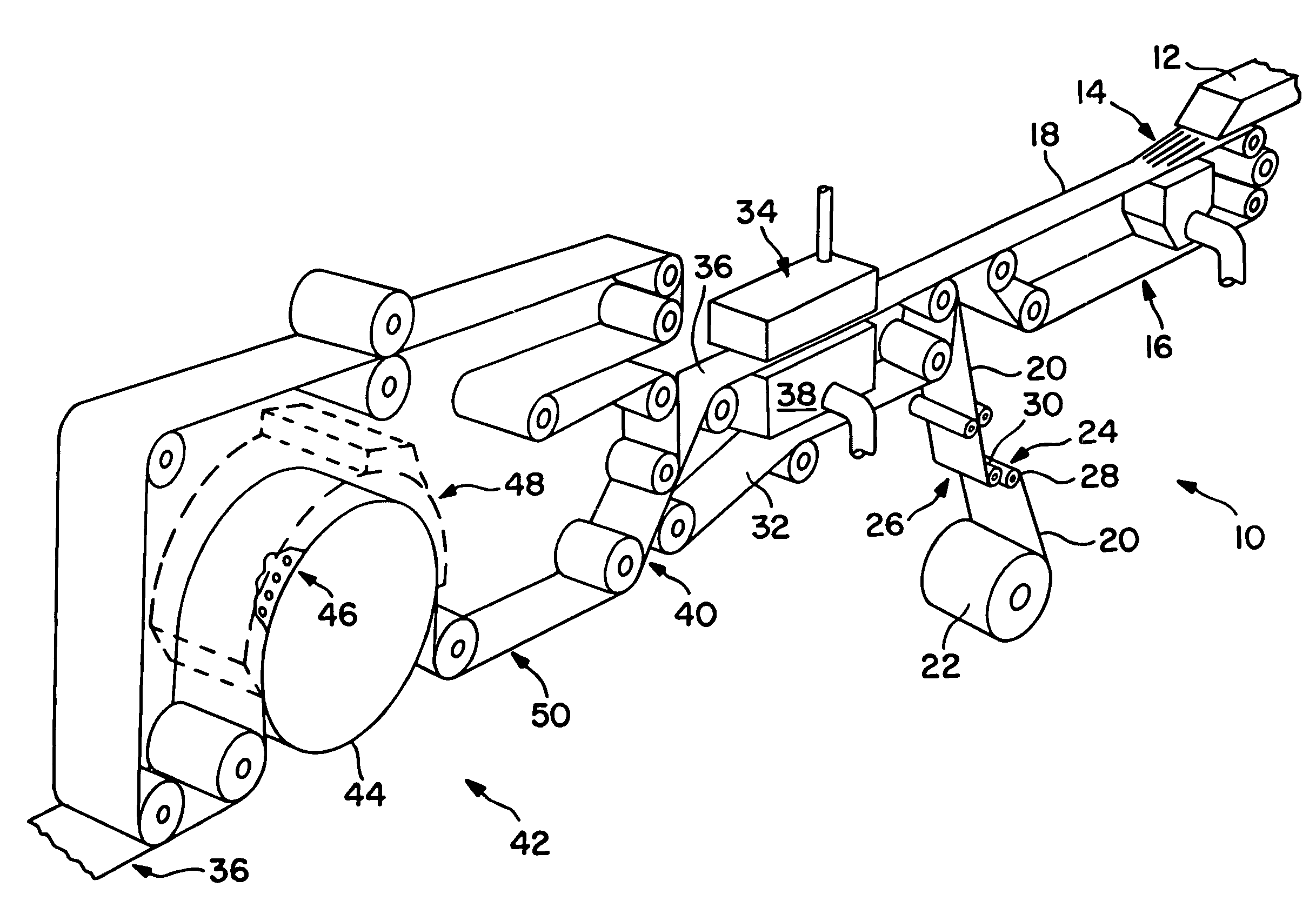

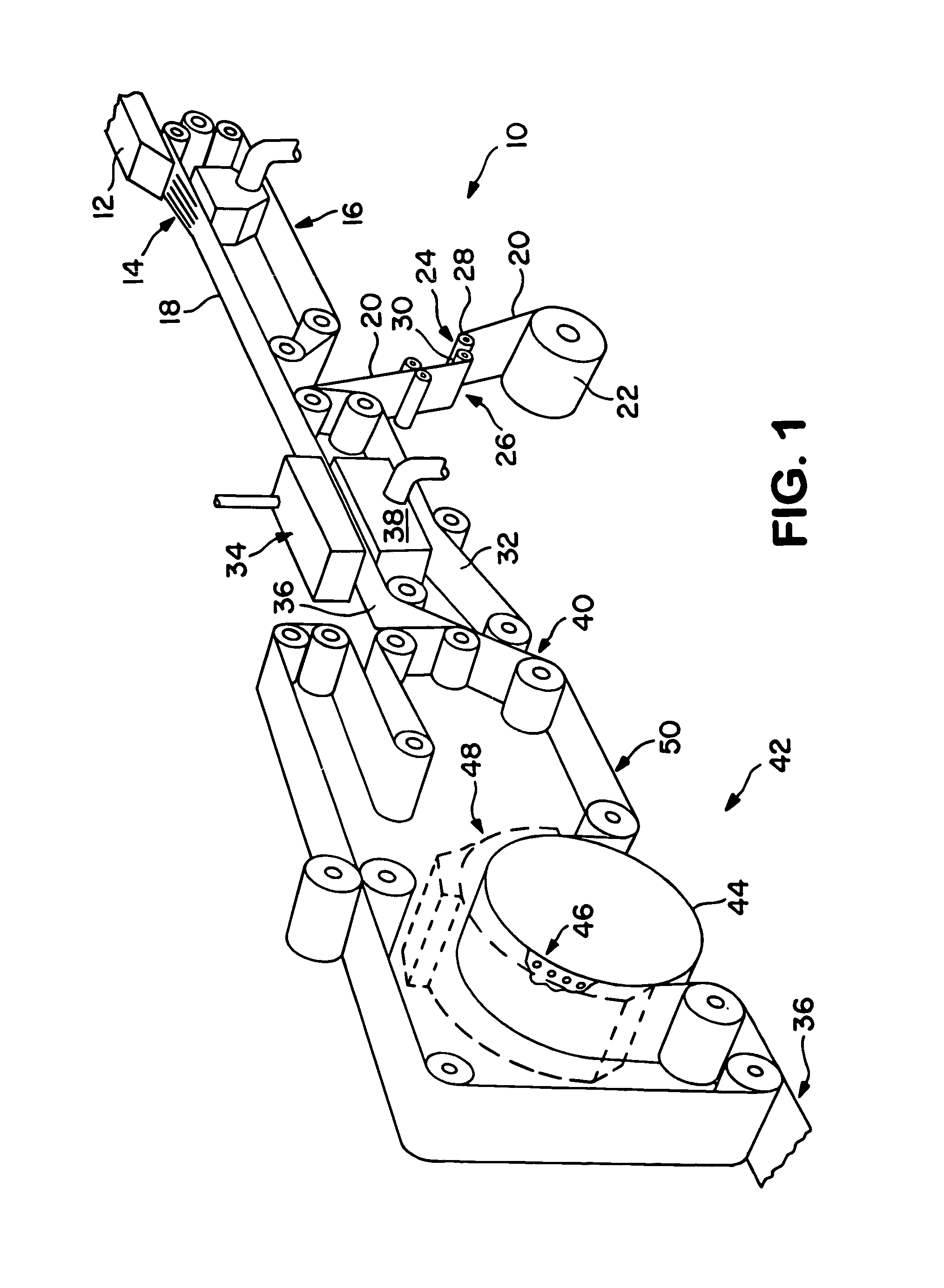

Hydroengorged spunmelt nonwovens

A hydroengorged spunmelt nonwoven formed of thermoplastic continuous fibers and a pattern of fusion bonds. The nonwoven has either a percentage bond area of less than 10 percent, or a percentage bond area of at least 10% wherein the pattern of fusion bonds is anisotropic.

Owner:FIRST QUALITY NONWOVENS

Soft and bulky composite fabrics

A composite fabric is provided that contains staple fibers hydraulically entangled with a nonwoven web formed from continuous filaments. A portion of the staple fibers is entangled with the web, while another portion protrudes through the web. The resulting surface topography has one surface with a preponderance of the smooth, staple fibers, and another surface with a preponderance of the continuous filaments from the nonwoven web, but also including some of the protruded smooth, staple fibers. Thus, each surface contains smooth staple fibers and is soft.

Owner:KIMBERLY-CLARK WORLDWIDE INC

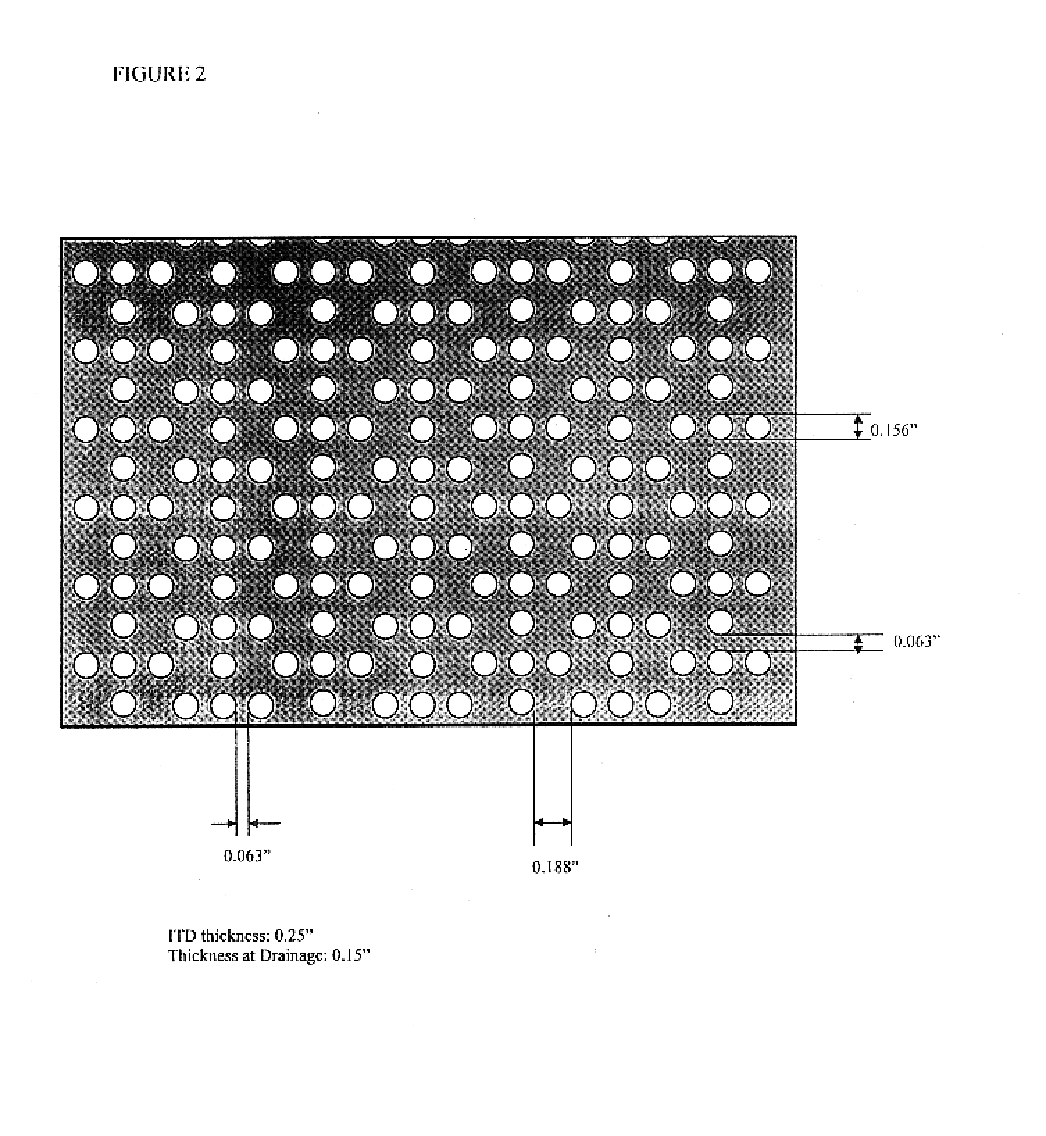

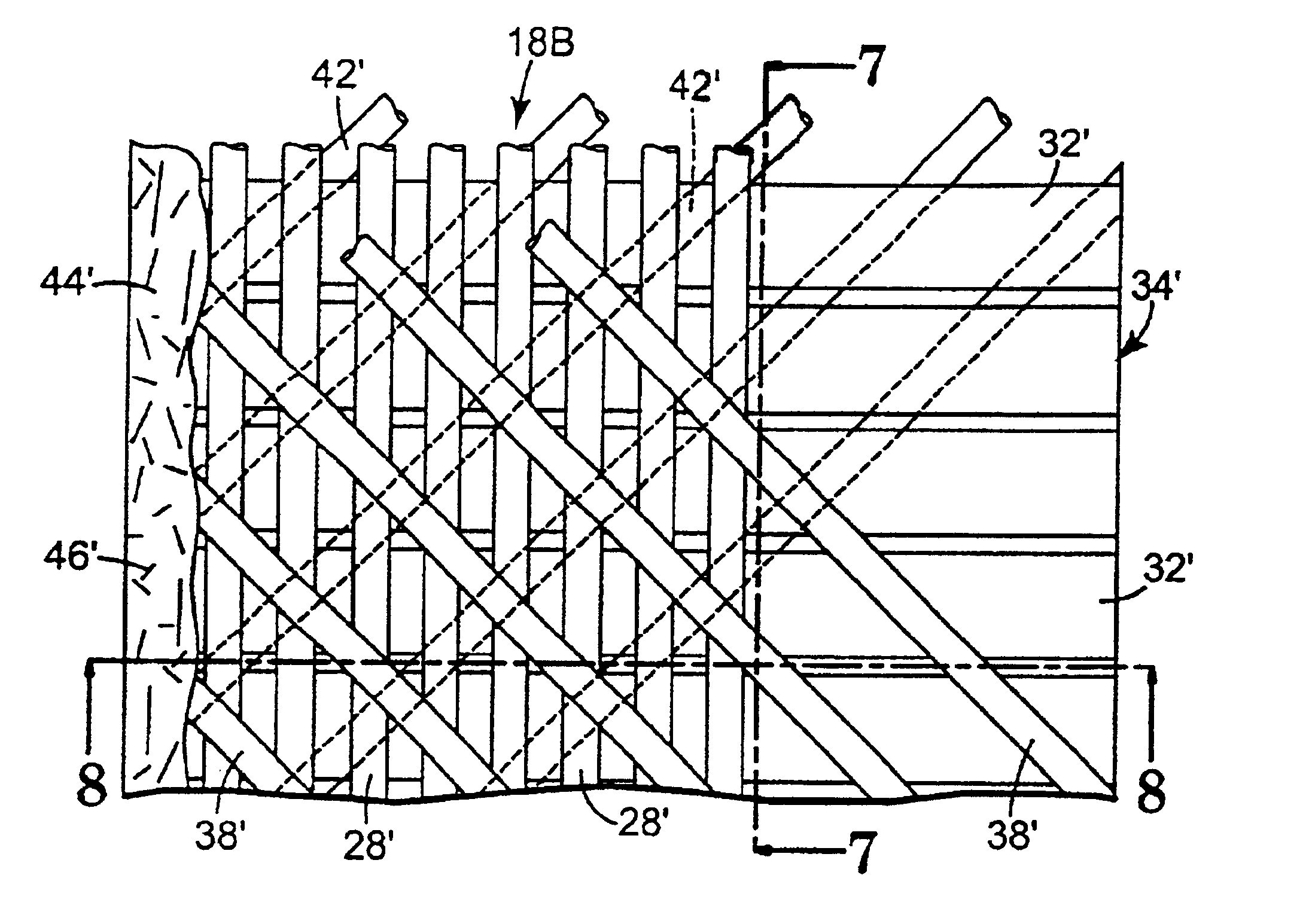

Industrial fabric, and method of making thereof

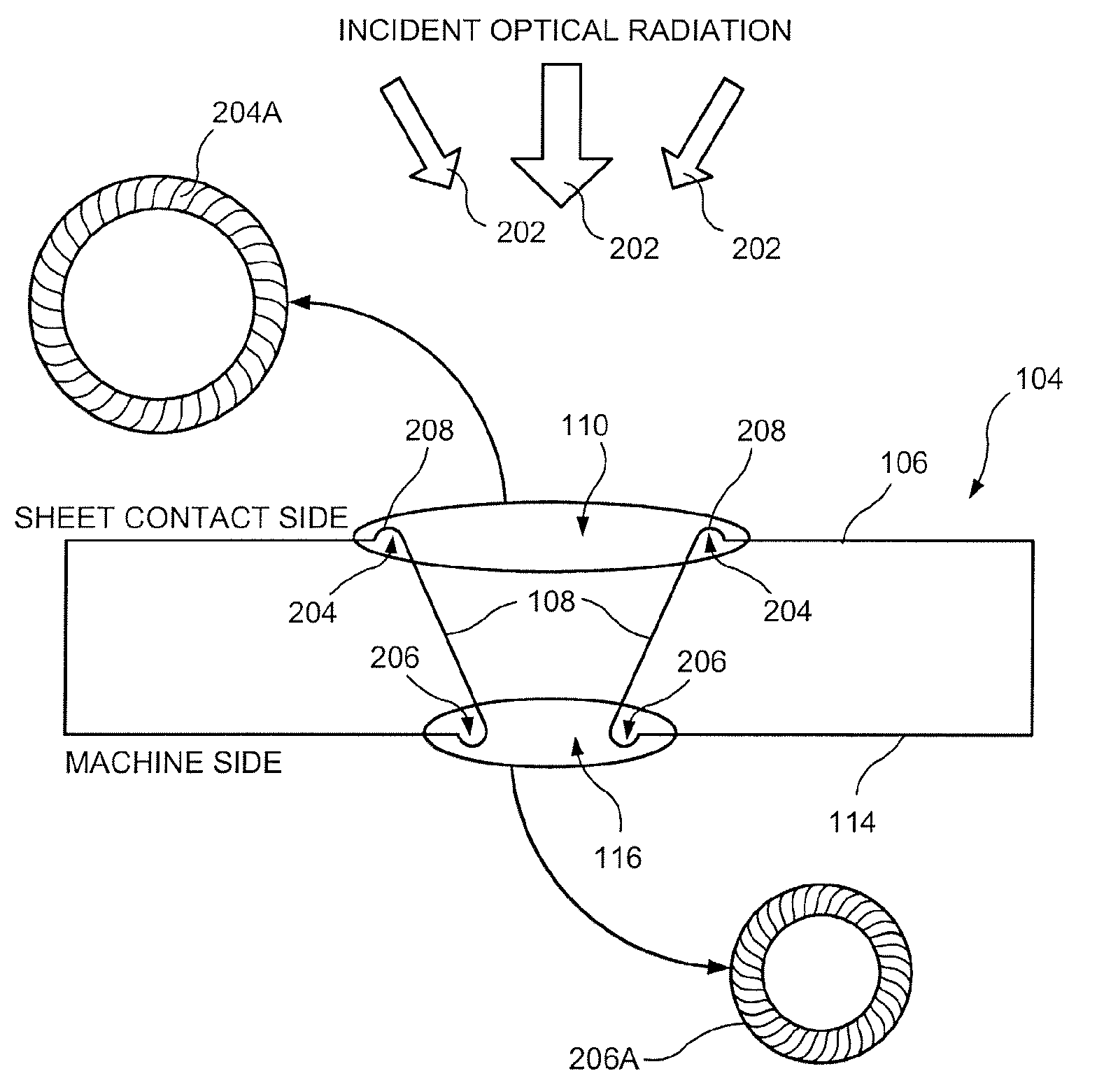

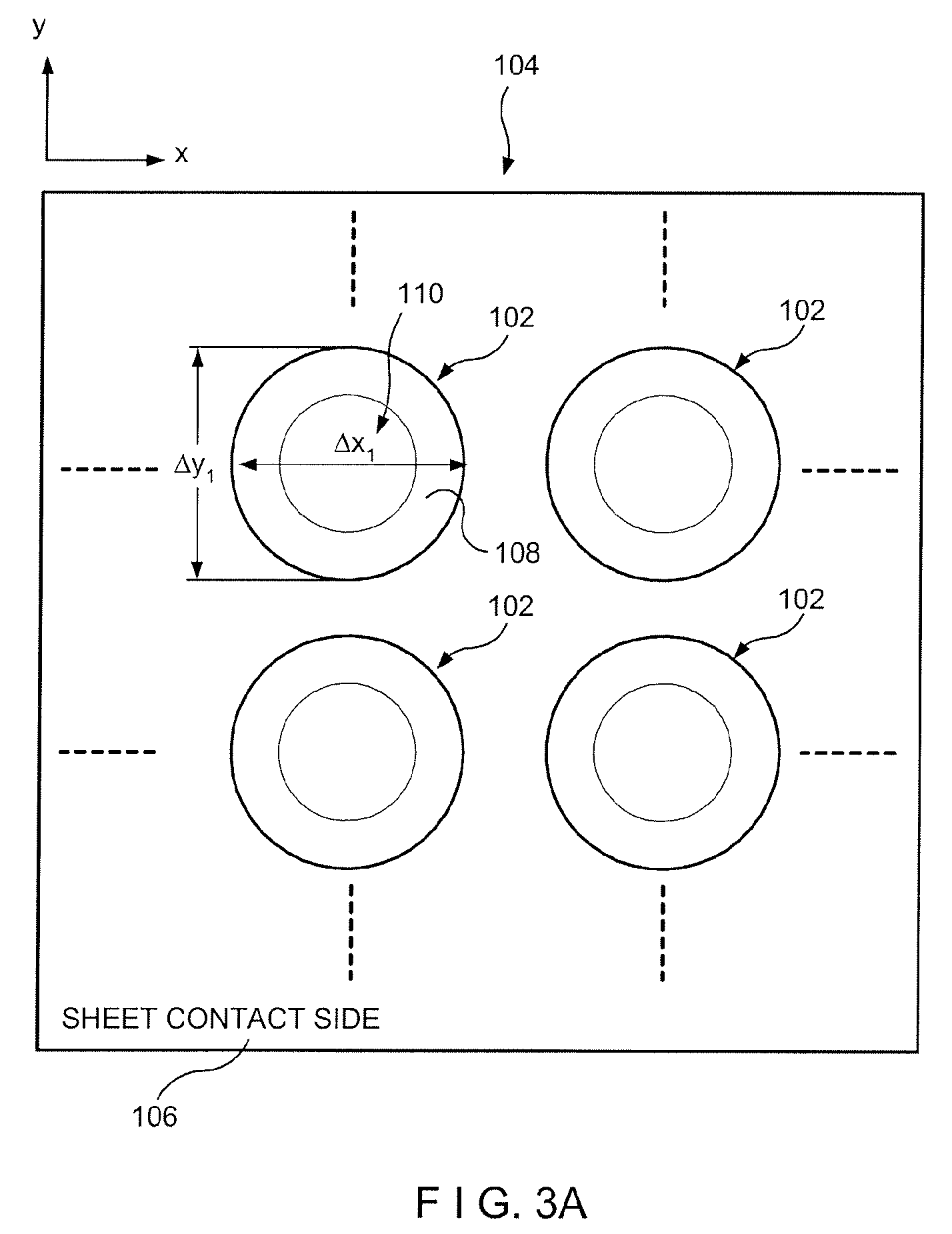

ActiveUS8822009B2Wet shapingEasy to cleanPattern makingSynthetic resin layered productsEngineeringMaterial Perforation

A support member such as a belt or sleeve includes a topographical pattern on its sheet contact side. A plurality of land areas, corresponding depressions, through voids, and / or groove areas are formed on the top surface of the support member to produce the topographical pattern. The land areas, corresponding depressions, through voids, and / or groove areas may be formed by graving, cutting, etching, embossing, mechanical perforation or a combination thereof. The improved belt or sleeve imparts desired physical characteristics, such as bulk, appearance, texture, absorbency, strength, and hand to a nonwoven product produced thereon.

Owner:ALBANY INT CORP

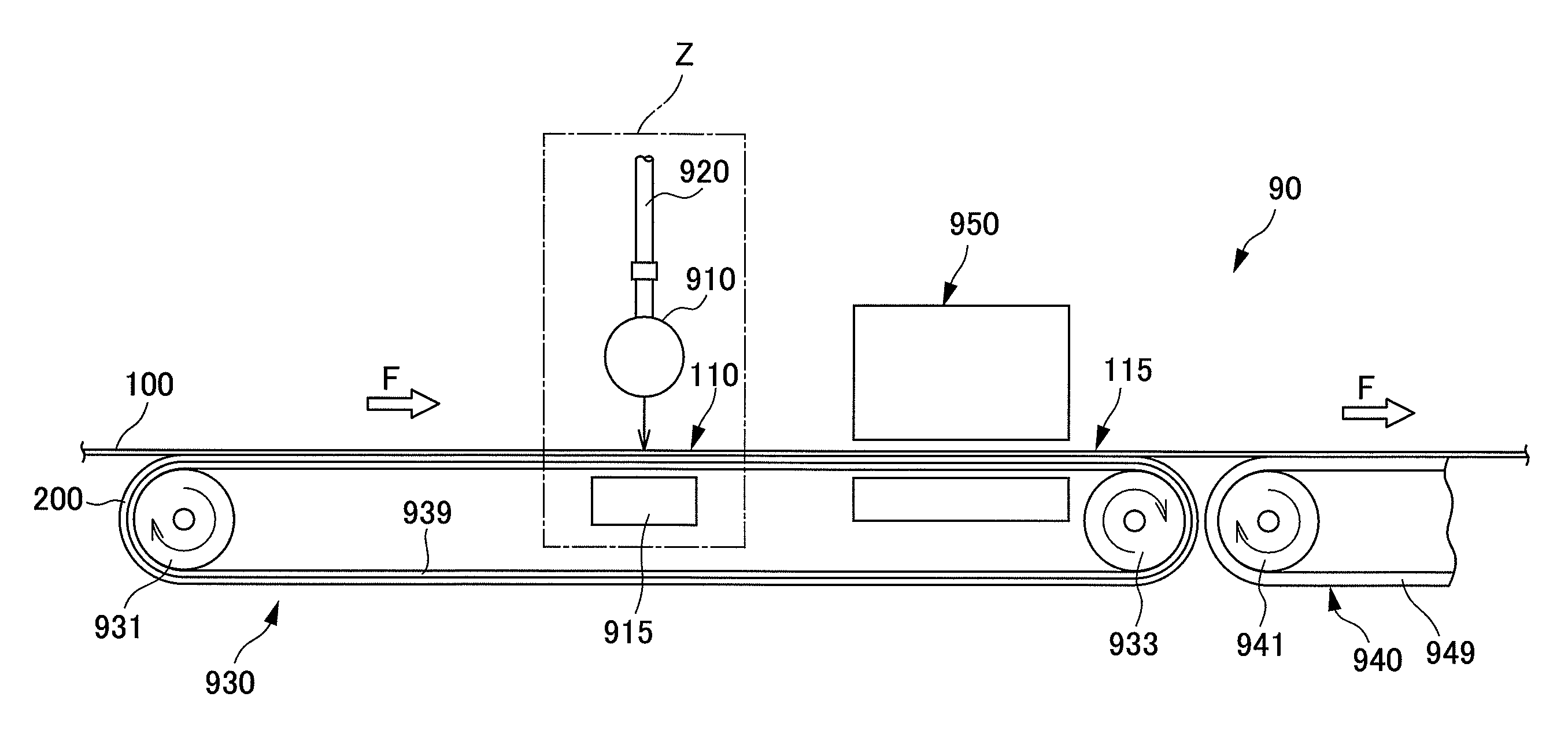

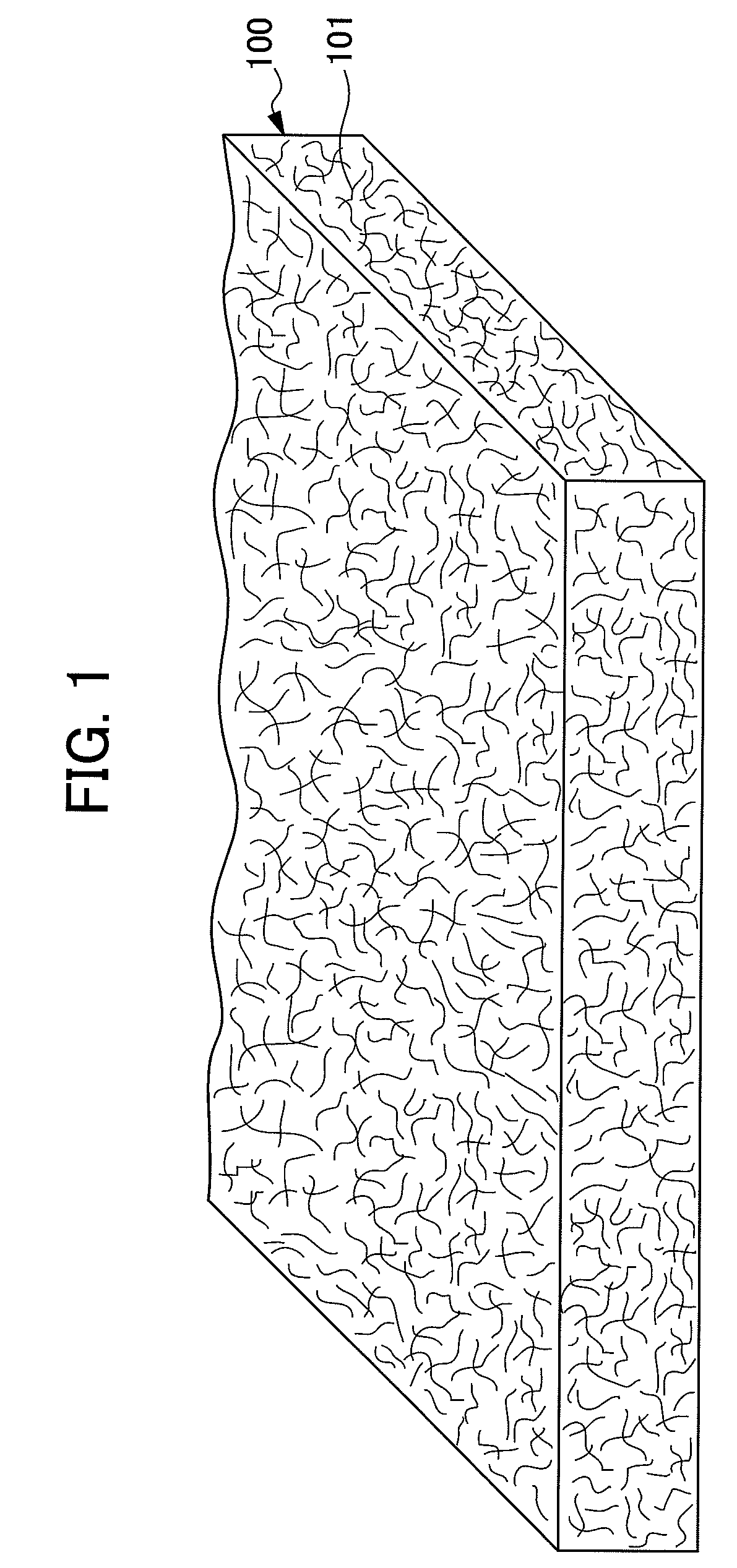

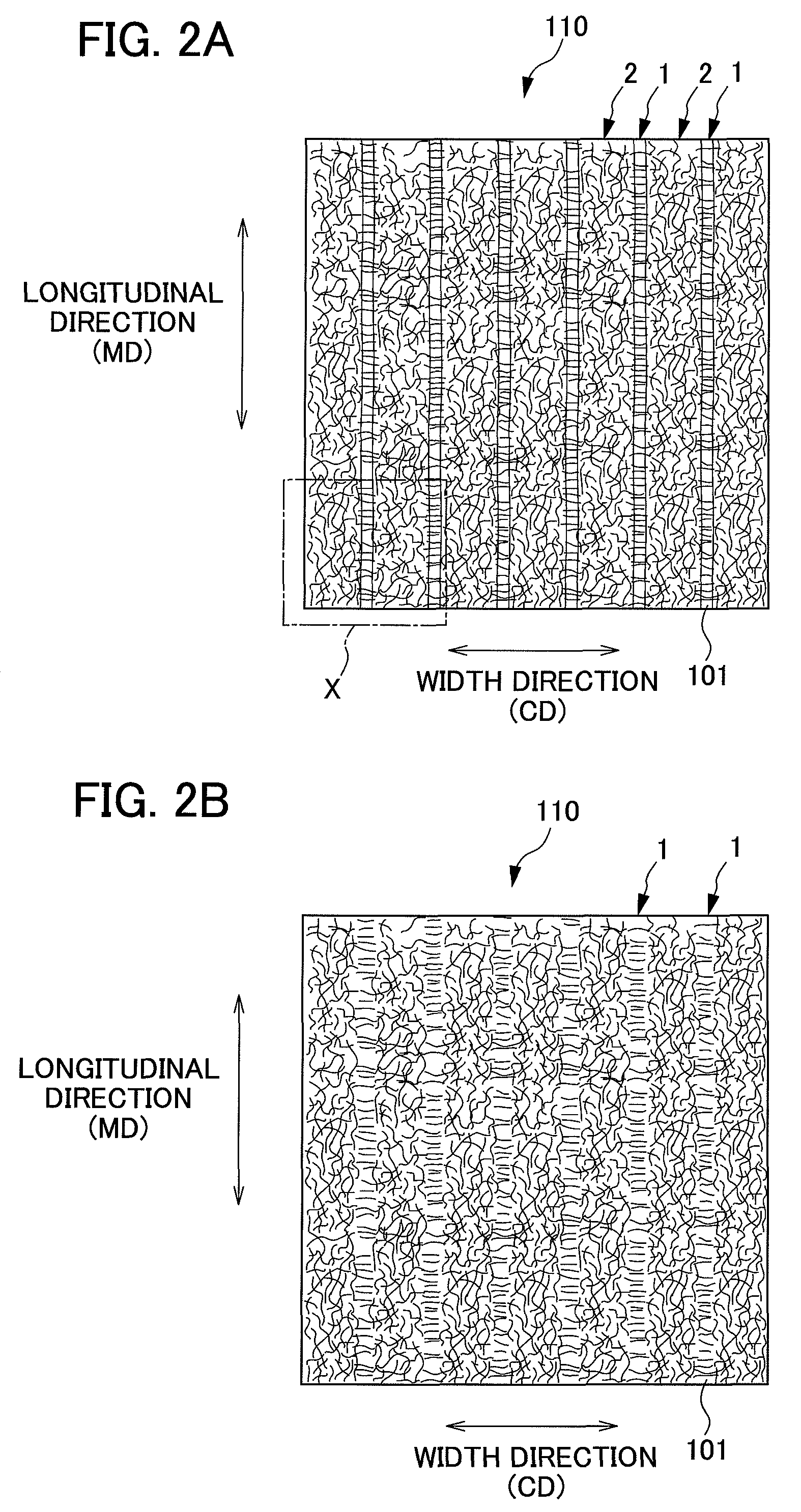

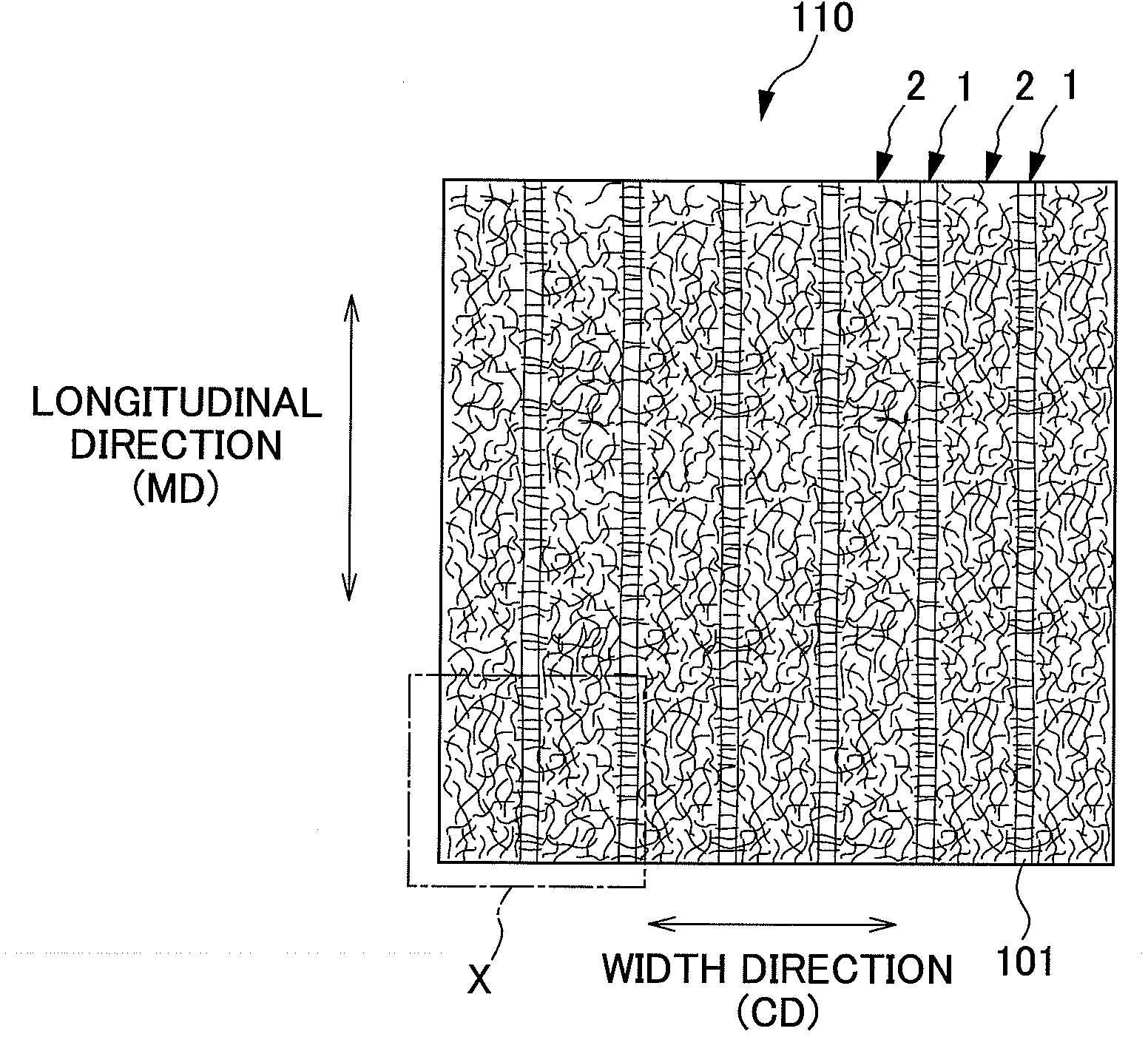

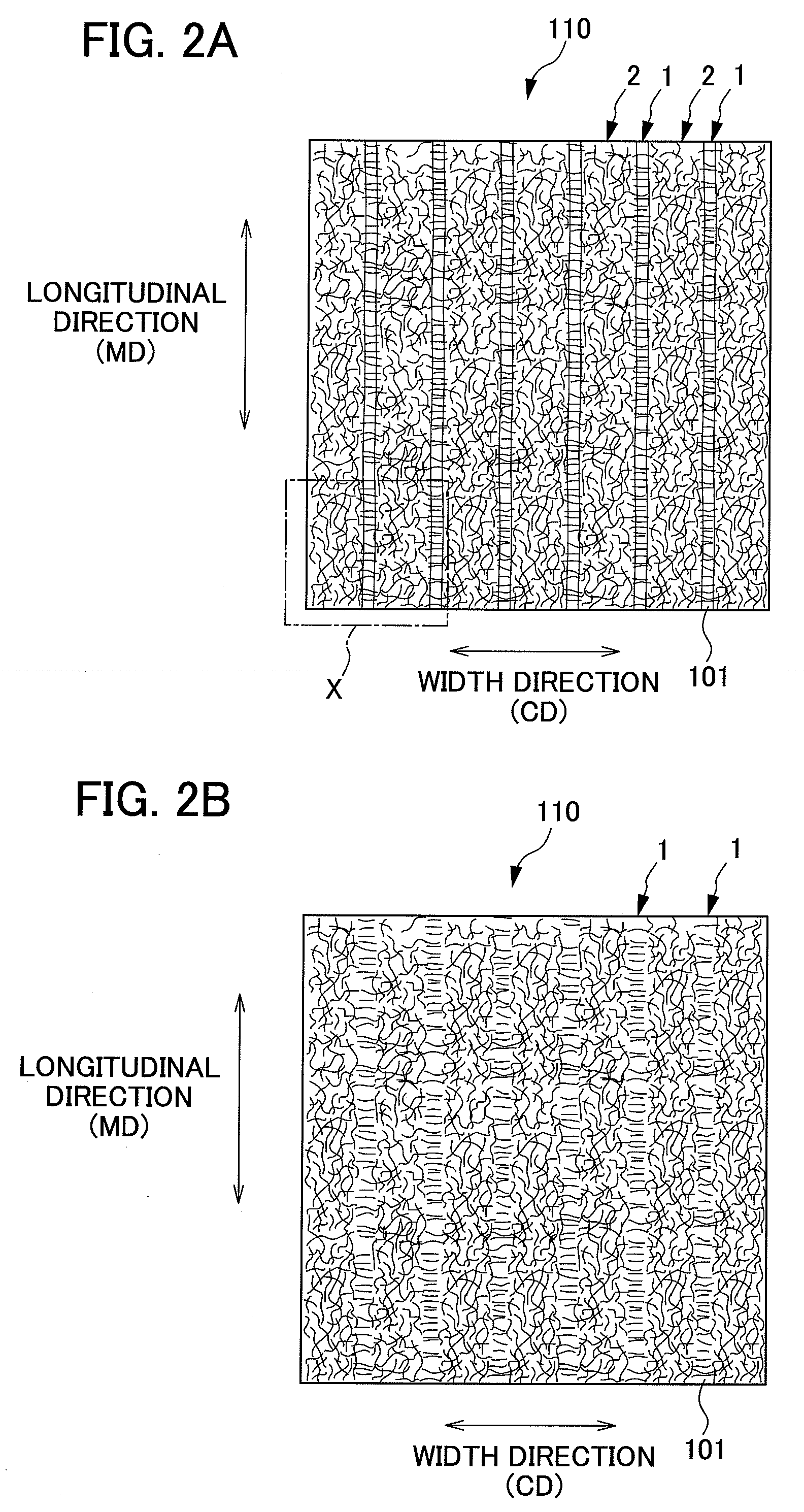

Nonwoven fabric, nonwoven fabric manufacturing method, and nonwoven fabric manufacturing apparatus

The present invention provides a nonwoven fabric of which at least one of fiber orientation, fiber density, and basis weight is adjusted, and in which at least one of a predetermined groove portion, an opening, and a protrusion is formed, a manufacturing method for the nonwoven fabric, and a nonwoven fabric manufacturing apparatus. The nonwoven fabric manufacturing apparatus of the present invention manufactures a nonwoven fabric of which at least one of fiber orientation, fiber density, and basis weight is adjusted, or in which at least one of a predetermined groove portion, an opening, and a protrusion is formed by blowing fluid mainly containing gas onto a fiber web which is formed in a sheet shape, and which is in a state where at least a portion of the fibers constituting the fiber aggregate has a degree of freedom.

Owner:UNI CHARM CORP

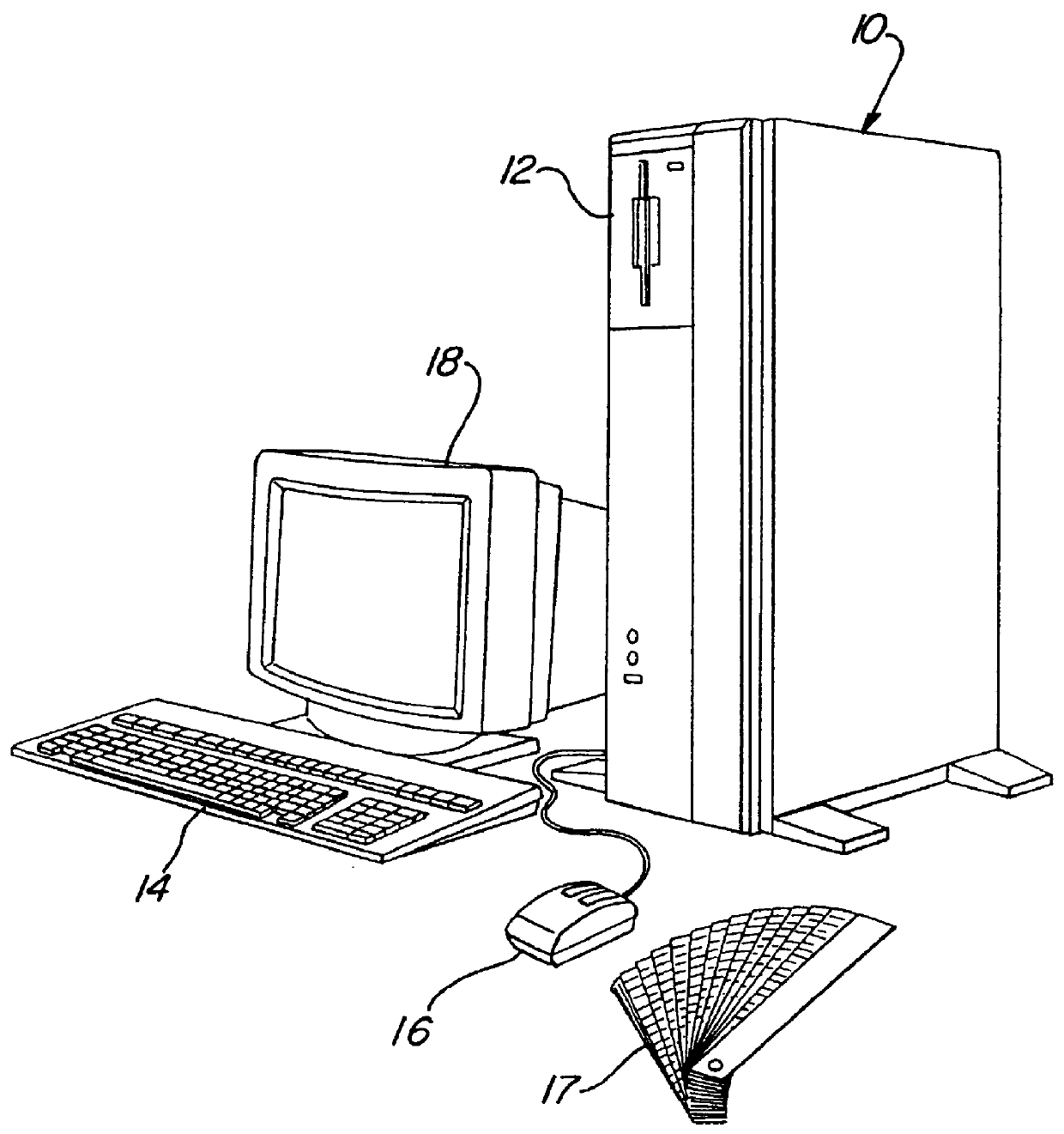

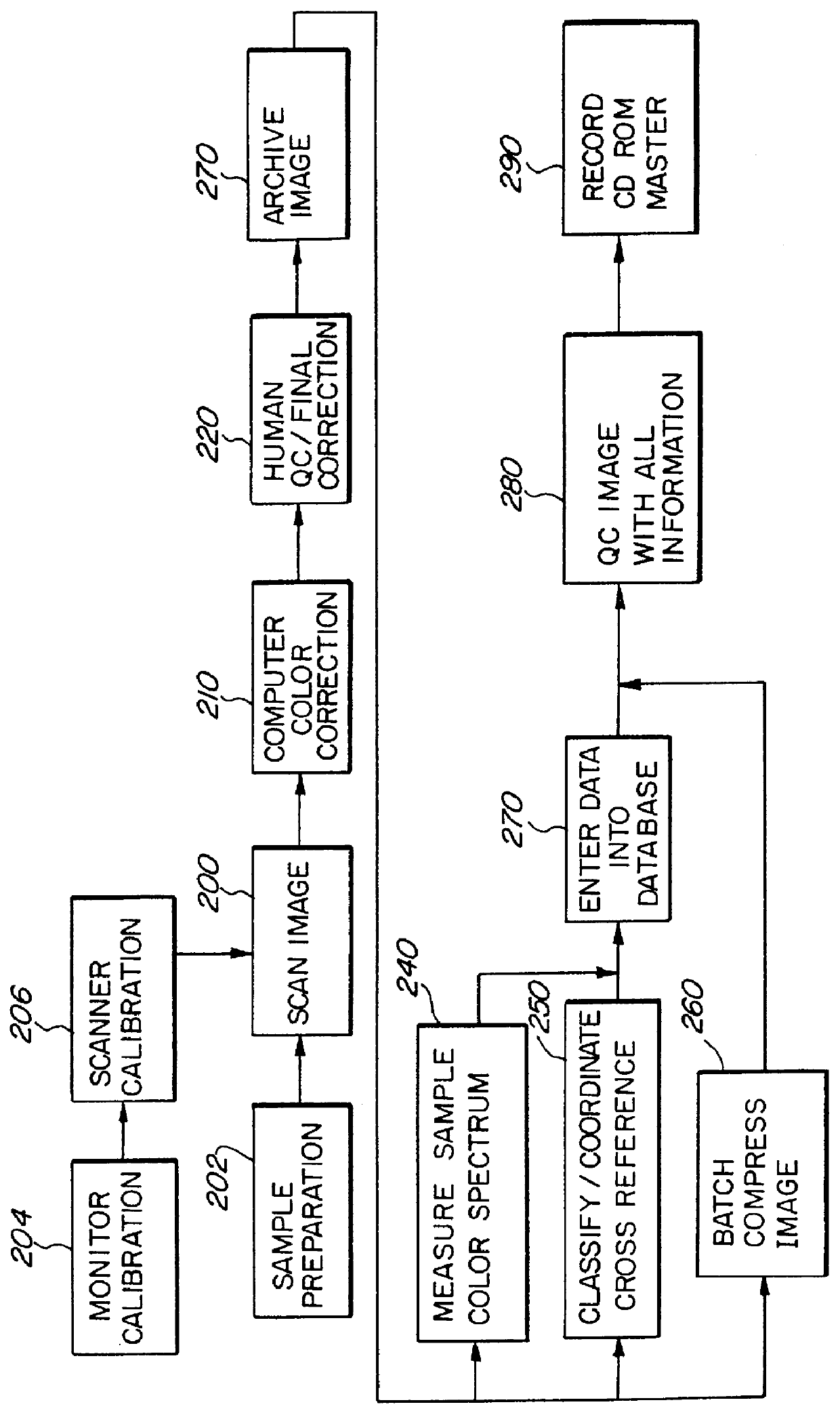

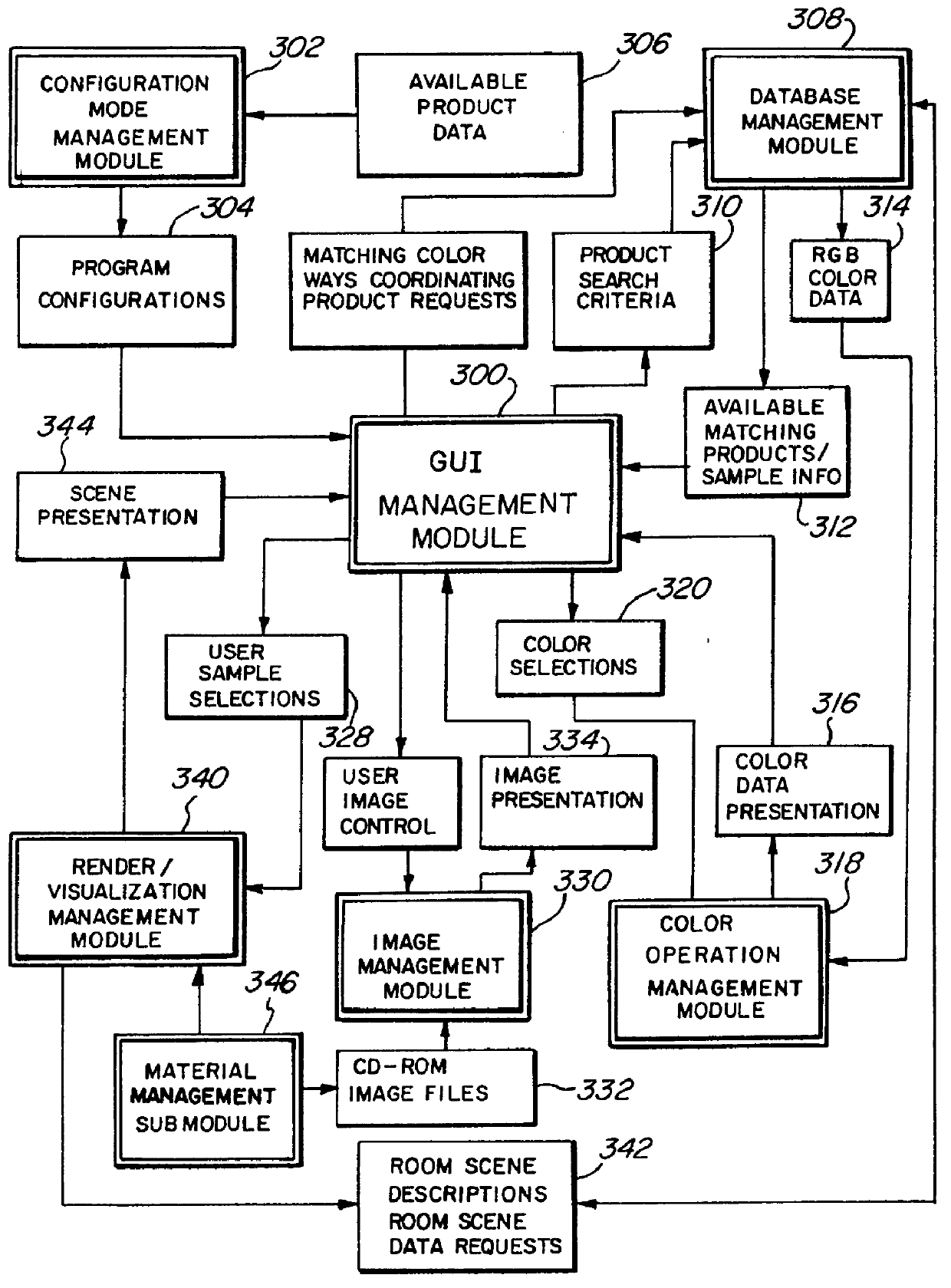

Spectrally coordinated pattern search-imaging system and method

InactiveUS6122391AChoose simpleDigital data information retrievalTexturing/coloringColor imageCD-ROM

A system for selecting decorative materials is based on large numbers of high-resolution, full color images of decorative materials stored in a compressed format on an inexpensive medium such as a CD-ROM. In creating the ROM, each image is coordinated with additional information such as style of pattern, type of material, and other auxiliary information. Before final compression and storage of the image data color information is added by spectrophotometrically analyzing the decorative material. Color values for a background color and up to four foreground colors are determined. Individual colors are then referenced to a comprehensive color standard system containing a large number of standardized color swatches. Spectrophotometric color referencing allows the data records to be rapidly searched on the basis of color, as well as the other information in the record. Wallpaper patterns, drapery material, floor covering, or paint can then be rapidly selected on the basis of matching color. Various patterns and paints can be compared side by side on a high-resolution computer monitor that has been calibrated to produce an accurate color image. Finally, the chosen paints and other decorating materials can be rendered onto a room image so that the consumer can view an accurate simulation of the chosen materials.

Owner:AUTODESK INC

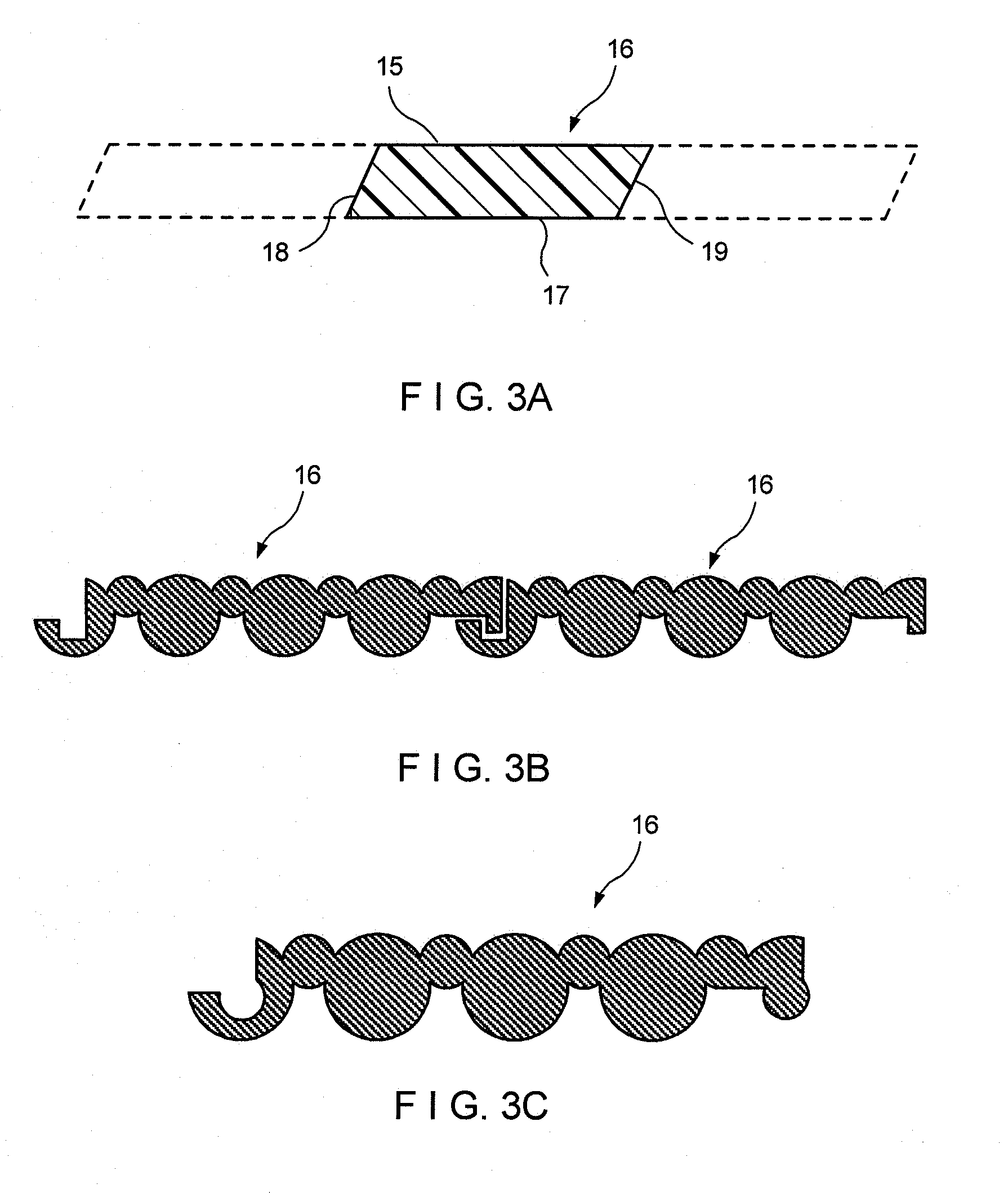

Nonwoven webs made from treated fibers

ActiveUS20080319407A1Superior initial tensile strengthIncrease surface areaPattern makingBaby linensFiberMedicine

The invention relates to a nonwoven web with superior initial tensile strength. The web constructed from at least one type of fiber that has been modified to increase its specific surface area. The fiber has a specific surface area of at least 55 m2 / g. The invention also relates to use of the nonwoven web with superior initial tensile strength for the making of a disposable absorbent article. These include, diapers, training pants, incontinence pants, tampons, female hygiene pads and wipes.

Owner:THE PROCTER & GAMBLE COMPANY

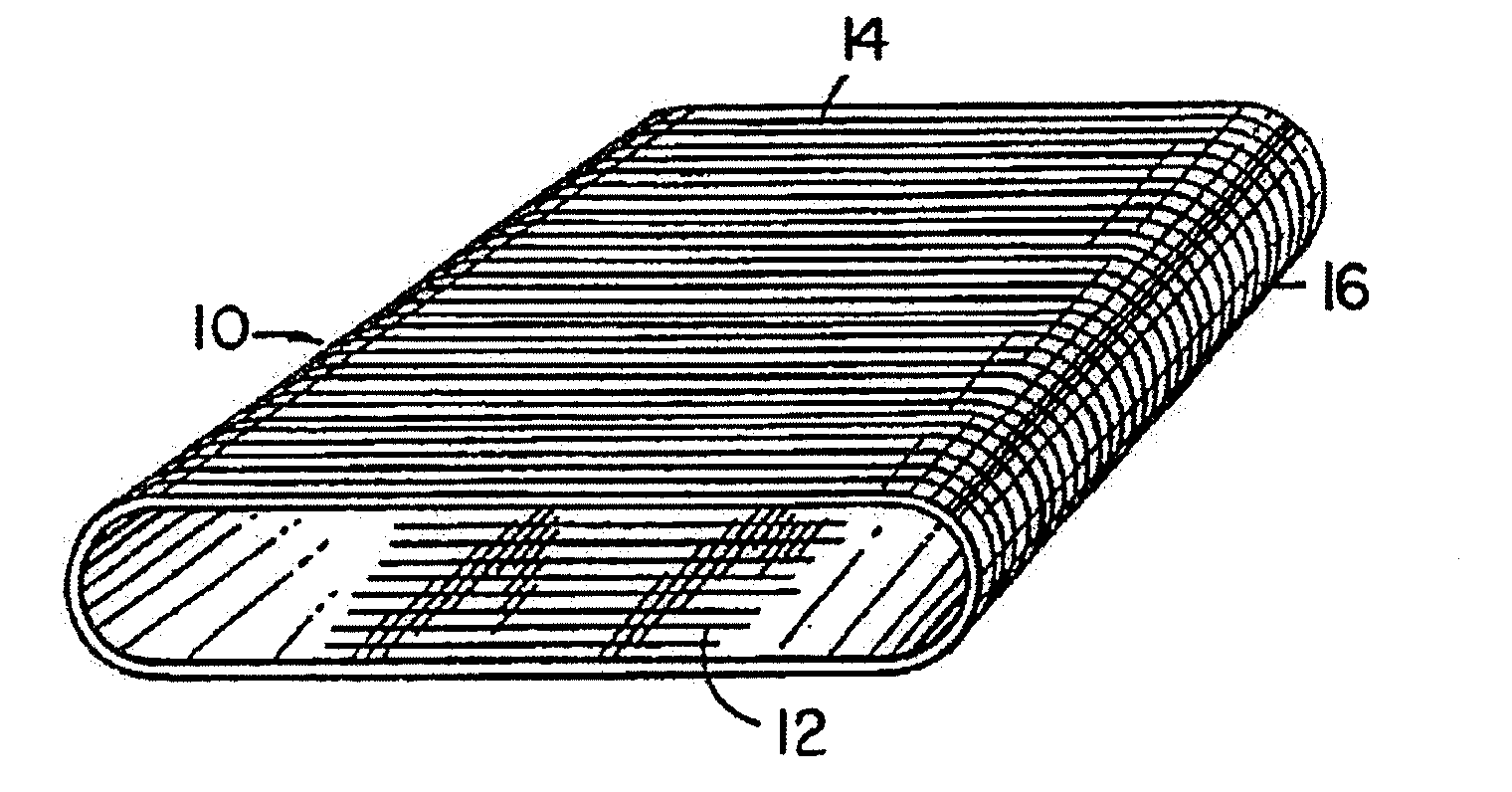

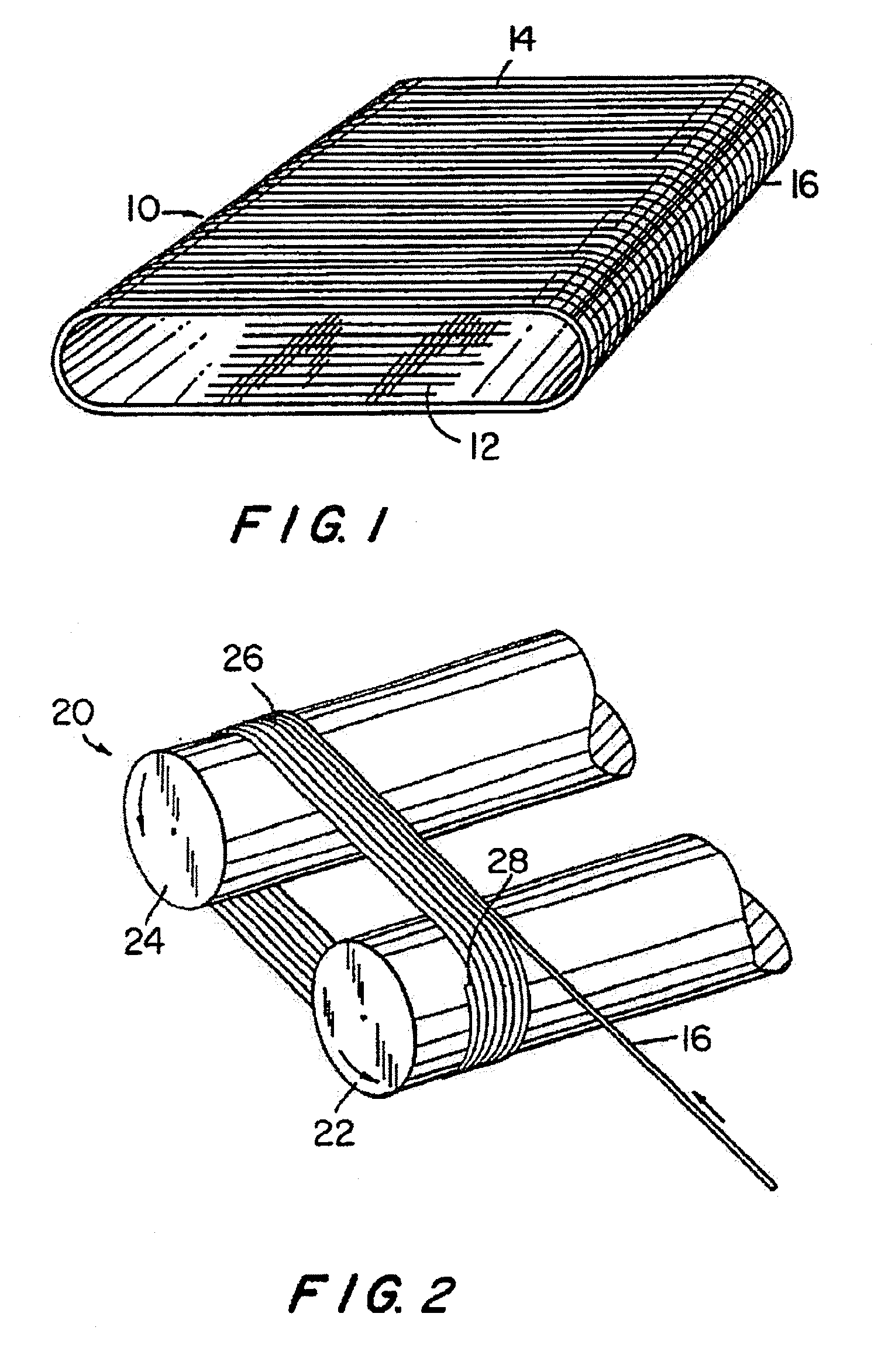

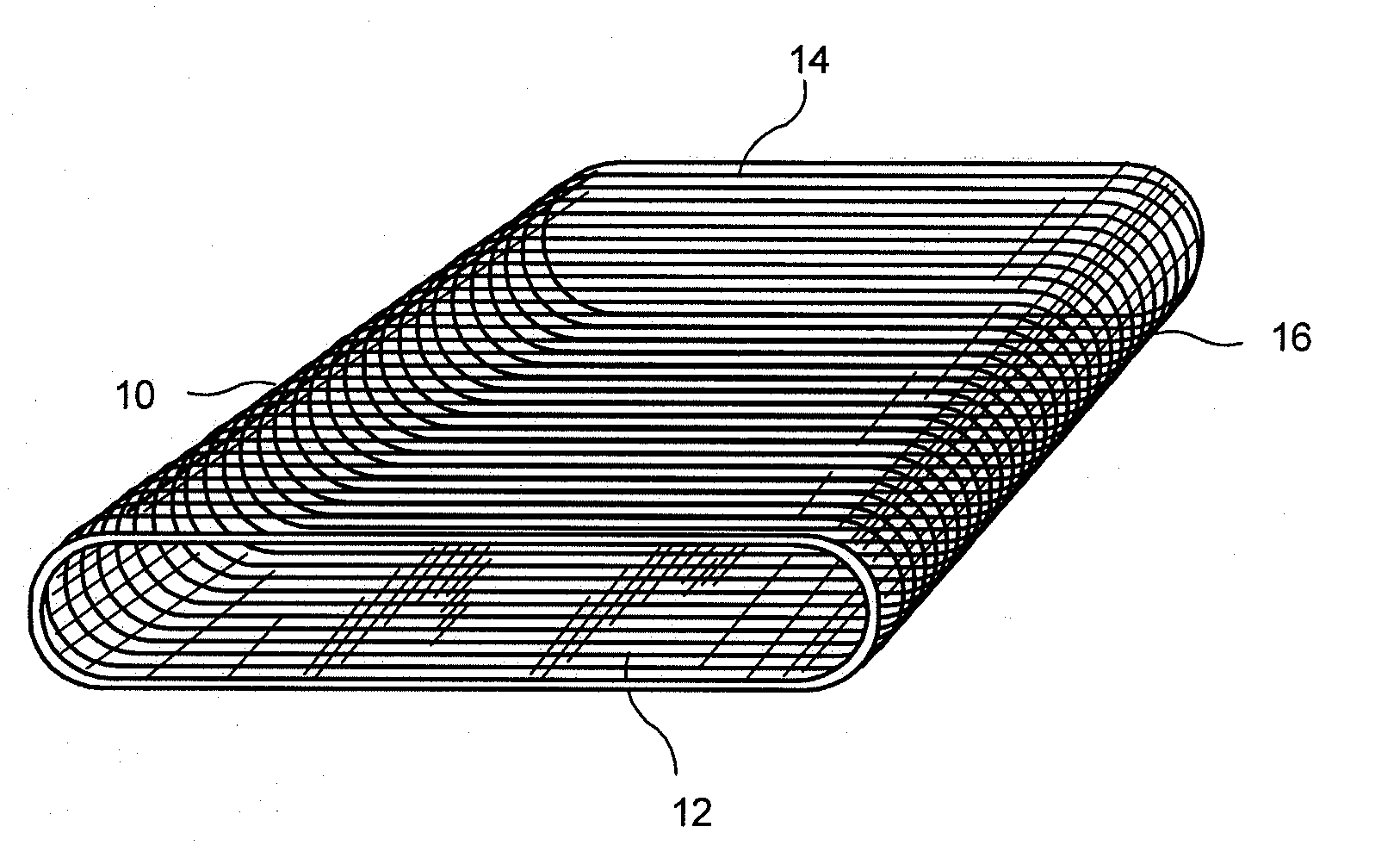

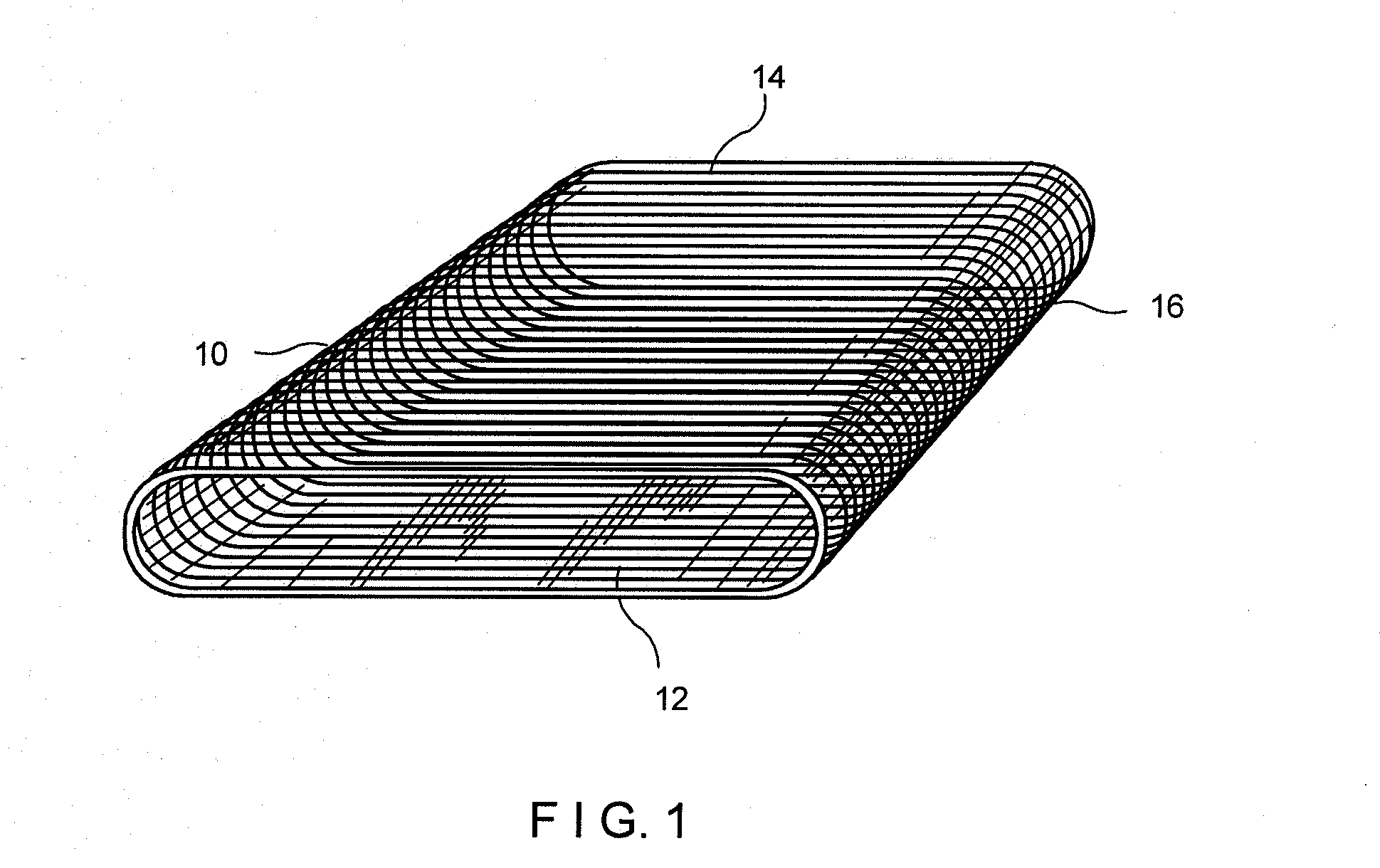

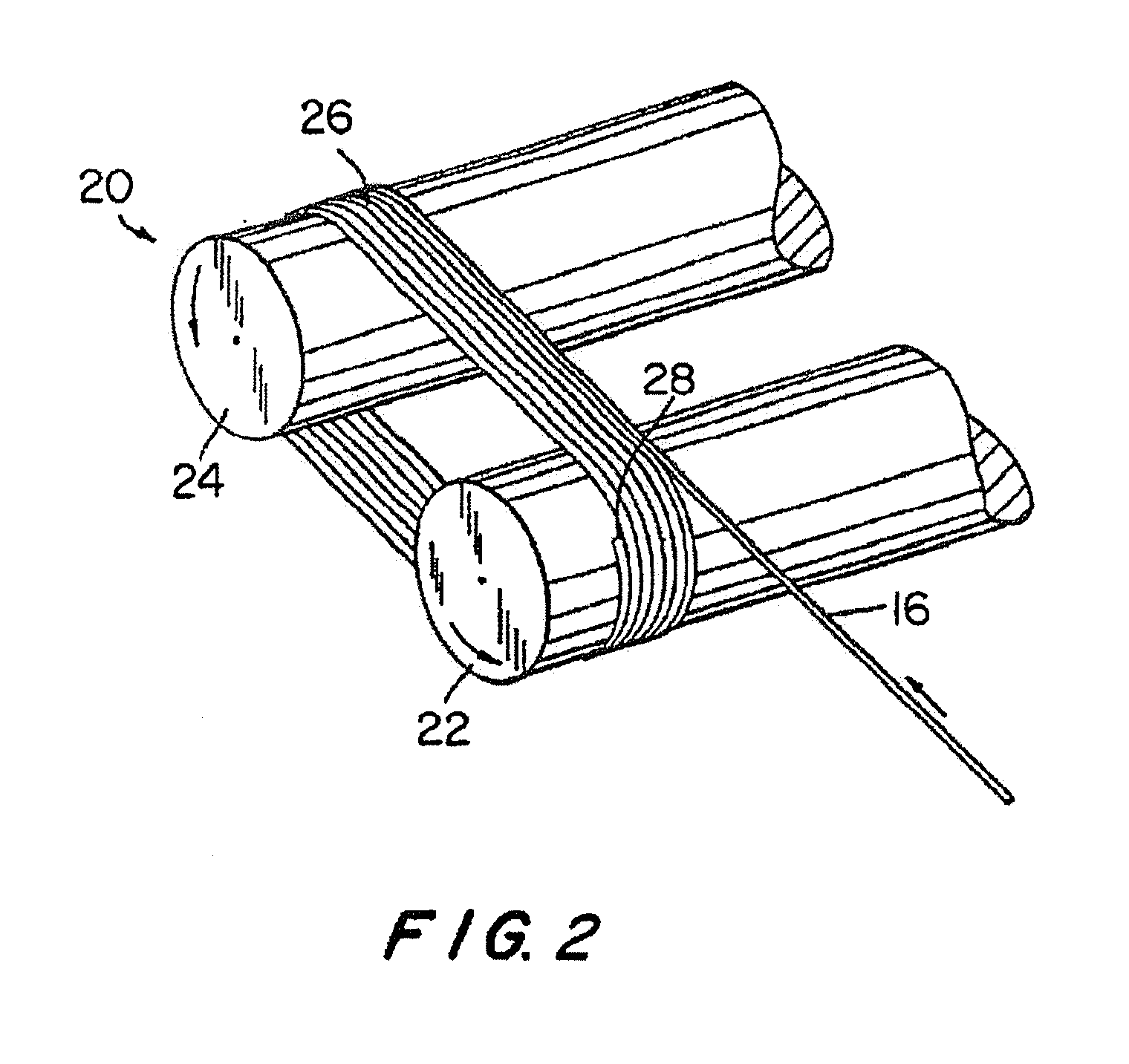

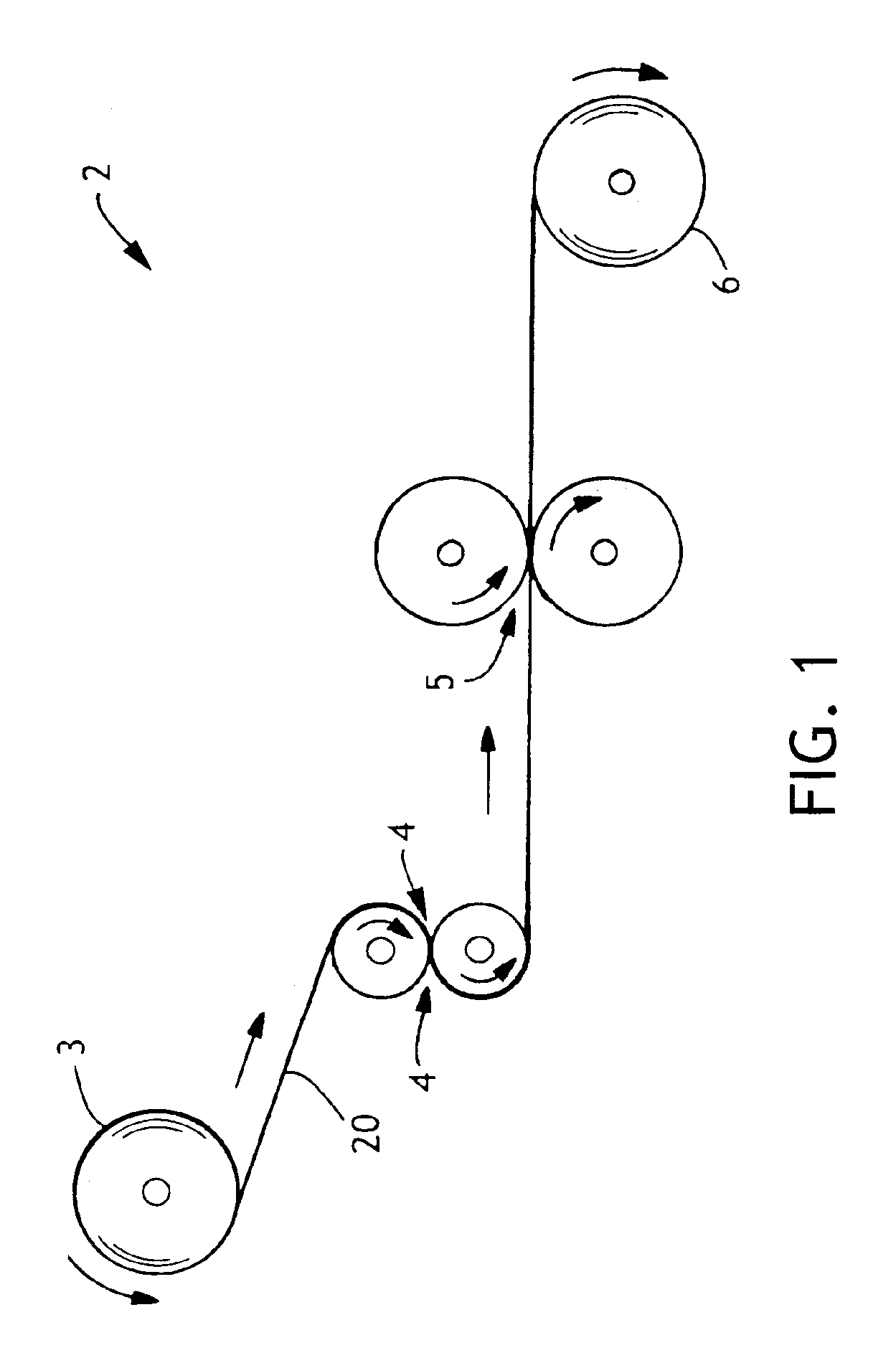

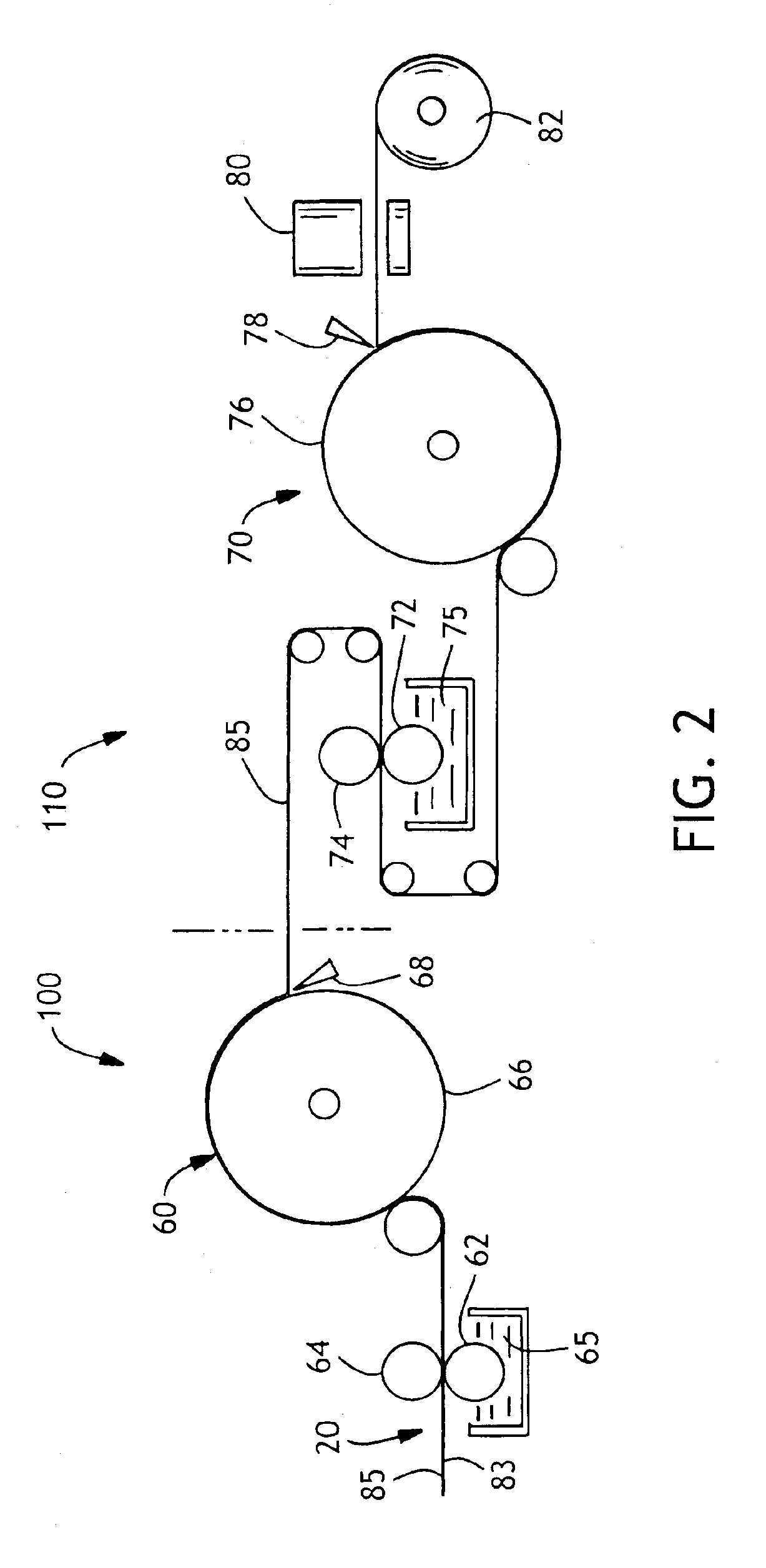

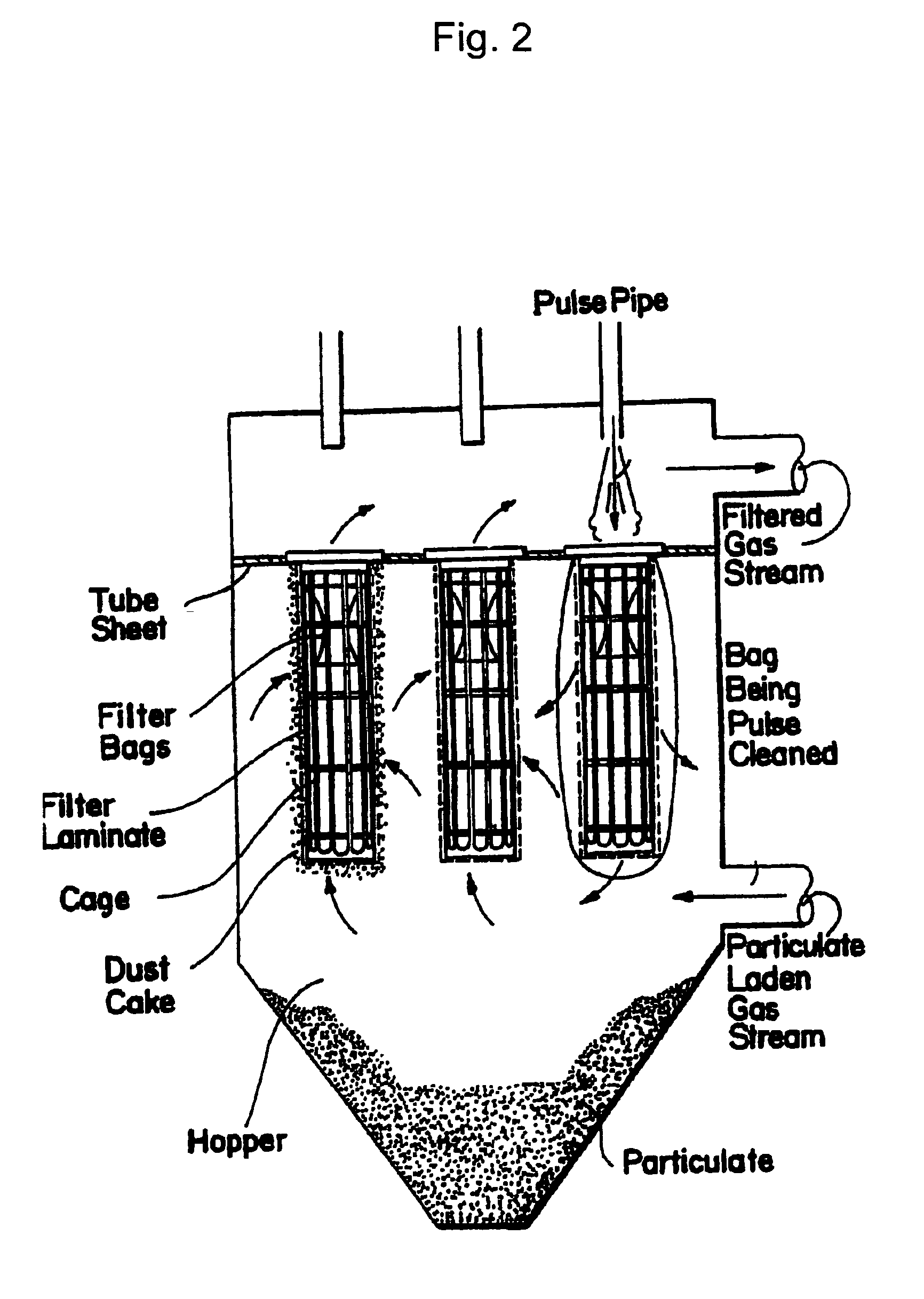

Industrial fabric including spirally wound material strips

ActiveUS20100230064A1Improved fiber supportFacilitated releaseFilament handlingNeedling machinesStrappingUltrasonic welding

An industrial fabric, belt or sleeve and a method of making the fabric, belt or sleeve are disclosed. The industrial fabric, belt or sleeve is produced by spirally winding strips of polymeric material, such as an industrial strapping or ribbon material, and joining the adjoining sides of the strips of material using ultrasonic welding or laser welding techniques. The fabric, belt or sleeve may then be perforated using a suitable technique to make it permeable to air and / or water.

Owner:ALBANY INT CORP

Industrial fabric including spirally wound material strips

ActiveUS20100236034A1Facilitated releaseStable supportNon-fibrous pulp additionNatural cellulose pulp/paperUltrasonic weldingStrapping

An industrial fabric such as an endless belt or sleeve for use in the production of nonwovens, and a method of making thereof are disclosed. The industrial fabric is produced by spirally winding strips of polymeric material, such as an industrial strapping or ribbon material, and joining the adjoining sides of the strips of material using ultrasonic welding or laser welding techniques. The fabric may then be perforated using a suitable technique to make it permeable to air and / or water.

Owner:ALBANY INT CORP

Leather-like sheet and production process thereof

InactiveUS20110045231A1Excellent in soft handExcellent in appearance durabilityLayered productsFibre treatmentNonwoven fabricWear resistance

This invention provides a leather-like sheet excellent in hand softness and appearance durability, as a composite sheet consisting of a nonwoven fabric composed of ultrafine long fibers in which ultrafine fibers with a fiber fineness of 0.0001 to 0.5 dtex are entangled with each other, and a woven or knitted fabric, characterized in that at least some of the aforementioned ultrafine fibers pass through the woven or knitted fabric, that the appearance is grade 3 or higher while the abrasion loss is 10 mg or less in the evaluation of abrasion resistance, and that the sheet is substantially composed of only a fiber material of a non-elastic polymer.

Owner:TORAY IND INC

Imaged nonwoven fabric for cleaning applications

The present invention is directed to enhancing the cleaning of surfaces by the contact application of a non-apertured nonwoven fabric having a three-dimensional image imparted therein. The three-dimensional image of the non-apertured nonwoven fabric induces the formation of lather due to pronounced surface projections that come in contact with the cleaning surface and provide air passageways that are parallel to the plane of the substrate. The imaged nonwoven fabric disclosed herein exhibits low linting qualities thereby reducing the potential of fiber contamination of the cleaned surface and is sufficiently durable that the sample can be used in a brisk manner.

Owner:POLYMER GROUP INC

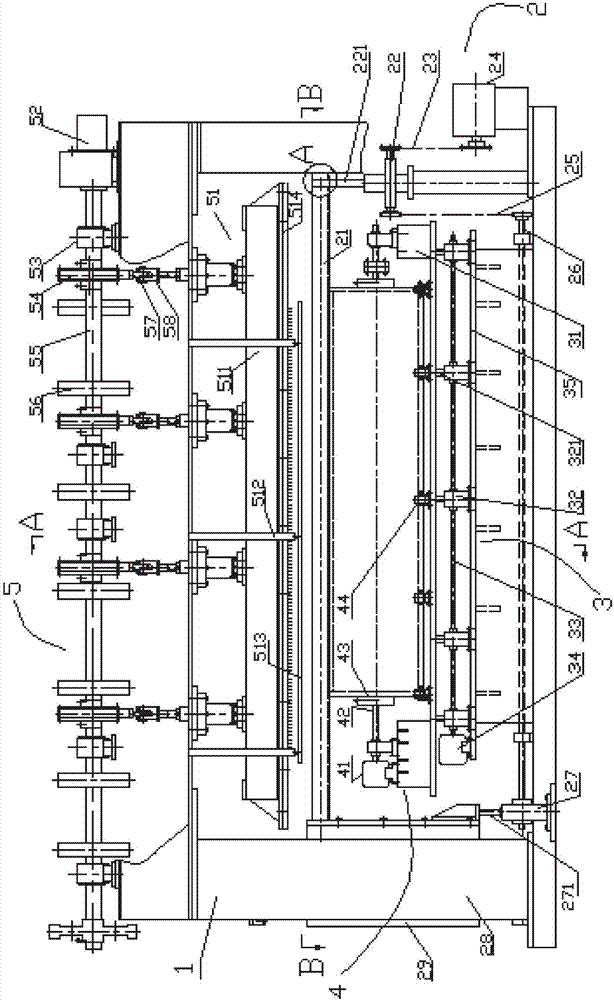

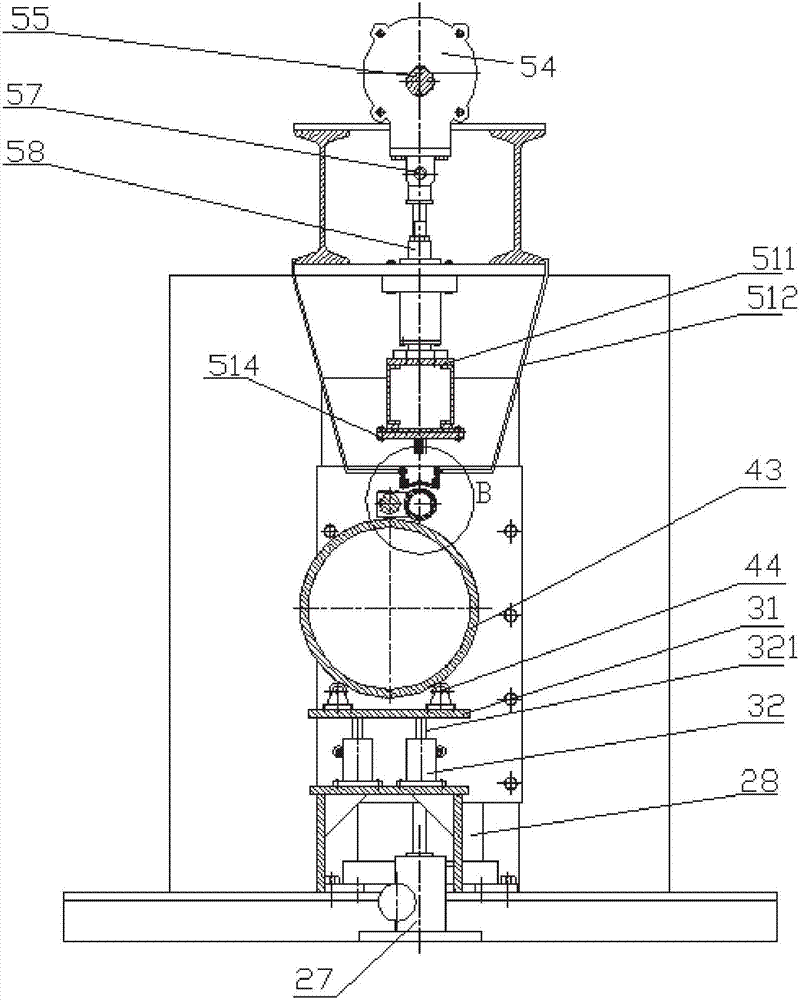

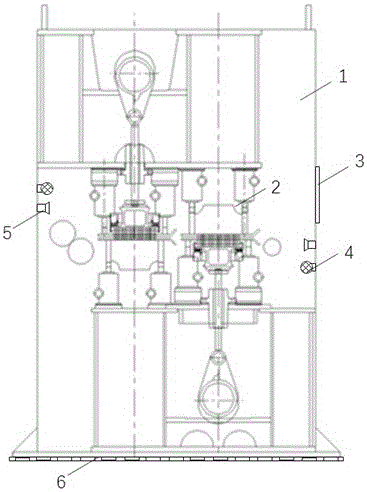

Small diameter felt cover needling machine

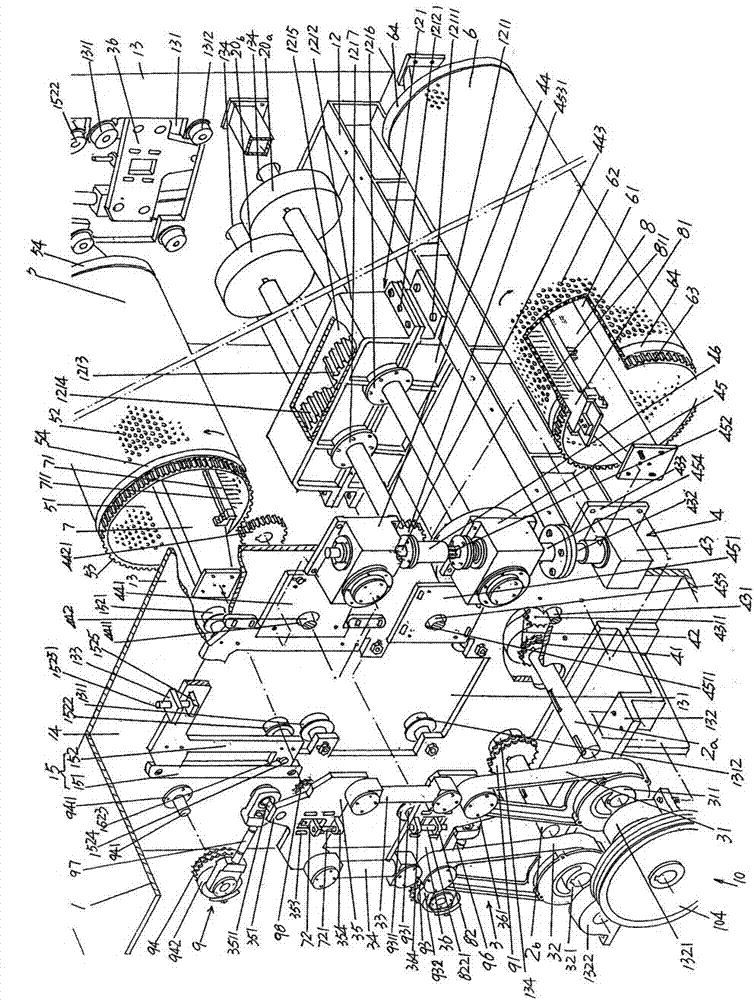

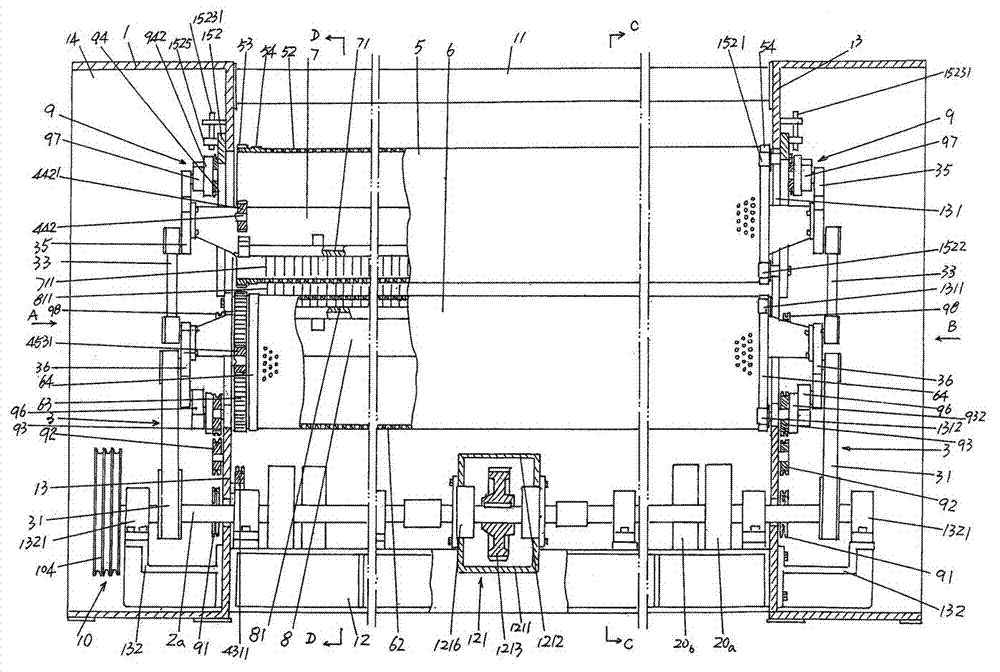

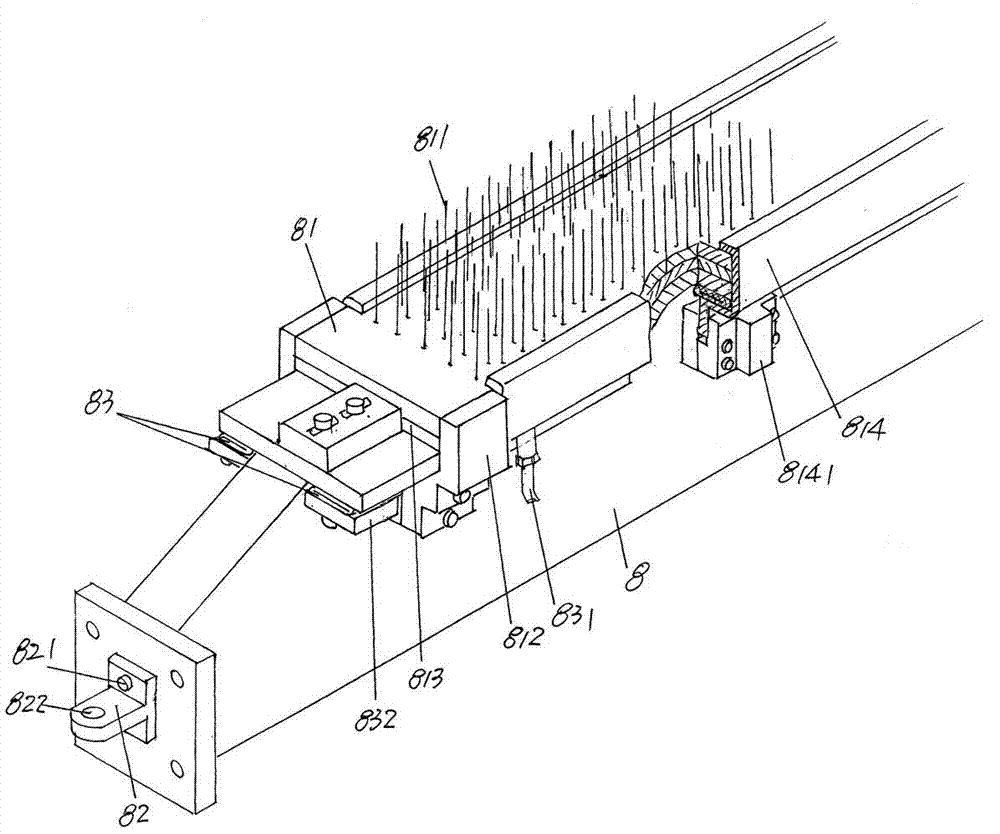

InactiveCN106988023AQuality improvementSimple mechanical structureNeedling machinesMechanical engineering

The invention relates to a small diameter felt cover needling machine. The small diameter felt cover needling machine comprises a rack, an assembly and disassembly part, a platform support part, a carrier roller support part and a needling part, the assembly and disassembly part, the platform support part, the carrier roller support part and the needling part are all arranged on the rack, the assembly and disassembly part completes assembly and disassembly of a felt cover product, the needling part completes needling motion, the platform support part is mainly used for achieving support for parts like a drum and motion of a support platform, and the carrier roller support part completes support for a carrier roller. According to the small diameter felt cover needling machine, a felt cover with good quality and a small size can be produced, and the technical problem in the prior art is solved that a common needling machine cannot produce the felt cover with the good quality and the small size.

Owner:SHANGHAI INST OF TECH

Method and device for producing a composite nonwoven for receiving and storing liquids

Known methods involve applying a layer of particularly highly absorbent fibers such as woodpulp on a carrier nonwoven and then compacting the composite nonwoven with the aid of water entanglement. One disadvantage of the compacting method is the high woodpulp fiber loss and the associated purification of the circulating water for the entanglement device. According to the invention, a fine layer of microfibers is initially applied before applying the woodpulp fibers. The microfibers are evenly distributed on the carrier nonwoven using, for instance, a meltblown process and the woodpulp fibers are only then applied in the separating layer. The water during entanglement can no longer merge the woodpulp fibers into the carrier nonwoven due to the fact that the microfibers act as a barrier.

Owner:FLEISSENER GMBH & CO MASCHFAB & ALBIS SPA +1

Entangled fabric wipers for oil and grease absorbency

InactiveUS7022201B2Enhance certain characteristicNon-fibrous pulp additionNatural cellulose pulp/paperCelluloseFiber

A composite fabric comprising a necked and creped spunbond nonwoven web of monocomponent fibers hydraulically entangled with a fibrous component that comprises cellulosic fibers. The nonwoven web contains thermoplastic fibers and the fibrous component comprises greater than about 50% by weight of the fabric.

Owner:KIMBERLY-CLARK WORLDWIDE INC

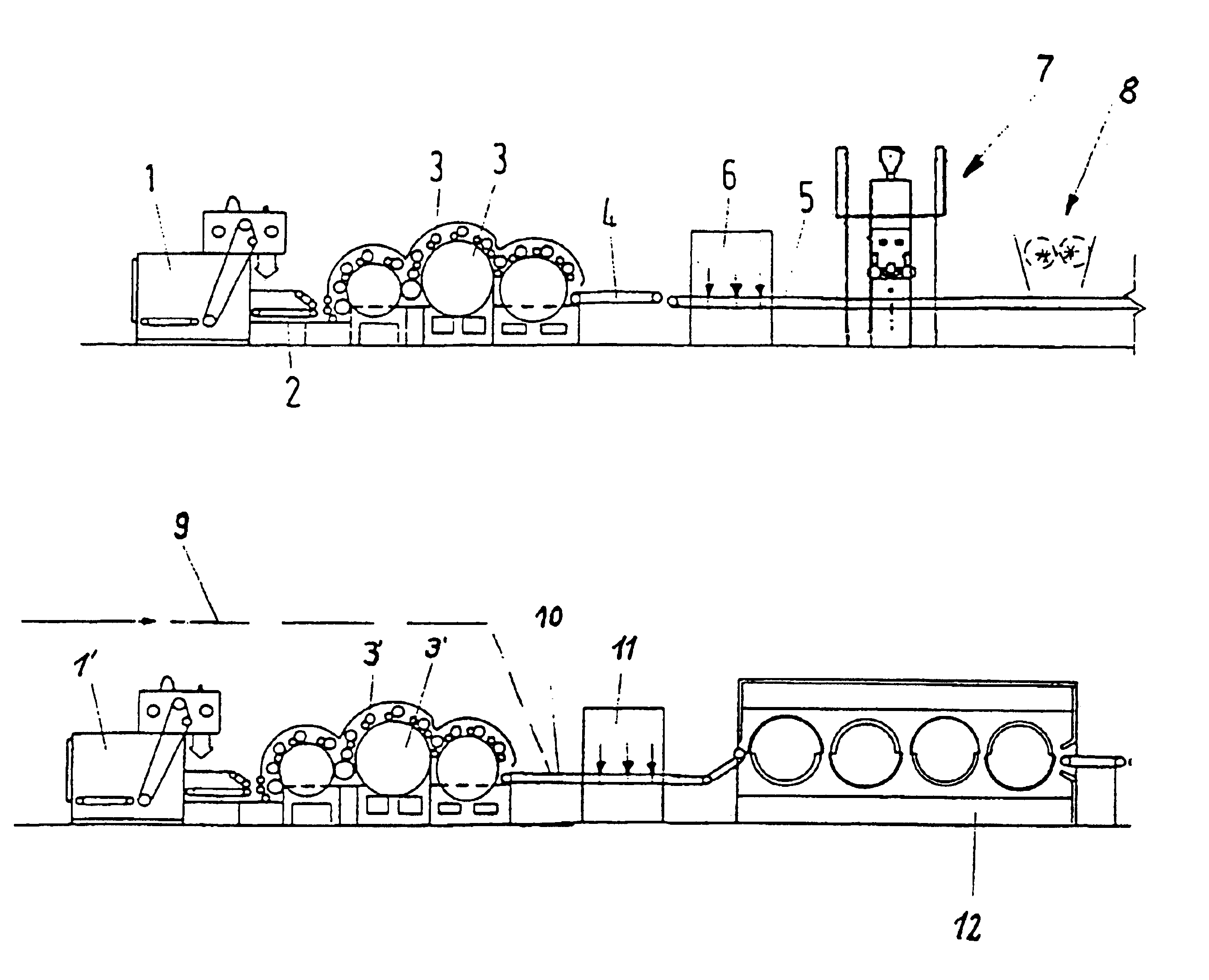

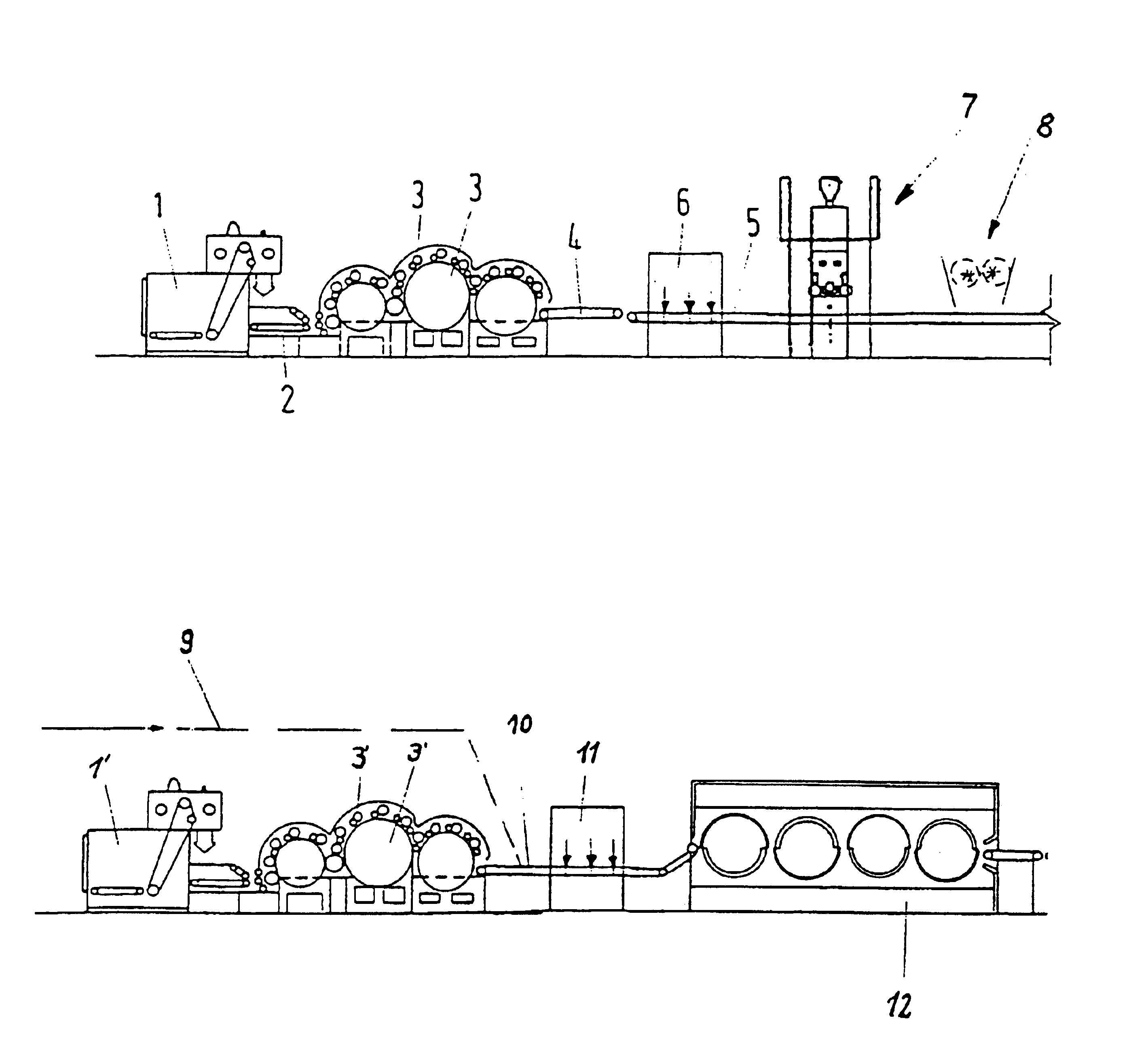

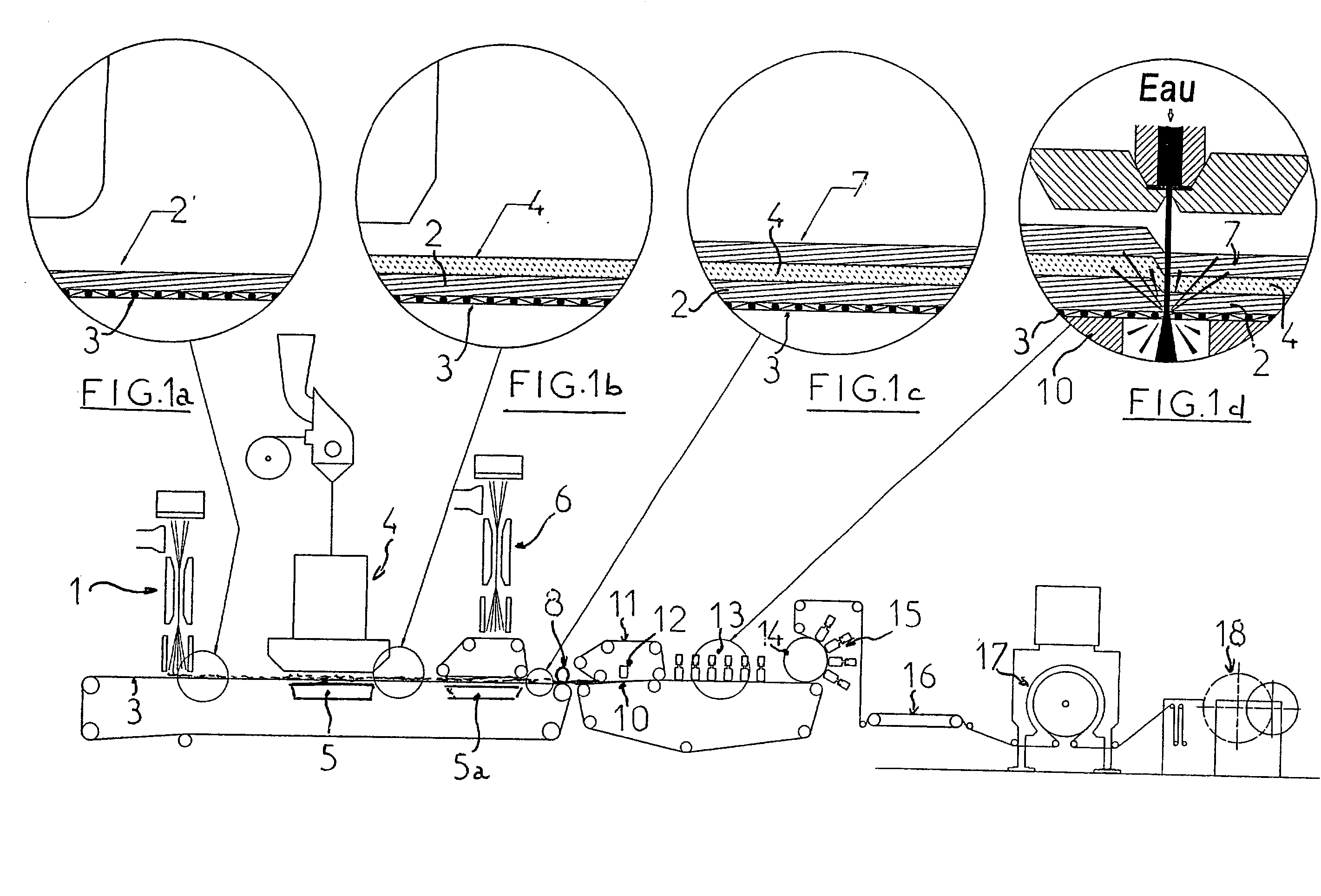

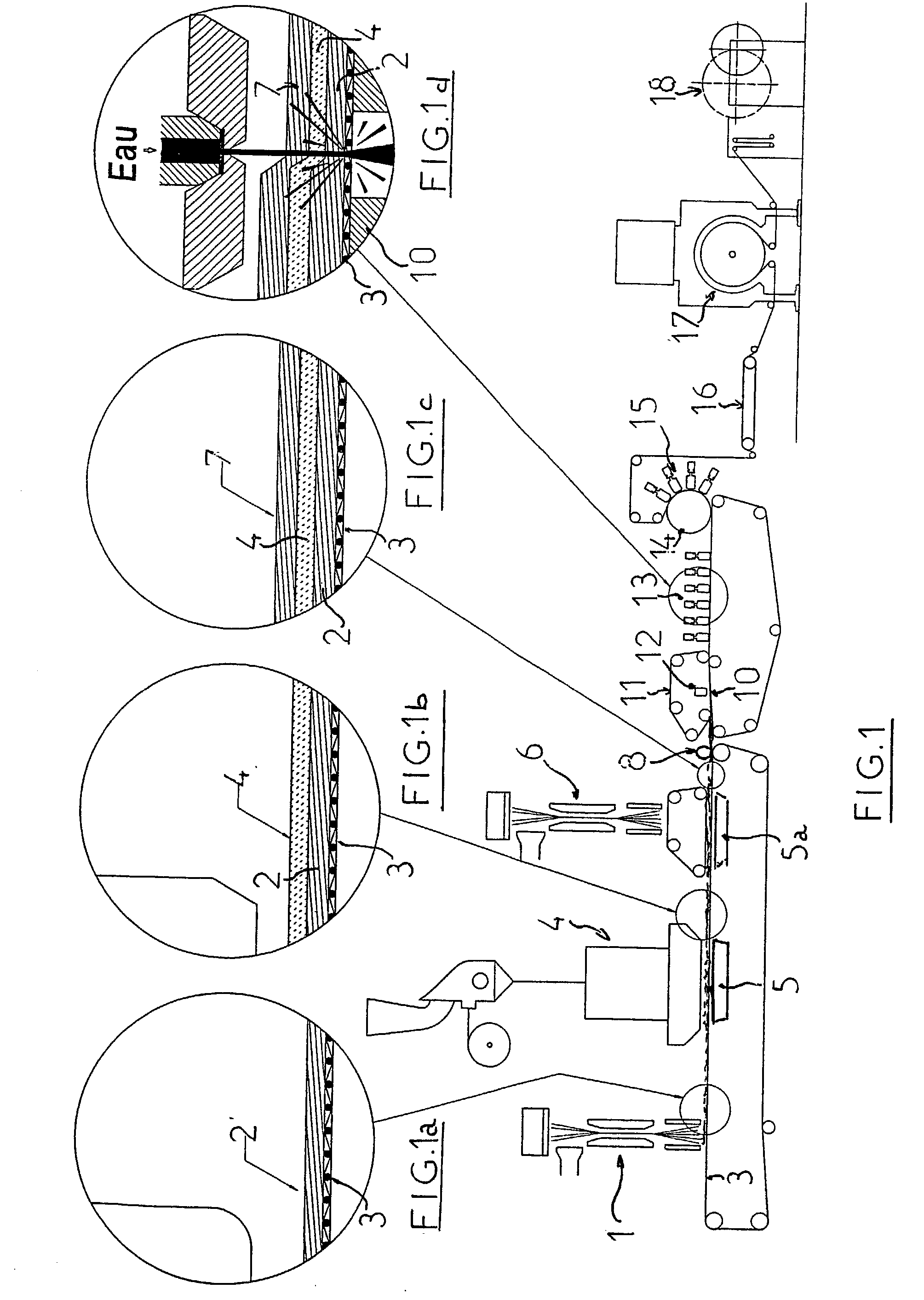

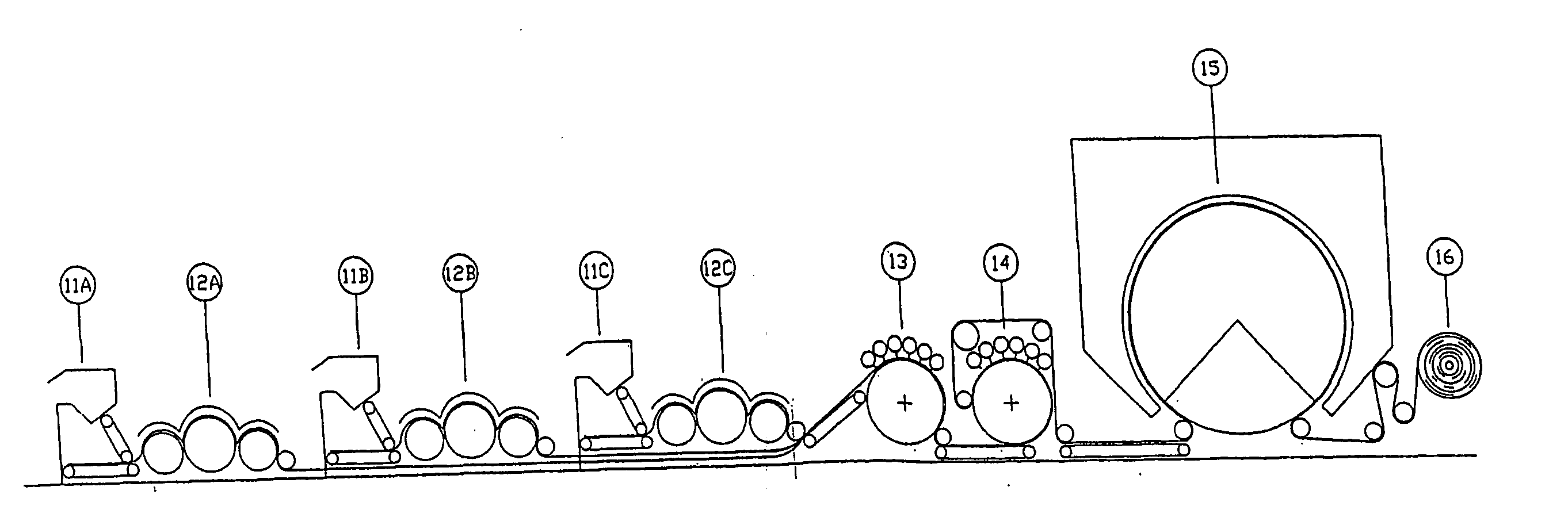

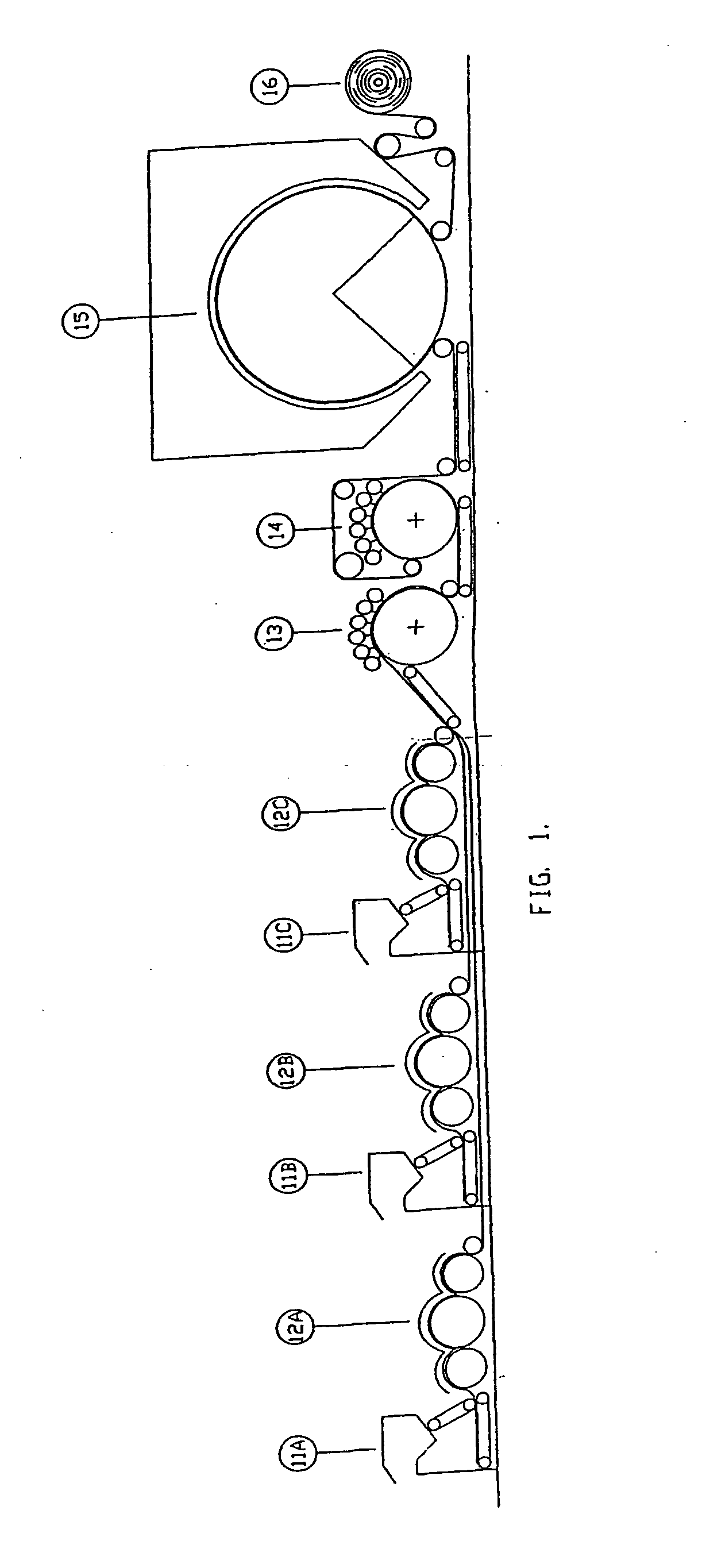

Method for producing a complex nonwoven fabric and resulting novel fabric

The invention concerns a method for producing a complex nonwoven fabric which consists in continuously producing a complex wherein a first web of a cellulosic fibres (4) is continuously sandwiched between two webs of spunbonded filaments (2, 7), and which consists in: producing a first web of spunbonded filaments (2), the bundle of extruded and drawn filaments being received on a mobile conveyor belt (3) in the form of a non-bonded lap; depositing on said web 92) by airlaid process a second web of cellulosic fibres (4); depositing on the textile web (4) a second web (7) of non-bonded continuous filaments; transferring the resulting complex onto an installation (9) for water-jet bonding and hydro-entanglement consolidation; and in drying the nonwoven mixed product and then recuperating it, for example in the form of a cloth wind-up (18).

Owner:PERFOJET RIETER +1

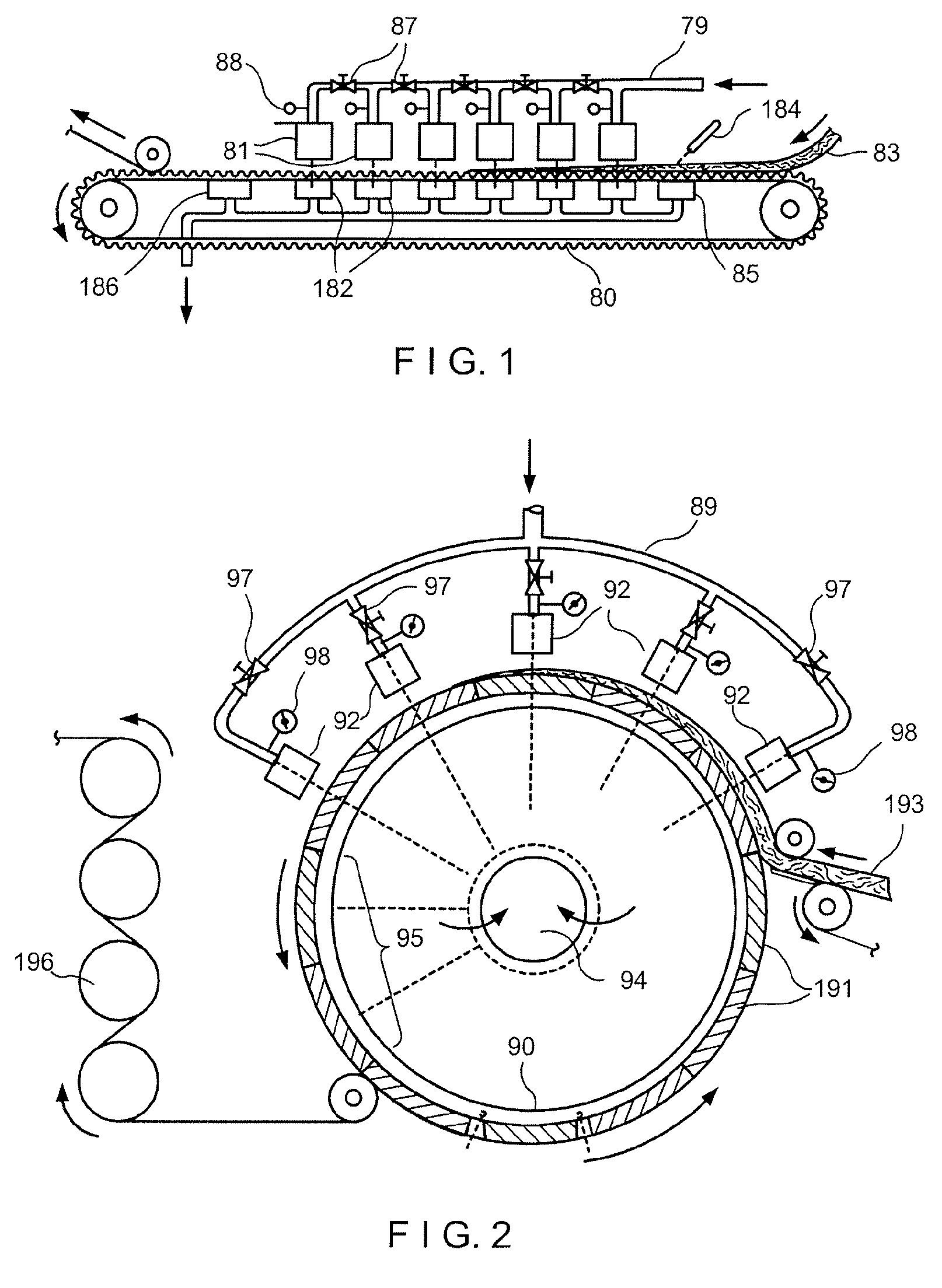

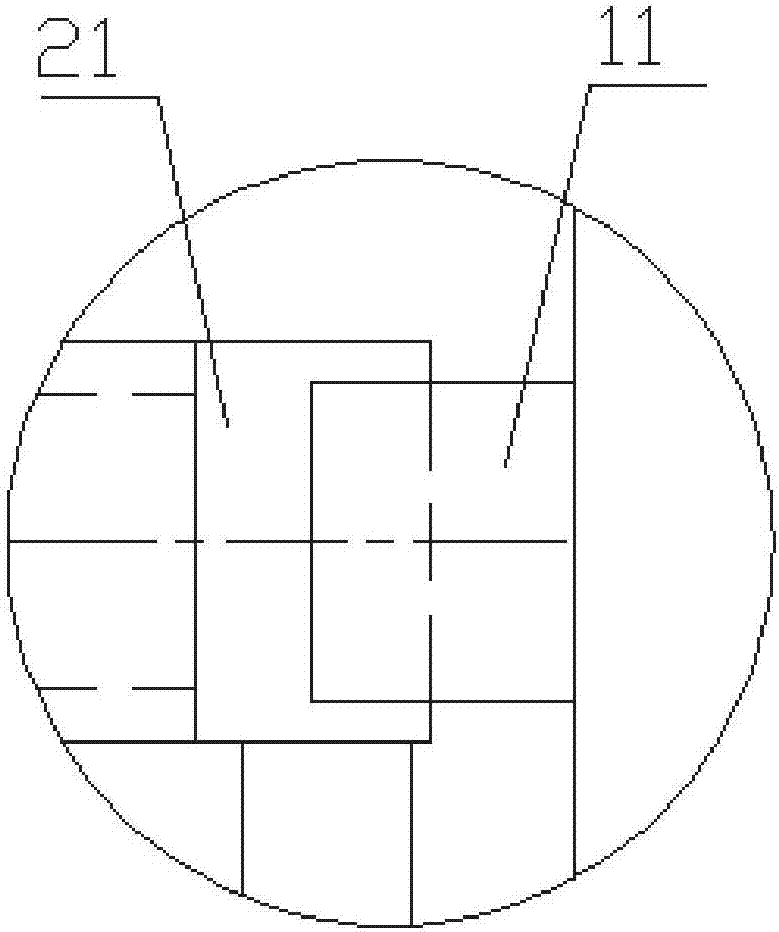

Roller type needling machine

ActiveCN102808290BSaving zero draftGuaranteed zero draftNeedling machinesNeedle penetrationWall plate

A drum-type needling machine belongs to the field of non-woven machinery. It includes a pair of chassis, a needle beam is set on the chassis wallboard of the pair of chassis to penetrate into the relief cavity, and a transmission box is arranged in the middle of the lower cross frame of the chassis; the first and second main shafts are supported between the pair of chassis; a pair of Connecting rod mechanism; roller driving mechanism, connected with the first main shaft; upper roller and lower roller, supported between a pair of chassis, cooperate with the roller driving mechanism; upper needle beam and lower needle beam, fixed on the middle part of the upper needle beam Needle board, the upper needle board is arranged with upper needles, the lower needle board is fixed in the middle of the lower needle beam, and the lower needle board is arranged with lower needles; a pair of connecting rod swing traction mechanisms are arranged in the chamber of a pair of chassis, It is connected with the link mechanism in the box cavity and is also connected with the second main shaft in transmission; the power transmission mechanism arranged on the case is connected with the first main shaft in transmission. Advantages: It helps to improve production efficiency, shorten the process flow, save energy consumed by needle looms; improve the grade of non-woven products.

Owner:CHANGSHU FEILONG NON WOVEN MACHINERY

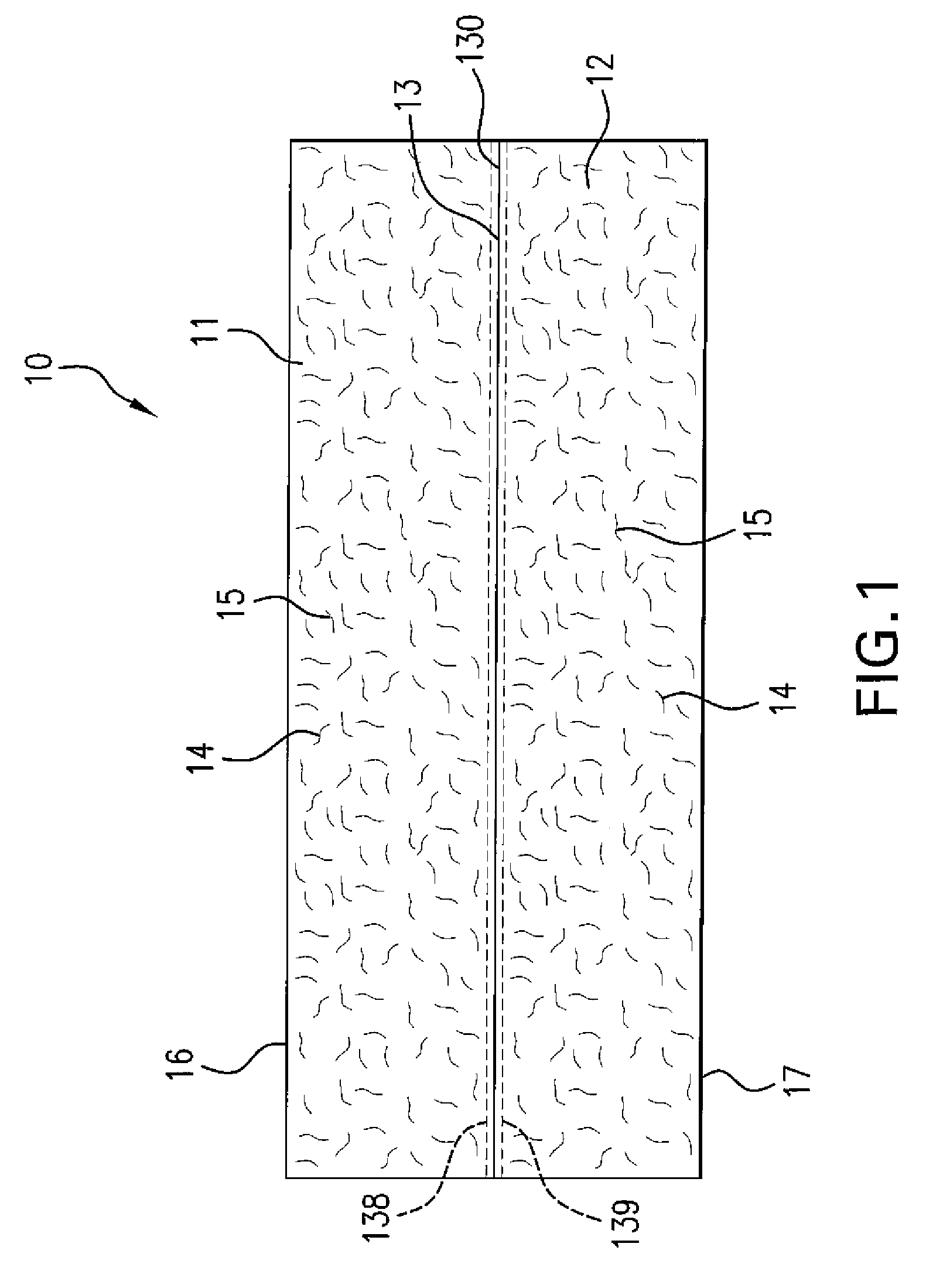

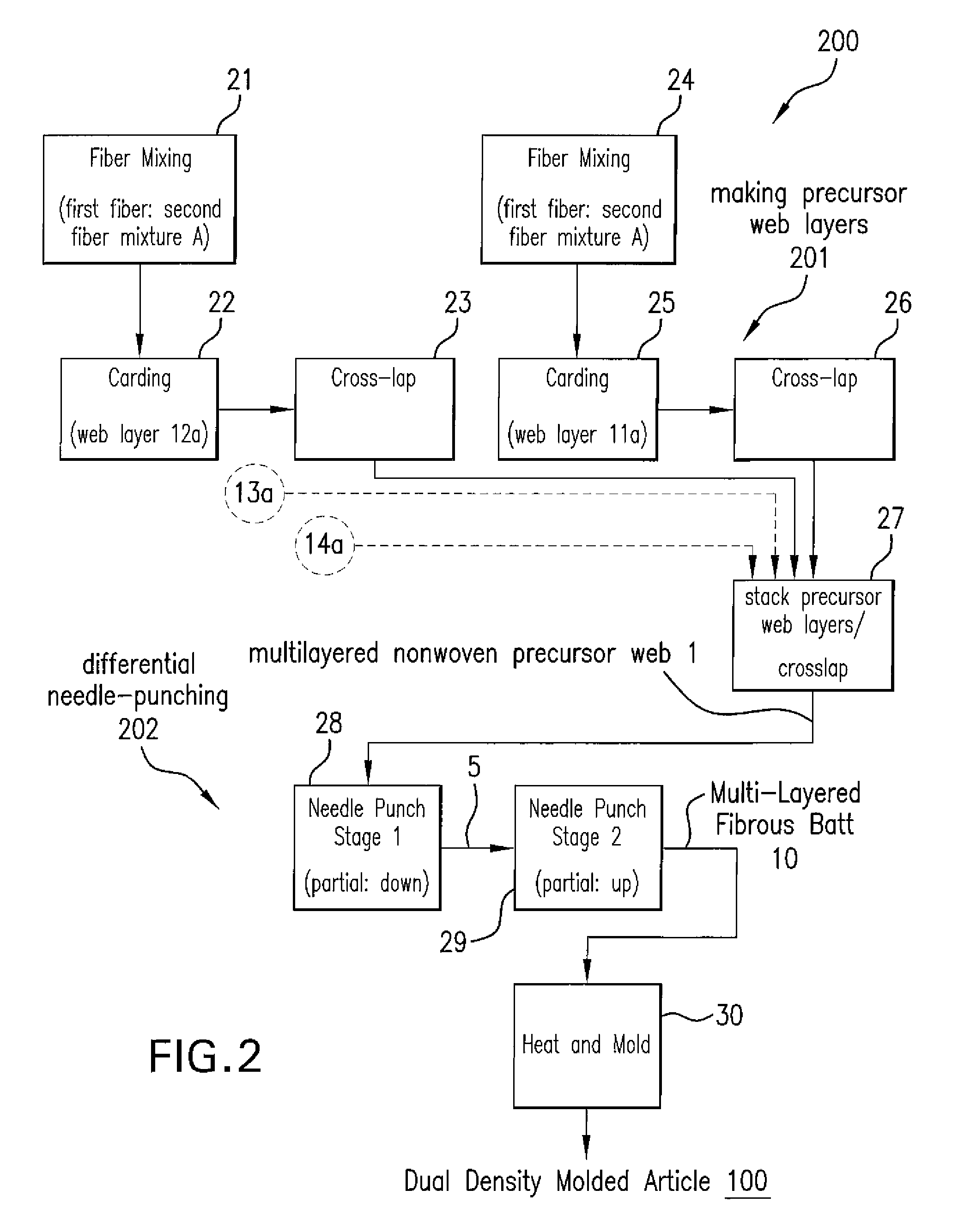

Nonwoven multilayered fibrous batts and multi-density molded articles made with same and processes of making thereof

InactiveUS7928025B2Reduce complexityLow costSynthetic resin layered productsNeedling machinesFiberNeedle penetration

Owner:AVINTIV SPECIALTY MATERIALS INC +1

Entangled fabrics containing staple fibers

InactiveUS6958103B2Enhance certain characteristicNon-fibrous pulp additionNatural cellulose pulp/paperFiberEngineering

Owner:KIMBERLY-CLARK WORLDWIDE INC

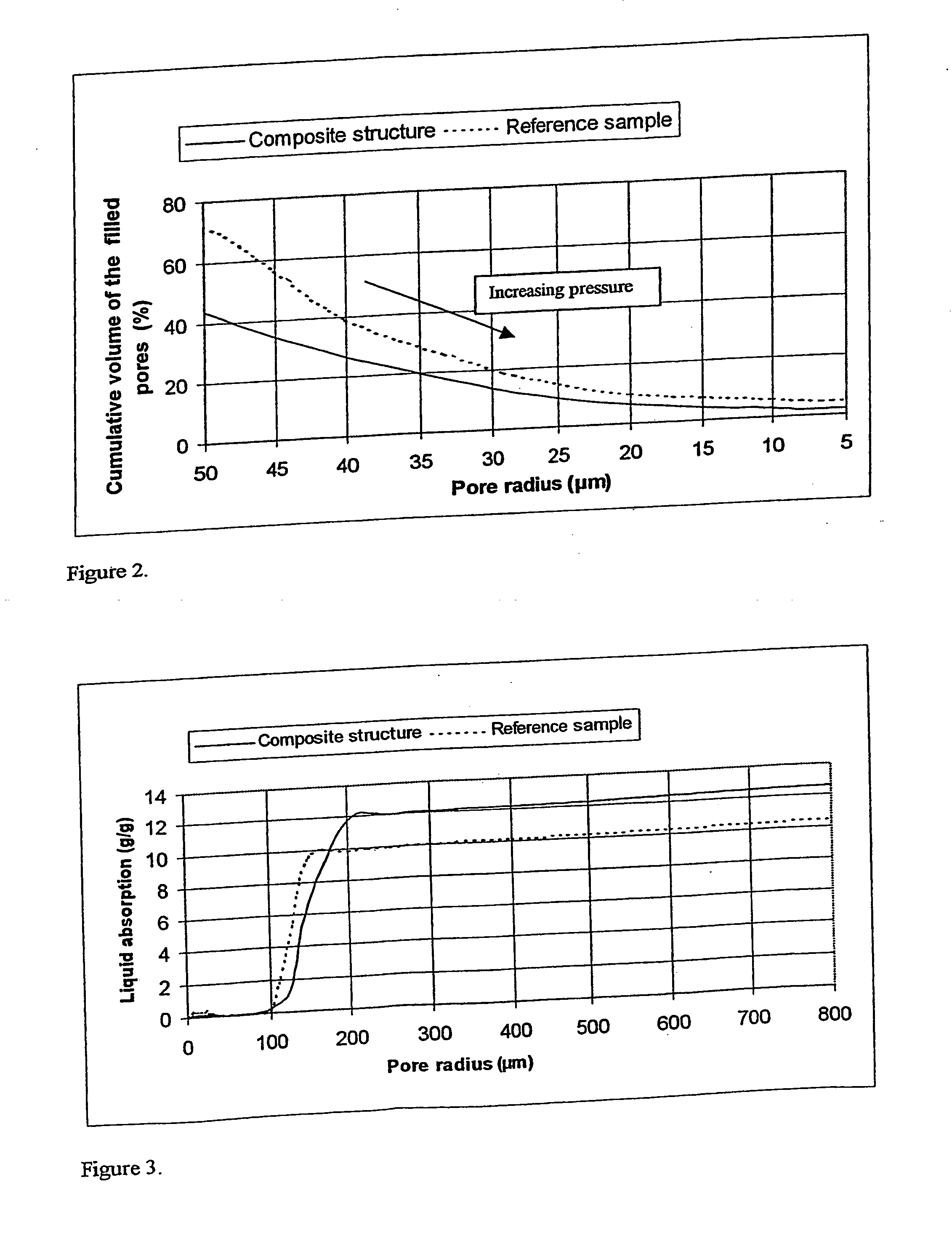

Composite nonwoven its use and method of manufacture

InactiveUS20050090175A1Excellent liquid absorptionGood release effectPattern makingNeedling machinesPolymer scienceFibrous layer

The invention concerns a composite nonwoven formed from fibrous layers bonded together by entanglement of fibers of the layers, wherein the fibrous layers comprise first and second outer layers each comprising a mixture of hydrophobic and hydrophilic fibers, as well as an intermediate layer of hydrophobic fibers sandwiched between the first and the second outer layers, the weight ratio between the hydrophobic and hydrophilic fibers in the first and the second layers being 20:80 to 80:20. The invention also concerns the manufacture of the nonwoven, as well as its use, especially as a wet wipe.

Owner:SUOMINEN NONWOVENS

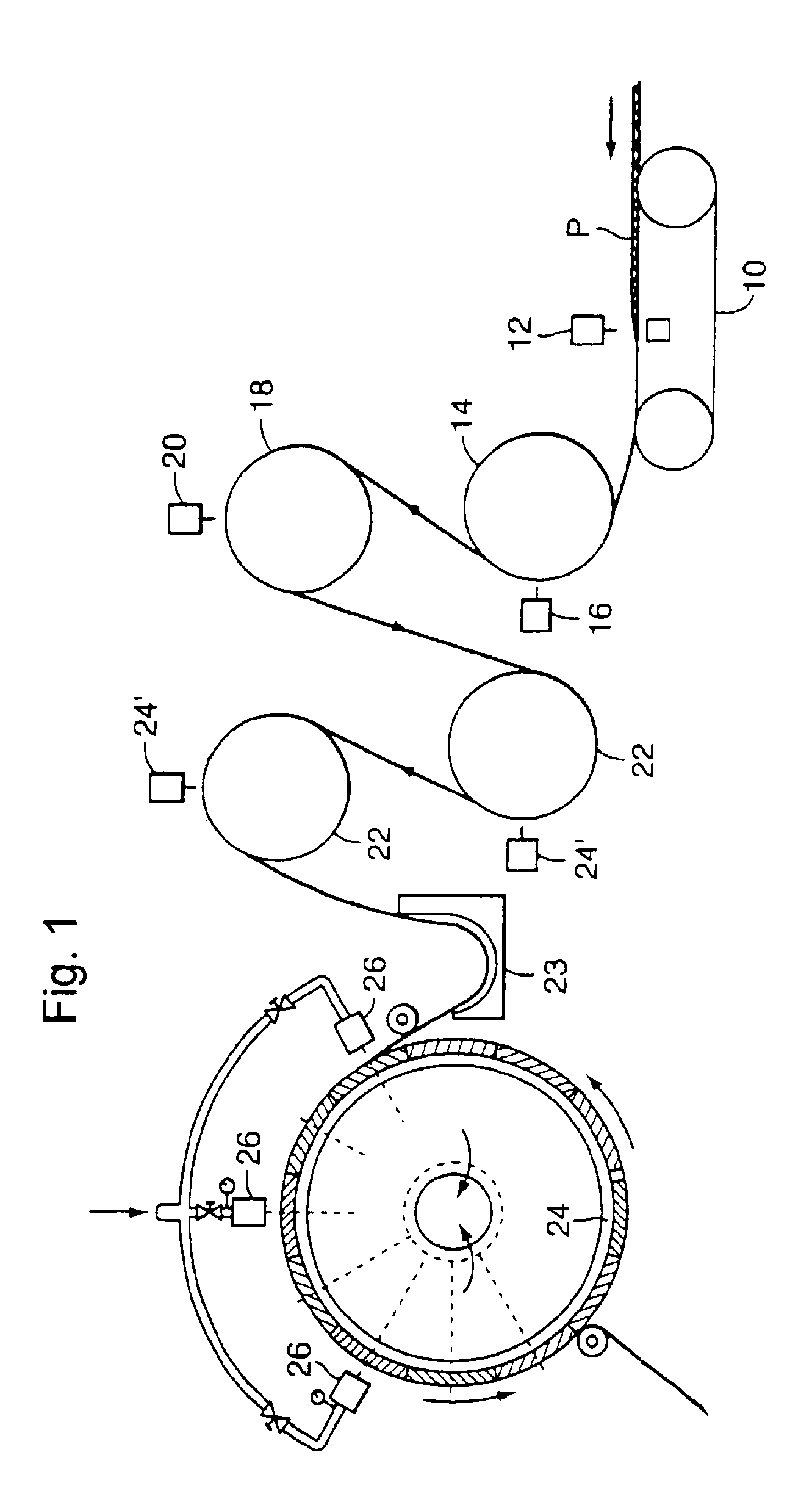

Hydroentangled filter media with improved static decay and method

InactiveUS6942711B2Improve filtering effectGood strength propertiesCombination devicesDispersed particle filtrationFilter mediaEngineering

The present invention is directed to a filter media comprised of an electro-conductive scrim so as to improve on the dissipation time of an electrostatic charge. Further, the present invention is directed to a method of making such a filter media, which is formed through hydroentanglement, thus avoiding the deleterious effects of mechanical needling, while providing a filter media having the requisite strength characteristics, without possessing a limiting factor in performance. The filtration media of the present invention also demonstrates a highly desirable uniformity for cost-effective use.

Owner:AVINTIV SPECIALTY MATERIALS INC

Method of making a reinforcing mat for a pultruded part

A method of preparing a reinforcing structure for use in manufacture a pultruded part where the reinforcing structure is pulled through a pultrusion die in a continuous longitudinal pull direction. The method includes arranging a plurality of first reinforcing fibers in a transverse direction and attaching a permeable transport web of staple fibers to the first reinforcing fibers such that the portion of the first reinforcing fibers oriented in the direction transverse comprises at least 40% of a volume of materials comprising the reinforcing structure.

Owner:PELLA

Low-noise needling machine

The invention discloses a low-noise acupuncture machine, which includes an acupuncture machine body, an acupuncture mechanism, a noise processor, a deviation correction microphone, a reverse sound wave speaker, and a shock absorbing pad. The acupuncture mechanism is arranged in the acupuncture machine body. The noise processor is arranged outside the acupuncture machine body, the deflection correction microphone is arranged beside the acupuncture mechanism and connected to the noise processor, the reverse sound wave speaker is arranged beside the acupuncture mechanism and connected to the noise processor, the The shock absorbing pad is arranged at the bottom of the acupuncture machine body. Through the above method, the present invention provides a low-noise acupuncture machine, which uses a noise processor to obtain the working frequency of the acupuncture mechanism and generates reverse sound waves for noise reduction, greatly reducing the noise pollution of the acupuncture machine, and using cushioning and shock-absorbing pads to avoid The resonance noise of the equipment greatly reduces the overall noise of the acupuncture machine.

Owner:CHANGSHU ZHENTAI NONWOVEN MACHINERY

Leather-Like Sheet And Method Of Manufacturing The Same

InactiveUS20090274862A1Dense feelingElegant surface appearanceFibre treatmentSynthetic resin layered productsFiberVitrification

A leather-like sheet composed of a microfine-fiber entangled body made of bundles of microfine fibers and an elastic polymer impregnated therein. The bundles of microfine fibers are composed of microfine monofibers having an average cross-sectional area of 0.1 to 30 μm2 and have an average cross-sectional area of 40 to 400 μm2. The bundles of microfine fibers exist in a density of 600 to 4000 / mm2 on a cross section taken along the thickness direction of the microfine-fiber entangled body. The elastic polymer contains 30 to 100% by mass of a polymer of ethylenically unsaturated monomer. The polymer of ethylenically unsaturated monomer is composed of a soft component having a glass transition temperature (Tg) of less than −5° C., a crosslinkable component, and optionally a hard component having a glass transition temperature (Tg) of higher than 50° C. and another component. The polymer of ethylenically unsaturated monomer is bonded to the microfine fibers in the bundles of microfine fibers. The leather-like sheet has a flexibility and hand such as dense feeling each resembling natural leathers and a high quality appearance. The leather-like sheet is highly stable in quality such as fastness and surface abrasion resistance and excellent in practical performance.

Owner:KURARAY CO LTD

Nonwoven fabric, nonwoven fabric manufacturing method, and nonwoven fabric manufacturing apparatus

The present invention provides a nonwoven fabric of which at least one of fiber orientation, fiber density, and basis weight is adjusted, and in which at least one of a predetermined groove portion, an opening, and a protrusion is formed, a manufacturing method for the nonwoven fabric, and a nonwoven fabric manufacturing apparatus. The nonwoven fabric manufacturing apparatus of the present invention manufactures a nonwoven fabric of which at least one of fiber orientation, fiber density, and basis weight is adjusted, or in which at least one of a predetermined groove portion, an opening, and a protrusion is formed by blowing fluid mainly containing gas onto a fiber web which is formed in a sheet shape, and which is in a state where at least a portion of the fibers constituting the fiber aggregate has a degree of freedom.

Owner:UNI CHARM CORP

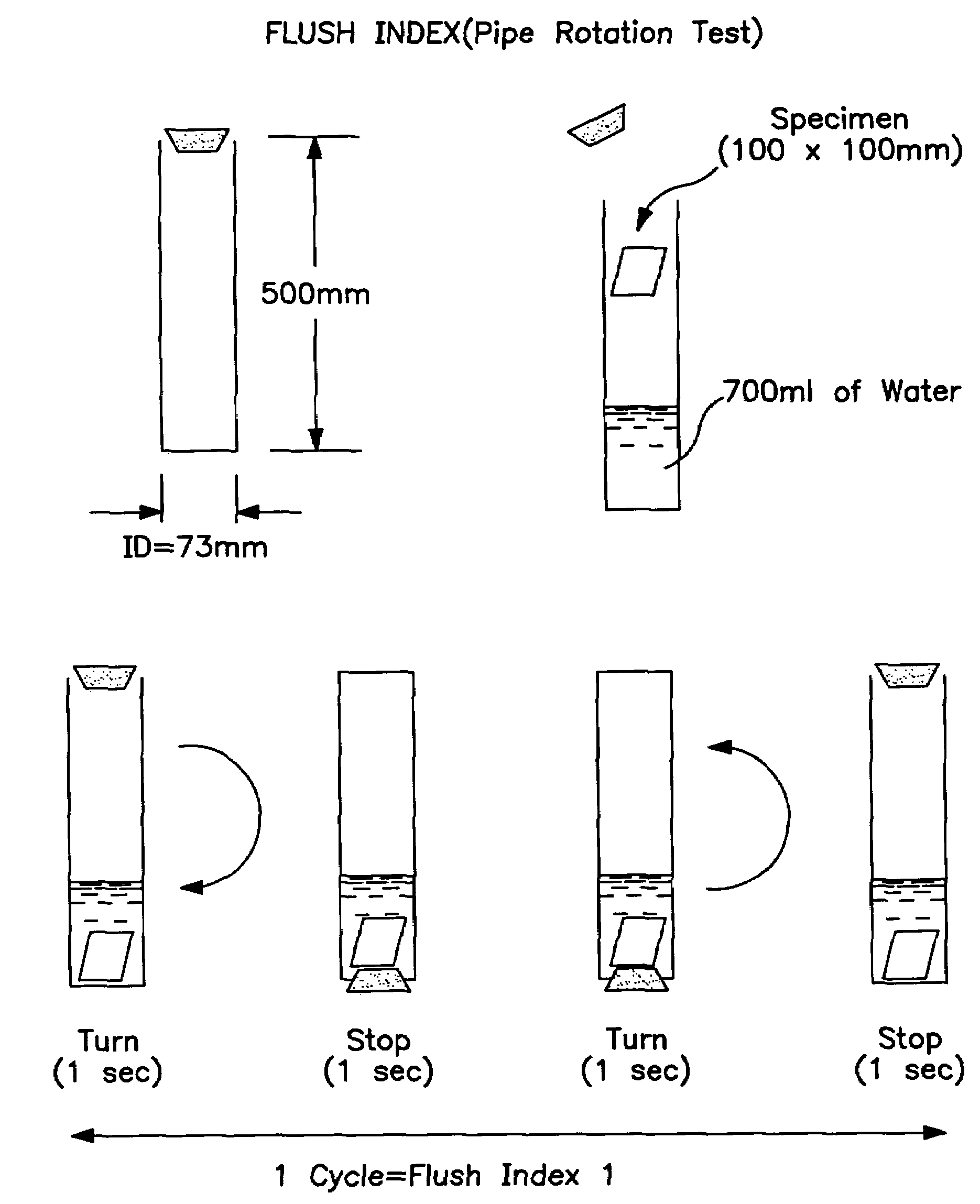

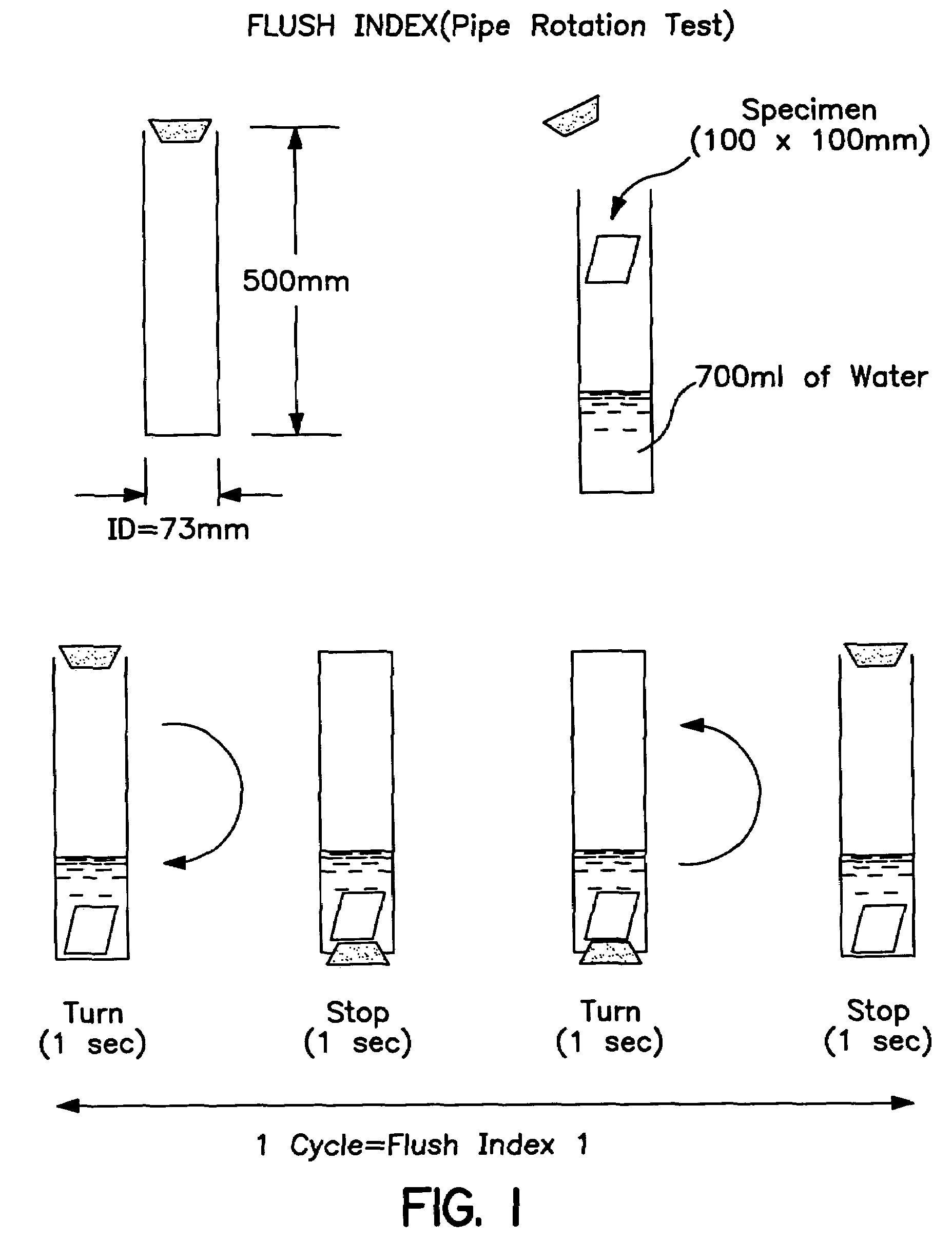

Disposable nonwoven wiping fabric and method of production

InactiveUS7732357B2Improve wet strengthImprove aestheticsCosmetic preparationsMake-upPolymer scienceCellulose fiber

Disclosed is a fibrous nonwoven web material and a method of manufacture thereof. The fibrous nonwoven web material includes natural cellulose fibers, manmade cellulose fibers and synthetic fibers. The manmade cellulose fibers are preferably high crystallinity cellulose fibers. The fibrous nonwoven web material has appreciable wet strength yet is capable of dispersing in most aqueous environments with only mild agitation. The fibrous nonwoven web material can be wet laid from an aqueous dispersion of fibers.

Owner:SUOMINEN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com