Small diameter felt cover needling machine

A technology of needle looms and felt sleeves, which is applied in the field of acupuncture machines, can solve the problems of inability to produce good quality and small size felt sleeves, and achieve the effect of increasing rigidity, increasing rigidity and stability, and simple mechanical structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] A specific embodiment will be described in detail below in conjunction with the accompanying drawings.

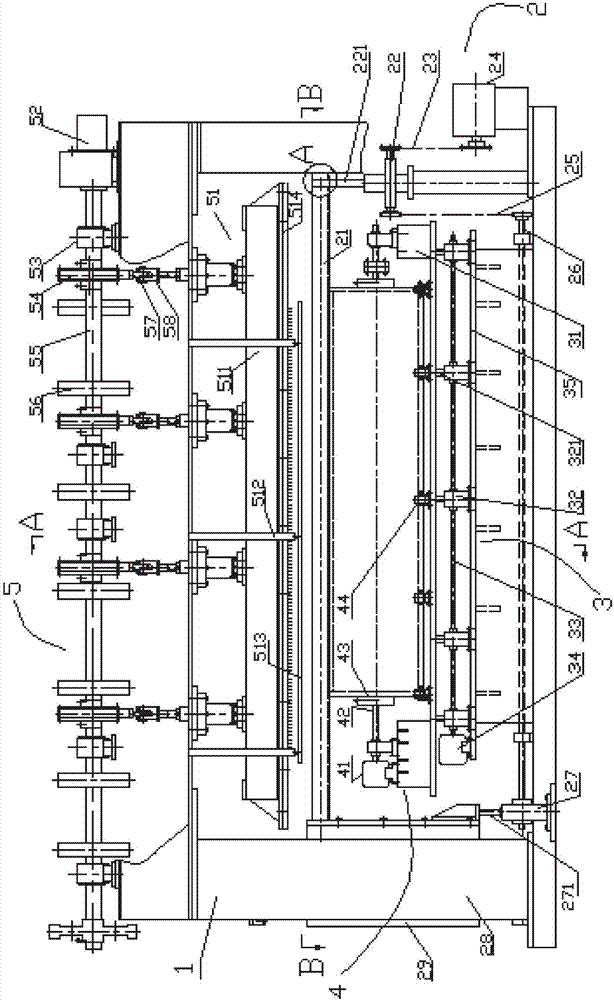

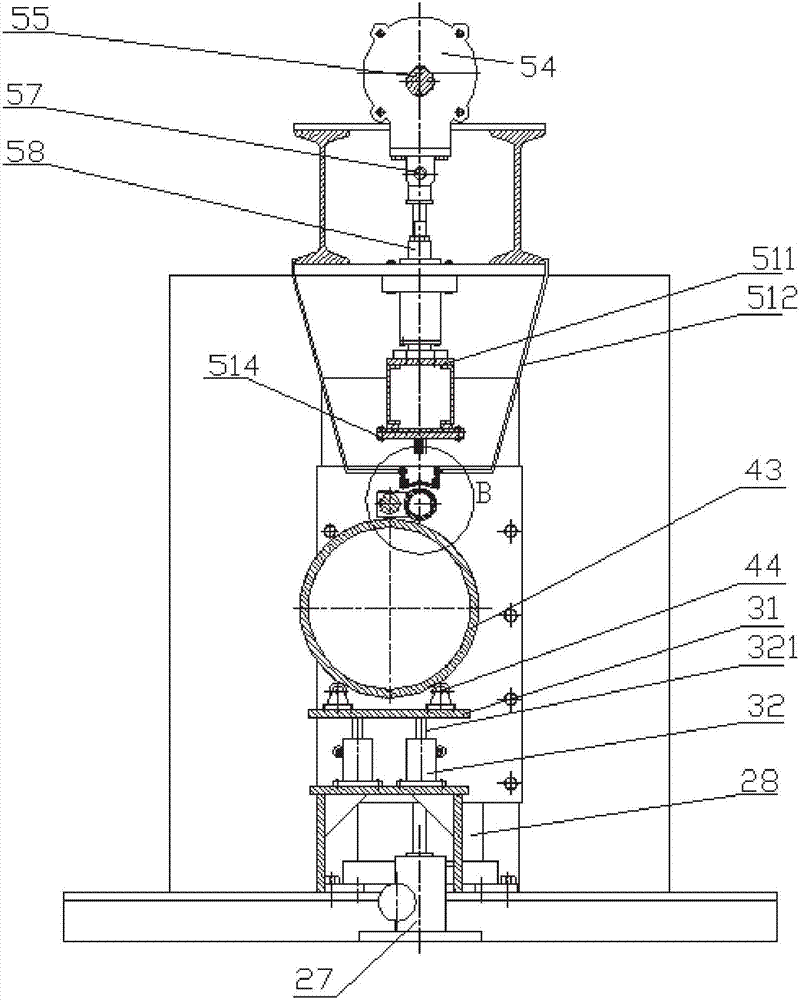

[0032] Please refer to Figure 1-Figure 9 , a small-diameter felt sleeve needling machine, including a frame 1, an assembly and disassembly part 2, a platform support part 3, an idler support part 4 and an acupuncture part 5, an assembly and disassembly part 2, a platform support part 3, and an idler support part 4 and acupuncture part 5 are both arranged on the frame 1:

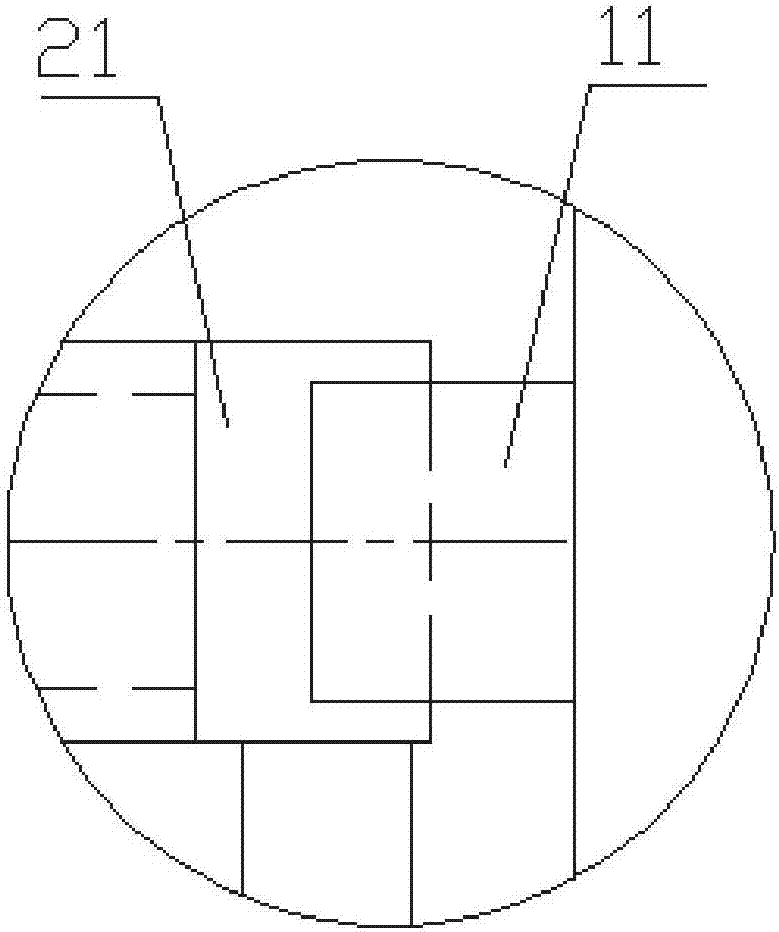

[0033]Assembly and disassembly part 2, assembly and disassembly part 2 completes the assembly and disassembly of felt cover products, assembly and disassembly part 2 includes column 28, sleeve 29, left worm gear and worm lifting mechanism 27, right worm and gear lifting mechanism 22, assembly and disassembly motor 24, assembly and disassembly Remove transmission shaft 26 and supporting roller 21, column 28, left worm gear lifting mechanism 27, right worm gear lifting mechanism 22 and assembly and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com