Patents

Literature

214results about How to "Good strength properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

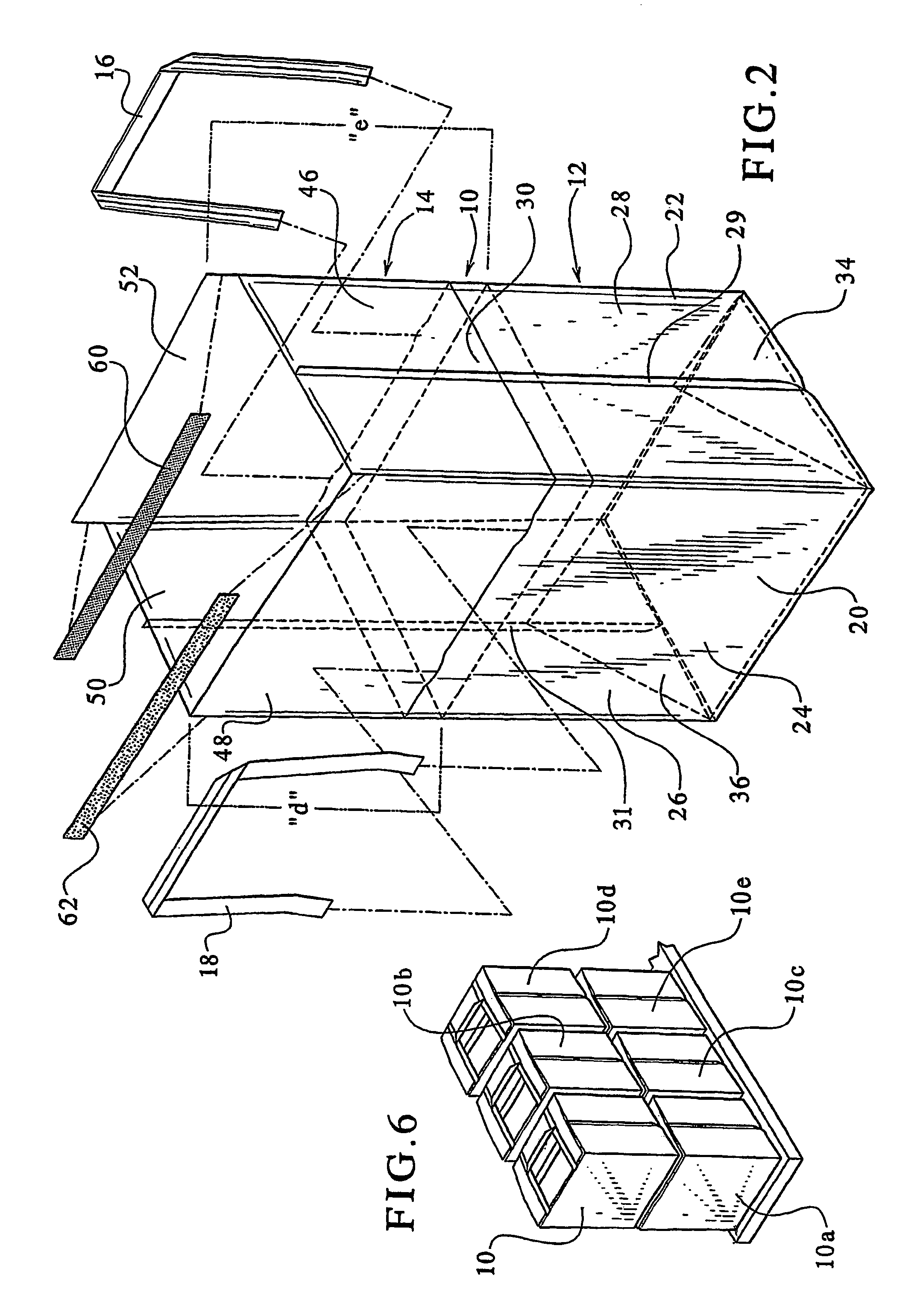

Flexible container having flat walls

InactiveUS7207716B2Improve stabilitySimple methodEnvelopes/bags making machineryBoxes/cartons making machineryPlastic materialsFlat panel

Owner:NESTEC SA

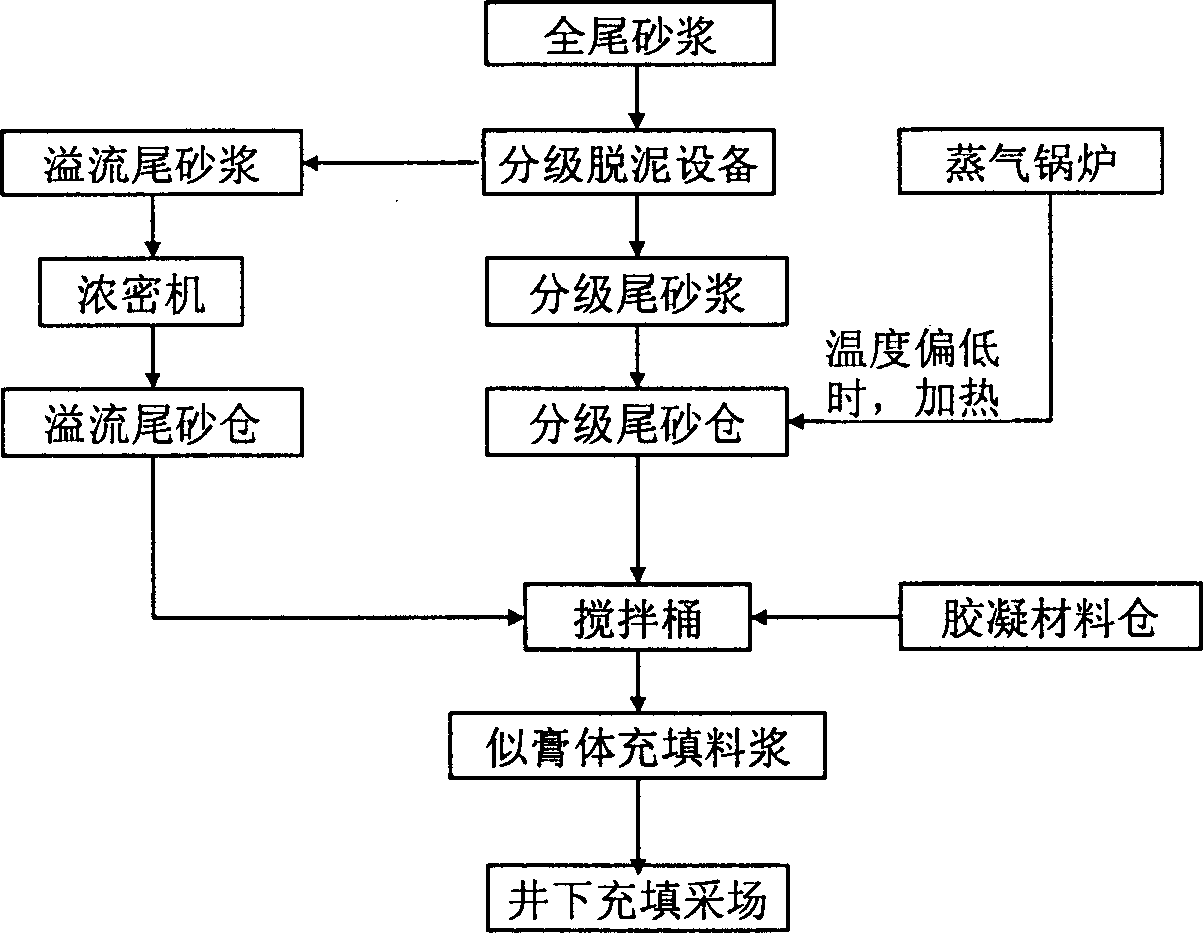

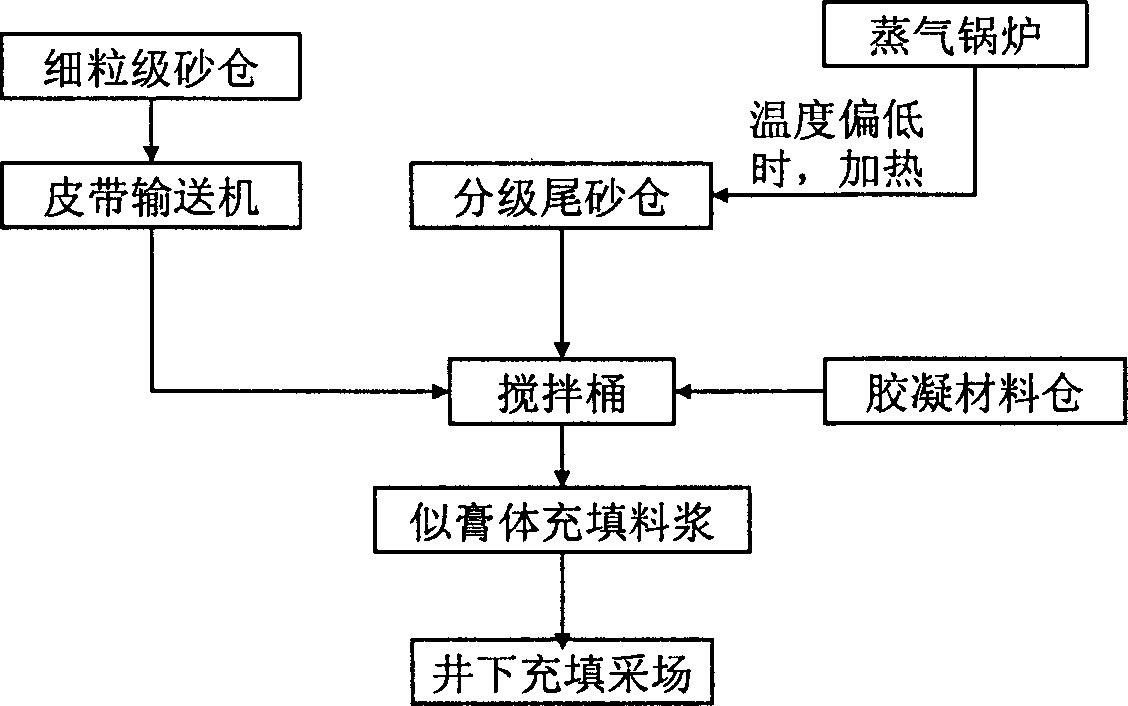

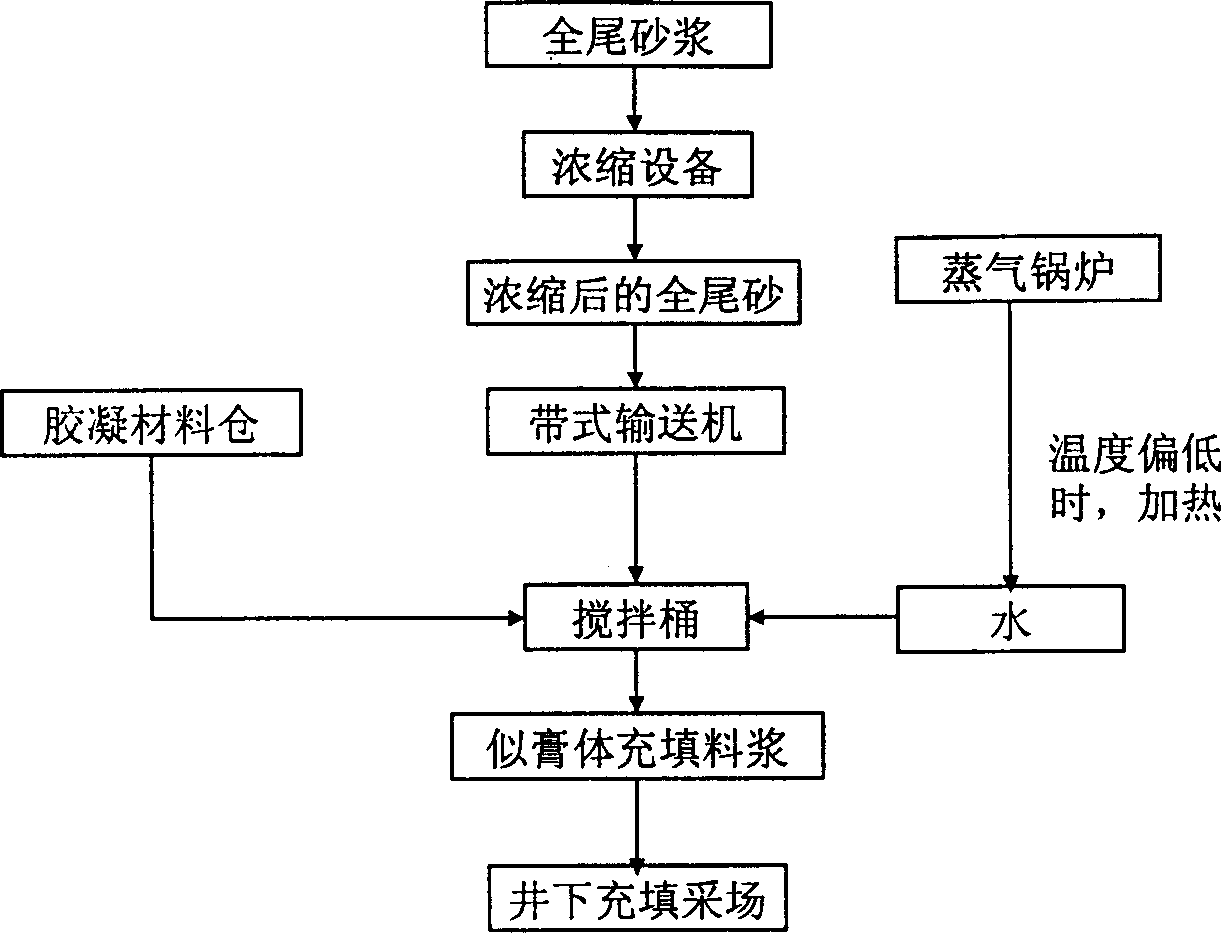

Cementing materials for filling, slurry and preparing and filling processes

InactiveCN1424275AReduce manufacturing costLess investmentSolid waste managementMaterial fill-upSlurrySulfur containing

A gelatining material similar to cream for filling underground working surface is preapred from the Ca-contained non-crystal and microcrystal material, alkali and / or sulfur contained exciting material, active material, aggregate and regulator. A filling slurry is prepared from said gelatining material, filling aggregate, fine particles, regulator and water through heating to at least 18 deg.C and proportional mixing.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +2

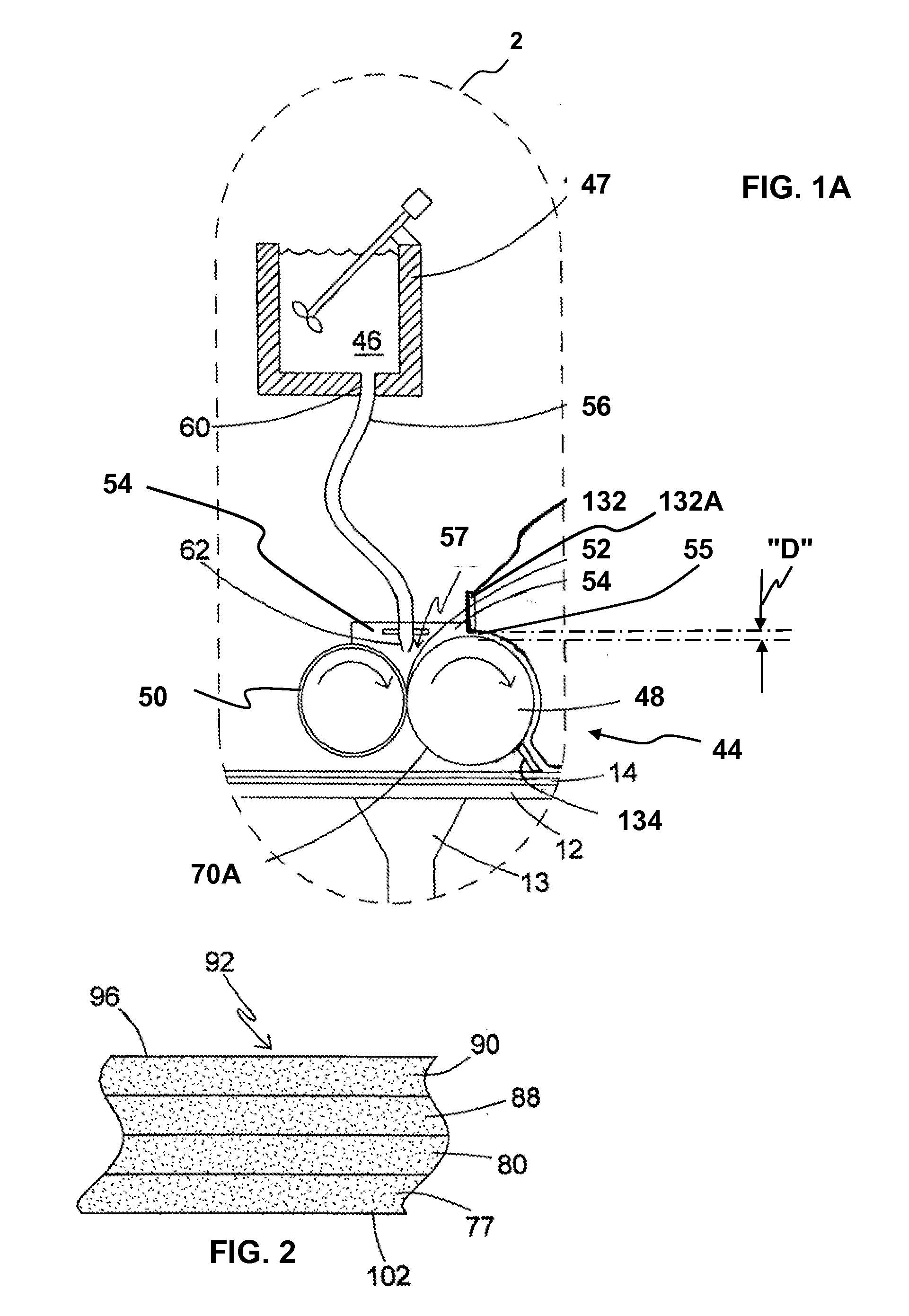

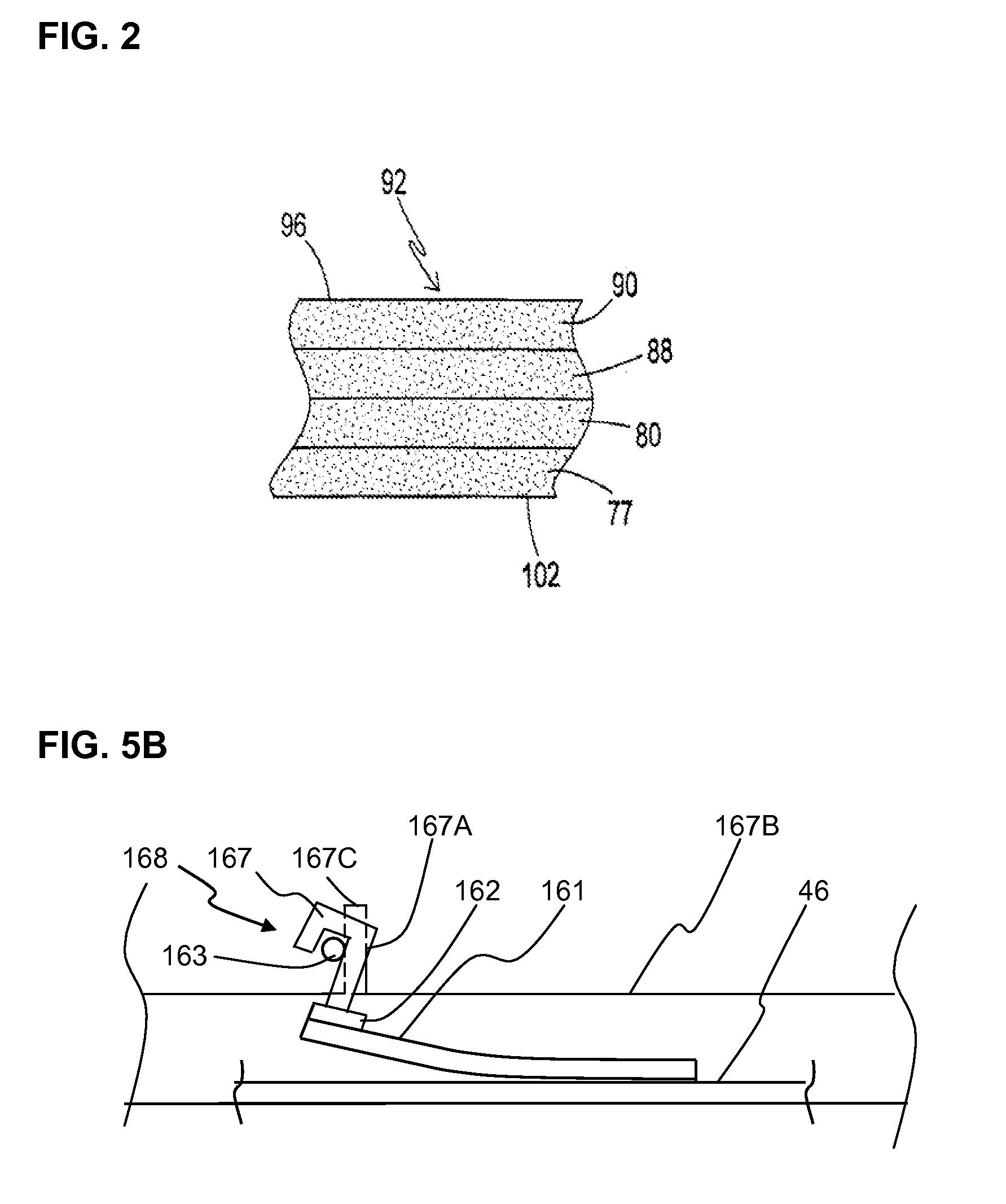

Panel smoothing process and apparatus for forming a smooth continuous surface on fiber-reinforced structural cement panels

InactiveUS20080099133A1Remove pock marks or groovesA large amountSolid waste managementTransportation and packagingProduction lineSurface layer

A vibrating flexible smoothing sheet or shroud disposed transversely of a direction of travel of a formed fiber panel including gypsum-cementitious slurry and embedded chopped fibers. The sheet is used to smooth the surface of the panel as it exits a fiber embedment station of a structural cementitious panel production line to remove grooves and other non-uniform surface imperfections to reduce the need for costly finishing after the panels are cured and cut to size. The flexible sheet is designed to float over the surface of the formed panel without tearing or otherwise damaging the surface of the heavily fiber reinforced surface layers of the panel. The vibrating sheet is pivotally mounted on the side dams of the web production line so it can float over the panel surface during use, but be raised off the line when not in use.

Owner:UNITED STATES GYPSUM CO

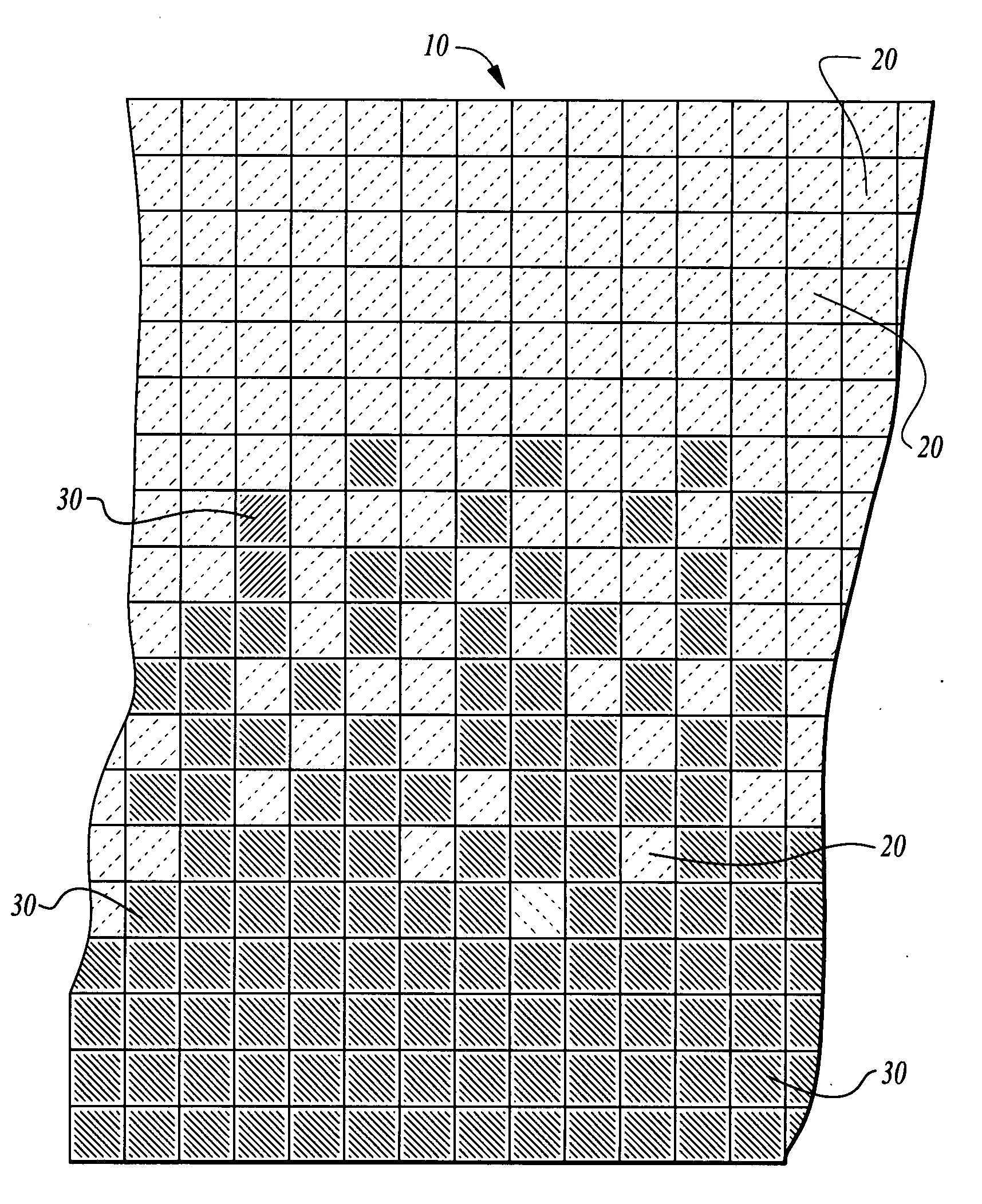

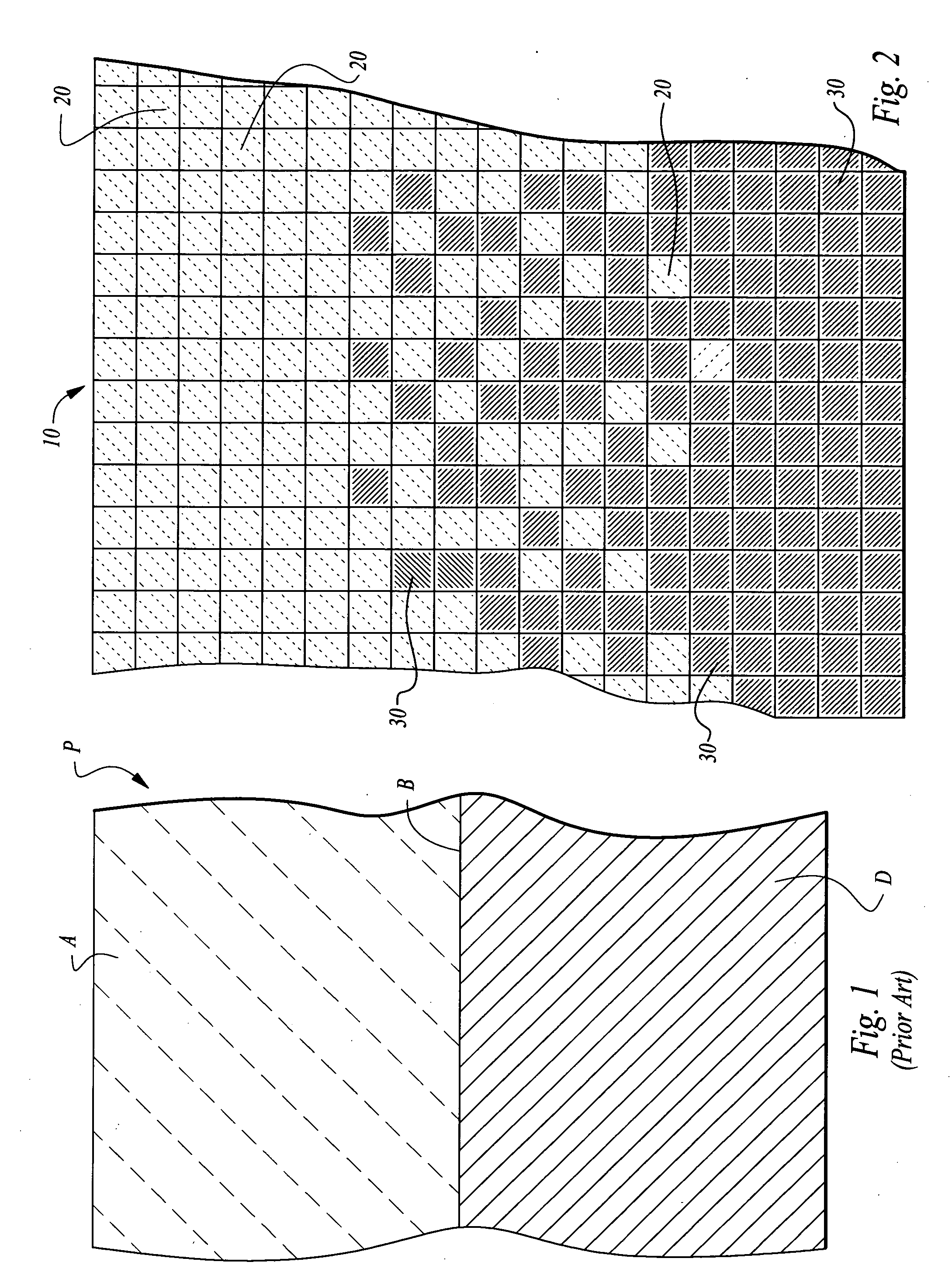

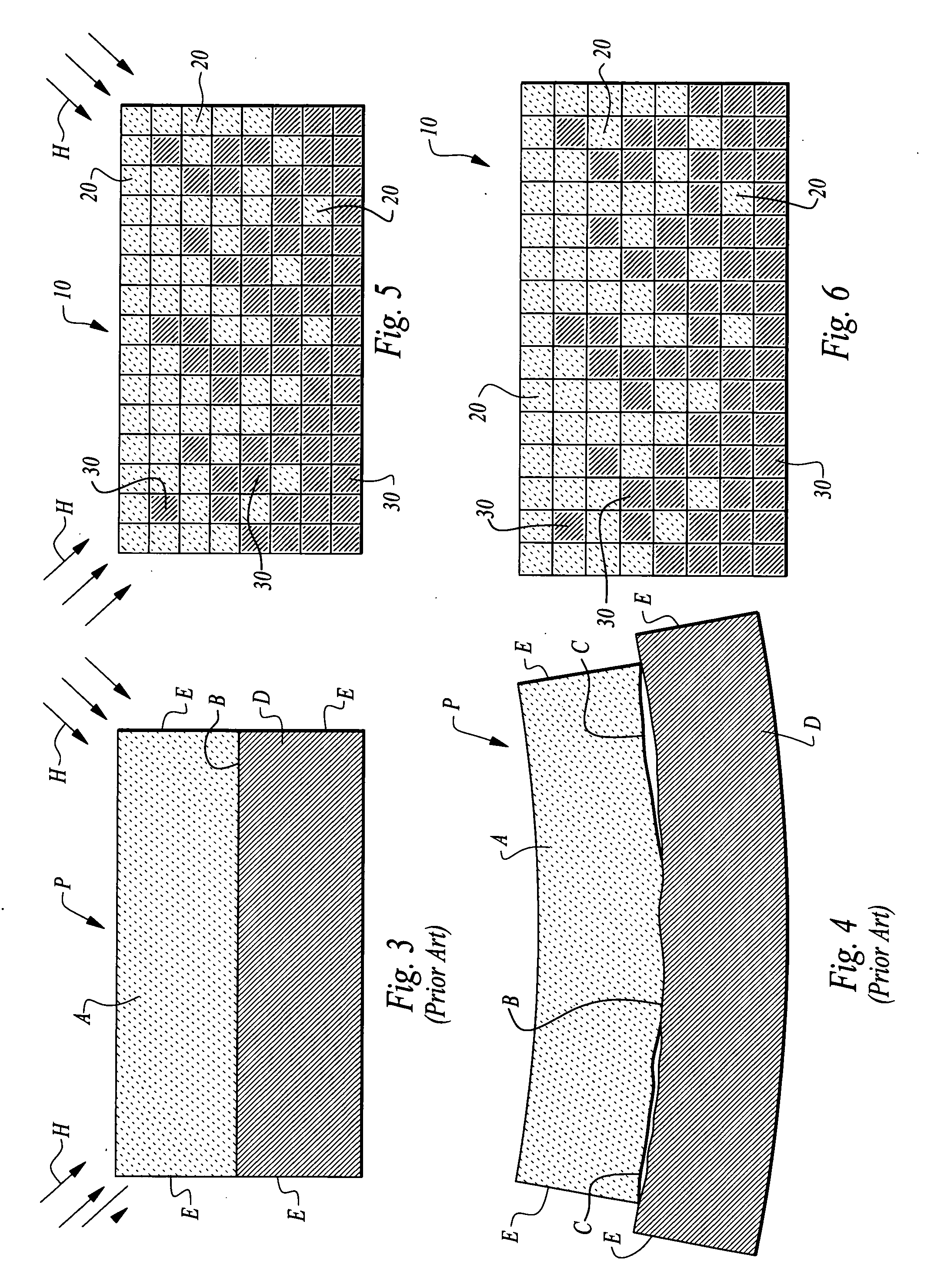

Boundary configurations for multi-material print-forming

InactiveUS20100009133A1Distribute pressureMinimise concentrationAdditive manufacturing apparatusLiquid surface applicatorsMulti materialEngineering

A print-forming method is disclosed which provides a method to engineer and design boundaries between the materials used in devices. The boundary includes primarily a first material on one side and primarily a second material on the other side. At least some of the second material is located on the first material side of the boundary and at least some of the first material is located on the second material side of the boundary in a precise pattern that achieve the objectives of the design. This approach is then extended to 3-dimensional shapes with any number of materials. Material properties that differ from each other thus do not exhibit an abrupt transition within the overall structure, but rather are accommodated within the boundary region. Various different exemplary boundary region configurations are disclosed, as well as techniques for optimizing this print-forming manufacturing within boundary regions.

Owner:EOPLEX

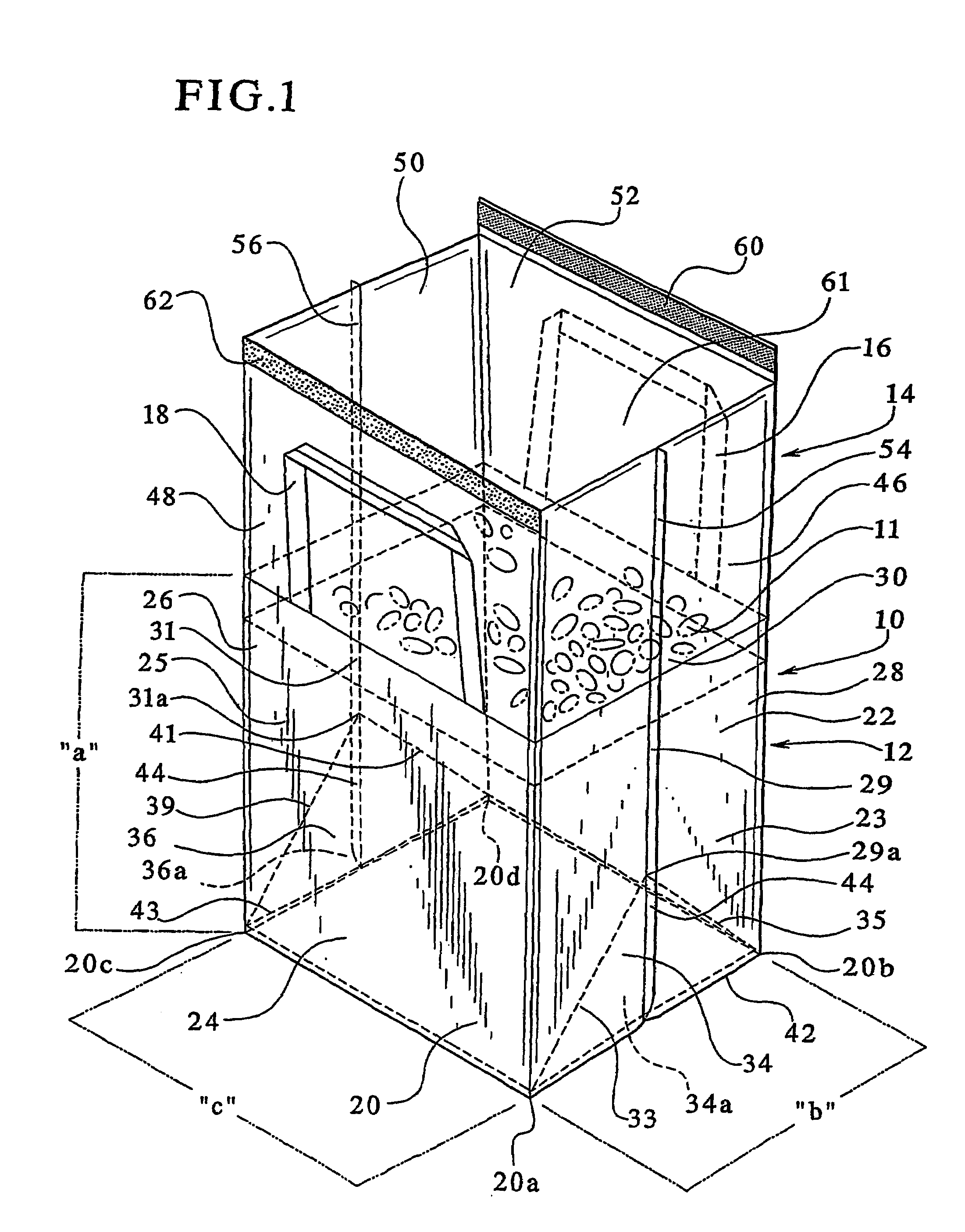

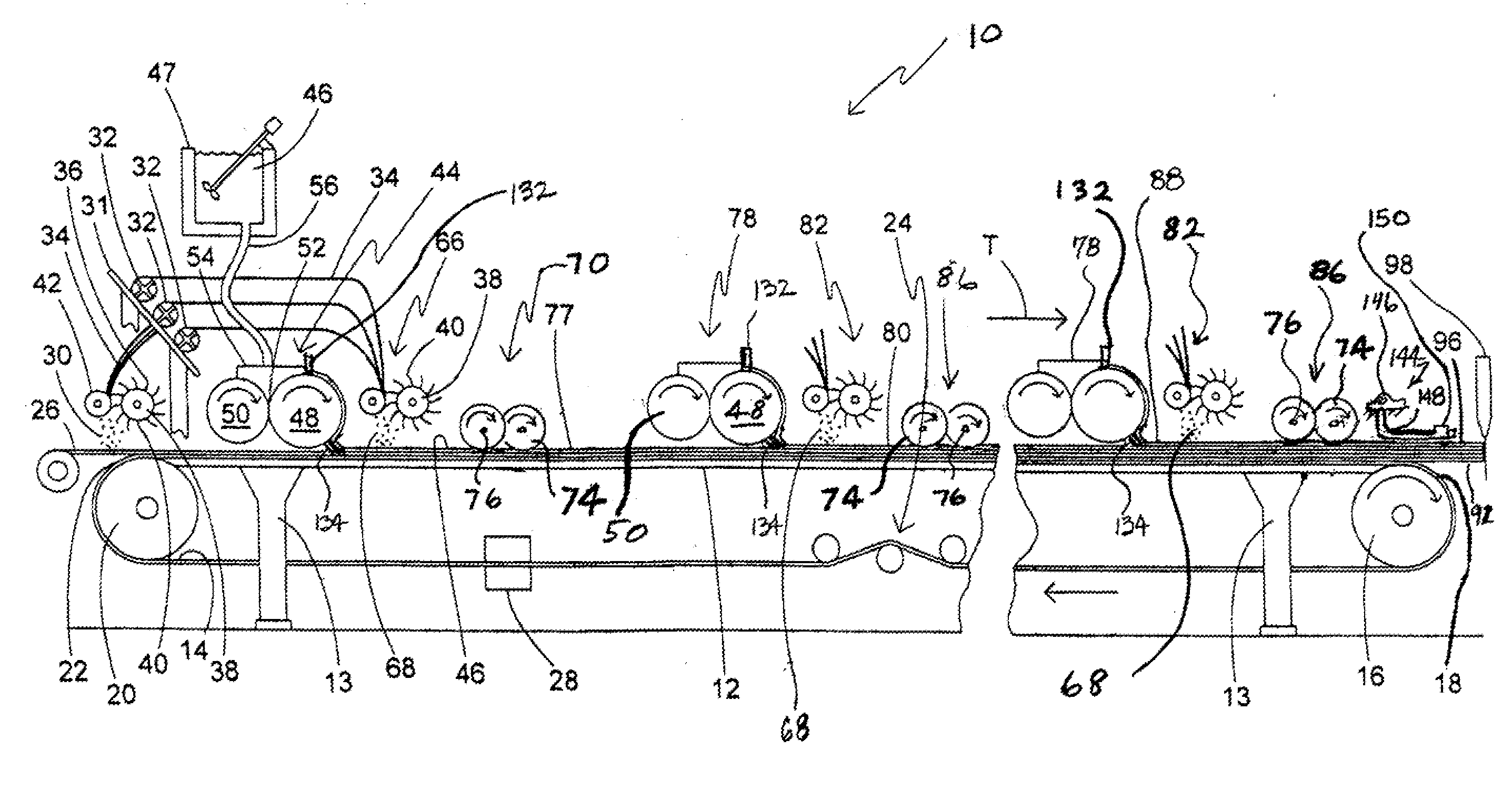

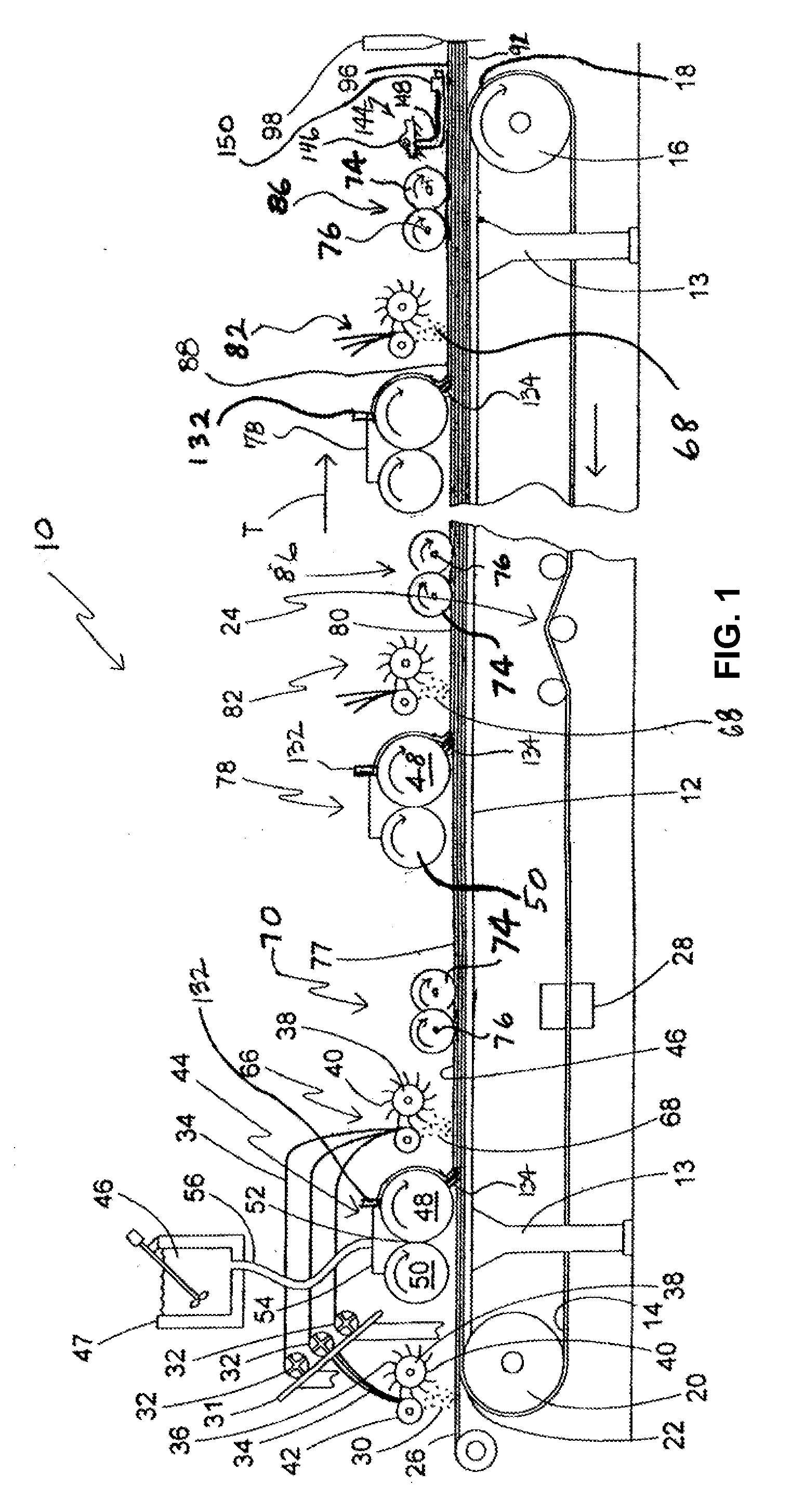

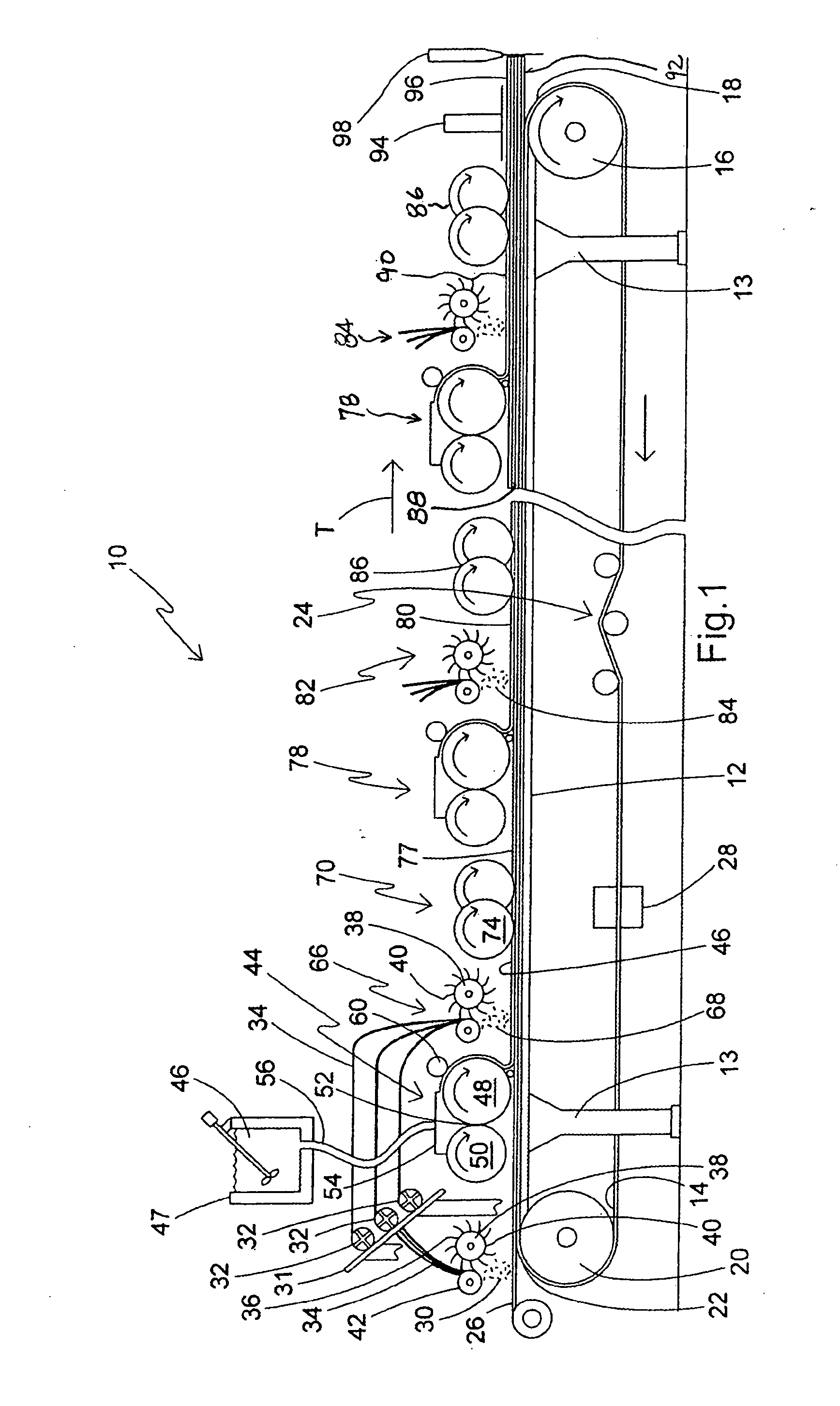

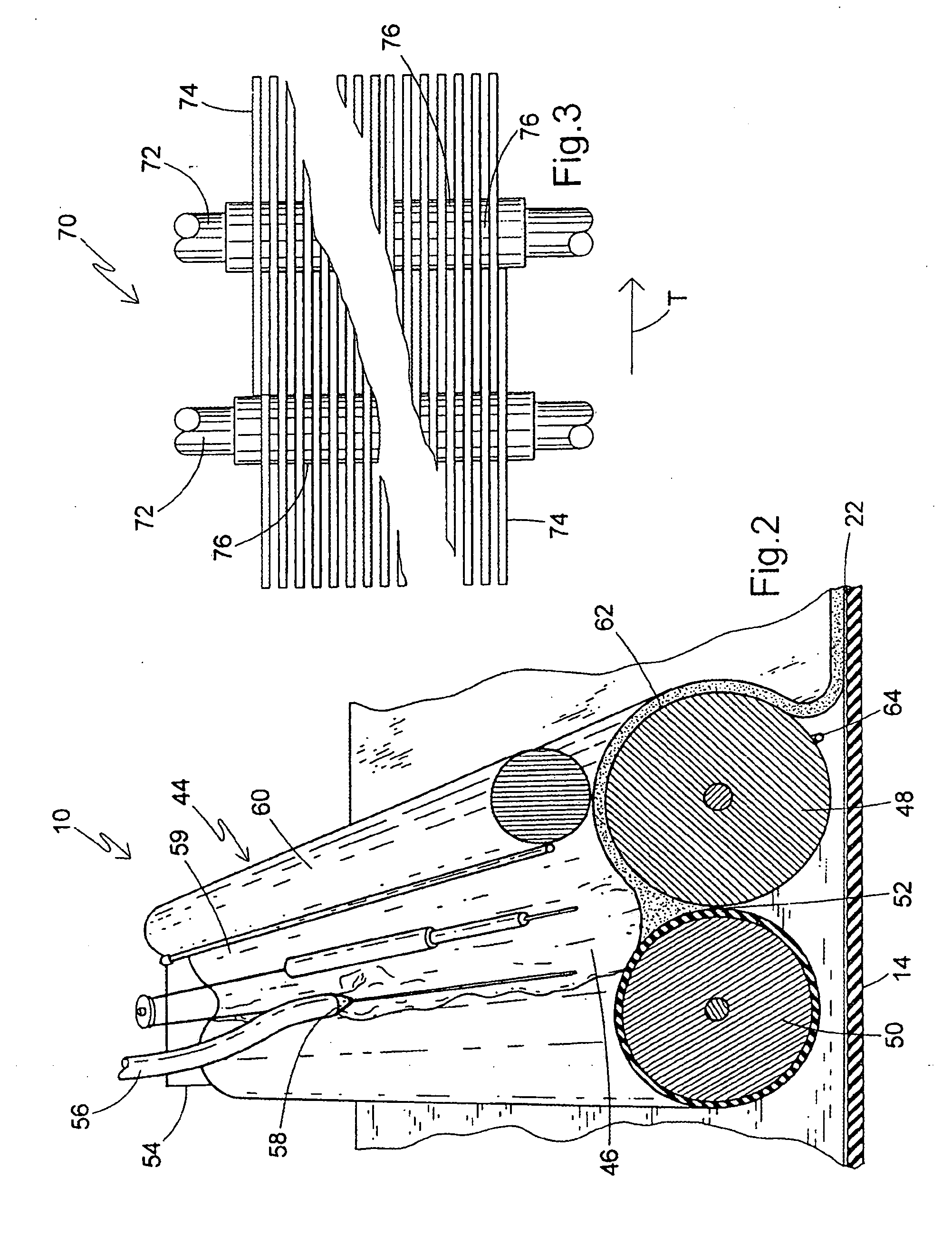

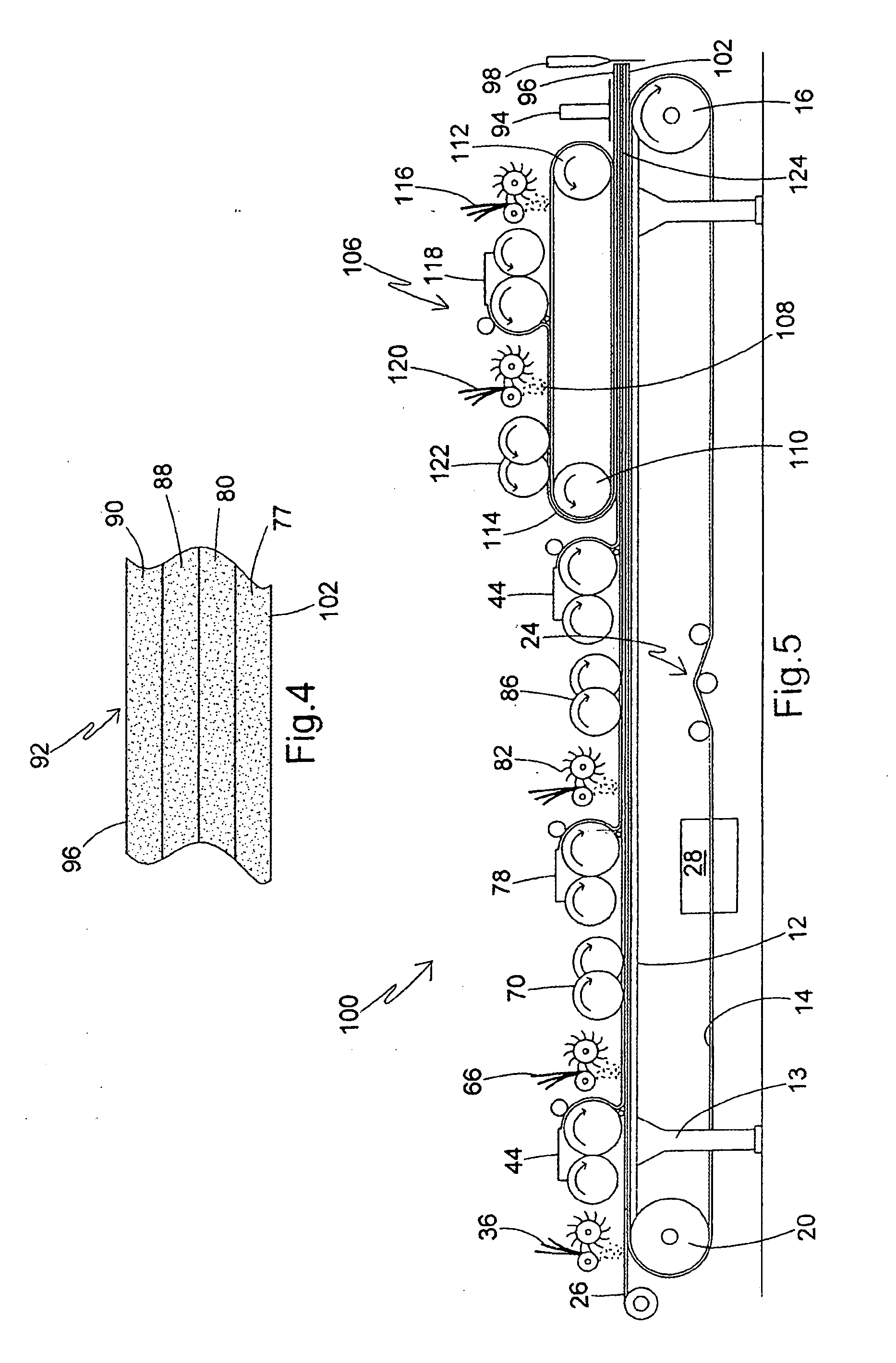

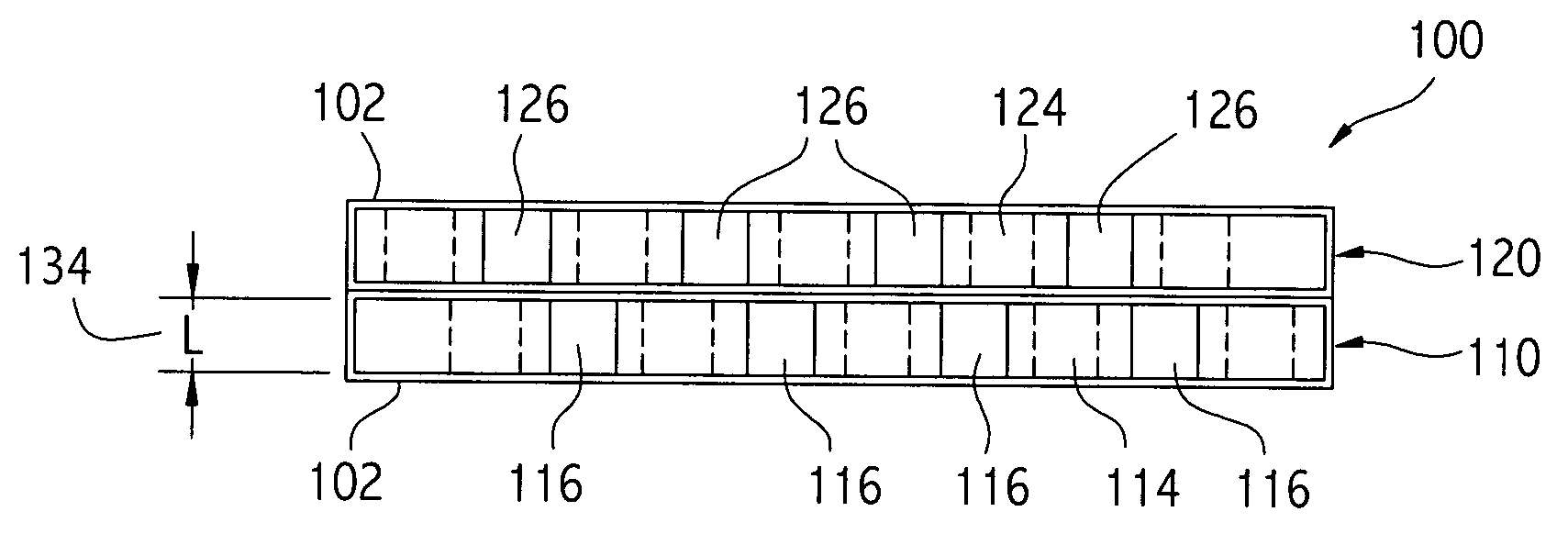

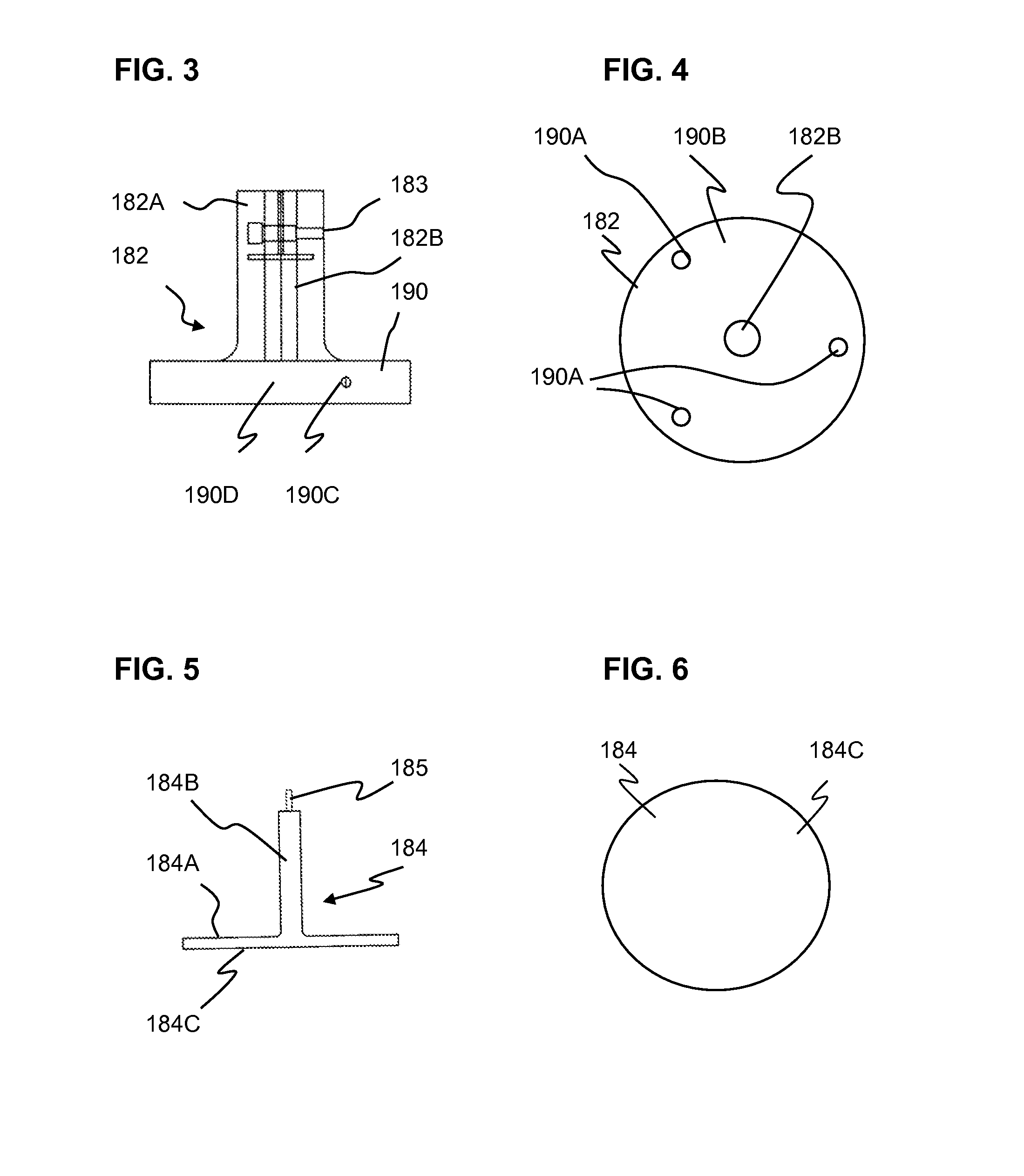

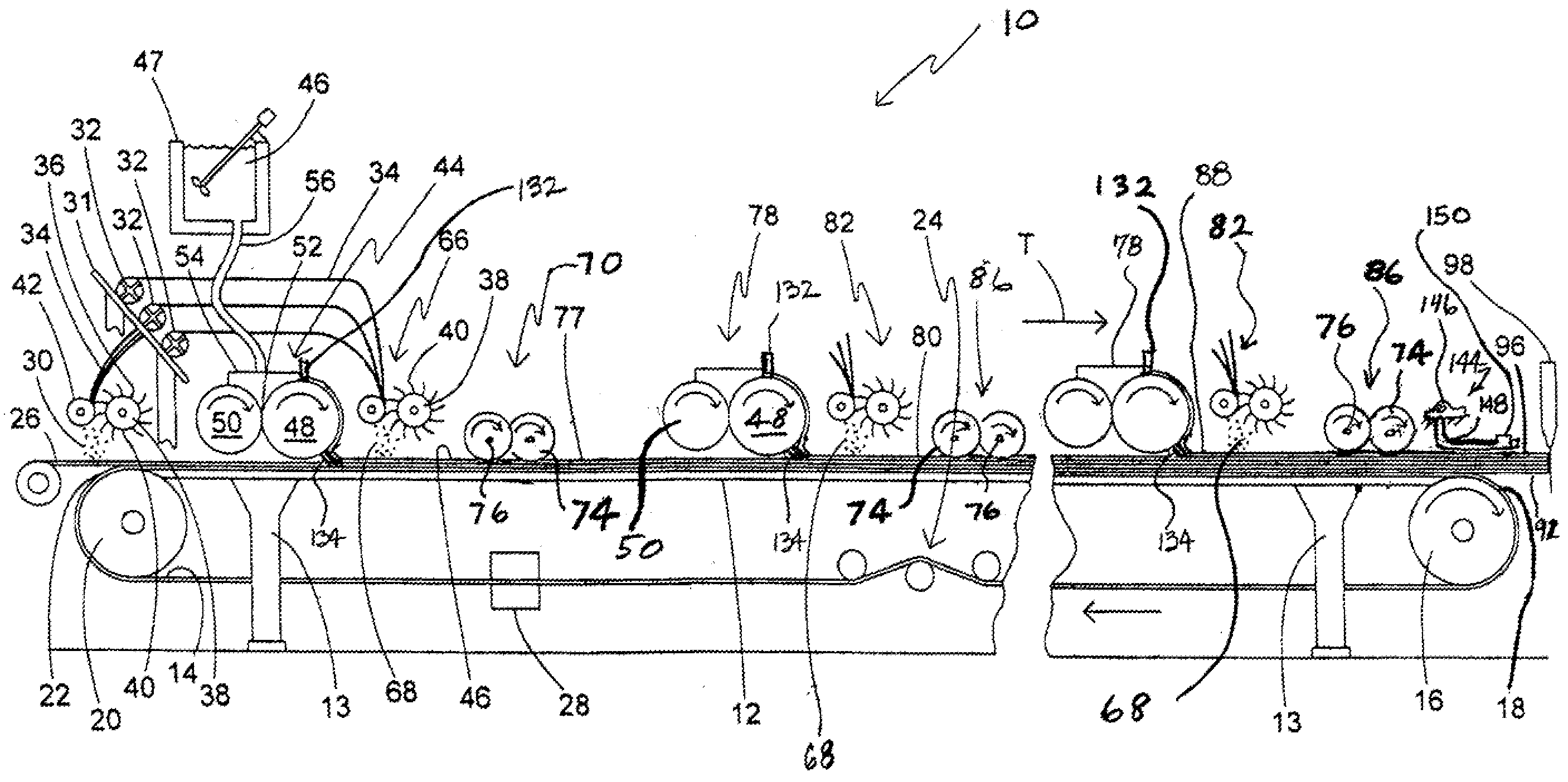

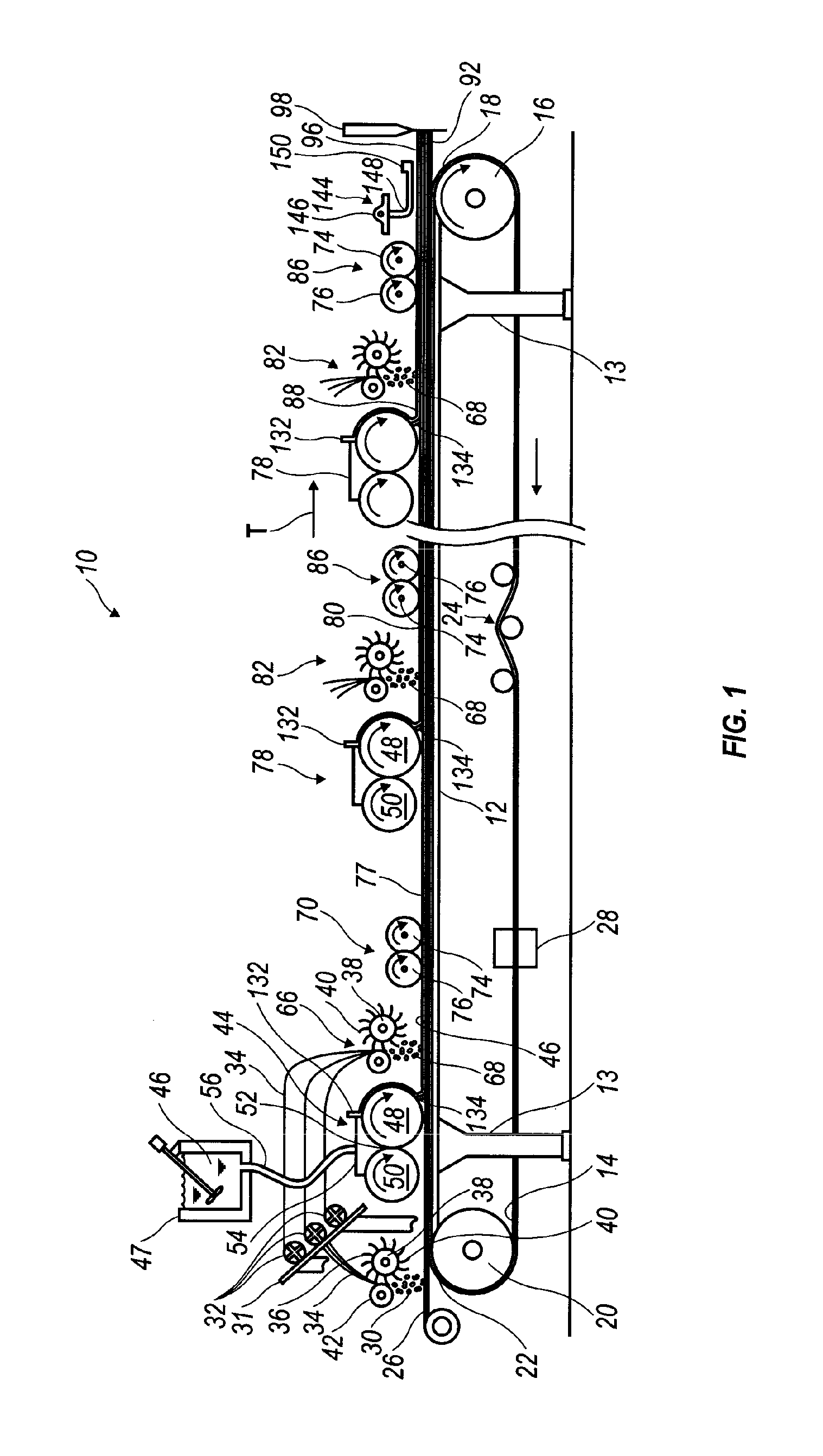

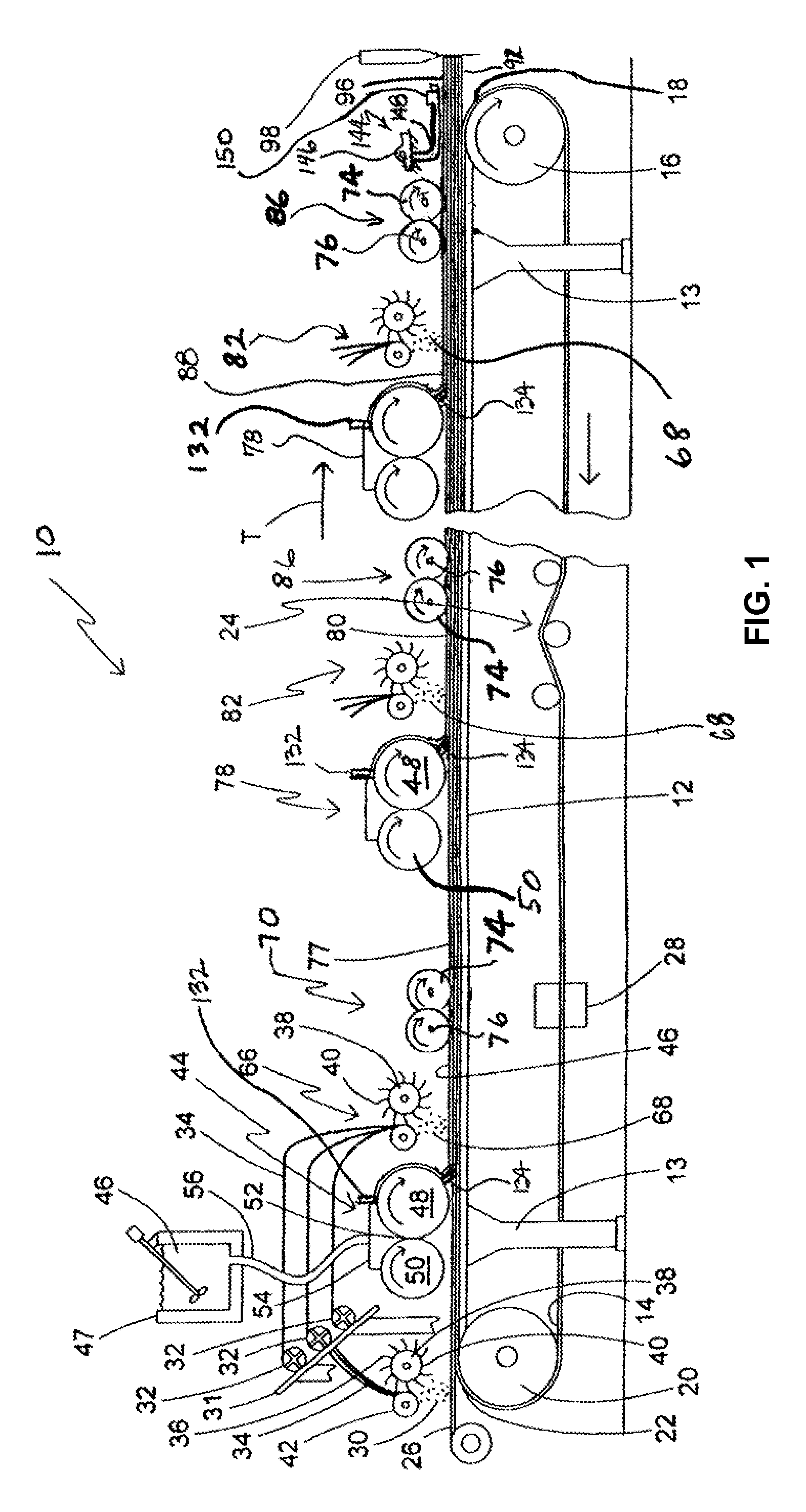

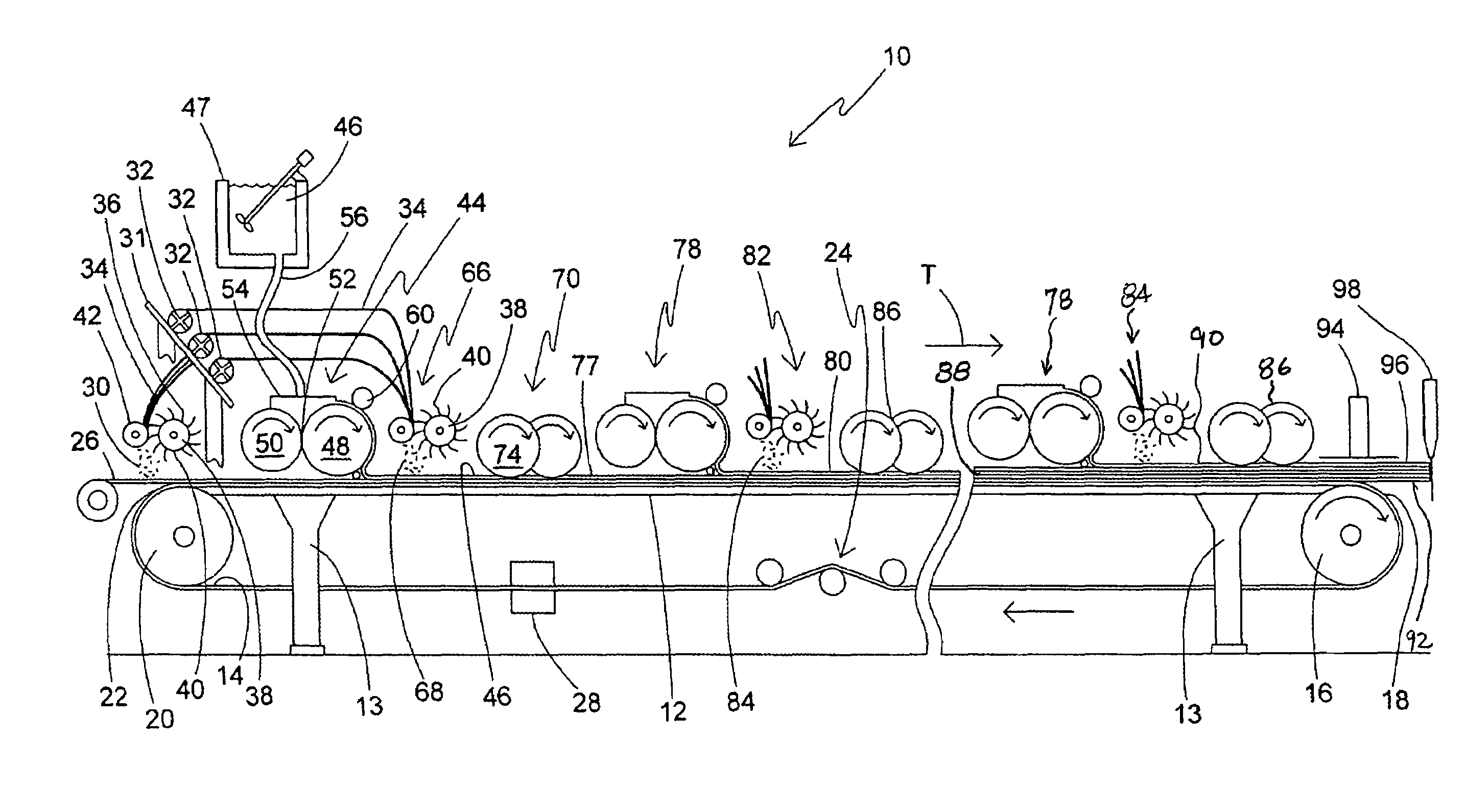

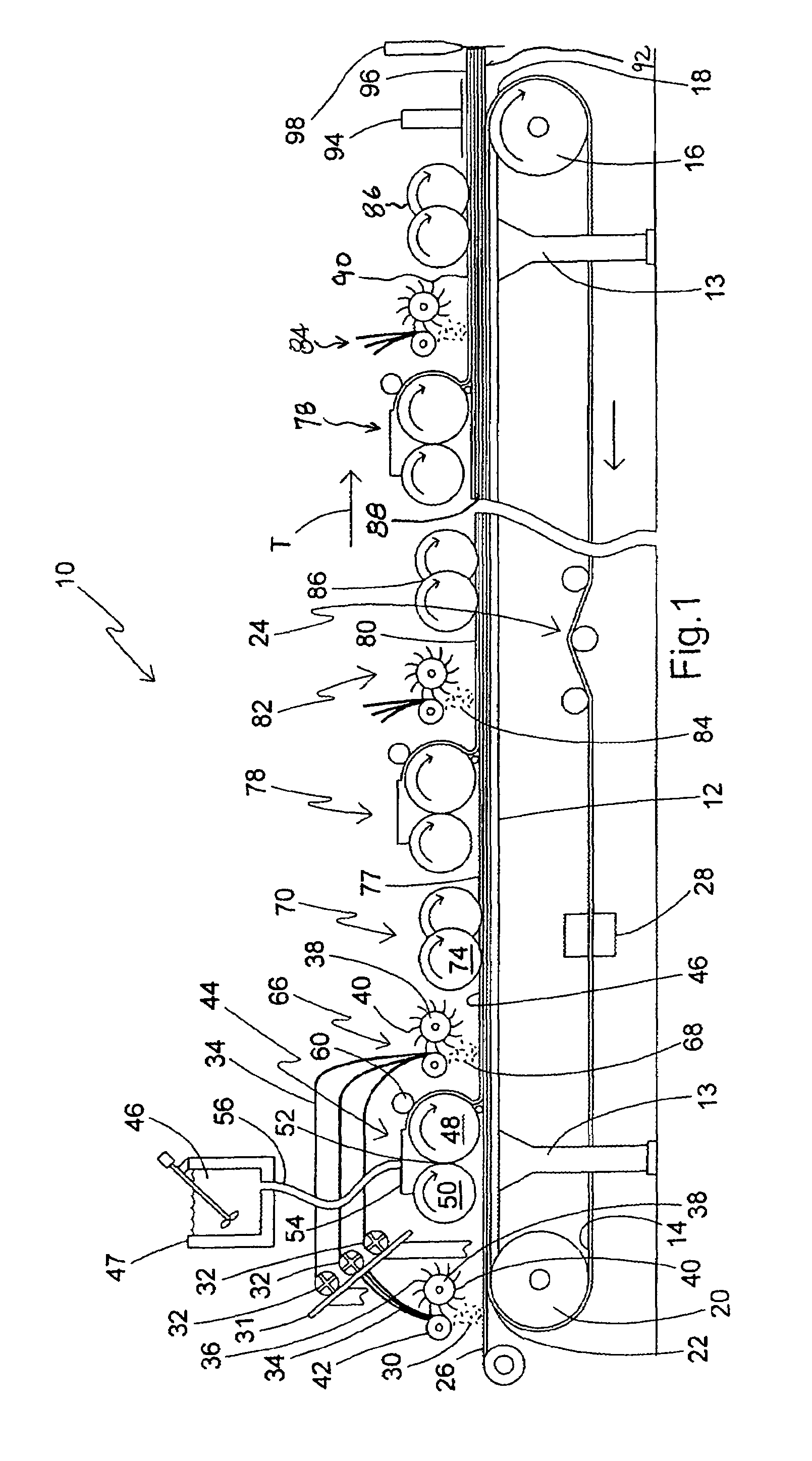

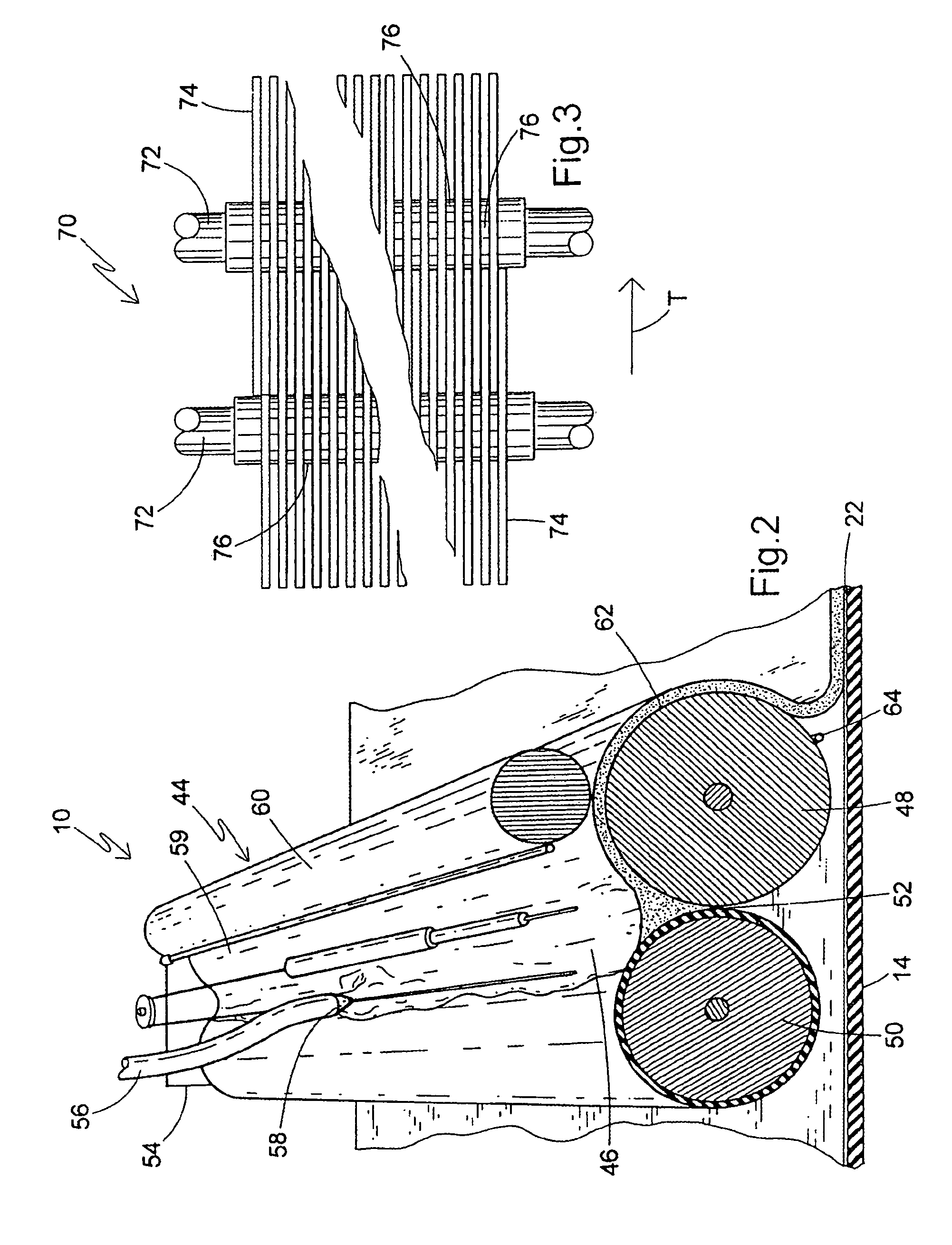

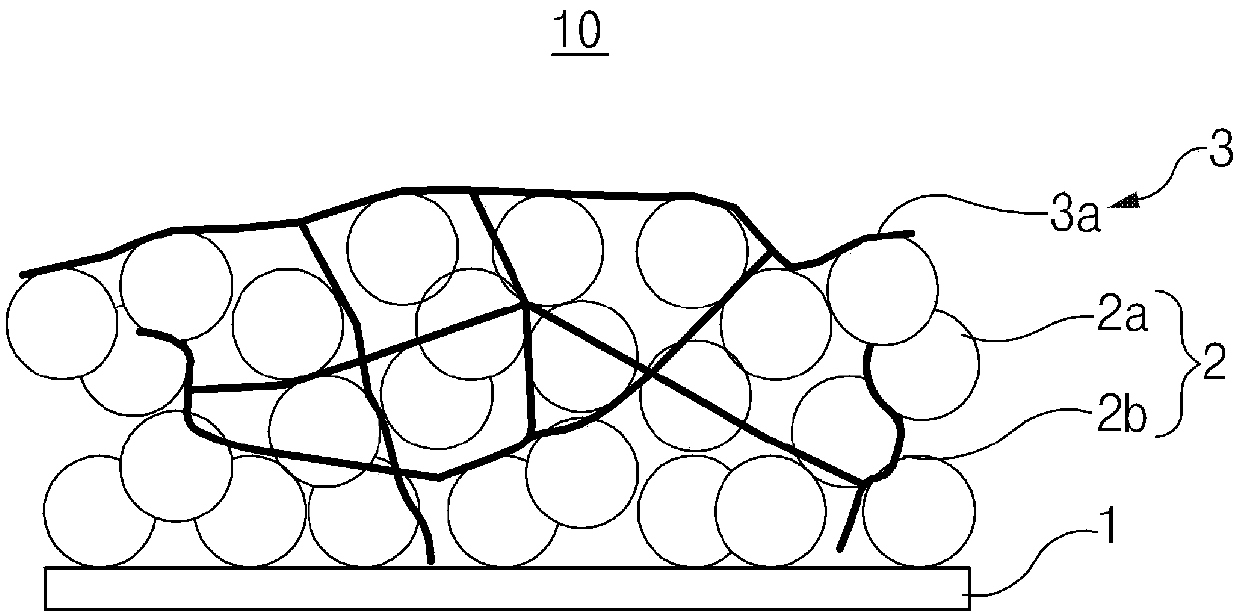

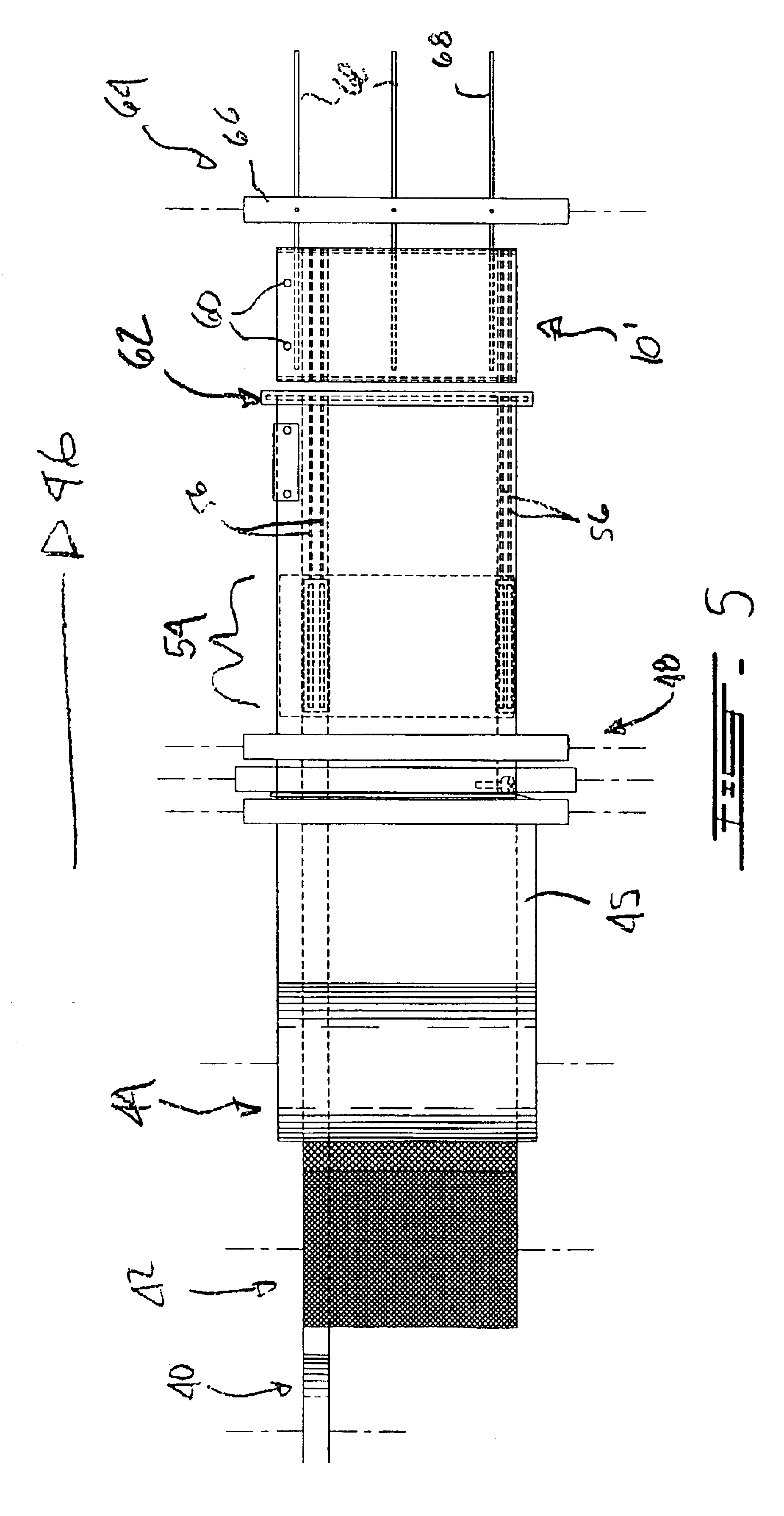

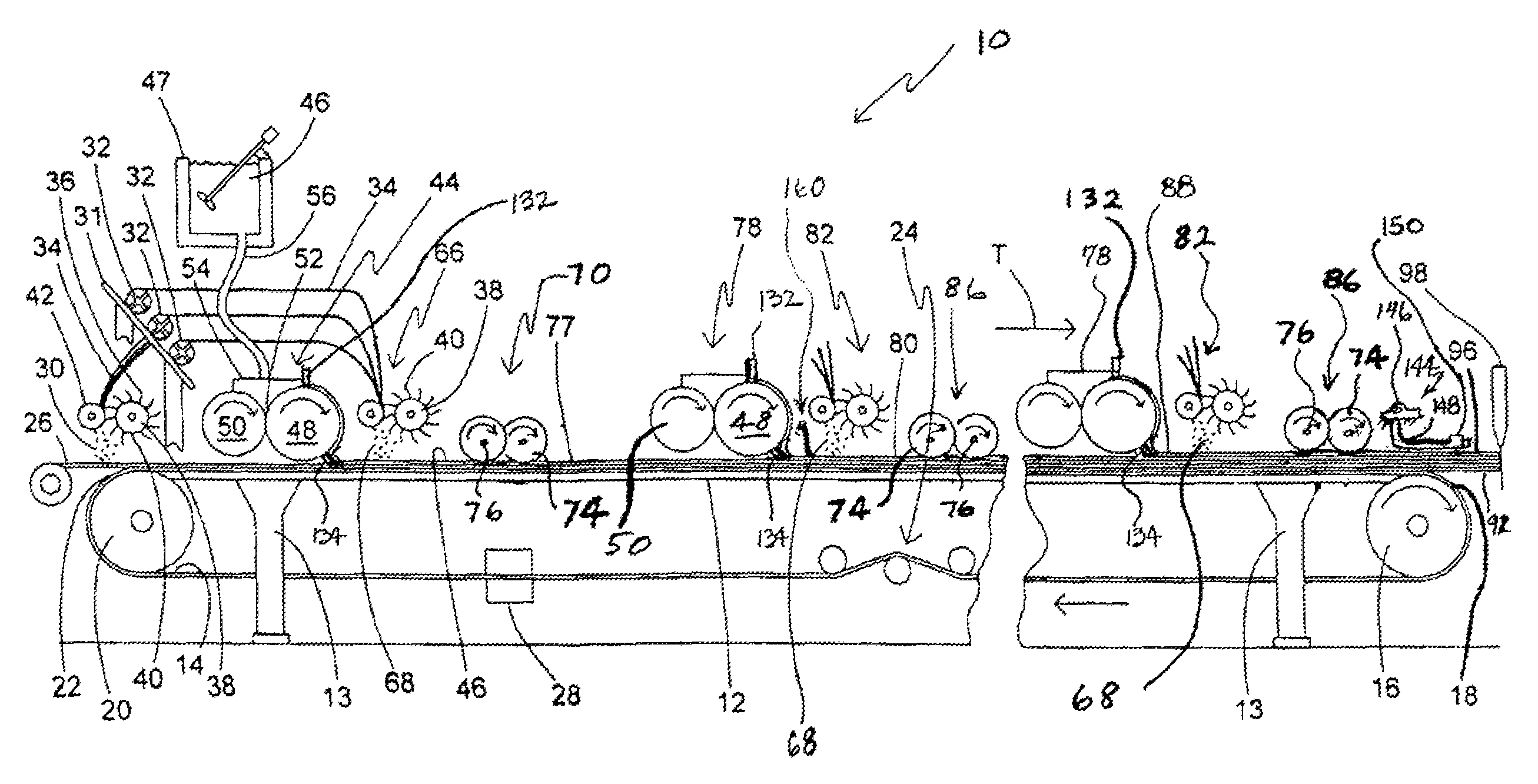

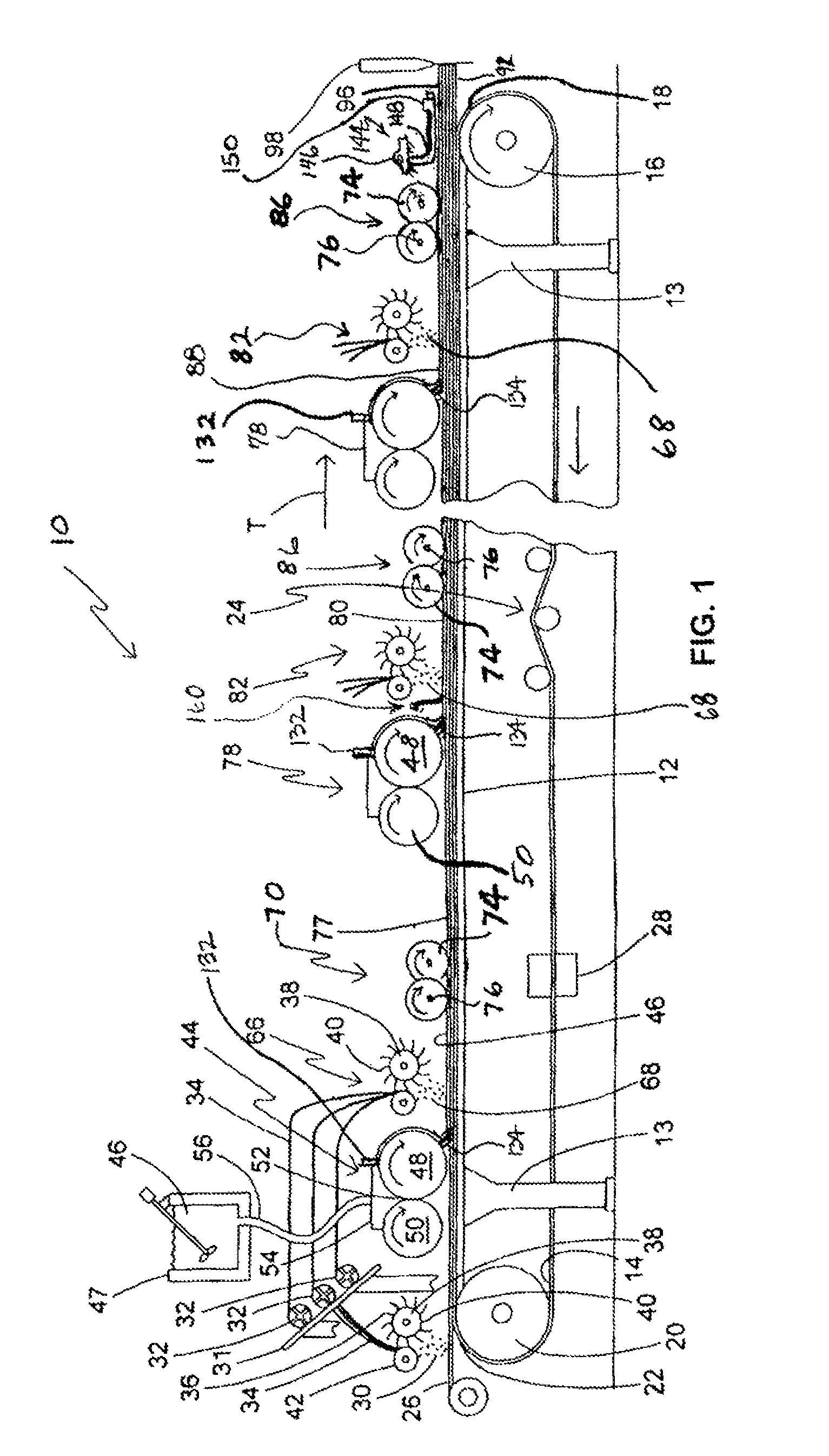

Multi-layer process and apparatus for producing high strength fiber-reinforced structural cementitious panels with enhanced fiber content

ActiveUS20070110970A1Good strength propertiesA large amountLiquid surface applicatorsConstruction materialCement boardSlurry

A process for producing fiber-reinforced structural cementitious panels made of at least one layer of fiber reinforced cementitious slurry, the process for each such layer of slurry including providing a moving web; depositing a first layer of individual, loose fibers upon the web; depositing a layer of settable slurry upon the deposited first layer of individual, loose fibers; depositing a second layer of individual, loose fibers upon the deposited layer of settable slurry; and actively embedding both layers of individual, loose fibers into the layer of slurry to distribute the fibers throughout the slurry.

Owner:UNITED STATES GYPSUM CO

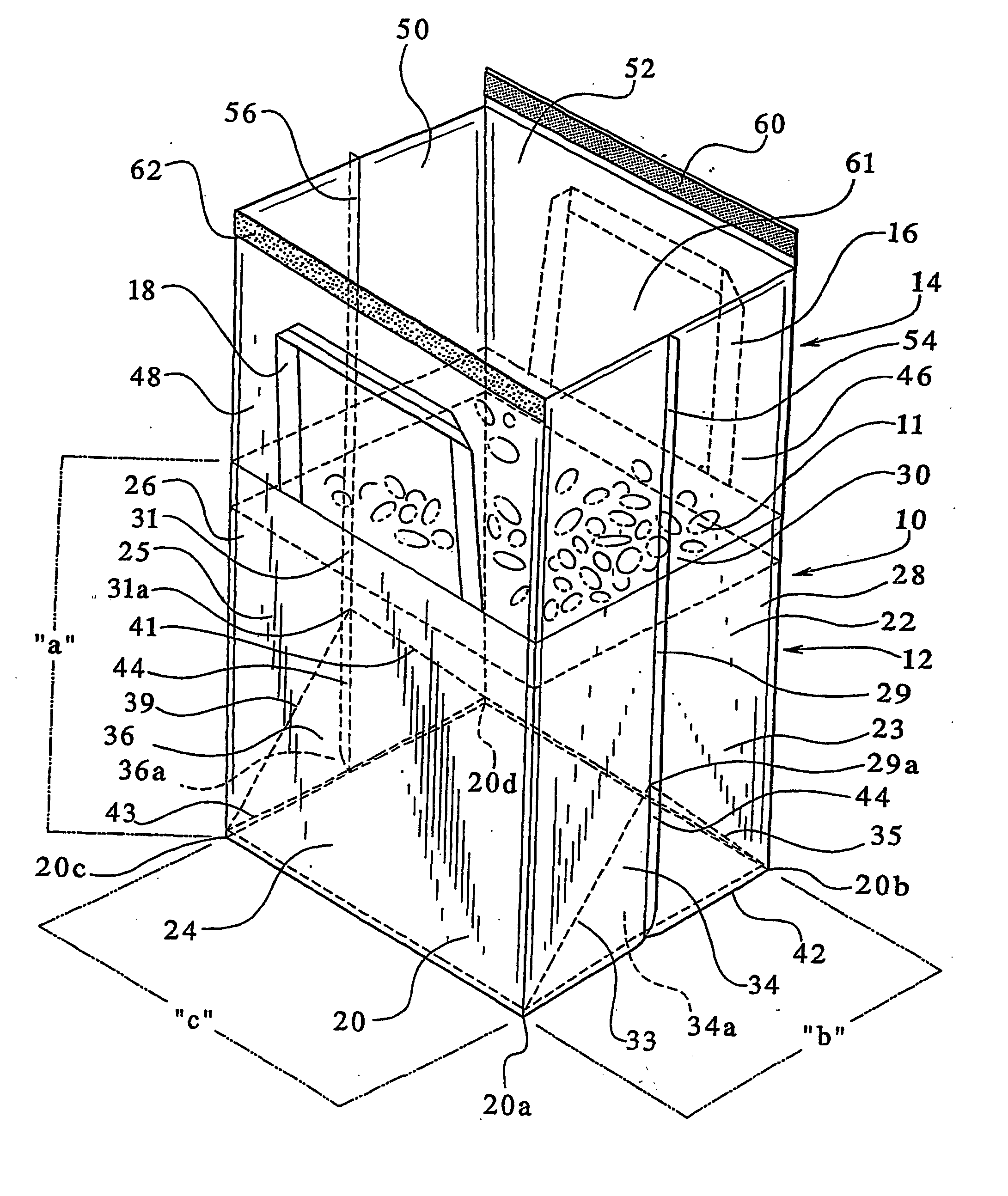

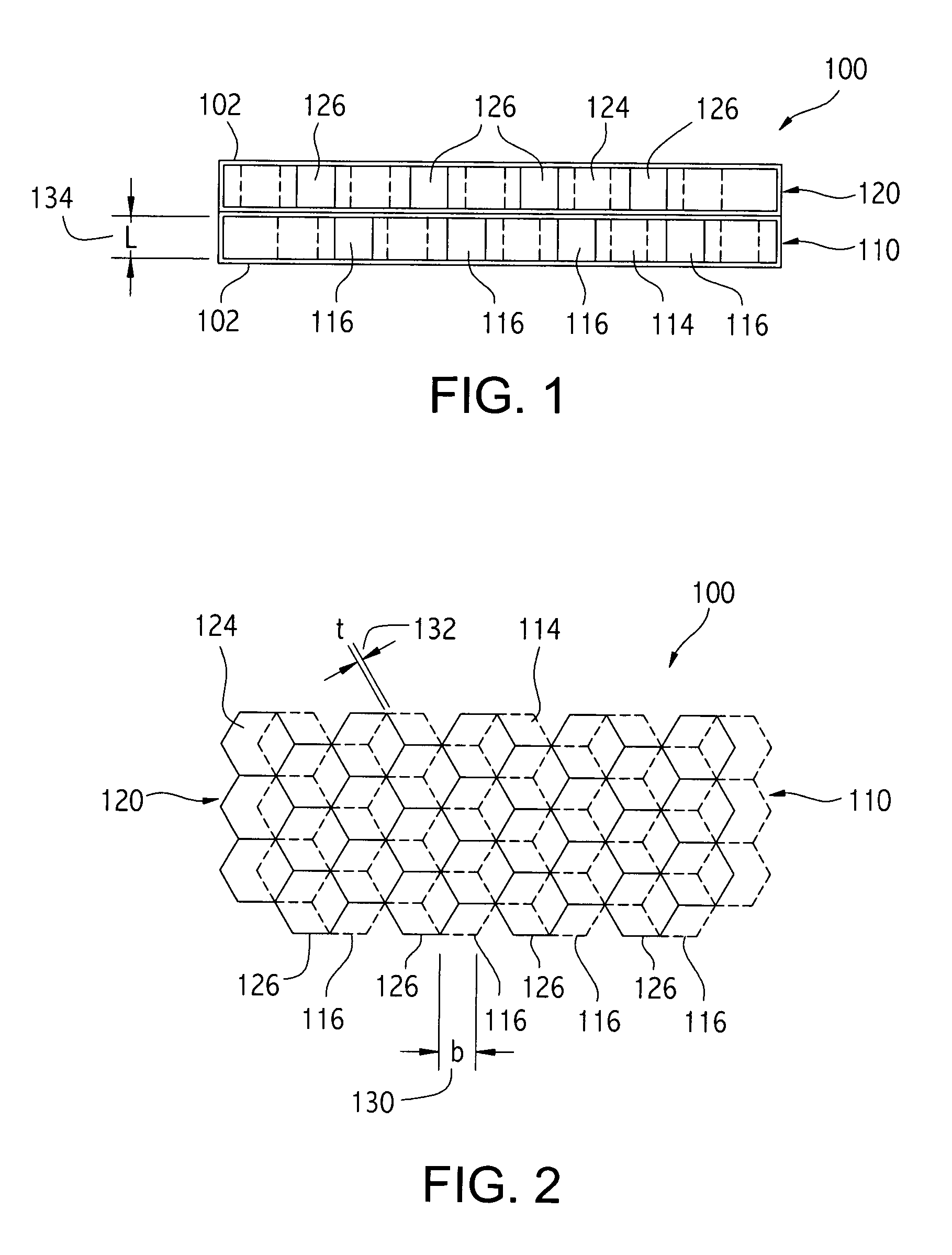

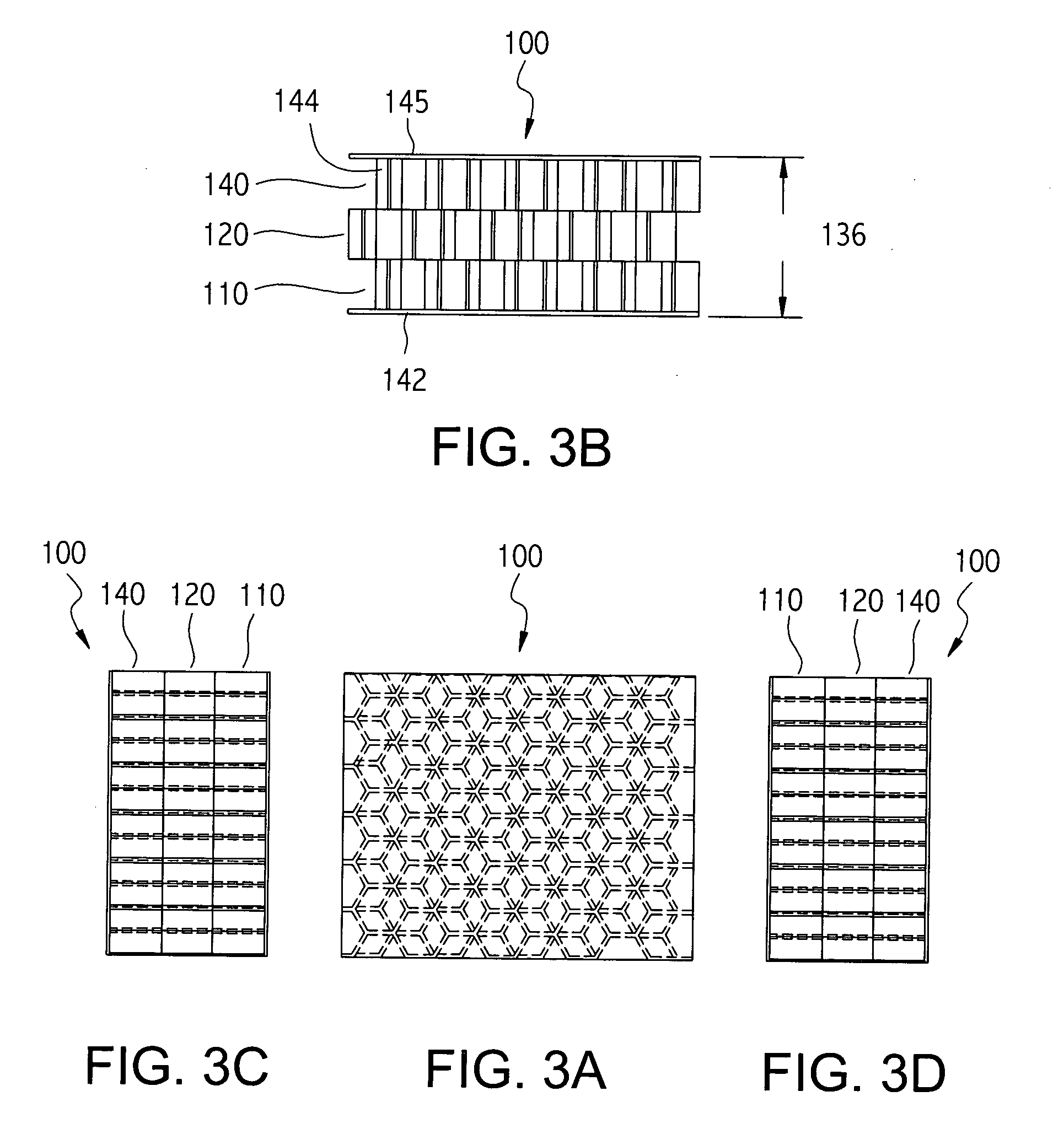

Insulation system having vacuum encased honeycomb offset panels

InactiveUS20050042416A1High strengthIncrease thermal resistanceThermal insulationSynthetic resin layered productsHoneycombEngineering

An insulation system comprising layers of honeycomb cores where each core is enclosed in a sealed container made of radiation barrier material. The container is evacuated and becomes a vacuum enclosure for the honeycomb cores. To reduce the heat transfer between the honeycomb cores, the cores are placed in an offset arrangement.

Owner:BOARD OF TRUSTEES OF UA FOR & ON BEHALF OF UAH

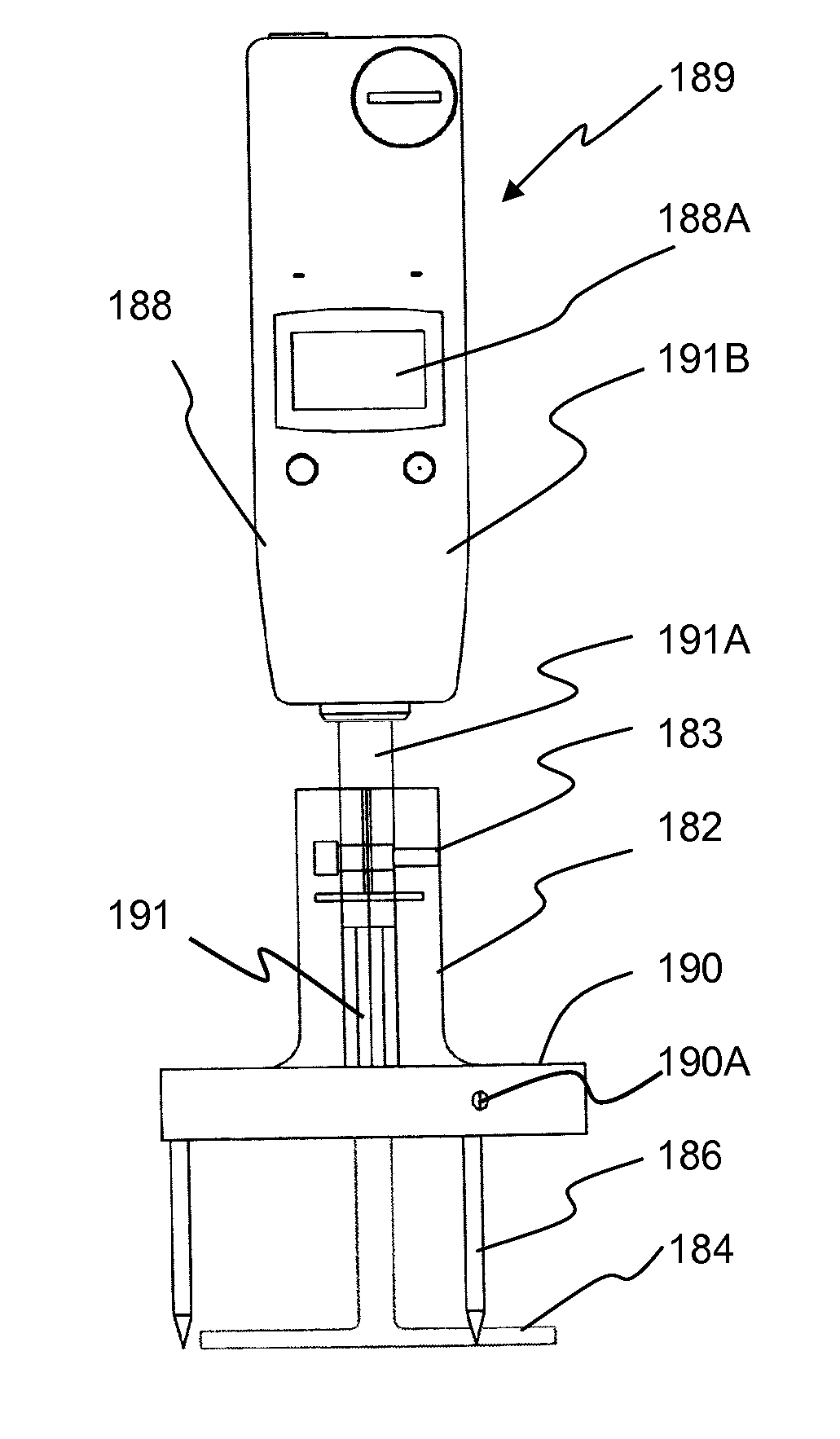

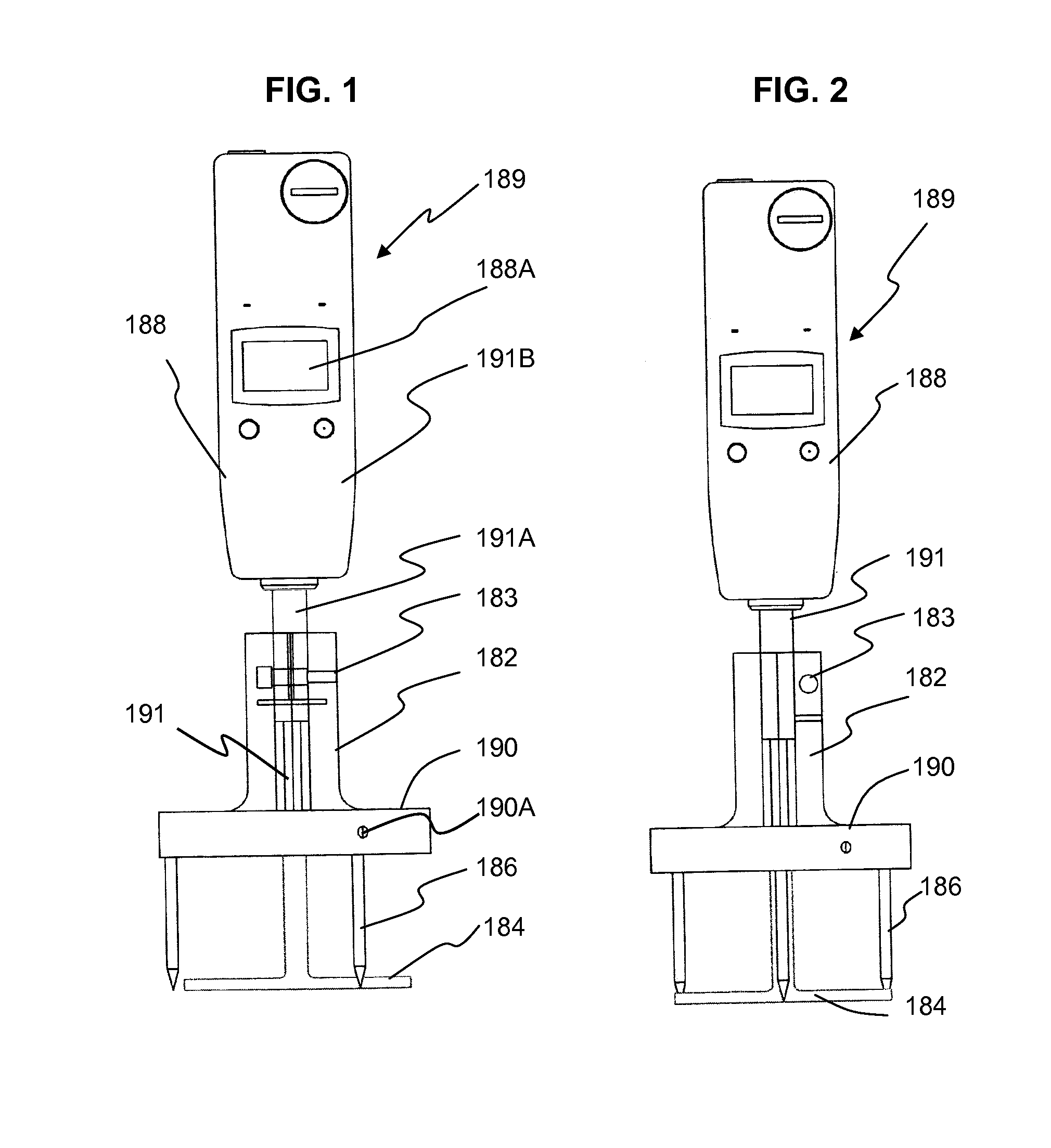

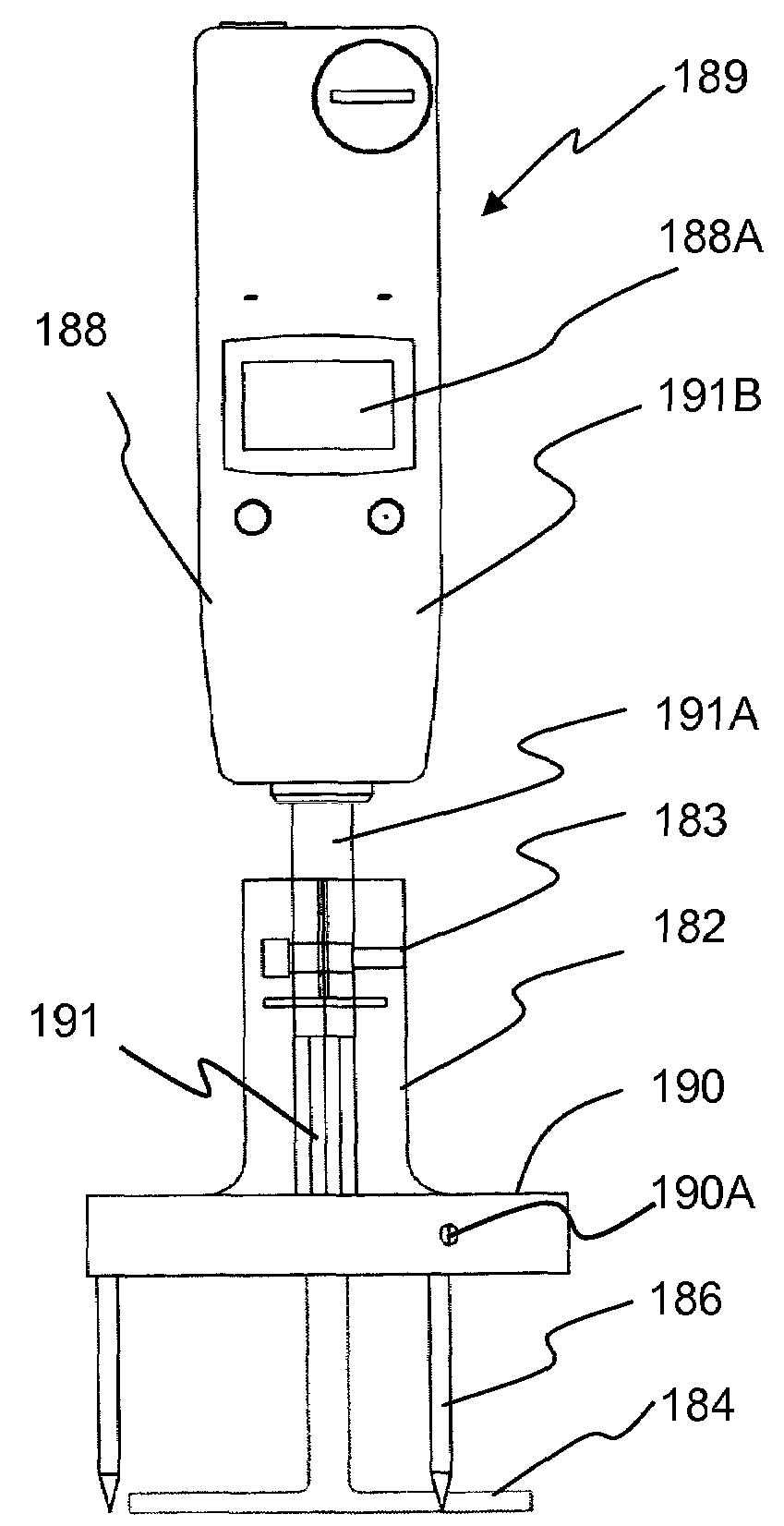

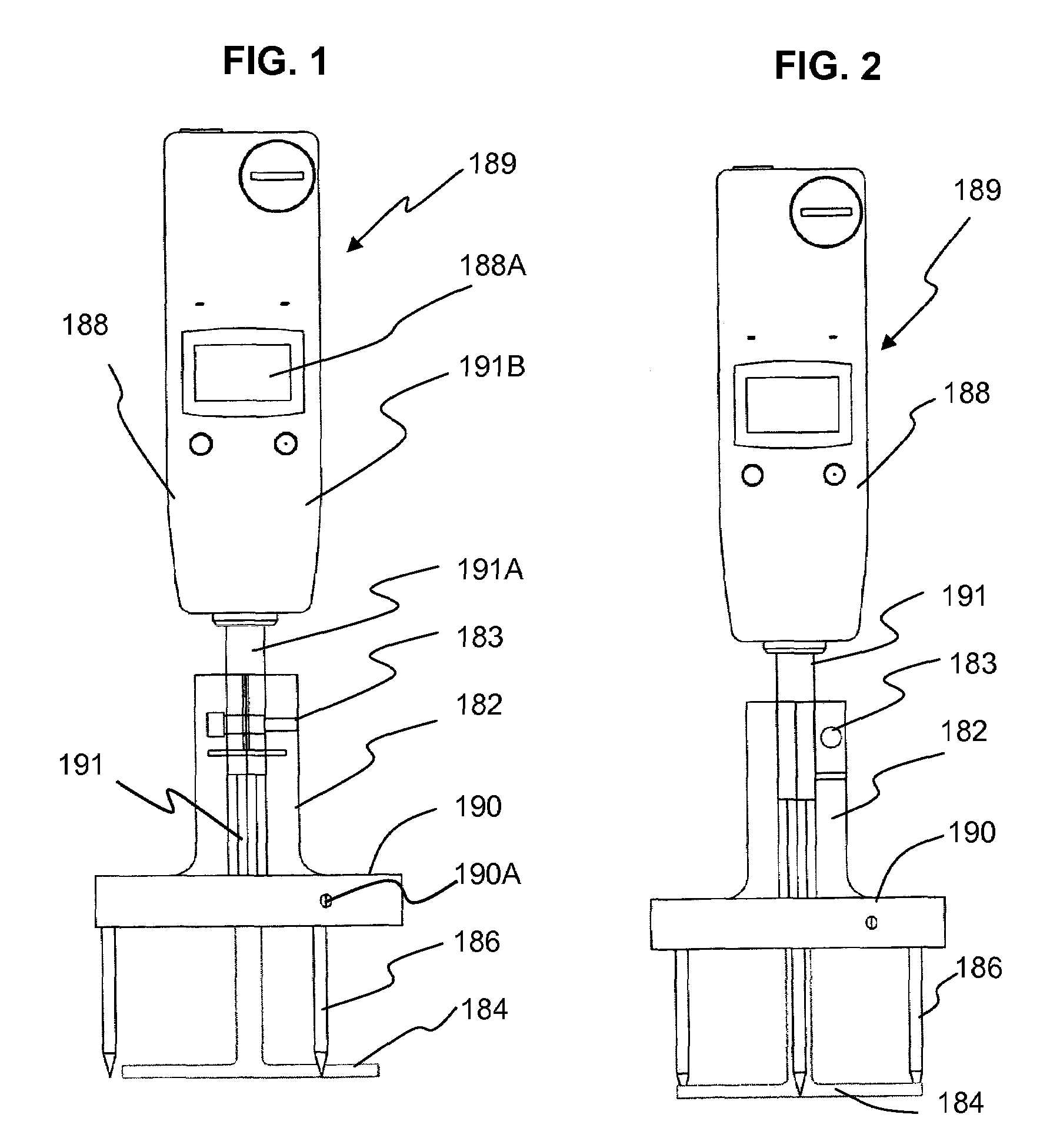

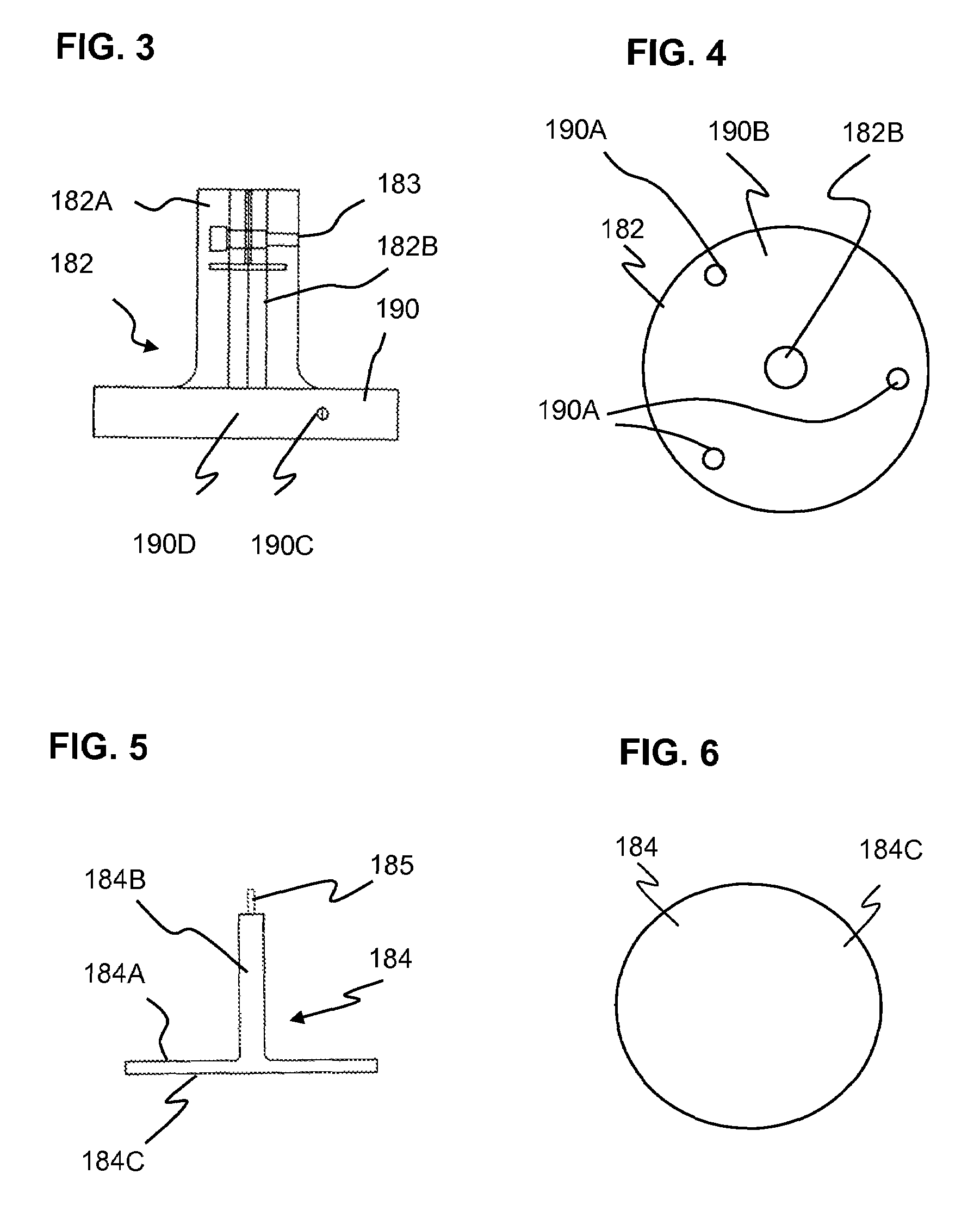

Wet slurry thickness gauge and method for use of same

InactiveUS20080110276A1Assist in quality controlEqually distributedMechanical measuring arrangementsStrength propertiesDisplay deviceSlurry

A handheld wet slurry thickness gauge and method for its use. The thickness gauge includes a distance displacement measurement gauge, a skirt, a platen and support legs. The distance displacement measurement gauge includes a case, a vertical stem, and a vertical spindle. The stem extends from the case. The spindle is slidably supported to move in an axial direction within the stem. The case body has a display for indicating a linear displacement of the spindle. The skirt has a central through-hole for receiving the stem of the gauge and retaining the stem in an upright position. The measuring platen has a platen base and a platen shaft extending upwardly from the platen base and attached to the spindle. The support legs extend downwardly from the skirt. The platen is below the skirt.

Owner:UNITED STATES GYPSUM CO

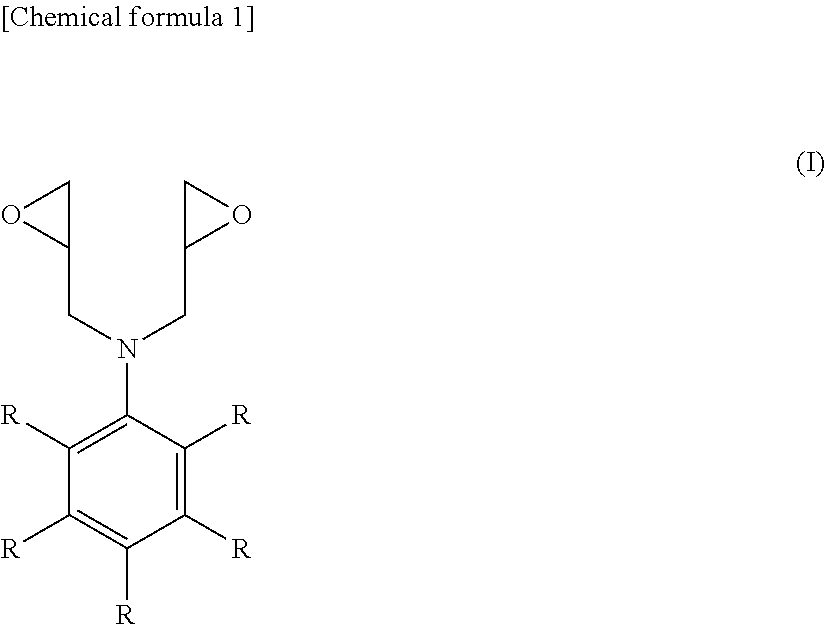

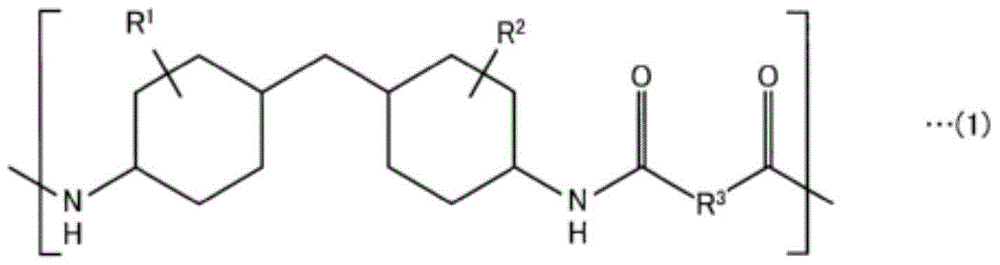

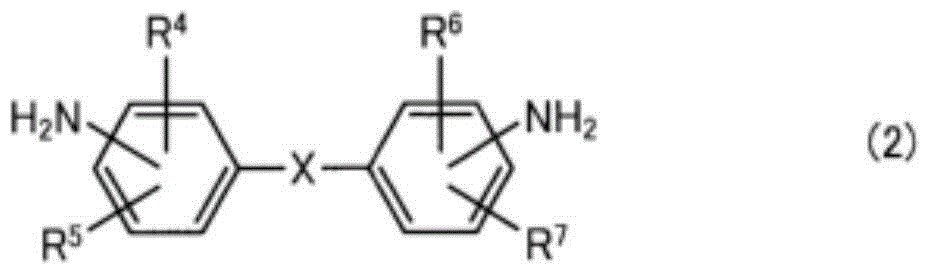

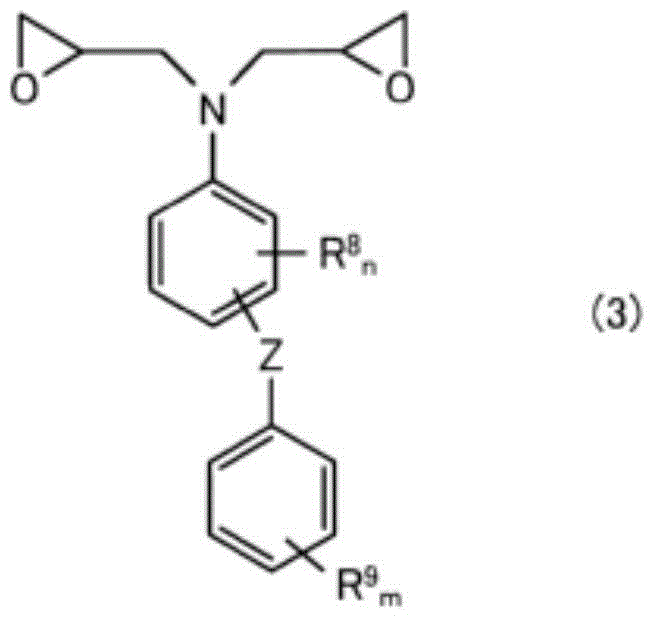

Epoxy resin composition, prepreg and fiber-reinforced composite material

ActiveUS20110184091A1Excellent elastic modulusImprove heat resistanceSynthetic resin layered productsThin material handlingOxazolidoneHeat resistance

An epoxy resin composition comprising an epoxy resin [A], an amine-based curing agent [B] and a block copolymer [C] as components, wherein the epoxy resin [A] contains [Aa] an epoxy resin having at least one structure selected from a condensed polycyclic structure, biphenyl structure and oxazolidone ring structure; [Ab] an epoxy resin selected from a polyfunctional amine type epoxy resin [Ab1] and a liquid bisphenol type epoxy resin [Ab2], and the block copolymer [C] is at least one block copolymer selected from the group consisting of S-B-M, B-M and M-B-M. The present invention provides an epoxy resin composition that can be cured to form a cured product excellent in heat resistance, elastic modulus and toughness.

Owner:TORAY IND INC

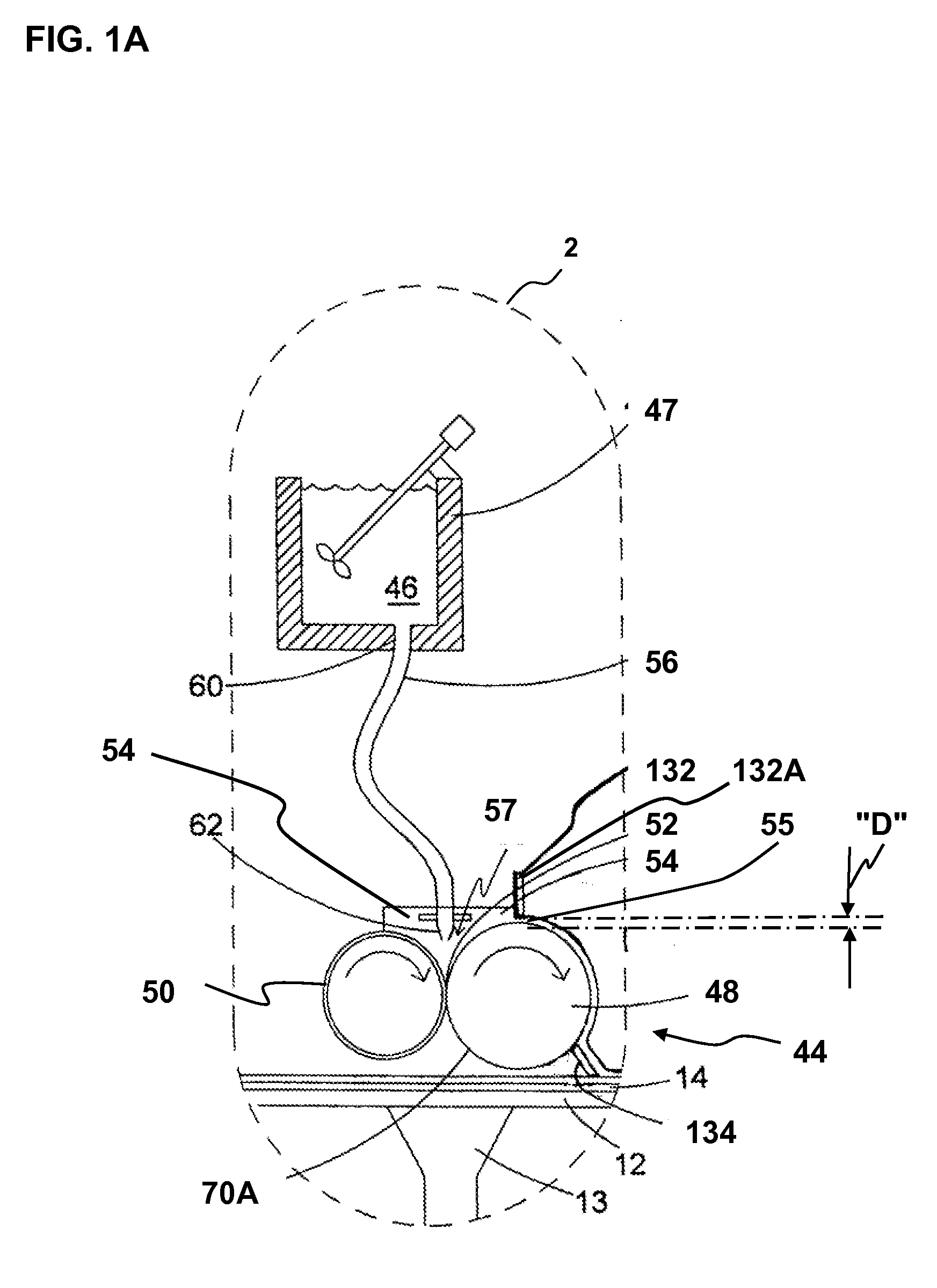

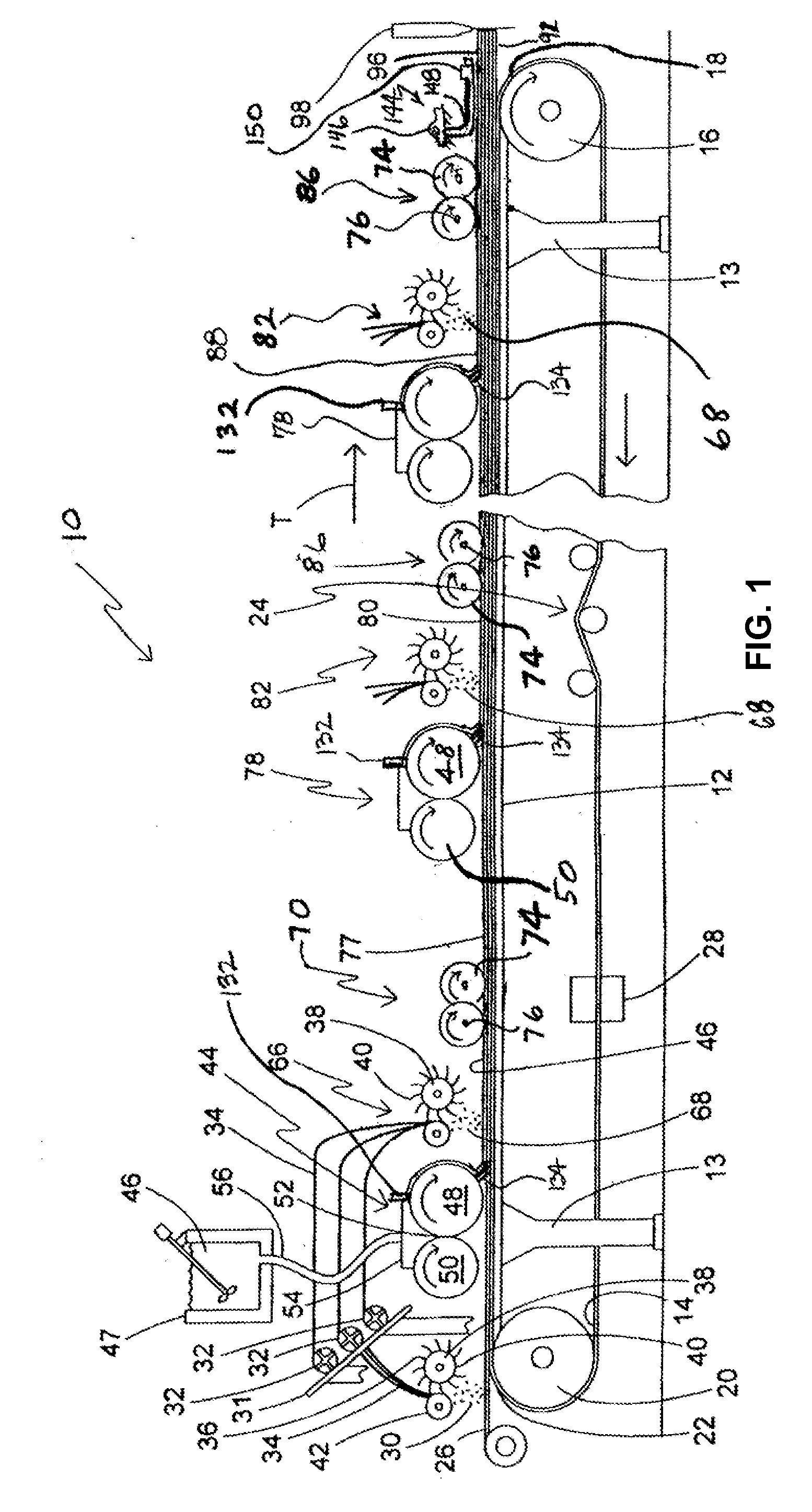

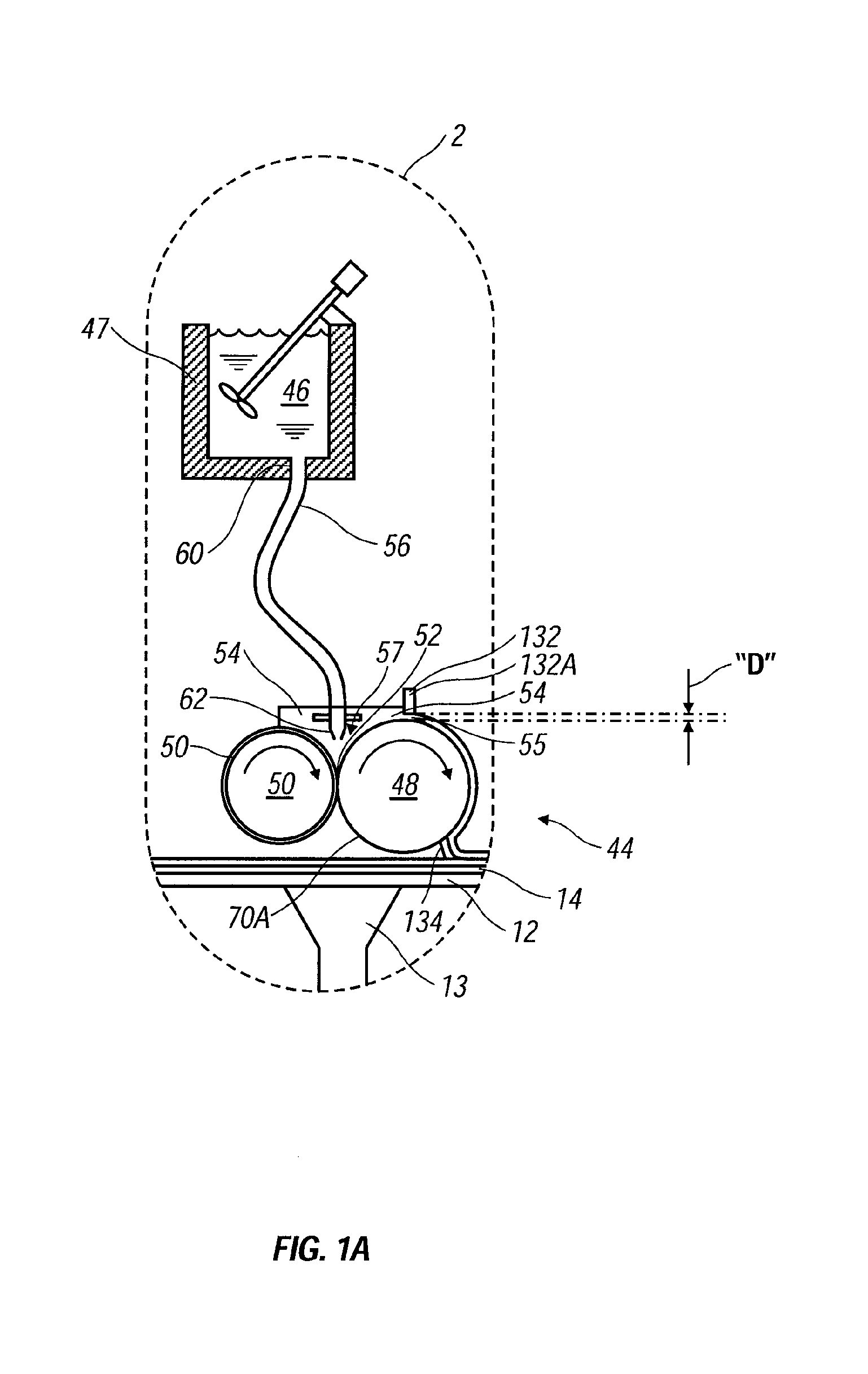

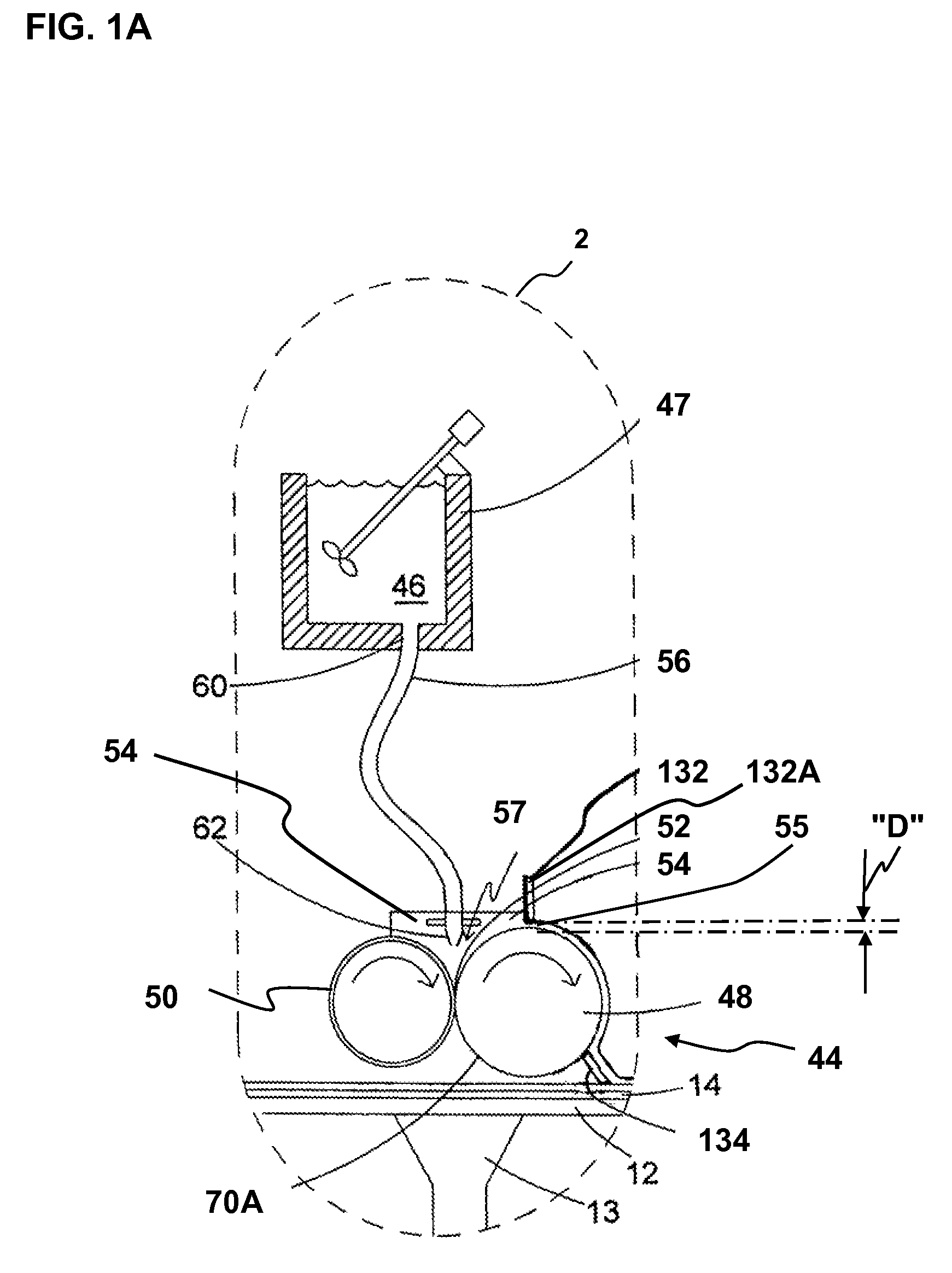

Process and apparatus for feeding cementitious slurry for fiber-reinforced structural cement panels

ActiveUS20080099171A1Good strength propertiesA large amountNon-fibrous pulp additionNatural cellulose pulp/paperEngineeringFibre reinforcement

A head-box for depositing slurry upon a moving web including a main metering roll, a companion roll disposed in closely spaced relation to the metering roll and a vibrating gate which forms a nip between the metering roller and the gate. The nip is arranged to retain a supply of the slurry, and the rolls are driven so slurry retained in the nip progresses over an upper outer peripheral surface of the metering roll to be deposited upon the web. Also, preferably included is a doctor blade disposed in operational relationship to the metering roll for directing the slurry downwardly from the outer metering roll surface to a point above the surface of a carrier for a fiberglass layer upon which the slurry layer is deposited. The vibrating gate and doctor blade may be pivotally mounted to either side of the surfaces of the head-box.

Owner:UNITED STATES GYPSUM CO

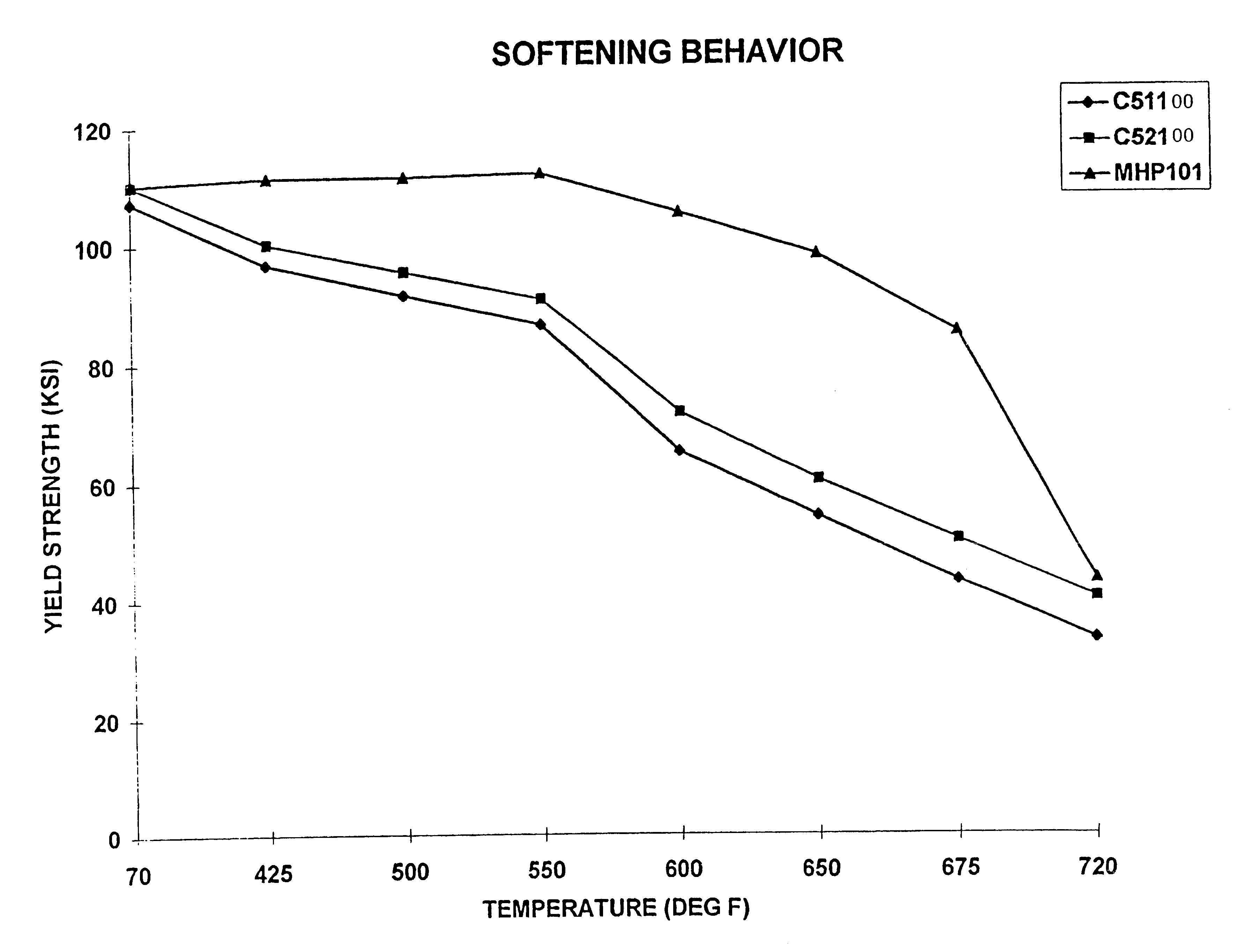

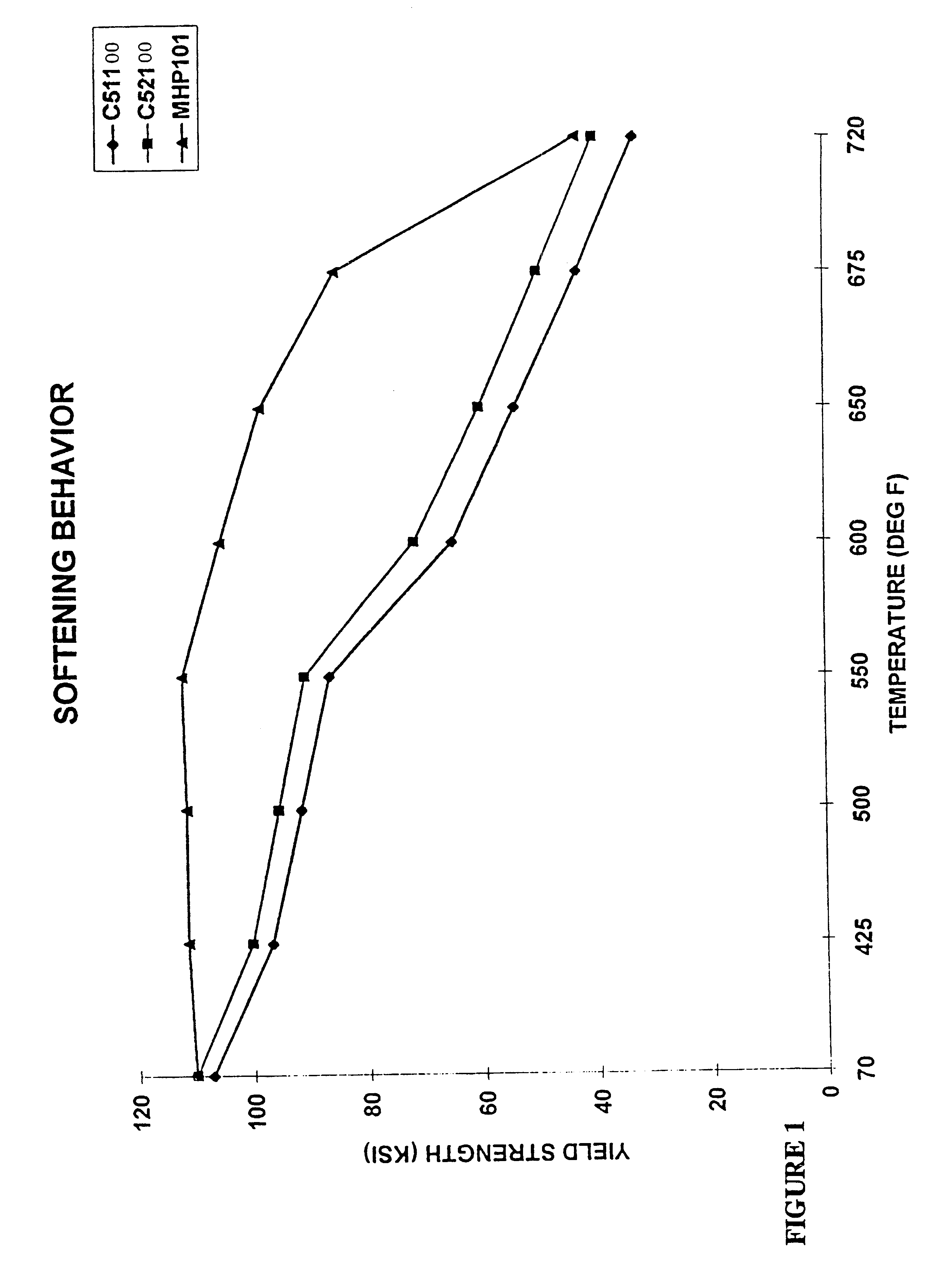

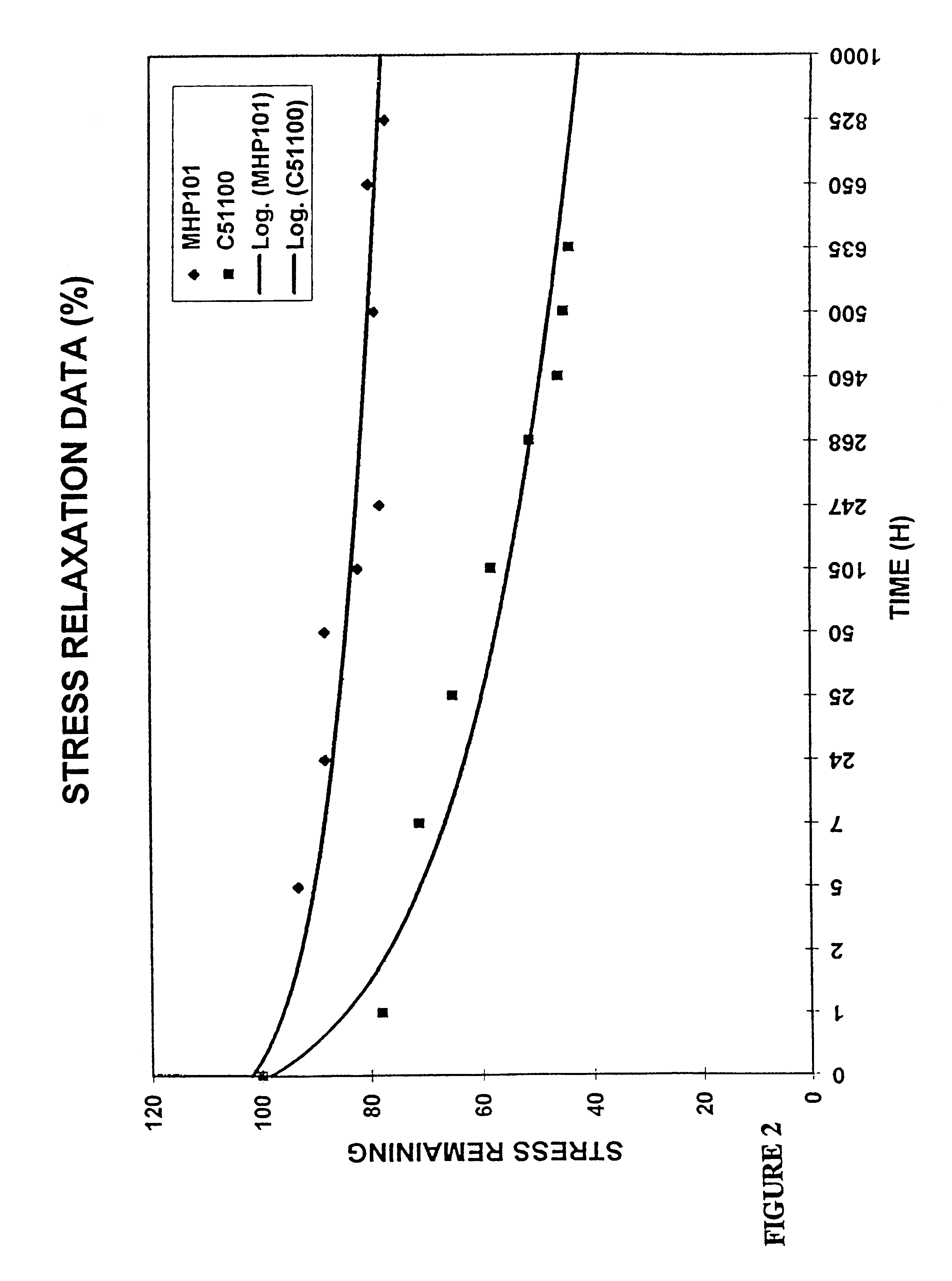

Copper based alloy featuring precipitation hardening and solid-solution hardening

InactiveUS6379478B1Good molding effectOptimal spring propertyCoupling contact membersPhosphor bronzeSolid solution

Owner:MILLER THE

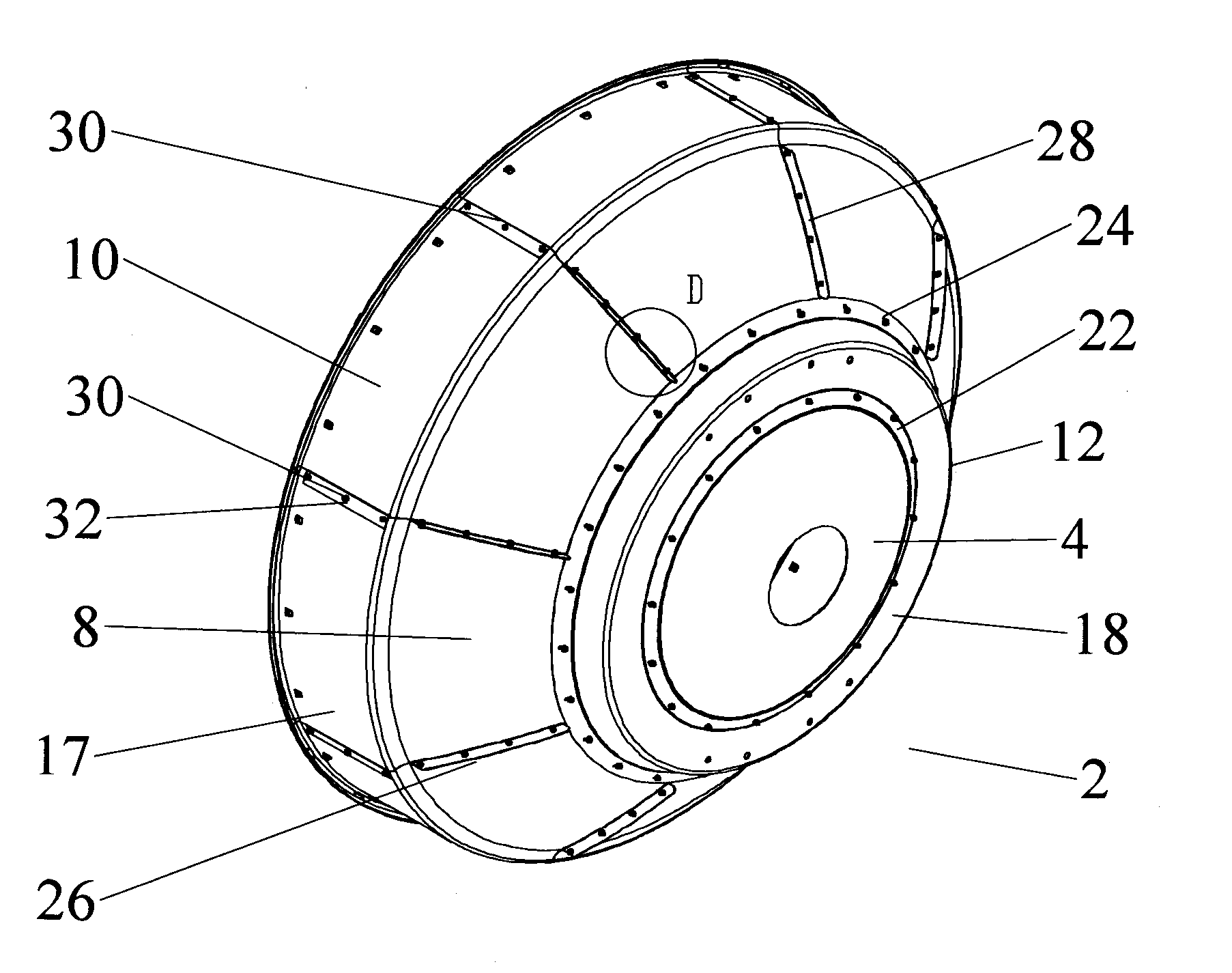

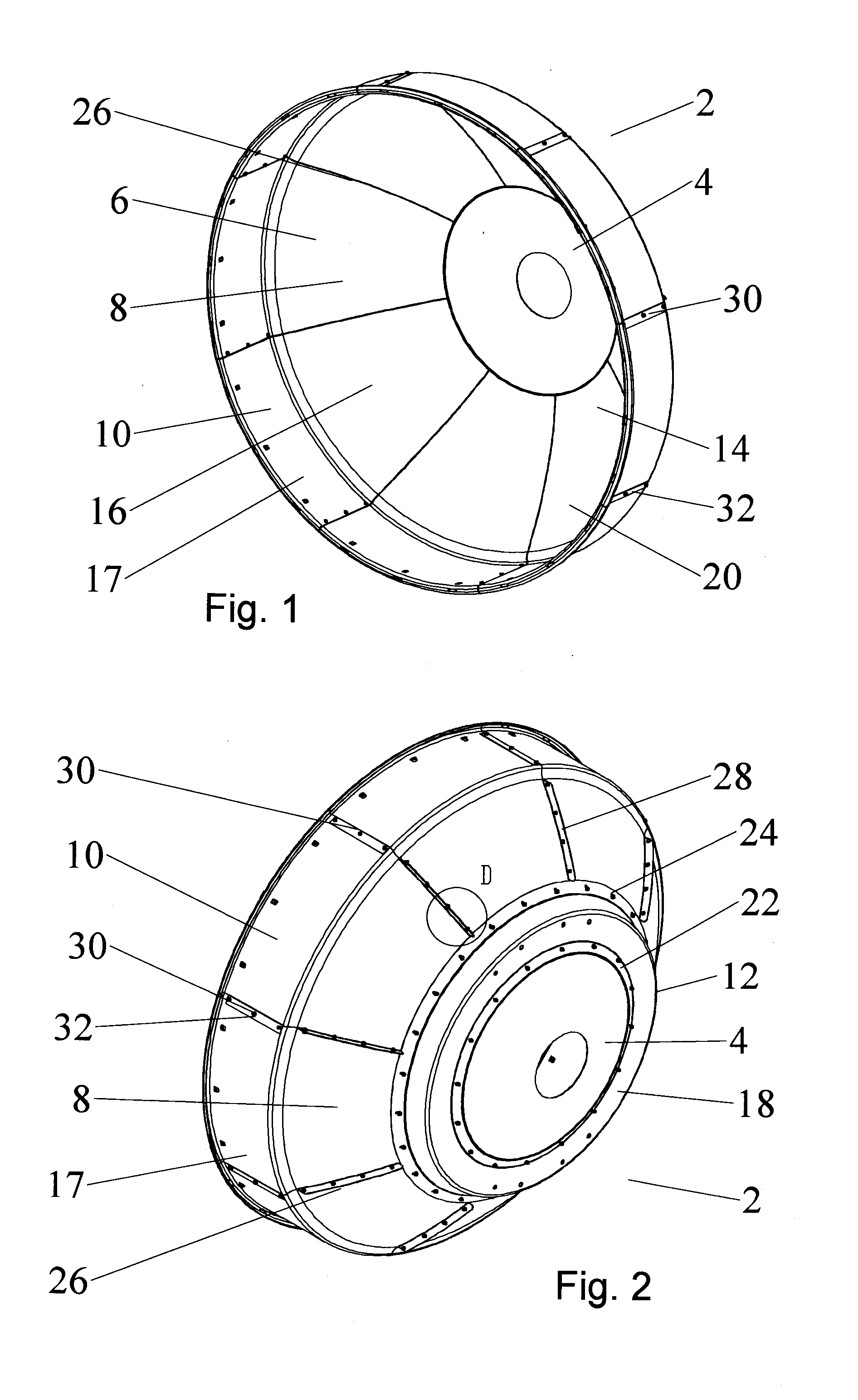

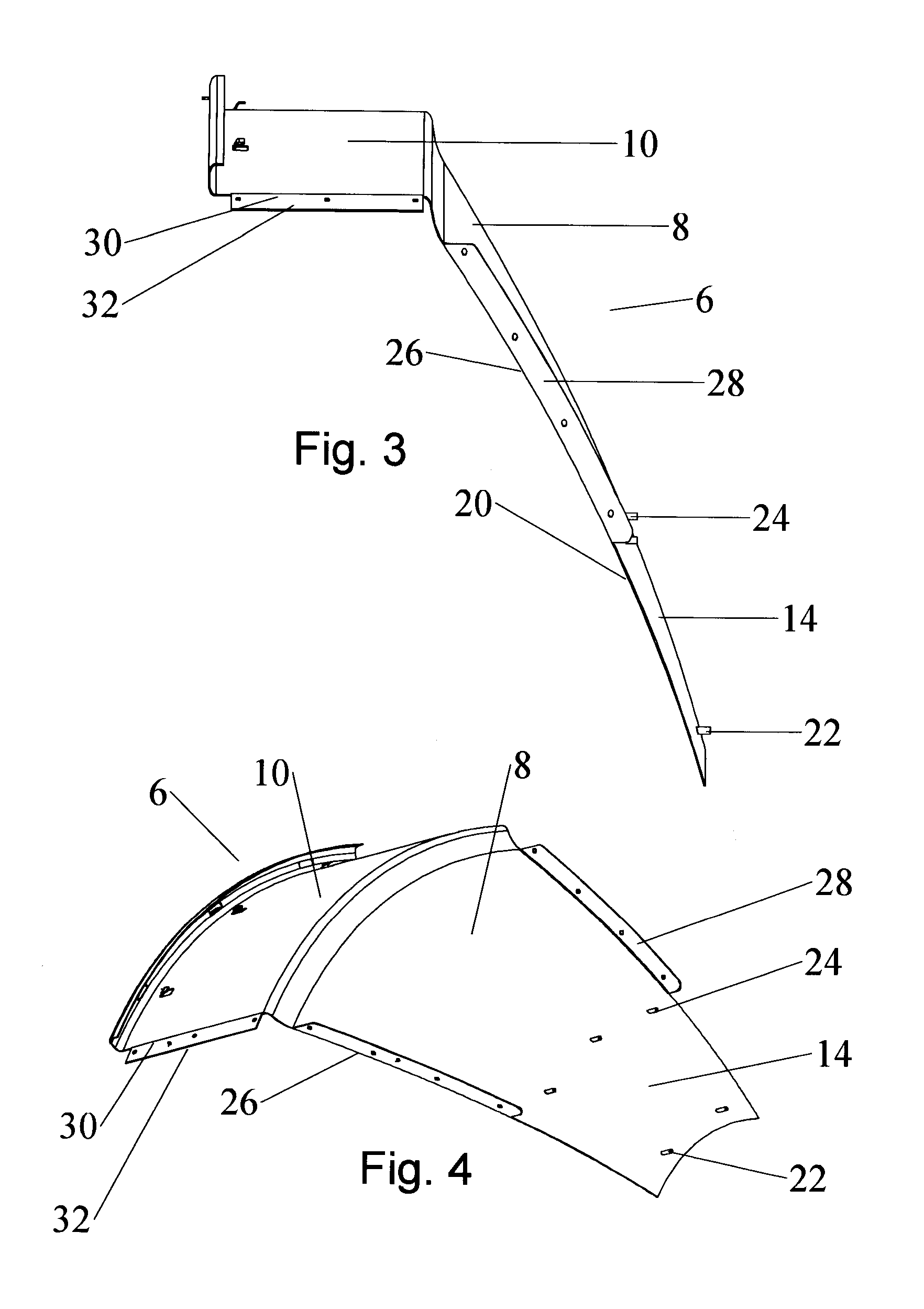

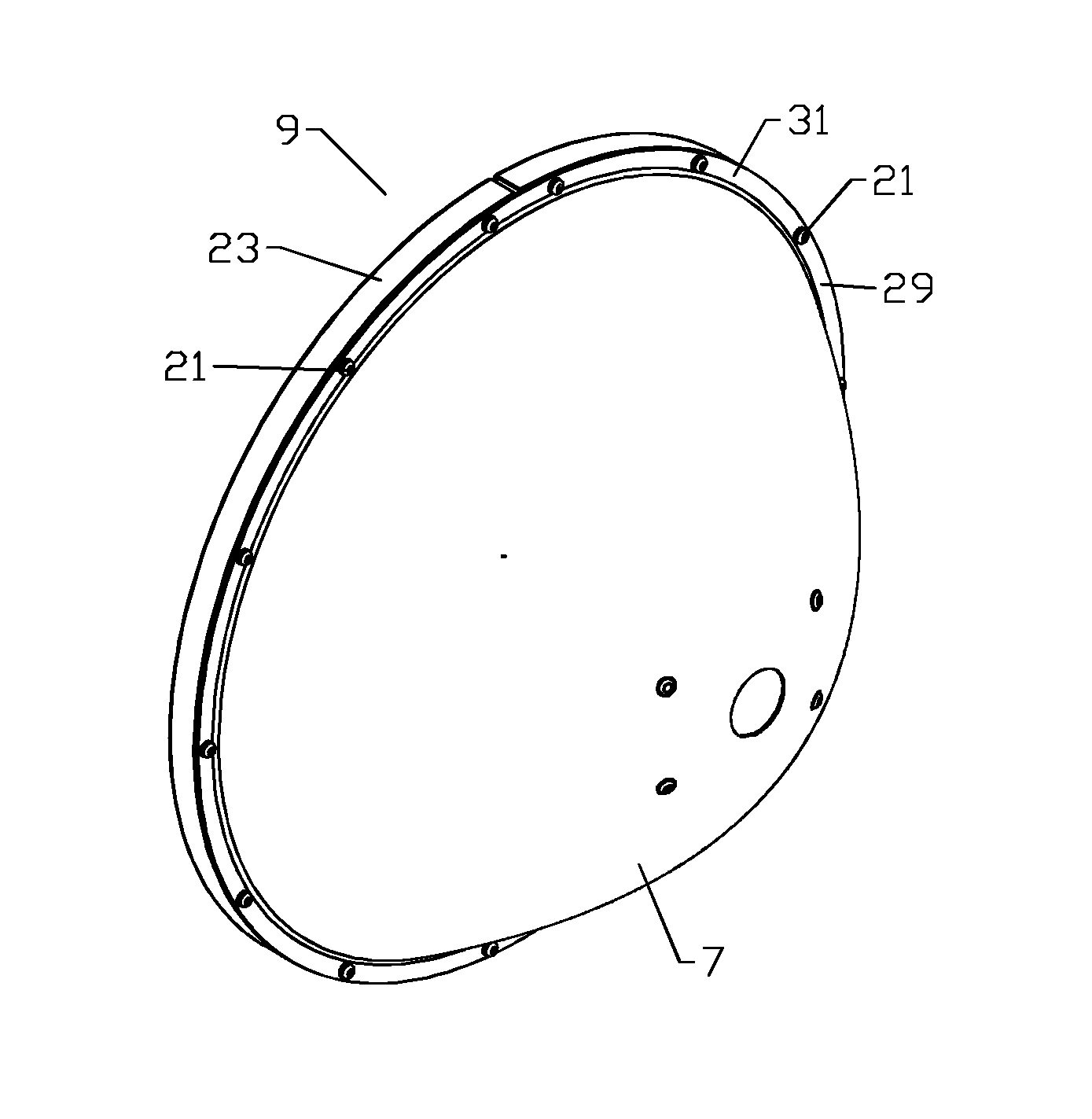

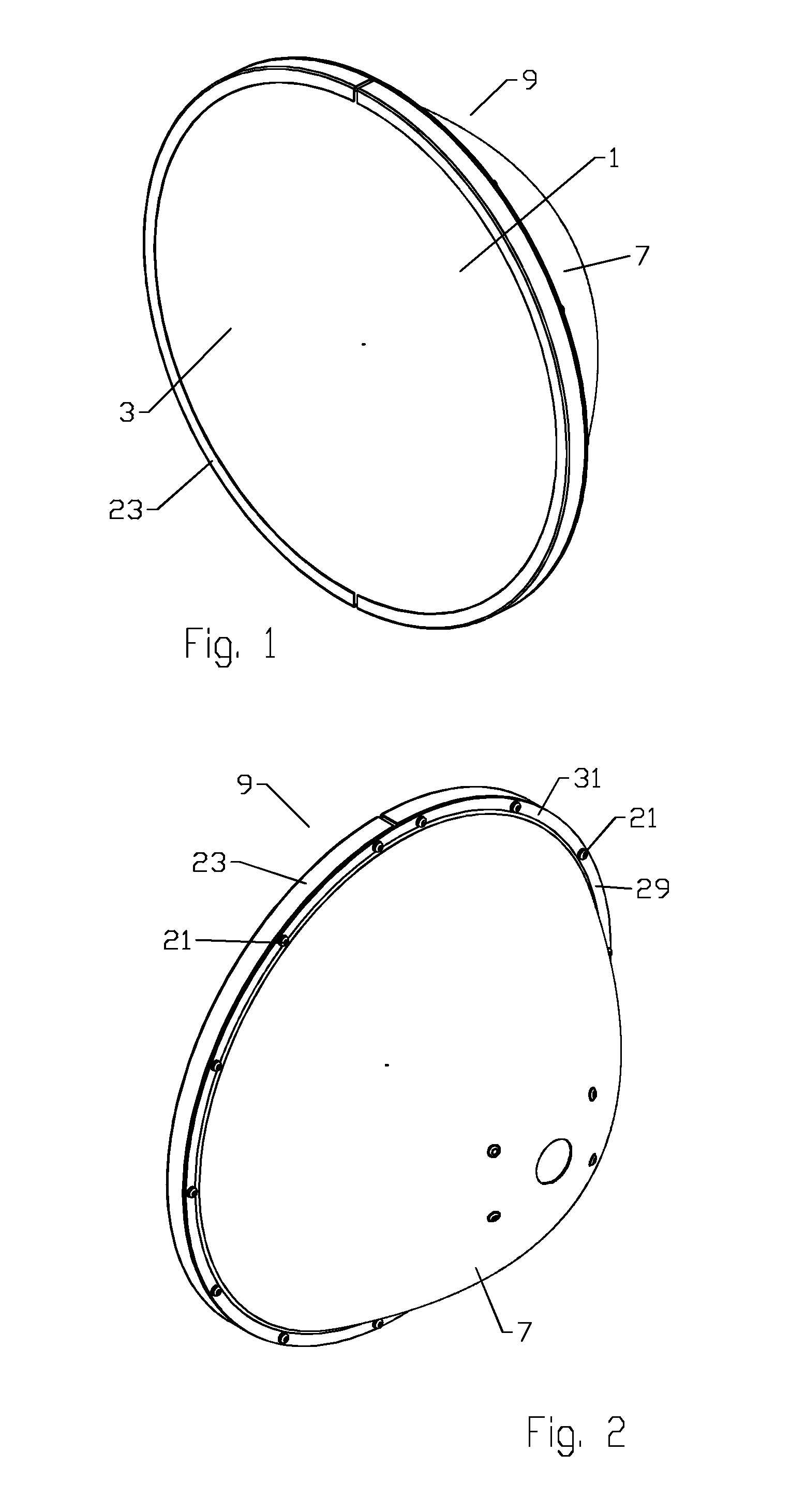

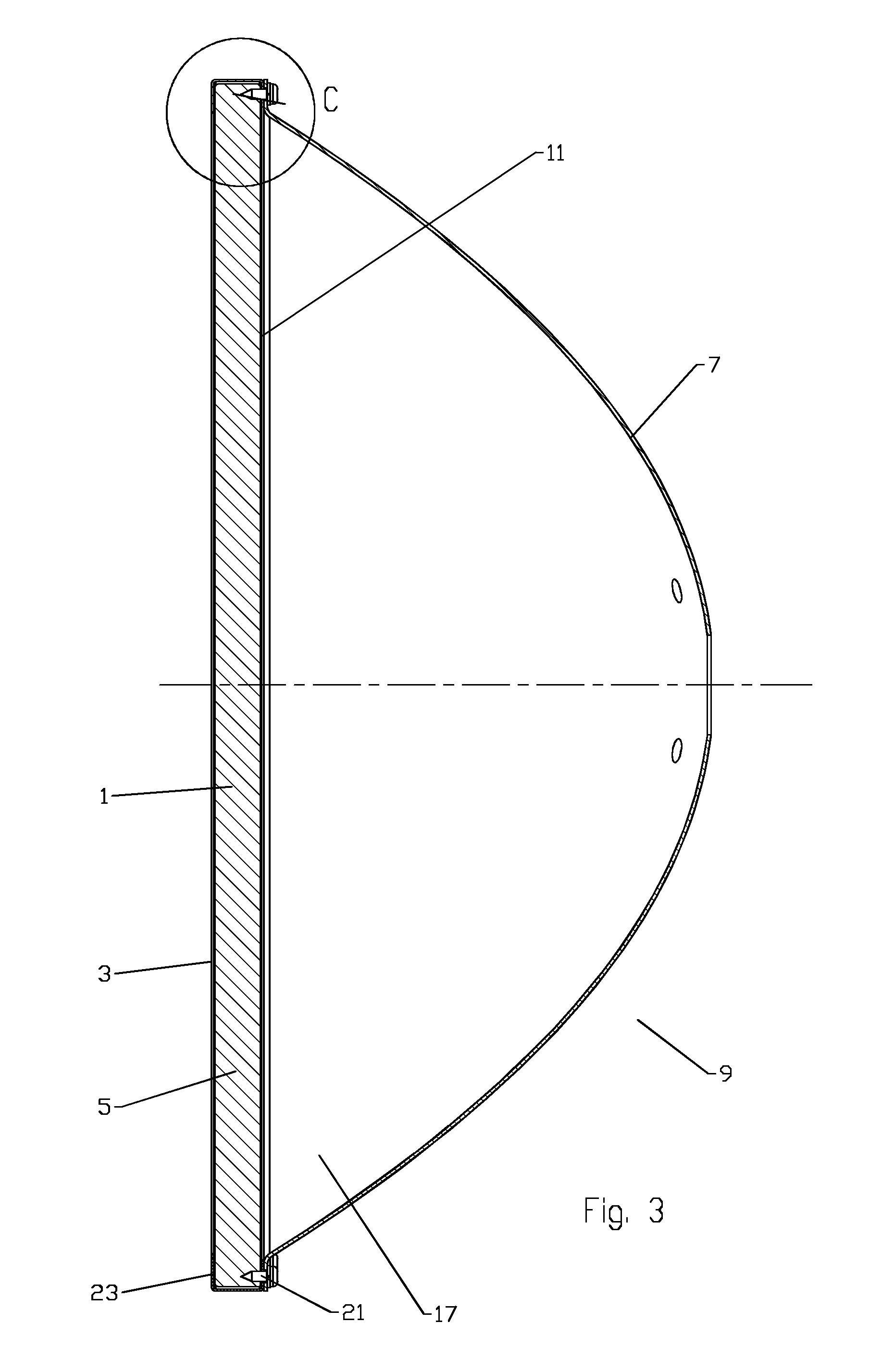

Segmented antenna reflector with shield

InactiveUS20110291914A1Improve rigidityImprove the level ofCollapsable antennas meansAntenna supports/mountingsEngineeringElectrical and Electronics engineering

An antenna reflector includes a central segment with a peripheral coupling portion and a plurality of peripheral segments, each provided with a reflector portion and a shield portion. A proximal portion of each shield portion is dimensioned to couple with the peripheral coupling portion, a reflector portion edge of each peripheral segment is dimensioned to couple with adjacent reflector portion edges and a shield portion edge of each peripheral segment is dimensioned to couple with adjacent shield portion edges. The central segment and the reflector portion of the peripheral segments together form a reflector dish. The shield portions together provide a circumferential shield extending from a periphery of the reflector dish along an antenna boresight of the reflector dish.

Owner:COMMSCOPE TECH LLC

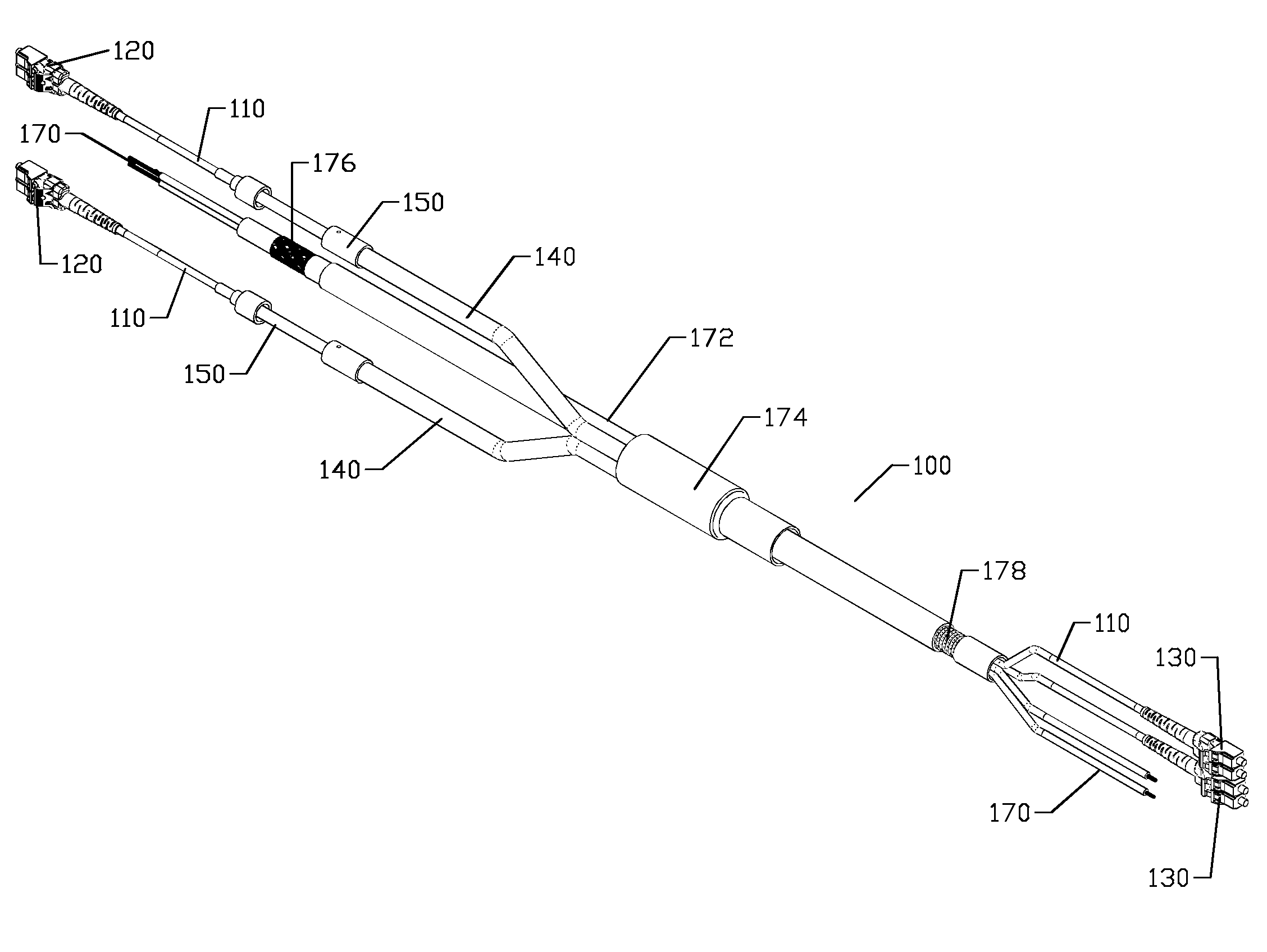

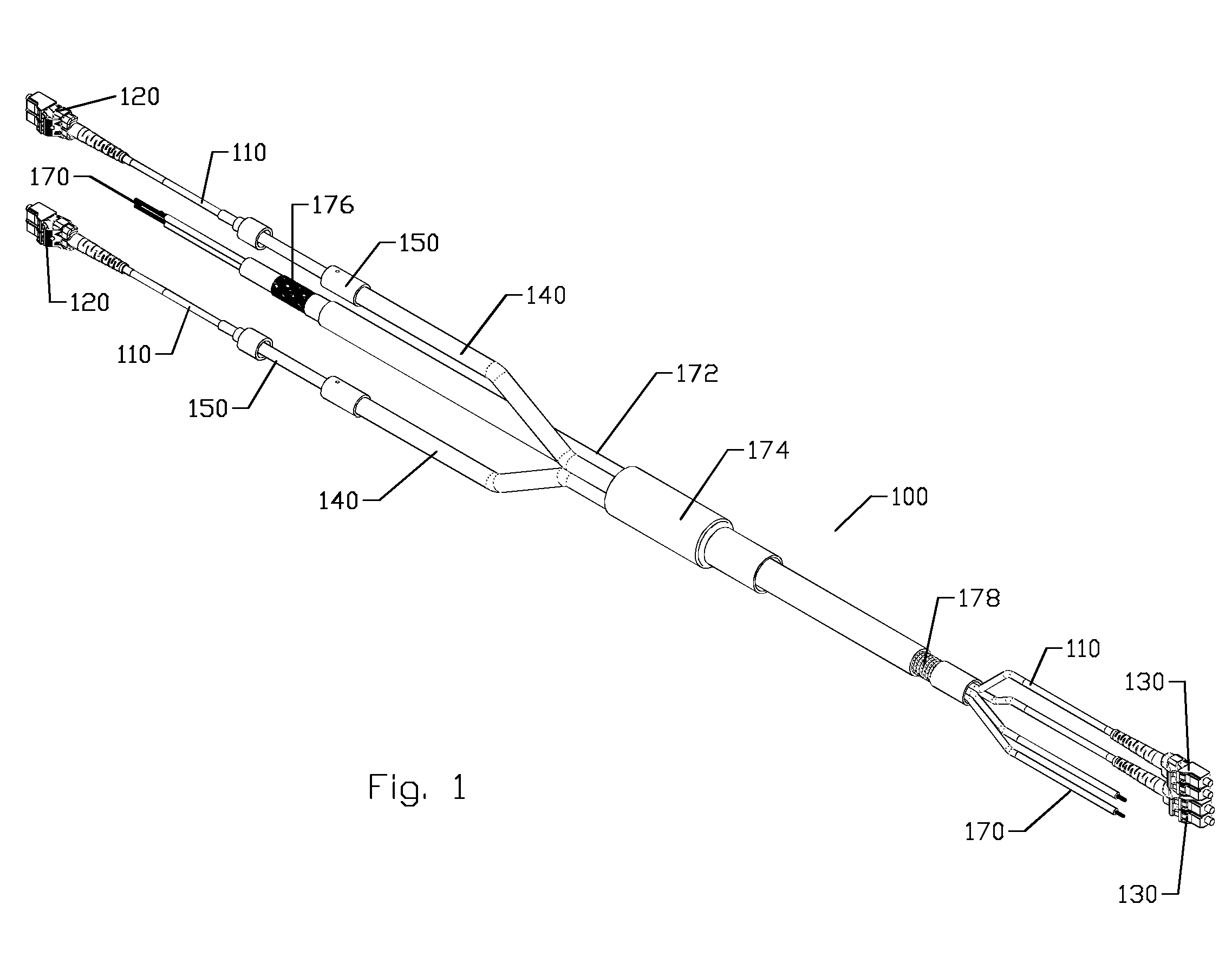

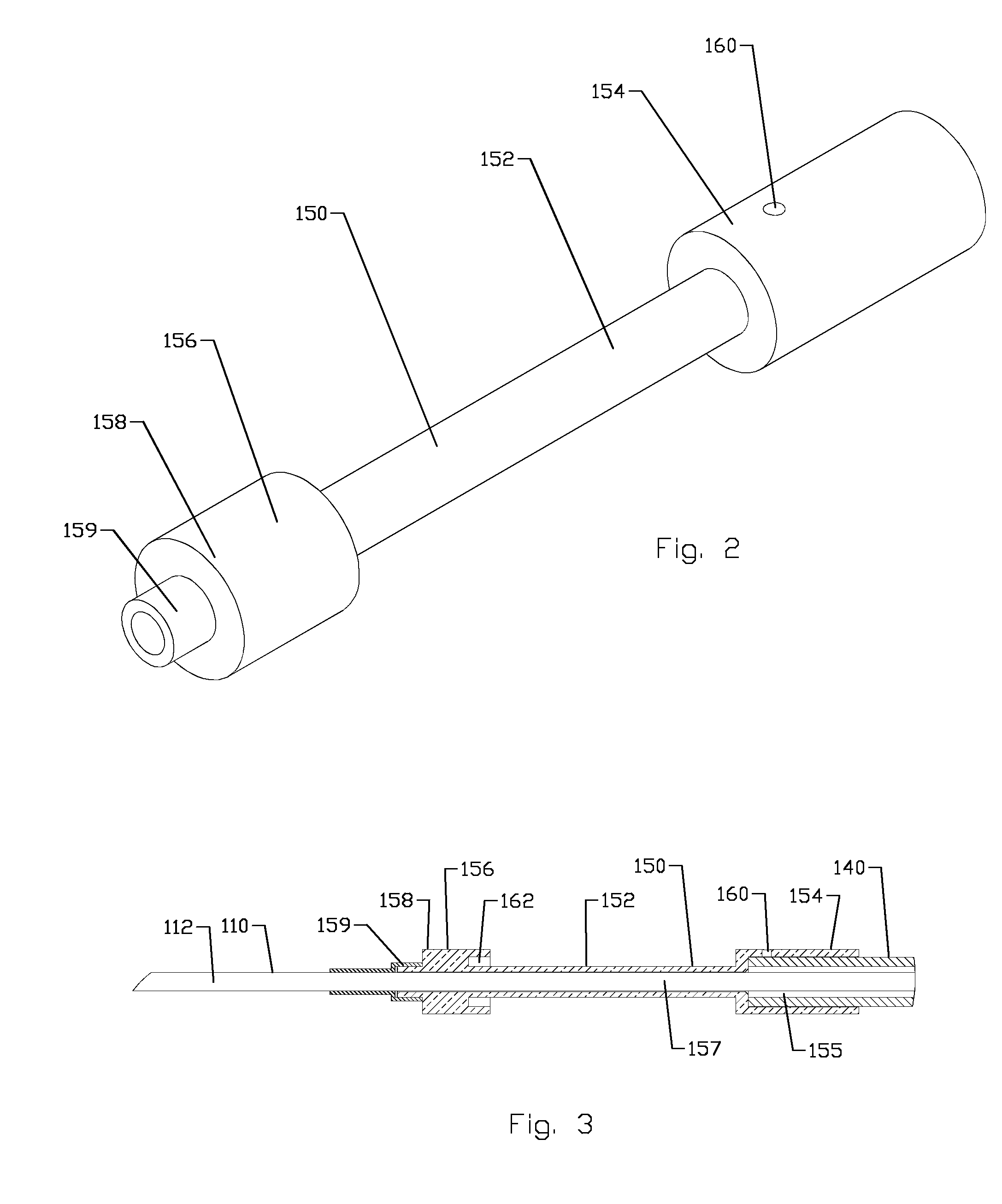

Universal remote radio unit bird armored fiber optic cable assembly

InactiveUS20150168657A1Avoid repetitionSimplify sourcing for the userLayered productsOptical fibre/cable installationRadio unitFiber

A fiber optic cable has a cable core that includes at least one optical fiber coupled to a fiber optic connector. A cable adapter sleeve is axially mounted on the cable core to surround the cable core, the cable adapter sleeve including a body portion that has a first outer diameter and a collar that has a second outer diameter that is greater than the first outer diameter. A crush sleeve is seated within a crush groove of the collar.

Owner:COMMSCOPE TECH LLC

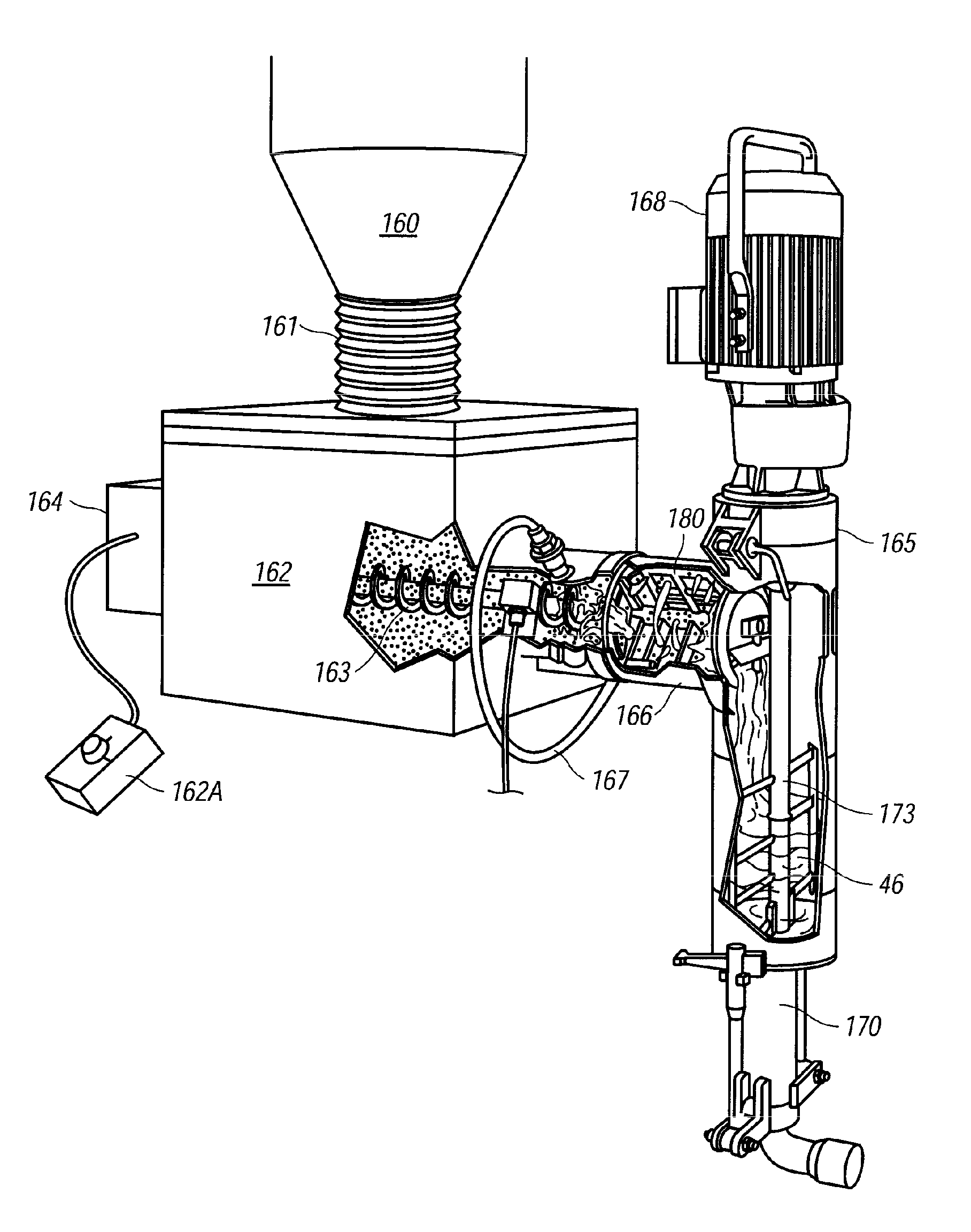

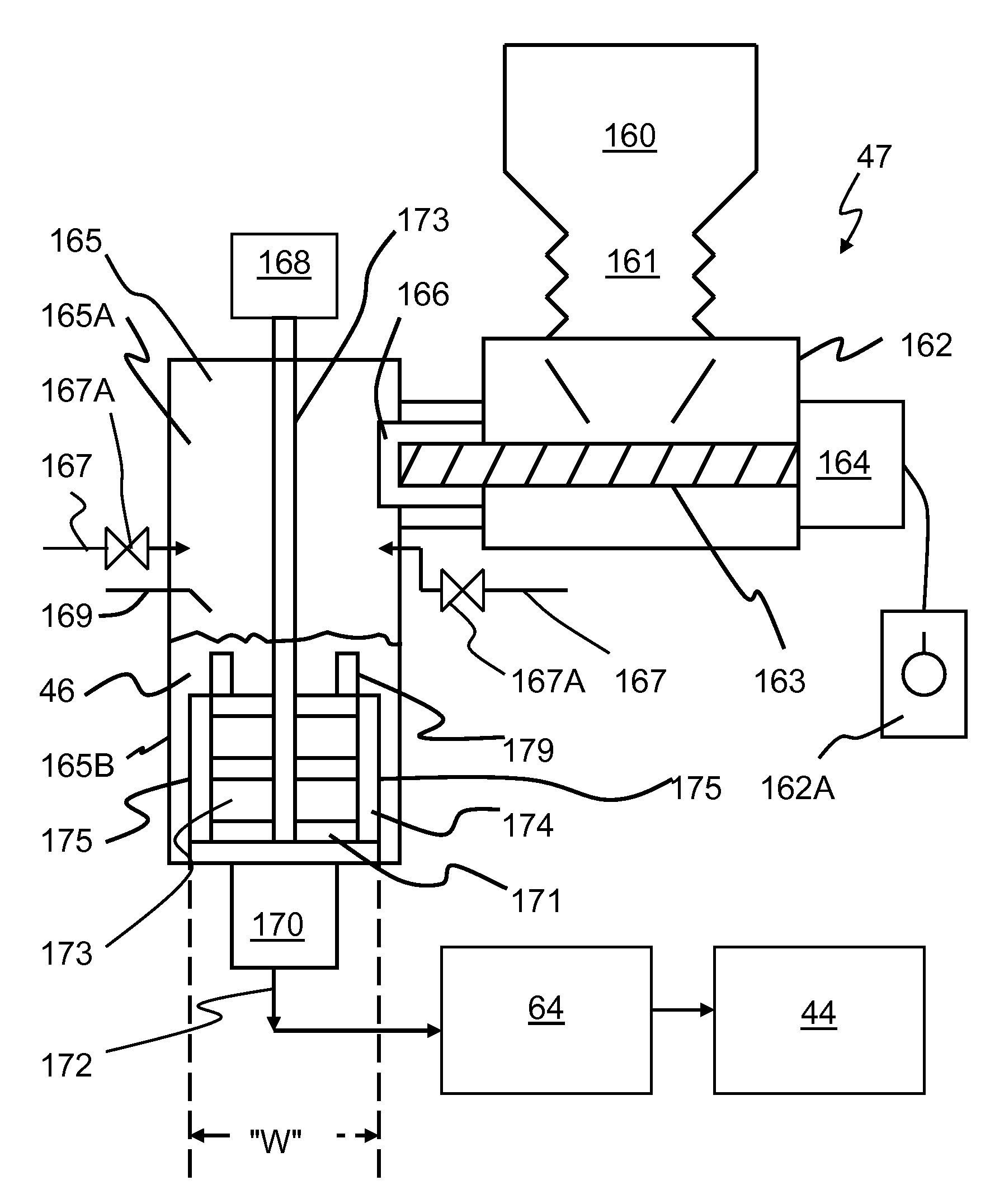

Method for wet mixing cementitious slurry for fiber-reinforced structural cement panels

InactiveUS7524386B2Increase volumeSmall sizeSolid waste managementRotary stirring mixersProduction lineVertical mixing

A process employing a wet mixer having a vertical mixing chamber for forming a wet slurry of a cementitious powder and liquid. The vertical mixing chamber is designed to provide the required amount of mixing to provide thoroughly mixed, uniformly thin slurry within a mixing residence time that allows for adequate supply of slurry to ensure continuous operation of an associated cement panel production line. Gravity feed for supply of cementitious powder and water to the slurry mixing area of the chamber is also disclosed.

Owner:UNITED STATES GYPSUM CO

Method for wet mixing cementitious slurry for fiber-reinforced structural cement panels

ActiveUS7513963B2Increase volumeSmall sizeSolid waste managementTransportation and packagingProduction lineVertical mixing

A wet mixer apparatus and method for its use, the mixer having a vertical mixing chamber for forming a wet slurry of a cementitious slurry and water. The vertical mixing chamber is designed to provide the required amount of mixing to provide thoroughly mixed, uniformly thin slurry within a mixing residence time that allows for adequate supply of slurry to ensure continuous operation of an associated cement panel production line. Gravity feeding for separate supply of cementitious powder and water to the slurry mixing area of the chamber without pre-mixing of the powder and water is also disclosed.

Owner:UNITED STATES GYPSUM CO +1

Waterproof primer for buildings

InactiveCN102127344AImprove permeabilityReduce strong alkalinityAntifouling/underwater paintsPaints with biocidesEmulsionAdhesive

The invention provides a waterproof primer for buildings, which comprises the following components in percentage by weight: 40-60% of cationic emulsion, 0.5-1.0% of organosilicon adhesive force accelerator, 0.1-0.5% of defoaming agent, 0.01-0.3% of bactericide, 1-5% of film-forming assistant, 0.5-5% of thickening agent and the balance of water. By selecting the proper cationic emulsion, the alkali-curing substrate-sealed waterproof primer for buildings has the advantages of high alkali resistance, high sealing performance, high binding strength, excellent functional characteristics and strong adaptability to the substrate, and is easy and convenient for construction.

Owner:ASIA PAINT SHANGHAI +1

Multi-layer process for producing high strength fiber-reinforced structural cementitious panels with enhanced fiber content

ActiveUS7670520B2Good strength propertiesReduce equipmentLiquid surface applicatorsConstruction materialCement boardSlurry

A process for producing fiber-reinforced structural cementitious panels made of at least one layer of fiber reinforced cementitious slurry, the process for each such layer of slurry including providing a moving web; depositing a first layer of individual, loose fibers upon the web; depositing a layer of settable slurry upon the deposited first layer of individual, loose fibers; depositing a second layer of individual, loose fibers upon the deposited layer of settable slurry; and actively embedding both layers of individual, loose fibers into the layer of slurry to distribute the fibers throughout the slurry.

Owner:UNITED STATES GYPSUM CO

Prepreg and carbon-fiber-reinforced composite material

ActiveCN104487495AImprove adhesionGood strength propertiesCarbon fibresThin material handlingBinding energyCarbon fiber reinforced composite

Provided are a prepreg and a carbon-fiber-reinforced composite material having excellent long-term storage stability and adhesiveness between a carbon fiber and a matrix resin. The present invention is a prepreg made by impregnating a sizing-agent-coated carbon fiber, which is coated with a sizing agent including an aliphatic epoxy compound (A) and an aromatic epoxy compound (B1), with a thermosetting resin composition including a thermosetting resin (D), a latent curing agent (E), and, if necessary, an additive (F) other than the thermosetting resin (D) and the latent curing agent (E), the prepreg being characterized in that the ratio ((a) / (b)) between (a) the height of a binding energy component attributed to CHx, C-C, and C=C and (b) the height of a binding energy component attributed to C-O in a C1s core spectrum obtained by measuring the surface of said sizing-agent-coated carbon fiber by X-ray photoelectron spectroscopy is within a predetermined range.

Owner:TORAY IND INC

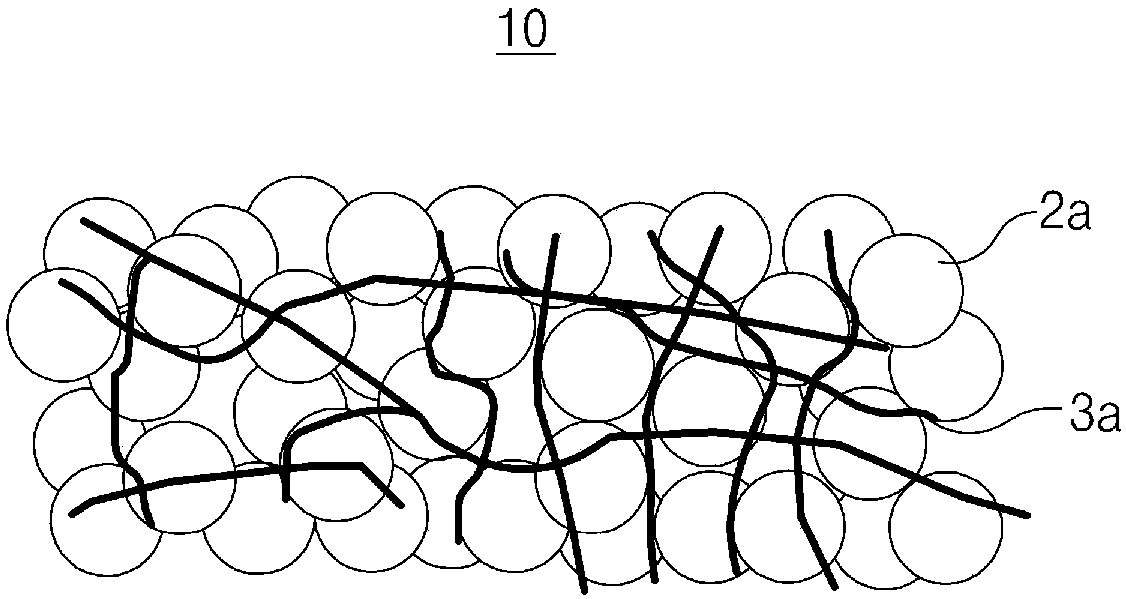

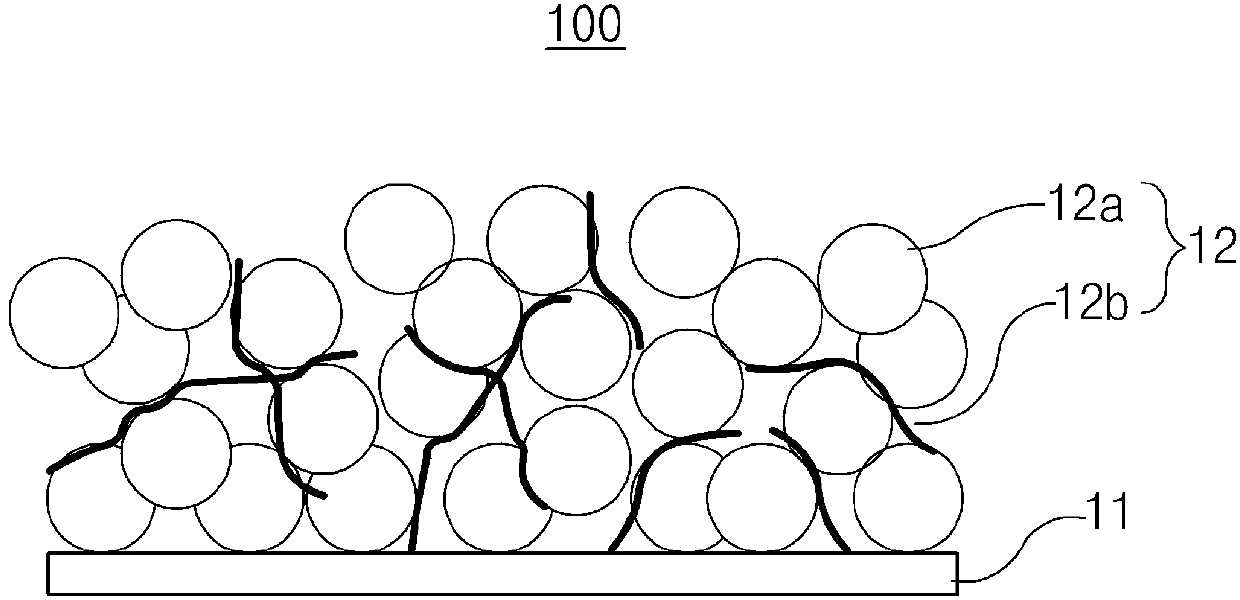

Cathode for secondary battery and secondary battery comprising same

ActiveCN108028355AImprove output characteristicsGood strength propertiesMaterial nanotechnologyCarbon nanotubesElectrical batteryCharge transfer resistance

The present invention provides a cathode for a secondary battery and a secondary battery comprising the same, wherein the cathode for a secondary battery comprises: a cathode current collector; a porous cathode active material layer positioned on the surface of the cathode current collector and comprising a cathode active material and a first carbon nanotube; and a conductive layer on which the cathode active material layer is positioned on the surface thereof, wherein the conductive layer comprises a porous network structure formed by a plurality of second carbon nanotubes and the porosity ofthe cathode active material layer is a porosity of +10 volume% or more. The cathode for a secondary battery according to the present invention forms an electrical network inside and across the surface of the cathode active material layer by using carbon nanotubes having strength properties as well as excellent electrical conductivity, such that it is possible to keep material resistance in the active material layer low while greatly reducing charge transfer resistance whereby the output properties of the battery can be remarkably improved.

Owner:LG ENERGY SOLUTION LTD

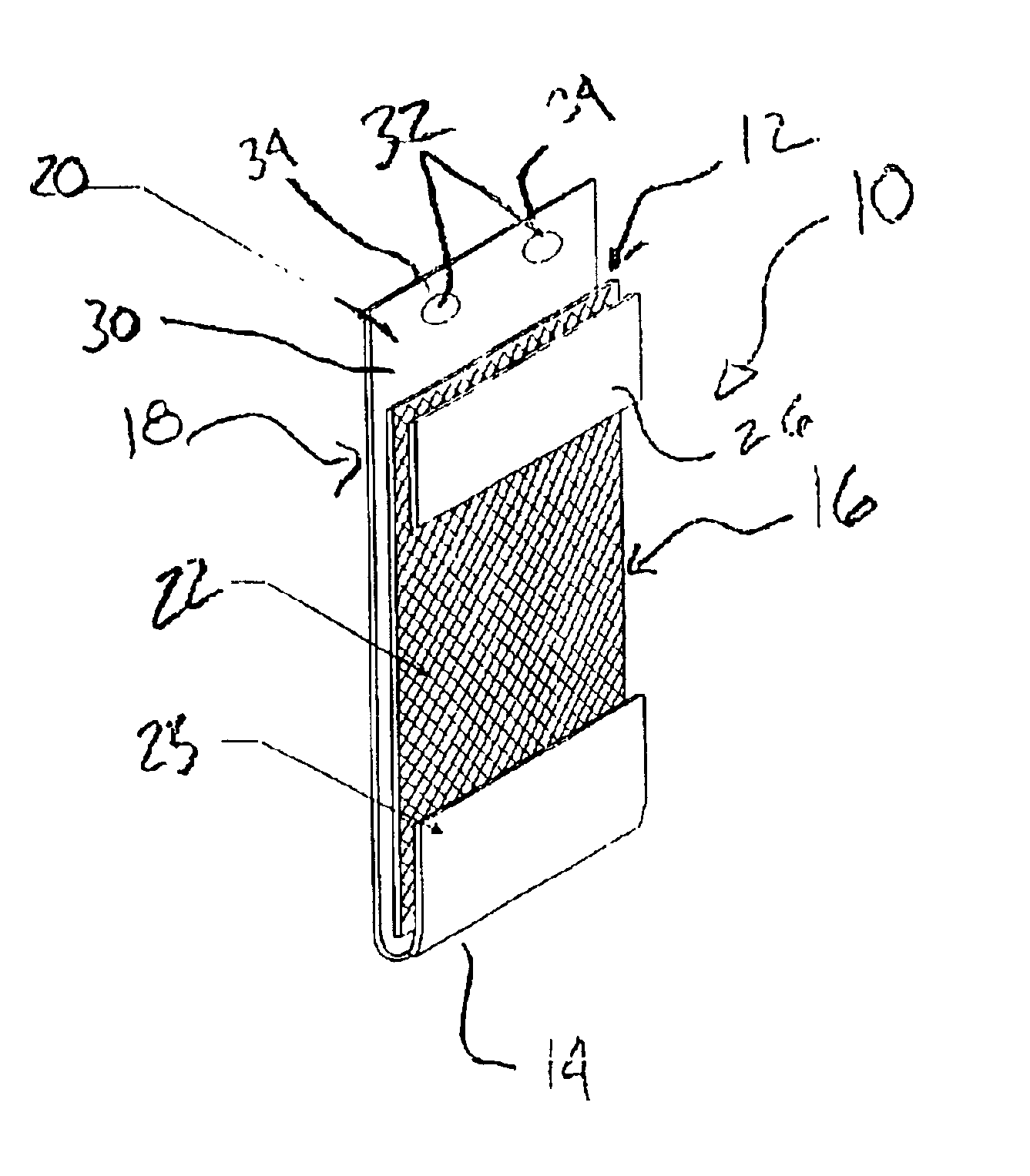

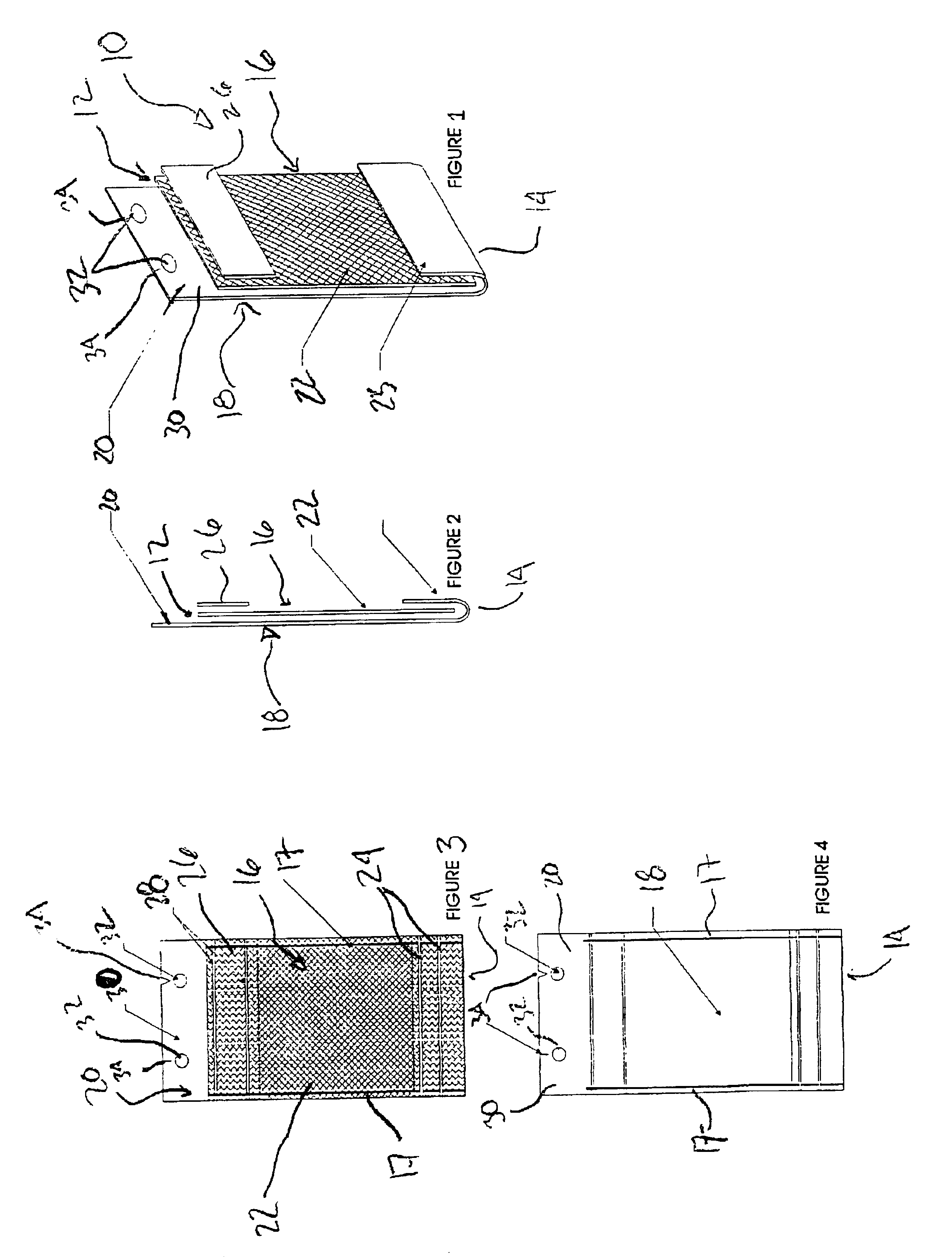

Vented breathable bag for perishable products

InactiveUS6866620B2Make fastPerishable product bagsEnvelopes/bags making machineryBoxes/cartons making machineryProduction lineAutonomation

A process for making successive product bags on an automated production line, comprises the steps of: a) providing a mesh sheet and first and second plastic sheets on rolls, unwinding the mesh sheet and the first and second plastic sheets from the rolls, b) while the sheets are advanced through the production line, folding one longitudinal edge portion of the second plastic sheet over the mesh sheet, c) sealing the folded portion of the second plastic sheet to one longitudinal side of the mesh sheet and the first plastic sheet to an opposed longitudinal side of the mesh sheet to form a master web, and d) sealing and cutting the master web along longitudinally spaced-apart lines transverse to a direction of travel of the sheets to thereby produce a succession of individual bags having one panel at least partly made of a mesh material.

Owner:FRIEDMAN HERSHEY

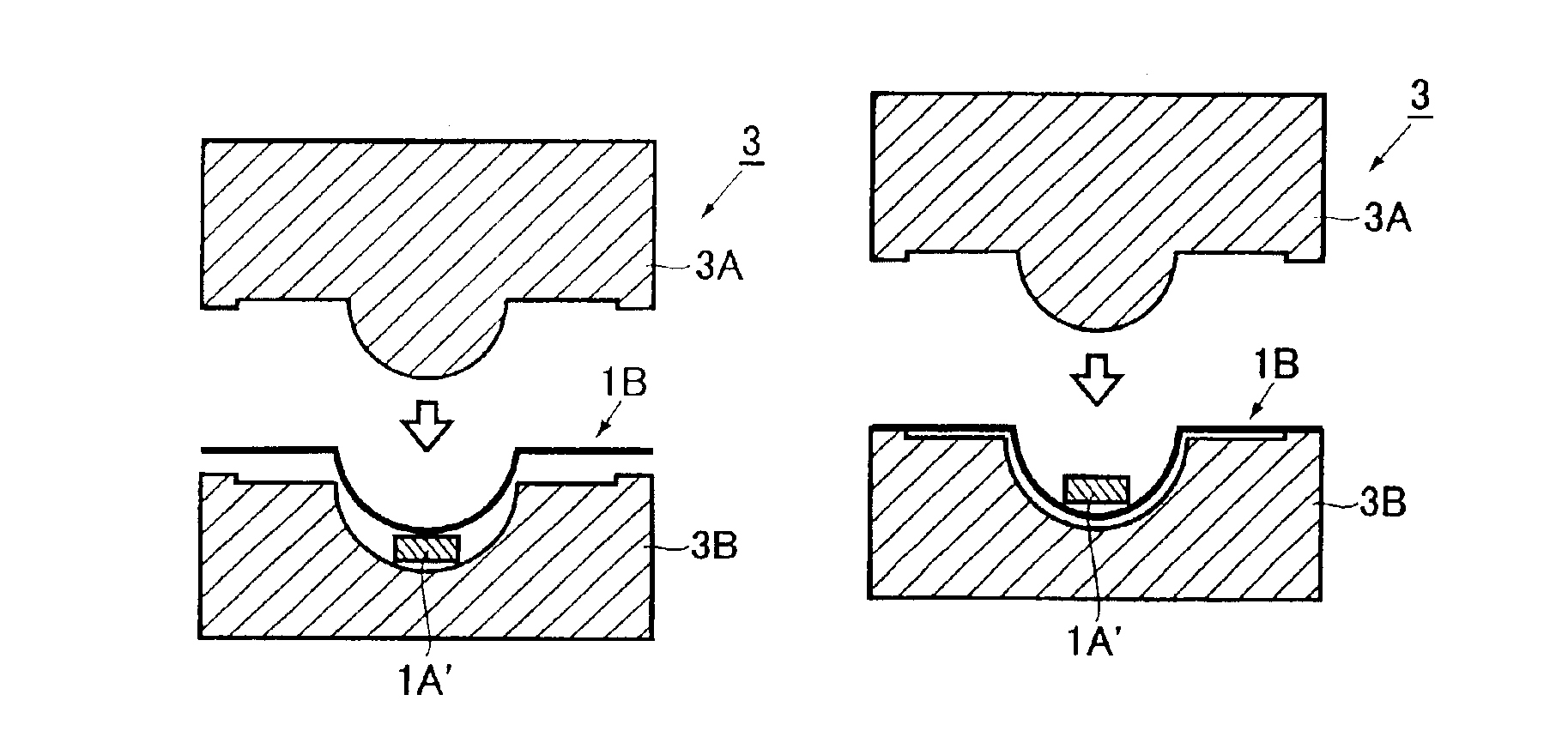

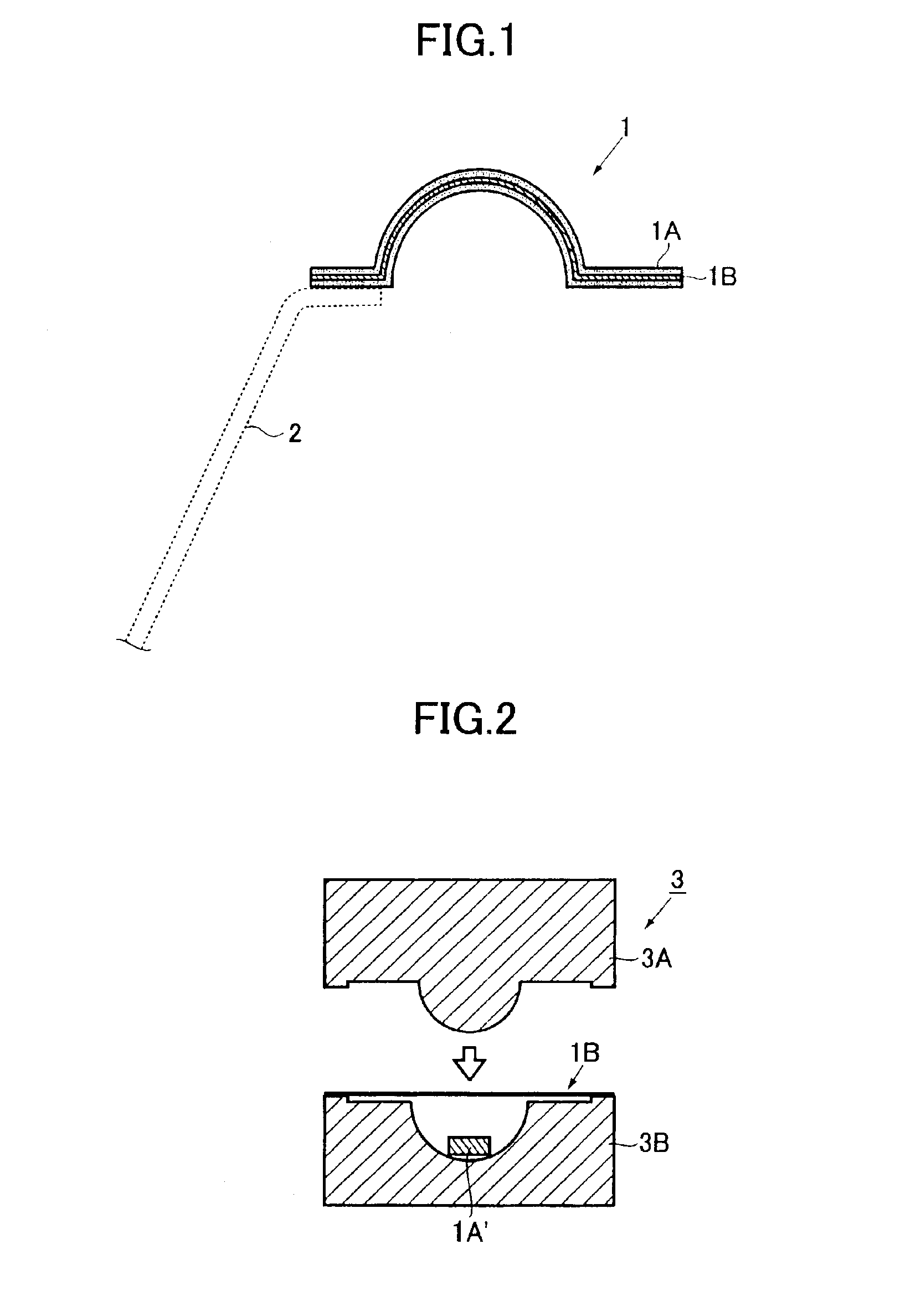

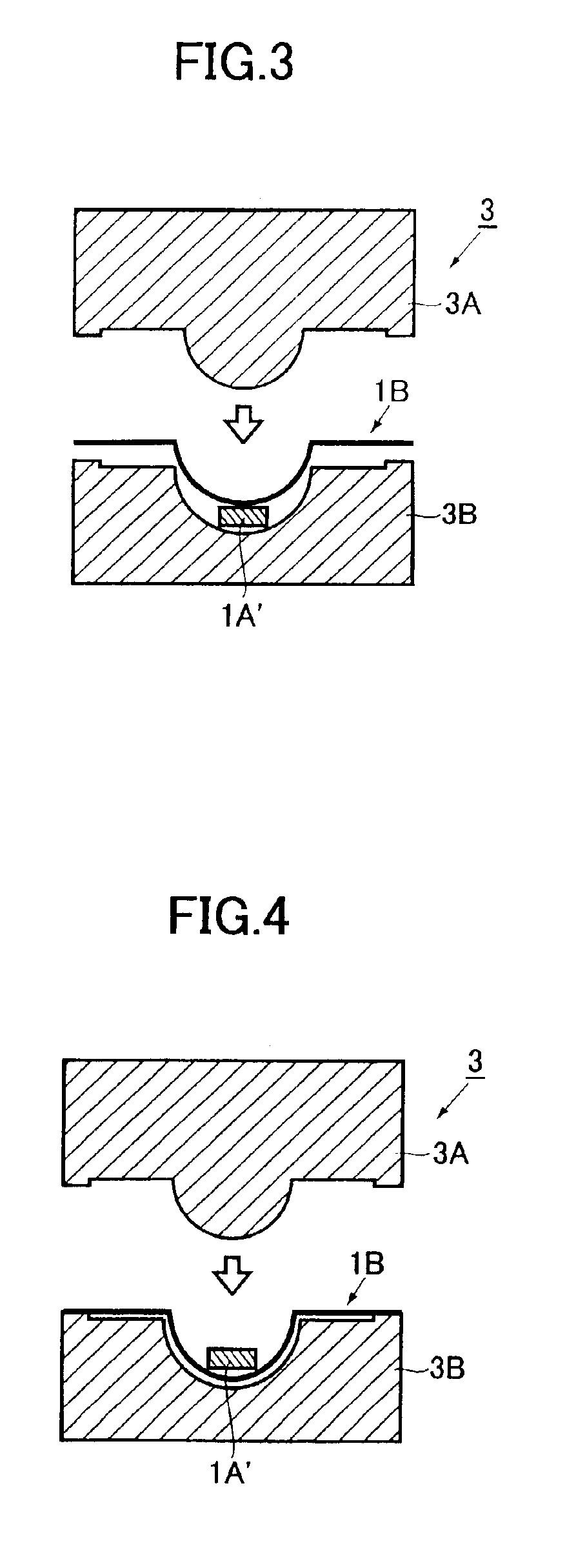

Surround for speaker system and manufacturing method thereof

InactiveUS6892850B2Highly durable to withstandIncrease the sound pressure levelLoudspeaker diaphragm materialsSound producing devicesAramidesEngineering

A speaker's surround to be attached to an edge of a diaphragm in a speaker system is provided, which is capable of keeping its predetermined shape while repeating elastic deformation for accommodating large amplitude vibration of the diaphragm. Further, the surround is highly durable to withstand the repeated large amplitude vibration, and which can achieve high sound pressure levels. The surround for a speaker system includes a surround piece made of a rubber mold and a base member embedded in the surround piece. The base member is obtained by soaking a cloth material made of cotton or aramid fiber with a thermosetting resin such as phenol resin, and press-formed with heat into a predetermined shape. The surround thus has enhanced its shape maintaining capability.

Owner:PIONEER CORP +1

Broad band radome for microwave antenna

ActiveUS20150116184A1High strengthHigh precisionRadiating element housingsDomestic articlesFastenerEngineering

A radome for an antenna is provided as a composite of an isotropic outer layer and a structural layer of foamed polymer material. The composite is dimensioned to enclose an open end of the antenna. The radome may be retained upon the antenna by a retaining element and fasteners. The outer layer may be a polymer material with a water resistant characteristic.

Owner:COMMSCOPE TECH LLC

Wet slurry thickness gauge and method for use of same

InactiveUS7475599B2Assist in quality controlEqually distributedTesting/calibration apparatusForce measurementDisplay deviceHand held

A handheld wet slurry thickness gauge and method for its use. The thickness gauge includes a distance displacement measurement gauge, a skirt, a platen and support legs. The distance displacement measurement gauge includes a case, a vertical stem, and a vertical spindle. The stem extends from the case. The spindle is slidably supported to move in an axial direction within the stem. The case body has a display for indicating a linear displacement of the spindle. The skirt has a central through-hole for receiving the stem of the gauge and retaining the stem in an upright position. The measuring platen has a platen base and a platen shaft extending upwardly from the platen base and attached to the spindle. The support legs extend downwardly from the skirt. The platen is below the skirt.

Owner:UNITED STATES GYPSUM CO

Hydrofining catalyst of diesel oil and preparation method thereof

InactiveCN101591560AIncrease cetane numberImprove desulfurization and denitrification activityRefining to eliminate hetero atomsMolecular sievePoor quality

The invention relates to a hydrofining catalyst of diesel oil, comprising a carrier and active constitutes. The active constitute is one or more of the VIB group metals and the VIII group metals, wherein, the carrier is composed of one or more of SAPO-5, SAPO-11, ZSM-22 and ZSM-23 molecular sieves which have one-dimensional pore canals, and gamma-Al2O3. The invention further discloses a preparation method of the catalyst on the basis of disclosing the hydrofining catalyst of diesel oil. The hydrofining catalyst prepared by the method in the invention can prevent the diesel oil distillates from cracking, realize the aromatics hydrogenation saturation of poor quality diesel oil, and simultaneously effectively realize the desulfuration and denitrification of poor quality diesel oil.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD +1

Cotton-like lining cloth and production process thereof

The invention relates to cotton-like lining cloth which is formed by blending viscose fibre / polyester staple fiber blended yarn serving as warp yarn and functional polyester filament serving as weft yarn, wherein the functional polyester filament can absorb and discharge moisture. In addition, a production process of the cotton-like lining cloth is further related. The production process includes the following steps: 1, warp yarn selection; 2 weft yarn selection; 3, weaving; 4, overflow desizing and bleaching processing or overflow desizing and bath dyeing processing; 5, dehydration; 6, scotching; 7, sizing; 8, coating calendaring; 9, perching volume classification; and 10, laboratory sample detection.

Owner:CPL NEW MATERIAL TECH CO LTD

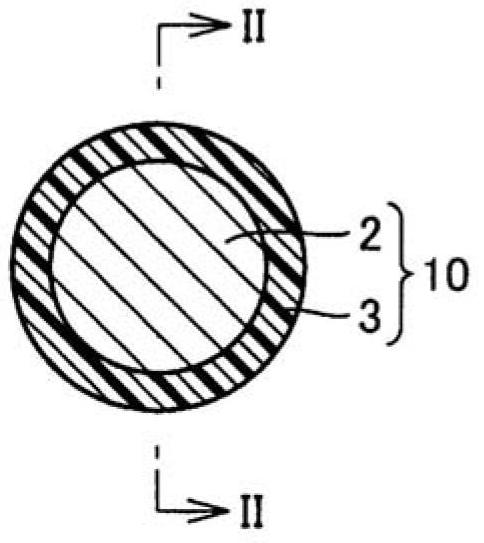

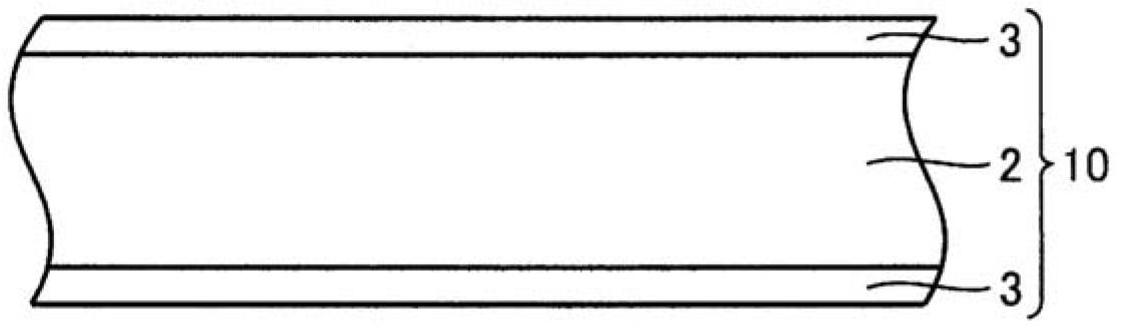

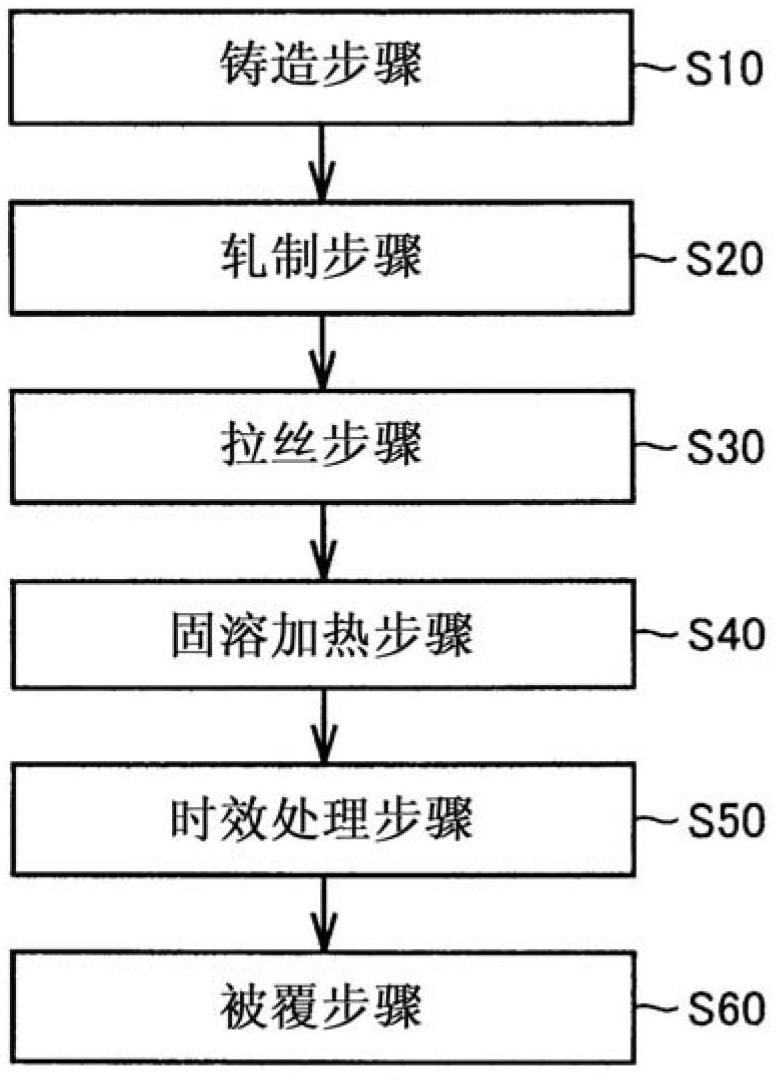

Aluminum alloy wire

ActiveCN102695813AGood bending propertiesGood strength propertiesSingle bars/rods/wires/strips conductorsApparatus for heat treatmentSolid solutionUltimate tensile strength

Provided are an aluminum alloy wire (2) having excellent flexing characteristics, strength, and electrical conductivity, a twisted aluminum alloy wire, a covered electric wire (10) including the alloy wire or twisted wire, a wire harness including the covered electric wire (10), a process for producing the aluminum alloy wire, and a process for producing the covered electric wire (10). The aluminum alloy wire (2) contains, in mass%, 0.1-1.5% Mg, 0.03-2.0% Si, and 0.05-0.5% Cu, the remainder comprising Al and impurities. The aluminum alloy wire (2) satisfies the relationship 0.8=Mg / Si (by mass)=3.5, and has a conductivity of 35-58 %IACS, a tensile strength of 150-400 MPa, and an elongation of 2% or more. This aluminum alloy wire (2) is produced through the steps of casting, rolling, wire drawing, and solution heat treatment in this order. By using the specific composition and by conducting a solution heat treatment after wire drawing to sufficiently bring the additional elements into a solid-solution state, the aluminum alloy wire (2) having excellent flexing characteristics can be obtained.

Owner:SUMITOMO ELECTRIC IND LTD +2

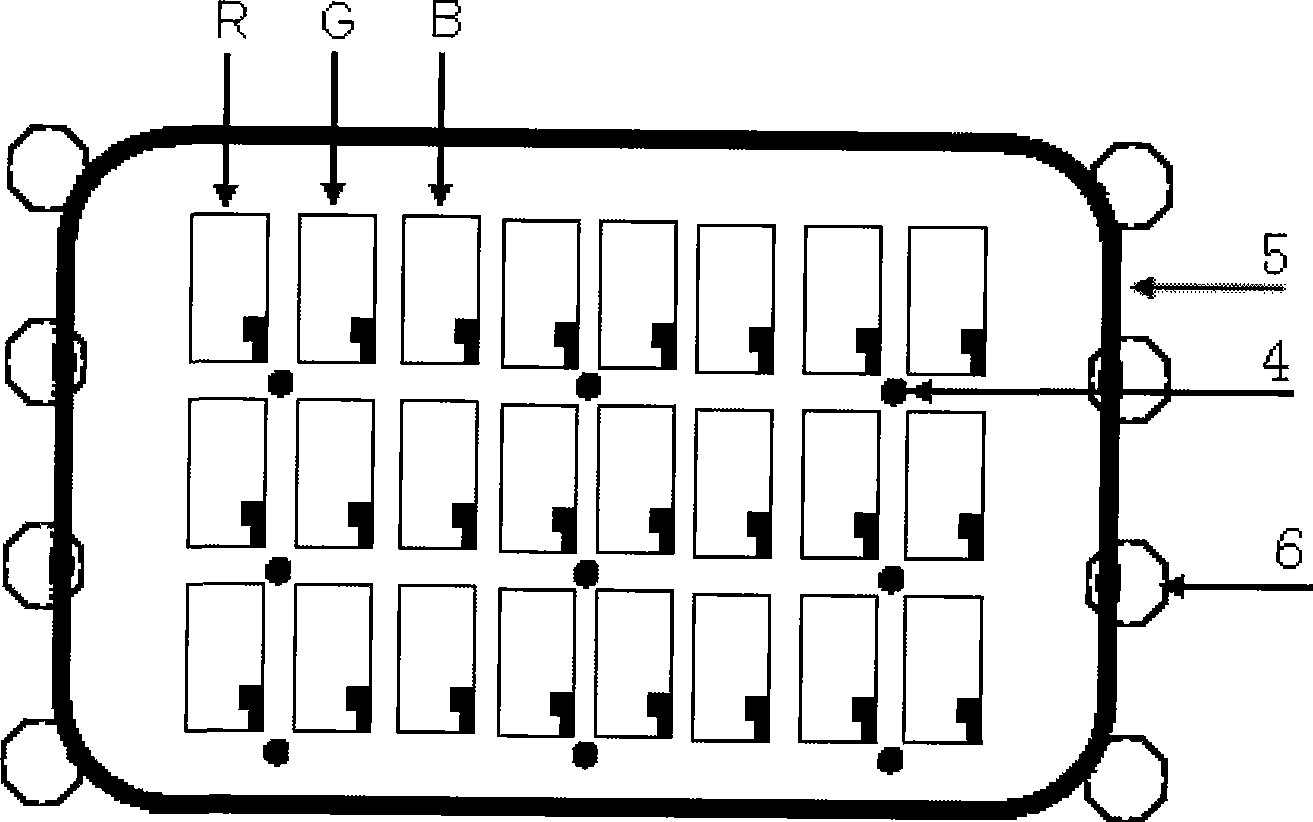

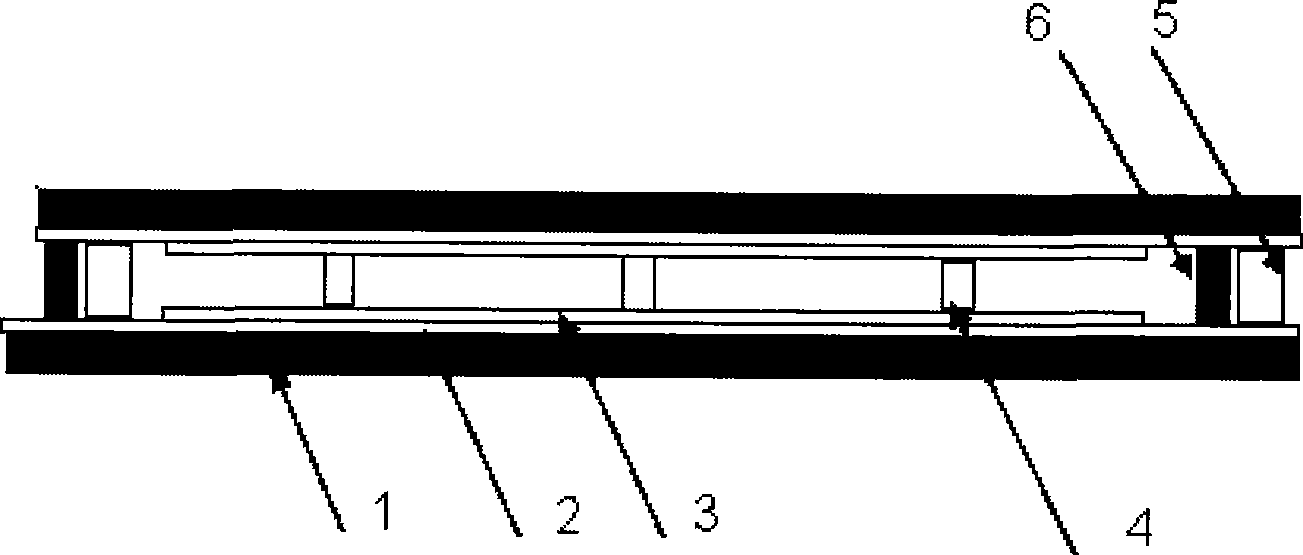

Liquid crystal display panel structure and manufacturing method thereof

ActiveCN101546069AImprove support strengthImprove conductivityNon-linear opticsLiquid-crystal displayAdhesive

The invention discloses a liquid crystal display panel structure and a manufacturing method thereof, belonging to the technical field of the liquid crystal displays and being invented aiming to improve the display quality of the liquid crystal display. The liquid crystal display panel structure comprises a color film substrate and an array substrate which are oppositely arranged, supporting spacers are evenly distributed in a display area at one side of the color film substrate relative to the array substrate, the edge at one side of the color film substrate relative to the array substrate is stuck with the edge at one side of the array substrate relative to the color film substrate through frame sealing adhesive to form a closed area, and the closed area is filled with liquid crystals; a conducting spacer is arranged on the edge at one side of the color film substrate relative to the array substrate and is embedded in the frame sealing adhesive, and both ends of the conducting spacer are respectively in contact with the two substrates to realize the electric connection between the two substrates; and the conducting spacer has good supporting strength and good electric conductivity. The invention is suitable for improving the display quality of the liquid crystal display.

Owner:K TRONICS (SUZHOU) TECH CO LTD +1

Method for smoothing cementitious slurry in the production of structural cementitious panels

ActiveUS8163352B2Remove pock marks and groovesA large amountLiquid surface applicatorsSolid waste managementProduction lineSurface layer

A vibrating smoothing device or plate transverse to a direction of travel of deposited gypsum-cementitious slurry and embedded chopped fibers. The plate is used to smooth the top surface of the slurry panel as it exits a first fiber embedment station and a second slurry depositing station before passing through a second fiber embedment station of a structural cementitious panel production line to remove grooves and other non-uniform surface imperfections to have the slurry cover the embedded fibers. The plate is designed to float over the surface of the formed slurry without tearing or otherwise damaging the surface of the heavily fiber reinforced surface layers of the formed slurry before it sets. The vibrating plate is pivotally mounted on the web production line so it can float over the panel surface during use, but be raised off the line when not in use.

Owner:UNITED STATES GYPSUM CO

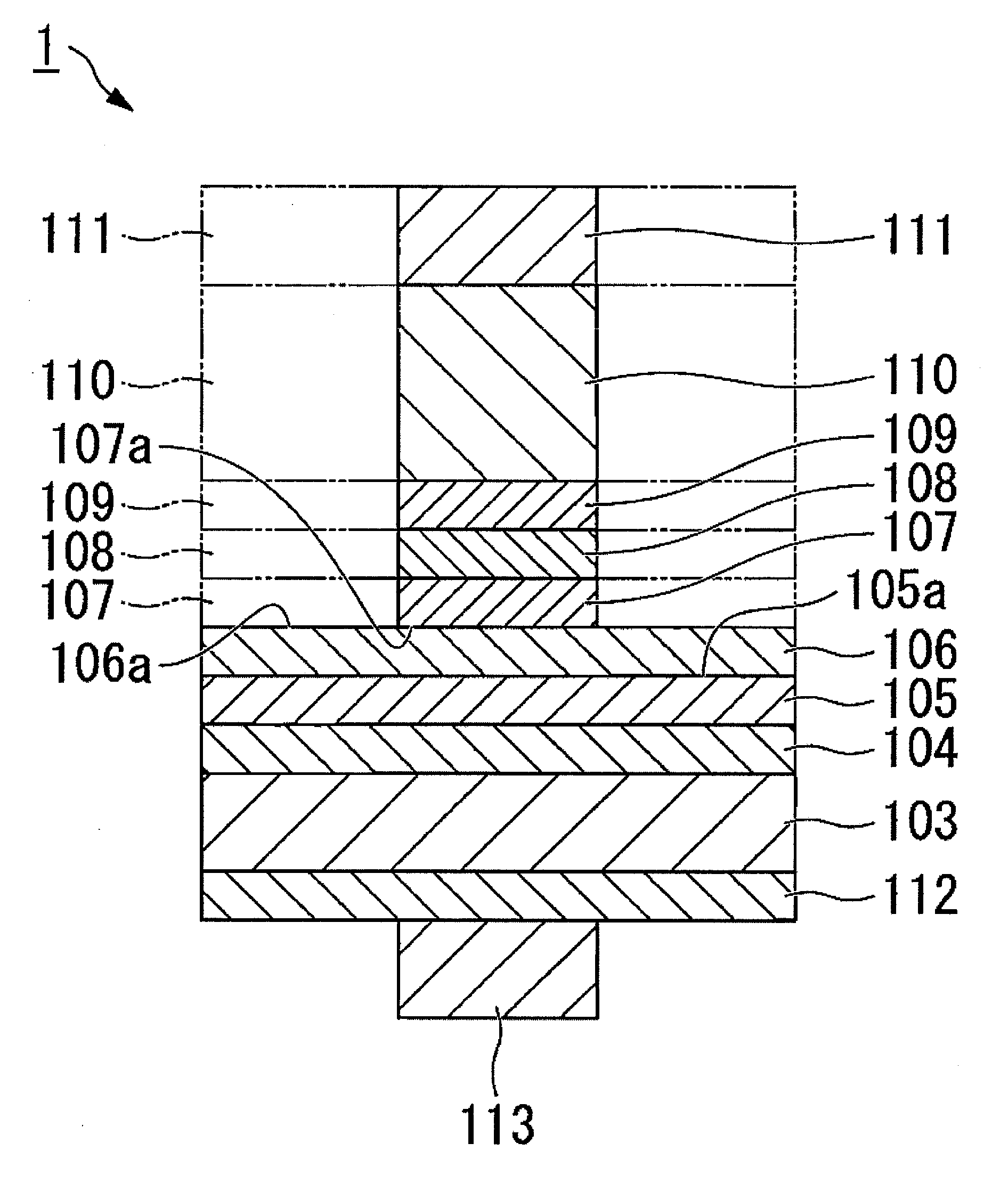

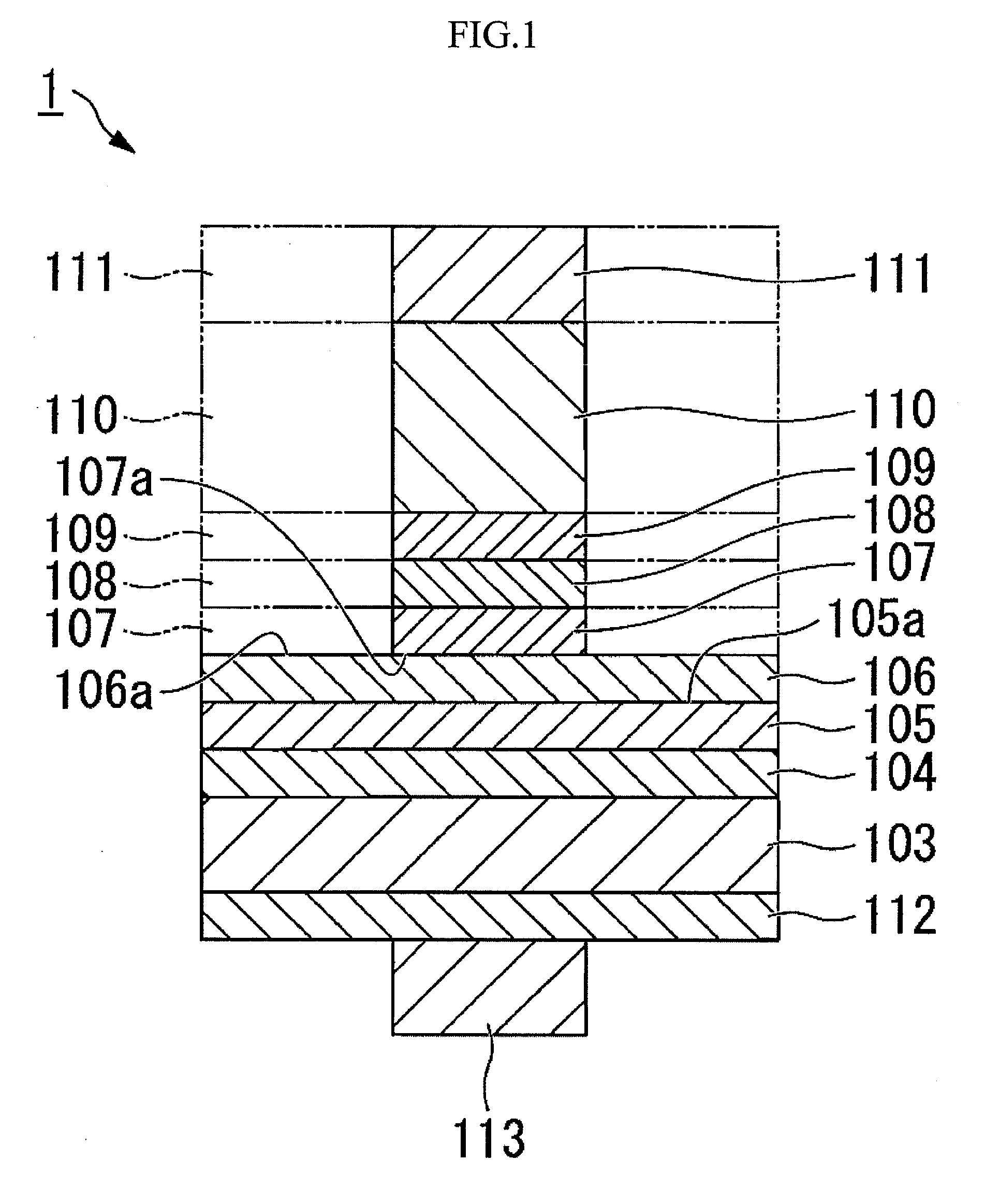

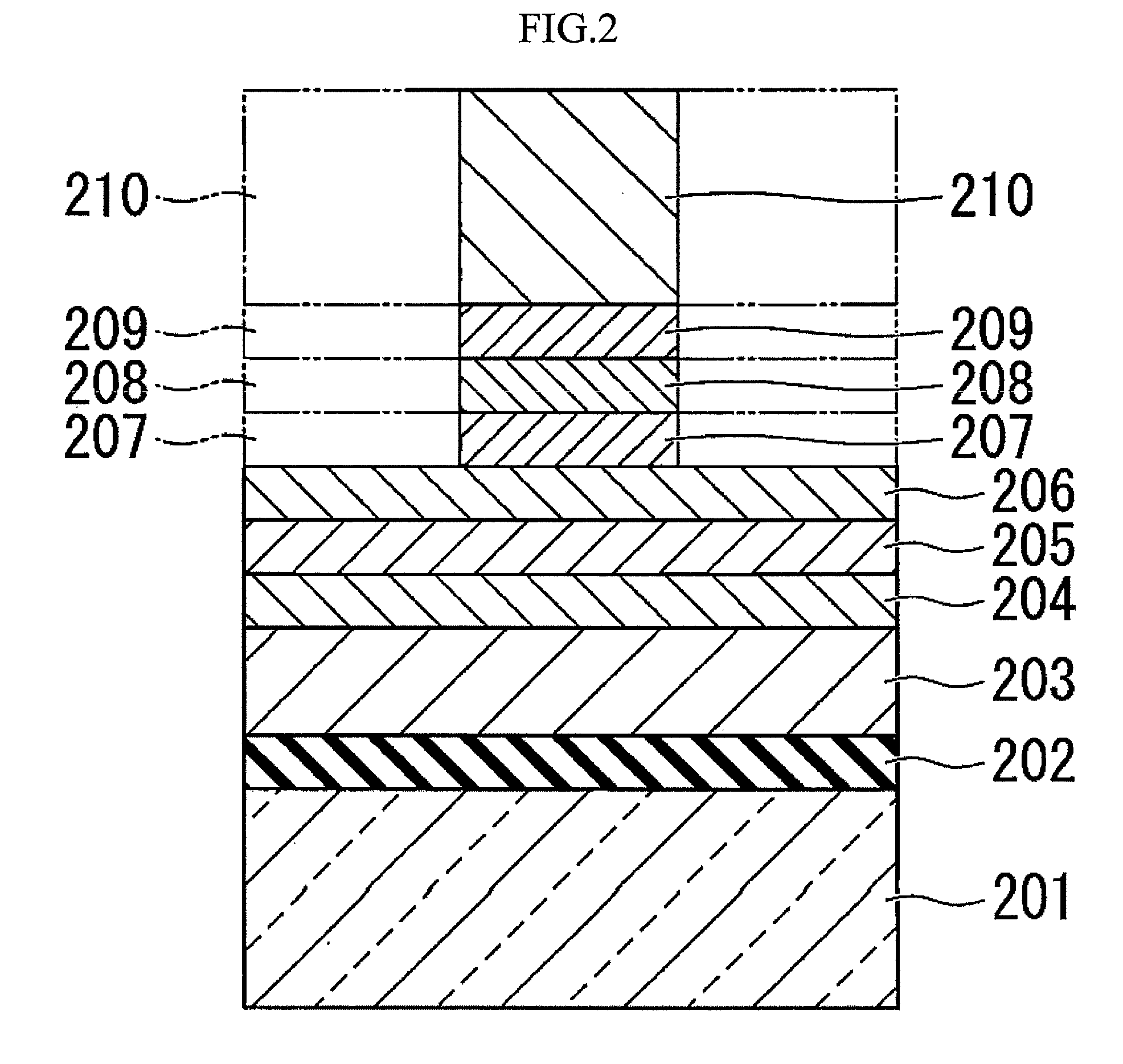

Nitride semiconductor light-emitting device and production method thereof

ActiveUS20090283793A1Good strength propertiesLight extraction efficiency can be improvedSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialLight emitting device

Disclosed is a semiconductor device which is improved in output power efficiency since reflection by the substrate is reduced. This semiconductor device is also excellent in strength characteristics of a supporting substrate. Also disclosed is a method for producing such a semiconductor device. Specifically disclosed is a nitride semiconductor device wherein at least an n-type semiconductor layer, a light-emitting layer, a p-type semiconductor layer, a metal film layer and a plated metal plate are sequentially stacked in this order on a substrate. This nitride semiconductor device is characterized in that the metal film layer and the plated metal plate are partially formed on the p-type semiconductor layer. Also disclosed is a nitride semiconductor device having a structure wherein at least an n-type semiconductor layer, a light-emitting layer, a p-type semiconductor layer, a metal film layer and a plated metal plate are sequentially stacked in this order, the device characterized in that the metal film layer and the plated metal plate are partially formed on the p-type semiconductor layer and a light-transmitting material layer is formed on the p-type semiconductor layer in a region where the metal film layer and the plated metal plate are not formed.

Owner:TOYODA GOSEI CO LTD

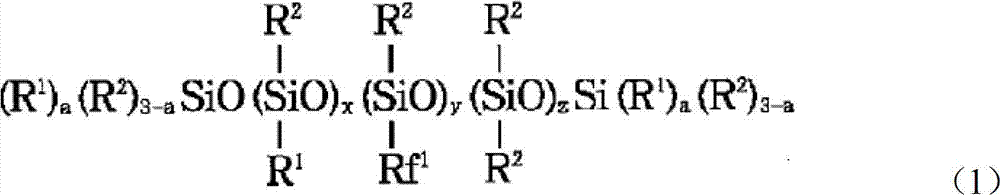

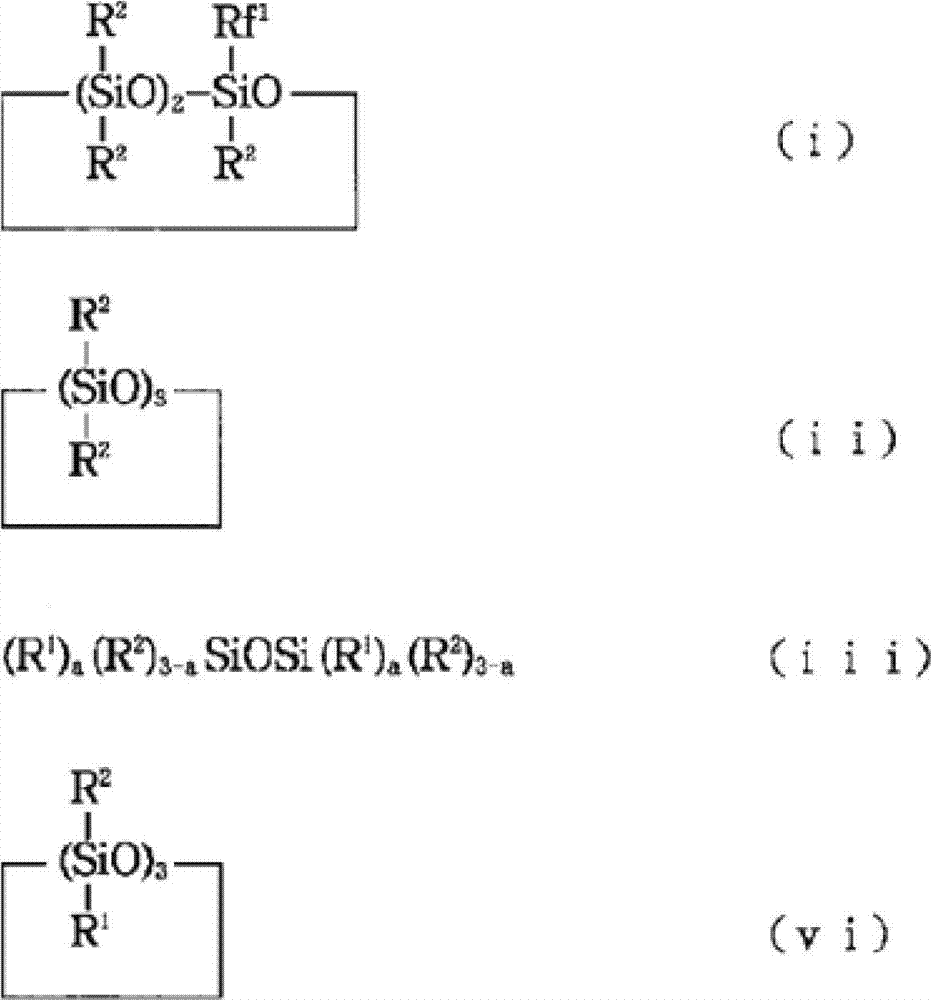

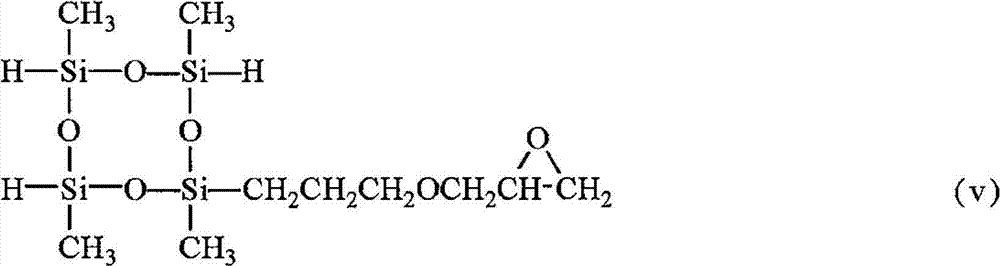

Addition curing type silicone composition and optical element

The present invention provides an addition curing type silicone composition capable of obtaining a cured substance having a very high transparency, a good strength characteristic, and excellent optical element properties such as light extraction efficiency and so on. The present invention also provides an optical element which is sealed by using the cured substance of the composition. The addition curing type silicone composition of the present invention at least comprises: (A) 100 parts by mass of linear chain shaped organopolysiloxane; (B) 1-100 parts by mass of organopolysiloxane having a branched chain structure, wherein the branched chain structure contains a siloxane unit represented by SiO4 / 2 and / or RSiO3 / 2; (C) organosilicon compound of which one molecule has more than two hydrogen atoms bonded to a silicon atom, wherein a molar ratio between a total aliphatic series unsaturated group of the (A) composition and the (B) composition and a SiH group of the (C) composition is 0.2 <= SiH group / aliphatic series unsaturated group <= 5.0; and (D) effective dose of platinum group metal catalyst.

Owner:SHIN ETSU CHEM IND CO LTD

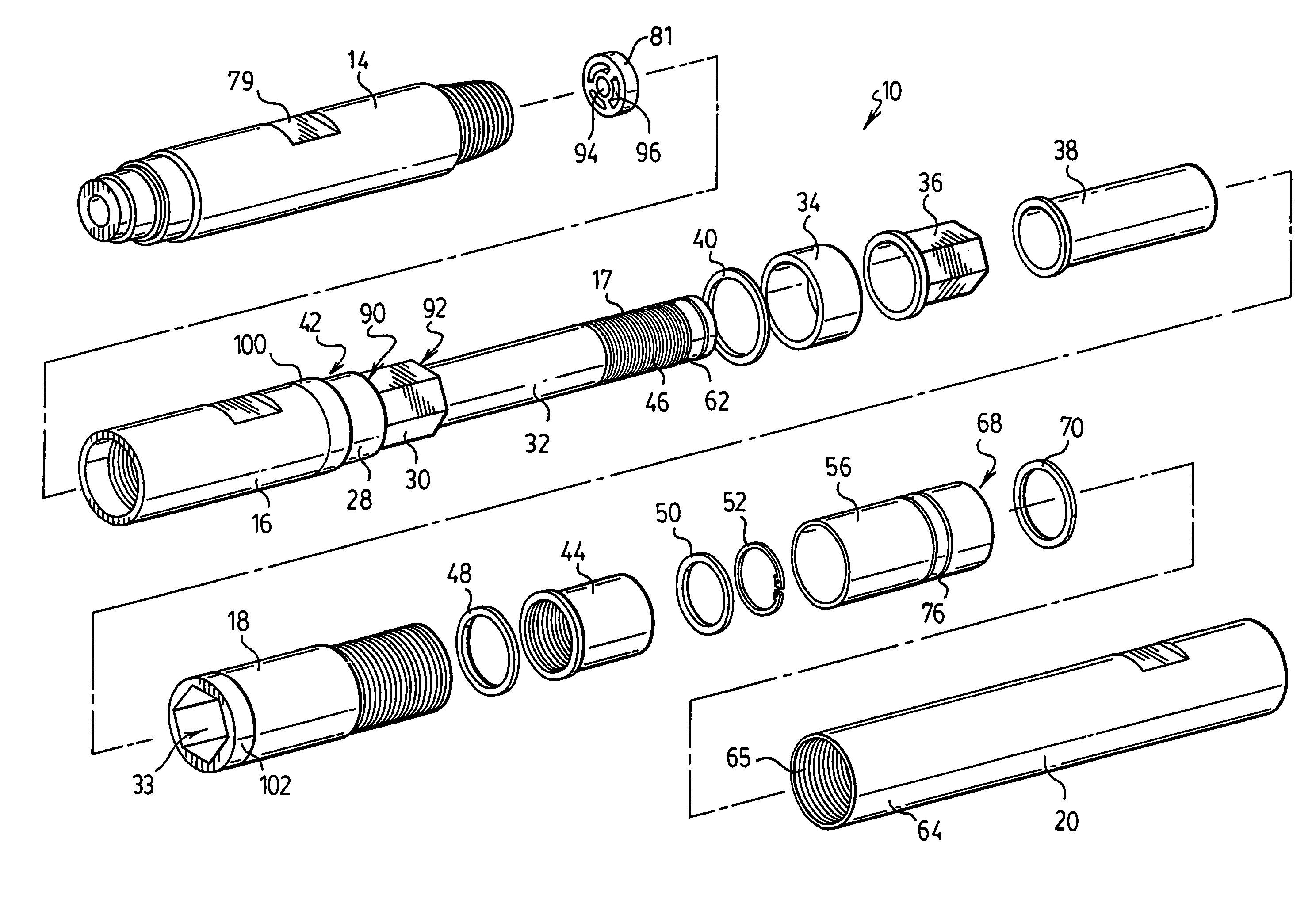

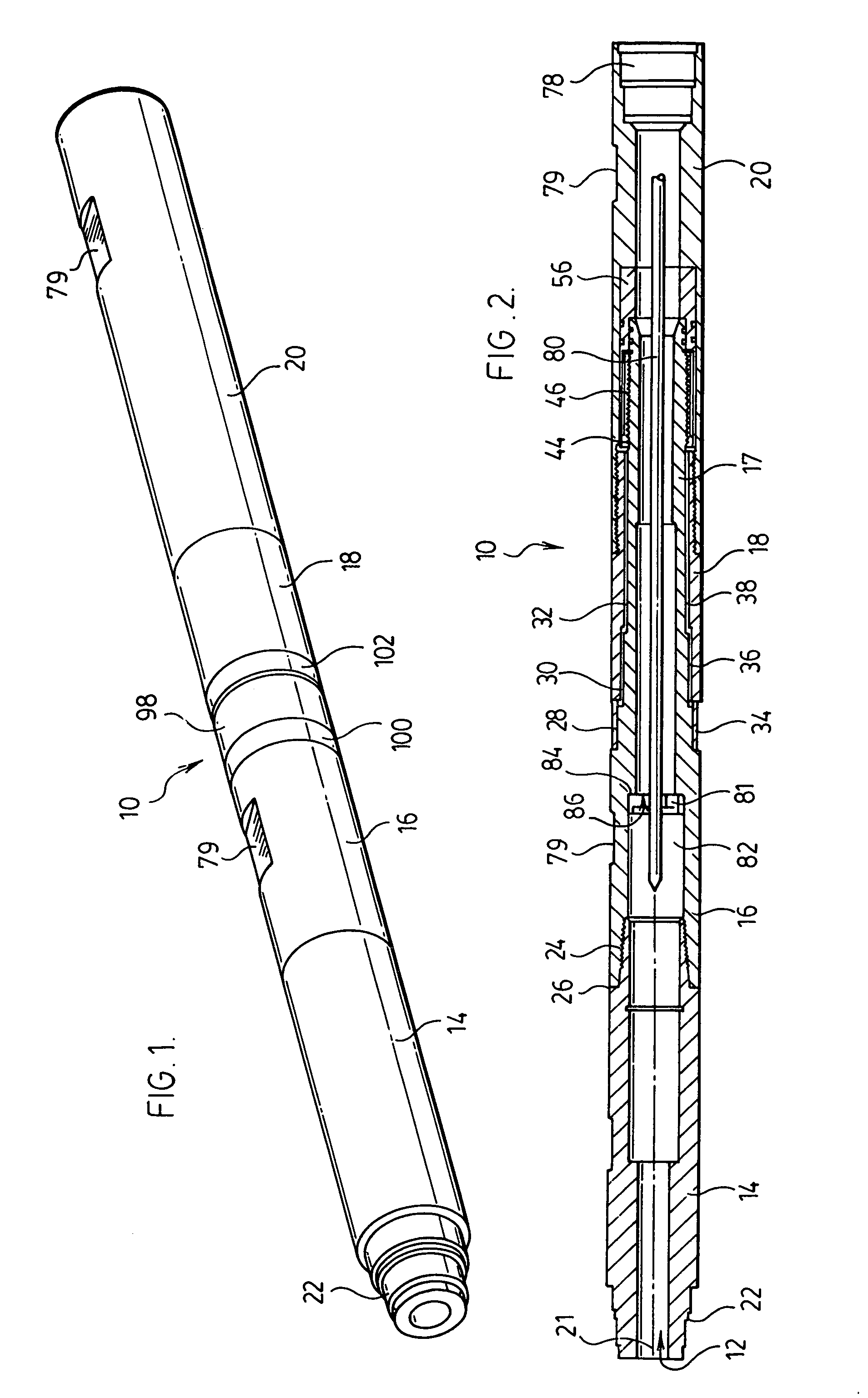

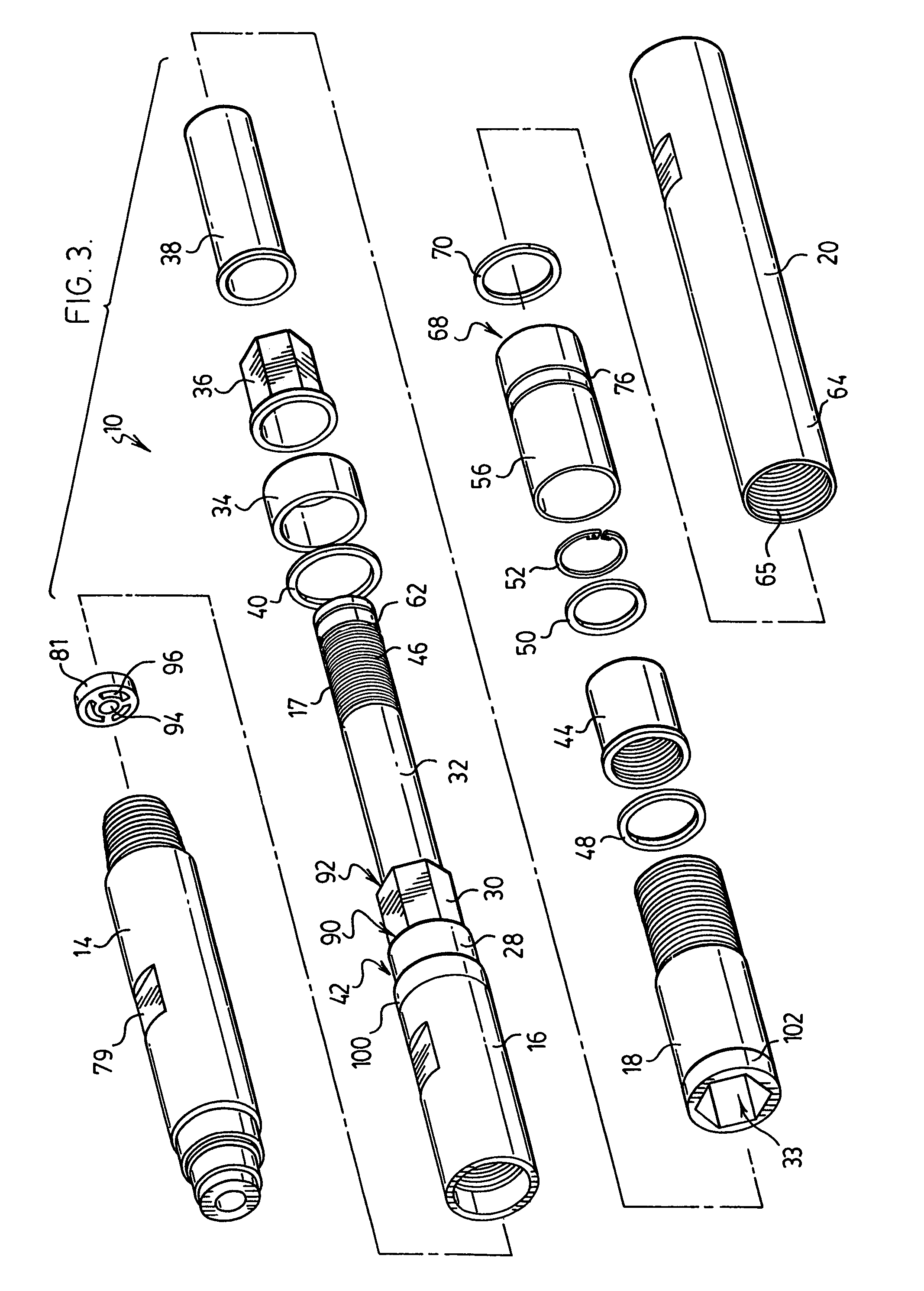

Electrical isolation connector subassembly for use in directional drilling

InactiveUS7032930B2Good strength propertiesSmall gap regionSleeve/socket jointsDrilling rodsElectricityGalvanic isolation

An electrical isolation connector subassembly for interconnecting adjacent tubular drill rods of a drilling system used in drilling bore holes in earth formations, the connector comprising an electrically insulative sleeve being sandwiched between two electrically isolated subassembly components, the sleeve providing an exterior gap between the edges of the spaced apart electrically isolated components, the exterior gap having a width of less than 50 cm.

Owner:RYAN ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com