Patents

Literature

125results about "Loudspeaker diaphragm materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

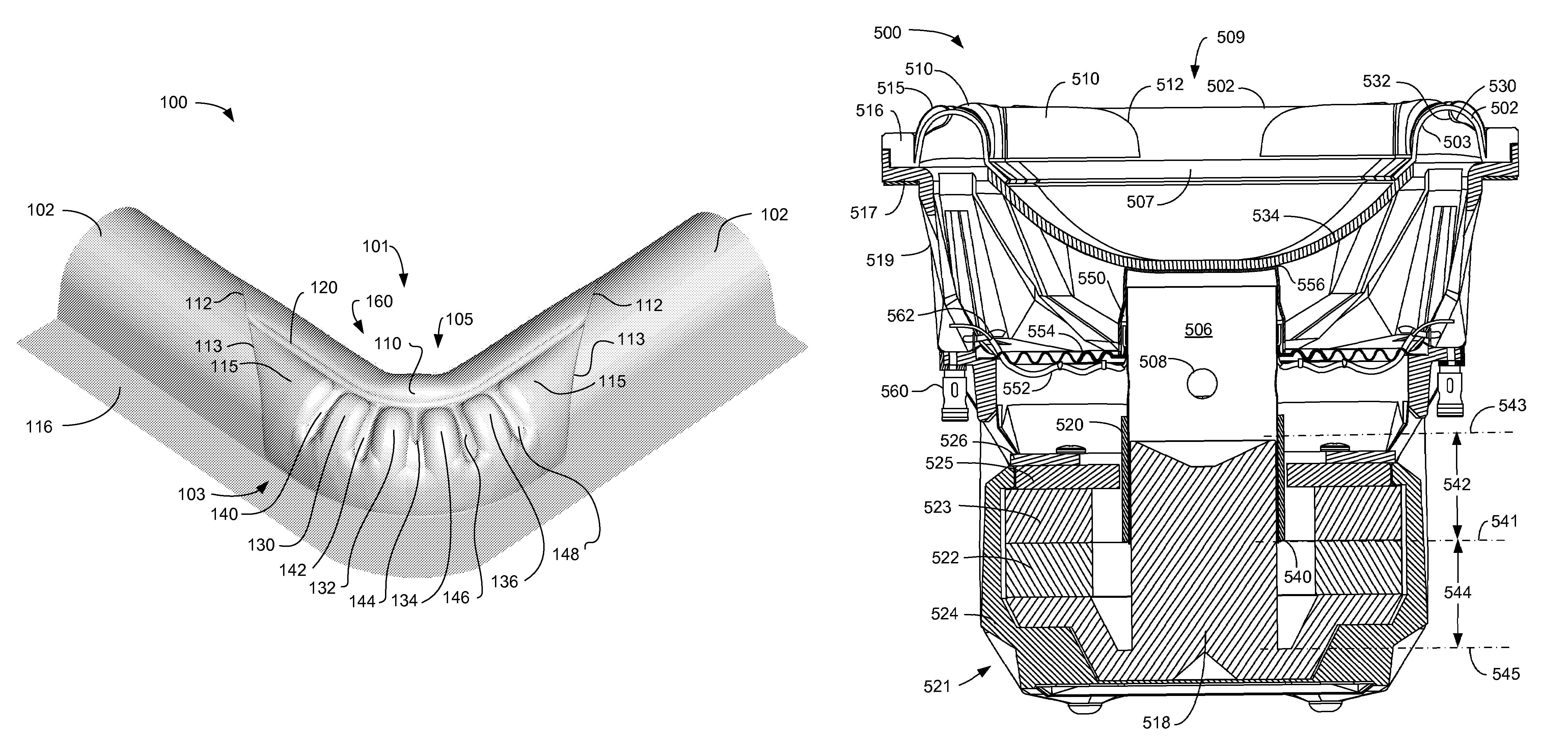

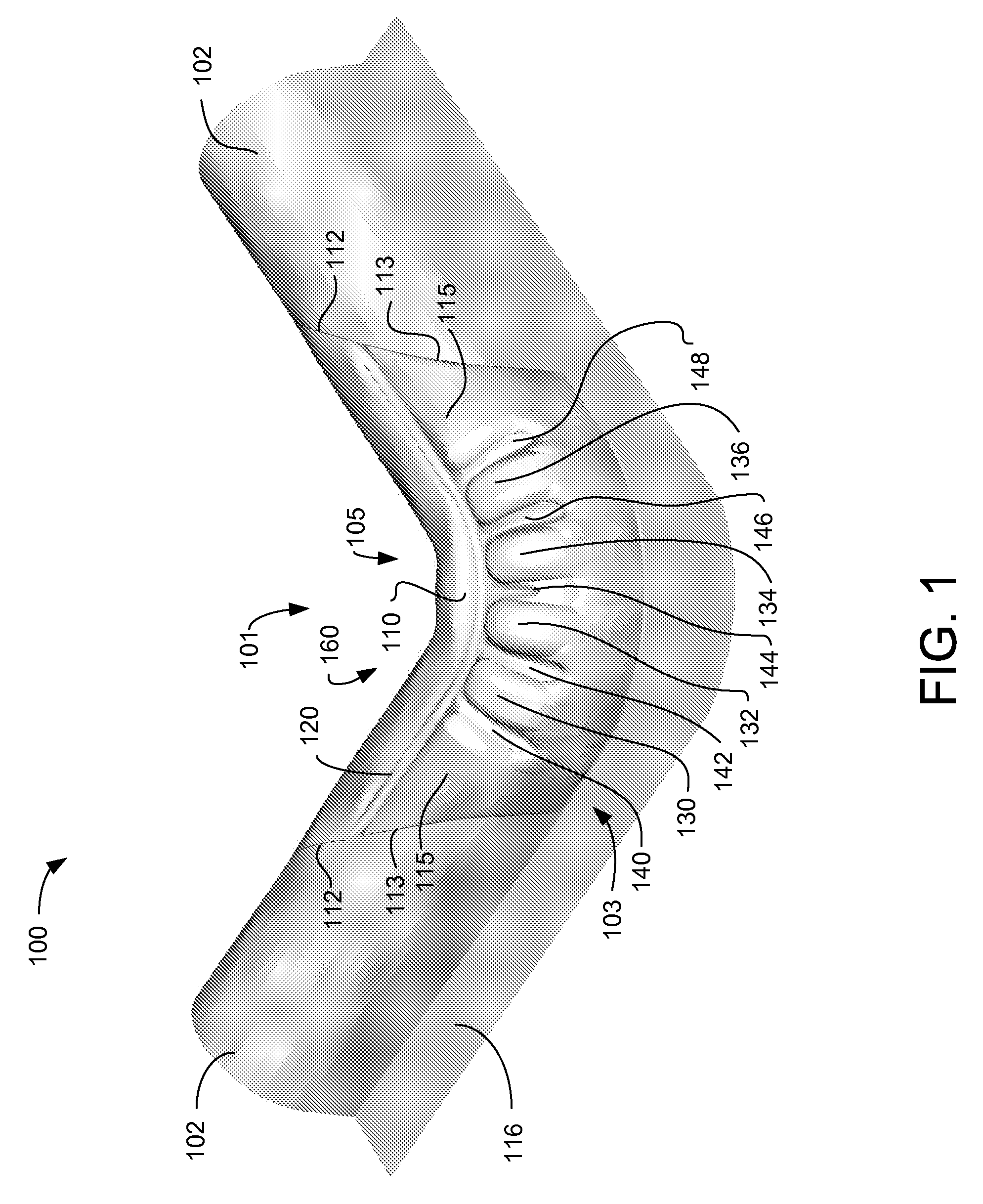

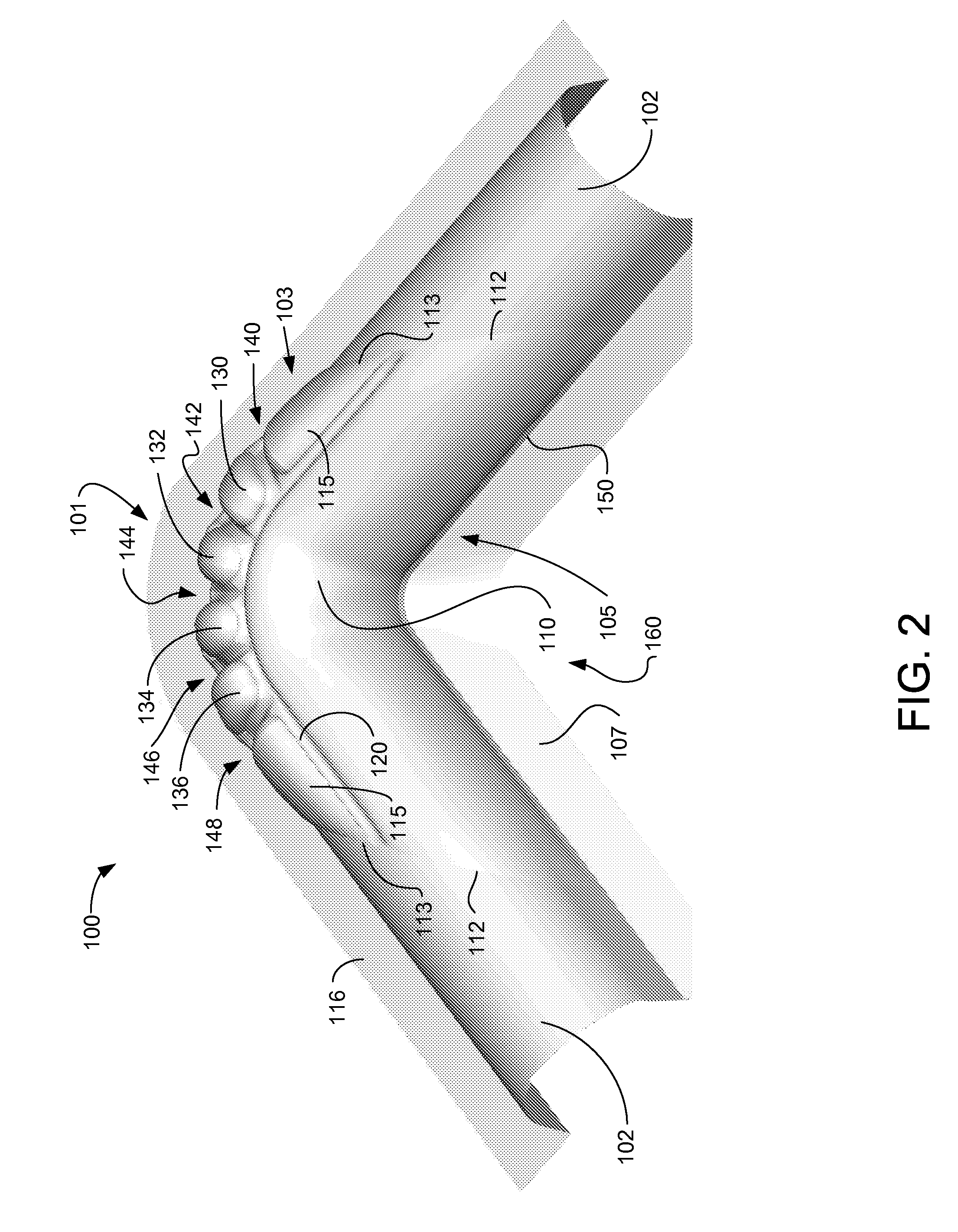

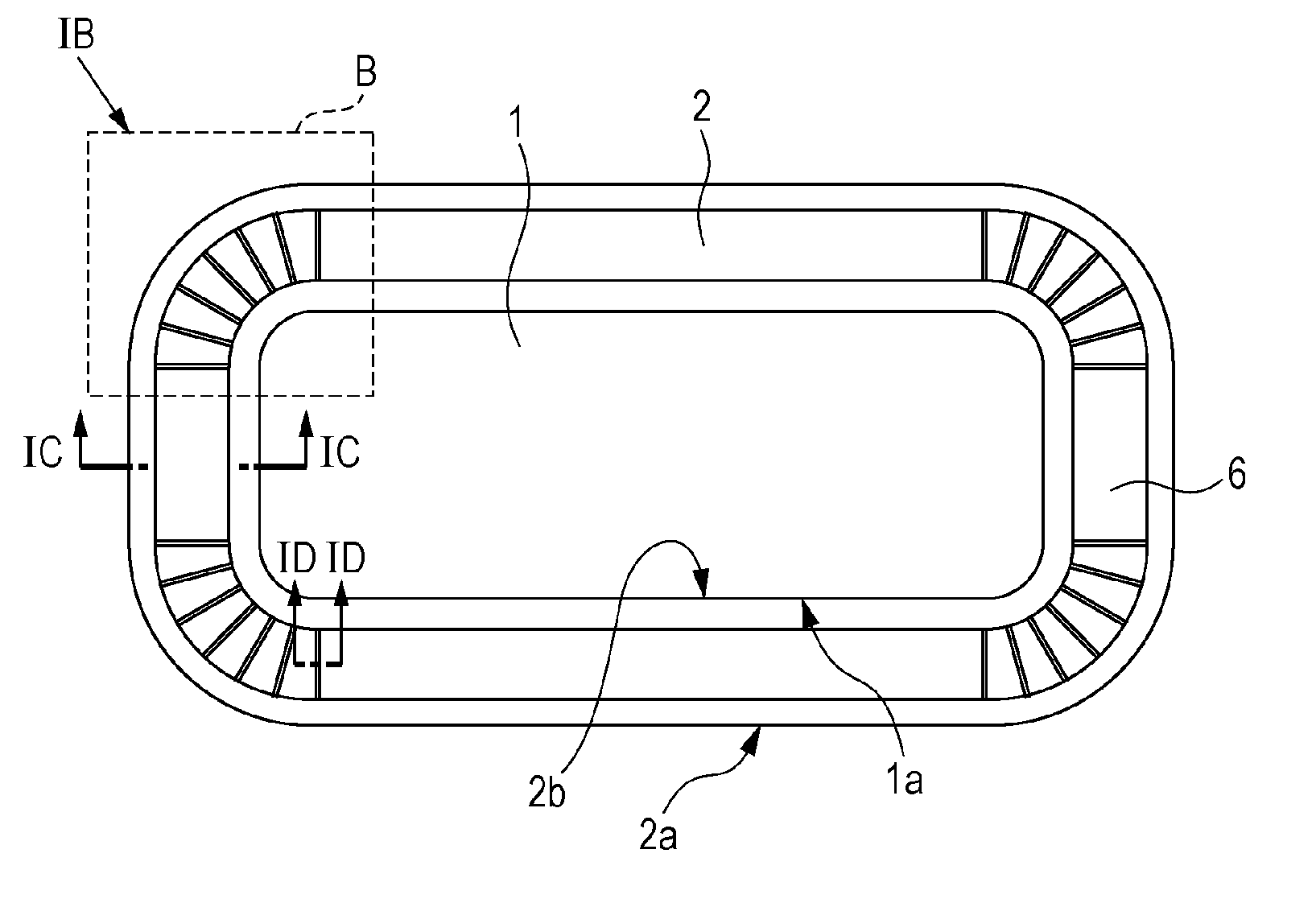

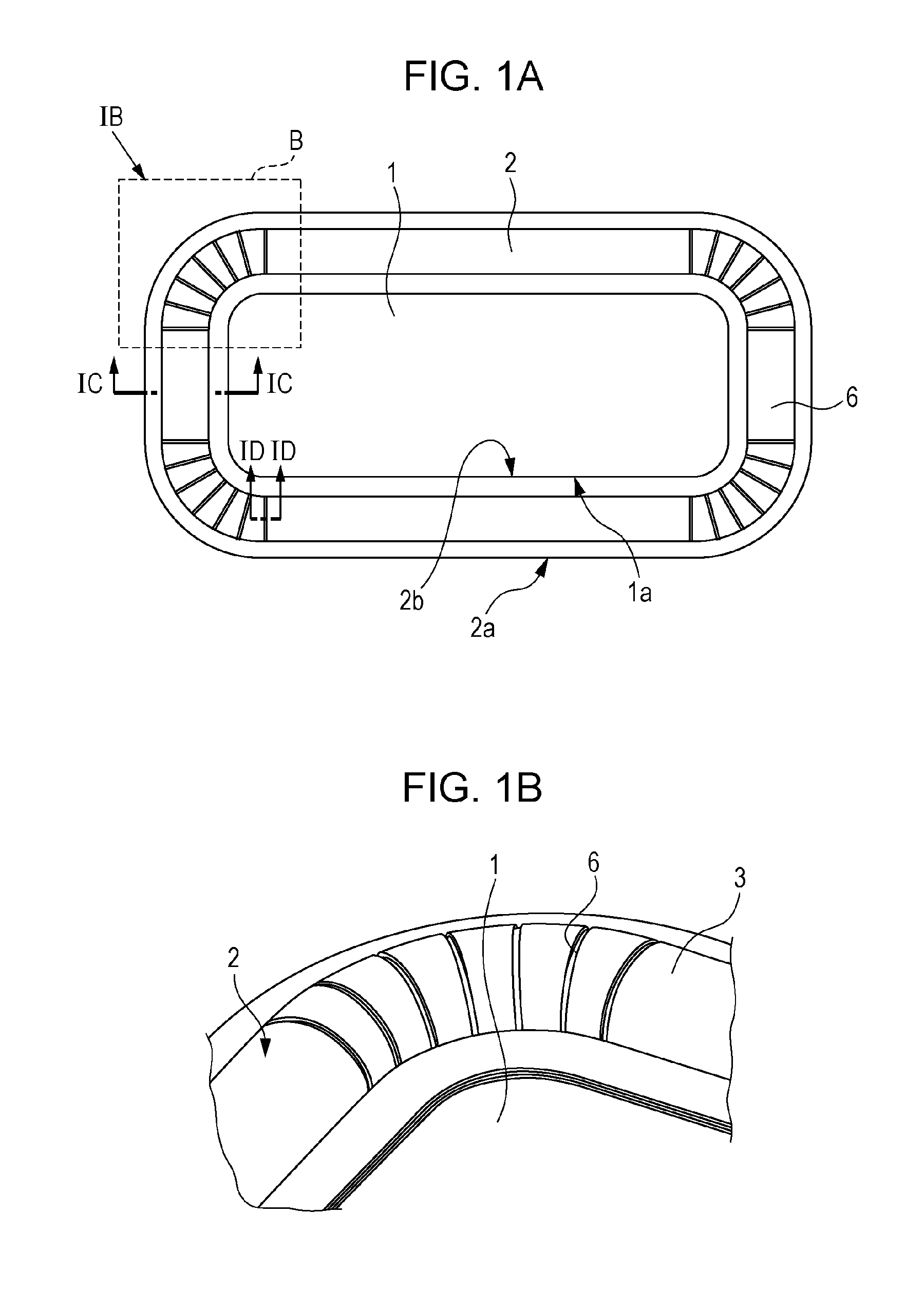

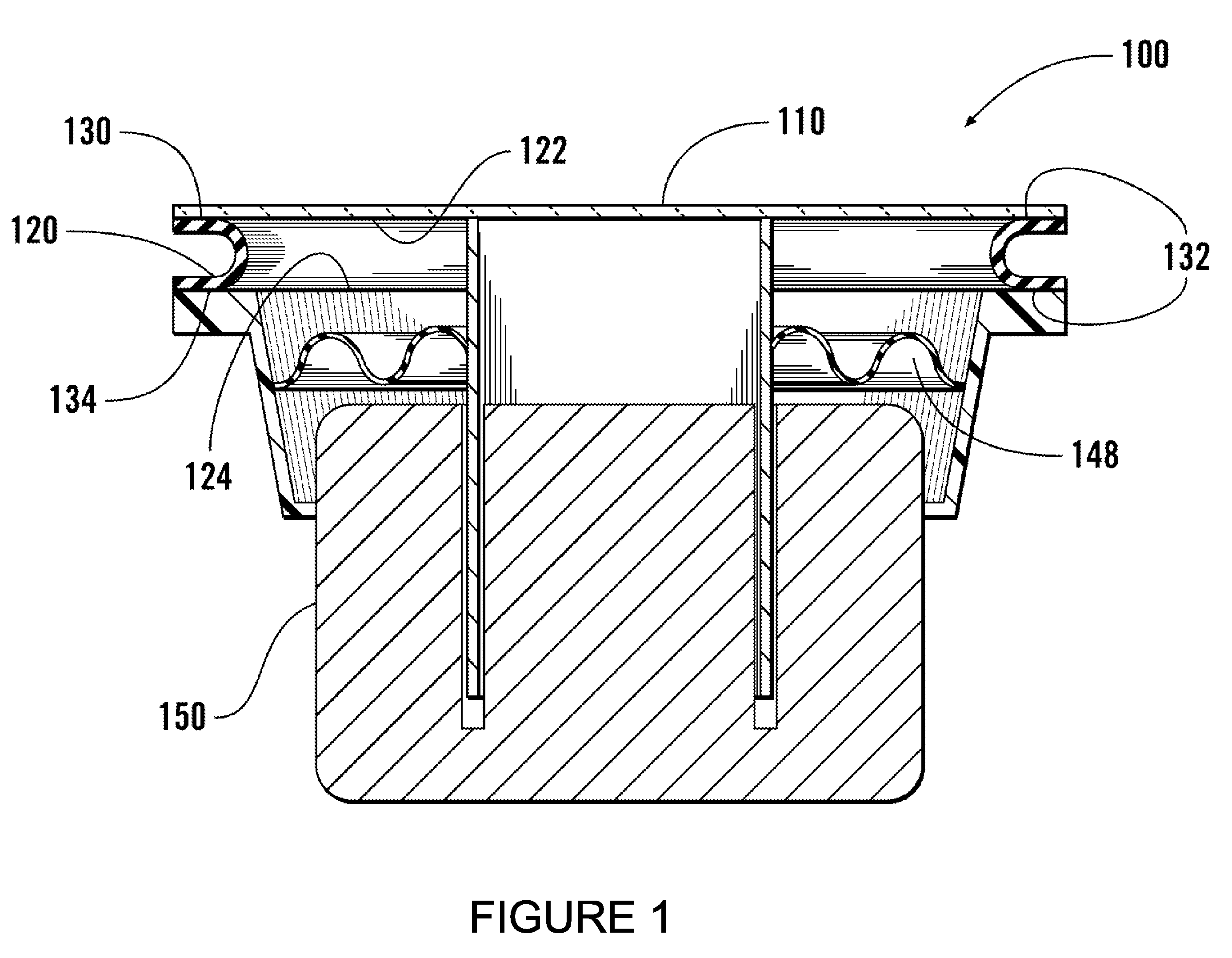

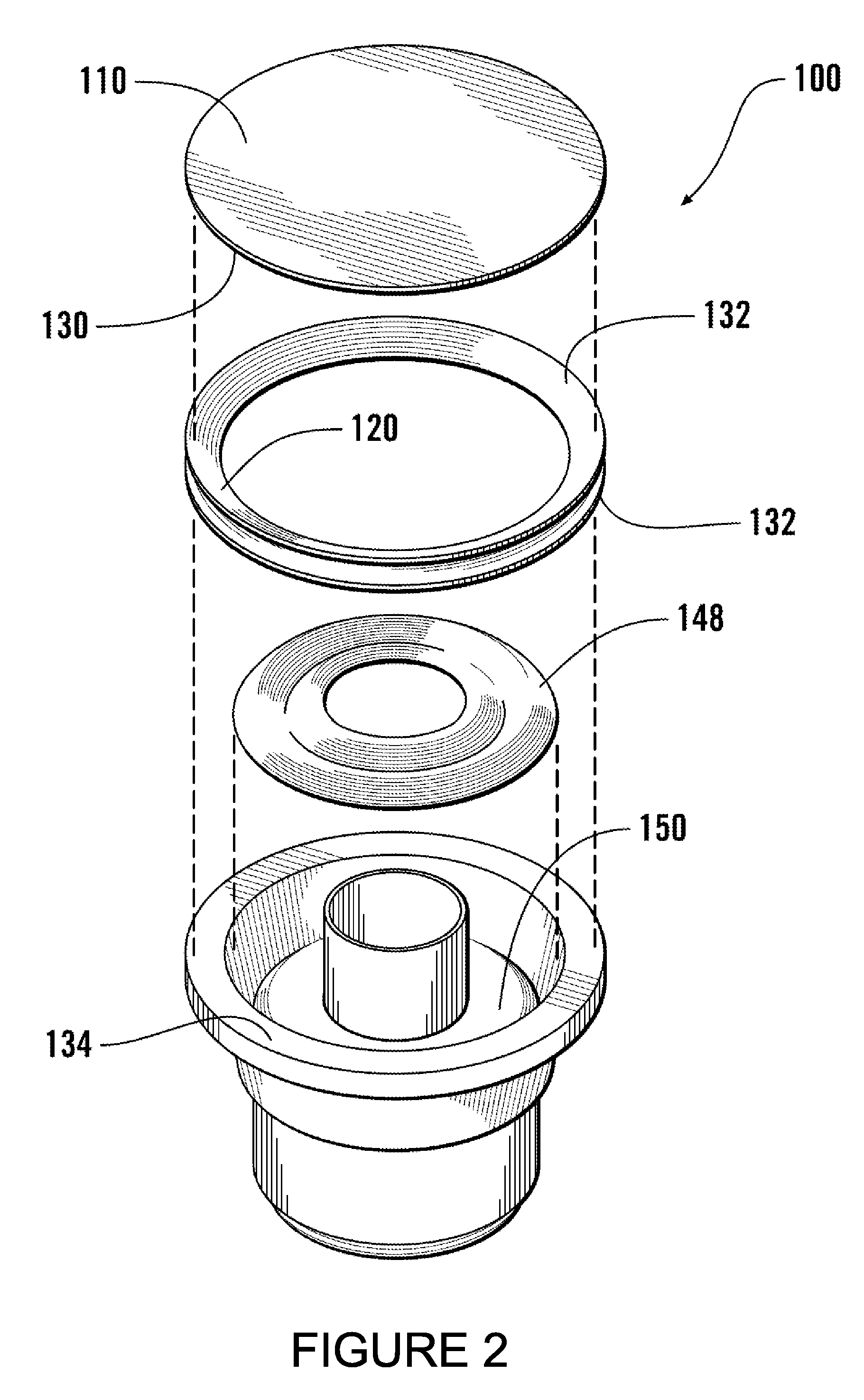

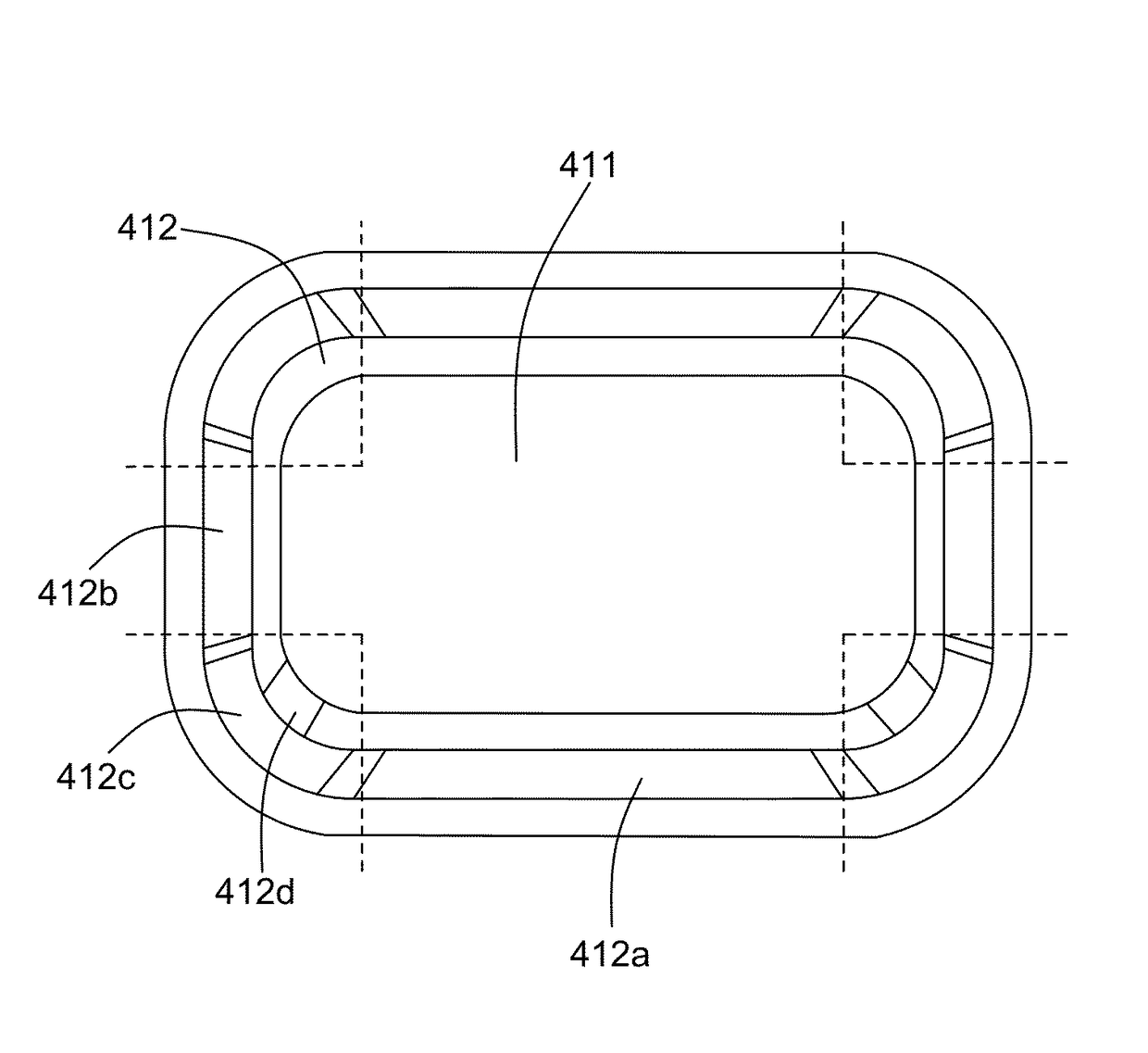

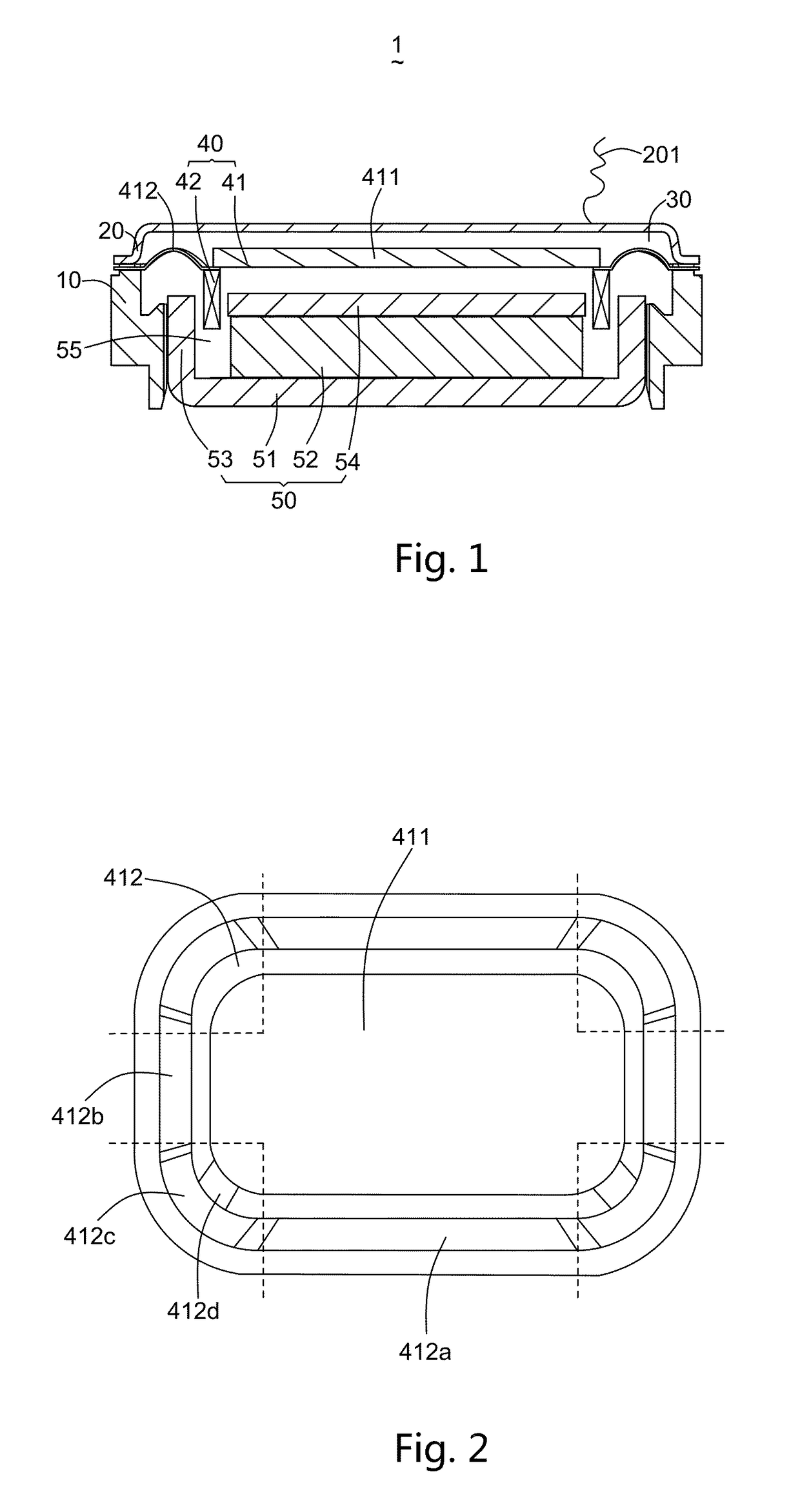

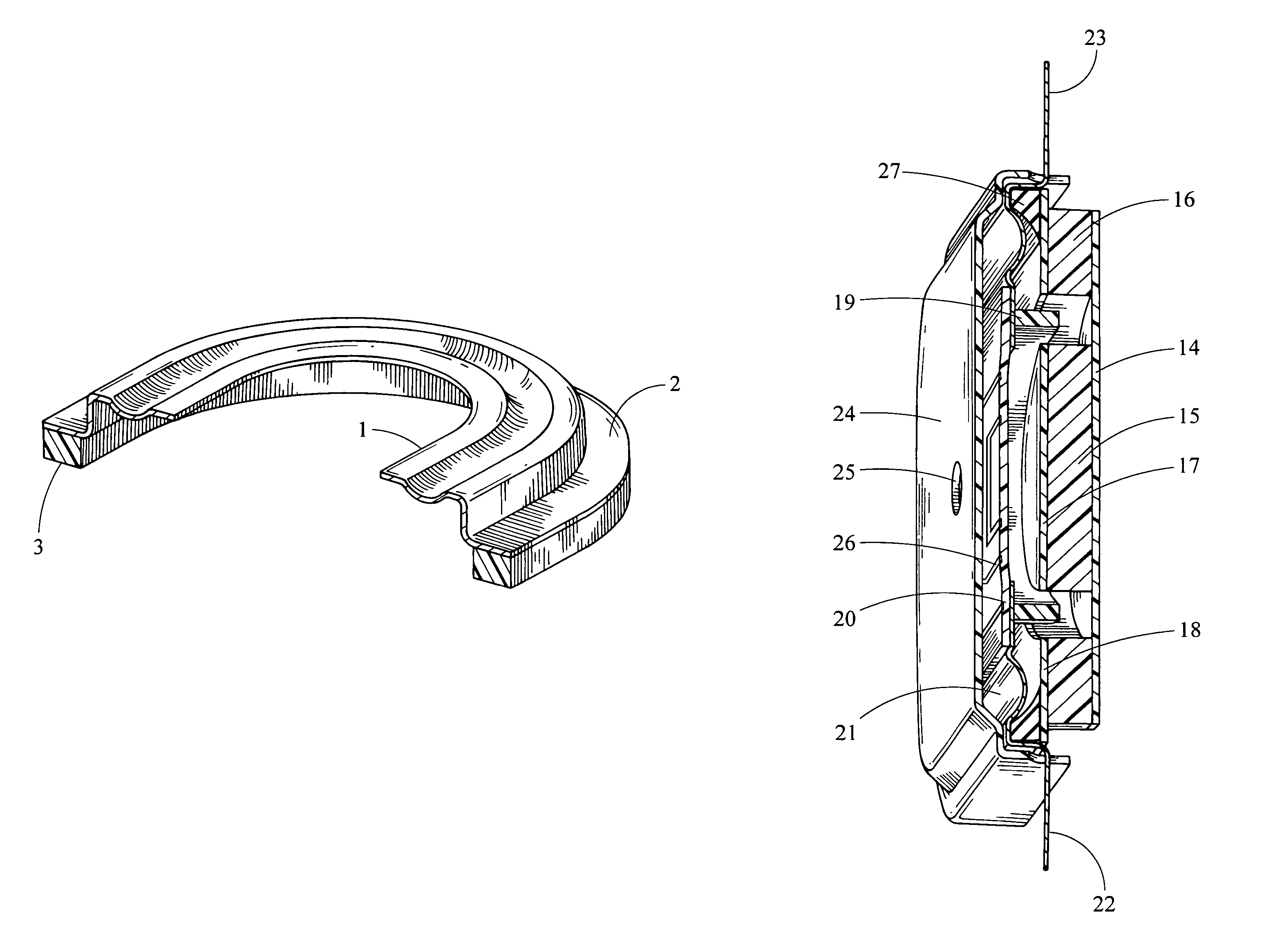

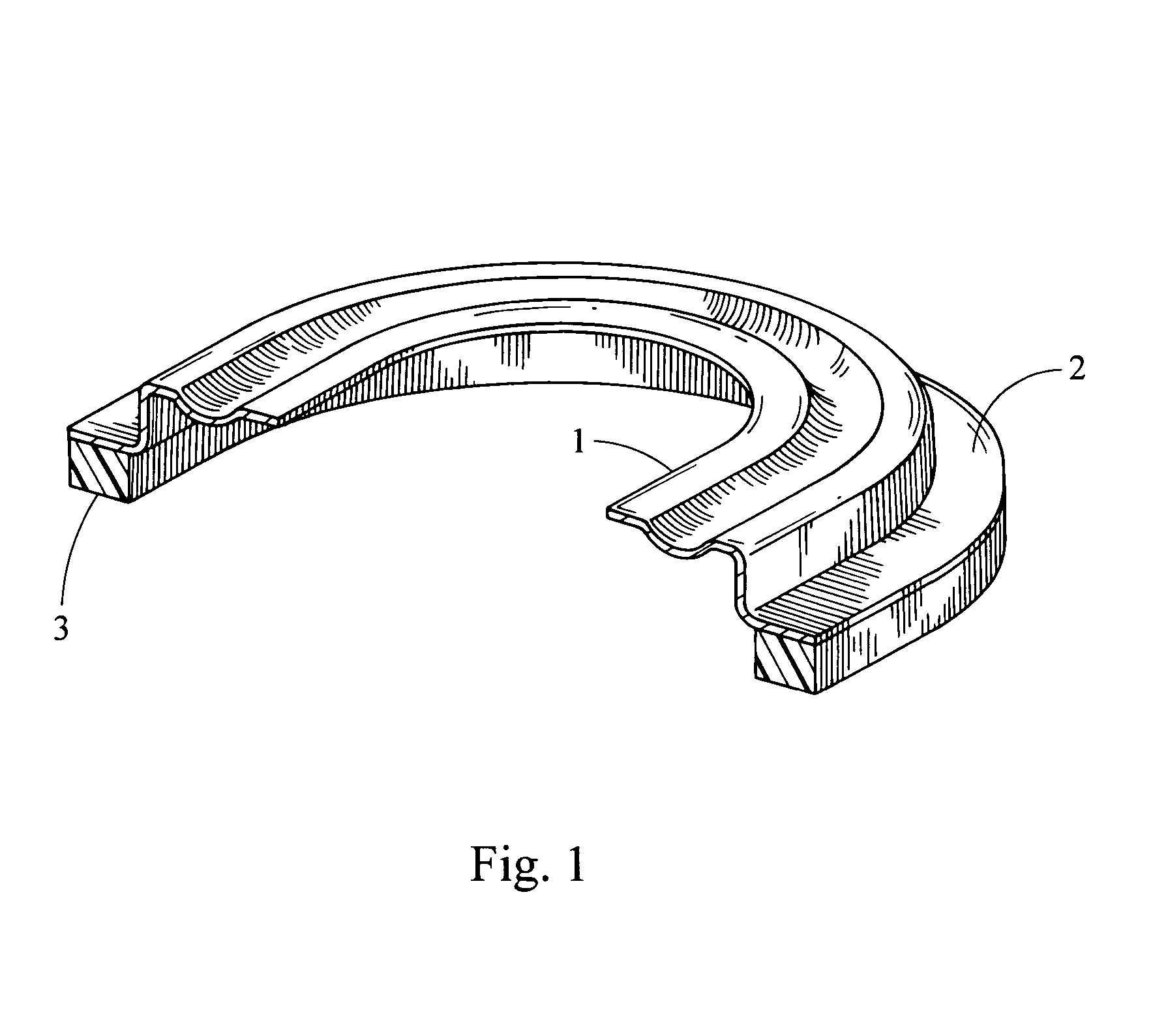

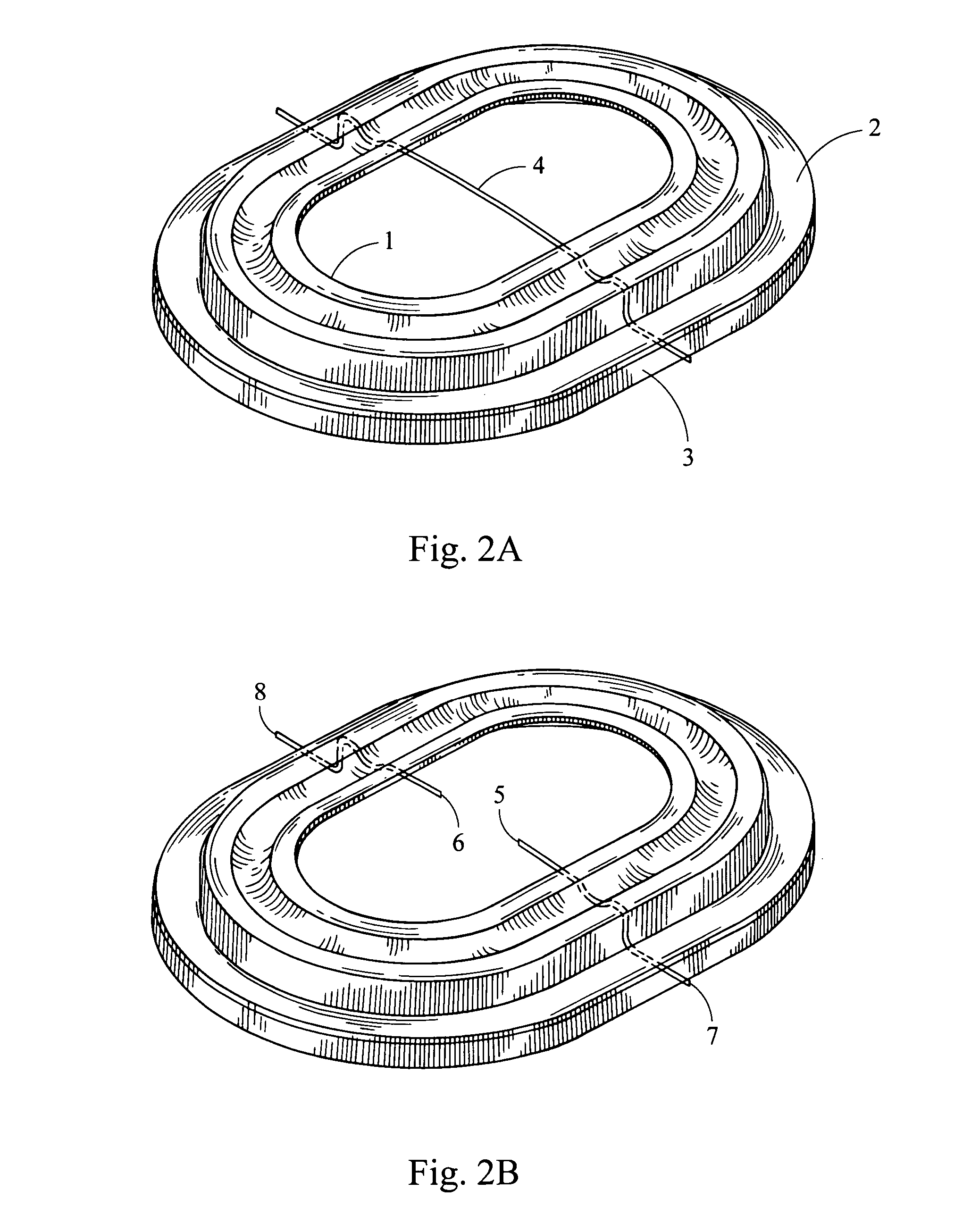

Square speaker

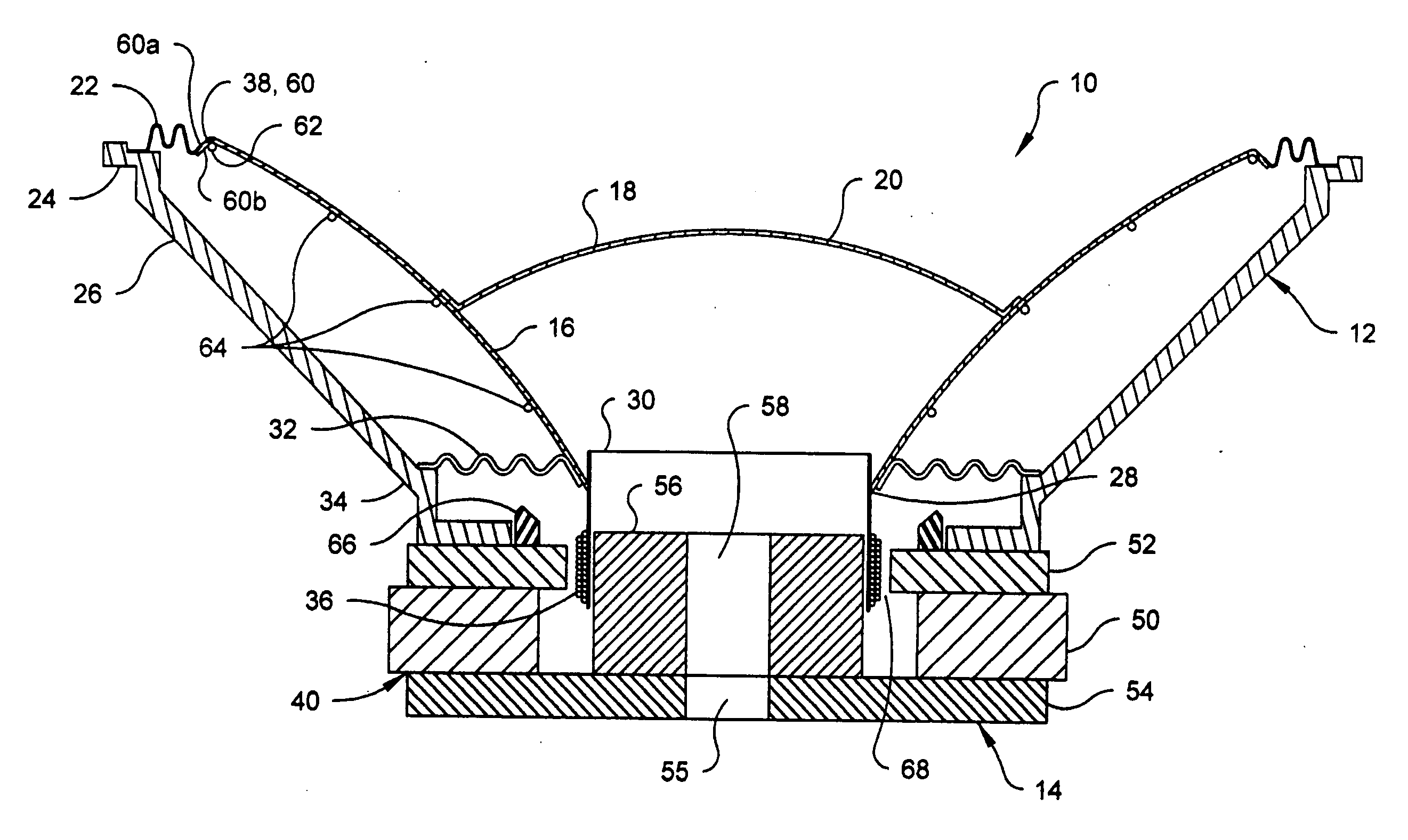

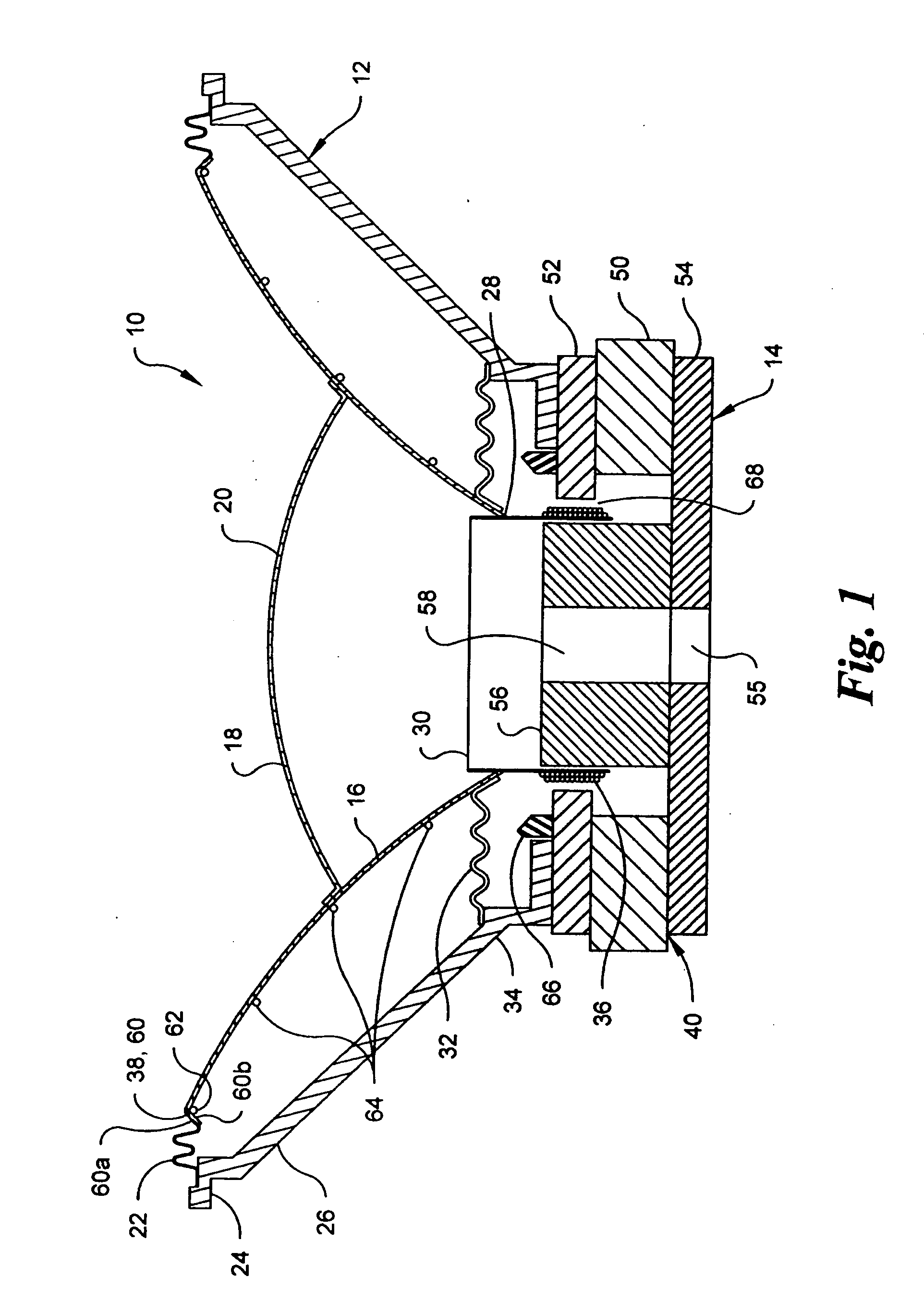

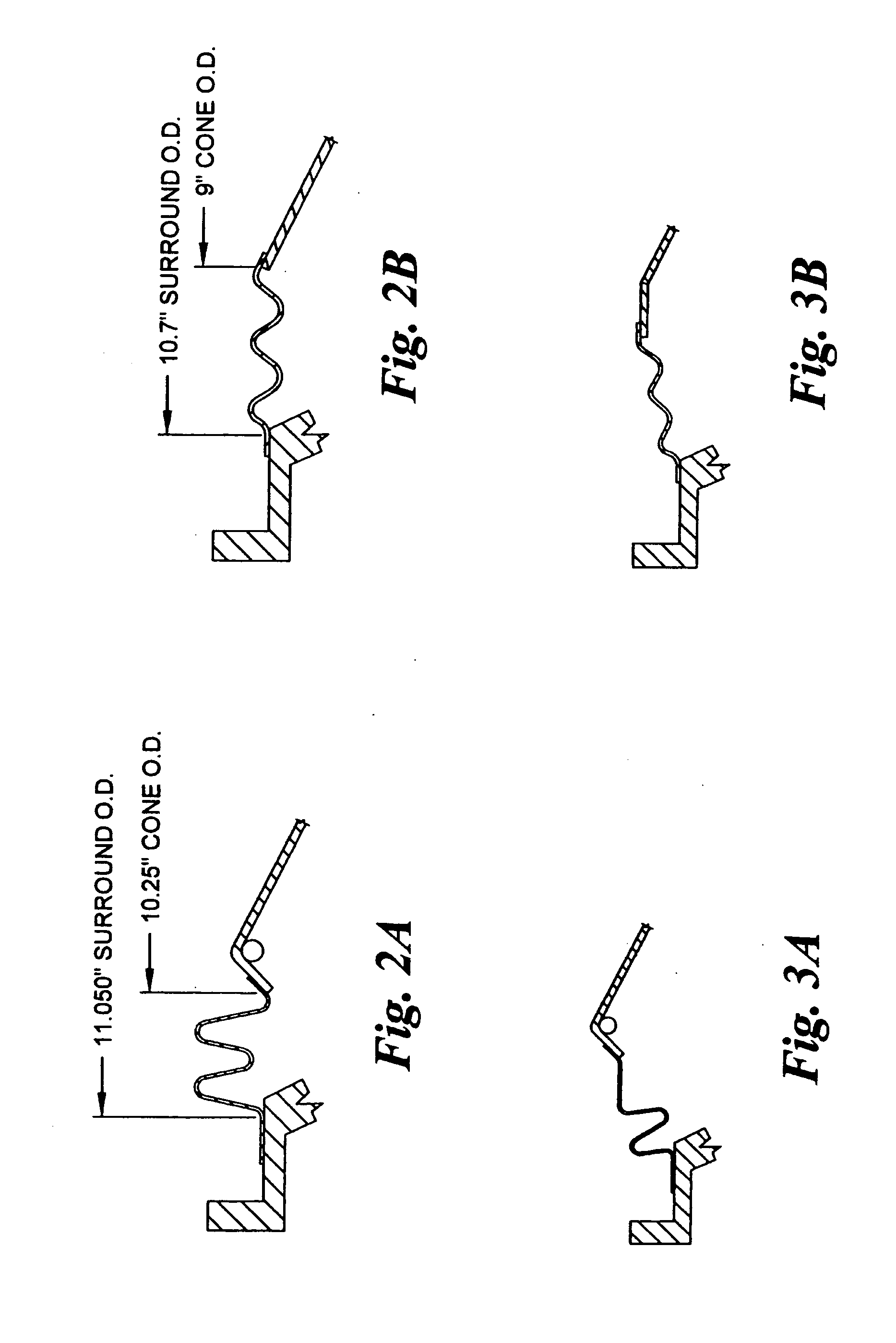

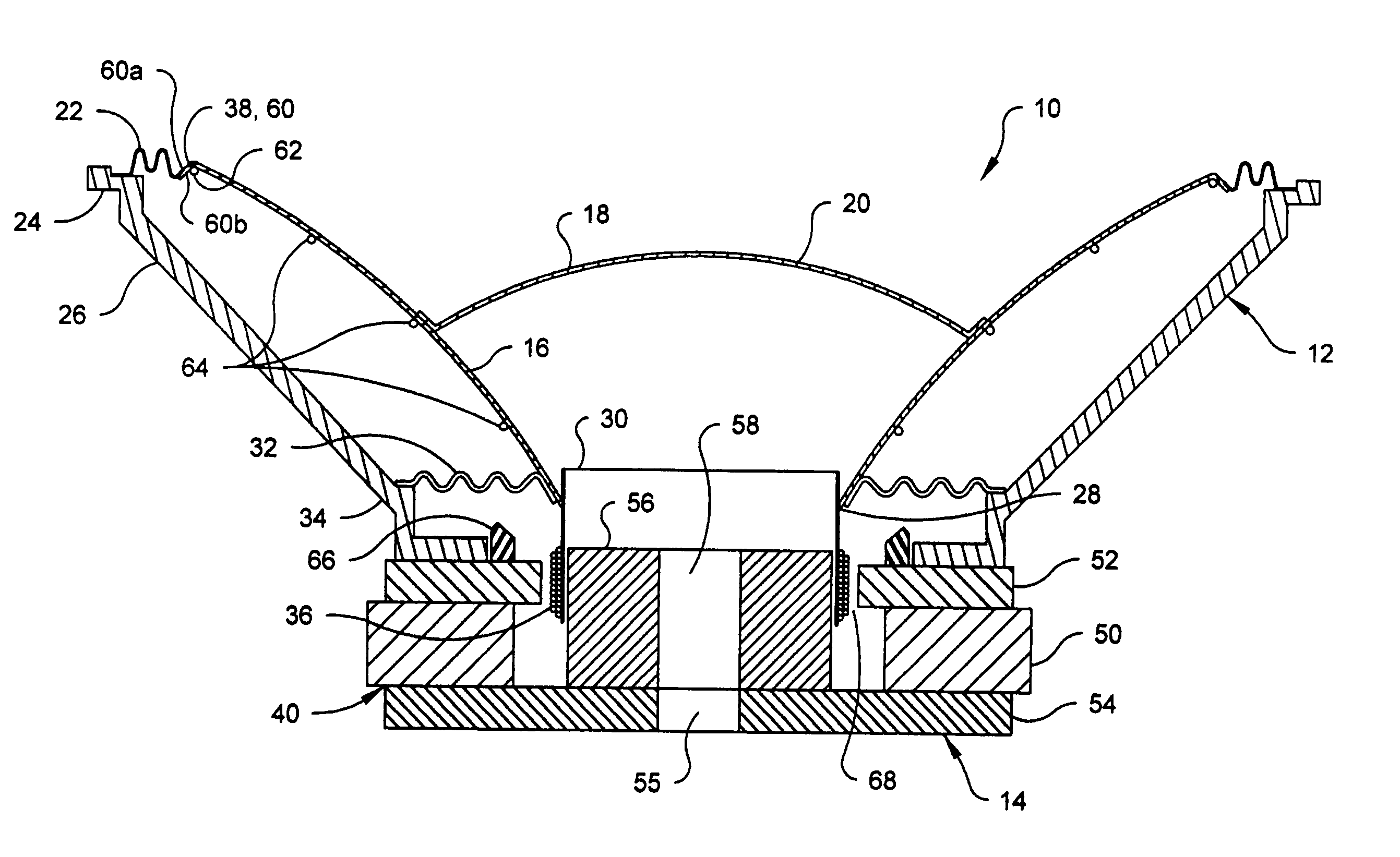

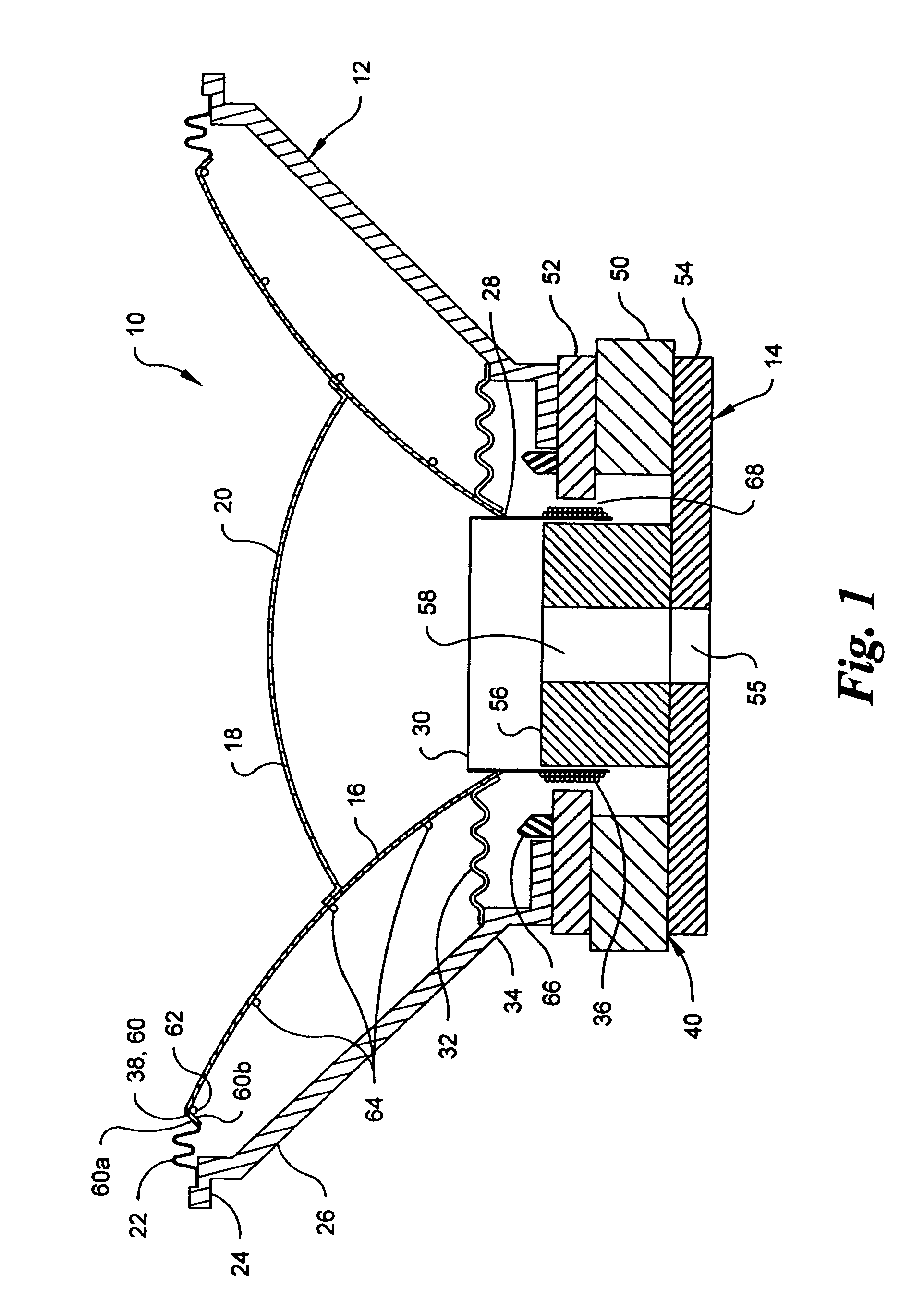

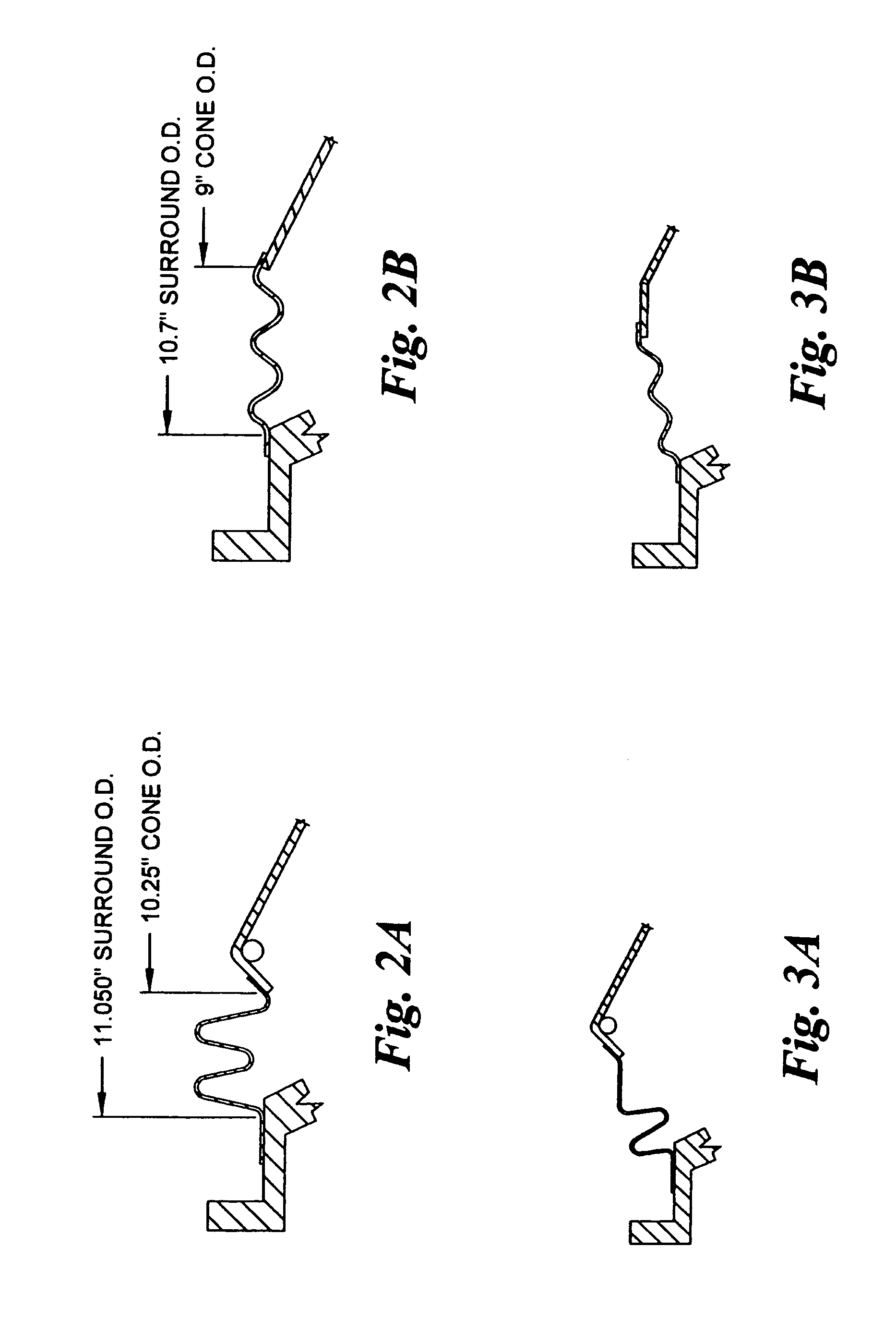

ActiveUS7275620B1Increase amplitudeLoudspeaker diaphragm materialsLoudspeaker diaphragm shapeEngineeringVolume displacement

A square speaker is disclosed having a novel surround with a novel rounded corner design and with a magnet assembly and former sized, shaped, and arranged to exploit the increased excursions enabled by the novel surround. The arcuate portion of the rounded corner features smoothed trapezoidal circumferential undulations of the radially outer portion and an extension pad forms the arcuate portion of the radially inner portion of the rounded corner. An apex groove separates the inner portion from the outer portion. Tapered protrusions of the outer portion flank the smoothed trapezoidal circumferential undulations. The rounded corner is bounded by edges making angles of between 20 degrees and 40 degrees (preferably about 35 degrees) with straight sides of the square surround. Most of the outer perimeter of the entire inner flange adjoins the inner portions of the rounded corners. Significant increases in volume displacement per speaker size are achieved.

Owner:MITEK

Acoustic device and electronic equipment

ActiveCN109803215ALower resonance frequencyRaise the resonance frequencyLoudspeakersLoudspeaker diaphragm materialsCapacitanceThermoplastic elastomer

The embodiment of the invention provides an acoustic device and electronic equipment, the acoustic device comprises a first closed cavity and a second closed cavity, a spacing part can be at least partially and flexibly deformed, the first closed cavity is adjacent to a vibrating diaphragm, and the second closed cavity is far away from the vibrating diaphragm; When the vibrating diaphragm vibrates, the internal sound pressure of the first closed cavity is changed, the flexible deformation part is deformed along with the change of the sound pressure in the first closed cavity, and the volume ofthe first closed cavity is flexibly adjusted; The second sealed cavity seals sound waves generated when the flexible deformation part deforms in the second sealed cavity, and the flexible deformationpart is of a single-layer structure made of a thermoplastic elastomer material layer or a multi-layer composite structure at least compounded with a thermoplastic elastomer material layer. Therefore,the acoustic device provided by the invention can increase the sound capacitance of the flexible deformation part, thereby reducing the resonant frequency of the sound production device and effectively improving the low-frequency effect of the sound production device.

Owner:GOERTEK INC

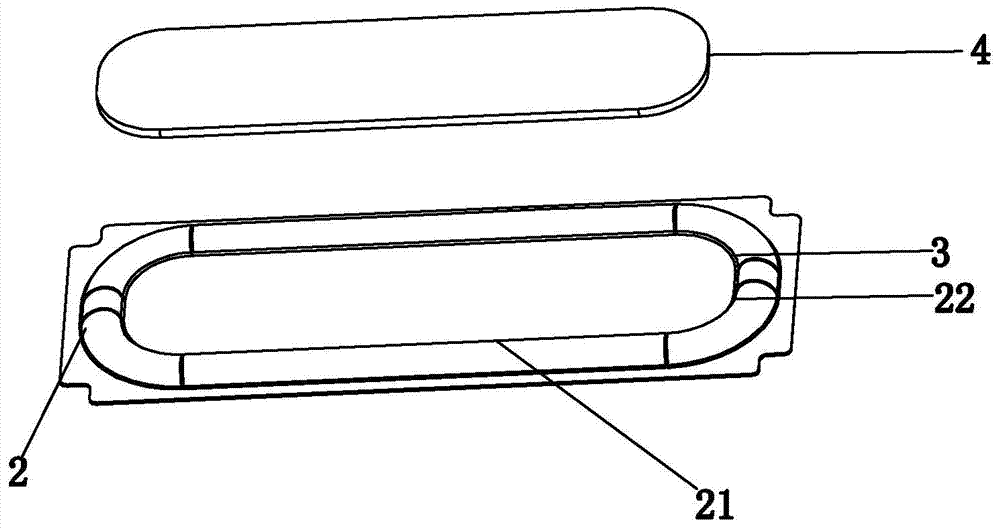

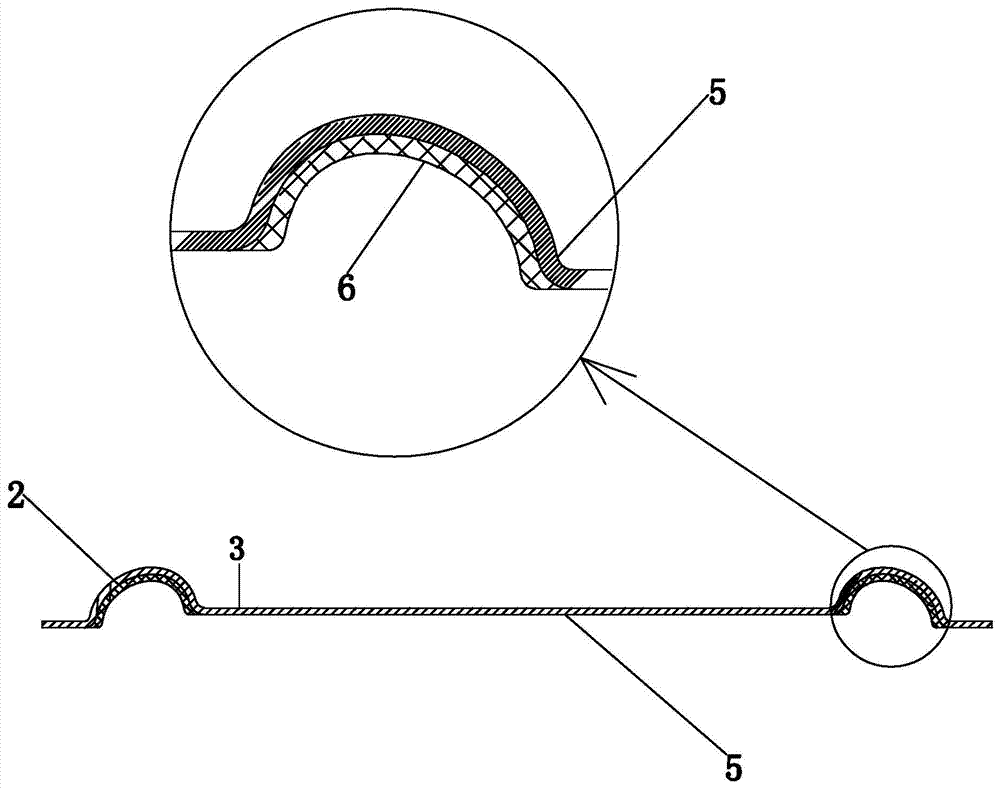

Laser welded speaker and vibration plate thereof

InactiveUS20150208179A1Improve performanceQuality improvementSingle transducer incorporationMicrophonesEngineeringInfrared laser beam

A laser welded speaker, comprising a magnet, a voice coil disposed around the magnet, a vibration plate fixedly disposed on the voice coil, and a housing for accommodating the magnet, the voice coil and the vibration plate is provided. The vibration plate comprises a vibration plate top arc and a vibration plate edge, the vibration plate top arc is surrounded by the vibration plate edge and is laser welded to the vibration plate edge, one of the vibration plate top arc and the vibration plate edge is made of a first laser-penetrable material, and the other is made of a first laser-absorbable material, wherein the first laser-penetrable material contains a first organic pigment, the first laser-penetrable material containing the first organic pigment is capable of being penetrated by a first infrared laser beam, and wavelength of the first infrared laser beam ranges from 700 nm to 1600 nm.

Owner:MERRY ELECTRONICS SUZHOU

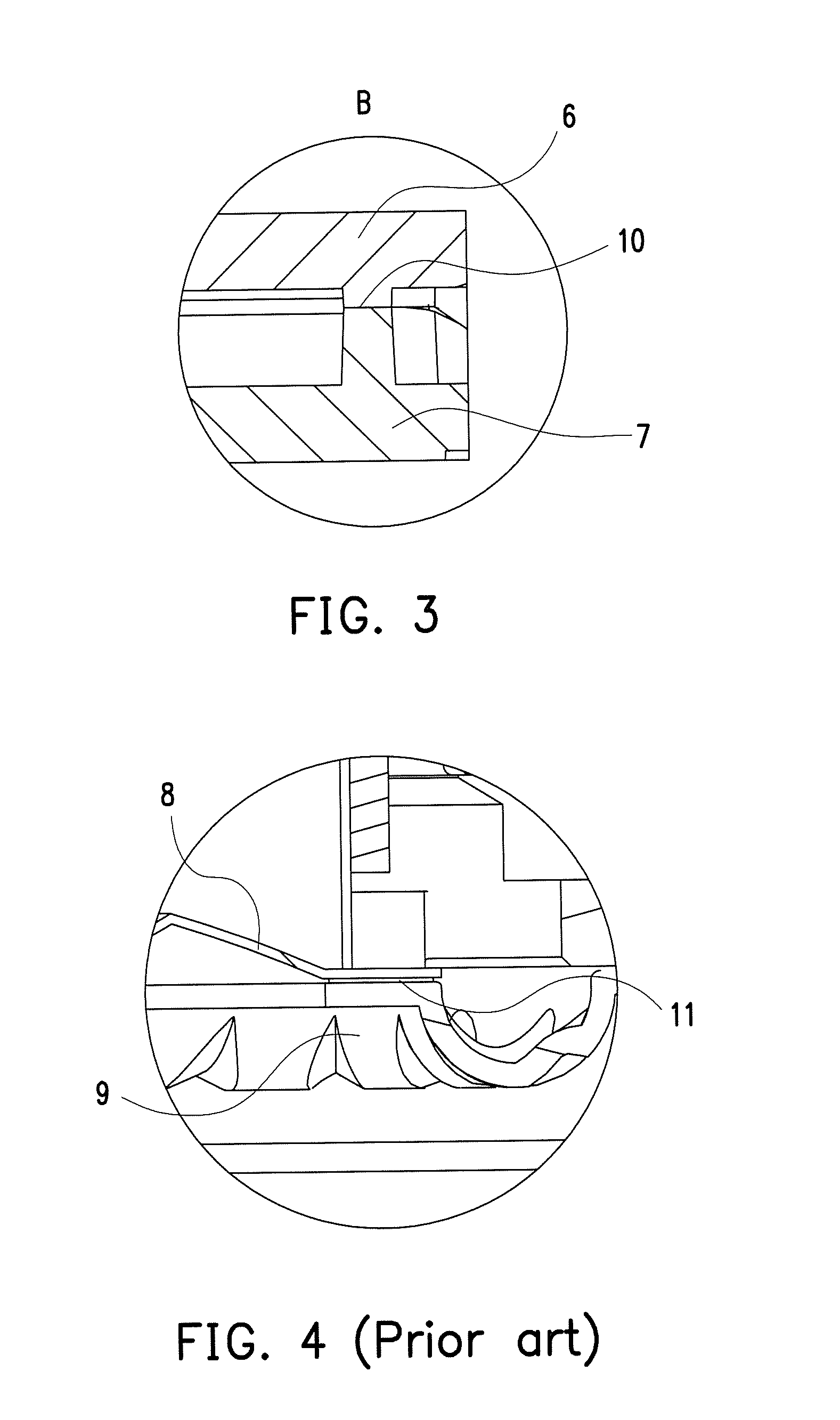

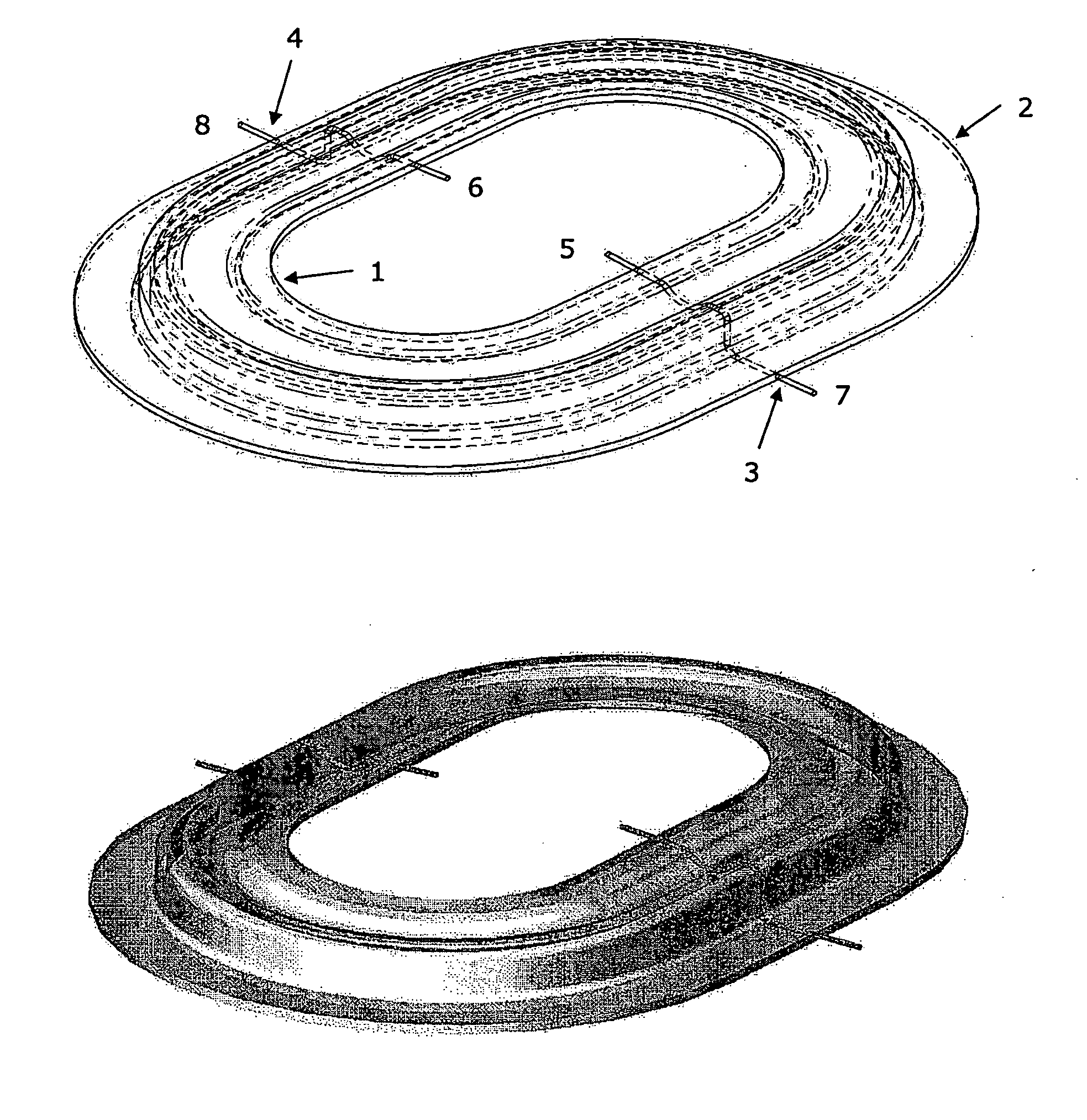

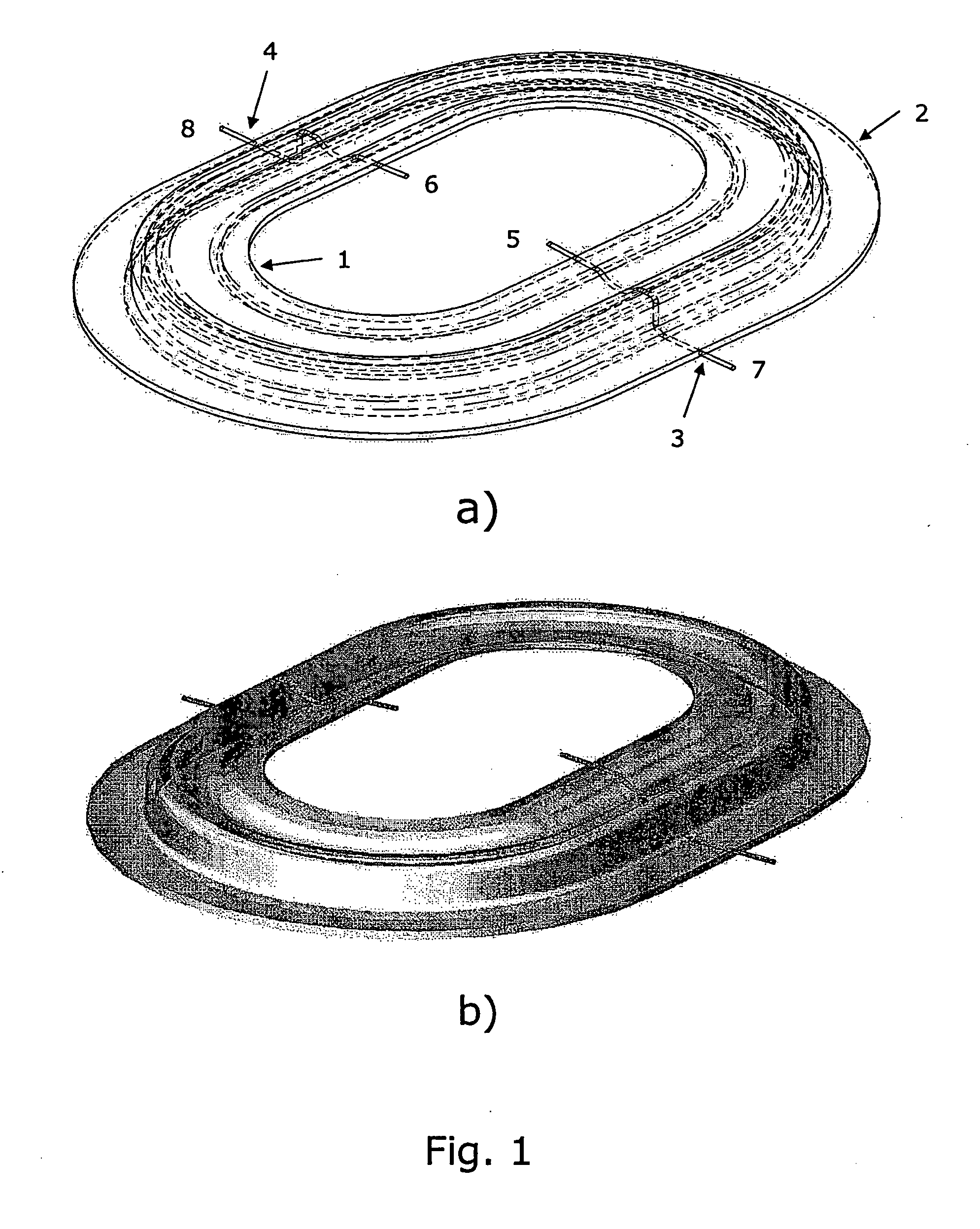

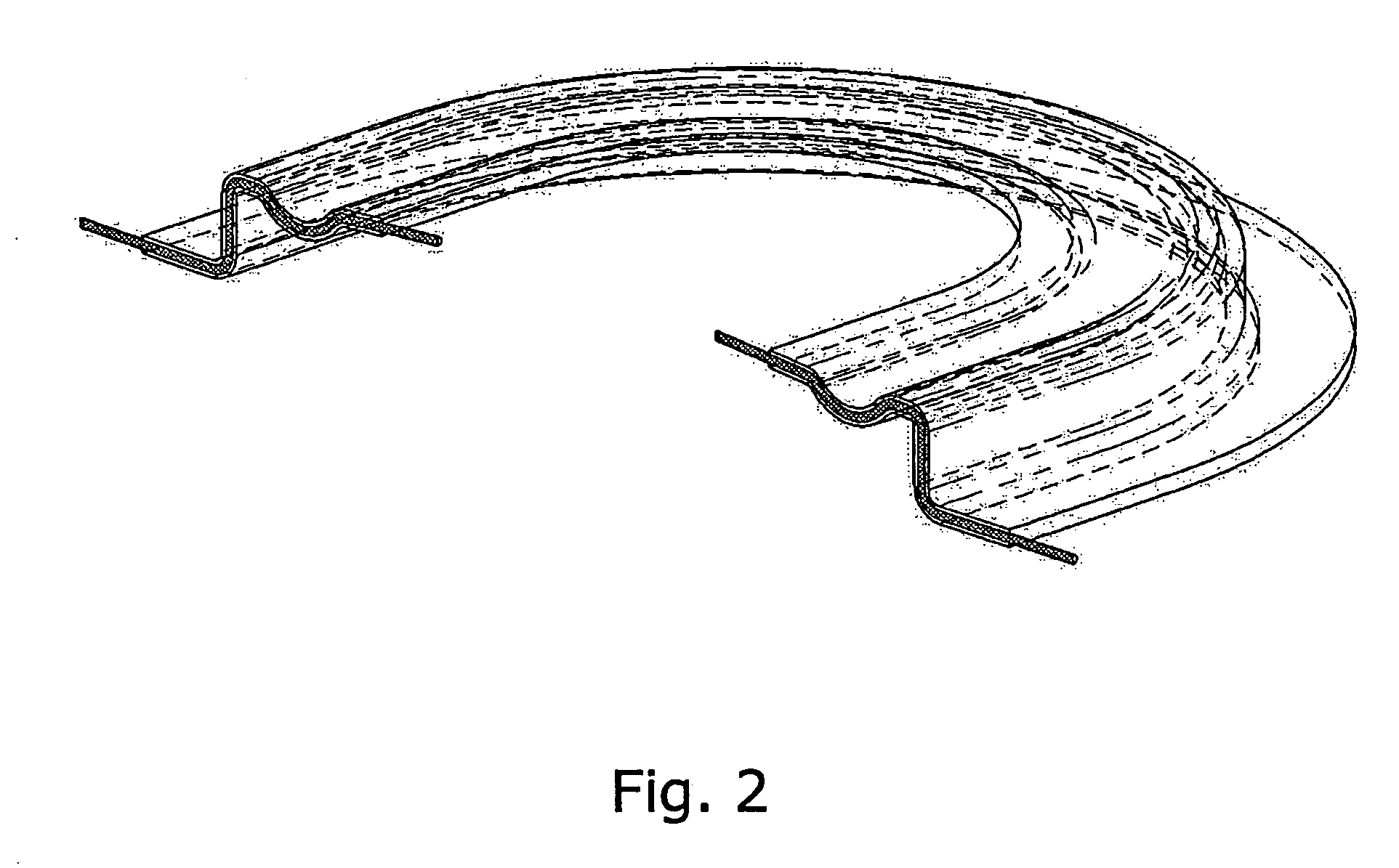

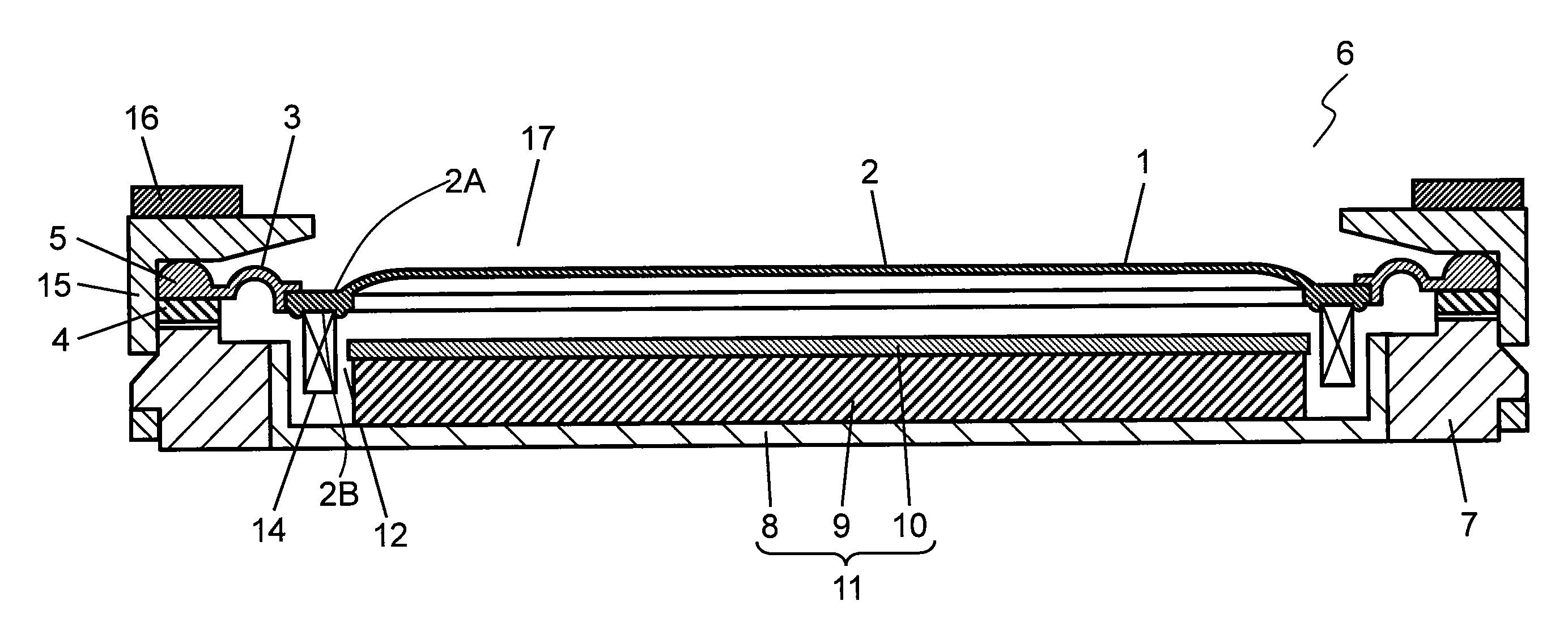

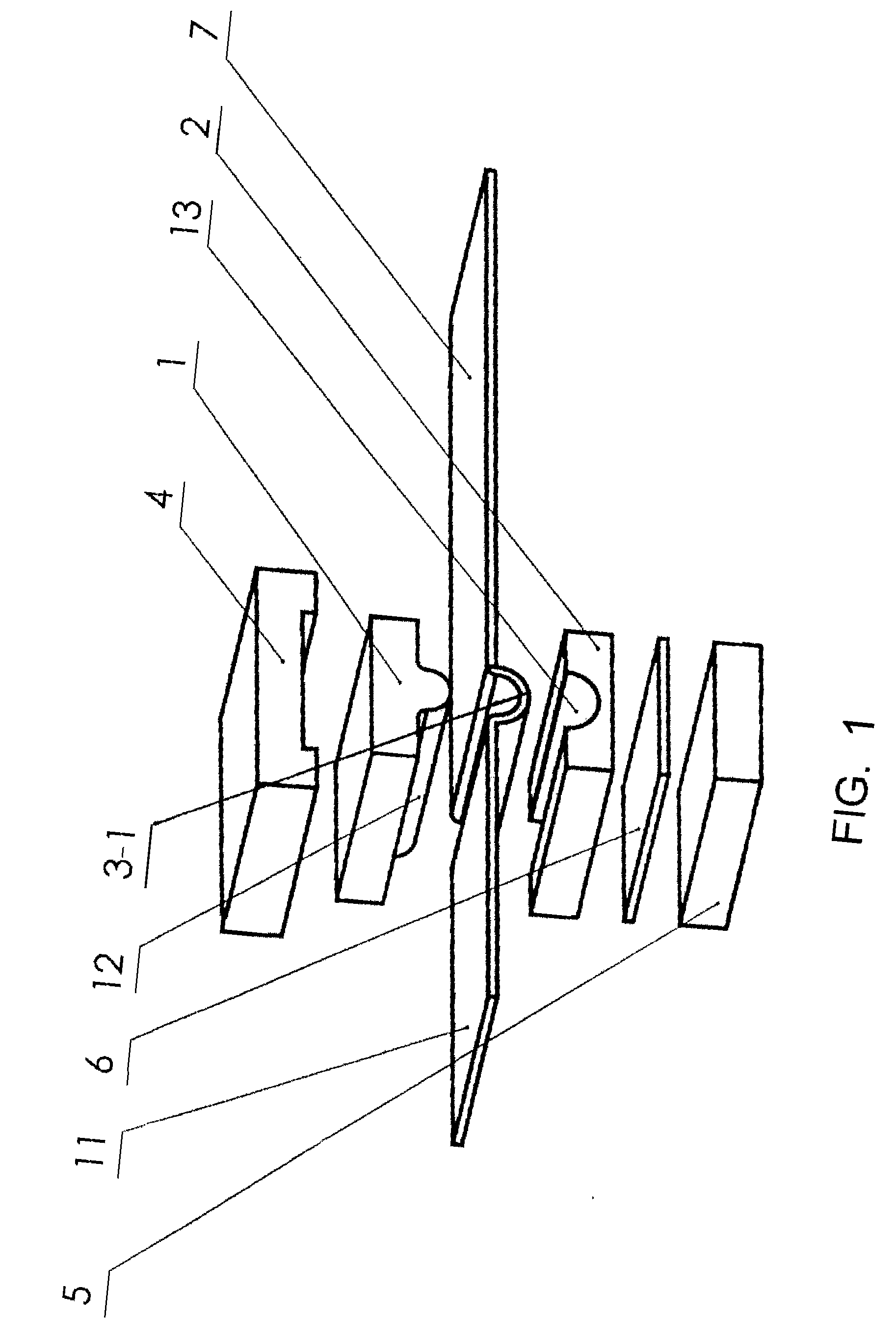

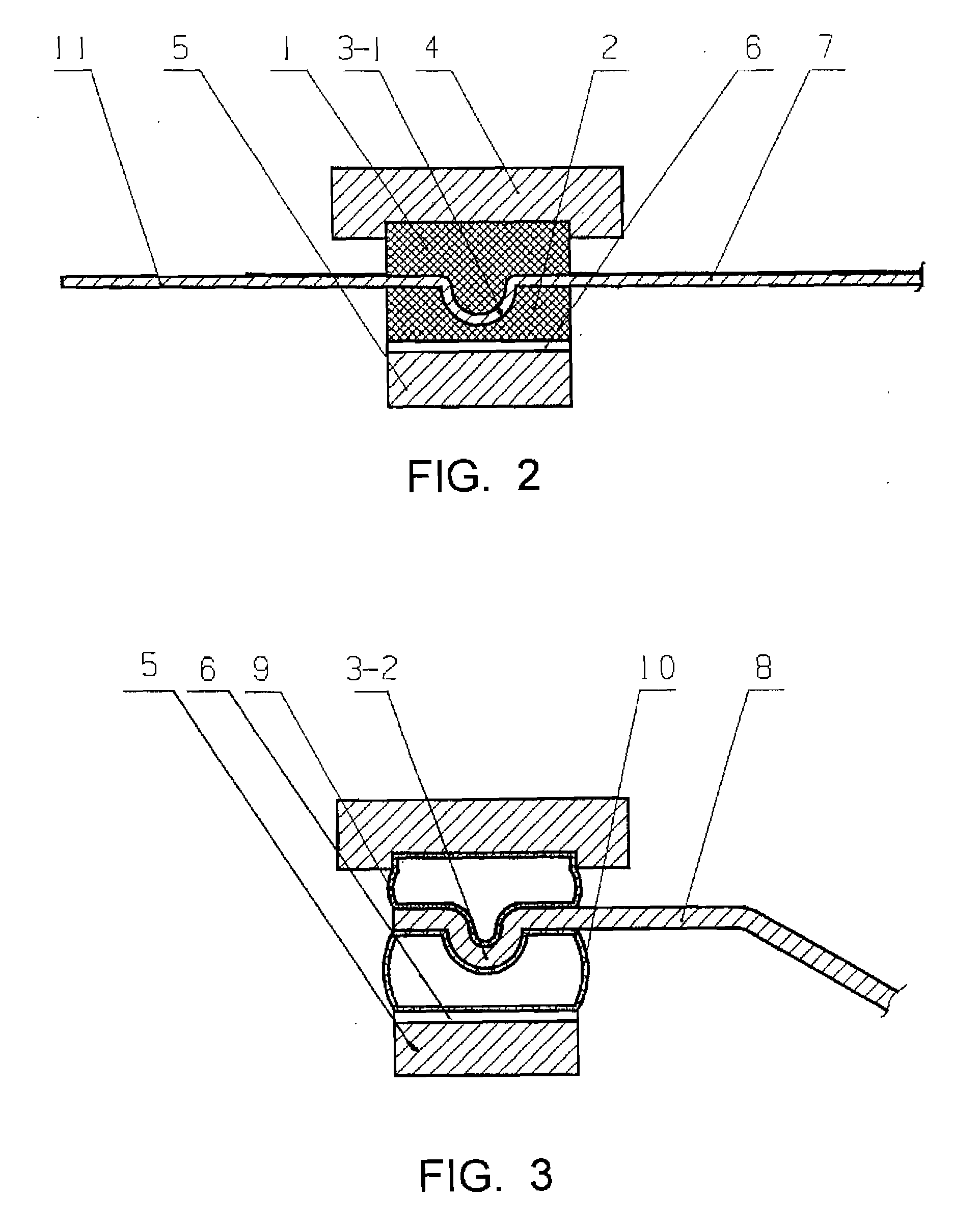

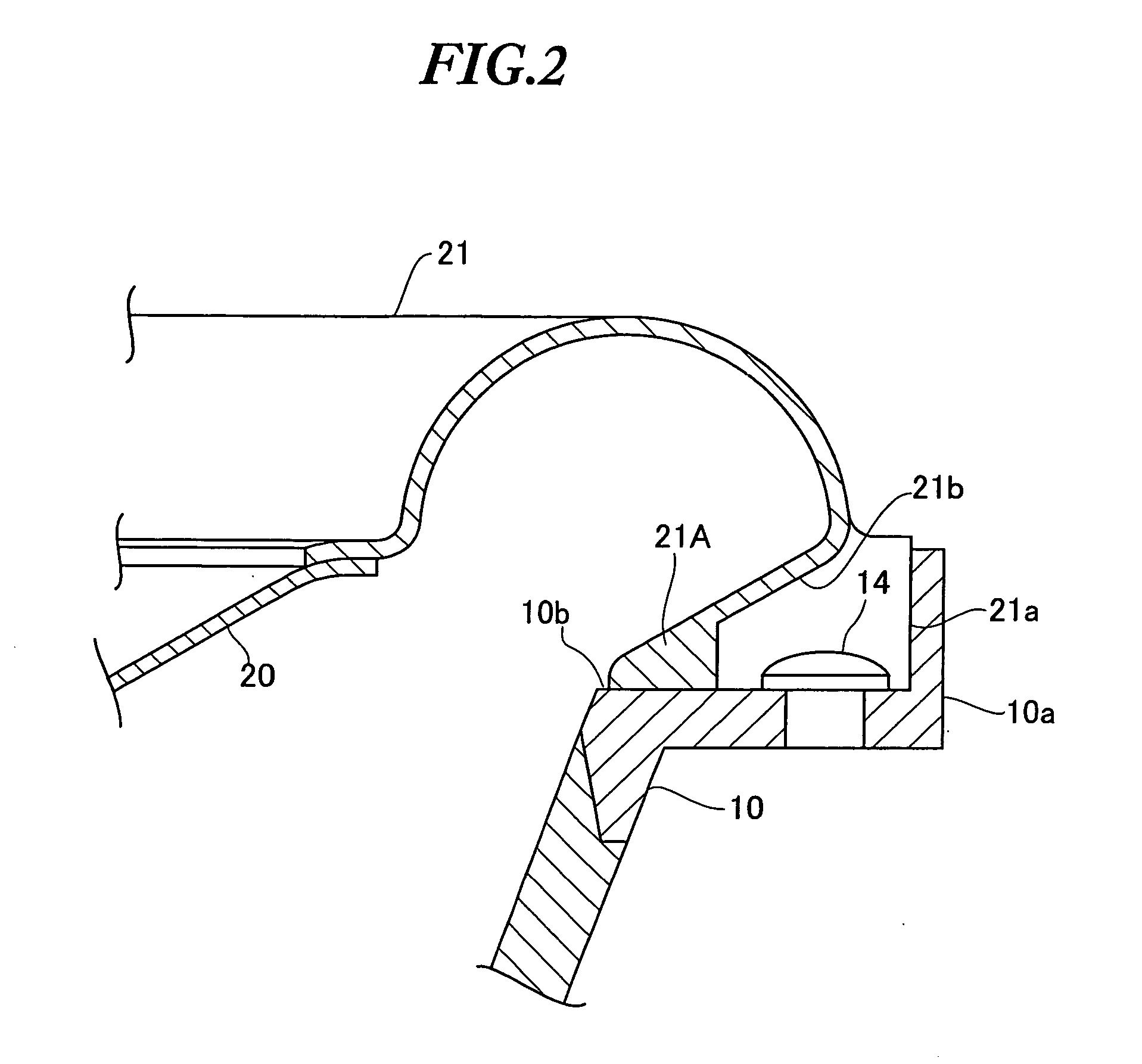

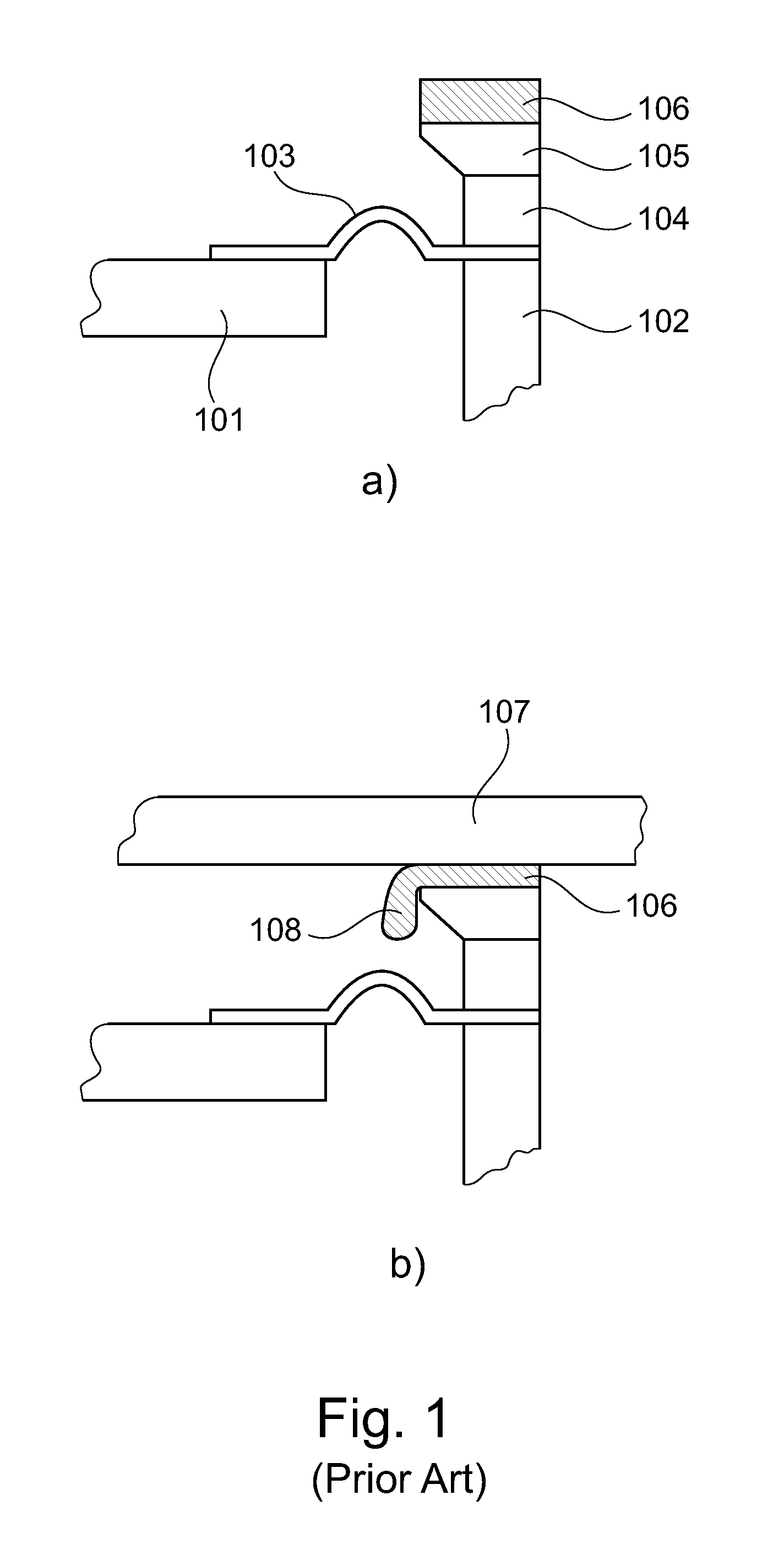

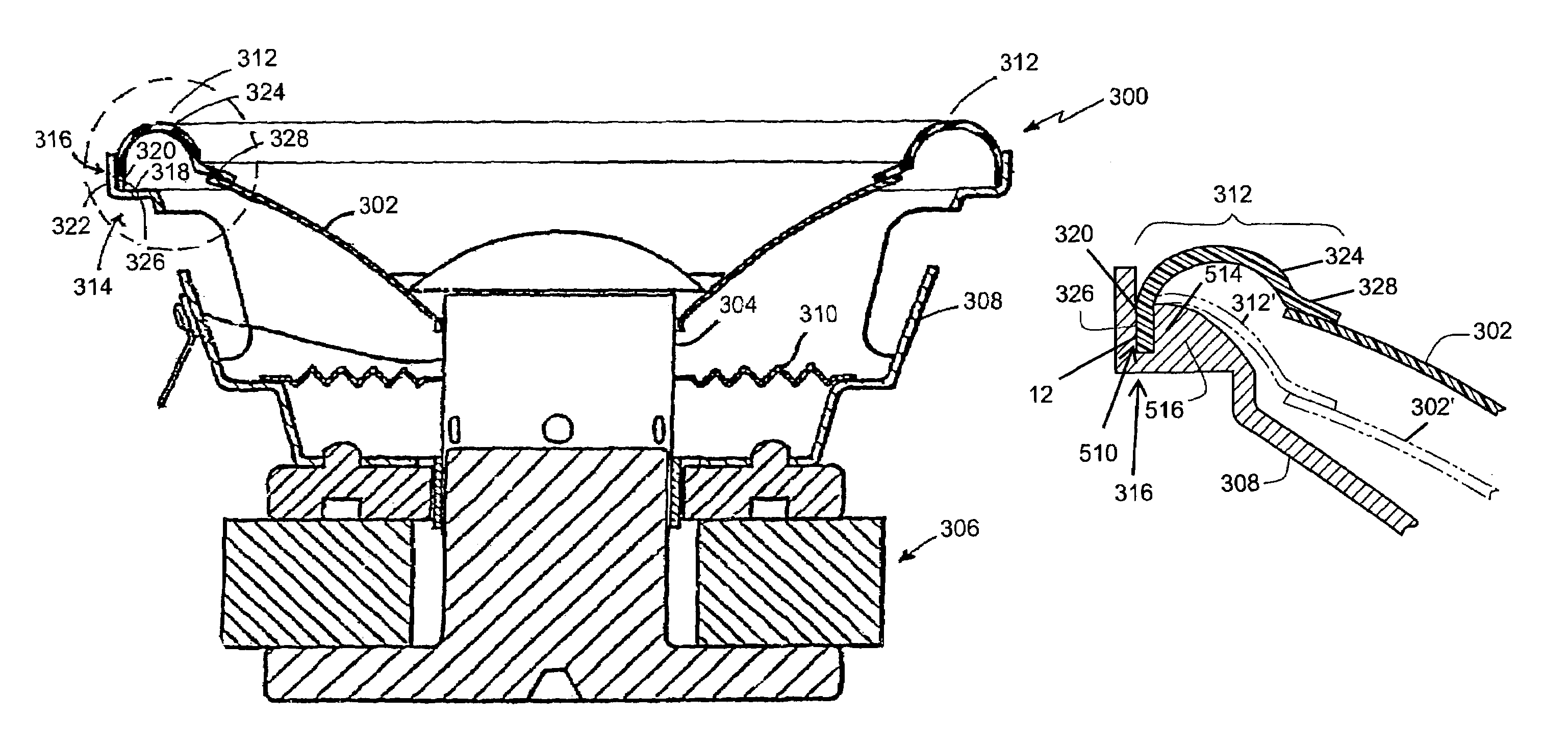

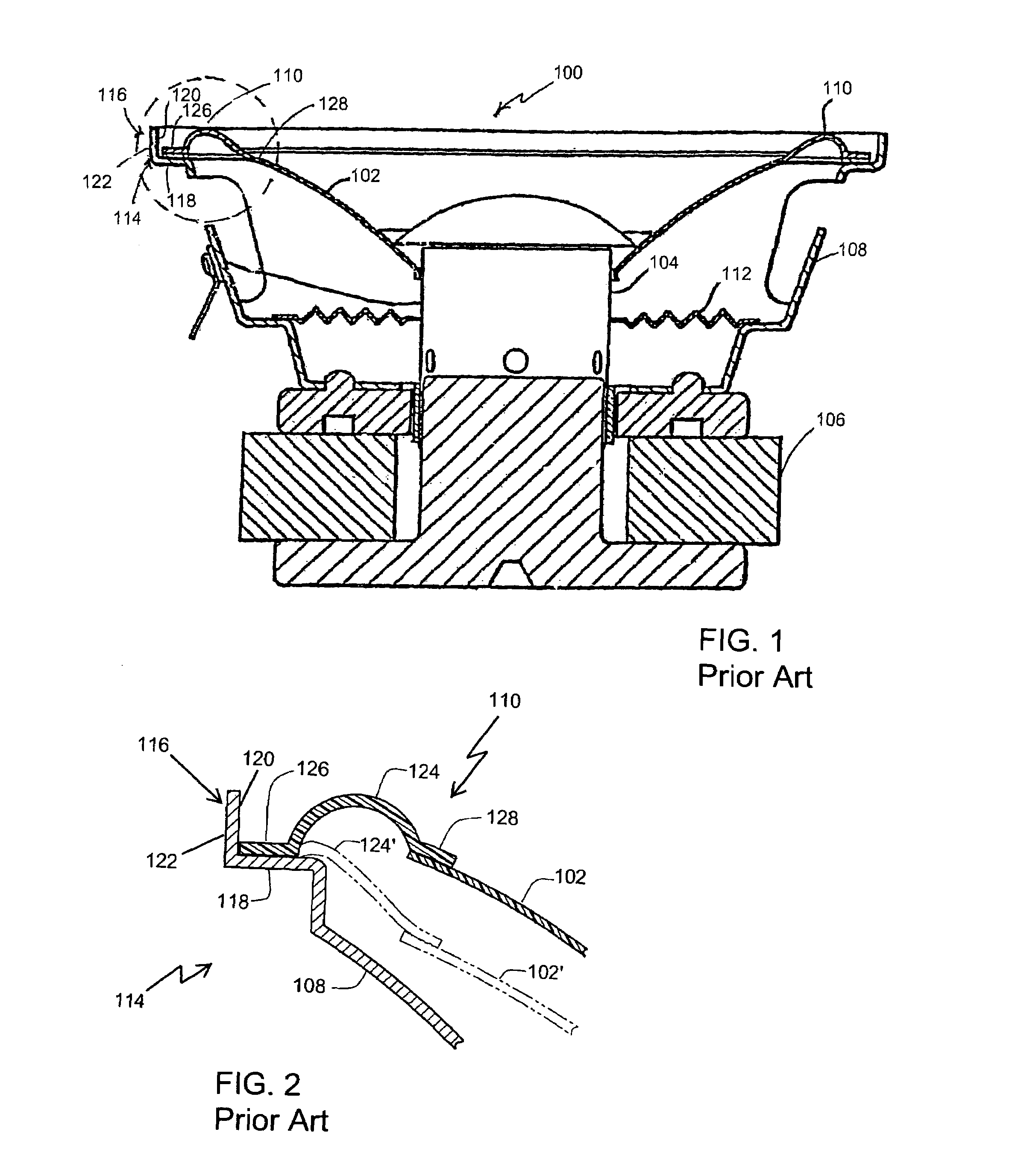

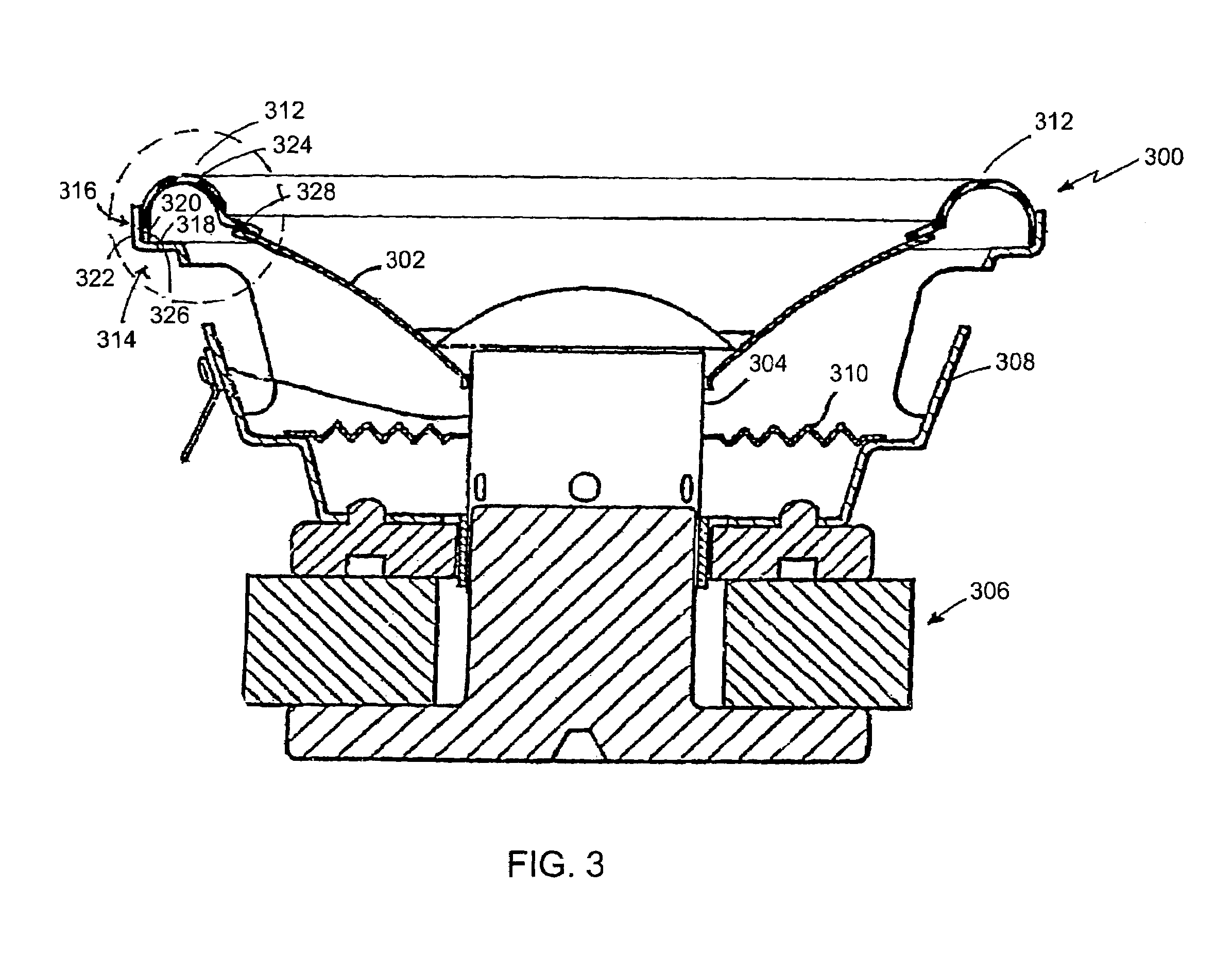

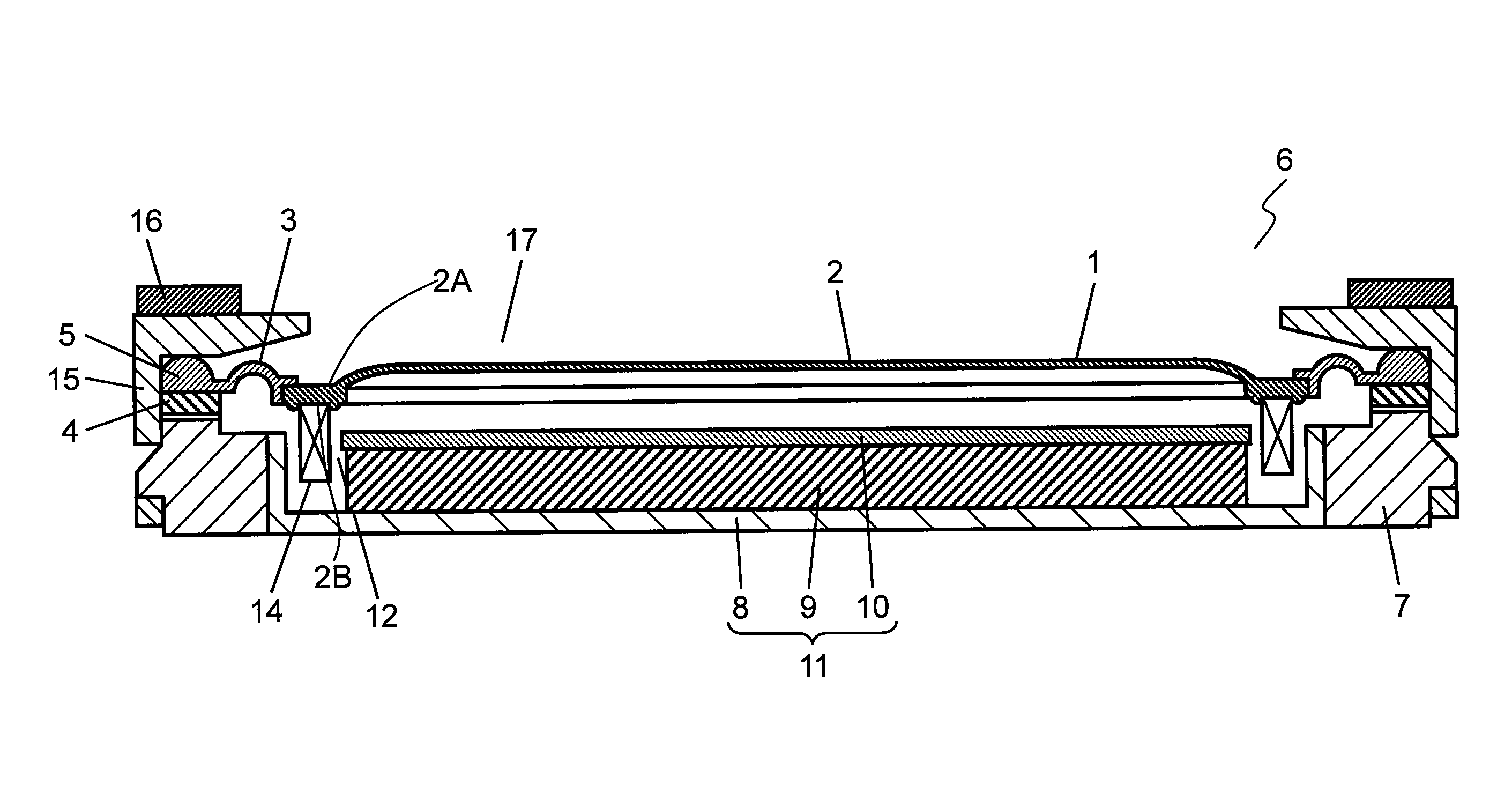

Insert moulded surround with integrated lead-out wires

InactiveUS20070071274A1Lower resonance frequencyFlat Frequency ResponseLoudspeaker diaphragm materialsLoudspeaker diaphragm shapeTransducerEngineering

The present invention relates to a suspension member for a diaphragm and to an electro-acoustic transducer applying such suspension member. The suspension member comprises an inner portion being adapted to be attached to a piston, an outer portion being adapted to be coupled to a substantially stationary portion of an associated electro-acoustic transducer, and a flexible member connecting the inner and outer portions. The flexible member comprises at least one electrically conducting element adapted to transport electrical signals across the suspension member.

Owner:SONION HORSENS

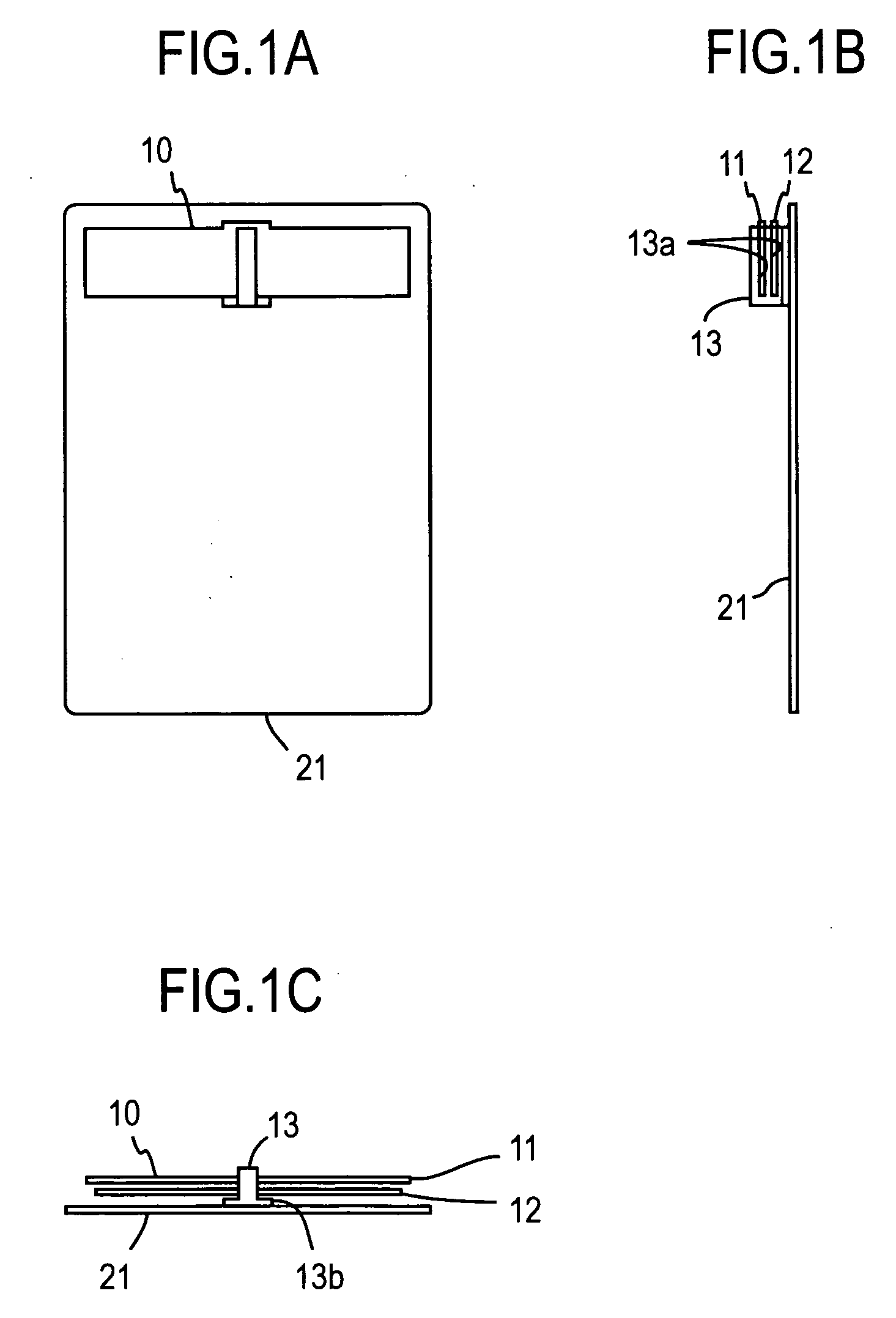

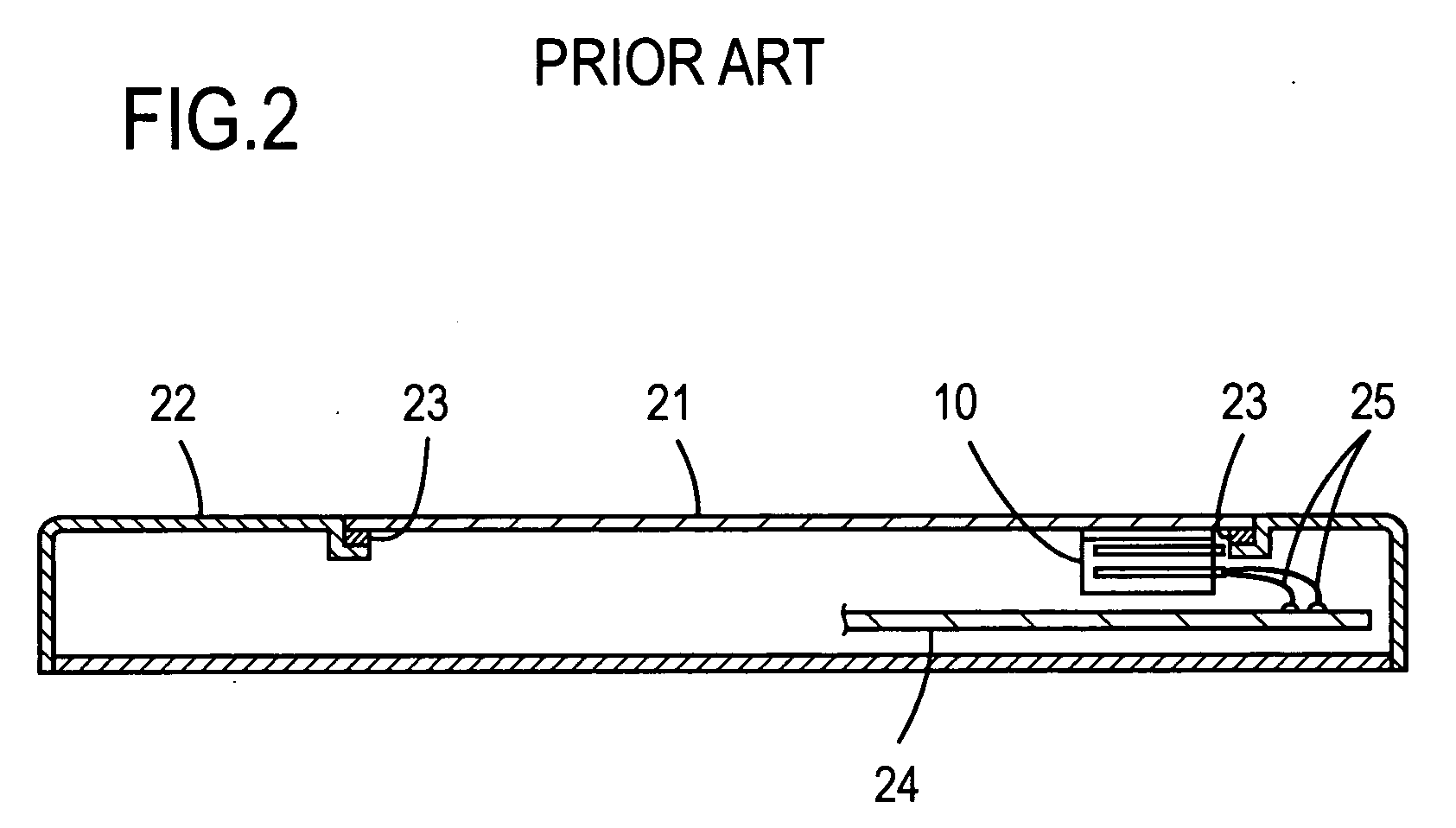

Flat panel speaker

InactiveUS20060093165A1High sensitivityReduce distortion problemsLoudspeaker diaphragm dampingBending wave transducersEngineeringHardness

A flat panel speaker has a construction in which an actuator 10 vibrates a panel to radiate sound, the panel being held at a peripheral portion thereof on a frame by gaskets, wherein the gasket provided at a position opposite from a position at which the actuator is placed has a higher hardness than that of the gasket provided at another position. The side on which the gasket having the higher hardness is placed is a substantially fixed end to facilitate vibration of the panel, thereby improving sound quality.

Owner:HOSIDEN CORP

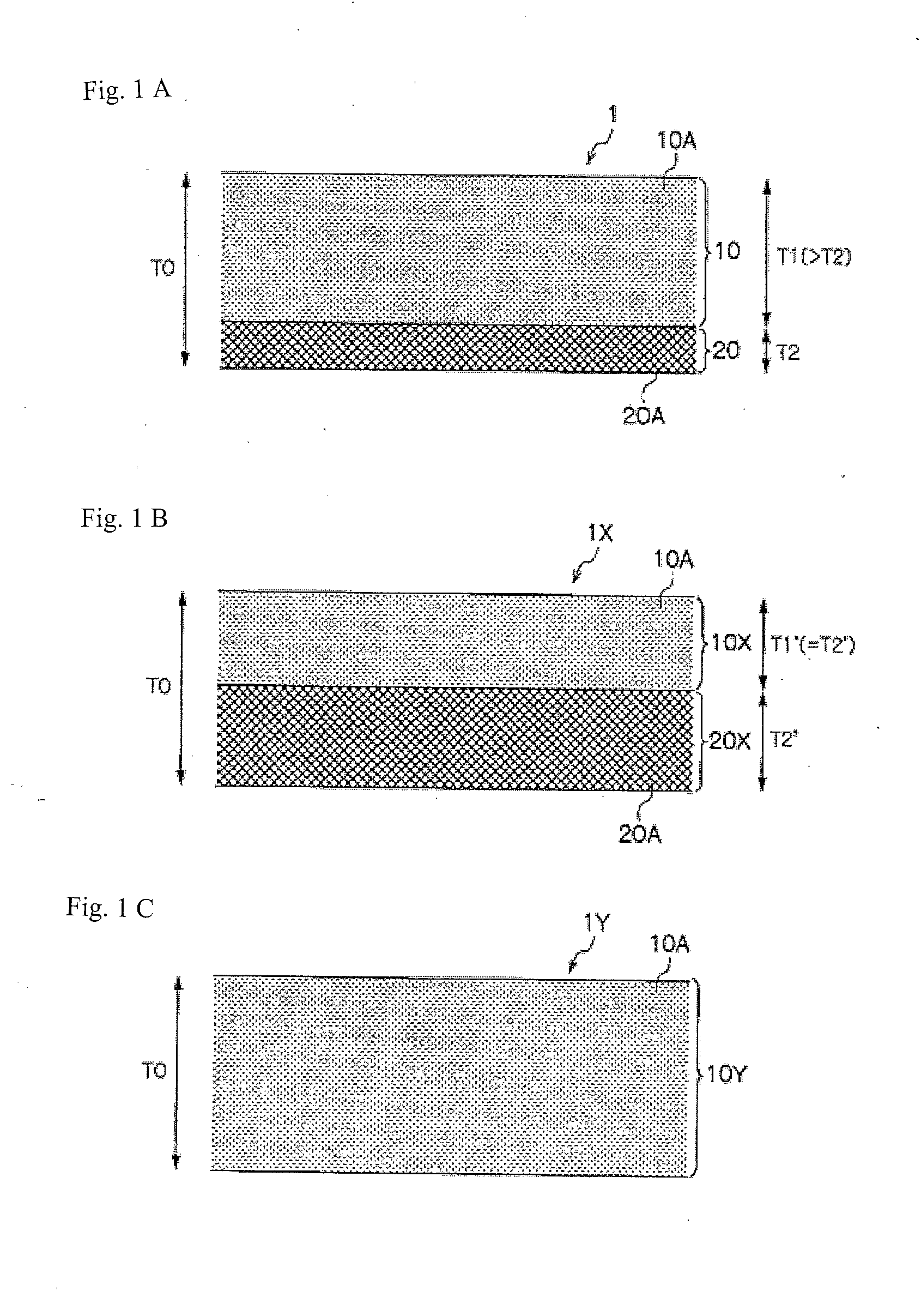

Speaker diaphragm, and speaker and handheld terminal device using said speaker diaphragm

InactiveUS20120237076A1Loudspeaker diaphragm materialsLoudspeaker diaphragm shapeTerminal equipmentEngineering

A speaker diaphragm includes a body vibrating to generate a sound, an edge fusion-bonded to an outer circumference portion of the body, a projection provided on an upper surface of the edge, and a gasket provided on a lower surface of the edge. The edge is made of material different from that of the body. The projection is made of material identical to that of the edge. The gasket is made of material identical to that of the body. A speaker including the diaphragm has waterproof property by itself.

Owner:PANASONIC CORP

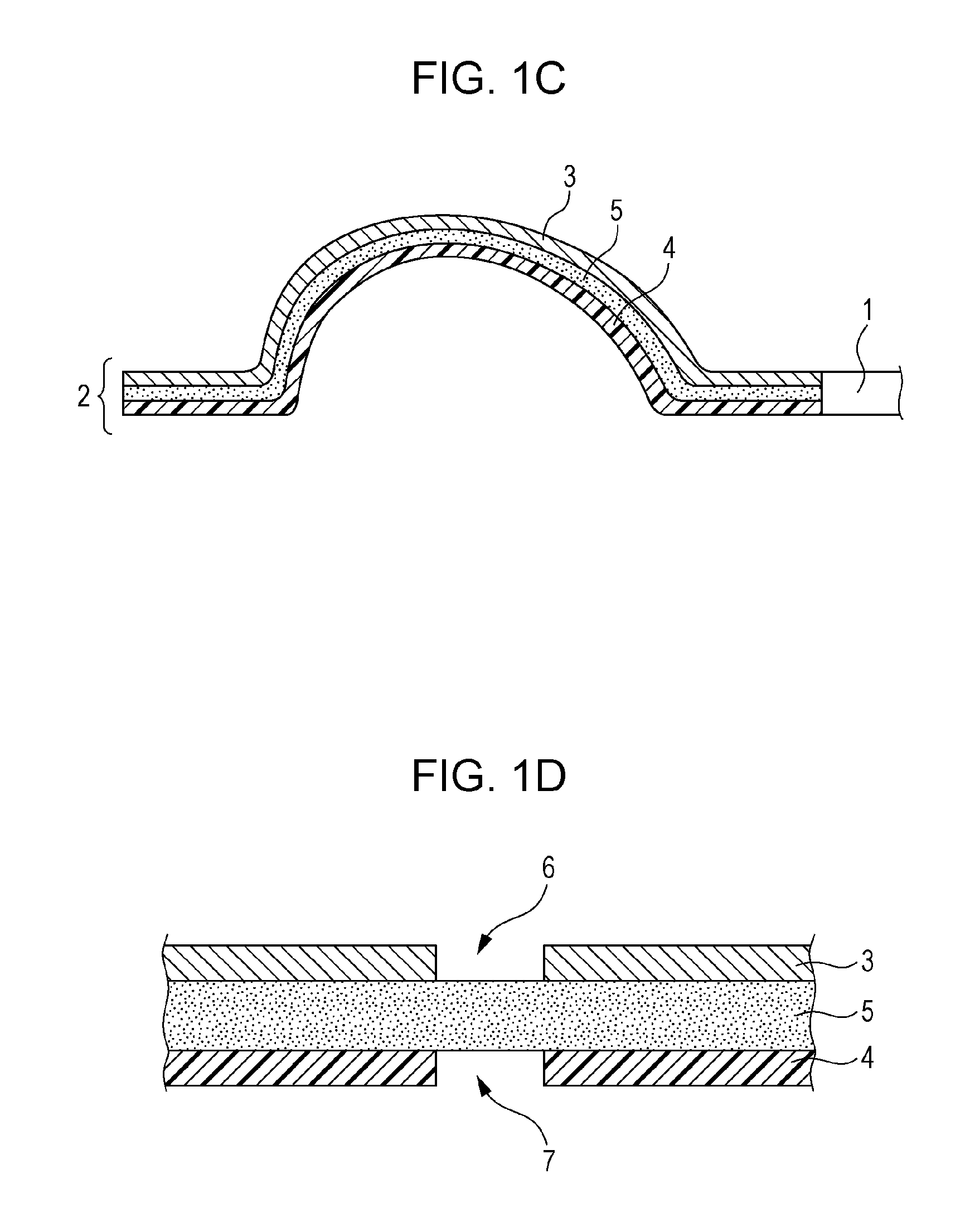

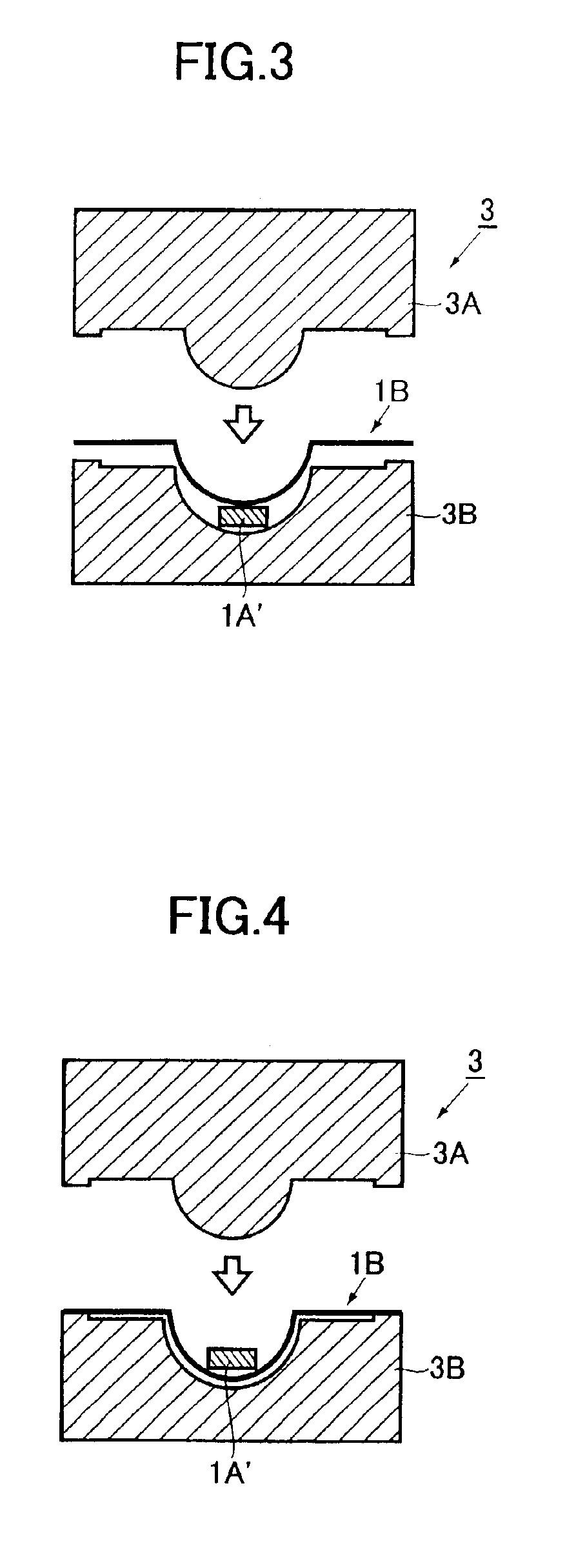

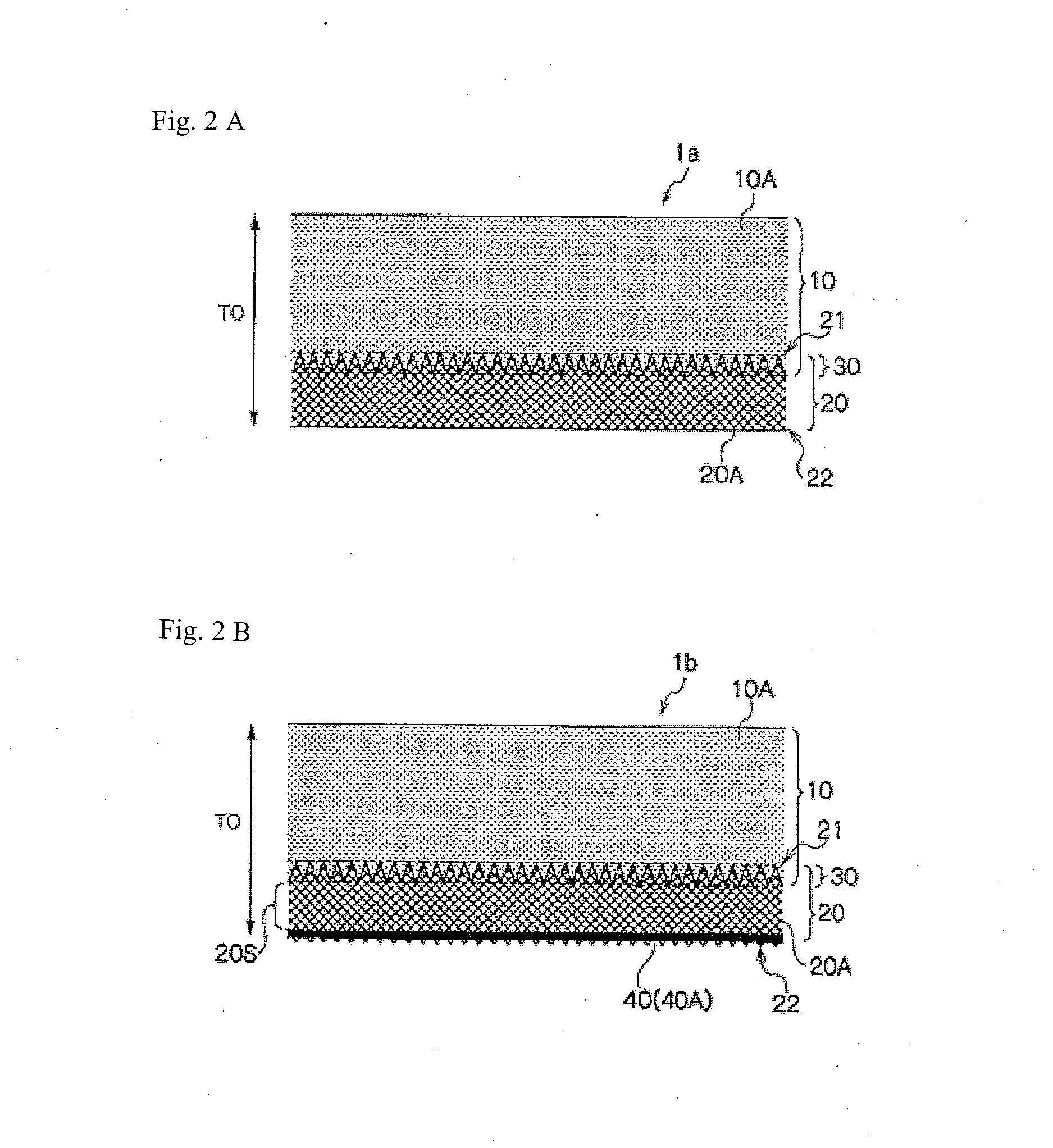

Speaker diaphragm, speaker, device, and method for manufacturing speaker diaphragm

ActiveUS20160014522A1Reduce supportImprove linearityRecord carriersTransducer detailsEngineeringLoudspeaker

A speaker diaphragm includes: a vibrator; and a suspension adhered to an outer peripheral part of the vibrator and supporting the vibrator so that the vibrator can vibrate, at least part of the suspension including a top surface member constituting a top surface part of the suspension, a rear surface member constituting a rear surface part of the suspension, and an intermediate member between the top surface member and the rear surface member, these members being stacked, the intermediate member having a rigidity lower than that of at least one of the top surface member and the rear surface member, the top surface member having one or more first holes, the rear surface member having one or more second holes, and at least some of the first holes and second holes being dispose so as to overlap across the intermediate member in a direction in which the members are stacked.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

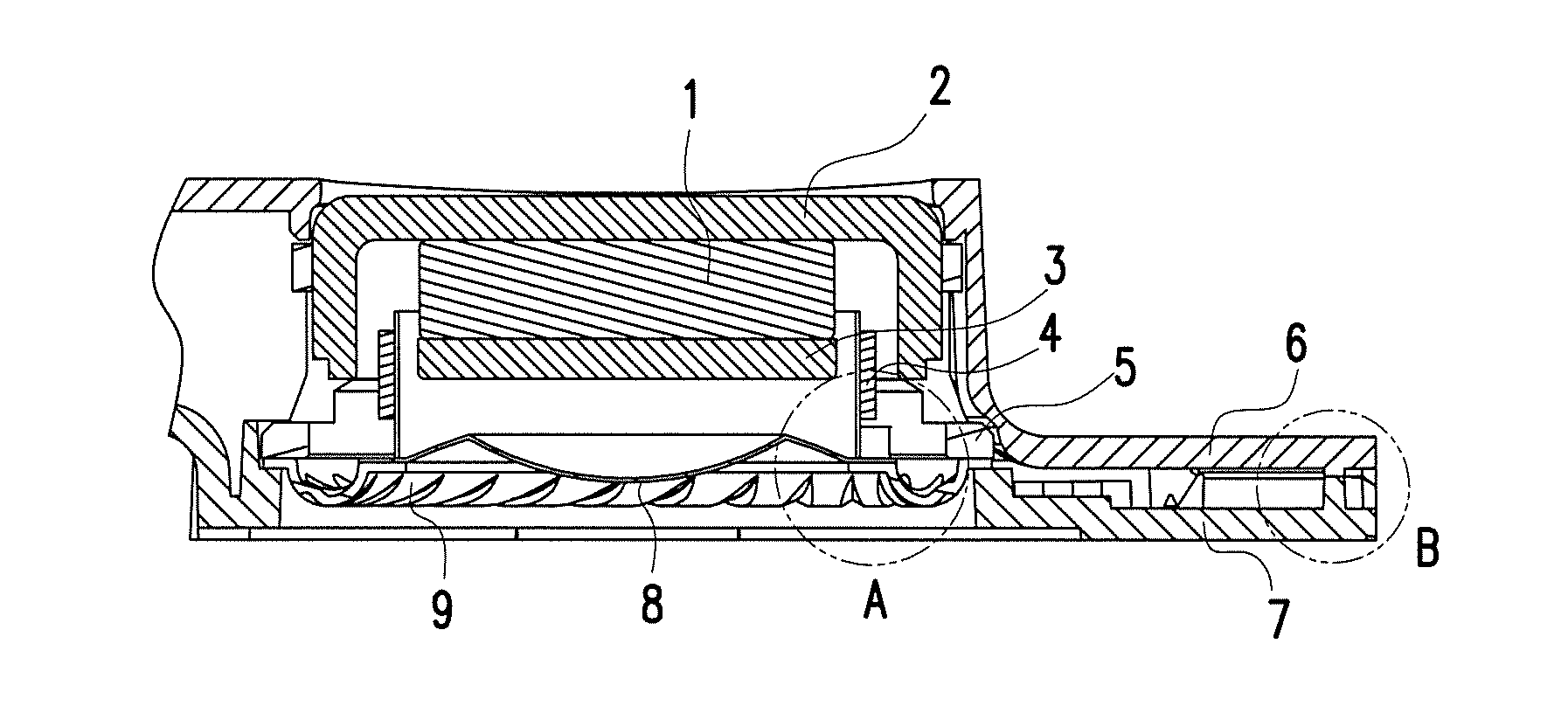

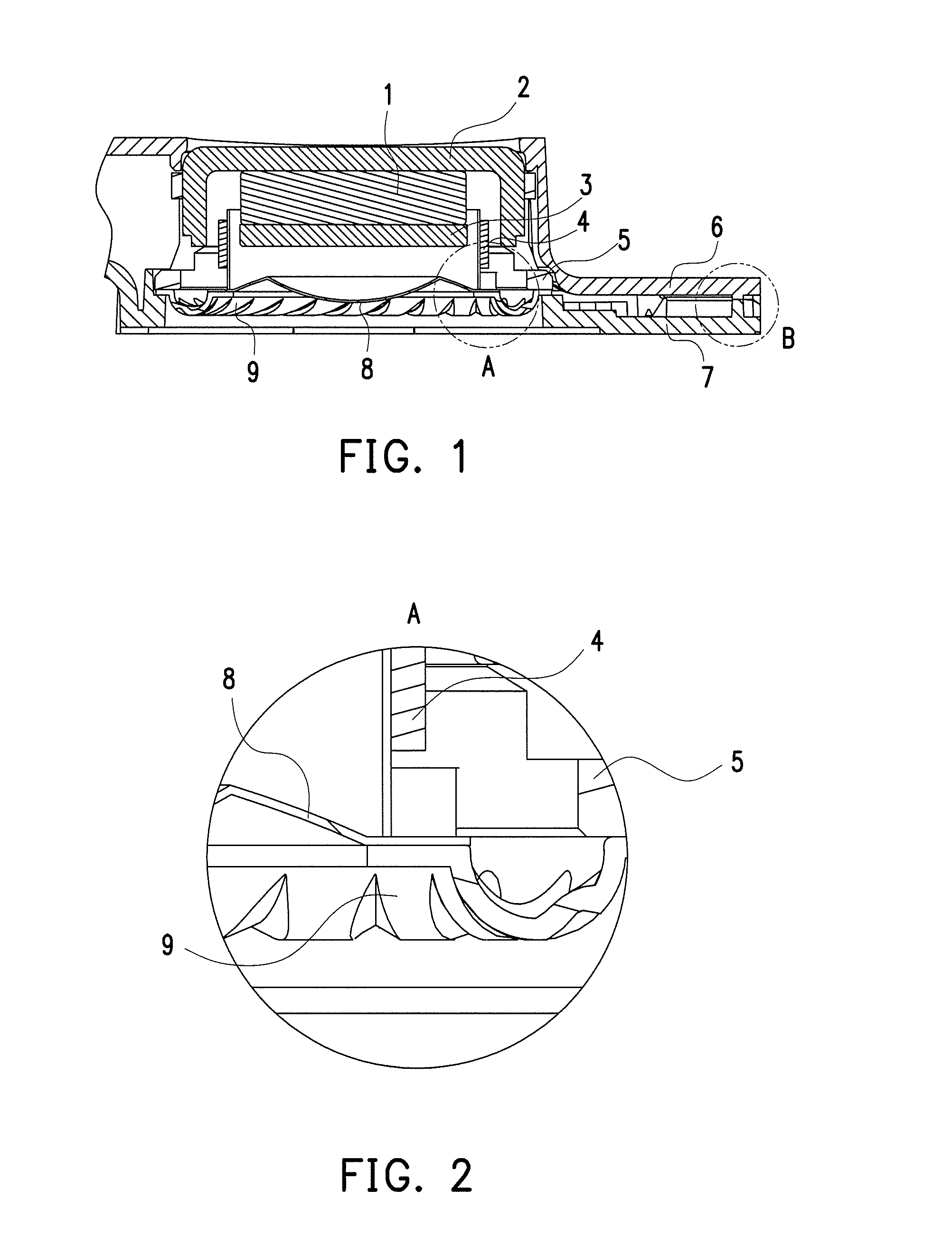

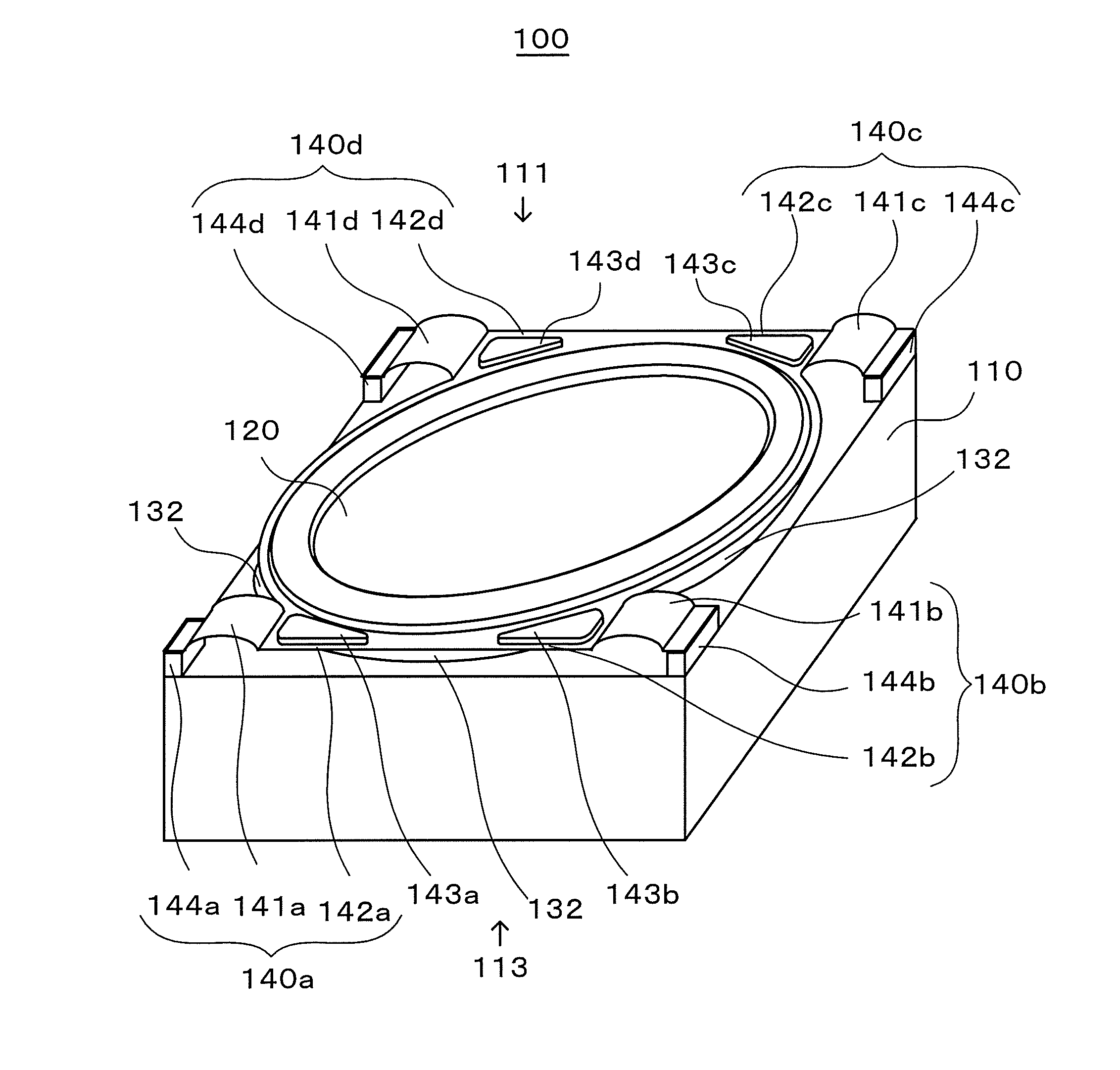

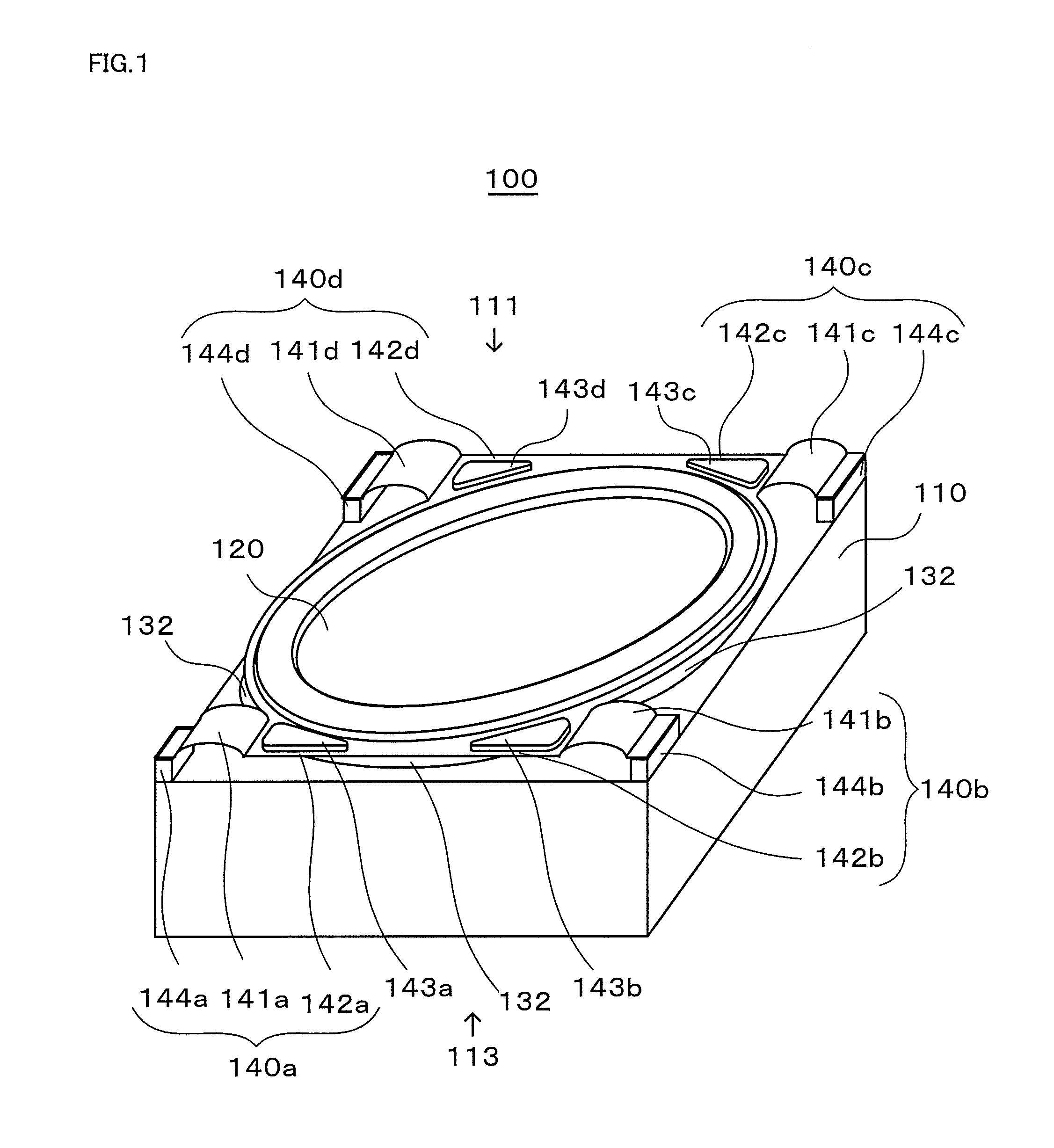

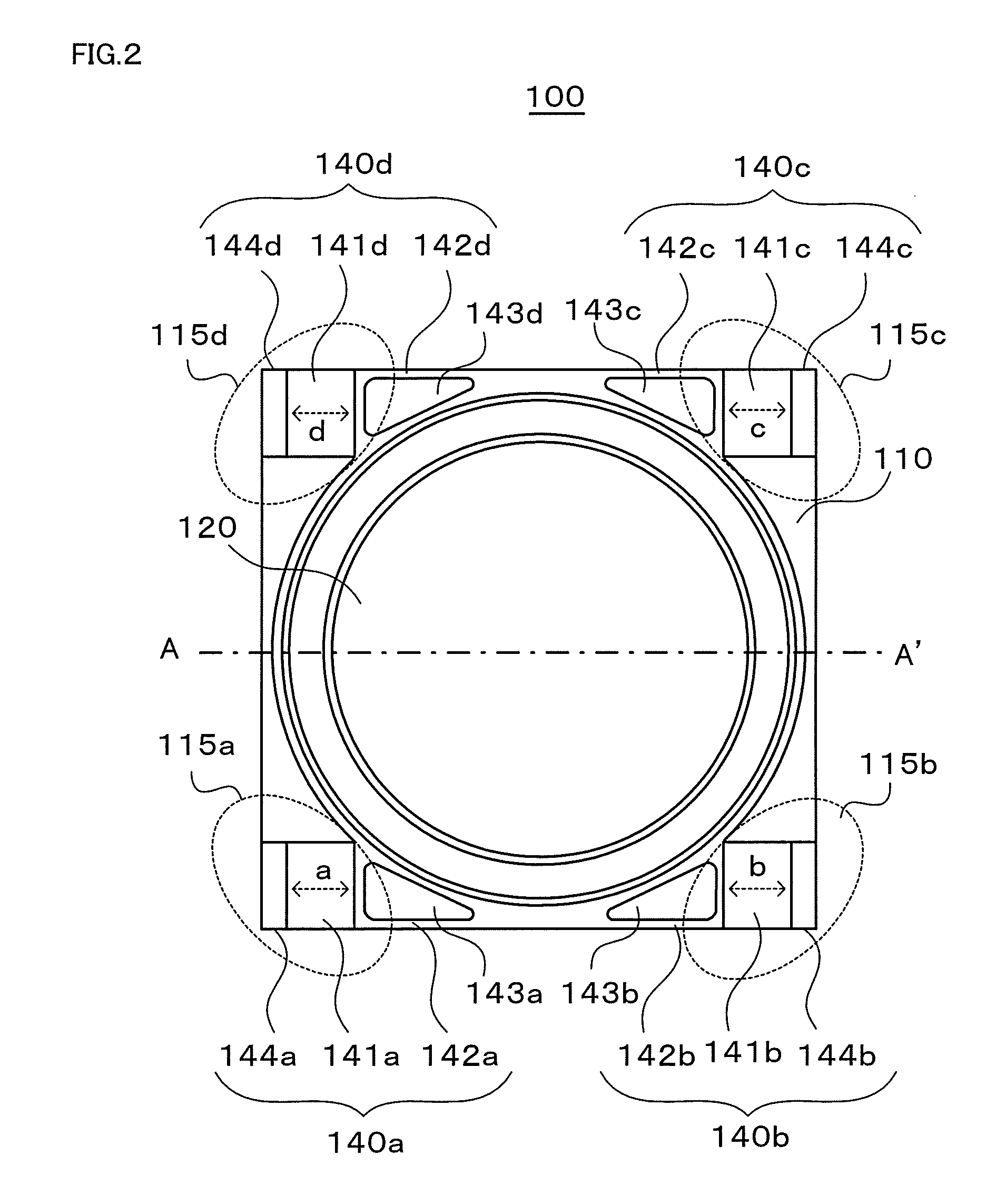

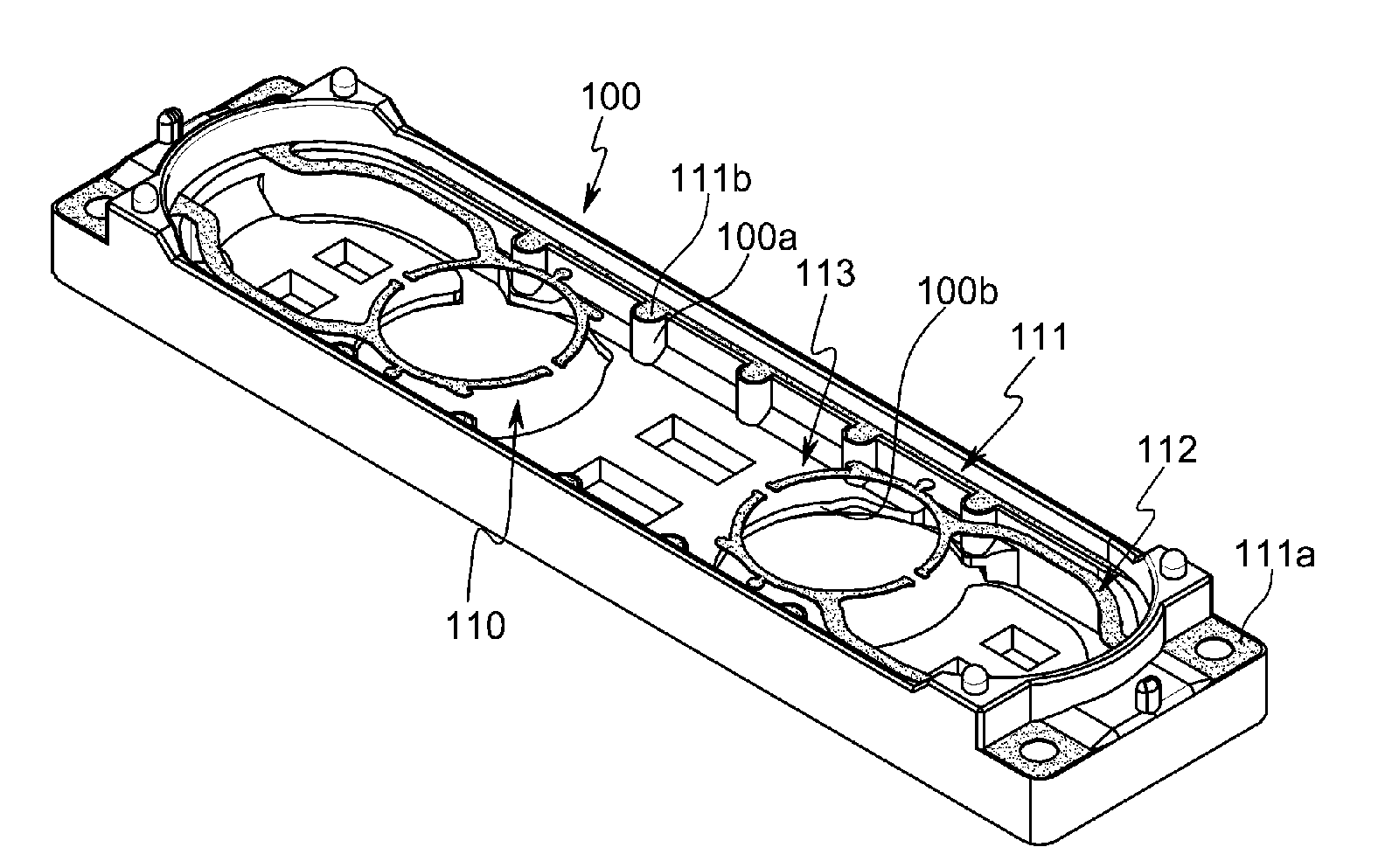

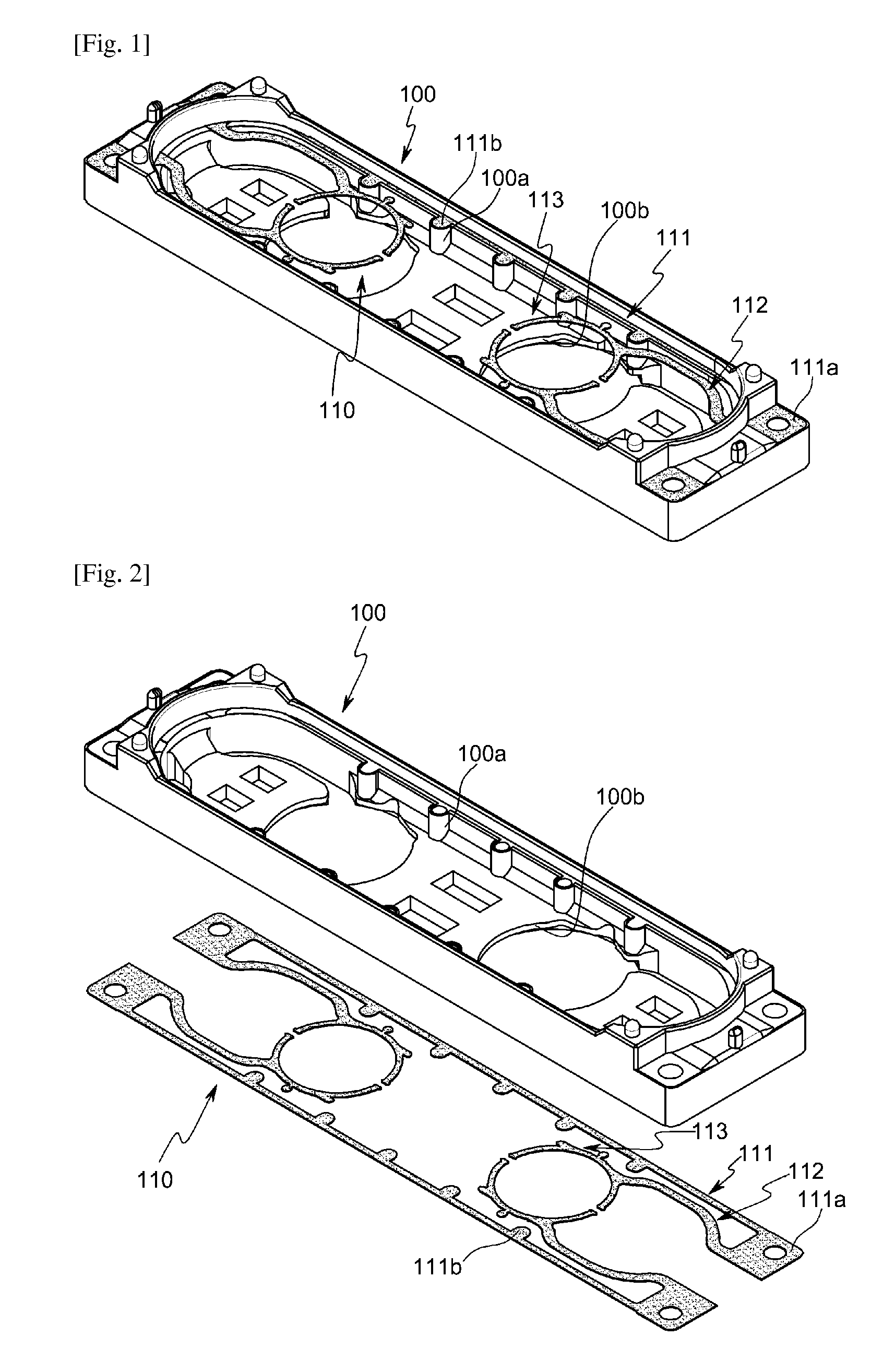

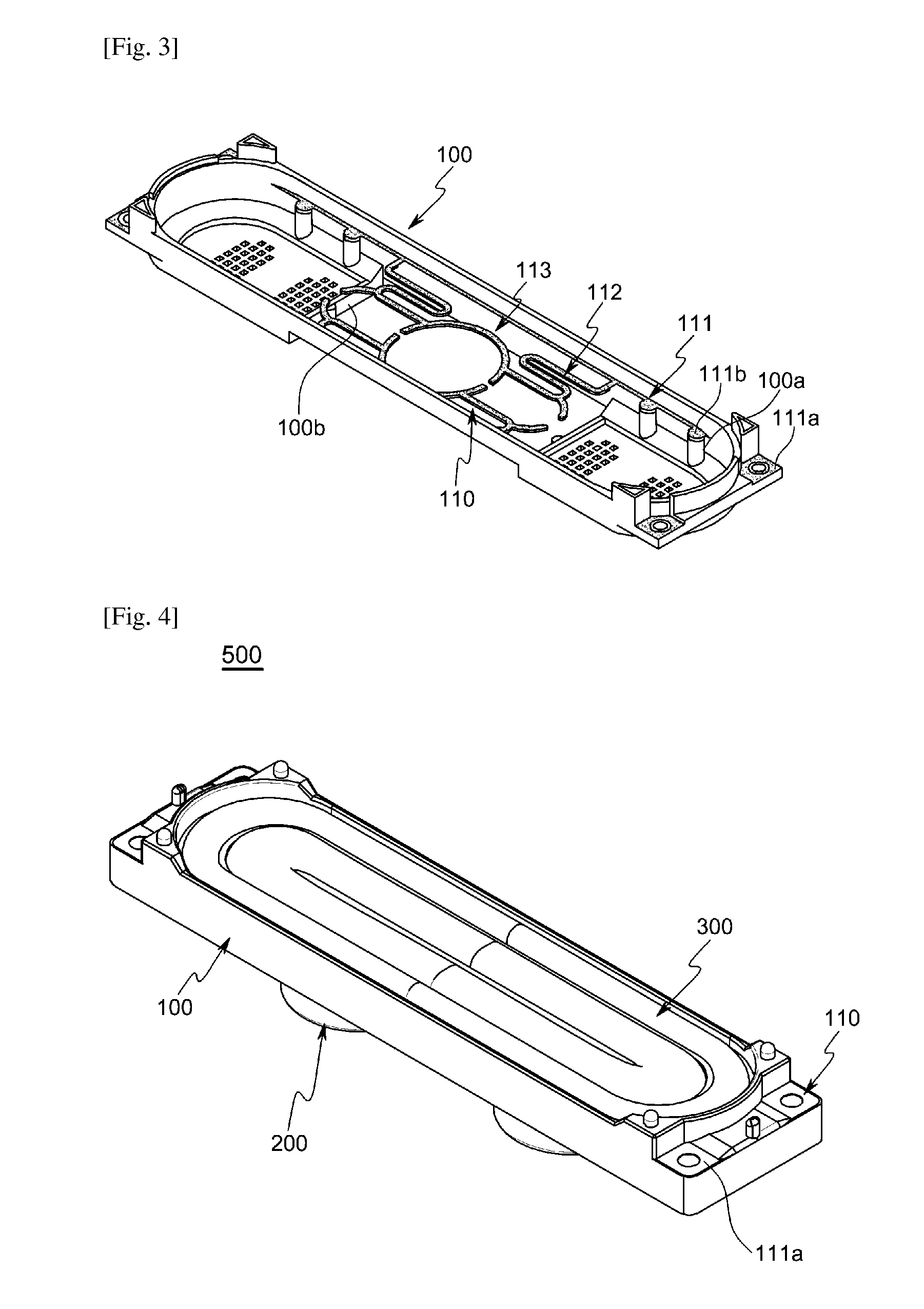

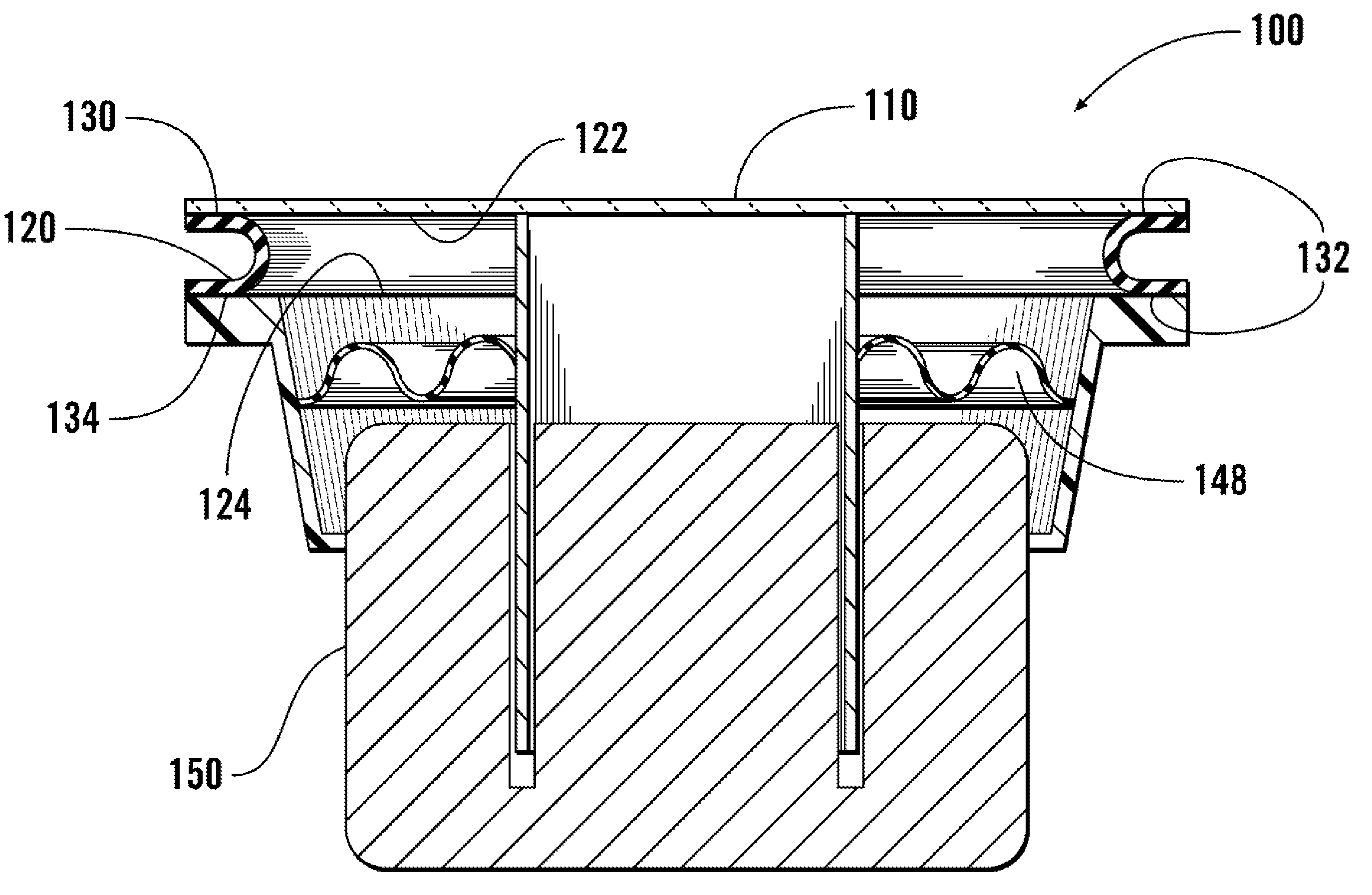

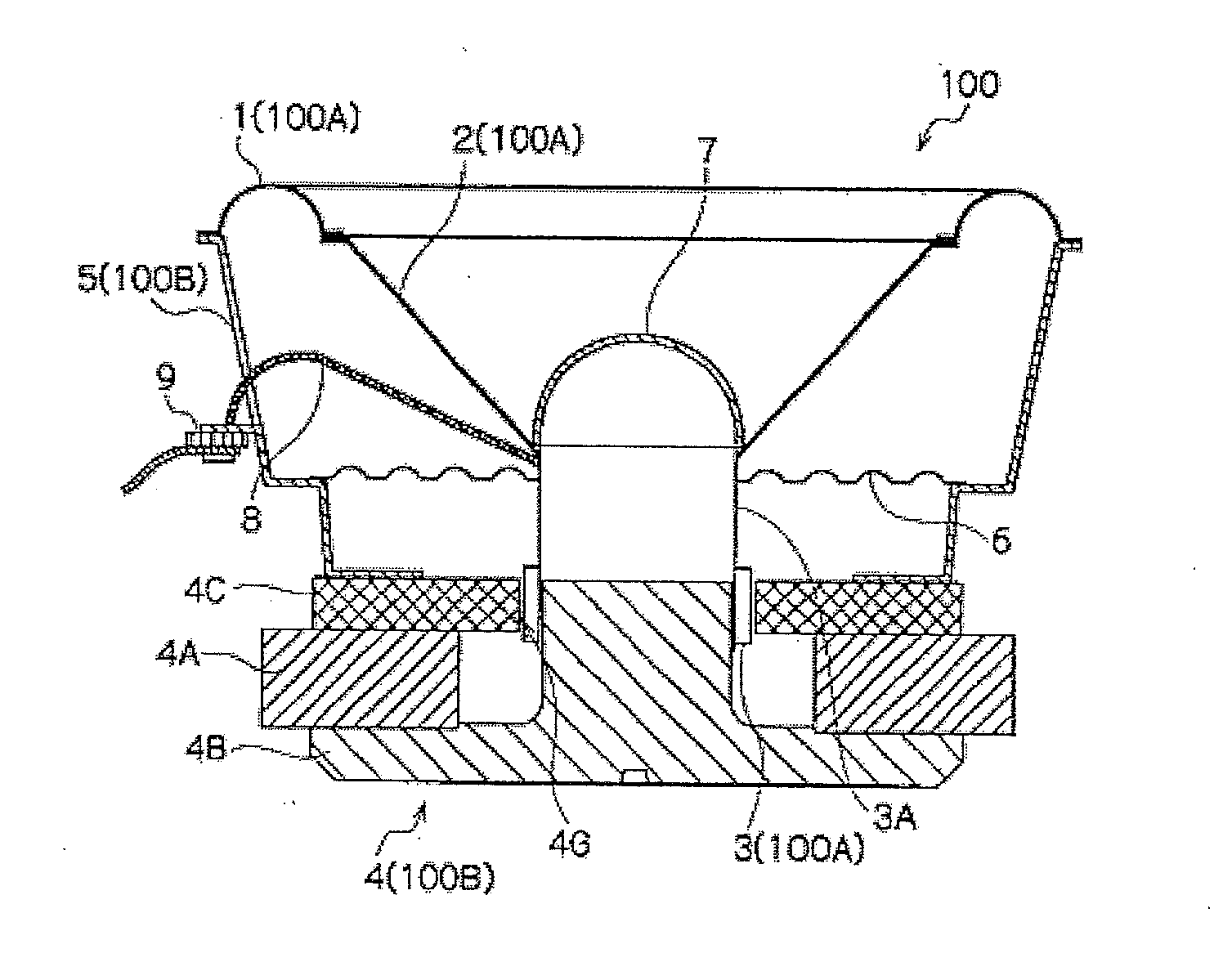

Speaker, and mobile electronic device

ActiveUS20120106774A1Improving bass characteristicAdd supportSingle transducer incorporationPolymeric diaphragmsEngineeringLoudspeaker

A speaker and the like, which is capable of wideband reproduction by improving the bass characteristic, and which is suitable for size reduction, is provided.A housing (110) includes one main surface (111) having a polygonal shape, and an opening portion (112) in the one main surface. A diaphragm (120) is disposed in the opening portion so as to cover the one main surface, except for corner regions (115a, 115b, 115c, and 115d) which are areas in the vicinity of respective vertices of a polygonal shape of the one main surface. A driving unit (130) causes the diaphragm to vibrate so as to generate a sound corresponding to a signal inputted from an outside. A plurality of movable supports (140a, 140b, 140c, and 140d) is disposed in the respective corner regions, for supporting the diaphragm by joining the housing and the diaphragm such that the diaphragm is vibratable.

Owner:PANASONIC CORP

Loudspeaker including a cone circumscribed by a stiffener

The present invention is a loudspeaker. The loudspeaker includes a frame, a cone having an outer edge in a shape of a reverse angle flange, and a reinforcing ring bonded to a back side of the flange.

Owner:COMMUNITY LIGHT & SOUND

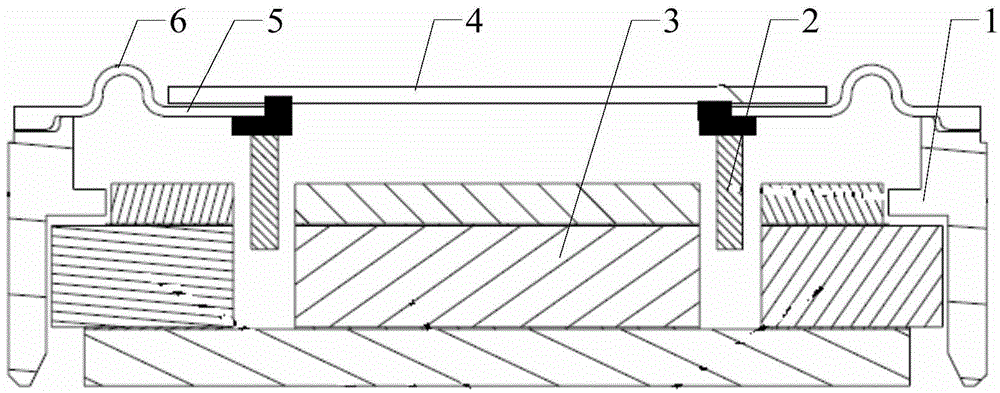

Vibration film component

InactiveCN104754472AStrong mechanical propertiesIncrease vibration amplitudePolymeric diaphragmsSynthetic resin layered productsFilm baseInjection moulding

The invention discloses a vibration film component, and relates to the technical field of electro acoustical products. The vibration film component comprises a vibration film, wherein the vibration film comprises a middle portion and a fold ring portion which wraps around the periphery of the middle portion. The vibration film furthermore comprises a vibration film base layer and a silica gel layer, wherein the silica gel layer is integrated in the vibration film base layer at least partially, the vibration film base layer is a polymer material layer, the silica gel layer is integrated in the surface of the fold ring portion, and the silica gel layer and the polymer material layer are injection molded. The vibrating film component achieves recombination of the silica gel layer and the polymer material layer by arranging the silica gel layer in the surface of the fold ring portion, and thereby improves compliance of the vibration film, enhances chemical stability and adaptability to temperature of the vibration film, optimizes acoustic performances, and improves products yield rate.

Owner:GOERTEK INC

Speaker frame and speaker having the same

InactiveUS20160261966A1Low costShorten the timeLoudspeaker transducer fixingLoudspeakersEngineeringSynthetic resin

Owner:SJ&S

Surround for speaker system and manufacturing method thereof

InactiveUS6892850B2Highly durable to withstandIncrease the sound pressure levelLoudspeaker diaphragm materialsSound producing devicesAramidesEngineering

A speaker's surround to be attached to an edge of a diaphragm in a speaker system is provided, which is capable of keeping its predetermined shape while repeating elastic deformation for accommodating large amplitude vibration of the diaphragm. Further, the surround is highly durable to withstand the repeated large amplitude vibration, and which can achieve high sound pressure levels. The surround for a speaker system includes a surround piece made of a rubber mold and a base member embedded in the surround piece. The base member is obtained by soaking a cloth material made of cotton or aramid fiber with a thermosetting resin such as phenol resin, and press-formed with heat into a predetermined shape. The surround thus has enhanced its shape maintaining capability.

Owner:PIONEER CORP +1

Loudspeaker diaphragm and loudspeaker

ActiveCN108551643AImprove structural strengthAvoid breakingPolymeric diaphragmsLoudspeakersElastomerPolyester

The invention discloses a loudspeaker diaphragm and a loudspeaker. The diaphragm comprises a thermoplastic polyester elastomer film layer, wherein the thermoplastic polyester elastomer is a copolymerformed by a polyester hard segment A and a polyether or aliphatic polyester soft segment B, wherein the mass percent of the polyester hard segment A is 10%-95%. The loudspeaker diaphragm is high in structural strength, difficult to damage, good in toughness resilience performance and good in sound production effect.

Owner:GOERTEK INC

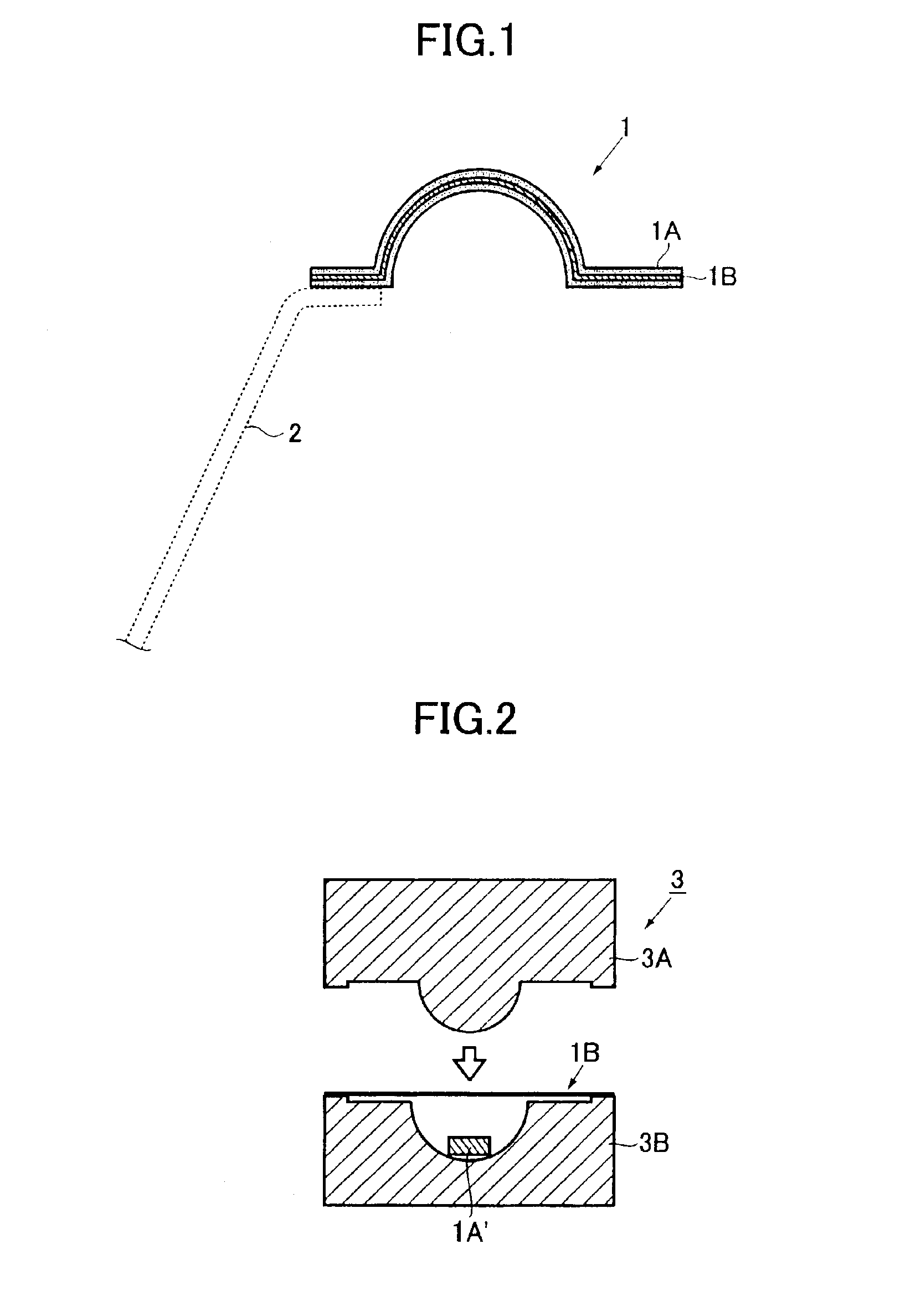

Loudspeaker edge

Owner:PANASONIC CORP

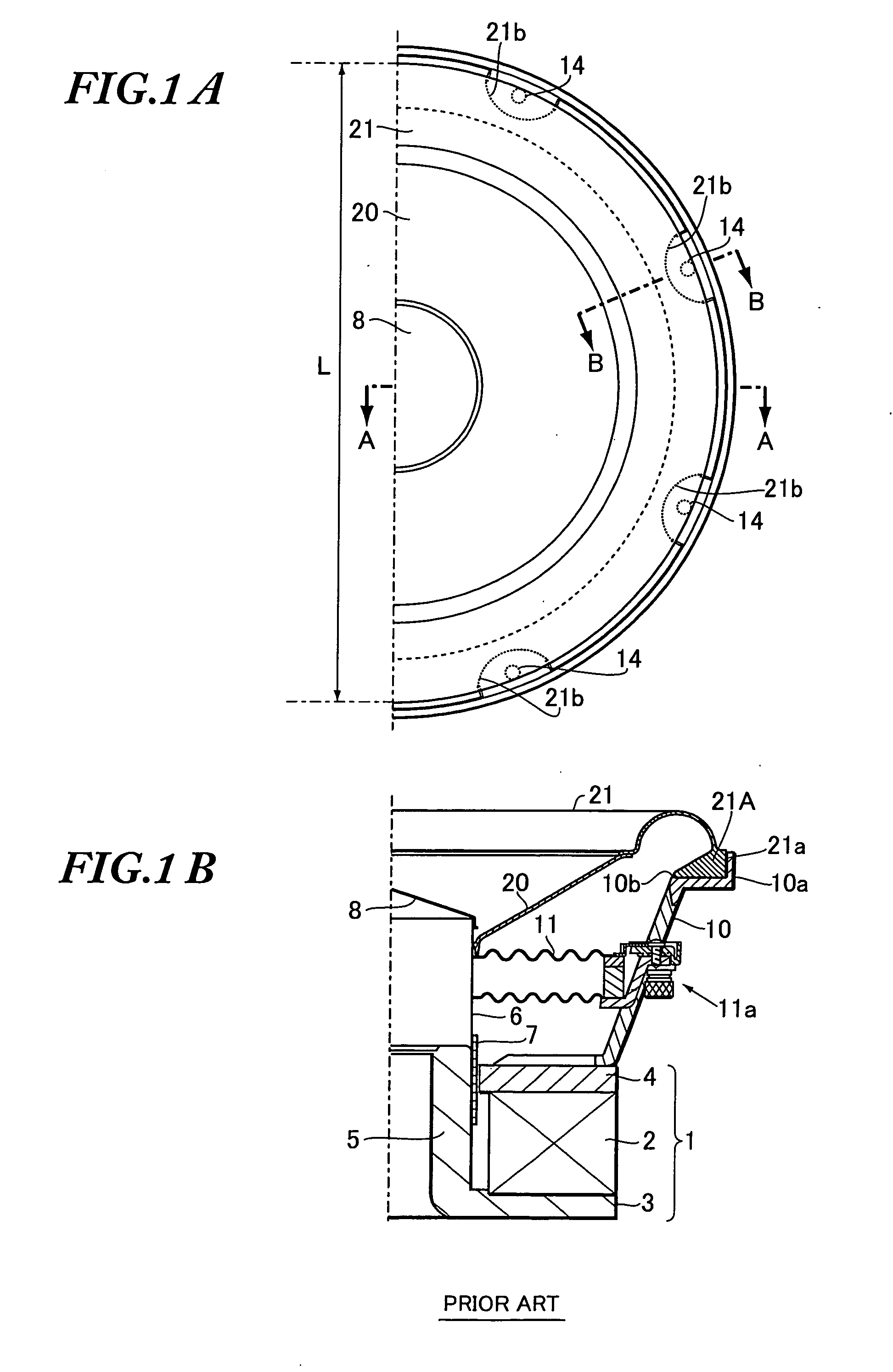

Loudspeaker edge

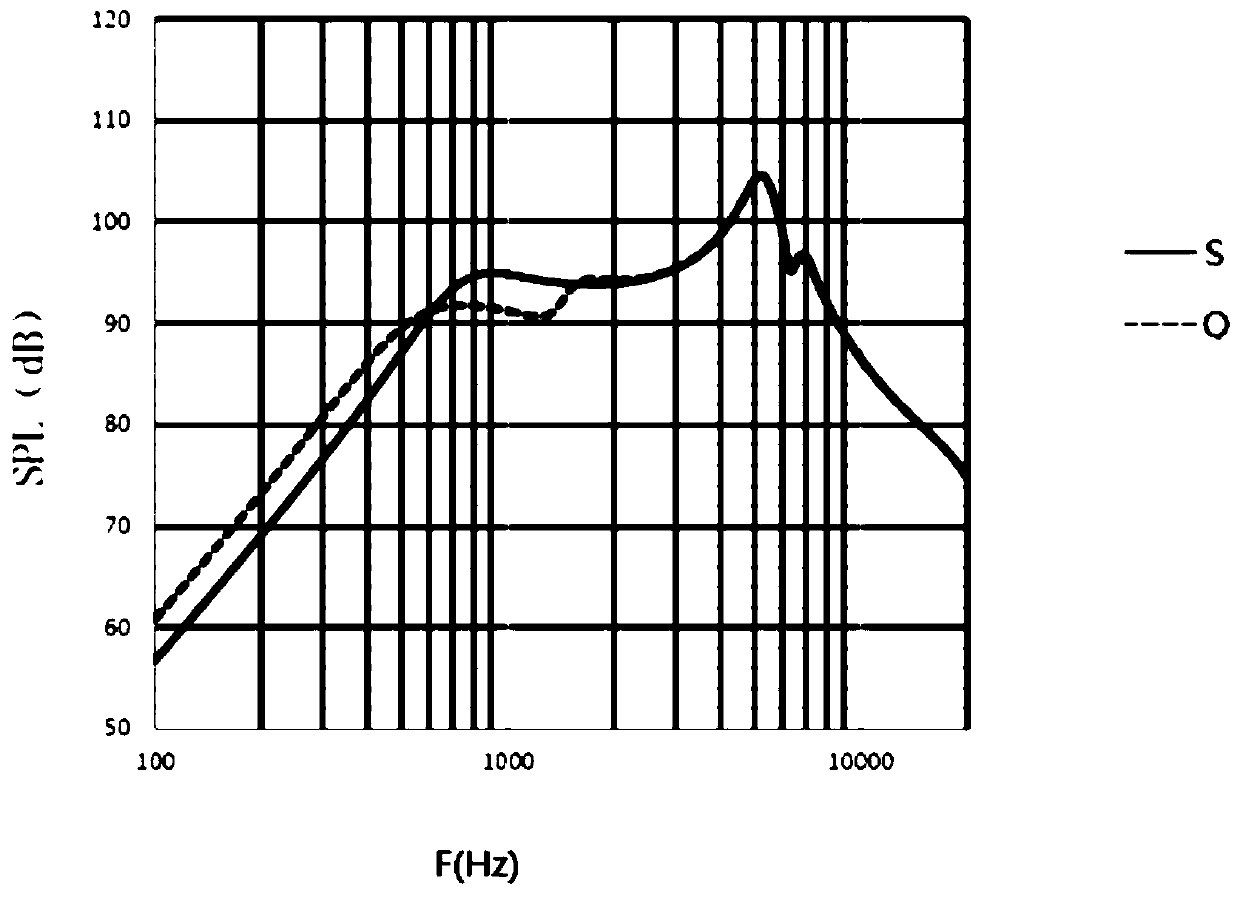

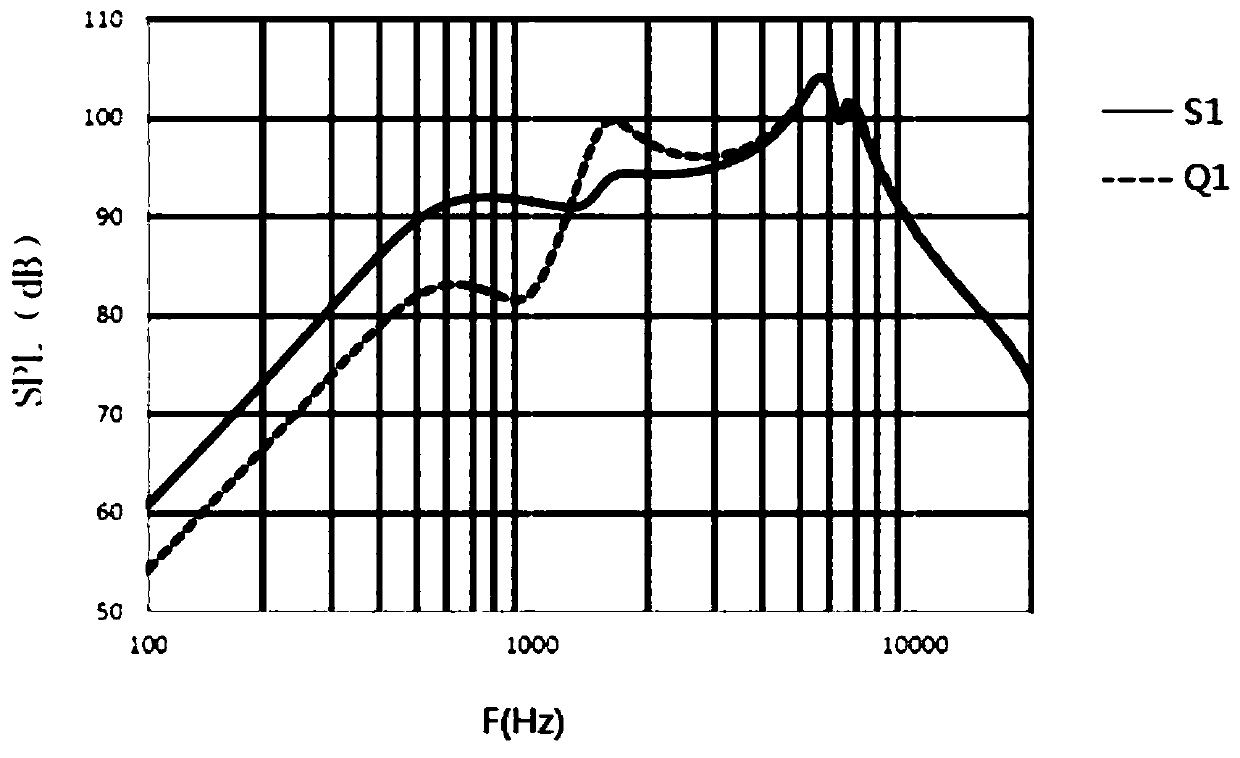

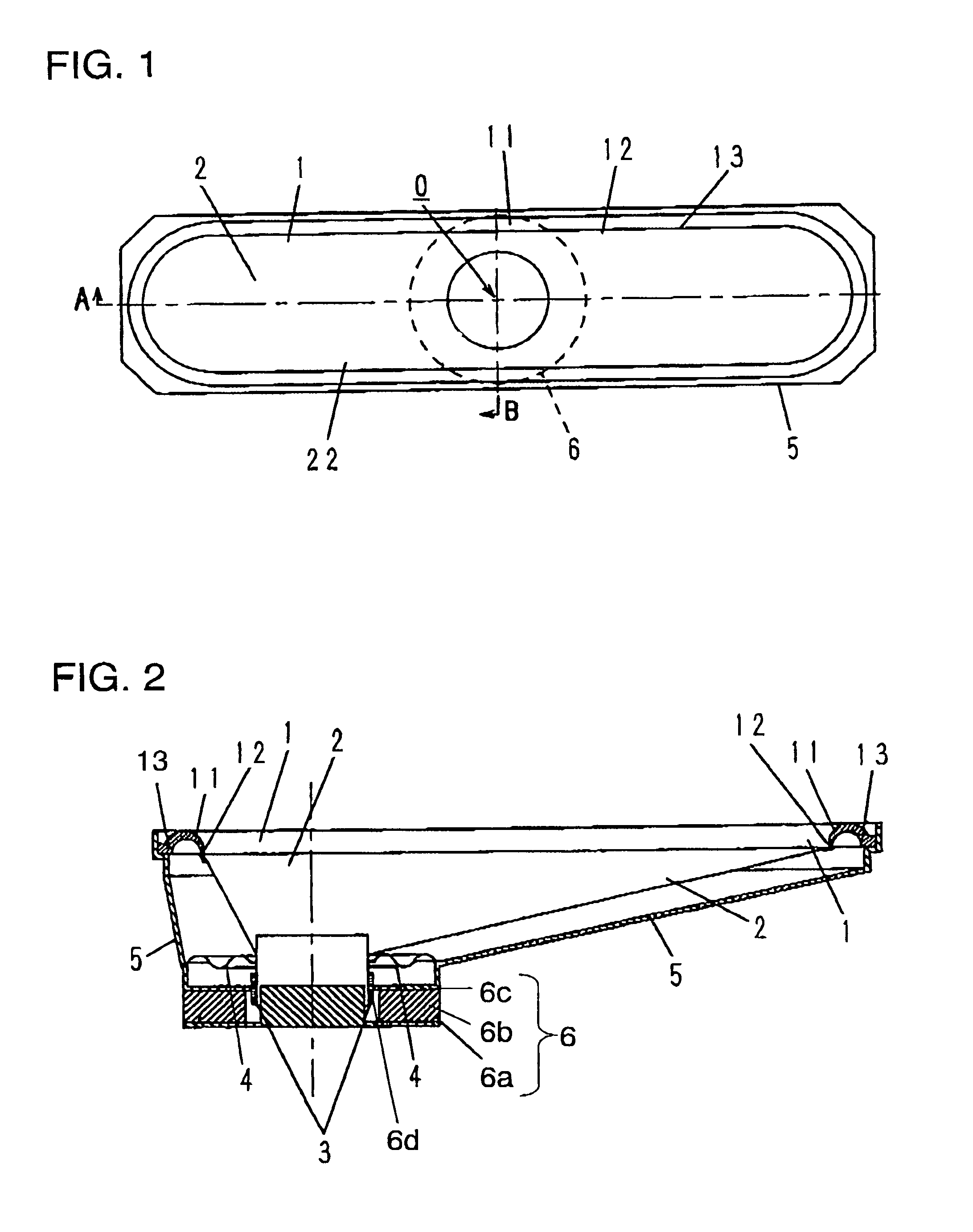

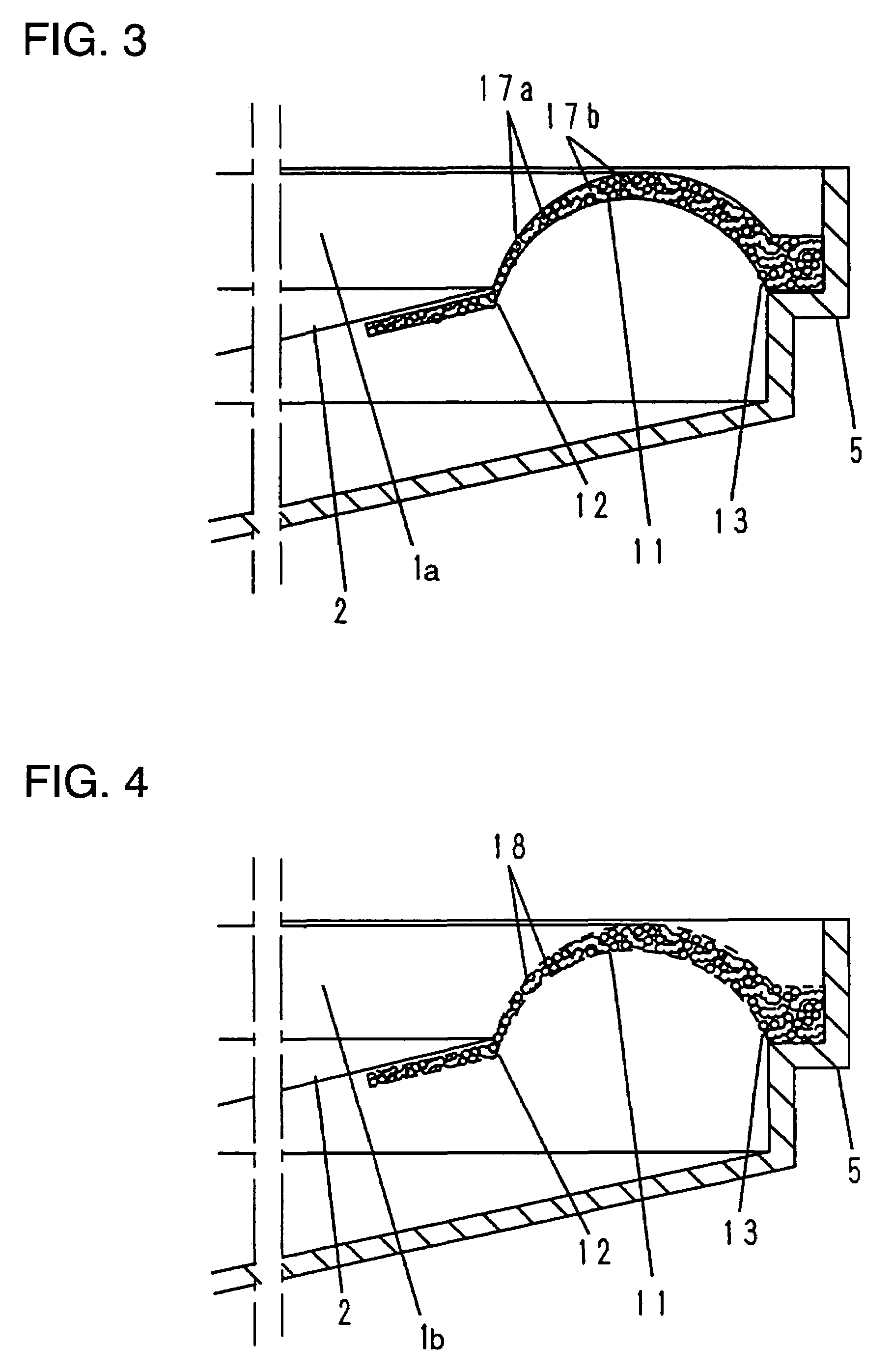

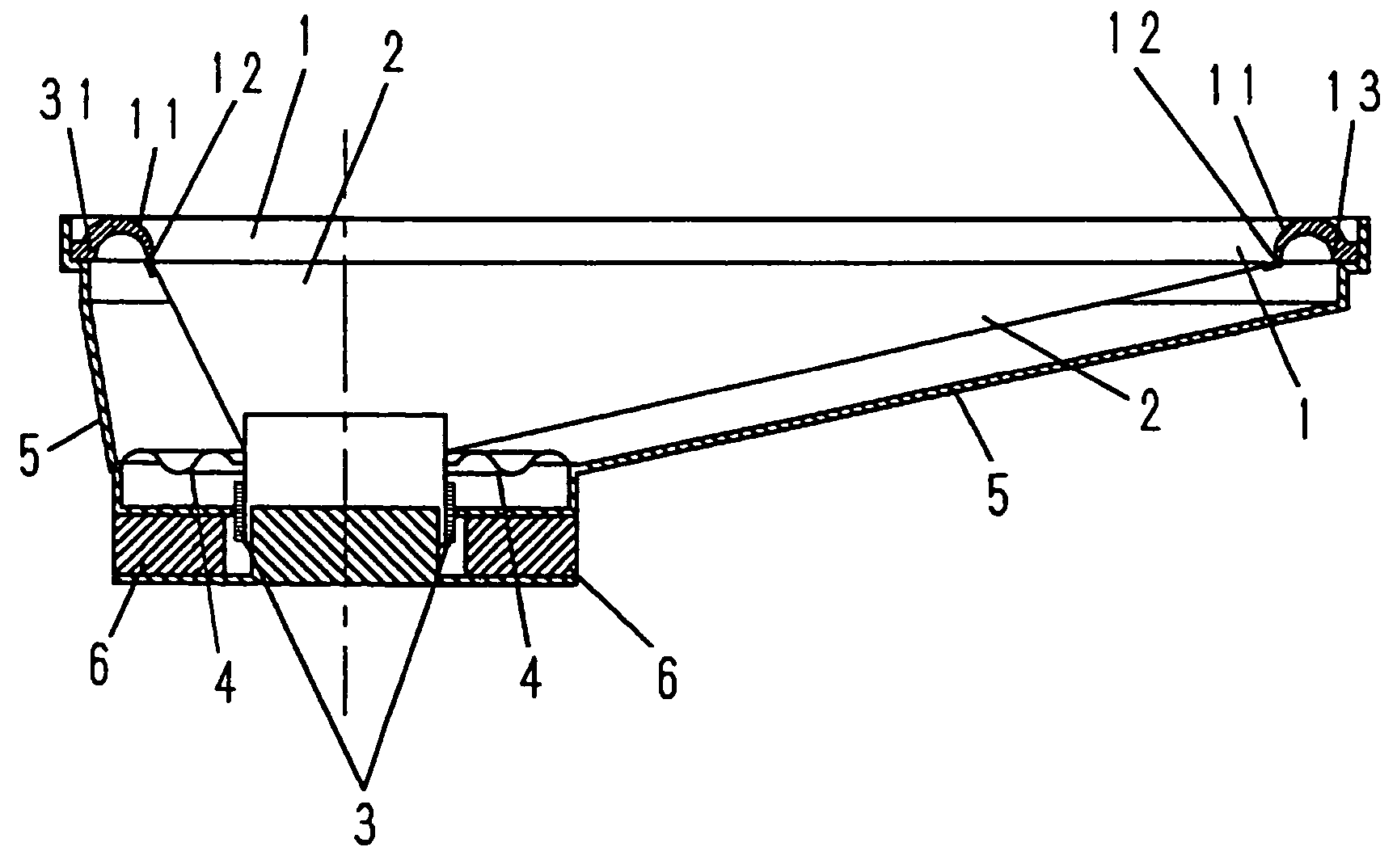

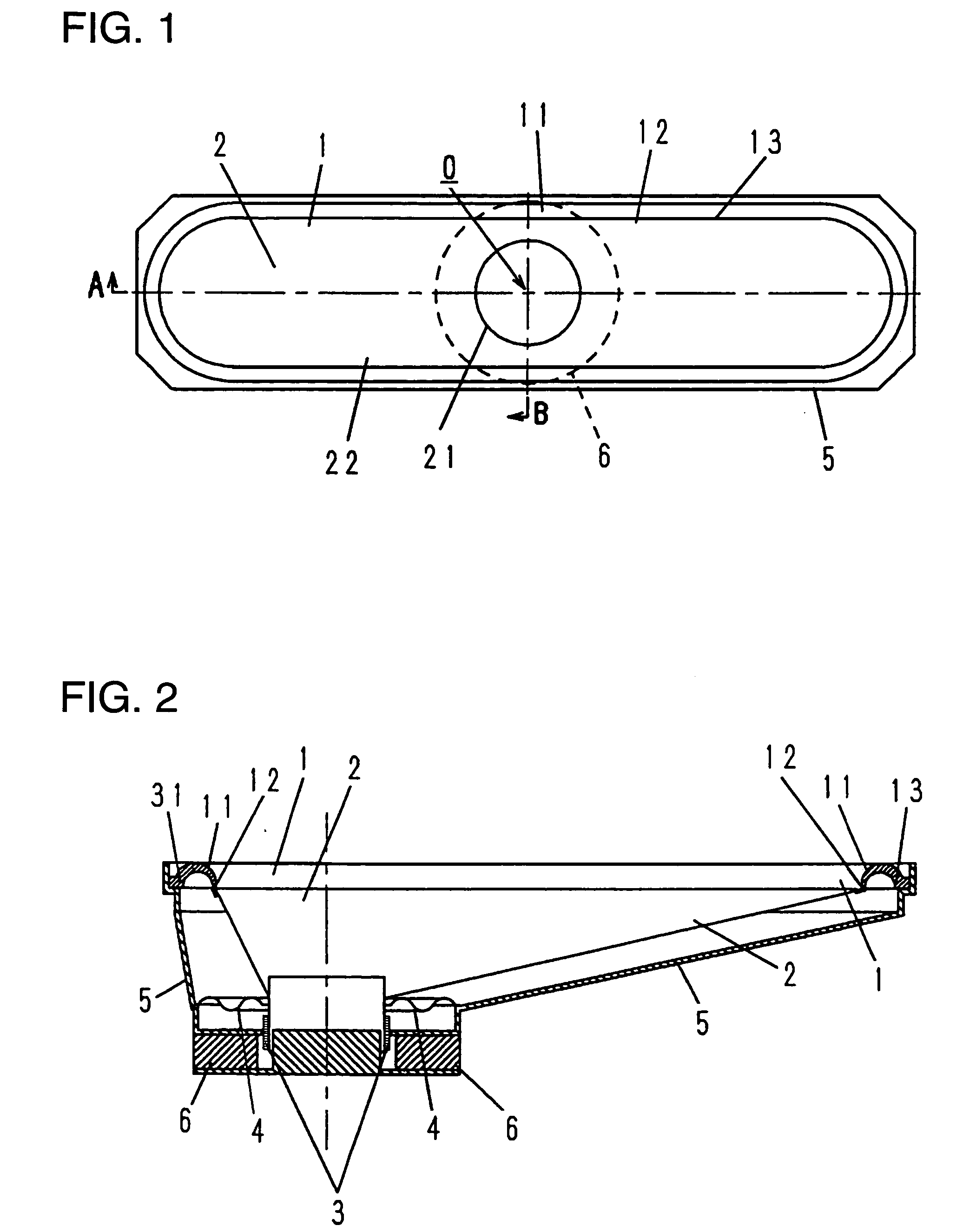

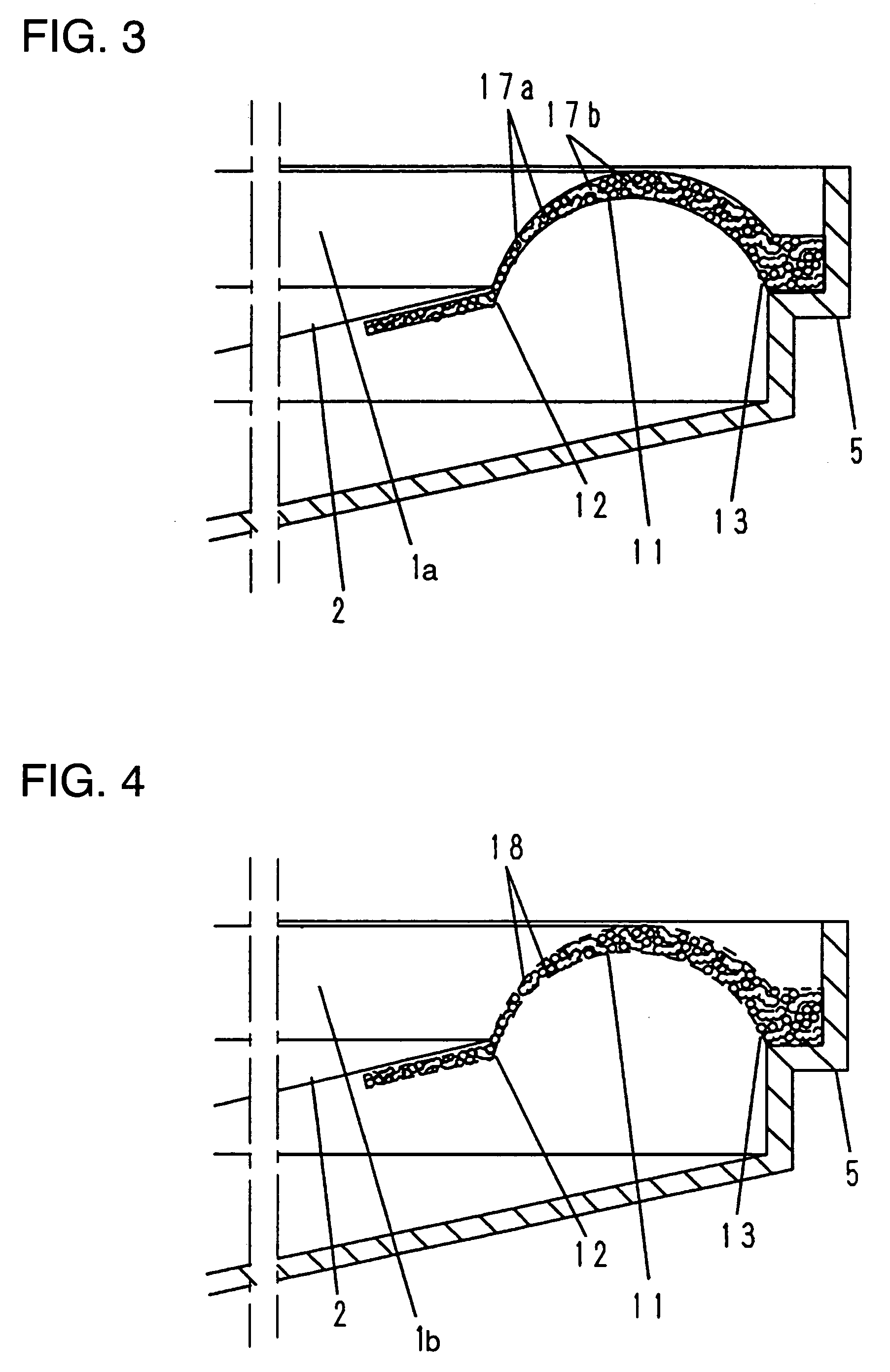

InactiveUS20050226456A1Loudspeaker diaphragm materialsLoudspeaker diaphragm shapeStanding waveMechanical impedance

The present invention provides a loudspeaker which is excellent in acoustic characteristics such as frequency characteristics and distortion characteristics. Particularly, edge 1 is formed in such manner that a thickness of sectional shape in radial direction increases from inner periphery portion 12 toward outer periphery portion 13. Due to this structure, a mechanical impedance of edge 1 against diaphragm 2 is decreased and bad influences on a vibration mode of the diaphragm are suppressed, and also, vibration energy is absorbed by the thick portion of the outer periphery portion, thereby suppressing standing waves of the diaphragm. The structure increases an efficiency of the medium and high frequency range sounds radiated from the loudspeaker, and further, greatly contributes to improve frequency characteristics, nonlinear distortion characteristics, and transient characteristics.

Owner:PANASONIC CORP

Loudspeaker including a cone circumscribed by a stiffener

The present invention is a loudspeaker. The loudspeaker includes a frame, a cone having an outer edge in a shape of a reverse angle flange, and a reinforcing ring bonded to a back side of the flange.

Owner:COMMUNITY LIGHT & SOUND

Separate Support Structure for Loudspeaker Diaphragm

ActiveUS20090010480A1Reduce vibrating massImprove performanceLoudspeaker diaphragm materialsLoudspeaker diaphragm shapeElastomerLoudspeaker

A support structure for supporting and protecting the diaphragm of loudspeaker includes a first elastomer which has a first interface with a camber shape, a second elastomer which has a second interface with a complemental shape of the first interface, the first elastomer and the second elastomer combine together from both sides of the support part of the loudspeaker diaphragm. The separate support structure in the present invention is fit for many kinds of loudspeakers and propitious to increase the technical characteristics of loudspeakers.

Owner:DING YI

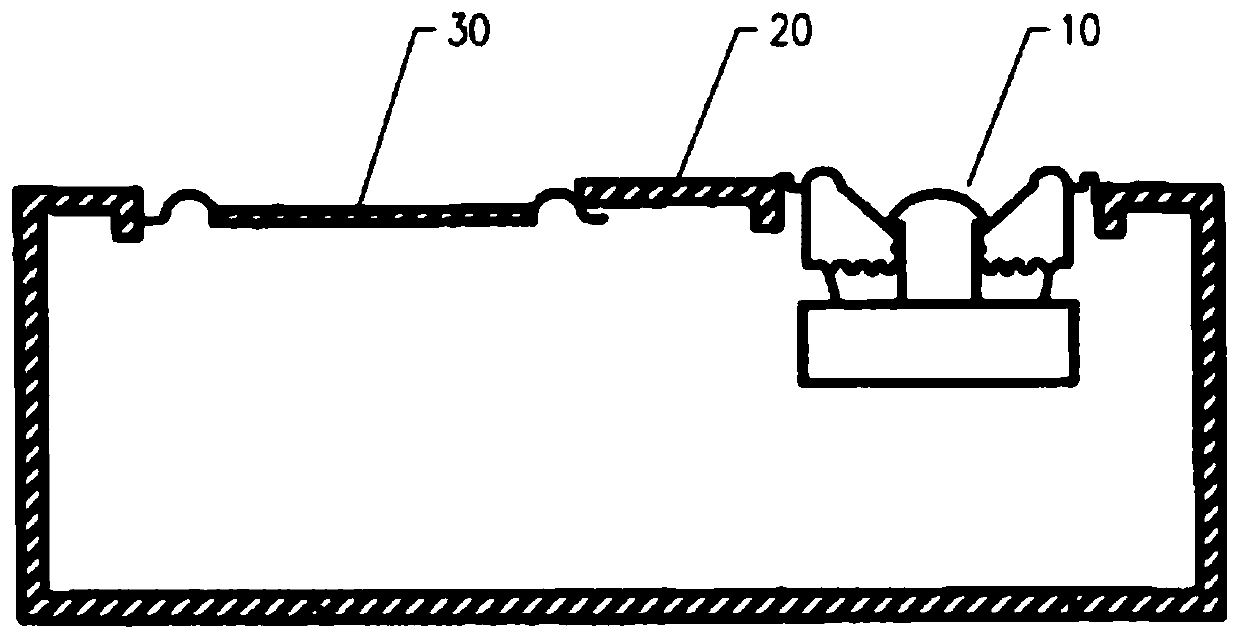

Loudspeaker with rear surround support

InactiveUS20100172537A1Transducer detailsLoudspeaker diaphragm materialsMechanical componentsEngineering

An improved dynamic loudspeaker that eliminates all visible mechanical components except the diaphragm when viewed from the front in a mounting baffle, and enables all of the front exposed diaphragm surface to emit sound. The surround support is entirely located within the perimeter edge of the diaphragm. A conventional dynamic loudspeaker motor / driver and voice coil system sized to fit behind and entirely inside the perimeter edge of the acoustic diaphragm permits the entire diaphragm to visually fill an opening in a mounting baffle and emit sound.

Owner:CAMPBELL JACK BLAINE

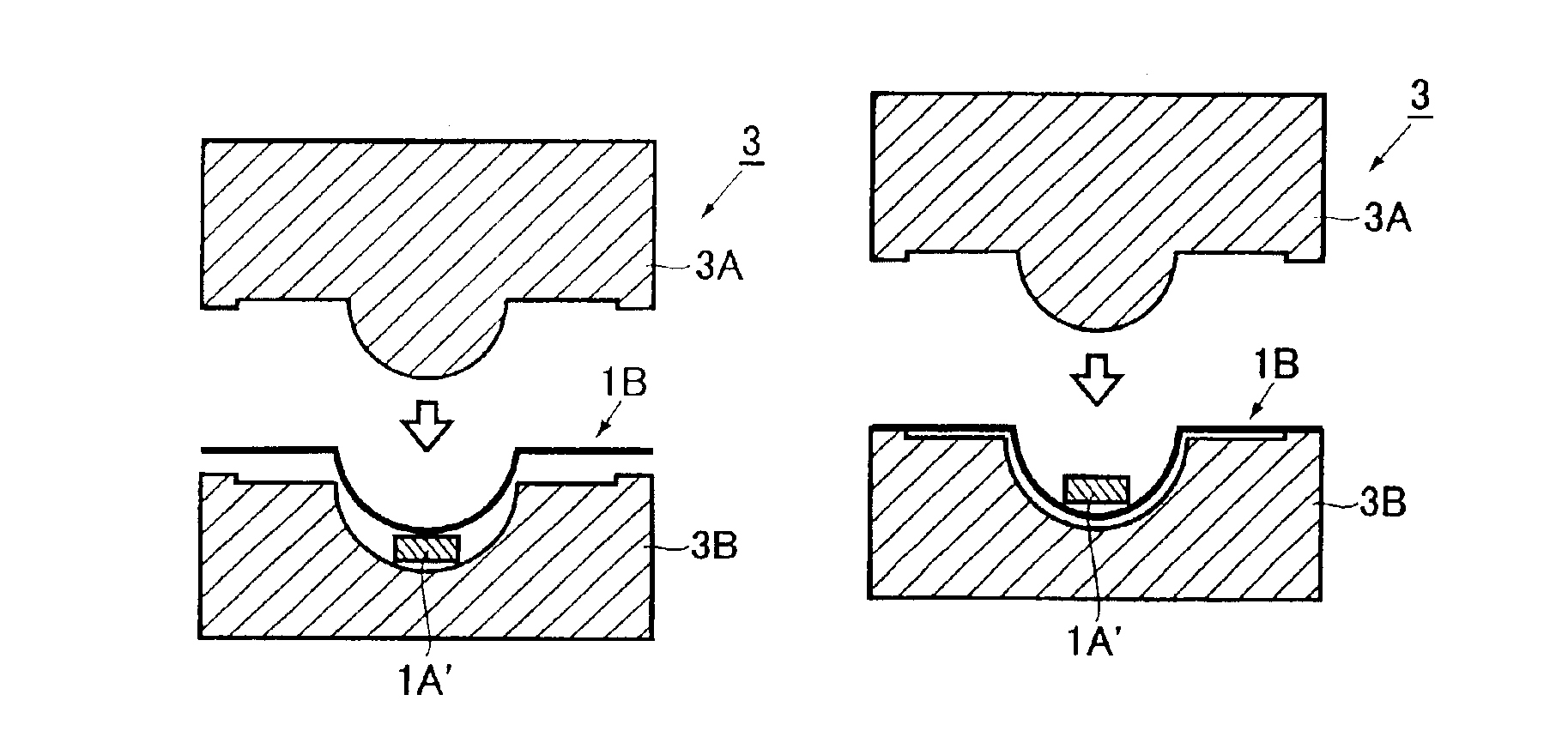

Method of manufacturing speaker edge member

InactiveUS20070145637A1Shorten production timeReduce manufacturing costLoudspeaker diaphragm materialsManufacturing technologySplit lines

It is an object of the present invention to improve a speaker edge member manufacturing process in which a substrate is introduced into an edge member molding material by virtue of insertion molding, to prevent a trouble such as a crack on a parting line or the like, thus shortening a manufacturing time and thus reducing a manufacturing cost. An edge member molding die has at least a male die and a female die, as well as an annular cavity formed corresponding to the speaker edge member within the die when the die is closed, while a dividing line is formed by virtue of the dividing surfaces of the male die and the female die, along a circumferential direction in a generally central portion of the annular cavity. An edge member manufacturing method comprises the steps of: attaching the substrate into the edge member molding die; introducing the edge member formation material into the edge member molding die before or after attaching the substrate into the edge member molding die; heating / pressurizing the substrate and the edge member formation material in the edge member molding die so as to obtain a molded edge member. At this time, the outer edge portion of the substrate is located in a position separated a predetermined distance from the dividing line of the die.

Owner:PIONEER CORP +1

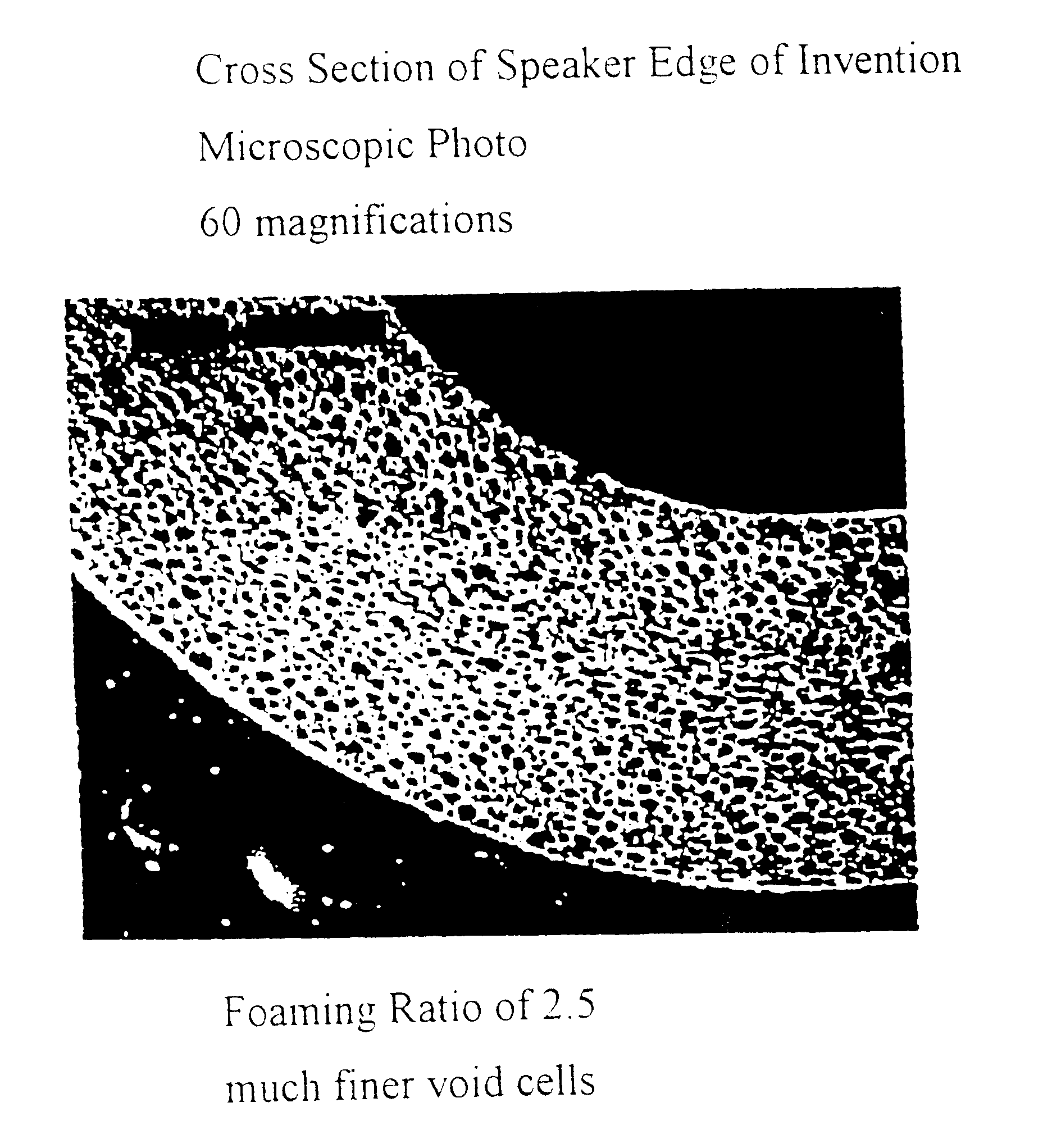

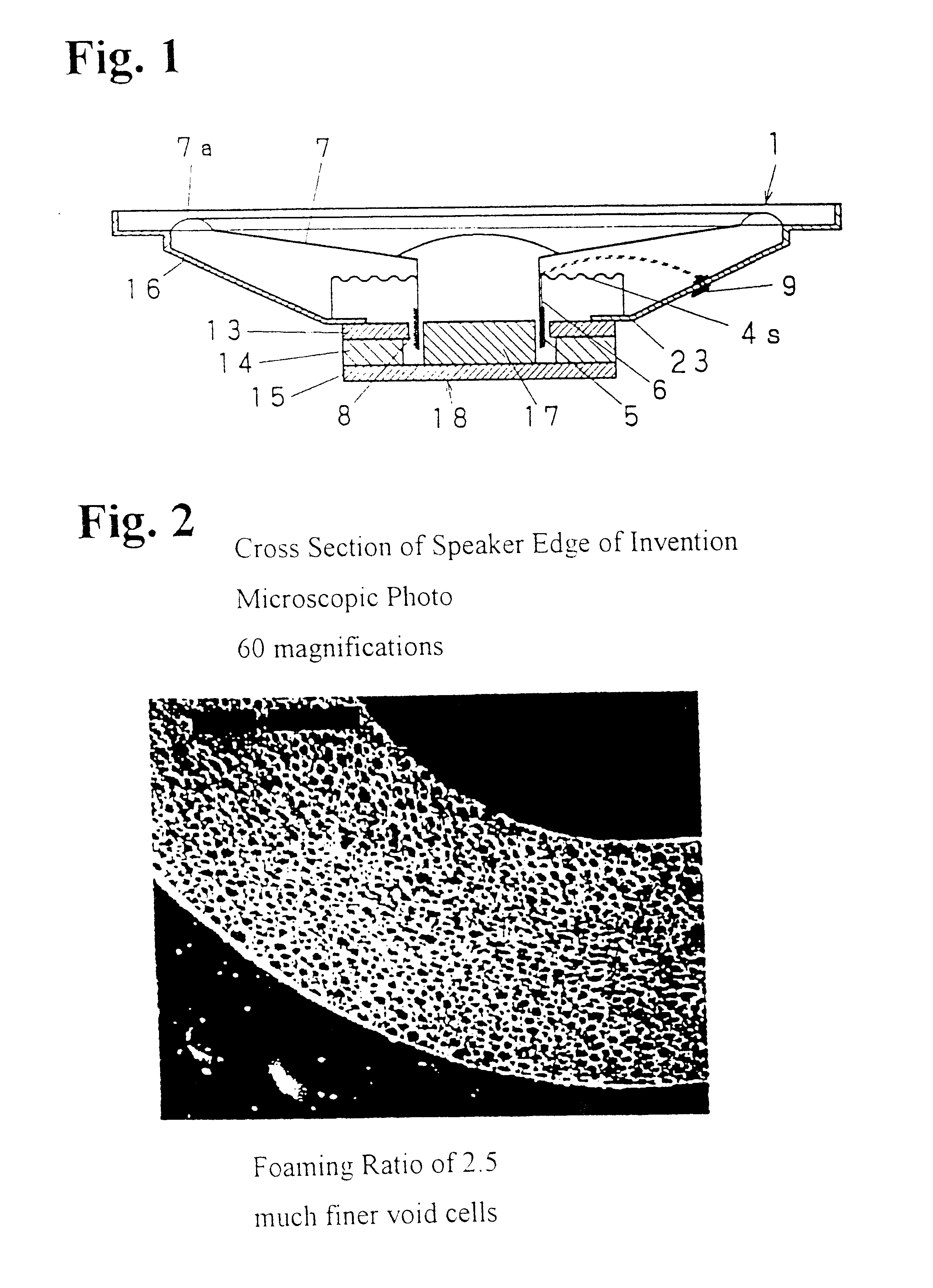

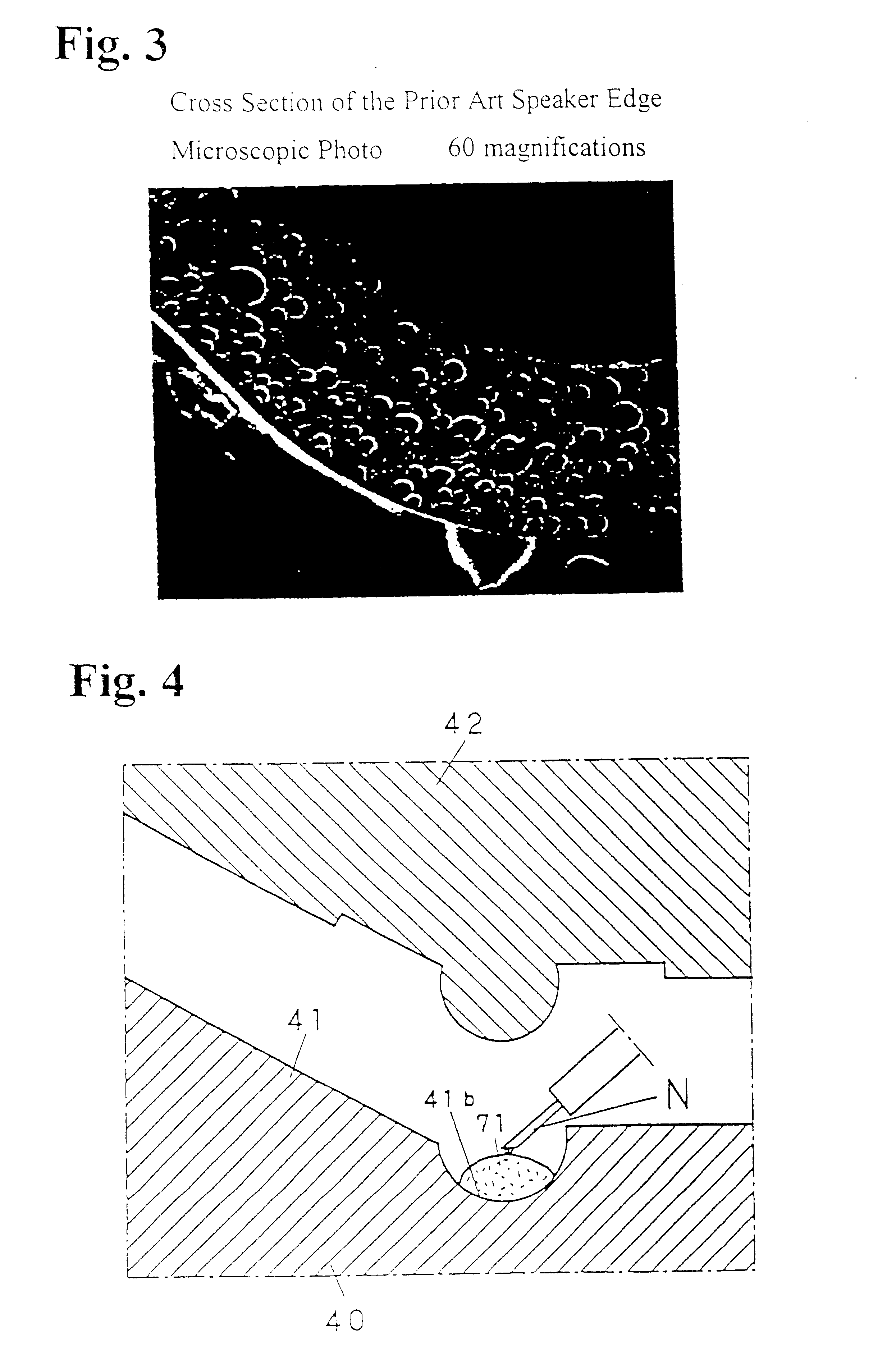

Speaker edge, method of foam-molding the same, apparatus for foam-molding the same, speaker edge foam-molding system, and speaker employing the speaker edge

InactiveUS6680430B2Stringed musical instrumentsLoudspeaker diaphragm materialsAdditive ingredientEngineering

Owner:STARLECS +1

Miniature speaker

InactiveUS10250993B1Improve stabilityLower surface energyLoudspeakersLoudspeaker diaphragm materialsEngineeringAcoustic wave

The present application discloses a miniature speaker. The miniature speaker includes a vibration system including a diaphragm, a voice coil for driving the diaphragm, and a suspension connected to the voice coil; a magnetic circuit system interacting with the voice coil for driving the diaphragm to radiate sound waves; and a frame for accommodating the vibration system and the magnetic circuit system. The suspension includes an outer edge connecting to the frame, an inner edge engaging with the voice coil, and a plurality of spring arms connecting the outer edge to the inner edge. The suspension includes a first isolative layer, a second isolative layer, and a conductive layer. The first isolative layer forms a mounting surface out of which at least part of the conductive layer exposes for connecting to the voice coil.

Owner:AAC TECH PTE LTD

Suspension member with integrated sealing member

InactiveUS20140369547A1Loudspeaker diaphragm materialsLoudspeaker diaphragm shapeElastomerTransducer

The present invention relates to a suspension member for suspending a moveable piston structure of a transducer, the suspension member comprising tolerance compensation means comprising an elastomeric material, said tolerance compensation means being formed as a structure extending in a direction so as to form an acoustical seal between a first chamber and a second chamber.

Owner:GETTOP EURO R&D

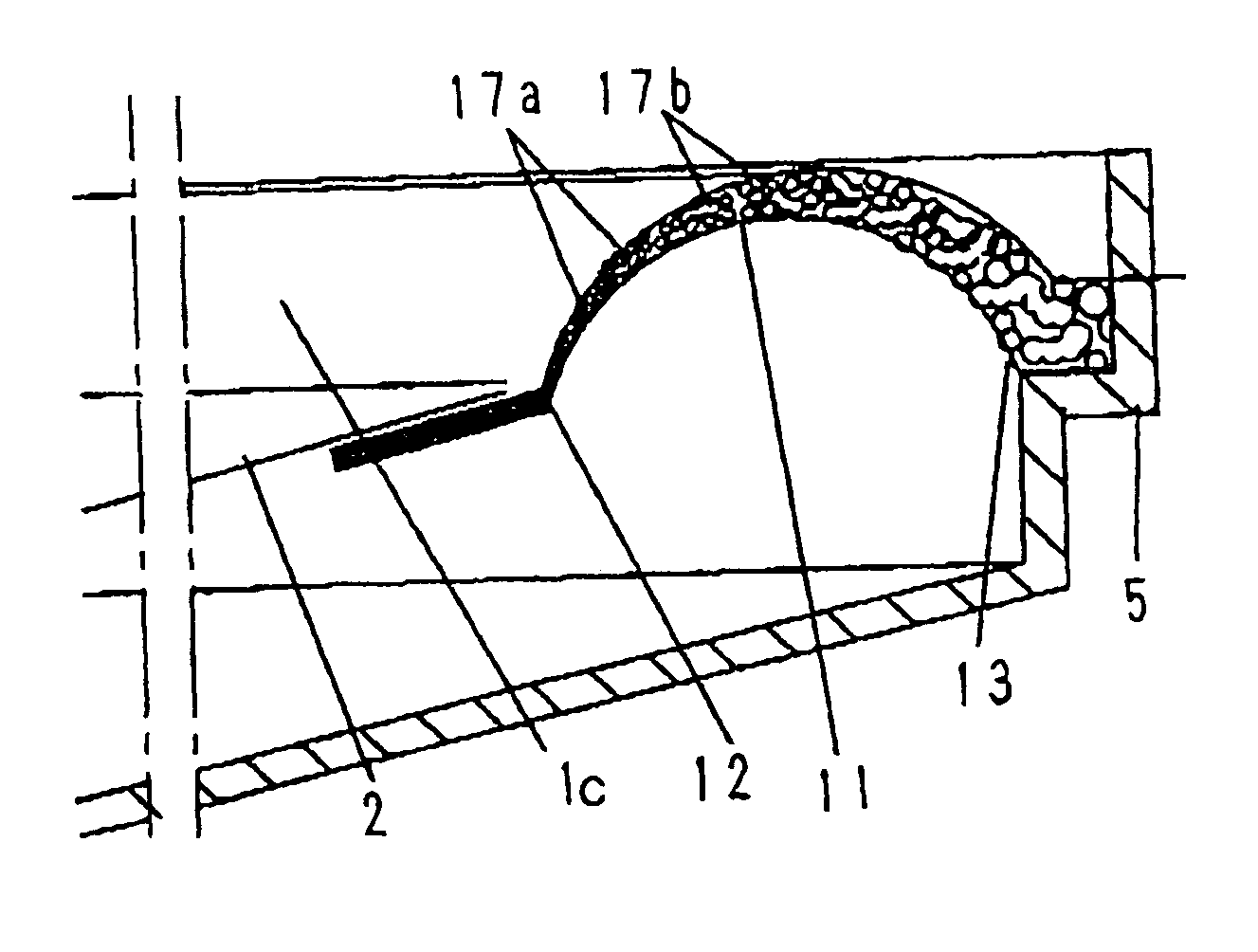

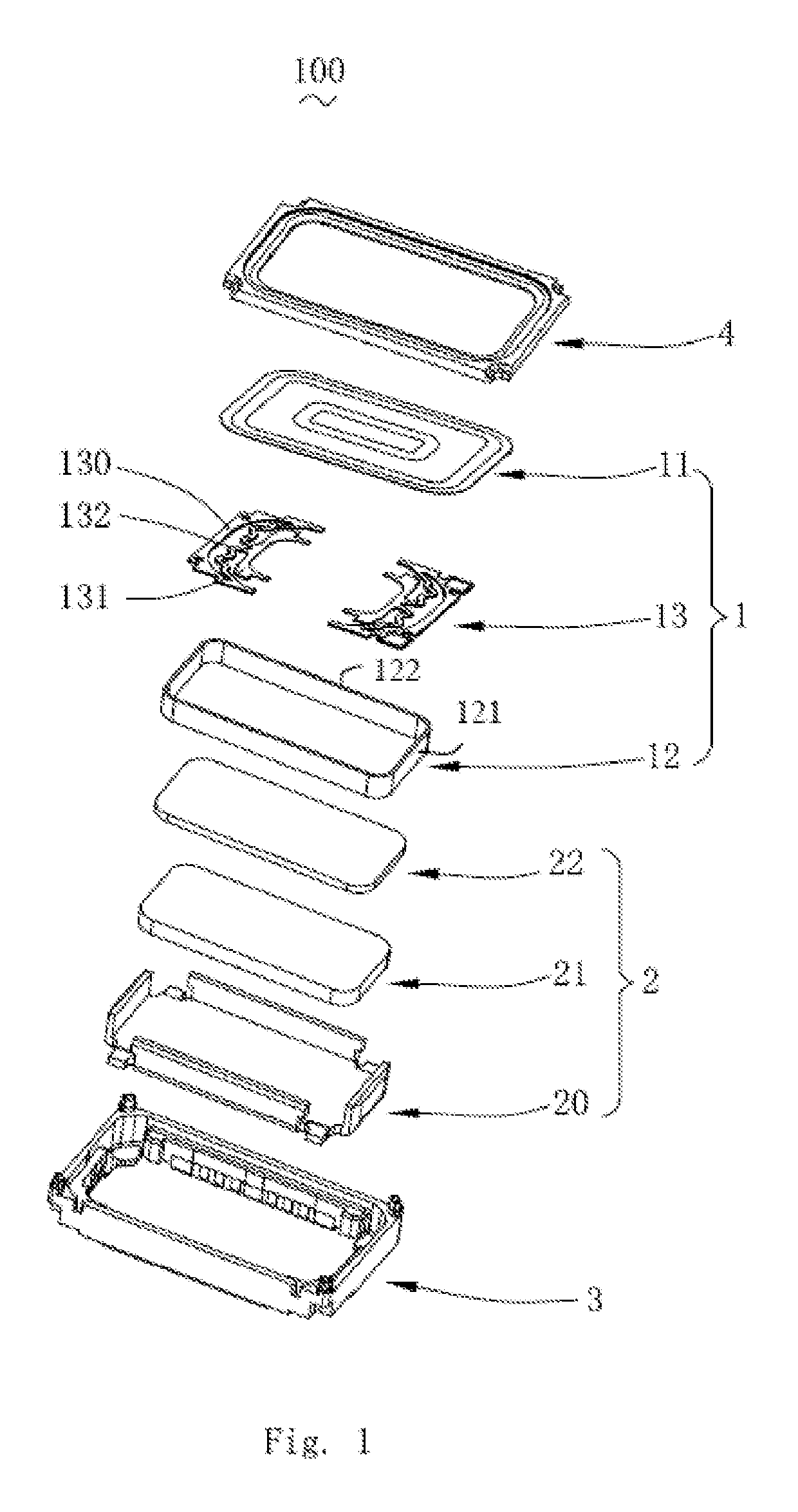

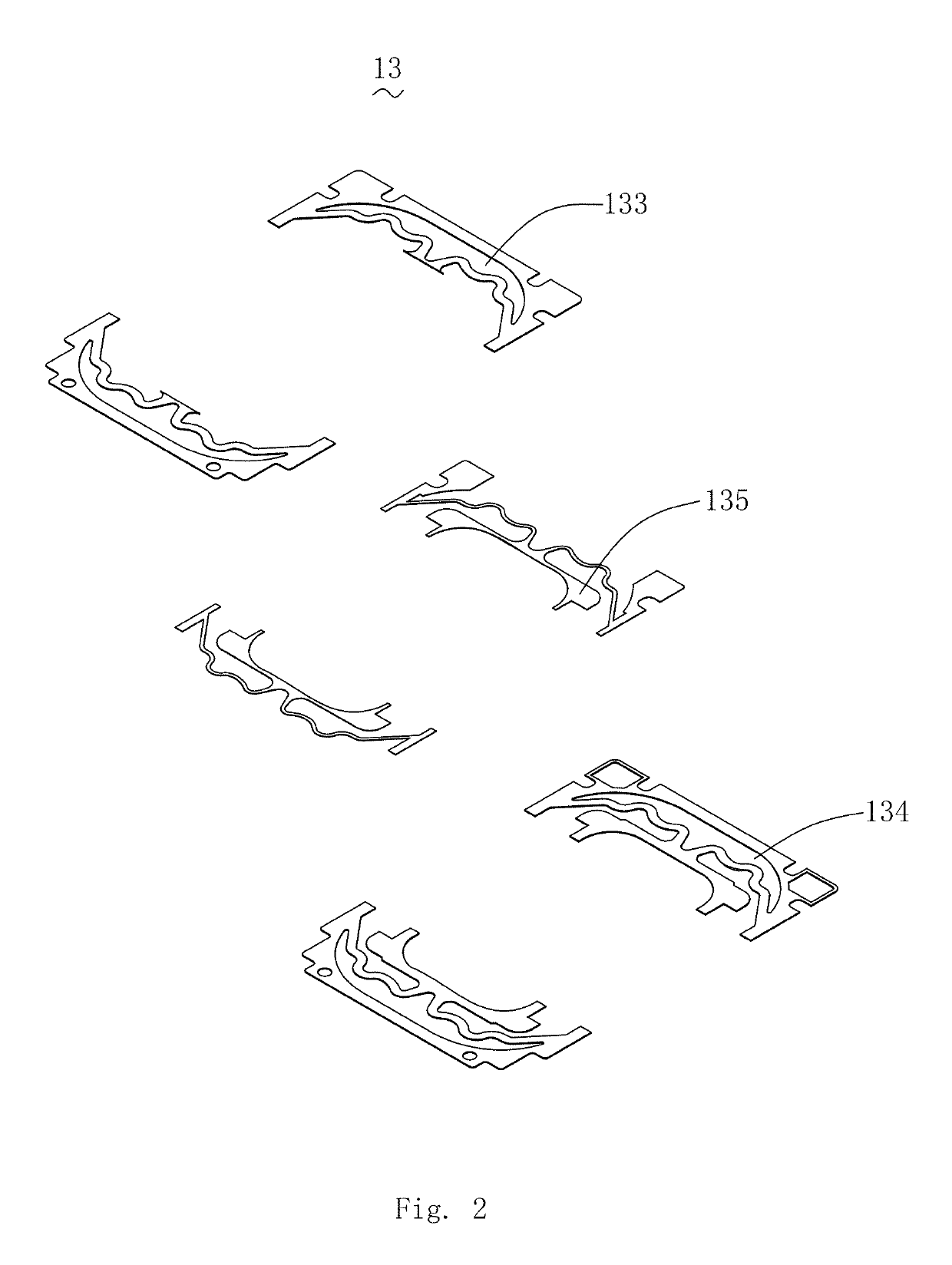

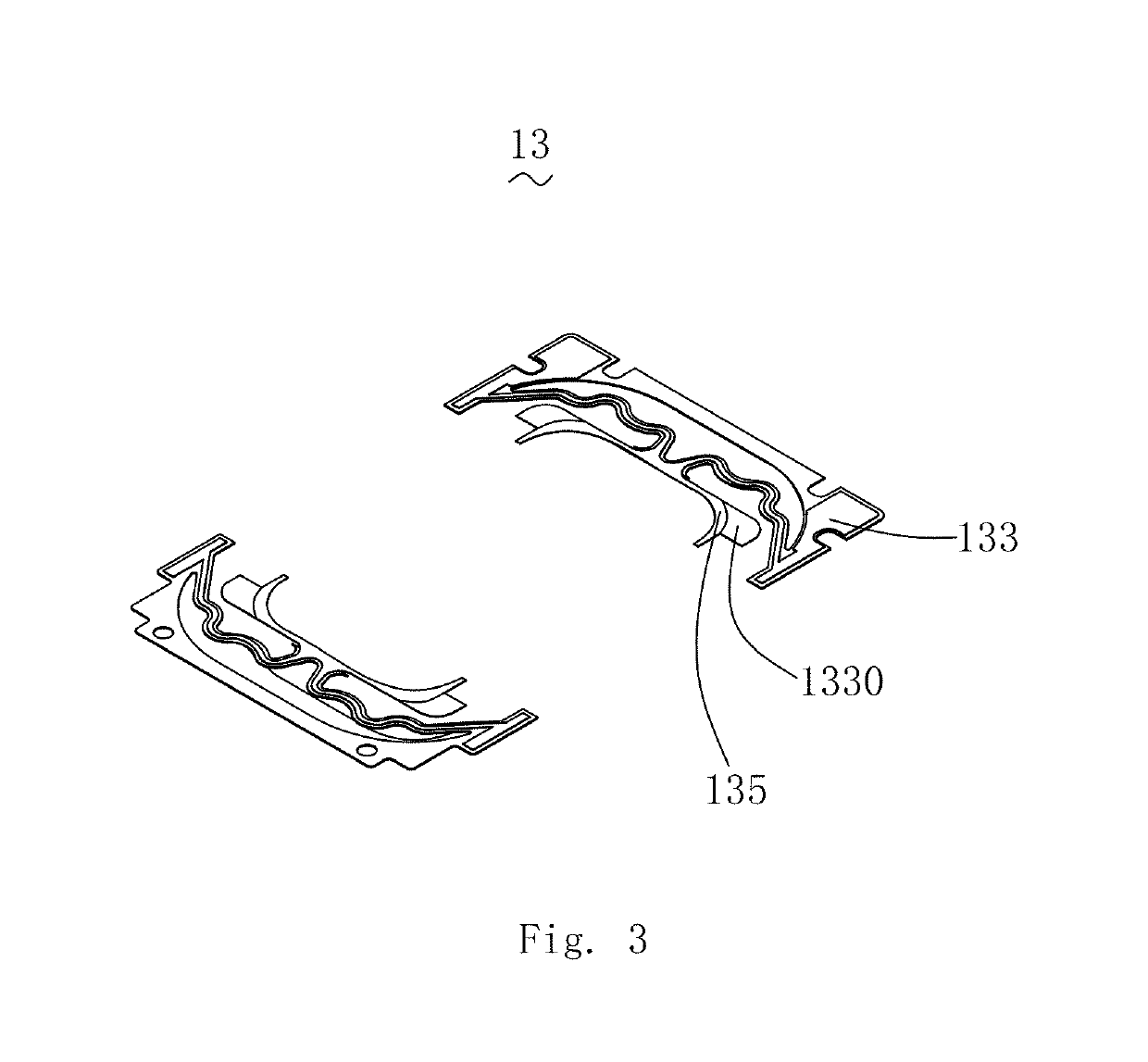

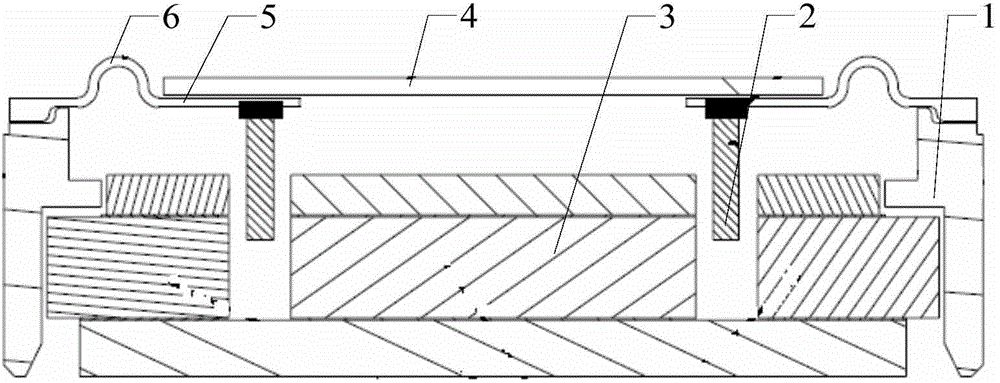

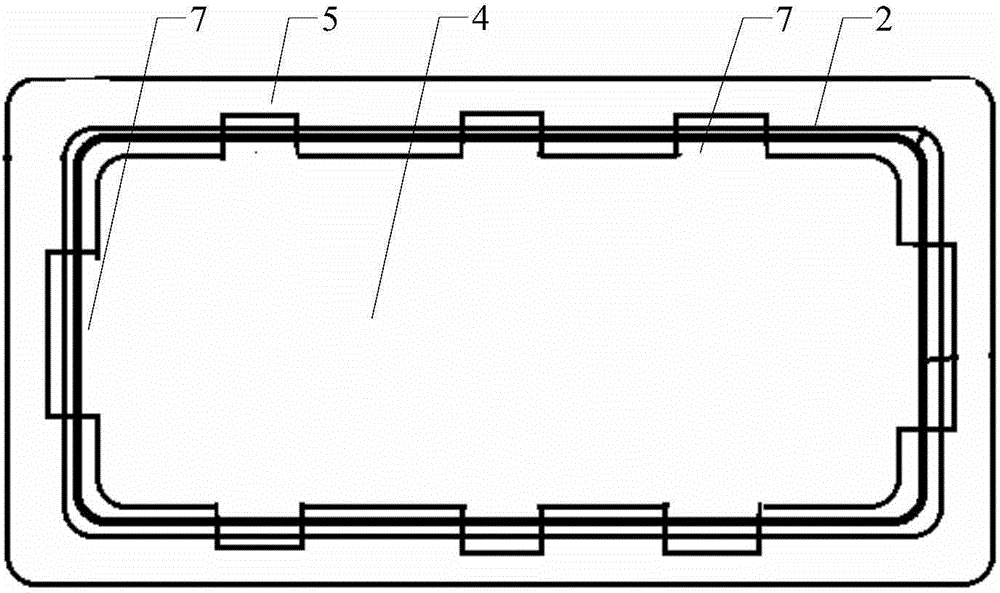

Electronic equipment and loudspeaker thereof

ActiveCN104936105AQuality improvementGood for balancing vibrationPolymeric diaphragmsLoudspeakersLow distortionReciprocating motion

The invention discloses a loudspeaker of electronic equipment. The loudspeaker comprises a hollow frame (1) connected with the electronic equipment, a vibrating device for vibrating and producing sound, a voice coil (2) for driving the vibrating device to move, and a magnetic circuit (3) having magnetic property installed at the lower end in the hollow frame (1), wherein an end face opening is installed at the upper end of the hollow frame (1); the vibrating device covers the end face opening; one end of the voice coil (2) is connected with the vibrating device, while the other end can enter a slit of the magnetic circuit (3) and repeatedly move; the vibrating device comprises a vibrating diaphragm and a globe roof (4) fixedly installed in the middle of the vibrating diaphragm; an outer edge of the vibrating diaphragm is connected with an outer edge of the end face opening; the vibrating diaphragm is a single elastic diaphragm. The loudspeaker can output the voice frequencies having lower distortions at large power and at high volume. The invention further discloses electronic equipment comprising the loudspeaker.

Owner:SHANDONG GETTOP ACOUSTIC

Speaker surround structure for maximizing cone diameter

A surround that is generally arched in shape and that includes a radial exterior flange that extends downward from exterior side of the arched portion of the surround and that adhesively attaches to the inner wall or edge of the mounting ring of the frame of the loudspeaker.

Owner:HARMAN INT IND INC

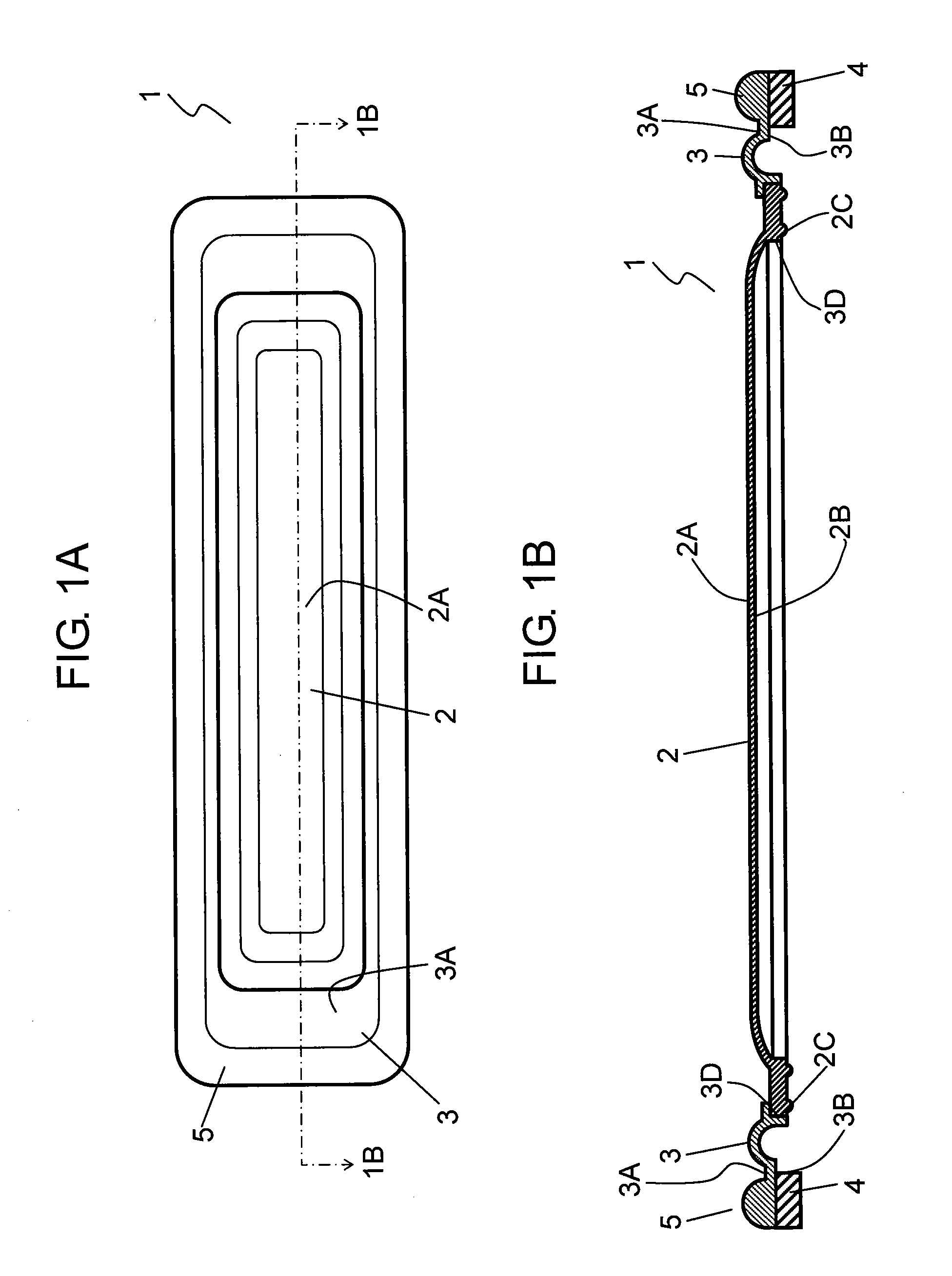

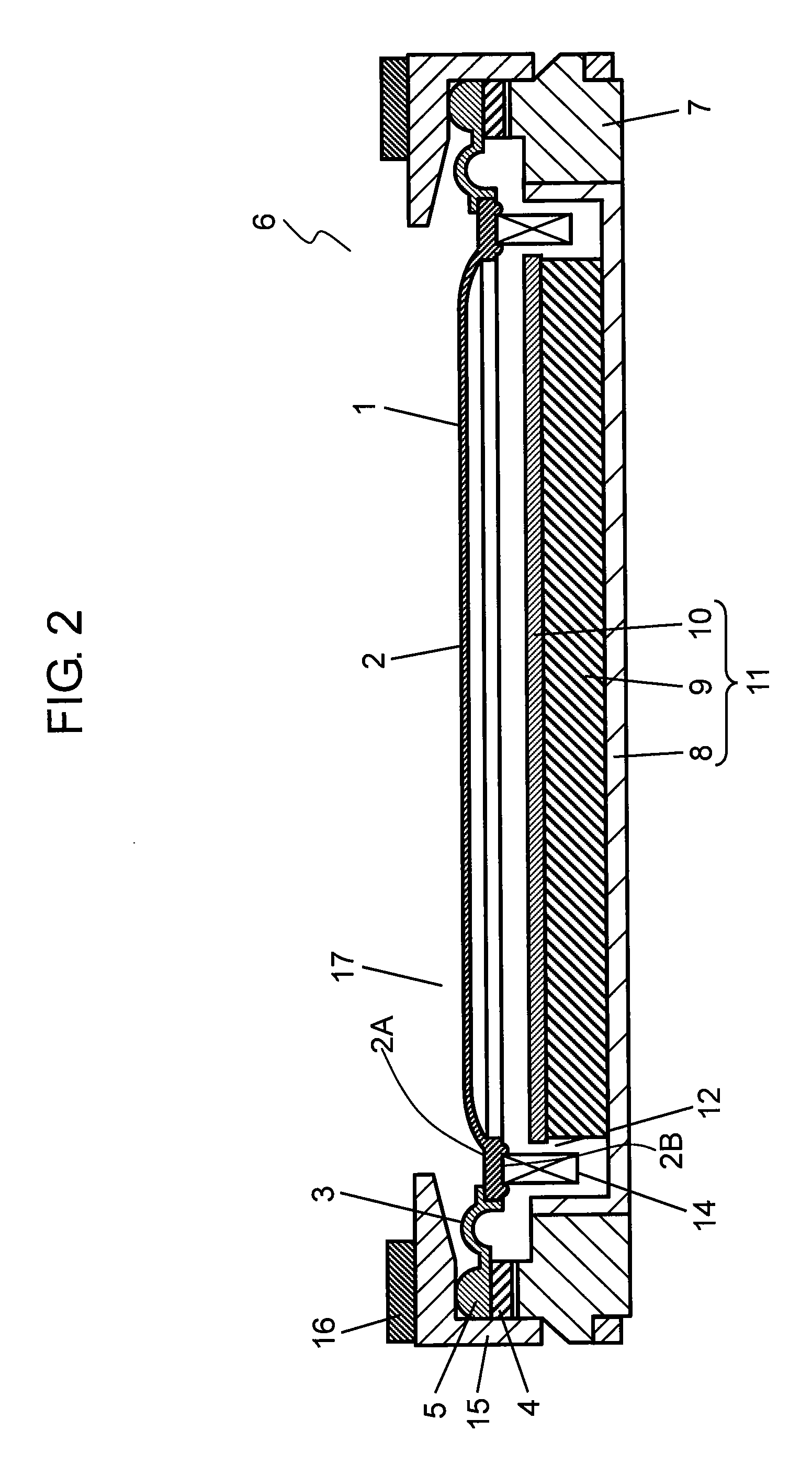

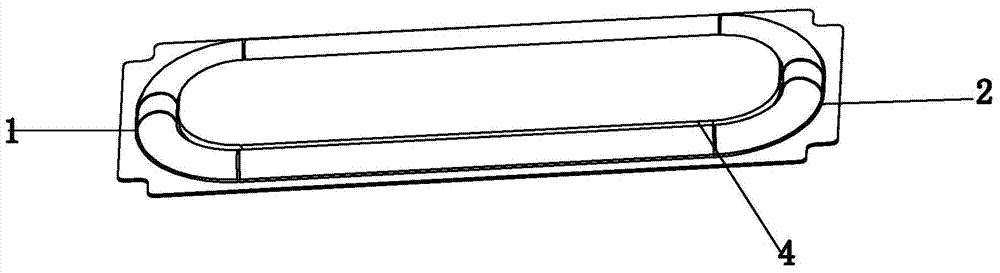

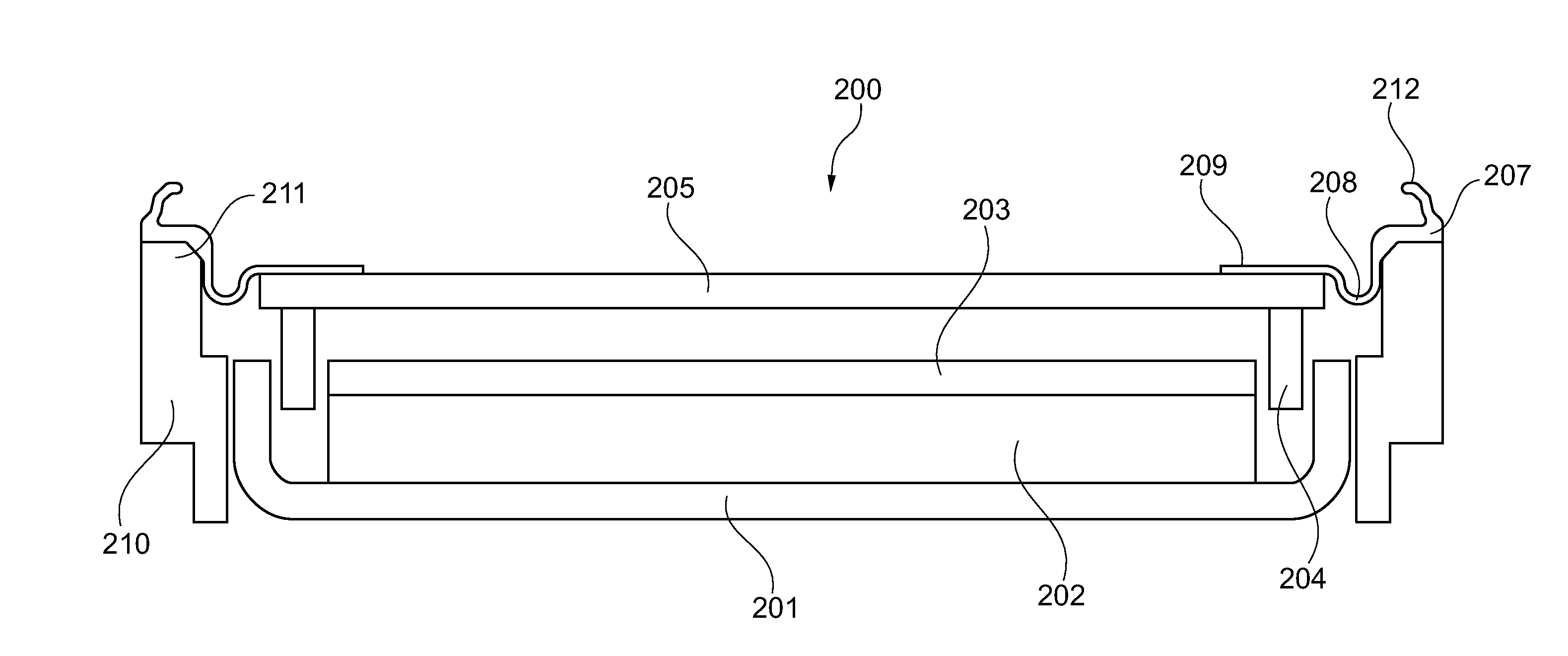

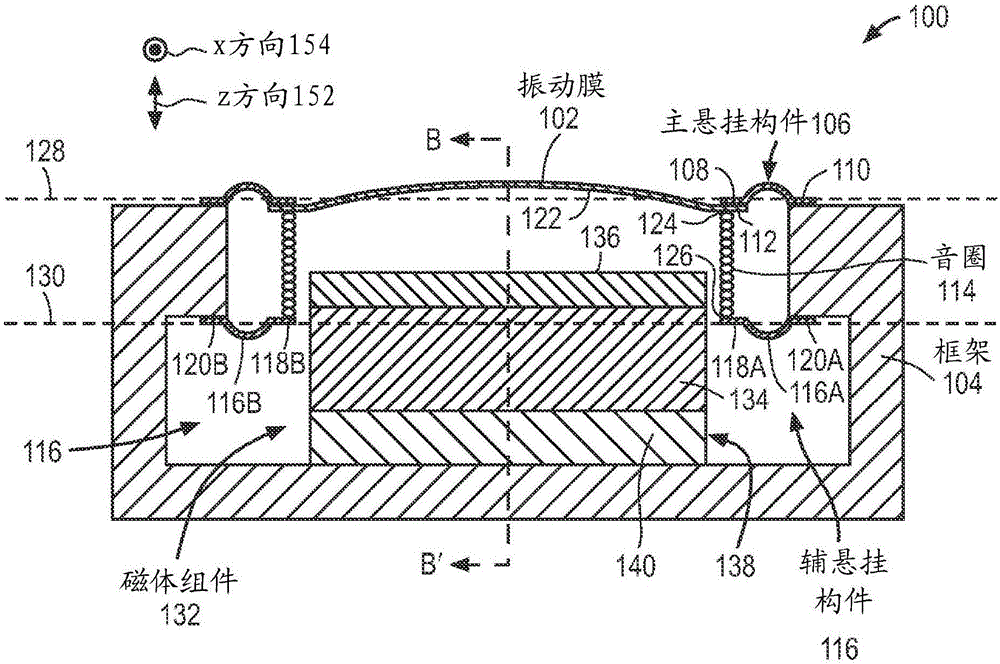

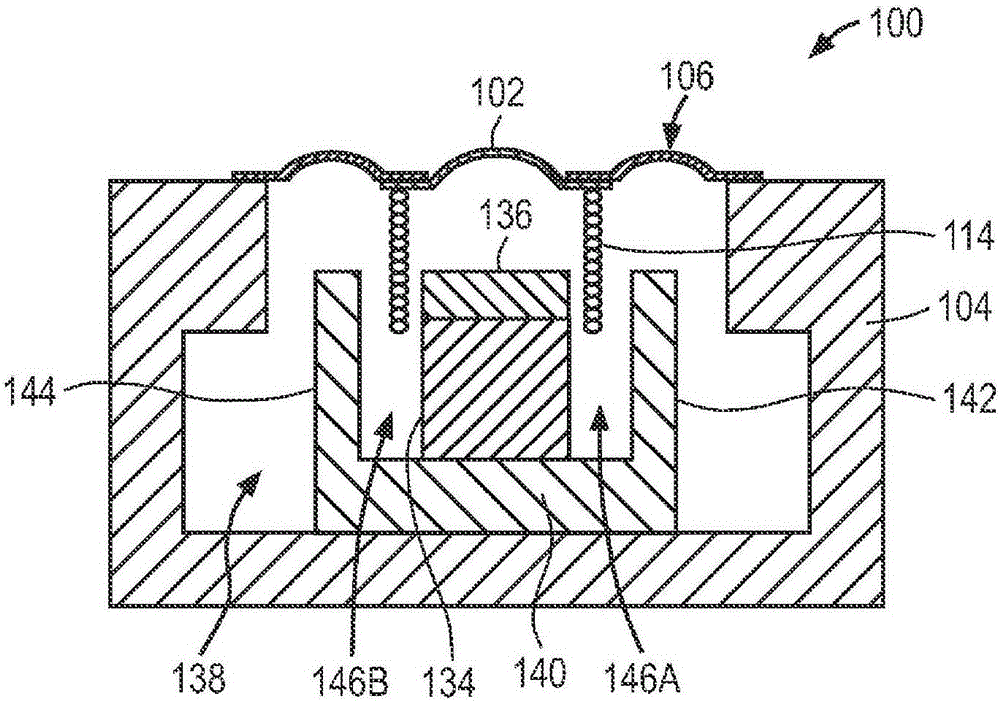

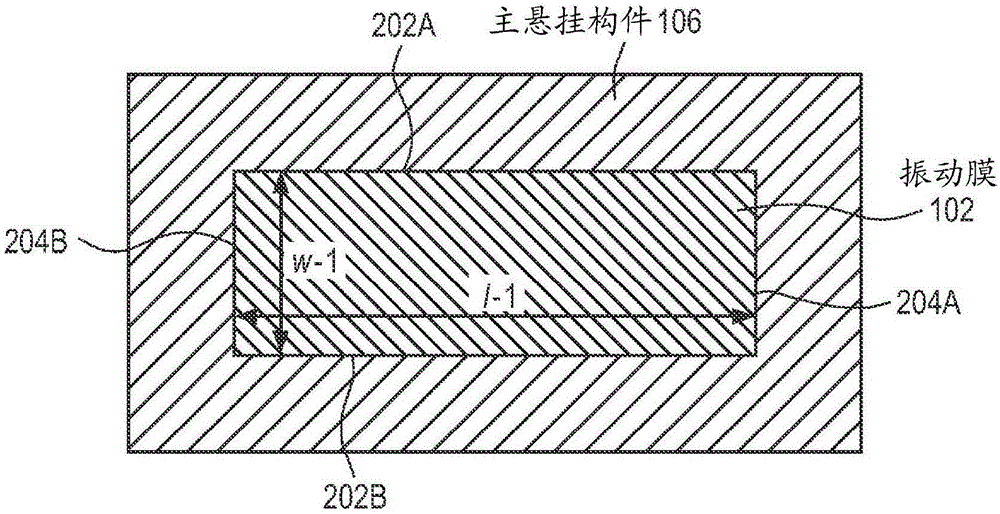

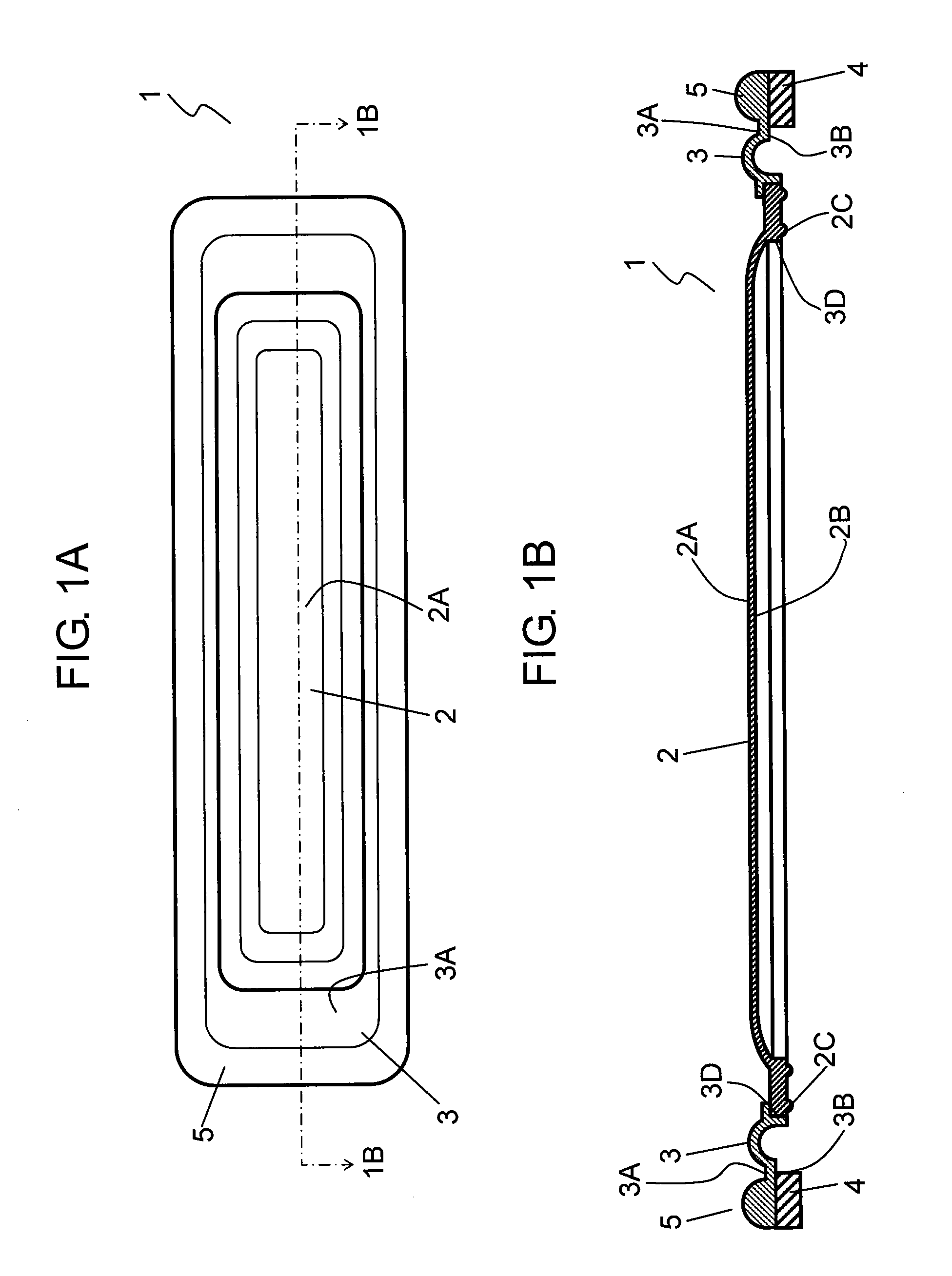

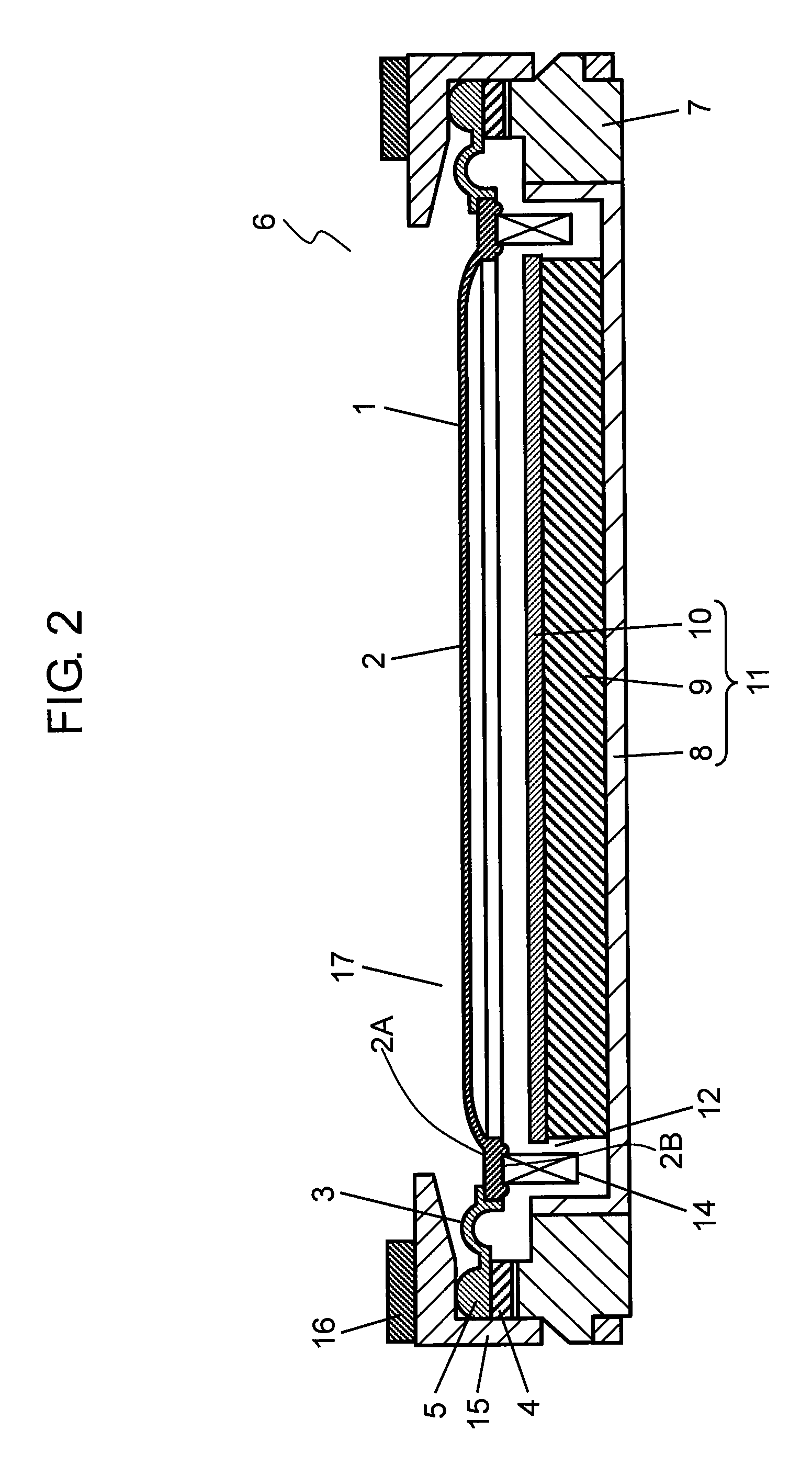

High aspect ratio microspeaker having a two-plane suspension

A microspeaker includes a frame and a diaphragm having length sides that are longer than its width sides. A magnet is positioned below the diaphragm. A yoke includes a base portion positioned below the magnet and sidewalls which extend from the base portion, the yoke sidewalls positioned only along a length dimension of the magnet. A voice coil includes an upper end attached to a bottom face of the diaphragm and a lower end positioned within a gap formed between the length dimension of the magnet and the yoke sidewalls. A first suspension member is attached to the length sides and the width sides of the diaphragm and the frame. The first suspension member is within a first plane. A second suspension member is attached to the lower end of the voice coil and the frame. The second suspension member is in a second plane different from the first plane.

Owner:APPLE INC

Micro speaker with capacitors formed by conductive cover and diaphragm

A micro speaker is disclosed. The micro speaker includes a diaphragm and a voice coil for driving the diaphragm, the diaphragm including a conductive dome a suspension surrounding the conductive dome; a conductive front cover located adjacent to and keeping a distance from the conductive dome; and a capacitor formed by the conductive dome and the conductive front cover for outputting electrical signals according to vibrations of the diaphragm and for detecting real-time replacement of the diaphragm.

Owner:AAC TECH PTE LTD

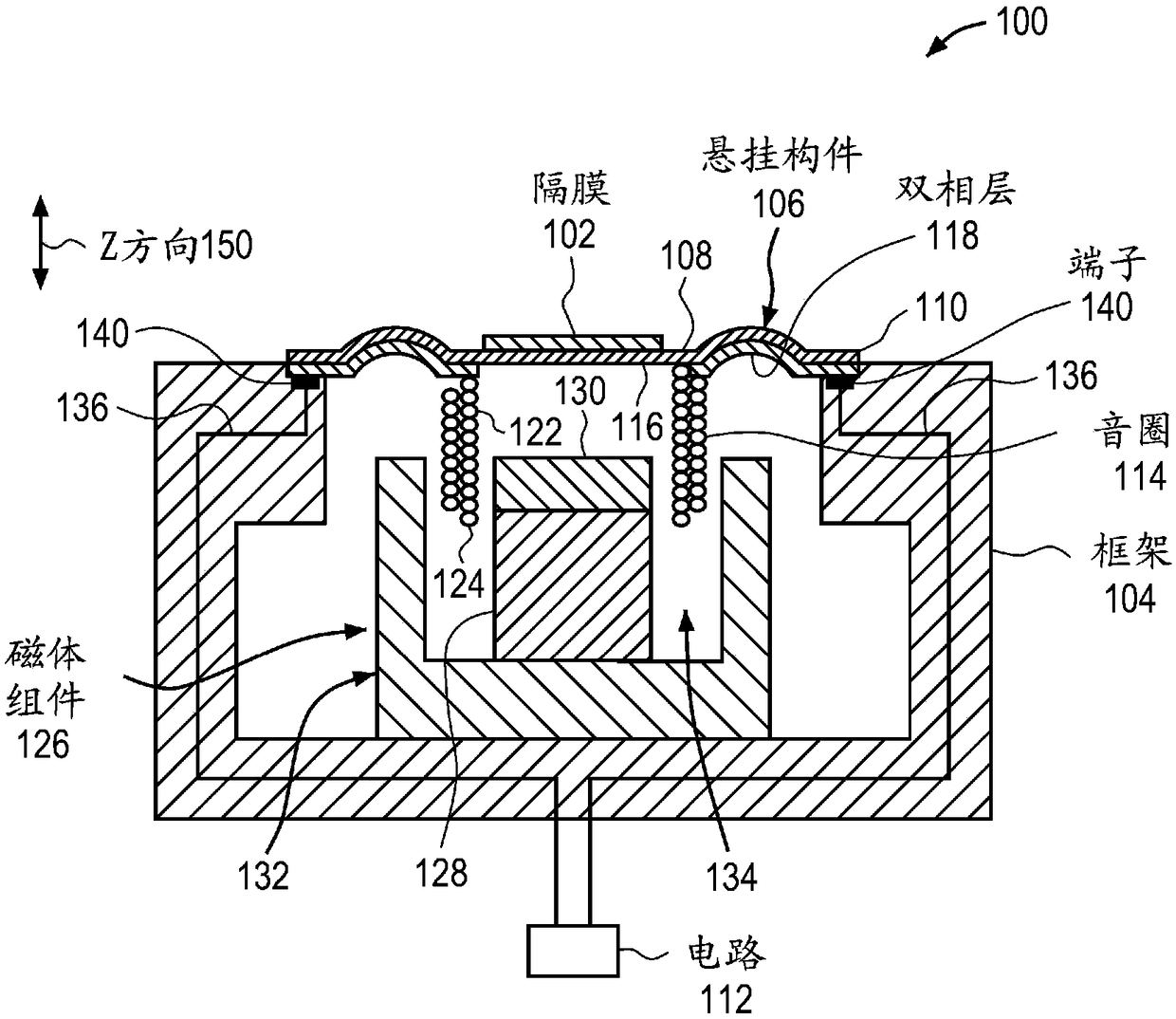

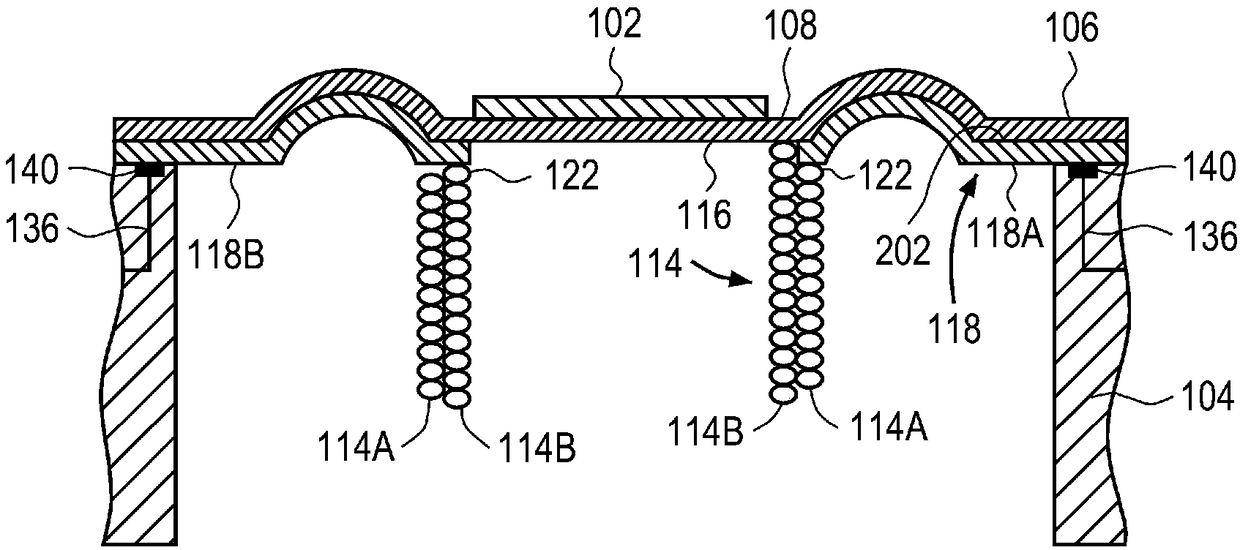

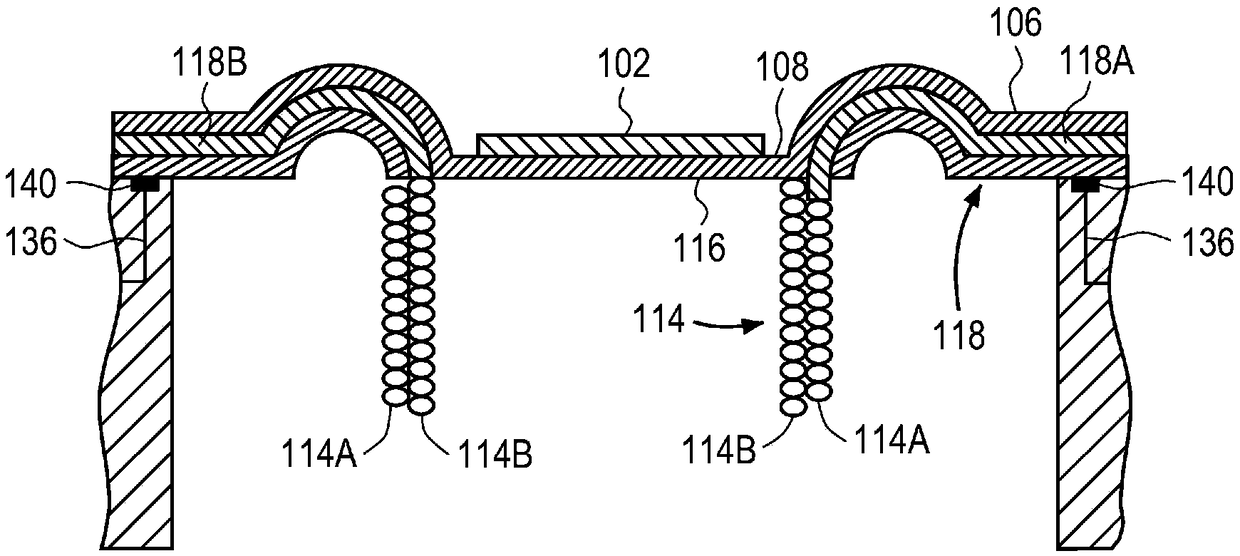

Transducer having a conductive suspension member

ActiveCN108605176AUniform driveLoudspeakersLoudspeaker diaphragm materialsElectrical connectionTransducer

A speaker including a frame, and a magnet assembly coupled to the frame. The magnet assembly forms an air gap through which a magnetic flux is directed. The speaker further including a voice coil suspended in the air gap, a diaphragm coupled to the voice coil and a compliant suspension member for suspending the voice coil within the air gap. The suspension member includes an electrically conductive biphasic member for providing an electrical connection between the voice coil and a circuit coupled to the frame.

Owner:APPLE INC

Speaker edge, method for manufacturing same and speaker

A speaker edge includes a resin layer including a resin member and a fiber layer including a tangled fiber body. A melting temperature of the tangled fiber body is higher than a melting temperature of the resin member. The hardness of the tangled fiber body is lower than the hardness of the resin member.

Owner:PIONEER CORP +1

Speaker diaphragm, and speaker and handheld terminal device using said speaker diaphragm

InactiveUS8705790B2Loudspeaker diaphragm materialsLoudspeaker diaphragm shapeTerminal equipmentEngineering

A speaker diaphragm includes a body vibrating to generate a sound, an edge fusion-bonded to an outer circumference portion of the body, a projection provided on an upper surface of the edge, and a gasket provided on a lower surface of the edge. The edge is made of material different from that of the body. The projection is made of material identical to that of the edge. The gasket is made of material identical to that of the body. A speaker including the diaphragm has waterproof property by itself.

Owner:PANASONIC CORP

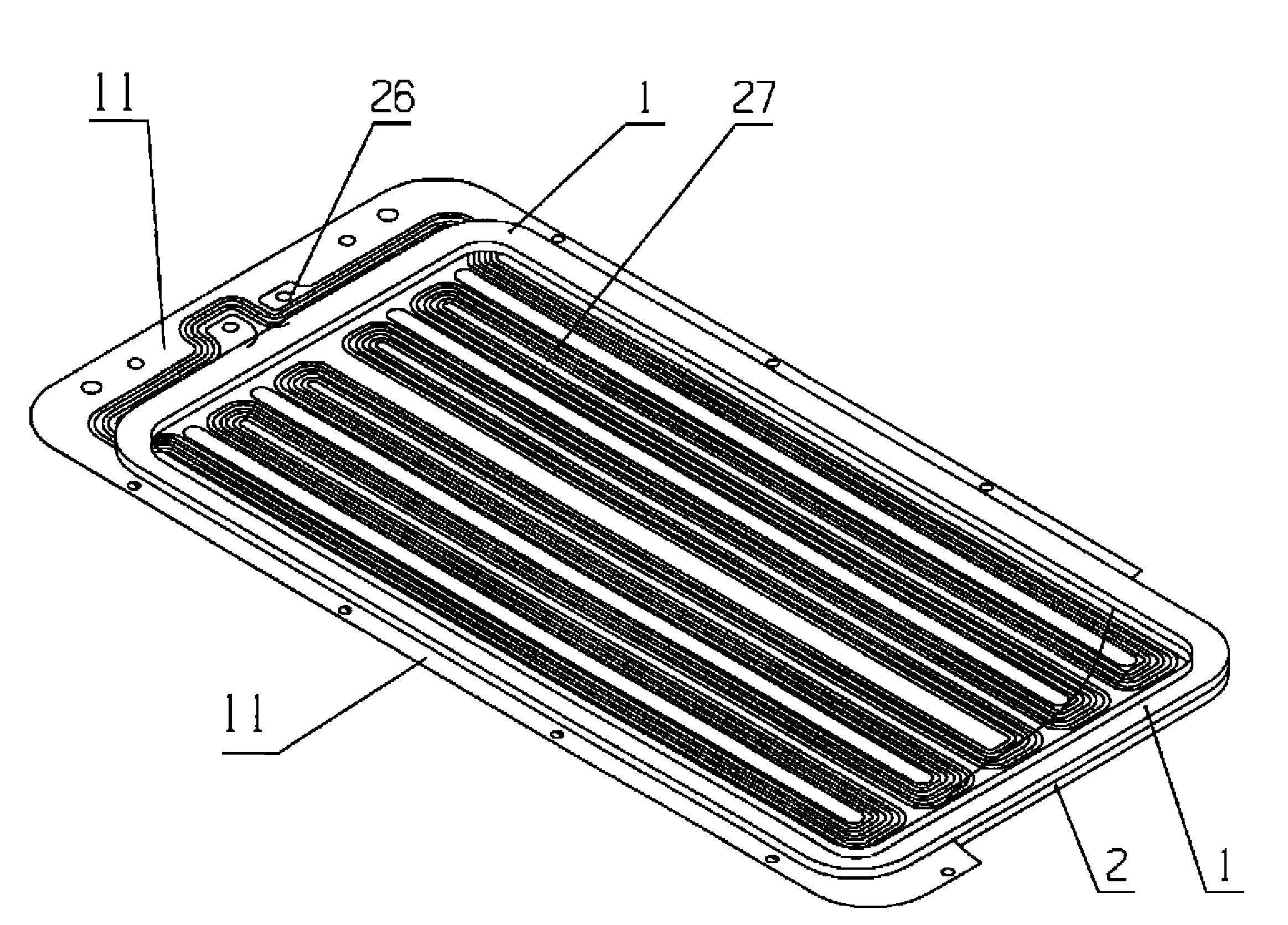

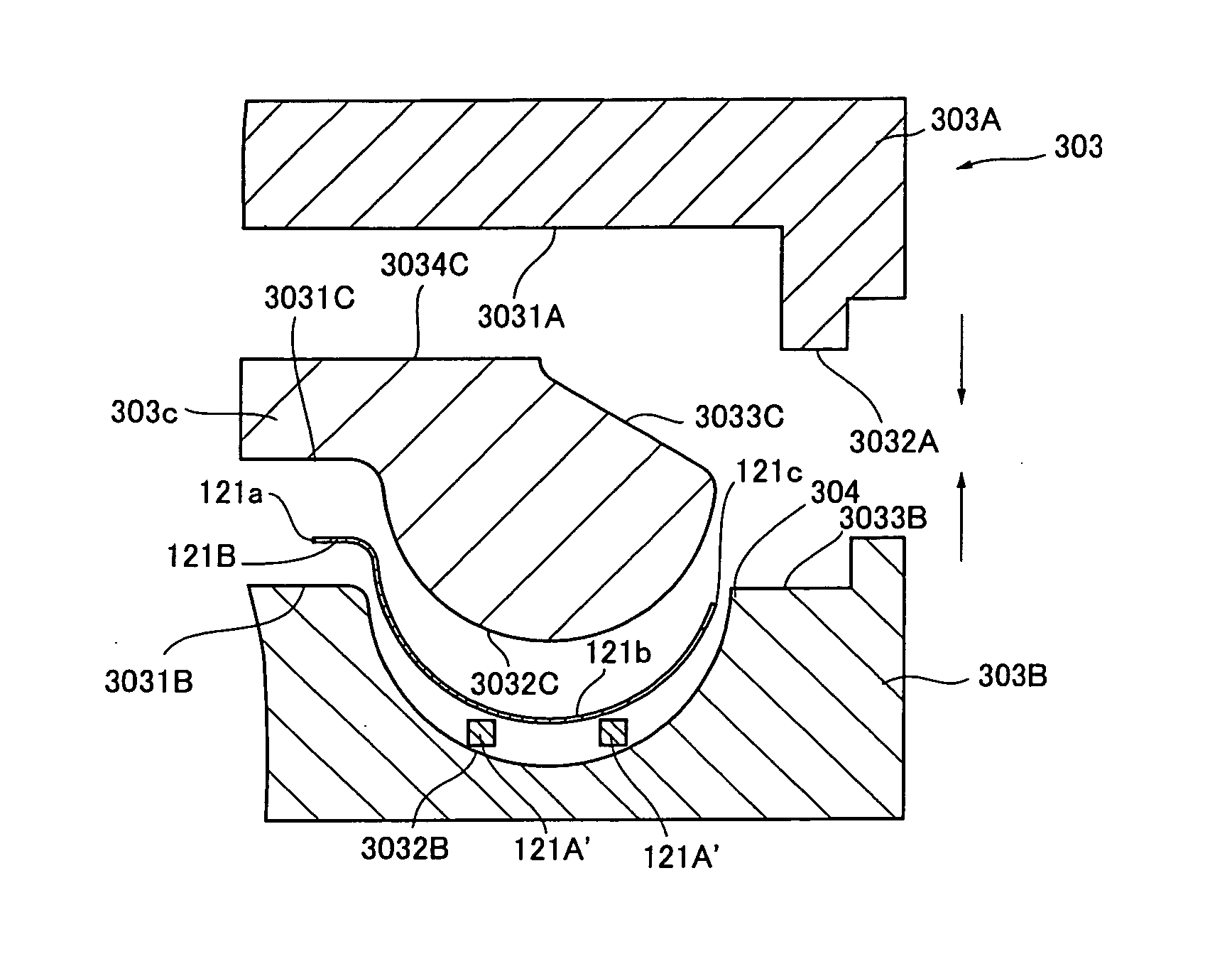

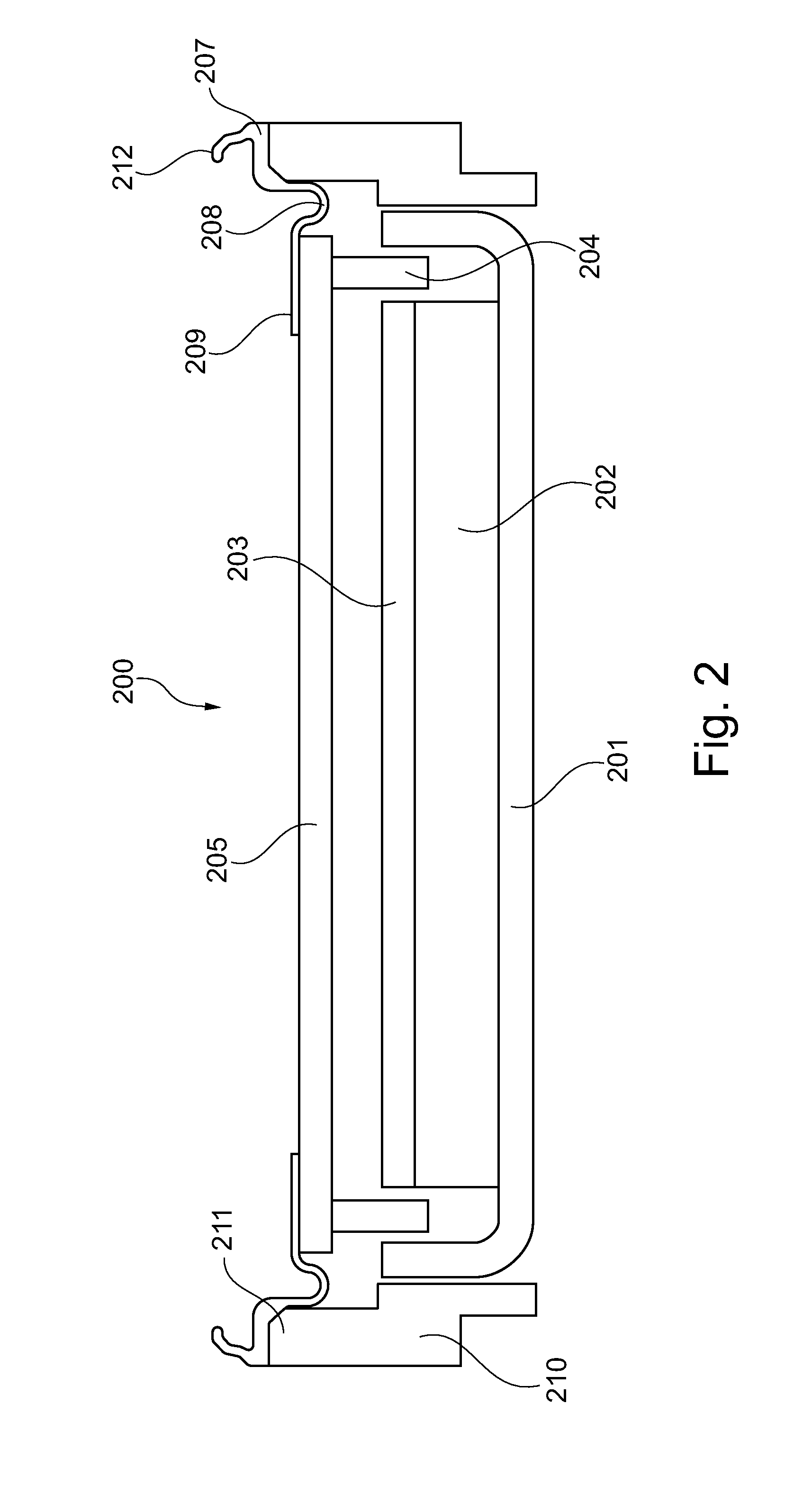

Insert molded surround with mechanical support

ActiveUS7974433B2Easy to assembleLoudspeaker diaphragm materialsCircuit lead arrangements/reliefTransducerEngineering

A suspension member for a diaphragm, the suspension member comprising an inner portion being adapted to be attached to a substantially stiff piston part, a outer portion arranged on or integrated with a substantially stiff support member so as to mechanically stabilize the suspension member, and a flexible member connecting the inner and outer portions. The present invention further relates to an electro-acoustic transducer, preferably a miniature electro-acoustic transducer, applying such suspension member.

Owner:SHANDONG GETTOP ACOUSTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com