Vibration film component

A diaphragm component and film base technology, which is applied in the direction of plane diaphragm, polymer diaphragm, speaker diaphragm shape, etc., can solve the difficulty of forming and processing polymer diaphragm, affect product quality and service life, and affect product acoustics Performance and other issues, to achieve the effect of improving listening yield, improving temperature adaptability, and improving reliability and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

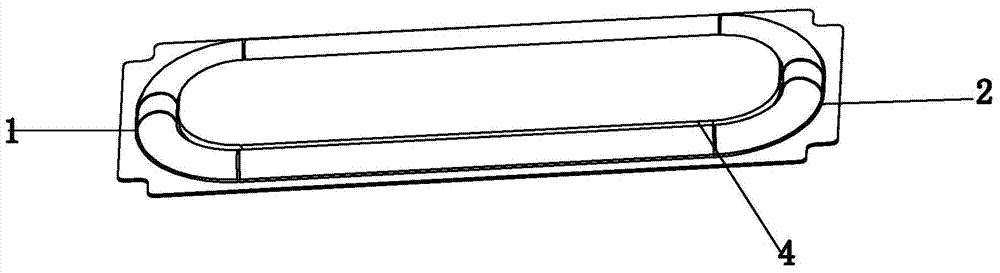

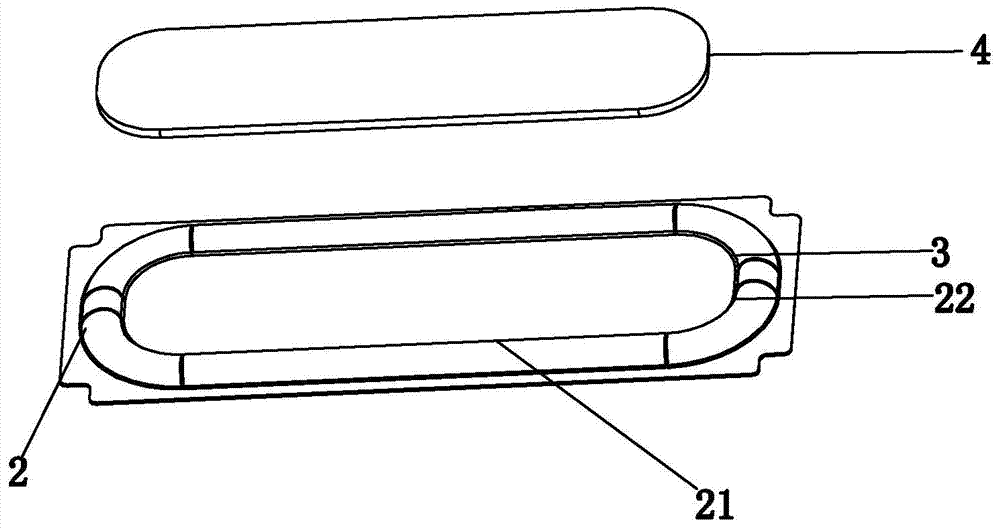

[0028] refer to Figure 1-Figure 3 Shown is the structure of the diaphragm assembly of Embodiment 1 of the present invention. In this embodiment, the base layer of the diaphragm is a single layer of polymer material, and the middle part of the diaphragm is the base layer of the diaphragm.

[0029] Such as Figure 1-Figure 3 As shown, the diaphragm assembly includes a diaphragm 1 , and the diaphragm 1 includes a middle part 3 and a ring part 2 surrounding the outer periphery of the middle part 3 . The diaphragm assembly also includes a reinforcing part 4 arranged in the middle of the diaphragm 1. The reinforcing part 4 is combined with the upper side or the lower side of the middle part 3, and is generally polyether ether ketone (PEEK), thermoplastic polyurethane elastomer (TPU ) or a single-layer or multi-layer structure composed of other polymer materials can effectively enhance the performance of the diaphragm 1 at high frequencies.

[0030] The diaphragm 1 includes a diap...

Embodiment 2

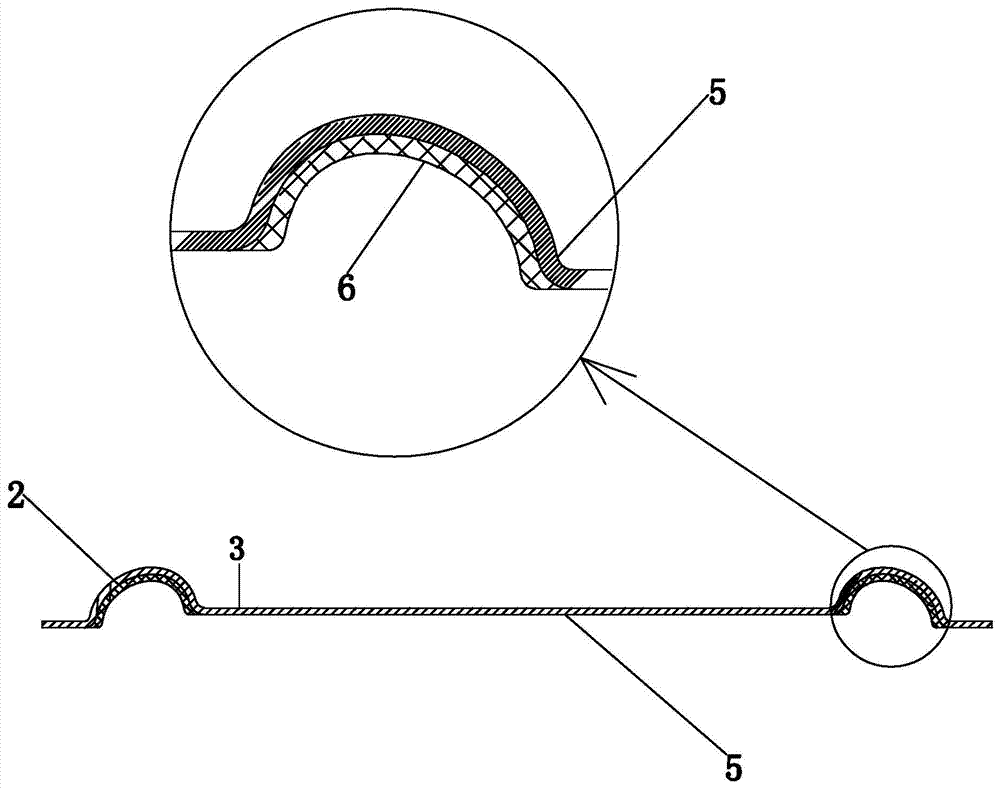

[0039] Figure 4 Shows the second embodiment of the diaphragm assembly of the present invention, this embodiment is basically the same as the first embodiment, the difference lies in:

[0040] The middle part 3 of the diaphragm 1 is a composite structure of the diaphragm base layer 5 and the silica gel layer 6 , that is, the silica gel layer 6 is bonded to the surfaces of the ring part 2 and the middle part 3 at the same time, and is injection molded.

Embodiment 3

[0042] Figure 5 Shows the third embodiment of the diaphragm assembly of the present invention, this embodiment is basically the same as the first embodiment, the difference lies in:

[0043]The diaphragm base layer 5' is two polymer material layers, including a polyetheretherketone (PEEK) material layer 7 and a thermoplastic polyurethane elastomer (TPU) material layer 8. It should be noted that the polymer material layer is not limited to the above-mentioned Two kinds, you can choose polyethylene terephthalate (PET), polyethylene naphthalate (PEN), polyetheretherketone (PEEK), polyetherimide (PEI), polyphenylene sulfide Any two of (PPS), polyarylate (PAR), thermoplastic polyurethane elastomer (TPU). It should be noted that, during specific implementation, the vibrating film base layer 5' is not limited to the above-mentioned materials, and may also be other two kinds of polymer material layers.

[0044] Such as Figure 5 As shown, an adhesive layer 9 is provided between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com