High resistively nine-layer co-extrusion-blown moulding film and its preparation process

A technology of blown film and co-extrusion, which is applied in the field of high-barrier nine-layer co-extrusion blown film and its preparation, and blown film, which can solve the problems of high raw material cost, film curling, and many processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

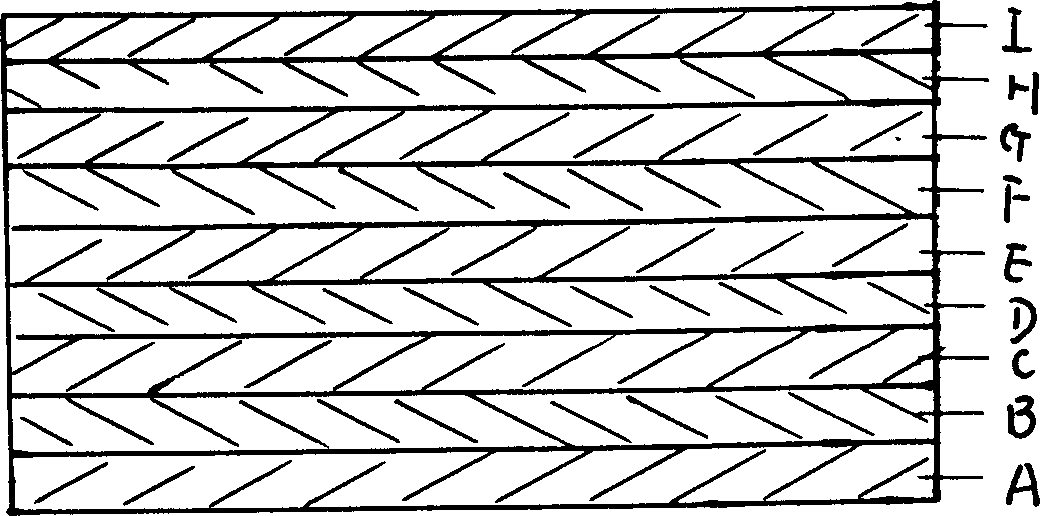

[0088] Preparation of nine-layer co-extruded blown film with high barrier of about 160 microns, see figure 1 .

[0089] The uppermost layer (I) uses an extruder to mix the main raw material resin PA and additives evenly in the mixing hopper at the front of the extruder, then plasticizes the resin at 160-280°C and extrudes it into the final part of the mold. In the runner of the upper layer (I);

[0090] For the second layer (H), use an extruder to plasticize the adhesive material resin at 160-280°C, and extrude it into the runner of the second layer (H) of the mould;

[0091] The third layer (G) uses an extruder to uniformly stir the main raw material resin PE and additives in the mixing hopper at the front of the extruder, then plasticizes the resin at 160-280°C and extrudes it into the first layer of the mold. In the flow channel of the third layer (G);

[0092] For the fourth layer (F), use an extruder to plasticize the adhesive material resin at 160-280°C, and extrude i...

Embodiment 2

[0102] Preparation of nine-layer co-extrusion blown film with high barrier of about 80 microns

[0103] The uppermost layer (I), with an extruder, the main raw material resin PA or PET and additives are uniformly stirred in the mixing hopper at the front of the extruder, and the resin is plasticized at 160-280°C, and extruded into the mold. In the runner of the uppermost layer (I);

[0104] For the second layer (H), use an extruder to plasticize the adhesive material resin at 160-280°C, and extrude it into the runner of the second layer (H) of the mould;

[0105] The third layer (G) uses an extruder to uniformly mix the main raw material resins LDPE, HDPE and additives in the mixing hopper at the front of the extruder, then plasticize the resin at 160-280°C and extrude it into the mold In the runner of the third layer (G), the weight ratio of LDPE to HDPE is 1:2. Additives may or may not be added here.

[0106] For the fourth layer (F), use an extruder to plasticize the adh...

Embodiment 3

[0113] Preparation of nine-layer co-extrusion blown film with high barrier of about 70 microns

[0114] The uppermost layer (I), with an extruder, the main raw material resin PP or HDPE and additives are uniformly stirred in the mixing hopper at the front end of the extruder, and the resin is plasticized at 160-280°C and extruded into the mold. In the runner of the uppermost layer (I);

[0115] For the second layer (H), use an extruder to plasticize the adhesive material resin at 160-280°C, and extrude it into the runner of the second layer (H) of the mould;

[0116] The third layer (G) uses an extruder to uniformly stir the main raw material resins HDPE, LLDPE and additives in the mixing hopper at the front of the extruder, then plasticizes the resin at 160-280°C and extrudes it into the mold In the runner of the third layer (G), wherein the weight ratio of HDPE to LLDPE is 1:3;

[0117]For the fourth layer (F), use an extruder to plasticize the adhesive material resin at 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com