Patents

Literature

265results about How to "Large adjustment space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

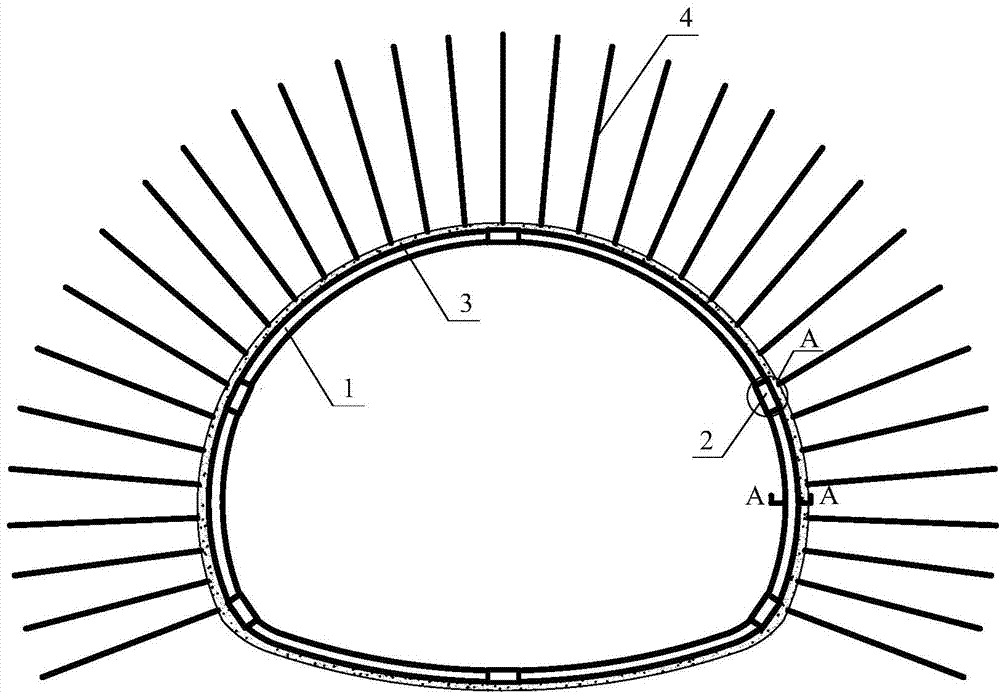

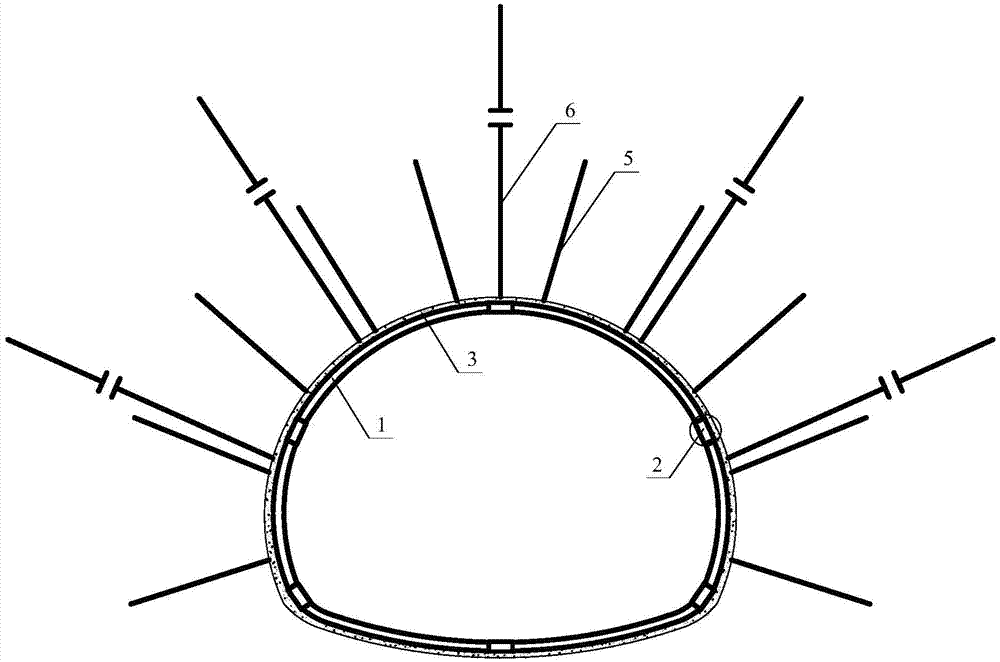

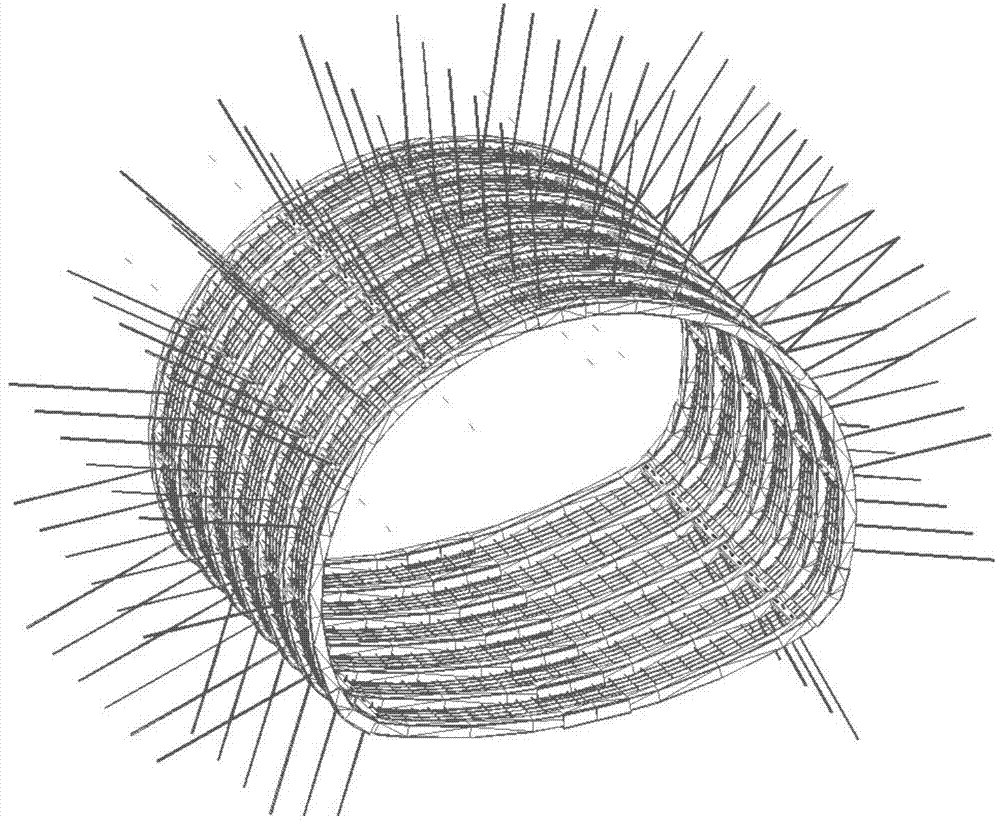

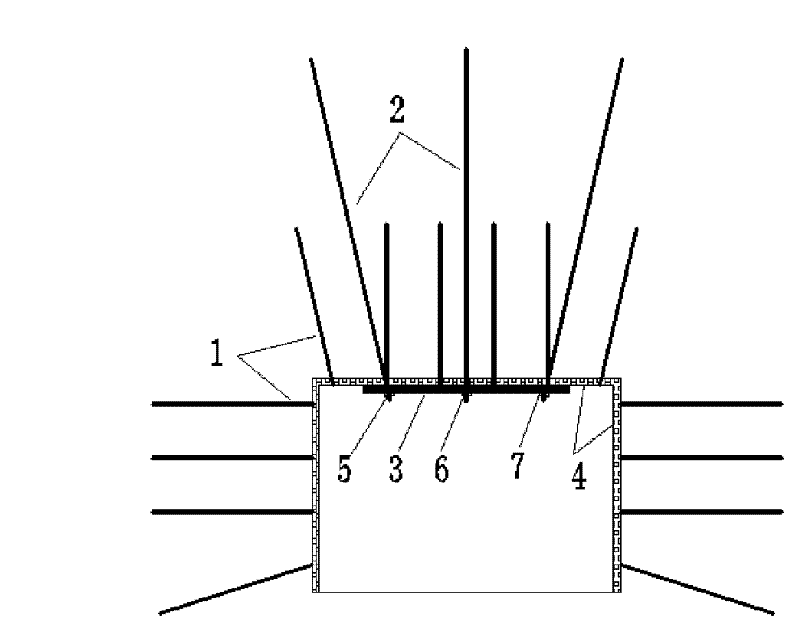

Square steel confined concrete arch center wall back filling bolting-grouting support system and construction method

InactiveCN103615273AImprove self-supporting capacityFill in timeAnchoring boltsSupporting systemRock tunnel

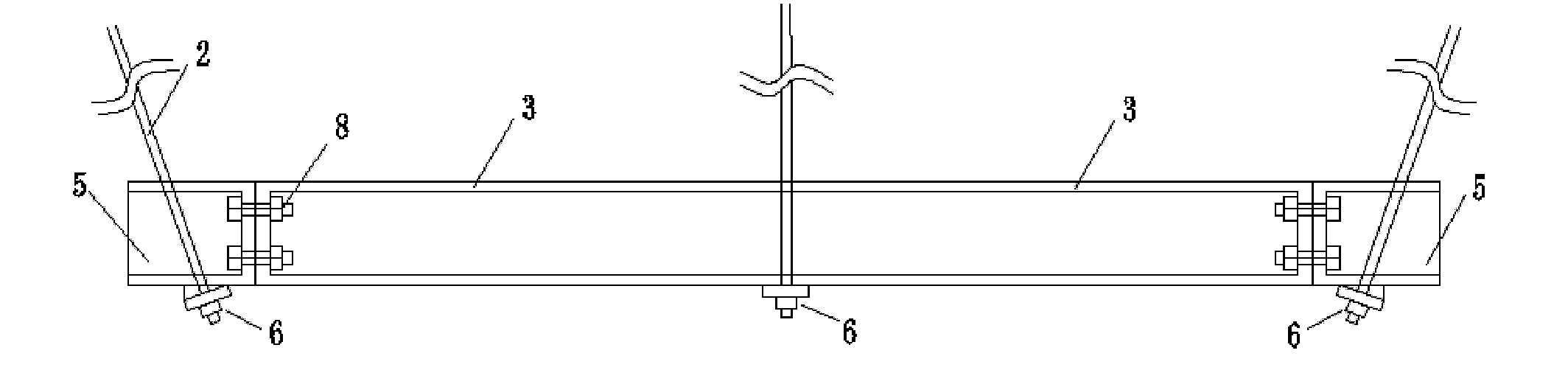

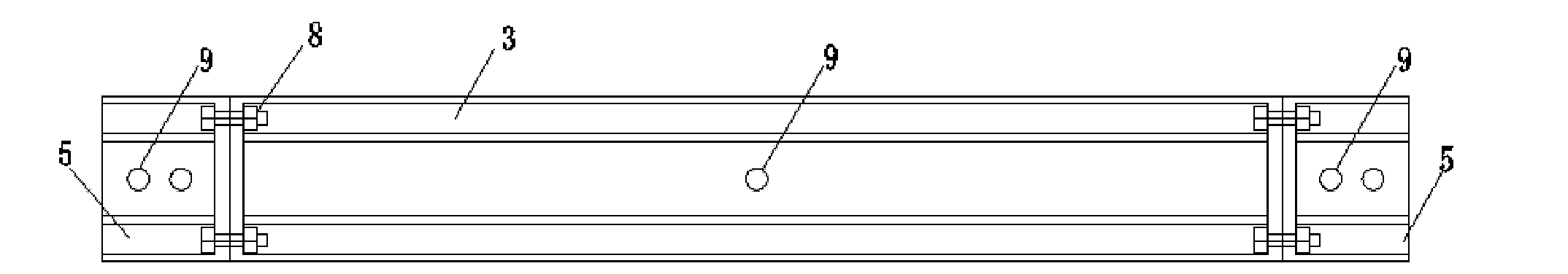

The invention discloses a square steel confined concrete arch center wall back filling bolting-grouting support system and a construction method. The square steel confined concrete arch center wall back filling bolting-grouting support system comprises high-strength anchor rods, grouting anchor rods, grouting anchor cables and multiple square steel confined concrete arch centers, wherein adjacent square steel confined concrete arch centers are connected through longitudinal beams, anchor rod holes are formed in the longitudinal beams, longitudinal beam anchor rods penetrate the longitudinal beams through the anchor rod holes to be anchored into a surrounding rock, a wall back filling layer is arranged between the square steel confined concrete arch centers and the surrounding rock, and the square steel confined concrete arch centers, the wall back filling layer and the tunnel surrounding rock are connected through the longitudinal beam anchor rods. The high-strength anchor rods, the grouting anchor rods and the grouting anchor cables are constructed before the square steel confined concrete arch centers are erected. The square steel confined concrete arch center wall back filling bolting-grouting support system and the construction method are applicable to supporting of underground projects including weak broken surrounding rock tunnels and the like, the square steel confined concrete arch center wall back filling bolting-grouting support system has the advantages of being high in strength, good in stability, reasonable in stress and the like, and the square steel confined concrete arch center wall back filling bolting-grouting support system and the construction method can effectively improve the primary supporting strength after tunnel excavation and ensure the stability of the tunnel surrounding rock.

Owner:SHANDONG UNIV

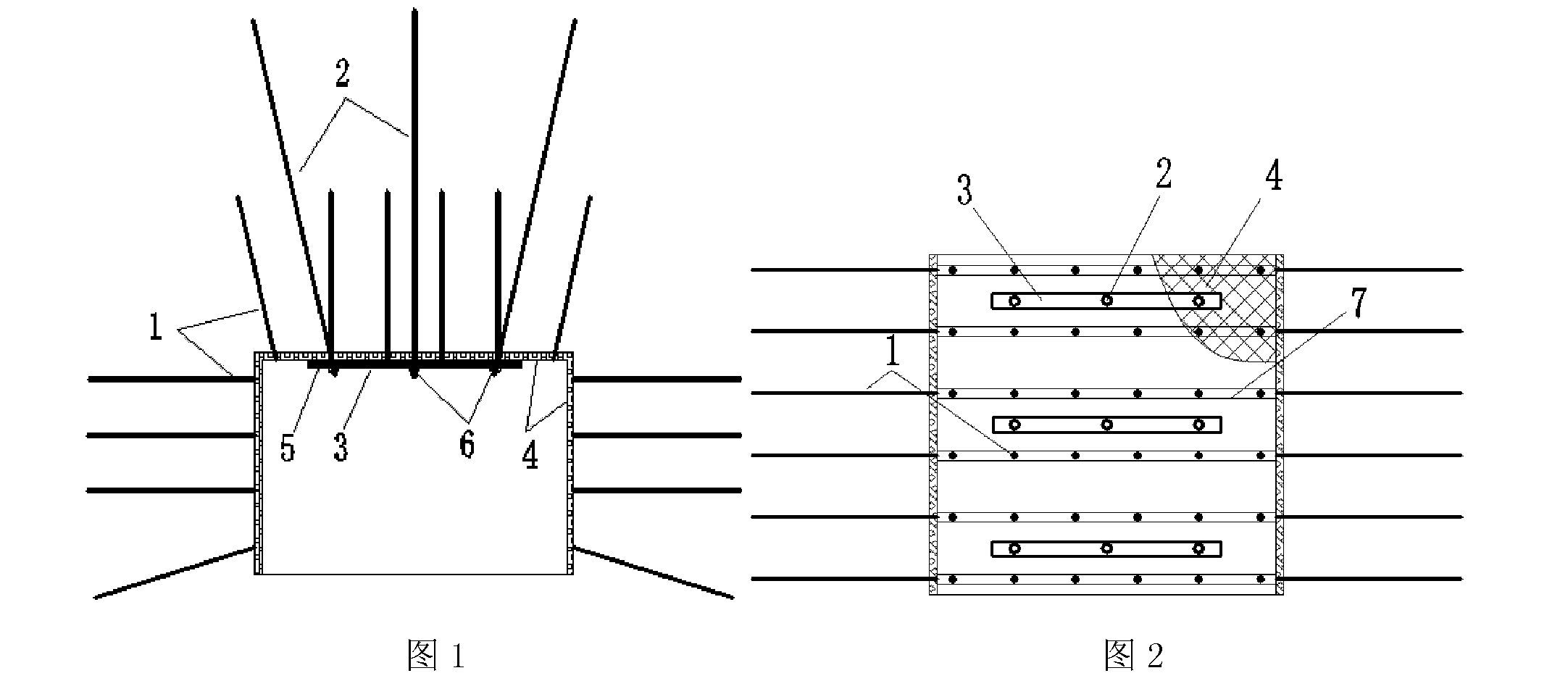

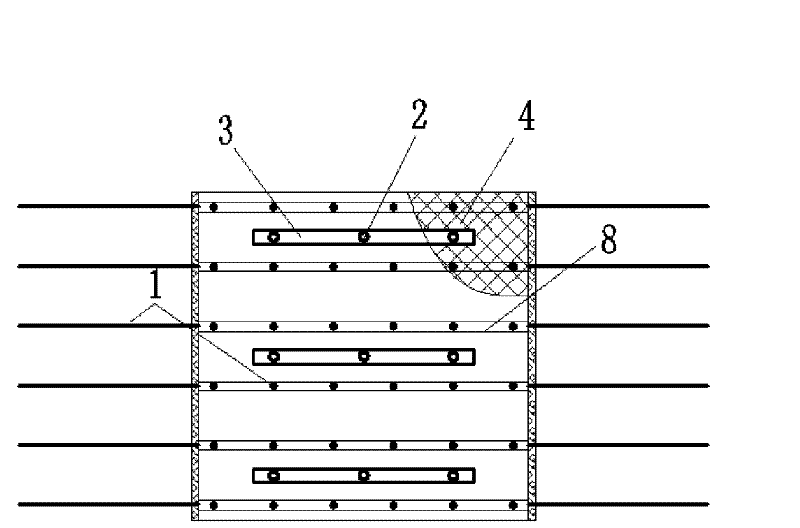

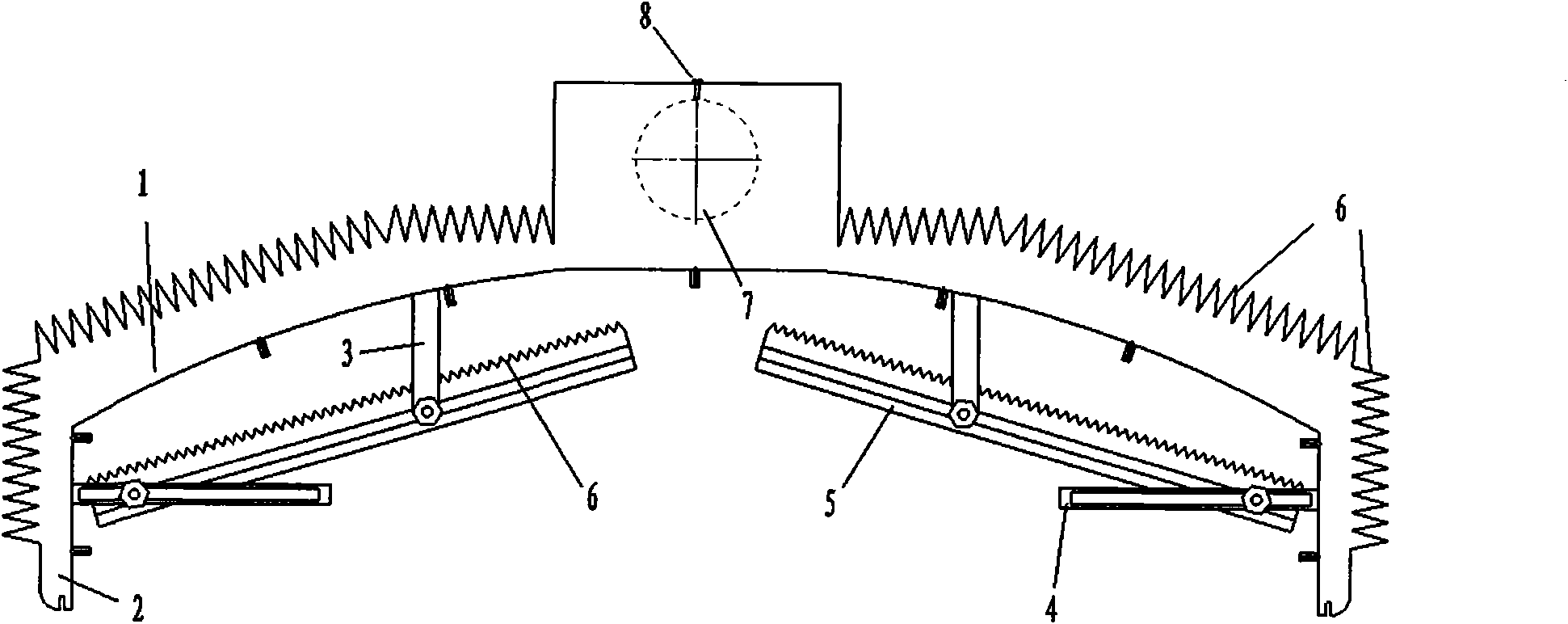

Semi-rigid abnormal beam anchor cable truss roadway supporting system

InactiveCN102182483AGuaranteed integrityEfficient deliveryMine roof capsAnchoring boltsSupporting systemRock bolt

The invention relates to a semi-rigid abnormal beam anchor cable truss roadway supporting system. A metal net is paved on the surface of a roadway, a semi-rigid abnormal beam anchor cable truss is arranged at a coal-rock roof or a roadway side, the semi-rigid abnormal beam anchor cable truss is formed by abnormal beams with semi-rigid nodes and anchor cables or anchor rods, and each abnormal beam is provided with a plurality of anchor cables or anchor rods; the anchor cables and anchor rods are anchored into a rock layer by passing through the abnormal beams and the metal net and apply a prestress to form an extrusion and annular protection function on surrounding rocks; and outer anchor ends of the anchor cables and anchor rods are provided with trays and locks, the trays and the locks make the end heads of the anchor cables or anchor rods tightly matched with the abnormal beams. The invention has the advantages that: (1), the protective surface area is large, the rigidity is high, stability is not easy to loss, and the integrality of the supporting system is ensured; (2), a steel material is saved, the cost is reduced, and the efficiency is increased; (3), the strength is high, and the regulation space of the whole supporting performance is large; and (4) the semi-rigid nodes can play a role of better flexible yield, and the stability and the safety of the whole supporting system are ensured.

Owner:SHANDONG UNIV

High resistively nine-layer co-extrusion-blown moulding film and its preparation process

InactiveCN1724254AAvoid pollutionReduce processSynthetic resin layered productsSurface layerEngineering

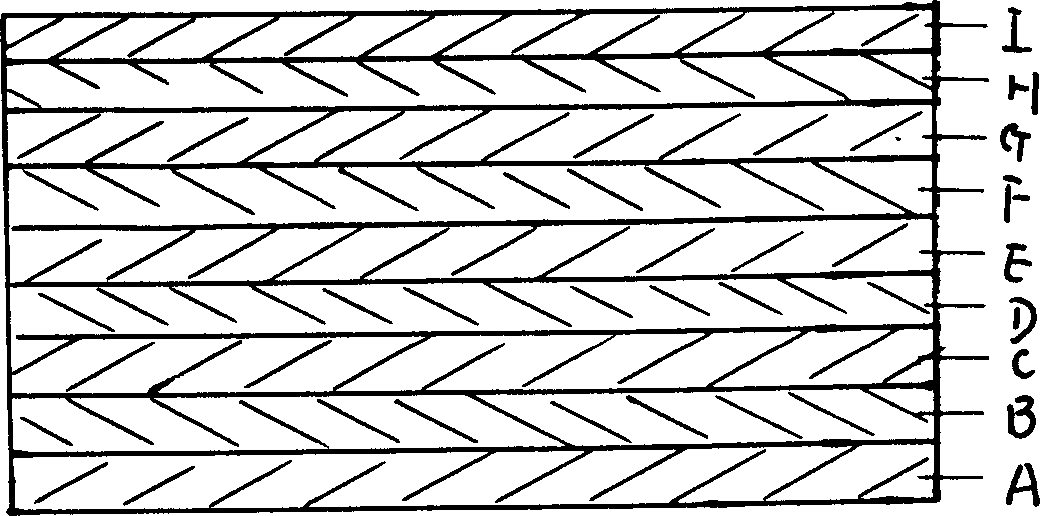

A high-isolation 9-layer plastic film with 25-300 microns in thickness and high mechanical and optical performance has an external surface layer and a thermally sealed bottom layer and is prepared through extruding out 9 film layers, overlapping via a single die, and co-extruding out while blow moulding.

Owner:S & H SPECIAL NEW MATERIAL JIANGYIN

Gas oil base invert oil-emulsion drilling fluid and preparation method

InactiveCN102796497AStrong salt resistanceGood temperature resistanceDrilling compositionTemperature resistanceChemistry

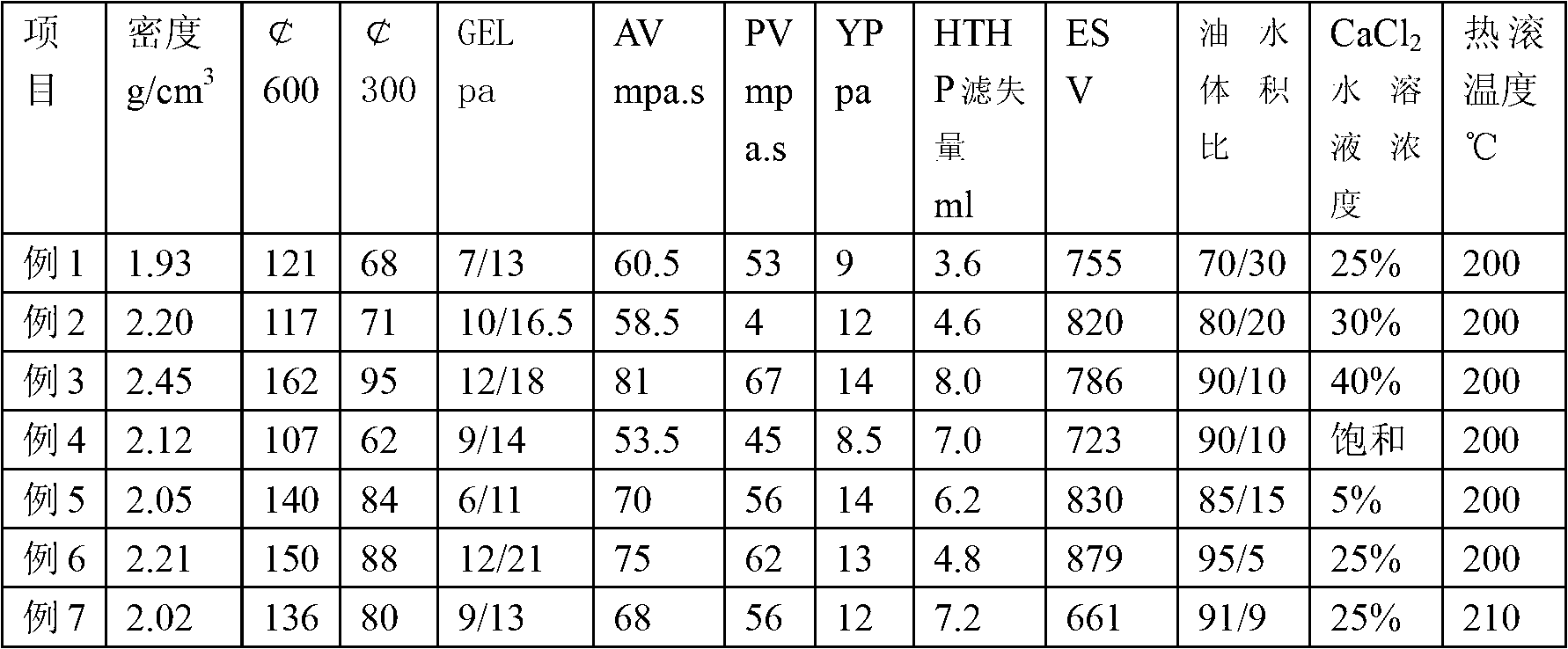

The invention relates to a gas oil base invert oil-emulsion drilling fluid and a preparation method, wherein the total volume of gas oil and calcium chloride aqueous solution is 100 parts: the volume ratio of oil phase to water phase is between 95:5 and 70:30, and the concentration of calcium chloride aqueous solution is 5%-saturation; the required gas oil, primary emulsion, auxiliary emulsion and wetting agent are added into a high speed mixing beaker, and are mixed at high speed for 2-5 minutes; the calcium chloride aqueous solution is added and mixed at high speed for 15 minutes; organic soil, calcium oxide and a fluid loss agent are added and mixed at high speed for 10 minutes; and the required amount of barite is added according to density, and is mixed at high speed for 25 minutes. The gas oil base invert oil-emulsion drilling fluid is used for overcoming the defects of the existing gas oil base drilling fluid and solving the problems of the salt resistance and temperature resistance of the gas oil base drilling fluid, and can resist the temperature above 200 DEG C.

Owner:COSL CHEM TIANJIN +1

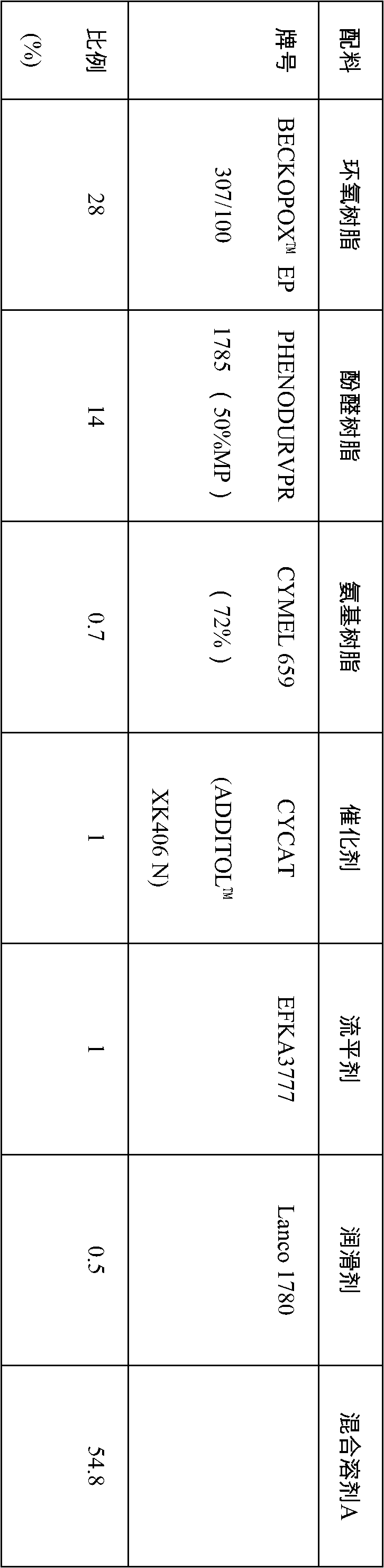

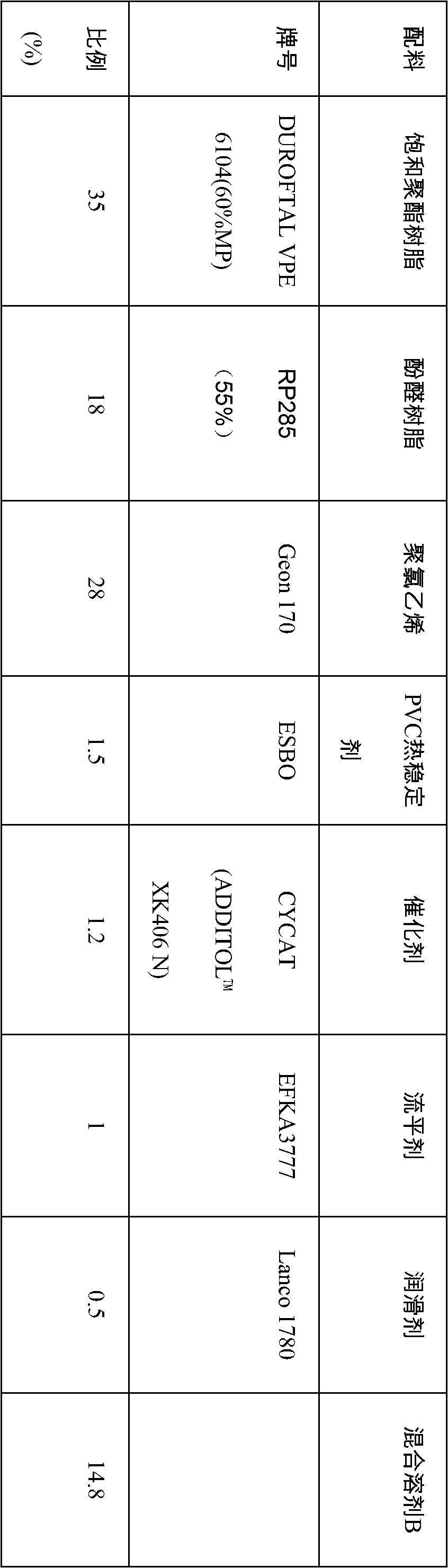

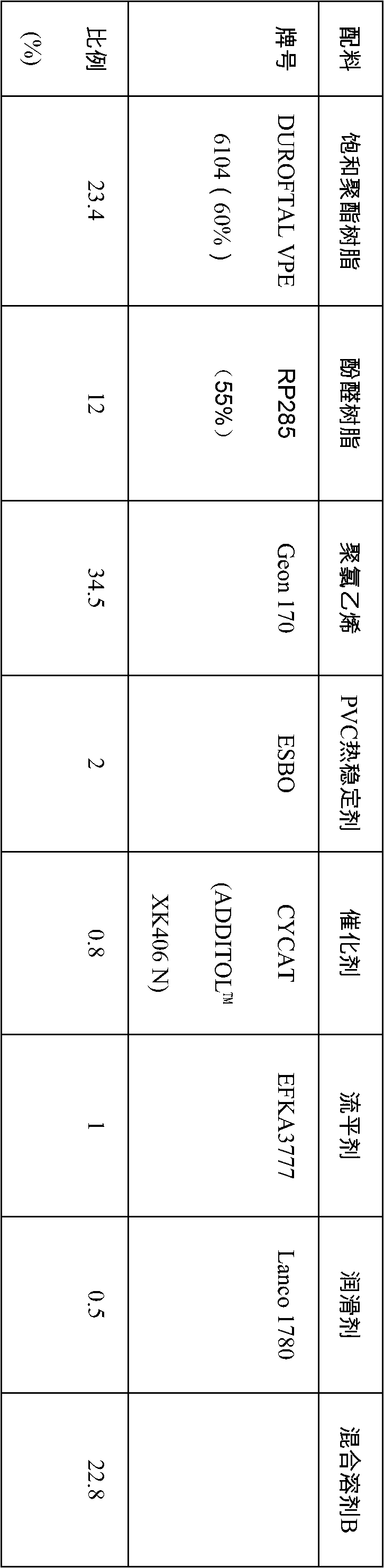

Coating composition and application of coating composition to metal base material

The invention discloses a coating composition and an application of the coating composition to a metal base material. The solid content of the coating composition is 40-70%. The coating composition comprises the following components of, by weight, 5-60% of saturation polyester resins, 0-25% of crylic acid resins, 2-30% of crossing-link agents, 20-80% of polyvinyl chloride homopolymer, 0-15% of additives, 0-40% of pigments and the balance dilution solvents, wherein average molecular weight Mn of the saturation polyester resins is 3000-8000, the vitrification temperature of the saturation polyester resins is 10-20 DEG C, the acid value of the saturation polyester resins is 0-5, the hydroxyl value of the saturation polyester resins is 30-90, and the saturation polyester resins are free of neopentyl glycol. The coating composition is free of bisphenol-A diglycidyl glycerol ether (BADGE) and bisphenol A (BPA). According to the coating composition, the polyester resins which meet requirements can be easily obtained, improved space of resin performances is large, 40%-70% of the solid content of final products can be achieved, and a large quantity of organic solvents are saved.

Owner:HANGZHOU CPMC +1

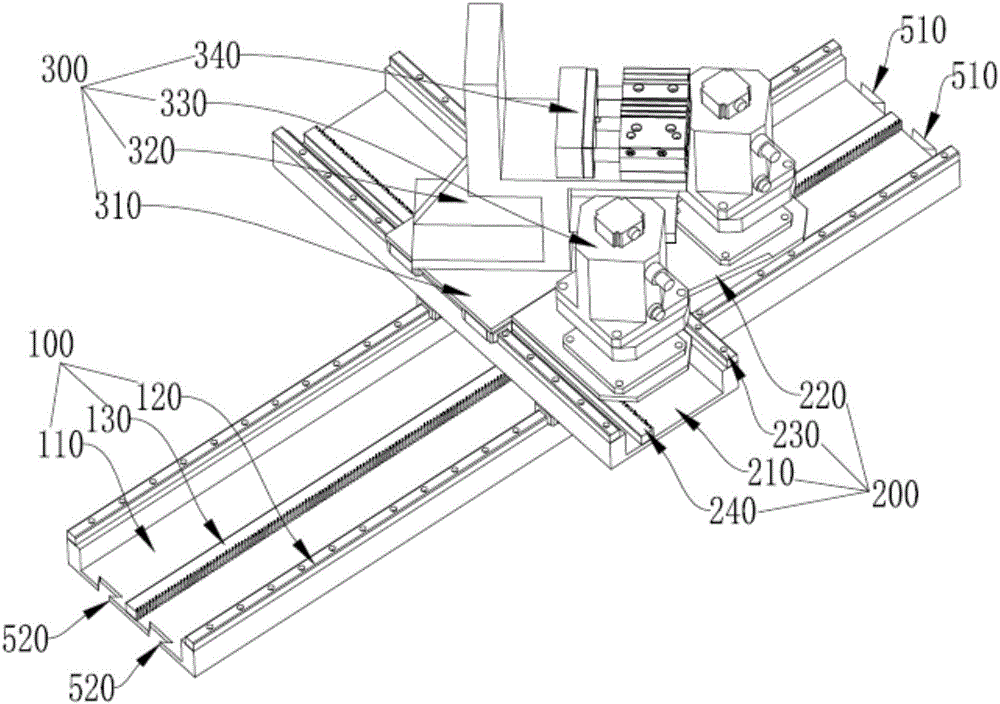

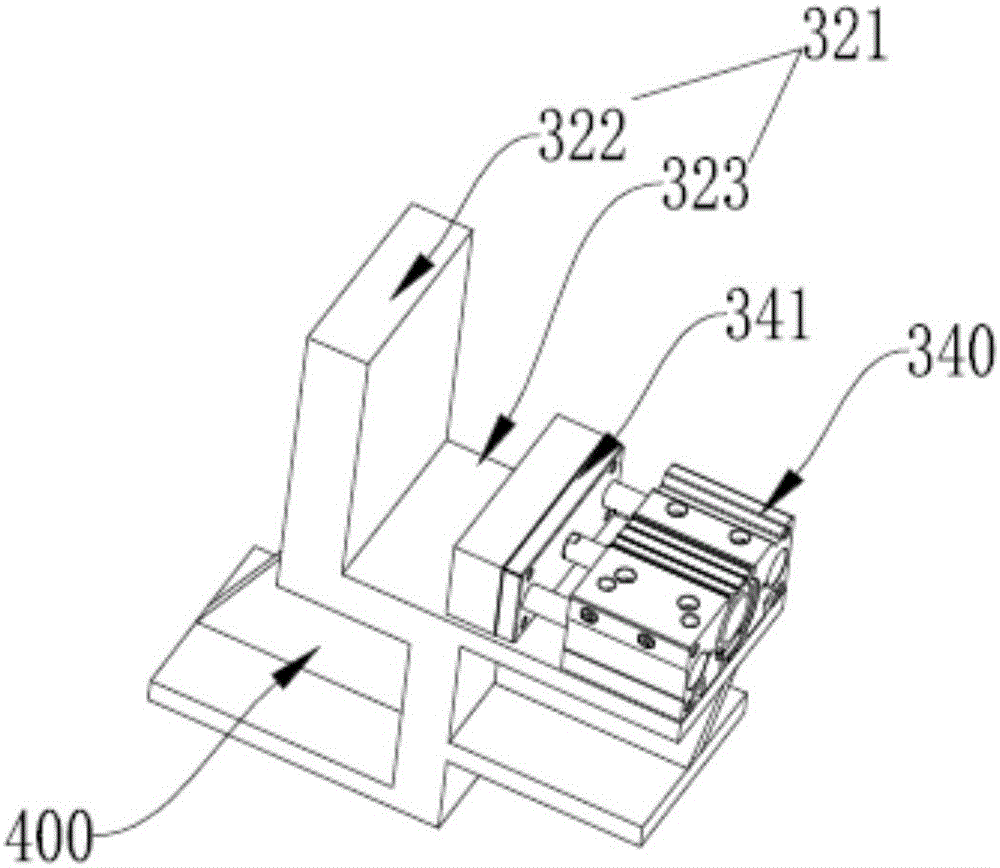

Combined clamp

ActiveCN106271736AAdjust levelIncrease the itineraryLarge fixed membersPositioning apparatusShortest distanceComputer module

The invention provides a combined clamp which comprises adjustable clamps and a positioning clamp; each adjustable clamp is composed of an X-direction track module, an Y-direction track module and a clamp module; each clamp module is installed on the corresponding Y-direction track module in a sliding manner; each Y-direction track module is installed on the corresponding X-direction track module in the sliding manner; connection devices are arranged at the head and the tail of each X-direction track module; and each X-direction track module has the function of extending a stroke. According to the combined clamp provided by the invention, the X-direction track modules can be mutually spliced, so that the stroke is extended, and the combined clamp can be used in different spaces; each Y-direction track module which walks on the corresponding X-direction track module can have a short-distance Y-direction track, so that after being installed on the corresponding Y-direction track module in the sliding manner, each clamp module can has a larger adjustment space in the X direction and the Y direction, and in this case, more workpieces with different sizes can be clamped; and in addition, after the workpieces are clamped, the combined clamp has the adjustment function.

Owner:FOSHAN PRATIC CNC SCI & TECH

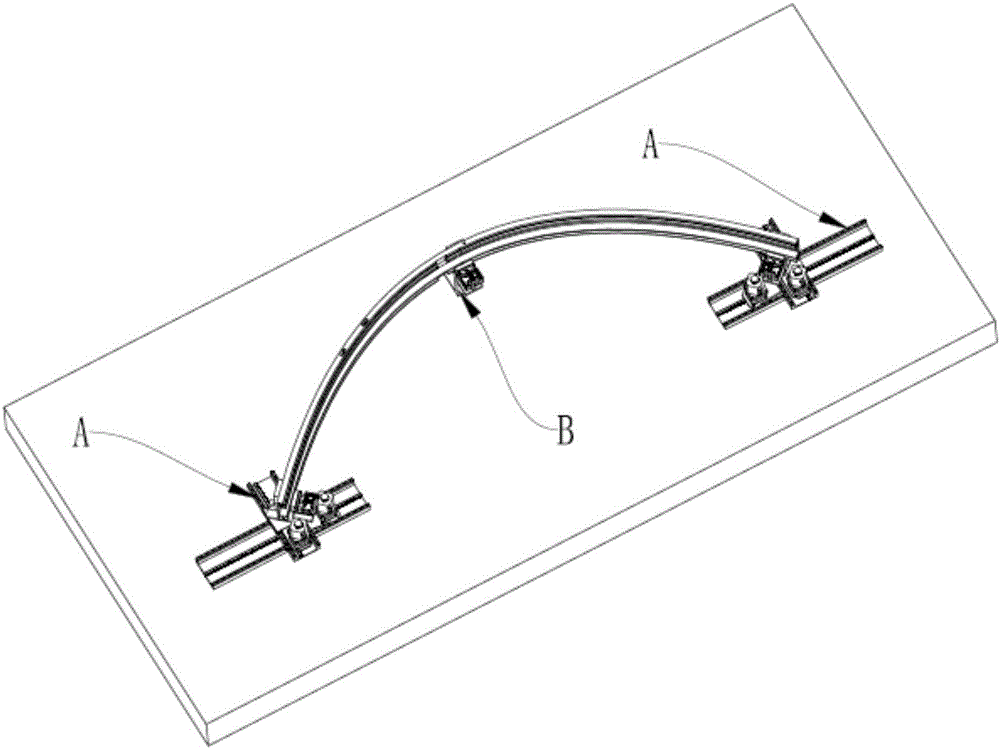

Yielding type special-shaped beam anchor rope truss roadway support system

InactiveCN102200020AIncrease surface areaGuaranteed integrityAnchoring boltsSupporting systemShaped beam

The invention relates to a yielding type special-shaped beam anchor rope truss roadway support system. A metal net is laid on the surface of the roadway. A yielding type special-shaped beam anchor rope truss is arranged on the coal rock roof or roadside. The yielding type special-shaped beam anchor rope truss comprises special-shaped beams, a yielding device and anchor ropes or anchor rods, wherein each special-shaped beam is provided with a plurality of anchor ropes or anchor rods; the anchor ropes or anchor rods penetrate through the special-shaped beams and the metal net and are anchored into rock layers; and outer anchoring ends of the anchor ropes and anchor rods are provided with the yielding device and a tray for letting the end tips of the anchor ropes and anchor rods to be in contact with the special-shaped beams and exerting yielding action. The yielding type special-shaped beam anchor rope truss roadway support system has the advantages of large surface protecting area and high rigidity and is not easy to become unstable; steel is saved, cost is reduced, and efficiency is improved; strength is high, the performance adjustment space of an entire support is great; and the yielding device plays the action of effective yielding, and coupling yielding support ensures the stability and safety of the entire support system.

Owner:SHANDONG UNIV

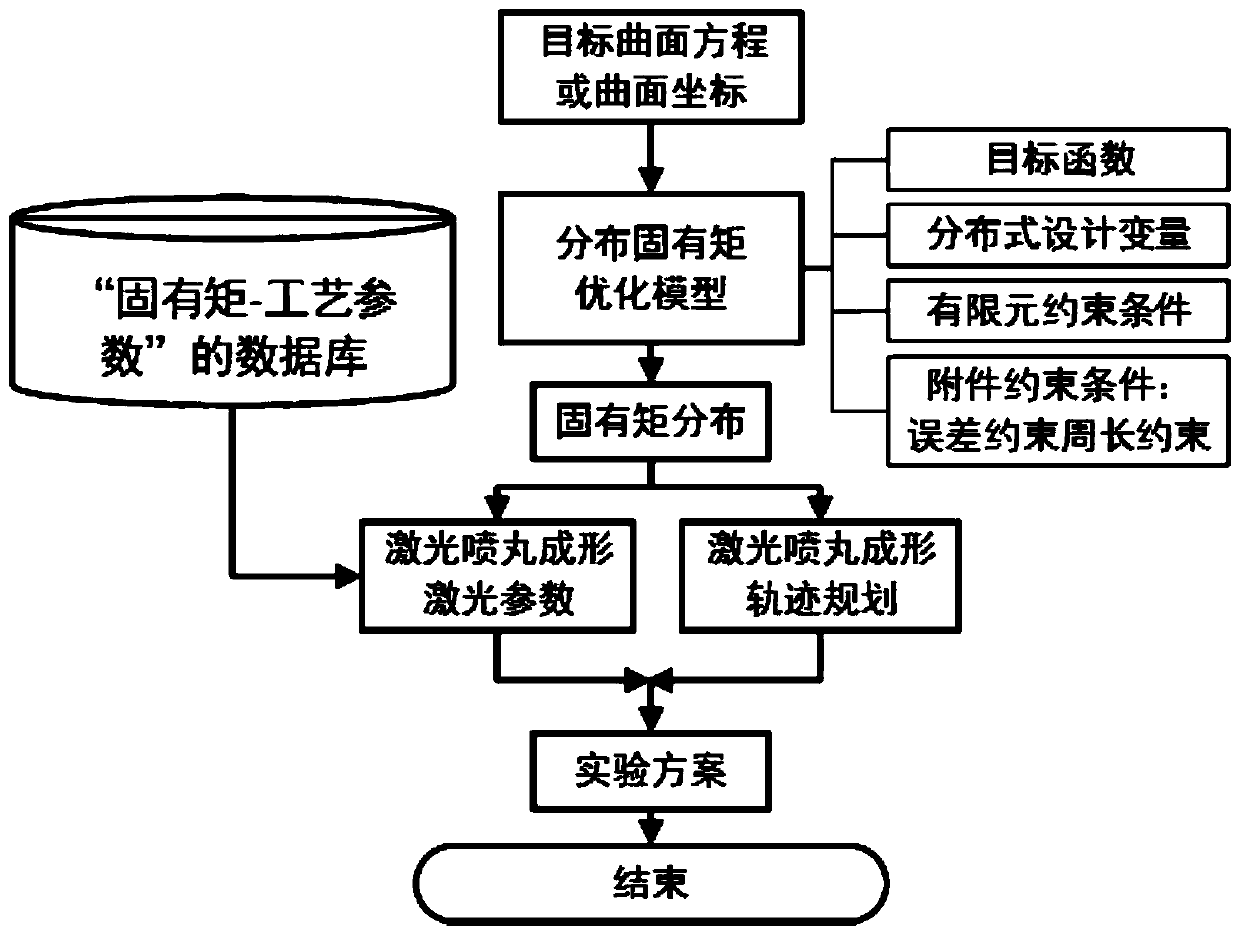

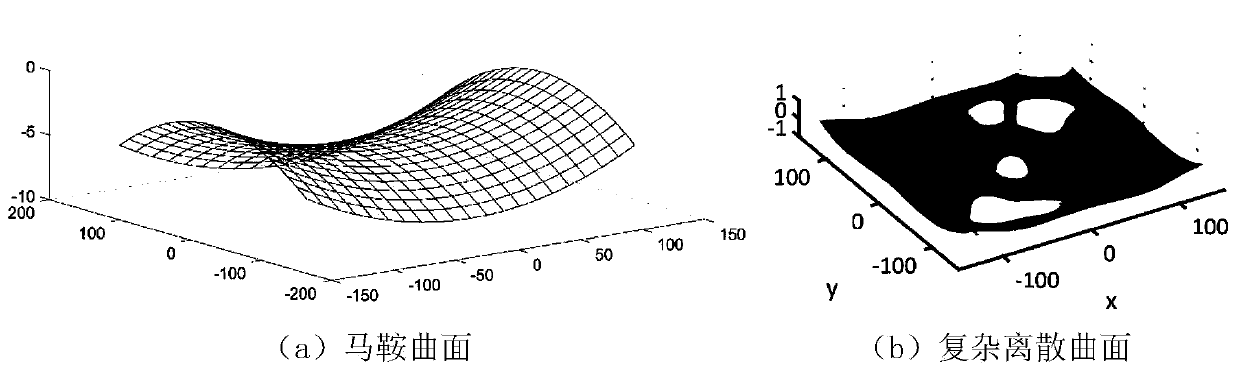

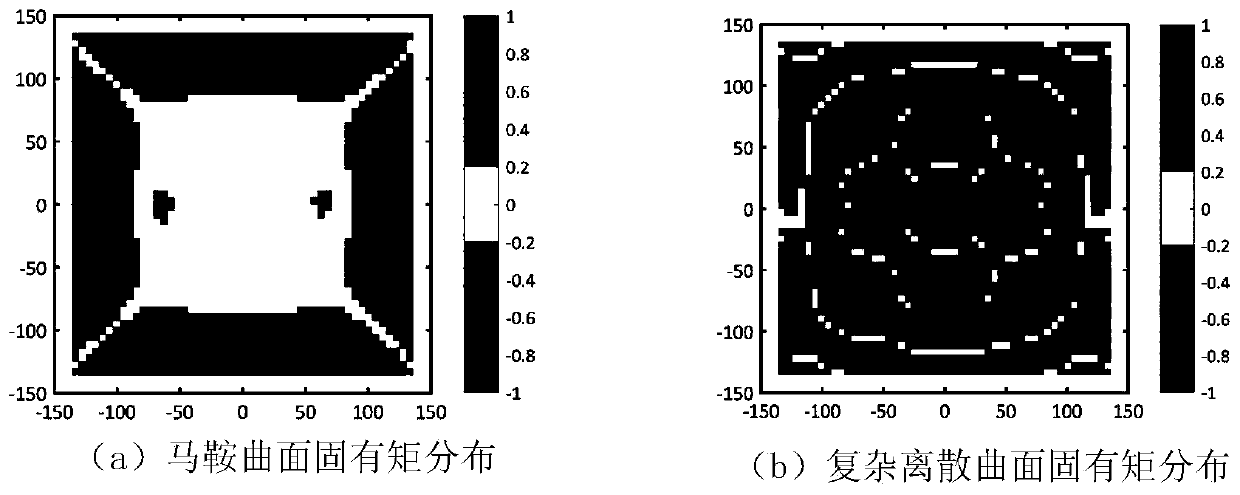

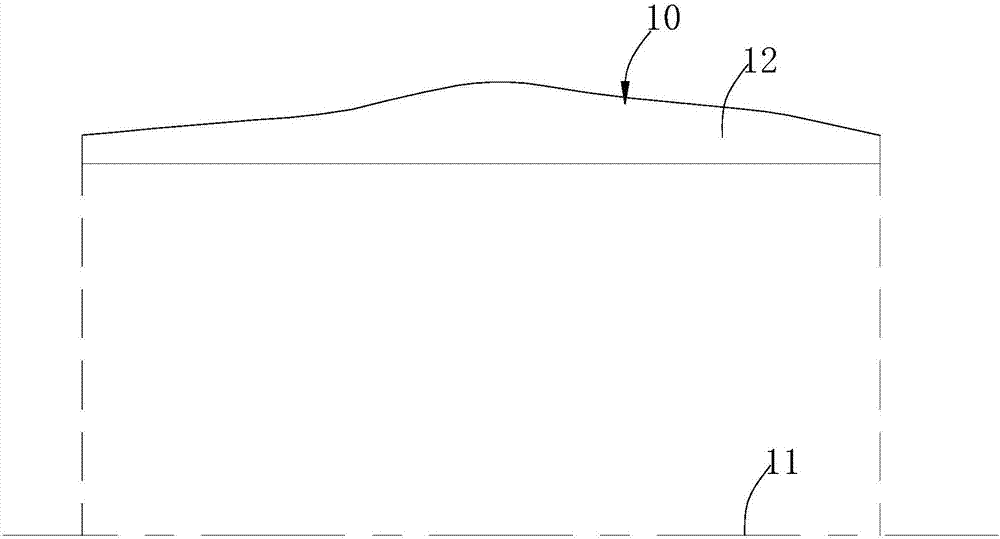

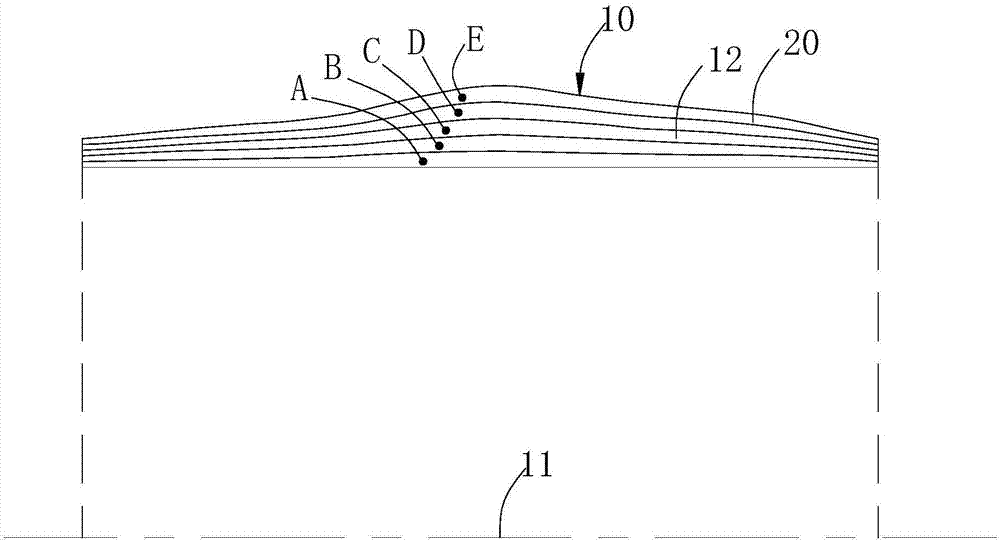

Method for determining distributed process parameters of laser peening forming complex curved surface

ActiveCN110543654AImprove fatigue resistanceAccelerated corrosionComplex mathematical operationsShell theoryPartial differential equation

The invention provides a method for determining distributed process parameters of a laser peening forming complex curved surface. The method comprises the following steps: establishing a function relationship between a deflection curved surface and an intrinsic moment based on plate shell mechanics, and establishing an optimization model based on partial differential equation constraint by takinga distributed intrinsic moment function as a design variable; according to a curved surface parameter equation or a curved surface coordinate of the workpiece, dispersing a target curved surface, selecting an appropriate optimization algorithm to solve an optimization model, and calculating a distributed natural moment; dividing into a plurality of isoparametric areas convenient for process operation according to the size of the distributed natural moment, and determining a laser peening forming scanning scheme in each area; and establishing a process database corresponding to process parameters and inherent moments through experiments, determining the experiment process parameters, and determining the optimal distributed process parameters in combination with the requirements of residualstress. The method for determining the complex curved surface forming technological parameters is established on the basis of the elastic plate shell theory, and high efficiency and precision are achieved.

Owner:SHANGHAI JIAO TONG UNIV

Electric deposition nickel pottery plating solution and preparing method thereof

The invention provides an electric deposition nickel pottery plating solution and a preparing method thereof. The method is characterized by using electric deposition nickel or nickel-base alloy plating solution as base plating solution, and adding insoluble inorganic nonmetallic micron-grade particles pretreated by non-ionic potyoxyethylene ether surfactant in the base plating solution, so that nickel pottery coating is deposited on a metal matrix. The invention employing non-ionic activator can effectively increase decentrality, stability, evenness and suspension degree of particles, promote codeposition for particles, reduce particle content in the plating solution, improve conductivity of the plating solution, and greatly increase organization performance of the nickel-base composite coating. The invention has advantages of simple process and easy execution.

Owner:HEFEI UNIV OF TECH

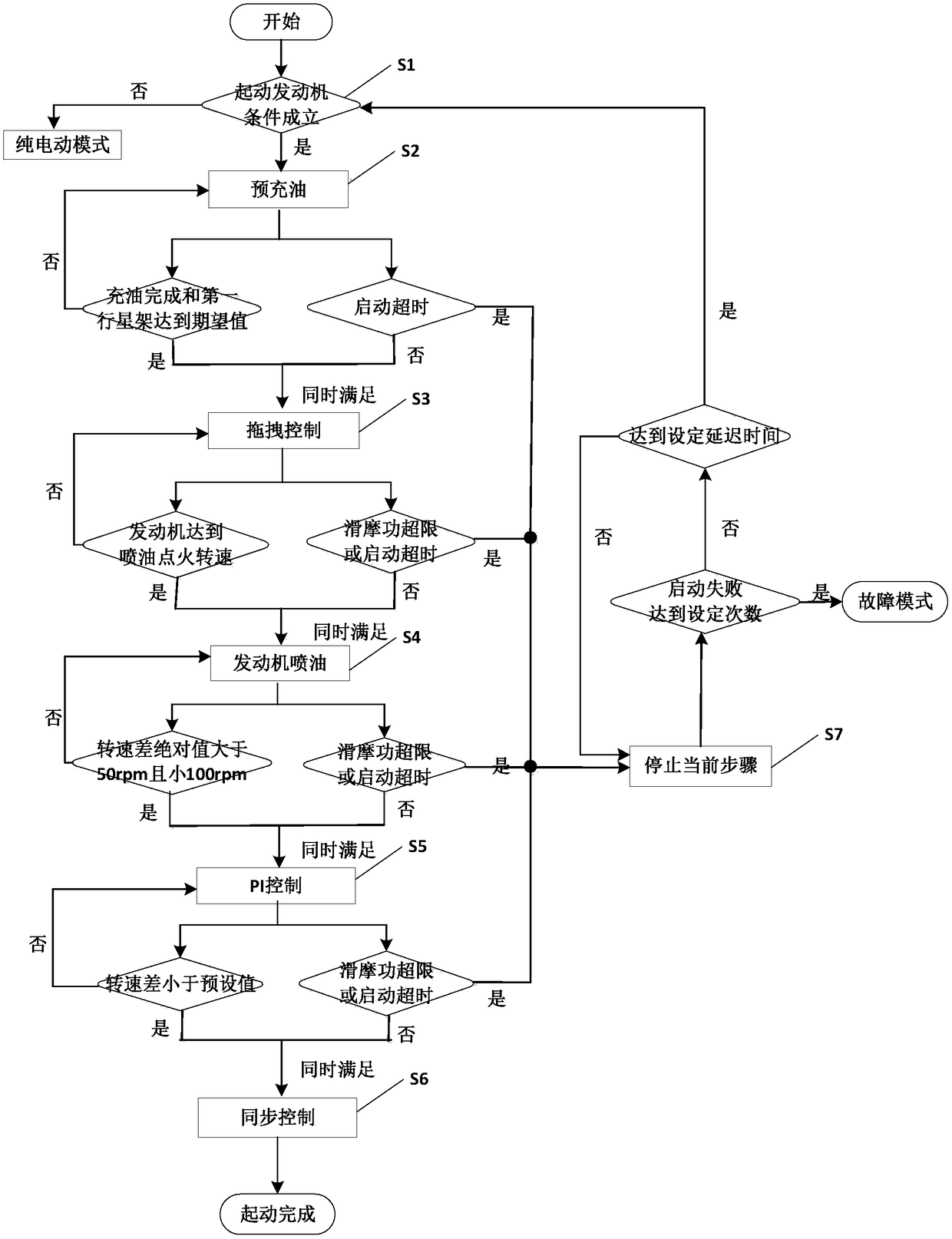

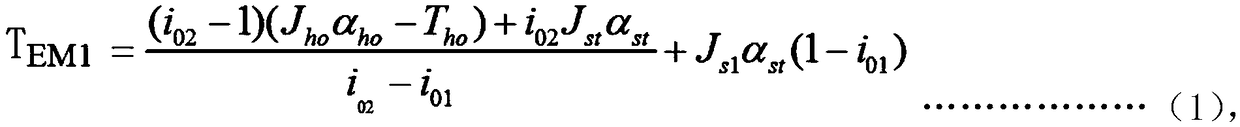

Control method for starting engine by using clutch of deep hybrid power automobile

The invention provides a control method for starting an engine by using a clutch of a deep hybrid power automobile. The method comprises the steps that whether or not starting demands of the engine are met is judged by a starting demand judging module, if yes, the steps of oil filling of a first clutch, the dragging of an engine of the first clutch, oil spraying control of the engine, PI controlling and first clutch closing are sequentially conducted, and the starting of the engine is completed; during the oil filling process of the first clutch, starting process time tes of a current engine is judged, slipping work Q of a unit area of a current first clutch and the starting process time tes of the engine are judged in the steps of the dragging of the engine of the first clutch, the oil spraying control of the engine and the PI controlling, if judging results exceed limiting values, current steps are ceased, whether or not judging failing times are exceeded is judged, and judging stepsof the starting demands of the engine are executed again or a fault mode is entered according to judging results. The method is easy and achievable, and the smoothness of the starting process of theengine can be ensured to prevent the shaking of the automobile.

Owner:科力远混合动力技术有限公司

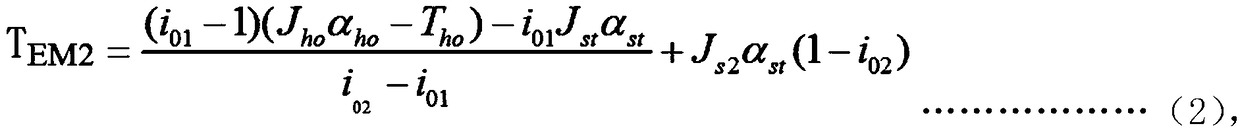

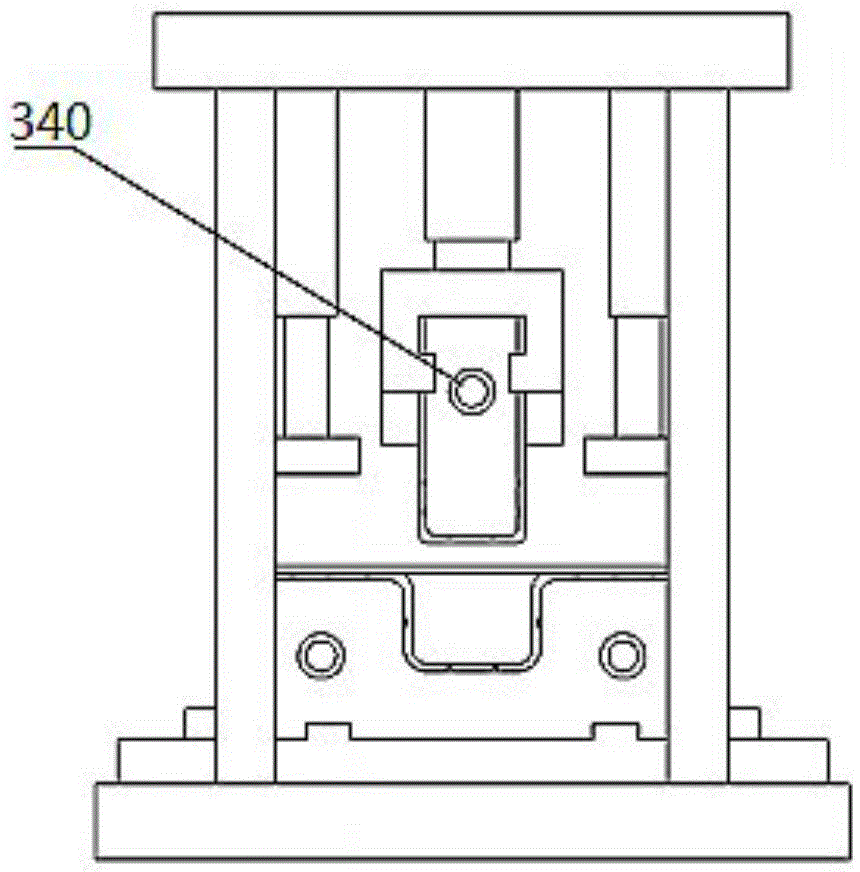

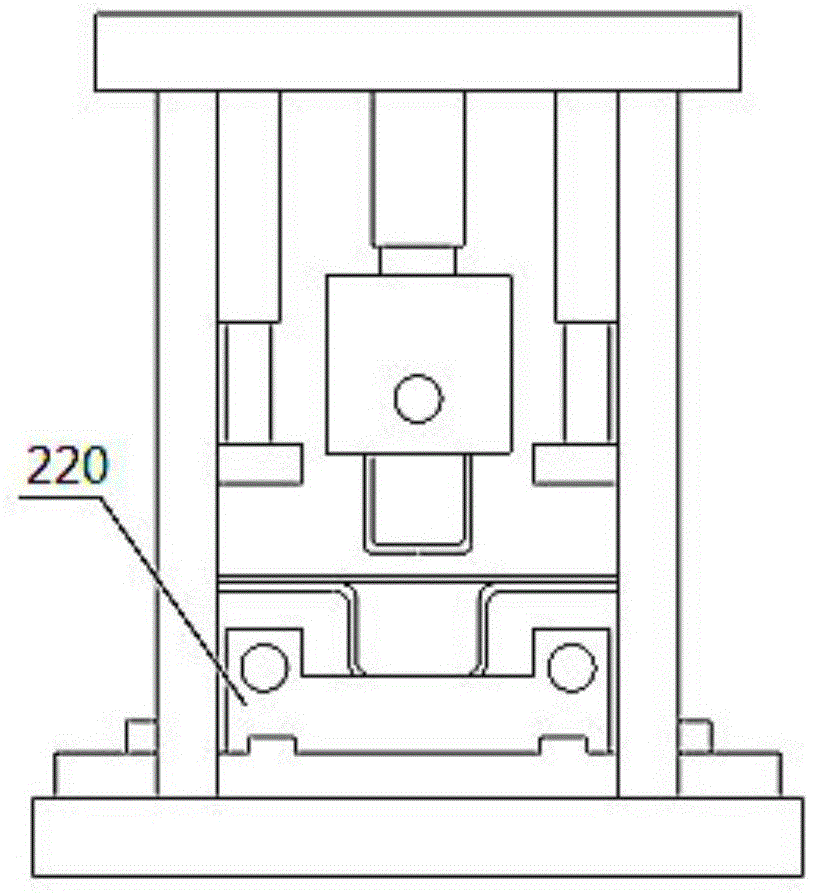

Hot forming punching device of automobile energy absorbing structure and punching method

InactiveCN105598282AOptimal intensity distributionAchieve preparationShaping toolsPunchingSheet steel

The invention discloses a hot forming punching device of an automobile energy absorbing structure. The hot forming punching device comprises an assembled female die, an assembled male die, a blank holder and a driving mechanism, wherein the assembled die comprises a plurality of female templates which are tightly and fixedly connected with one another; the assembled male die is arranged below the assembled female die and comprises a plurality of male templates which are tightly and fixedly connected with one another; the blank holder is arranged above the assembled female die and is used for pressing a steel plate to be punched; the driving mechanism is respectively connected with the assembled male die and the blank holder and drives the assembled male die and the blank holder to move downward to perform punching operation; cooling channels are formed in the female templates and / or the male templates. The invention further provides a hot forming punching method of the automobile energy absorbing structure. In the device, as each template is provided with an independent cooling channel, the adjusting space of cooling rate is great, and various strengths and optimal distribution of the strengths can be realized according to the requirements.

Owner:JILIN UNIV

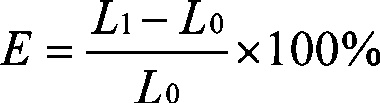

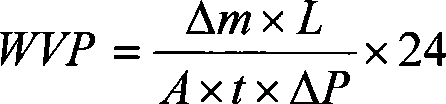

Degradable non-poisonous seed-coating agent and preparation method thereof

InactiveCN101416650AHigh adhesionSeed coat capacity is goodBiocideAnimal repellantsChemistryApparent viscosity

A degradable nontoxic seed coating agent comprises basic materials of water-soluble chitosan of 1.0-1.5wt%, gelatine of 0.05-0.1wt%, glycerol of 0.05-0.1wt%, PVA of 1.0-1.5wt% and plant extract of remainder, with the tensile strength of 18.7MPa, elongation of 10.1%, vapor transmission rate of 12.69g.mm / mm2.hr.mmHg, air permeability of (CO2)0.358*10-10ml.cm / cm2s.cmHg, air permeability of (O2)0.215*10-10ml.cm / cm2s.cmHg, hygroscopic rate of 47% and apparent viscosity of 290cp; uses water-soluble chitosan, PVA and plant extract to form seed coating film to not only meet performance requirement of conventional seed coating agents, but remarkably improve performance of film.

Owner:DALIAN POLYTECHNIC UNIVERSITY

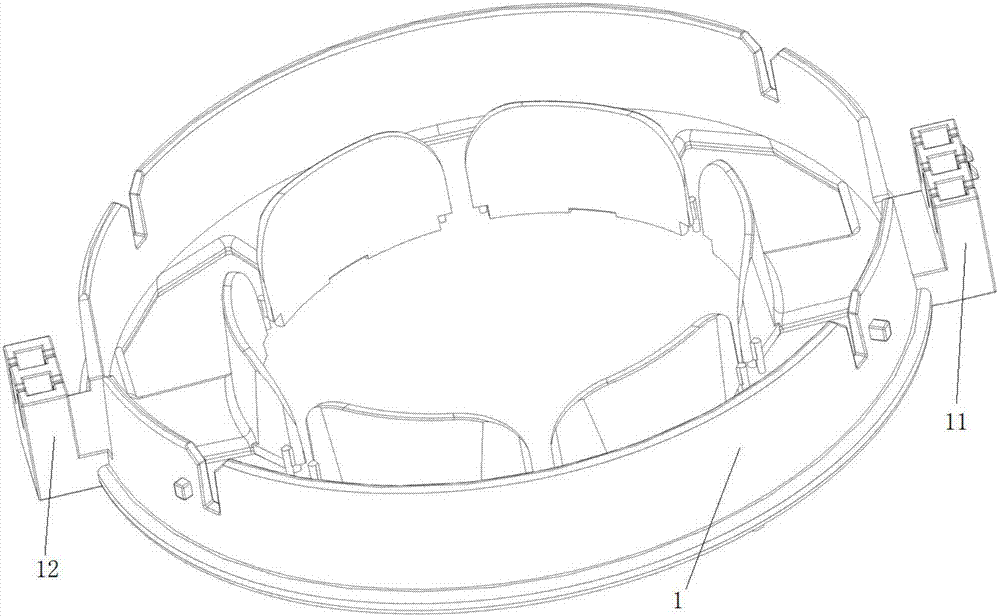

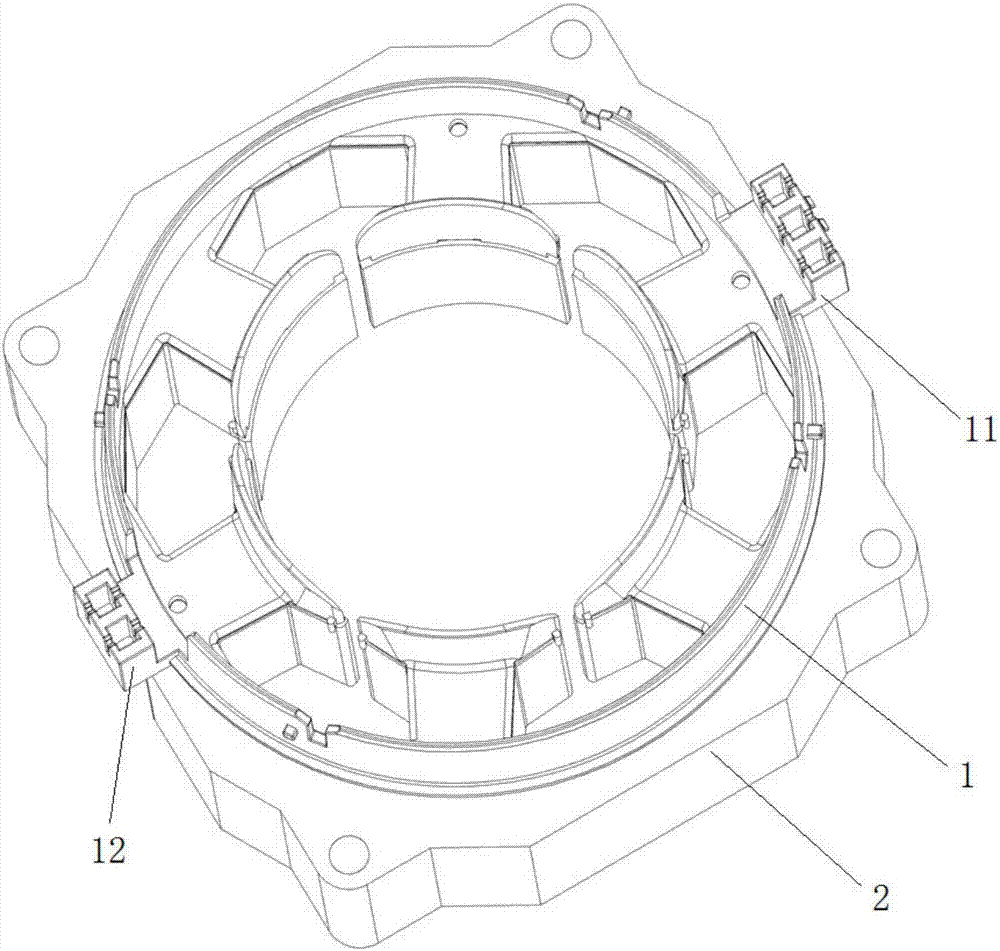

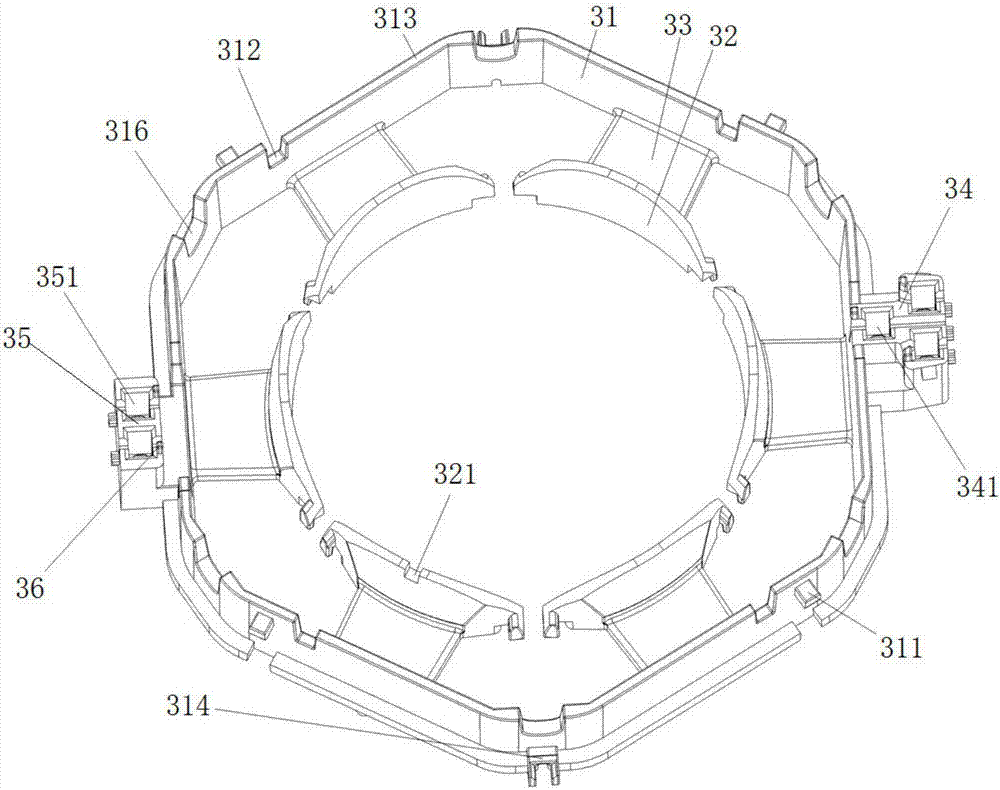

Insulation framework and motor stator

ActiveCN107492968ALarge adjustment spaceEasy to adjustWindings insulation shape/form/constructionEngineeringElectrical and Electronics engineering

The invention relates to an insulation framework and a motor stator, and relates to the technical field of a motor. The insulation framework comprises an insulation framework main body, wherein a three-phase leading-out line terminal slot part is arranged on the insulation framework main body, three terminal slots are formed in the three-phase leading-out line terminal slot part, a line pressing terminal is arranged in each terminal slot, and the centers of the three terminal slots in the three-phase leading-out line terminal slot part are not in a straight line. The motor stator comprises the insulation framework. By the insulation framework, the creepage distance among the line pressing terminals in the three terminal slots in the three-phase leading-out line terminal slot part of the insulation framework can be effectively extended, so that the insulation pressure-resistant grades among three-phase winding enameled wires and among the line pressing terminals are improved, and finally, the running reliability of the motor is improved.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

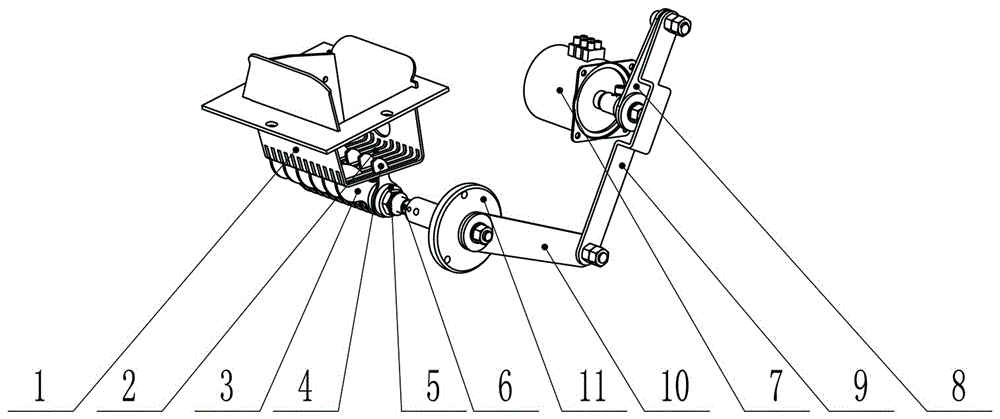

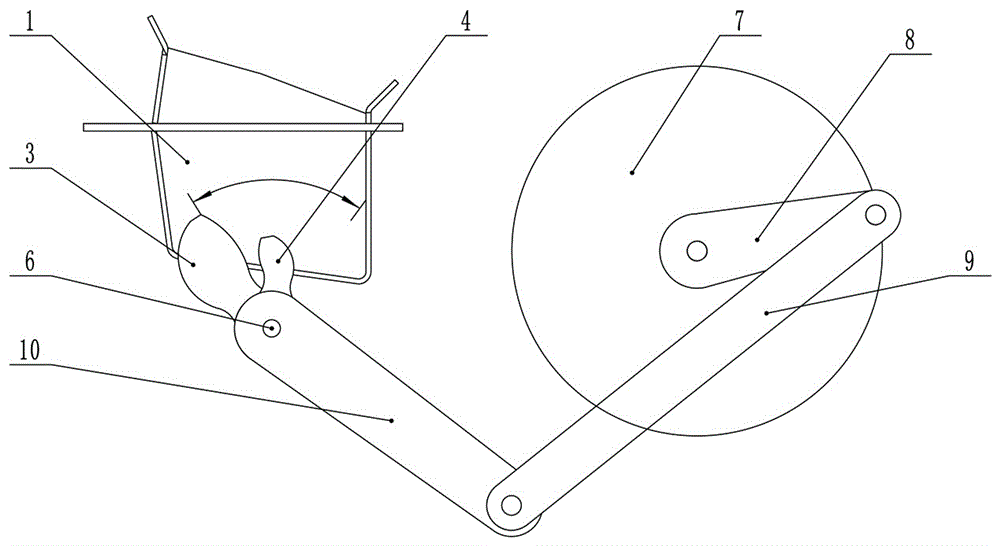

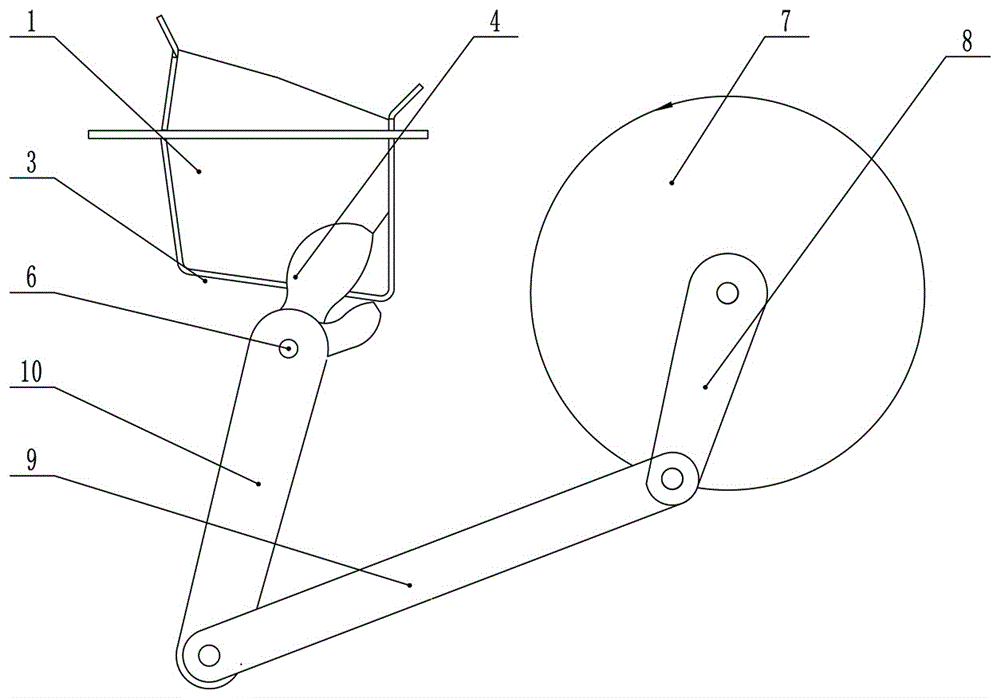

Automatic slag removal structure of biomass particle fireplace

PendingCN106765231AAvoid dischargeSufficient air intakeLighting and heating apparatusCushioningMotor drive

The invention provides an automatic slag removal structure of a biomass particle fireplace. The automatic slag removal structure comprises a combustion pool, a slag removal ventilation device and a power mechanism, wherein a plurality of rows of groove-shaped air vents are formed in the bottom of the combustion pool; the slag removal ventilation device comprises a rotary shaft as well as slag removal tooth sheets and ventilation tooth sheets which are installed on the rotary shaft at intervals, and retaining rings are arranged between the slag removal tooth sheets and the ventilation tooth sheets in a cushioning manner so that the slag removal tooth sheets and the ventilation tooth sheets are inserted in the groove-shaped air vents at intervals and in a staggered manner; a speed reduction motor drives the rotary shaft to carry out reciprocating swing motion through a crank-link mechanism; and included angles are arranged between the slag removal tooth sheets and the ventilation tooth sheets in a manner of corresponding to the groove-shaped air vents, and the swing range of the slag removal tooth sheets and the swing range of the ventilation tooth sheets cover the length of the whole groove-shaped air vents during a swing process. The speed reduction motor drives the rotary shaft to rotate to drive the slag removal tooth sheets to swing, slags are crushed and discharged from the groove-shaped air vents, the groove-shaped air vents are dredged, and the ventilation tooth sheets are mainly used for dredging the groove-shaped air vents which the slag removal tooth sheets cannot arrive at, so that the purposes of slag removal and ventilation in a combustion chamber are achieved.

Owner:HENAN SHENHOU IND CO LTD

Special material for injection grade non-halogen flame-retardant wire plug and preparation method thereof

ActiveCN101161719AGood physical and mechanical propertiesFlat surfaceCouplings bases/casesHalogenSmooth surface

The invention discloses special material and preparation method for injection molding level halogen-free flame retardation wire plug. The special material adopts elastic body and polyolefin resin as base material with expansion type flame retardant, flame retarding synergist, compatilizer, antioxidant and processing agent added. After intensive mixing, the special material is obtained through extrusion and pelleting by a BUSS mixing roll with autoweighing blanking device. The method has good mixing effect, stable compounding formula and high processing efficiency and the particles prepared via the method have even size and bright appearance. The flame retardation rating of produces prepared via the method reaches UL94V-0 level, the tiptop fusion index reaches 55g / 10min, and Shore hardness is from 65A to 95A in case of qualified flame retardation level and high fusion index. The composite material provided by the invention is environmental-friendly material which completely meets current international environmental requirements on halogen-free material. The material which not only has good flame retardation performance and flowing property but also enables smooth surface and good felt of products is suitable for manufacturing various injection molding level wire plugs with high flame retardation requirements.

Owner:SHANGHAI KINGFA SCI & TECH +1

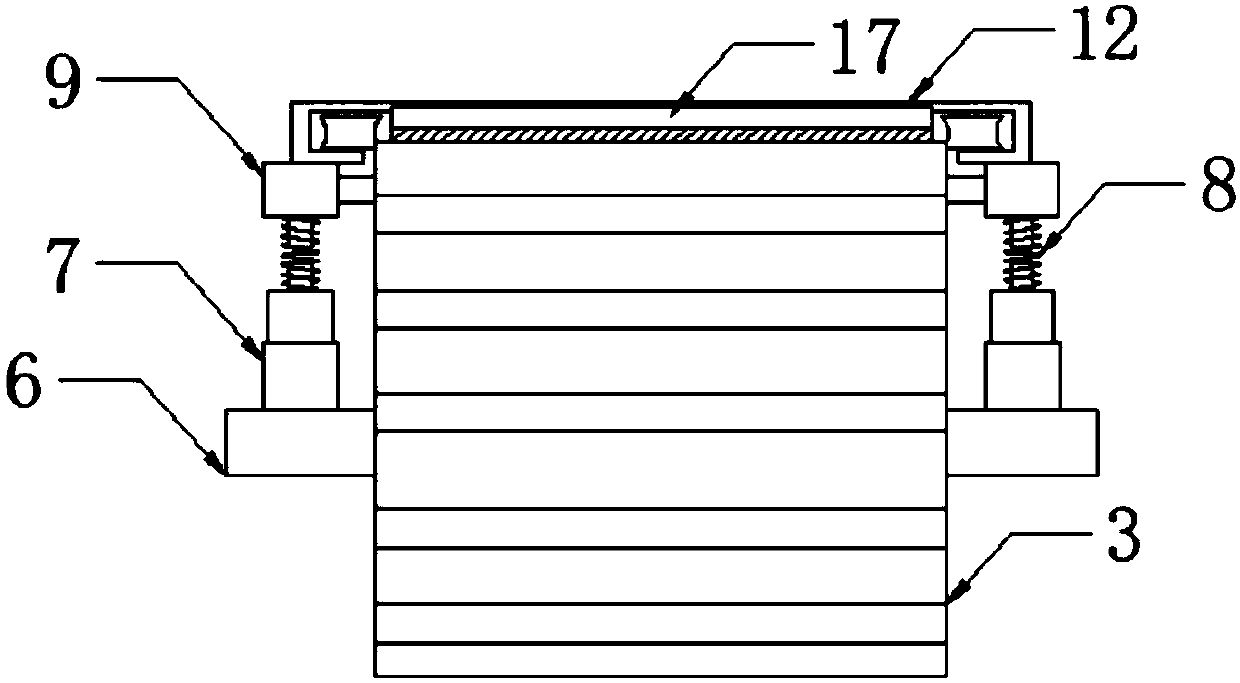

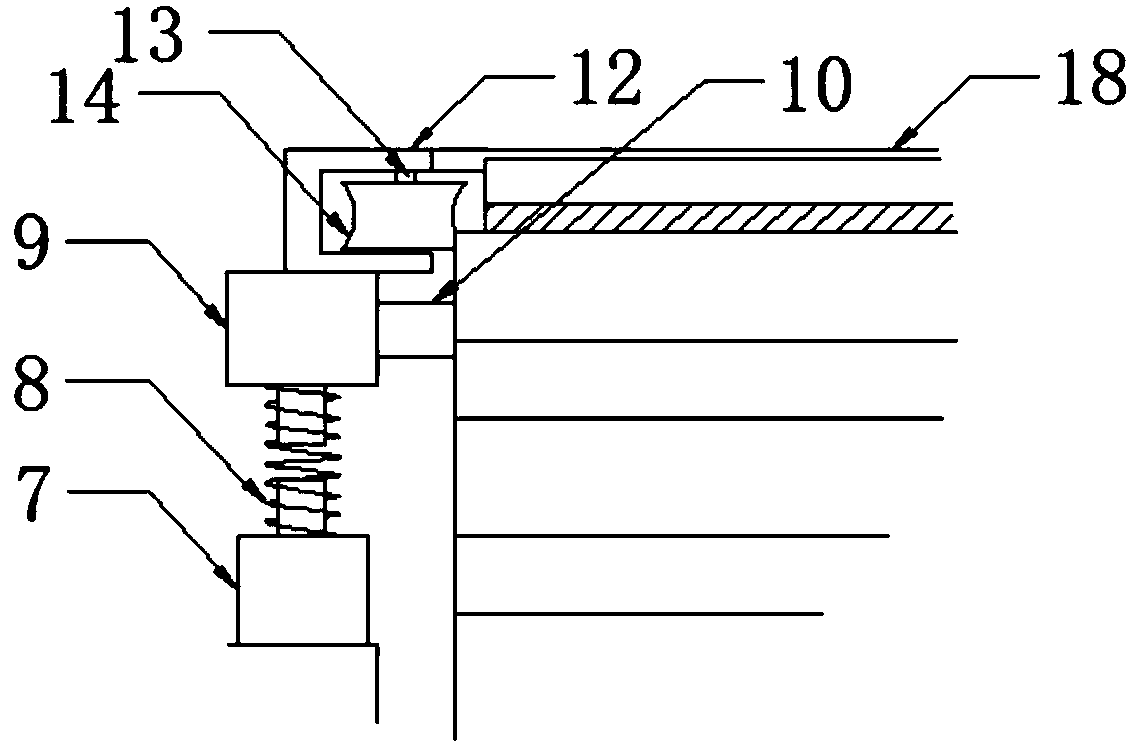

Movable fixture for casting sand box

InactiveCN105834380ATo achieve the purpose of clampingLarge adjustment spaceMoulding flasksEngineeringMechanical engineering

The invention discloses a movable fixture for casting a sand box. The movable fixture comprises a base plate, a clamping plate, a first screw rod, a first nut, a second screw rod and a second nut, wherein the first screw rod and the second screw rod are fixedly arranged at a fixed end of the base plate; the first screw rod is near a clamping end of the base plate; the second screw rod is far from the clamping end of the base plate; the first screw rod and the second screw rod penetrate through screw holes in the clamping plate for coating the clamping plate on the first screw rod and the second screw rod; and the first nut is screwed on the first screw rod above the clamping plate, and the second nut is screwed on the second screw rod below the clamping plate for limiting the clamping plate between the first nut and the second nut. Through a mode of matching two screw rods with the nuts, the fixture has larger adjusting space of a clamping range, and is wider in the application range compared with a U-shaped fixture; and meanwhile, the movable fixture uses the base plate and the clamping plate for clamping the sand box to solve the problem of incapability of inserting in the screw rods for fastening due to disalignment of upper and lower boxes.

Owner:KOCEL EQUIP

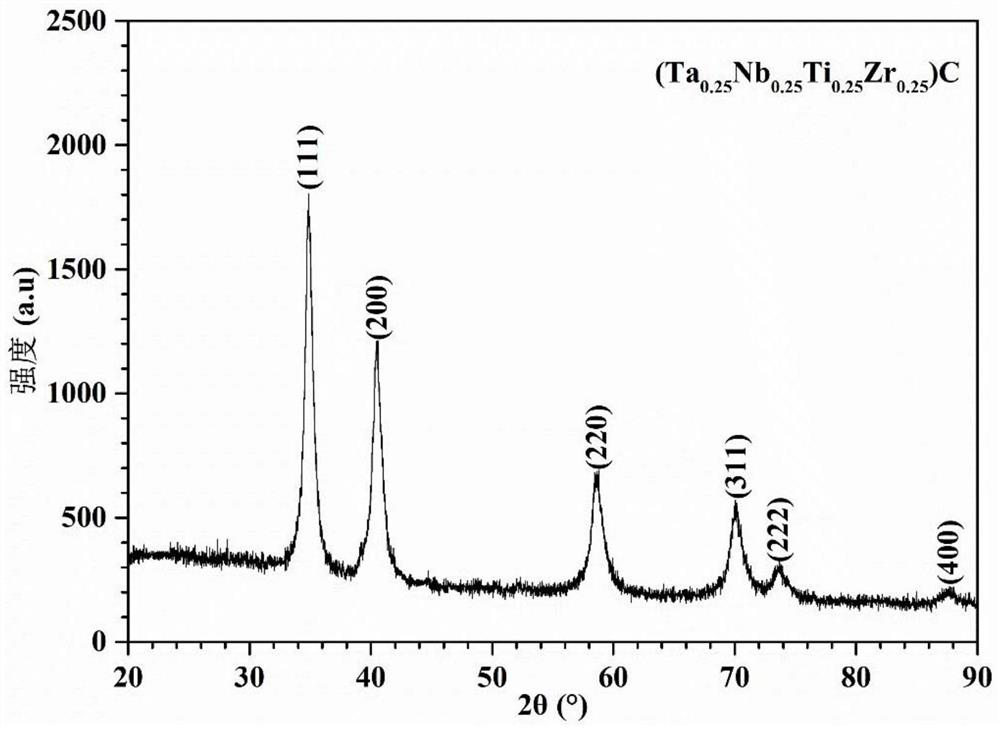

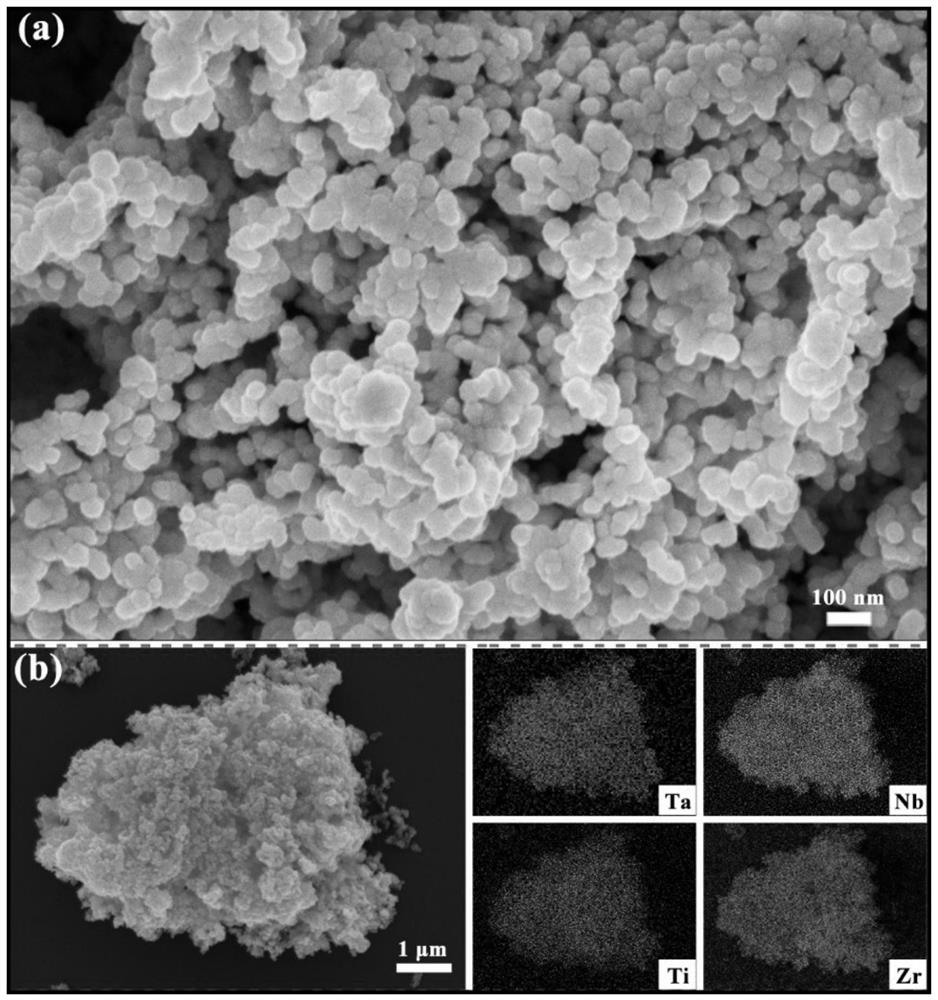

High-entropy carbide ceramic nano-powder as well as preparation method and application thereof

The invention discloses high-entropy carbide ceramic nano-powder as well as a preparation method and application thereof. The high-entropy carbide ceramic nano-powder is prepared by pre-pressing metal oxide powder, carbon powder, magnesium powder and NaF into sheets, sintering, washing with water and pickling, wherein the metal oxide powder is prepared from at least four of ZrO2, TiO2, Ta2O5, Nb2O5 and Cr2O3 according to an equal molar ratio. The high-entropy carbide ceramic nano-powder is small in particle size, uniform in metal element distribution and low in oxygen impurity content, and the preparation method of the high-entropy carbide ceramic nano-powder has the advantages of being easy to operate, low in operation temperature, short in reaction time, low in equipment requirement and the like, and is suitable for large-scale industrial production.

Owner:SOUTH CHINA UNIV OF TECH

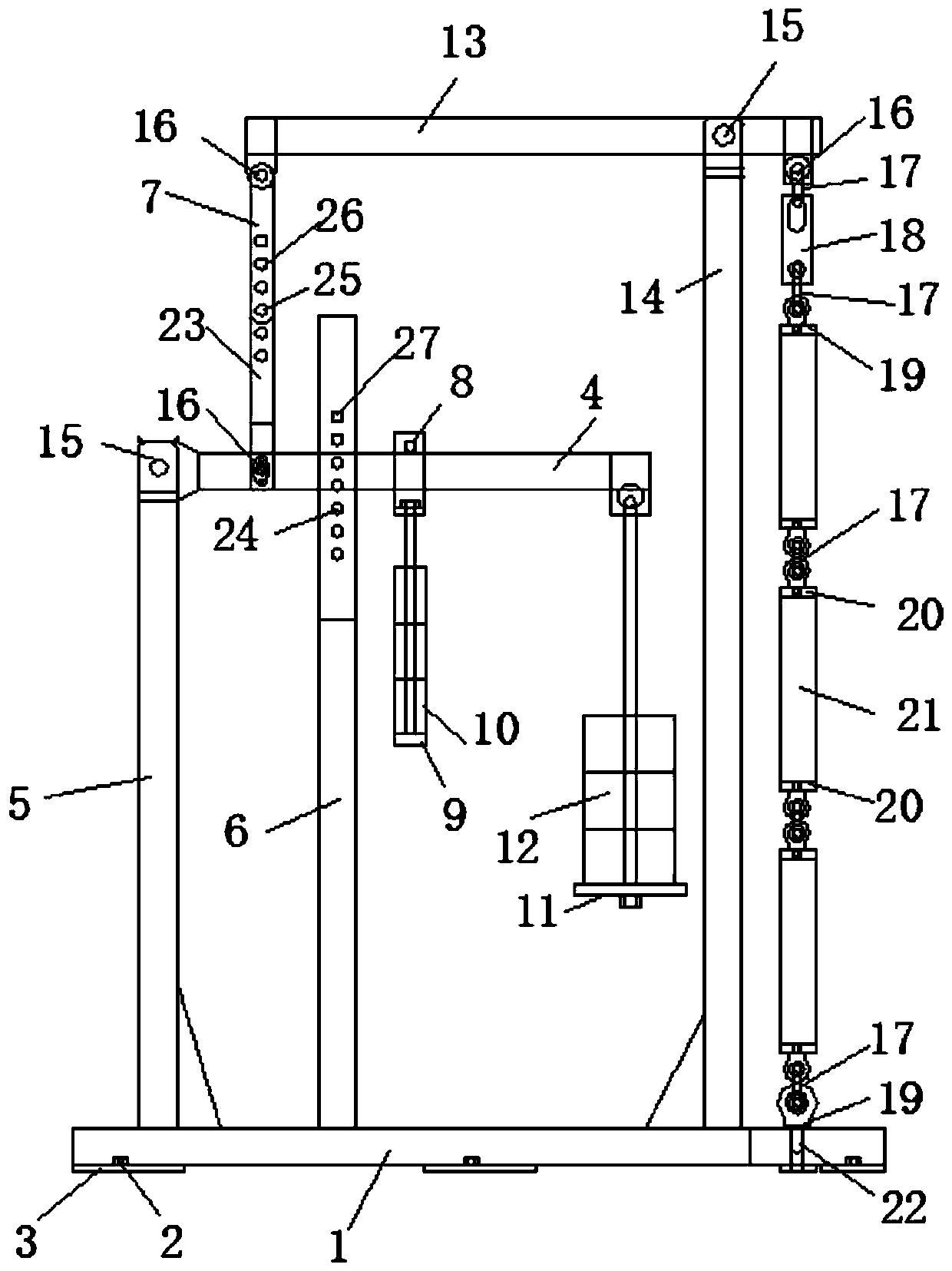

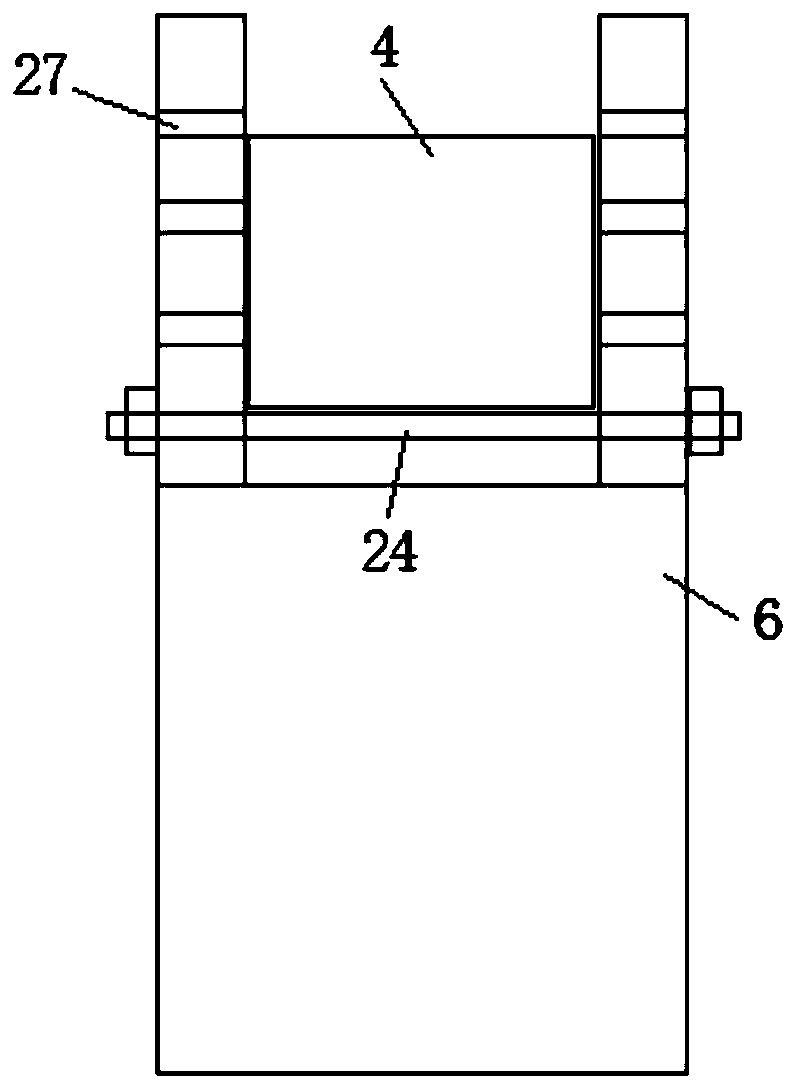

Double-lever stretching creep device with continuously adjustable load and test method thereof

InactiveCN110376061AHeavy loadSafety Issues Against FallsMaterial strength using tensile/compressive forcesConstant loadSteel frame

The invention relates to a double-lever stretching creep device with a continuously adjustable load and a test method thereof. The device comprises a fixed steel frame, a main load bearing lever, a main load bearing support, an auxiliary load bearing lever, an auxiliary support, a protection device, a constant-load balance weight device, a slidable balance weight device, an adjustable connecting device, a concrete test piece device and a load sensor. The lower ends of the main load bearing support and the auxiliary support are fixedly connected to the fixed steel frame. The main load bearing lever is connected with the main load bearing support by a main bearing; and the auxiliary load bearing lever is connected with the auxiliary support by the main bearing. One end of the main load bearing lever is connected with the fixed steel frame by the concrete test piece device; and the other end of the main load bearing lever is connected with the auxiliary load bearing lever by the adjustable connecting device. According to the r stretching creep device, the gravity load is increased by the double levers and the load amplification factor not lower than a ratio of 10 to 1 can be realized.The whole stretching creep device and scheme are simple and are easy to operate; and the safety and reliability are high.

Owner:SOUTHEAST UNIV

Method for preparing cubic calcium carbonate from lime dust

InactiveCN108017079ASimple production processImprove carbonization efficiencyCalcium/strontium/barium carbonatesDispersityCalcium hydroxide

The invention discloses a method for preparing cubic calcium carbonate from lime dust. Calcium hydroxide emulsion is prepared from the lime dust and water in a certain ratio through a digestion reaction, multi-stage deslagging and aging are performed, refined calcium hydroxide emulsion is obtained, a crystal form controller is added, carbon dioxide is introduced simultaneously for a carbonizationreaction, calcium carbonate emulsion with certain concentration can be obtained, then dehydration, drying, crushing and packaging are performed on the calcium carbonate emulsion, and a cubic industrial precipitated calcium carbonate product is obtained finally. The problems that the process is complex, particle size of the product is non-uniform and the dispersity is poor when carbide slag and limestone are taken as raw materials for preparing calcium carbonate at present are solved.

Owner:XINJIANG CORPS MODERN GREEN CHLOR ALKALI CHEM ENG RES CENT LTD +1

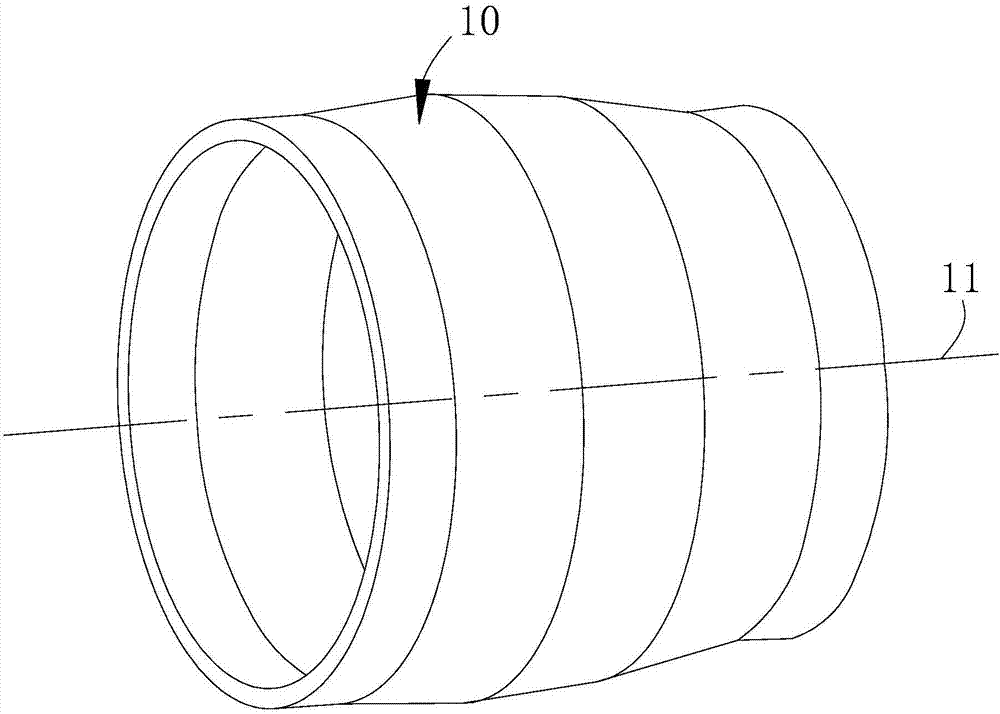

Large-size and thickness-changing revolved body precast body and manufacturing method thereof

ActiveCN108004650AOvercome the problem of not being able to weave rotor preforms with a diameter exceeding 500mmUnlimited diameterWoven fabricsEngineeringLarge size

The invention discloses a large-size and thickness-changing revolved body precast body. The wall thicknesses of the large-size and thickness-changing revolved body precast body change continuously inthe axial direction, the thickness-changing revolved body precast body is formed by winding multiple layers of a thickness-changing precast body which is three-dimensional laminated structural fabric,and the weft direction of the thickness-changing precast body and the central axis of the thickness-changing revolved body precast body are located in the same plane. The invention further disclosesa manufacturing method of the revolved body precast body. The method comprises the steps of 1, determining size parameters of the thickness-changing revolved body precast body to be produced; 2, determining even layering number of the thickness-changing revolved body precast body to be produced, and determining size parameters of the thickness-changing precast body according to the size parametersof the thickness-changing revolved body precast body; 3, weaving the thickness-changing precast body on a weaving machine and completing weaving; 4, winding the thickness-changing precast body on a revolved body core mould continuously to obtain the thickness-changing revolved body precast body. The large-size and thickness-changing revolved body precast body and the manufacturing method thereofhave the advantages that manufacturing is continuous, efficiency is high, and the diameter of the thickness-changing revolved body is not limited.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

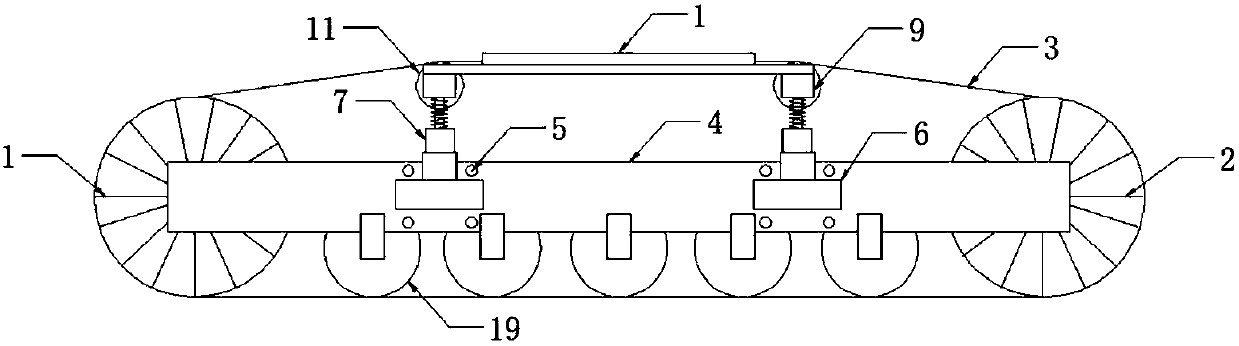

Crawler belt tensioning mechanism of crawler belt tractor

ActiveCN107662660AImprove cleanlinessLarge adjustment spaceEndless track vehiclesDrive wheelEngineering

The invention discloses a crawler belt tensioning mechanism of a crawler belt tractor. The mechanism includes a drive wheel and a driven wheel, the outer parts of the drive wheel and the driven wheelare sleeved with crawler belts, a plurality of thrust wheels are arranged between the drive wheel and the driven wheel, the two sides of the drive wheel and the two sides of the driven wheel are fixedly connected through two blocking plates, and the two ends of one side of each blocking plate are symmetrically provided with pairs of bolt holes. Through guide wheels arranged on a first rotating shaft in a sleeving mode, when the crawler belt needs to be tensioned, the height of a switch regulating electric hydraulic rod is controlled through an electric hydraulic rod arranged on the control panel, the tensioning degree of the crawler belt is thus adjusted, and it is convenient for people to operate the mechanism. The two guide wheels are arranged, when one of the two guide wheels is damaged, the other one of the two guide wheels can continuously tension the crawler belt, through the bolt holes formed in the different positions on the blocking plates, the height of a first fixing block can be adjusted, the regulation space of the electric hydraulic rod is thus increased, and the tensioning operation is easily conducted.

Owner:HUNAN NONGFU ELECTROMECHANICAL

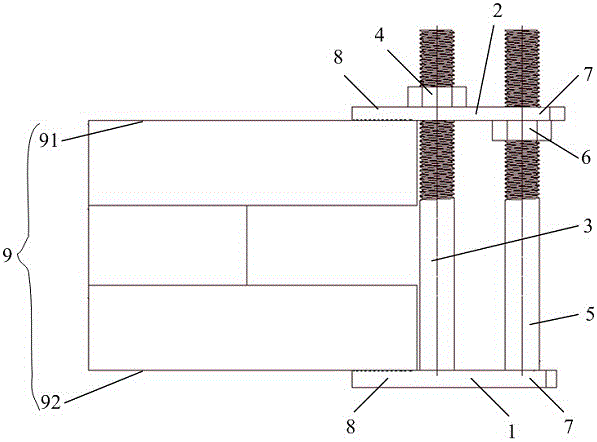

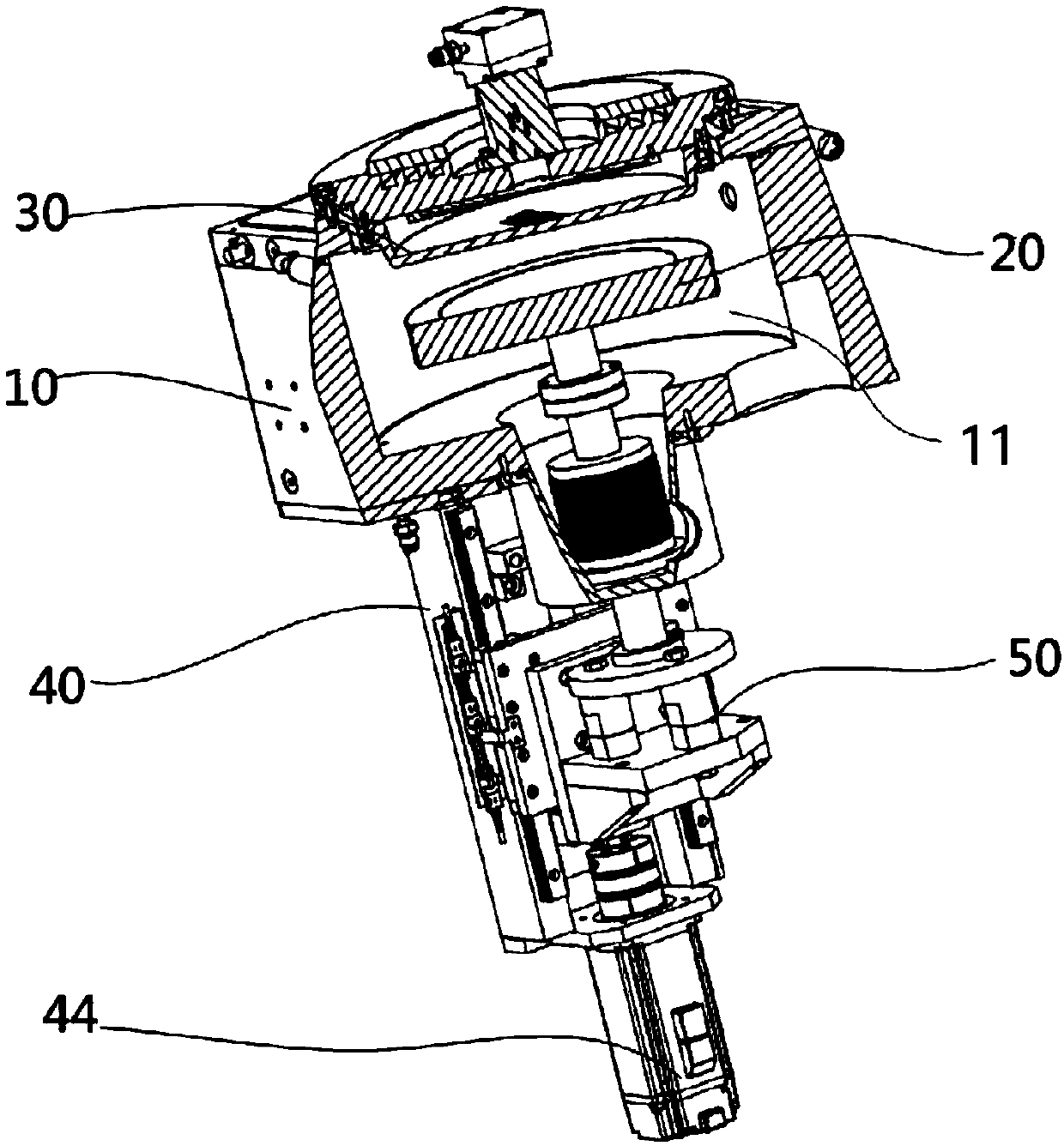

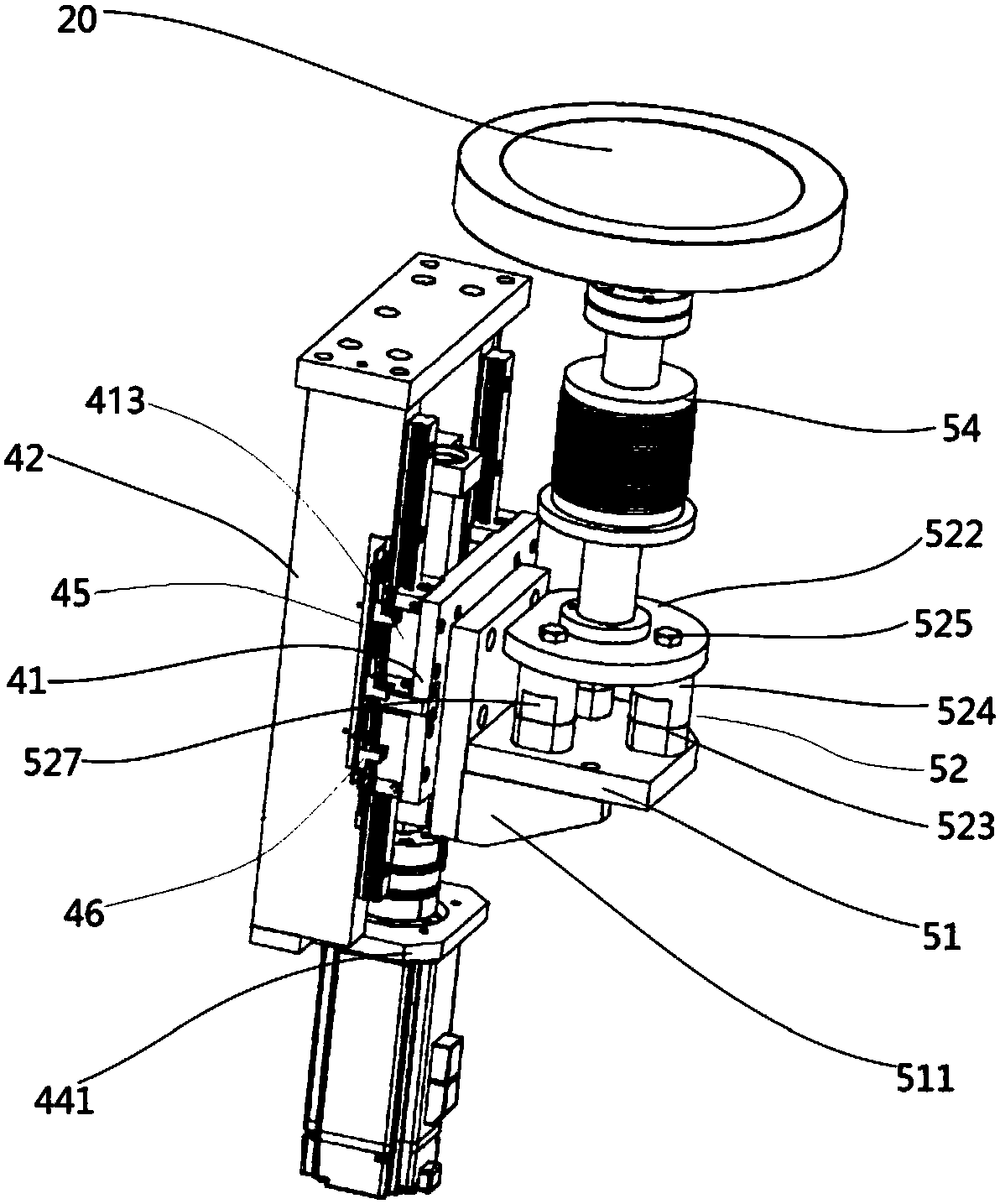

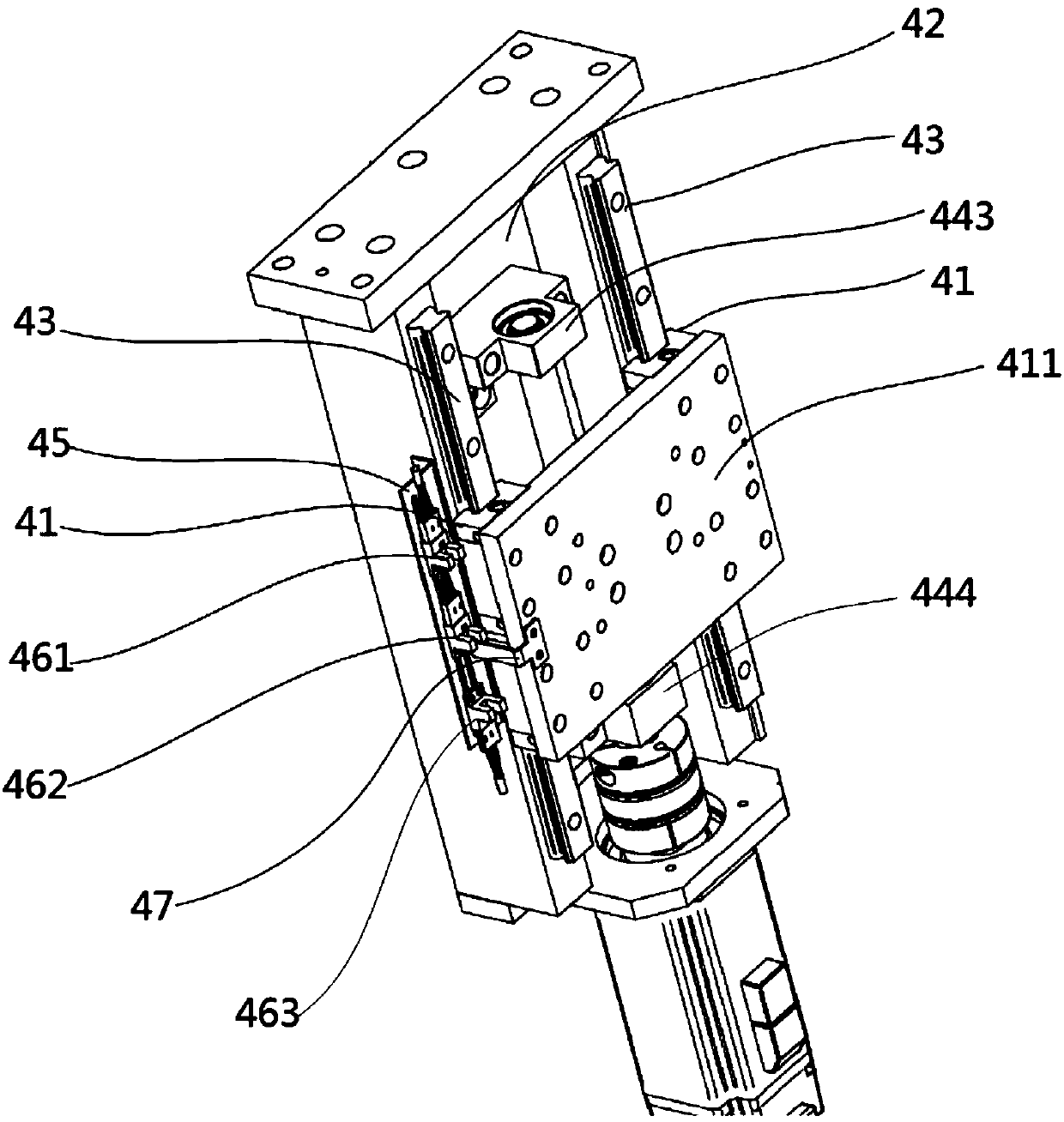

Chemical vapor deposition coating device

ActiveCN107723683APoor process uniformityEasy to operateChemical vapor deposition coatingGas phaseEngineering

The invention discloses a chemical vapor deposition coating device. The chemical vapor deposition coating device comprises a shell (10), a carrying table (20), a gas evenly-dividing disc (30), a lifting adjusting mechanism (40) and a horizontal adjusting mechanism (50). The shell comprises a vacuum cavity (11) with an opening in the lower end; the carrying table (20) is arranged in the vacuum cavity, the gas evenly-dividing disc (30) is arranged above the interior of the shell and is roughly parallel to the carrying table, the lifting adjusting mechanism (40) is arranged on the outer side of the bottom of the shell, one end of the horizontal adjusting mechanism (50) is connected to the carrying table, the other end of the horizontal adjusting mechanism (50) is connected to the lifting adjusting mechanism, and the horizontal adjusting mechanism and the lifting adjusting mechanism can cooperate with each other to adjust the position, in the horizontal direction and the vertical direction, of the carrying table at the same time. The chemical vapor deposition coating device can strictly control the precision in the vertical direction, errors brought by machining and mounting can be overcome in the horizontal direction, operation is convenient, and the adjusting space is large.

Owner:JIANGSU LEUVEN INSTR CO LTD

Polyvinyl chloride floorboard substrate and preparation method thereof

The invention discloses a polyvinyl chloride floorboard substrate and a preparation method thereof, belonging to the technical field of polyvinyl chloride boards. The polyvinyl chloride floorboard substrate solves the problems of high cost and poor quality in the existing product. The polyvinyl chloride floorboard substrate is prepared from 80-100 parts of polyvinyl chloride SG8 resin, 100-120 parts of heavy calcium carbonate, 50 parts of floorboard substrate moldboard reclaimed material, 7-8 parts of foaming regulator 903, 2-3 parts of foaming regulator 902, 2.8-4.9 parts of composite stabilizer, 0.6-1.2 parts of internal lubricant ZB-60, 0.35-0.7 part of polyethylene (PE) wax, 0.2-0.5 part of AP, 0.5-0.8 part of plasticizer OA3, 0.3-0.4 part of heat-release AC (azodicarbonamide) foaming agent, 1.4-1.6 parts of heat-absorption Zhongkai c-2 foaming agent, 2-5 parts of ferrite yellow powder and 2-4 parts of CPE (chlorinated polyethylene). The preparation method comprises the following steps: mixing, plastifying and foaming, and extruding to obtain the finished product. The product can be widely used in office buildings, shopping malls, schools, gymnasia, hospitals and other locations.

Owner:SHANDONG HUIFENG NEW MATERIAL TECH CO LTD

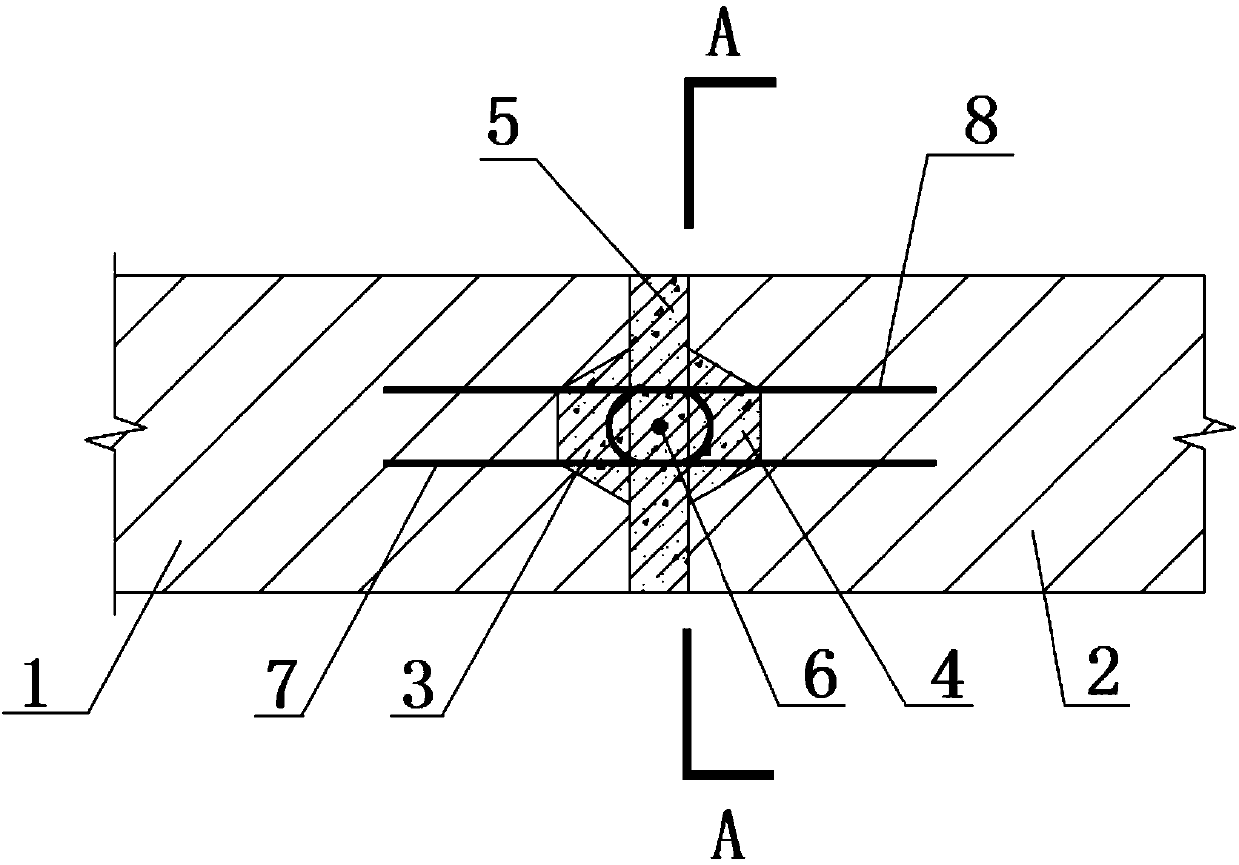

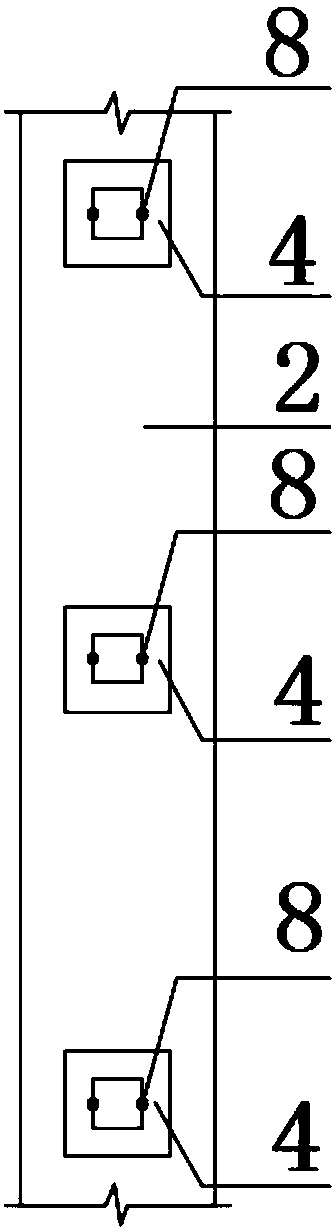

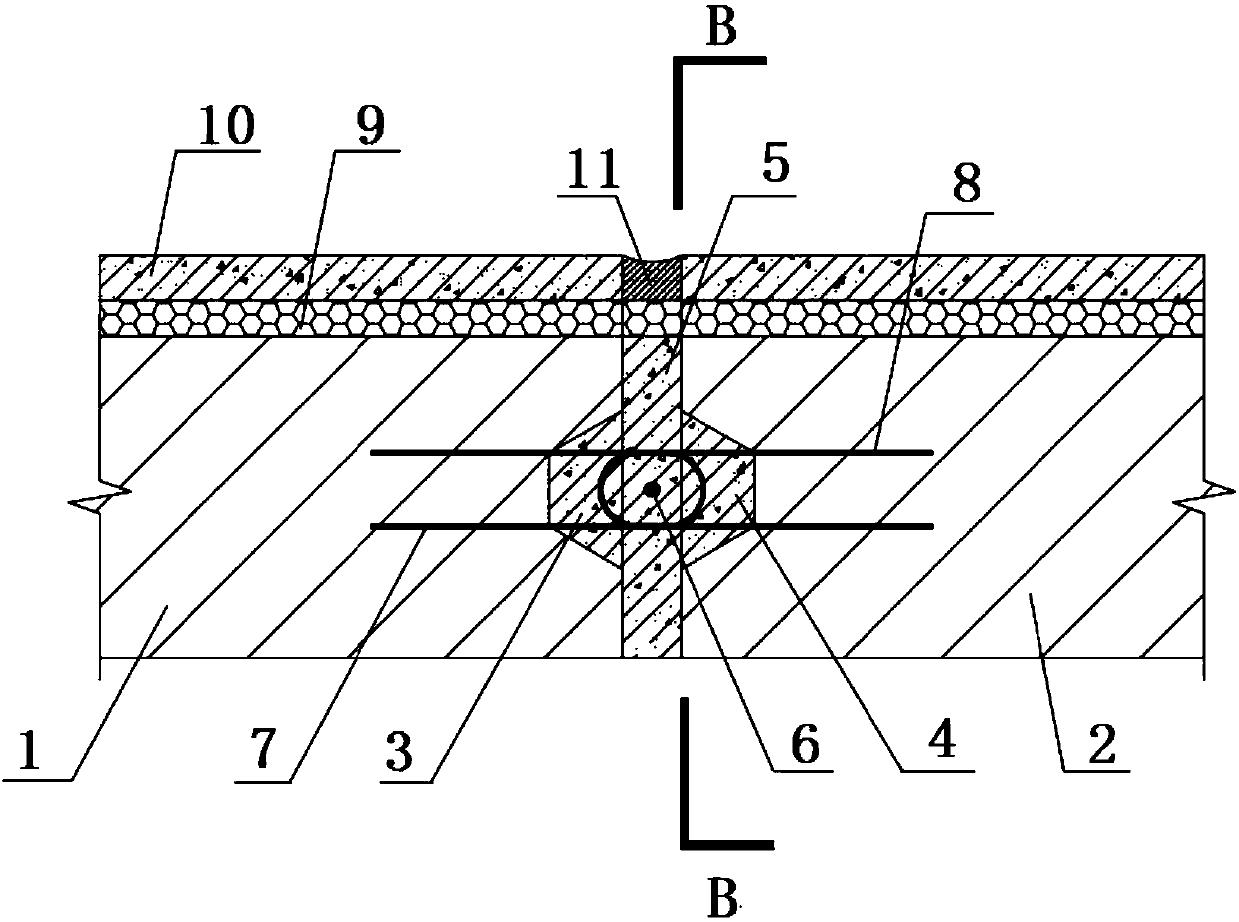

Connecting joint of adjacent wallboards and construction method of connecting joint

PendingCN107916730AImprove sound insulationEliminate the defects of poor thermal insulation and sound insulationWallsClassical mechanicsEngineering

Owner:HUNAN YUANDA ENG DESIGN CO LTD

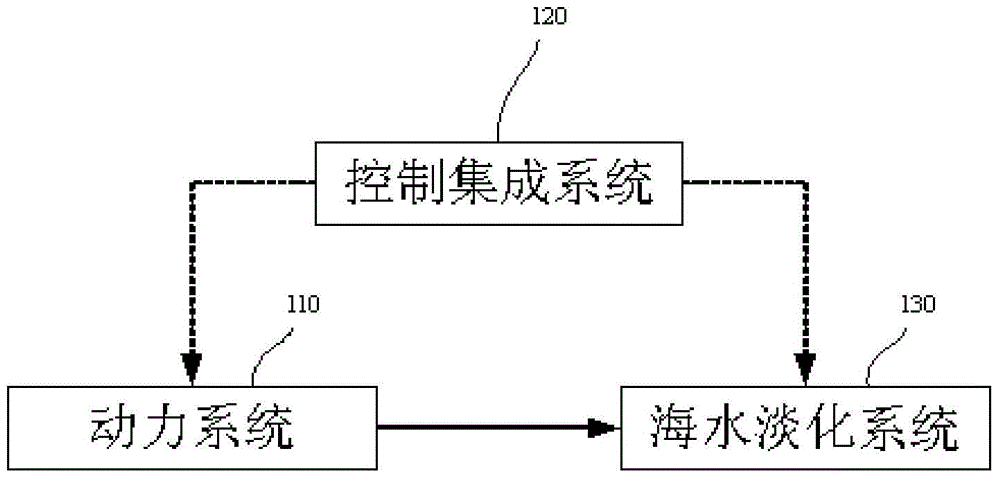

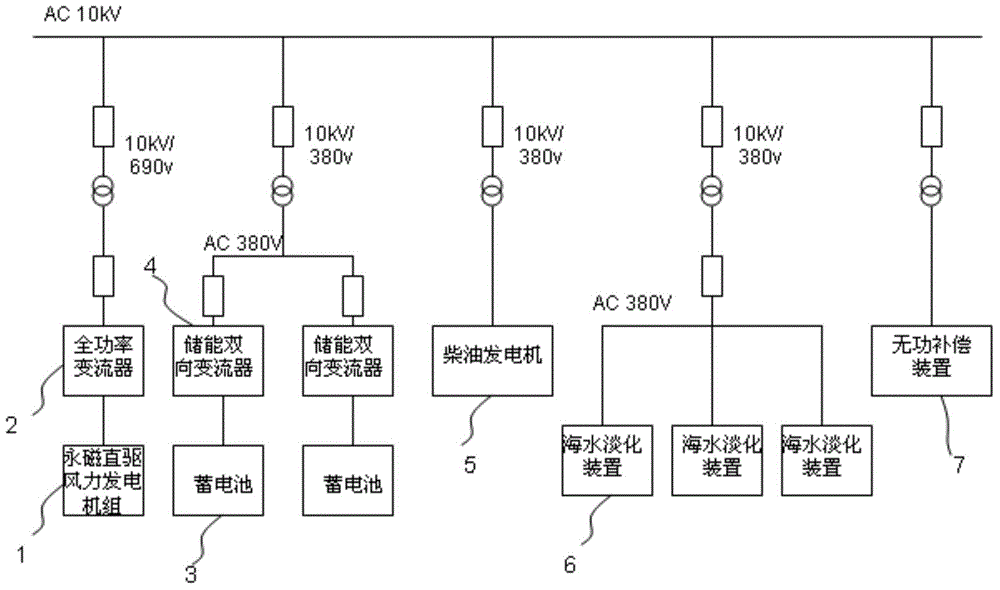

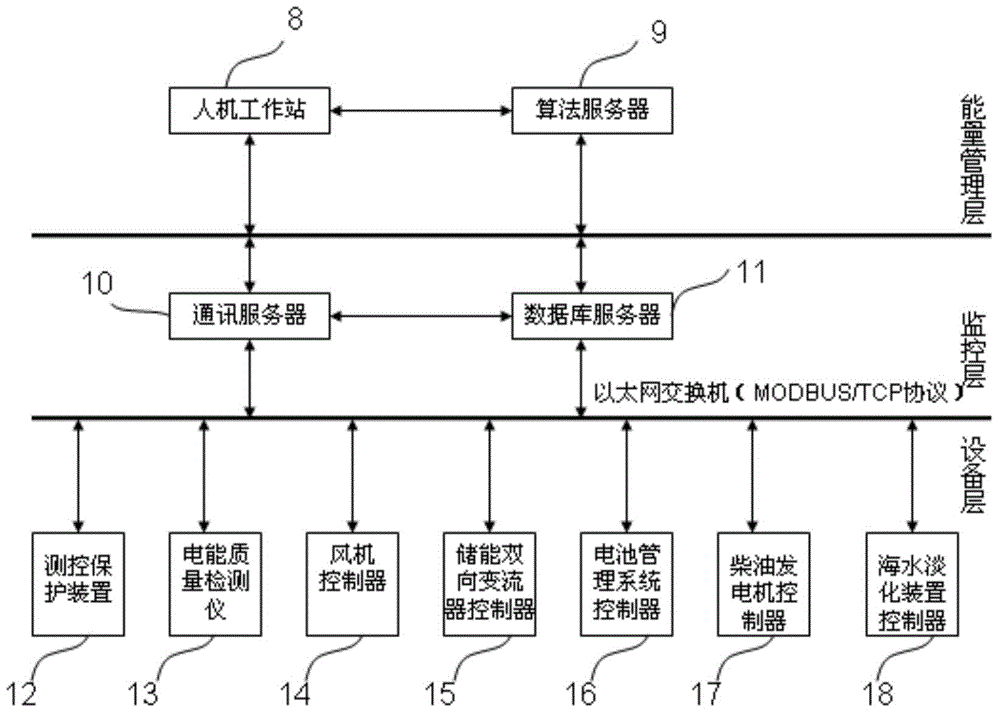

Wind power sea water desalination integrated system and method for isolated grid

ActiveCN105016428AImprove the utilization rate of wind powerGuaranteed smooth operationGeneral water supply conservationSeawater treatmentSeawaterWind power

The invention provides a wind power sea water desalination integrated system for an isolated grid. The wind power sea water desalination integrated system comprises a power system, a control integrated system and a sea water desalination system. The power system supplies power to sea water desalination devices by optimized dispatching of the control integrated system. The control integrated system is used for controlling the power system. The power system comprises wind turbine generators, at least one energy storage system and diesel generators. The control integrated system is used for controlling the power system. The sea water desalination system comprises the sea water desalination devices. The wind turbine generators, the energy storage systems, the generators and the sea water desalination devices are connected to the micro-grid in parallel. The system solves the problem that energy consumption of traditional sea water desalination industry is high, and the technical problems that an existing sea water desalination device adopting wind power energy needs to use a large number of storage batteries, electricity energy loss is high, maintenance is difficult and cost is high.

Owner:JIANGSU FENGHAI NEW ENERGY SEA WATER DESALINIZATION DEV

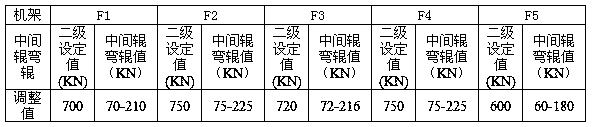

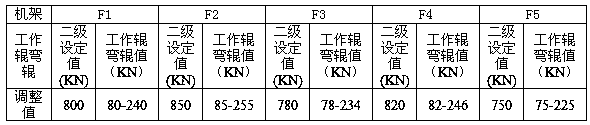

Method for improving rolling stability of high-strength IF steel

ActiveCN108746213AReduce rolling reductionReduce the bending valueRollsMetal rolling arrangementsReduction rateStrip steel

The invention provides a method for improving the rolling stability of high-strength IF steel. Five F1-F5 cold rollings are adopted. Before rolling, rolling reduction allocation is adjusted to ensurethat the absolute reduction rate of an F2 rack is 80-85% of that of an F1 rack, and the absolute reduction rate of an F3 rack is 50-55% of that of an F1 rack. Working rollers of the F1-F3 racks are working rollers with convexity. Intermediate rollers have the roller shifting values that secondary set values are increased by 5-10%. The working rollers and the intermediate rollers have the roller bending values that are 10-30% of the secondary set values. Small-bending-force control is realized in a rolling process. The roller bending parameter can be adjusted within a wider space. After wave generation among the racks in the rolling process, plate shape adjustment can be rapidly performed. Stable rolling of strip steel is guaranteed. The operation is convenient. Rolling burst of strip steelor pulling scratch of the rollers are greatly reduced.

Owner:HANDAN IRON & STEEL GROUP +1

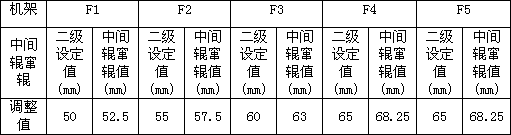

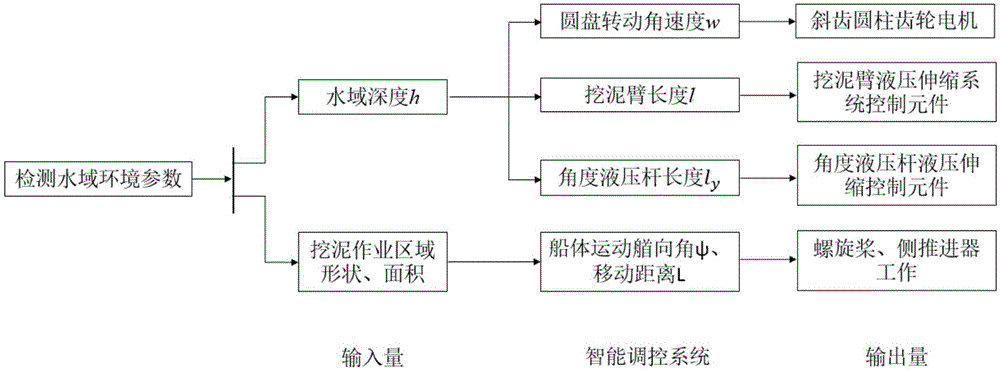

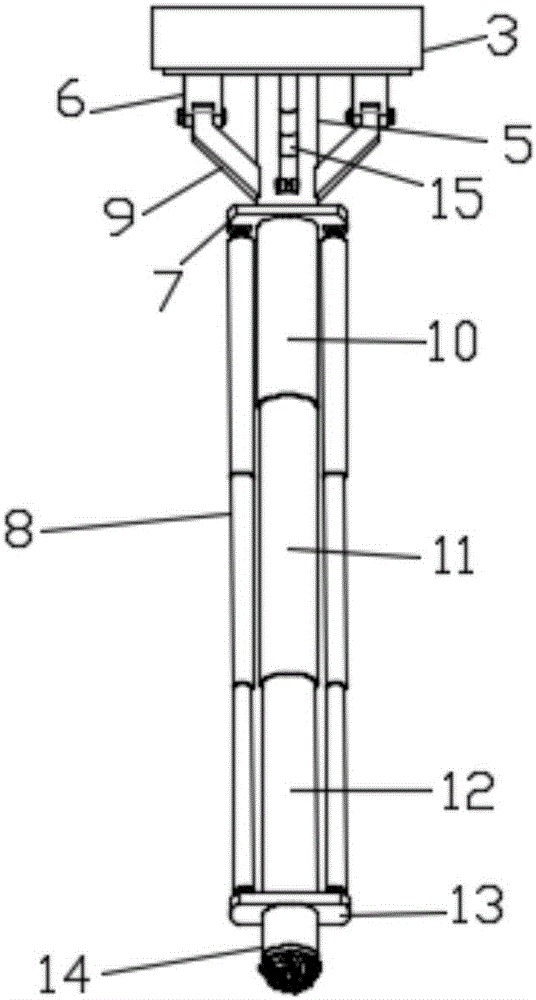

Retractable mud dredging system based on spiral working manner

ActiveCN106245696AEasy to operateImprove securityMechanical machines/dredgersCircular discMarine engineering

The invention discloses a retractable mud dredging system based on a spiral working manner. The system is mainly composed of a rotary mechanism which is arranged on a ship body, close to a ship bottom part, of a midship position, and is used for providing power for rotating a mud digging arm, a hydraulic regulation and control mechanism which is used for regulating and controlling a working state of the mud digging arm, and a reamer mechanism mounted at a tail end of the mud digging arm. A circular disc rotates to drive the mud digging arm to rotate, and the length of the mud digging arm and an angle between the mud digging arm and a plane of a ship bottom base are regulated through utilizing a hydraulic system, so that a reamer moves along a spiral line track; and a mud digging working radius is continuously changed, and the mud digging work of a round surface region is finally realized. Based on the realization of the functions, the design can enlarge the area of single-time working of a mud digging ship, and frequent movement of a ship body of the mud digging ship is reduced, so that the power consumption is reduced and the mud digging efficiency is improved.

Owner:WUHAN UNIV OF TECH

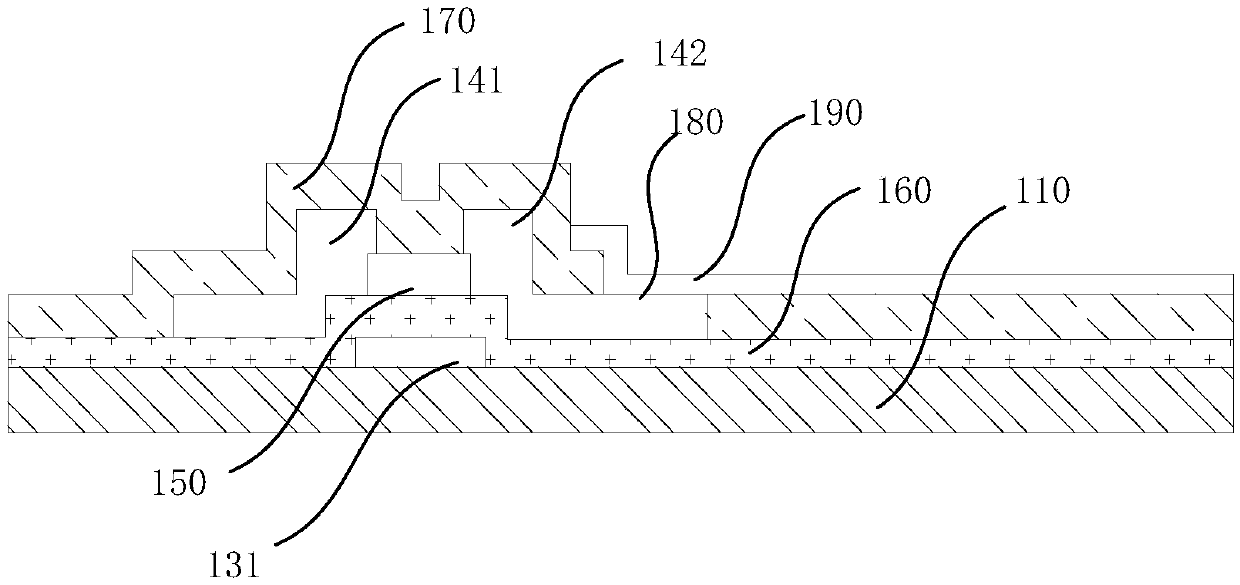

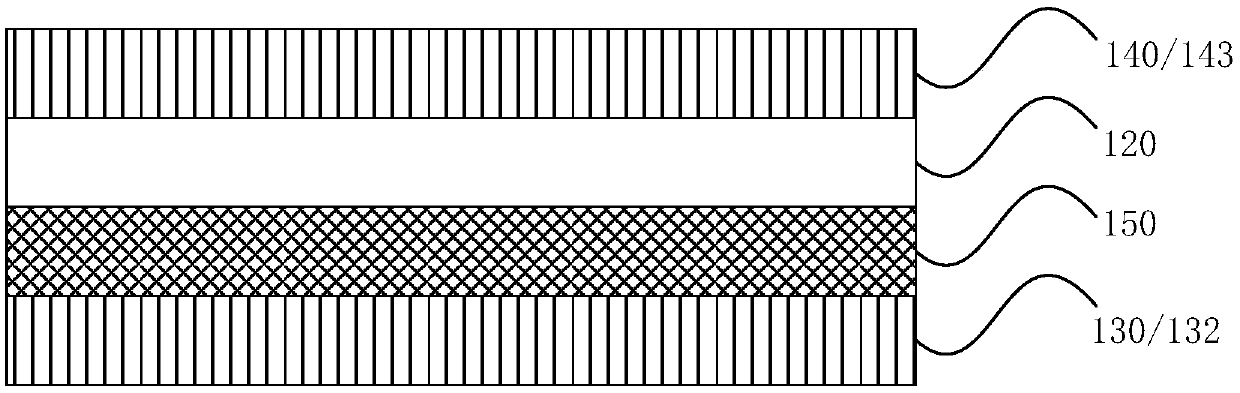

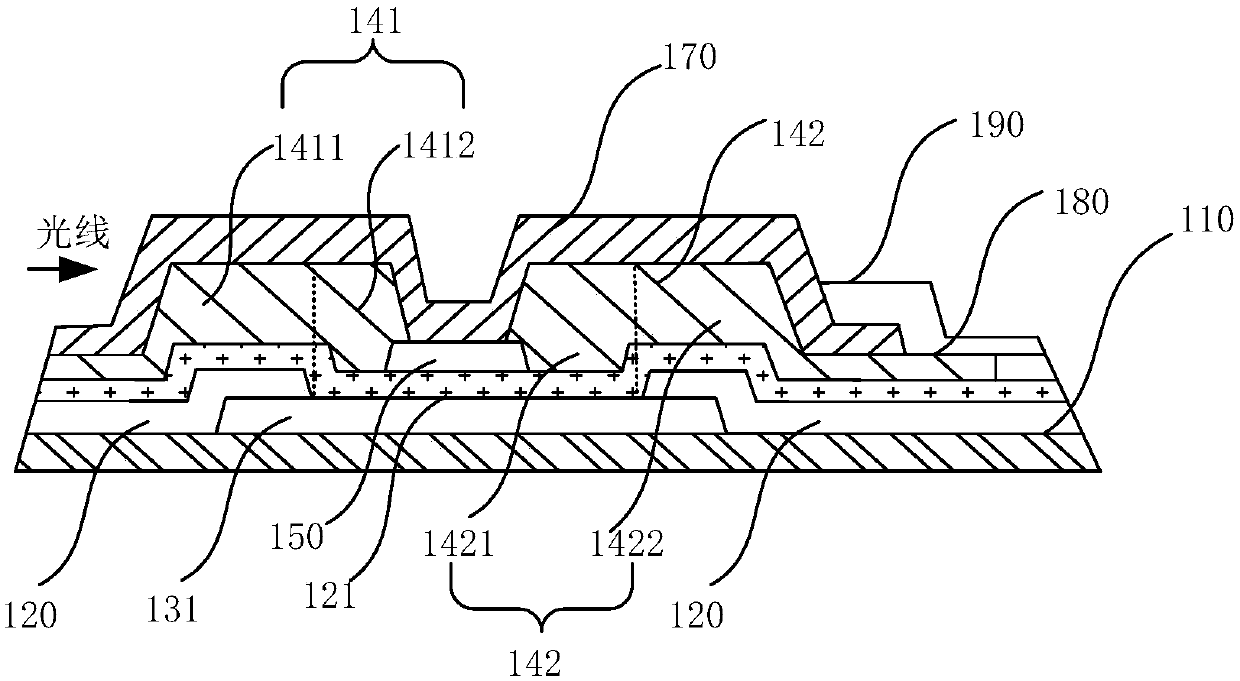

Display panel, manufacturing method and display device

ActiveCN109557735AGuaranteed qualityReduce coupling capacitanceSolid-state devicesNon-linear opticsCapacitanceOptoelectronics

The invention discloses a display panel, a manufacturing method and a display device. The display panel comprises a first substrate, a first metal layer formed on the first substrate, a second metal layer as well as a black color resistance layer formed between the first metal layer and the second metal layer. According to the scheme, the black color resistance layer is added between the first metal layer and the second metal layer, and the black color resistance layer has a certain thickness, so that a distance between the first metal layer and the second metal layer is increased, coupling capacitance between the first metal layer and the second metal layer is reduced, then circuit loads of the first metal layer and the second metal layer are reduced, and quality of the display panel is guaranteed.

Owner:HKC CORP LTD

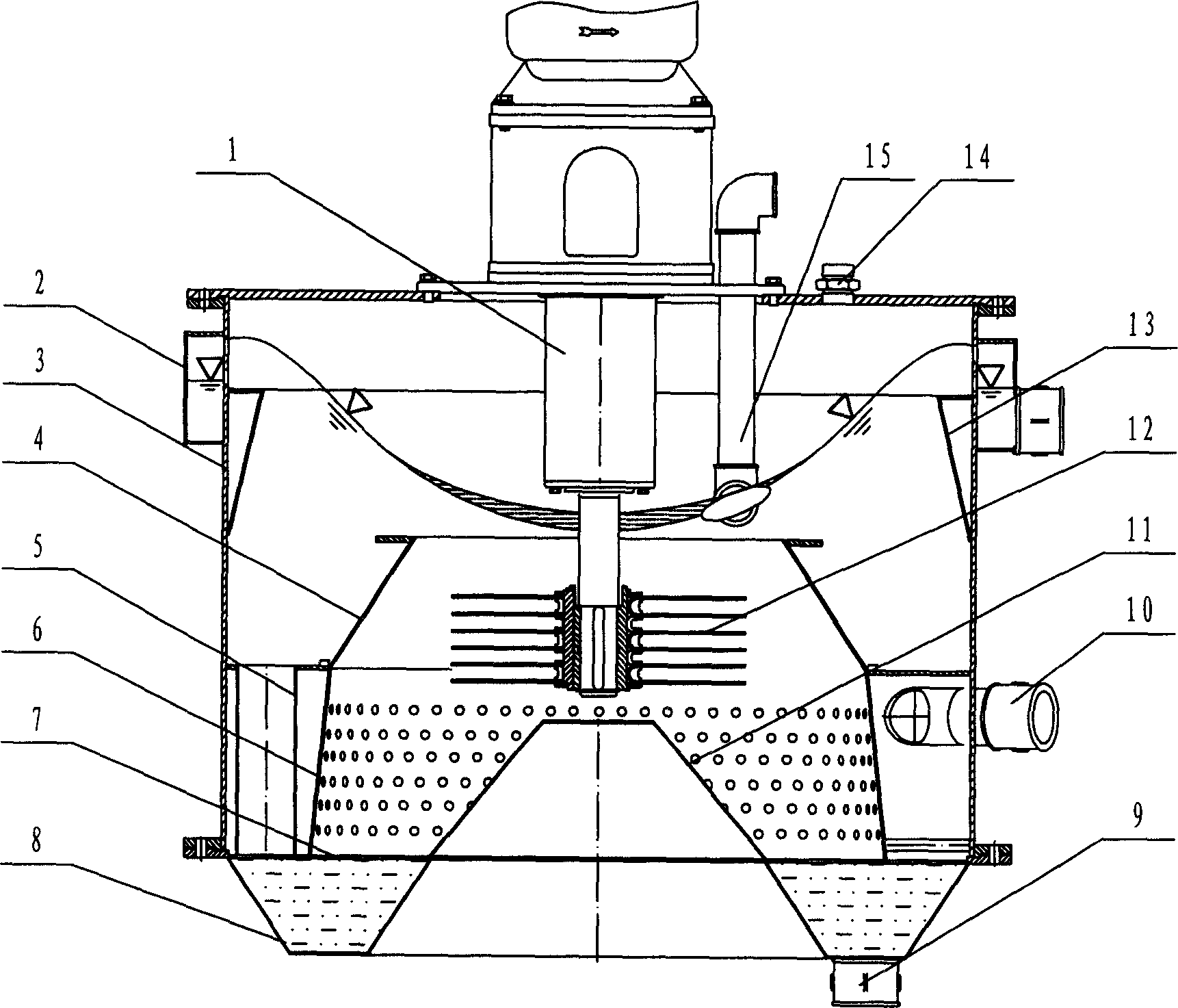

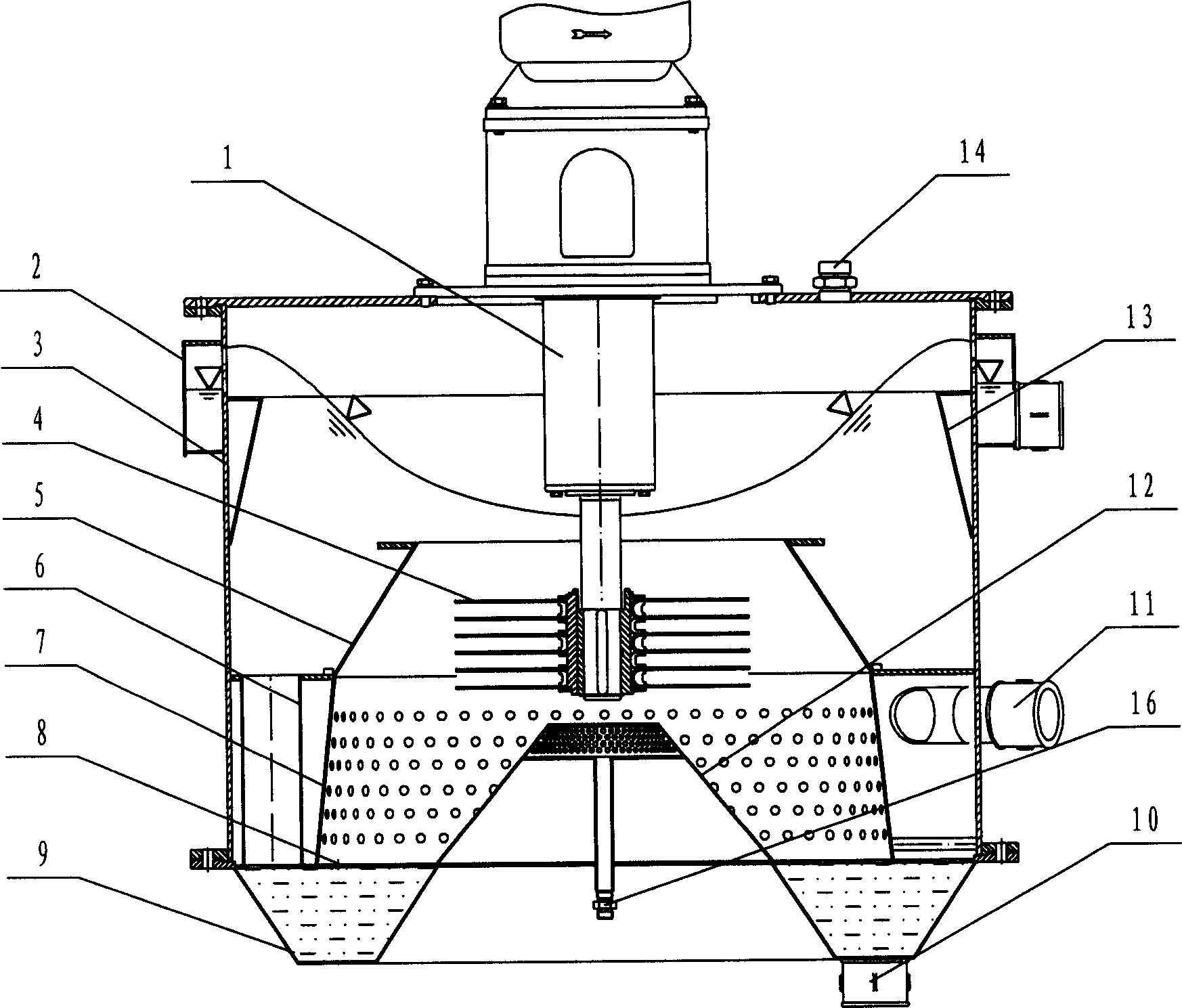

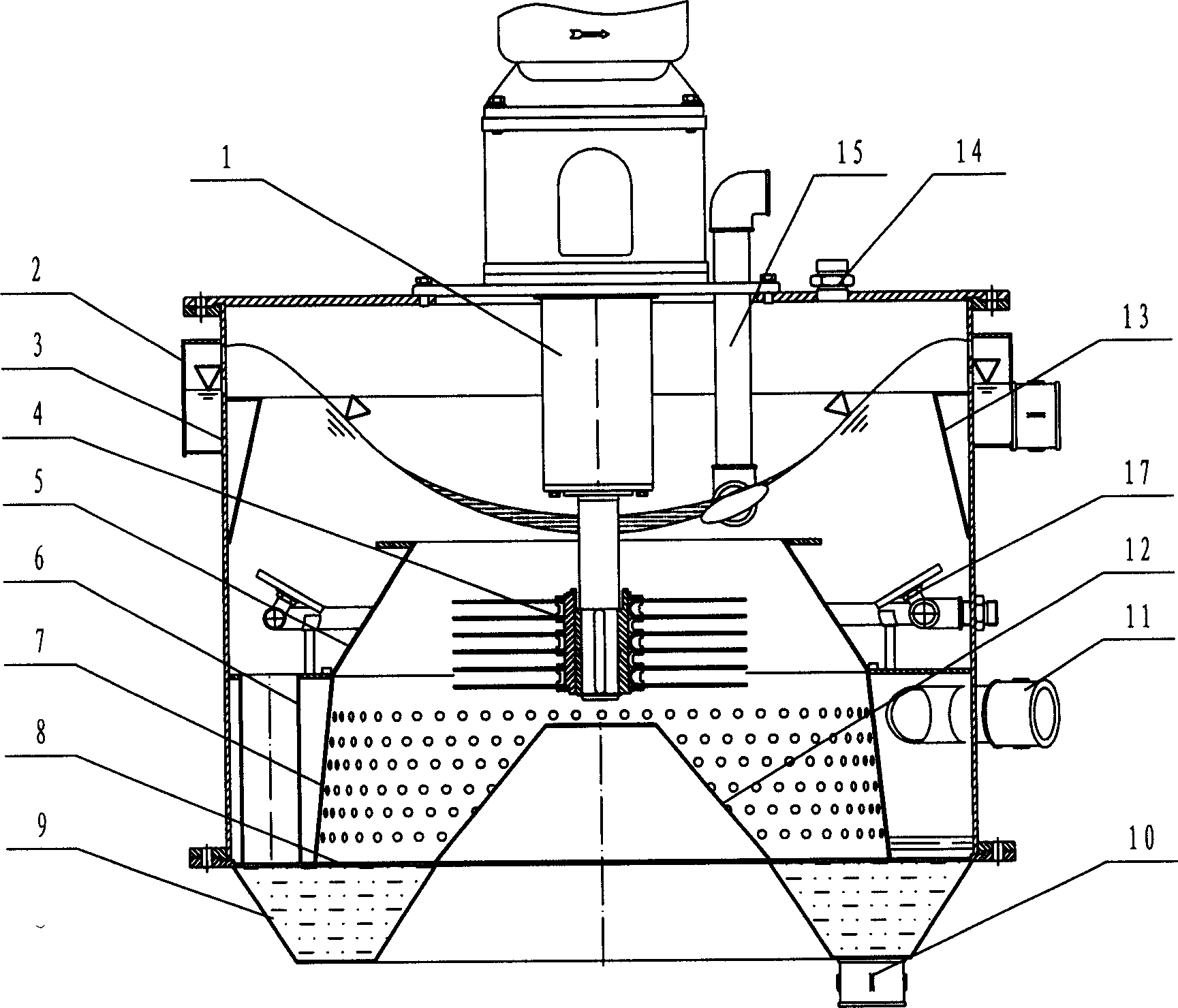

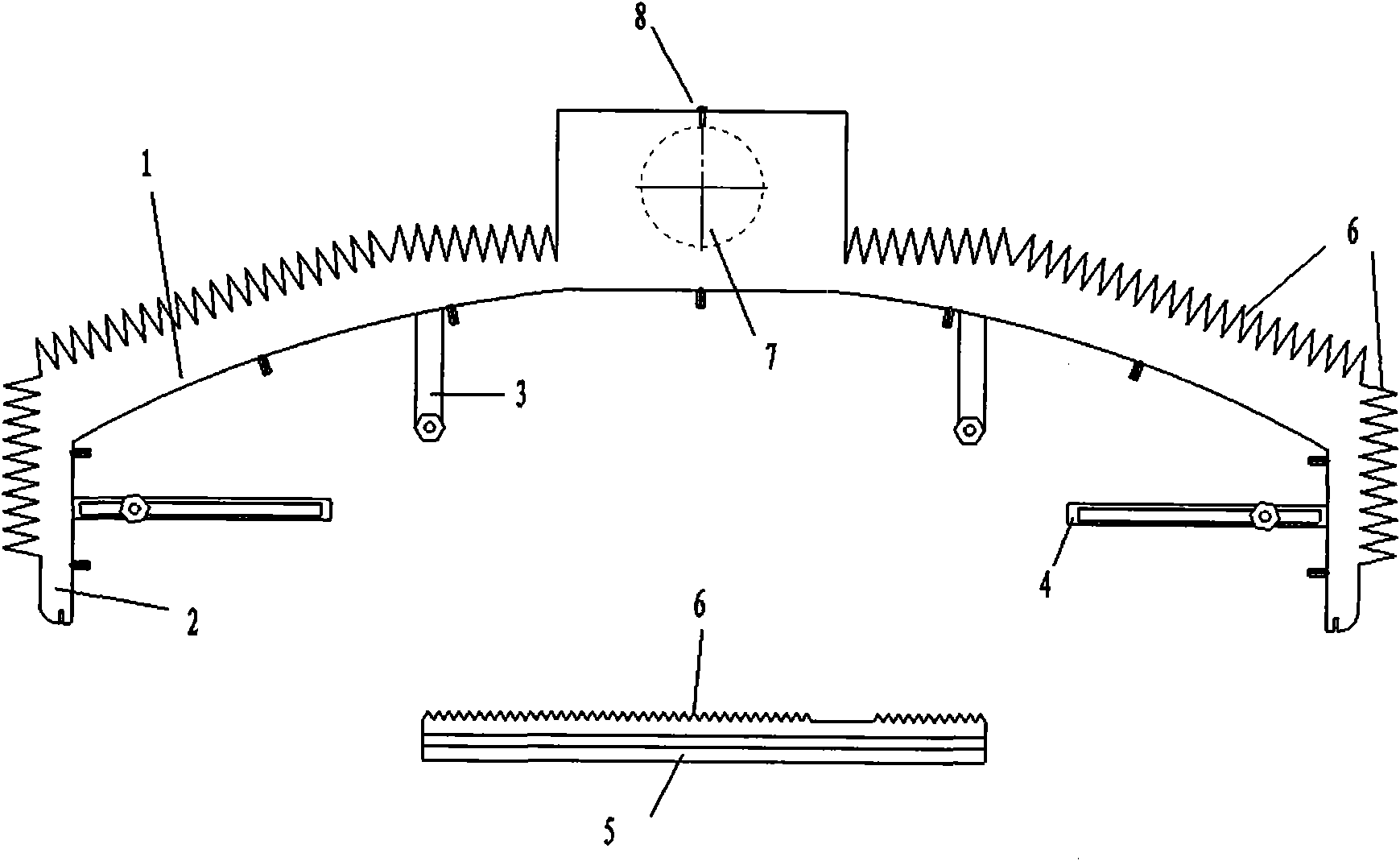

Multifunctional high speed clarifier

InactiveCN1631799AHigh densityStrong spinning abilityWater/sewage treatment by flocculation/precipitationWater/sewage treatment by flotationFiberEngineering

The invention relates to water processing mechanical technological field, including 3, 1 4,condensing 9, shielding plate 8, 7 main separating 5, tri-13, 15 and 17 . The conventional (1) separates the particle with too large diameter, and too small processing speed of (2) compare with this the invention uses 4 whose line-material is averagely arranged in different layers as the compound (3), depending on water-driving separation, (4) multi-functions to do (5) in the same cavity by steps, increasing the efficiency of separation, enlarging the load 10~100 times, shortening the time for procession, it makes use of (6) to increase the (7), so that equipment size can be smaller and several ones can be compacted into only one, besides, (8) has decreases the air pressure requirement of (9). It can be applied in separation of solid-liquid, fat-water and fiber-water.

Owner:高根树

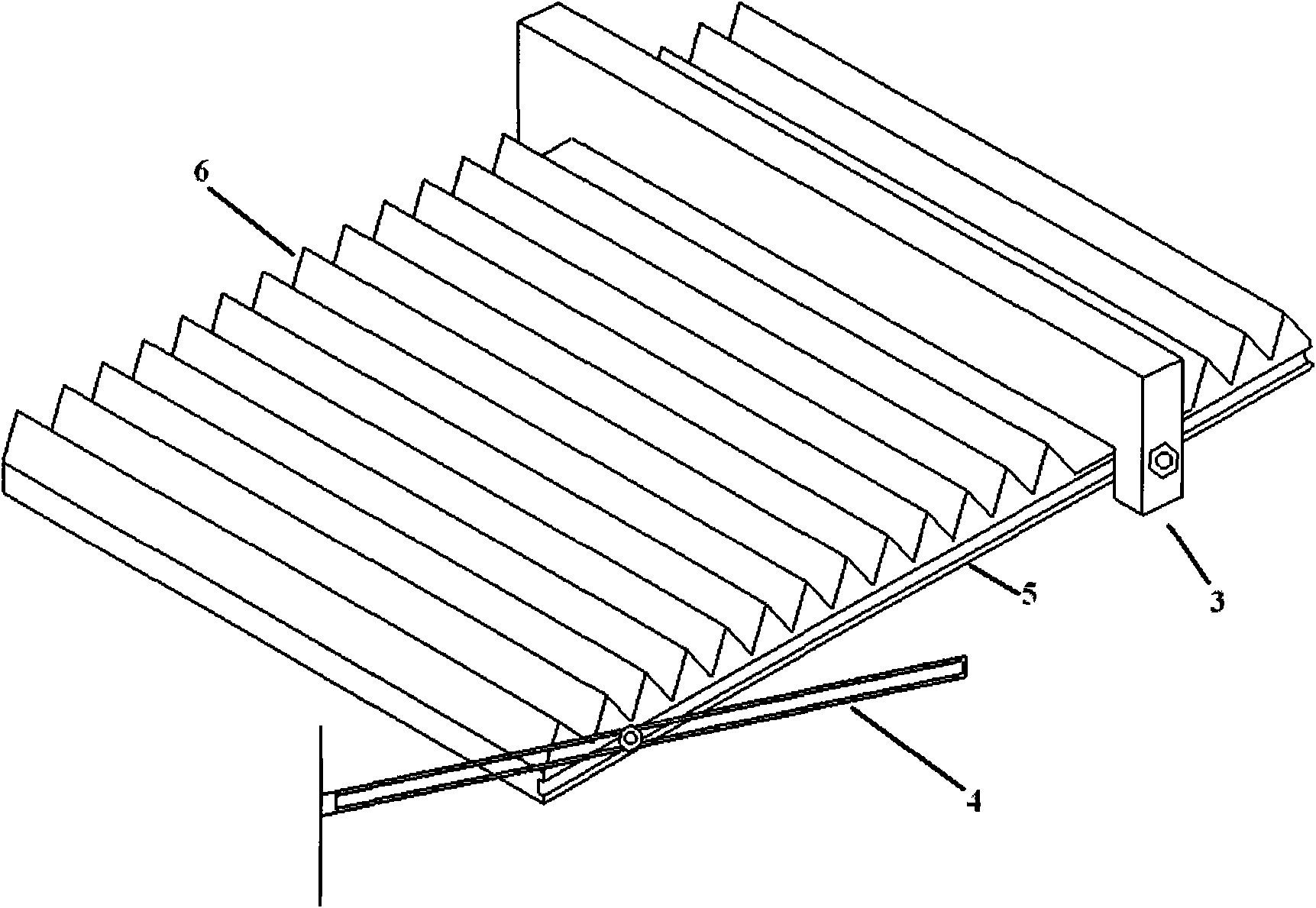

LED street lamp with adjustable light path and angle

InactiveCN101886776AReduce the temperatureExtended service lifePoint-like light sourceLighting heating/cooling arrangementsEngineeringRoad surface

The invention provides an LED street lamp with adjustable light path and angle. The LED street lamp comprises an LED light source and a heat dissipation system thereof; an LED light source module is fixed on a heat dissipation pedestal through a high heat-conducting material; serrated heat dissipation passages formed on the heat dissipation pedestal and the surface of the lamp can improve the heat dissipation property of the LED light source module and prolong the service life of an LED; and the heat dissipation pedestal is fixed in the lamp through a bracket. The included angle of the plane of the heat dissipation pedestal and the pavement can be adjusted by adjusting the bracket so as to fulfill the purposes of adjusting the luminous light path and angle and adjusting the illumination area of the pavement.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com