Retractable mud dredging system based on spiral working manner

A mud system and screw technology, applied in the field of retractable dredging system, can solve the problems of limited dredging area and low work efficiency, and achieve the effects of reducing manual operation, improving work efficiency, and increasing the area of single operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

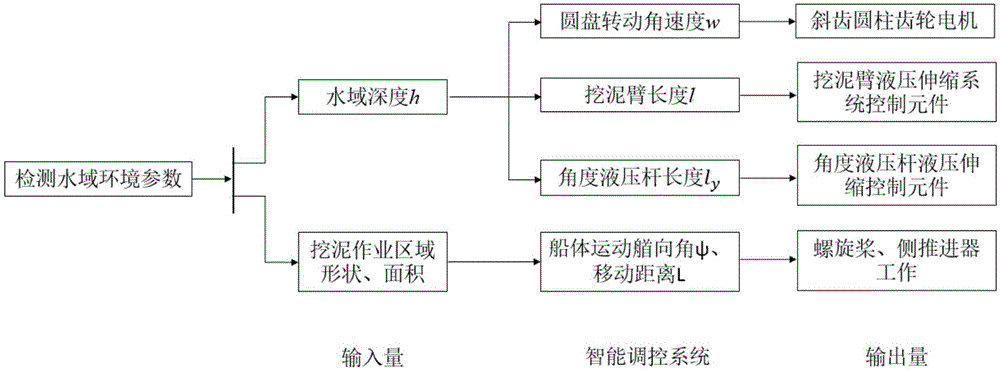

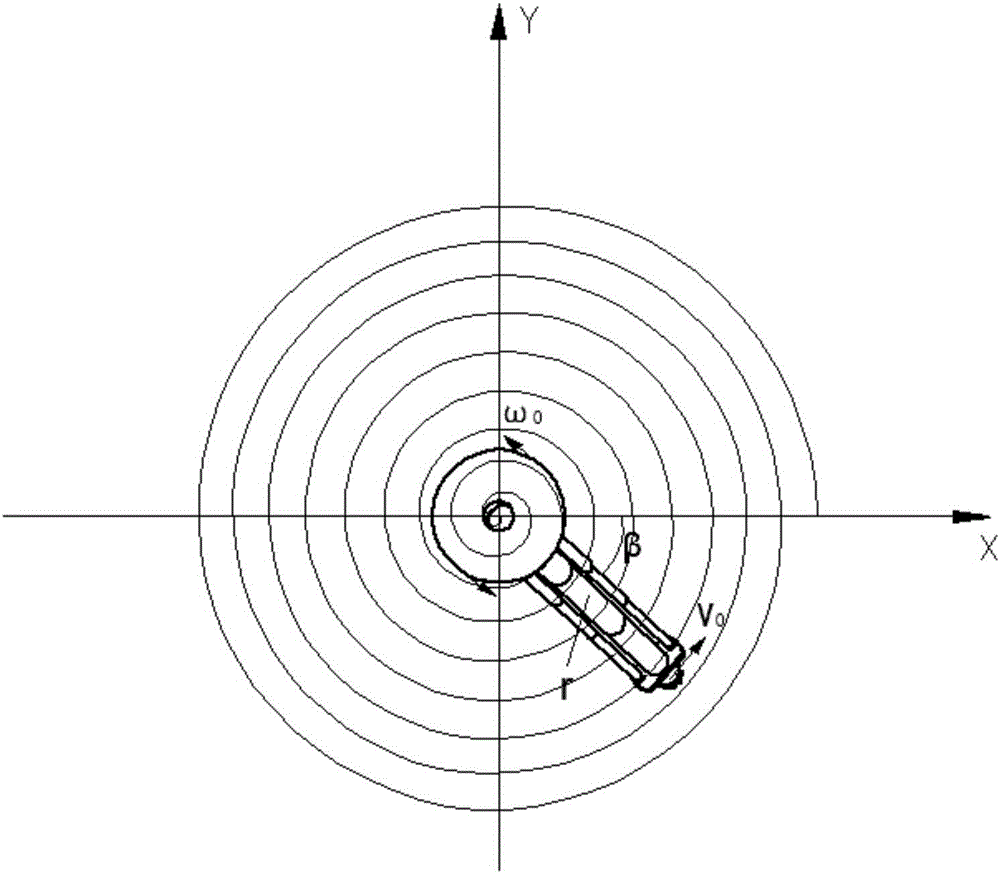

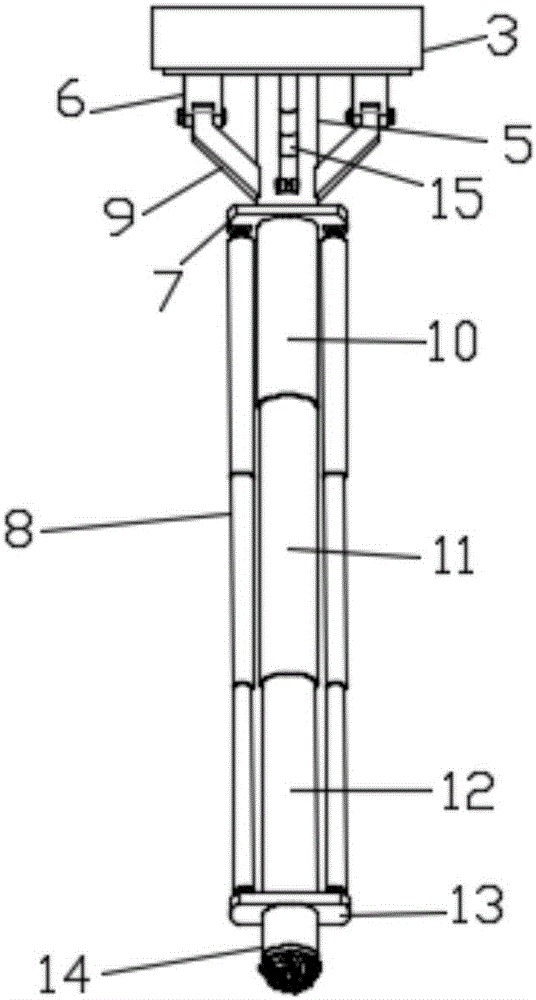

[0037] The telescopic dredging system based on the spiral operation method provided by the present invention is mainly composed of a gear-driven rotating disc coordinated with a hydraulically driven hydraulic arm and a hydraulic control mechanism. The length of the dredging arm and the angle between the dredging arm and the plane of the ship's bottom are adjusted, so that the reamer moves along the helical trajectory, constantly changing the radius of the dredging operation, and finally realizes the circular area dredging operation.

[0038] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited.

[0039] The retractable dredging system based on the spiral operation mode provided by the present invention (which can be referred to as the dredging system) has a structure as follows: Figure 3-Figure 7 As shown, its position on the ship is as follows Figure 12 , Figure 13 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com