Patents

Literature

37 results about "Shell theory" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shell Theory. The shell theory is based on the elasticity mechanics and some engineering assumptions (such as Kirchhoff hypothesis, Kirchhoff-Love assumption, etc.), and studies the stress distribution, deformation, and stability of shell structures under external forces.

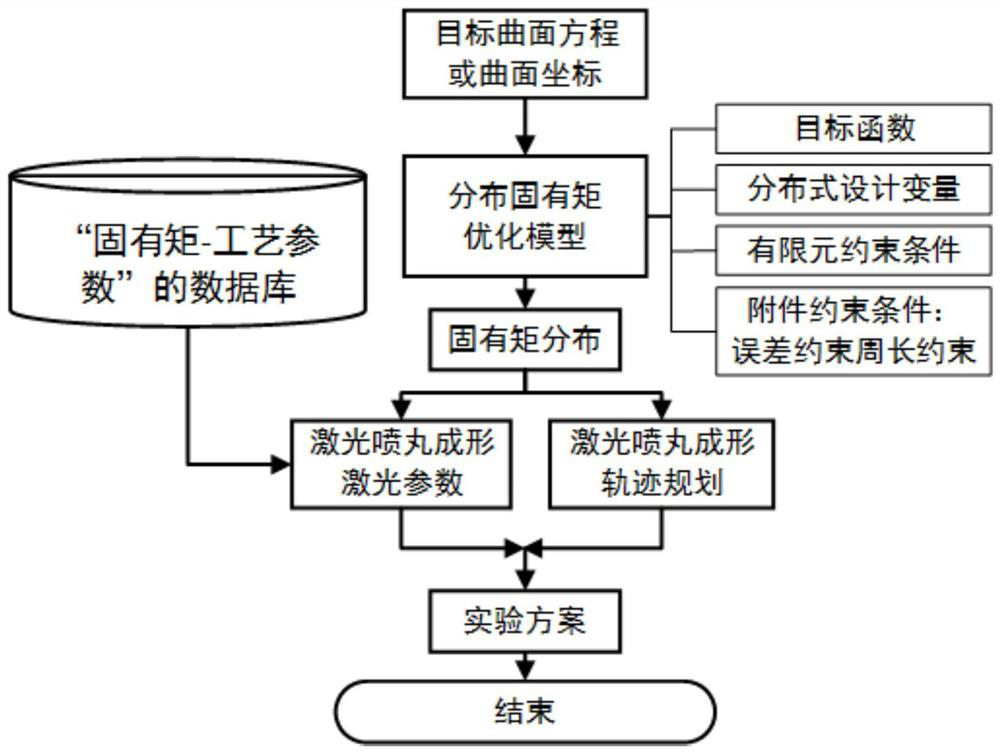

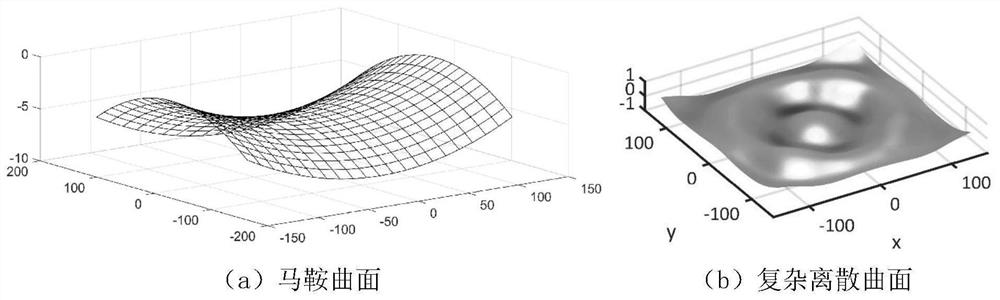

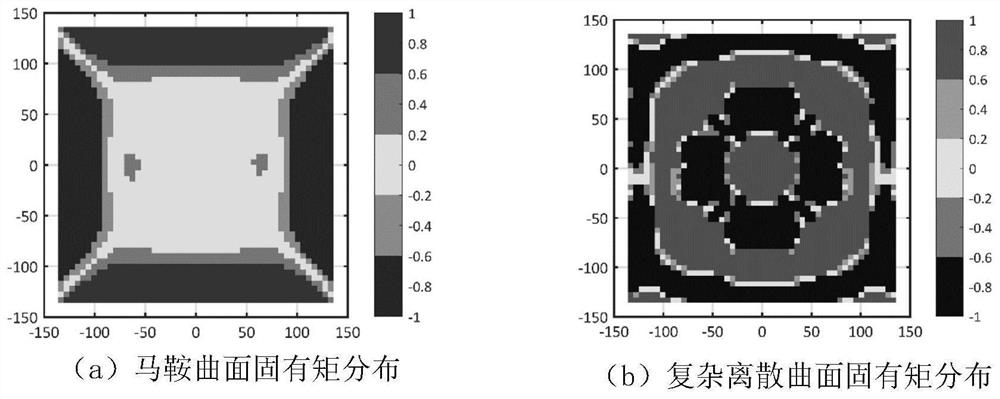

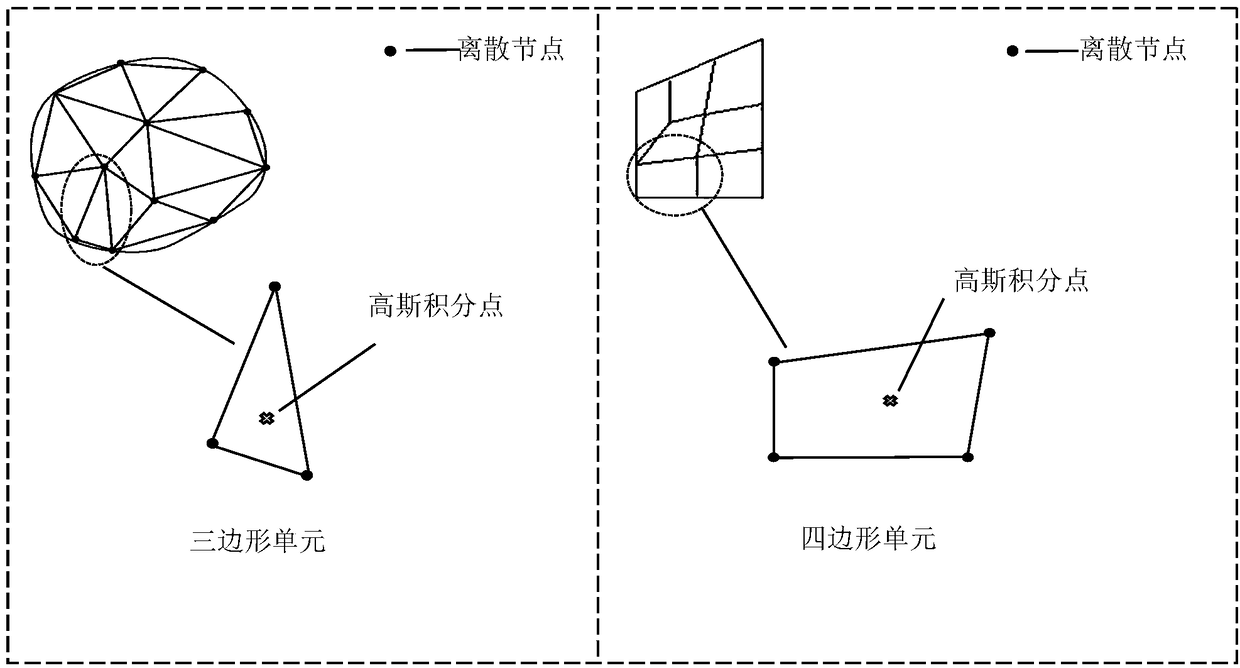

Method for determining distributed process parameters of laser peening forming complex curved surface

ActiveCN110543654AImprove fatigue resistanceAccelerated corrosionComplex mathematical operationsShell theoryPartial differential equation

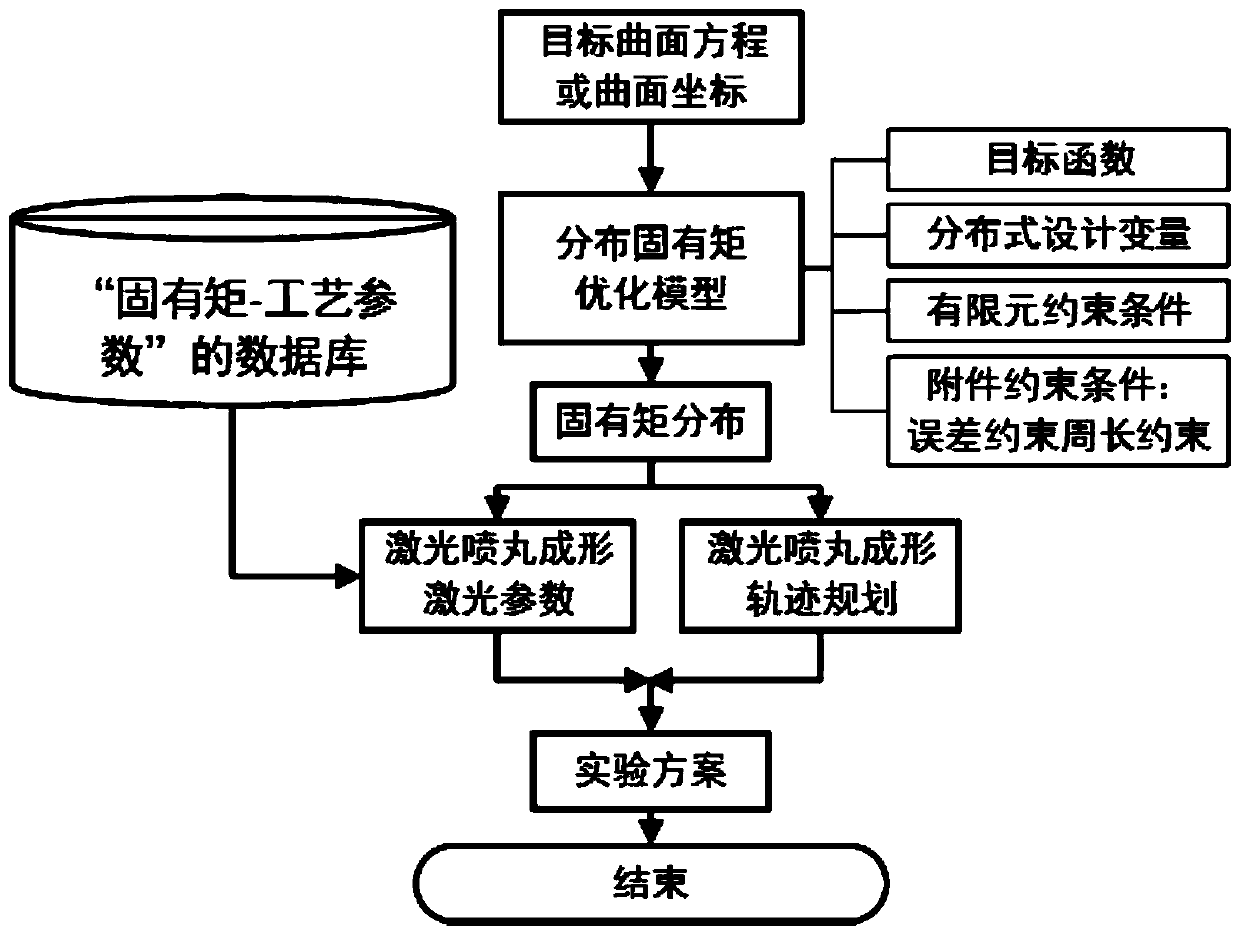

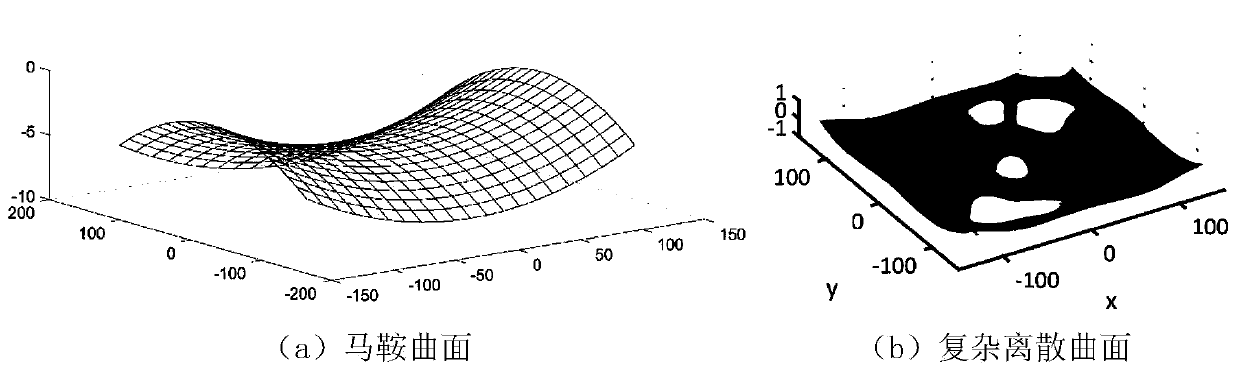

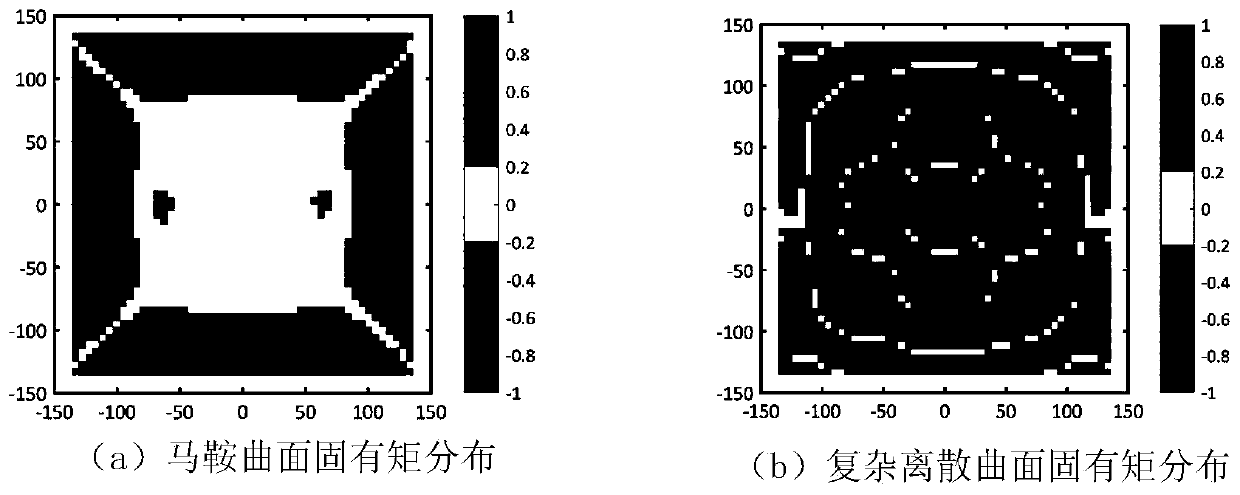

The invention provides a method for determining distributed process parameters of a laser peening forming complex curved surface. The method comprises the following steps: establishing a function relationship between a deflection curved surface and an intrinsic moment based on plate shell mechanics, and establishing an optimization model based on partial differential equation constraint by takinga distributed intrinsic moment function as a design variable; according to a curved surface parameter equation or a curved surface coordinate of the workpiece, dispersing a target curved surface, selecting an appropriate optimization algorithm to solve an optimization model, and calculating a distributed natural moment; dividing into a plurality of isoparametric areas convenient for process operation according to the size of the distributed natural moment, and determining a laser peening forming scanning scheme in each area; and establishing a process database corresponding to process parameters and inherent moments through experiments, determining the experiment process parameters, and determining the optimal distributed process parameters in combination with the requirements of residualstress. The method for determining the complex curved surface forming technological parameters is established on the basis of the elastic plate shell theory, and high efficiency and precision are achieved.

Owner:SHANGHAI JIAO TONG UNIV

Subway tunnel segment service performance detection method based on wave velocity determination

InactiveCN102955004AAnalysing solids using sonic/ultrasonic/infrasonic wavesShell theoryFlexural waves

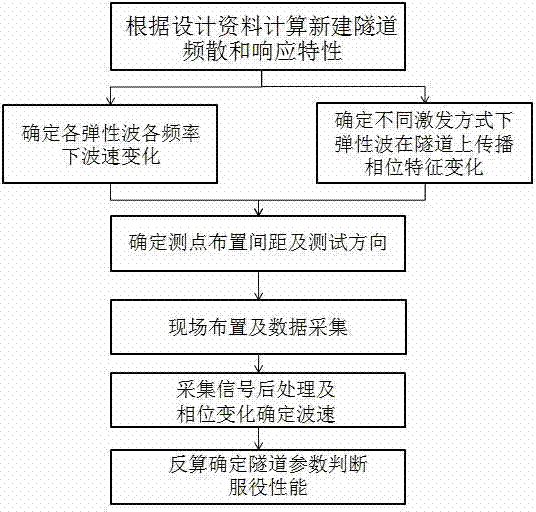

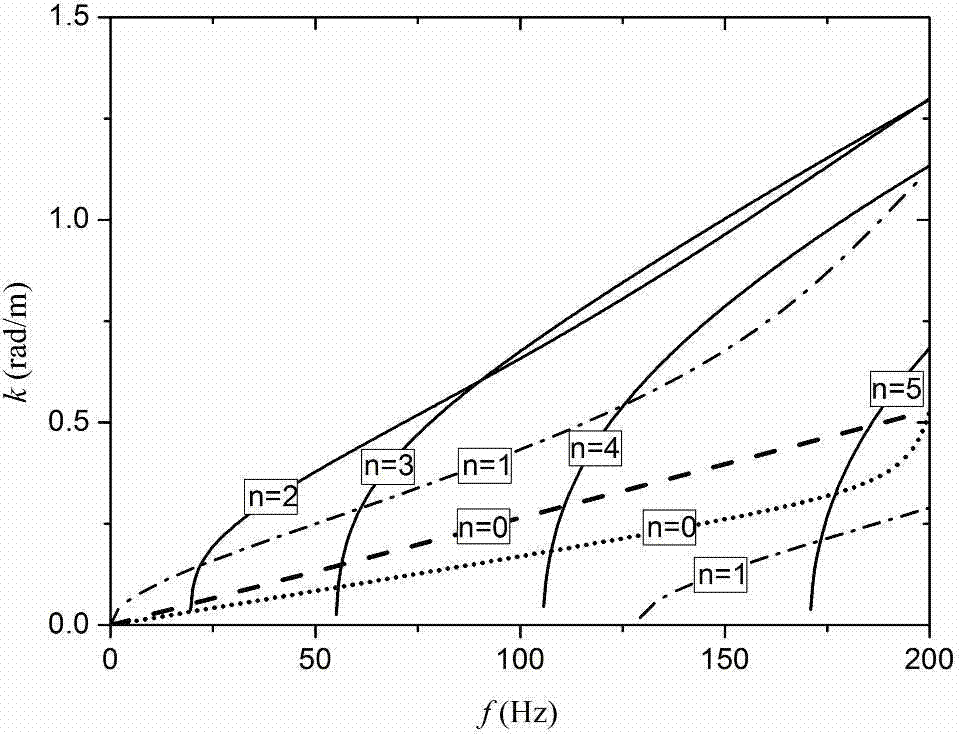

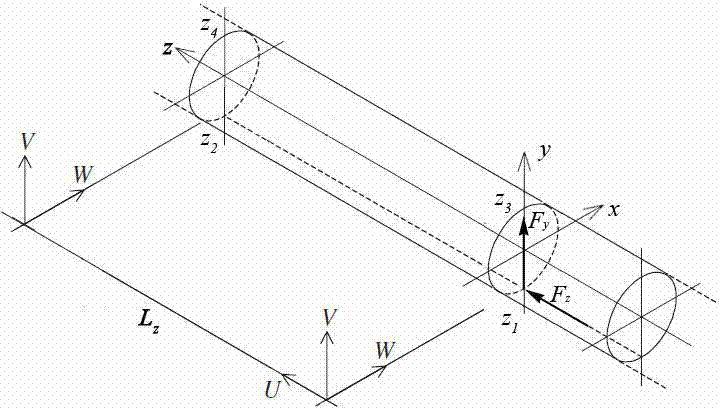

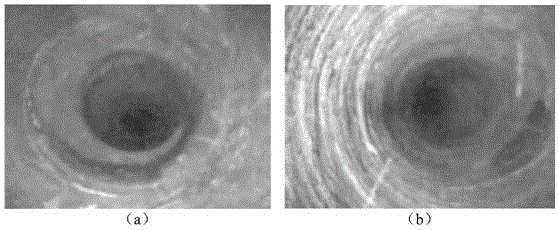

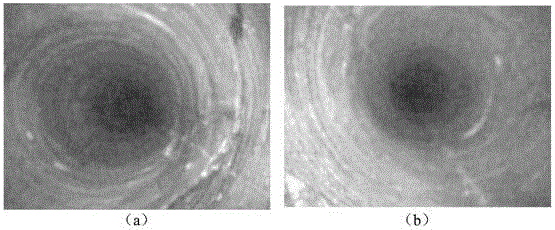

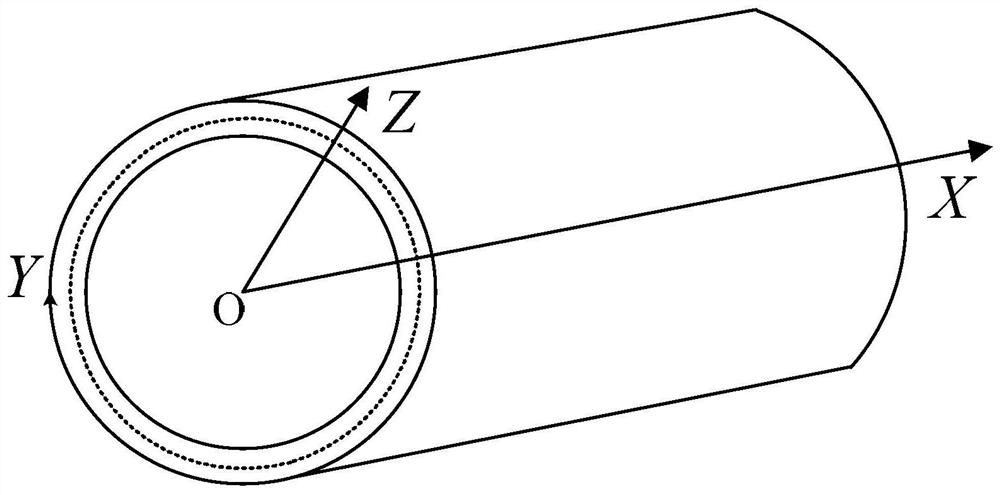

The present invention relates to a subway tunnel segment service performance detection method based on wave velocity determination. According to the method, on the basis of hollow tubular structure modality dispersion analysis based on a thin-walled shell theory, propagation laws and propagation velocities of various elastic waves in a tubular structure are determined; a wired testing system is adopted or a wired testing system is matched with an internet-of-things technology to reasonably set an acceleration and a velocity sensor; and vibration signals are dynamically collected through specific hammer and other pulse wave excitation manners, and frequency phase characteristics of the signals are determined through HHT (Hilbert-Huang transformation) and other signal post-treatment manners so as to extract wave velocities of specific bending waves and compression waves to determine a structure service performance between various detection points.

Owner:TONGJI UNIV

Filling mining overlying rock fault zone height determining method based on plate and shell theory

The invention belongs to the field of coal mine filling mining rock layer control, and particularly relates to a filling mining overlying rock fault zone height determining method based on a plate and shell theory. The method comprises the following steps of firstly, judging the position of a hard rock layer; then, obtaining the critical load and the limit displacement of the hard rock layer; next, obtaining the free space height under the hard rock layer and the overlying load on the hard rock layer; and judging whether the fault zone develops or not by comparing the critical load with the overlying load on the hard rock layer and comparing the limit displacement with the free space height under the hard rock layer. Various basic parameters related in the method can be obtained after working face mining design completion by methods such as geological data and experiment tests. The method has the advantages that the theoretical and data basis can be provided for the overlying rock damage prevention and treatment measures adopted in the filling mining process; and the disaster due to filling mining working face overlying rock damage is reduced. The method provided by the invention has wide practicability on the analysis of the filling mining overlying rock activity rule.

Owner:LIAONING TECHNICAL UNIVERSITY

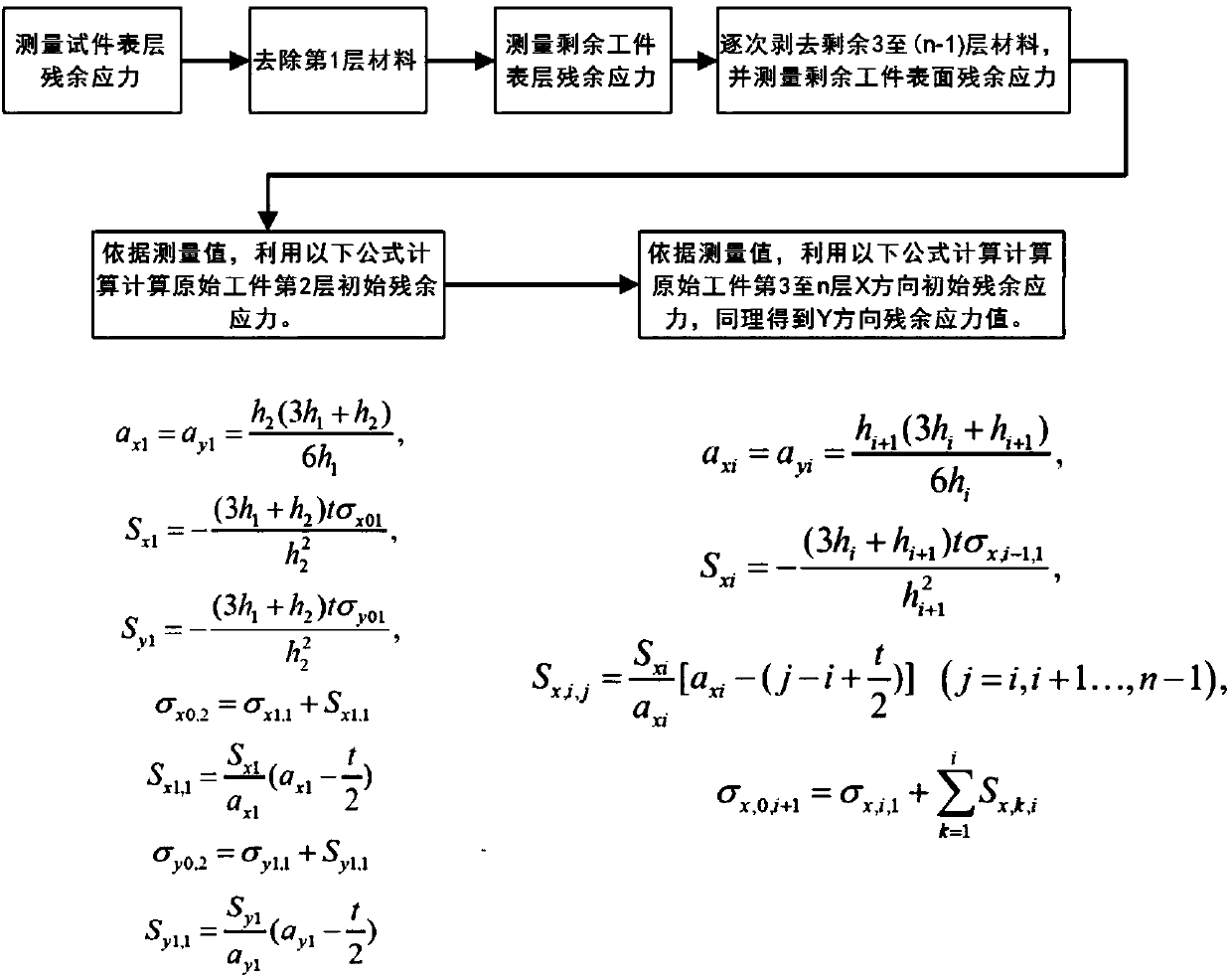

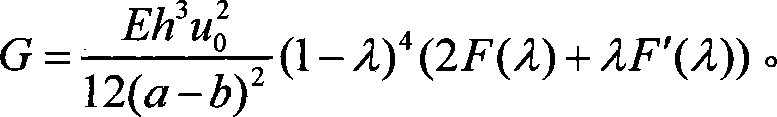

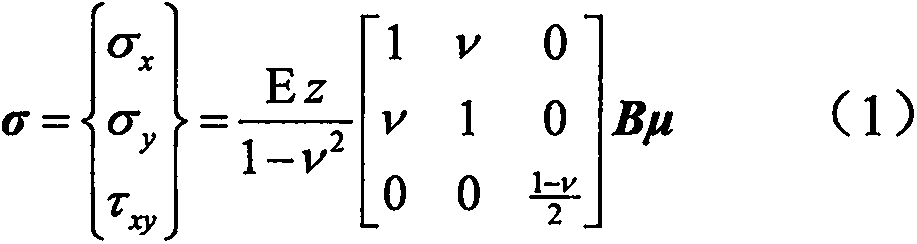

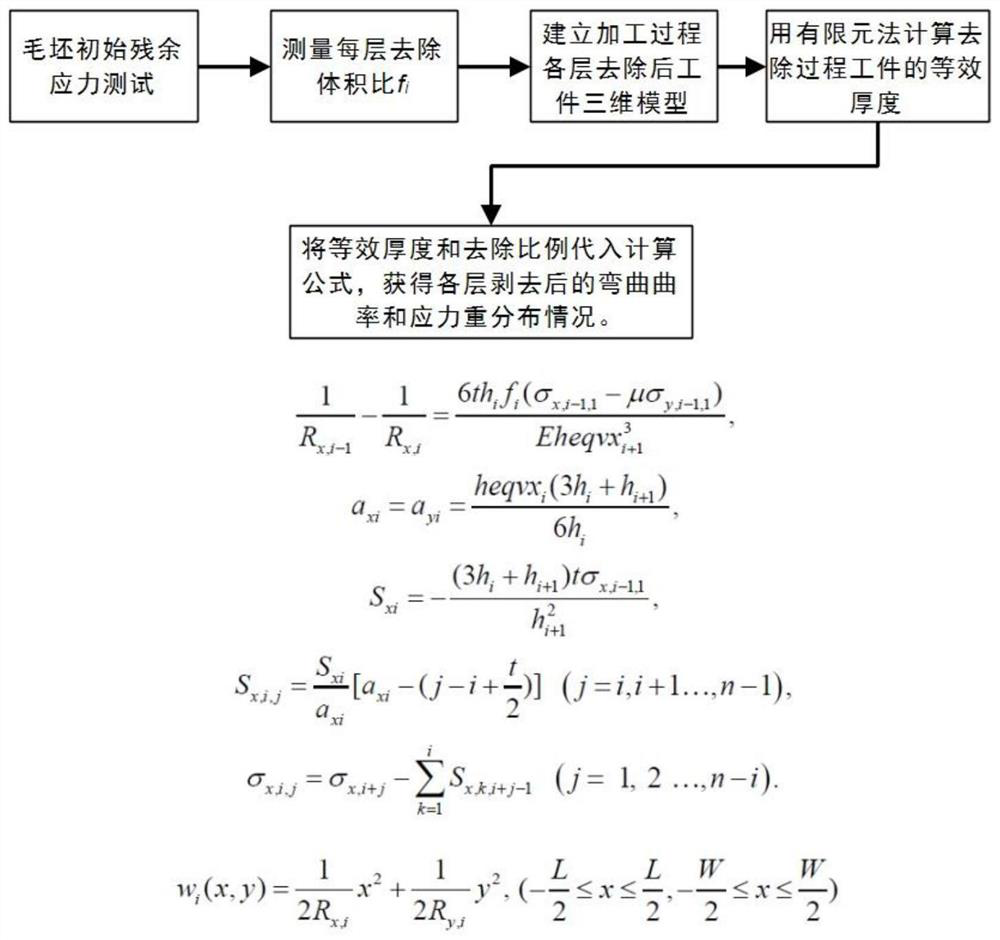

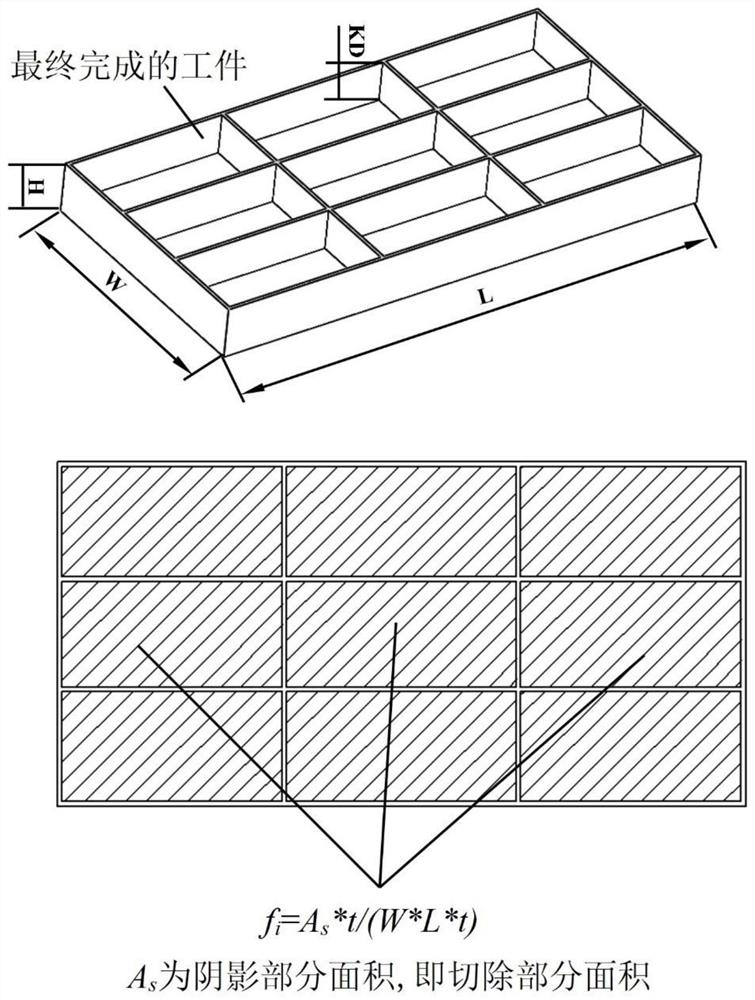

Correcting method for layer-peeling-method residual stress measurement value based on plate and shell theory

InactiveCN107729605AImprove correction accuracySimple procedureGeometric CADDesign optimisation/simulationShell theoryCalculation methods

The invention provides a correcting method for a layer-peeling-method residual stress measurement value based on the plate and shell theory. For increasing the measurement accuracy of the residual stress inside a material of the layer peeling method, based on the elastic mechanics and the plate and shell theory, a calculating method for releasing of the residual stress inside the material in the material removing process is deduced, and therefore the conversion relationship between surface residual stress peeled layer by layer and initial residual stress of a layer is established; under the condition that all kinds of surface residual stress after layer peeling are known, the initial residual stress of the layer can be reversely calculated and obtained.

Owner:BEIHANG UNIV

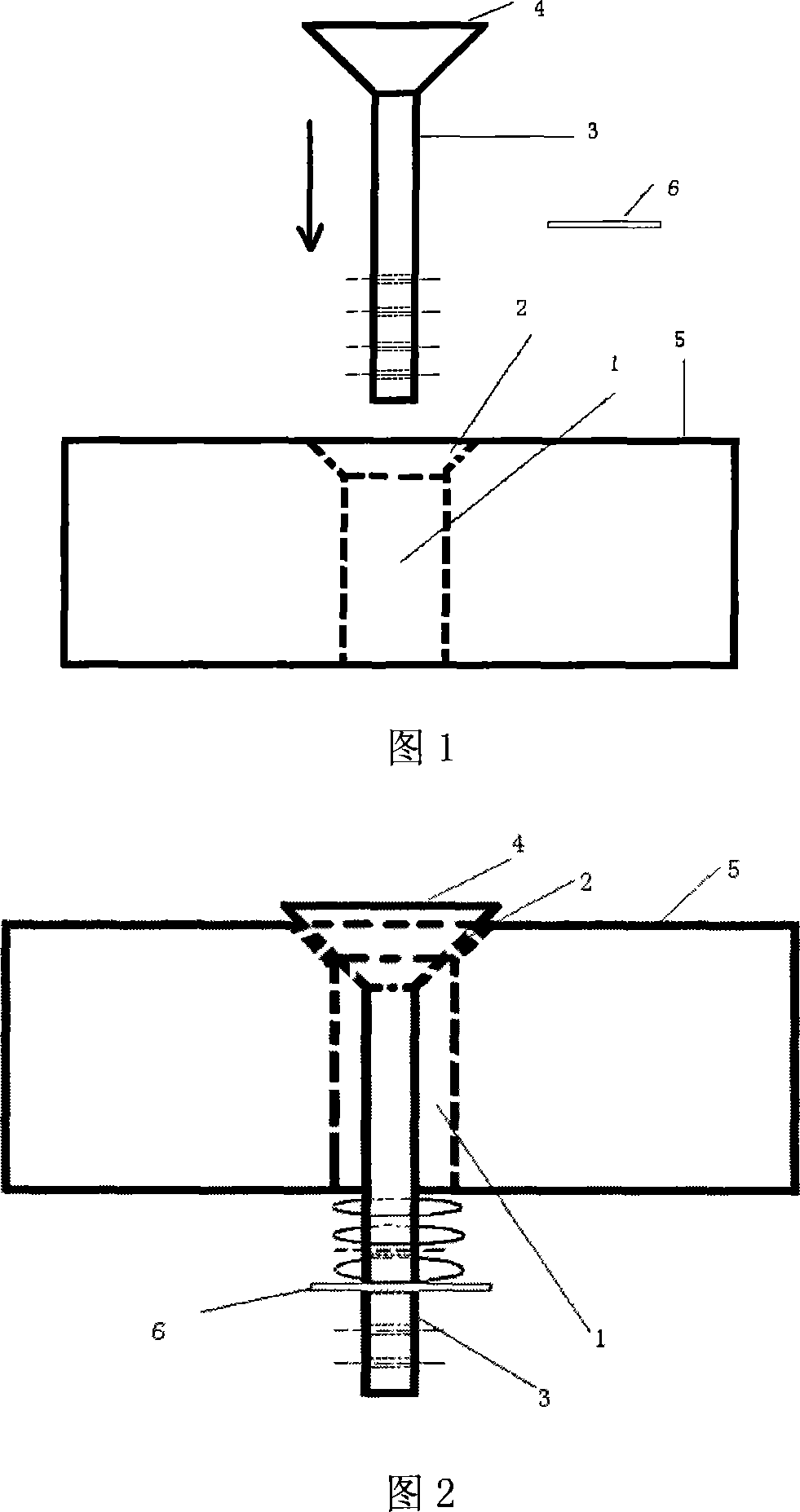

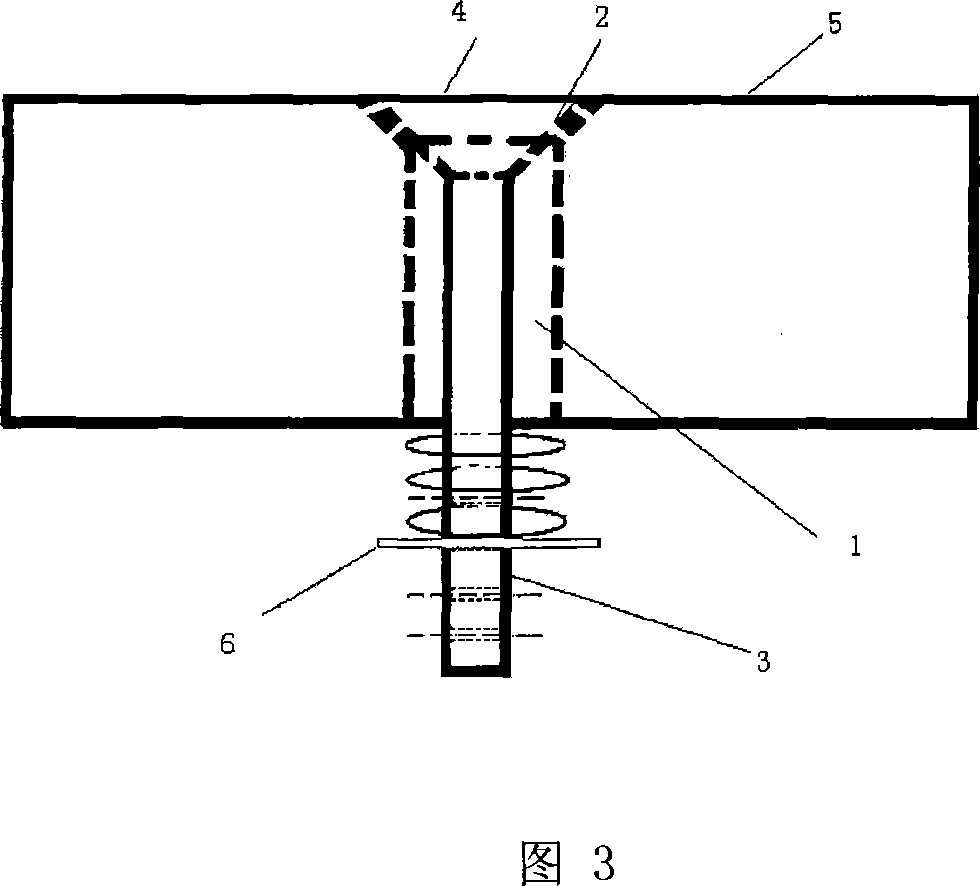

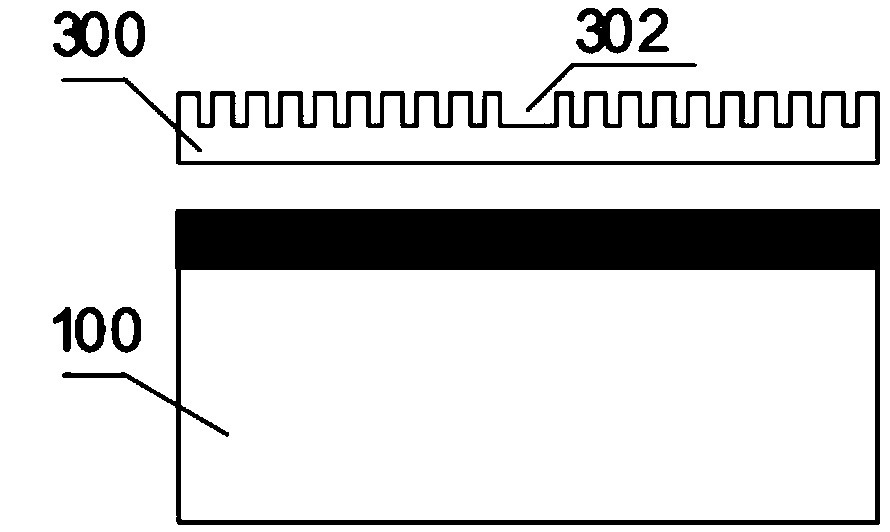

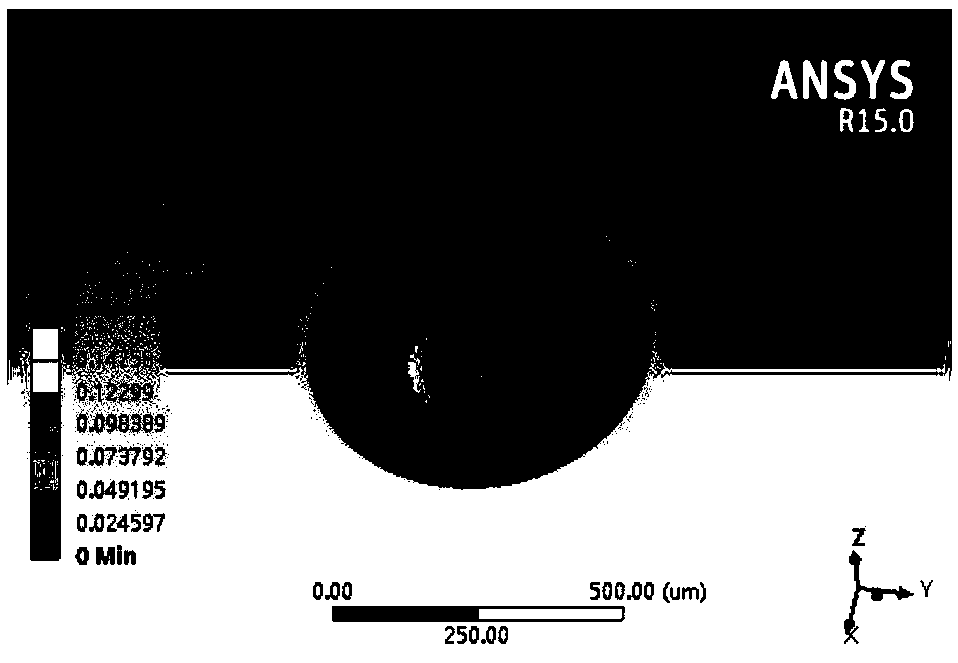

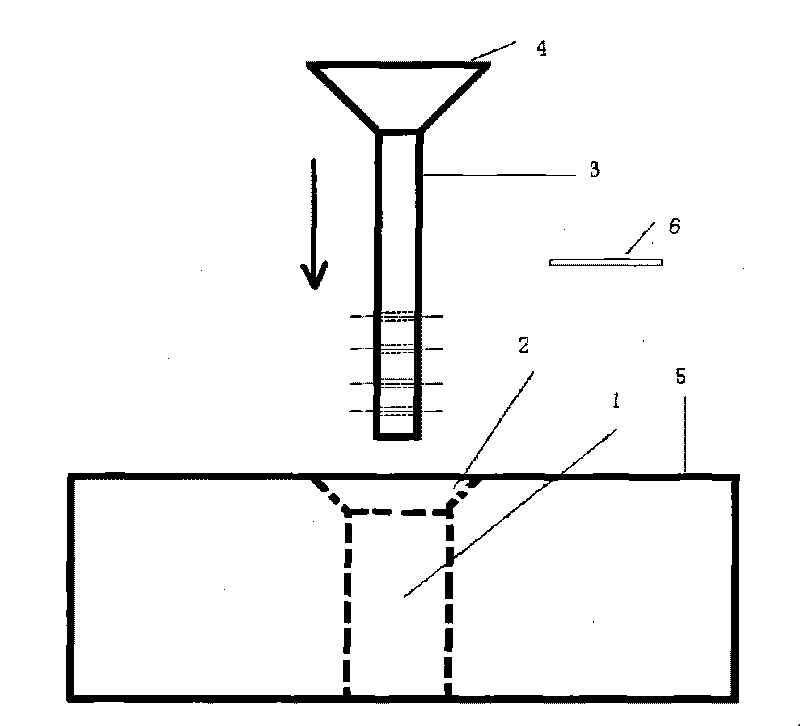

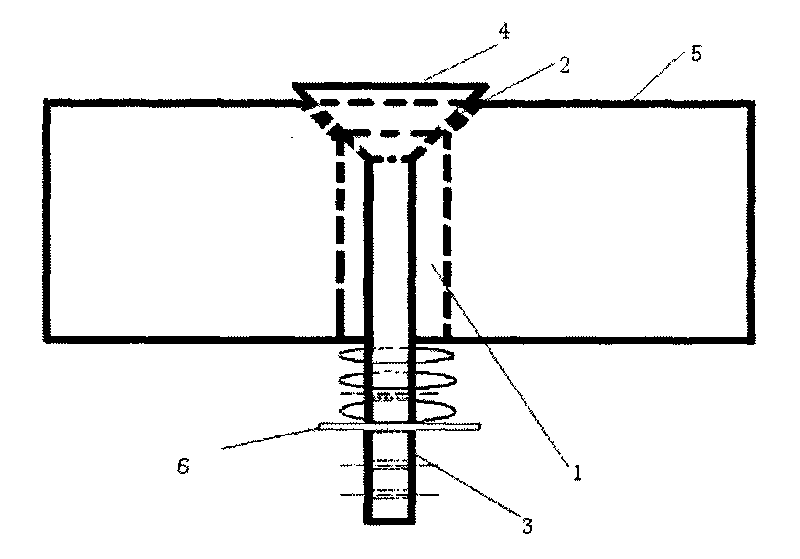

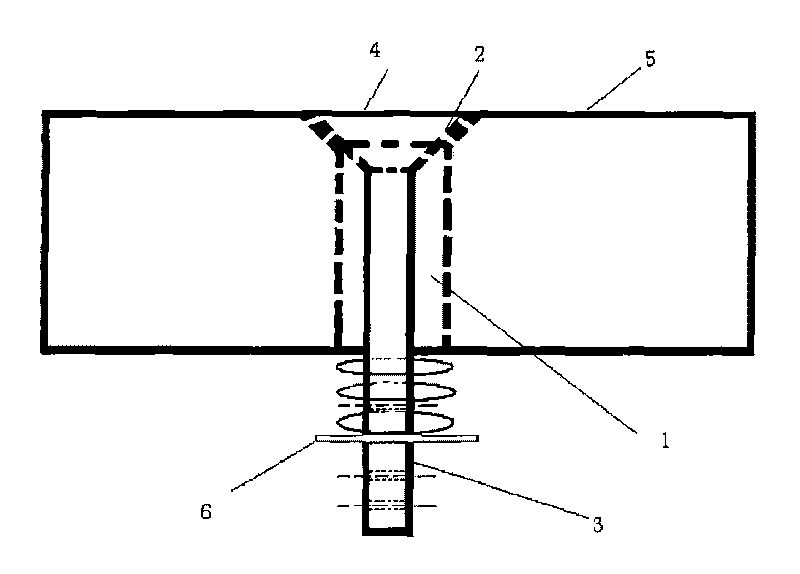

Back penetration measuring method for film base binding performance

InactiveCN101122561ABreak outSimplify traditional craftSemiconductor/solid-state device testing/measurementUsing mechanical meansBasementShell theory

The invention relates to a back penetration type measurement method for film-substrate cohesion performance in the measurement technical field. An ejector rod is adopted by the invention to penetrate the basement system of a part to be measured. Load is arranged on the lower end of the ejector rod. And the ejector rod is pushed to make a film deformed in a way of bending. The defection and the load of the film are respectively obtained by corresponding sensors when loaded in a static load form. The film-substrate cohesion of the part to be measured under static load is worked out through the plate shell theory. When load is added in a dynamic form, a relationship between the crack growth length and the cycle number, which is used for evaluating the fatigue performance of the film, is built up through measuring the radius of a film salient area and recording the cycle number. The invention solves the technical problems in present technology that the precast of the part to be measured is complex and the basement system is limited by silicon material. The invention can quantitatively measure the film-substrate cohesion performance, precisely determine the film-substrate cohesion and obtain the fatigue performance parameters of the film.

Owner:SHANGHAI JIAO TONG UNIV

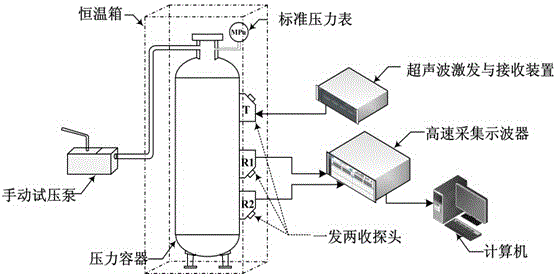

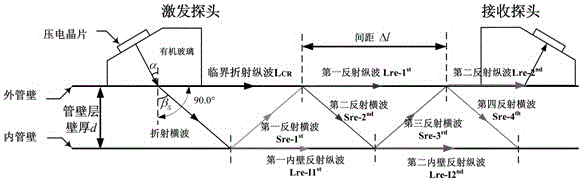

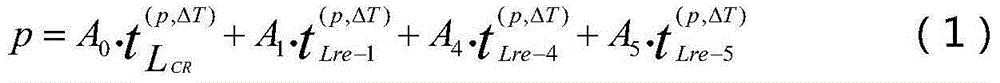

Ultrasonic non-intervention pressure detection method based on information fusion of plurality of transition waveforms

The invention discloses an ultrasonic non-intervention pressure detection method based on information fusion of a plurality of transition waveforms. According to the method, a critical refraction longitudinal wave, a first reflection longitudinal wave, a fourth reflection longitudinal wave and a fifth reflection longitudinal wave are selected as pressure detection waveforms; and the relation between a pressure in a container and an ultrasonic speed is derived by the use of an ultrasonic sound elasticity principle and a plate and shell theory, and then the measuring module of the relation between a time delay and the container pressure is established according to the relation between the ultrasonic speed and the time delay. Based on the idea of information fusion, a plurality of waveforms are used as detection waveforms, and under the condition that time delay measuring precision of a single ultrasonic wave is not high, the relatively high pressure detection precision can still be realized. According to the method, transmission time delays, including pressure information and temperature information, of each waveform serve as input variables of the measuring module, and there is no need to measure temperature parameters of a container wall, so that errors generated in the temperature measuring process is avoided. Verified by experiments, the method is relatively high in measuring precision.

Owner:ZHEJIANG UNIV

Computing method for accurately analyzing internal pressure strength of grid reinforced cylindrical shell

ActiveCN106777741AImprove carrying capacityReduce structural weightGeometric CADSpecial data processing applicationsInternal pressureShell theory

The invention provides a computing method for accurately analyzing the internal pressure strength of a grid reinforced cylindrical shell. The computing method comprises the following steps: 1) performing 'flattening' treatment on rigidity of ribs in the grid reinforced cylindrical shell; 2) calculating the tension and compression stiffness of the ribs according to the laminated shell theory; 3) obtaining a rib / skin mass ratio and longitudinal and horizontal equivalent thicknesses of the grid reinforced cylindrical sell according to a tension and compression stiffness computation formula; and 4) computing the internal pressure strength of the grid reinforced cylindrical sell. The computing method provided by the invention is suitable for all kinds of grid form structures, and is used for designing and computing the internal pressure strength under the joint load action of pure internal pressure, axial pressure, bending moment and internal pressure, thereby obtaining ultimate bearing capacity; and the method is more intuitive and clear as well as simple and convenient, and is favorable for improving the bearing capacity of a grid reinforced structure, reducing the weight of the structure and realizing accurate and fast design of strength.

Owner:DALIAN UNIV OF TECH +1

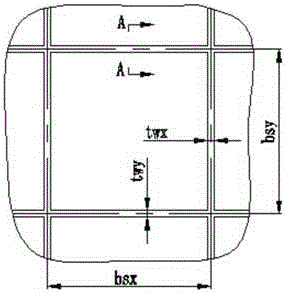

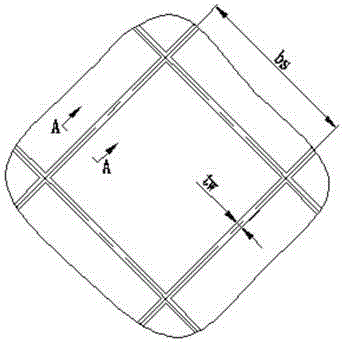

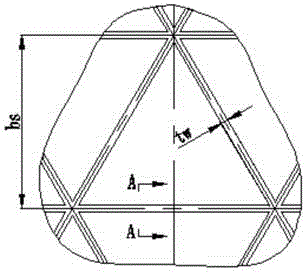

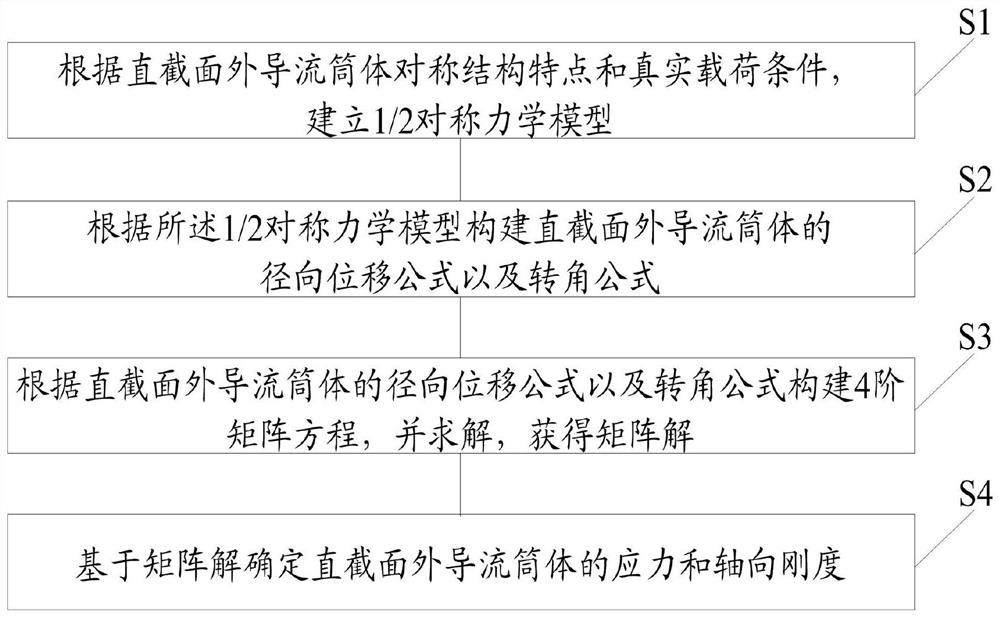

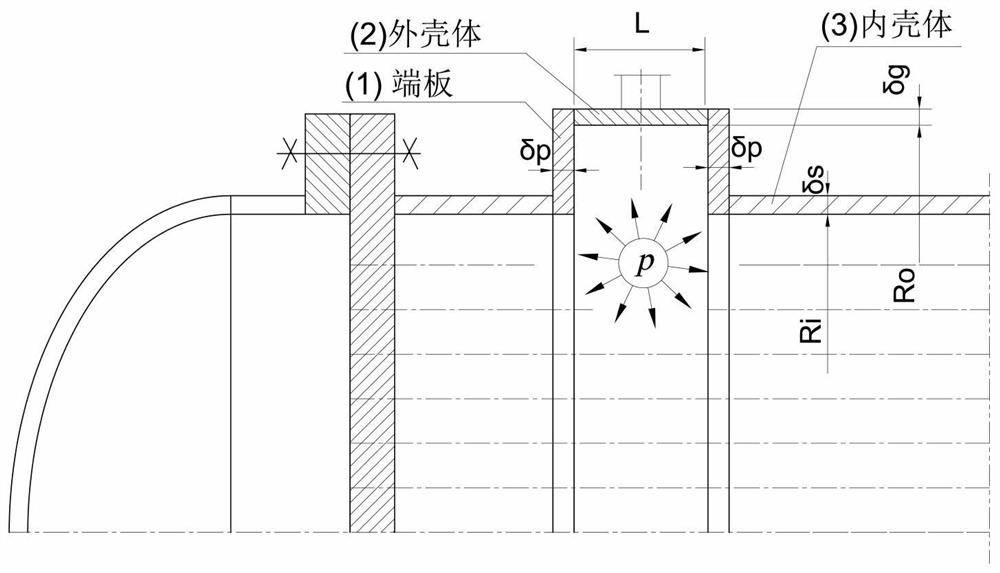

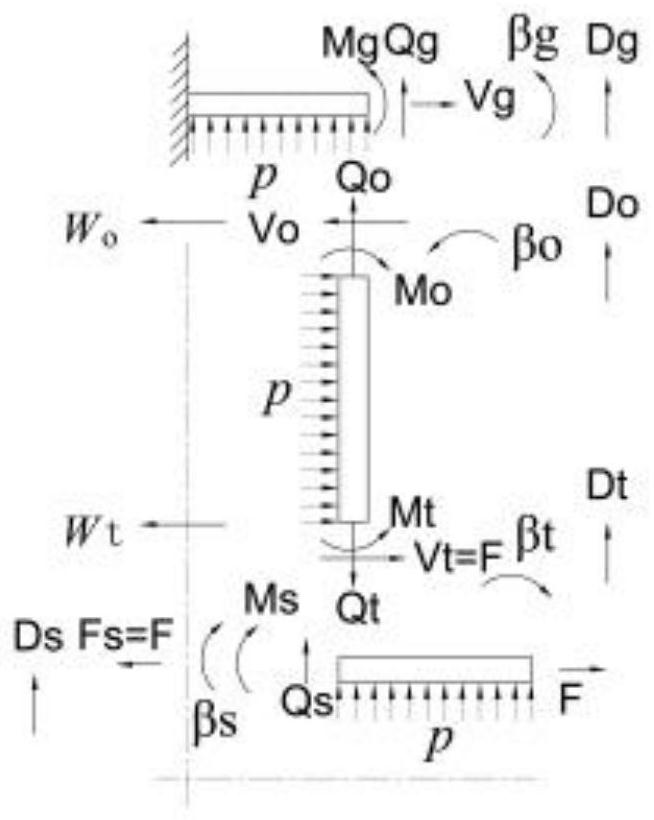

Stress and rigidity calculation method and system for straight-section outer guide cylinder

ActiveCN113032981AIncrease stressIncrease stiffnessGeometric CADDesign optimisation/simulationShell theoryMatrix solution

The invention provides a stress and rigidity calculation method and system for a straight-section outer guide cylinder, and the method comprises the steps: firstly building a 1 / 2 symmetric mechanical model according to the symmetric structure characteristics and real load conditions of the straight-section outer guide cylinder; secondly, according to the 1 / 2 symmetric mechanical model, constructing a radial displacement and rotation angle formula of the straight-section outer guide cylinder; constructing a four-order matrix equation according to the radial displacement and a rotation angle formula, and solving to obtain a matrix solution; and finally, determining the stress and the axial rigidity of the straight-section outer guide cylinder based on the matrix solution. The established 1 / 2 symmetric mechanical model not only considers symmetric structure characteristics and real load conditions of the straight-section outer guide cylinder, but also considers discontinuous structure boundary influence, the straight-section outer guide cylinder is split into three basic elements for stress analysis, the axial rigidity of the straight-section outer guide cylinder is obtained through an accurate plate-shell theory solution, the axial rigidity of the straight-section outer guide cylinder is calculated through a precise plate-shell theory, and the accuracy of calculating the stress and rigidity of the outer guide cylinder is further improved.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST

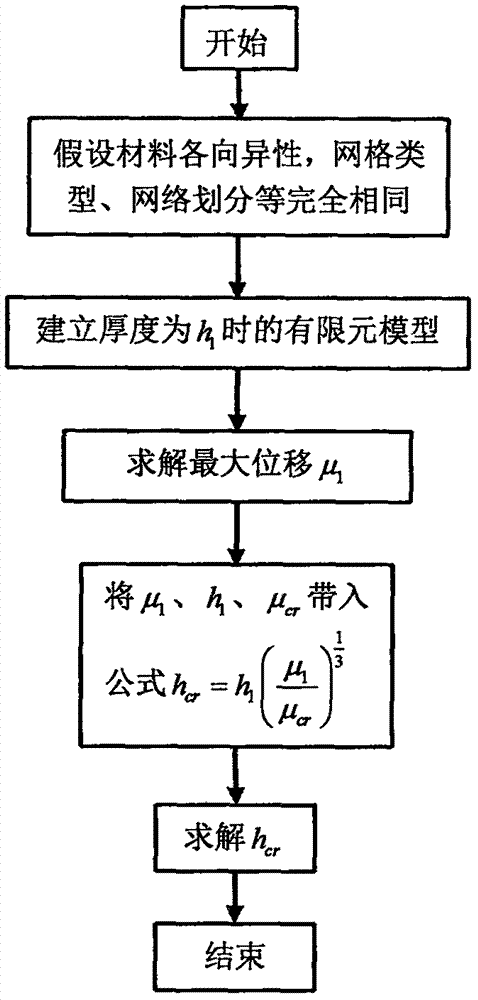

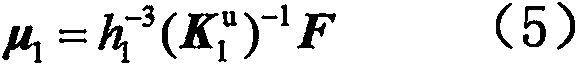

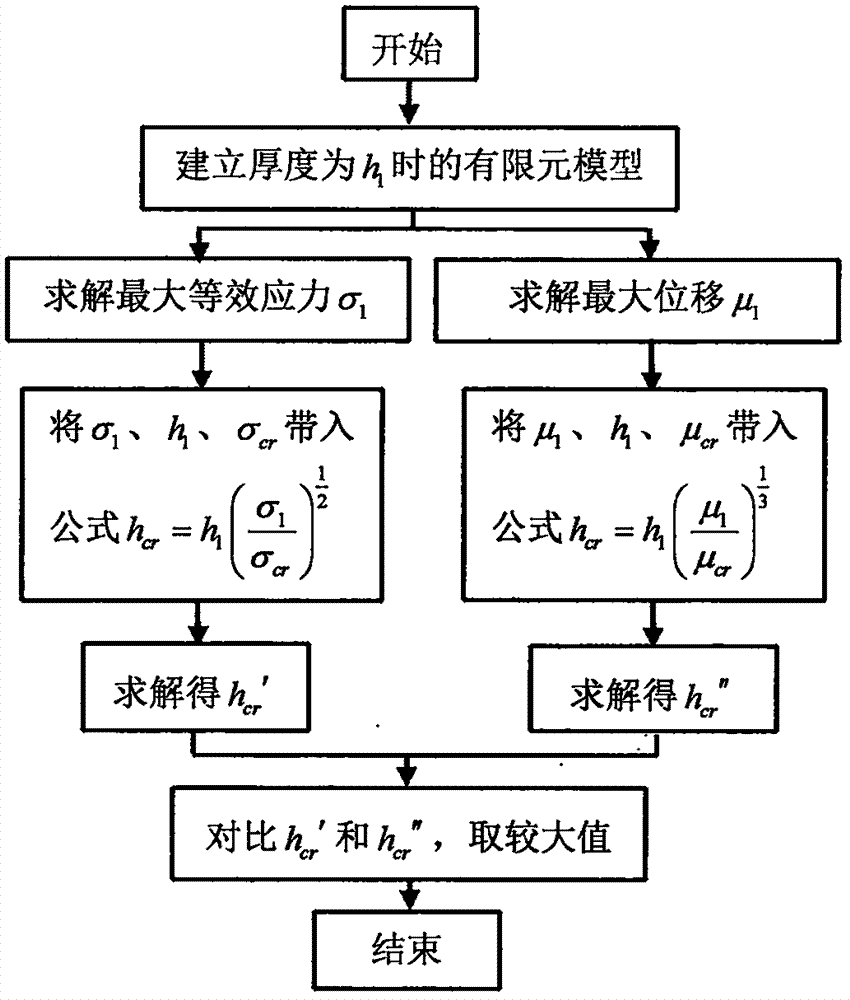

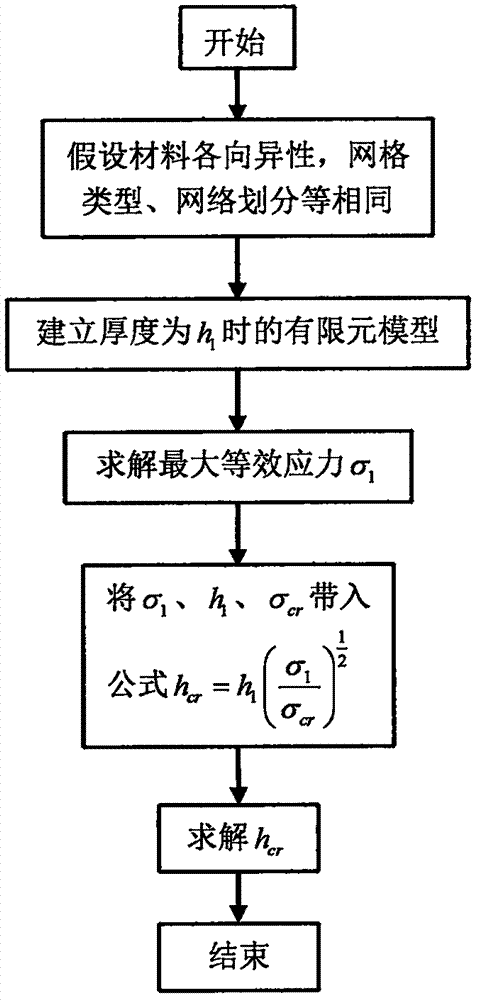

Rapid complex plate and shell thickness optimization design method based on maximum displacement

InactiveCN107292047ASmall amount of calculationEasy to solveGeometric CADDesign optimisation/simulationShell theoryFast optimization

The invention relates to a rapid complex plate and shell thickness optimization design method based on maximum displacement, and belongs to the field of rapid mechanical structure optimization design. According to a finite element theory and the theoretical relation among stress, load, displacement and a rigidity matrix in a plate and shell theory, an optimal plate and shell thickness calculation formula based on maximum displacement is deduced. As the influence of complex structural characteristics on structural performance cannot be ignored, the thickness of a complex plate and shell structure is difficultly calculated directly by the plate and shell theory. The method can be used for rapidly calculating the optimal solution of the complex plate and shell structure meeting corresponding critical maximum displacement requirements, and has the advantages of rapidness, small calculation amount, easiness in solution and the like.

Owner:GUIZHOU UNIVERSITY OF FINANCE AND ECONOMICS

Bolt connection cylindrical shell structure dynamic characteristic calculation and analysis method

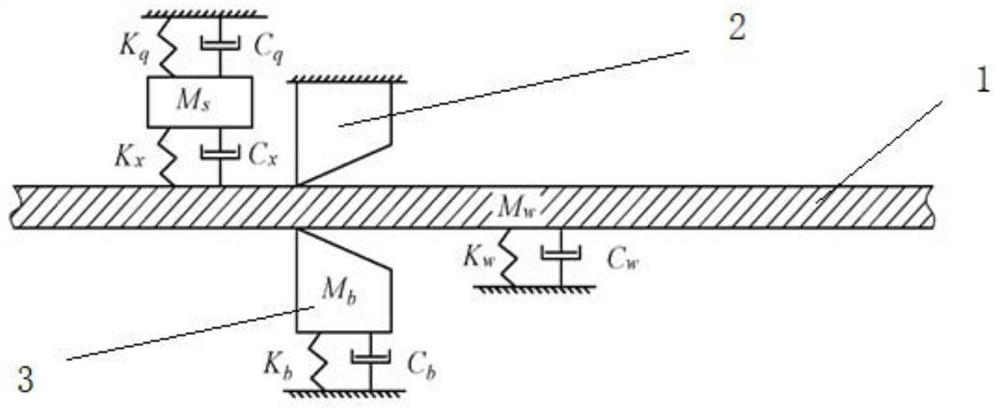

ActiveCN110569585AImprove calculation accuracyEasy to calculateSpecial data processing applicationsShell theoryMechanical models

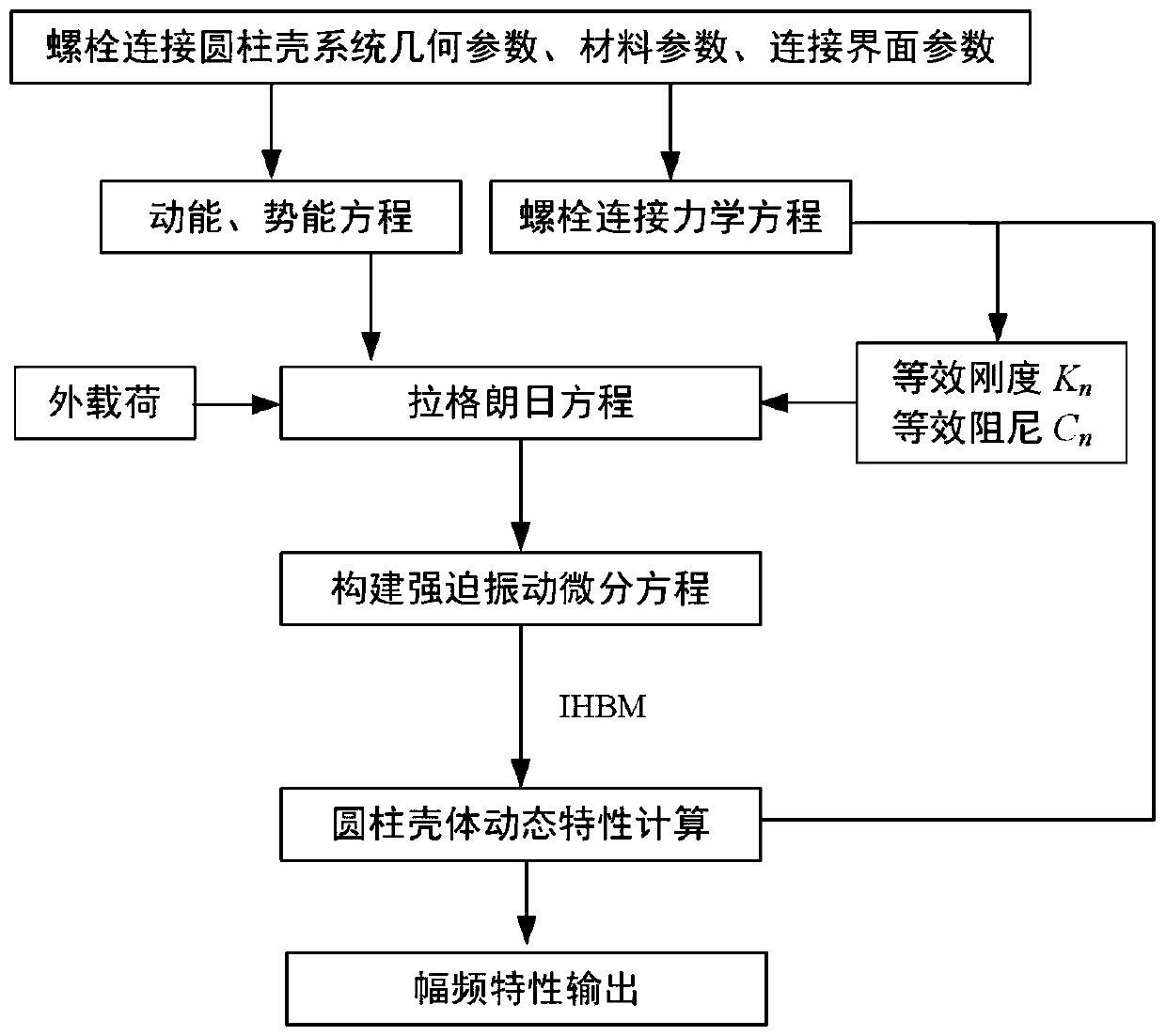

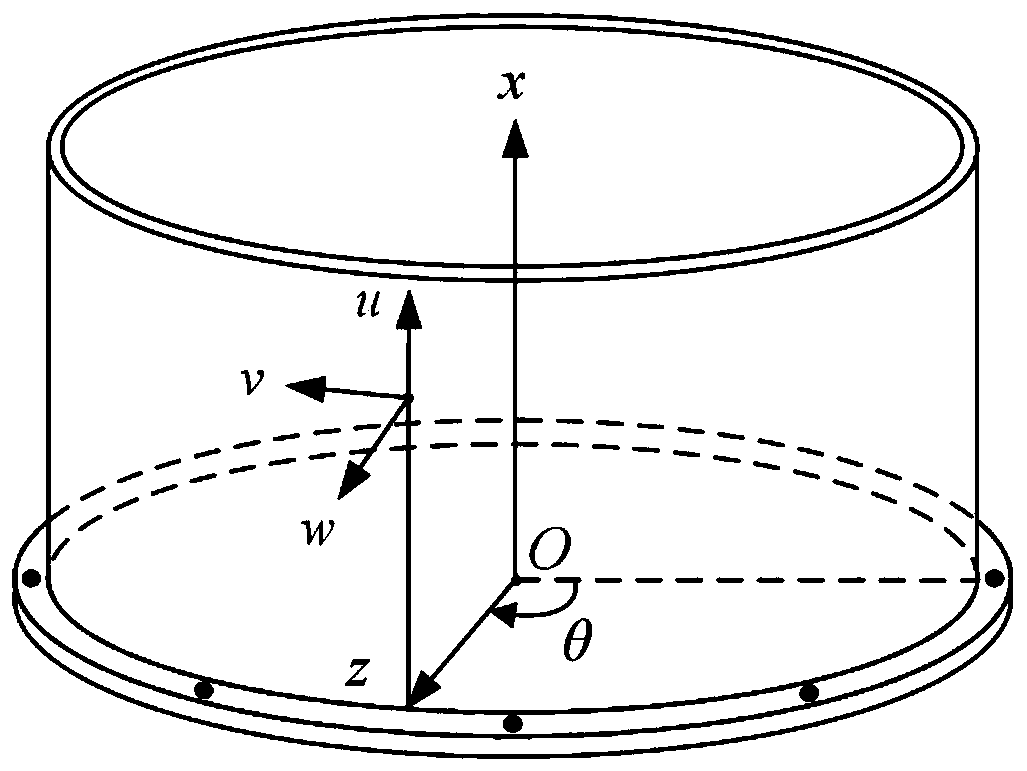

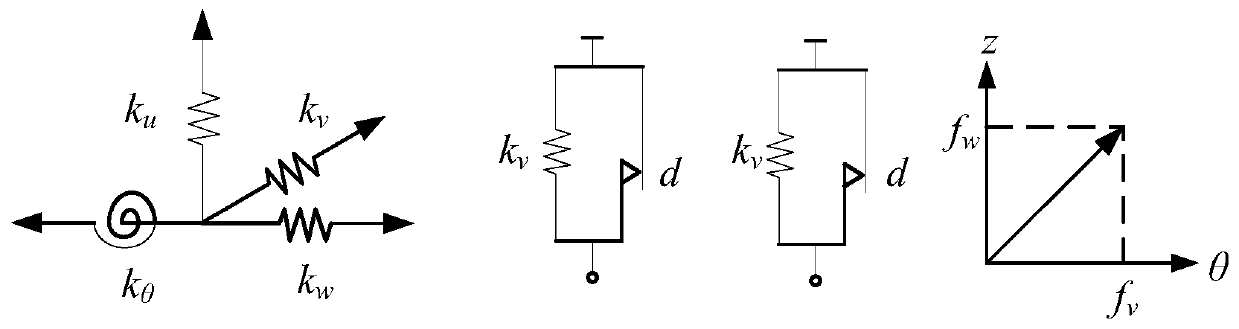

The invention provides a bolt connection cylindrical shell structure dynamic characteristic calculation and analysis method, and belongs to the technical field of mechanical dynamics. The method comprises the following steps: establishing a cylindrical shell energy equation according to a plate-shell theory; establishing a load excitation equation according to the external load condition; establishing a bolt connection mechanical equation according to the bolt connection characteristics; solving bolt connection equivalent stiffness and equivalent damping according to first-order Fourier decomposition; accurately expressing different load characteristics through component force in each vibration displacement direction; obtaining a forced vibration differential equation of the bolt connection cylindrical shell structure through a Lagrange equation; and solving the dynamic characteristics of the bolted connection cylindrical shell structure by applying an incremental harmonic balance method. The method starts from the establishment of a bolted connection equivalent mechanical model, is applied to a cylindrical shell structure, achieves the solving of the vibration response according to the demands of different actual working conditions, simplifies the modeling and calculation process, is high in precision, is high in universality, and the like.

Owner:NORTHEASTERN UNIV

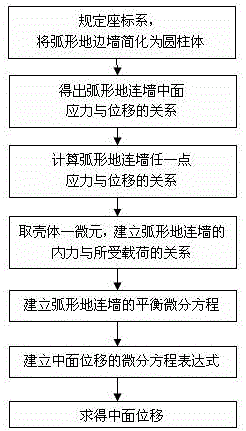

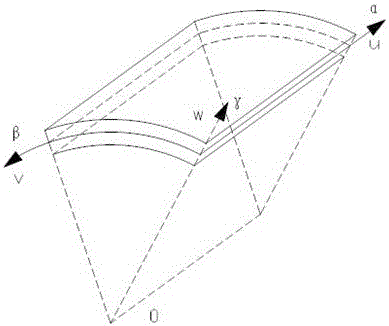

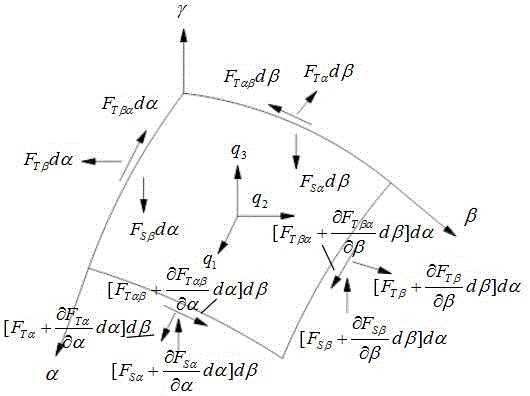

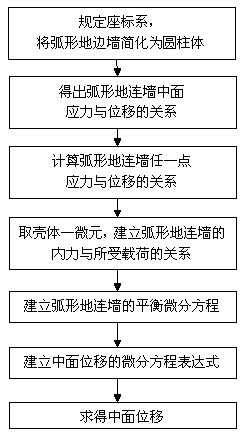

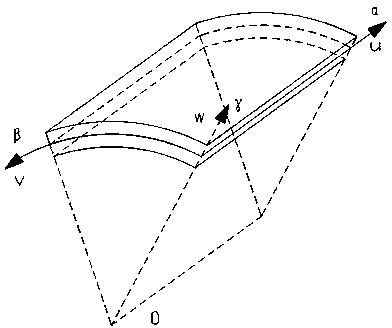

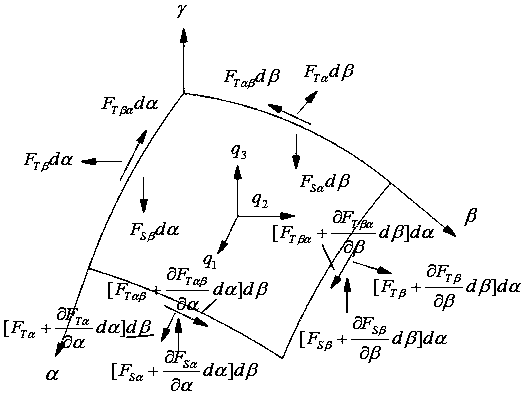

Method for calculating side displacement of arc-shaped underground continuous wall

InactiveCN105808505AAccurate lateral displacementMeasurement devicesComplex mathematical operationsShell theoryStructural engineering

Provided is a method for calculating side displacement of an arc-shaped underground continuous wall. The method comprises the steps that the arc-shaped underground continuous wall is simplified as a cylindrical shell, a curvilinear coordinate system is established, the relationship between surface strain in the arc-shaped underground continuous wall and the displacement is established according to a classical shell theory, the relationship between stress of any point of the arc-shaped underground continuous wall and the displacement and a balance differential equation of any infinitesimal in the arc-shaped underground continuous wall are determined according to the Hooke's law, a balance differential equation of the arc-shaped underground continuous wall is deduced, and therefore the side displacement of the arc-shaped underground continuous wall is determined according to boundary conditions of corresponding working conditions.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Finite element analysis-based complex plate shell thickness quick optimization design method

InactiveCN107357986ASmall amount of calculationEasy to solveGeometric CADDesign optimisation/simulationShell theoryElement analysis

The invention relates to a finite element analysis-based complex plate shell thickness quick optimization design method and belongs to the field of mechanical structure quick optimization design. According to a theoretical relationship among a stress, a load, a displacement and a stiffness matrix in a finite element theory and a plate shell theory, optimal plate shell thickness calculation formulae about a maximum equivalent stress and a maximum displacement are derived respectively. For the structure of a complex plate shell, the thickness of the complex plate shell is difficultly calculated by directly using the plate shell theory because the influence of complex structure features on structure performance cannot be ignored. The method can quickly calculate out an optimal solution simultaneously meeting the conditions of corresponding maximum equivalent stress and maximum displacement, and has the advantages of quickness, accuracy, small calculation amount, easiness in solving and the like.

Owner:GUIZHOU UNIVERSITY OF FINANCE AND ECONOMICS

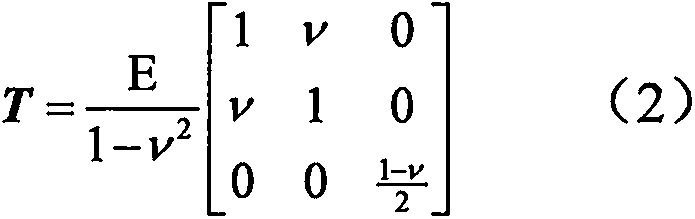

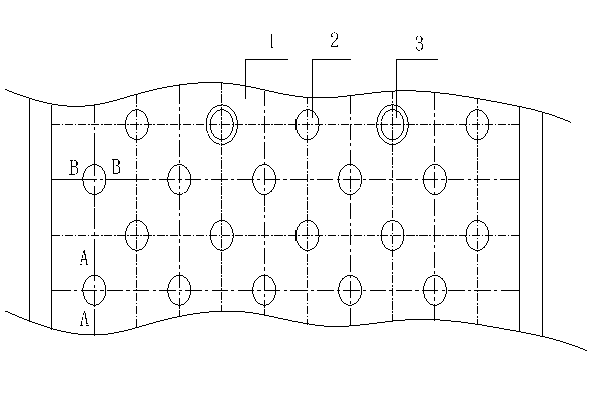

Ellipsoidal corrugated heat transmission sheet structure for air/gas preheater

InactiveCN103363831ALarge heat transfer surfaceImprove heat transfer coefficientLaminated elementsShell theoryHeat transmission

The invention relates to an ellipsoidal corrugated heat transmission sheet structure. Corrugation of a heat transmission sheet corrugated section consists of semi-ellipsoidal curved surfaces arrayed in a matrix manner; long axes of the semi-ellipsoidal curved surfaces are in the same direction as the long side of a heat transmission sheet; and middle axes of the semi-ellipsoidal curved surfaces are in the same direction as the broad side of the heat transmission sheet. The structure has the following advantages that: 1) the corrugation of the heat transmission sheet consists of the semi-ellipsoidal curved surfaces, and is provided with a larger heat transmission surface, so that a coefficient of heat transmission is increased; 2) the semi-ellipsoidal curved corrugation has higher strength and rigidity according to a shell theory, and does not deform easily; and 3) the structure is simple, is formed by one-time stamping; and the production cost is lowered. With the adoption of the structure, a heat transmission area is increased; the strength and the rigidity are improved; the flow channel resistance is reduced simultaneously; the new balance between the reduced flow resistance and a good heat transmission effect is achieved; and a significant progress is obtained.

Owner:SHANGHAI LALLEEN ENG TECH

Rapid complex shell thickness optimization design method based on maximum equivalent stress

InactiveCN107346358ASmall amount of calculationEasy to solveGeometric CADDesign optimisation/simulationShell theoryFast optimization

The invention relates to a rapid complex shell thickness optimization design method based on maximum equivalent stress and belongs to the field of rapid optimization design of mechanical structures. According to the method disclosed by the invention, the optimal shell thickness calculation formula based on the maximum equivalent stress is deduced according to a theoretical relation among the stress, load, displacement and stiffness matrix in a finite element theory and a plate shell theory. Aiming at the complex shell structure, since the influence of the complex structure characteristic on the structural performance cannot be neglected, the thickness of the complex shell is difficult to be directly calculated by the plate shell theory. The method is capable of rapidly calculating the optimal solution under the condition that the corresponding maximum equivalent stress is met, and has the advantages of rapidness, small calculation amount, simplicity in solution and the like.

Owner:GUIZHOU UNIVERSITY OF FINANCE AND ECONOMICS

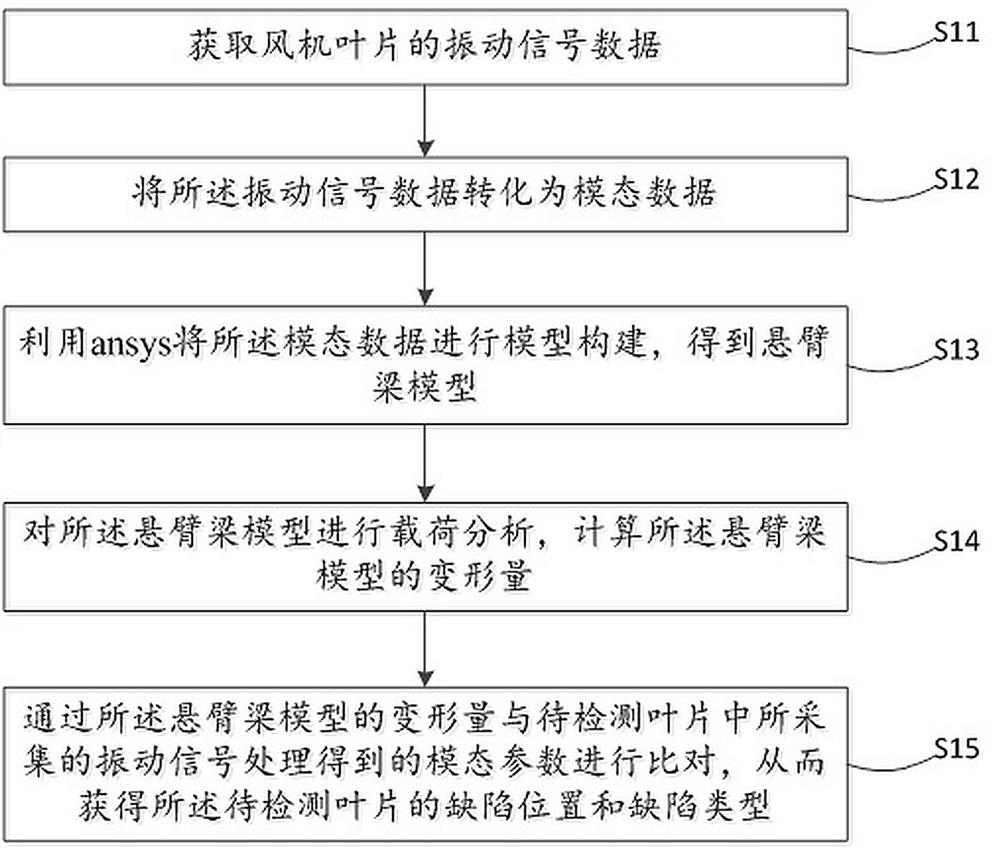

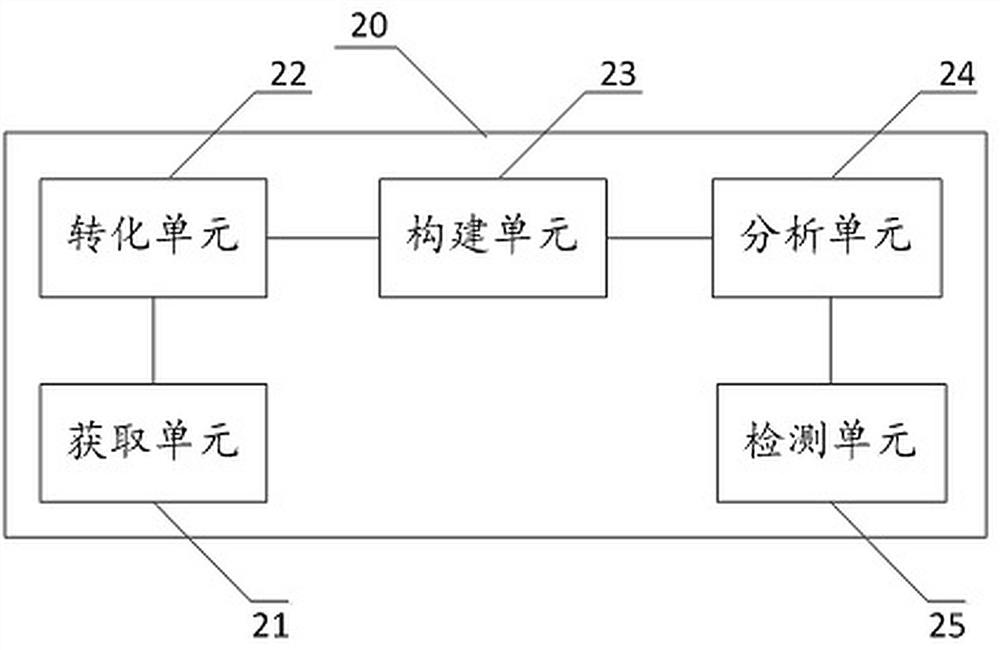

Blade detection method based on blade load analysis

PendingCN113323816AEasy to planReduce downtimeMachine part testingMachines/enginesShell theoryElement analysis

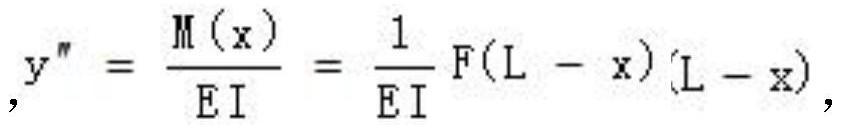

The invention discloses a blade detection method based on blade load analysis, and belongs to the technical field of wind driven generators. The method comprises the following steps: 1, monitoring and acquiring vibration signal data of a fan blade through a sensor for detecting vibration of the fan blade, and converting the vibration signal data into modal data; 2, constructing the modal data in the step 1 into a model through a finite element analysis (FEA) tool, and adding an orthotropic material constitutive relation and geometrical characteristics of a plate-shell theory on the model to obtain a cantilever beam model comprising parameters of a fan blade load F and a stiffness matrix K; 3, conducting static load analysis on the cantilever beam model obtained in the step 2, and calculating the deformation u of the cantilever beam model, wherein u = {F} / [K], {F} represents comprehensive force borne by the blade and comprises self gravity and wind power, and [K] represents the stiffness matrix; and 4, conducting dynamic load analysis on the cantilever beam model obtained in the step 2, applying full constraint to the root of the blade, conducting modal analysis on the single blade through finite element software, obtaining the first six-order vibration mode and the inherent frequency of the blade, and obtaining the vibration mode node position of the blade fault position in the blade bending direction, so that the defect position and the defect type of the to-be-detected blade are obtained.

Owner:东方电气集团科学技术研究院有限公司

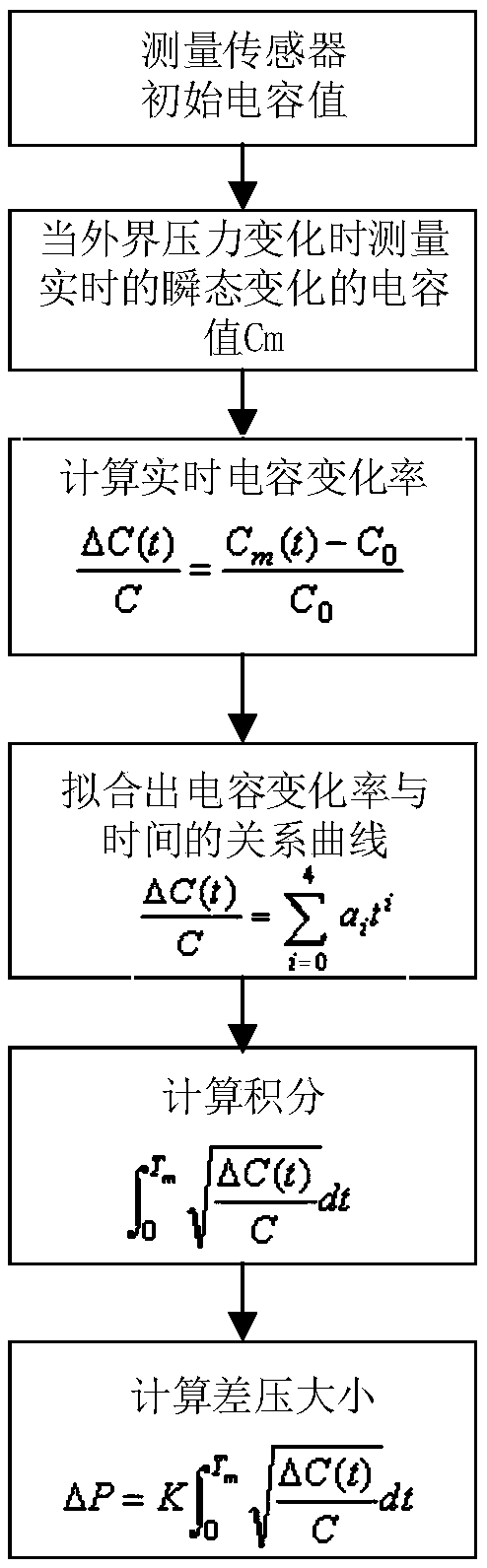

Capacitive pressure difference sensor and output characteristic calculation method thereof and manufacturing method therefor

ActiveCN109029828ASimple processing methodImprove detection resolutionDesign optimisation/simulationSpecial data processing applicationsShell theoryImage resolution

The invention discloses a capacitive pressure difference sensor and an output characteristic calculation method thereof and a manufacturing method therefor. The invention establishes a calculation method of static and dynamic output characteristics of the sensor by using an ideal gas state equation and a plate-shell theory, and particularly provides a method for processing a pressure sensing filmthrough vacuum high-temperature annealing. A novel pressure difference sensor for dynamically detecting pressure in real time provided by the invention has the characteristics of simple sensor processing method and higher gas pressure detection resolution. The pressure sensing film having a circular hole and a cavity can be formed in one step by annealing a trench etched into a specific structurein high-temperature vacuum environment, without complicated SOI (Silicon-On-Insulator, silicon on an insulating substrate) or a complicated method for etching a cavity and a pressure sensing film on asilicon wafer.

Owner:JIANGSU UNIV

Back penetration measuring method for film base binding performance

InactiveCN101122561BBreak outSimplify traditional craftSemiconductor/solid-state device testing/measurementUsing mechanical meansBasementShell theory

The invention relates to a back penetration type measurement method for film-substrate cohesion performance in the measurement technical field. An ejector rod is adopted by the invention to penetrate the basement system of a part to be measured. Load is arranged on the lower end of the ejector rod. And the ejector rod is pushed to make a film deformed in a way of bending. The defection and the load of the film are respectively obtained by corresponding sensors when loaded in a static load form. The film-substrate cohesion of the part to be measured under static load is worked out through the plate shell theory. When load is added in a dynamic form, a relationship between the crack growth length and the cycle number, which is used for evaluating the fatigue performance of the film, is built up through measuring the radius of a film salient area and recording the cycle number. The invention solves the technical problems in present technology that the precast of the part to be measured is complex and the basement system is limited by silicon material. The invention can quantitatively measure the film-substrate cohesion performance, precisely determine the film-substrate cohesion and obtain the fatigue performance parameters of the film.

Owner:SHANGHAI JIAOTONG UNIV

A Method of Calculating the Side Displacement of Arc Ground Connecting Wall

InactiveCN105808505BAccurate lateral displacementMeasurement devicesComplex mathematical operationsShell theoryCurvilinear coordinates

A method for calculating the lateral displacement of an arc-shaped ground connection wall. The method simplifies the arc-shaped ground connection wall into a cylindrical shell, establishes a curved coordinate system, and establishes the mid-plane strain and displacement of the arc-shaped ground connection wall according to the classical shell theory According to Hooke's law to determine the relationship between stress and displacement at any point on the arc-shaped ground wall, and the equilibrium differential equation of any microelement in the arc-shaped ground wall, the arc-shaped ground wall is deduced Balanced differential equations, according to the boundary conditions of the corresponding working conditions, so as to determine the lateral displacement of the arc-shaped connecting wall.

Owner:EAST CHINA JIAOTONG UNIVERSITY

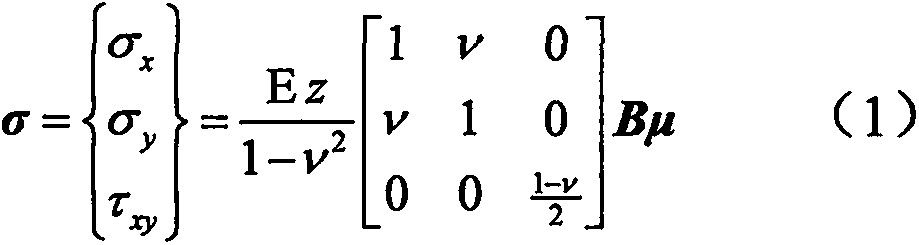

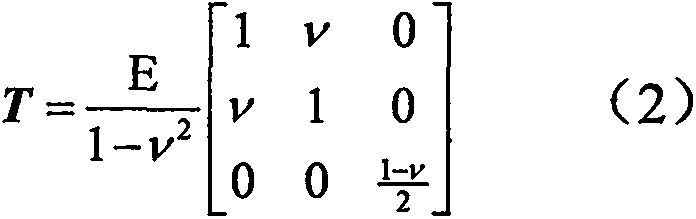

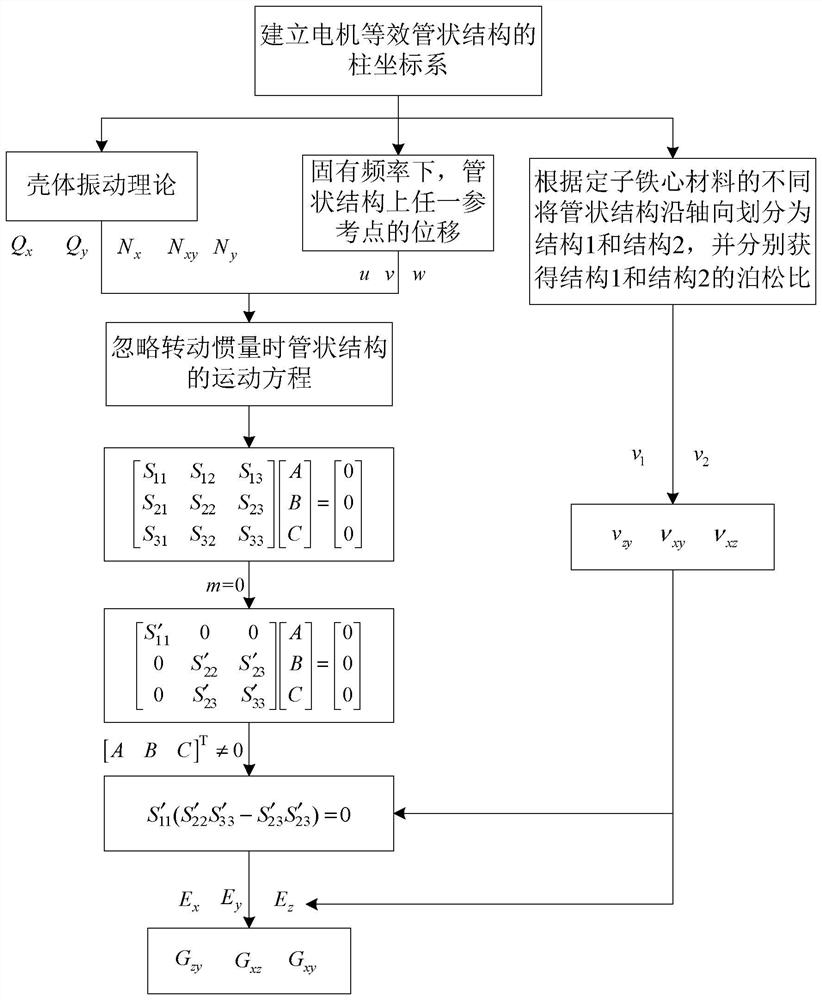

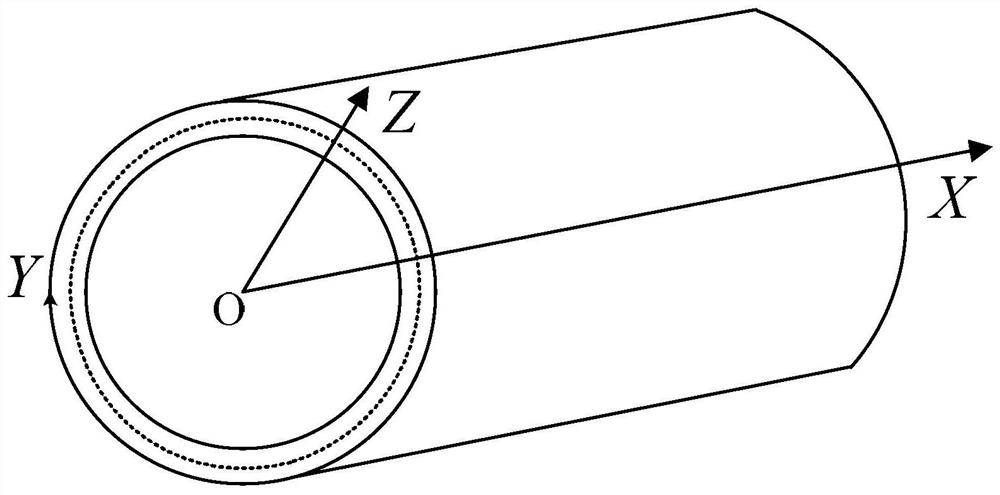

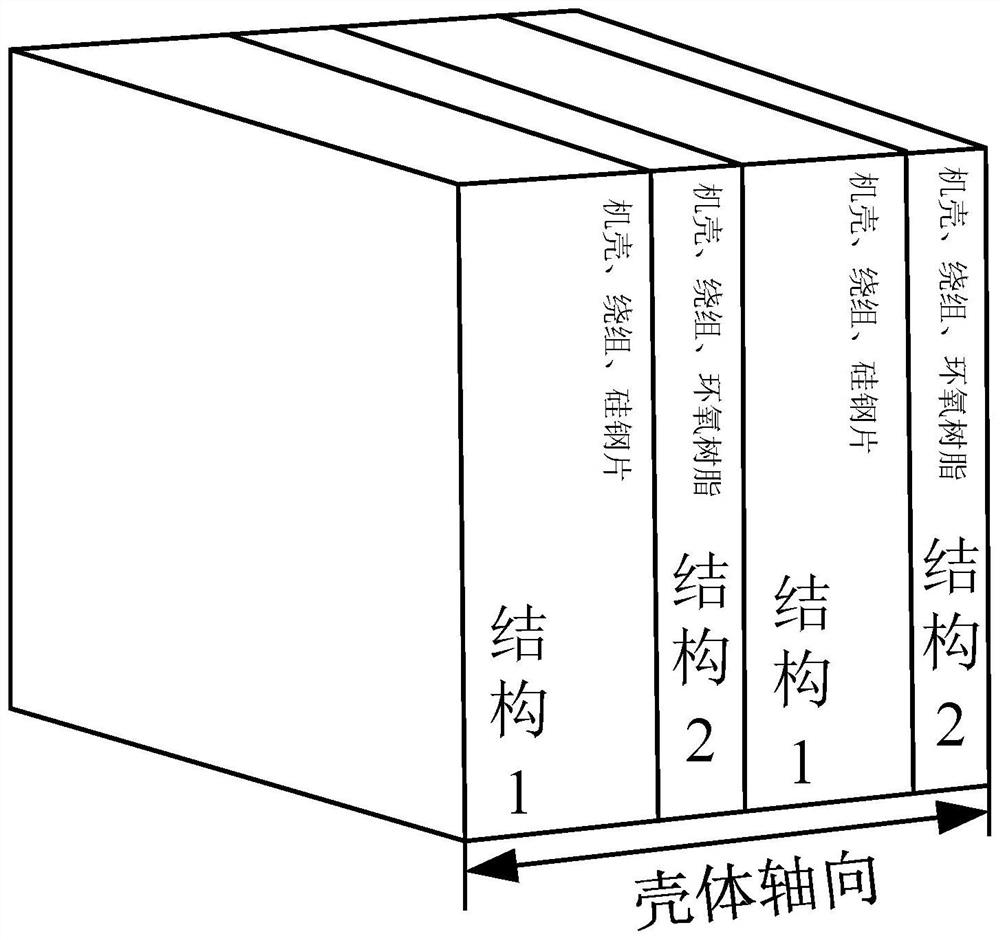

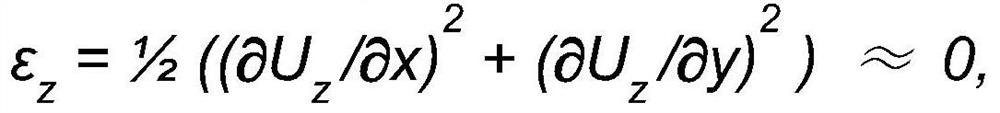

A Method for Calculating Orthotropic Material Parameters of Motors

ActiveCN114547946BSimple calculationQuick calculationGeometric CADSustainable transportationShell theoryElectric machine

A method for calculating orthotropic material parameters of a motor belongs to the field of motors. The present invention is to solve the problem that the existing method is difficult to calculate during the modal analysis of the motor. The method for calculating the orthotropic material parameters of the motor described in the present invention utilizes the orthotropic analytical model with the shell theory as the core, and uses the easily measured low-order radial natural frequency and its corresponding order. As an input condition, the orthotropic material parameters of the motor can be calculated simply and quickly. At the same time, the present invention considers the lamination structure of the stator core of the motor, and avoids the error caused by ignoring the reduction of the axial stiffness; the low-order radial natural frequency and its corresponding order are used as input conditions, which are simple, accurate and easy to obtain.

Owner:HARBIN UNIV OF SCI & TECH

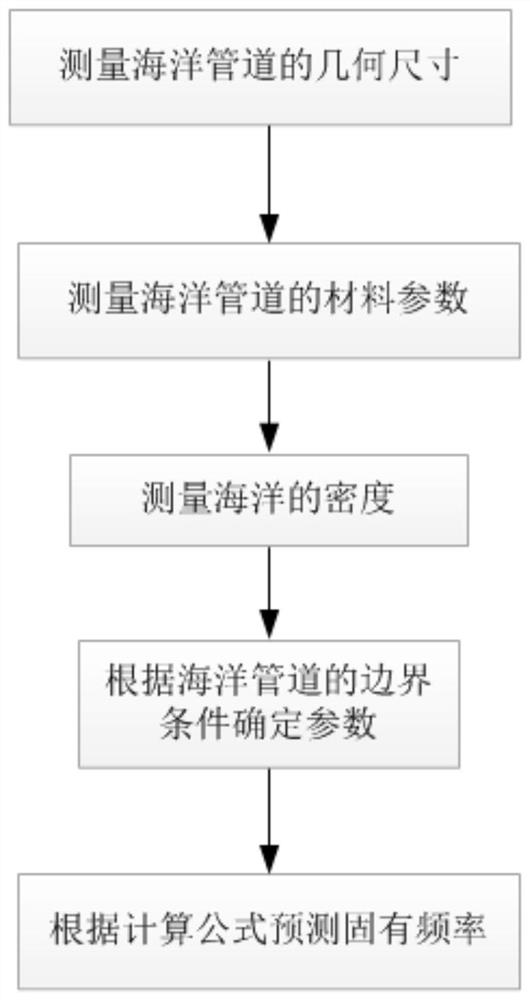

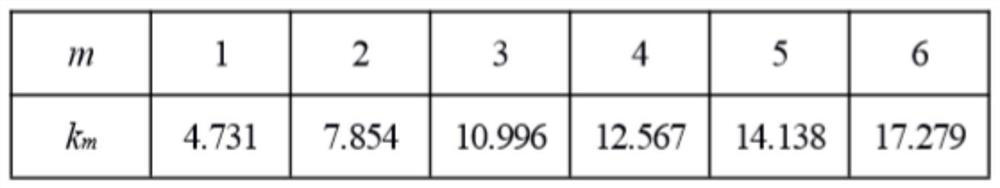

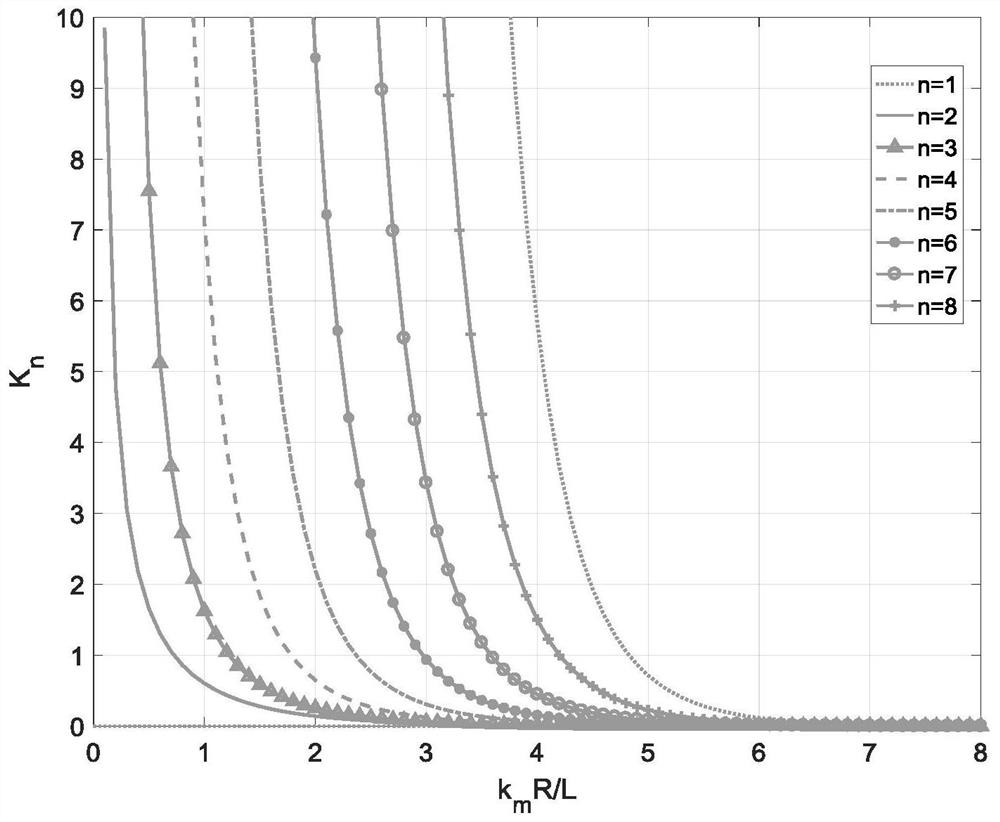

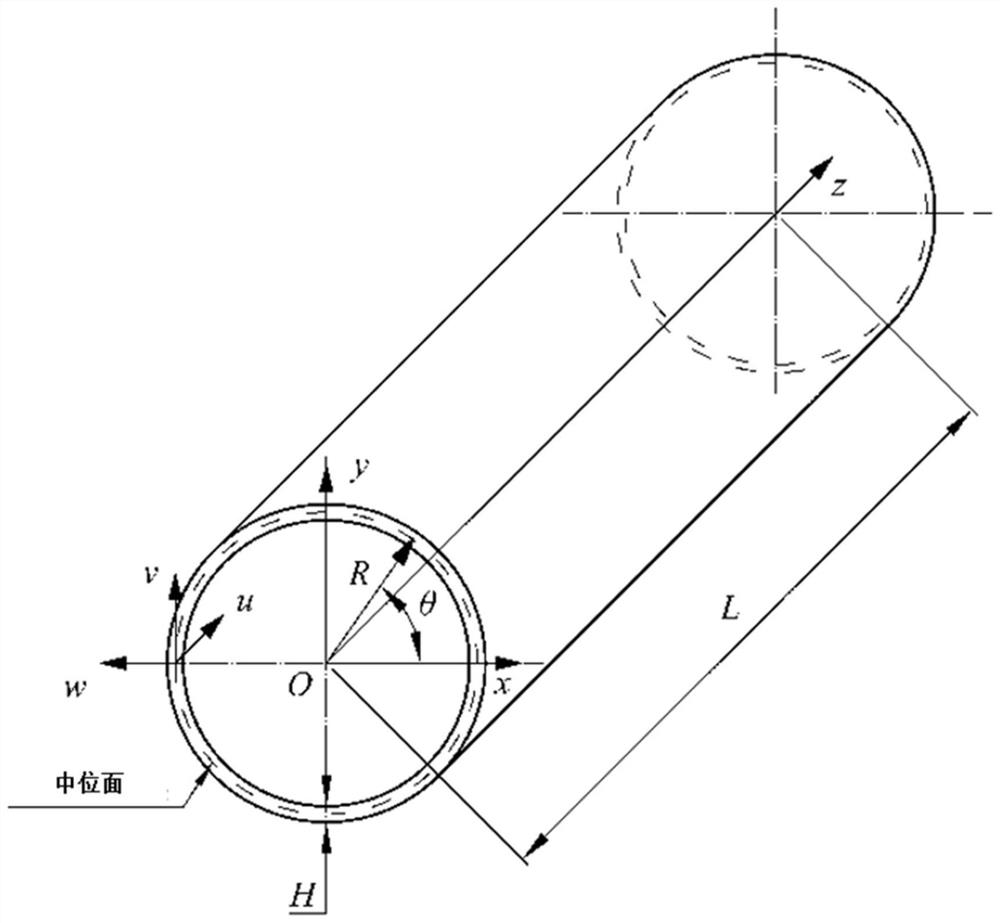

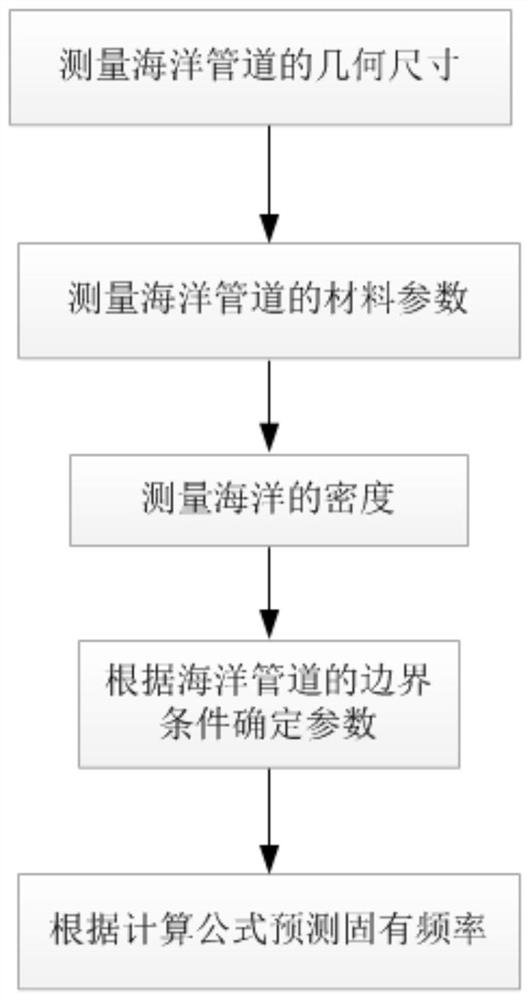

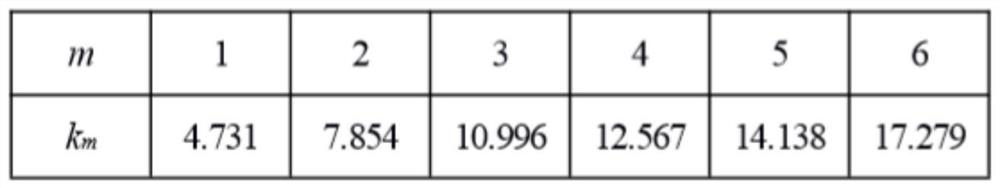

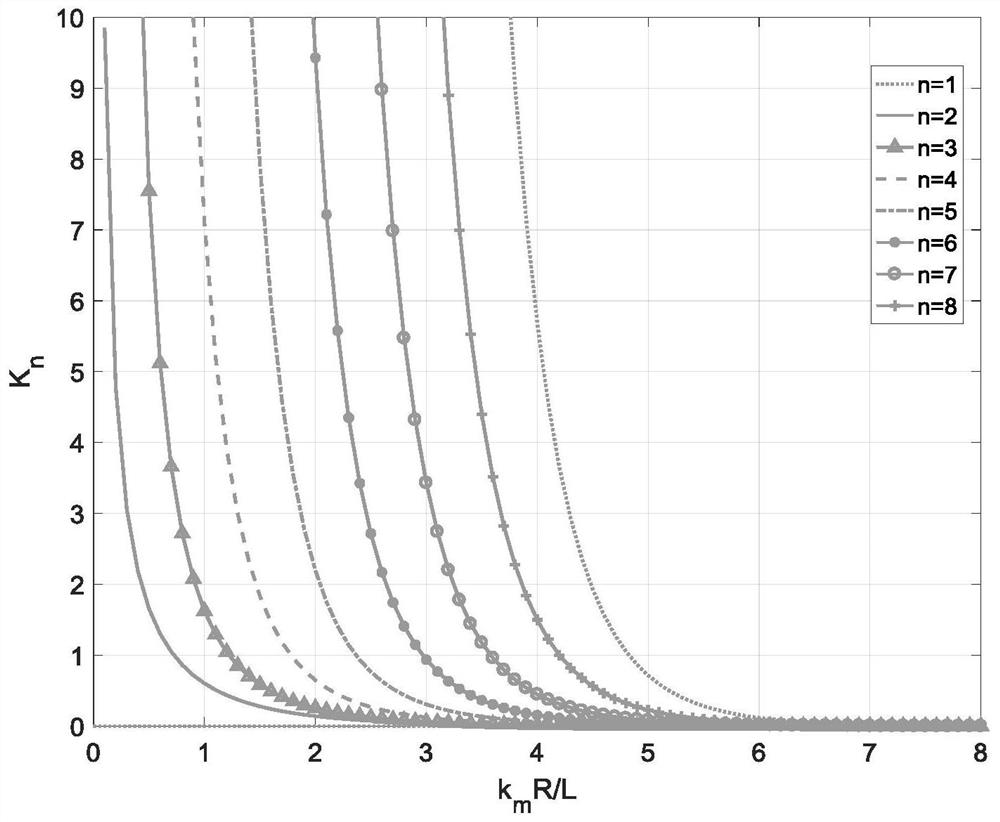

A method for calculating the natural frequency of natural vibration of marine pipelines

ActiveCN112484840BAccurate predictionSimple calculationSubsonic/sonic/ultrasonic wave measurementSustainable transportationShell theoryMarine engineering

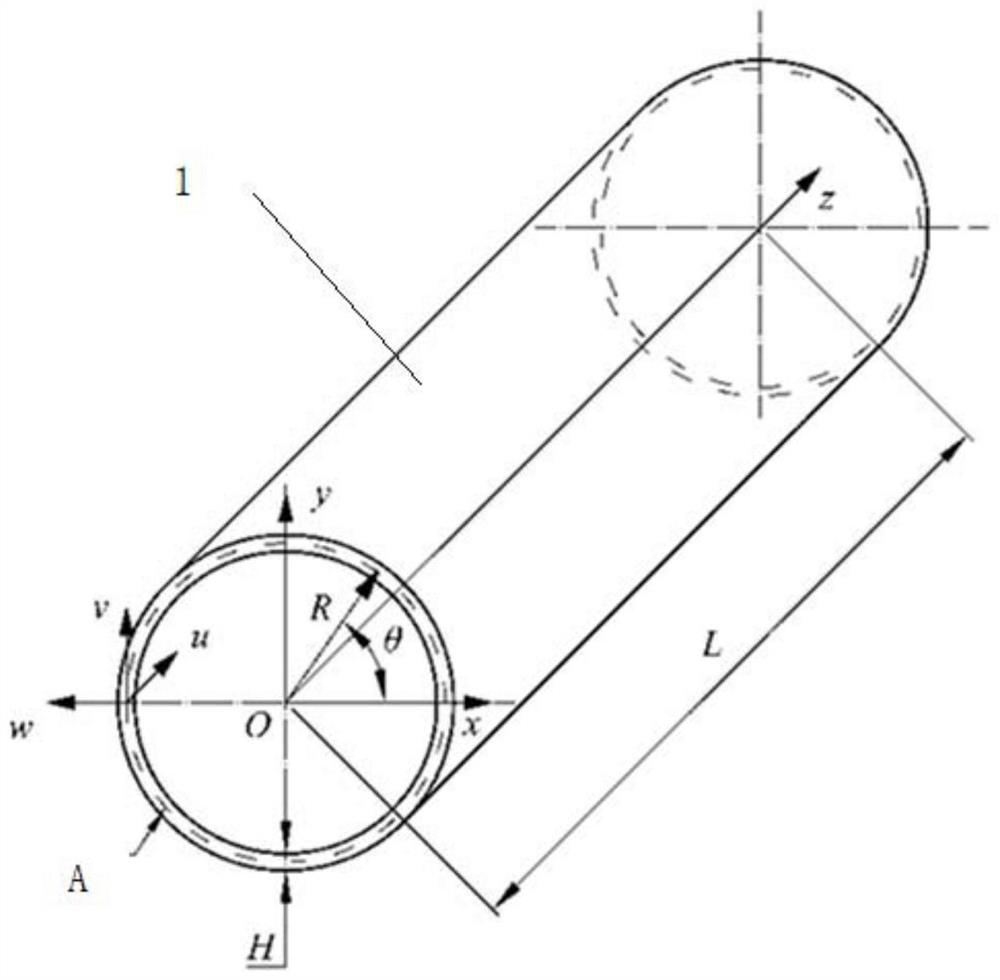

The invention discloses a method for calculating the natural frequency of marine pipeline natural vibration. The specific steps are: measuring the radius R, length L, wall thickness h and density ρ of the marine pipeline; determining the Young's modulus E and Poisson's ratio of the marine pipeline material μ; measure the density ρ of seawater f ; Calculate the natural frequency of the free vibration of the ocean pipeline when the fluid-structure interaction effect is considered by the natural frequency calculation formula. The invention is based on the plate and shell theory, considers the influence of the fluid-solid coupling effect of the fluid and the shell structure on the free vibration of the shell, analyzes the free vibration phenomenon of the marine pipeline as a whole, and proposes a more reasonable and simpler natural frequency calculation method.

Owner:JINAN UNIVERSITY

Method for Determining the Distributed Process Parameters of Laser Shot Peening Forming of Complex Curved Surfaces

ActiveCN110543654BImprove fatigue resistanceAccelerated corrosionGeometric CADDesign optimisation/simulationShell theoryPartial differential equation

The invention provides a method for determining distributed process parameters of a laser peening forming complex curved surface. The method comprises the following steps: establishing a function relationship between a deflection curved surface and an intrinsic moment based on plate shell mechanics, and establishing an optimization model based on partial differential equation constraint by takinga distributed intrinsic moment function as a design variable; according to a curved surface parameter equation or a curved surface coordinate of the workpiece, dispersing a target curved surface, selecting an appropriate optimization algorithm to solve an optimization model, and calculating a distributed natural moment; dividing into a plurality of isoparametric areas convenient for process operation according to the size of the distributed natural moment, and determining a laser peening forming scanning scheme in each area; and establishing a process database corresponding to process parameters and inherent moments through experiments, determining the experiment process parameters, and determining the optimal distributed process parameters in combination with the requirements of residualstress. The method for determining the complex curved surface forming technological parameters is established on the basis of the elastic plate shell theory, and high efficiency and precision are achieved.

Owner:SHANGHAI JIAOTONG UNIV

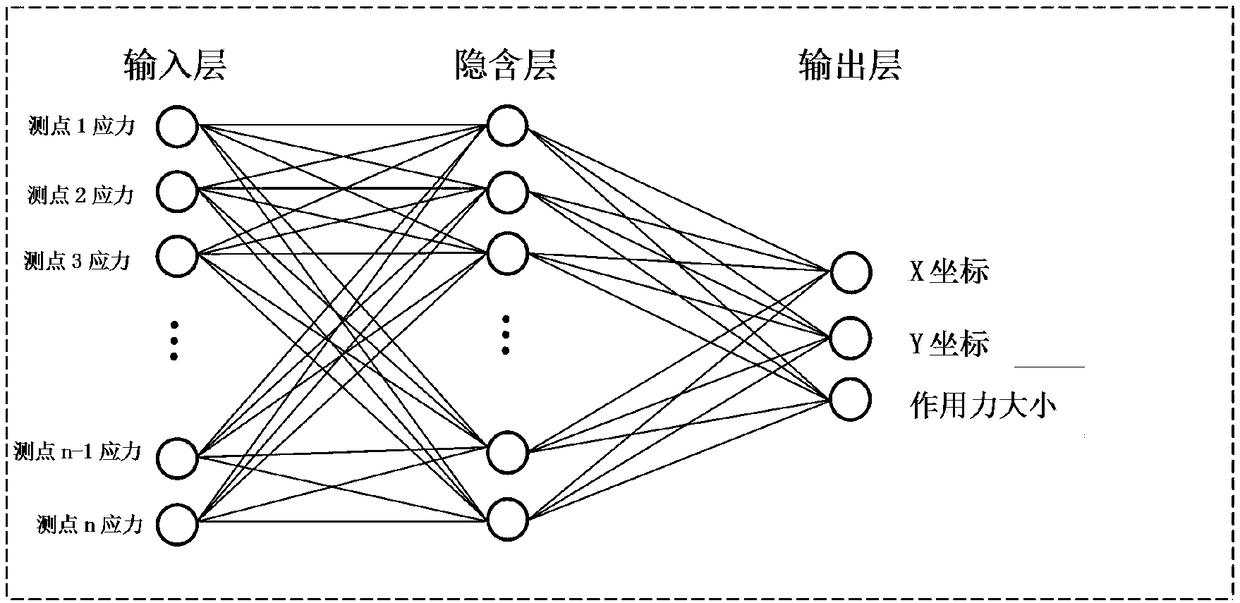

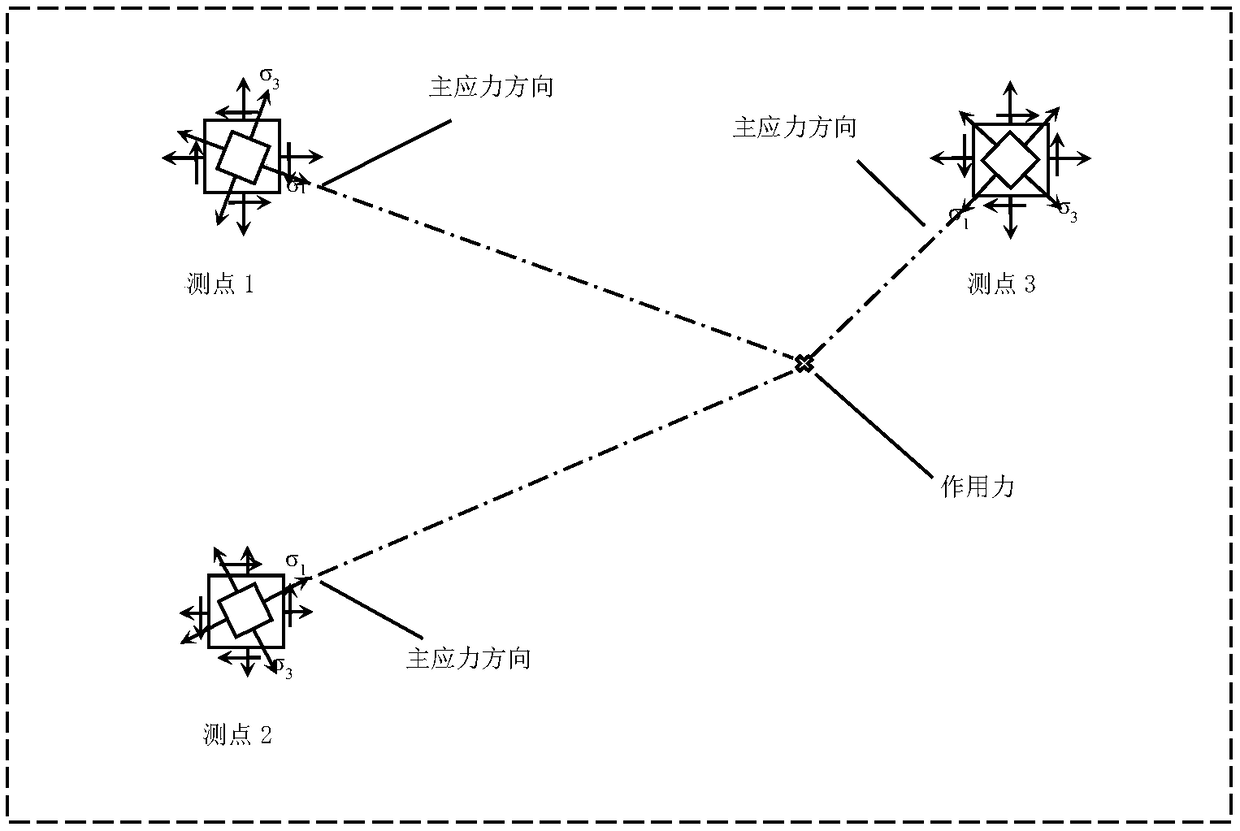

Robot intelligent perception skin system based on finite element plate and shell theory learning library

ActiveCN107229792BReduce in quantityLow costDesign optimisation/simulationNeural architecturesShell theoryDiscretization

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

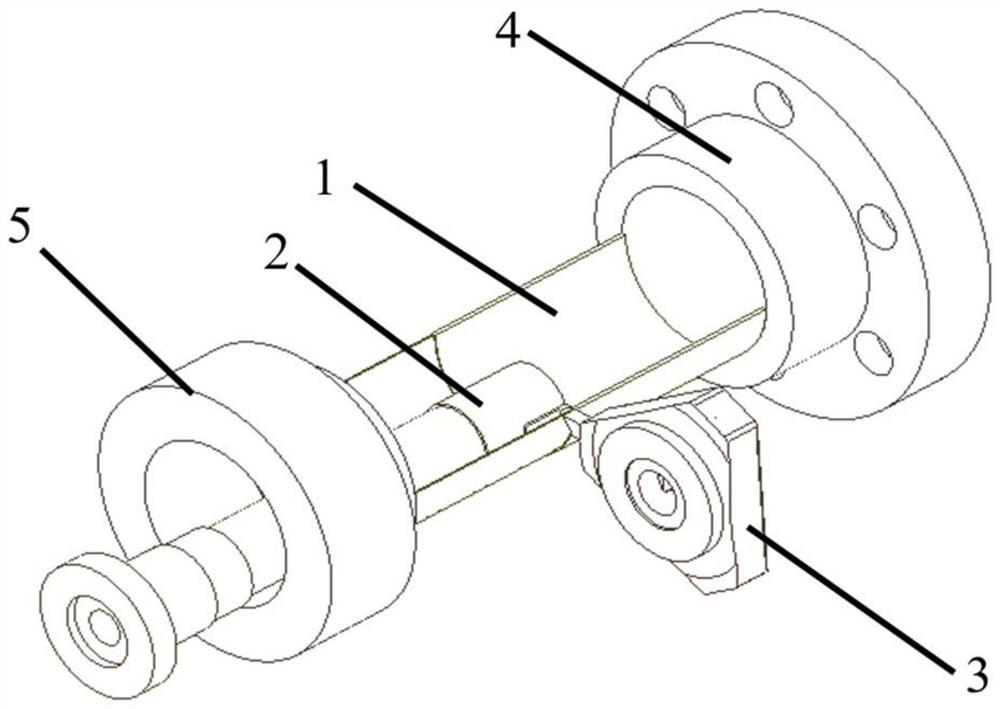

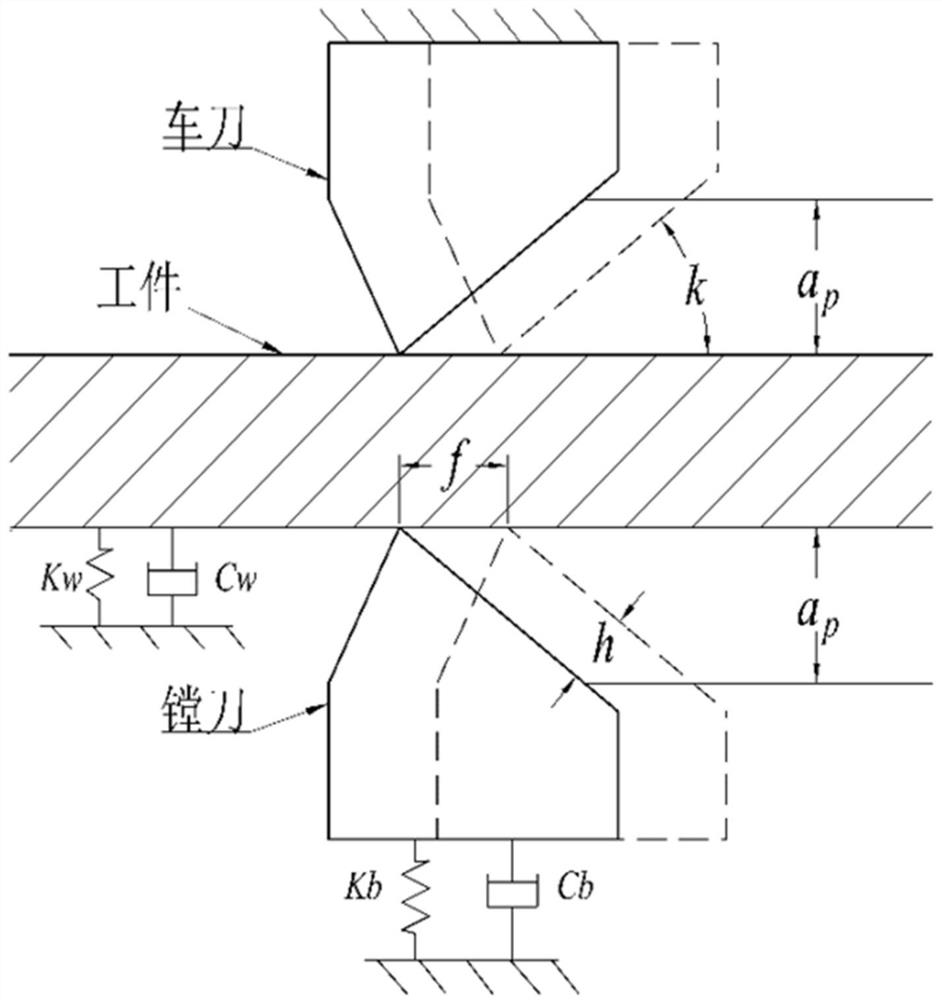

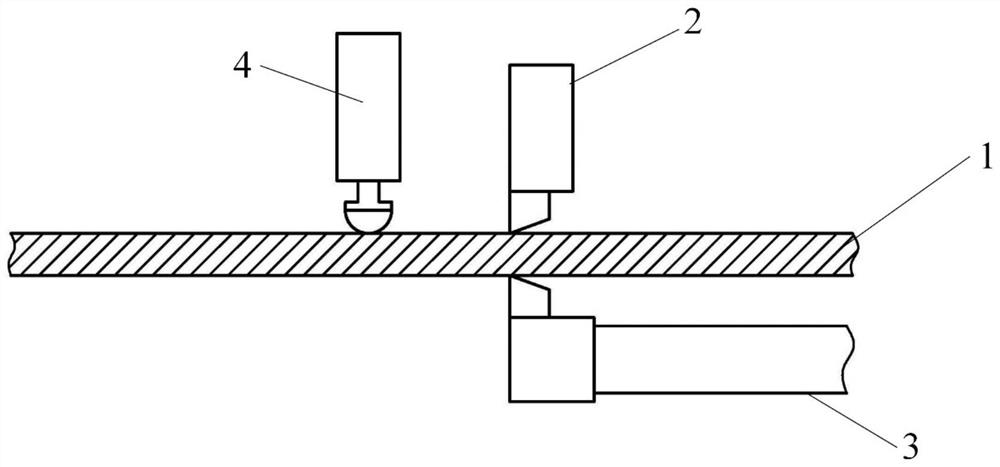

Thin-walled cylinder mirror image cutting modeling method based on shell theory

PendingCN112149239AImprove consistencyGeometric CADDesign optimisation/simulationShell theoryKinetics equation

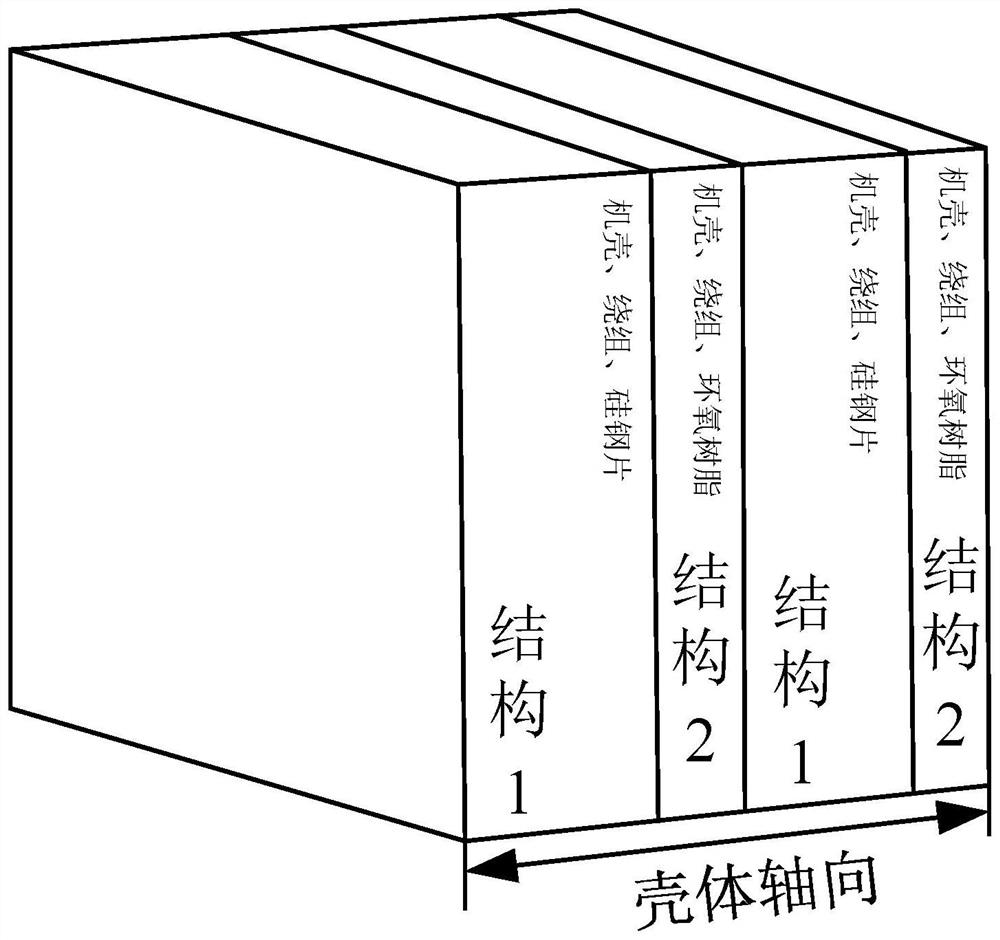

The invention discloses a thin-walled cylinder mirror image cutting modeling method based on a shell theory. The method comprises the following steps that 1, a thin-walled cylinder mirror image cutting process system is simplified; a turning tool is equivalent to a rigid body, a boring rod and a thin-walled cylinder are equivalent to a flexible body, and the thin-walled cylinder of a machined object can be seen as a cylindrical shell; a workpiece is to be fixed, centripetal force and Coriolis force generated when the part rotates are ignored, and the machining process is simplified into forcedvibration of the static cylindrical shell under excitation of rotating force; 2, a forced vibration equation of the rotary thin-walled cylinder is established by applying a shell theory; 3, a boringrod vibration kinetic equation is established; 4, a dynamic cutting force model of the cutting process system is established; and step 5, a mirror image cutting kinetic model of the thin-walled cylinder is established, and calculating and solving are carried out by utilizing a Runge-Kutta method.

Owner:TIANJIN UNIV

Thin-walled cylinder mirror image cutting modeling method based on shell theory and supported by follow-up air floatation

PendingCN114462156AImprove consistencyGeometric CADDesign optimisation/simulationProcess systemsShell theory

The invention provides a follow-up air floatation supporting thin-walled cylinder mirror image cutting modeling method based on the shell theory. The method comprises the following steps that S1, systematic dynamics modeling is conducted on a workpiece; S2, systematic dynamics modeling is conducted on a boring rod; s3, modeling is carried out on the dynamic cutting force of the cutting process system; S4, modeling is carried out on the cutting process system without support; and S5, modeling is carried out on the cutting process system with follow-up air floatation support. According to the follow-up air floatation supporting thin-walled cylinder mirror image cutting modeling method based on the shell theory, complex modal shape and workpiece rotation of a thin-walled cylinder in the circumferential direction and the axial direction are considered, and turning / boring machining of the thin-walled cylinder is converted into vibration response of a cylindrical shell under the rotating load; a follow-up air flotation supporting device commonly used in production is added, the number of supports and the positions of supporting points can be adjusted according to the process, and the vibration response of the thin-walled cylinder part under the mirror image machining process can be simulated truly.

Owner:CHINA NORTH ENGINE INST TIANJIN

A Calculation Method for Warping Deformation of Plate Parts Caused by Residual Stress Release

ActiveCN107704657BImprove calculation accuracyImprove computing efficiencyGeometric CADDesign optimisation/simulationShell theoryMachining process

In order to improve the manufacturing accuracy of plate parts and obtain the deformation information of the parts in advance in the manufacturing stage, a calculation method for the warpage deformation of plate parts caused by the release of residual stress is proposed. Based on elastic mechanics and plate and shell theory, this method calculates the warping deformation of plate parts during processing by equating the release of residual stress to the uniform moment applied on the edge of the plate. Based on the calculation results of this method, the manufacturing errors of different forms of plate parts can be predicted, which provides a theoretical basis for improving manufacturing accuracy.

Owner:BEIHANG UNIV

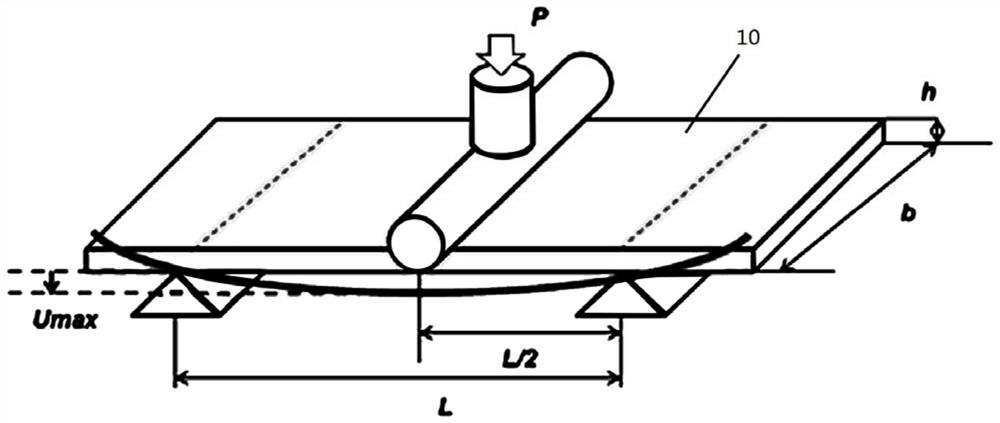

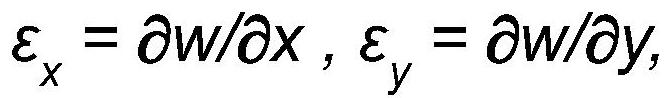

Method for Obtaining Modulus of Elasticity of Plate Members

ActiveCN110018050BWide range of sizesEasy to parseMaterial strength using tensile/compressive forcesShell theoryElastic modulus

The invention discloses a method for obtaining the modulus of elasticity of a plate-shaped member, which includes the following steps: S10: Establish three-point force test conditions to obtain the pressure P on the plate-shaped member and the pressure P generated based on the pressure P Deflection Umax; S20: Obtain the relational formula of elastic modulus E, pressure P, and deflection Umax of the plate-shaped member based on the plate and shell theory; S30: Calculate the elastic modulus E of the plate-shaped member based on the pressure P and deflection Umax. The invention obtains the elastic modulus of the plate-shaped member by introducing the calculation formula of the plate-shell theory, so that the sample size is not limited by the width of ASTM and GB test specifications, and the range of the measurable object size is wider. The calculation process of the elastic modulus takes into account the influence of the width of the plate-shaped member on the elastic modulus, so that the calculated elastic modulus is closer to the real elastic modulus.

Owner:HEFEI LCFC INFORMATION TECH

Method for calculating parameters of orthotropic material of motor

ActiveCN114547946ASimple calculationQuick calculationGeometric CADSustainable transportationShell theoryElectric machine

The invention discloses a method for calculating orthotropic material parameters of a motor, and belongs to the field of motors. The method aims to solve the problem that an existing method is high in calculation difficulty during motor modal analysis. According to the method for calculating the orthotropic material parameters of the motor, the orthotropic analysis model with the shell theory as the core is utilized, the low-order radial inherent frequency easy to measure and the corresponding order of the low-order radial inherent frequency serve as input conditions, and the orthotropic material parameters of the motor can be simply and rapidly calculated. Meanwhile, a motor stator core lamination structure is considered, and errors caused by neglecting reduction of axial rigidity are avoided; the low-order radial inherent frequency and the corresponding order thereof are used as input conditions which are simple, accurate and easy to obtain.

Owner:HARBIN UNIV OF SCI & TECH

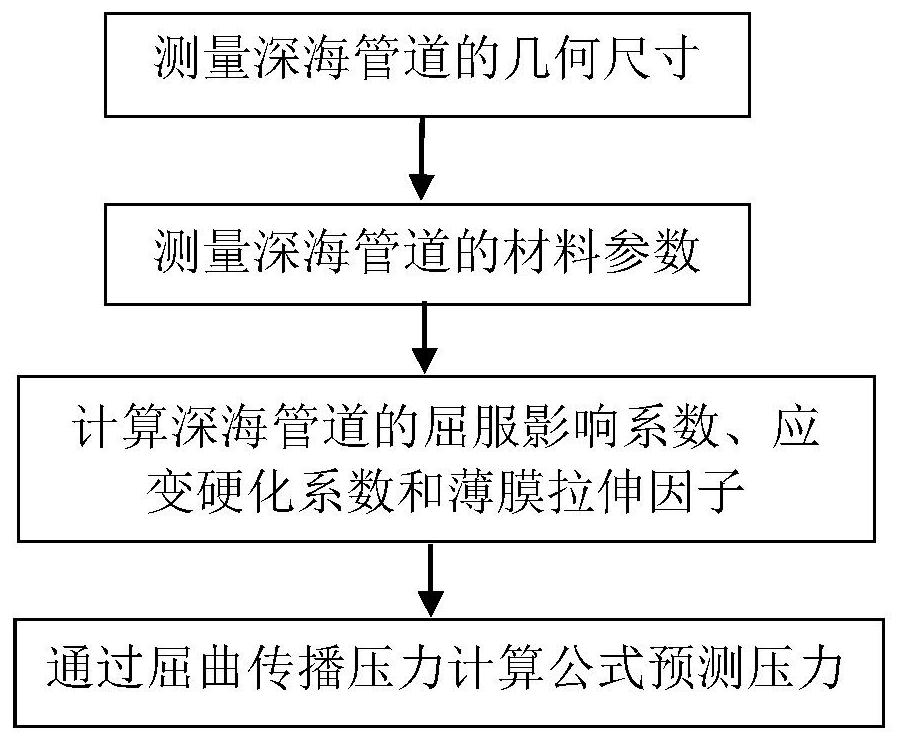

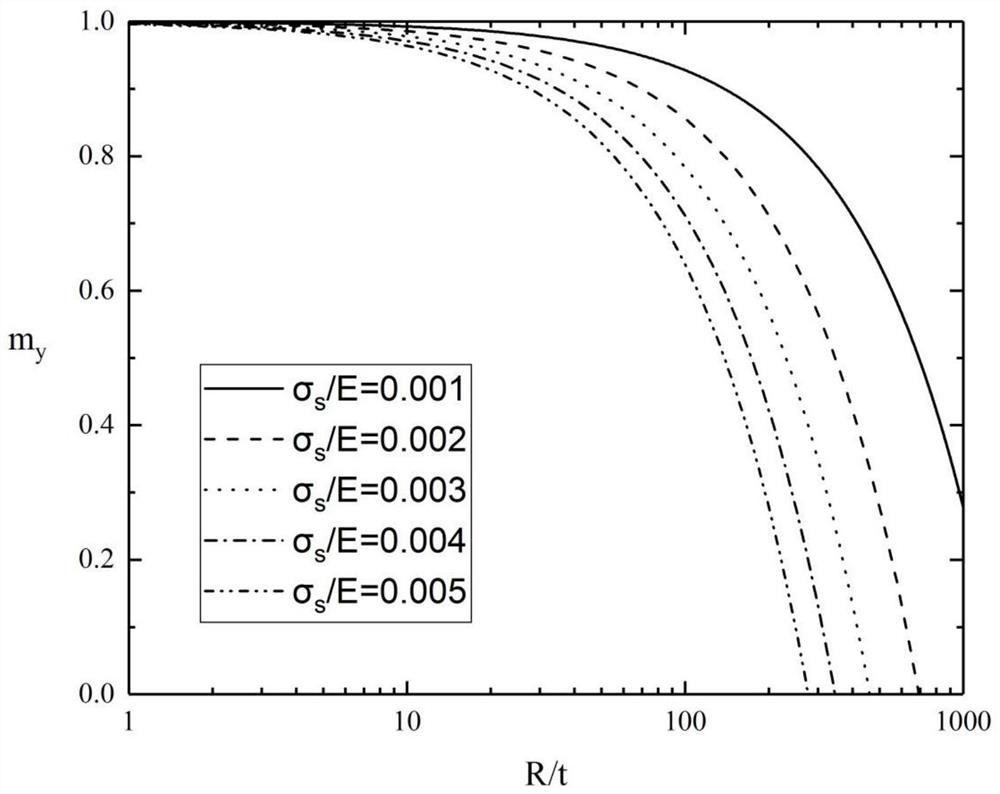

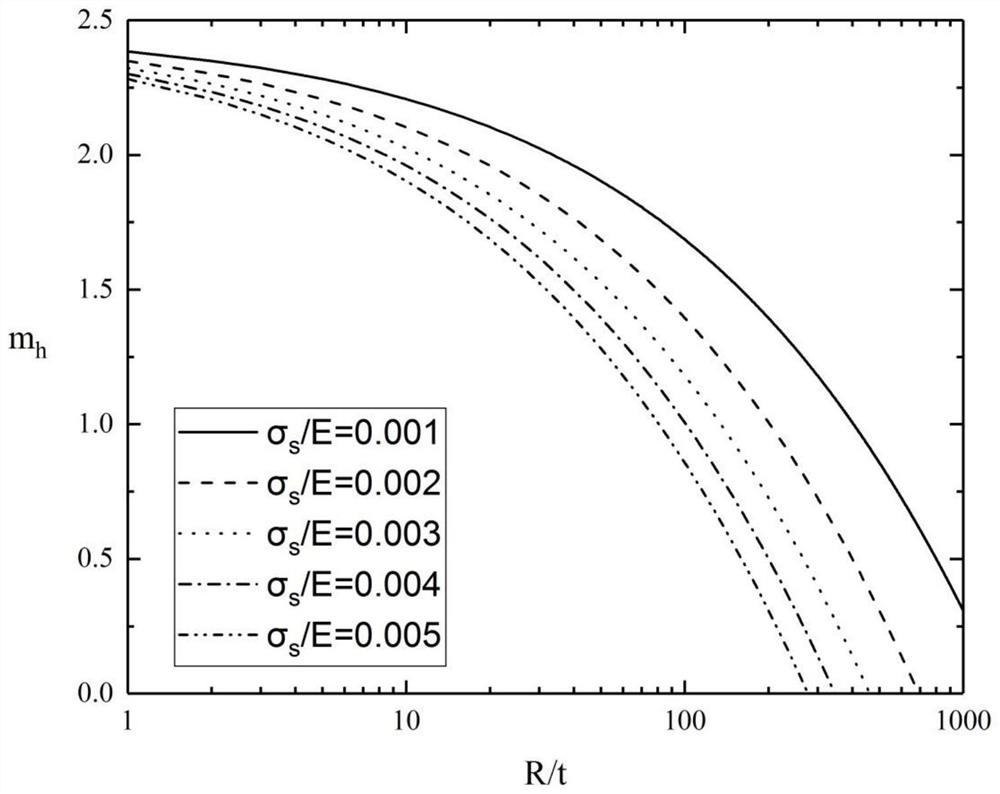

A calculation method based on the pressure of deep -sea pipelines based on plate shell theory

ActiveCN111177944BAccurate predictionSimple calculationDesign optimisation/simulationShell theoryStructural engineering

The invention discloses a method for calculating the buckling propagation pressure of a deep-sea pipeline based on the plate and shell theory. The specific steps are: measuring the radius R and wall thickness t of the deep-sea pipeline; The yield strength σ was obtained by fitting the hardening elastoplastic constitutive relation s and linear hardening modulus E 1 ;Calculate yield influence factor m y , Strain hardening coefficient m h and film tension factor n; the buckling propagation pressure of the deep-sea pipeline is calculated by the buckling propagation pressure calculation formula. Based on the plate and shell theory, the present invention considers the influence of the film stretching effect of the shell structure in the buckling propagation process, analyzes the buckling propagation phenomenon of the deep-sea pipeline as a whole, and proposes a more accurate and reasonable buckling propagation pressure calculation method.

Owner:JINAN UNIVERSITY

Determination method of overburden fault zone height based on plate and shell theory in filling mining

The invention belongs to the field of strata control in coal mine filling and mining, and in particular relates to a method for determining the height of a fractured zone of overlying strata in filling mining based on the plate and shell theory. The method first judges the position of a hard rock stratum, and secondly obtains the critical load and limit displacement of the hard rock stratum, and then Obtain the height of the free space below the hard rock layer and the overlying load of the hard rock layer, and judge whether the fault zone is developed by comparing the critical load with the overlying load of the hard rock layer, the limit displacement and the height of the free space below the hard rock layer; the basic parameters involved in this method , can be obtained according to geological data, laboratory tests and other methods after the mining design of the working face is completed. Disasters caused by destruction, the present invention has wide practicability in analyzing the law of overburden rock activity in filling mining.

Owner:LIAONING TECHNICAL UNIVERSITY

Method for calculating natural frequency of natural vibration of marine pipeline

ActiveCN112484840AAccurate predictionSimple calculationSubsonic/sonic/ultrasonic wave measurementSustainable transportationShell theoryMarine engineering

The invention discloses a method for calculating the natural frequency of natural vibration of a marine pipeline. The method comprises the following specific steps: measuring the radius R, the lengthL, the wall thickness h and the density [rho] of the marine pipeline; determining the Young modulus E and the Poisson's ratio [mu] of the marine pipeline material; measuring the density rhof of seawater; and calculating the free vibration inherent frequency of the marine pipeline through an inherent frequency calculation formula when the fluid-solid coupling effect is considered. Based on the plate-shell theory, the influence of the fluid-solid coupling effect of the fluid and the shell structure on free vibration of the shell is considered, the free vibration phenomenon of the marine pipelineis integrally analyzed, and a more reasonable, simpler and more convenient inherent frequency calculation method is provided.

Owner:JINAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com