Patents

Literature

83results about How to "Large heat transfer surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

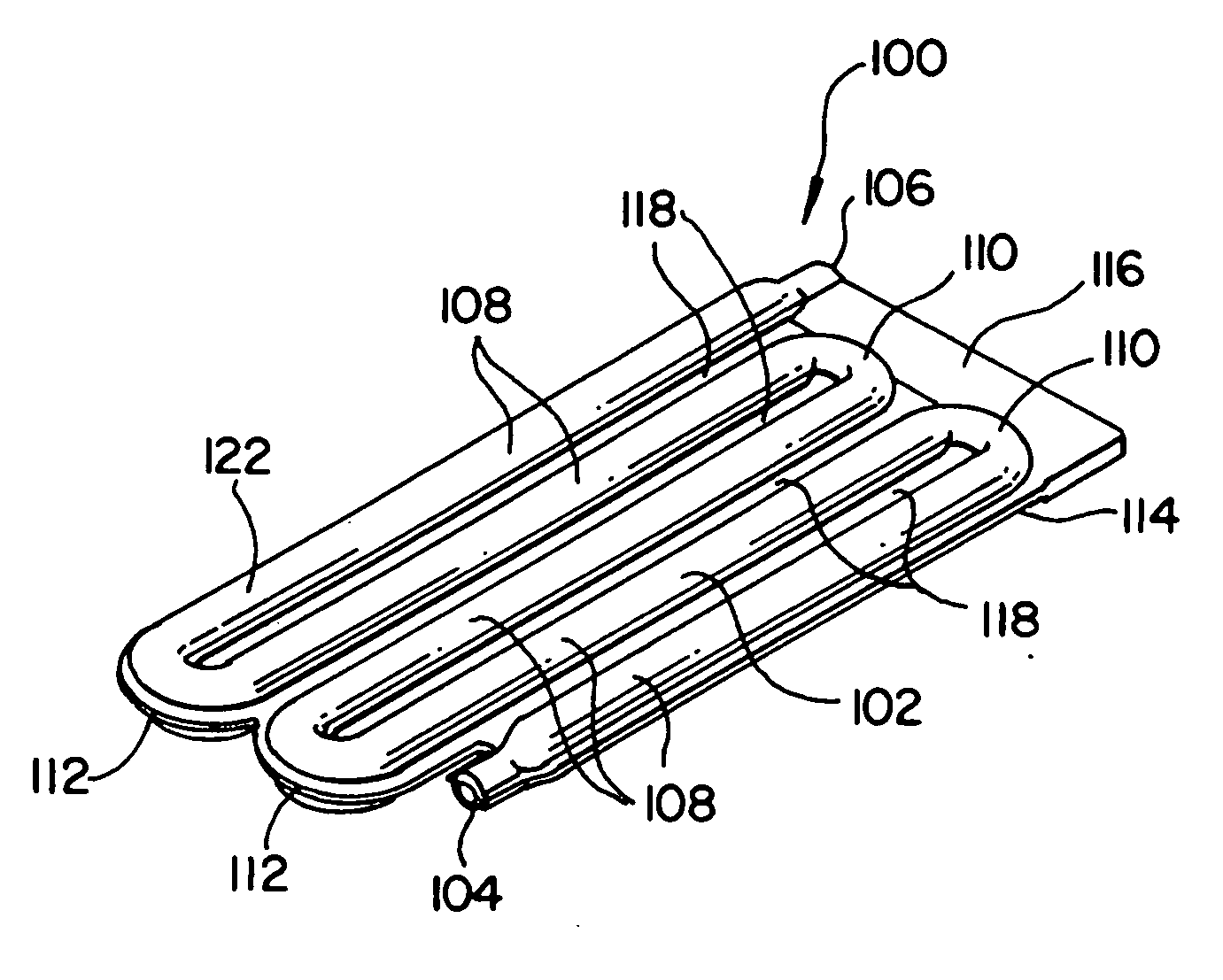

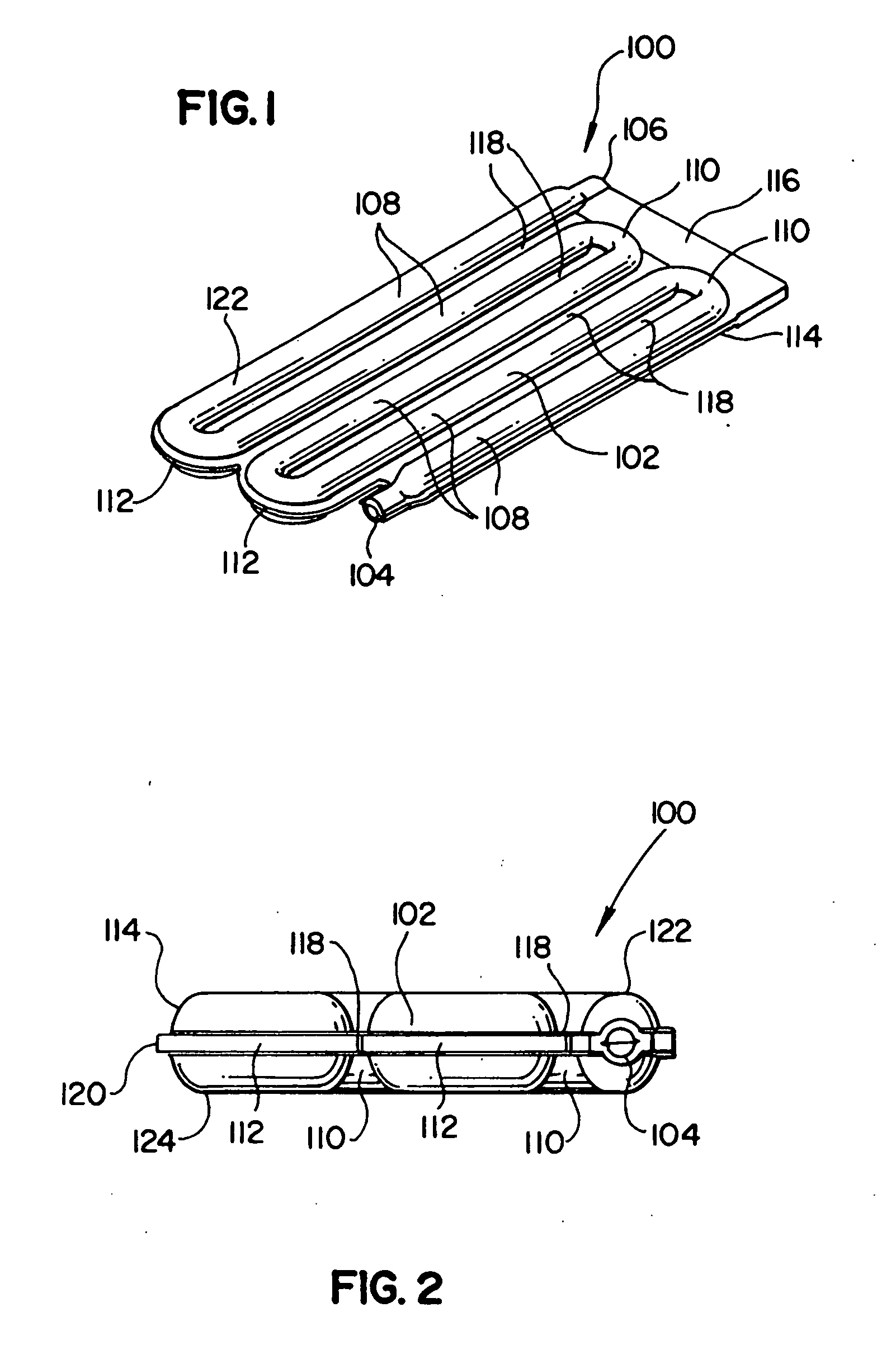

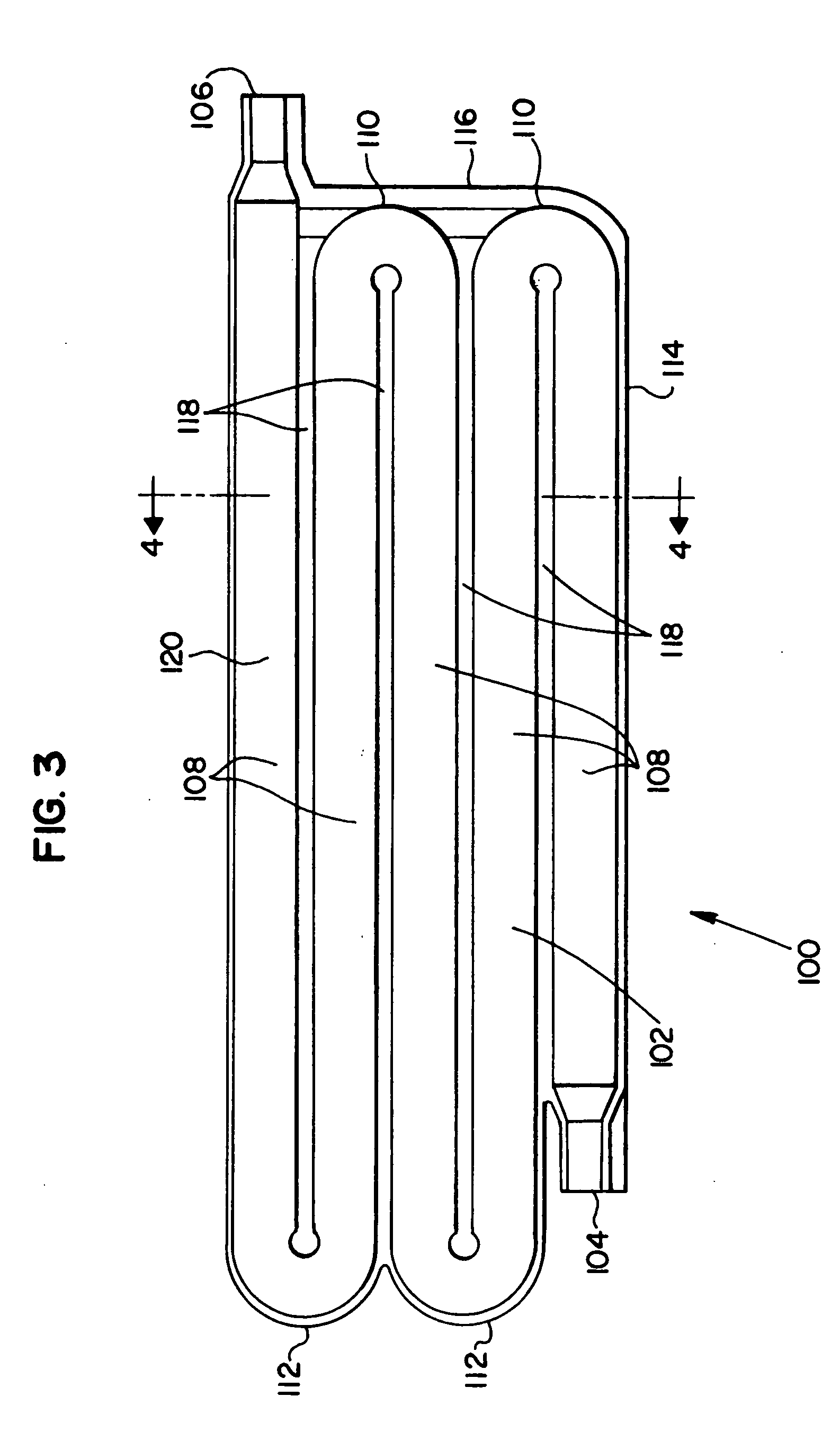

Heat exchanger and fluid reservoir

InactiveUS20060021745A1Low flow conditionEfficient heat exchangeStationary conduit assembliesDomestic articlesPlate heat exchangerDead volume

Improved fluid reservoir designs providing for little or no dead volume or un-swept volume while providing efficient heat exchange are disclosed. Representative fluid reservoirs can have a serpentine flow passage with a cross-section selected such that fluid flow sweeps the entire cross-sectional volume while reducing or eliminating dead volume. The cross-sectional shape of the flow passage can be selected to have a larger surface contact with the cooling environment relative to circular cross-sections. The fluid reservoirs can be molded from two sheets of polymer material that are joined to form the fluid reservoir. Alternatively, the fluid reservoir can be formed from flexible polymer materials that are bonded along seams to demarcate a flow channel. Fluid reservoirs can be located either upstream or downstream of a filtering system to provide chilled filtered liquid. Fluid reservoirs can be associated with an appliance, such as a refrigerator. Methods of fabricating the fluid reservoirs are also disclosed.

Owner:3M INNOVATIVE PROPERTIES CO

Method for preparing water-soluble solid styrene/acrylic resin and application thereof

InactiveCN101575397AAvoid it happening againAvoid cloggingInksCoatingsAcrylic resinUnsaturated monomer

The invention discloses a method for preparing water-soluble solid styrene / acrylic resin and application thereof. The method prepares the required resin by simultaneously performing free radical polymerization reaction and esterification reaction on an aromatic vinyl unsaturated monomer, an aliphatic vinyl unsaturated monomer, an unsaturated carboxylic acid monomer, fat alkanol, an initiating agent and an alpha-methyl styrene dimer in a reactor. In the method, the alpha-methyl styrene dimer is added as a chain transfer agent to reduce the branching degree and avoid the generation of gel and the blockage of the reactor; and simultaneously, the added fat alkanol performs esterification reaction with acroleic acid to inhibit the esterification reaction between an alcohol ether solvent and the acroleic acid, thus the viscosity of the reaction mixture is controlled effectively, and the finally prepared resin has narrow molecular weight distribution (Mw / Mn is less than 2.0), low molecular weight (Mw is less than 10,000), few organic volatile matters, and good wetting dispersion of pigment, and can be applied to preparing water color ink, coating or oil polish.

Owner:SUN YAT SEN UNIV

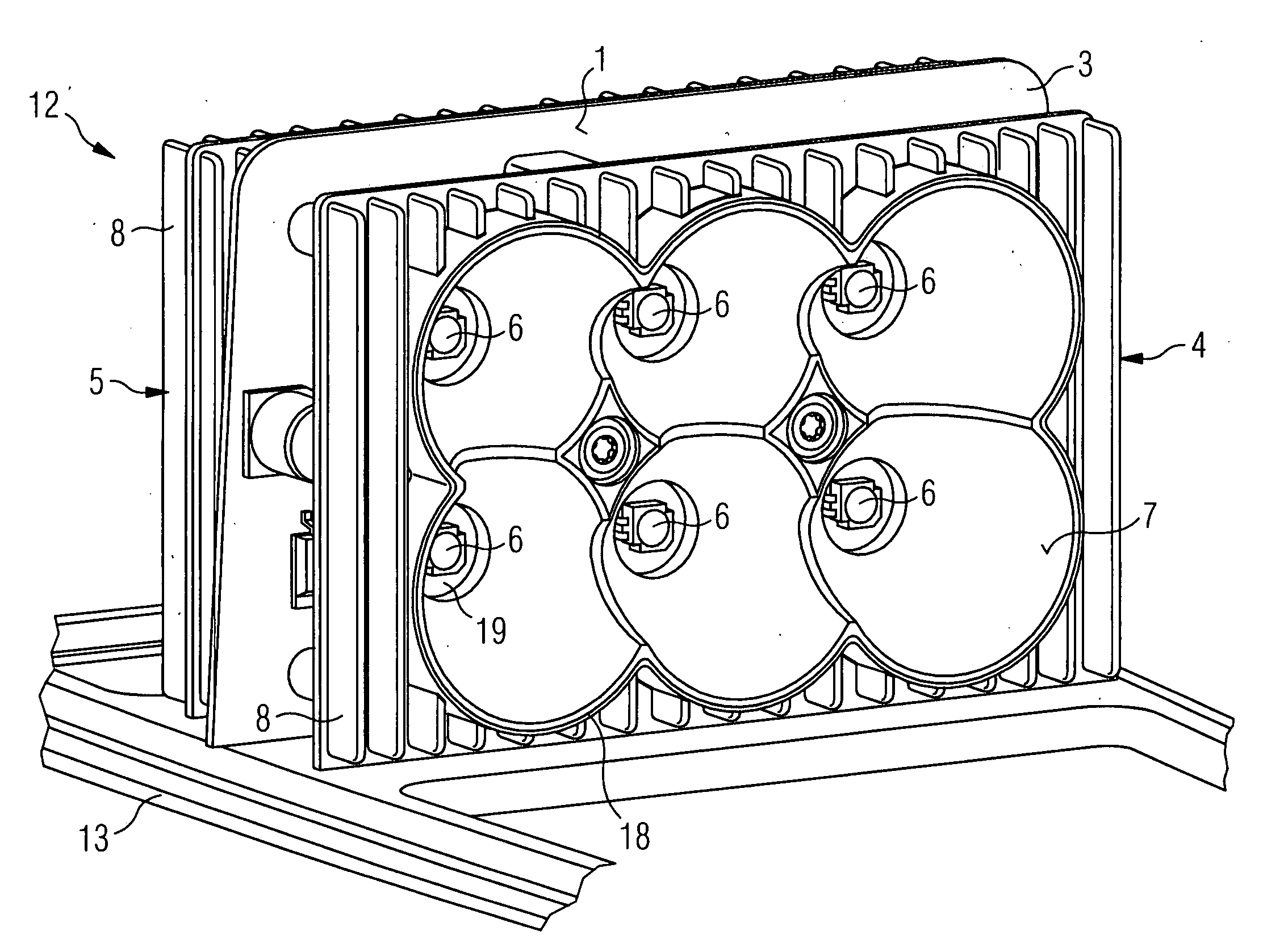

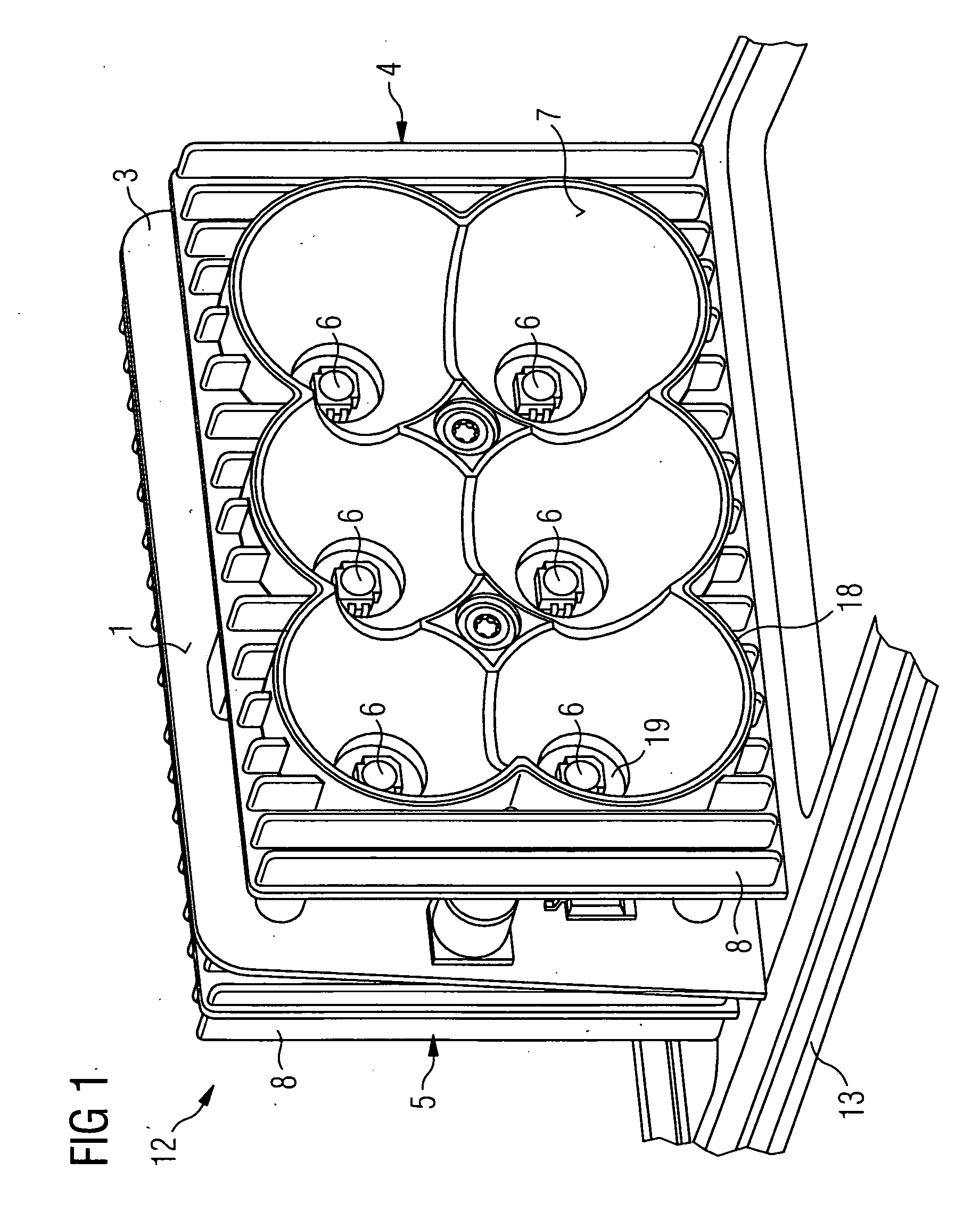

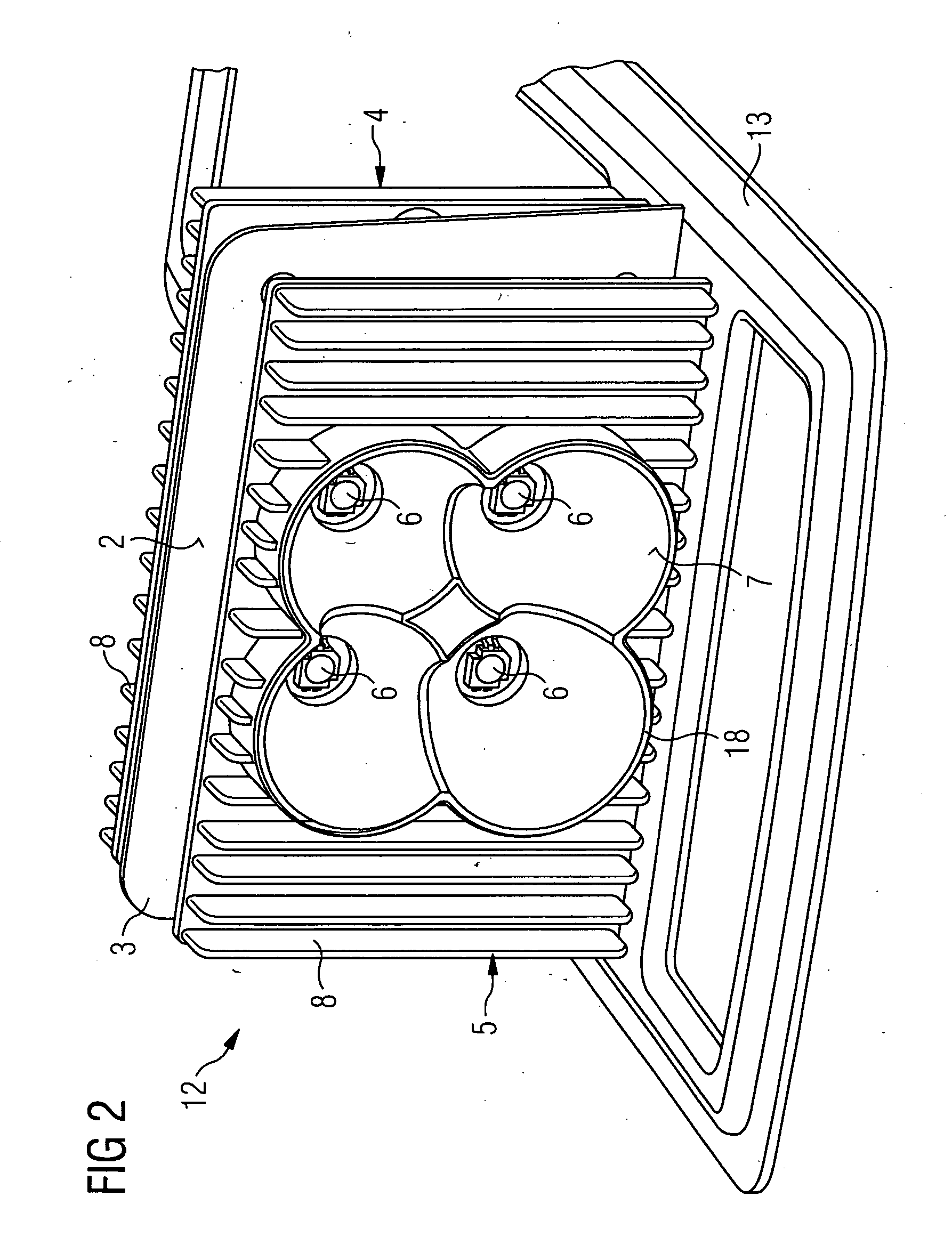

Illumination unit

ActiveUS20080291631A1Improve cooling effectSpace minimizationPoint-like light sourceLighting heating/cooling arrangementsHeat conductingLight-emitting diode

There is described an illumination unit with a planar carrier part having a plurality of light-emitting semiconductor components, in particular high-power light-emitting diodes, arranged on both sides of a main surface. On each side of the carrier part a heat sink is provided in each case. Each of the semiconductor components is connected in an efficient heat-conducting manner to a heat sink provided on an opposite side of the carrier part by way of a heat conducting means that is fed through an opening in the carrier part. At least one reflector is embodied on each heat sink having a reflective surface which concentrates the emitted light from a semiconductor component which is arranged on the side of the carrier part facing this heat sink.

Owner:OSRAM GMBH

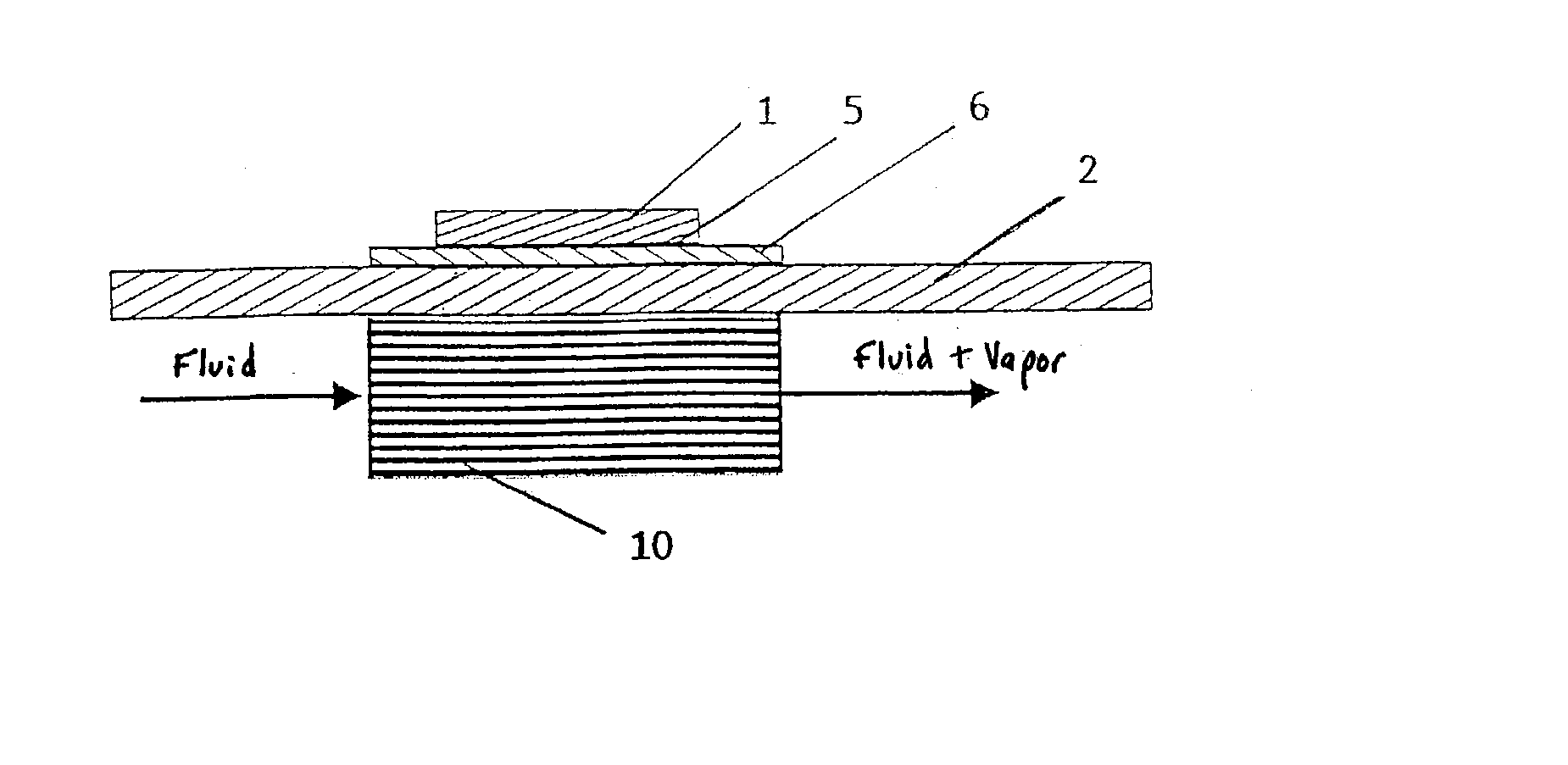

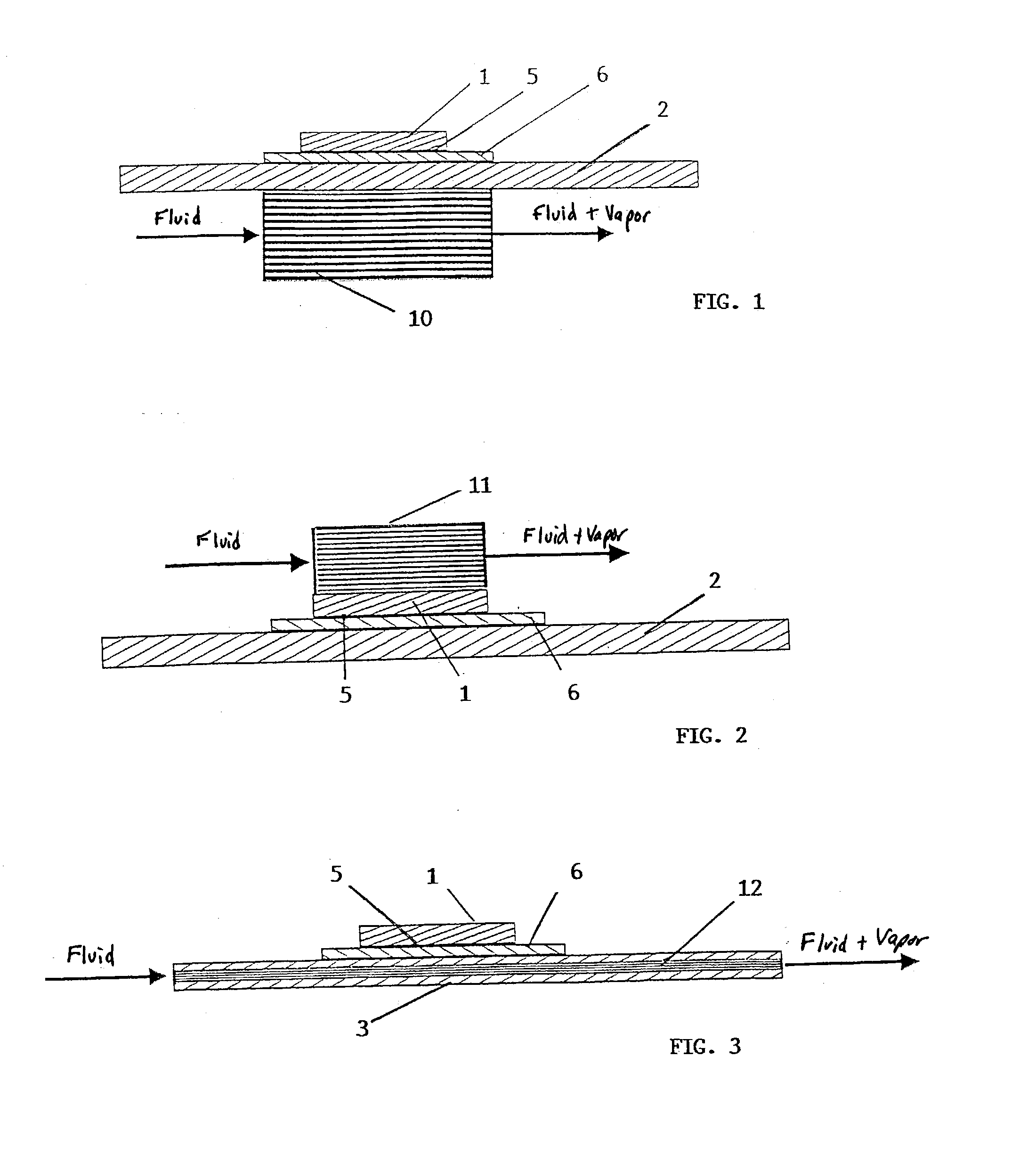

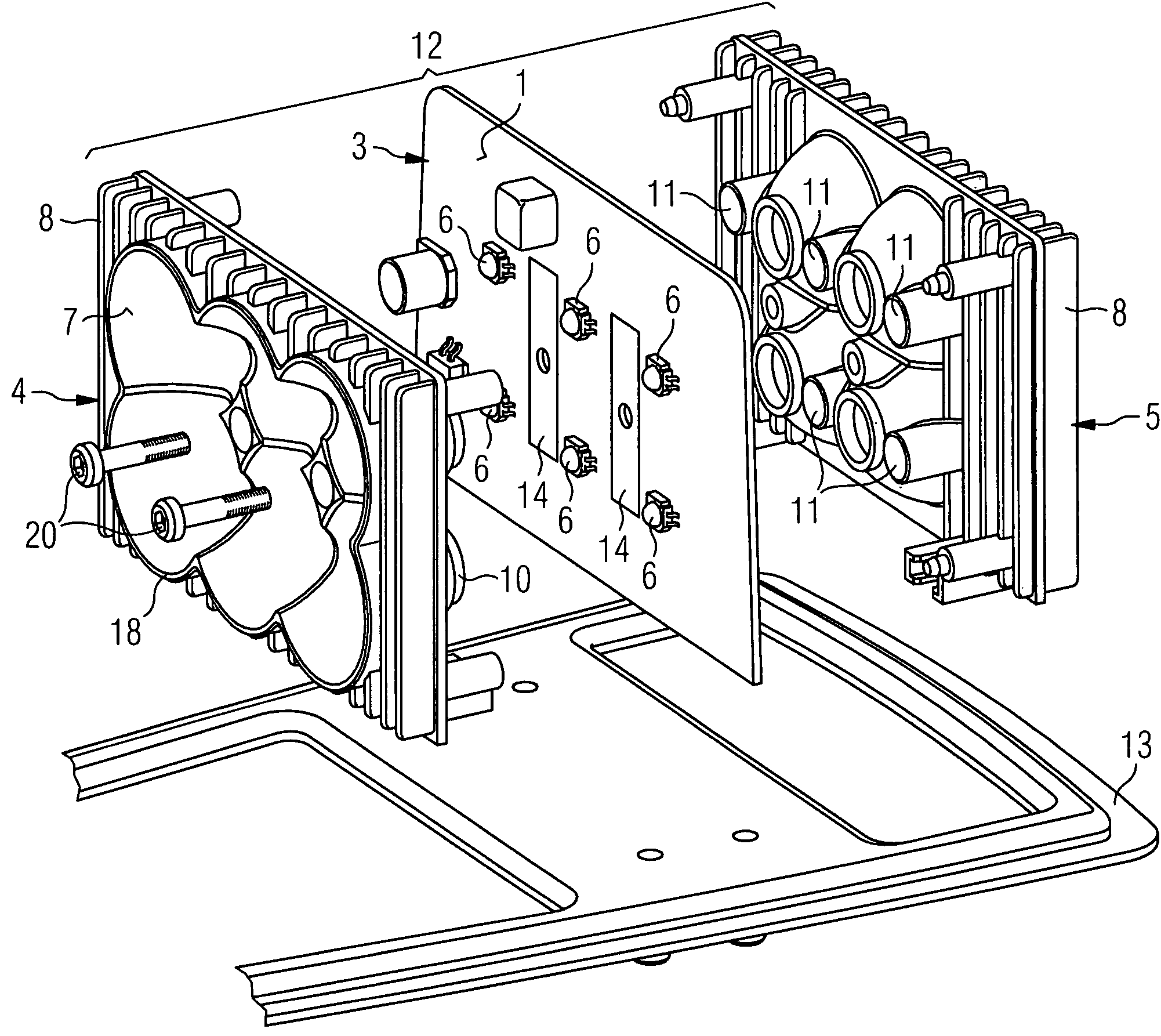

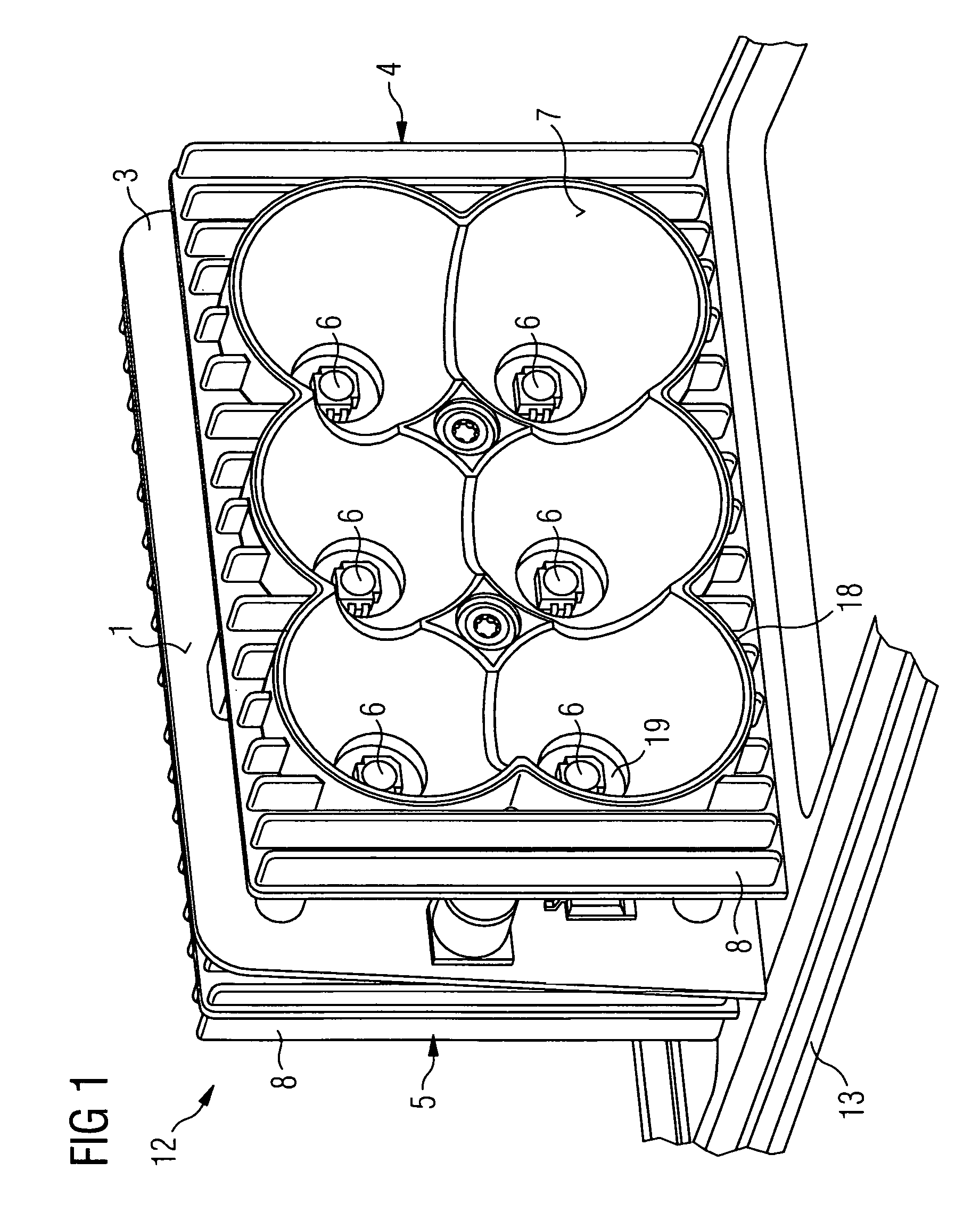

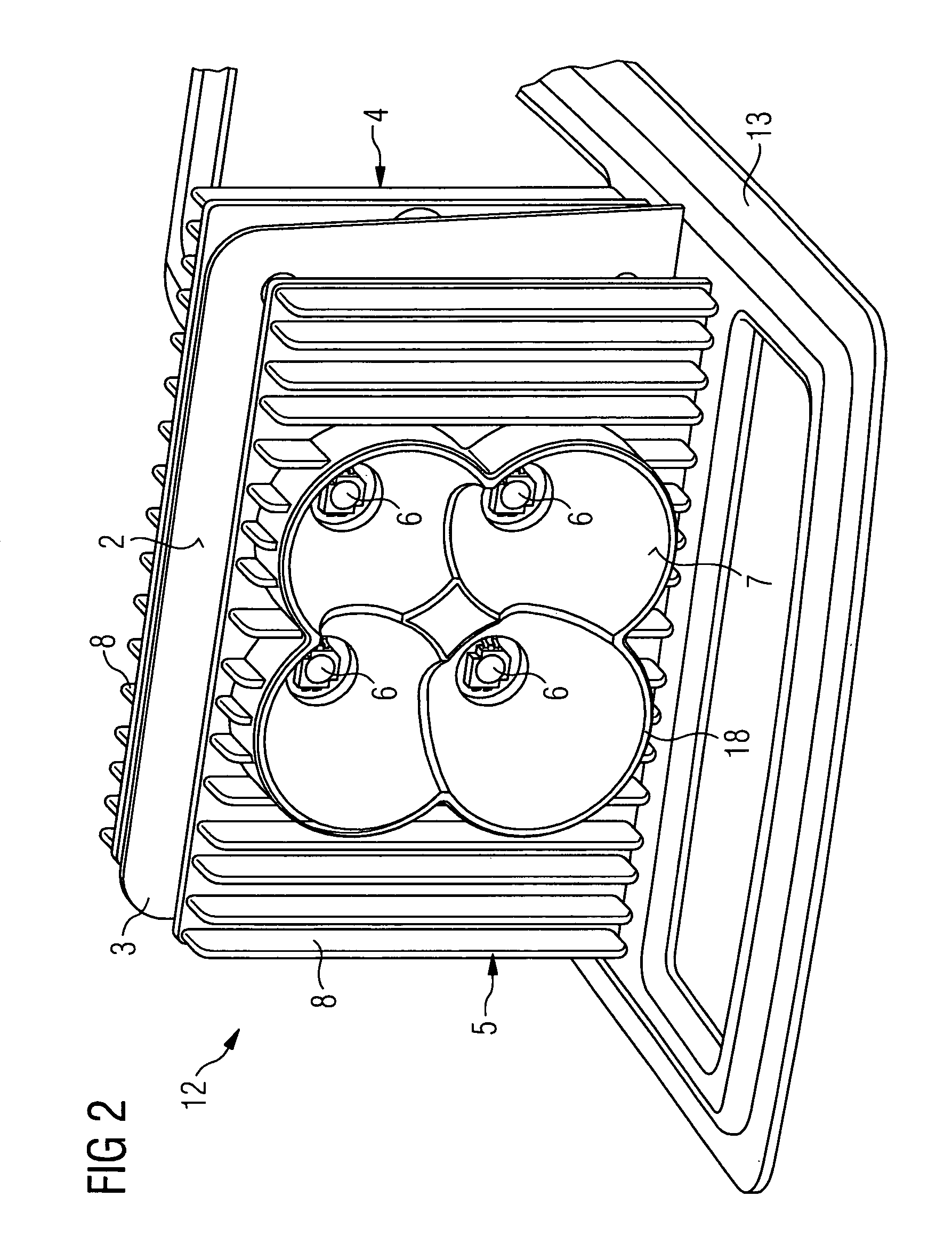

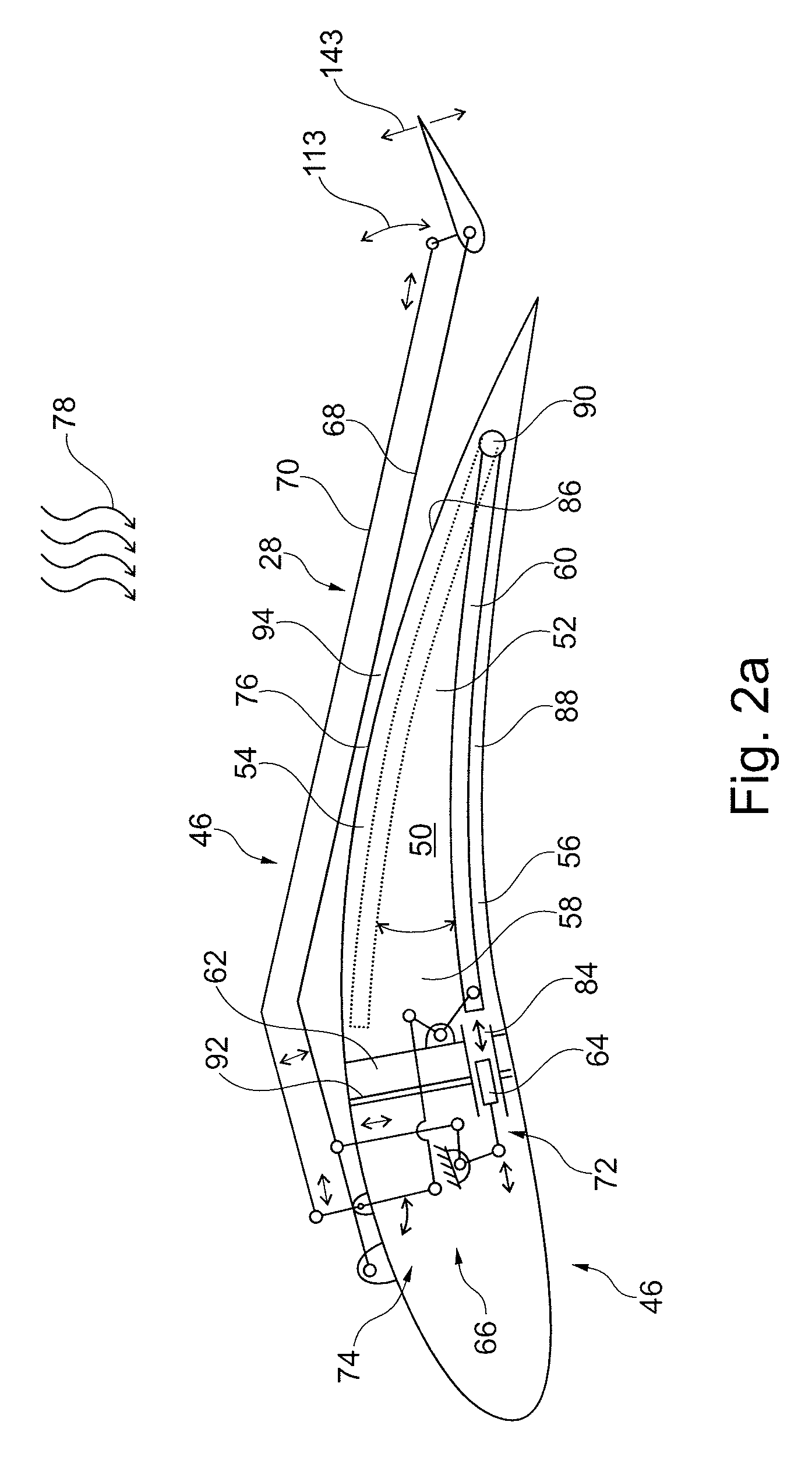

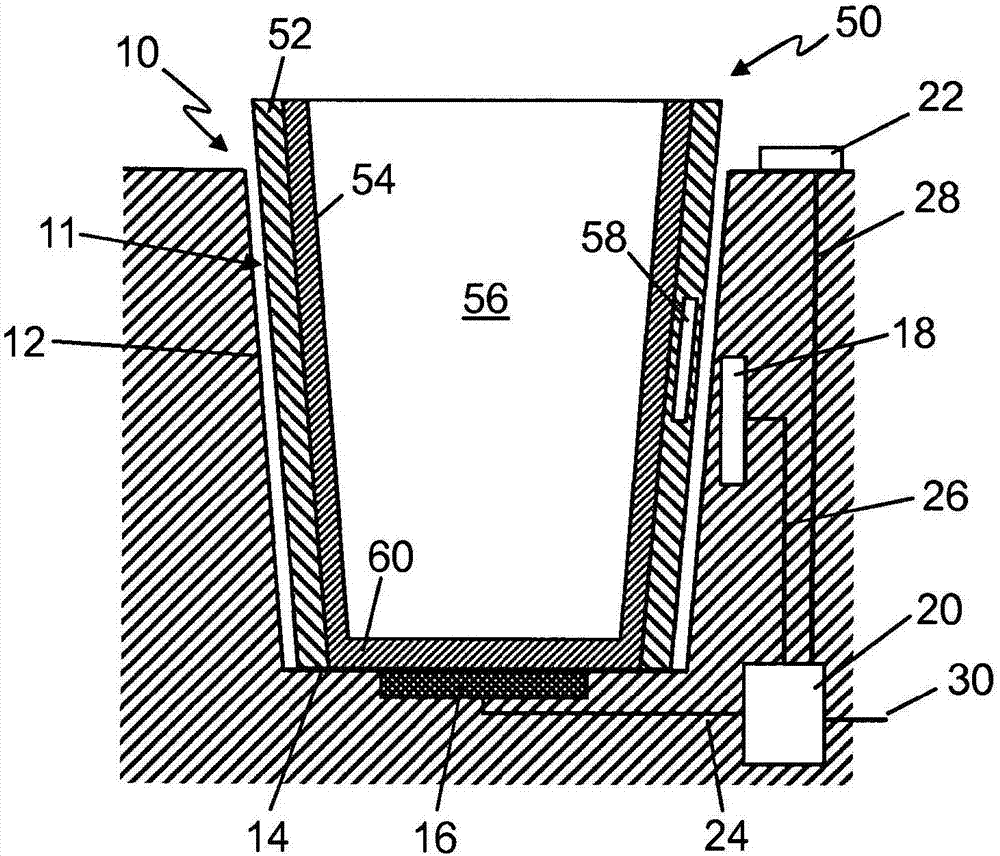

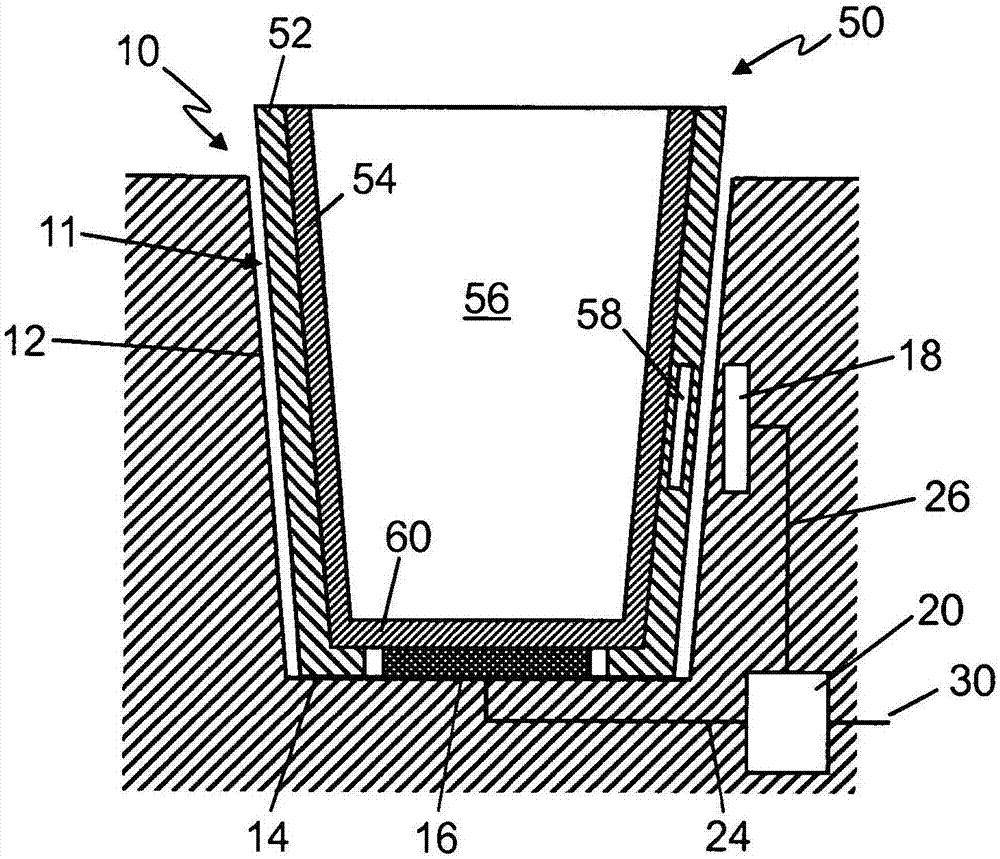

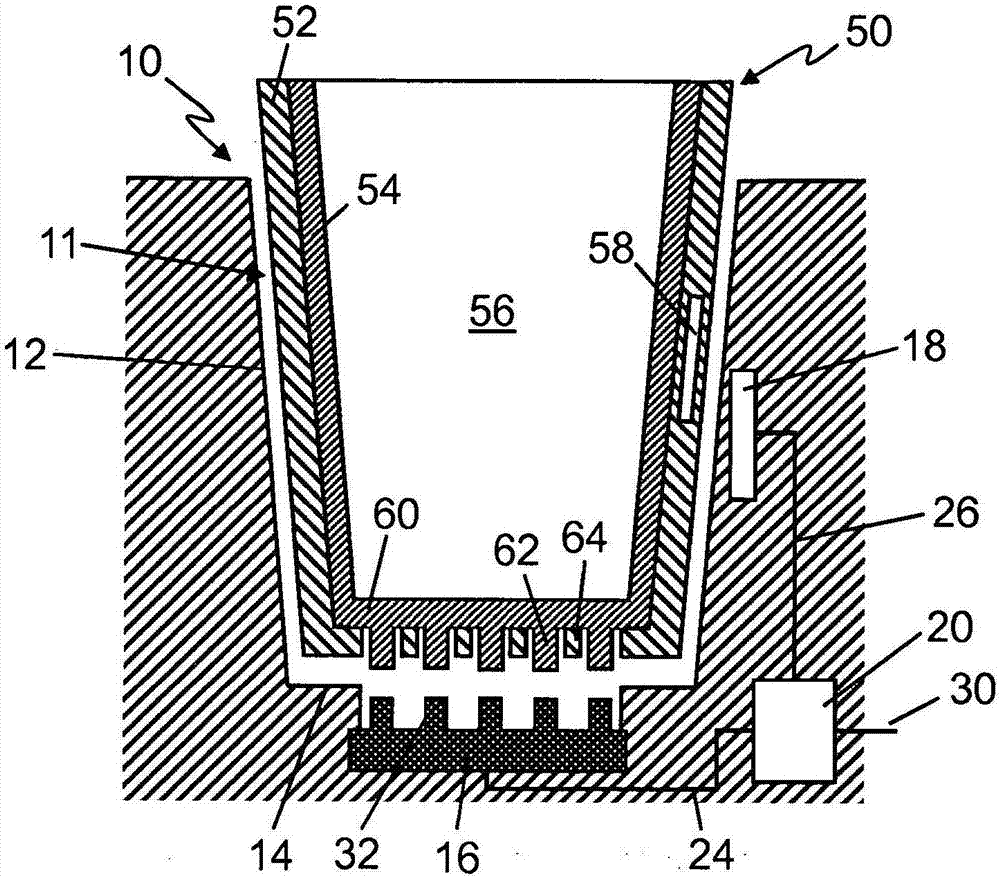

Cooling device for cooling components of the power electronics, said device comprising a micro heat exchanger

InactiveUS20030178178A1Large heat transfer surfaceLarge heat flowDomestic cooling apparatusSemiconductor/solid-state device detailsNuclear engineeringCooling power

The present invention relates to a cooling device, in particular for cooling of components of power electronics, using a coolant which flows through a micro heat exchanger (10) having a good heat contact with the component (1), and wherein the coolant is selected in such a way that it evaporates in the micro heat exchanger (10) at the desired component temperature.

Owner:ROBERT BOSCH GMBH

Illumination unit

ActiveUS7794115B2Improve cooling effectSpace minimizationLighting support devicesPoint-like light sourceHeat conductingEngineering

There is described an illumination unit with a planar carrier part having a plurality of light-emitting semiconductor components, in particular high-power light-emitting diodes, arranged on both sides of a main surface. On each side of the carrier part a heat sink is provided in each case. Each of the semiconductor components is connected in an efficient heat-conducting manner to a heat sink provided on an opposite side of the carrier part by way of a heat conducting means that is fed through an opening in the carrier part. At least one reflector is embodied on each heat sink having a reflective surface which concentrates the emitted light from a semiconductor component which is arranged on the side of the carrier part facing this heat sink.

Owner:OSRAM GMBH

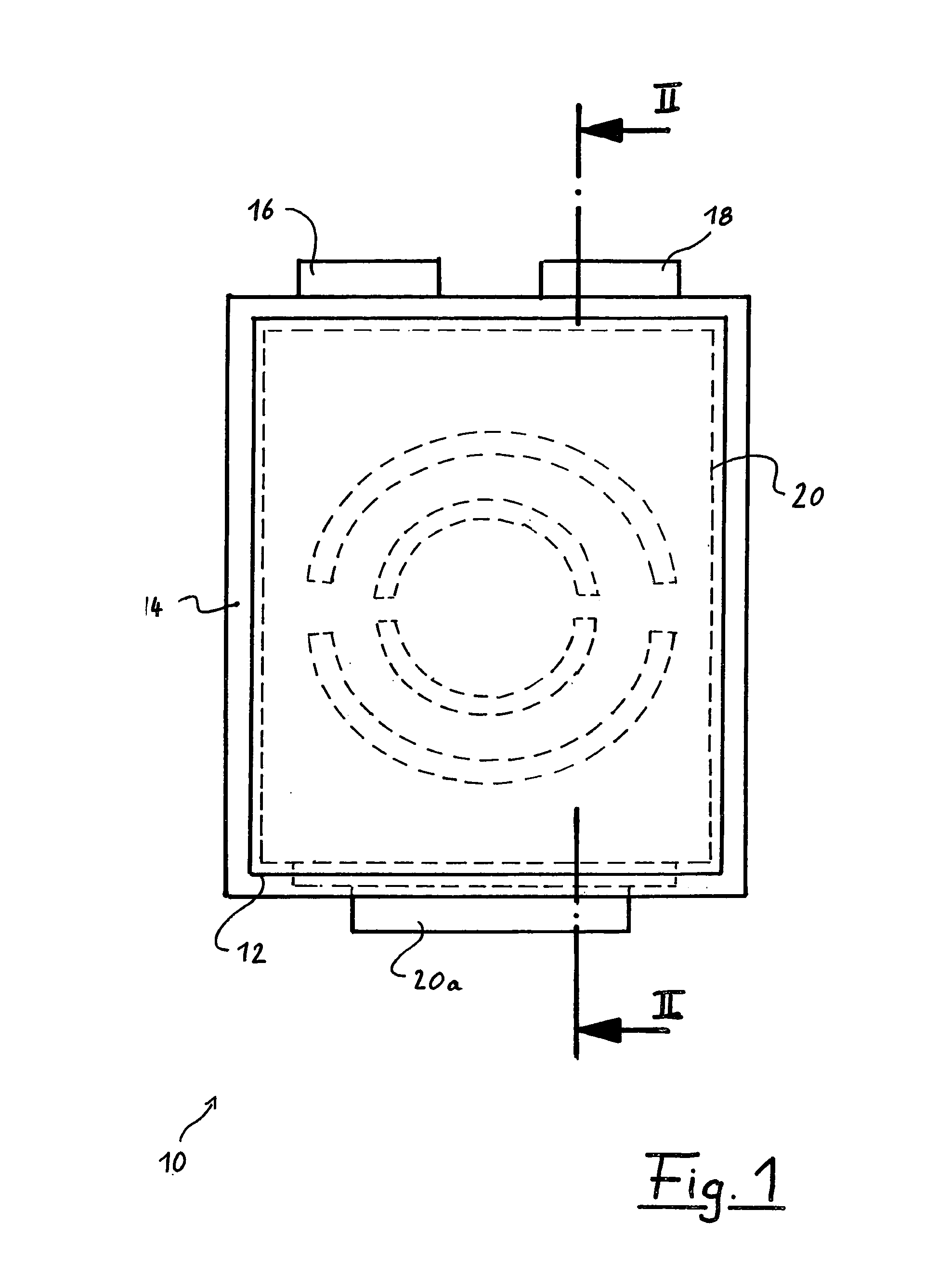

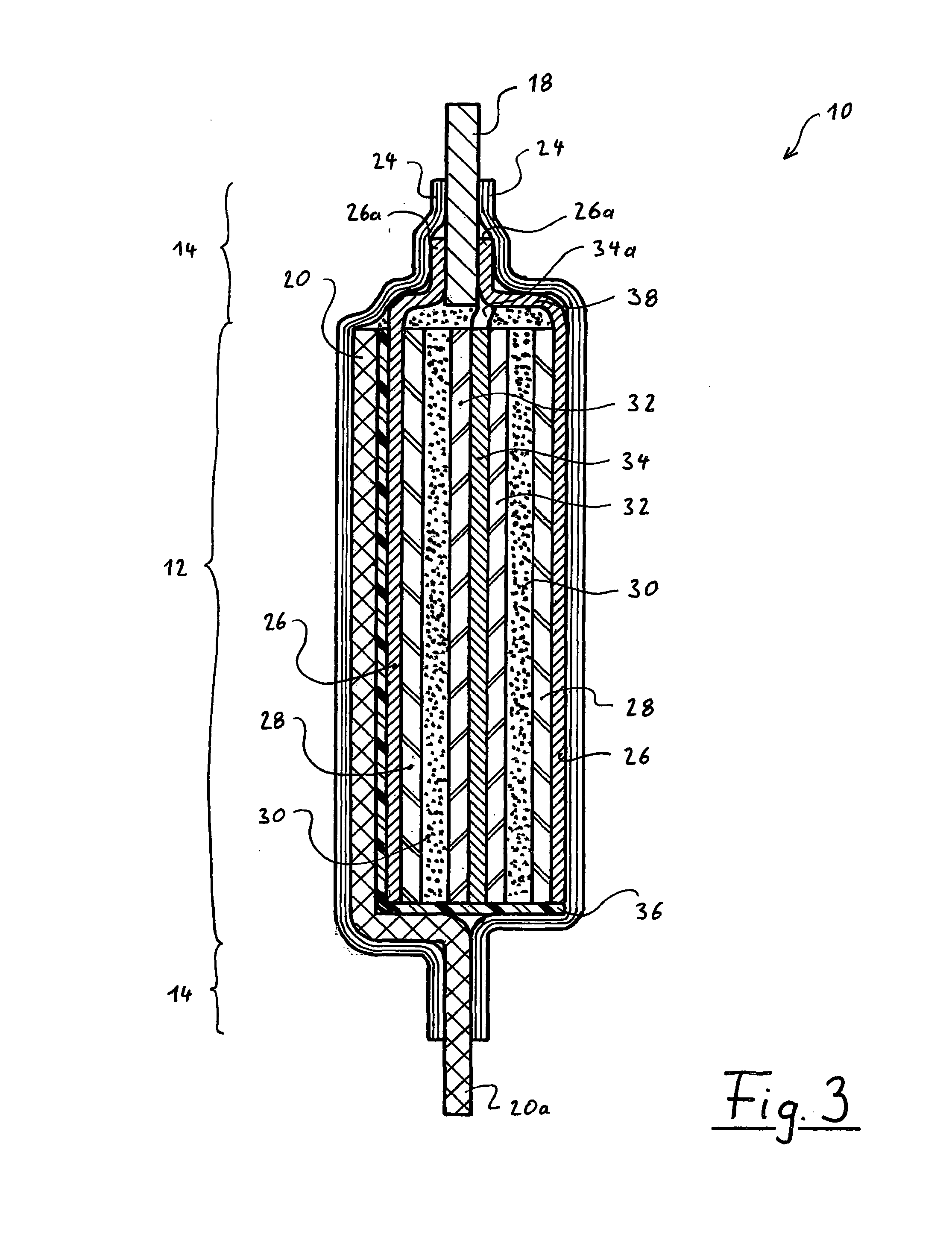

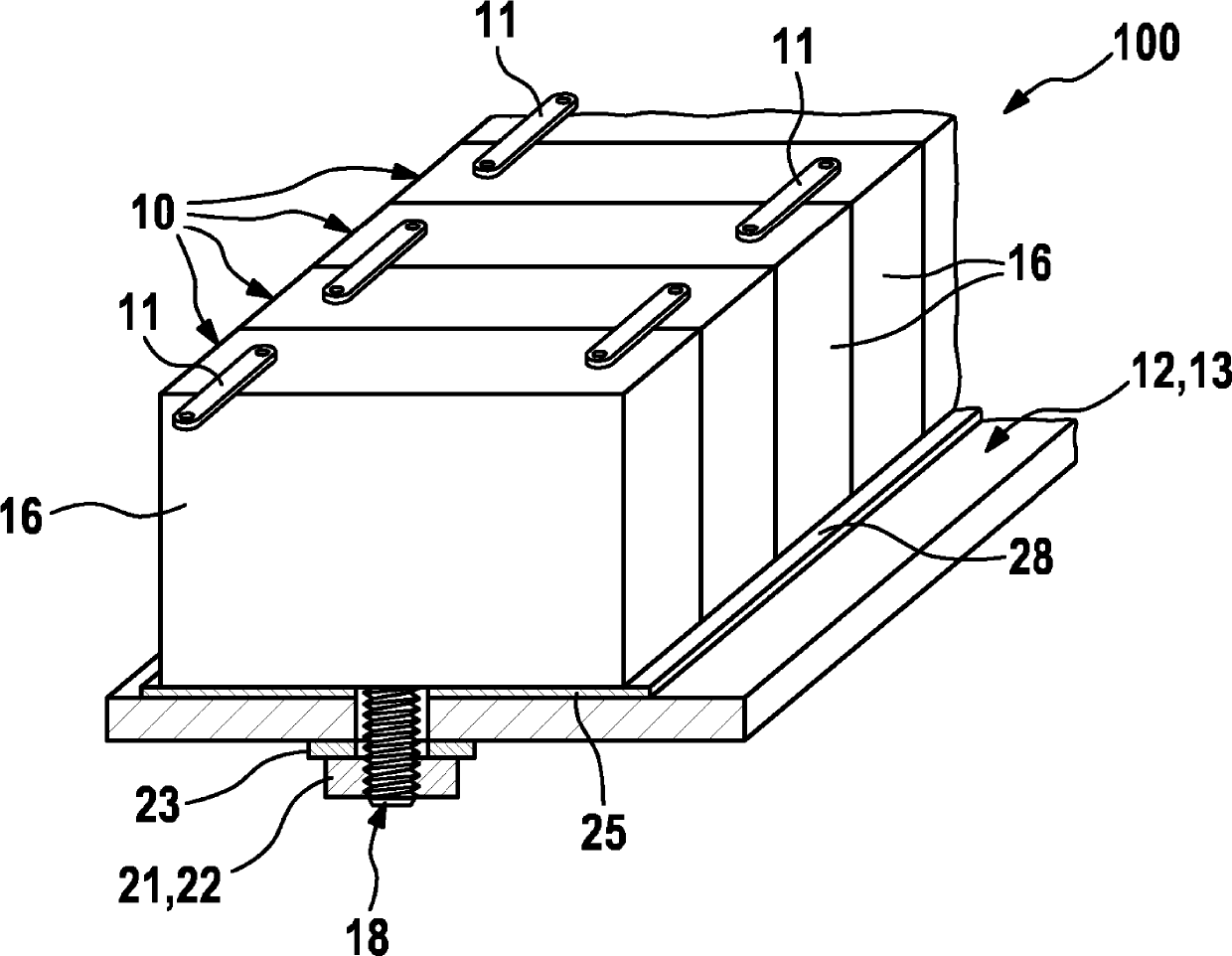

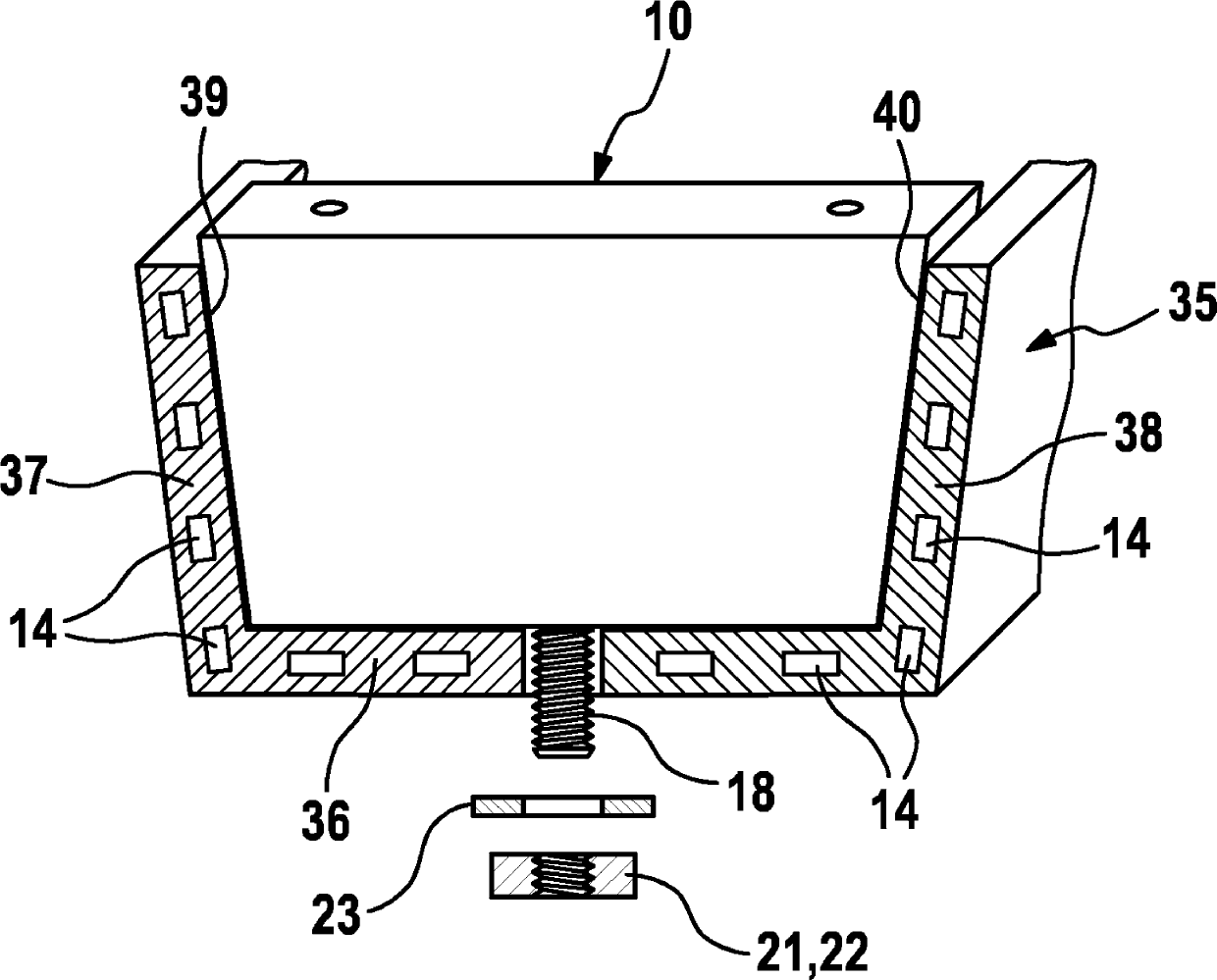

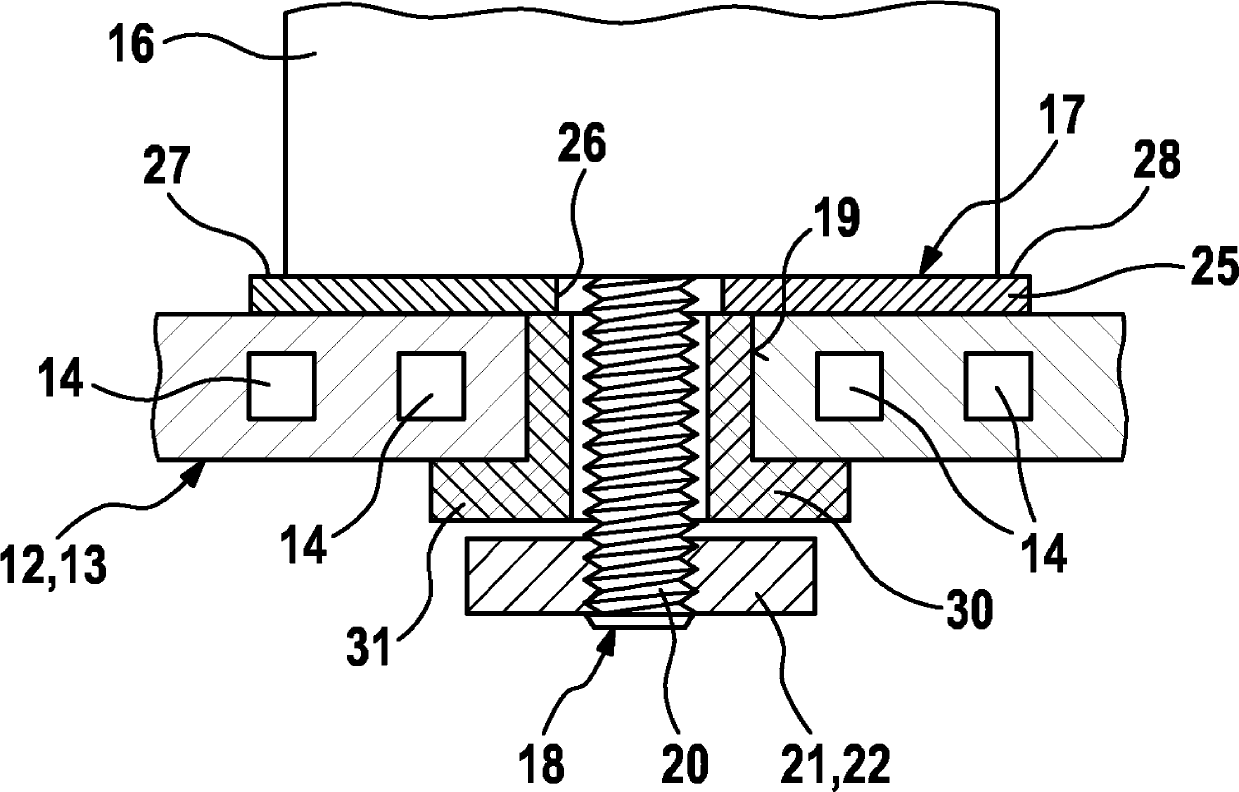

Electrical energy storage cell and apparatus

InactiveUS20130164594A1Easy to manufactureLarge heat transfer surfaceSmall-sized cells cases/jacketsCell temperature controlElectricityHeat conducting

The invention relates to an electrical energy storage cell comprising an electrical energy storage structure, a housing which receives the electrical energy storage structure and surrounds it in a sealed manner, and at least two contact elements which are accessible outside the housing for the electrical connection to electrode regions of the electrical energy storage structure. At least one heat conducting element, which is constructed separately from the electrical energy storage structure and is designed and equipped to absorb heat from the electrical energy storage structure and to release heat to outside of the housing, is disposed inside the housing. The invention also relates to an electrical energy storage device comprising an array of electrical energy storage cells.

Owner:LI TEC BATTERY

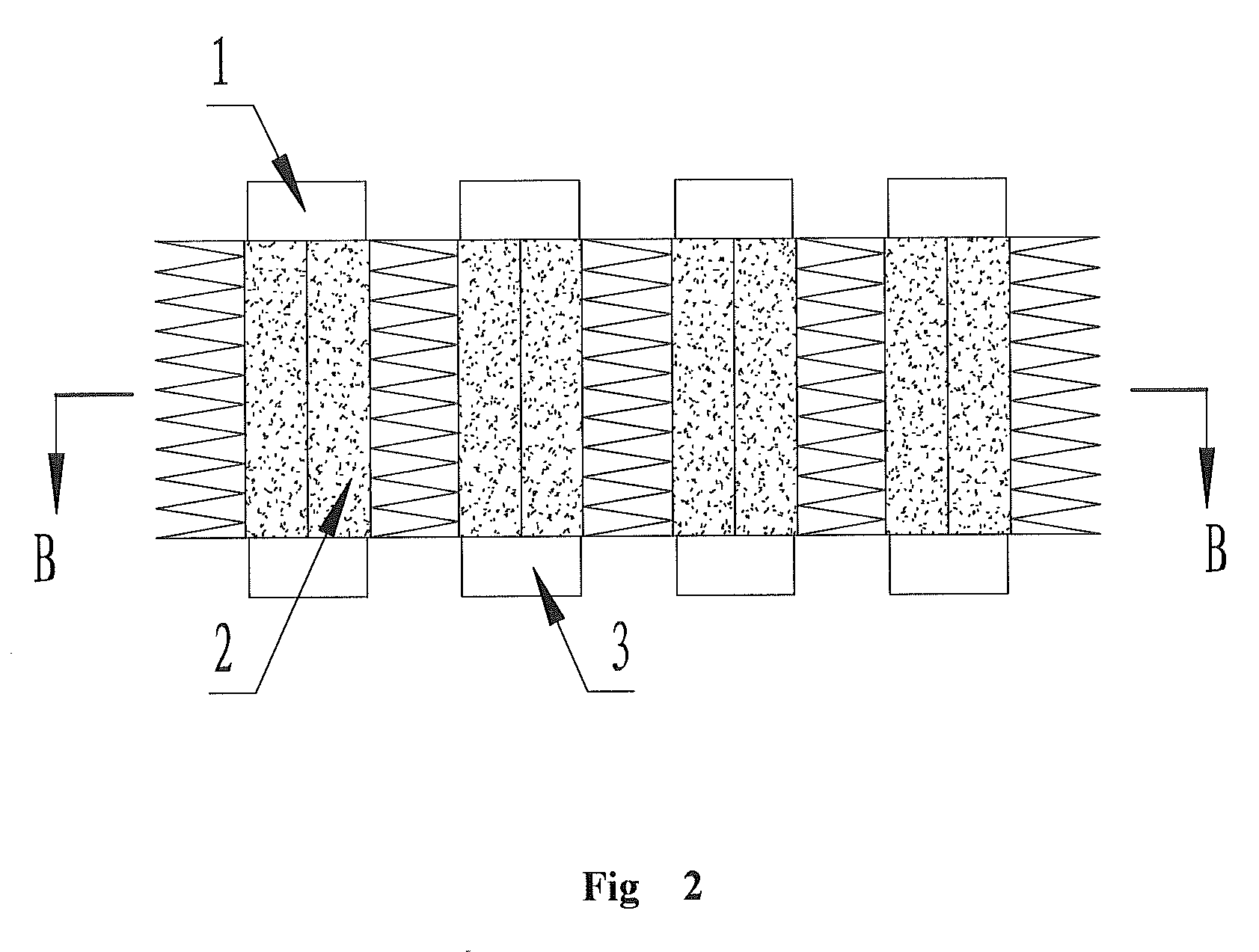

Tube-fin type heat exchange unit with high pressure resistance

InactiveUS20100230084A1Large heat transfer surfaceImprove pressure resistanceHeat transfer modificationTubular elementsEngineeringHeat sink

The present invention disclosed a tube-fin type heat exchange unit with high pressure resistance, wherein said heat exchange unit comprises a plurality of tubes, foam metal and a plurality of heat dissipation fins; said tubes and said heat dissipation fins are spaced arranged; said foam metal is located in the interspace between said tubes and the superface of said heat dissipation fins; and solder is disposed between said tubes and said foam metal, and between said foam metal and the superface of said heat dissipation fins to make a firm connection. The heat exchange unit of the present invention has good heat exchange performance, high pressure resistance and small volume, so it is suitable for volume production and could be widely applied in heat exchangers for vehicle, industry and civil use.

Owner:NANNING BALING TECHNOLOGY CO LTD

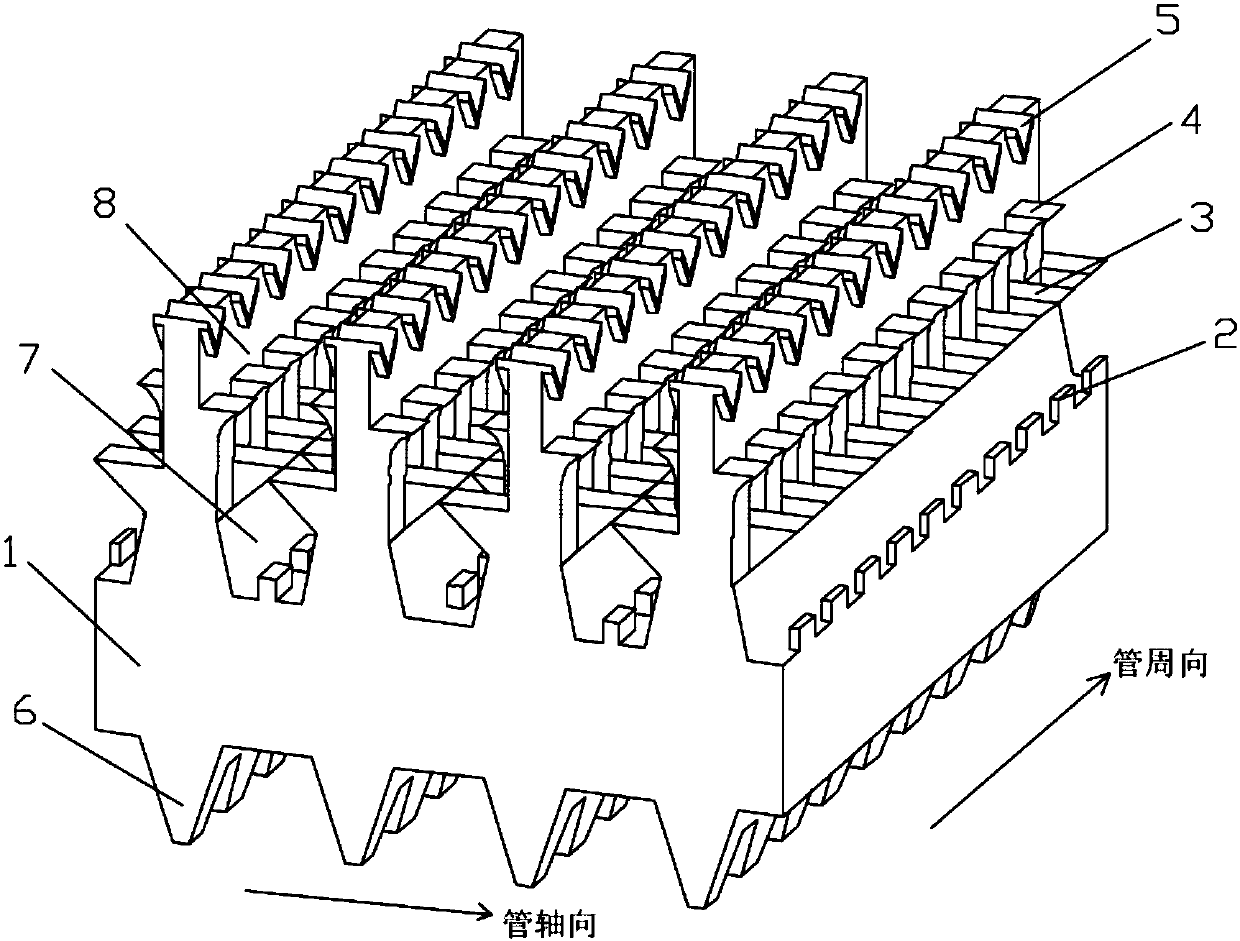

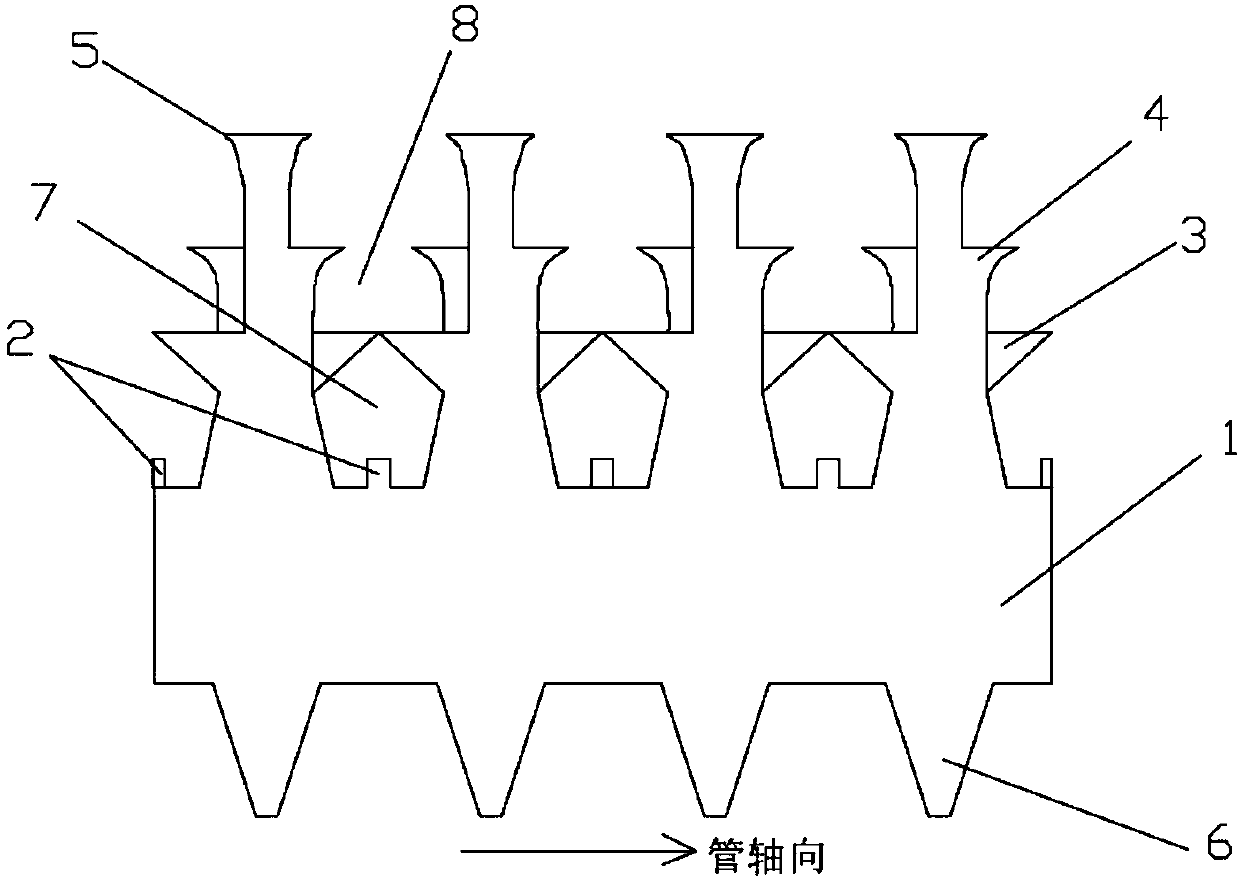

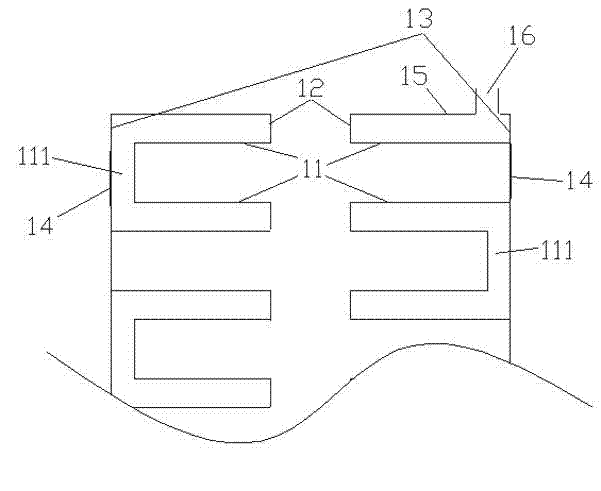

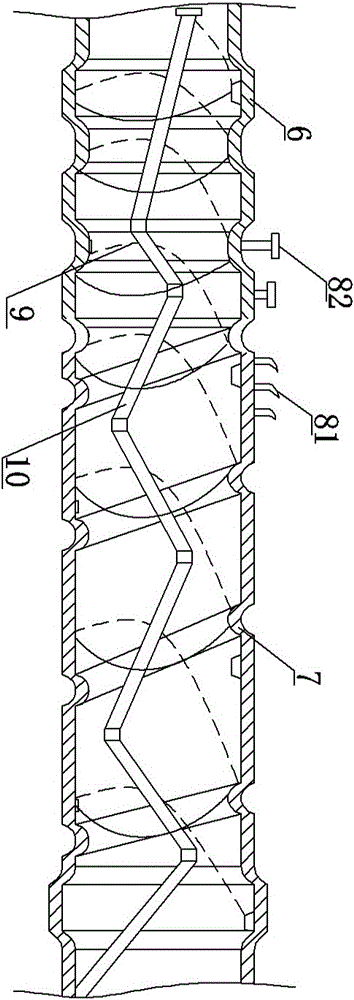

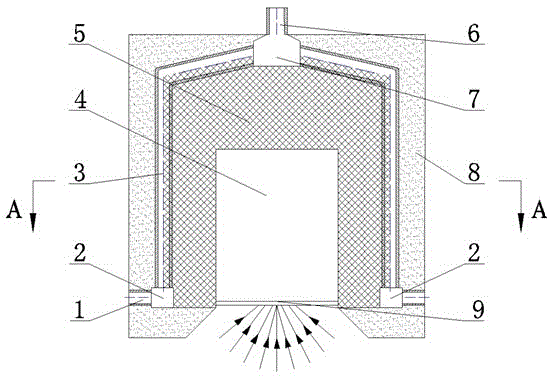

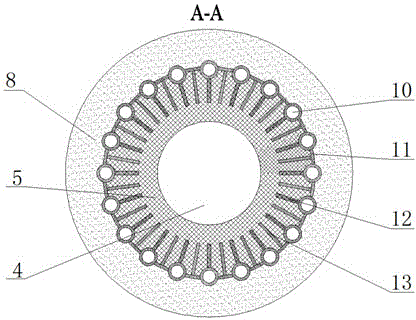

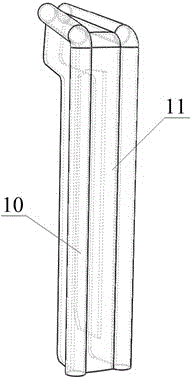

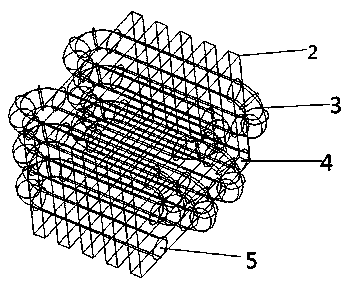

Internal and external finned tube inside evaporating and condensing dual-use ladder-shaped grid

PendingCN107782192AIncrease contact areaImprove evaporation performanceEvaporators/condensersTubular elementsEngineeringDistribution grid

The invention relates to an internal and external finned tube inside an evaporating and condensing dual-use ladder-shaped grid. The internal and external finned tube comprises a pipe base body, spiraljagged inner fins, spiral jagged outer fins, inter-groove double wedges, grid fins, ladder fins and triangular top teeth. The grid fins are located on both sides of the spiral jagged outer fins, thegrid fins on the two sides of the same spiral jagged outer fins are staggered, the ladder fins are located on both sides of the spiral jagged outer fins and on the outside of the grid fins, the ladderfins on the two sides of the same spiral jagged outer fins are staggered, the ladder fins on the same side are interleaved with the grid fins, the inner side of the grid fins, the spiral jagged outerfins, the pipe base body, and the inter-groove double wedges enclose an evaporation chamber, the outer side of the grid fins, the spiral jagged outer fins, and the ladder fins enclose an enhanced cavity, the evaporation chamber and the enhanced cavity communicate with each other through gaps. The internal and external finned tube can improve heat transfer efficiency of evaporation and condensation and belongs to the technical field of enhanced heat transfer tubes.

Owner:SOUTH CHINA UNIV OF TECH

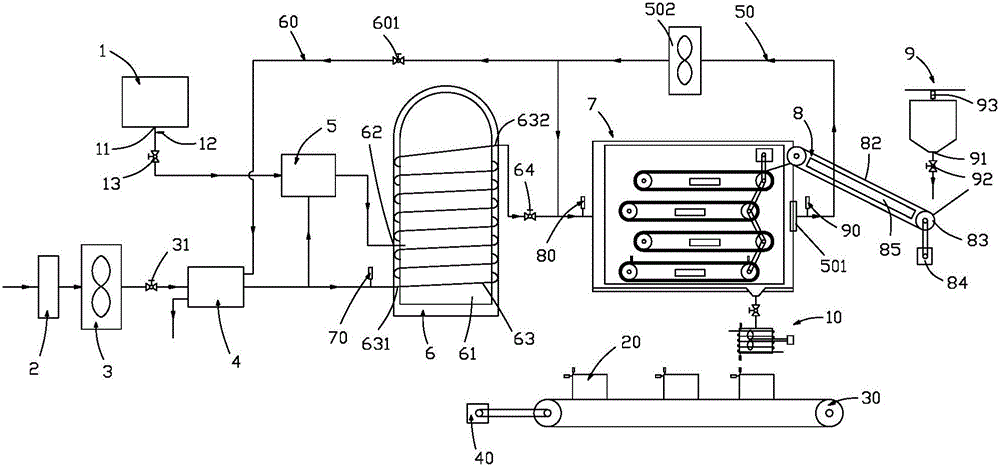

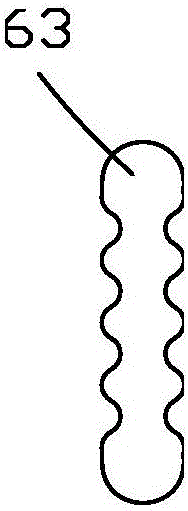

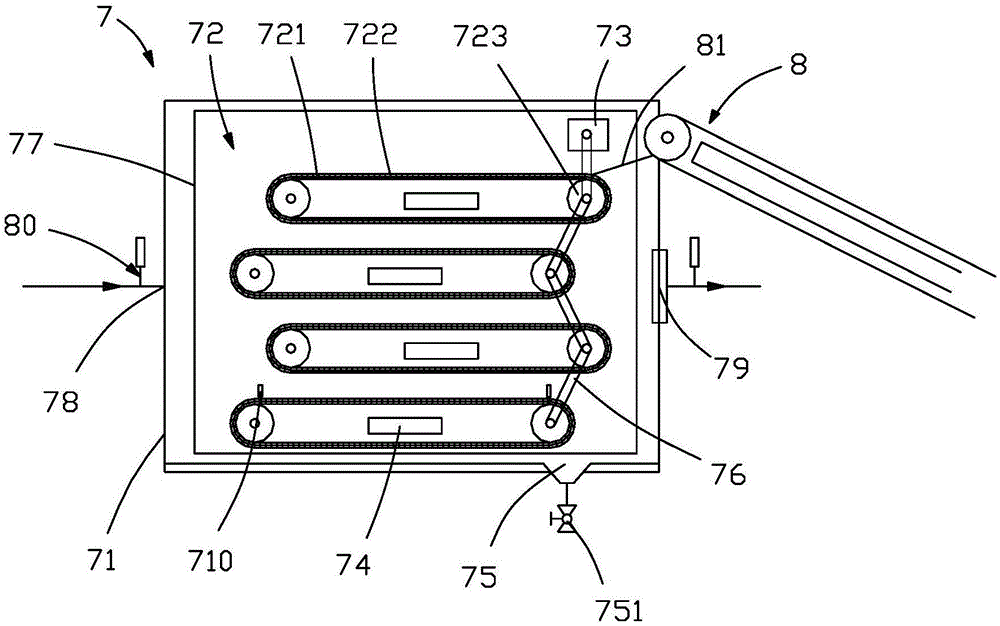

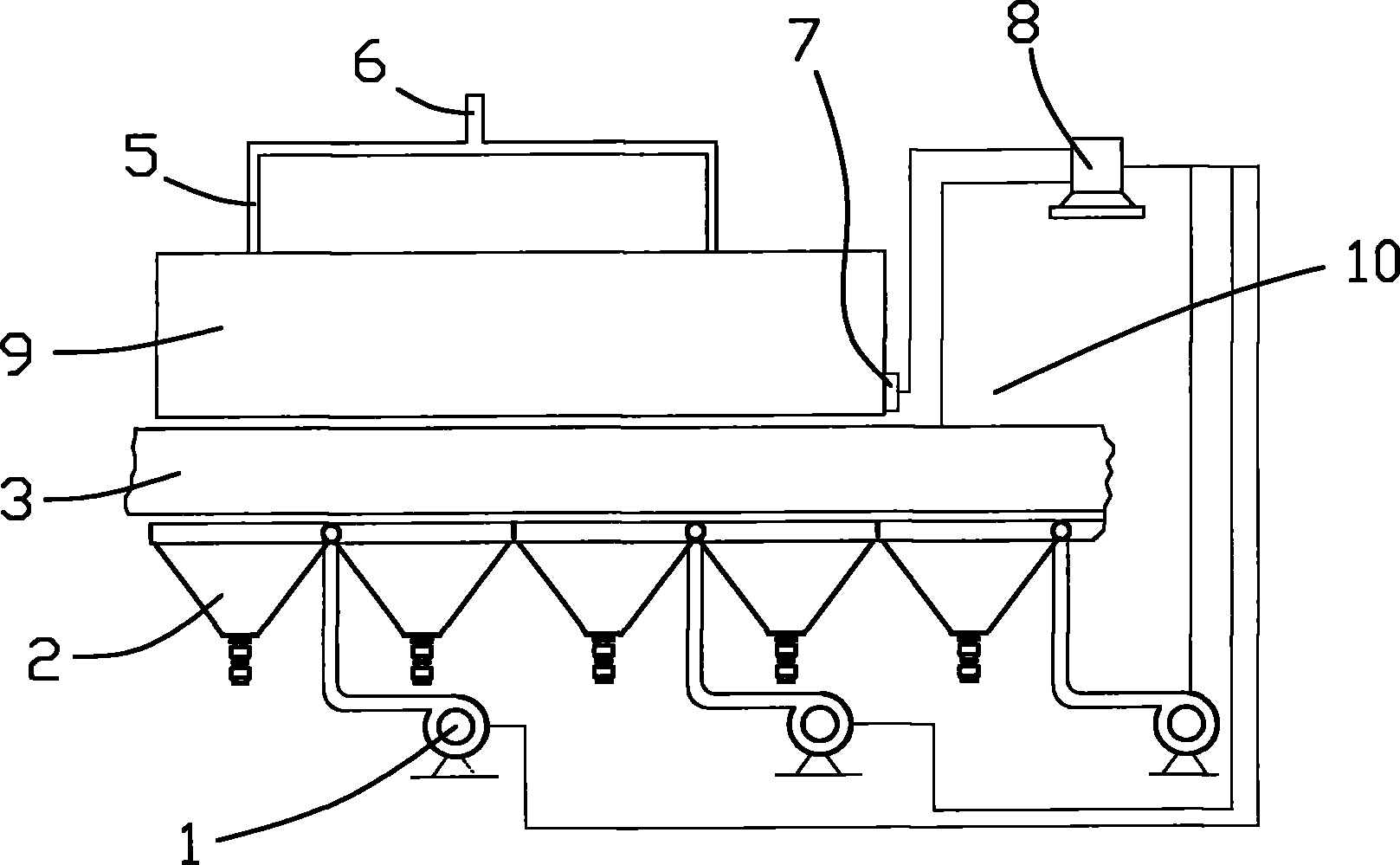

Full-automatic tea leaf drying device

ActiveCN106288727ASolve pollutionAvoid moisture returnTea dryingDrying gas arrangementsMechanical equipmentEngineering

The invention provides a full-automatic tea leaf drying device, and belongs to the field of tea leaf processing mechanical equipment. The full-automatic tea leaf drying device comprises a fuel storage bin, a first draught fan, a boiler, a drying box, a feeding device and a leaf storage bin. The fuel storage bin and the first draught fan are connected with the boiler, and the boiler is then connected with the drying box. The leaf storage bin is sequentially connected with the feeding device and the drying box. A heat exchange pipe is arranged on the inner wall of the boiler and provided with a heat exchange pipe opening end and a heat exchange pipe outlet end which are connected with the first draught fan and the drying box correspondingly. The drying box is provided with a hot air inlet end and a hot air outlet end which are connected with each other through a hot air circulation pipe. The hot air circulation pipe is provided with a second draught fan and a hot air extension pipe which is provided with a first electromagnetic valve in a penetrating manner. The full-automatic tea leaf drying device can achieve automatic feeding, drying, discharging and cooling of the tea leaf drying process and can accurately control the drying degree of tea leaves and improve the tea leaf drying quality and drying efficiency, and the device is easy and convenient to operate.

Owner:江西浮梁贡茶叶有限公司

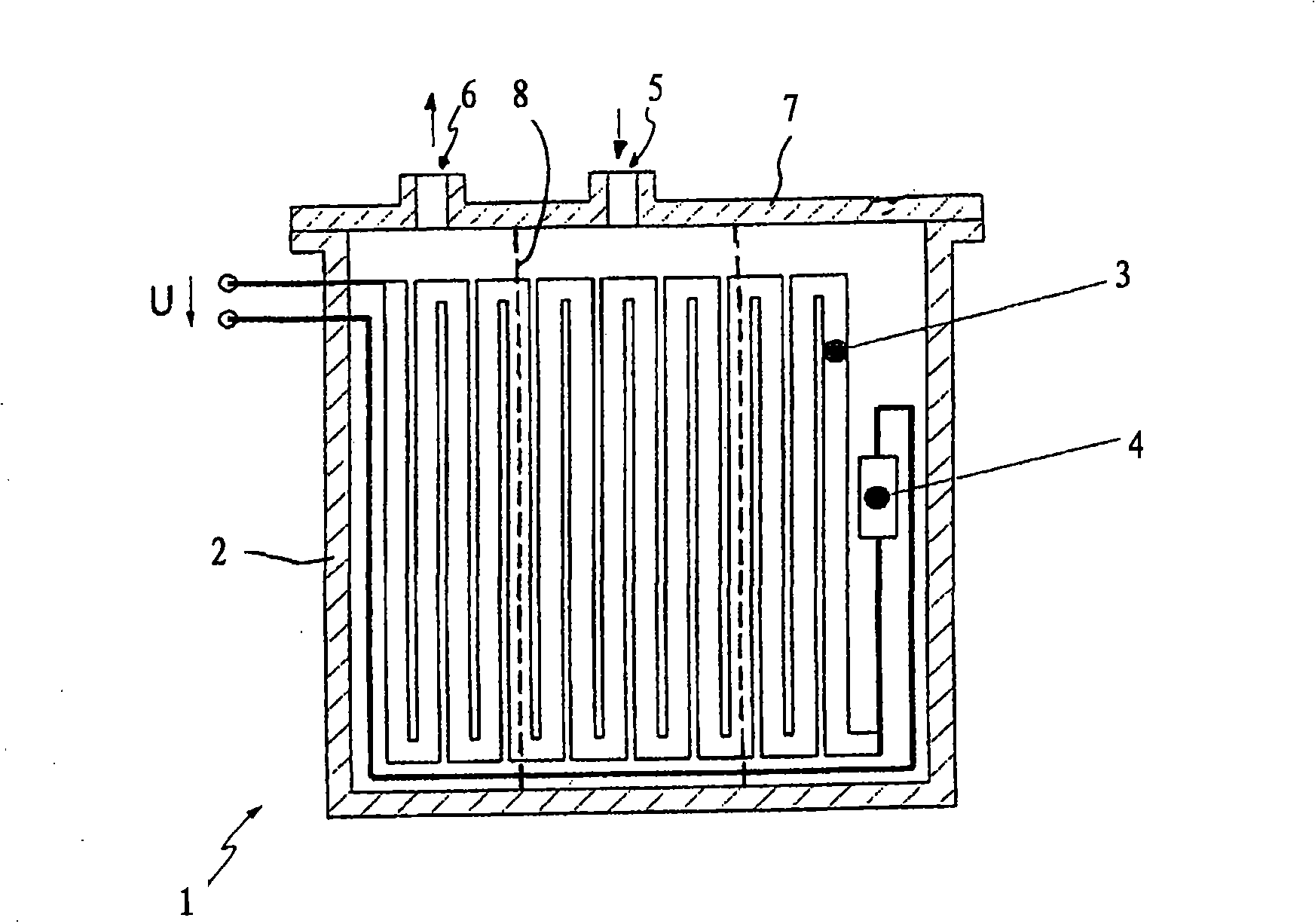

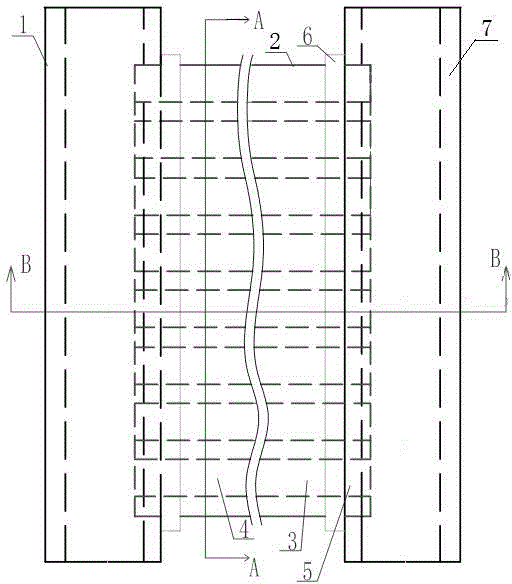

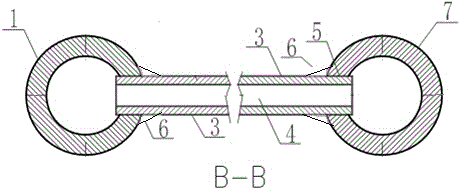

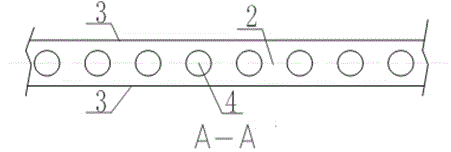

Fluid container and reductant supply system with such a fluid container

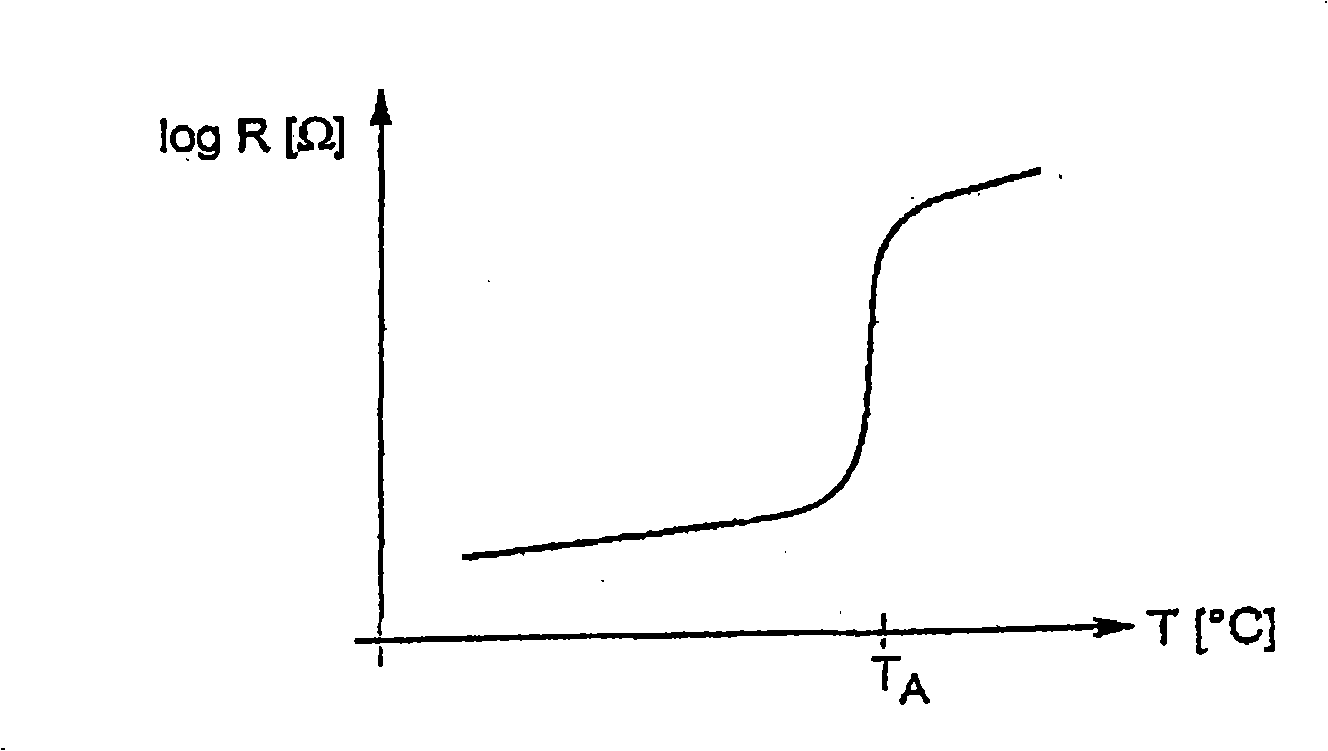

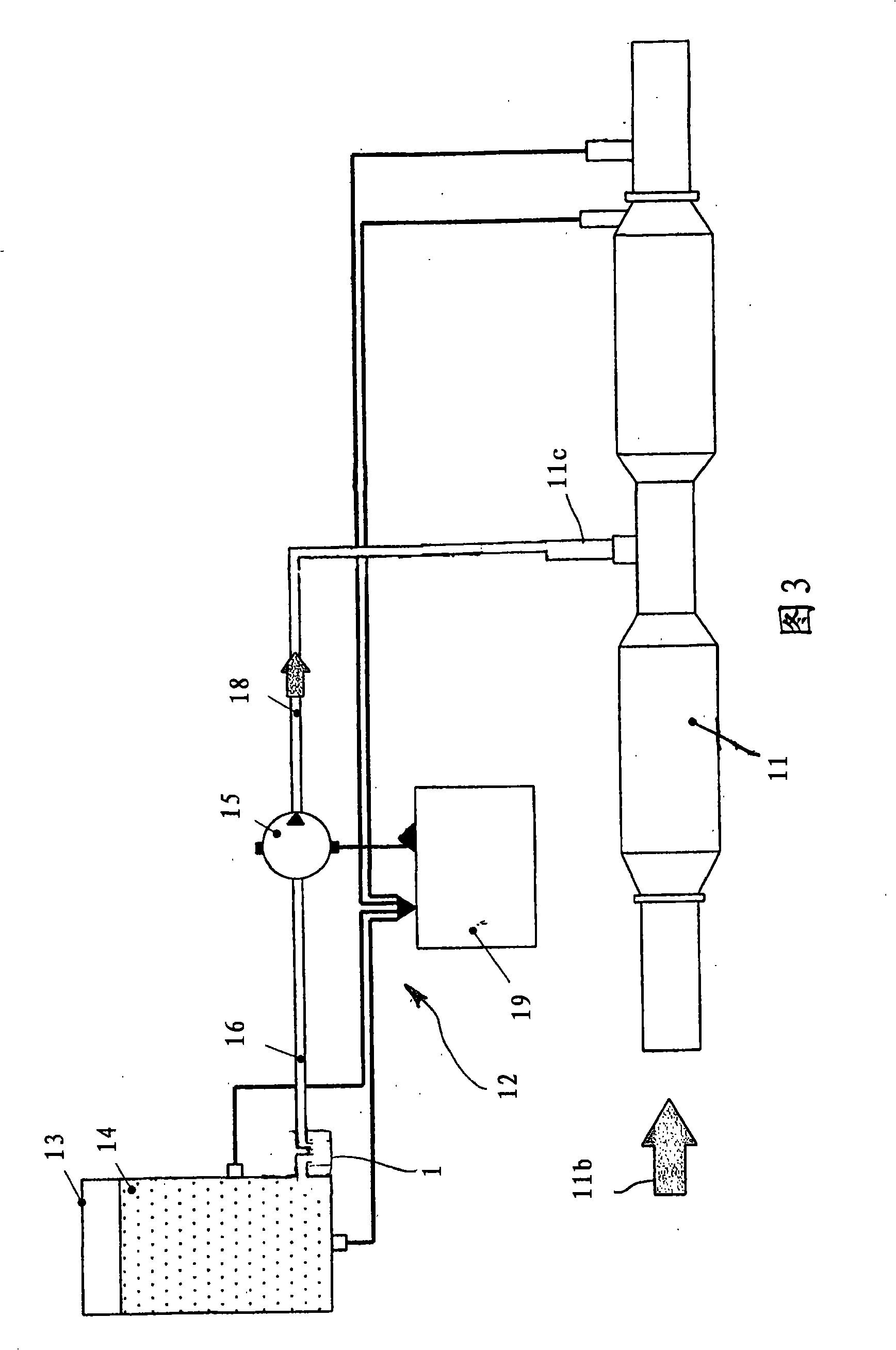

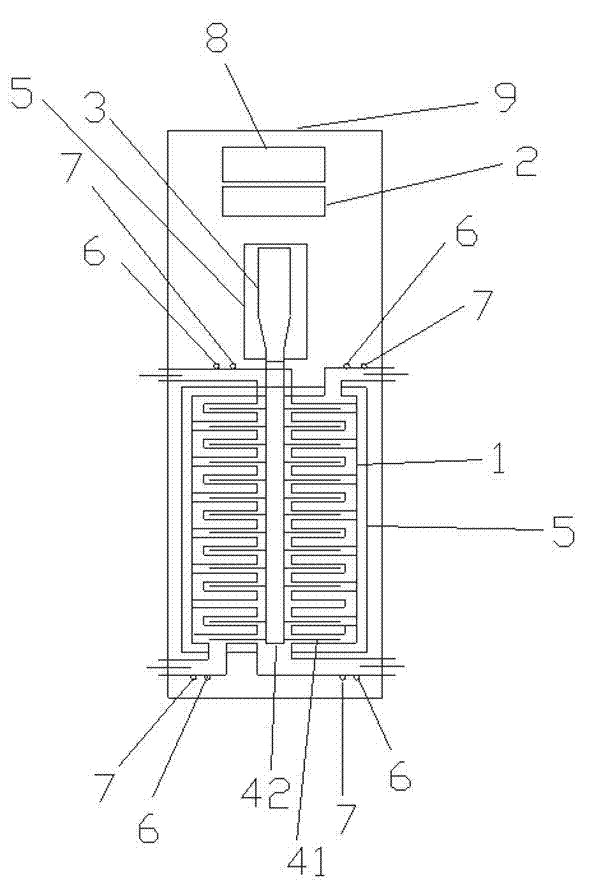

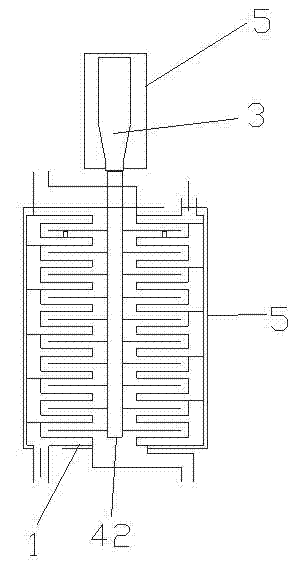

ActiveCN101306746ALimit heating currentFast response time combined withInternal combustion piston enginesExhaust apparatusElectrical resistance and conductanceMarine engineering

The invention relates to a fluid vessel for motor vehicle. The vessel is provided with a vessel wall (2) which is made of plastic and has at least one metal resistant heating element (3). According to the invention, the vessel wall (2) is provided with at least one PPTC element (4) for preventing from being overheated. The PPTC element is connected in series with at least one heating element (3).

Owner:EICHENAUER HEIZELEMENTE +1

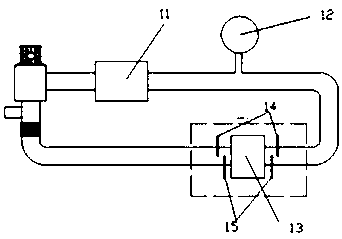

Baffle high-efficient heat exchanger

ActiveCN103090700AExtended stayLarge heat transfer surfaceVibration cleaningStationary tubular conduit assembliesUltrasound devicePlate heat exchanger

The invention discloses a baffle high-efficient heat exchanger which comprises a corrugation baffle high-efficient heat exchanger shell and an ultrasound device, and preferably comprises a heat-exchanging efficiency real-time monitoring and controlling system. Heat exchanging media flow in the corrugation baffle high-efficient heat exchanger in a baffle mode; the ultrasound device comprises an ultrasound generation mechanism and an ultrasound wave transmission and vibration mechanism, wherein the ultrasound wave transmission and vibration mechanism is arranged inside the corrugation baffle high-efficient heat exchanger shell; and the heat-exchanging efficiency real-time monitoring and controlling system is used for monitoring the temperature and the pressure of the outlet or the inlet of the heat exchanger to obtain heat-exchanging efficiency through calculation, adjusting flow of the heat exchanger according to the heat-exchanging efficiency and ensuring that the heat exchanger is kept in the best heat-exchanging state. Because the baffle heat exchanger is combined with ultrasound wave technologies in the baffle high-efficient heat exchanger, the purposes of preventing and eliminating contamination, preventing a metal shell body from being corroded and improving heat-exchanging efficiency are achieved; the heat-exchanging efficiency real-time monitoring and controlling system can timely record and display to provide reliable data for production operation; and heat-exchanging efficiency is improved, energy consumption is reduced, and environment is further protected.

Owner:江苏坤升环境科技有限公司

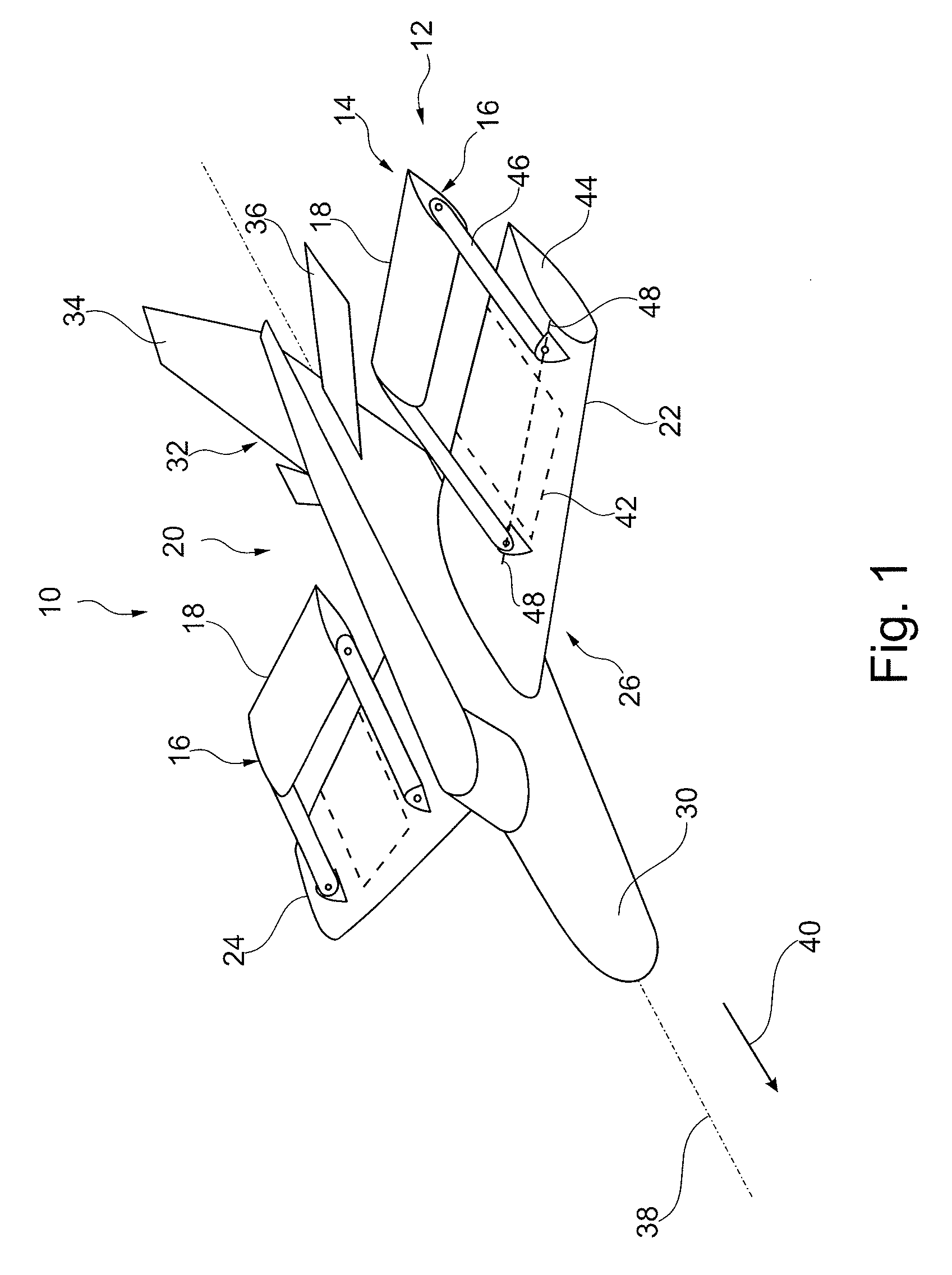

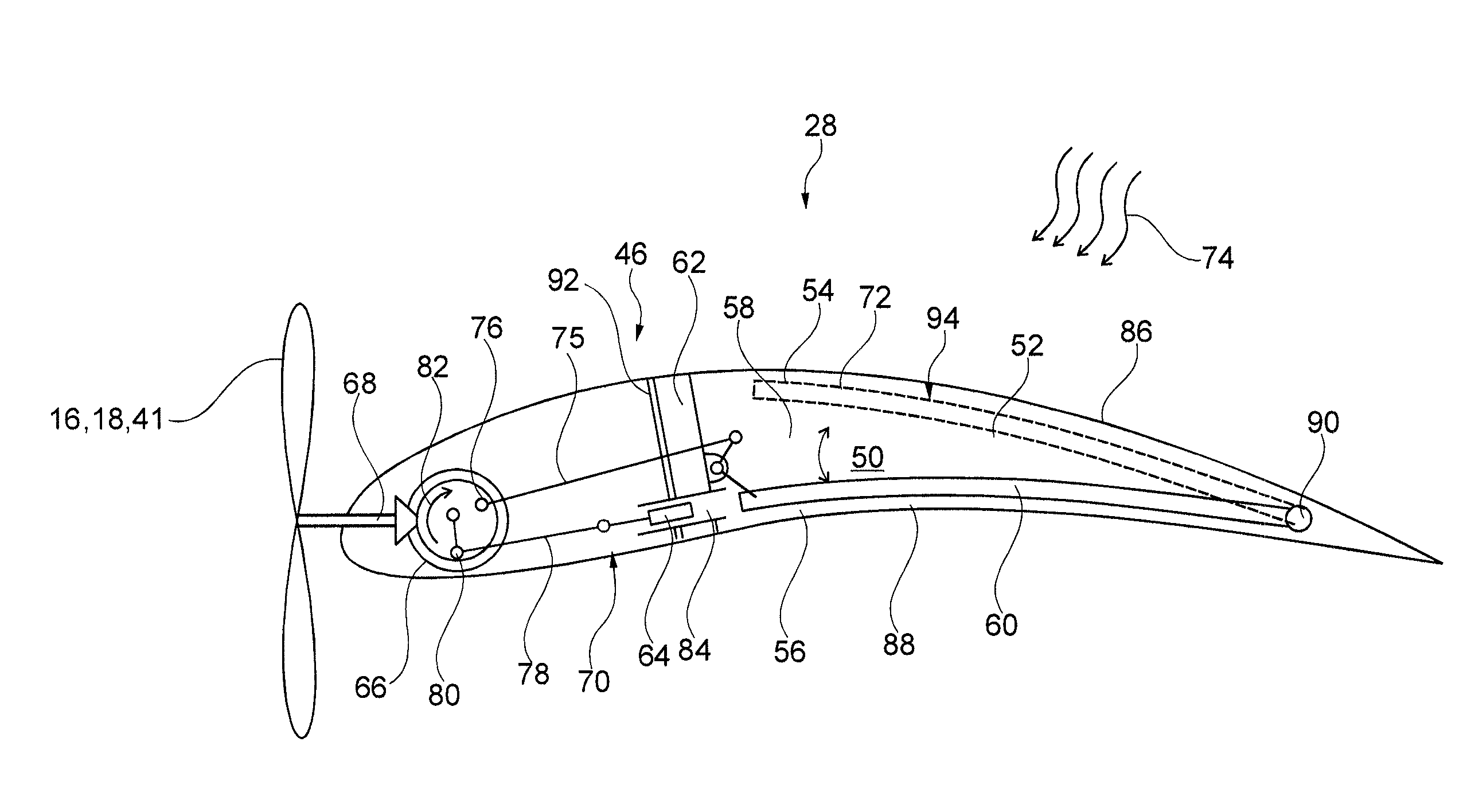

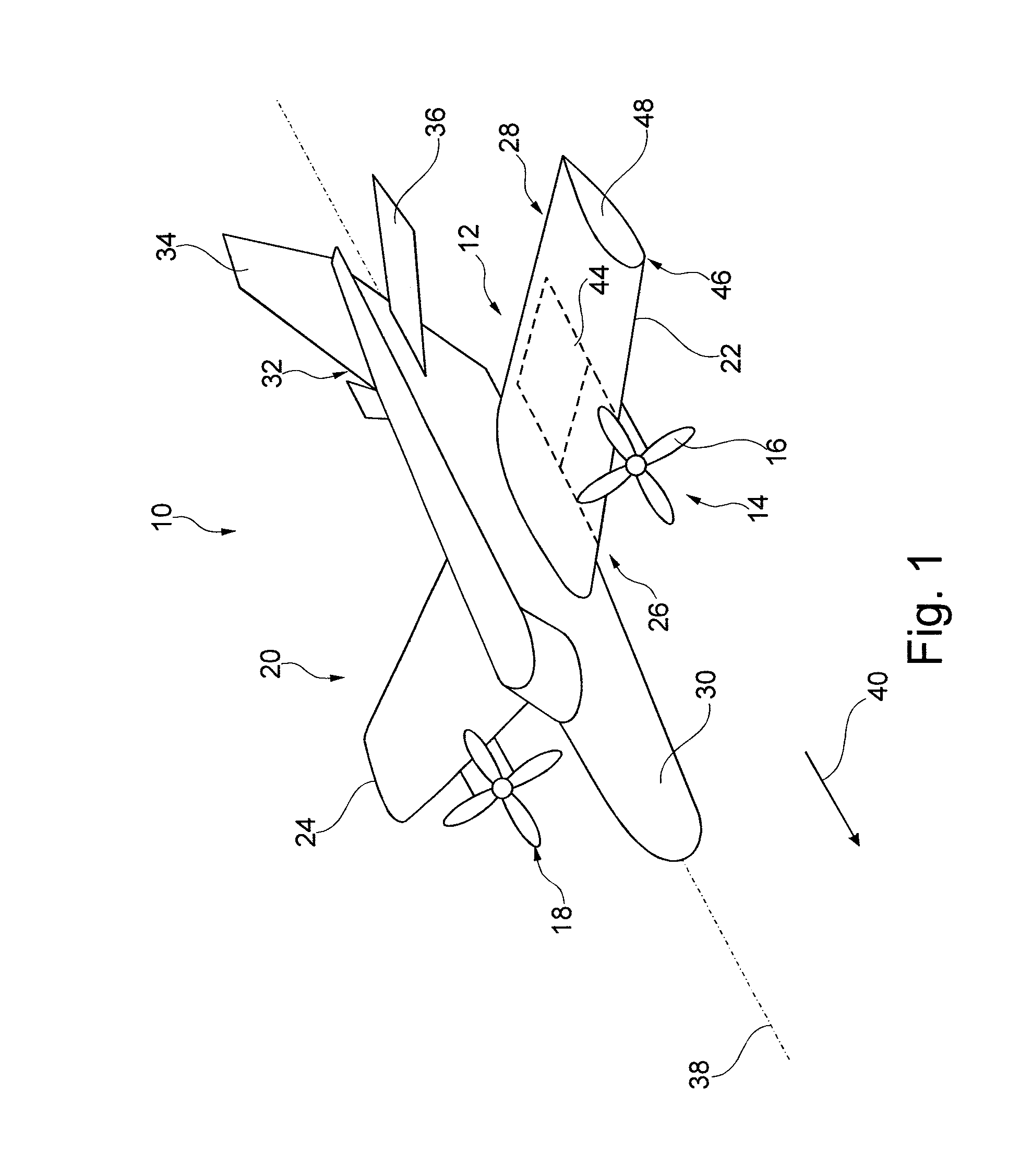

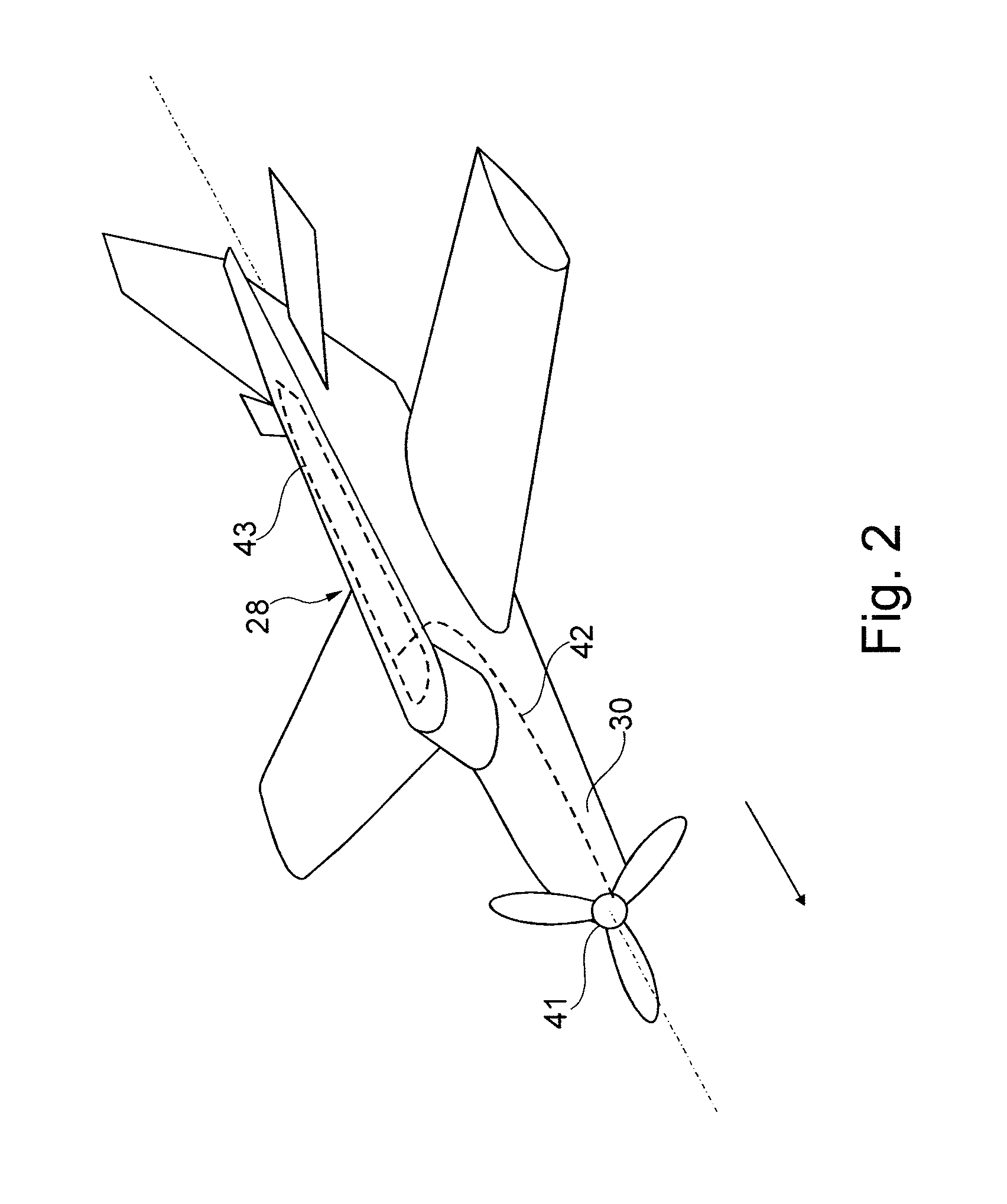

Stirling engine with flapping wing for an emission-free aircraft

InactiveUS9080450B2Reduce temperature differenceLarge heat transfer surfaceBlade accessoriesEfficient propulsion technologiesThermal energyFlight direction

Owner:AIRBUS DEFENCE & SPACE

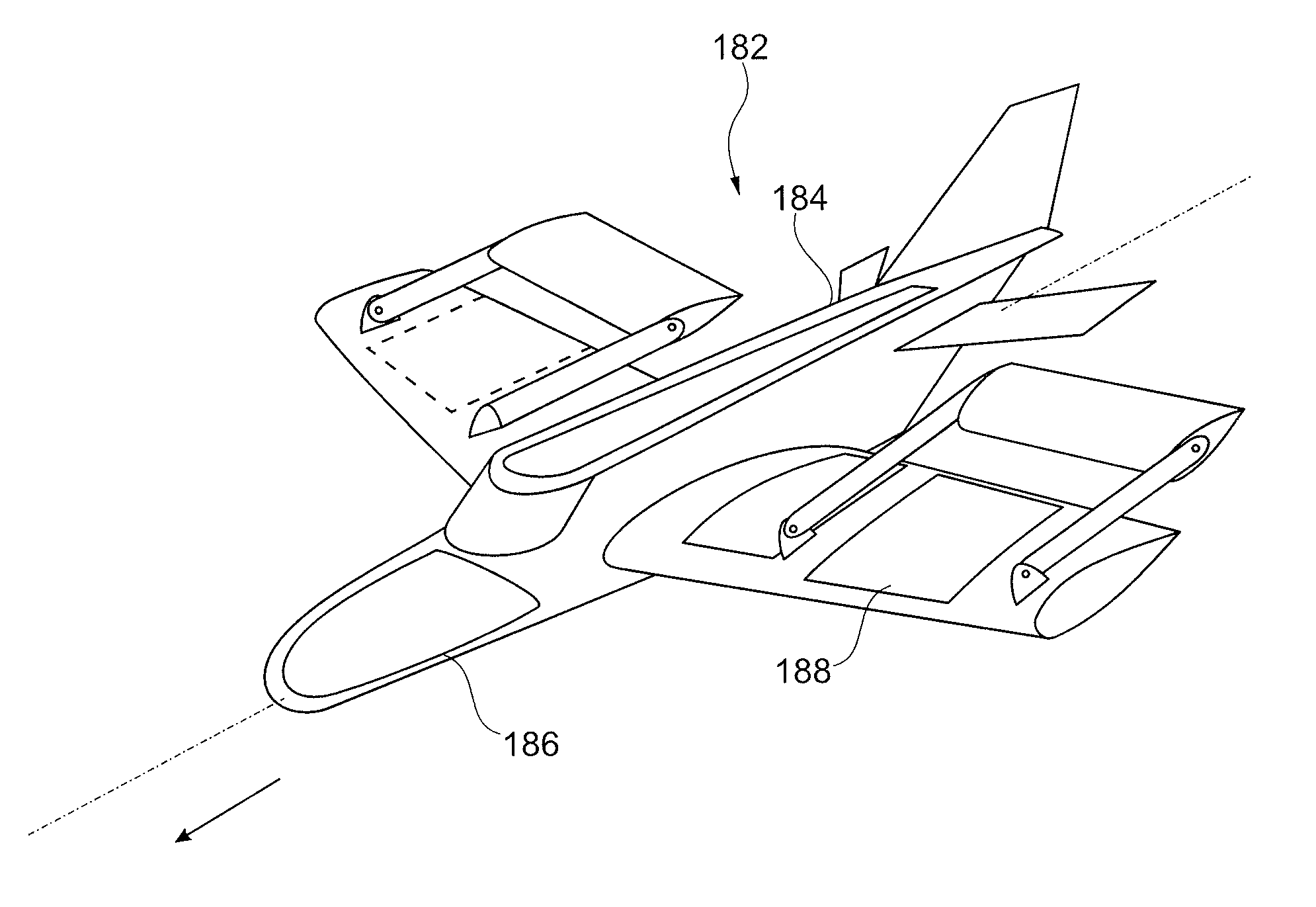

Stirling engine for an emission-free aircraft

ActiveUS20130160451A1Reduce temperature differenceLarge heat transfer surfaceGas turbine plantsWingsThermal energyThermal radiation

Aircraft with an emission-free drive and method for emission-free driving of an aircraft. The aircraft includes a drive device structured and arranged to generate thrust, a lift device structured and arranged to generate lift, and a heat engine structured and arranged to convert thermal energy into kinetic energy to drive the drive device. The heat engine includes at least one flat-plate Stirling engine drivable by solar thermal radiation.

Owner:AIRBUS DEFENCE & SPACE

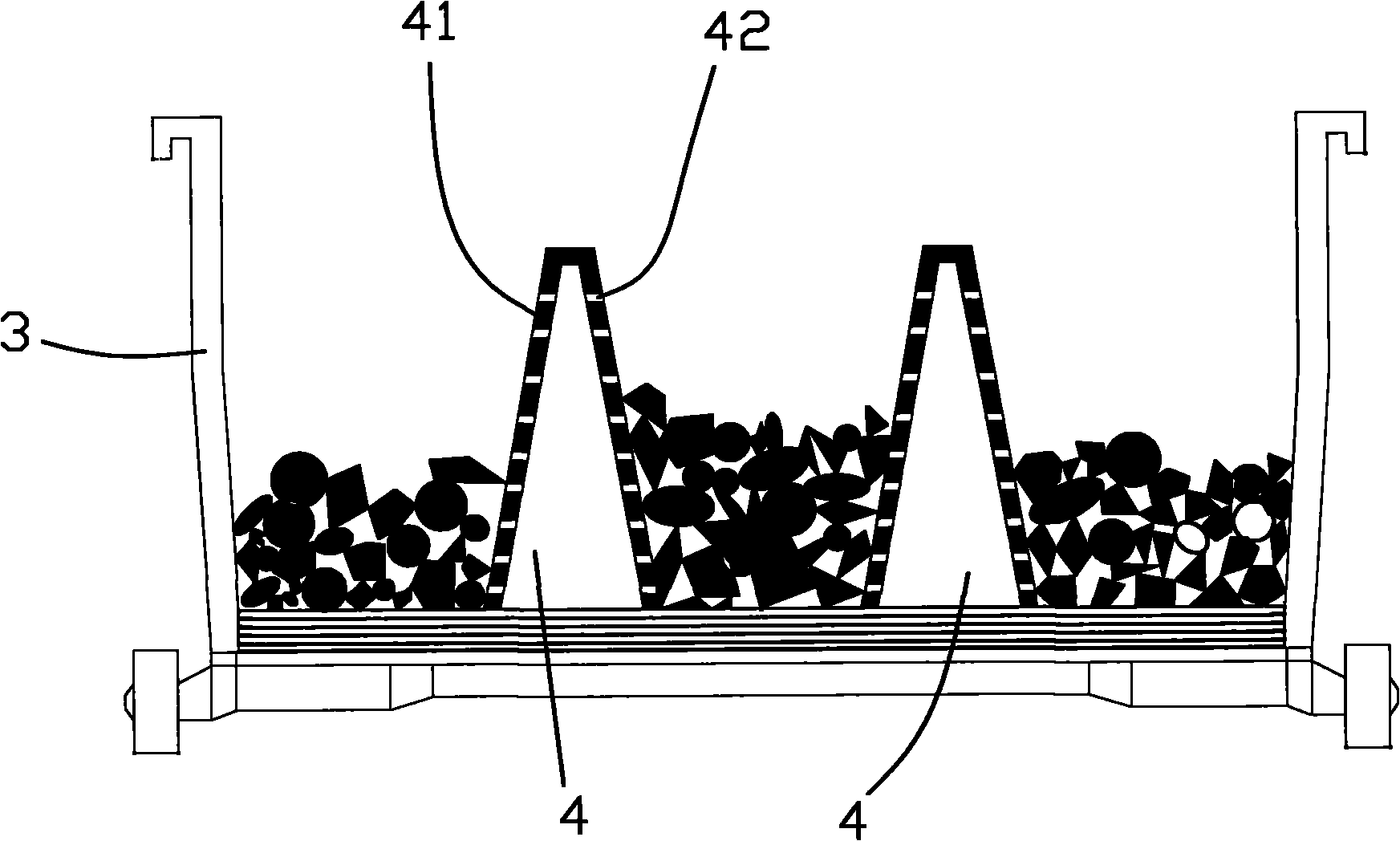

Enhanced heat exchange device for sinter of circular cooler

InactiveCN102032797AGuaranteed temperatureIncrease mass flowHandling discharged materialCold airEngineering

The invention discloses an enhanced heat exchange device for sinter of a circular cooler, comprising a trolley and the circular cooler arranged at the bottom of the trolley, wherein the trolley is internally provided with a plurality of enhanced wind boxes of which the side walls are provided with a plurality of guiding channels, the outlets of the guiding channels correspond to different parts in the trolley from bottom to top, and cold air is blown into the trolley by the guiding channels after blasted into the enhanced wind boxes by the circular cooler. By the arrangement of the enhanced wind box inside the trolley of the circular cooler, the heat exchange area is increased, in addition, due to the adoption of a variable-frequency air blower, the volume of blast can be adjusted through a control device according to a temperature sensor at the tail end of a circular cooling cover, the mass flow of smoke can be improved as much as possible on the basis of ensuring the temperature inside the circular cooling cover, and the recovery rate of hot energy of sinter is improved.

Owner:BEIJING CENTURY BENEFITS

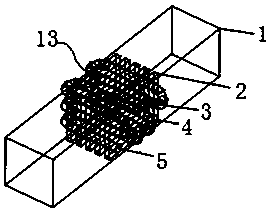

Double-slot type strengthened pipe type heat exchanger

ActiveCN105890405AReduce thicknessIncrease fluid velocityHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerCoil spring

The invention provides a double-slot type strengthened pipe type heat exchanger. By the adoption of the double-slot type strengthened pipe type heat exchanger, heat transfer can be enhanced greatly, and energy consumption is saved, so that heat transfer efficiency is improved effectively, and the heat exchange effect is good. The double-slot type strengthened pipe type heat exchanger comprises a shell. Pipe plates are mounted at the two ends of the shell. Baffle plates alternately arranged are arranged on the position, between the pipe plates, of the inner wall of the shell. The baffle plates are perpendicular to the shell in the length direction. Heat exchange pipes penetrate the baffle plates and are fixed to the pipe plates at the two ends in a turning square arrangement manner. An inlet communicating with the shell and a feeding opening communicating with the heat exchange pipes are formed in the upper wall of the outer portion of the shell. An outlet communicating with the shell and a discharging opening communicating with the heat exchange pipes are formed in the lower wall of the outer portion of the shell. Cross grain slots and spiral slots are formed in the peripheral face of the outer wall of each heat exchange pipe in a rolling manner and alternately distributed in the outer wall of each heat exchange pipe. Fins are manufactured on the outer wall of each heat exchange pipe. A spiral spring and a wave strip are inserted into each heat exchange pipe and arranged in each heat exchange pipe in a crossed manner.

Owner:WUXI PROFESSIONAL COLLEGE OF SCI & TECH

Battery assembly

ActiveCN104272498AGood and reliable electrical insulationImprove thermal conductivityCells cooling/heatingSecondary cellsEngineeringMechanical engineering

The invention relates to a battery assembly (100) consisting of several battery cells (10) which are electrically connected to each other and which respectively comprise a preferably prismatic cell housing (16). Each cell housing (16) comprises at least one fastening projection (18) on the base of the cell (17), said fastening projection protruding through an opening (19) of a cooling element (12) embodied as a cooling plate (13) or as a cooling housing (35) for the cell housings (16). Said fastening projection (18) interacts with a tensioning element (22) which maintains the cell housing (16) against the cooling element (12).

Owner:ROBERT BOSCH GMBH

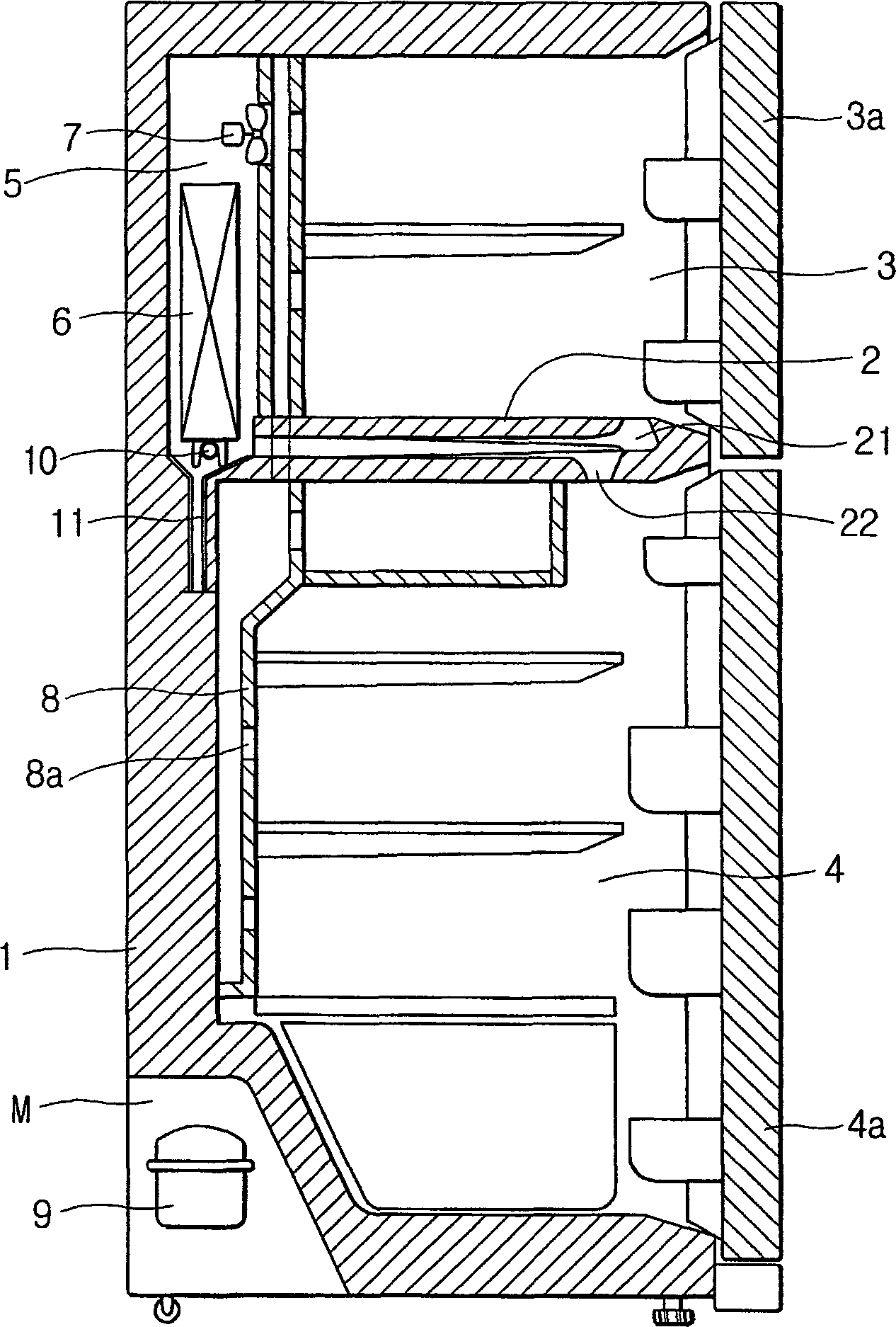

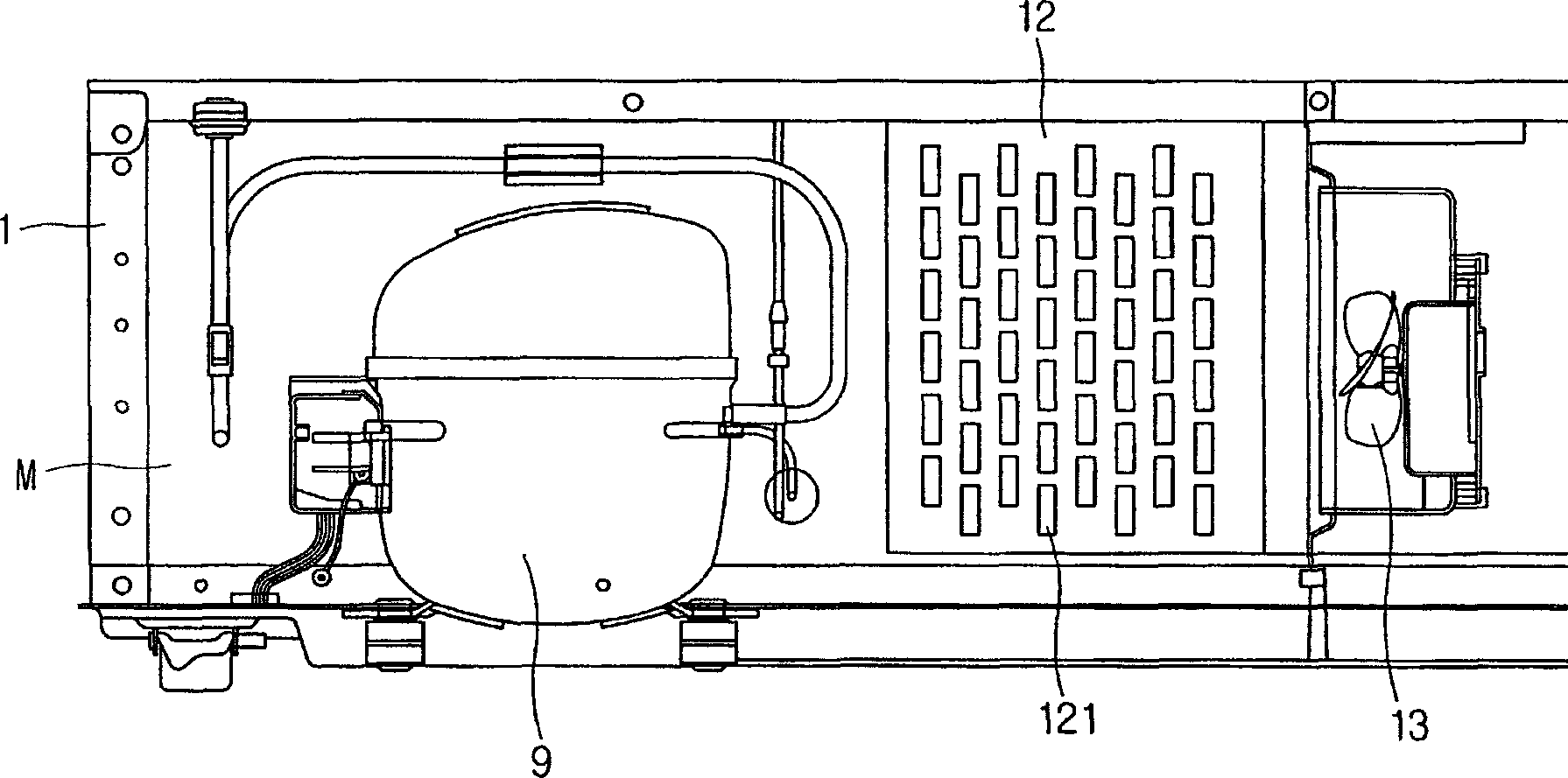

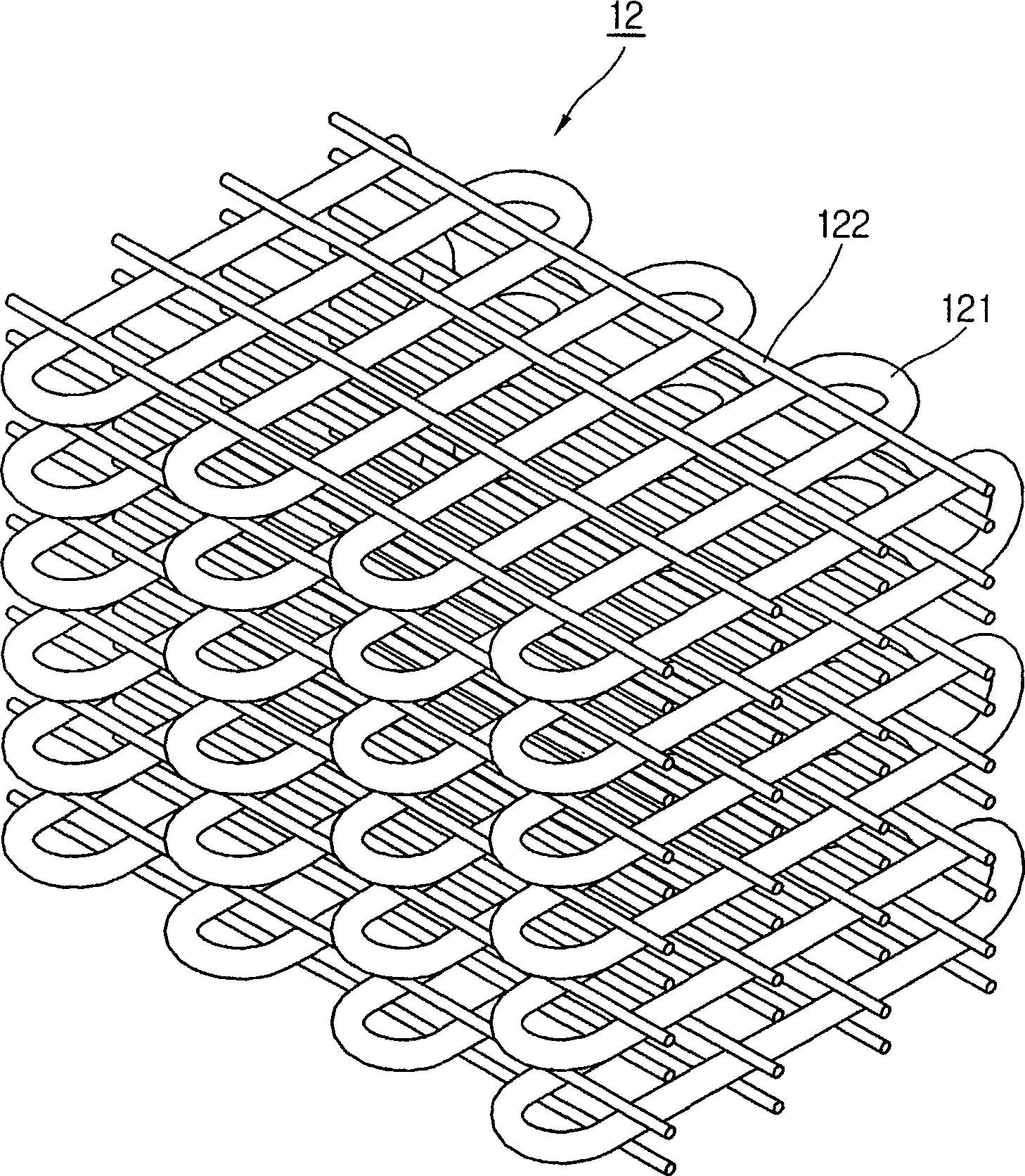

Condenser of refrigerator

InactiveCN1846101AReduce the differenceReduce the difference in flow rateEvaporators/condensersStationary conduit assembliesRefrigerantRefrigerated temperature

A condenser for a refrigerator includes an inline arrangement in which a refrigerant tube is arranged such that refrigerant tube parts are arranged in lines in the forward and backward direction, and a staggered arrangement in which the refrigerant tube parts are arranged at the rear side of the inline arrangement in the forward and backward direction to misaligned with each other, such that the difference of air flow between a front side and a rear side thereof is minimized when heat exchange with ambient air in the condenser is performed by blowing operation of a cooling fan installed to a side of the condenser.

Owner:LG ELECTRONICS INC

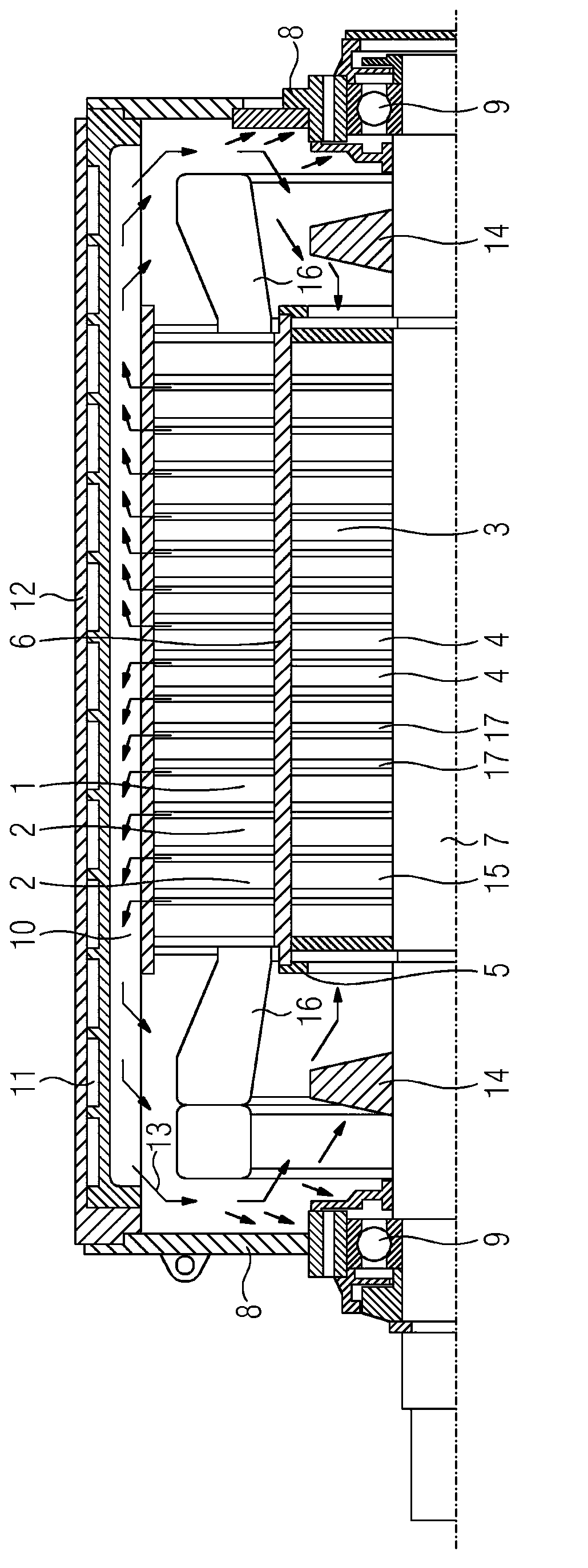

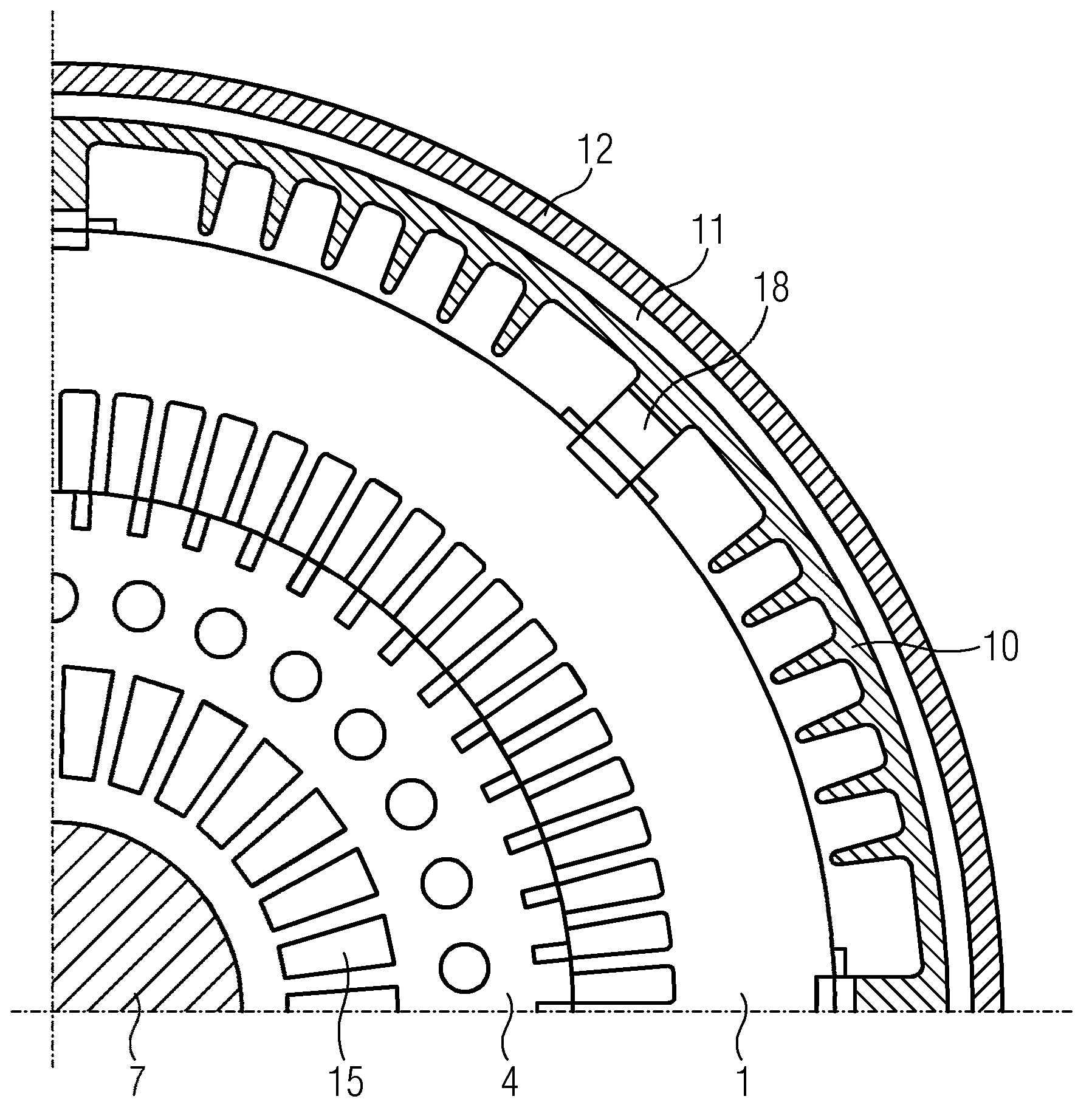

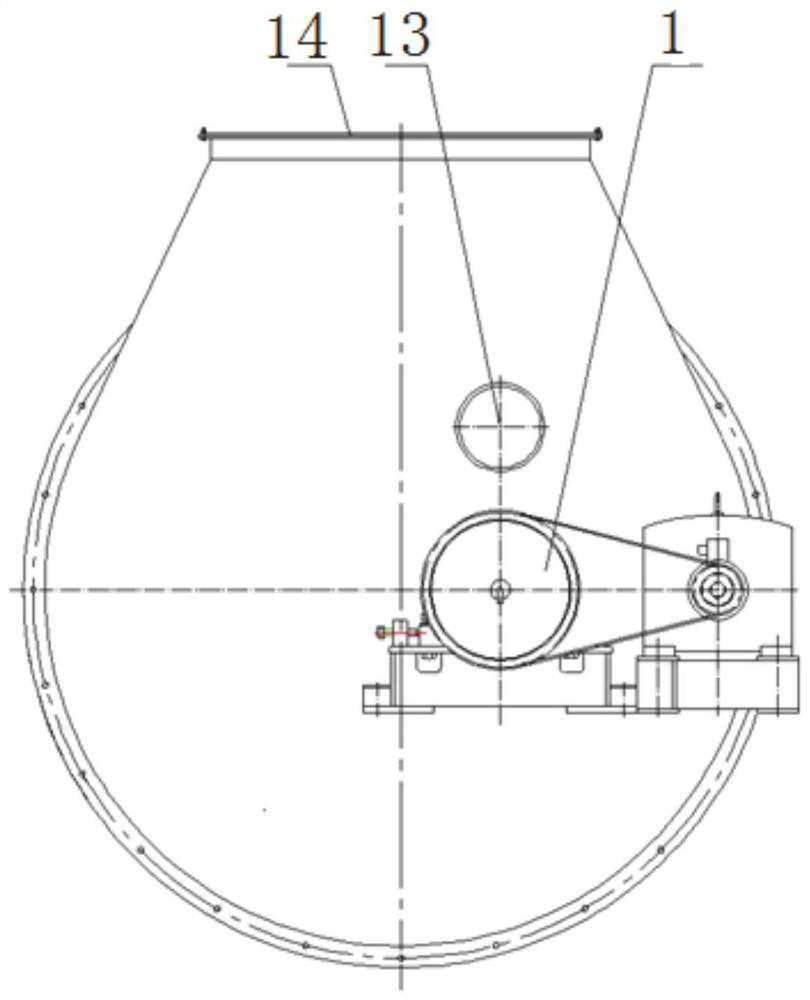

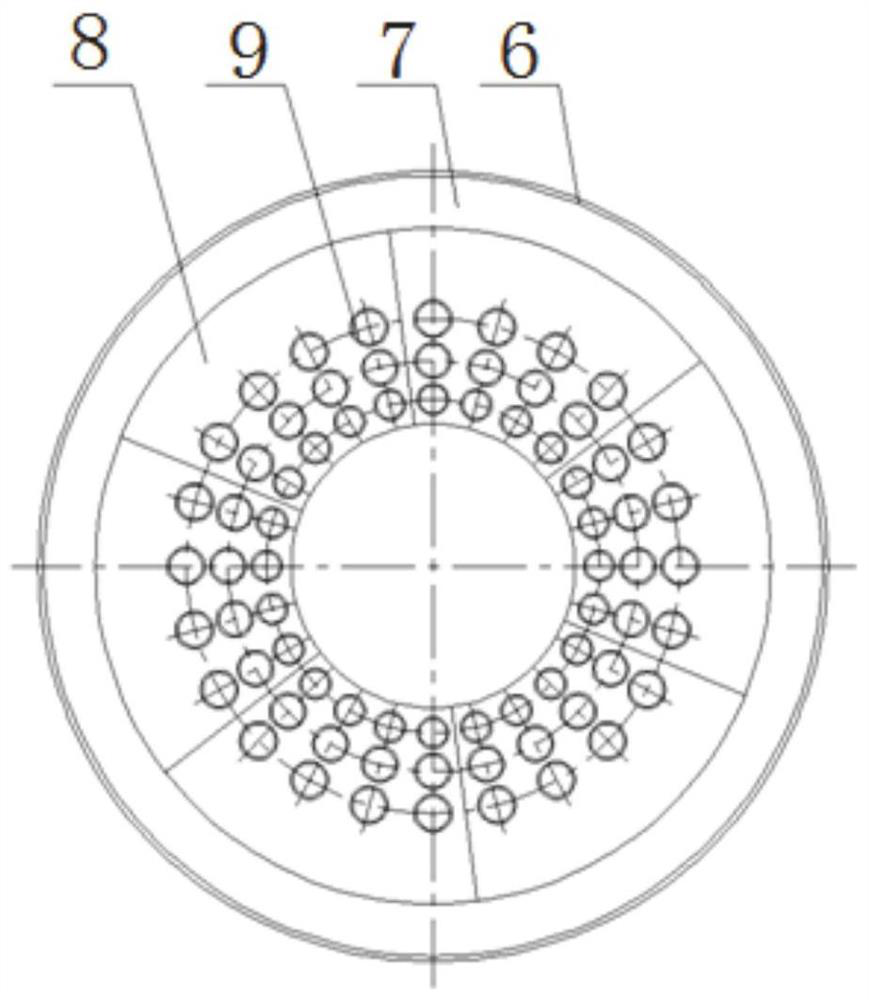

Dynamoelectric machine having air/liquid cooling

InactiveCN102939700AImprove cooling effectLarge heat transfer surfaceWind energy generationMechanical energy handlingWind systemDirect liquid cooling

The invention relates to dynamoelectric machine, in particular a wind generator, comprising a stator (1), which is designed as a laminated core and has a winding system, which forms winding heads (16) on the end faces of the stator (1), and a rotor (3), which is designed as a laminated core and which is connected to a shaft (7) in a rotationally fixed manner, wherein the stator (1) and the rotor (3) are arranged in a housing, wherein the shaft (7) is supported by means of bearings (9), which are arranged in bearing shields (8), wherein the laminated core of the stator (1) and / or rotor (3) has axially extending cooling channels (15), wherein the bearing shields (8) form a closed interior together with the housing, said interior having at least one closed inner cooling circuit, wherein the housing has an outer jacket (12) and an inner jacket (19) facing the stator (1); and arranged at a distance from the outer jacket in some sections, wherein the outer jacket (12) and the inner jacket (19) combined form a cooling jacket (11), in particular a liquid cooling jacket, the axial extension of which equals at least the axial extension of the laminated core of the stator (1).

Owner:SIEMENS AG

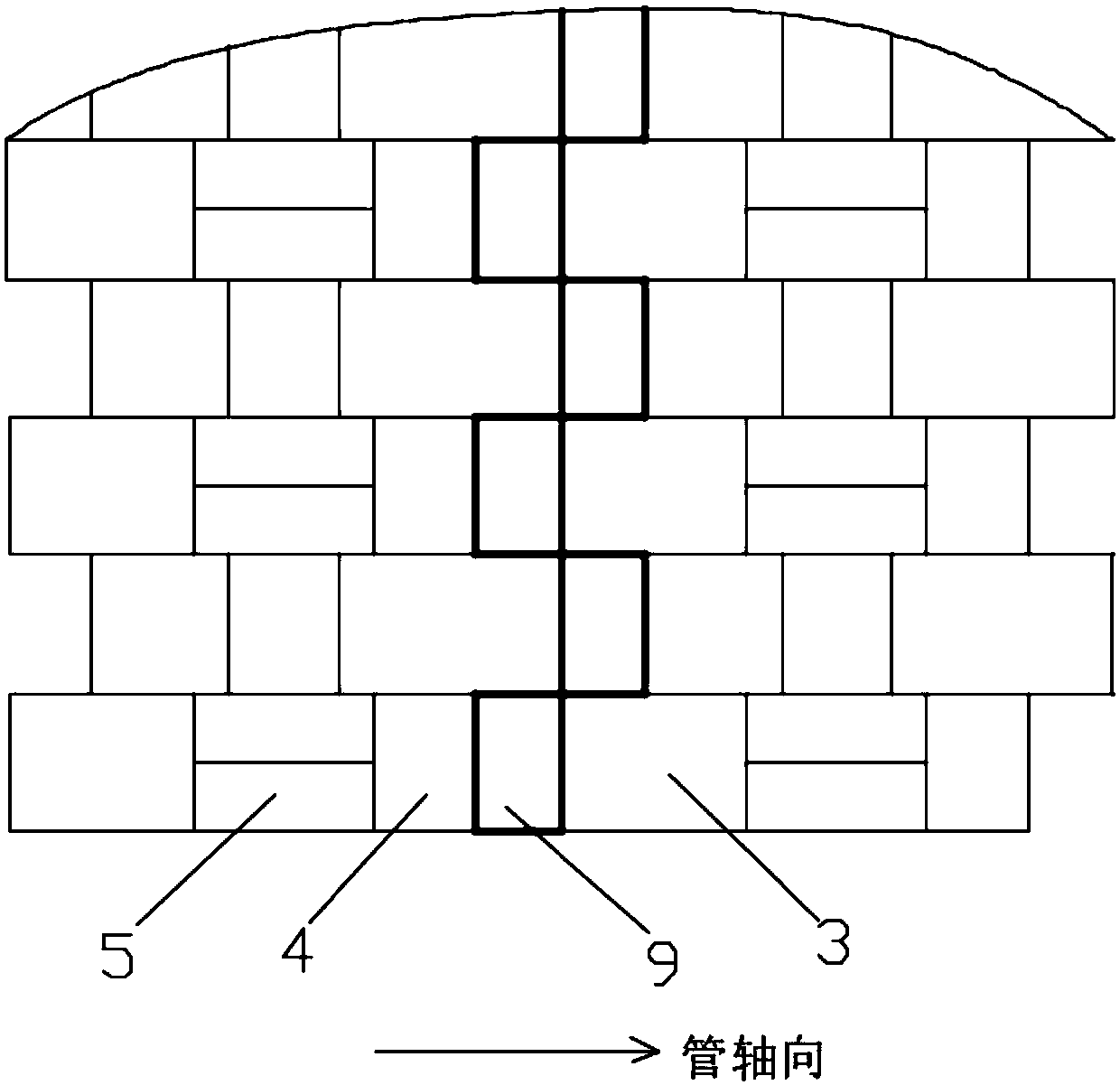

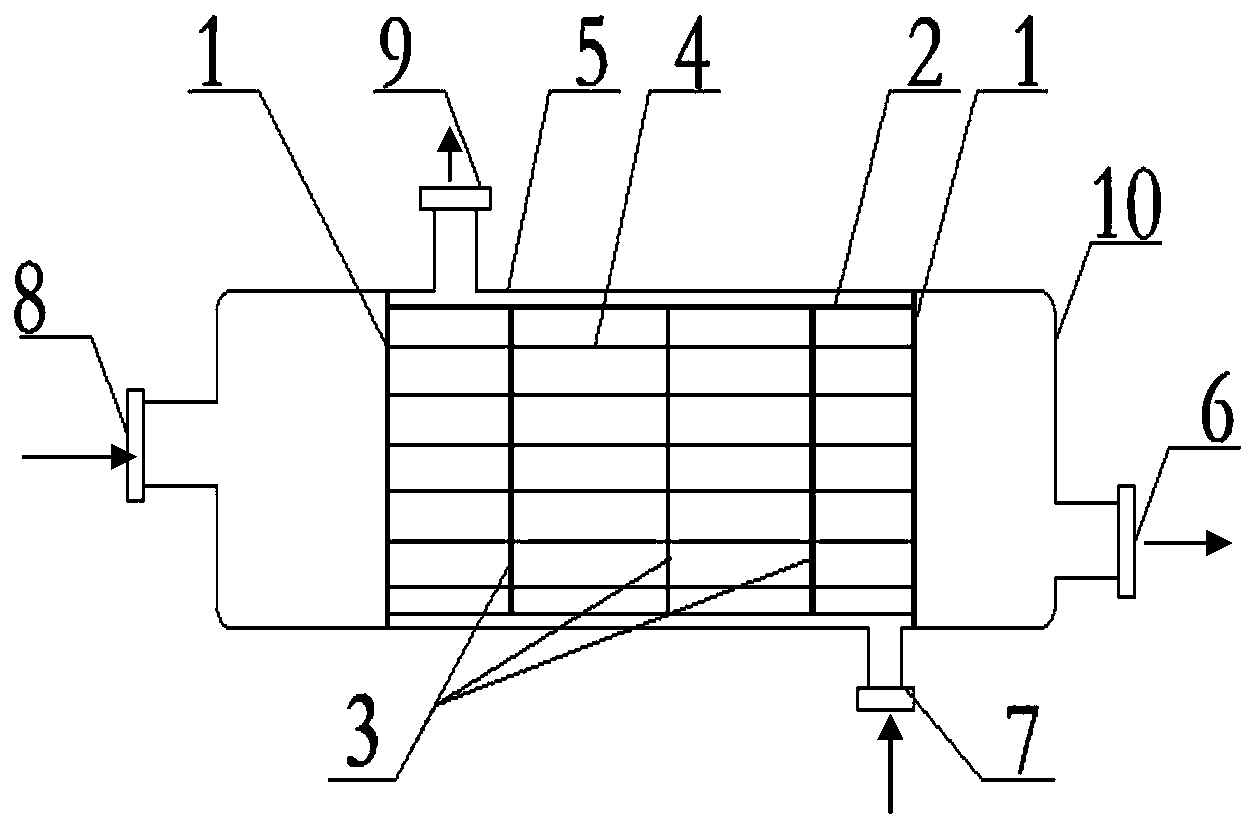

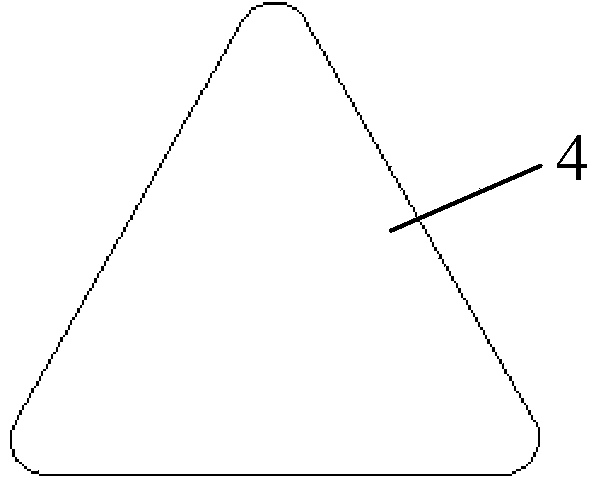

Heat exchanger and heat exchange enhancement method

ActiveCN104034188AEnhanced convective heat transferEasy to cleanHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerGrating

The invention relates to the technical field of heat exchange, and discloses a heat exchanger and a heat exchange enhancement method. The heat exchanger comprises a shell side cylinder, tube plates, a tube bundle and baffling grating plates, wherein the tube plates, the tube bundle and the baffling grating plates are installed in the shell side cylinder. The tube bundle penetrates through the baffling grating plates and is fixedly connected with the tube plates at the two ends of the tube bundle, the sections of tubes of the tube bundle are of a polygonal structure, the edges of the tubes of the polygonal structure are chamfered, the baffling grating plates and the tube plates are respectively provided with installation holes and fixing holes, the installation holes and the fixing holes are matched with the tubes in shape, the baffling grating plates are arranged in parallel in the tube side direction, and arch-shaped gratings of the adjacent baffling grating plates are distributed in a staggered mode. When fluid in a shell side flows through the gratings of the baffling grating plates, Karman vortexes are formed, and resistance of the fluid is little during spin flowing, so that flowing speed of a boundary layer is increased, convective heat transfer of the fluid is effectively enhanced, cleaning dead corners do not exist on inner walls of the tubes, and the tubes are easy to clean. Gaps among the tubes of the tube bundle are similar to rectangles, the Venturi effect is achieved, and the heat exchange effect is greatly improved.

Owner:卡硼瑞(北京)科技有限公司

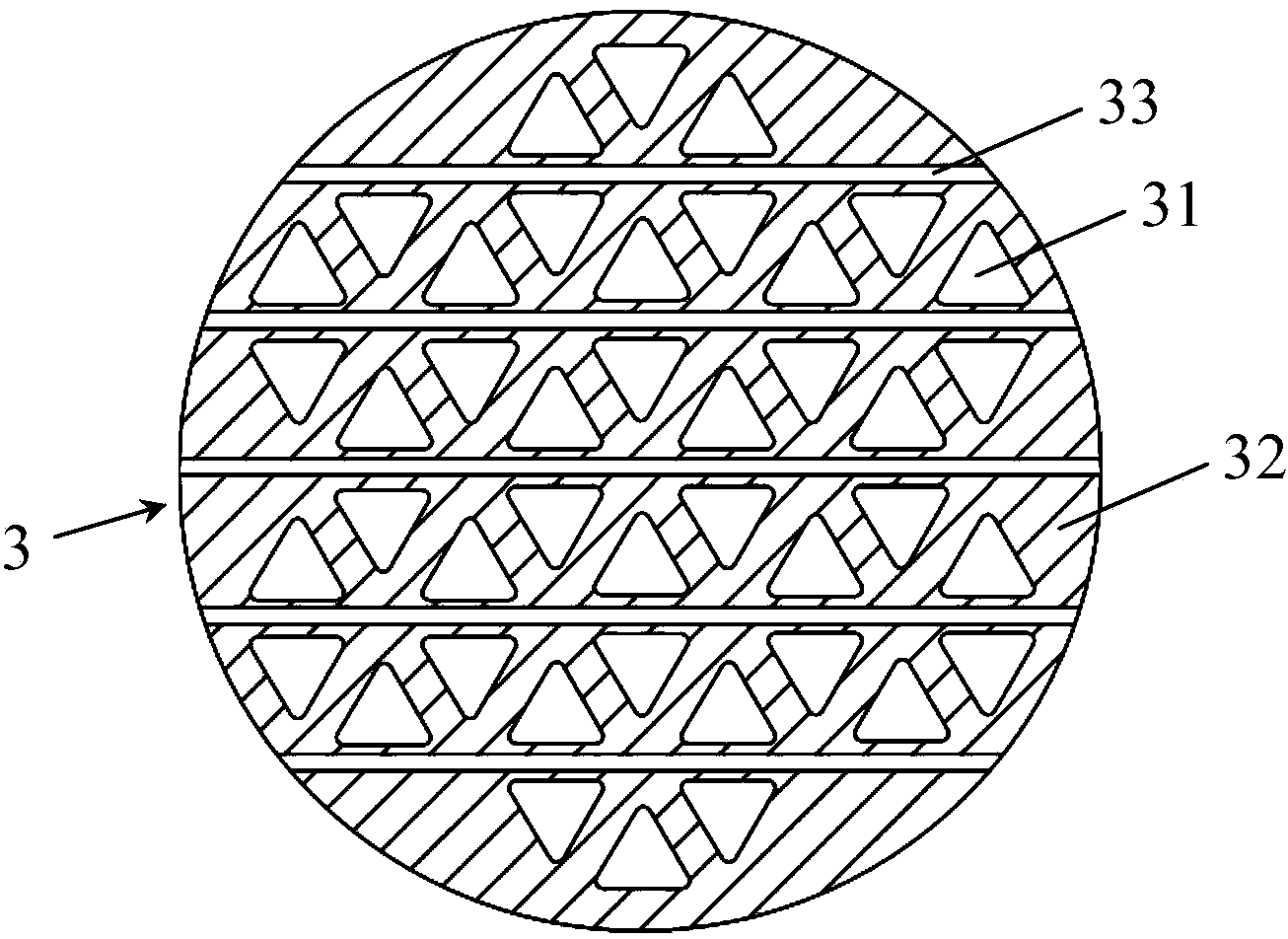

Improved heat transmission and accumulation solar heat collection device

ActiveCN104567028ARealize integrationSimple arrangementSolar heating energySolar heat devicesInsulation layerHeat transmission

The invention discloses an improved heat transmission and accumulation solar heat collection device. The device comprises a cool fluid inlet pipe, an annular splitter cavity, a reinforcement heat exchanger tube, a heat collection cavity, a heat accumulator, a hot fluid outlet pipe, a confluence cavity, an insulating layer and a lens; the heat collection device body is sequentially provided with the heat collection cavity, the heat accumulator and the reinforcement heat exchanger tube from inner to outer; the lower end of the reinforcement heat exchanger tube is connected with the annular splitter cavity which is connected with the cool fluid inlet pipe, the upper end of the reinforcement heat exchanger tube is connected with the confluence cavity which is connected with the hot fluid outlet pipe, and the heat collection cavity opening is provided with the lens; an insulation layer is respectively paved outside the cool fluid inlet pipe, the annular splitter cavity, the reinforcement heat exchanger tube, the heat accumulator and the confluence cavity. The device is characterized in that reinforcement fins are increased and the heat accumulator structure is optimized, when the solar thermal collector is integrated with heat absorption, heat accumulation and heat exchange, the pipeline is simplified in design, the heat transmission capacity is reinforced, the radial temperature difference of the heat accumulator is reduced and the reliability of the system is improved.

Owner:ZHEJIANG UNIV

Beverage holder and beverage container

ActiveCN107531173ARapid coolingHeating fastVehicle arrangementsMachines using electric/magnetic effectsTemperature controlTelecommunications

Owner:DR SCHNEIDER KUNSTWERKE

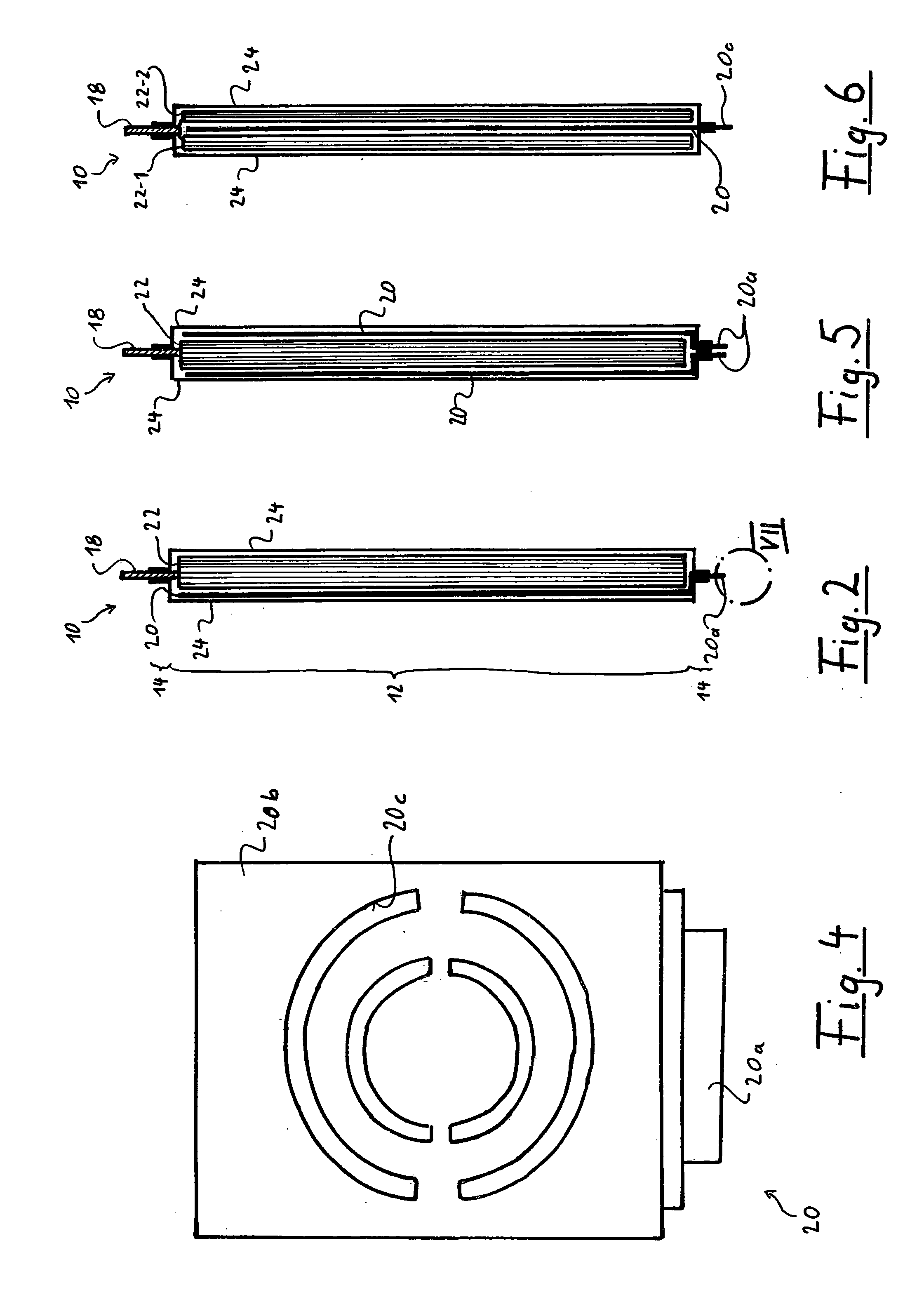

Heat transfer surface and microporous flow passages or small-hole flow passages integrated planar perforated-plate heat exchanger

InactiveCN104677150AZero noiseReduce thermal resistanceStationary plate conduit assembliesCapillary networkEngineering

The invention relates to a heat transfer surface and microporous flow passages or small-hole flow passages integrated planar perforated-plate heat exchanger which comprises a flow distribution pipe, a flow collection pipe and a heat exchange perforated plate. The heat exchange perforated plate is connected between the flow distribution pipe and the flow collection pipe, the heat exchange perforated plate is internally and parallelly provided with a plurality of microporous flow passages or small-hole flow passages, and two ends of the microporous flow passages or the small-hole flow passages are communicated with the flow distribution pipe and the flow collection pipe respectively. Sections of the flow distribution pipe and the flow collection pipe are C shaped, and two ends of the heat exchange perforated plate are welded C-shaped openings of the flow distribution pipe and the flow collection pipe respectively to form an integral flow passage communicated structure. Compared with a traditional capillary network heat exchanger, the planar perforated-plate heat exchanger structurally has the advantages of avoidance of secondary construction for forming of the heat exchange surface, high heat exchange efficiency, low cost, convenience in mounting and the like.

Owner:王文虎

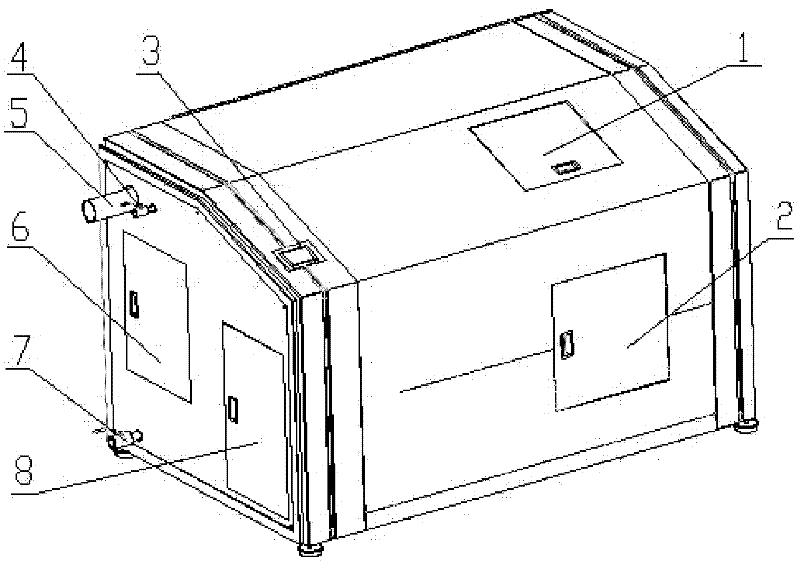

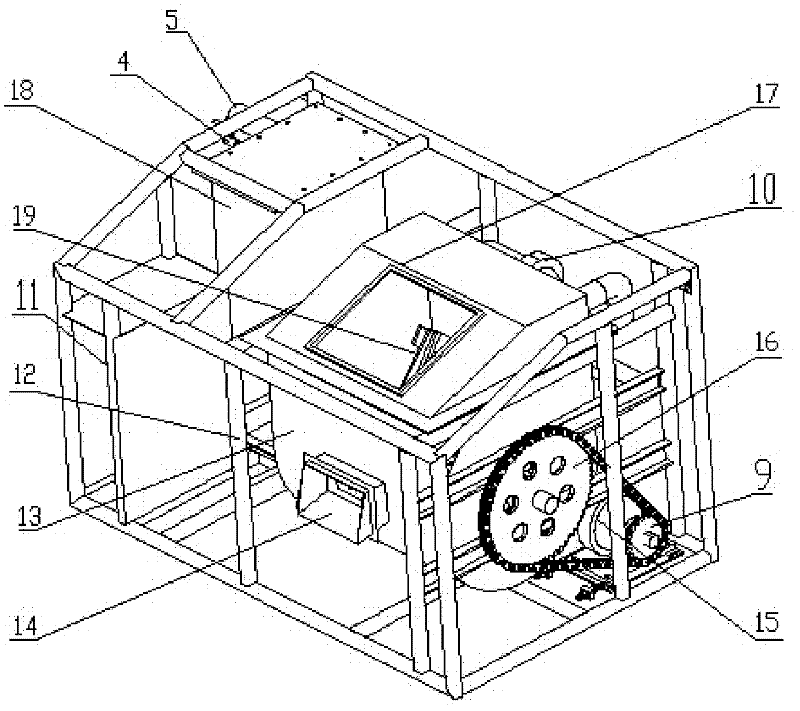

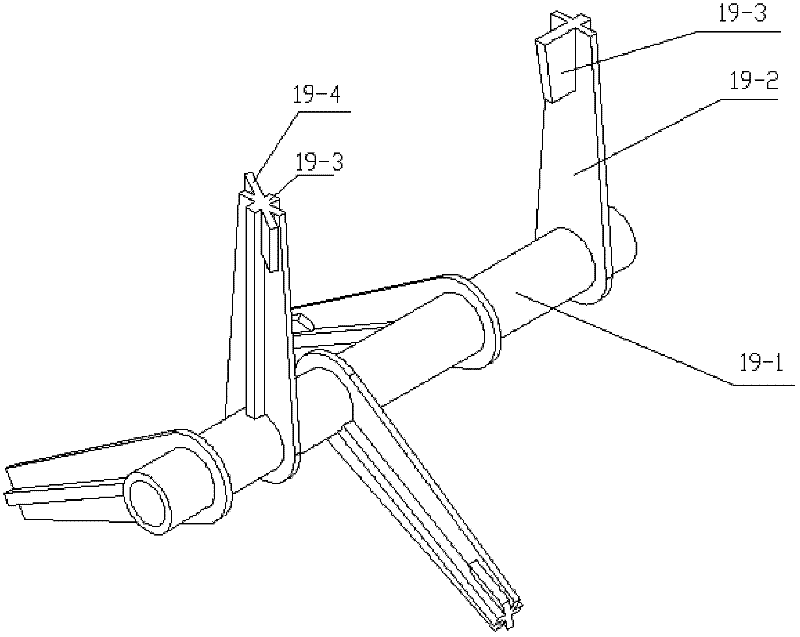

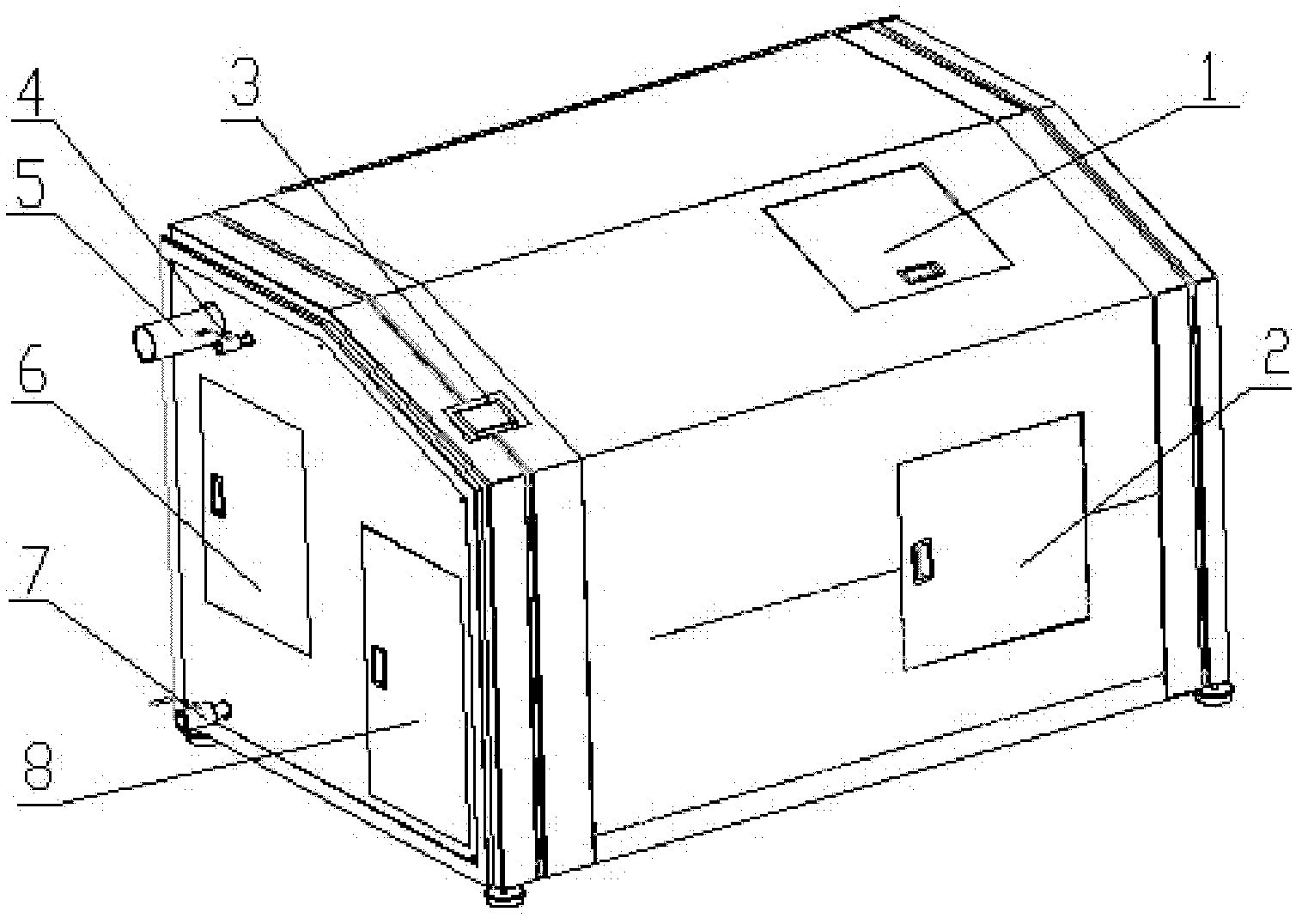

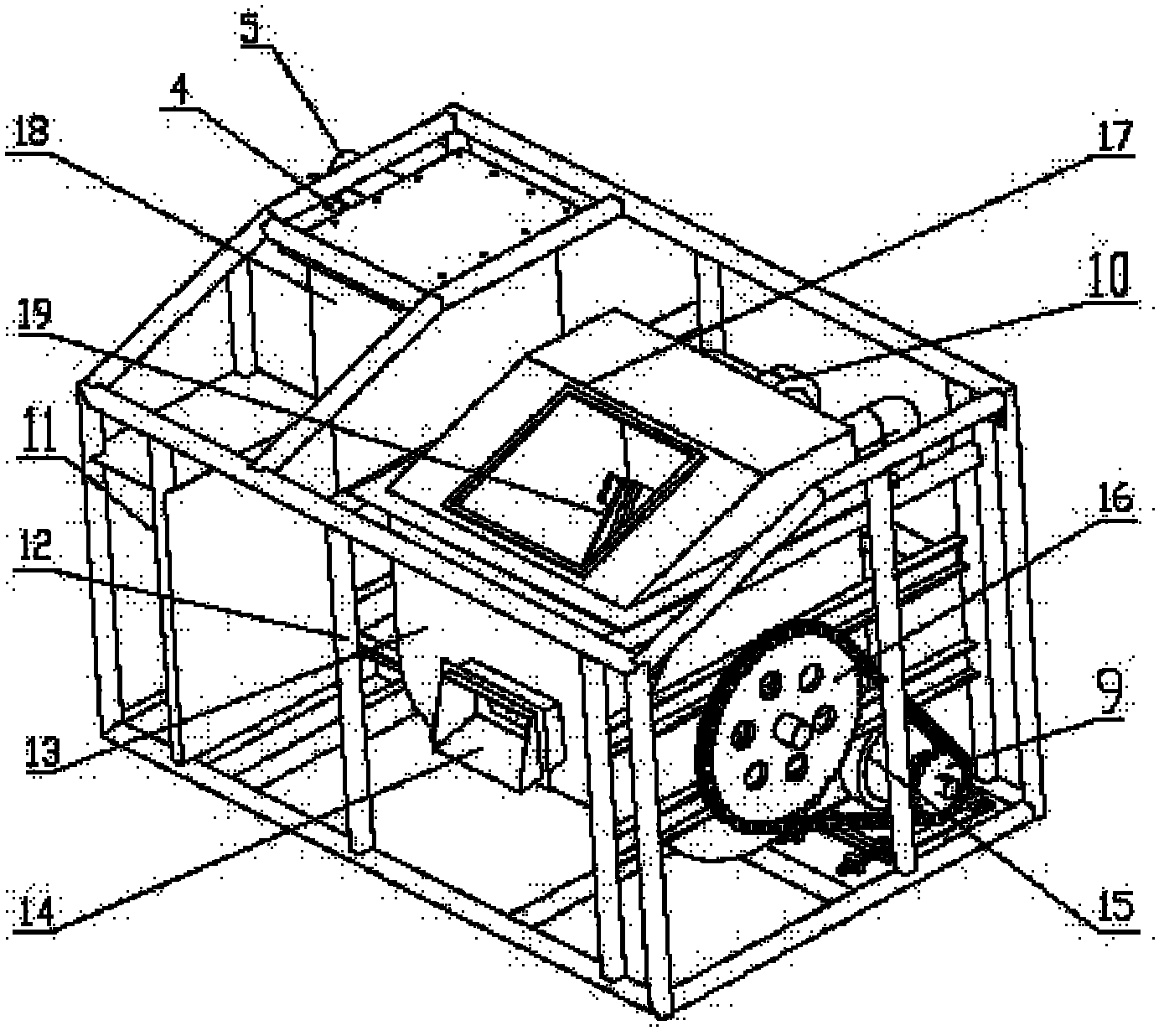

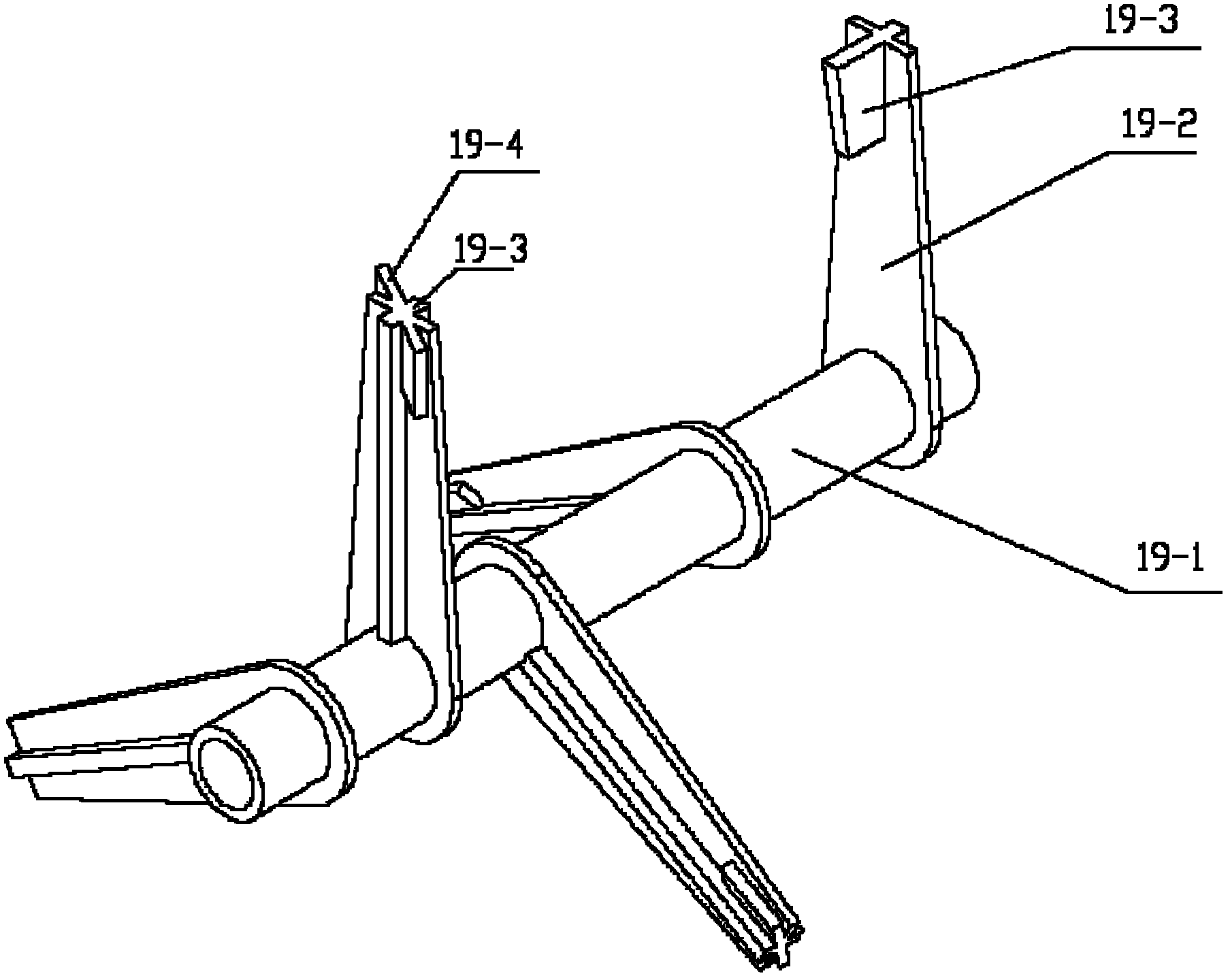

Organic waste disposal machine

ActiveCN102399093AStir wellAdequate responseClimate change adaptationOrganic fertilisersEngineeringOrganic fertilizer

The invention discloses an organic waste disposal machine, which comprises a main frame and fixed panels for outer surfaces of the main frame, wherein the upper panel is provided with a flip cover with a seal; a display screen is arranged on the left side of an upper panel; the upper part of a lateral panel is provided with a water inlet and an air outlet hole, and the lower part of the lateral panel is provided with a water outlet; the water inlet, the air outlet hole and the water outlet are connected with a deodorization tower; the lower part of the front panel is provided with a discharge port with a seal; a reaction cabin is arranged in the main frame; a stirring shaft is arranged in the reaction cabin and comprises a poke shaft; the poke shaft is provided with blades; heads of the stirring blades at the two ends of the poke shaft are provided with main boards which are perpendicular to the blades; and the main boards are distributed on the two sides of the blades, wherein one side of the main boards is short, and the other side of the main boards is in contact connection with the poke shaft. In the invention, waste and decomposing bacteria are put into the reaction cabin according to a certain proportion and are uniformly reacted in a constant-temperature continuous stirring process, so that the organic waste is converted into useful organic fertilizer, and secondary pollution is avoided.

Owner:天津百利阳光环保设备有限公司

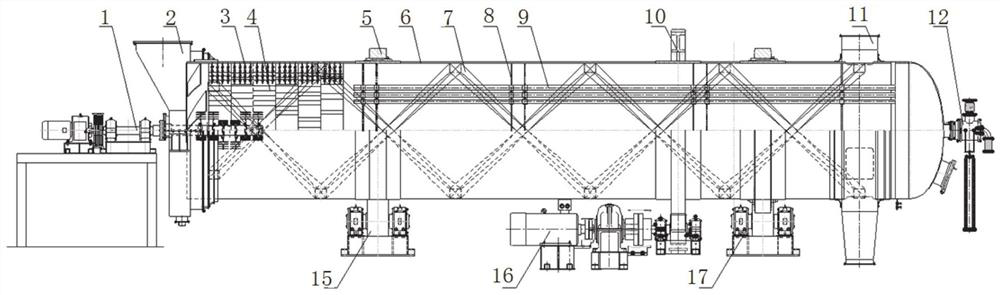

Steam rotary all-in-one machine and method for drying high-humidity and high-viscosity materials

PendingCN114183998AIncrease the heat exchange areaEnhance heat and mass transferDrying solid materials with heatGranular material dryingEngineeringChain link

The invention provides a steam and rotation all-in-one machine and method for drying high-humidity and high-viscosity materials. The steam and rotation all-in-one machine at least comprises a scattering device, a barrel and a feeding cover. The feeding cover is communicated with the feeding end of the cylinder body, the scattering device is arranged at the feeding end of the cylinder body, and a feeding port and an air inlet are formed in the feeding cover; a material guide plate and a plurality of material lifting plates are arranged on the inner wall of the cylinder body close to the feeding end of the cylinder body, a plurality of chains are arranged between the adjacent material lifting plates, and a steam heat exchange pipe is arranged at the middle section and / or the rear end in the cylinder body; a material returning spiral pipe is arranged on the inner wall of the cylinder body, the material returning spiral pipe is opposite to the position of a material falling opening of the cylinder body, and an outlet of the material returning spiral pipe is formed behind a material guide plate at the feeding end; according to the invention, the material inlet is arranged above the end part scattering device, and high-humidity and high-viscosity materials entering the drying machine fall on the end part scattering device which runs at a high speed, are cut, scattered and thrown out at a high speed, so that the heat exchange area between the materials and air is increased, and the mass and heat transfer is enhanced.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

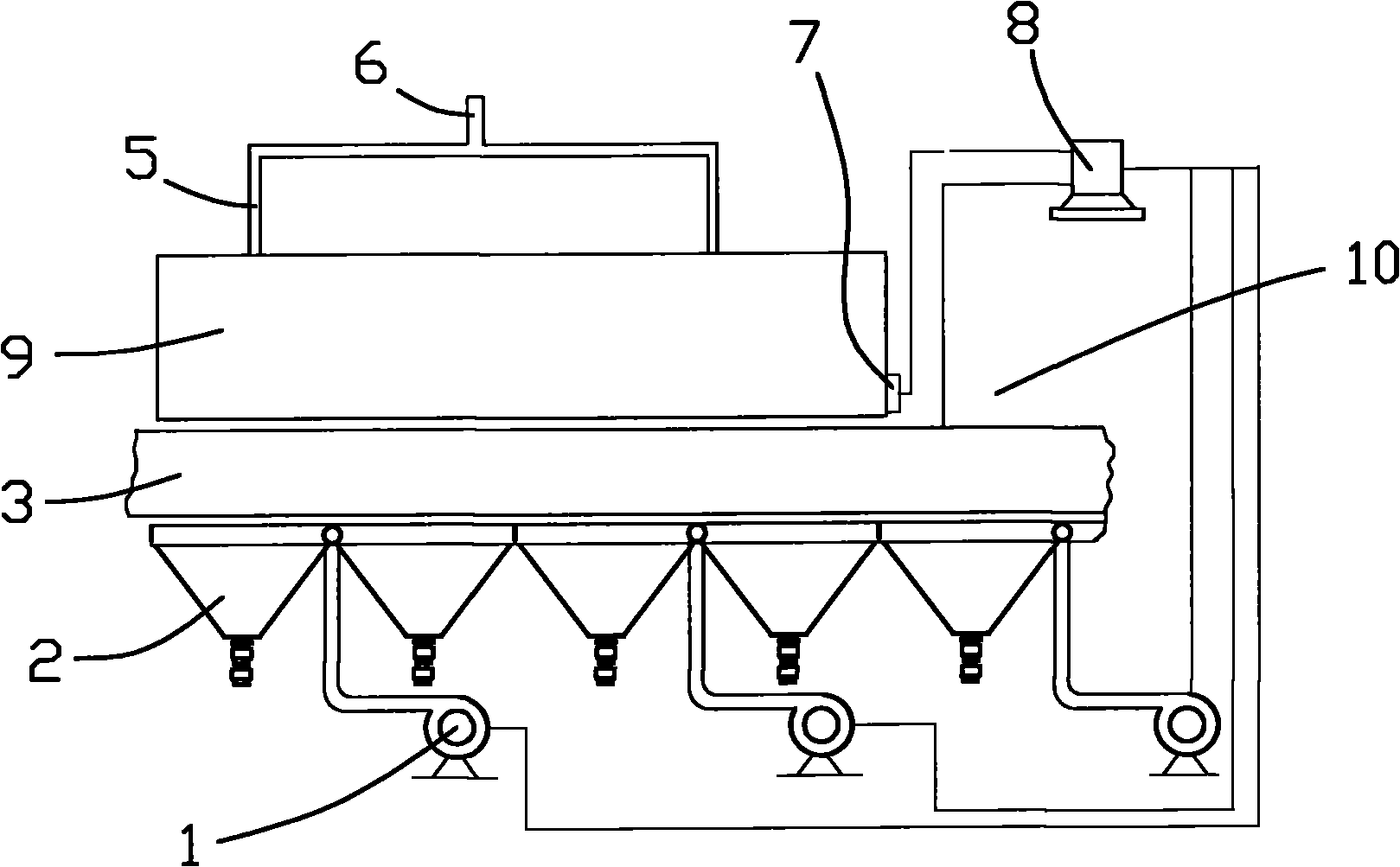

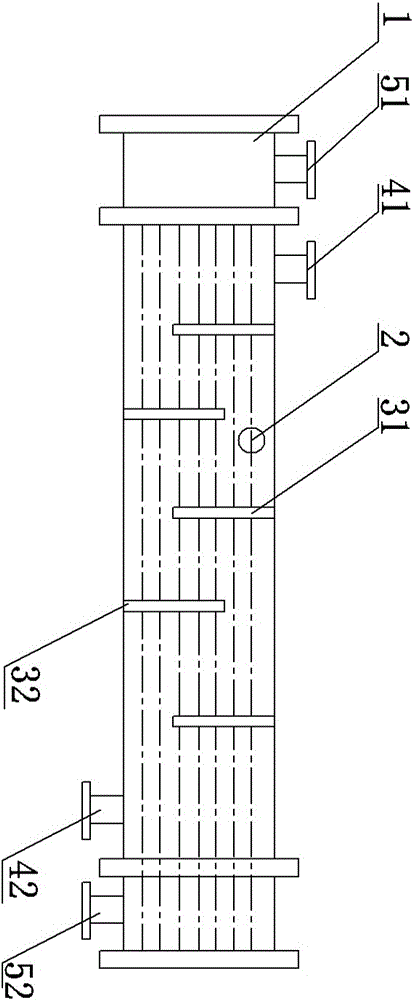

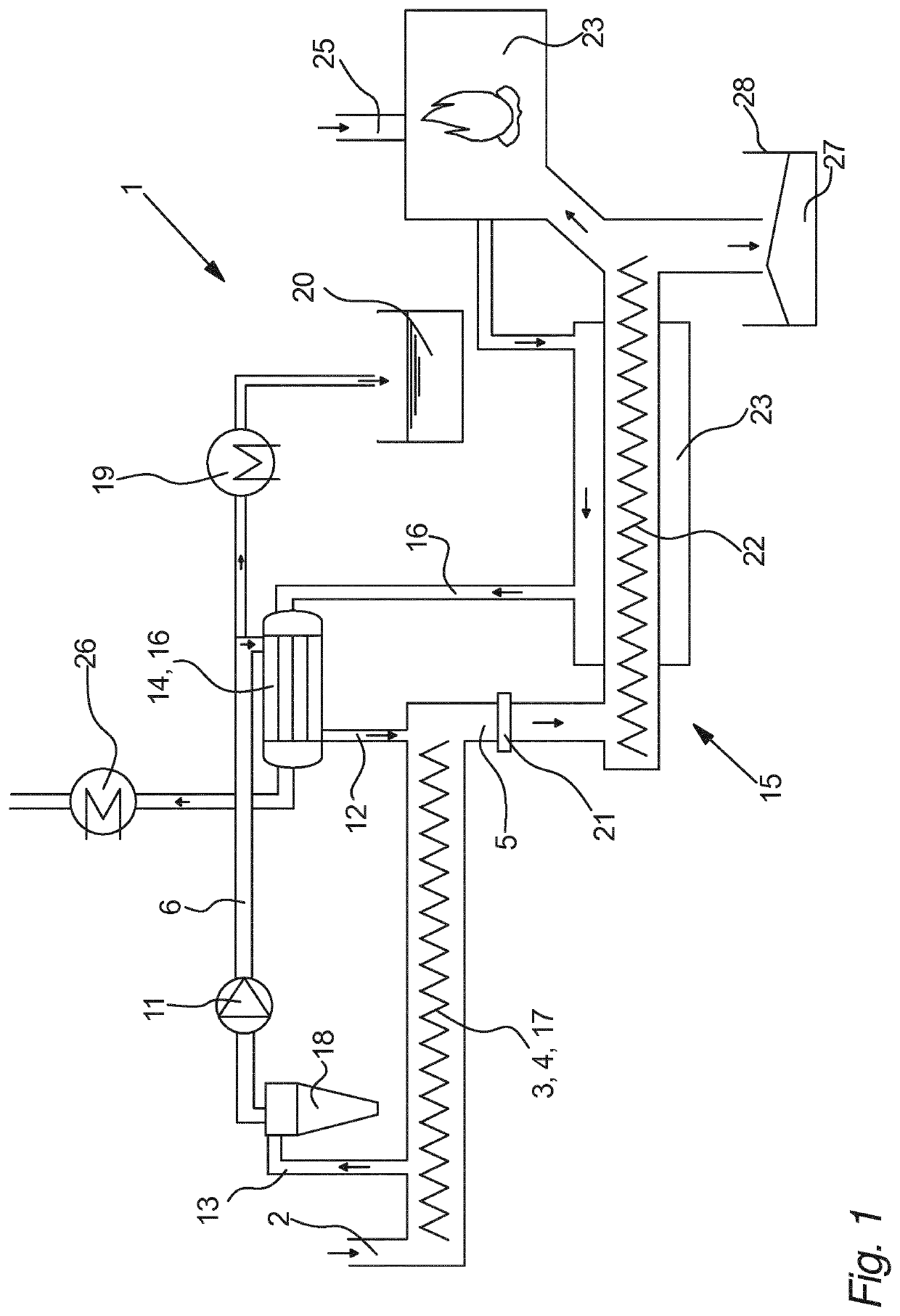

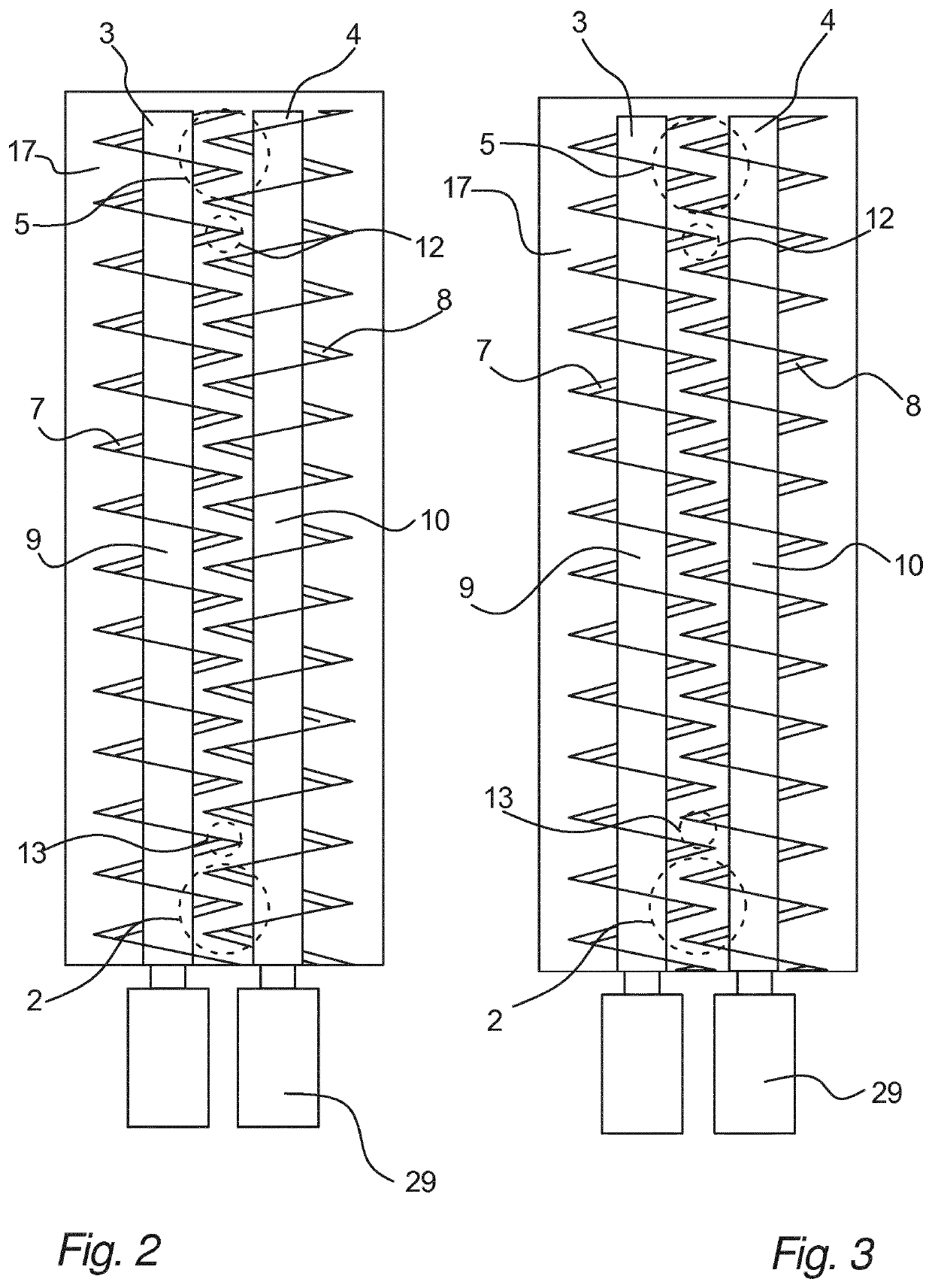

A slurry drying plant, a method for drying slurry and use of a slurry drying plant

ActiveUS20190376742A1Easy to handleEasy to storeDrying solid materials with heatDrying gas arrangementsSlurryEngineering

Disclosed is a slurry drying plant (1) comprising a slurry inlet (2) for feeding slurry to the slurry drying plant (1) and two or more meshing screw conveyors (3, 4) arranged to at least partly divide the slurry while conveying the slurry in a transport direction from the slurry inlet (2) to a slurry outlet (5). The slurry drying plant (1) further includes slurry heating means (6) comprising means for passing superheated steam substantially at atmospheric pressure past the slurry and the two or more meshing screw conveyors (3, 4), while they are conveying the slurry. Furthermore, a method for drying slurry and use of a slurry drying plant (1) is disclosed.

Owner:AQUAGREEN LICENSE APS +1

Organic waste disposal machine

ActiveCN102399093BStir wellAdequate responseClimate change adaptationOrganic fertilisersOrganic manureOrganic fertilizer

Owner:天津百利阳光环保设备有限公司

Pipe-plate type heat exchanger adopting foamy copper material

InactiveCN108692592ASimple structureCompact structureStationary tubular conduit assembliesHeat exchange apparatusFlue gasWater flow

The invention relates to a pipe-plate type heat exchanger adopting a foamy copper material. Multiple foamy copper plates are placed in parallel at intervals, and an S-shaped cooling water pipeline alternately crosses back and forth between the foamy copper plates, so that the foamy copper heat exchanger is formed and is arranged in a flue shell. When a flue gas flows in from one end of a flue andpasses through the foamy copper heat exchanger in the middle, the flue gas penetrates through the gaps between the foamy copper plates and the S-shaped cooling water pipe, one part of heat in the flue gas directly exchanges heat through the S-shaped cooling water pipe, and the other part of heat in the flue gas is transferred to cooling water through the foamy copper plates or stored in gap spaces of the foamy copper plates so as to be absorbed by cooling water; and the low-temperature flue gas subjected to heat exchange with the cooling water flows out from the other end of the flue. The heat exchanger is compact in structure, small in volume and high in heat exchange efficiency, and not only can be applied to recycling flue gas waste heat and water, but also can be applied to recyclingwater in other waste heat and waste gases.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

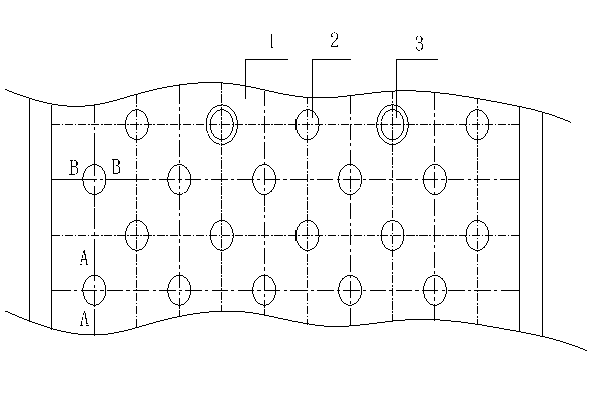

Ellipsoidal corrugated heat transmission sheet structure for air/gas preheater

InactiveCN103363831ALarge heat transfer surfaceImprove heat transfer coefficientLaminated elementsShell theoryHeat transmission

The invention relates to an ellipsoidal corrugated heat transmission sheet structure. Corrugation of a heat transmission sheet corrugated section consists of semi-ellipsoidal curved surfaces arrayed in a matrix manner; long axes of the semi-ellipsoidal curved surfaces are in the same direction as the long side of a heat transmission sheet; and middle axes of the semi-ellipsoidal curved surfaces are in the same direction as the broad side of the heat transmission sheet. The structure has the following advantages that: 1) the corrugation of the heat transmission sheet consists of the semi-ellipsoidal curved surfaces, and is provided with a larger heat transmission surface, so that a coefficient of heat transmission is increased; 2) the semi-ellipsoidal curved corrugation has higher strength and rigidity according to a shell theory, and does not deform easily; and 3) the structure is simple, is formed by one-time stamping; and the production cost is lowered. With the adoption of the structure, a heat transmission area is increased; the strength and the rigidity are improved; the flow channel resistance is reduced simultaneously; the new balance between the reduced flow resistance and a good heat transmission effect is achieved; and a significant progress is obtained.

Owner:SHANGHAI LALLEEN ENG TECH

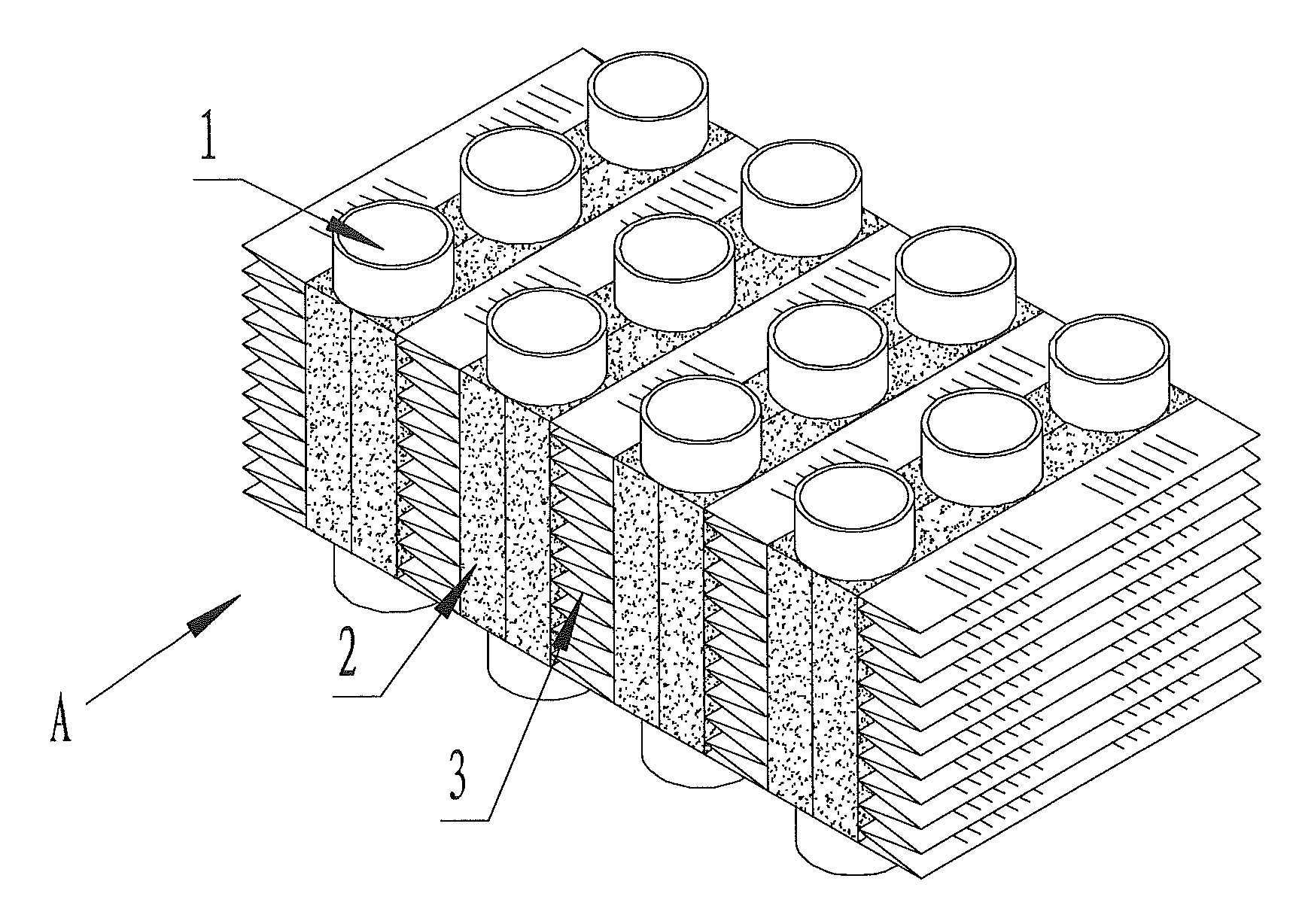

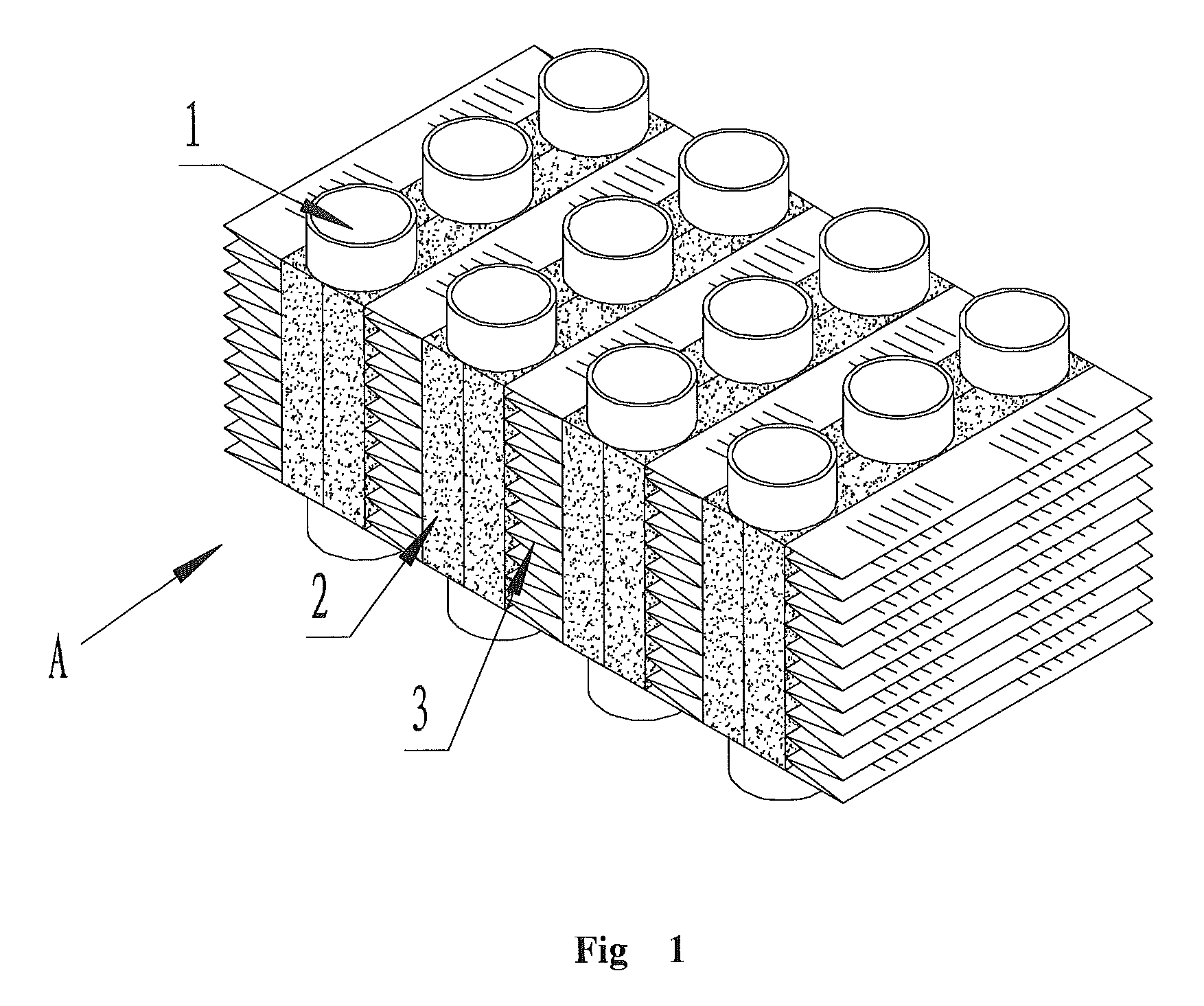

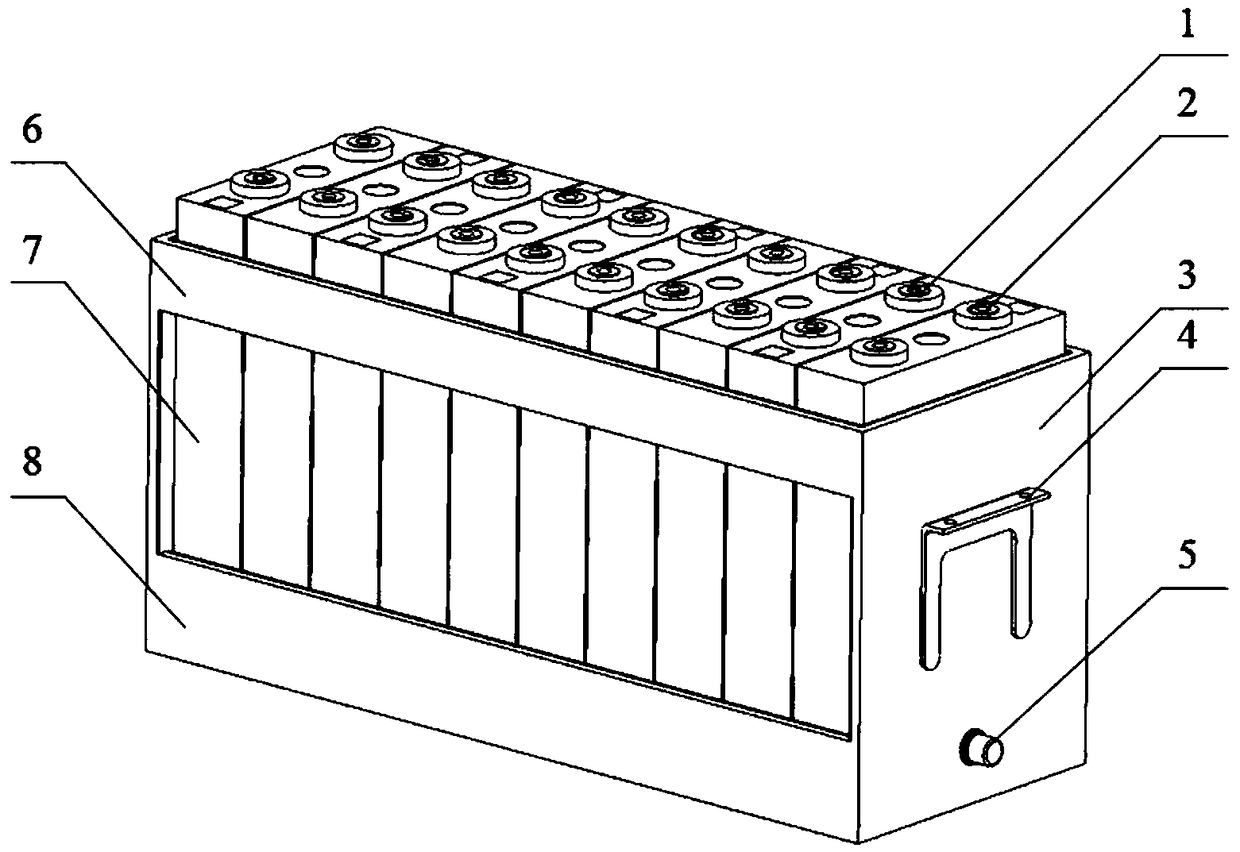

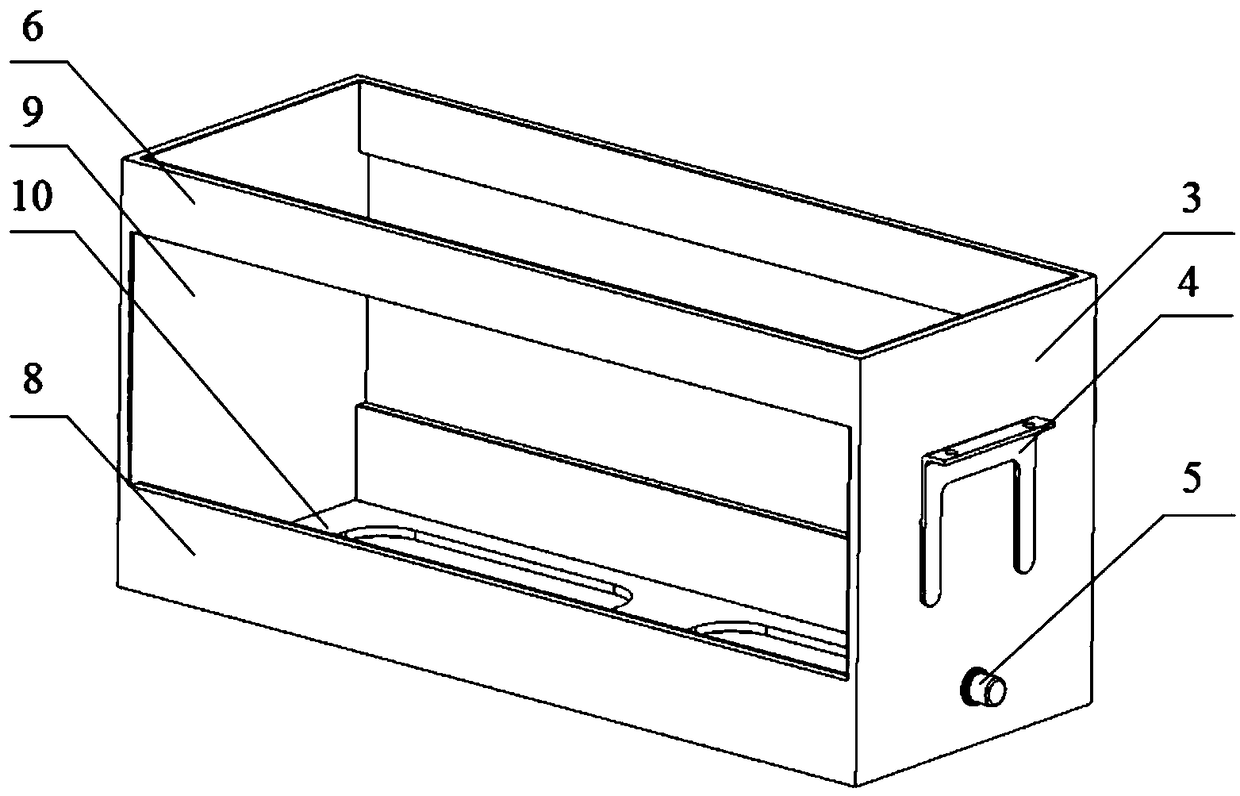

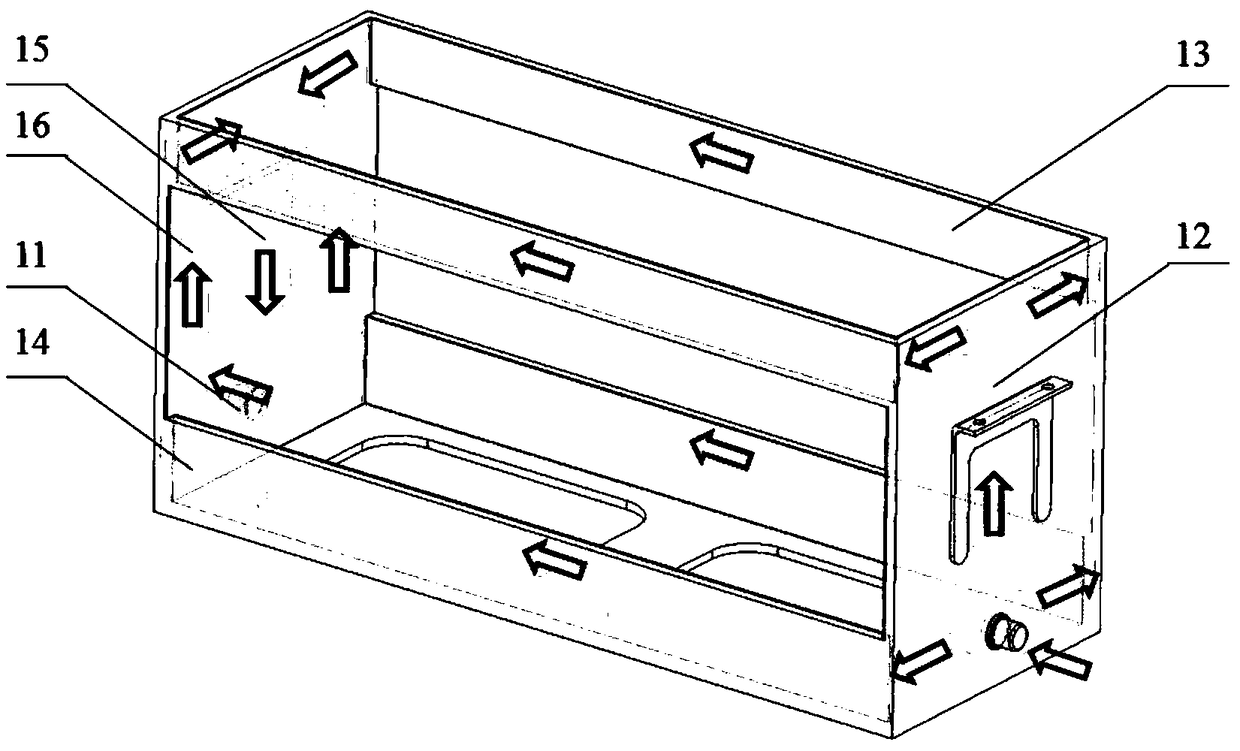

Power battery module and liquid cooling system integrated structure

ActiveCN108767151AImprove temperature uniformityLarge heat transfer surfaceSecondary cellsCell component detailsPower batteryCooling effect

The invention discloses a power battery module and liquid cooling system integrated structure. The power battery module and liquid cooling system integrated structure comprises a battery module and amodule frame. The battery module is composed of a plurality of single battery cells arranged in parallel, and the battery module is placed in the module frame. The module frame is provided with a cooling cavity, a liquid inlet and a liquid outlet are formed in the outer wall of the module frame, and the liquid inlet and the liquid outlet communicate with the cooling cavity. The liquid inlet and the liquid outlet are provided with flow guide blocks which are in a cone shape, and the cone tip of the flow guide blocks are arranged outwards. The power battery module and liquid cooling system integrated structure has simple structure and good cooling effect.

Owner:开沃新能源汽车集团股份有限公司

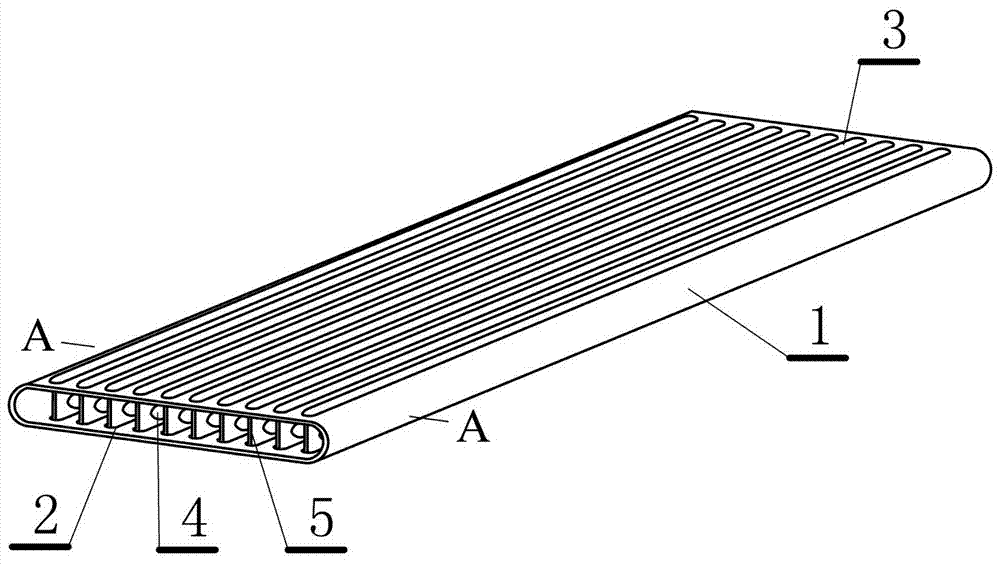

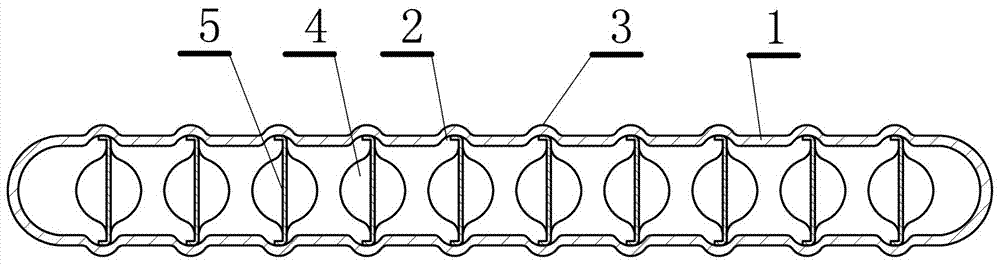

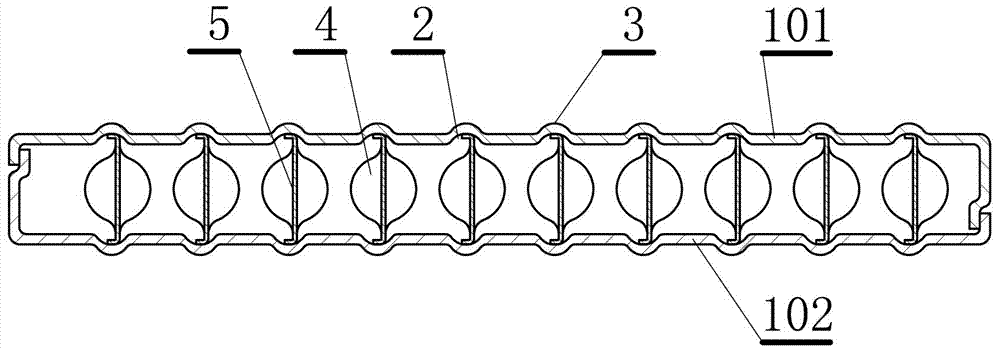

Heat exchange tube with inner fins and heat exchanger

ActiveCN106871689AReduce layoutReduce solder jointsStationary tubular conduit assembliesTubular elementsPlate heat exchangerHigh volume manufacturing

The invention relates to a heat exchange tube with inner fins and a heat exchanger. The heat exchange tube comprises a tube body, wherein the section of the tube body is in a strip rectangular shape. Multiple paired strip-shaped concave portions in the motion direction of fluid in the tube are correspondingly arranged on the upper face and the lower face in the tube body, and the multiple strip-shaped concave portions form strip-shaped protrusions on the outer surface of the tube body. At least one fin with point protrusions or short-line-shaped protrusions is connected in the up-and-down corresponding strip-shaped concave portions. According to the heat exchange tube, by means of the manner of arranging the cooling fins in the heat exchange tube, a heat transfer face is increased, the fins serve as a secondary heat transfer face, hot air flow heats the fins, and heat on the fins is transmitted into cooling liquid through the strip-shaped protrusions while being transmitted to the surface of the heat exchange tube through the strip-shaped protrusions on the heat exchange tube; and the point-shaped or short-line-shaped protrusions arranged on the fins can stir and disturb flowing air, carbon deposition is avoided, and the heat exchange efficiency is improved. Due to the fact that the tube body and the fins can be produced in a stamped manner, on the premise of meeting the heat exchange requirement, fin arrangement can be reduced, the fins are reduced, welding points are few, reliability is improved, welding is quite convenient, the heat exchange tube is suitable for mass production, and the beneficial effect of being low in manufacturing cost is achieved.

Owner:BEIJING U BRIDGE CHAOYANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com