Battery assembly

A technology of battery components and battery cells, which is applied to battery pack parts, electrical components, secondary batteries, etc., can solve the problems of limiting the heat flow of battery cells, such as dimensional tolerances, and achieve good heat discharge, good thermal conductivity, and high insulation properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

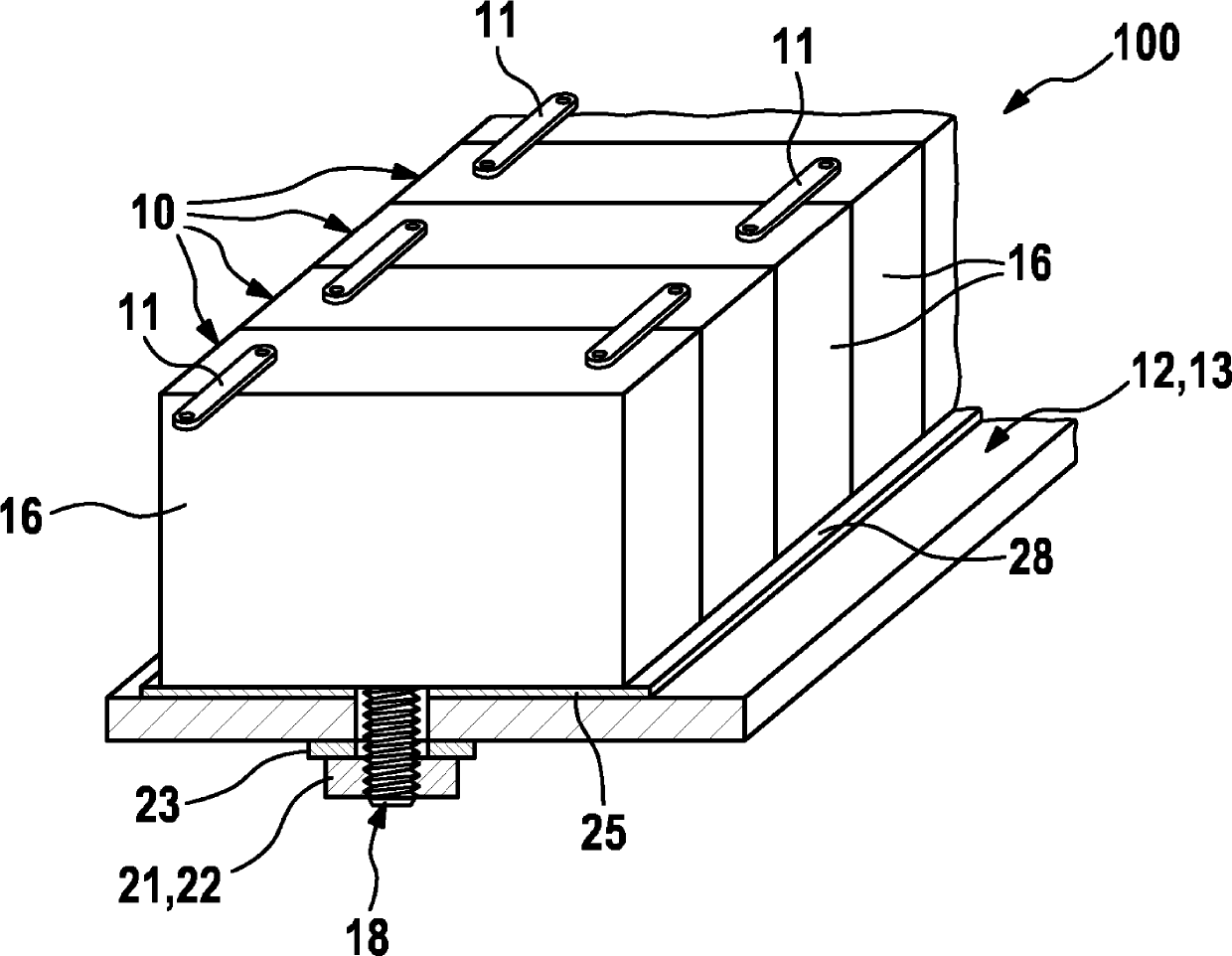

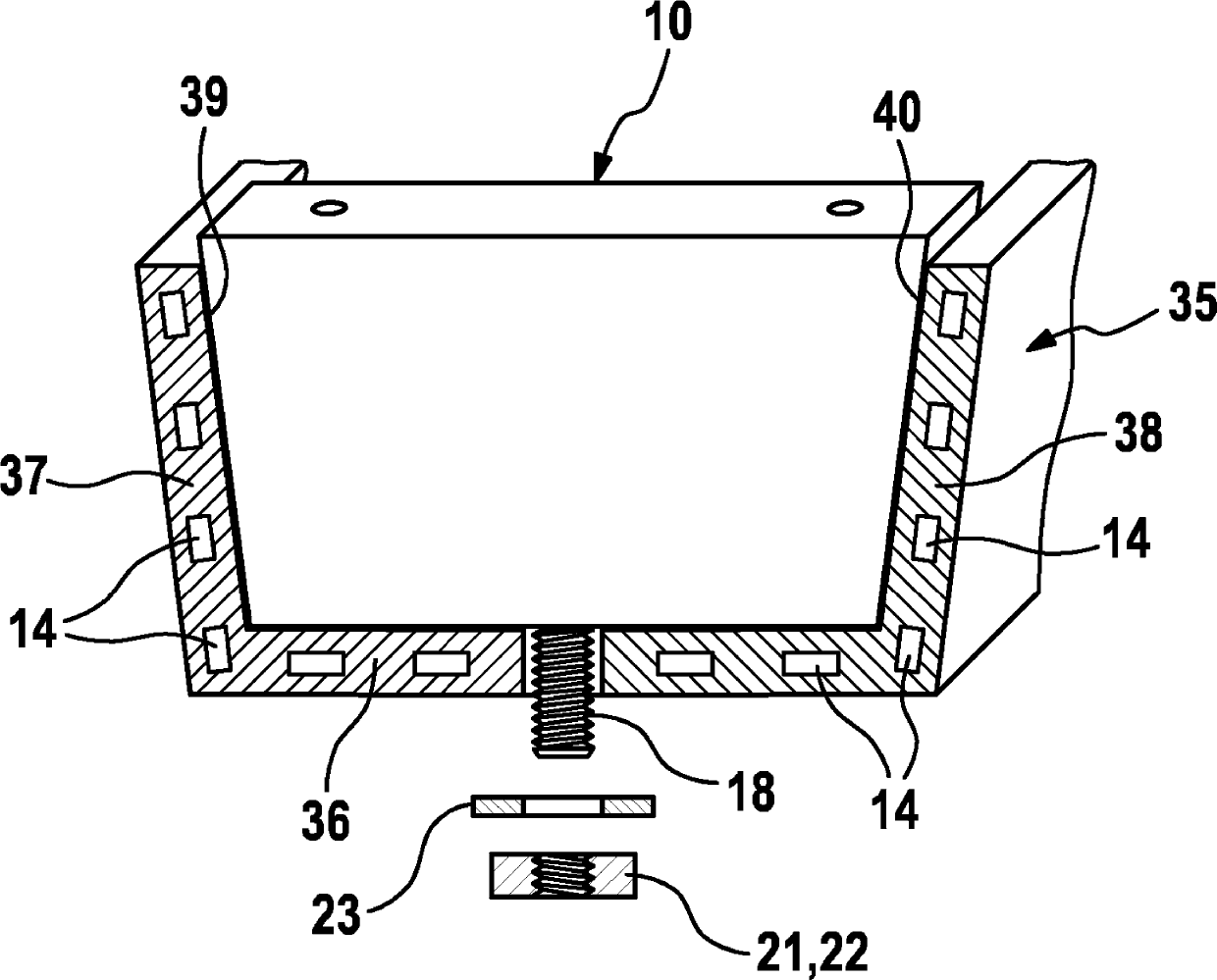

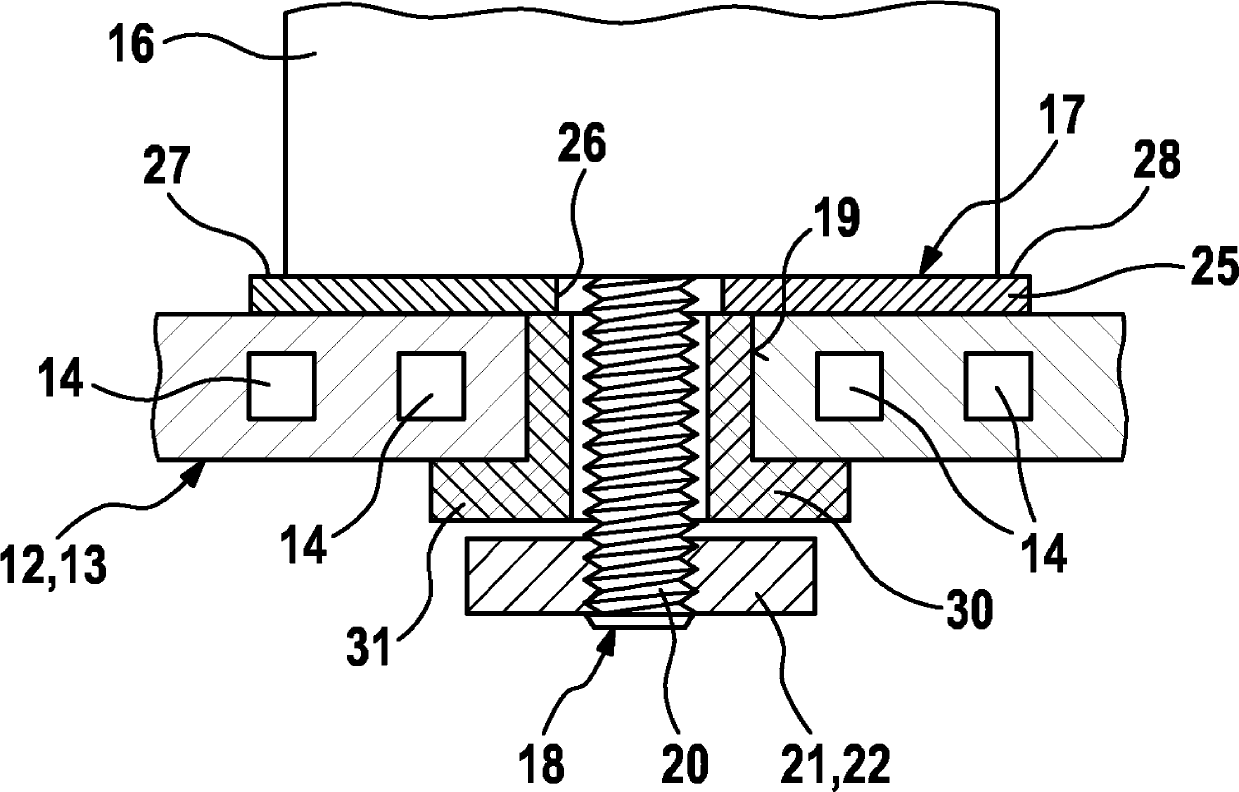

[0021] exist figure 1 shows a first battery assembly 100 according to the invention, as it is used in particular, but not limitedly, as a component of a voltage supply device for supplying energy to at least one electric drive motor in a hybrid vehicle. The battery pack 100 comprises a plurality of generally identically constructed battery cells 10 which, depending on requirements, are electrically connected in series or in parallel by means of cell connectors 11 . Obviously, it is also possible to provide a plurality of battery assemblies 100 which are in turn electrically connected to each other. In practice, an energy supply device in a hybrid vehicle may comprise, for example, approximately one hundred battery cells 10 interacting with each other.

[0022] In order to dissipate the heat losses of the individual battery cells 10 , which occur through chemical processes, in particular when electricity is drawn from the battery elements 10 , in order to thereby avoid thermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com