Patents

Literature

963 results about "Aging property" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified, weather resisting polypropylene material

This invention discloses a modified polypropylene material used as elements of home appliances, such as outdoor hulls of air-conditioners and panels of automobiles. The modified polypropylene material comprises: polypropylene resin 65-85 wt.%, toughening modifier 1-18 wt.%, mineral reinforcer 0-25 wt.%, coupler 0.1-0.8 wt.%, processing auxiliary 0.2-2 wt.%, photostabilizer 0.2-2 wt.% and colorant 0.1-1.5 wt.%. Compared with present polypropylene material, the modified polypropylene material has improved weathering resistance and anti-aging property.

Owner:CGN JUNER NEW MATERIALS

Anti-oil and fire-retardant chlorinated polyethylene sheath material with good weather resistance and preparation method thereof

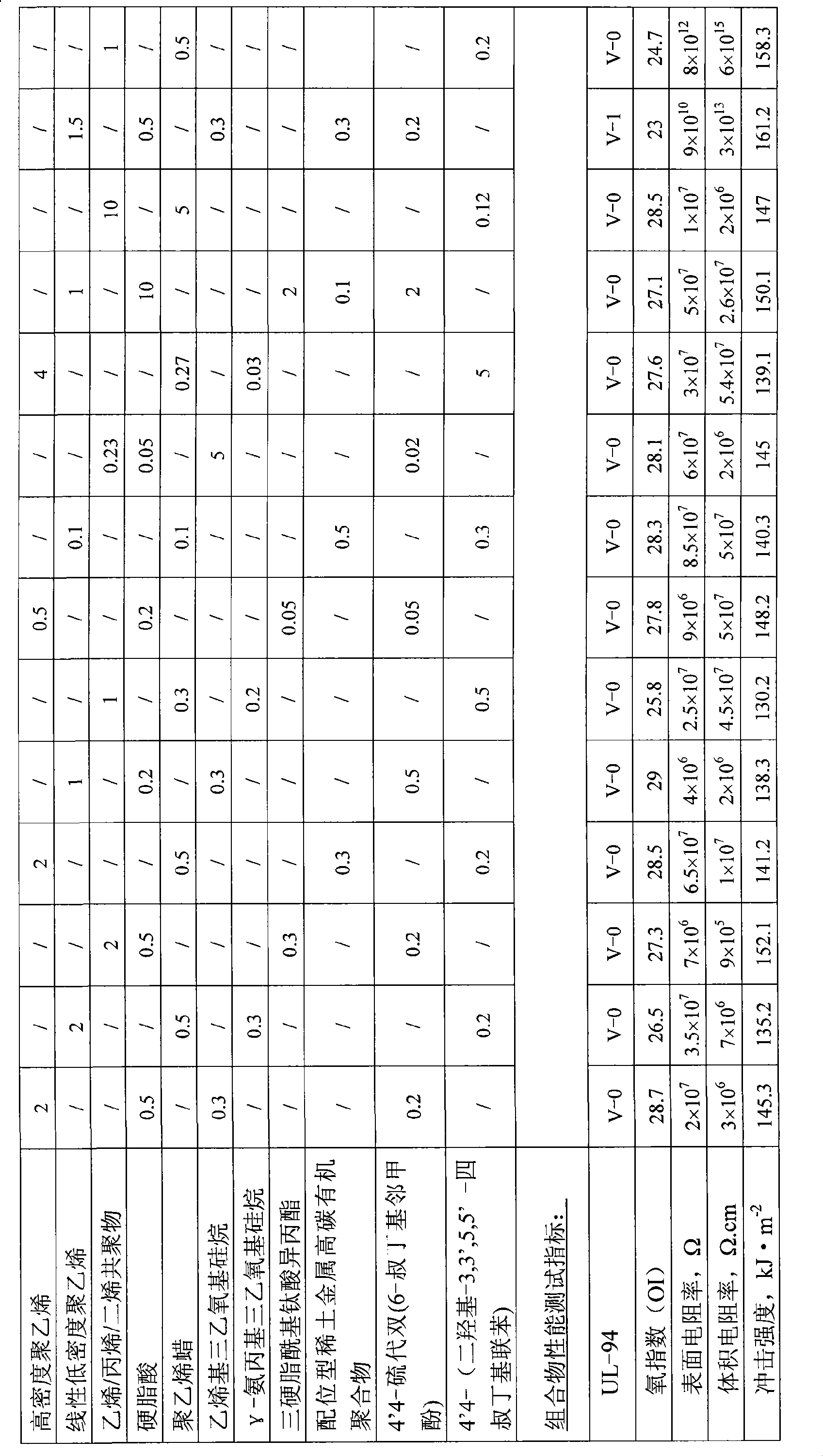

ActiveCN101597410AGood oil resistanceReach high temperaturePlastic/resin/waxes insulatorsClimate change adaptationPolymer scienceUltra fine

The invention relates to an anti-oil and fire-retardant chlorinated polyethylene sheath material with good weather resistance and a preparation method thereof. The sheath material uses chlorinated polyethylene rubber as main raw material and adds chlorosulfonated polyethylene rubber, triallyl isocyanurate, 1,3-bis (tert-butyl peroxide isopropyl) benzene, trioctyl trimellitate, carbon black, antioxidant 1010, ultra-fine talc powder, antimony trioxide, and high-activity magnesium oxide R-150 according to ratios; the preparation method is as follows: at first, mixing part of the auxiliary agents, then mediating, internal mixing, open mixing, granulating and extruding are carried out on the mixture to form cables, thus the cables are obtained. In the formula, high temperature resistant plasticizer is utilized, various auxiliary agents with appropriate proportions are added into the formula, so that chlorinated polyethylene rubber cable material can reach a high temperature of 105 DEG C, and can be used at the lowest temperature of minus 50 DEG C. The sheath material has the advantages of good anti-aging property, excellent electrical insulation and mechanical property, environmental protection and high flame resistance, thereby being suitable for cold and oil-contaminated severe environment and transmission and distribution circuits of which the current-carrying capacities are large and the rated voltages are at or below 450 / 750V. Meanwhile, compared with traditional chloroprene rubber cable material, the sheath material has the characteristics of low cost, fast extruding speed and high output benefit.

Owner:NINGBO WELL ELECTRIC APPLANCE CO LTD

Novel EVA adhesive film

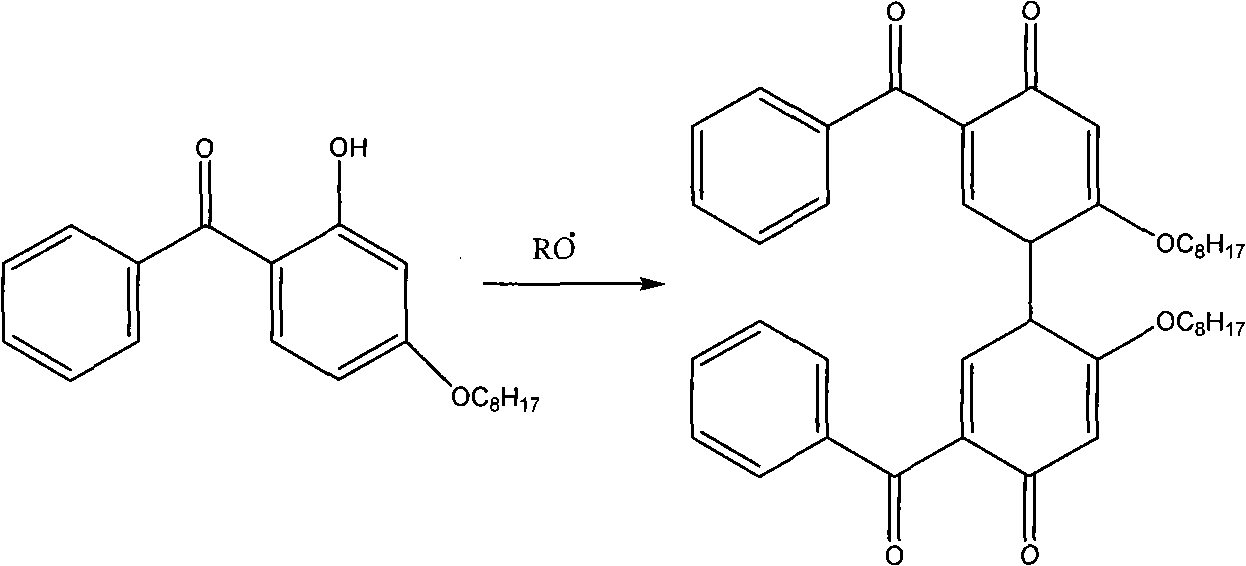

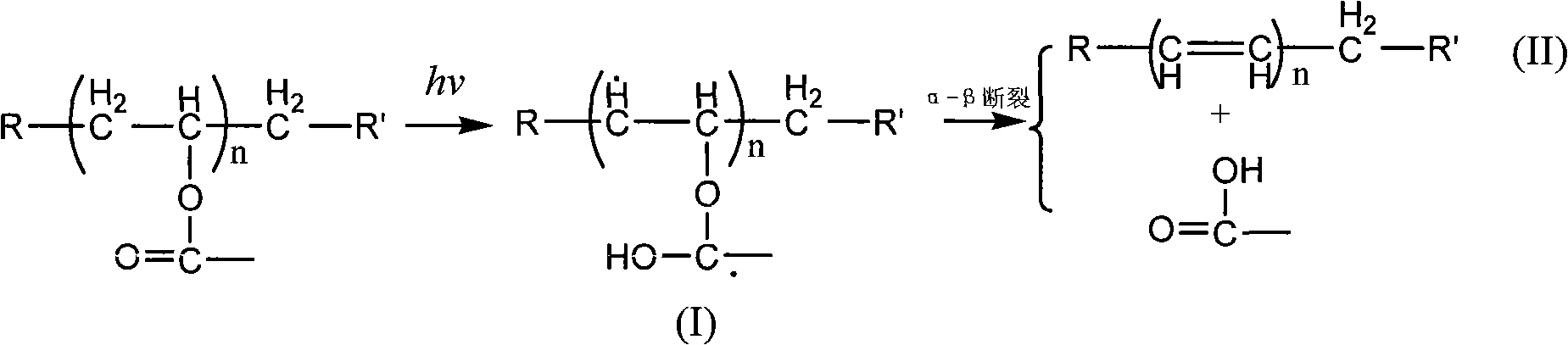

InactiveCN101353558AStrong free radical capture abilityGeneration of blockingFilm/foil adhesivesElectrical equipmentLight energyAdhesive

The invention provides an EVA adhesive film without adding uvioresistant absorbent, which is prepared mainly by the raw materials according to the mass ratio as follows: ethylene-vinyl acetate copolymer, 100 parts; peroxide type crosslinking agent 0.1 to 10 parts, phenolic or phosphite type antioxidant 0.05 to 5 parts; and hindered amine light stabilizer, 0.01 to 5 parts. As the ultraviolet absorbent is not used, the EVA adhesive film obtained does not produce ultra-violet cut-off, leads the solar modules to receive UV district light energy, thereby having higher photoelectric conversion efficiency and excellent uvioresistant anti-aging property, and guaranteeing the service life of PV modules.

Owner:HANGZHOU FIRST APPLIED MATERIAL CO LTD

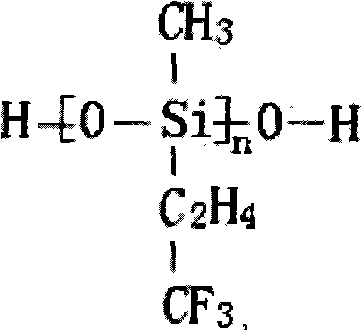

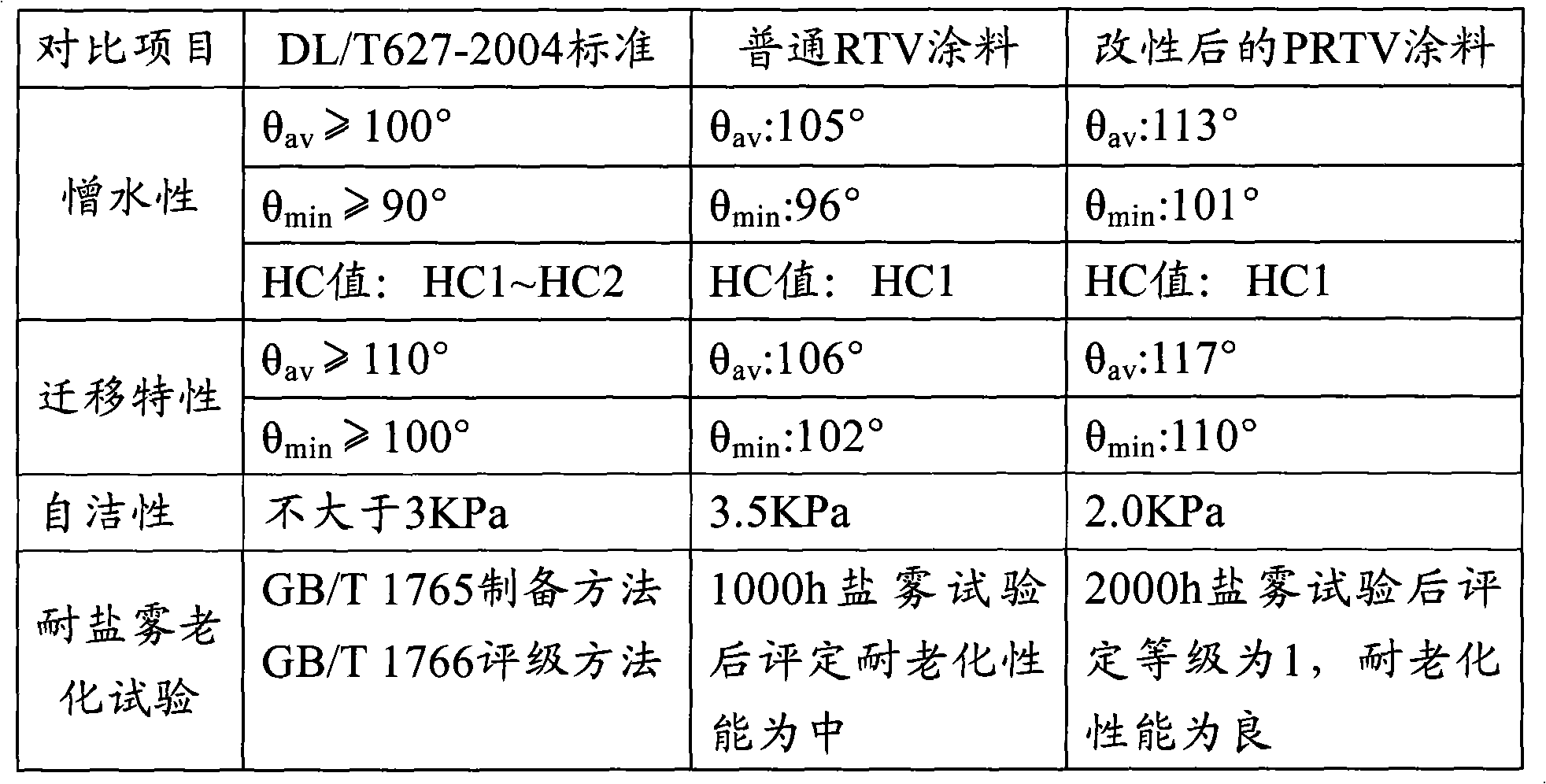

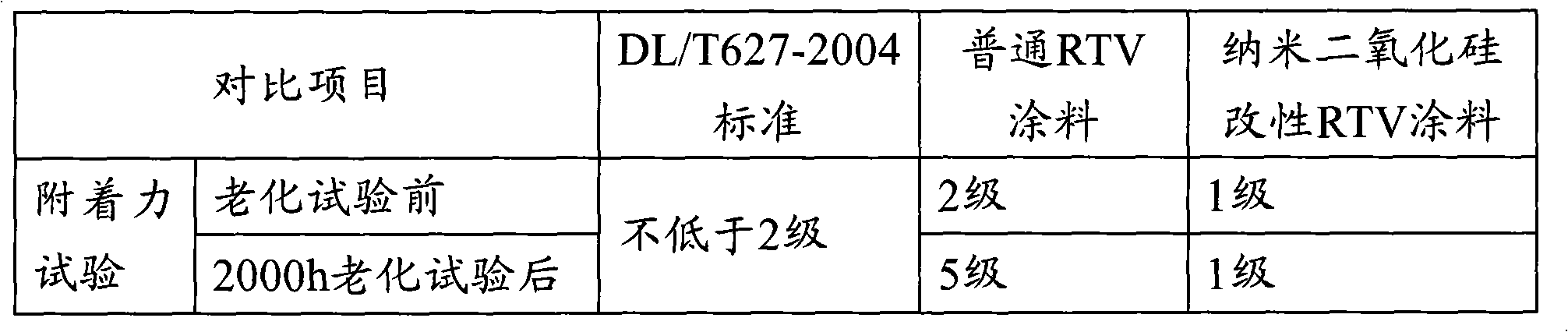

Composition for anti-pollution flashover coating and anti-pollution flashover coating

InactiveCN101942200AStrong mechanical propertiesExtended service lifeCoatingsPerformance indexSilicon dioxide

The invention provides a composition for an anti-pollution flashover coating and the anti-pollution flashover coating. The composition comprises the following components in part by weight: 25 to 40 parts of hydroxyl-terminated polyorganosiloxane, 5 to 15 parts of hydroxyl-terminated fluorine-containing polyorganosiloxane, 6.0 to 8.0 parts of nanometre silicon dioxide, 2.5 to 3.5 parts of nanometre calcium carbonate, 4.8 to 5.5 parts of cross-linking agent, 3.5 to 4.5 parts of wetting agent, 0.8 to 1.3 parts of silane coupling agent and 0.2 to 0.4 part of catalyst. The coating has the characteristic of long-term anti-pollution flashover effect and greatly improves the hydrophobicity, the hydrophobicity migration property, the tear strength, the shear strength, the acid and alkali resistance, the self-cleaning property and the aging property of a coating. The performance indexes of the coating are designed according to the actual needs of operation of electric equipment and by combining the development level of an organic silicon fluorine material. Requirements and limitations on the operation and maintenance of the equipment operating can be reduced to the maximum degree on the premise of guaranteeing the long-term anti-pollution flashover performance of the equipment.

Owner:广东鑫皇冠新材料有限公司

Plenum Cable Flame Retardant Layer/Component with Excellent Aging Properties

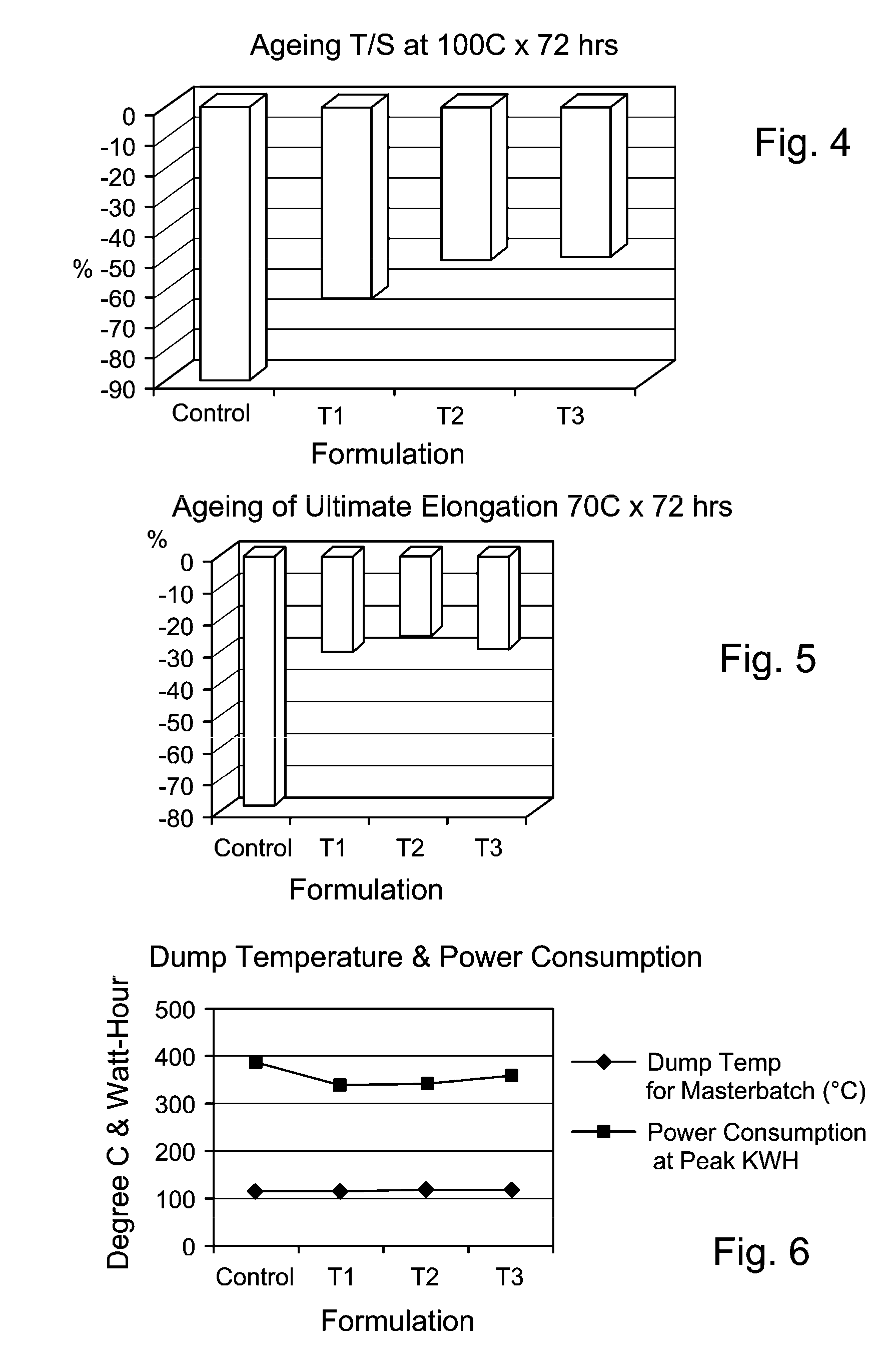

InactiveUS20080251273A1Excellent fire retardant and aging propertyInsulated cablesInsulated conductorsPolyolefinAging property

The present invention is a plenum cable component with excellent fire retardant and aging properties. The plenum cable component is prepared from a polyolefin-based composition, containing an olefinic polymer and a surface treated metal hydroxide. Depending upon the surface treatment, the composition may comprise other components. The present invention is also a method for selecting a composition for preparing the plenum cable component as a separator and a method for preparing a communications cable therefrom.

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

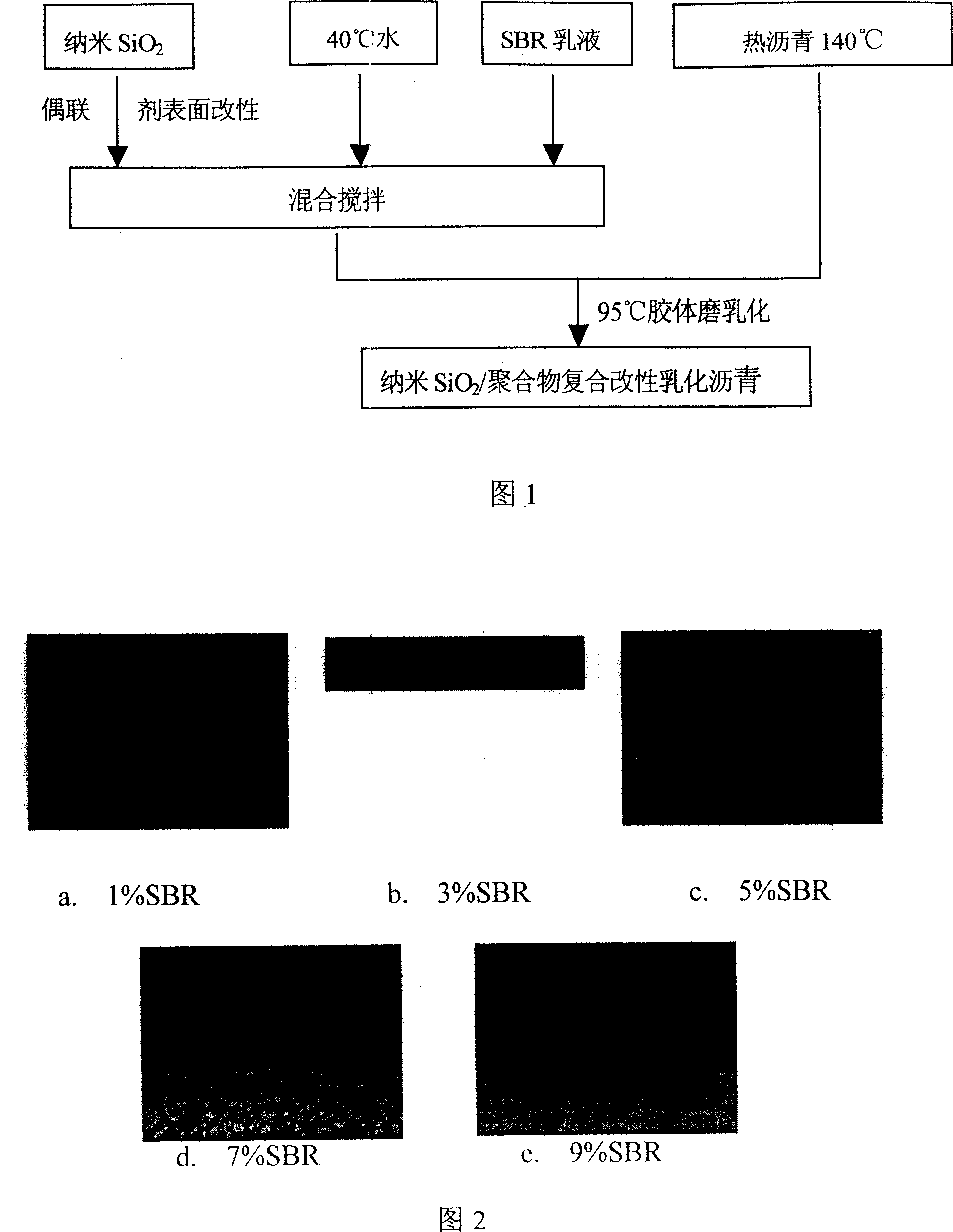

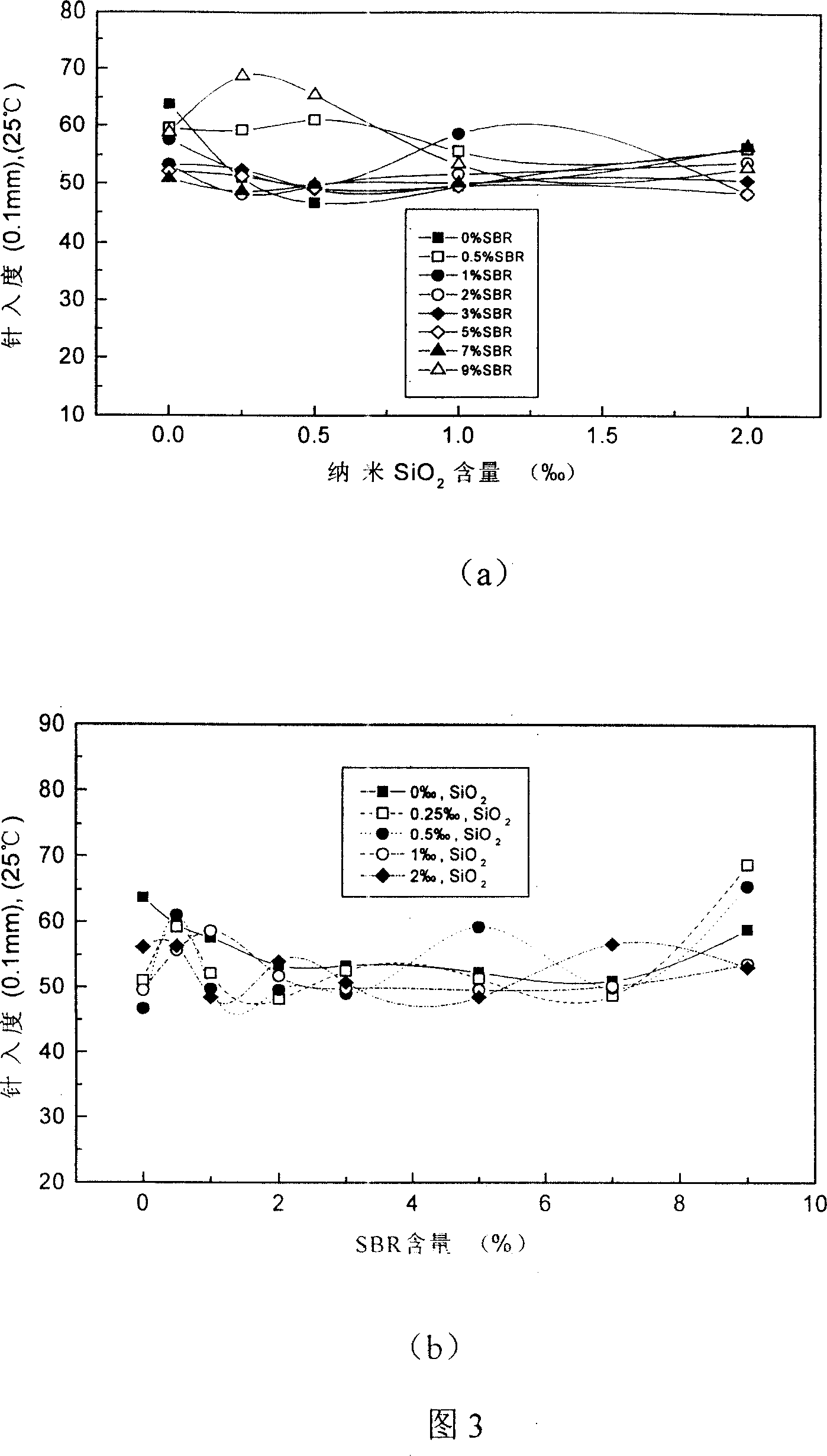

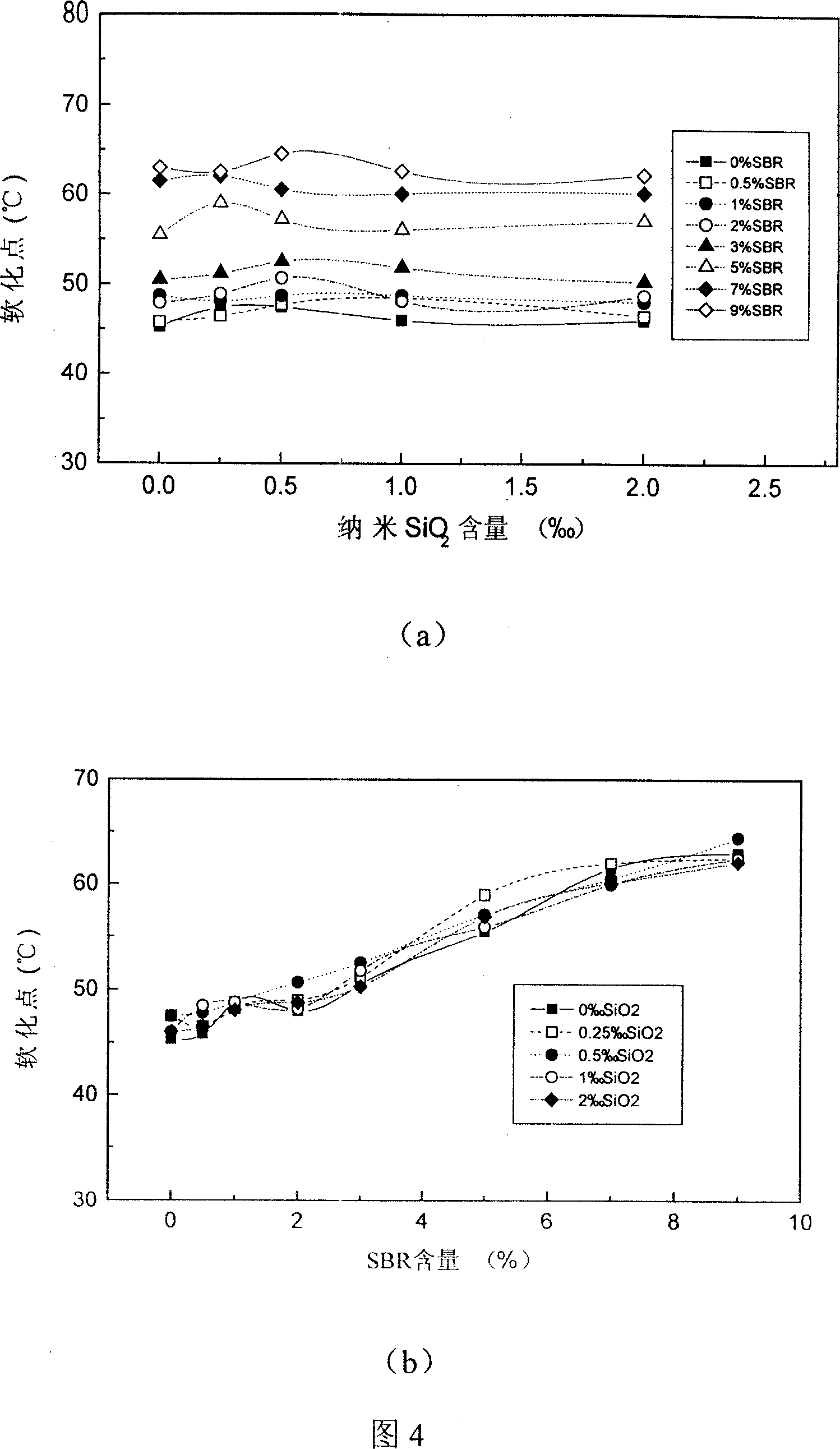

Inorganic nano particle and polymer composite modified emulsified asphalt

InactiveCN101143967AGood resistance to UV agingImprove heat aging performanceBuilding insulationsPolymer scienceButadiene-styrene rubber

A modified emulsion asphalt compounded by inorganic nano-particles and polymer contains 200-700 parts by weight of asphalt, 2-80 parts by weight of modified inorganic nano-particles, 5-50 parts by weight of styrene-butadiene rubber latex, and 170-793 parts by weight of water, wherein the modified inorganic nano-particles is prepared by mixing 95-98 parts by weight of inorganic nano-particles with 2-5 parts by weight of coupling agent, and each components are mixed, followed by normal emulsion treatment to get the emulsion asphalt. The invention utilizes unique surface effect, small size effect and macroscopic quantum tunneling effect etc. of the inorganic nano-particles to give the product comprehensive properties, such as good wear resistance, intensity sum, anti-aging property and fine waterproof effect etc. Using the invention can increase the road maintenance cycle and decrease the cost. Furthermore, the water-proof cost of construction industry is greatly decreased.

Owner:HUNAN UNIV

High heat-resistant rubber composite material for conveyor belt covering

InactiveCN101250305AImprove heat aging resistanceImprove wear resistanceConveyorsElastomerPolymer science

The invention relates to rubber composite material for high heat resistance conveyor belt covering layer, which comprises substrate rubber and relative addition auxiliary agent, and is characterized in that substrate rubber is metallocene low undersaturation EPT rubber, ethane-octene copolymerization elastomer (POE) or / and ethane-butene copolymerization elastomer, plasticizing agent in addition auxiliary agent is large molecular plasticizing agent with low molecular weight, anti-aging agent is response type anti-aging agent. The covering layer rubber composite material has excellent heat resistance aging property, abrasion resistance and adhesiveness property, since the invention adopts novel rubber substrate and the synergistic effect of anti-aging system, adhesion-promotion system and plasticization system which are compatible with the rubber substrate, thereby increasing the high temperature tolerance of conveyor belt, the long-term usage temperature can reach about 180 DEG C, and the viscosity of the conveyor belt and fabric layer all can reach to the standard of first-grade or quality products.

Owner:BEIJING UNIV OF CHEM TECH

Blend Partner with Natural Rubber for Elastomeric Compounds

Natural rubber blends, methods for making the same, and articles made therefrom are provided. The natural rubber blend includes at least one propylene copolymer containing ethylene derived units. The natural rubber blend can further include one or more reinforcing fillers, such as carbon black. The presence of the propylene copolymer significantly improves the ozone resistance and ageing properties of the natural rubber gum stock.

Owner:EXXONMOBIL CHEM PAT INC

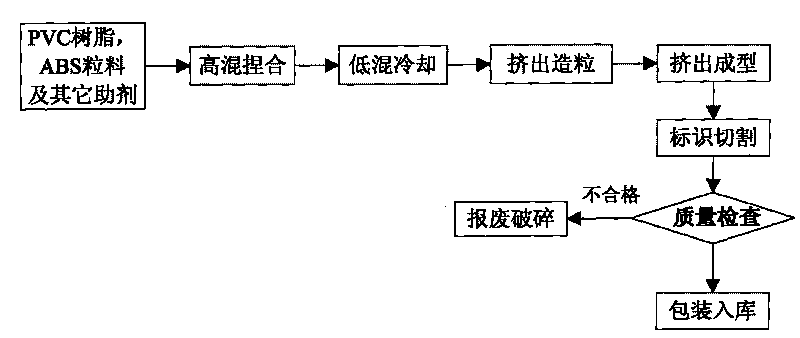

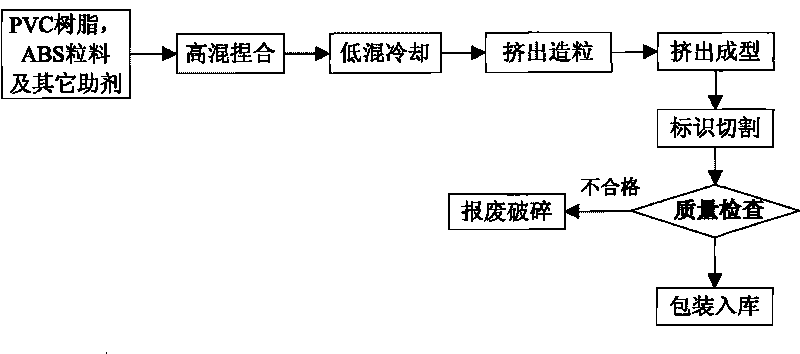

PVC/ABS blend and pipe thereof

ActiveCN101693778AImprove impact resistanceGood mechanical propertiesRigid pipesProcedure AgentsAntioxidant

The invention discloses a PVC / ABS blend and a pipe thereof. The PVC / ABS blend consists of the following components in parts by weight: 100 parts of PVC resin, 20 to 80 parts of ABS granules, 1 to 3 parts of stability agent, 1 to 2 parts of lubricant, 0 to 5 parts of impact modifier, 0 to 10 parts of compatibility agent, 0 to 1 part of antioxidant, 0 to 1 part of ultraviolet absorber, 0 to 3 parts of flame retardant, and 1 to 3 parts of processing aid. Each component in the PVC / ABS blend is subjected to high-speed heating mixing and then cooled-mixed slowly, and finally the PVC / ABS pipe is obtained by granulation extrusion and forming. By optimizing and selecting the components and dosage required by the PVC / ABS blend, the PVC / ABS pipe which has the advantages of good impact resistance, good flame retardant and anti-aging property, and excellent mechanical property is prepared.

Owner:湖南联塑科技实业有限公司

Inorganic/organic nano particle compound modification epoxy resin adhesive and preparation method thereof

InactiveCN103131374AImprove high temperature performanceEasy to prepareNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyResin adhesive

The invention relates to an inorganic / organic nano particle compound modification epoxy resin adhesive and a preparation method thereof, aiming at solving the problem that the existing toughened epoxy resin adhesive has low bonding strength at high temperature and poor high temperature aging performance. The preparation method comprises the following steps of: firstly preparing an epoxy resin component, and then preparing a curing agent component, thereby obtaining the inorganic / organic nano particle compound modification epoxy resin adhesive. When the adhesive is used, the epoxy resin component and the curing agent component are mixed uniformly at normal temperature, tensile shear strength of the adhesive at 150 DEG C can reach 10MPa-15MPa, the tensile shear strength of the adhesive at 250 DEG C still can reach 4MPa-5MPa, the bonding strength at high temperature is high, after ageing for 1000 hours at 150 DEG C, the retention rate of the tensile shear strength of the adhesive still can be above 80%, the high temperature ageing property of the adhesive is good, the preparation method of the adhesive is simple and is applicable to the fields of aviation, aerospace, mechanical automation, automobile and the like.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

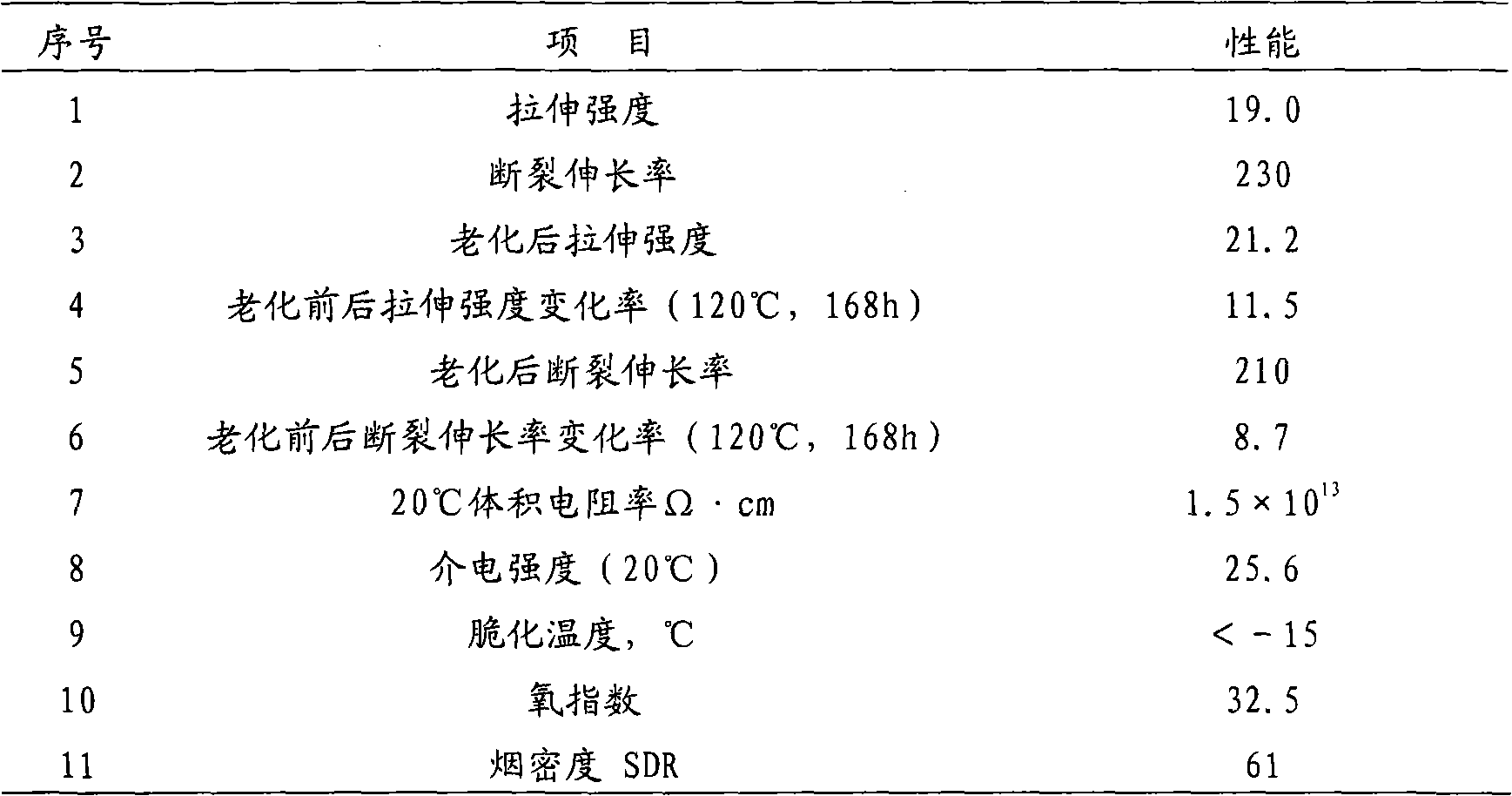

Silicone hydride crosslinked non-halogen flame-proof smoke-restraining polyvinyl chloride cable material and manufacturing process thereof

InactiveCN101319079AEasy to processPromote degradationInsulated cablesInsulated conductorsPolyvinyl chlorideFire retardant

The invention discloses a silane crosslinking HFFR flame retardant polyvinyl chloride cable material and a preparation technique thereof. The compositions by weight portion of the cable material are: 100 portions of polyvinyl chloride resin, 10 to 100 portions of a plasticizer, 0.5 to 10 portions of a silane cross-linking agent, 0.5 to 6 portions of a heat stabilizer, 30 to 100 portions of a metal hydroxide flame retardant, 1 to 10 portions of a metallic compound flame retardant synergist, 0.1 to 5 portions of a preventing cross-linking agent, 0.1 to 5 portions of a lubricant, 0.1 to 0.5 portion of an antioxidizer, 0.05 to 0.1 portion of dibutyl tin dilaurate and appropriate amount of a colorant. The cable material has the characteristics that the mechanical property is good, the mechanical intensity is increased by 20 to 30 percent compared with the uncrosslinked PVC cable material, the heat resistance is good, the electrical property is good, the specific volume resistance is increased by 3 to 5 times compared with the uncrosslinked PVC cable material, the insulating property of the cable is improved and the aging property is good.

Owner:LIAOCHENG UNIV

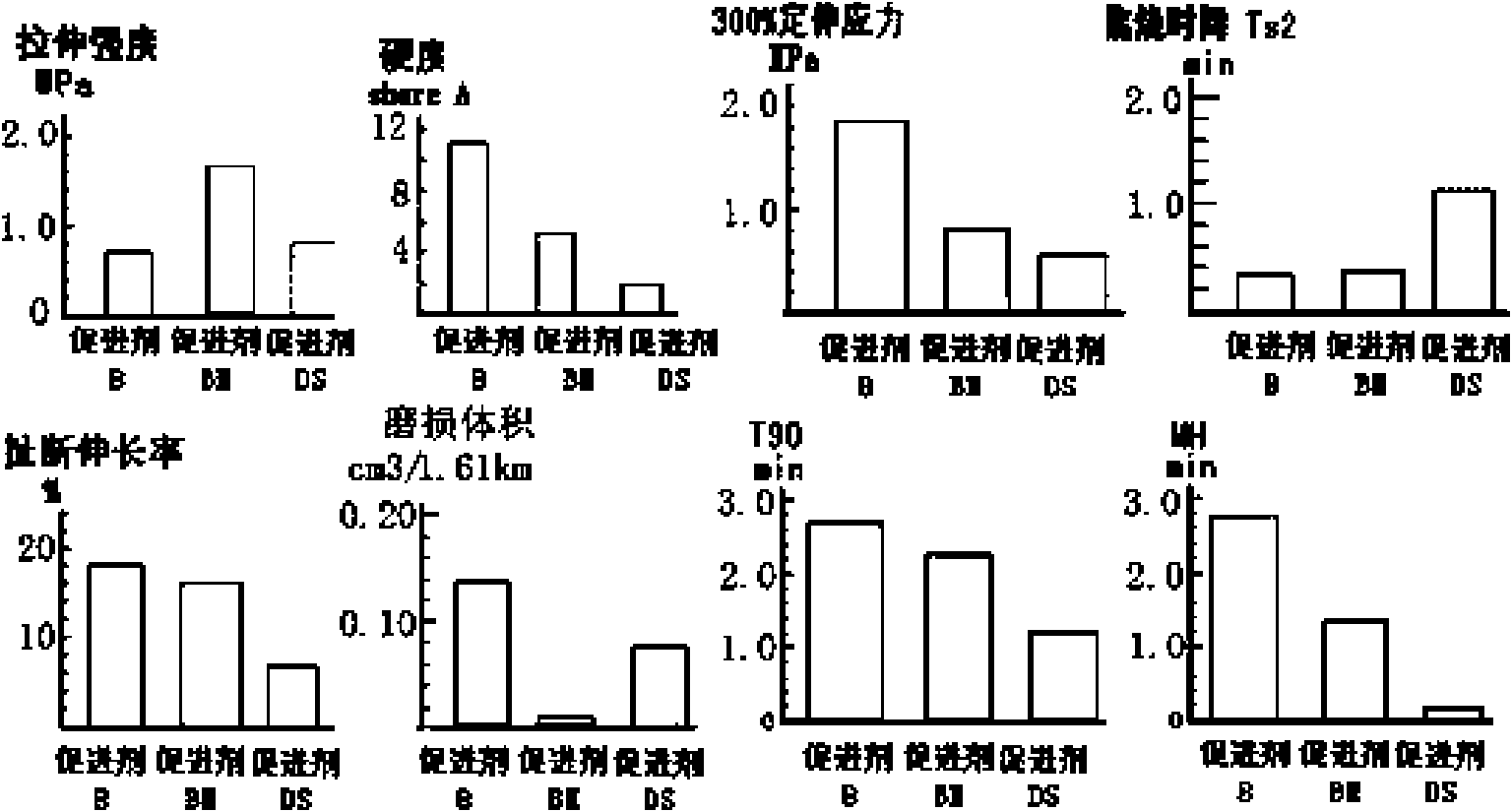

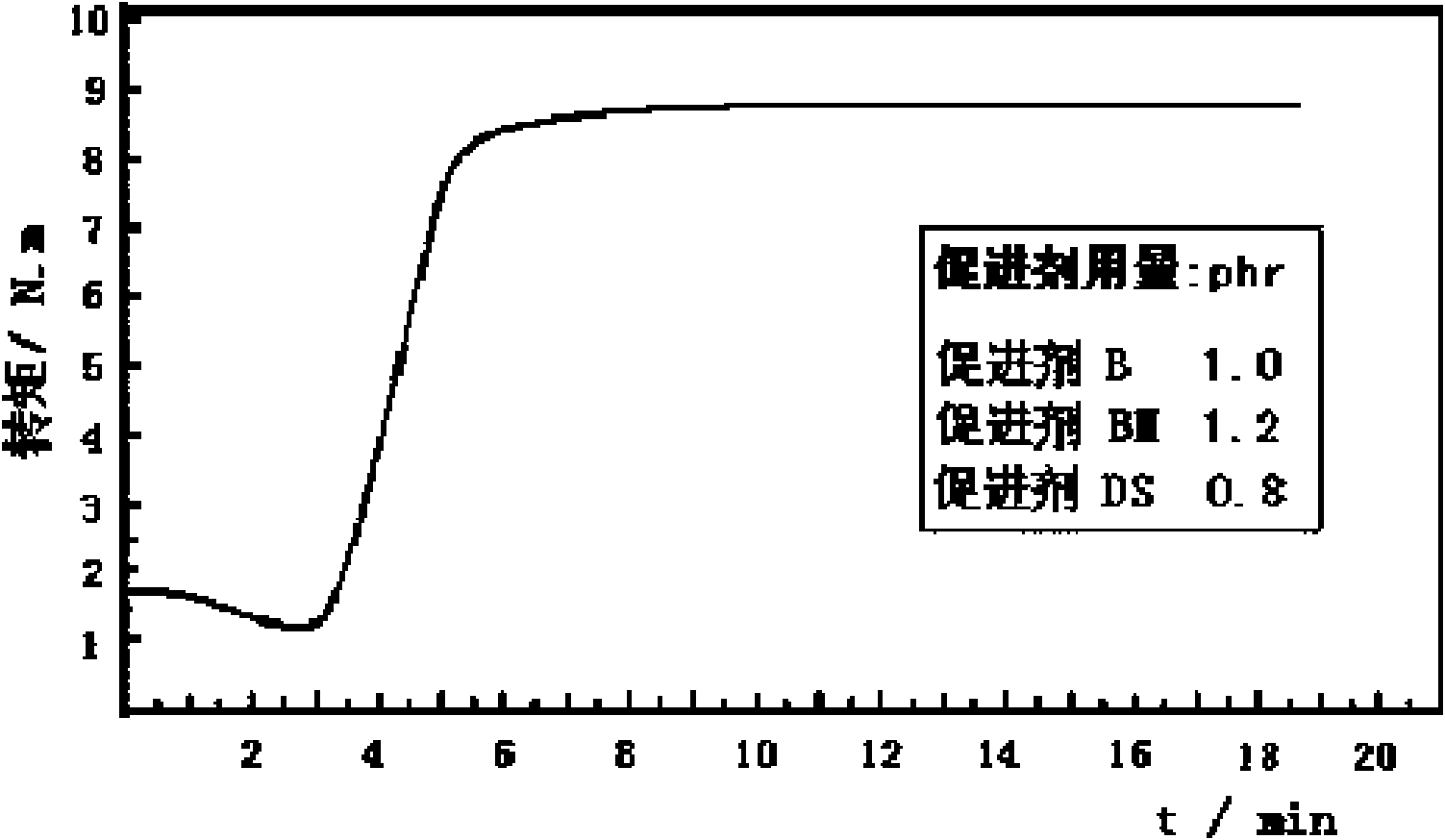

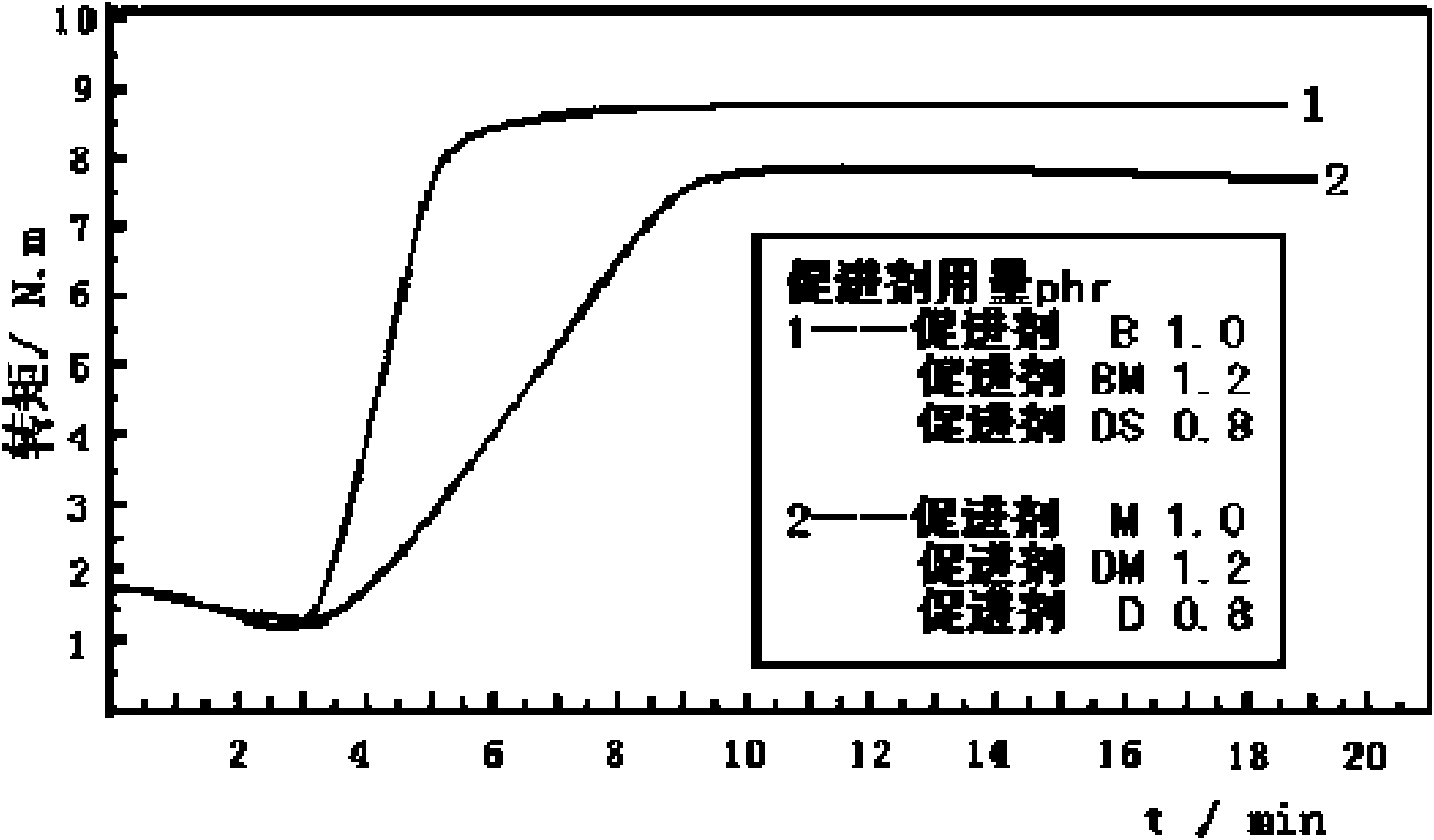

Vulcanized rubber for shoes capable of realizing high effective and fast vulcanization and preparation method and vulcanization process thereof

The invention discloses a vulcanized rubber for shoes capable of realizing high effective and fast vulcanization and a preparation method and a vulcanization process thereof. The vulcanized rubber isprepared from natural rubber, styrene-butadiene rubber, butadiene rubber, accelerator B, accelerator BM, accelerator DS, nanometer zinc oxide, rubber softening oil, sulphur, stearic acid, aging resister CD, carbon black N330, pine tar oil, solid coumarone, reclaimed rubber and pot clay. Compared with the prior art, the vulcanized rubber of the invention has suitable starting time of vulcanization,faster velocity of vulcanization and higher thermal oxidative aging property, the vulcanization efficiency is increased, and the heat-conducting property, processing safety and storage property of the rubber are increased in the vulcanization process; the provided vulcanization process can effectively shorten the vulcanization time, improve the vulcanization quality and increase the vulcanizationefficiency to 2-3 times of the original one.

Owner:JIHUA 3537 SHOE MAKING

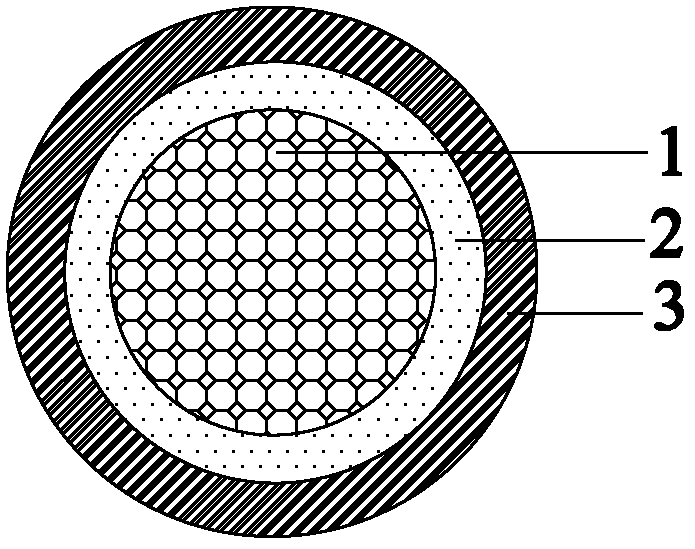

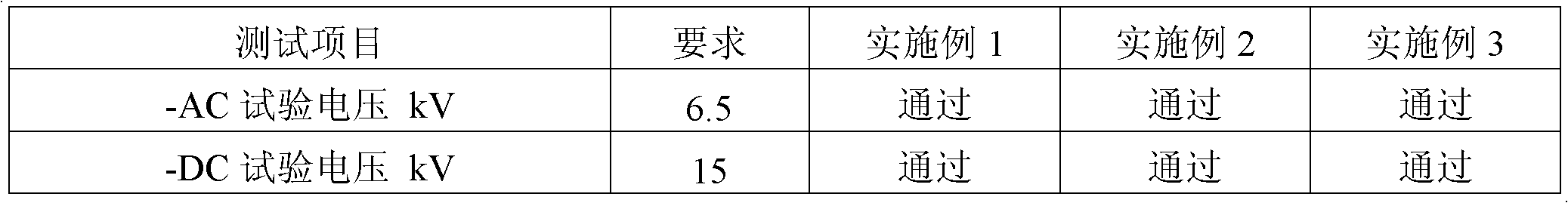

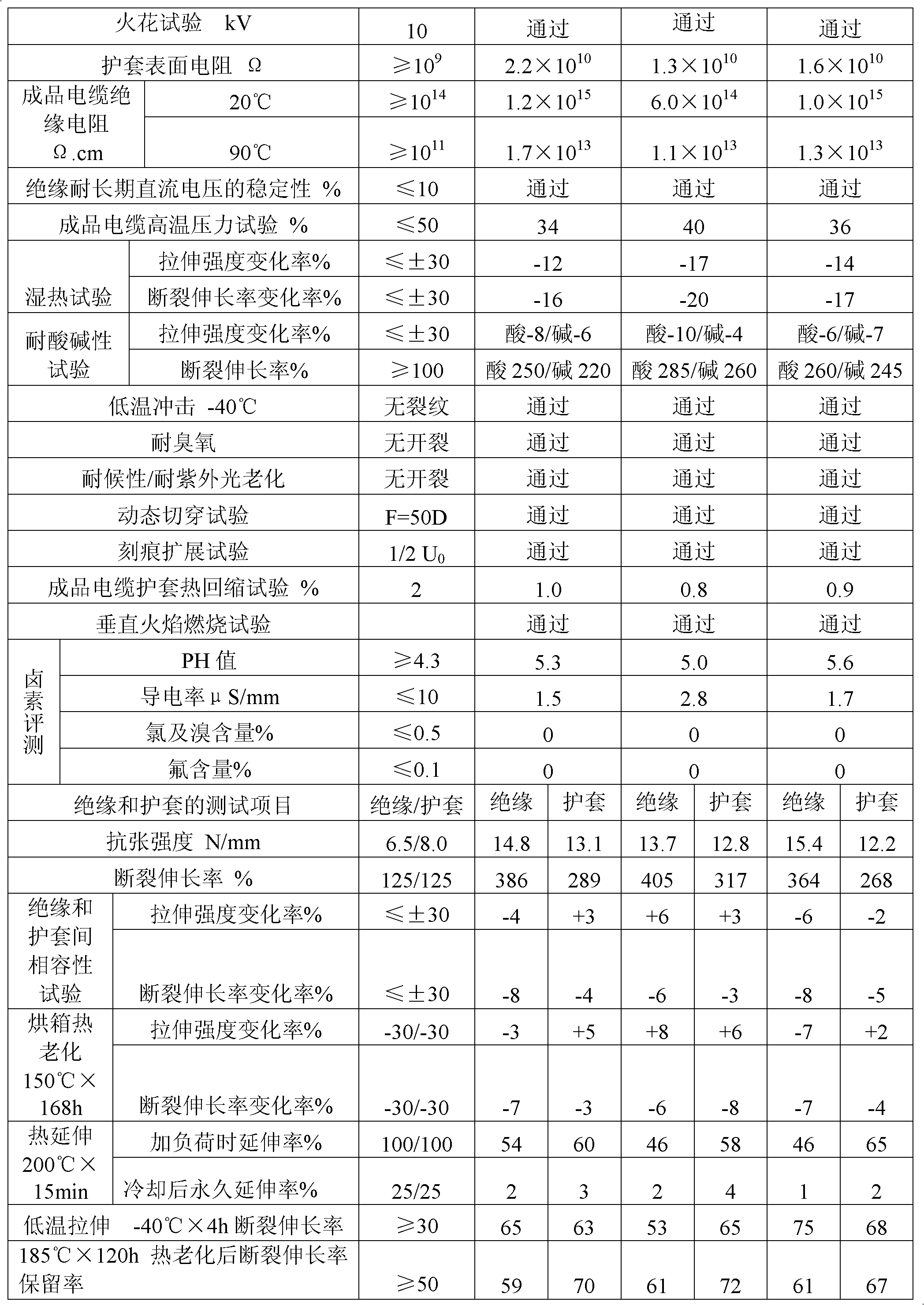

Photovoltaic cable and manufacturing method and application thereof

ActiveCN102610305AGood mechanical propertiesMeet environmental protection requirementsClimate change adaptationInsulated cablesThermal ageingCross-link

The invention discloses a photovoltaic cable and a manufacturing method and application thereof. The photovoltaic cable comprises an insulating layer and a jacket layer; the insulating layer comprises the following components: EVA (ethylene-vinyl acetate copolymer), LLDPE (linear low density polyethylene), EMA (ethylene-methyl acrylate), EVA-g-MAH (ethylene-vinyl acetate copolymer grafted maleic anhydride), magnesium hydrate, organic montmorillonoid, a cross-linked sensitizing agent, a lubricating agent, an antioxidant, a light stabilizer and a copper resisting agent; and the jacket comprisesthe following components: EVA, LLDPE, EMA, EVA-g-MAH, color masterbatch, magnesium hydrate, a phosphor series fire retardant, melamine chlorinated isocyanurates, zinc borate, a cross-linked sensitizing agent, a lubricating agent, an antioxidant, a light stabilizer and a copper resisting agent. According to the invention, the photovoltaic cable is manufactured by extruding insulating layer aggregates and jacket layer aggregates on a cable double-layer co-extrusion machine, wrapping the aggregates on the outer surface of a conductor in sequence and carrying out forming, air cooling, coiling andirradiation. The manufacturing method disclosed by the invention has the advantages of good machining property, favorable machining property and low cost and is suitable for industrial production; and the manufactured photovoltaic cable is environment-friendly and has excellent mechanical property, flame radiation resistance performance, thermal ageing property and weather fastness.

Owner:GUANGZHOU KAIHENG SPECIAL WIRE & CABLE

Formula of environment-friendly high-temperature-resisting fabric core rubber conveyer belt and processing technology

ActiveCN103467862AImprove high temperature resistanceHigh temperature fatigue resistanceConveyorsNon-macromolecular adhesive additivesPolymer scienceInternational standard

The invention discloses a formula of an environment-friendly high-temperature-resisting fabric core rubber conveyer belt and a processing technology, and aims to provide the formula of the environment-friendly high-temperature-resisting fabric core rubber conveyer belt which is simple in structure, convenient to use and small in odour, and the processing technology. The formula comprises cover rubber and adhesive rubber. The obtained environment-friendly high-temperature-resisting fabric core rubber conveyer belt has the advantages of superior high-temperature resistance, high high-temperature fatigue performance, high adhesion property and ageing property, and low possibility of ply separation blisters, and has small odour as compared with a conventional high-temperature-resisting rubber conveyer belt, and the conveyer belt can resist the test temperature of not higher than 180 DEG C, and has the highest short-time operation temperature of 450 DEG C, thereby meeting the international standard ISO4195 requirement.

Owner:ZHEJIANG DOUBLE ARROW RUBBER

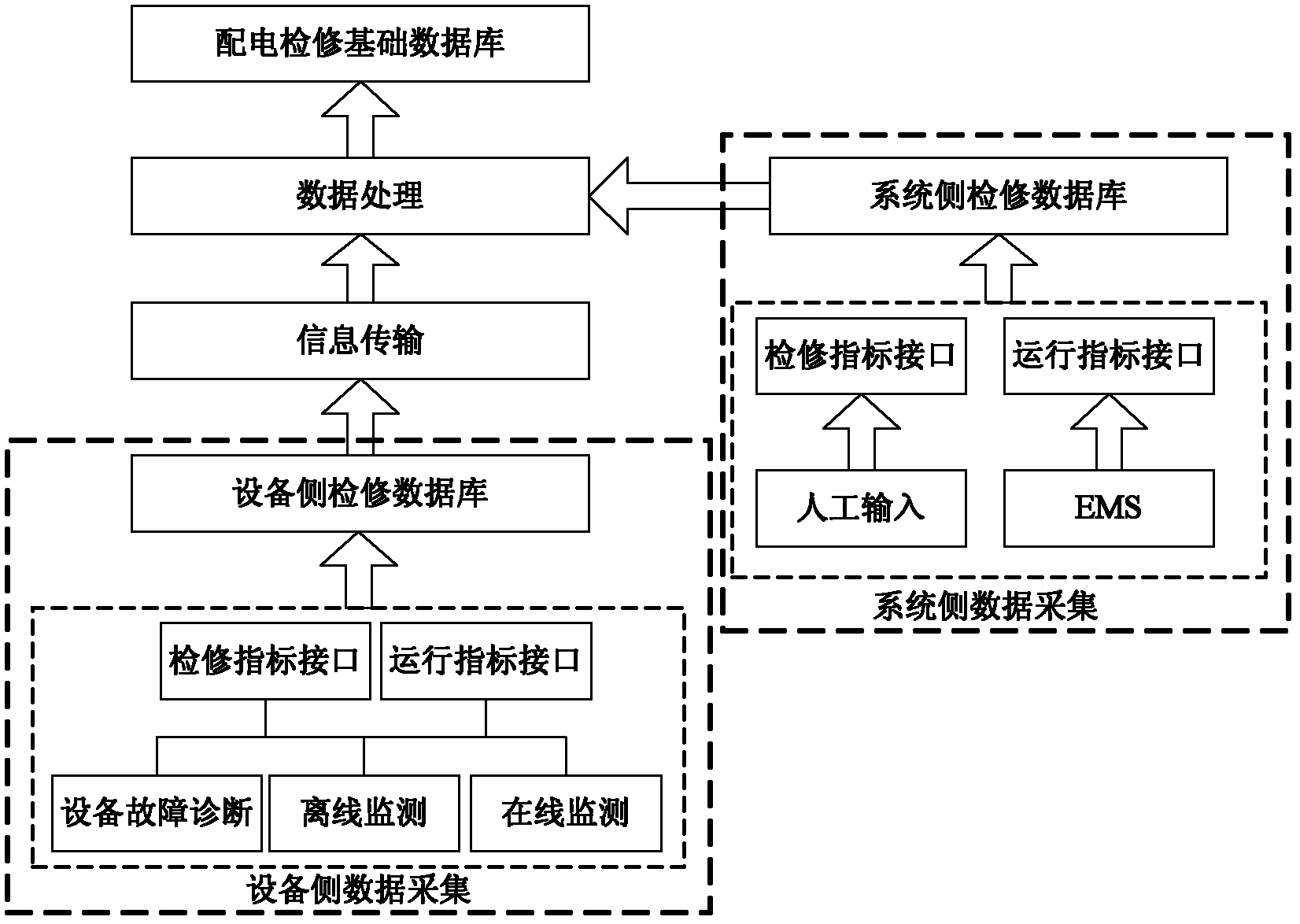

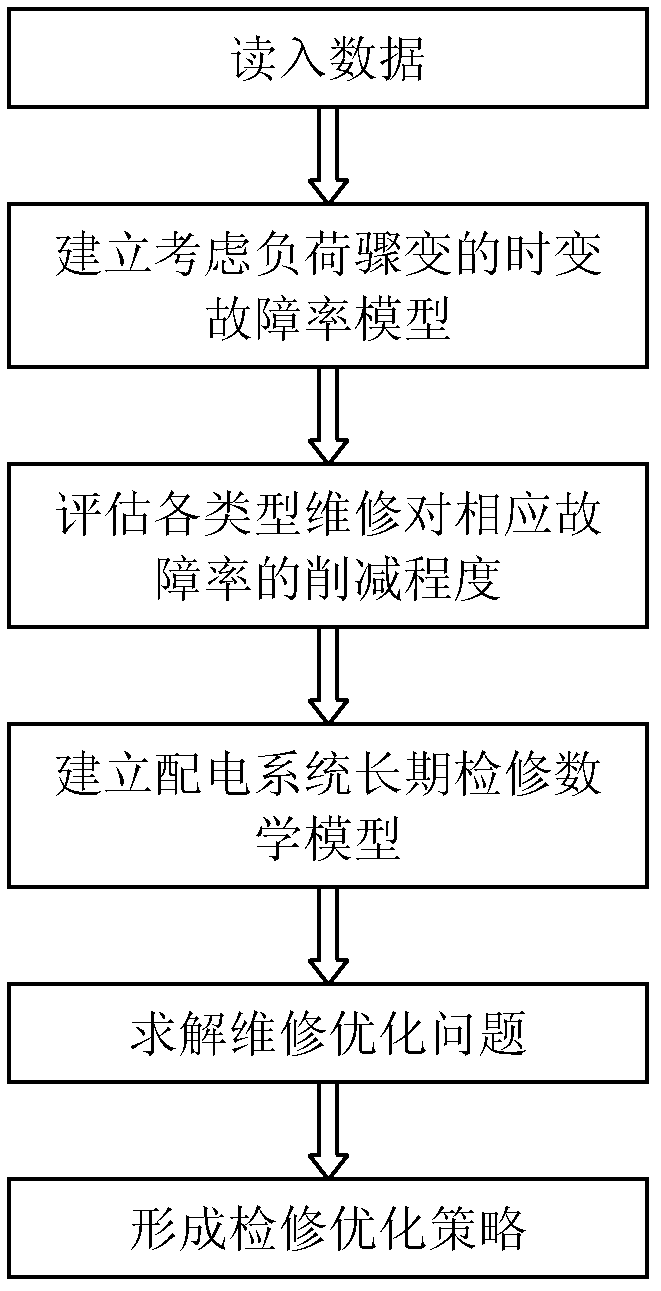

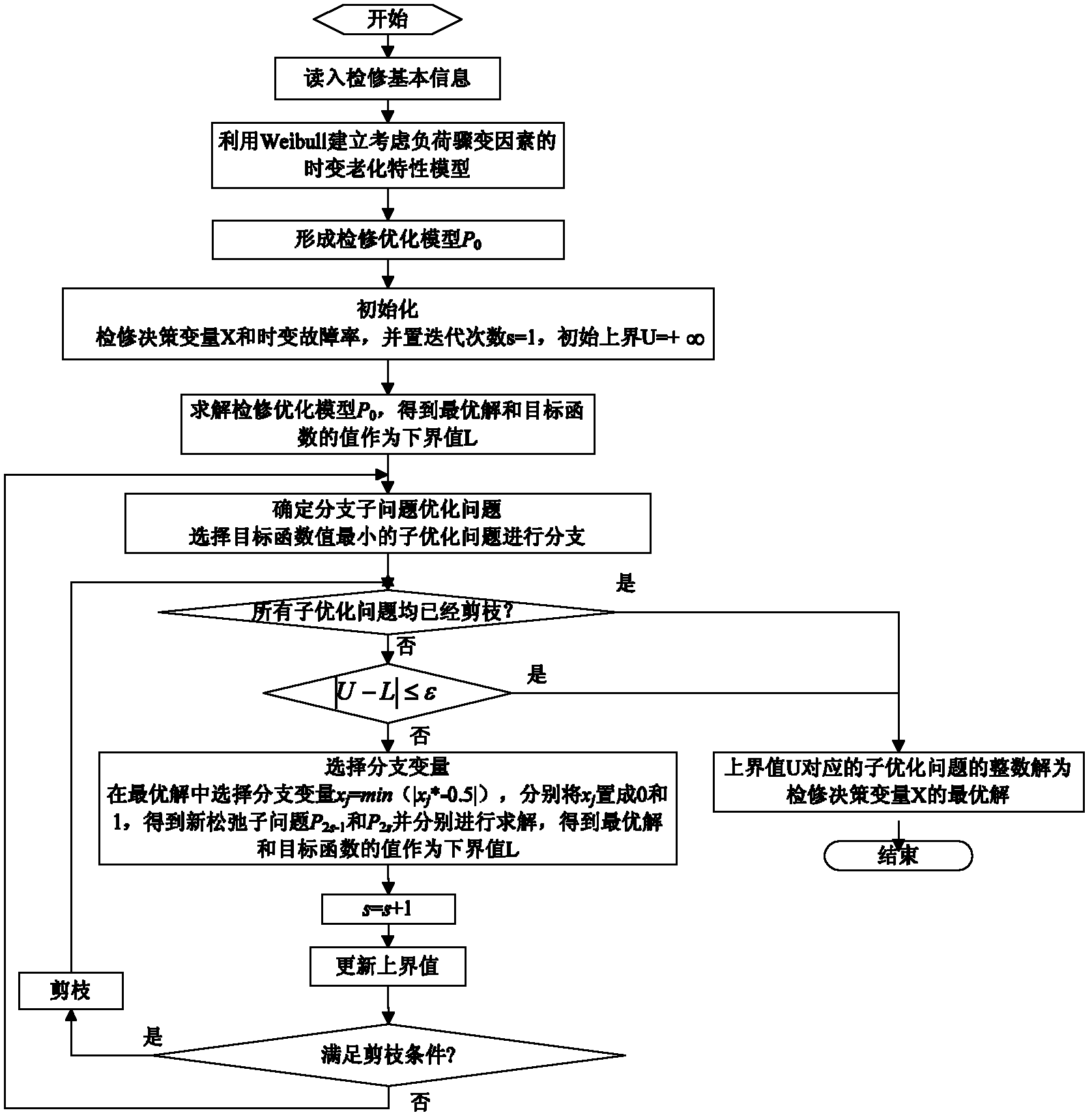

Method for generating long-term maintenance strategy of electric distribution system in view of ageing properties of element

InactiveCN102360467AImprove targetingReduce the blindness of maintenanceData processing applicationsInformation technology support systemFailure rateTransformer

The invention provides a method for generating a long-term maintenance strategy of an electric distribution system in view of ageing properties of an element. The method comprises the following steps of: step 1, collecting information to form a maintenance basic database for electric distribution; step 2, establishing a long-term maintenance optimizing model of the electric distribution system; and step 3, calling the maintenance basic database formed in the step 1, substituting the maintenance basic database into the long-term maintenance optimizing model of the electric distribution system in the step 2, and solving by using a branch-and-bound method to obtain the long-term maintenance strategy of the electric distribution system in view of the ageing properties of the element. From a view point of the electric distribution system, based on a time-variation ageing model of transformer and breaker equipment, the method provided by the invention can be used as a support of an electric distribution automatic system to effectively establish the long-term maintenance strategy of the electric distribution system by taking a minimum sum of a maintenance cost in a maintenance period and a cost caused by faults as a target function, considering losses to users and electric power companies which are caused when the equipment is stopped in the process of maintaining, and comprehensively considering the influence of the maintenance on the improvement of a failure rate of the equipment and the reliability of the system.

Owner:XI AN JIAOTONG UNIV

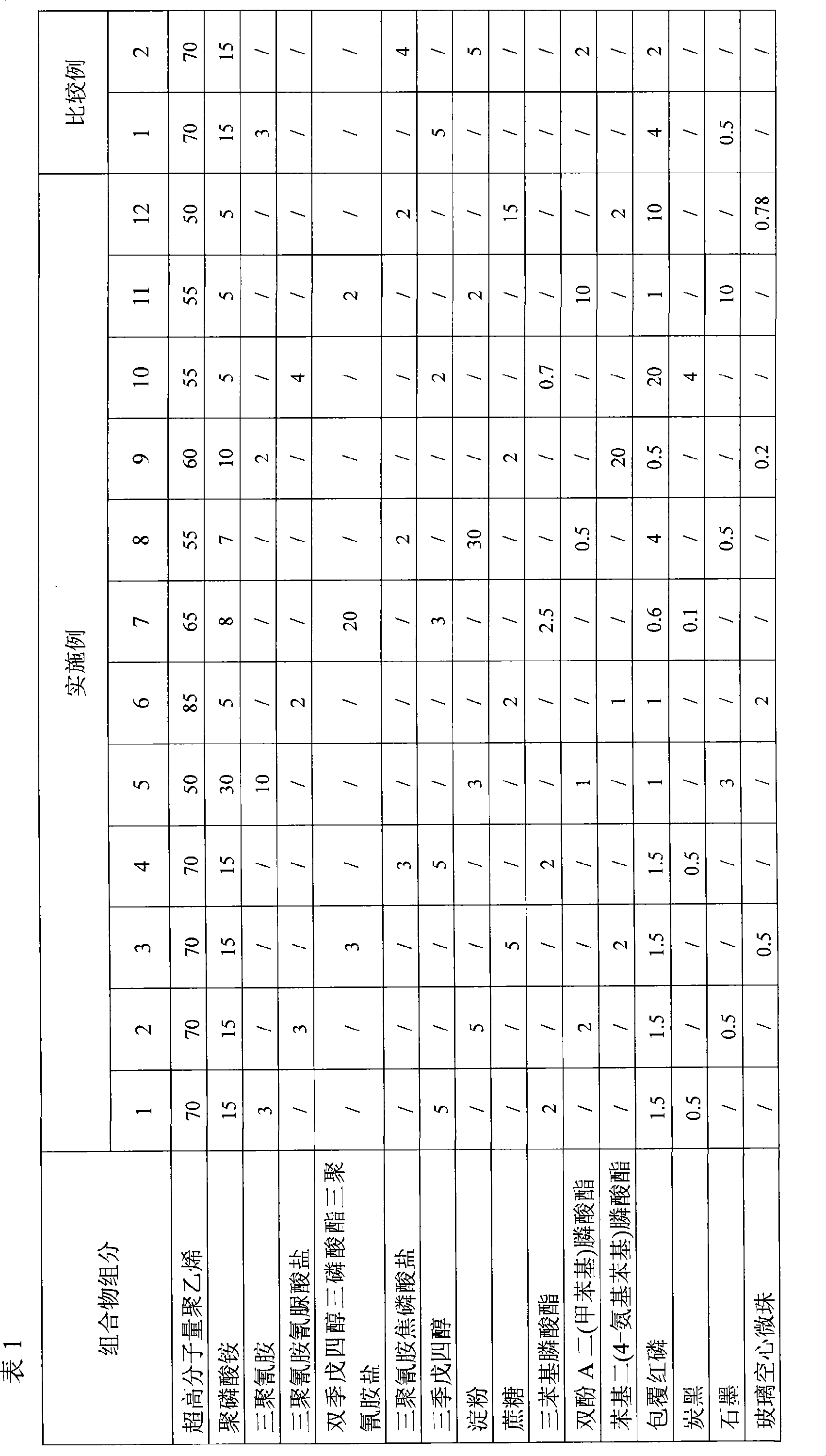

Antistatic halogen-free flame-retardant ultra-high molecular weight polyvinyl composite

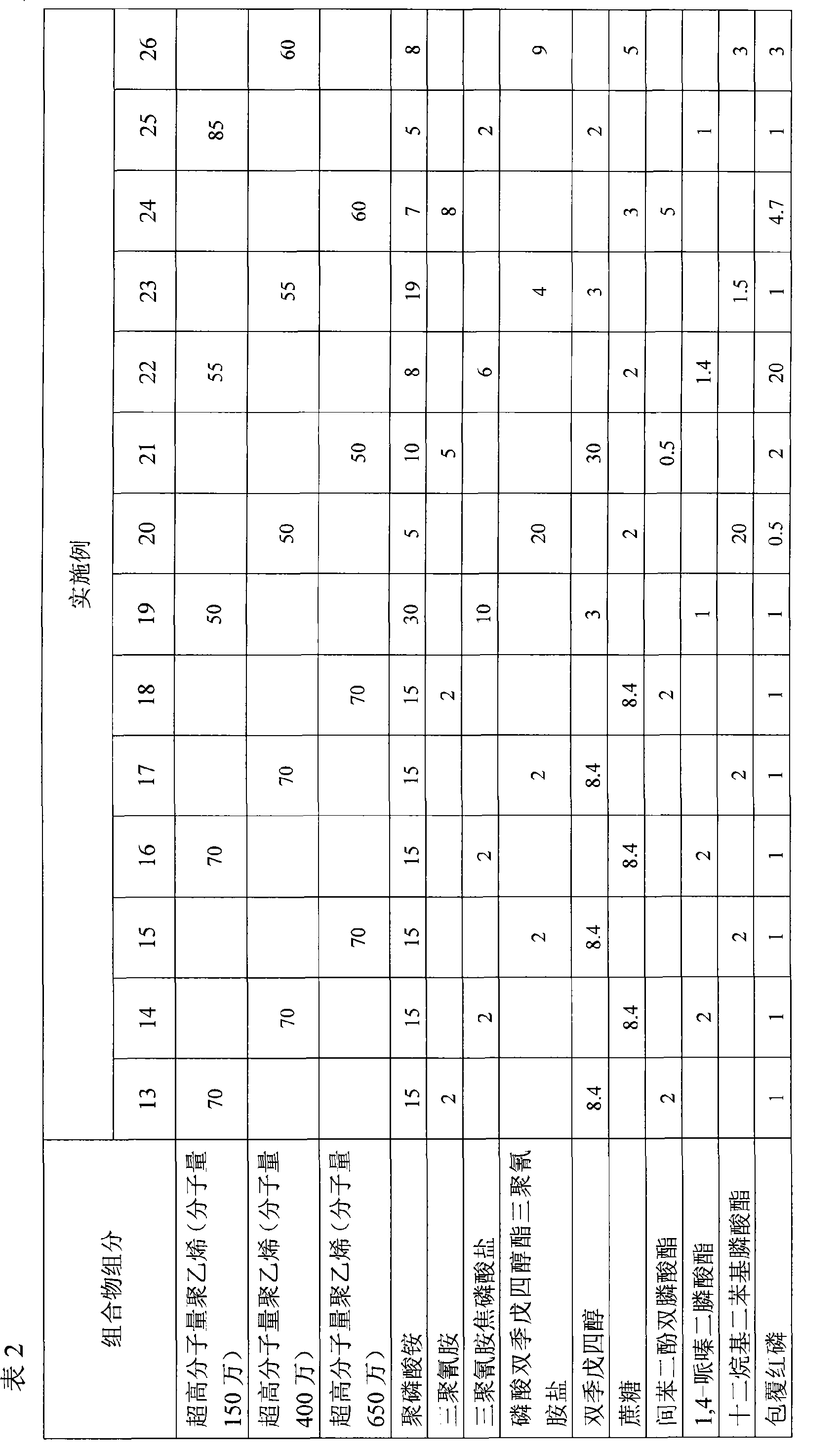

ActiveCN101434723AImprove flame retardant performanceImprove antistatic performanceAntioxidantUltra-high-molecular-weight polyethylene

The invention relates to an antistatic halogen-free fire-retardant super high molecular weight polythene composition. The weight portions of the compositions of the composition are as follows: 50 portions to 85 portions of super high molecular weight polythene, 5 portions to 30 portions of ammonium polyphosphate, 2 portions to 20 portions of melamine and derivatives thereof, 2 portions to 30 portions of polyhydroxy compound, 0.5 portion to 20 portions of phosphonate, 0.5 portion to 20 portions of encapsulated red phosphorus, 0.1 portion to 10 portions of antistatic agent, 0.1 portion to 10 portions of flow modifier, 0.05 portion to 10 portions of dispersant, 0.03portion to 5 portions of coupling agent and 0.02 portion to 5 portions of antioxidant. The composition does not contain halogen, has good fire retardancy and antistatic performance, and does not affect characteristics of the super high molecular weight polythene, i.e., good wearing resistance, anti-aging property and anti-corrosion performance. The composition can meet the needs of products replacing steel with plastics from various aspects.

Owner:SHANGHAI RES INST OF CHEM IND

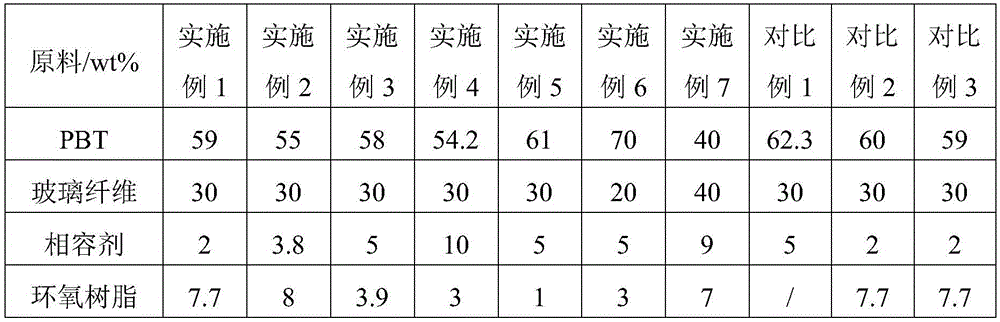

A kind of PBT material with good epoxy resin adhesion and preparation method thereof

Owner:上海日之升科技有限公司

Fast-curing structural adhesive and preparation method thereof

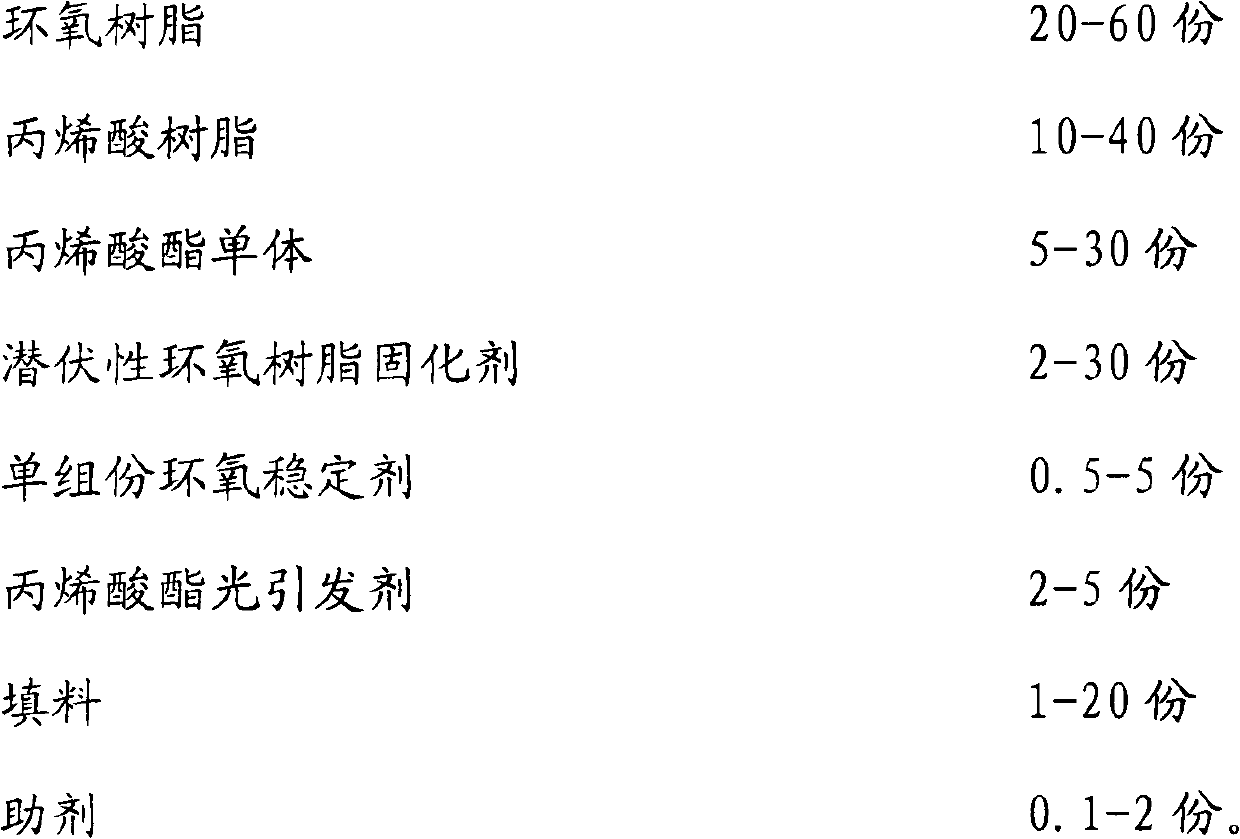

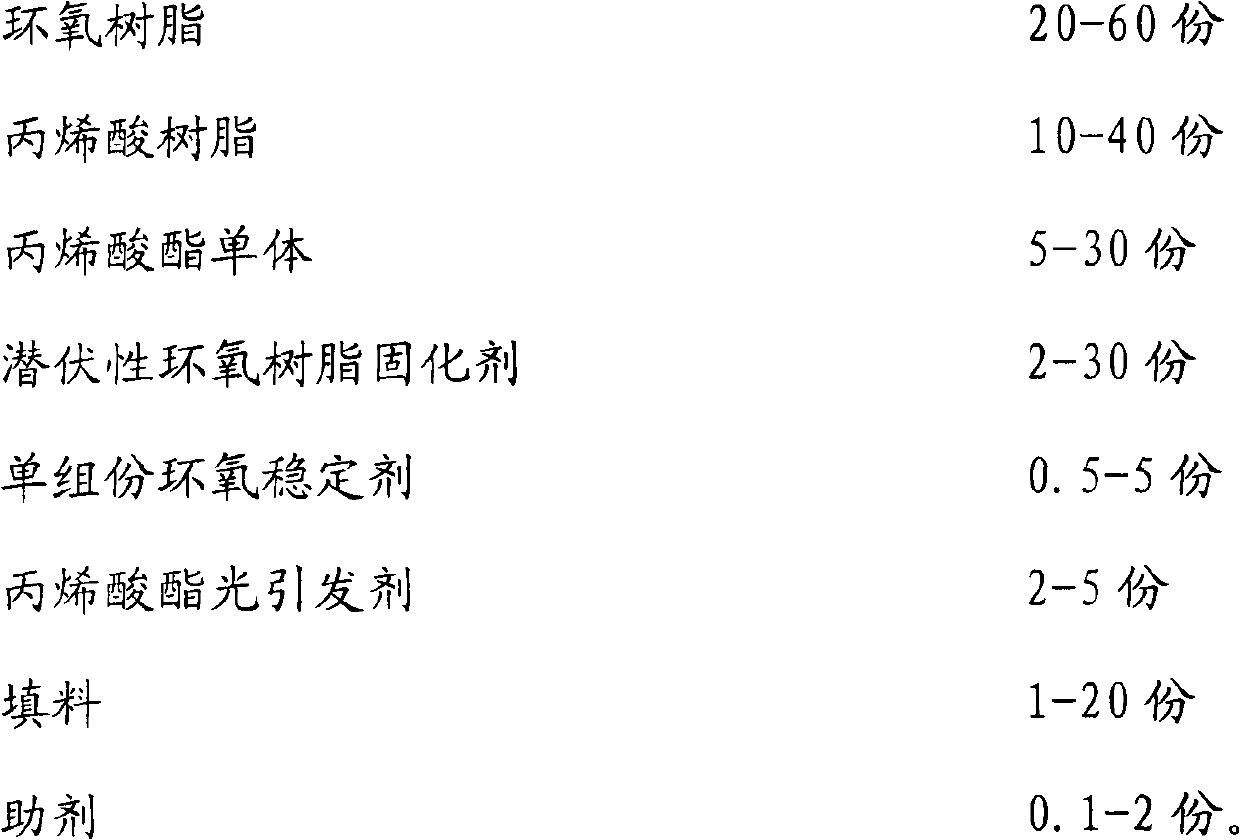

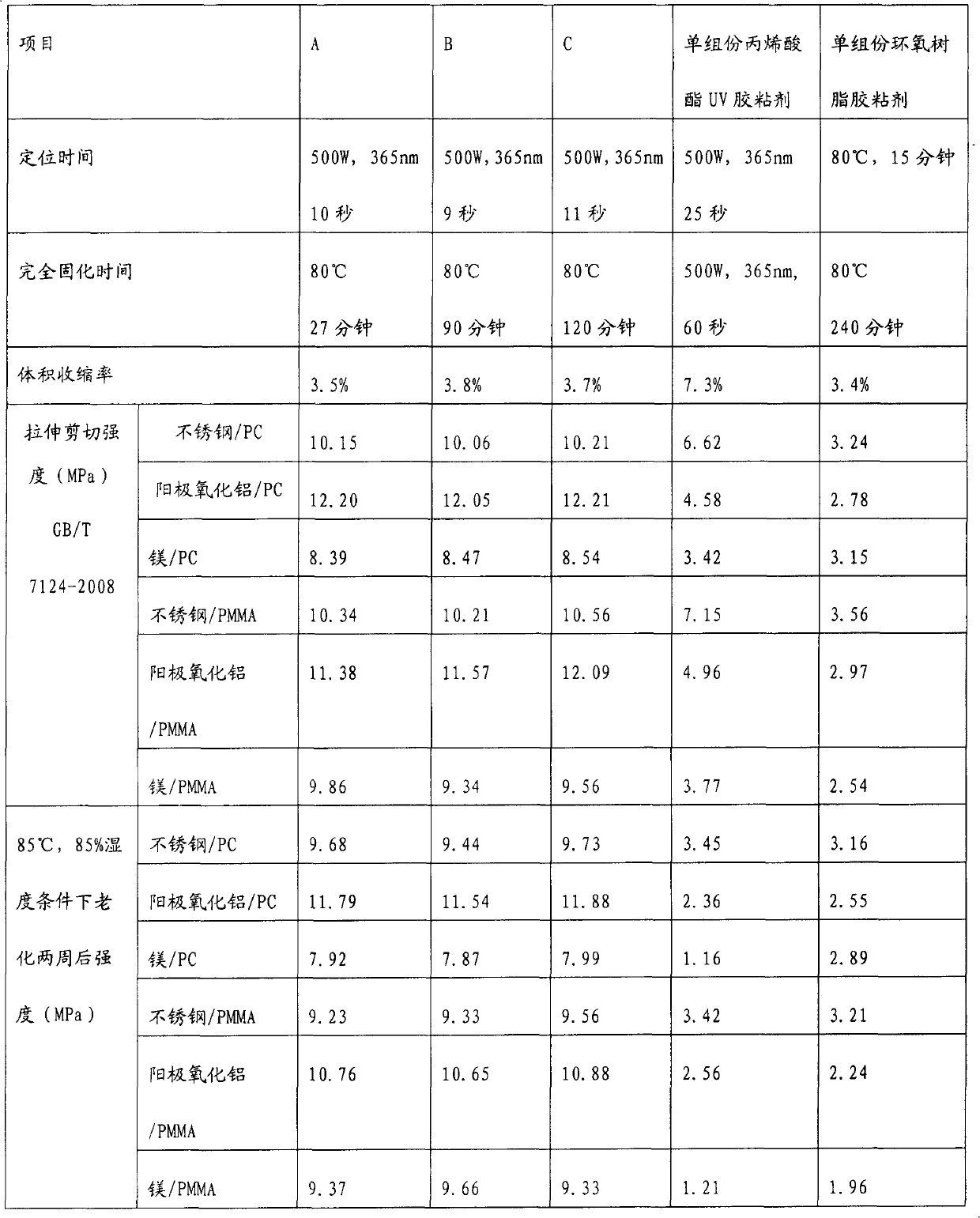

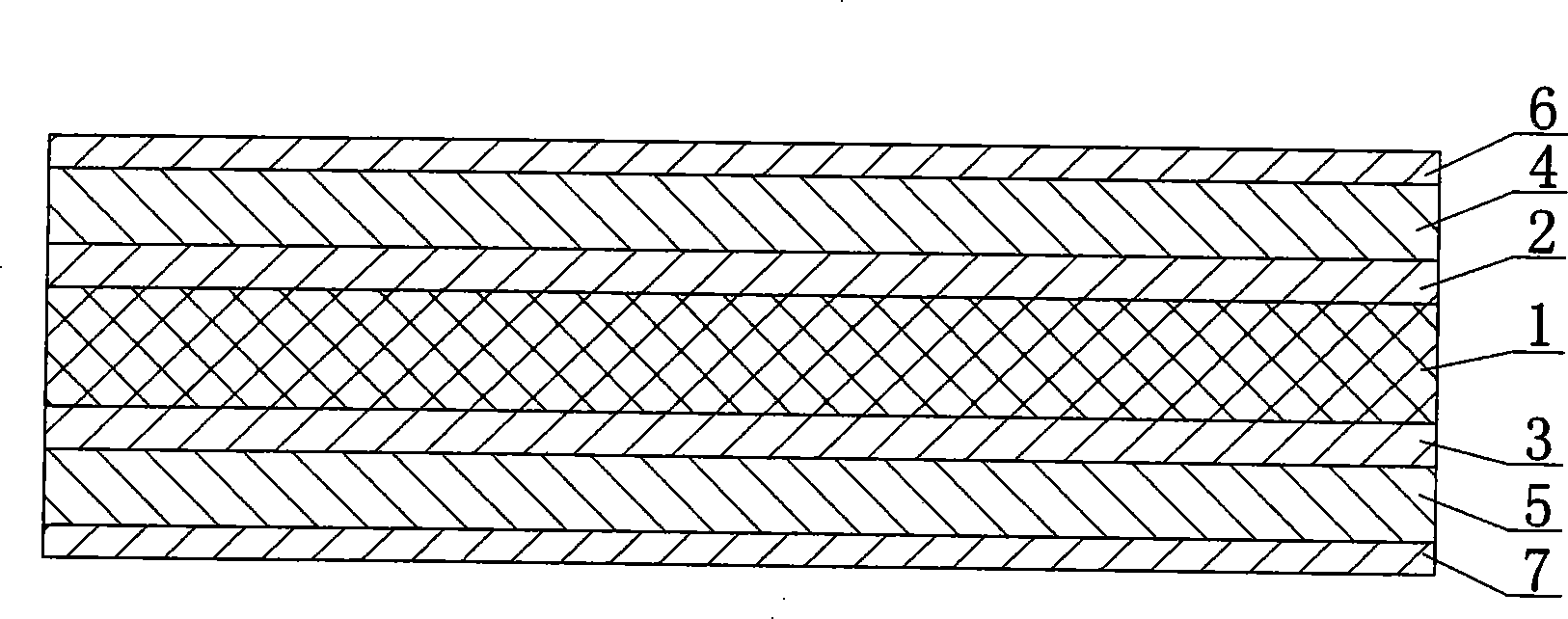

ActiveCN103305132ADoes not affect bond strengthResolution timeOrganic non-macromolecular adhesiveEpoxyAcrylic resin

The invention discloses a fast-curing structural adhesive comprising the following components: 20-60 parts of epoxy resin, 10-40 parts of acrylic resin, 5-30 parts of acrylate monomers, 2-30 parts of a latent epoxy resin curing agent, 0.5-5 parts of an one-component epoxy stabilizer, 2-5 parts of an acrylate photoinitiator, 1-20 parts of fillers, and 0.1-2 parts of an auxiliary agent. The invention further discloses a preparation method of the fast-curing structural adhesive. The fast-curing structural adhesive prepared according to the components and the preparation method effectively solves defects and insufficiencies of long positioning time and fully cured time, and poor resistance to heat aging properties.

Owner:塔威新材料科技(上海)有限公司

Method for preparing polytetrafluoroethylene spatial structure building film material

The invention relates to a producing method of a teflon spatial structure membrane comprising following steps: fiberglass cloth low temperature genapping treatment, fiberglass cloth bottom layer dipping treatment, structure layer dipping treatment, surface layer dipping treatment and sintering treatment. Low temperature high speed genapping, multitime coating low-temperature treatment, and once hyperthermia flash sintering effectively reduce tensile strength descending caused by high-sintering treatment. Since fiberglass cloth is used as backing material, dipping treatment is not needed to be performed on the fiberglass yarn, the procedure is simplified to facilitate the production thereof, and shortcomings in prior art are overcome which are modified fiberglass yarn weaving difficulty and intensity and plasticity descending caused by multitime sintering. The teflon spatial structure membrane produced by using the invented method has a bottom layer, a structure layer and a surface layer, is provided with high pulling-against intensity, high tearing-against intensity, anti-aging property, good flexibility, good light-admitting quality and a long service life, and can be used widely in air stations, gymnasiums, exhibition halls, large-scale factory buildings and factory building warehouses.

Owner:JIANGSU VEIK TECH & MATERIALS CO LTD

1E-level K1-type shrinkable tube used in nuclear power station and preparation method thereof

ActiveCN101661803AImprove flame retardant performanceImprove heat aging resistanceNuclear energy generationContainmentAging propertyFire retardant

The invention relates to a 1E-level K1-type shrinkable tube used in a nuclear power station, which comprises the following components by weight: 40 to 60 parts of base resin, 40 to 60 parts of hexyl-propyl rubber, 30 to 60 parts of flame retardant, 5 to 20 parts of antiradiation agent, 4 to 12 parts of antioxidizer, 2 to 5 parts of lubricant, and 3 to 8 parts of color masterbatch. The preparationmethod of the 1E-level K1-type shrinkable tube used in the nuclear power station comprises the following steps of: taking all the components by weight, carrying out mixed granulation by banburying ormixed granulation by a parallel double-screw extruder, then using a single-screw extruder for extrusion to form the tube, and carrying out radiation cross linking of cobalt 60 or electron accelerator50-180KGy to the tube, wherein the tube after the radiation cross linking expands by 2 to 6 times at the temperature of 90 to 150 DEG C. The shrinkable tube reaches and far exceeds the performance requirement of the 1E-level K1-type shrinkable tube used in the nuclear power station. The 1E-level K1-type shrinkable tube used in the nuclear power station has good flame retardant properties, can passV W-1 combustion test; has excellent heat-proof aging property, with the tensile strength and elongation at break of the product far stronger than the performance requirement; and outstanding intenseradiation-resistant function, and can pass AC withstand voltage test.

Owner:CHANGYUAN ELECTRONICS DONGGUAN +1

Reinforced toughening anti-aging polypropylene/nano calcium carbonate composite material and its preparation method

The invention discloses a reinforced toughened anti-aging PP / nano-calcium carbonate composite material, consisting of (weight parts) PP resin 100, composite coupling agent 2-30, long glass fibers 2-30, composite toughener 5-40, nano-fillers 5-40, composite antioxidants 0.2-2, and processing aids 0.5-5. This composite material not only retains the original fine performances of polypropylene resin, but also improves markedly the physical and mechanical properties, thermal aging properties by using nanomaterial / new antioxidant synthetic modification technology. This invention also discloses the preparation method for reinforced toughened anti-aging PP / nano-calcium carbonate composite material.

Owner:哈尔滨鑫达高分子材料股份有限公司

PVC profile outer cover used in base station antenna and preparation method thereof

ActiveCN101635385AImproves UV resistanceImprove impact toughnessRadiating element housingsUltravioletEngineering

The invention discloses a PVC profile outer cover used in a base station antenna and a preparation method thereof, which can not only improve the mechanical property, but also greatly improve high and low temperature resistant ageing property and ultraviolet ray resistant property, and greatly improve the electrical property of the material simultaneously. The PVC profile outer cover used in the base station antenna in the invention is manufactured by the following raw materials according to the mass ratio: 100 parts of PVC, 4-10 parts of inorganic modified padding, 0-10 parts of calcium carbonate, 1-2 parts of organic stannum stabilizing agent; 1-2 parts of metal soap stabilizing agent, 0.5-1.5 parts of lubricating agent, 4-12 parts of impact modifier, 1-3 parts of acrylic ester processing agent and 0-0.6 part of light stabilizer.

Owner:NANJING UNIV OF TECH +1

Silane crosslinked halogen-free flame-retardant polyethylene cable material and preparation method thereof

InactiveCN101880417AAffect mechanicsAffect appearancePlastic/resin/waxes insulatorsInsulated cablesLow-density polyethyleneAntioxidant

The invention relates to a silane crosslinked halogen-free flame-retardant polyethylene cable material and a preparation method thereof. The technical scheme of the invention is as follows: 45 to 65 percent by weight of low-density polyethylene, 5 to 10 percent by weight of ethylene-vinylacetate copolymer, 2 to 5 percent by weight of silane with the general formula of RSi(OR')3, 0.1 to 0.5 percent by weight of peroxide initiator, 0.01 to 0.1 percent by weight of crosslinked catalyst, 15 to 30 percent by weight of modified nano Mg(OH)2, 5 to 15 percent by weight of ammonium polyphosphate and 0.5 to 1 percent by weight of antioxidant 1010 are mixed under the temperature of 150DEG C to 160DEG C, and after pelleting, the cable material is produced. The materials can be easily obtained, the technique is simple, the oxygen index of the prepared cable material is 32.5 to 36, the tensile strength is 12MP to 15MP, and the elongation at break is 415 to 450 percent. Consequently, the cable material is characterized by high tensile strength, high elongation at break, high anti-aging property and high temperature resistance, and cannot harm the environment when being discarded.

Owner:WUHAN XINTIANDI SPECIAL CABLE +2

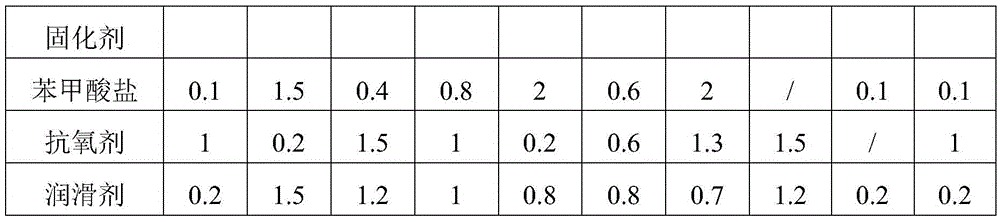

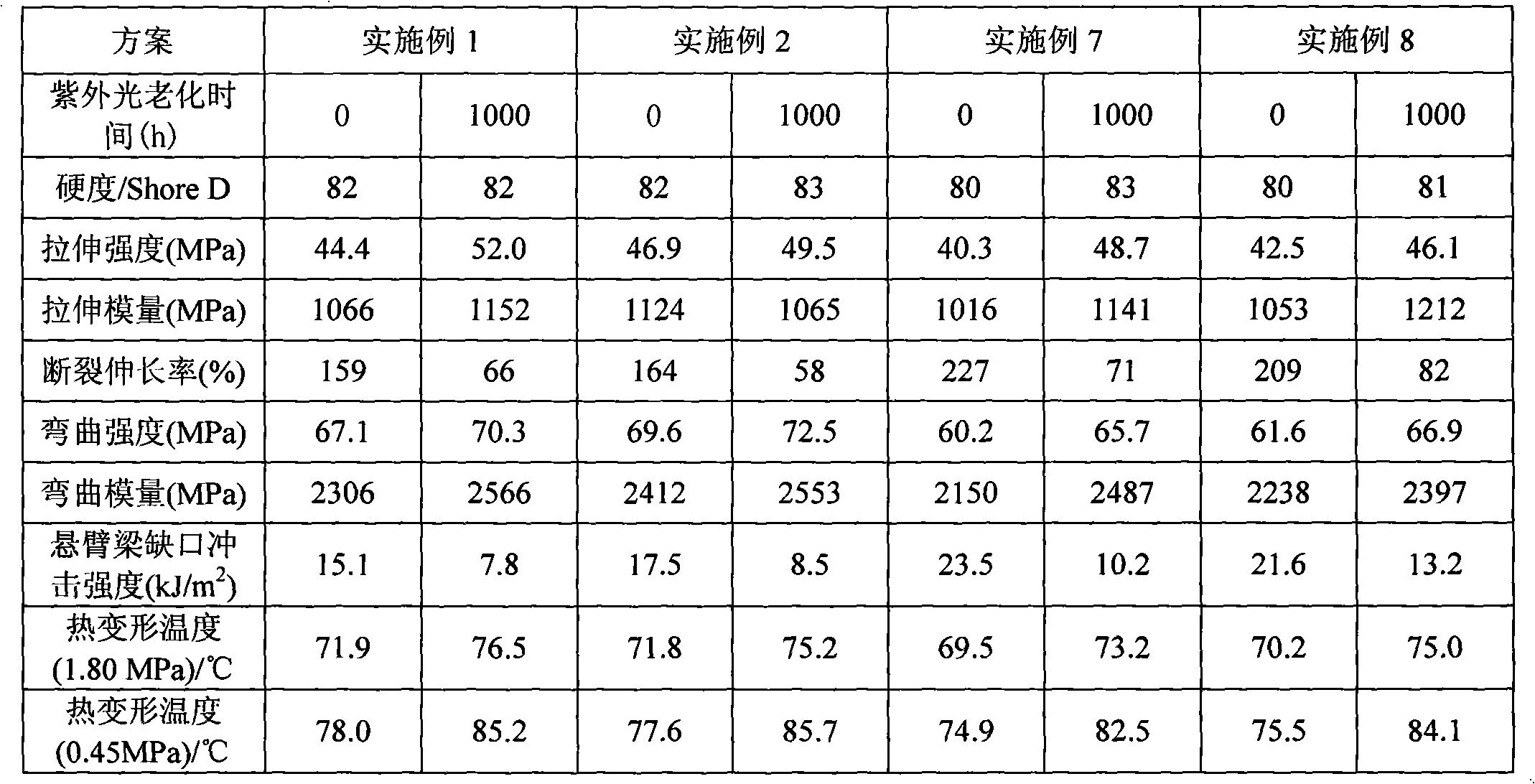

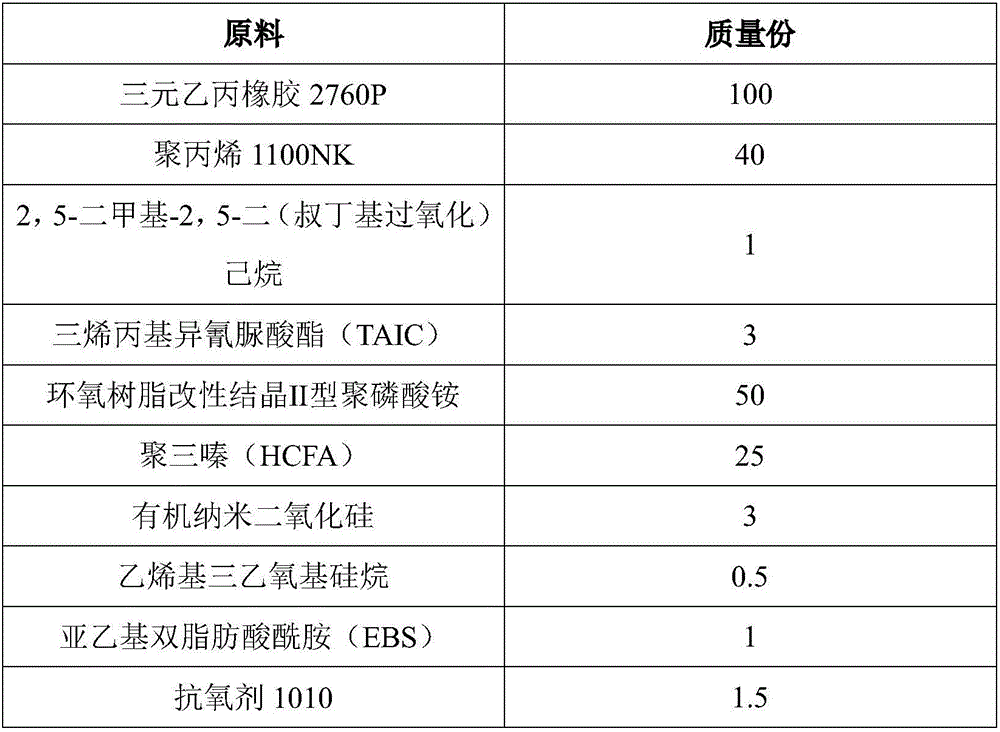

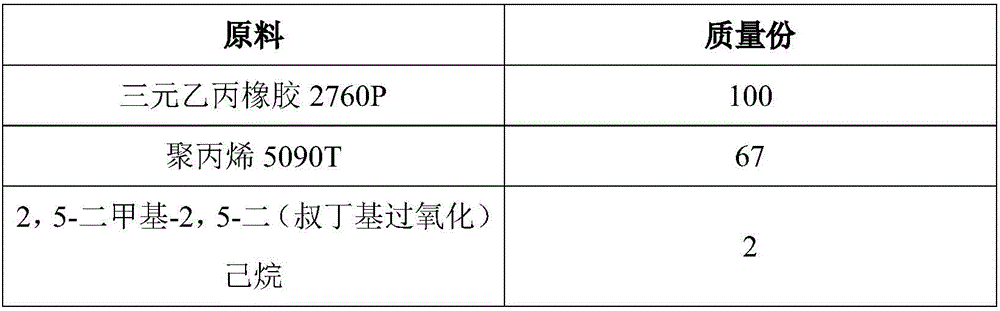

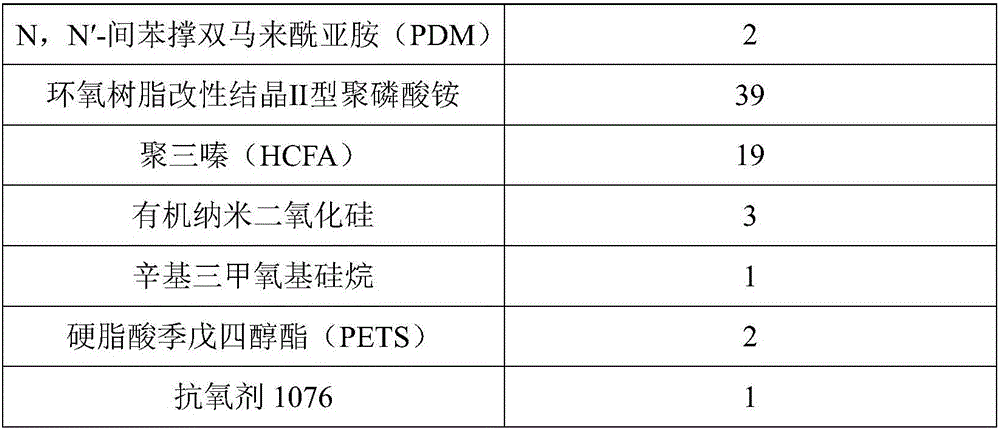

Halogen-free flame retardant dynamically vulcanized EPDM/PP thermoplastic elastomer and preparation method thereof

InactiveCN106589618AImprove flame retardant performanceImprove mechanical propertiesHydrolysisPolypropylene

The invention discloses a halogen-free flame retardant dynamically vulcanized EPDM / PP thermoplastic elastomer and a preparation method thereof. The EPDM / PP thermoplastic elastomer is prepared from, by mass, 100 parts of EPDM, 40-80 parts of polypropylene, 1-3 parts of crosslinking agent, 1-3 parts of auxiliary crosslinking agent, 44-78 parts of composite halogen-free flame retardant agent, 0.5-1 part of silane coupling agent, 1-2 parts of lubricant, and 1-2 parts of anti-oxidant. The preparation method comprises the steps of firstly mixing uniformly the composite halogen-free flame retardant agent and the silane coupling agent, adding EPDM, PP and lubricant, alloying, plasticizing the mixture, extruding, granulating, and finally adding the crosslinking agent, auxiliary crosslinking agent and the anti-oxidant, alloying, plasticizing, extruding the mixture and granulating. The EPDM / PP thermoplastic elastomer not only has a good flame retardant property which can attain the flame retardant level of UL94-V0, but also has an excellent mechanical property, anti-aging property and hydrolysis resistance. The halogen-free flame retardant dynamically vulcanized EPDM / PP thermoplastic elastomer has the advantages of being simple in preparation process, low in production cost, and easy for industrialized production.

Owner:GUANGDONG RES INSTITITUTE OF PETROCHEM & FINE CHEM ENG

Hot-fusible adhesive and method for preparing same

ActiveCN101307214AReduce melt viscosityHigh bonding strengthMineral oil hydrocarbon copolymer adhesivesOil/fat/wax adhesivesWaxPlasticizer

The invention provides a high temperature resistant hot melt adhesive which is made from an elastic body, synthesized high melting-point wax, synthetic resin, a plasticizer and an antioxidizer. The hot melt adhesive has high softening point, strong adhesive attraction and penetrability, and appropriate viscosity. The hot melt adhesive is used to splice a device; and the use method is simple and convenient, the device splicing is firm, and the high temperature resistant property and the anti-aging property are good. The product does not contain a poisonous solvent, thereby belonging to an environmental-friendly product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing chlorinated polyethylene modified butadiene acrylonitrile rubber foaming material

InactiveCN101215391AImproved ozone resistance and heat aging resistanceImprove flame retardant performanceNitrile rubberAcrylonitrile

The invention provides a CPE modified nitrile rubber forming material which has the advantages of environmental protection, low cost and wide application scope and a process for preparation. The process of the invention comprises adopting nitrile rubber 100 portions which is added with chlorinated polyethylene which is 10-100 portions, vulcanizing agent 1-5 portions, catalyst 1-3 portions, main forming agent 5-15 portions and composite regulating forming agent 1-8 portions in 100-190 DEG C to heat up for 10-100 minutes according to the weight portions, and getting modified nitrile rubber (NBR) forming material. The invention has the advantages of dramatically improving ozone proof and heat aging properties of the NBR forming material, promoting fire retardancy, abrasive resistance, and tensile strength of the NBR foaming material, obviously lowering production cost of the NBR foaming material, and meanwhile, keeping excellent manufacturing technique property, and having better environment-friendly properties, having excellent physical properties, bubble hole stability, simple technique and easy control.

Owner:谭成章

Laminated nanometer clay/waste rubber power composite modified asphalt material and preparation method thereof

InactiveCN104212191ASimple internal structureImprove performanceBuilding insulationsWaste rubberBituminous materials

The invention relates to a laminated nanometer clay / waste rubber power composite modified asphalt material and a preparation method thereof. The composite modified asphalt material comprises the following components in percentage by mass: 100 parts of matrix asphalt, 1-7 parts of laminated nanometer clay, 5-20 parts of waste rubber power and 1-5 parts of furfural extract oil. The laminated nanometer clay and the waste rubber power are adopted as modifiers for the matrix asphalt, a shear emulsifying machine is adopted as a dispersing device and a melt blending method is adopted in the preparation method. The preparation method comprises the following specific steps: heating until raw materials are molten and carrying out shear mixing. The composite modified asphalt material prepared by the preparation method has the advantages of excellent anti-rutting property, excellent UV aging property and storage stability. The preparation method has the characteristics of cheap raw materials, simple process and the like and provides an economical and environment-friendly solution for subsequent processing of waste tires. The composite modified asphalt material can be used in the fields of pavement of high-grade road surface, such as bridge and airport, construction and the like.

Owner:SOUTH CHINA UNIV OF TECH

Rubber framework grease seal for automobile gear box and manufacturing method thereof

InactiveCN101319082APrevent leakageSolve the problem of oil leakageEngine sealsDomestic articlesSodium stearateSulfur

The invention provides a rubber framework oil seal used for a gear box of an automobile and a manufacturing method thereof. The rubber framework oil seal comprises the following compositions in weight portion: 100 portions of activated chlorine type acrylate adhesive AR840, 0.5 to 1 portion of a vulcanizing activator stearic acid, 1.5 to 2 portions of a process additive TM-80, 2 to 3 portions of a vulcanizing agent sodium stearate, 0.5 to 0.6 portion of an accelerating agent sulfur and potassium stearate, 1 to 2 portions of an age inhibitor 445, 1 to 2 portions of MB, 4 to 6 portions of a strengthening agent carbon soot and 22 to 28 portions of a siliceous reinforcing agent. The rubber framework oil seal has the characteristics of stable size of hypoid gear oil of the gear box, oil resistance, anti-aging property, and sealing reliability, etc.

Owner:青岛茂林橡胶制品有限公司

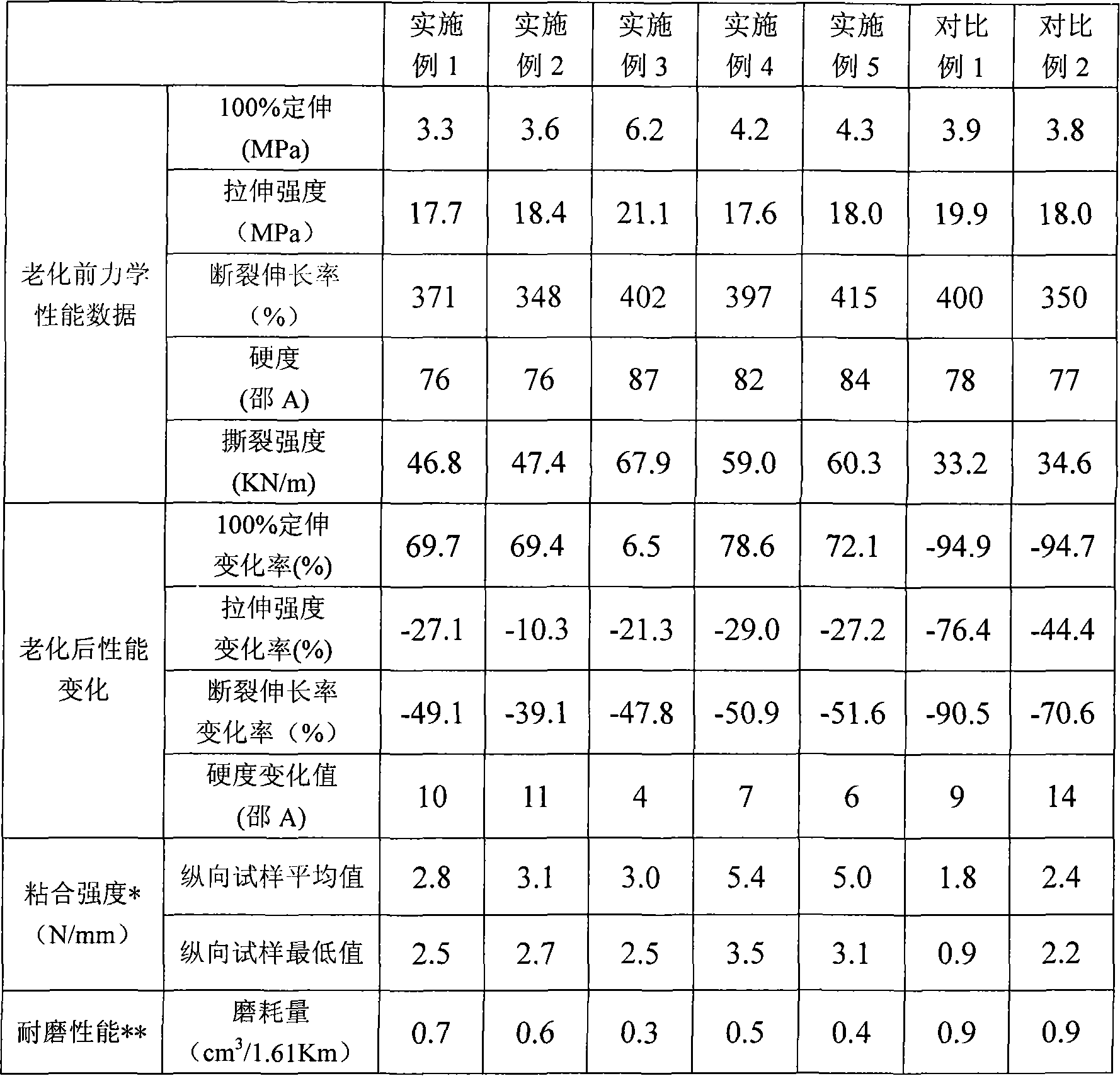

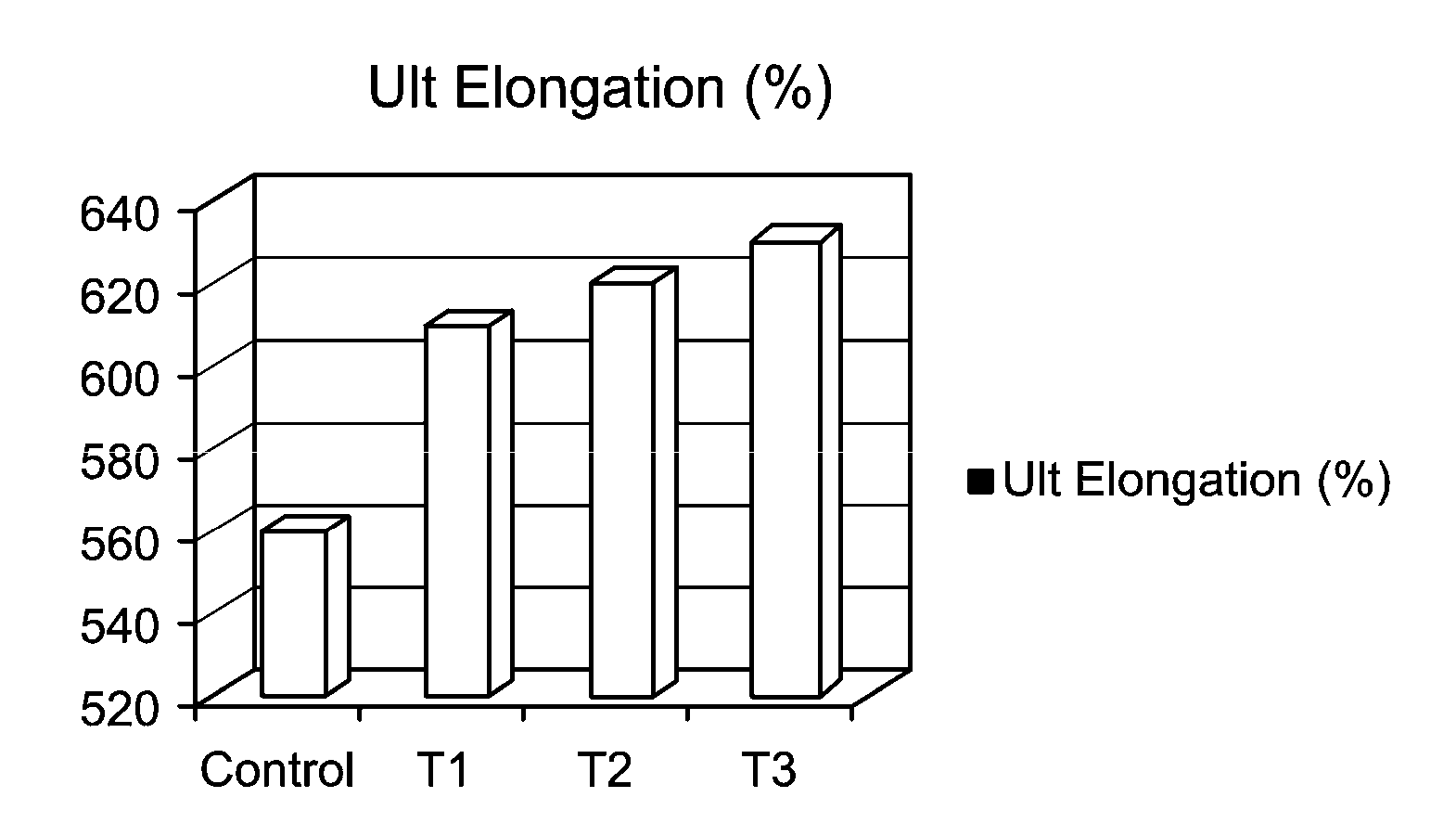

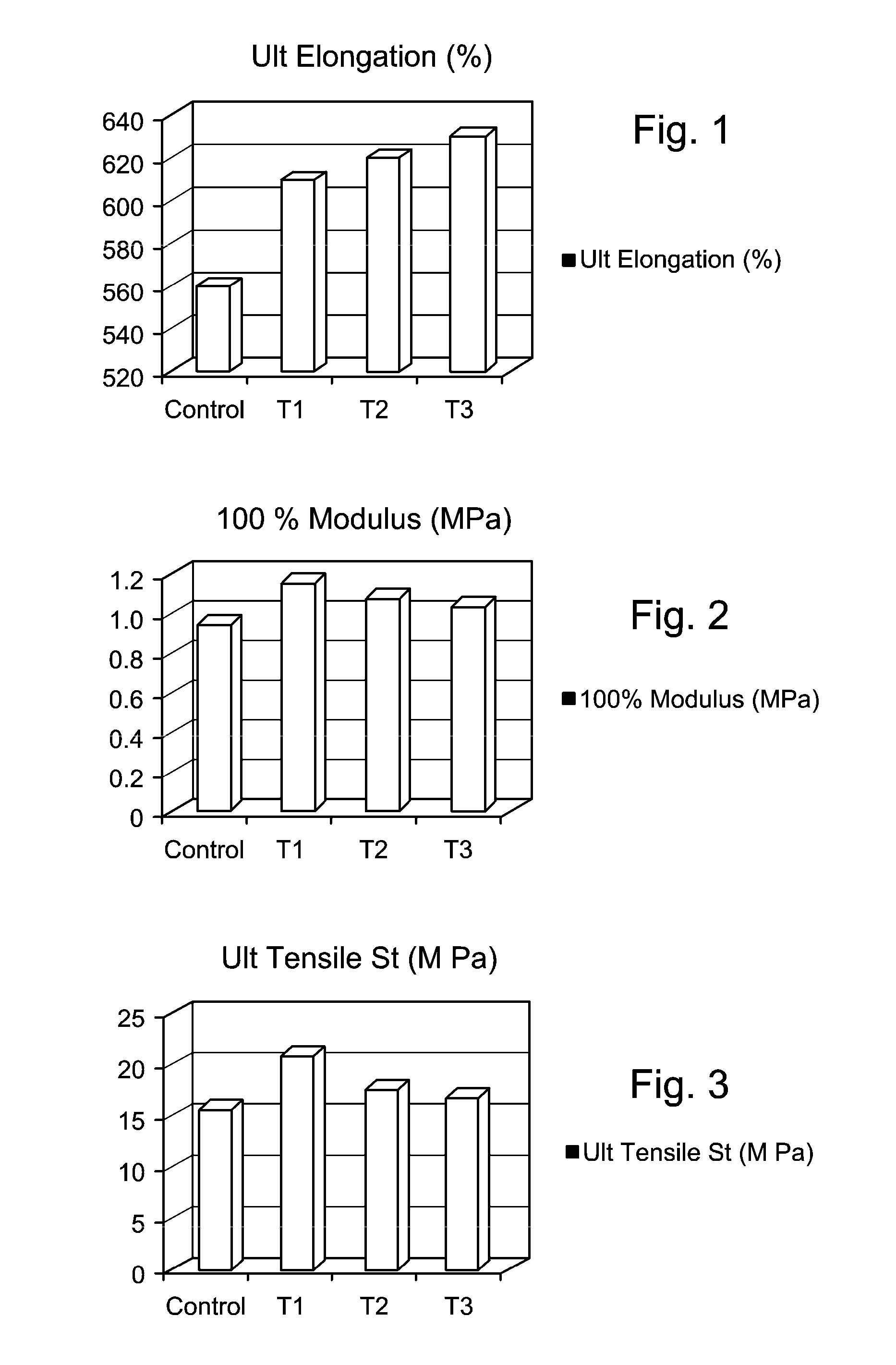

Latex film compound with improved tear resistance

InactiveUS7048977B2Increase elasticityIncrease resistanceClosuresClosure using stoppers2-mercaptobenzimidazoleAntioxidant

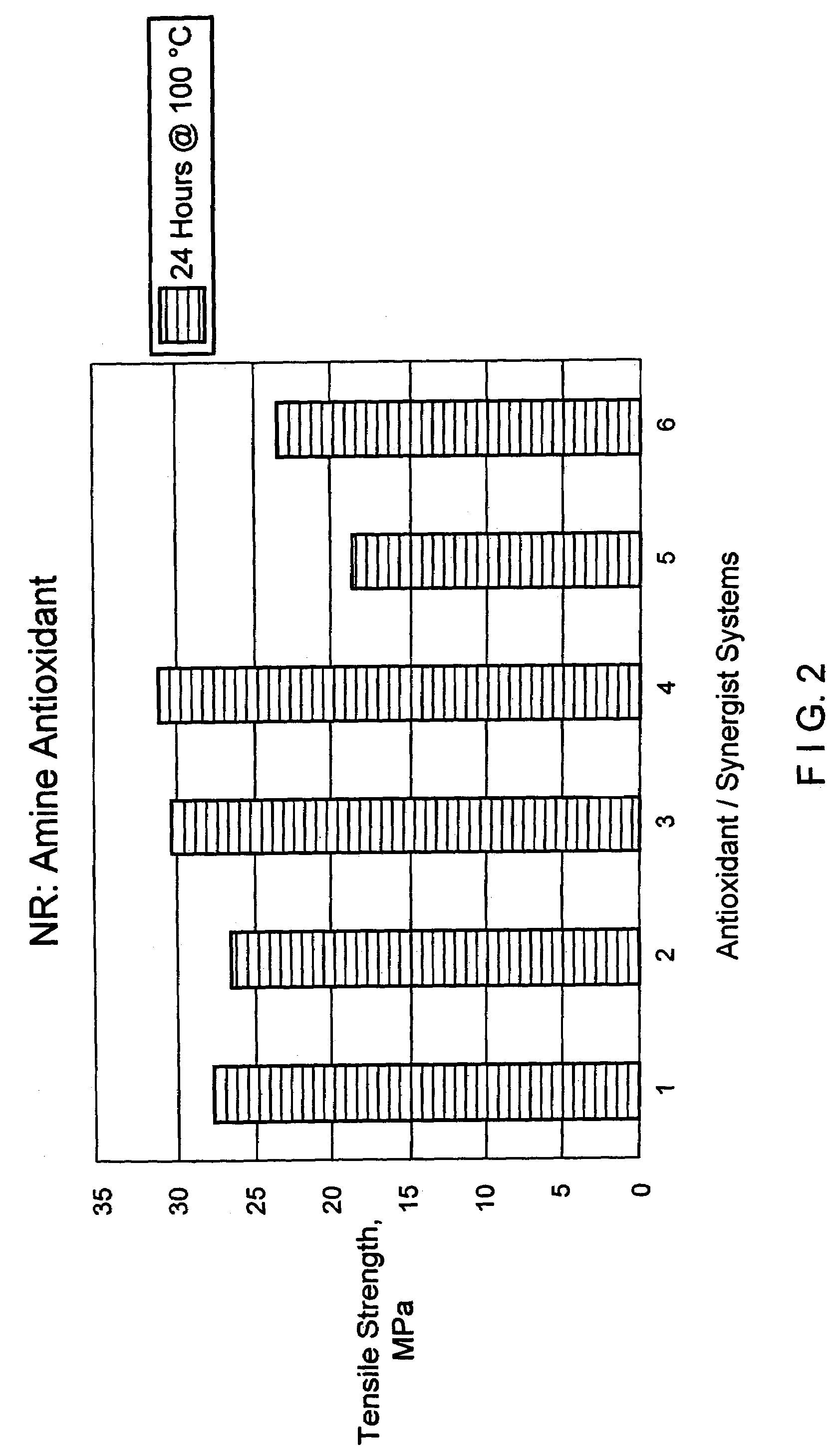

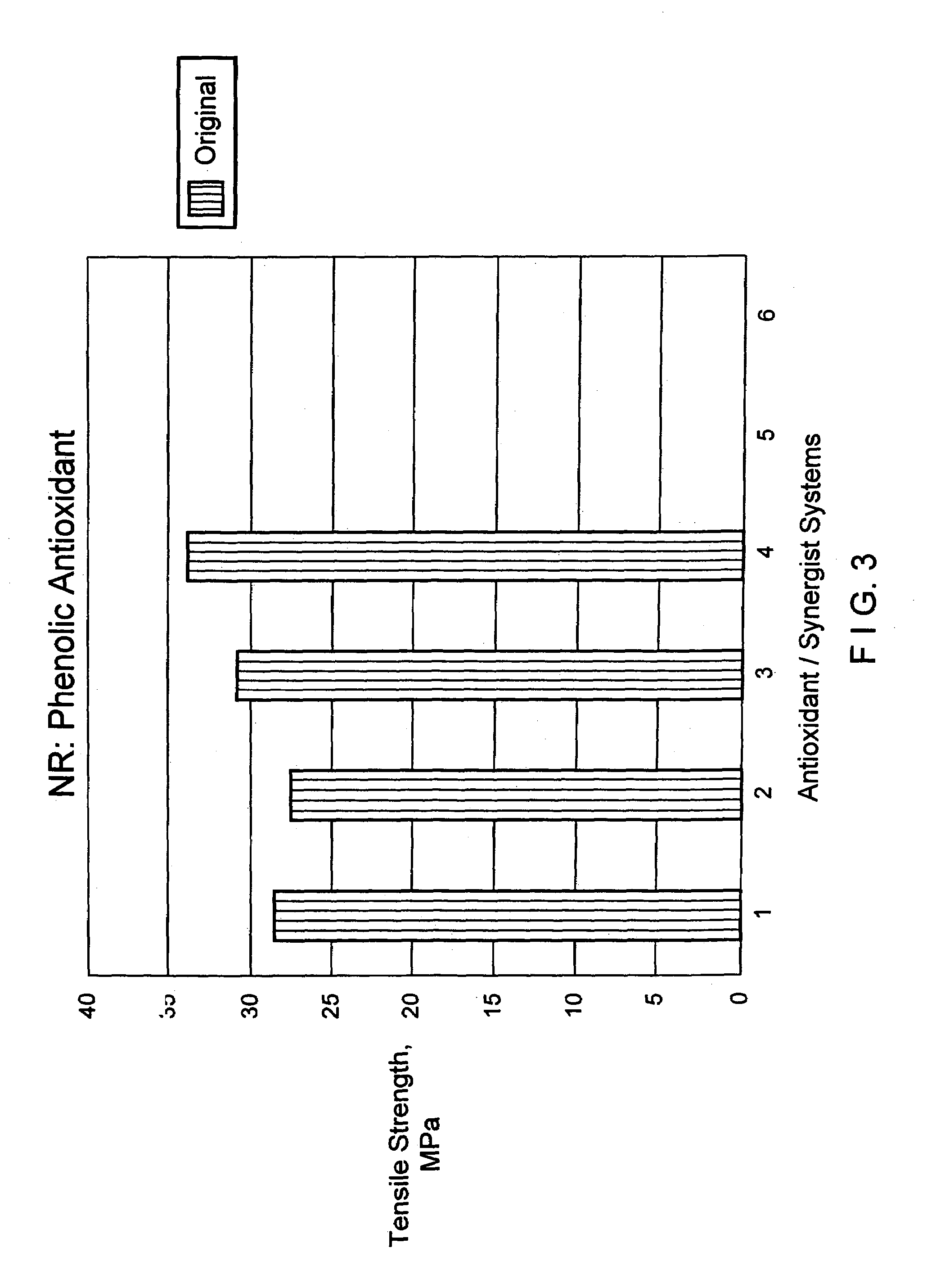

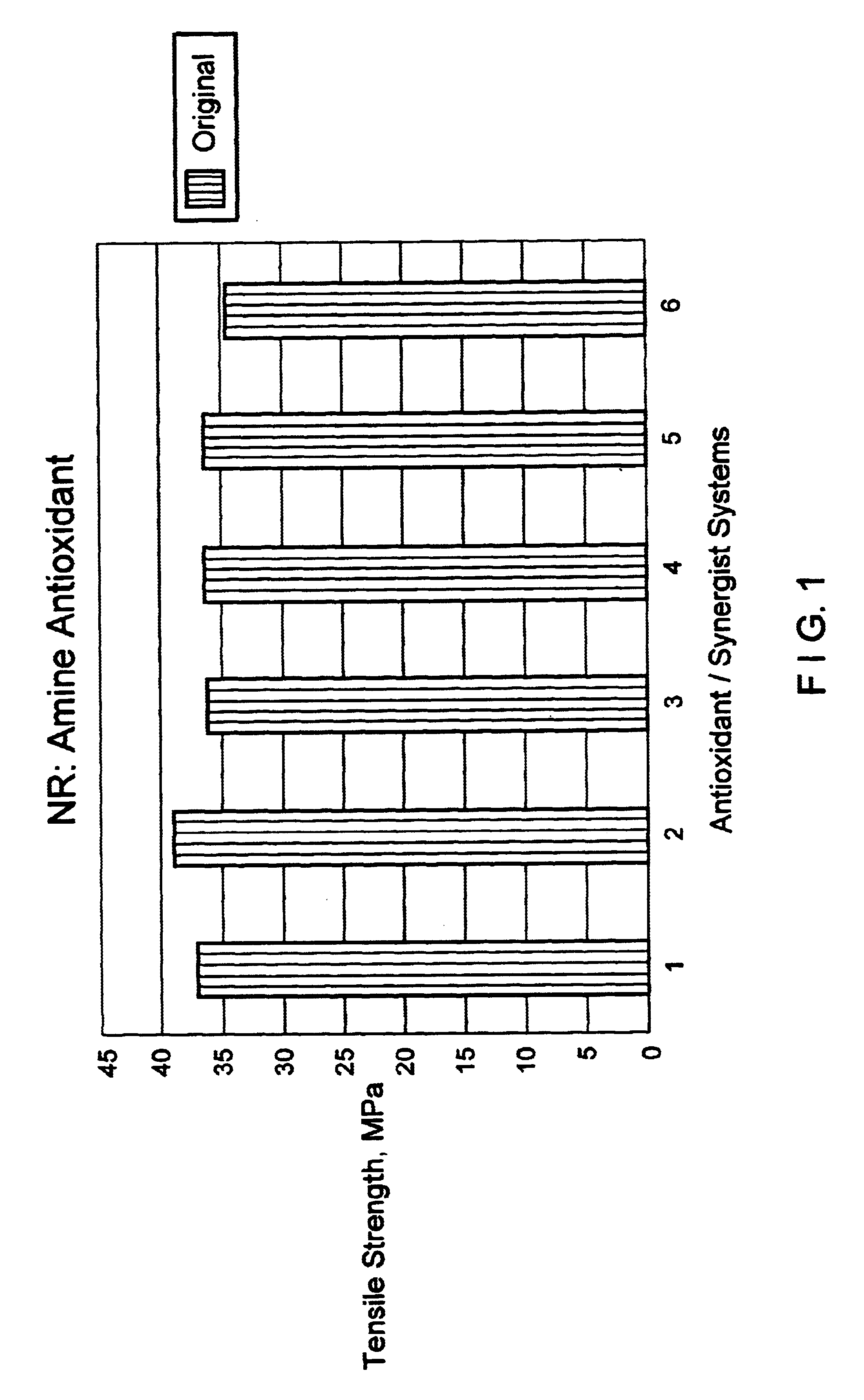

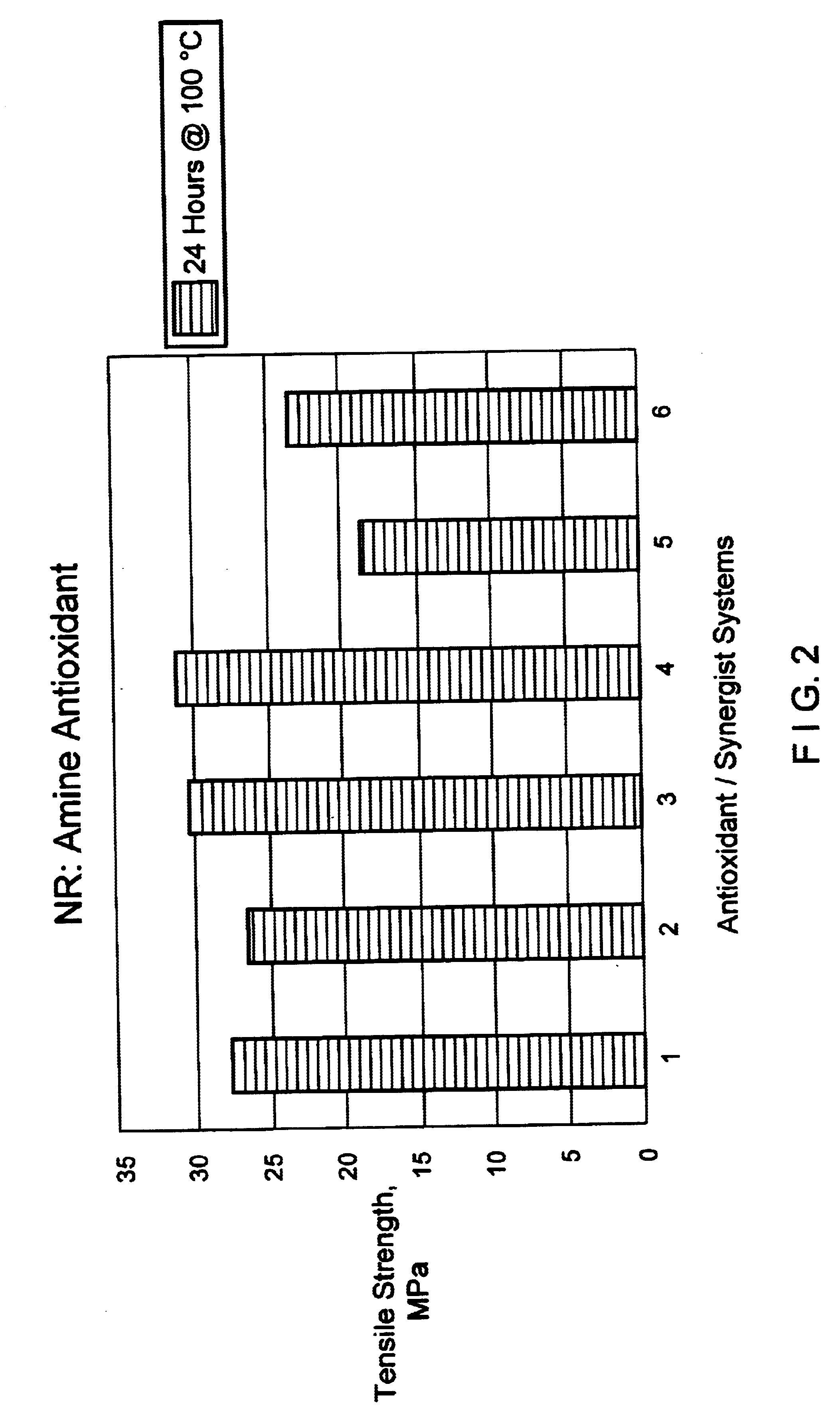

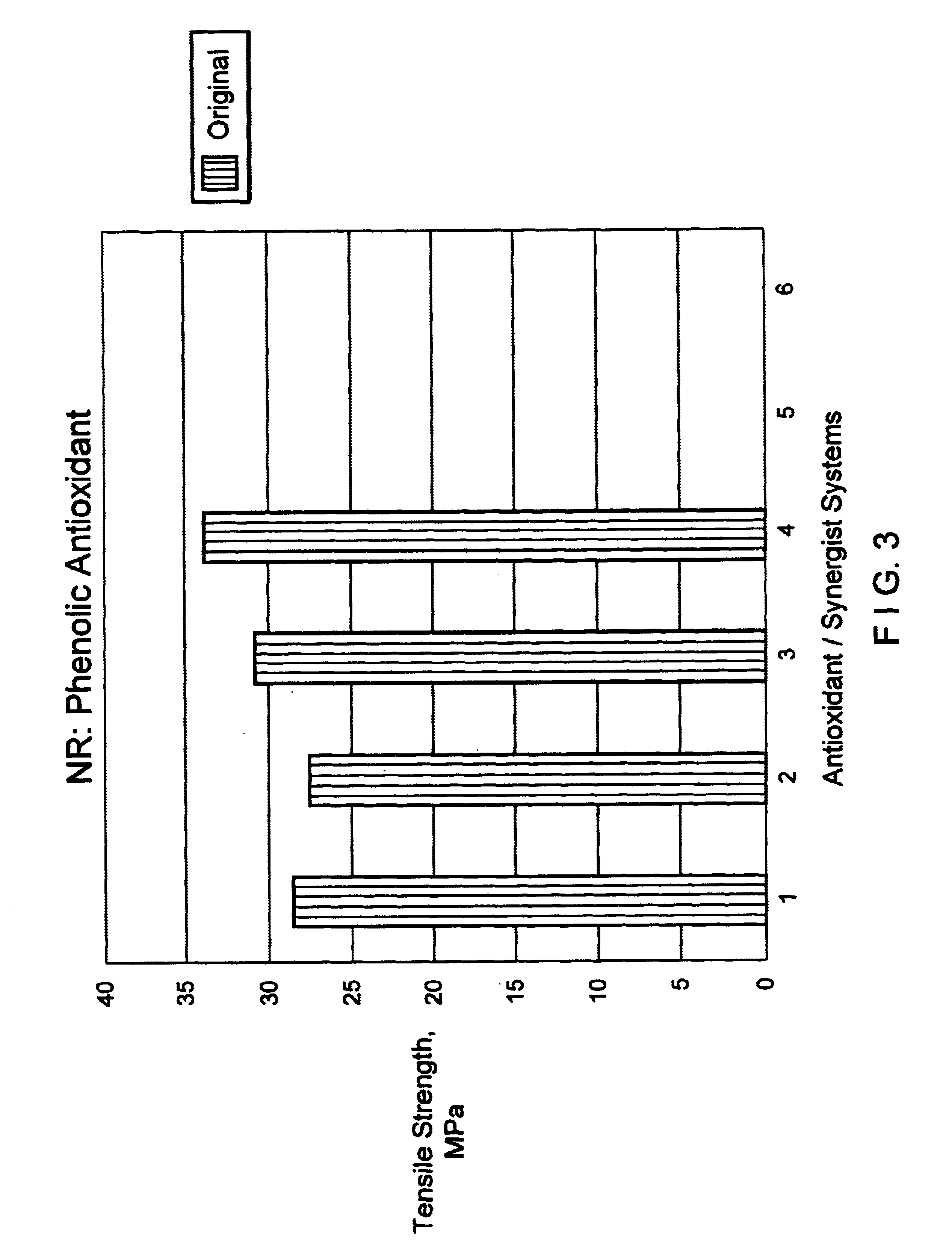

The invention relates to a method of enhancing the tear resistance, tensile strength, and the aging properties of a latex product by adding an antioxidant synergist with an antioxidant to a latex compound comprising of a polymer and a curing system comprised of an activator, crosslinker and accelerator and to the latex products formed therefrom. Antioxidant synergists which can be used with the present invention include 2-mercaptobenzimidazole (MBI), 2-mercaptotoluimidazole (MTI), zinc 2-mercaptobenzimidazole (ZMBI) and zinc 2-mercaptotoluimidazole (ZMTI). The latex products formed may be gloves but can also include threads, balloons and other latex-related products.

Owner:VANDERBILT CHEM LLC

Latex film compound with improved tear resistance

InactiveUS6653380B2Good effectDeterioration of propertyGranular deliverySolid balls2-mercaptobenzimidazoleAntioxidant

The invention relates to a method of enhancing the tear resistance, tensile strength, and the aging properties of a latex product by adding an antioxidant synergist with an antioxidant to a latex compound comprising of a polymer, a stabilizing system, a film surface conditioner and a curing system comprised of an activator, crosslinker and accelerator and to the latex products formed therefrom. Antioxidant synergists which can be used with the present invention include 2-mercaptobenzimidazole (MBI), 2-mercaptotoluimidazole (MTI), zinc 2-mercaptobenzimidazole (ZMBI) and zinc 2-mercaptotoluimidazole (ZMTI). The latex products formed may be gloves but can also include threads, balloons and other latex-related products.

Owner:VANDERBILT CHEM LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com