PVC/ABS blend and pipe thereof

A blend and PVC resin technology, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve the problems of not too high bending strength, poor processing fluidity, low thermal deformation temperature, etc., and achieve excellent mechanical properties , good aging resistance, good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

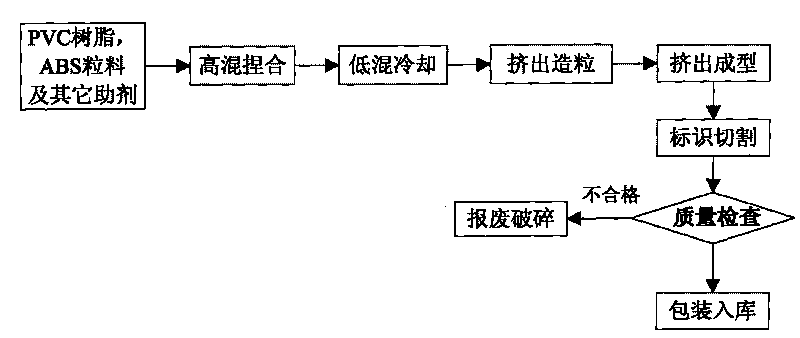

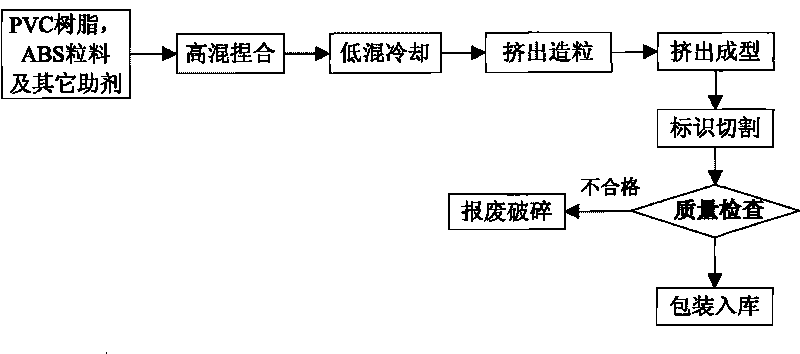

Image

Examples

Embodiment 1

[0037] The blend of PVC / ABS of the present embodiment, its each component and parts by weight thereof are as follows:

[0038] 100 parts of PVC resin;

[0039] 60 parts of ABS pellets;

[0040] Impact modifier MBS 3 parts;

[0041] Organotin T-178A 1 part;

[0042] 0.4 part of lubricant calcium stearate;

[0043] 10 parts of compatibilizer chlorinated polyethylene;

[0044] Antioxidant 1010 0.5 part;

[0045] Ultraviolet absorber UV531 0.3 part;

[0046] 2 parts of flame retardant chlorinated paraffin;

[0047] Processing aid PA-40 0.5 parts.

[0048] Each component in the above polyvinyl chloride transparent composition is first subjected to high-speed thermal mixing treatment through a thermal mixer, and the thermal mixing is performed to 130°C, and then discharged into the cold mixer to cool the mixed materials, and the cold mixing is performed to 45°C The material is discharged, granulated in the extruder, and the obtained pellets are extruded again, and various ma...

Embodiment 2

[0050] The blend of PVC / ABS of the present embodiment, its each component and parts by weight thereof are as follows:

[0051] 100 parts of PVC resin;

[0052] 80 parts of ABS pellets;

[0053] Impact modifier ACR 3 parts;

[0054] Organotin T-178A 0.8 parts;

[0055] 0.3 part of lubricant calcium stearate;

[0056] 10 parts of compatibilizer SAN (styrene-acrylonitrile copolymer);

[0057] Antioxidant 1010 0.5 part;

[0058]Ultraviolet absorber UV531 0.3 parts;

[0059] 2 parts of flame retardant chlorinated paraffin;

[0060] Processing aid K400P 0.5 part.

[0061] Each component in the above polyvinyl chloride transparent composition is first subjected to high-speed thermal mixing treatment through a thermal mixer, and the thermal mixing is performed to 130°C, and then discharged into the cold mixer to cool the mixed materials, and cold-mixed to 45°C The material is discharged, granulated in the extruder, and the obtained pellets are extruded again, and various main ...

Embodiment 3

[0063] 100 parts of PVC resin;

[0064] 40 parts of ABS pellets;

[0065] Impact modifier ACR 3 parts;

[0066] Organotin T-178A 1 part;

[0067] 0.5 part of lubricant calcium stearate;

[0068] 8 parts of compatibilizer SAN (styrene-acrylonitrile copolymer);

[0069] Antioxidant 1010 0.5 part;

[0070] Ultraviolet absorber UV531 0.3 part;

[0071] 2 parts of flame retardant chlorinated paraffin;

[0072] Other processing aids K400P 0.5 parts.

[0073] Each component in the above polyvinyl chloride transparent composition is first subjected to high-speed thermal mixing treatment through a thermal mixer, and the thermal mixing is performed to 130°C, and then discharged into the cold mixer to cool the mixed materials, and cold-mixed to 45°C The material is discharged, granulated in the extruder, and the obtained pellets are extruded again, and various main performance tests are carried out on the obtained pipes. The test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com