Patents

Literature

368results about How to "Good flame retardant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

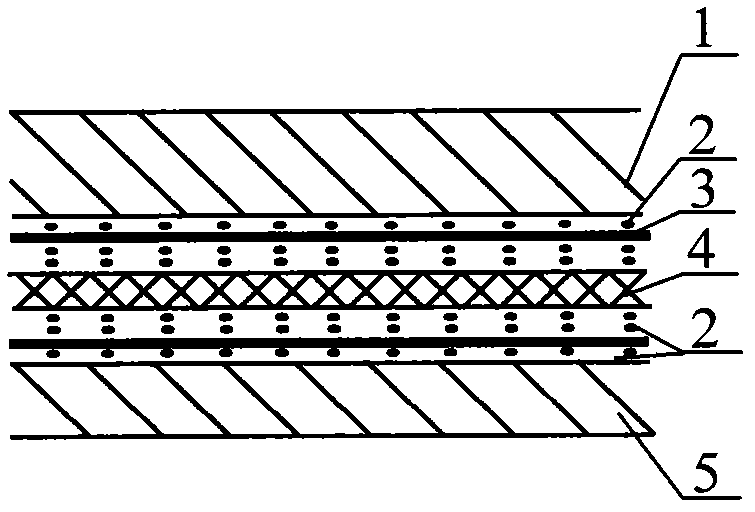

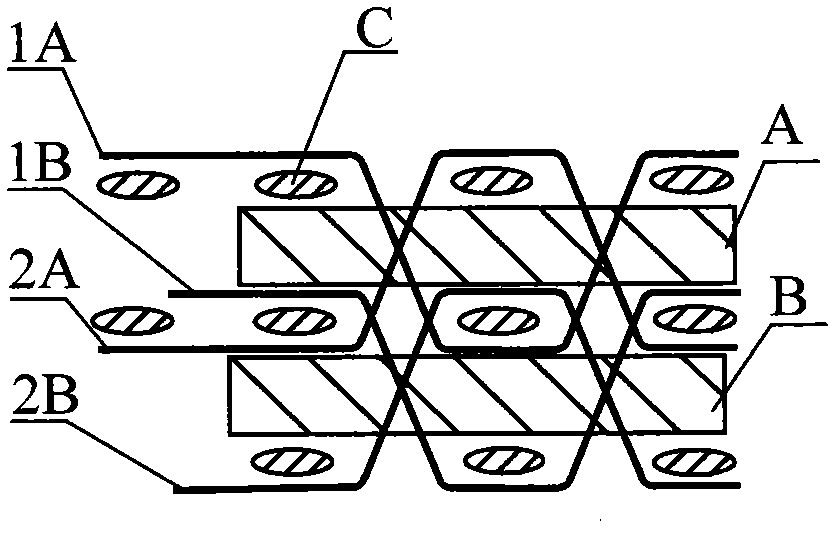

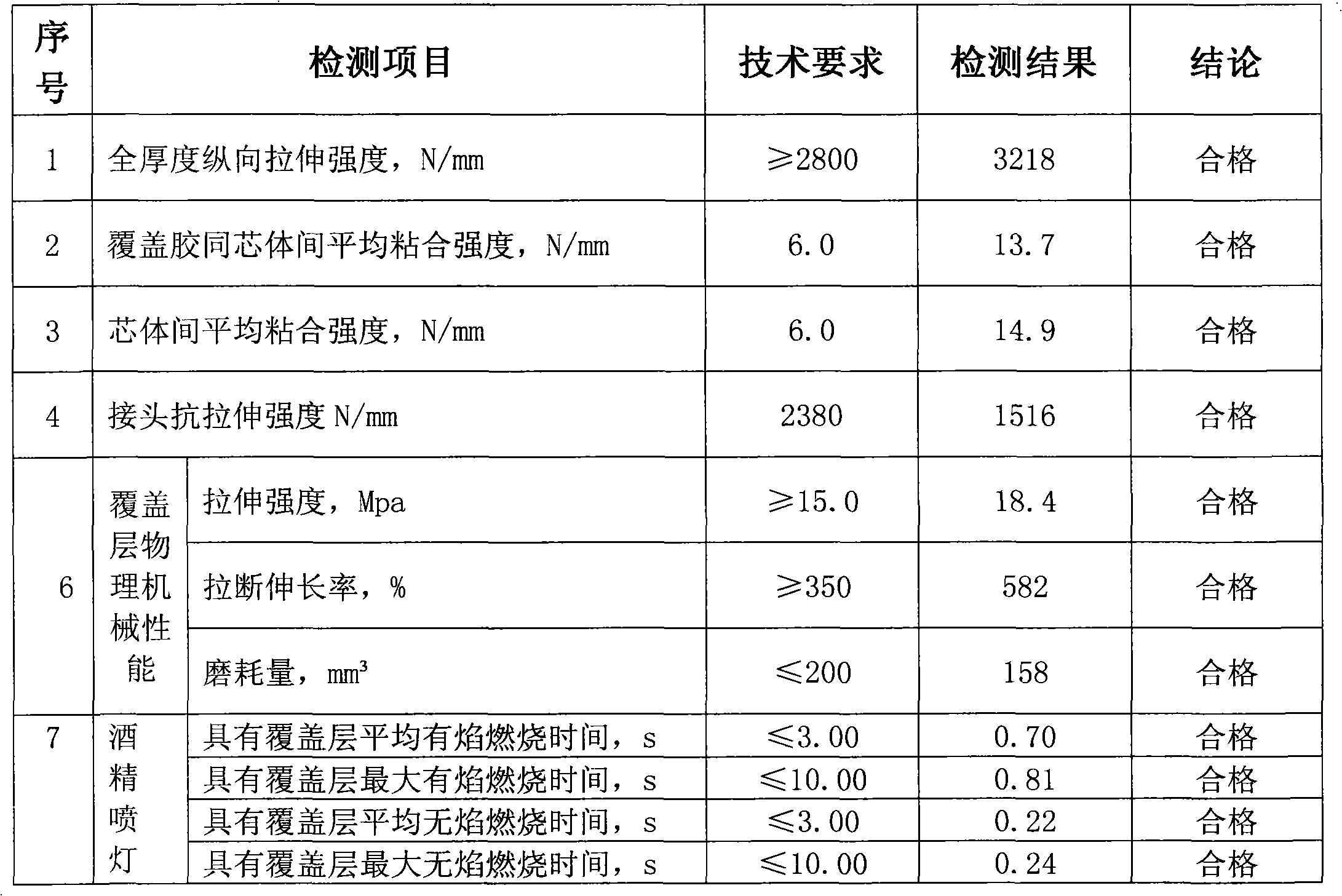

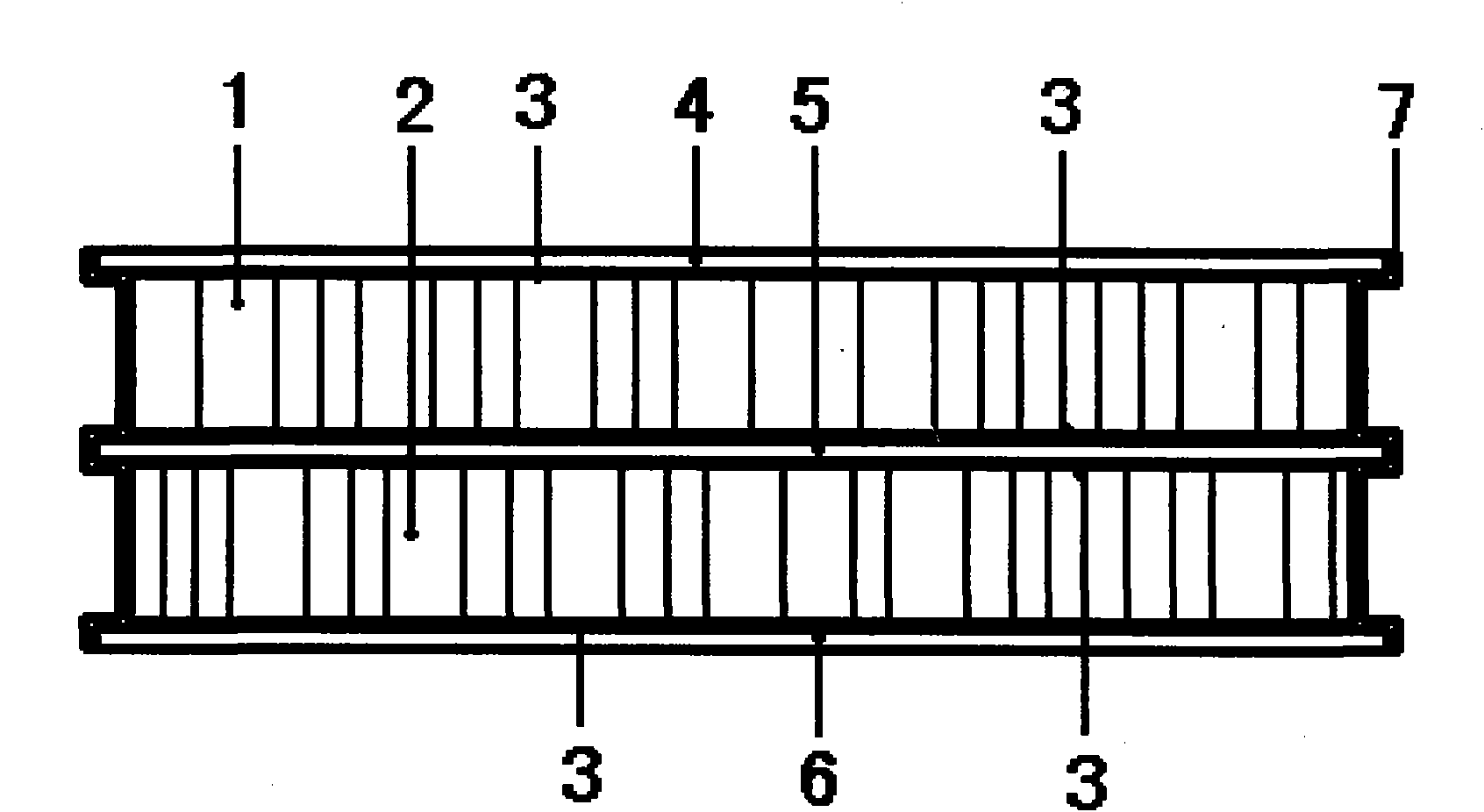

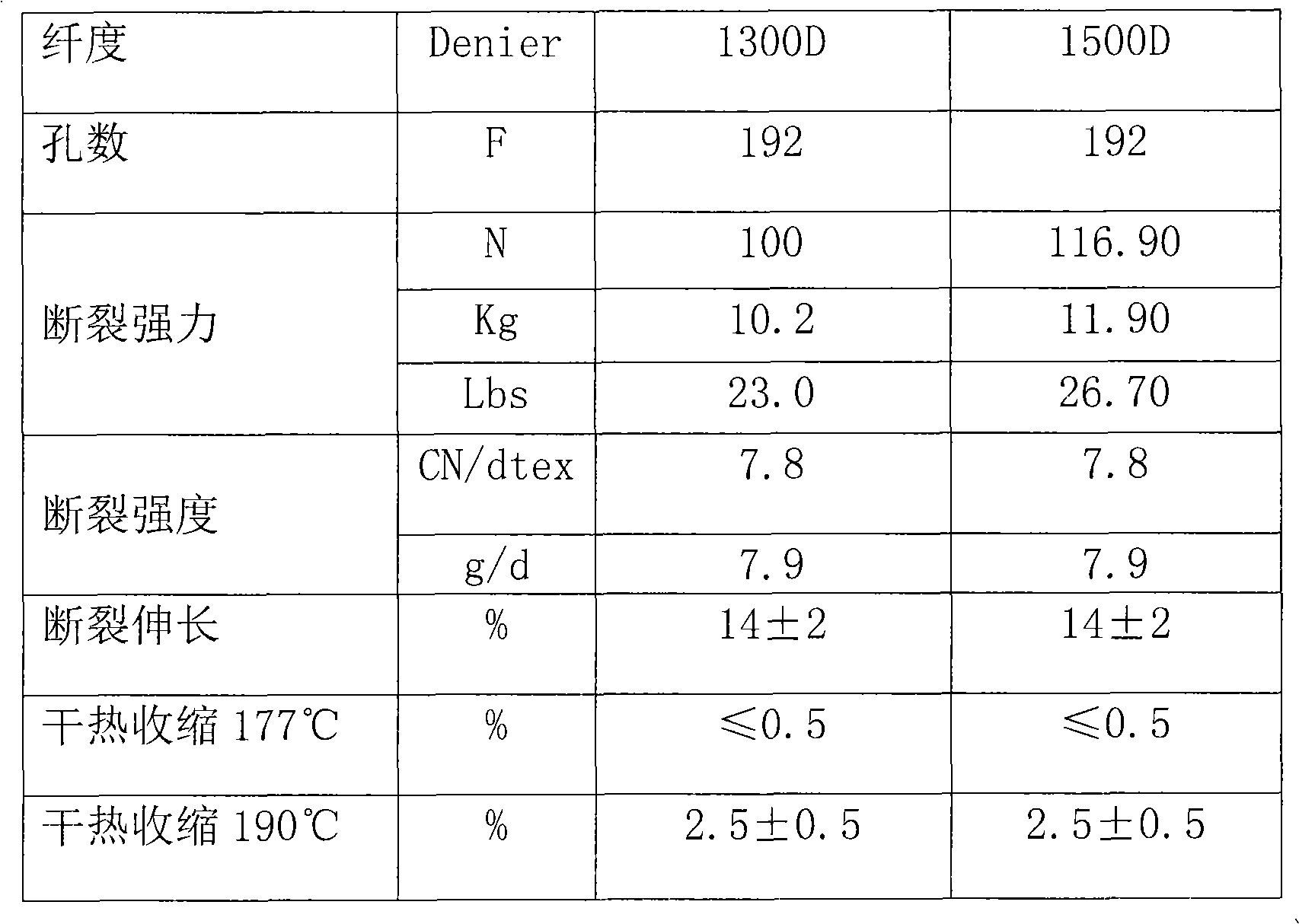

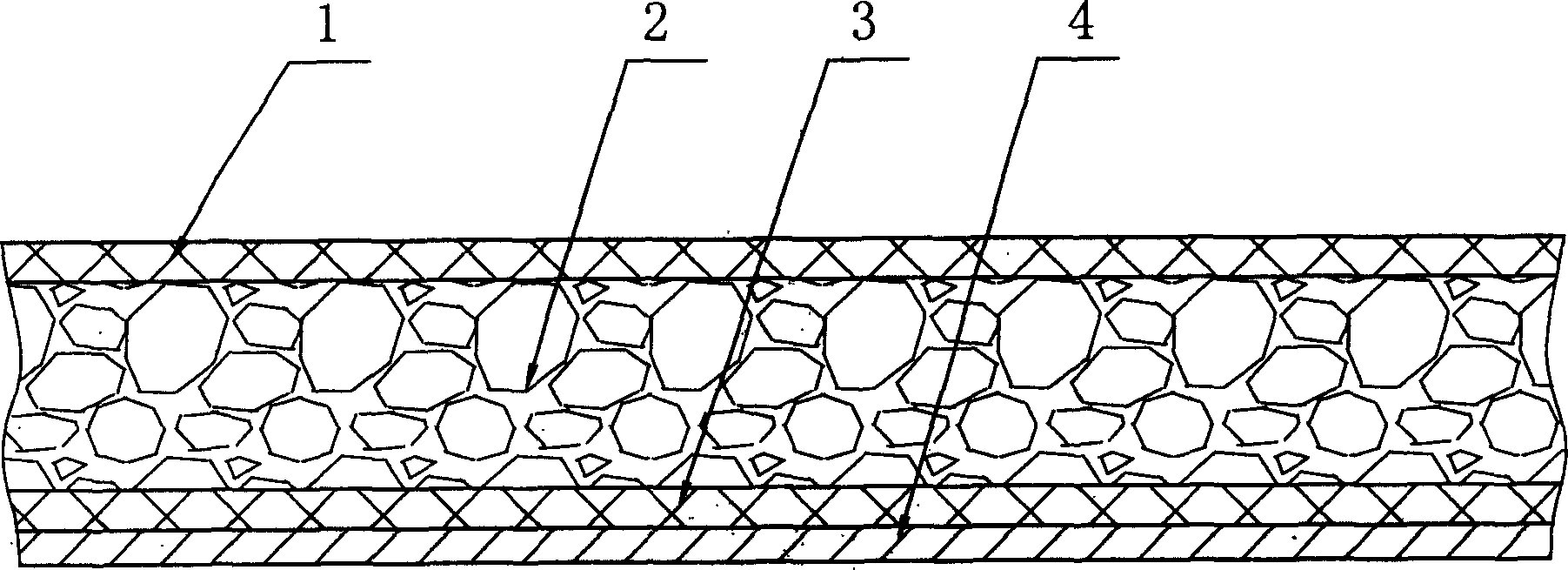

Flameretardant conveyor belt for aramid fiber core

The invention discloses a flameretardant conveyor belt for an aramid fiber core. A pull-resistant framework layer made from aramid fiber fibre. The flameretardant conveyor belt comprises an aramid fiber framework layer, two buffer layers and a flameretardant coverage glue layer, wherein the aramid fiber framework layer is a straight-longitude and straight-latitude structure, two sides of the aramid fiber framework layer are respectively provided with the buffer layer, two sides of the aramid fiber framework layer and the buffer layers are respectively glued with flameretardant bonding glue, the aramid fiber framework layer is bonded with the buffer layers by the flameretardant bonding glue, and the buffer layers are bonded with the flameretardant coverage glue layer by the flameretardant bonding glue. The flameretardant conveyor belt is good in integrated performance, high in the strength of a belt body, light in weight, good in adhesive force, flameretardant, static electricity-resistant, and good in corrosion resistance; the flameretardant conveyor belt is long in service life, low in operation kinetic energy consumption, small in the diameter of a transmission roller, and low in equipment cost; and the flameretardant conveyor belt is less in long-distance jointing times, low in integrated cost, convenient to joint, and good in jointing durability, so that the transportation requirement of multi-variety under a coal mine well can be met.

Owner:安徽天地人科技集团有限公司

Room-temperature moisture-curable single-component flame-retardant polyurethane sealant

ActiveCN102504752AGood flame retardantNo reduction in physical propertiesNon-macromolecular adhesive additivesOther chemical processesPlasticizerRoom temperature

The invention discloses a room-temperature moisture-curable single-component flame-retardant polyurethane sealant and a preparation method thereof. The sealant is prepared from the following raw materials in parts by weight: 30-55 parts of liquid polyether type polyurethane pre-polymer base stock, 10-30 parts of flame-retardant plasticizer, 0.1-1 part of silane coupling agent, 15-30 parts of flame-retardant powder, 10-30 parts of filler, 0.01-0.05 part of catalyst and 0.2-3 parts of methyl benzenesulfonyl isocyanate, wherein the liquid polyether type polyurethane pre-polymer base stock is prepared from the following raw materials in parts by weight: 32.8-57.64 parts of common polyether glycol, 28.82-54.67 parts of flame-retardant polyether glycol, 12.51-13.53 parts of polyisocyanates, and 0.01 part of catalyst. The room-temperature moisture-curable single-component flame-retardant polyurethane sealant is excellent in physical performance, thixotropic property and flame-retardant performance, and convenient for construction.

Owner:SHANDONG NORTH MODERN CHEM IND

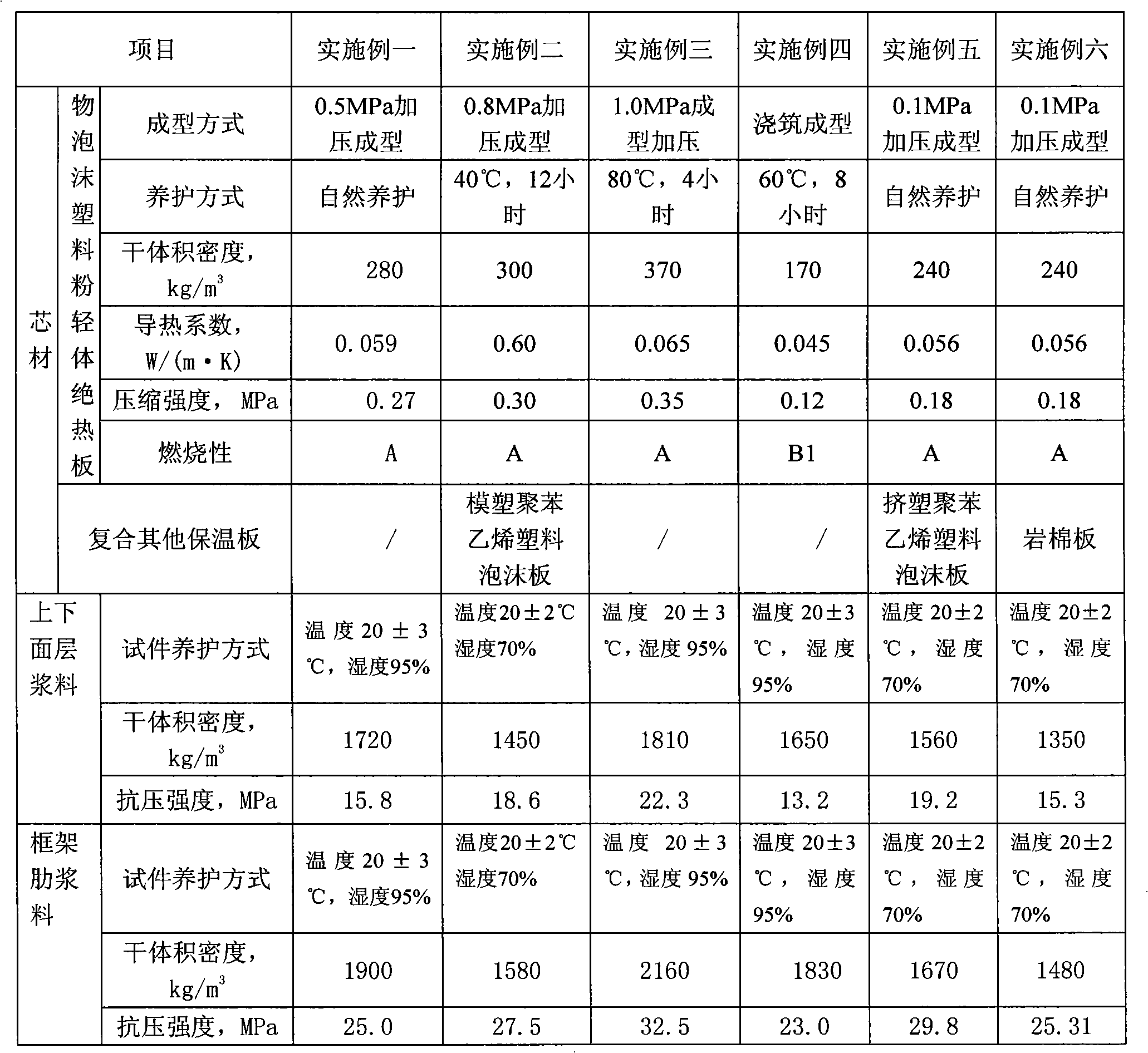

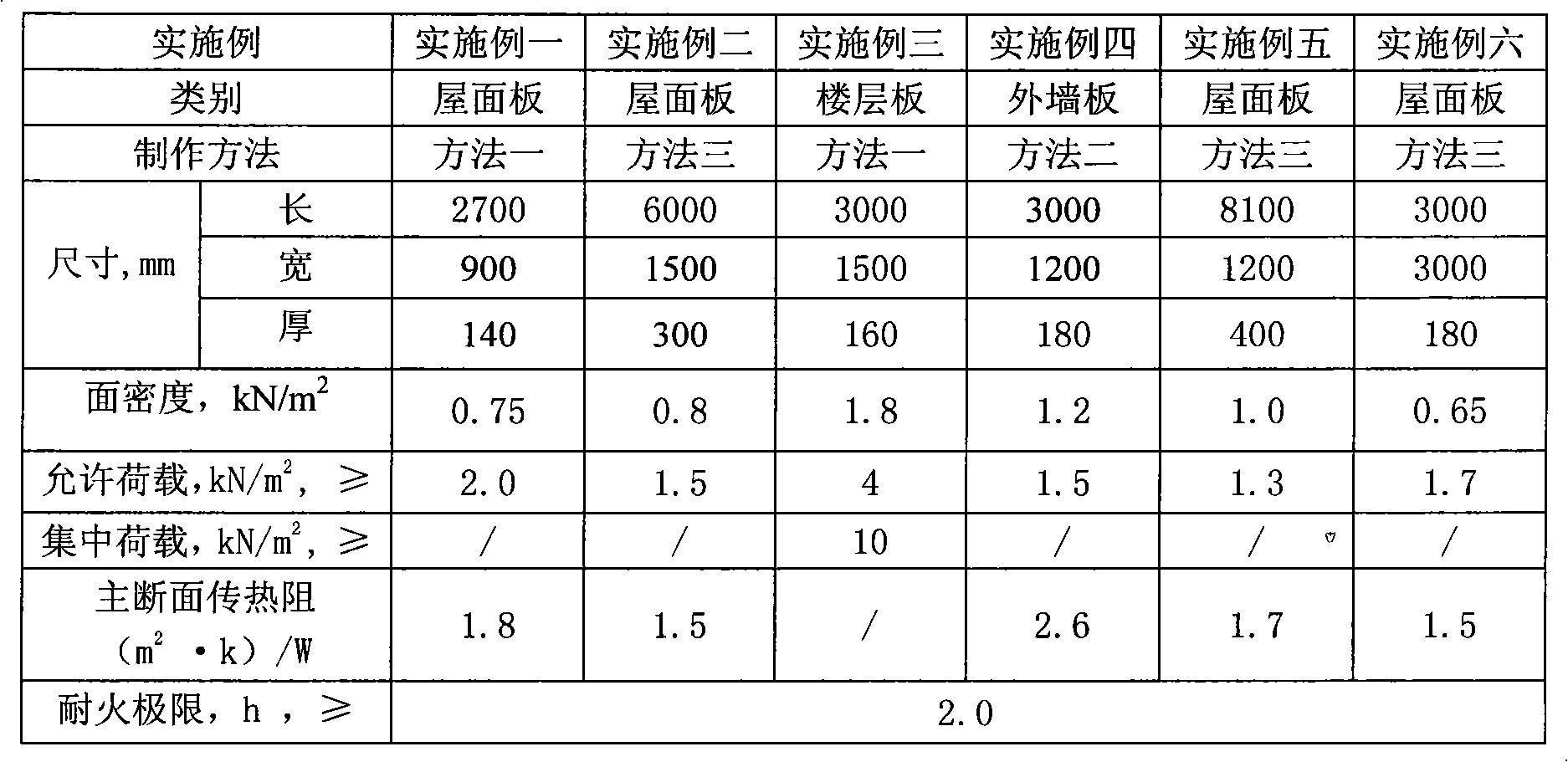

Environmentally-friendly, energy-saving and fireproofing lightweight roof panel, floor plate or wallboard

ActiveCN101914977AStable chemical propertiesGood insulation performanceRoof covering using slabs/sheetsConstruction materialCrack resistancePolystyrene

The invention relates to an environmentally-friendly, energy-saving and fireproofing lightweight roof panel, floor plate or wallboard, which comprises an upper surface layer, a lower surface layer and frame ribs. Insulating layers are arranged between the upper surface layer and the lower surface layer, and are cement polymer foamed plastic powder lightweight insulating plates or are formed by compounding the cement polymer foamed plastic powder lightweight insulating plates and any one of molded polystyrene foam plates, extruding-molded polystyrene foam plates and rock-wool slabs respectively; fiberglass alkaline-resistant mesh fabric is arranged in the upper surface layer and the lower surface layer; the frame ribs are fixedly connected to the lower surface layer; and an anticorrosion steel reinforcement frame is arranged in the frame ribs. In the environmentally-friendly, energy-saving and fireproofing lightweight roof panel, floor plate or wallboard of the invention, the lightweight insulating plates and lightweight surface layer mortar are manufactured by foamed plastic powder; the foamed plastic powder and heat-preservation foamed plastic form particles are applied to lightweight concrete; and materials for the upper and lower surface layers and the frame ribs are enhanced by two or more assorted fibers so as to fulfill the aims of lightweight, high strength, energy saving, sound insulation, fireproofing, crack resistance and durability.

Owner:辽宁际洲环保节能建材有限公司

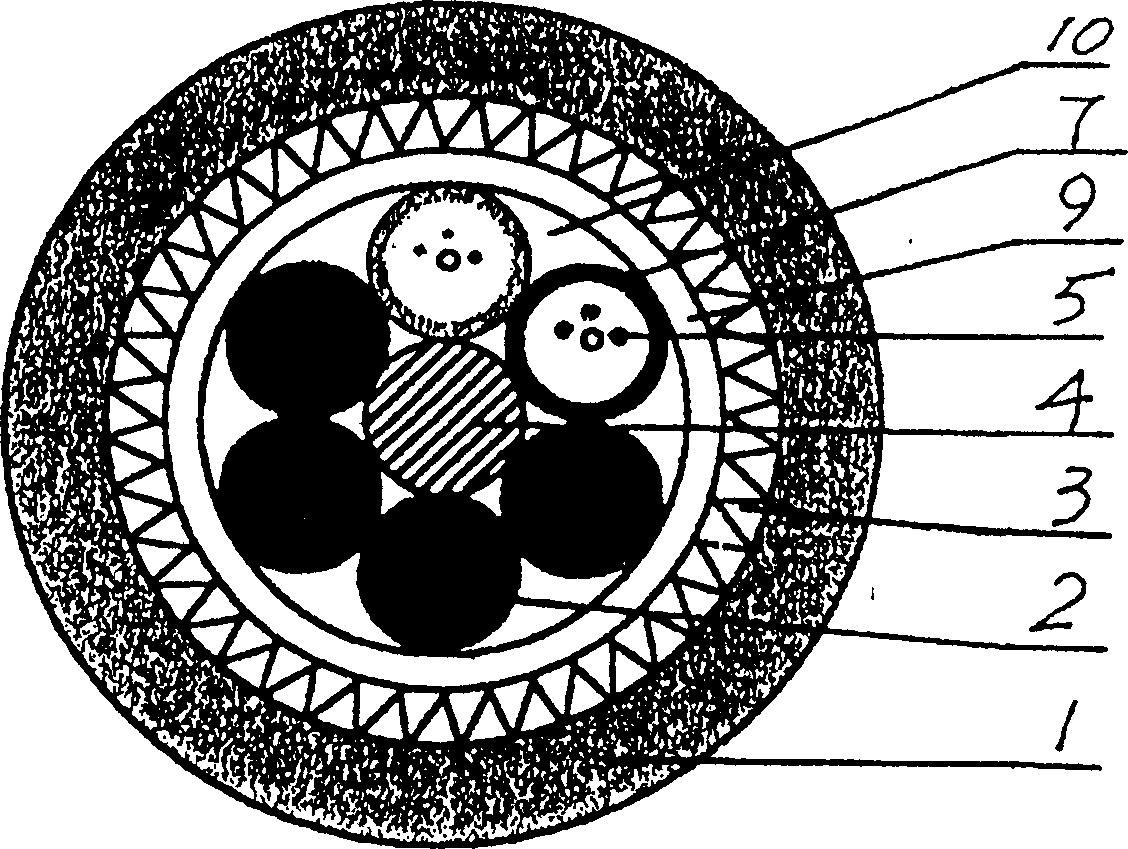

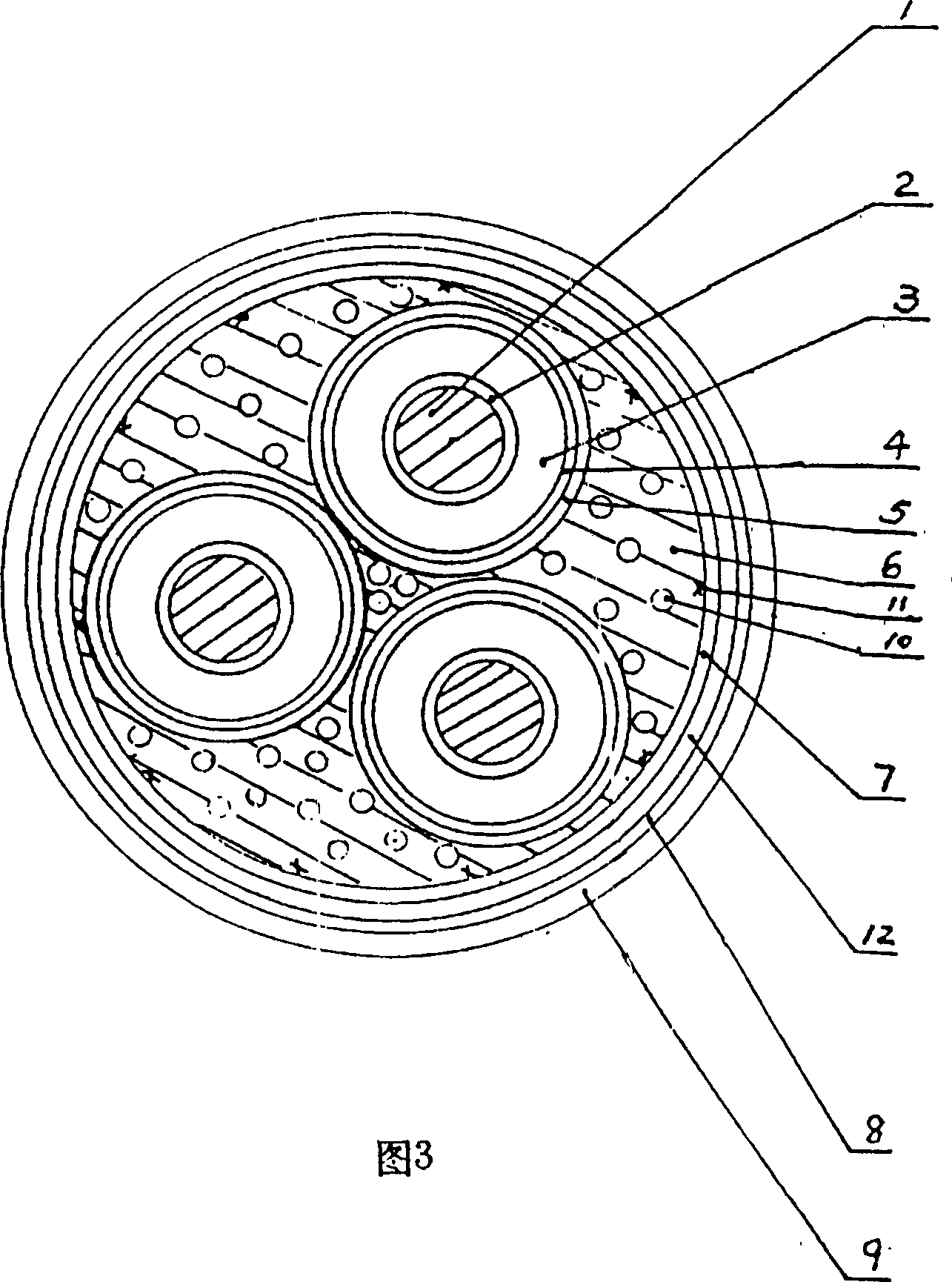

Novel environment-protection, rat-proof and ant-proof optical cable and processing technology thereof

ActiveCN102749693AHigh hardnessImprove toughnessFibre mechanical structuresRenewable PolyethyleneProtection layer

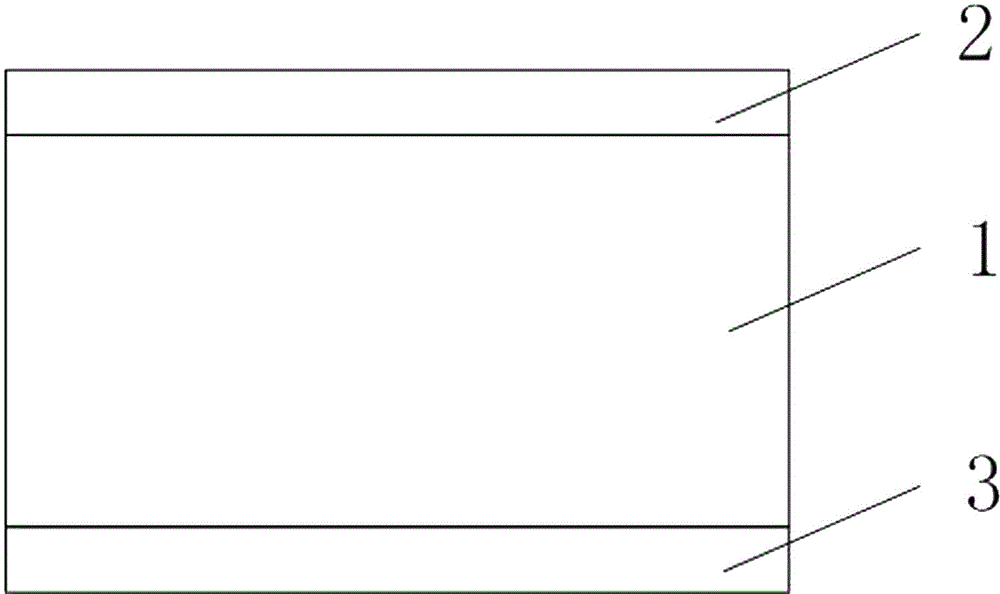

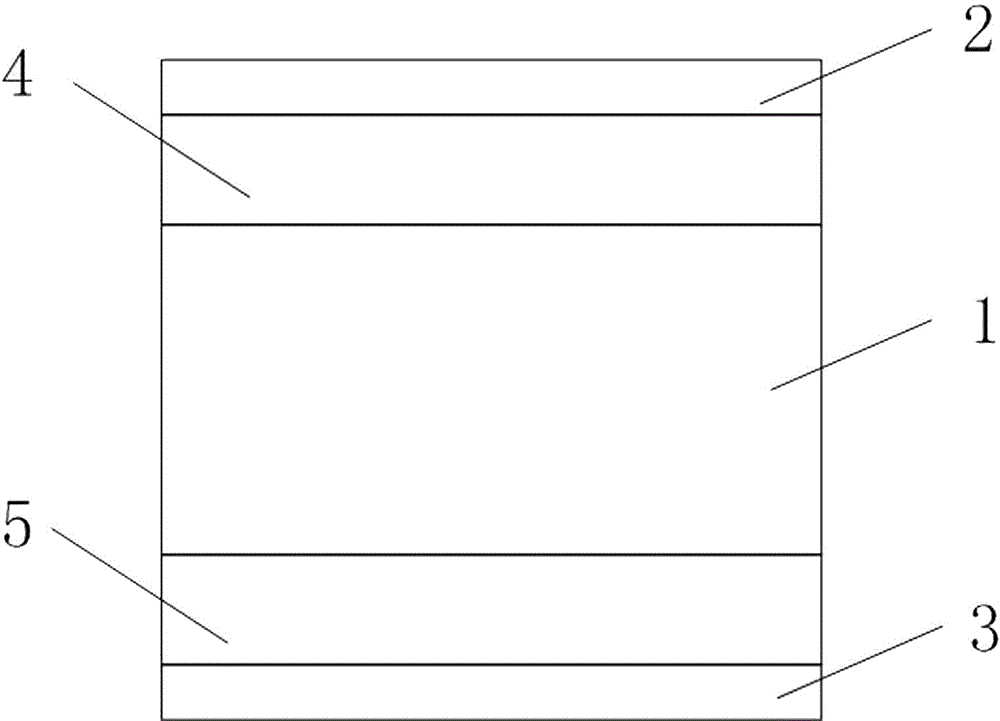

An environment-protection, rat-proof and ant-proof optical cable comprises a cable core and a sheath layer of a three-layer structure, wherein a steel strip or steel wire layer (3), a regeneration polyethylene material protection layer (2) and a nylon protection layer (1) are sequentially arranged from inside to outside, and the regeneration polyethylene material protection layer (2) is tightly attached to the nylon protection layer (1). The invention further relates to the technology for producing the environment-protection, rat-proof and ant-proof optical cable. Nylon adopted in one of the heath layer so that the environment-protection, rat-proof and ant-proof optical cable is good in rigidity and toughness. In addition, the corresponding processing technology is provided, compensation is carried out aiming at self defects of nylon, and the produced optical cable can prevent rats and ants efficiently. Simultaneously, the optical cable is low in cost, and the technical problem existing in the prior art is solved.

Owner:成都亨通光通信有限公司 +1

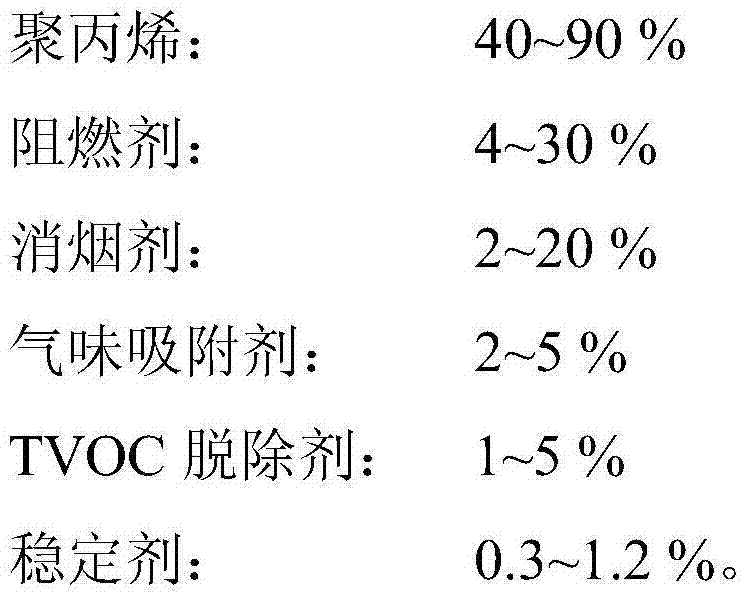

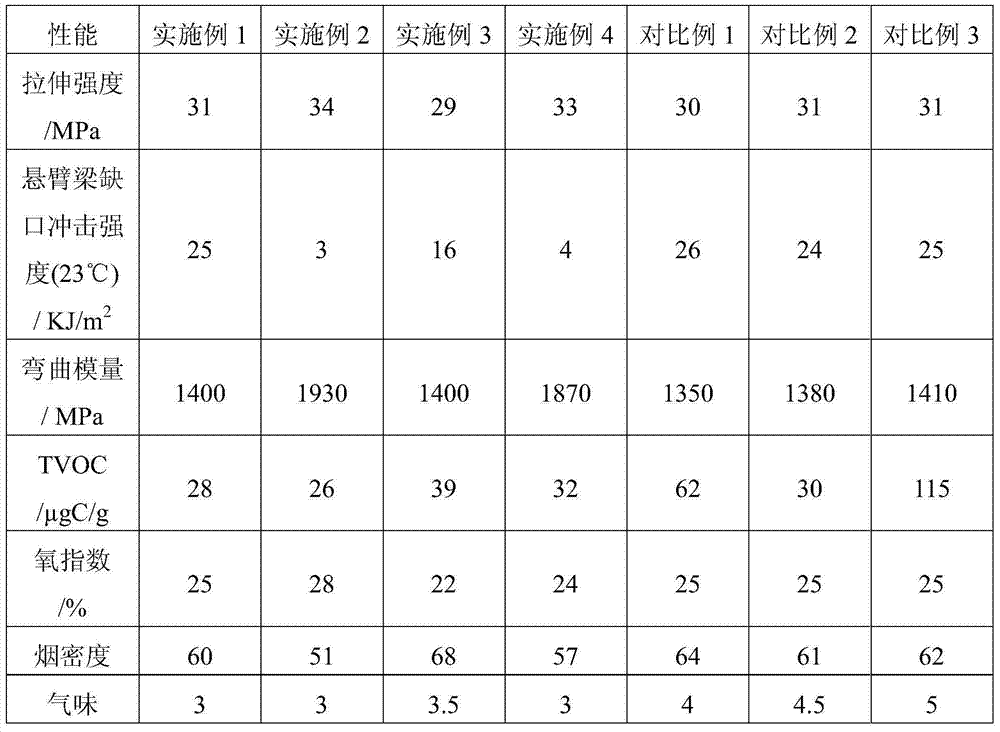

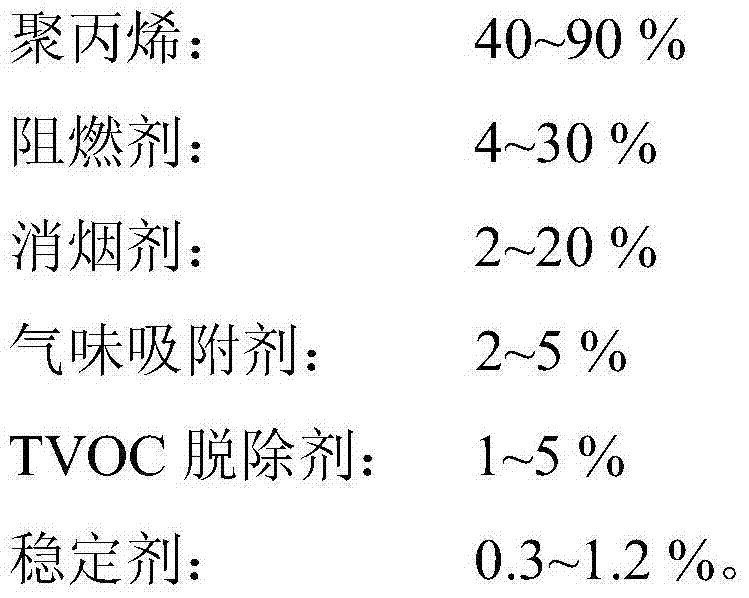

Environment-friendly flame retardant low-odor modified polypropylene and preparation method and application of modified polypropylene

ActiveCN103756135ALow smoke densityImprove mechanical propertiesSimple Organic CompoundsPolymer science

The invention belongs to the technical field of polypropylene materials, and discloses environment-friendly flame retardant low-odor modified polypropylene and a preparation method and application of modified polypropylene in inner decoration of a school bus. The environment-friendly flame retardant low-odor modified polypropylene comprises the following components by weight percent: 40-90% of polypropylene, 4-30% of a flame retardant, 2-20% of an antismoke agent, 2-5% of an odor adsorbent, 1-5% of a TVOC (Total Volatile Organic Compound) remover and 0.3-1.2% of a stabilizer. According to polypropylene provided by the invention, the effect of excellent mechanical property, good flame retardant effect and low smoke density is realized by selecting a special low-odor nitrogen and phosphorus halogen-free flame retardant and metal hydroxide as the antismoke agent. The odor adsorbent and the TVOC remover are added to effectively remove TVOC and other small molecular matters, so that the modified polypropylene which satisfies the demand on excellent mechanical property, good flame retardant effect, low smoke density, low odor and low TVOC is prepared, and the modified polypropylene can be suitable for inner decoration of the school bus.

Owner:TIANJIN KINGFA NEW MATERIAL +1

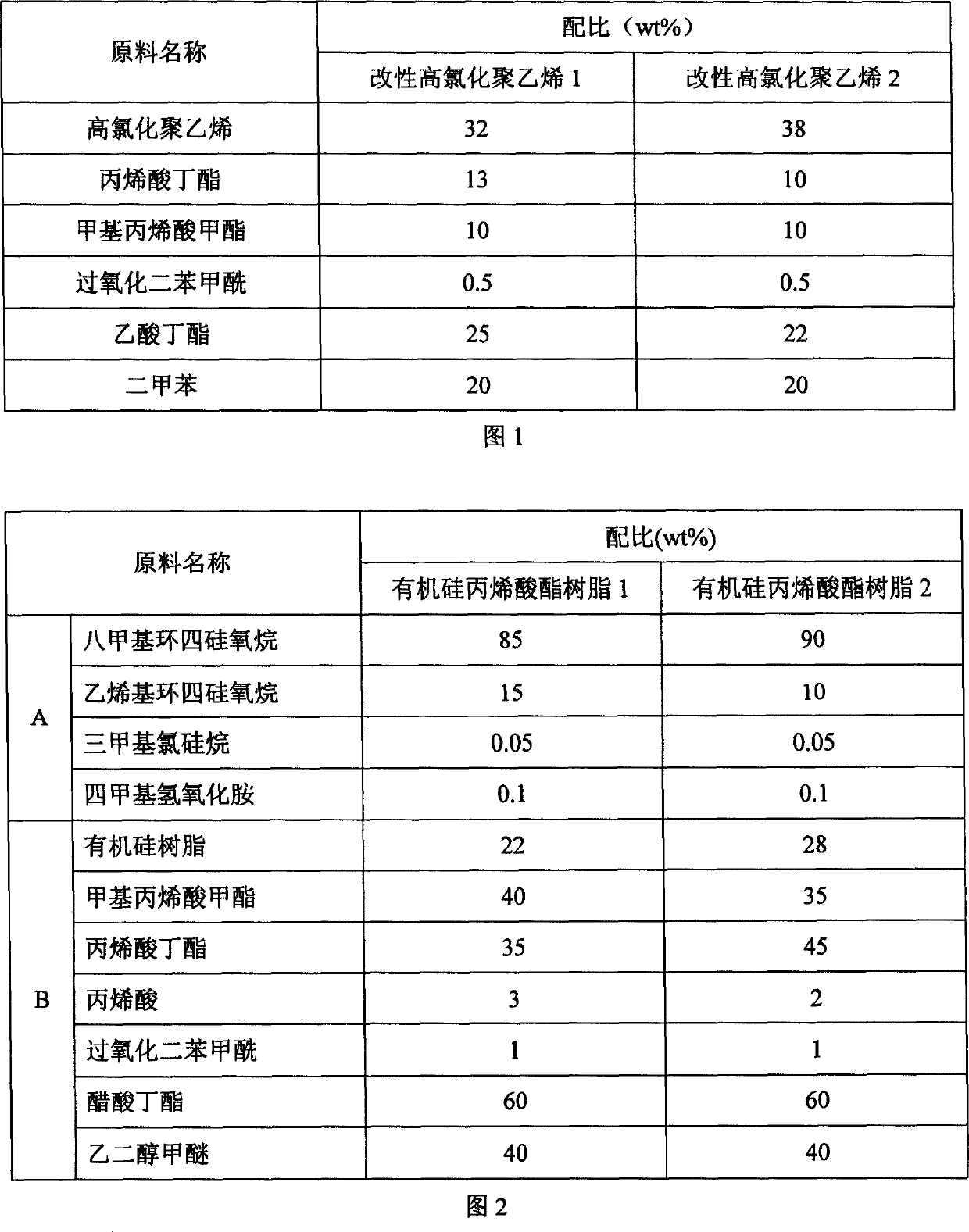

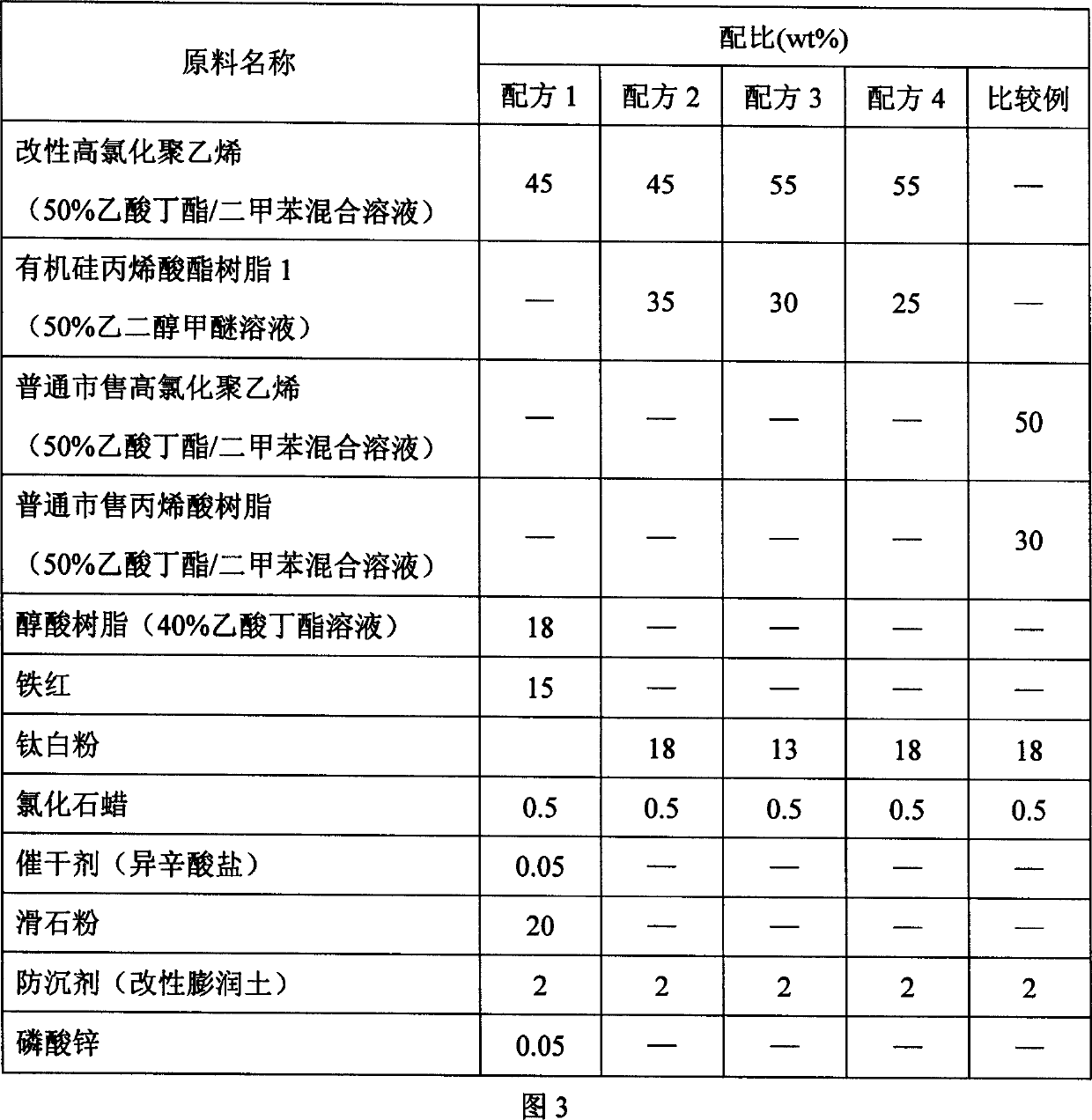

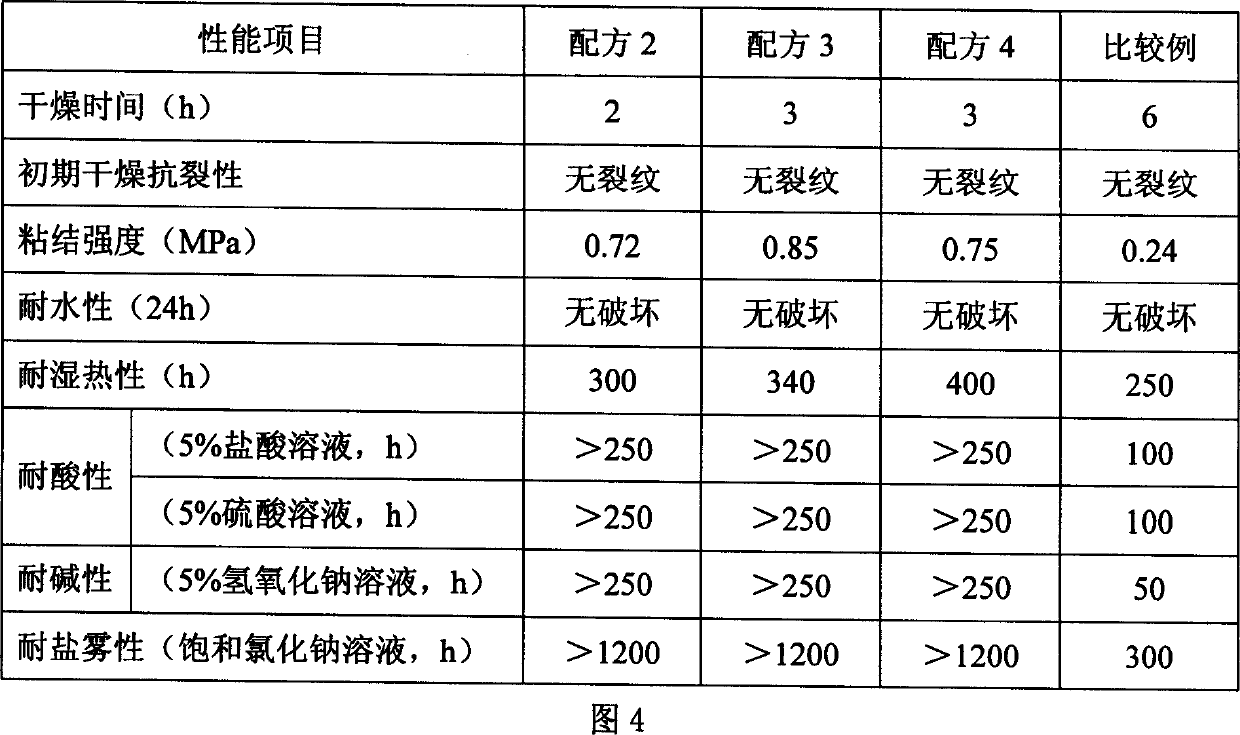

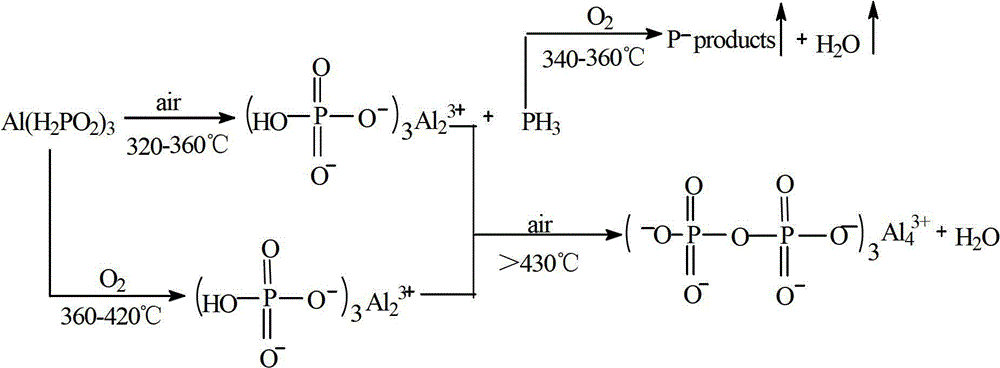

Steel-structure anti-corrosion coating and preparing mehtod thereof

An anticorrosion paint for steel structure is prepared from the modified high-chlorinated polyethylene and alkyd resin or organic silicon modified acrylic resin, filler and assistant through respectively preparing priming paint and surface paint. Its advantages are high resistance to acid, alkali, salty fog, moisture and high temp. and low cost.

Owner:TONGJI UNIV

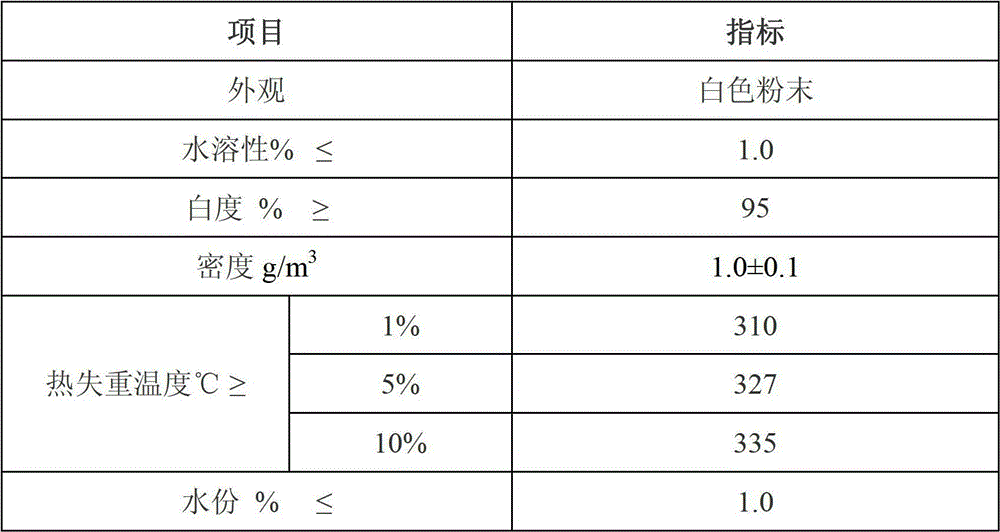

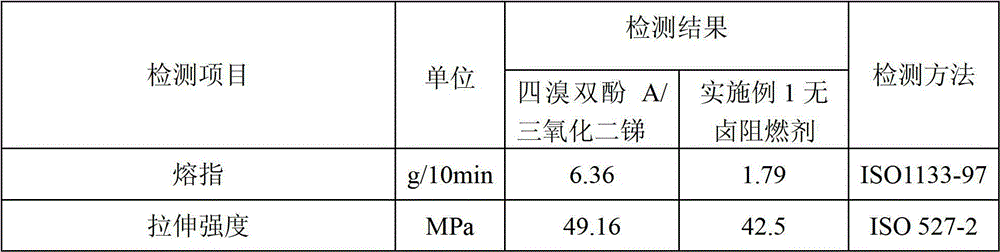

Special environmental-friendly halogen-free flame retardant for ABS (acrylonitrile butadiene styrene) resin

The invention discloses a special environmental-friendly halogen-free flame retardant for ABS (acrylonitrile butadiene styrene) resin. The flame retardant consists of aluminum hypophosphite as a main flame retardant and auxiliary flame retardants. The flame retardant can completely replace antimony bromide flame retardants and has the performance of better flame retardance, low smoke, low corrosion, good carbon formation performance, no toxicity and the like; in addition, when the flame retardant is applied to ABS, hydroplaning phenomenon cannot occur during extrusion processing, and no molten dripping phenomenon exists after combustion; and in addition, the cost is low.

Owner:JINAN TAIXING FINE CHEM

Fireproof moth-proof thermal mortar and preparation method thereof

The invention discloses fireproof moth-proof thermal mortar which is characterized in that the thermal mortar is prepared from the following raw materials in parts by weight: 310-360 parts of high-alumina cement, 200-250 parts of expanded perlite, 180-210 parts of attapulgite, 90-110 parts of waste polystyrene foam plastic crushed particles, 80-130 parts of starch, 120-160 parts of pyrite dross, 6-9 parts of sodium silicate, 18-35 parts of sierozem powder, 10-13 parts of aluminum hydroxide, 8-11 parts of cellulose formaldehyde, 0.4-0.8 part of dipterex, 12-15 parts of redispersible latex powder, 7-9 parts of benzenesulfonic acid and 3-6 parts of aids. The thermal mortar prepared from the raw materials such as the cement, expanded perlite, waste polystyrene foam plastic crushed particles, attapulgite and pyrite dross is light in volume weight, does not crack and has the advantages of fire resistance, moth resistance, high flame retardant property, non-toxicity, high adhesive force, high construction property, high cracking resistance and excellent weather resistance. Moreover, by adoption of the production process, the operation is simple and convenient, the quality is easily controlled, the performance is stable, and batch production is conveniently performed.

Owner:安徽众凯架业有限责任公司

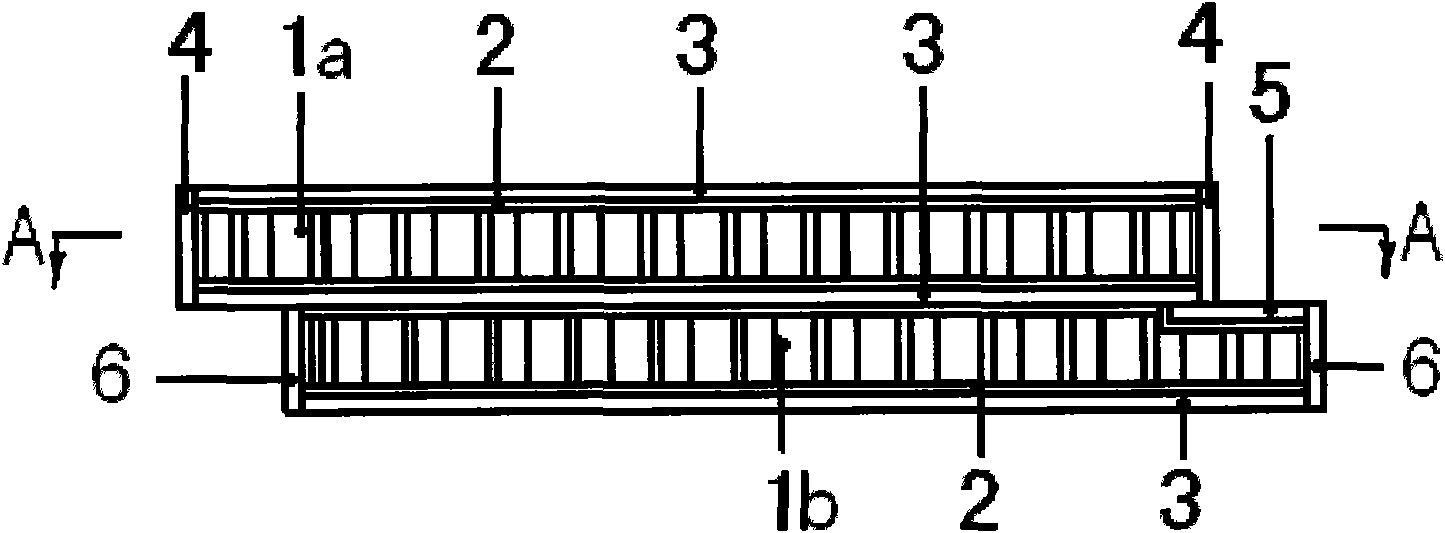

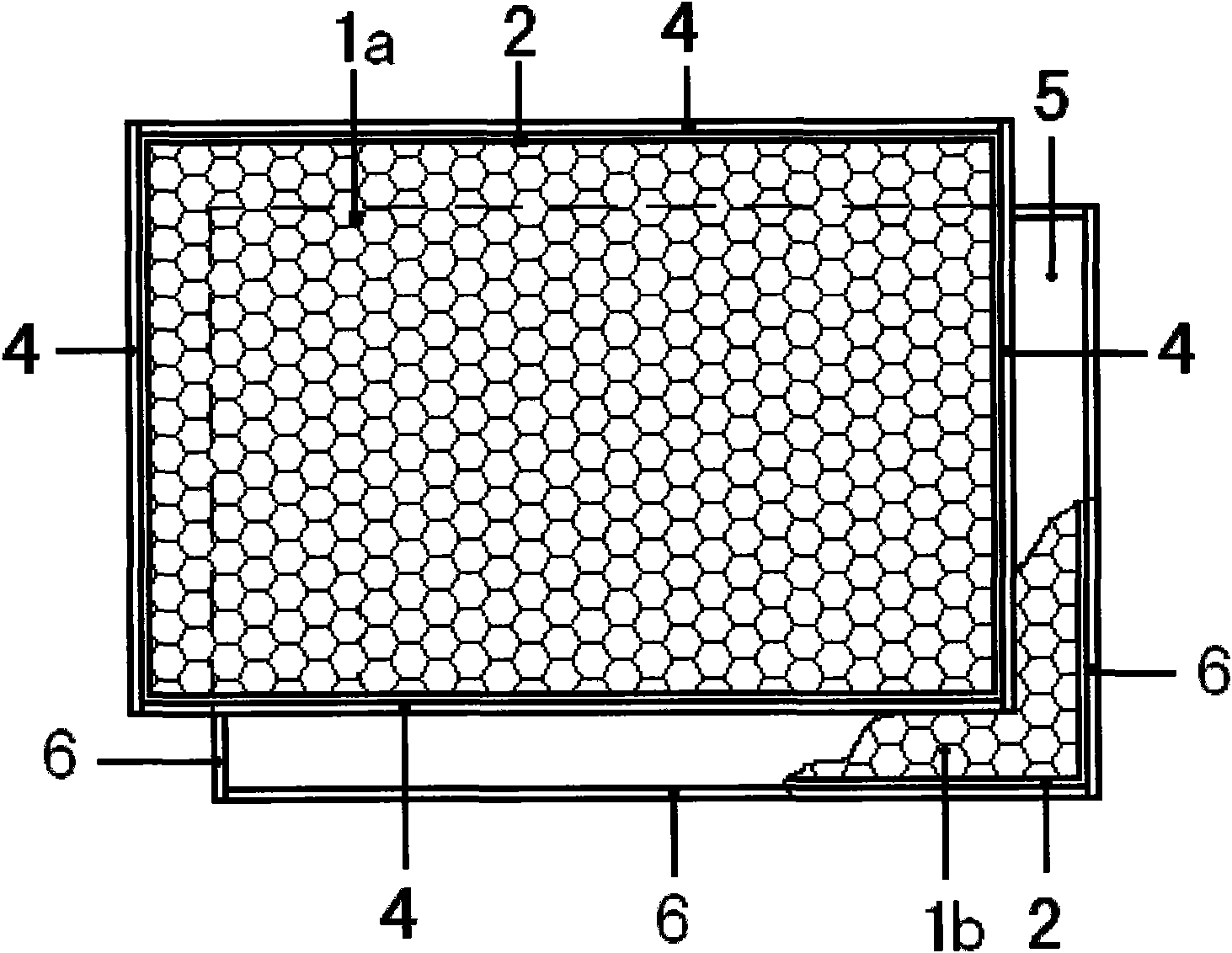

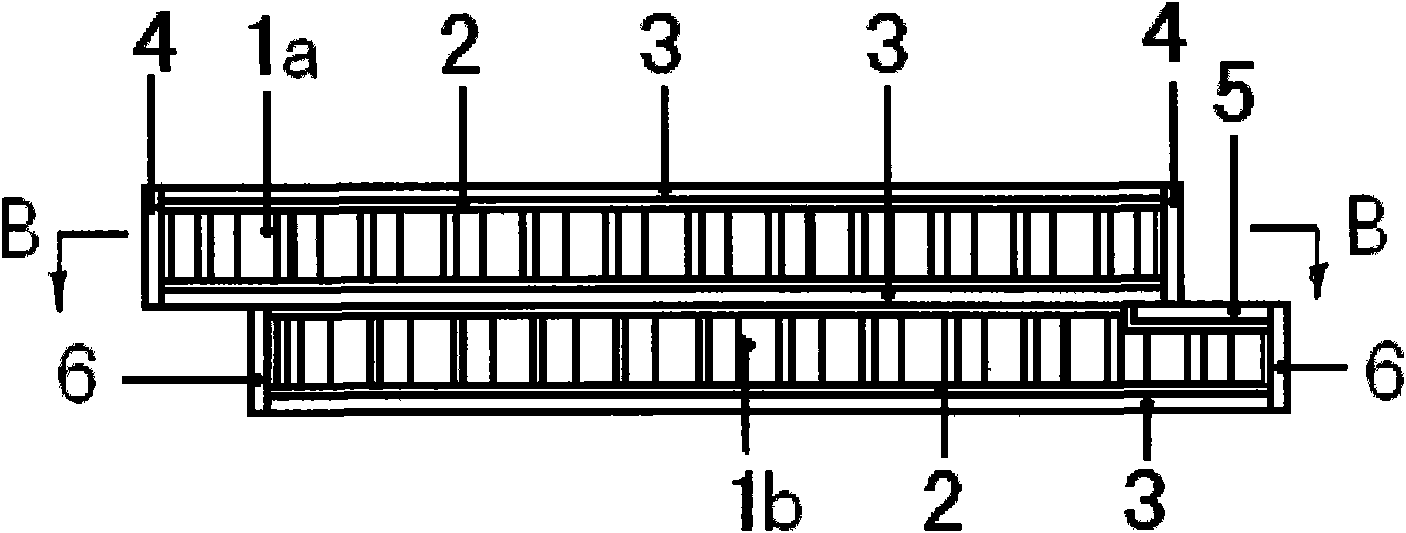

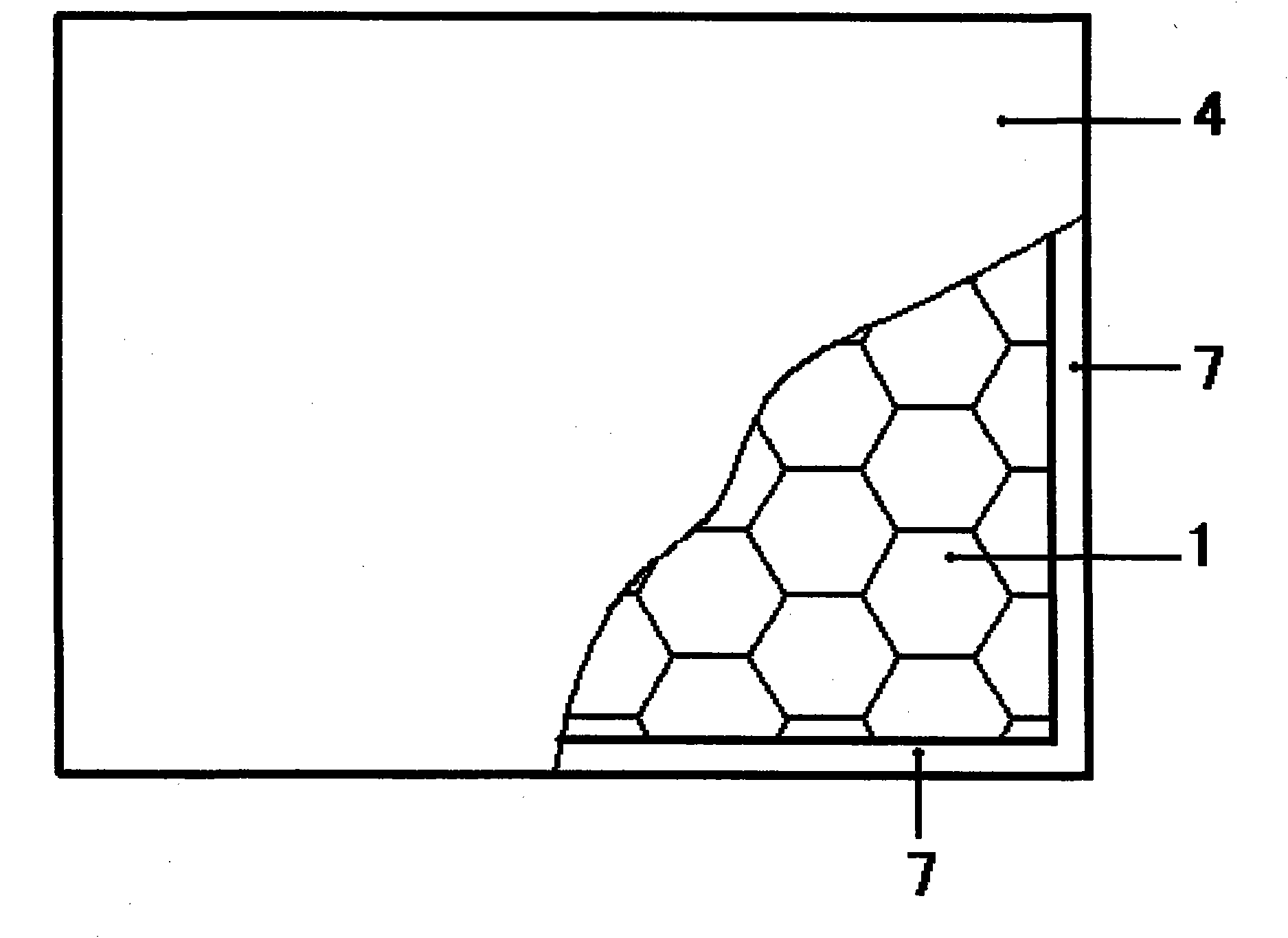

Flexible honeycomb sound-insulating and heat-insulating composite board

InactiveCN101608477AImprove insulation performanceGood flame retardantHeat proofingSound proofingCardboardHoneycomb

The invention relates to a flexible honeycomb sound-insulating and heat-insulating composite board having good performance in heat insulation and heat preservation, water resistance and flame resistance and belonging to the field of functional panels for building and decoration. In the invention, at least two double-layer board sound-insulating structures are formed by using the combination mode that two honeycomb cardboard filling core materials (1a, 1b) are sandwiched between an upper composite panel and a middle composite panel and between the middle composite panel and a lower composite panel respectively, wherein, the upper and the lower honeycomb cardboard filling core materials (1a, 1b) constitute hermetic air cavities between the two boards of the two double-layer board sound-insulating structures. Therefore, the honeycomb sound-insulating and heat-insulating composite board which integrates the characteristics of a single honeycomb cardboard and a single composite panel has the advantages of low density, low per-unit specific gravity, sound insulation, heat insulation, water resistance, flame resistance, high durability and the like.

Owner:耿忠平

Formula of reinforcement and flame retardant polypropylene

The invention discloses a formula of reinforcement and flame retardant polypropylene, which comprises polypropylene, a flame retardant, an antistatic agent, a flexibilizer, a heat resistant agent and a wear resistant agent, wherein the flame retardant is magnesium hydroxide, antimony oxide and hexabromocyclododecane; the antistatic agent is sodium alkyl sulfate; the flexibilizer is a copolymer of ethylene and octylene; the wear resistant agent is glass fiber; and the wear resistant agent is graphite. The formula of reinforcement and flame retardant polypropylene enables the prepared reinforcement and flame retardant polypropylene to have efficacies of good flame retardance, high plasticity, electric static resistance, good flexibility, high temperature resistance, wear resistance and the like.

Owner:SUZHOU NEW DISTRICT HUASHIDA ENG PLASTICS

Glass fiber reinforced PPS/PEEK (Polyphenylene Sulfide/Polyether-Ether-Ketone) alloy and preparation process thereof

The invention relates to a glass fiber reinforced PPS / PEEK alloy and a preparation process thereof. The glass fiber reinforced PPS / PEEK alloy comprises the following components in parts by mass: 1-99parts of polyphenylene sulfide, 1-99 parts of polyether-ether-ketone, 10-200 parts of glass fibers, 1-50 parts of fillers, 3-10 parts of a compatilizer, 5-30 parts of a flexibilizer, 0.2-2 parts of acoupling agent, 0.2-2 parts of an antioxidant and 0.5-3 parts of processing aids, wherein the sum of mass parts of the polyphenylene sulfide and polyphenyl ether is 100 mass parts. The alloy has hightoughness, impact cracking resistance, excellent strength and rigidity, excellent compatibility, high temperature resistance, flame retardant property, chemical corrosion resistance, solvent resistance, stress cracking resistance, excellent processability and other advantages, and can be safely applied to various electrical and electronic equipment units, vehicle equipment components as well as chemical equipment units even ships, bridges and building materials.

Owner:惠州法智力量法律咨询有限公司

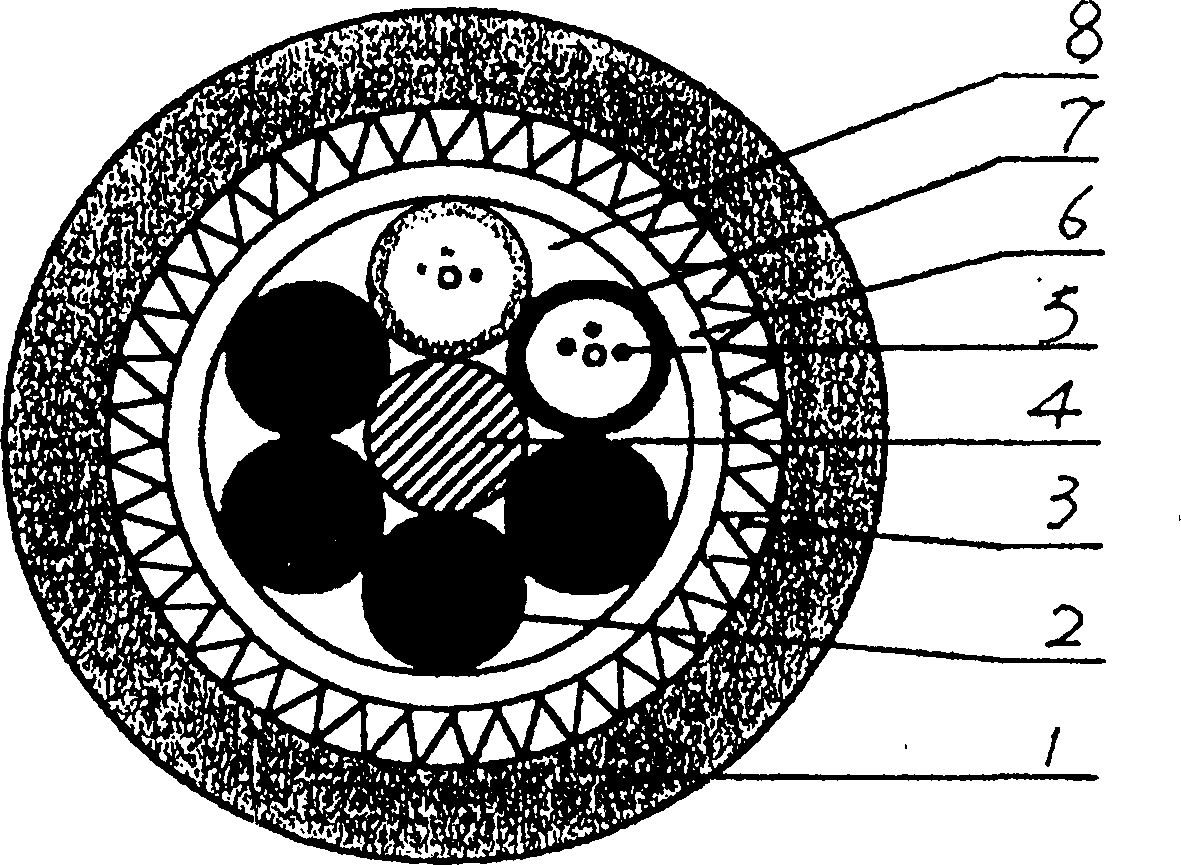

Layer-stranding fire-resisting, corrosive-proof and gopher protected communication outdoor cable

ActiveCN1444067AGood flame retardantGuaranteed long-term safe useFibre mechanical structuresFilling materialsAluminium

The layer-stranding fire-resistant anticorrosive gopher protected communication outdoor optical cable includes a cable core made up by stranding several steeves containing one or several optical fibres around a central reinforcement component, filling material received in the described sleeve, water-proof band layer winded round exterior of cable core; filling rubber which is filled between water-prooband layer and cable core and has the buffer function; and most external side fire-resistant layer. The described water-proof band exterior is equipped with a composite aluminium band layer, the aluminium band layer exterior is covered with polyvinyl protecting layer whose exterior is covered with a layer of stainless steel band, the exterior of the stainless steel band is covered with an adhesive layer whose exterior is covered with fire-resistant layer.

Owner:YANGTZE ZHONGLI OPTICAL FIBER & CABLE (JIANGSU) CO LTD +1

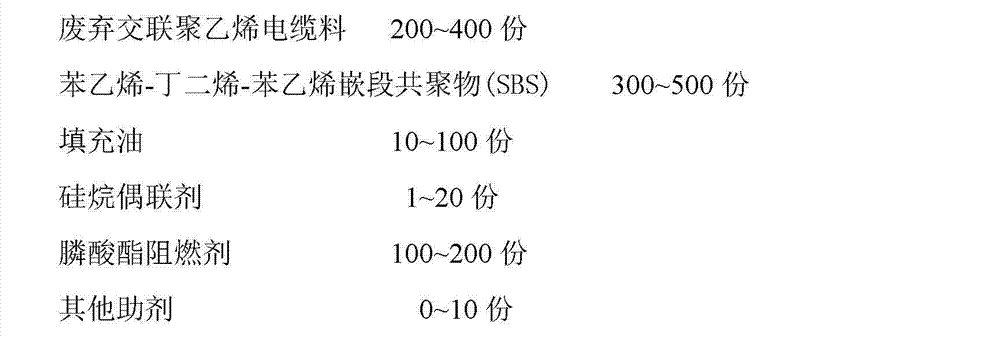

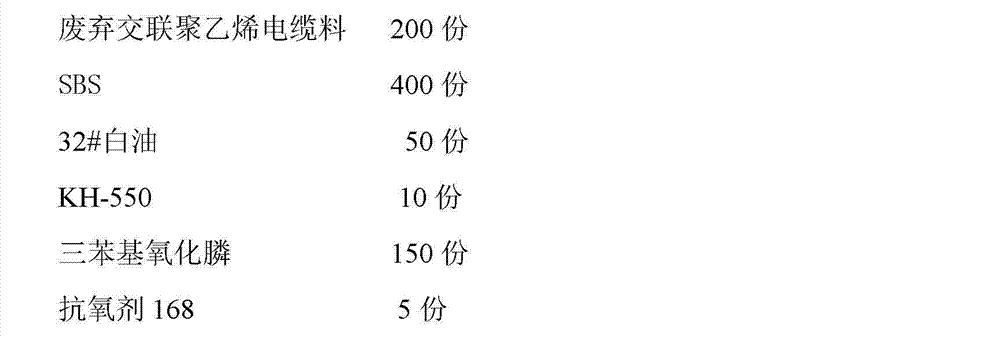

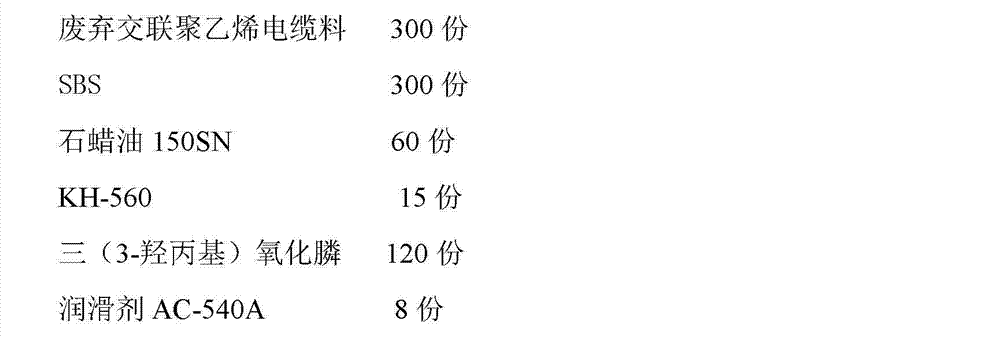

Flame retardant thermoplastic elastomer (TPE) made from waste crosslinked polyethylene cable materials and preparation method thereof

The invention discloses a flame retardant TPE made from waste crosslinked polyethylene cable materials and a preparation method thereof. The TPE comprises, by weight, 200-400 parts of the waste crosslinked polyethylene cable materials, 300-500 parts of styrene-butadiene-styrene block copolymers, 10-100 parts of extending oil, 1-20 parts of silane coupling agents, 100-200 parts of phosphonate flame retardants and 0-10 parts of other auxiliaries. According to the TPE, a path is provided for recycle of the waste crosslinked polyethylene cable materials, the cost and environmental pollution can be reduced, and resources can be saved. The prepared TPE is provided with good flame retardance and other performances up to standards.

Owner:江苏科瑞曼线缆科技有限公司

Nano-Mg-Al hydrotalcite fire-retardant EVA foaming material and preparation method thereof

InactiveCN105440420AImprove mechanical propertiesImprove flame retardant performanceCombustionFoaming agent

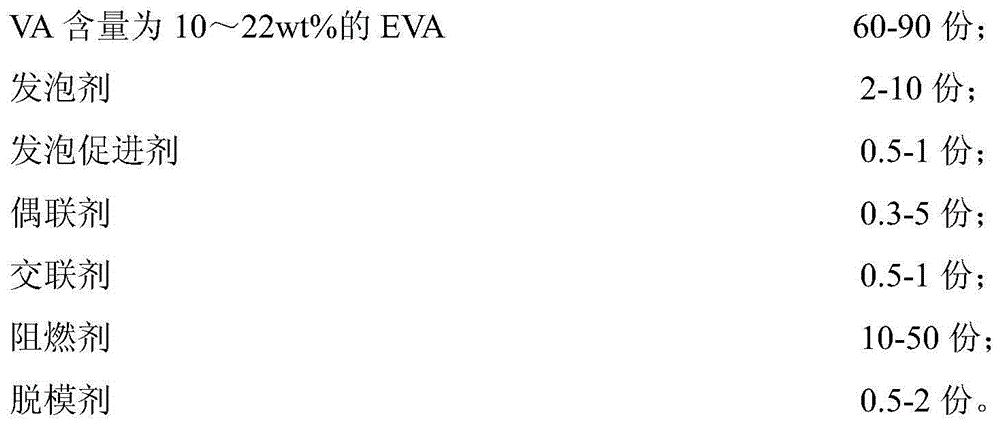

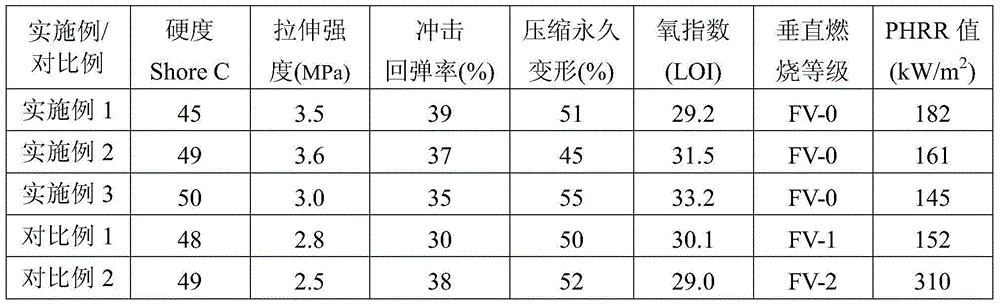

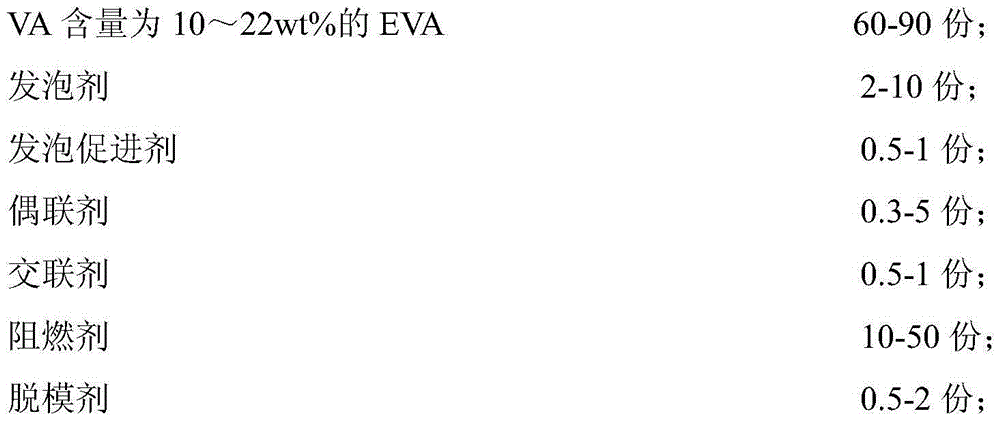

The present invention relates to a nano-Mg-Al hydrotalcite fire-retardant EVA foaming material comprising, by weight, 60-90 parts of an ethylene-vinyl acetate copolymer with 10-22wt% of VA, 2-10 parts of a foaming agent, 0.5-1 part of a foaming accelerator, 0.3-5 parts of a coupling agent, 0.5-1 part of a crosslinking agent, 10-50 parts of a flame retardant and 0.5-2 parts of a releasing agent, and the flame retardant is nano-Mg-Al hydrotalcite. Compared with traditional metal hydroxide flame retardants, the nano-Mg-Al hydrotalcite has great advantages in improvement of the limiting oxygen index, improvement of vertical combustion performances and reduction of heat release rate and other flame retardant aspects, and is better fire-retardant inhibitor. The present invention also provides a preparation method of the foaming material, and the method is simple to operate, the foaming process is not needed to be further modified or changed, production cost can be reduced, and energy can be saved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Flame retardant composite board and manufacture method thereof

InactiveCN104552488AHigh mechanical strengthGood nail gripWood veneer joiningDomestic articlesBruciteComposite plate

The invention provides a flame retardant composite board. The flame retardant composite board comprises a homogeneous naked panel and a facing layer arranged on at least one surface of the homogeneous naked panel, wherein the homogeneous naked panel is prepared from raw materials of, based on weight parts, 65-98.5 parts of plant straw particles, 3-10 parts of binder and 3-10 parts of fire retardant, wherein the fire retardant is prepared from raw materials of magnesium oxide, calcium sulfate, aluminum hydroxide, brucite, zinc molybdate and zinc borate. The flame retardant composite board has good chemical properties of fire retarding, water prevention, insect prevention and the like, and good physical and mechanical properties, can replace wood artificial boards, and is used in various fields. The invention further provides a manufacture method of the flame retardant composite board. The manufacture method of the flame retardant composite board mainly adopts a normal temperature cold press molding technology to solidify and shape the raw materials of the naked panel, not only greatly saves energy, but also improves product performance, enables the flame retardant composite board to have water prevention and fire prevention functions, and simultaneously can substantially reduce equipment cost, achieves a whole green production process, and does not cause pollution during the whole production process.

Owner:信阳美丽真好秸秆新材科技有限公司

Environment-friendly wall fireproof heat-preserving board and preparation method thereof

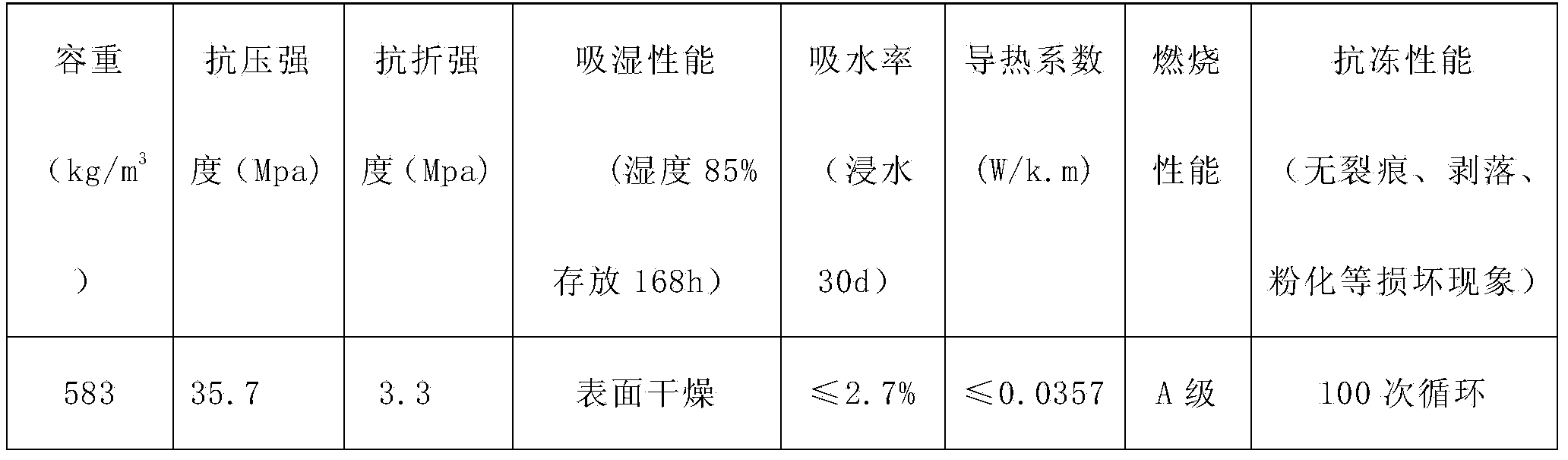

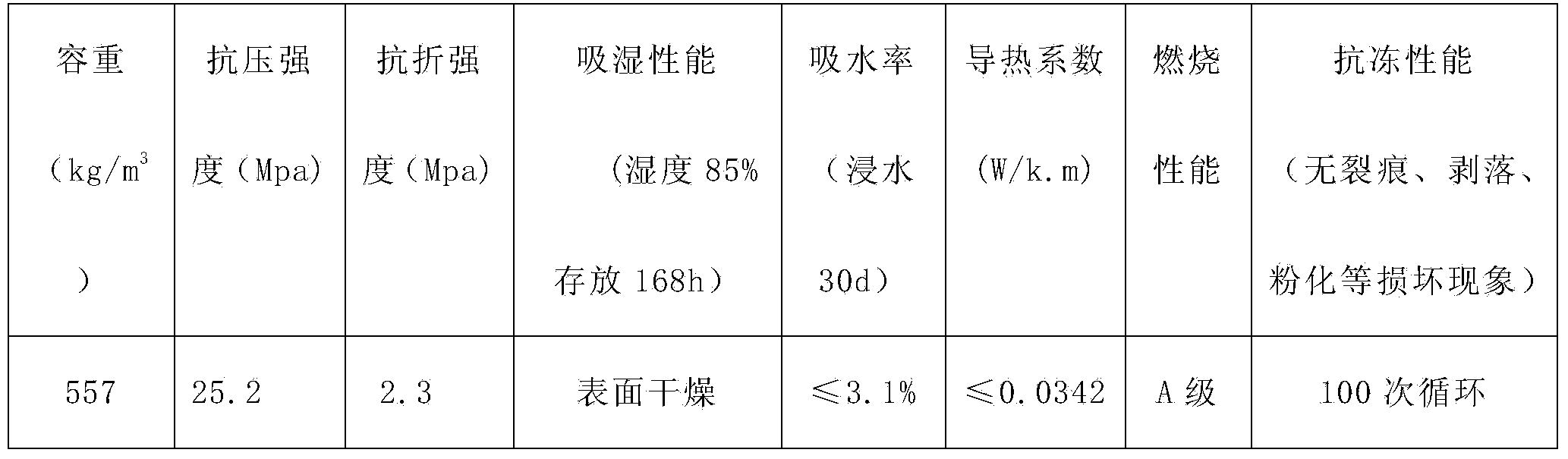

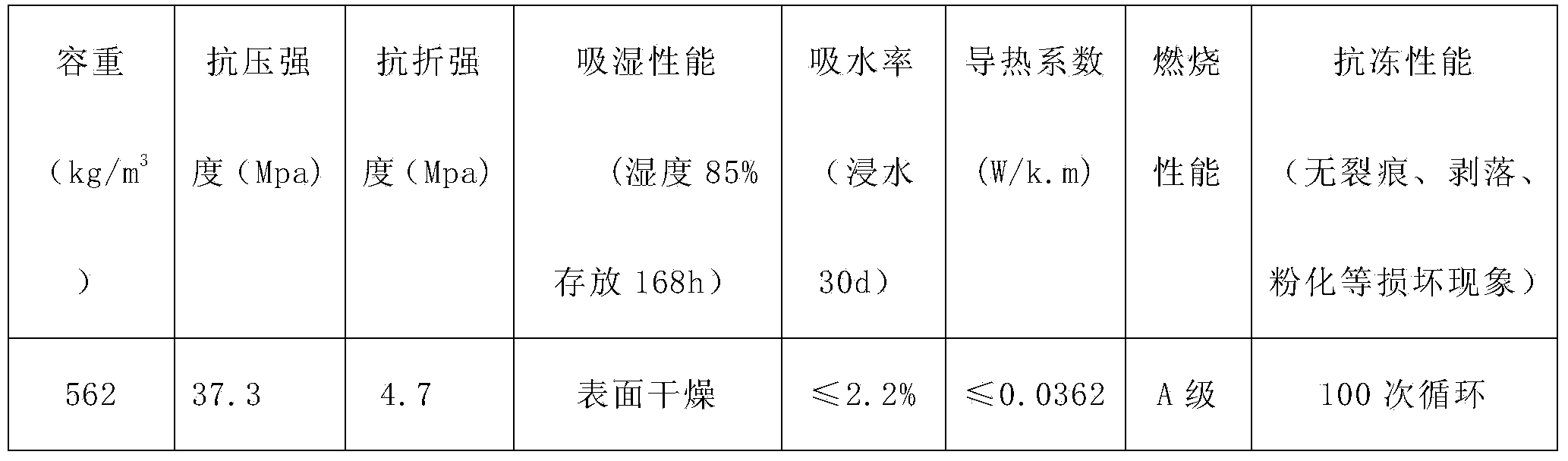

The invention discloses an environment-friendly wall fireproof heat-preserving board and a preparation method thereof. The environment-friendly wall fireproof heat-preserving board is prepared from the following raw materials in parts by weight: 26-60 parts of straw powder, 0.2-3 parts of guanylurea phosphate, 0.1-1.2 parts of boric acid, 15-45 parts of magnesium oxide, 5-15 parts of magnesium chloride or magnesium sulfate, 1-30 parts of coal ash or diatomite in powder, 0-30 parts of crushed crude pearlite or leech powder, 0.1-0.5 part of a styrene-acrylic emulsion, 0.1-0.5 part of calcium lignosulphonate and 5-25 parts of tap water. The preparation method comprises the following steps: first, mixing straw powder, guanylurea phosphate, boric acid, magnesium oxide, coal ash or the diatomite in powder, crushed crude pearlite or leech powder and calcium lignosulphonate; then, adding magnesium chloride or magnesium sulfate, the styrene-acrylic emulsion and tap water; and after fully and uniformly stirring at normal temperature, putting in a template, rolling, maintaining and demoulding to prepare the wall fireproof heat-preserving board. The environment-friendly wall fireproof heat-preserving board has the characteristics of high compression and breaking strength, good moisture absorption, water adsorption, flame retardant and anti-freezing performances, small heat conductivity coefficient, no formaldehyde, environmental friendliness, fireproofness and heat preservation.

Owner:ANHUI ZHONGYI NEW MATERIAL TECH CO LTD +1

Low-carbon environment-friendly cellular light composite wallboard

InactiveCN102155054AGood sound and heat insulation performance and pressure bearing capacityIncreased load carrying capacity and durabilityCovering/liningsHeat proofingCarbon dioxideEngineering

The invention discloses a low-carbon environment-friendly cellular light composite wallboard, comprising cellular paperboard inner core material, a waterproof heat-resisting adhesive layer, environment-friendly panels and a reinforced edge banding connecting and fastening strip. A cellular paperboard with a stable hexagon structure is used as the inner core material and has good sound insulation, heat-shielding performance and loading capacity. The waterproof heat-resisting adhesive layer firmly adheres an upper environment-friendly panel, a middle environment-friendly panel and a lower environment-friendly panel of the cellular paperboard inner core material together so as to form two double-board sound insulation structures, and the double-board sound insulation structures are also reliable heat insulation structures. The environment-friendly panels have the functions of sound insulation, heat insulation, antiflaming and appearance keeping and protecting and can improve the bearing capacity and durability of the cellular light composite wallboard. The reinforced edge banding connecting and fastening strip can exert sealing, moistureproof and supporting protective effects on the four sides of a single composite wallboard and also can exert connection function in wall surface combination and assembly during the installation of the composite wallboards. The prepared cellular light composite wallboard has low density and light weight and has the advantages of good sound insulating, heat insulating, waterproof, antiflamming performances and good durability. By applying the environment-friendly cellular light composite wallboard, the running time of a heating and ventilating equipment system can be reduced, thus consumption of energy source and discharge of carbon dioxide gas can be reduced, and a low-carbon environment-friendly pleasant environment is created.

Owner:YUNNAN JUHE CONSTR GROUP

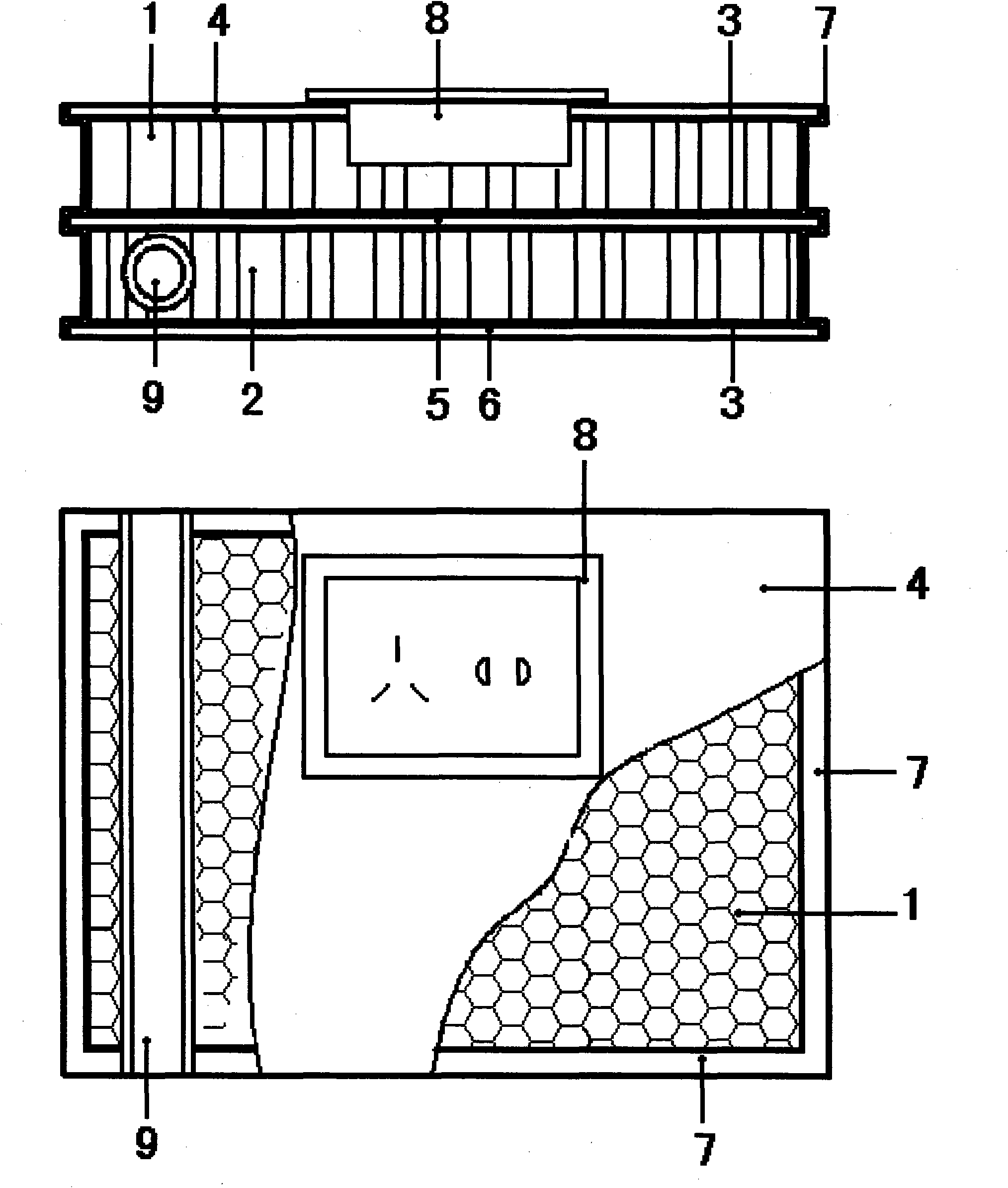

Coal mine air cylinder and manufacturing method thereof

InactiveCN101644164AGood abrasion and tear resistanceReduce weightTunnel/mines ventillationTextiles and paperPlasticizerAntistatic agent

The invention relates to a coal mine air cylinder which comprises gridding base cloth and a PVC calendered coating covered on the base cloth, wherein the PVC calendered coating is coated with antistatic agent, and the gridding base cloth is spun by taking twisting polyester fiber filament yarn as warp and weft; the PVC calendered coating comprises the components based on the parts by weight: 100 parts of SG-70 resin, 73-112 parts of plasticizer, 8-12 parts of inorganic fire retardant, 60-65 parts of inorganic filler, 0.2-1 part of anti-aging agent, 0.1 part of antiseptic, 20-25 parts of pigment and 6-12 parts of coupling agent. The coal mine air cylinder has the advantages of good abrasive resistance, tear resistance, light weight, water resistance, pollution and mould prevention, inflaming retarding, good antistatic effect, ageing resistance, long service life and single-width formation.

Owner:浙江天地塑业有限公司

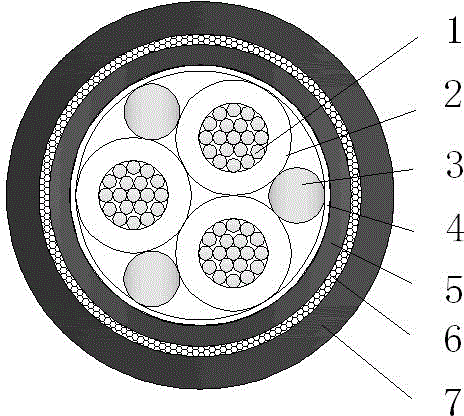

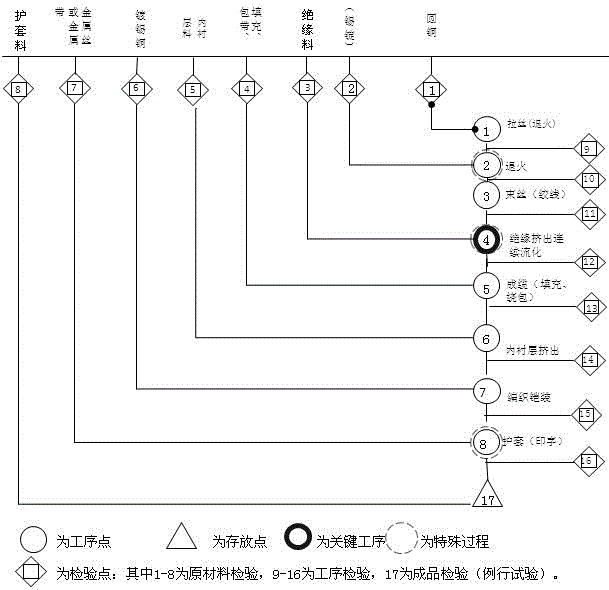

Lightweight flexible LSOH (Low Smoke Zero Halogen) fire-resistant low-voltage marine cable and process flow thereof

InactiveCN104681159ASmall heat insulationImprove insulation performanceFlexible cablesCable/conductor manufactureLow voltageShock resistance

The invention discloses a lightweight flexible LSOH (Low Smoke Zero Halogen) fire-resistant low-voltage marine cable and a process flow thereof. The lightweight flexible LSOH fire-resistant low-voltage marine cable comprises a tin-plated flexible conductor, a ceramic silicone rubber insulating layer, an LSOH flame-retardant filling material, an LSOH wrapping tape layer, an LSOH flame-retardant isolating sleeve, a metal braid armor shielding layer and an LSOH flame-retardant protection sleeve. The cable disclosed by the invention has the advantages of heat insulation, fire insulation, waterproofness, shock resistance, low thermal weight loss, low smoke, zero halogen, flame retardance and the like. In case of a fire, a hard shell formed by the insulating layer can take good effects of flame retardance, fire resistance, fire prevention and fire insulation and effectively ensures smoothness of a line. The cable has the advantages of being flexible, small in size, light in weight and excellent in mechanical property and electrical property, meets the requirement of a complex laying environment in a ship, can effectively save a ship space and reduce a light ship weight of the ship and improves a cargo dead weight of the ship.

Owner:ZHONGTIAN TECH IND WIRE&CABLE SYST CO LTD

Production method for fireproof, flame-resistant, medium-density fiber closet plate

InactiveCN109304787AAlleviate the contradiction between supply and demandHigh hardnessNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesFiberSizing

The invention discloses a production method for a fireproof, flame-resistant, medium-density fiber closet plate. The method comprises the steps of (1) preprocessing of raw materials, (2) screening, (3) steaming and boiling for softening, (4) grinding, (5) sizing and drying, (6) prepressing, (7) hot pressing, (8) sawing and sanding, (9) veneering and hot pressing and (10) edge cutting. In this way,a finished product is obtained. The method disclosed by the invention is characterized in that eucalyptus barks and branches and waste leftover bits and pieces left after panel manufacture are takenas main raw materials, other miscellaneous wood is added and waste is recycled, so wood resources can be utilized fully and effectively; and modified paraffin and flame-resistant urea-formaldehyde resin adhesive are added, so resistance of the product to fire and flame is greatly enhanced. The medium-density fiber cabinet plate is highly resistant to fire, flame and water and low in the content offormaldehyde, so the product is a safe and environment-friendly closet plate.

Owner:广西横州丽冠环保材料有限公司

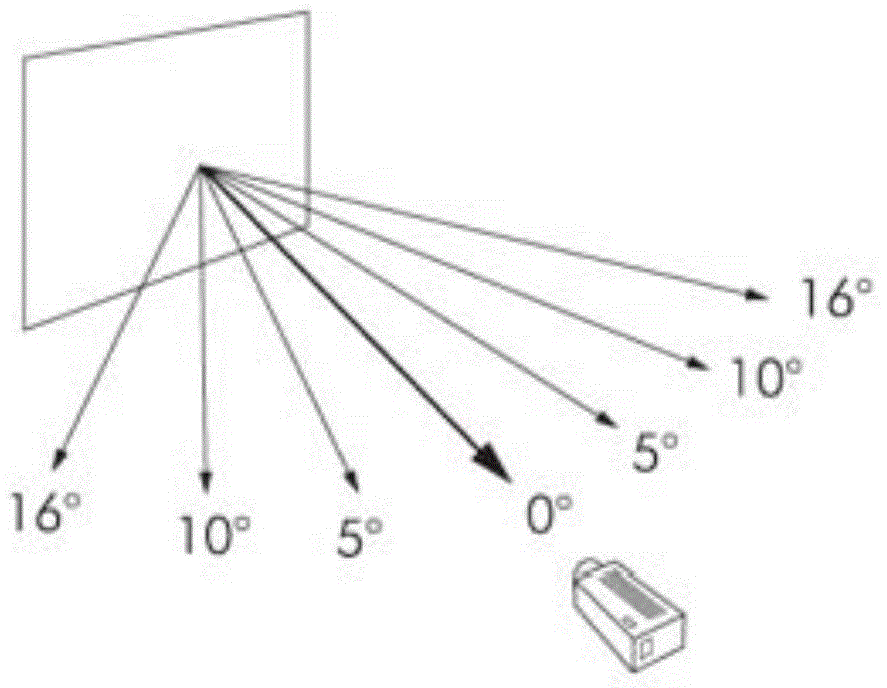

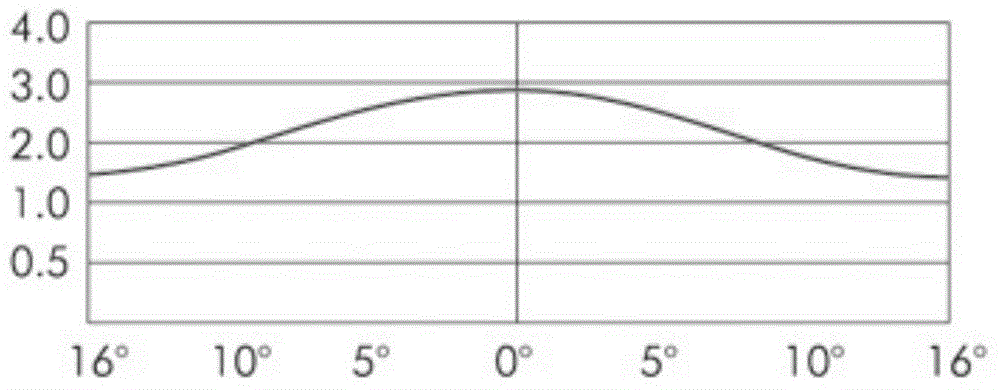

Grey micro-bead projection screen and manufacturing method thereof

The invention discloses a grey micro-bead projection screen which comprises a base material, a PVC black layer formed on one side of the base material and a functional film formed on the other side of the base material, wherein the functional film comprises a light absorption layer and micro-beads protruding out of the upper surface of the light absorption layer, and the functional film comprises, by mass, polystyrene 76%, matte grey coloring agent 2.5%, fire retardant 3%, bridging agent 6.2%, stabilizing agent 1%, defoaming agent 2.3%, wetting agent 3% and the balance micro-beads. The invention further discloses a manufacturing method of the grey micro-bead projection screen. The brightness of the projection screen is high, the gain is improved by more than 2.8 times, an effective scattering angle is larger than 32 degrees, and the grey micro-bead projection screen has the advantages of being high in definition and good in color reproduction and is a special screen for a home theater. Especially, the contrast ratio and black-grey contrast ratio can be well improved under the condition that the brightness is improved, and the perfect stainless frame effect is ensured. The screen surface has the advantages of being anti-corrosion, moisture-proof and flame-retarding, reducing longtime brightness decay and the like.

Owner:JIANGSU REDLEAF AUDIO & VISUAL EQUIP

Flame-retardant nanometer bamboo charcoal antibiosis filler fiber and manufacturing method thereof

InactiveCN102485981AWith flame retardant functionHas antibacterial functionHollow filament manufactureMelt spinning methodsSpinningBamboo charcoal

The invention provides a flame-retardant nanometer bamboo charcoal antibiosis filler fiber. The fiber comprises the following components, by mass, 1-20% of a nanometer bamboo charcoal antibiosis master batch and 80-99% of a sliced carrier. A manufacturing method of the fiber comprises the following steps: mixing the nanometer bamboo charcoal antibiosis master batch and the needed sliced carrier according to a certain ratio, uniformly stirring them, selecting a spinneret plate according to the fiber processing fineness and the section shape of the fiber, fusion-spinning, cooling, reeling, filament bunding, drafting, and spirally and curly cutting into short fibers to prepare the flame-retardant nanometer bamboo charcoal antibiosis filler fiber. The fiber of the invention has the advantages of substantial flame retardation and antibiosis, peculiar smell adsorption function possessing, soft handle, good elasticity, and wide application.

Owner:SHANGHAI JAROS NEW MATERIAL

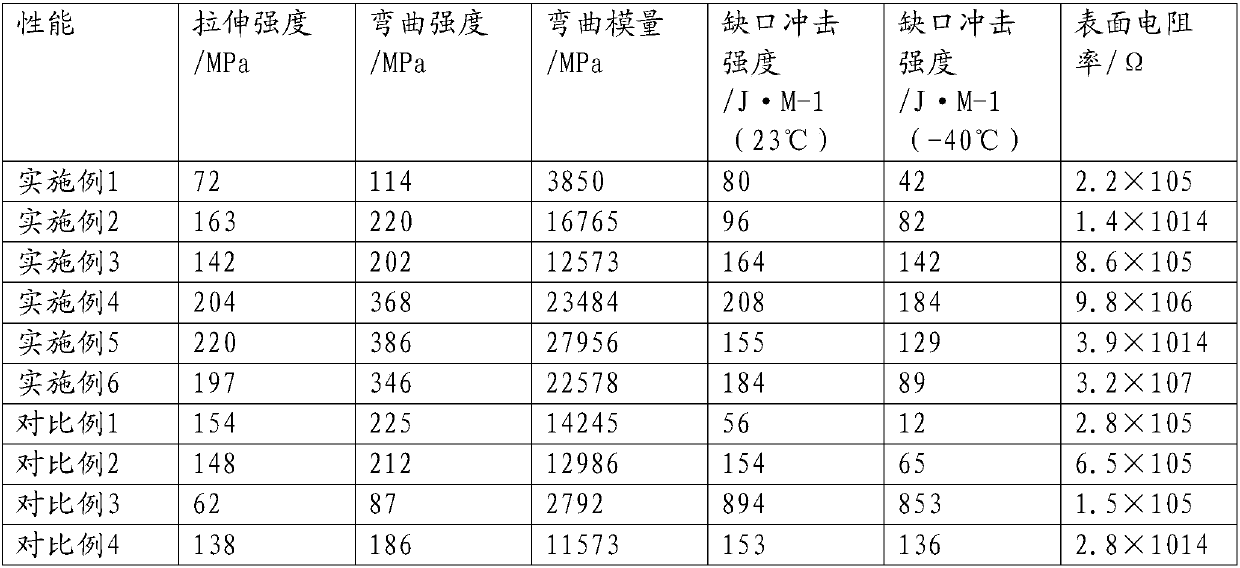

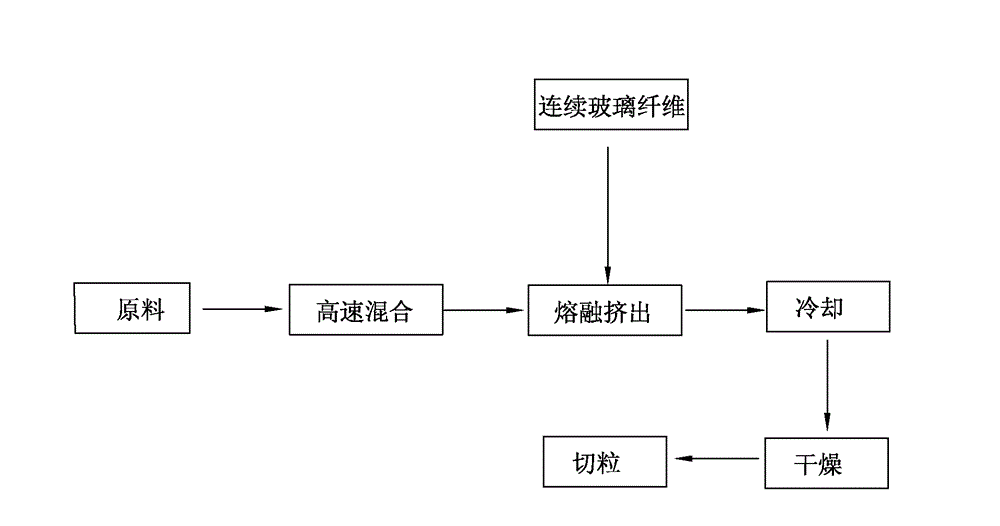

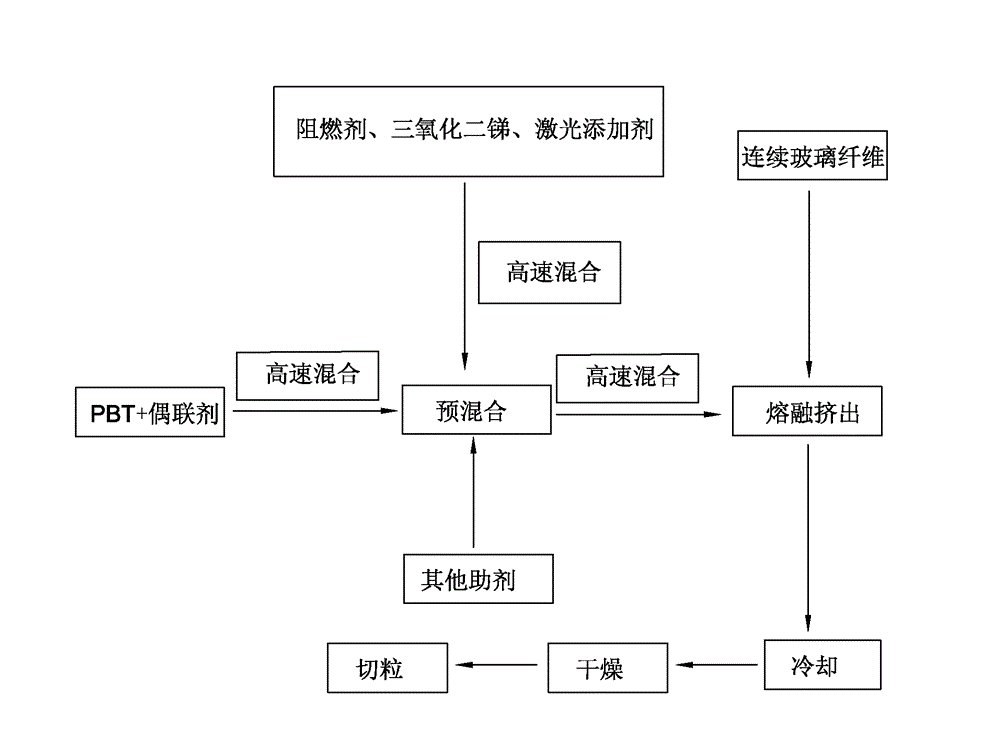

Glass fiber reinforced flame retardant polybutylene terephthalate resin composition with laser engraving function and preparation method thereof

ActiveCN102719062AGood mechanical propertiesGood flame retardantPolytetramethylene terephthalatePolymer chemistry

The invention belongs to the technical field of resin compositions and particularly relates to a glass fiber reinforced flame retardant polybutylene terephthalate resin composition with a laser engraving function and a preparation method thereof. The composition comprises, by weight, 43.2 to 73.2 parts of polybutylene terephthalate, 0 to 40 parts of continuous glass fibers, 9.5 to 15 parts of halogen flame-retardants, 3 to 5 parts of antimony trioxide, 3 to 5 parts of toughening agents, 0 to 0.5 part of coupling agents, 0.3 to 1.0 part of laser additives, 0.3 to 0.5 part of antioxidants, 0.3 to 0.5 part of lubricating agents and 0 to 0.5 part of carbon black. The resin composition simultaneously has good mechanical property, flame retardant property and laser marking performance, and evident laser marks in black, white or gray and the like can be made in a laser etching mode on matrices in different colors by the composition.

Owner:SUZHOU SILVER AGE TECH CO LTD

Preparation method of flame-retardance and light-resistance phosphorylation fatliquor

InactiveCN104152602AImprove flame retardant performanceImprove light resistanceLeather impregnationPhysical chemistrySilver molybdate

The invention discloses a preparation method of flame-retardance and light-resistance phosphorylation fatliquor. Concentrated sulfuric acid and silver molybdate are added in castor oil, the temperature is increased to 70-85 DEG C, and the condensation backflow insulation reaction is performed for 3-4 hours to obtain a product A; phosphorus pentoxide dispersion liquid is added in the product A for evenly mixing, and the temperature is increased to 70-90 DEG C and kept for 3-4 hours to obtain a product B; a light resistant material is added in the product B for evenly mixing, the temperature is increased to 60-80 DEG C and kept for 1-3 hours, a flame retardant material and cuprous chloride are added in the product B, the temperature is increased to 70 DEG C, and the mixing reaction is performed for 2-3 hours to obtain a product D; and sodium hydroxide solution is dripped in the product D to become neutral to obtain brown liquid, and the brown liquid is the flame-retardance and light-resistance phosphorylation fatliquor. The prepared fatliquor not only retains the sensory performance and mechanical strength of traditional fatliquor, but also has excellent flame retardance and light resistance.

Owner:ANYANG INST OF TECH

Processing method of multifunctional environment-friendly polyvinyl chloride composite decorative material

ActiveCN102218877AImprove environmental performanceReduce manufacturing costSynthetic resin layered productsPolyurea/polyurethane coatingsFiberCarbon fibers

The invention discloses a processing method of a multifunctional environment-friendly polyvinyl chloride composite decorative material, comprising the following steps of: preparing mixed slurry; mixing and evenly stirring an environment-friendly plasticizer and polyvinyl chloride paste resin; then adding nano calcium carbonate, ultrafine carbon fiber, an environment-friendly viscosity dropping agent and an environment-friendly stabilizing agent and evenly stirring to prepare scraping slurry; and then preparing a base material through a release paper processing technique. An environment-friendly plasticizer mixture is used to replace dioctyl phthalate (DOP) used in the prior art, compact honeycomb structures in the middle layer of the main raw material polyvinyl chloride paste resin are formed by adopting an environment-friendly assistant, the nano calcium carbonate and carbon fiber padding and the multifunctional environment-friendly polyvinyl chloride composite decorative material isprepared through post-processing techniques.

Owner:WUXI MANYOULI NEW COMPOSITE MATERIALS

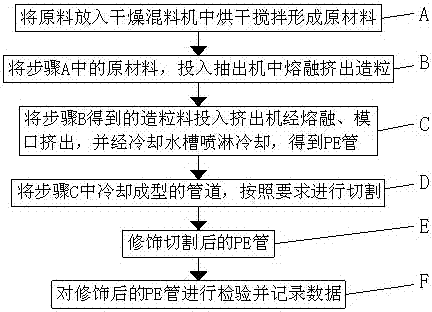

PE pipe production method

The invention discloses a PE pipe production method. The method comprises A, putting PE resin powder, color master batches, a clay nanocomposite material, a flame retardant, nanometer calcium carbonate, a dispersant, an antistatic agent, a coupling agent, a low temperature-resistant plasticizer and an antioxidant into a drying mixer together, and carrying out drying stirring to obtain a raw material, B, adding the raw material into an extractor and carrying out melting extrusion granulation, and C, putting the granulated material into an extruder, carrying out melting and extruding the material through a die outlet. The product is prepared from the PE resin powder, color master batches, clay nanocomposite, flame retardant, nanometer calcium carbonate, dispersant, antistatic agent, coupling agent, low temperature-resistant plasticizer and antioxidant through mixing. The PE pipe has good static resistance, corrosion resistance, flame resistance, flexibility, low temperature resistance, high temperature resistance, good fast crack growth fracture toughness and good pressure resistance and guarantees the safety of the PE pipe in any environments.

Owner:长兴佳能高分子材料有限公司

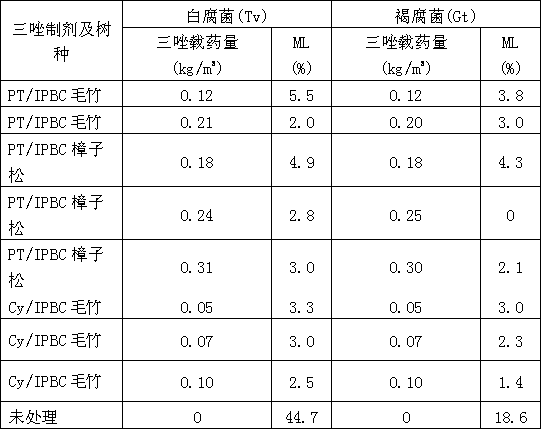

Wood and bamboo material corrosion and mold prevention modified combination agent and wood and bamboo material treating method

ActiveCN109015981AAnti-corrosionMildew proofWood treatment detailsReed/straw treatmentWater solubleFire retardant

The invention belongs to a wood and bamboo material corrosion and mold prevention modified combination agent and a wood and bamboo material treating method. The wood and bamboo material corrosion andmold prevention modified combination agent comprises, by weight, 0.04-0.10 part of triazole, 0.05-0.12 part of 3-iodo-2-propynyl butylcarbamate, 1-6 parts of water soluble dyes, 1-6 parts of dyeing assistants, 1-6 parts of fire retardants and 1-10 parts of polymerization inhibitors. A wood and bamboo material treated through the modified combination agent can simultaneously have the functions of corrosion prevention, mold prevention, dyeing, inflaming retarding and pharmaceutical composition loss resistance, and has the advantages of easy operation, easy implementation, low preparation and using cost, good durability and long service life.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Nano-calcium plastic fiber felt composite automobile inner decoratire lining board and its manufacturing method

A composite lining sheet for the internal decoration of car is composed of surficial nano-Ca / plasticl ayer, thermoplastic fibre felt, nano-Ca / plastic layer and non-woven cloth as substrate. It is prepared through proportionally mixing the waste plastics with nano-calcium carbonate, plastic modifier and stabilizer to obtain the nono-Ca / plastic powder, thermal fusing, applying it to the thermoplastic fibre felt, cold rolling, and attaching non-woven cloth to its one surface.

Owner:蒋姝华 +1

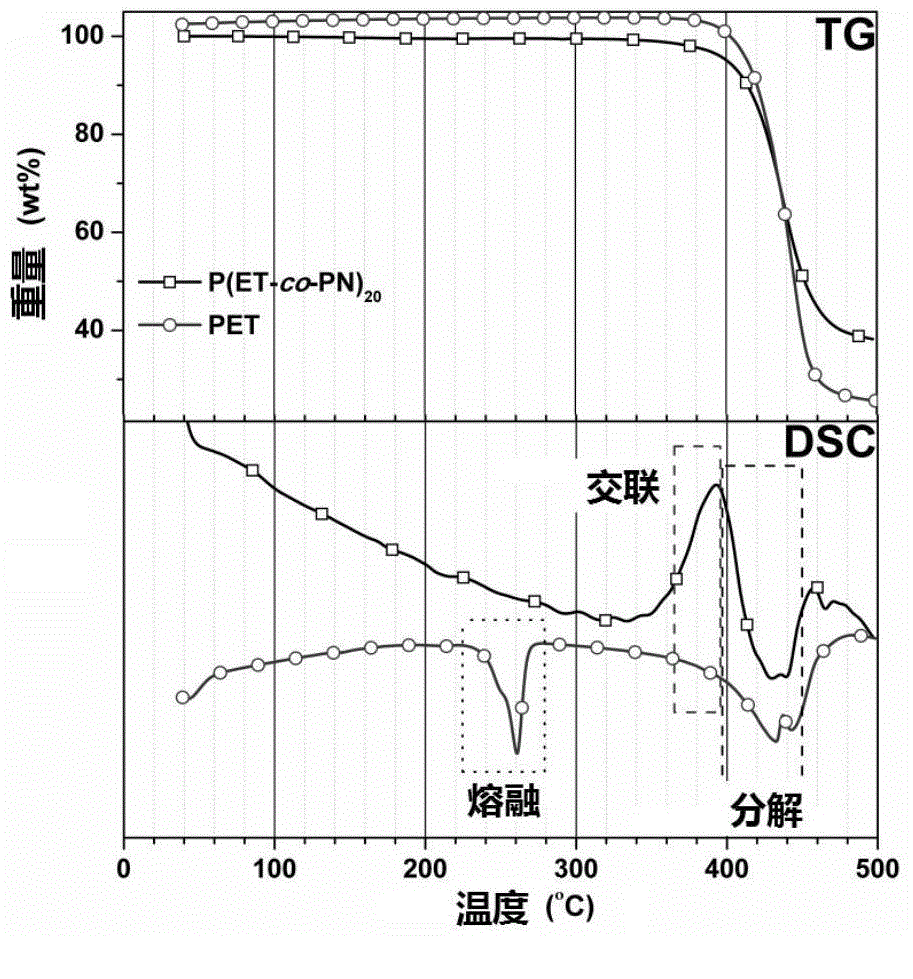

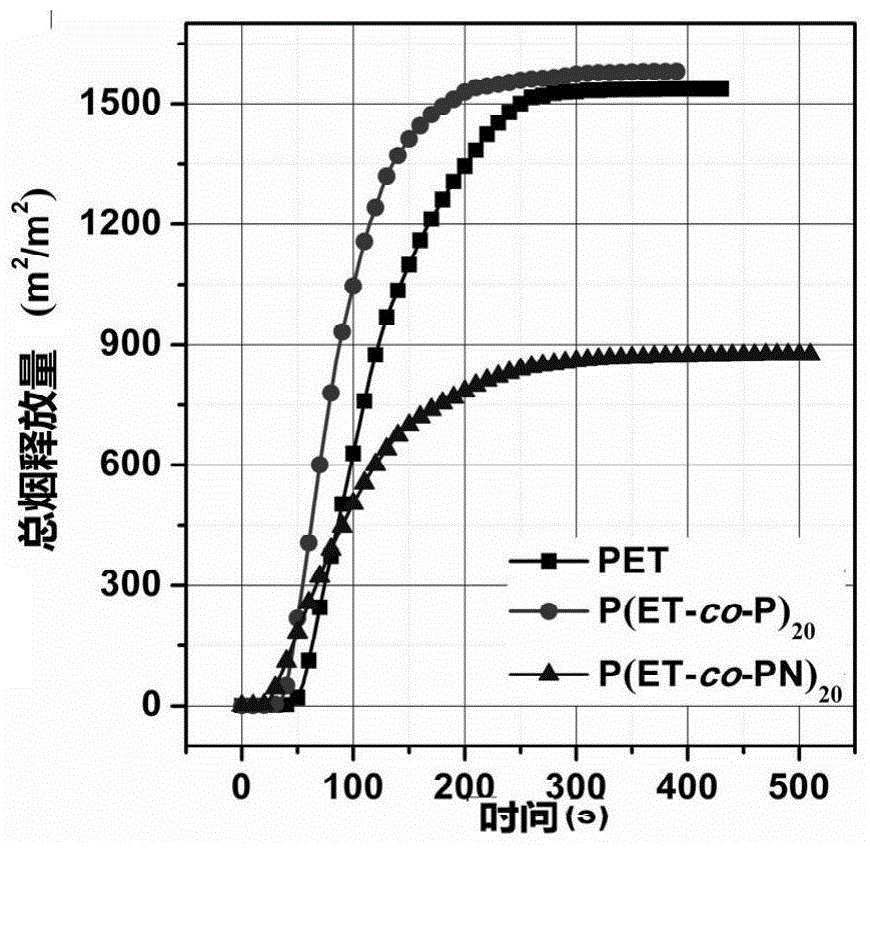

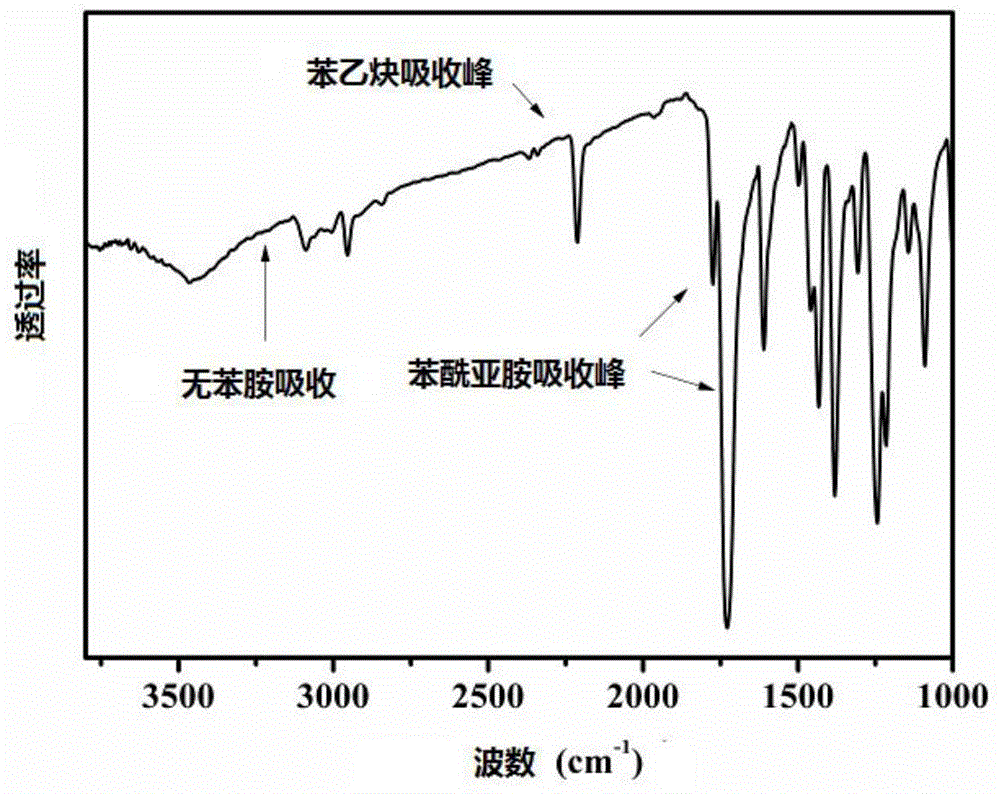

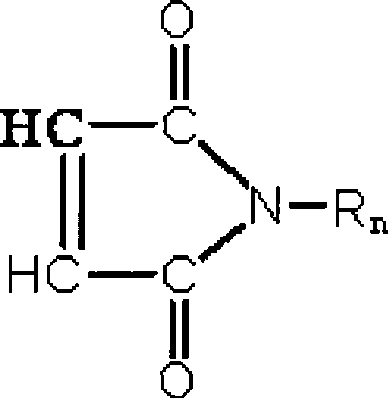

Monomer containing benzimide phenylacetylene structure, high temperature self-crosslinked copolyester and preparation method thereof

ActiveCN104592094AHigh self-crosslinking flame retardant efficiencyGood flame retardantOrganic chemistryPolymer scienceChemical reaction

The invention discloses a monomer containing a benzimide phenylacetylene structure. The monomer can enable self-crosslinking chemical reaction of a synthesized polymer under high temperature. The monomer containing a benzimide phenylacetylene structure and the structural units represented by I and II for synthesis of polyester can undergo random copolymerization to obtain high temperature self-crosslinked copolyester, and when the copolyester contains a PET structural unit, the characteristic viscosity number [eta] is 0.44-1.38dL / g, the vertical combustion UL-94 grade is from V-2 to V-0, the oxygen index LOI is 24.0-35.0%, and the cone calorimeter test peak heat release rate PHRR and the smoke release total amount are both lower than pure polyester. The invention also discloses a preparation method of the copolyester. The benzimide and phenylacetylene in the copolyester involved in the invention can generate synergistic cross-linking effect, so that the copolyester has very high flame-retardant and anti-dripping efficiency, and also the copolyester is endowed with excellent flame retardant, anti-dripping and smoke suppressing performance. The method provided by the invention is basically consistent with the synthesis method of conventional polyester, not only is mature in technology, and easy and convenient to operate, but also is easy to control and convenient for industrial production.

Owner:SICHUAN UNIV

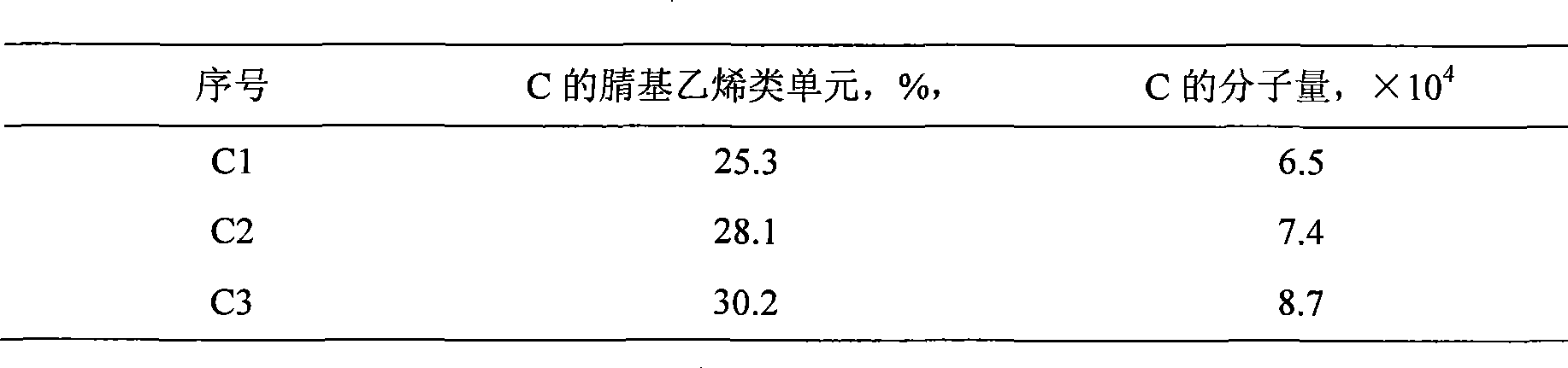

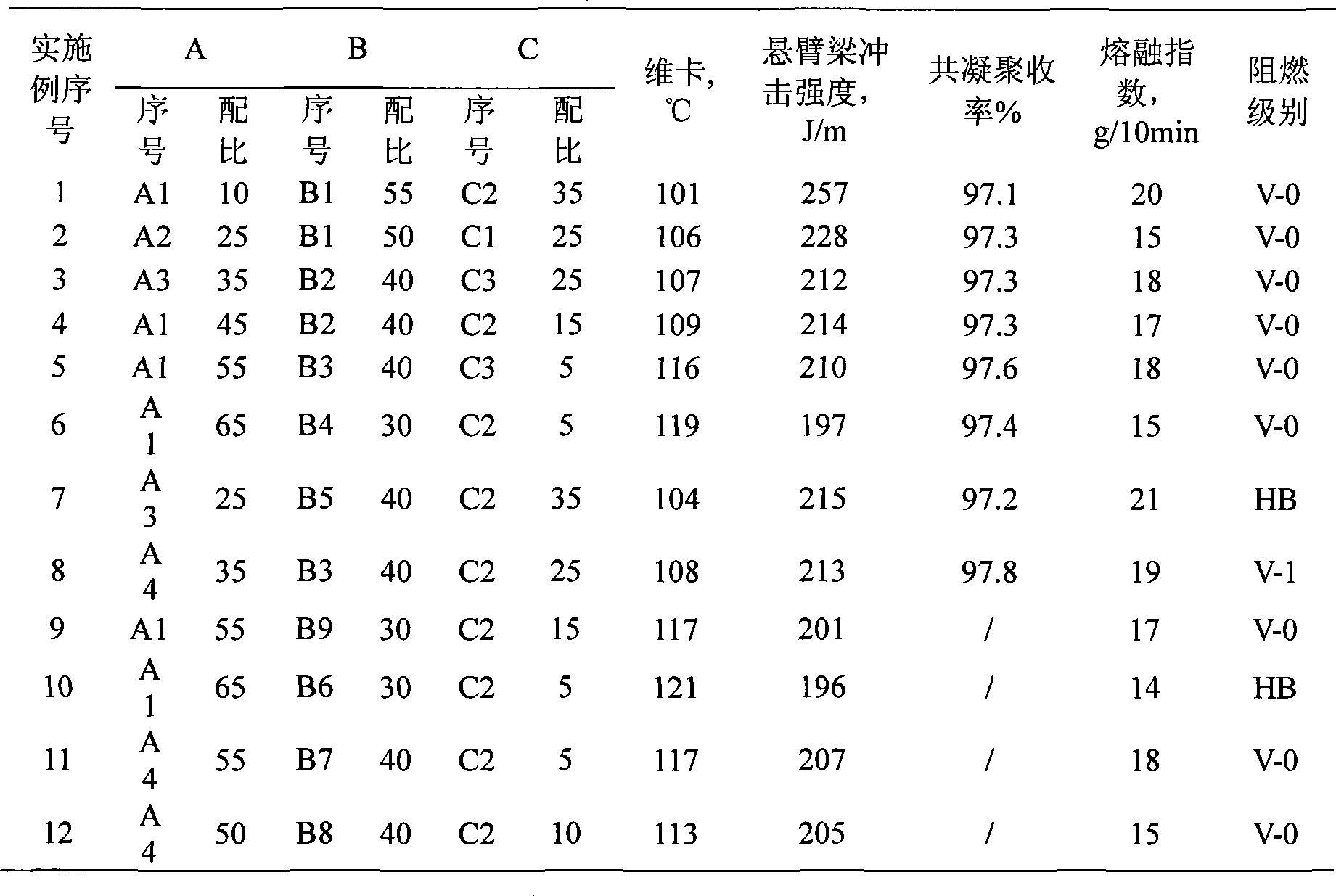

Heat resisting flame retardant resin composition and preparation thereof

The invention provides a halogen substituent maleimide heat-resistant flame-retardant resin composition and a preparation method thereof. Based on 100 parts by weight, the resin composition comprises 10-65 parts of halogen substituent maleimide heat-resistant flame-retardant resin, 30-55 parts of a graft polymer of a conjugated diene rubber graft aryl ethylene unit and a nitrile vinyl unit and 5-35 parts of a binary copolymer of aryl ethylene monomers and nitrile vinyl monomers. The halogen substituent maleimide heat-resistant flame-retardant resin composition prepared by the method has the advantages of flame retardation and high heat resistance, and the resin composition is a heat-resistant flame-retardant material with excellent properties. The prepared heat-resistant flame-retardant resin can be widely used for modifying heat resistance and flame retardance of such materials as ABS, PC, PBT and the like. As a material with excellent heat-resistant and flame-retardant properties, the resin composition can be used alone for preparing high heat-resistant and flame-retardant parts of automobiles and household electrical appliances.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com