Flame retardant thermoplastic elastomer (TPE) made from waste crosslinked polyethylene cable materials and preparation method thereof

A thermoplastic elastomer and cross-linked polyethylene technology, which is applied in the field of flame-retardant thermoplastic elastomer and its preparation, can solve the problems of air pollution, organic matter pollution of water sources, high landfill costs, etc., to reduce environmental pollution, superior flame-retardant, The effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

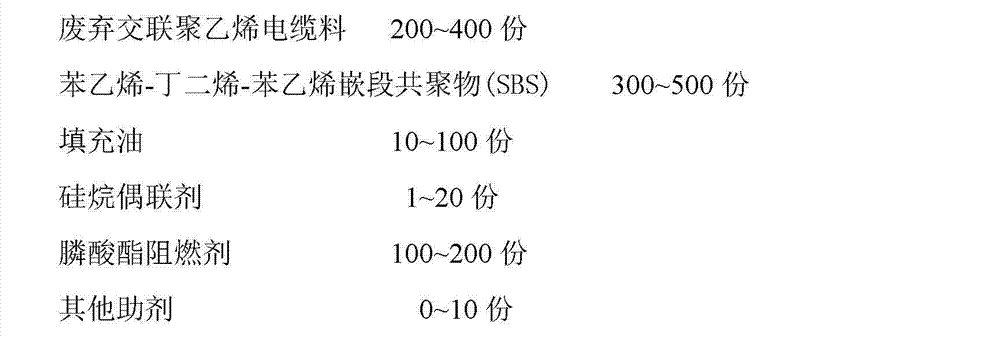

Method used

Image

Examples

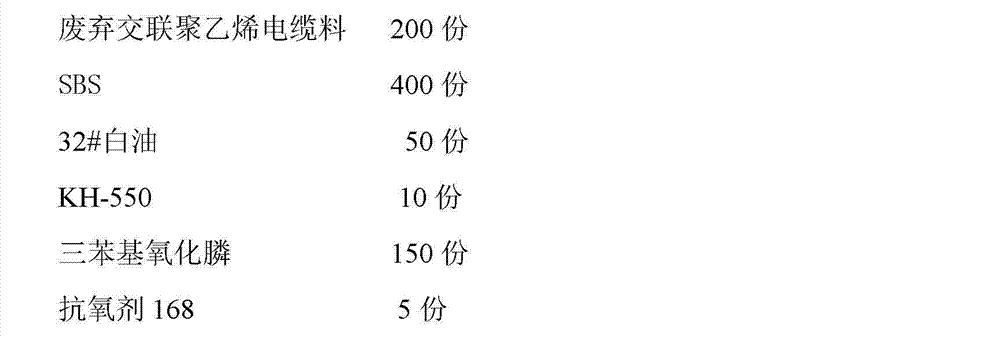

Embodiment 1

[0026]

[0027] (1) Routinely pulverize the waste XLPE cable material to obtain a coarse powder with a particle size of 0.1~10mm; then use the solid phase force chemical reactor (patent No. 95111258.9 solid phase force chemical reaction device) for solid-phase ultrafine pulverization to obtain ultrafine powders with a particle size of 20 μm to 100 μm. (2) Ultrafine powder of waste XLPE cable material, styrene-butadiene-styrene block copolymer (SBS YH 792, Baling Petrochemical), 32# white oil, KH-550 (Nanjing Nengde Chemical Co., Ltd.), triphenylphosphine oxide (Clariant), and antioxidant 168 (provided by Ciba) were added into a mixer and stirred evenly, and then blended and granulated by a twin-screw extruder. The output process is: the screw speed is 400r / min; the temperature from the machine head to the feeding port is: 205°C in the first zone, 215°C in the second zone, 220°C in the third zone, 225°C in the fourth zone, 220°C in the fifth zone, 220°C in the sixth zone, an...

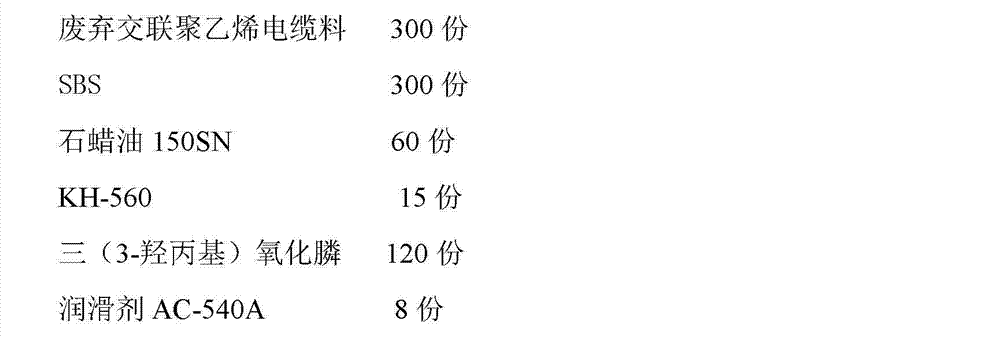

Embodiment 2

[0030]

[0031] (1) Routinely pulverize the waste XLPE cable material to obtain a coarse powder with a particle size of 0.1~10mm; then use the solid phase force chemical reactor (patent No. 95111258.9 solid phase force chemical reaction device) for solid-phase ultrafine pulverization to obtain ultrafine powders with a particle size of 20 μm to 100 μm. (2) Ultrafine powder of waste cross-linked polyethylene cable material, styrene-butadiene-styrene block copolymer (SBS YH 788, Baling Petrochemical), paraffin oil 150SN, KH-560 (Nanjing Energy German Chemical Co., Ltd.), three (3-hydroxypropyl) phosphine oxide (Clariant), and lubricant AC-540A (provided by Honeywell) were added to the mixer and stirred evenly, and then blended and granulated by a twin-screw extruder. The extrusion process is as follows: the screw speed is 350r / min; the temperature from the machine head to the feeding port is: 200°C in the first zone, 210°C in the second zone, 220°C in the third zone, 225°C in ...

Embodiment 3

[0034]

[0035]

[0036](1) Routinely pulverize the waste XLPE cable material to obtain a coarse powder with a particle size of 0.1~10mm; then use the solid phase force chemical reactor (patent No. 95111258.9 solid phase force chemical reaction device) for solid-phase ultrafine pulverization to obtain ultrafine powders with a particle size of 20 μm to 100 μm. (2) Ultrafine powder of waste XLPE cable material, styrene-butadiene-styrene block copolymer (SBS YH 792, Baling Petrochemical), 32# white oil, KH-550 (Nanjing Nengde Chemical Co., Ltd.), triphenylphosphine oxide (Clariant), and antioxidant 168 (provided by Ciba) were added into a mixer and stirred evenly, and then blended and granulated by a twin-screw extruder. The output process is: the screw speed is 400r / min; the temperature from the machine head to the feeding port is: 205°C in the first zone, 215°C in the second zone, 220°C in the third zone, 225°C in the fourth zone, 220°C in the fifth zone, 220°C in the six...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com