Monomer containing benzimide phenylacetylene structure, high temperature self-crosslinked copolyester and preparation method thereof

A technology containing phenylimide phenylacetylene and copolyester, which is applied in the field of high temperature self-crosslinking copolyester and its preparation, can solve the problems of limiting the application range of polyester and increasing smoke emission, and achieves high self-crosslinking The effect of combined flame retardant efficiency, flame retardant rate improvement, and good flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057]In a 250mL three-neck flask equipped with a nitrogen protection device, magnetic stirring, and a water trap equipped with a spherical condenser, add 10g of dimethyl 5-aminoisophthalate and 80mL of NMP. Under the protection of nitrogen, stir for 30 minutes to obtain a homogeneous solution, then add 11.9g of 4-phenylacetylene phthalic anhydride, heat the solution to 75°C, and keep it for 2h; then add 20g of toluene, the reaction is gradually heated to 180°C, and the generated water is passed through the water separator Take out; after reacting for 6-8 hours, cool to 120°C, pour the mixed solution into excess deionized water to obtain a yellow-green solid, filter it with suction, wash with water and dry. That is, dimethyl 5-(4-phenylacetylene benzimide)-1,3-dibenzoate was obtained.

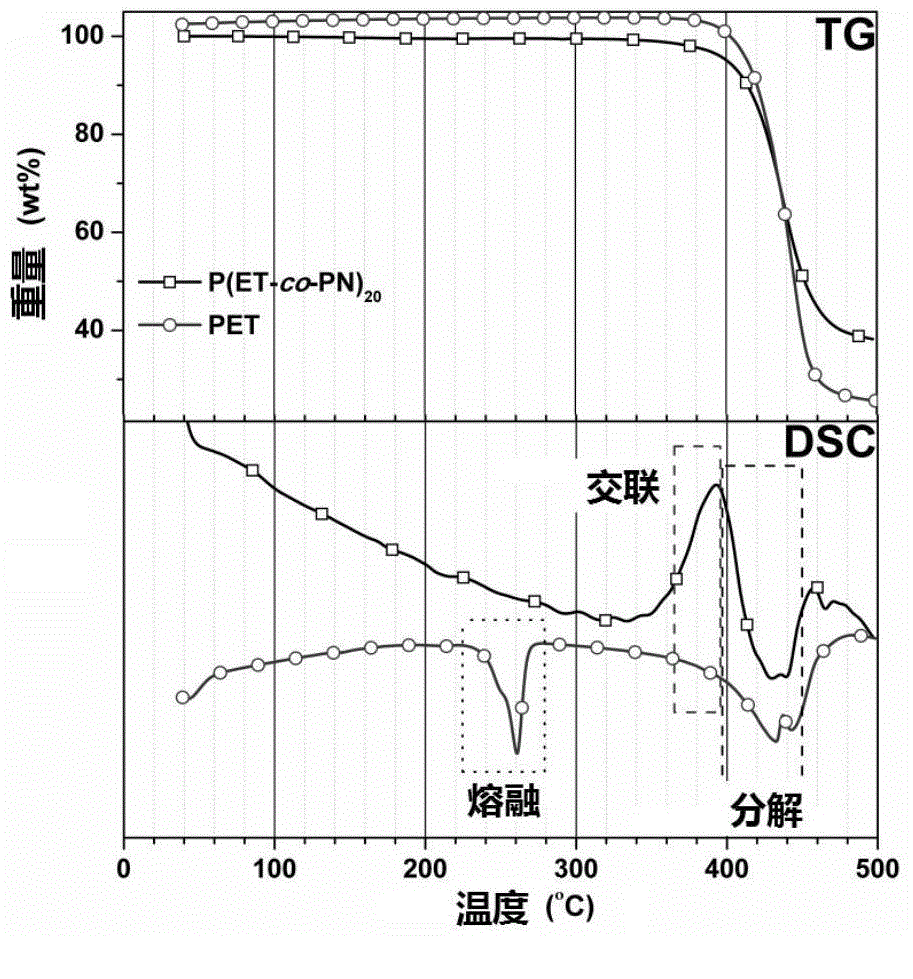

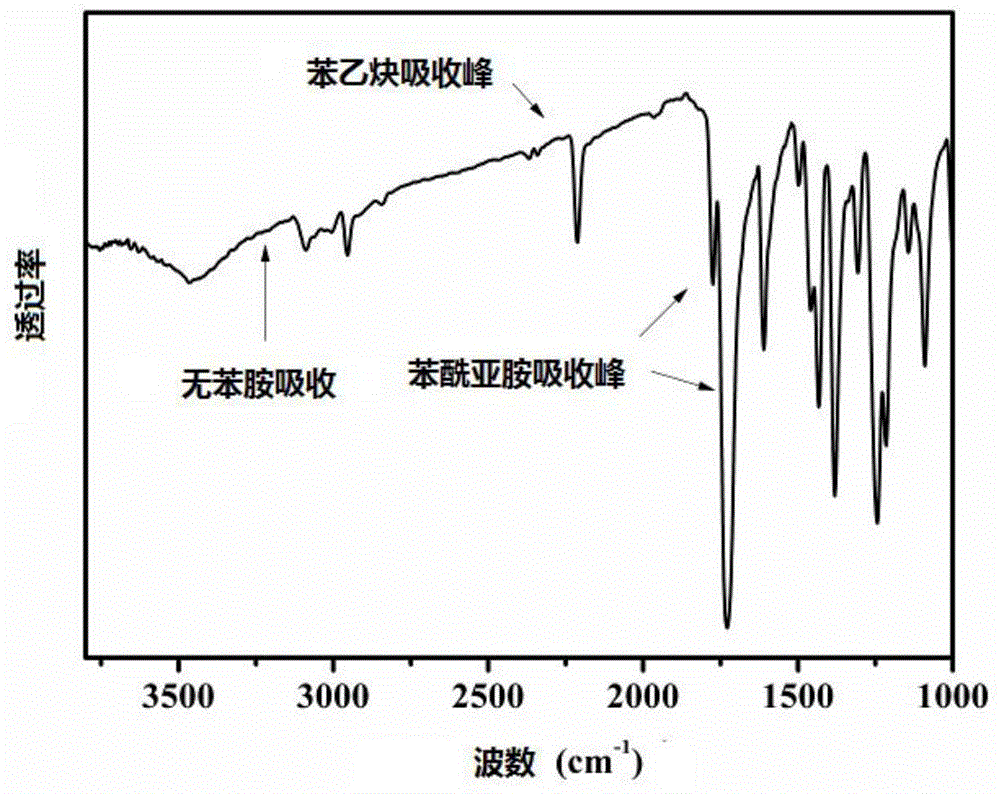

[0058] The infrared absorption characteristic peaks of the monomer are: 2920, 2853, 1780, 1722, 600, 1450cm -1 . Its NMR chemical shifts are: 8.2-8.6, 7.5-8.1, 3.9ppm. like figure 1 , fig...

Embodiment 2

[0060] Add 10 g of aniline and 80 mL of NMP to a 250 mL three-neck flask equipped with a nitrogen protection device, magnetic stirring, and a water trap equipped with a spherical condenser. Under the protection of nitrogen, stir for 30 minutes to obtain a homogeneous solution, then add 15g of 4-(4-acetylene phthalic anhydride)-1,2-dibenzoic acid, heat the solution to 75°C, and keep it for 2h; then add 20g of toluene, and the reaction is gradually heated to 180°C, the generated water is taken out by the water separator; after reacting for 6-8 hours, cool to 120°C, pour the mixed solution into excess deionized water, filter with suction, wash with water and dry. That is, 4-benzimide phenylacetylene-1,2-dibenzoic acid was obtained.

Embodiment 3

[0062] Add 10 g of aniline and 80 mL of NMP to a 250 mL three-neck flask equipped with a nitrogen protection device, magnetic stirring, and a water trap equipped with a spherical condenser. Under the protection of nitrogen, stir for 30 minutes to obtain a homogeneous solution, then add 15g of 5-(4-acetylene phthalic anhydride)-1,3-dibenzoic acid, heat the solution to 75°C and keep it for 2h; then add 20g of toluene, and the reaction is gradually heated to 180°C, the generated water is taken out by the water separator; after reacting for 6-8 hours, cool to 120°C, pour the mixed solution into excess deionized water, filter with suction, wash with water and dry. That is, 5-benzimide phenylacetylene-1,3-dibenzoic acid was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peak heat release rate | aaaaa | aaaaa |

| release amount | aaaaa | aaaaa |

| peak heat release rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com