Patents

Literature

30results about How to "Improve self-crosslinking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Foaming material for shoes

InactiveCN102532675ANarrow molecular weight distributionIncrease elasticityFootwearElastomerPolyolefin

The invention provides a foaming material for shoes. The foaming material comprises the following raw materials in parts by weight: 20-30 parts of ethylene-vinyl acetate copolymer, 20-30 parts of polyethylene, 15-25 parts of polyolefin elastomer, 1-10 parts of filler, 2-5 parts of foaming agent and 0.1-0.5 parts of cross-linking agent. The foaming material for the shoe provided by the invention has the characteristics of high elasticity, wear resistance, bacteria removal, odor removal and environmental friendliness, and leftover materials can be reutilized.

Owner:蔡龙源

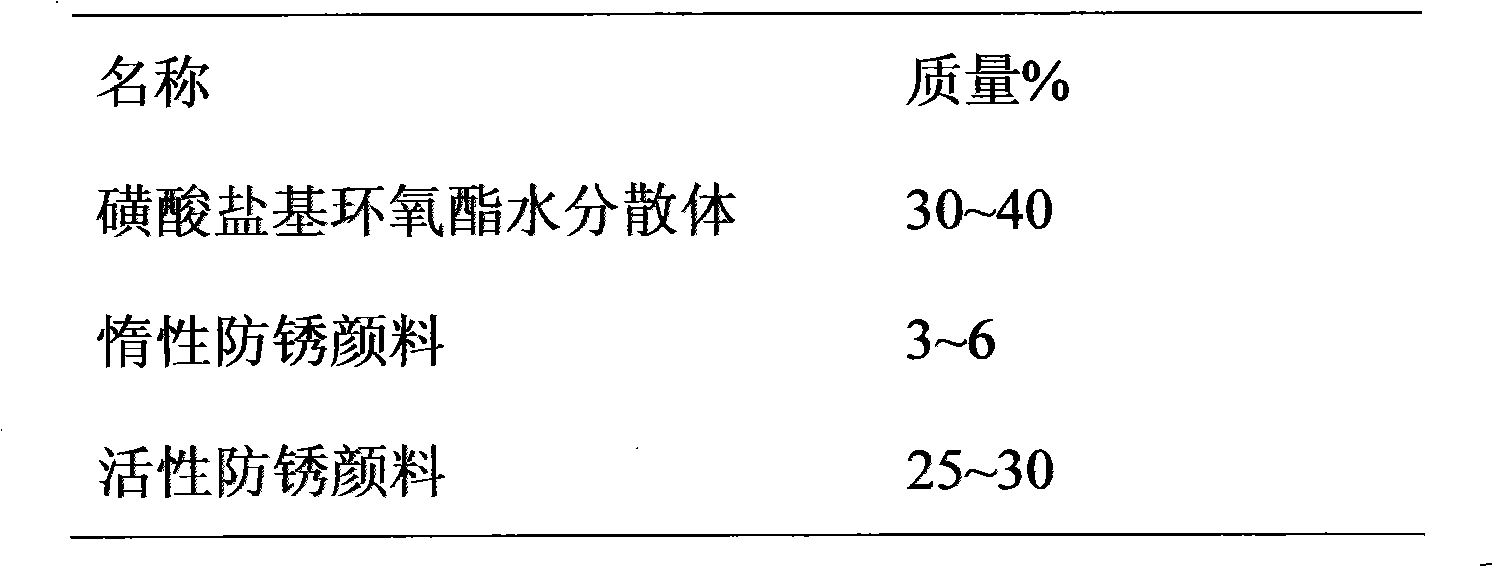

One-component waterborne epoxy ester anticorrosive priming paint used for automobile chassis and preparation method of one-component waterborne epoxy ester anticorrosive priming paint

The invention provides one-component waterborne epoxy ester anticorrosive priming paint used for an automobile chassis and a preparation method of the one-component waterborne epoxy ester anticorrosive priming paint. The priming paint is prepared from, by weight, 20-30% of waterborne epoxy ester resin, 2-45% of pigment, 0-15% of anti-rust pigment, 0-17% of filler, 0.5-2.0% of neutralization agent, 0-3.0% of wetting dispersant, 0.05-0.5% of defoamer, 0.1-1.0% of waterborne dryer, 0.1-0.5% of leveling agent, 0.1-0.5% of thickening agent and 20-40% of deionized water. The invention further provides the preparation method of the anticorrosive priming paint, and various indicators of the anticorrosive priming paint all reach the indicator level of solvent type automobile chassis anticorrosive priming paint; the anticorrosive priming paint can completely replace the solvent type automobile chassis anticorrosive priming paint, and is high in drying speed, good in storage stability, excellent in water resistance and corrosion resistance, good in self-crosslinking property, safe in use, wide in raw material source and low in cost, and large-scale application and promotion are convenient to achieve.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

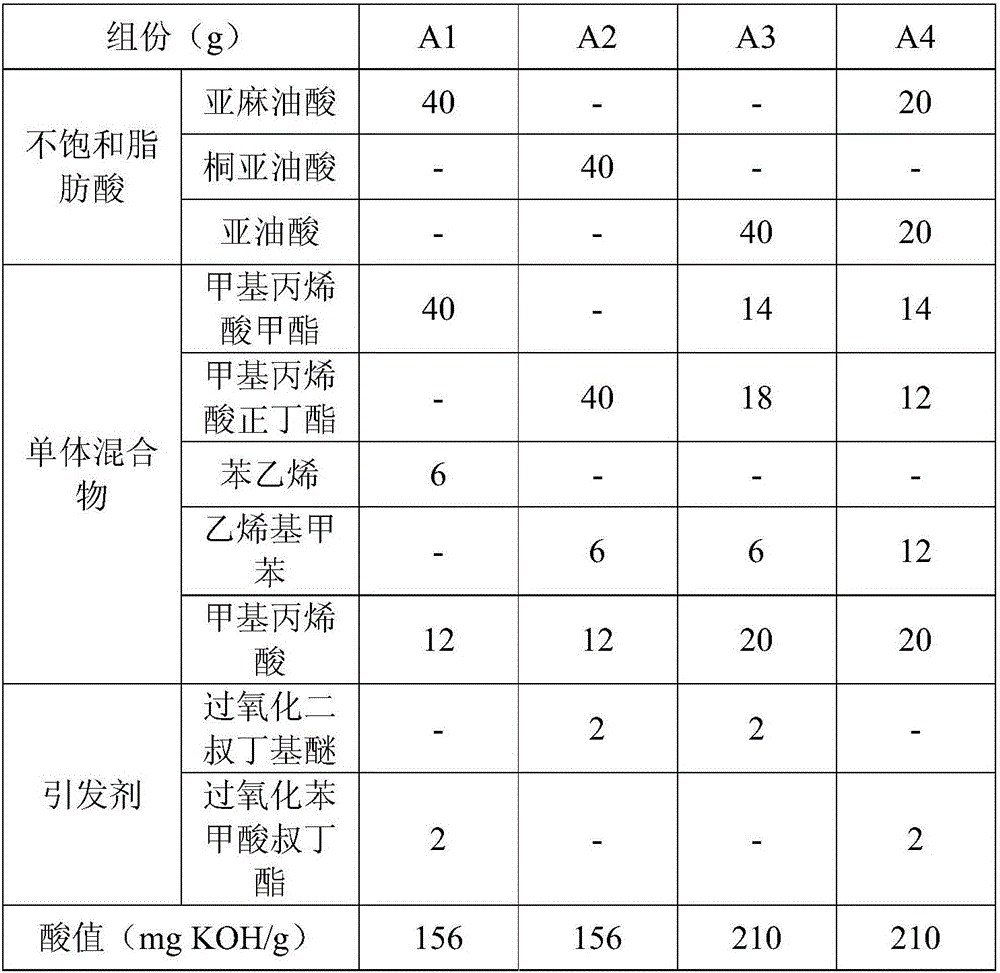

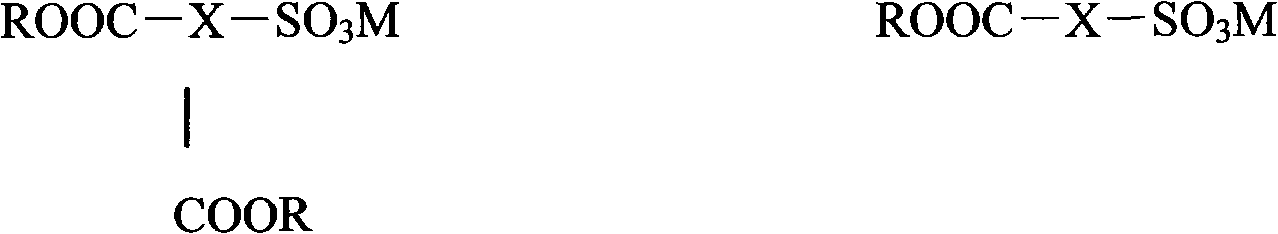

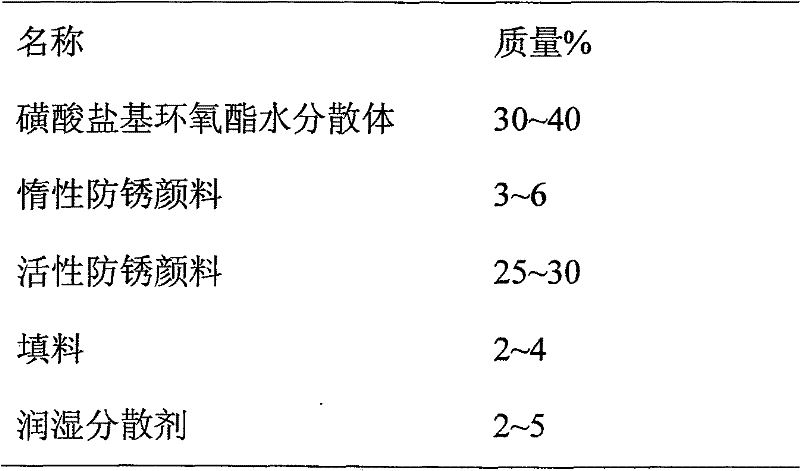

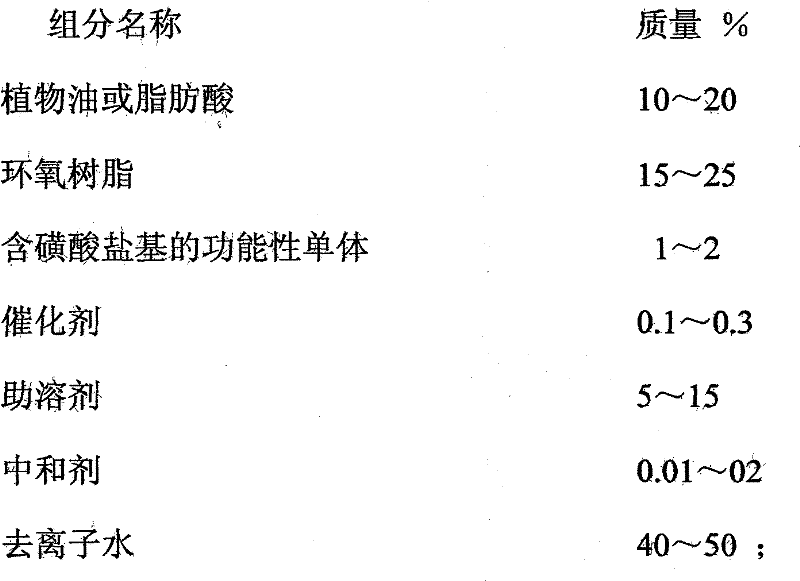

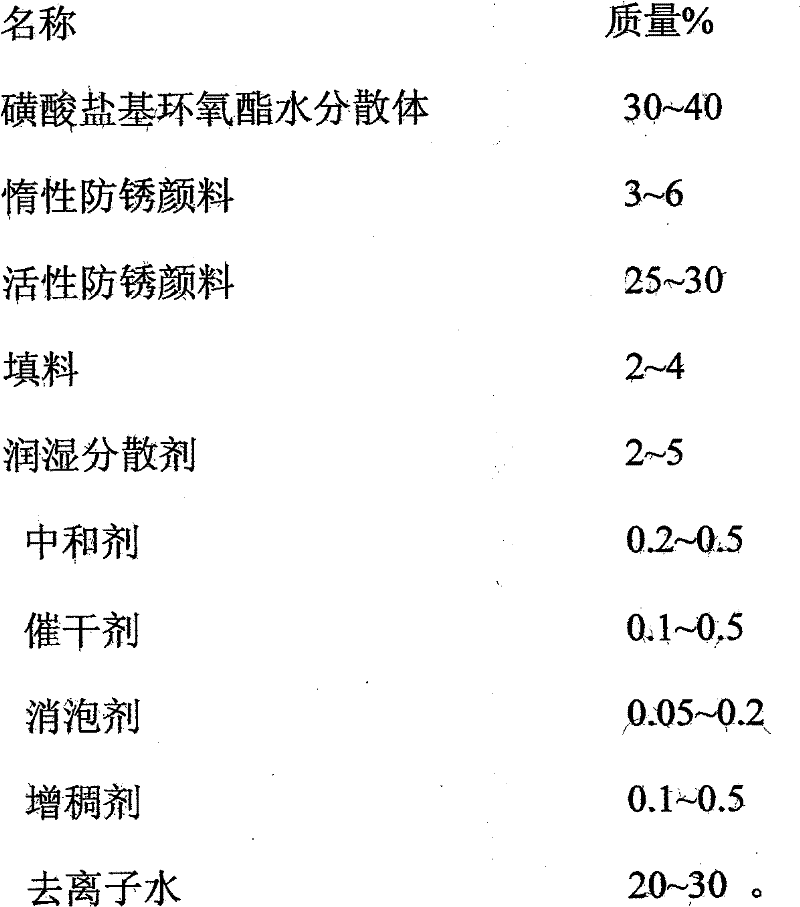

Self-crosslinking sulfonate-base epoxy ester aqueous dispersion and anti-corrosive primer thereof

ActiveCN101659740AGood storage stabilitySmall particle sizeAnti-corrosive paintsEpoxy resin coatingsEpoxySulfonate

The invention relates to a self-crosslinking sulfonate-base epoxy ester aqueous dispersion and an anti-corrosive primer thereof. The self-crosslinking sulfonate-base epoxy ester aqueous dispersion ischaracterized in that the aqueous dispersion is prepared by introducing a sulfonate functional monomer into epoxy resin, wherein vegetable oil or fatty acid, the epoxy resin and the functional monomercontaining a sulfonate base undergo esterification reaction in the presence of a catalyst; when the acid value is qualified, a latent solvent and a neutralizing agent are added into the mixture; andfinally, the mixture is diluted by deionized water to obtain the sulfonate-base epoxy ester aqueous dispersion. An aqueous anti-corrosive primer prepared by using the epoxy ester aqueous dispersion asa base material has excellent storage stability, and waterproof and anti-corrosive properties.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

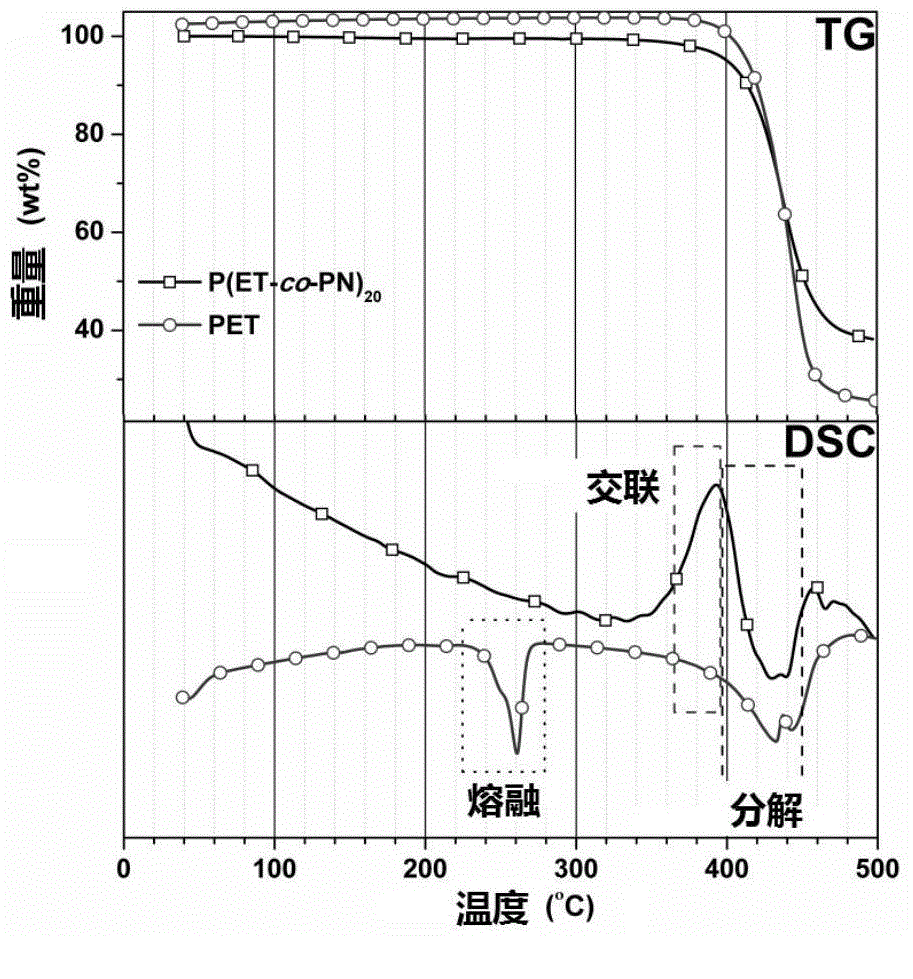

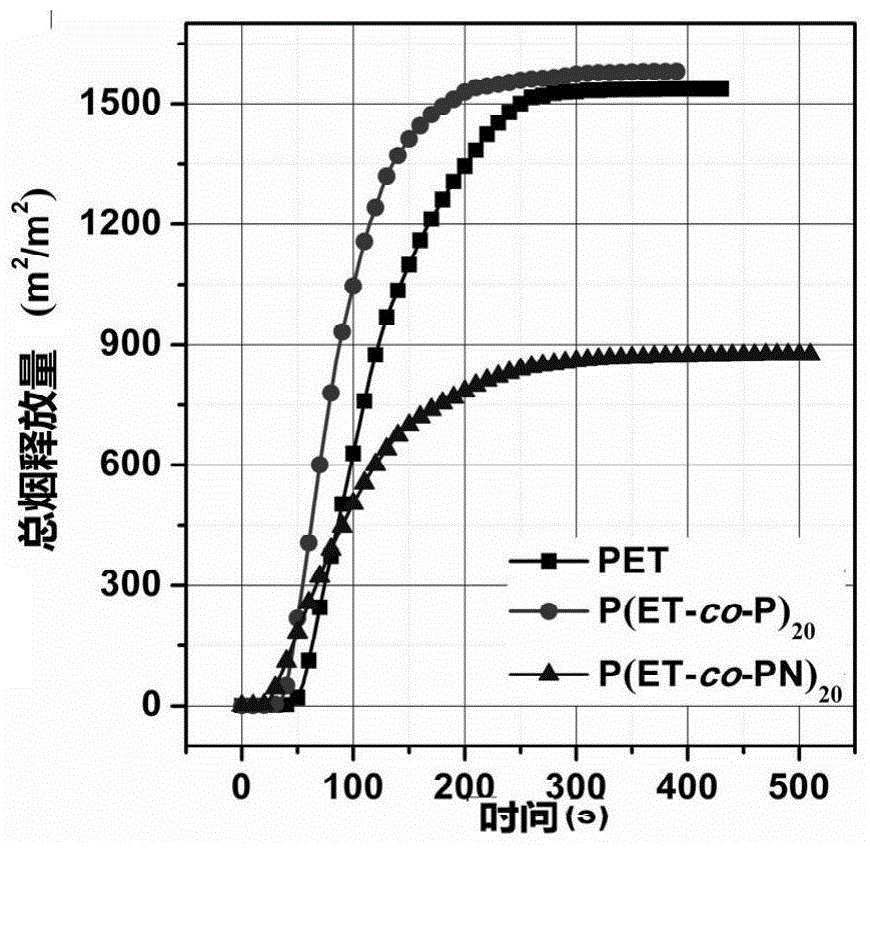

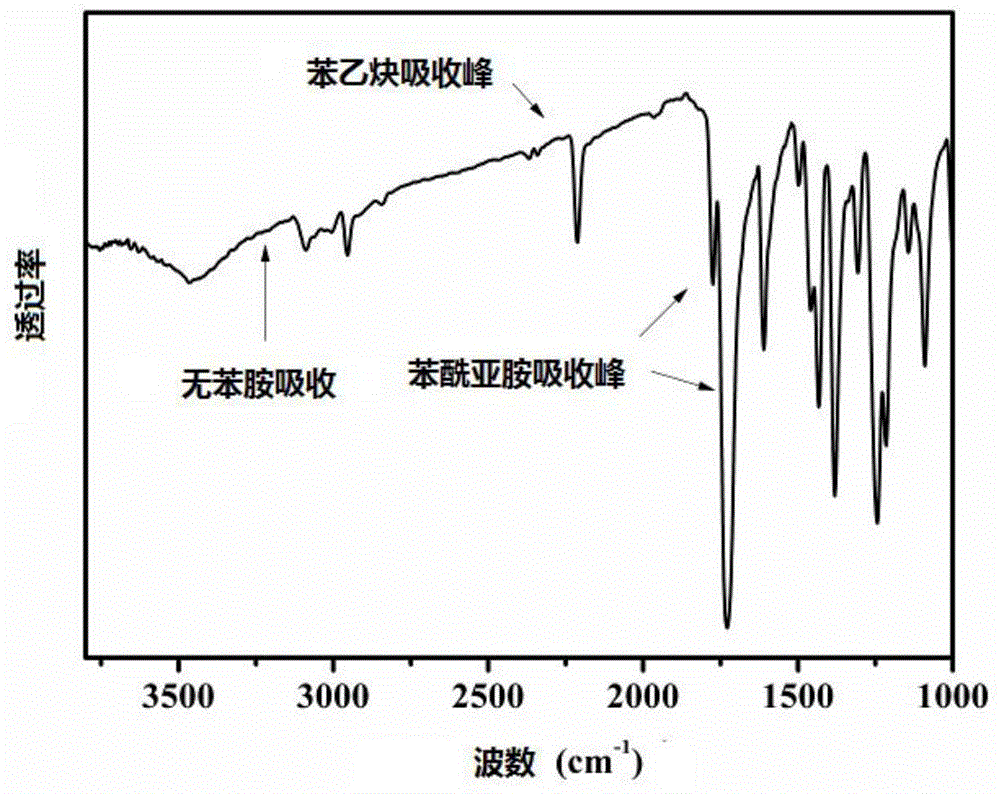

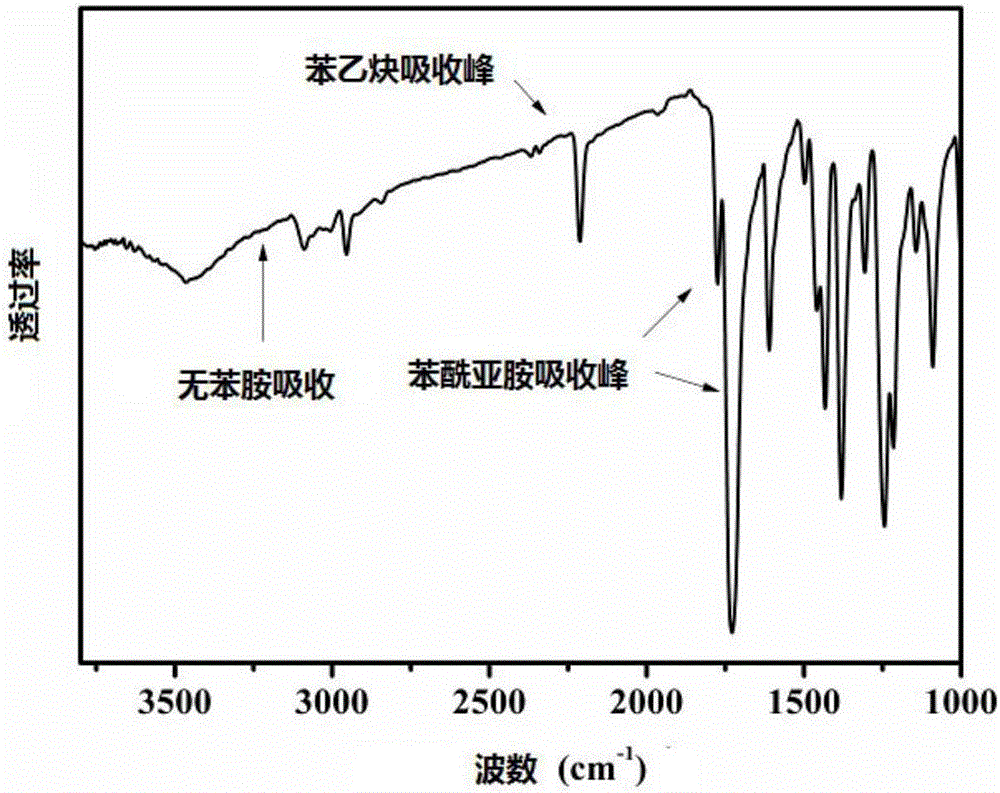

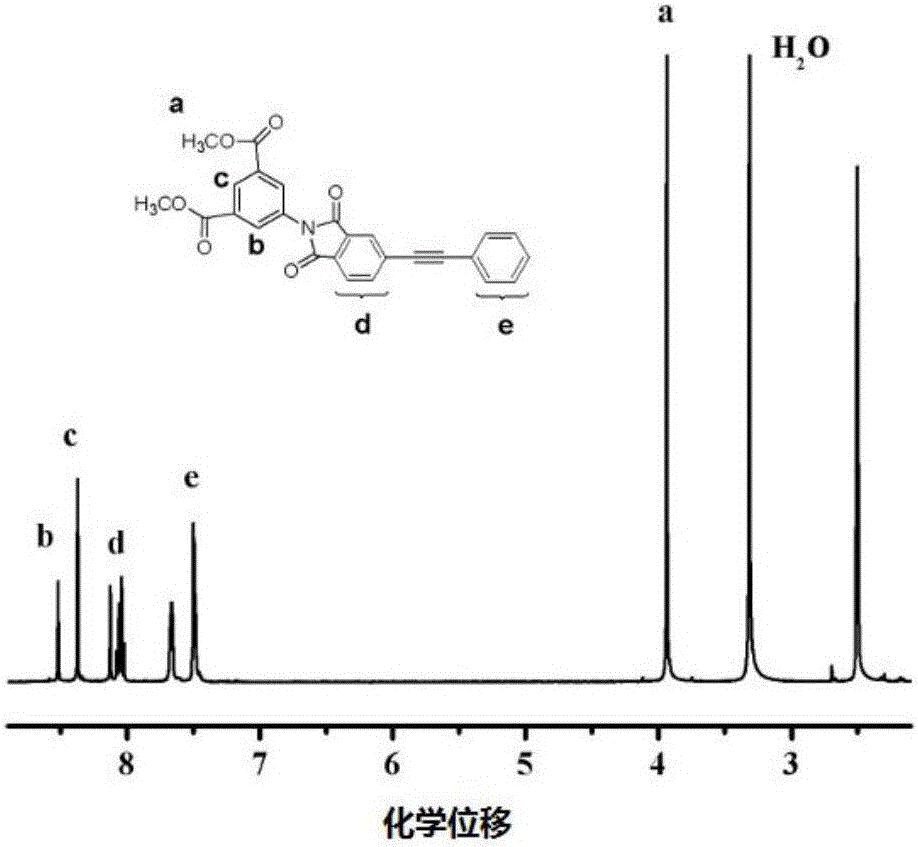

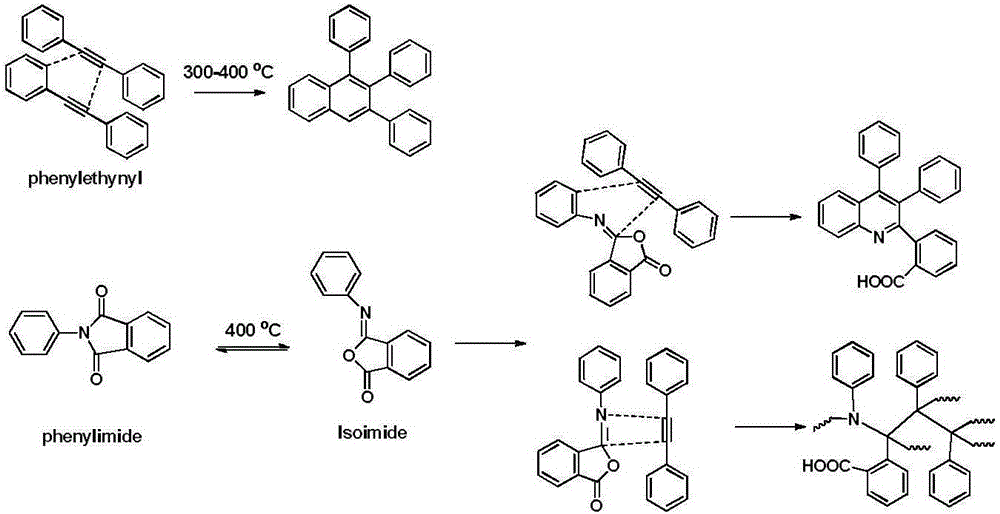

Monomer containing benzimide phenylacetylene structure, high temperature self-crosslinked copolyester and preparation method thereof

ActiveCN104592094AHigh self-crosslinking flame retardant efficiencyGood flame retardantOrganic chemistryPolymer scienceChemical reaction

The invention discloses a monomer containing a benzimide phenylacetylene structure. The monomer can enable self-crosslinking chemical reaction of a synthesized polymer under high temperature. The monomer containing a benzimide phenylacetylene structure and the structural units represented by I and II for synthesis of polyester can undergo random copolymerization to obtain high temperature self-crosslinked copolyester, and when the copolyester contains a PET structural unit, the characteristic viscosity number [eta] is 0.44-1.38dL / g, the vertical combustion UL-94 grade is from V-2 to V-0, the oxygen index LOI is 24.0-35.0%, and the cone calorimeter test peak heat release rate PHRR and the smoke release total amount are both lower than pure polyester. The invention also discloses a preparation method of the copolyester. The benzimide and phenylacetylene in the copolyester involved in the invention can generate synergistic cross-linking effect, so that the copolyester has very high flame-retardant and anti-dripping efficiency, and also the copolyester is endowed with excellent flame retardant, anti-dripping and smoke suppressing performance. The method provided by the invention is basically consistent with the synthesis method of conventional polyester, not only is mature in technology, and easy and convenient to operate, but also is easy to control and convenient for industrial production.

Owner:SICHUAN UNIV

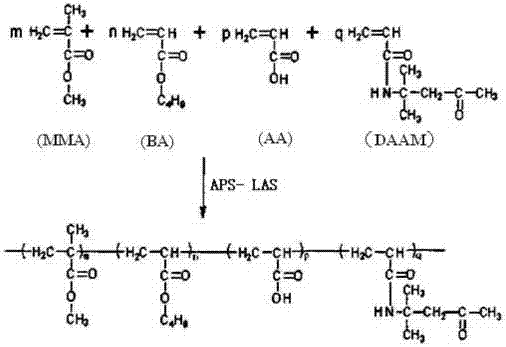

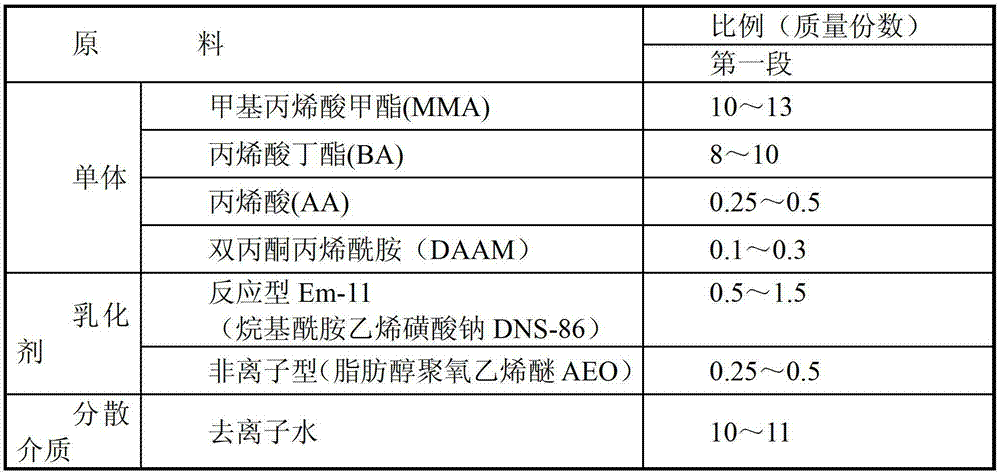

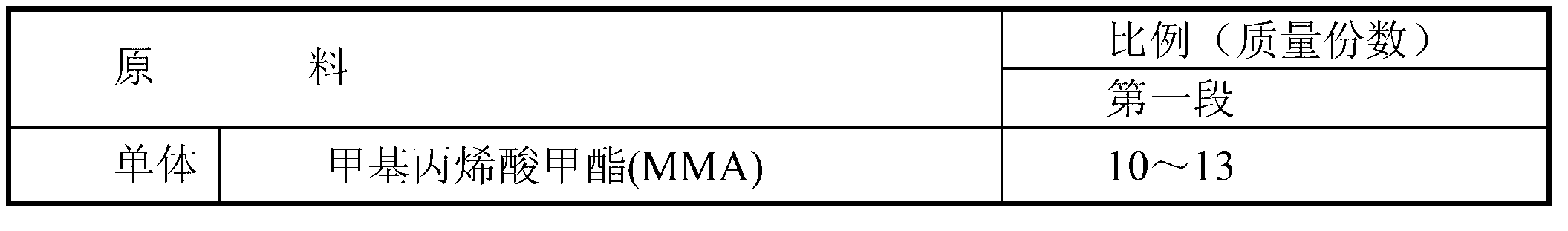

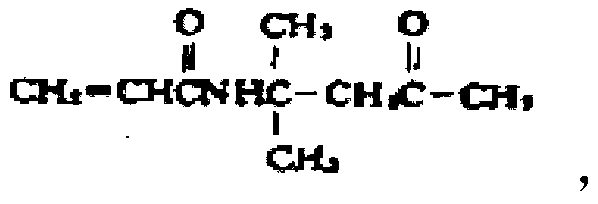

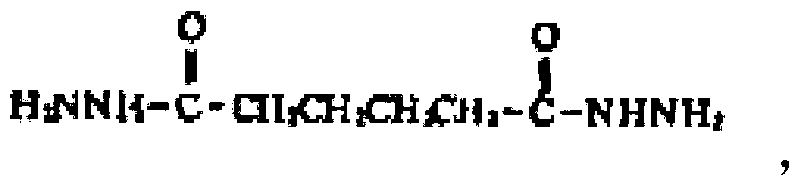

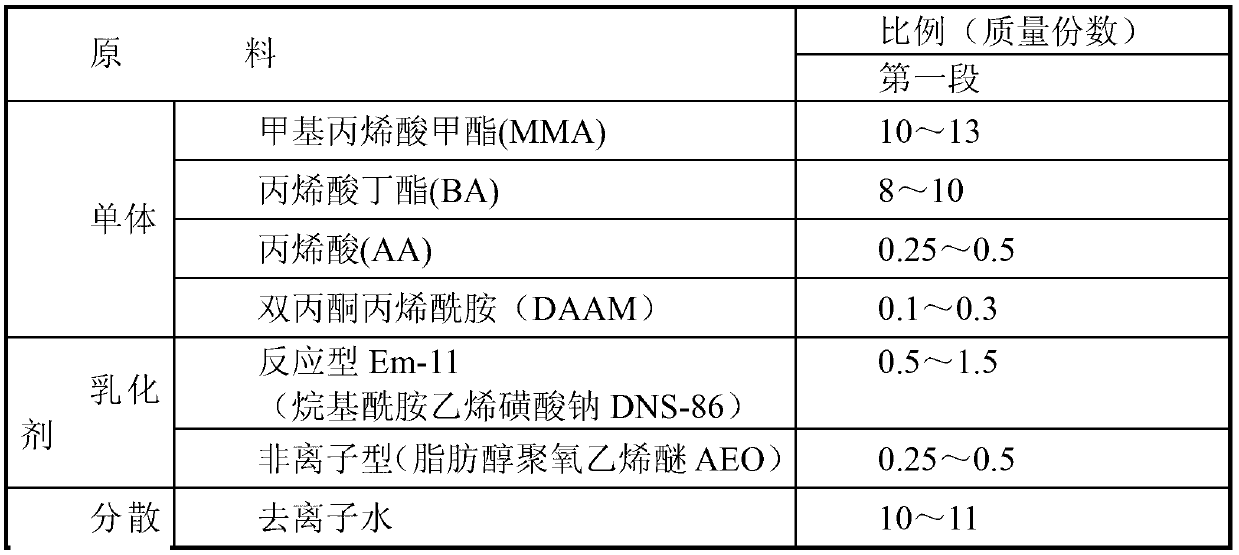

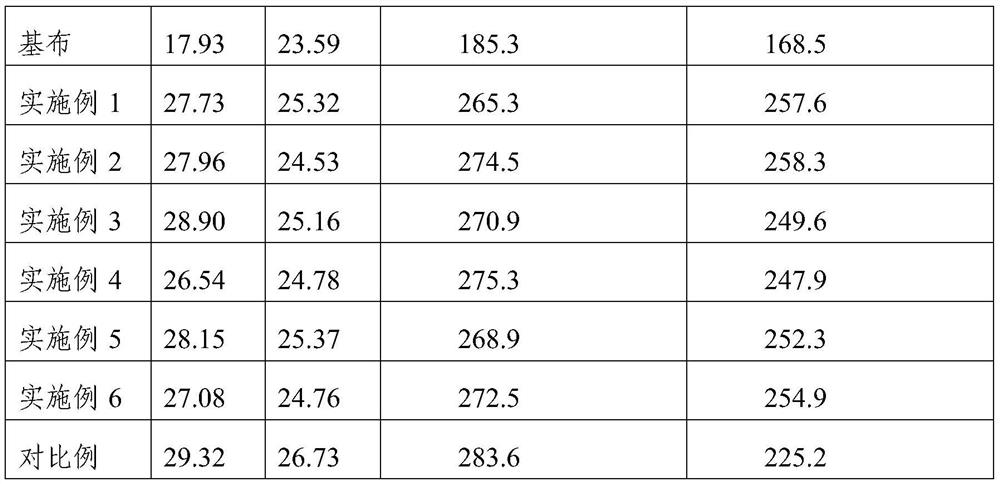

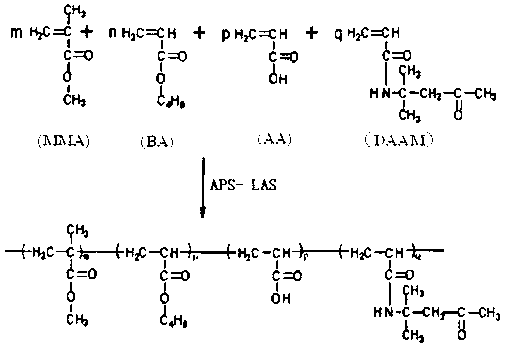

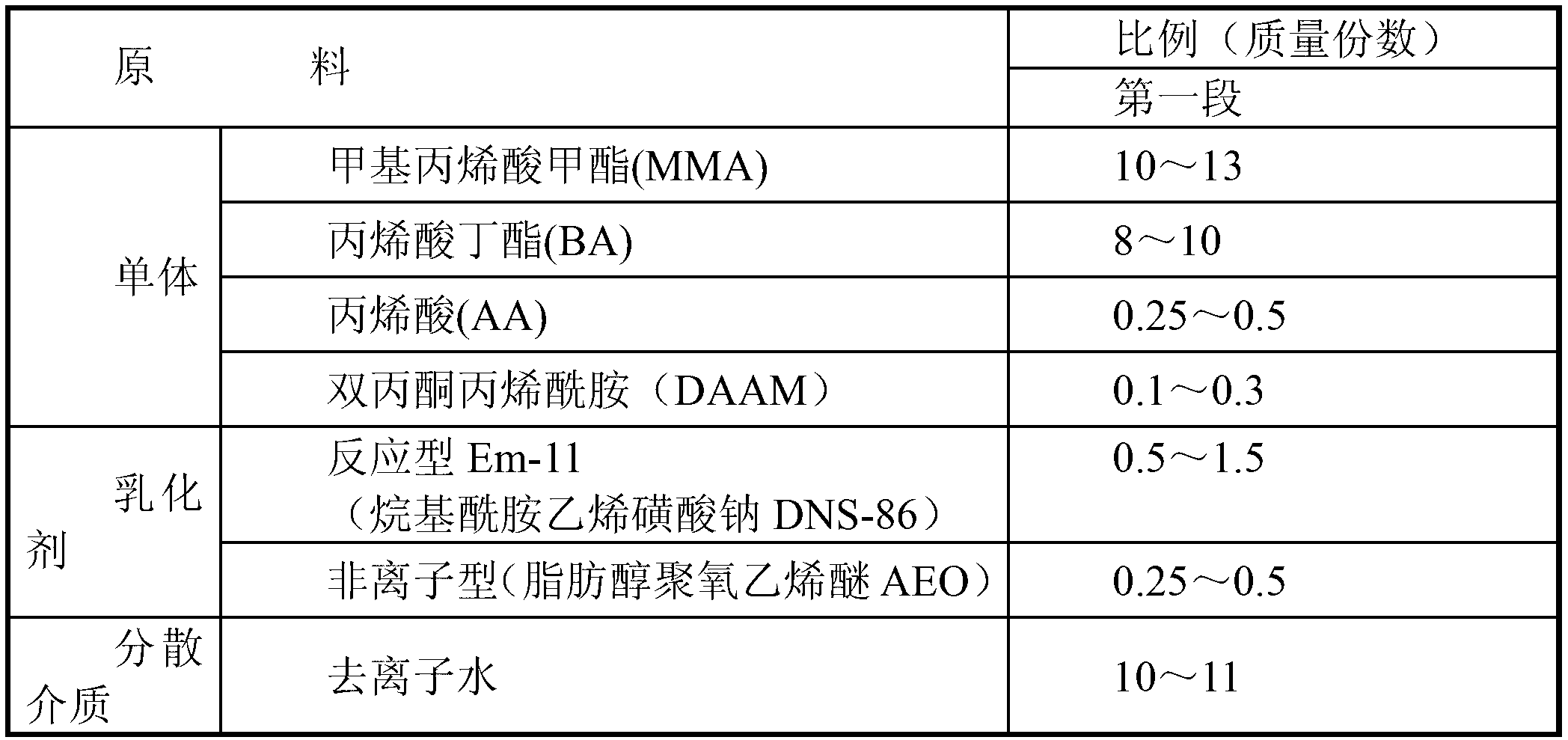

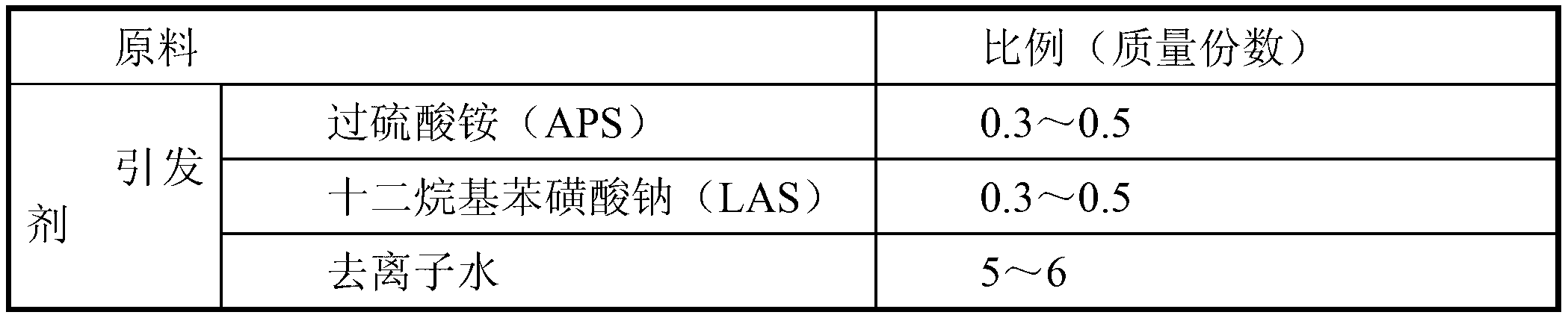

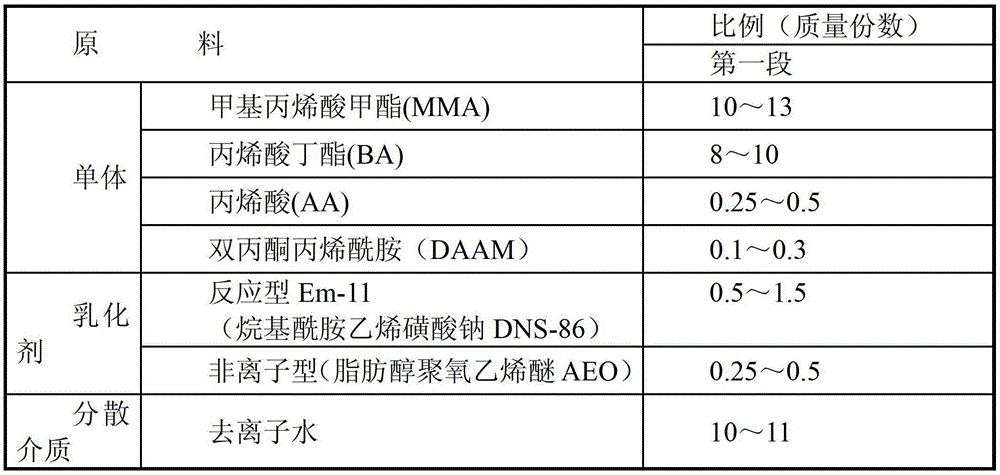

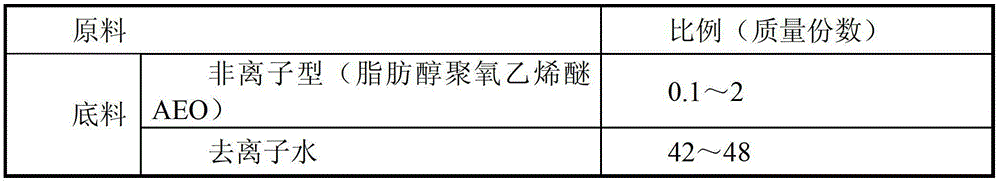

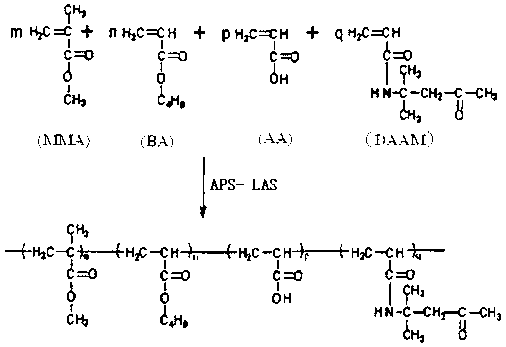

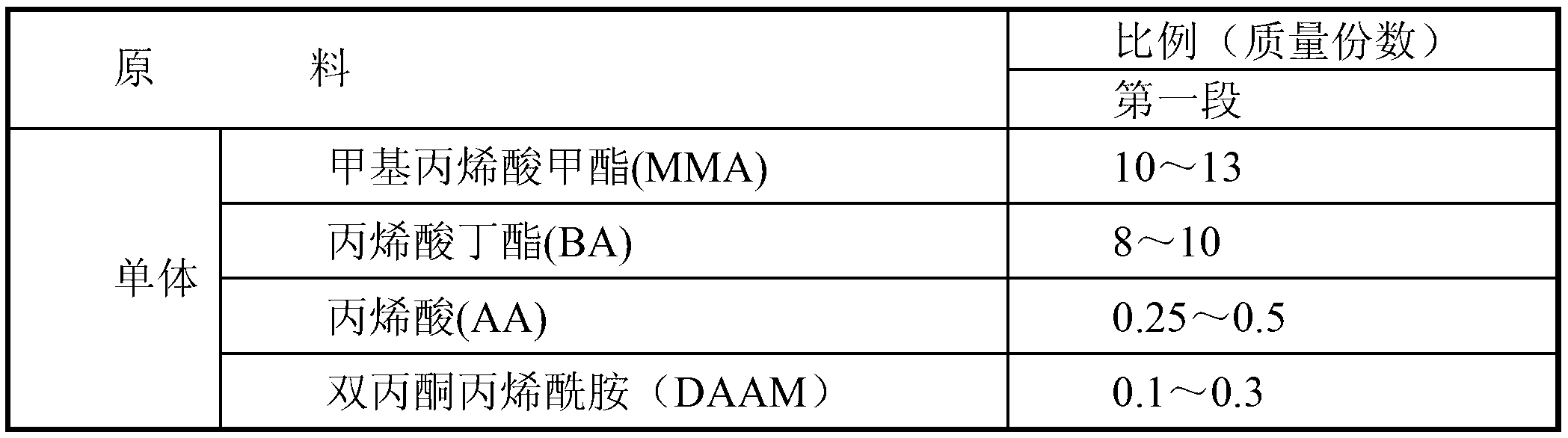

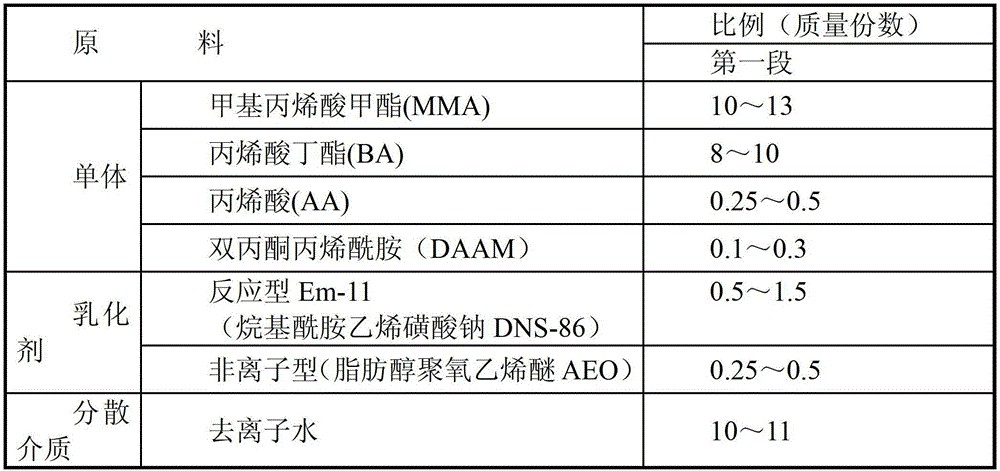

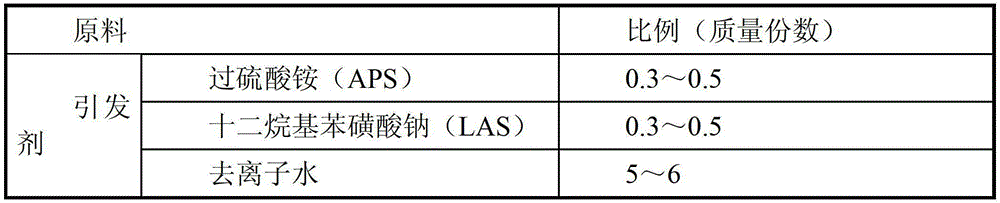

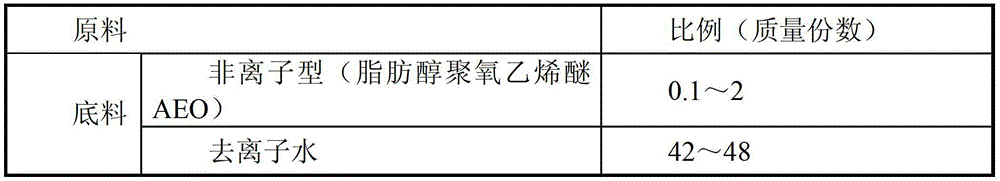

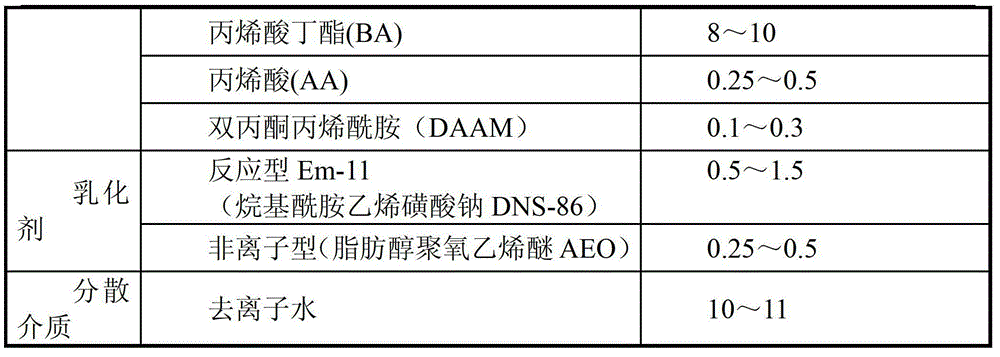

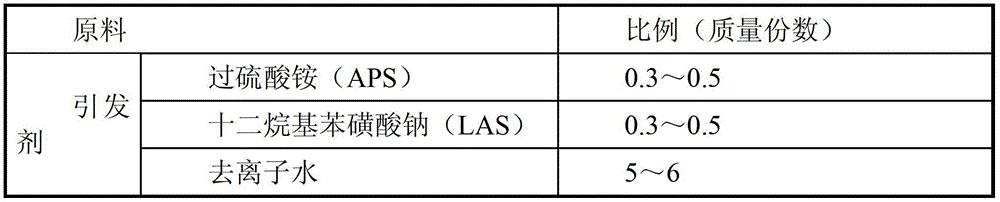

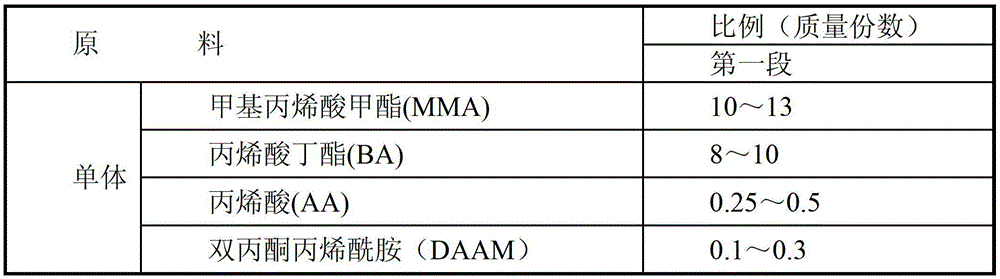

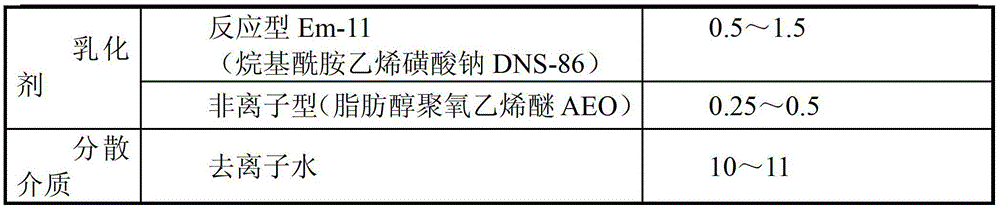

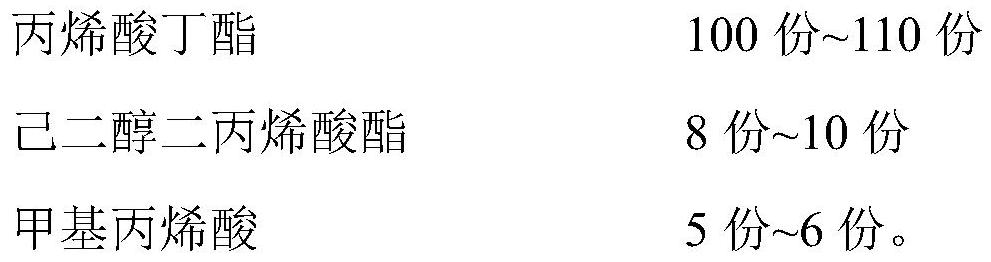

Water-based polyacrylate emulsion

The invention discloses a water-based polyacrylate emulsion, which is prepared from a preliminary emulsion, a seed emulsion, a secondary emulsion, 10% adipic dihydrazide aqueous solution and ammonia water, wherein the preliminary emulsion is prepared from methyl methacrylate, butyl acrylate, acrylic acid, diacetone-acryloamide, sodium alkyl amide vinyl sulfonate, fatty alcohol-polyoxyethylene ether and de-ionized water; the secondary emulsion is composed of monomers and an emulsifier, and the monomers include methyl methacrylate, butyl acrylate, acrylic acid and diacetone-acryloamide; and the emulsifier is prepared from fatty alcohol-polyoxyethylene ether and de-ionized water. The water-based polyacrylate emulsion is characterized in that diacetone-acryloamide (DAAM) is introduced into the system and simultaneously, adipic dihydrazide (ADH) is introduced to modify the branch chain so that the cross-linking sites in a system can be increased through introduction of diacetone-acryloamide (DAAM) and adipic dihydrazide (ADH) to modify a branch chain, so that the self-cross-linking performance of water-based PA can be improved and medium-temperature self-cross-linked base slurry is formed; and the roasting temperature can be appropriately reduced by 10-30 DEG C so that energy source can be saved.

Owner:长兴三伟热熔胶有限公司

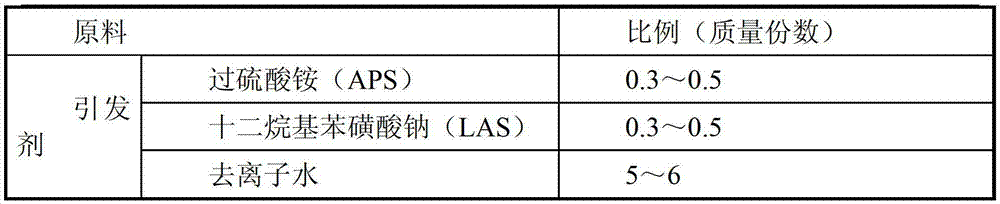

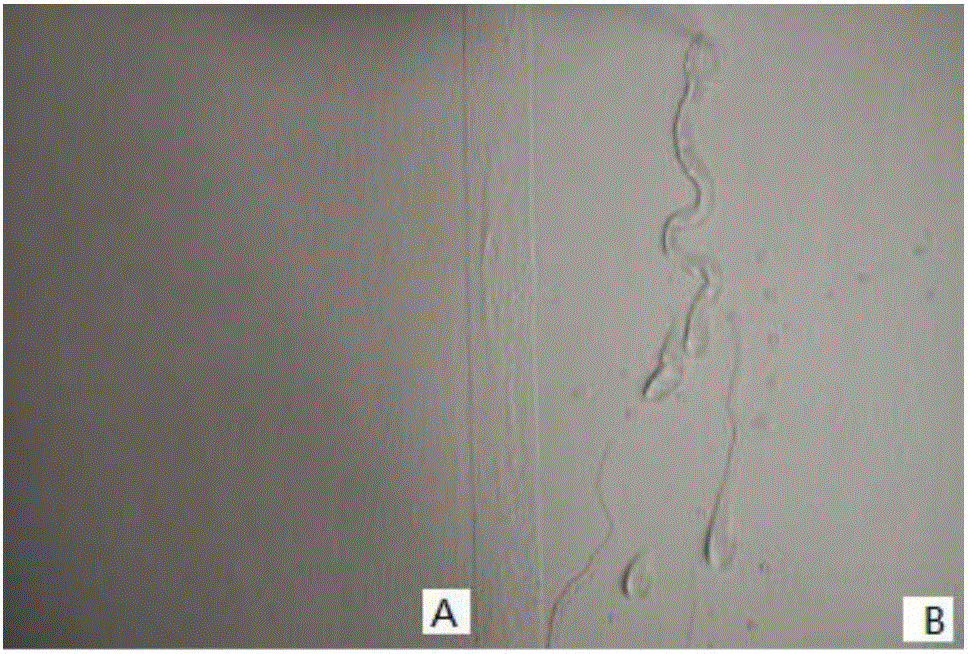

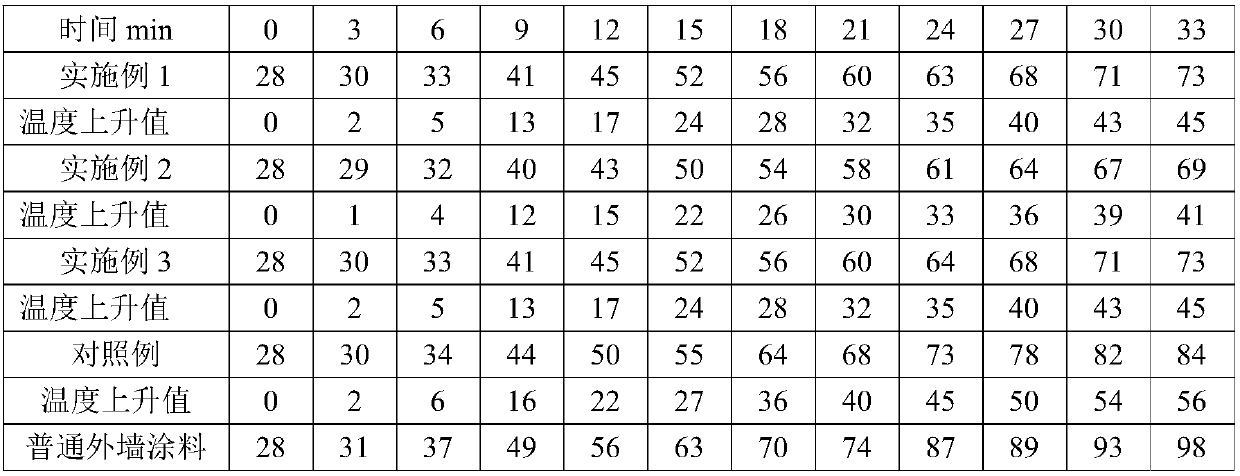

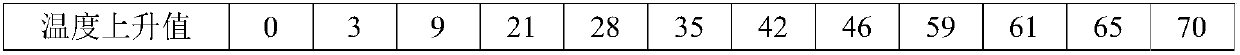

Inorganic reflective-insulation lotus leaf paint and preparation method thereof

ActiveCN106221323ALow thermal conductivityImprove stain resistanceFireproof paintsAntifouling/underwater paintsAluminum silicateBuffering agent

The invention discloses inorganic reflective-insulation lotus leaf paint which is mainly prepared from the following raw materials: an inosilicate film forming matter, a composite reflective insulation material, rutile titanium dioxide, waterborne acrylic emulsion, an organosilicone adjuvant, a silane coupling agent, glycol, a dispersing agent, a wetting agent, a defoaming agent, a thickening agent, a buffering agent, a viscosity stabilizer and water, wherein the composite reflective insulation material is prepared from the following raw materials: thermal reflective insulation powder, kieselguhr, a compound aluminium silicate functional pigment, aedelforsite and mica powder. The inorganic reflective-insulation lotus leaf paint not only has an excellent thermal reflective insulation effect on building base materials, but also is capable of reducing indoor temperature to 20-25 DEG C in summer by virtue of optimization on the composite reflective insulation material; the reflective insulation compound material contains no organic waste gases such as formaldehyde and no APEO, is health-care and environmental-friendly, achieves a lotus leaf effect and is antifouling. The invention also discloses a preparation method of the inorganic reflective-insulation lotus leaf paint.

Owner:广东伊思曼新材料科技有限公司

Self-cross-linking type waterborne polyacrylate powder-free base slurry for clothing fusible interlining

The present invention discloses a self-cross-linking type waterborne polyacrylate powder-free base slurry for a clothing fusible interlining. The self-cross-linking type waterborne polyacrylate powder-free base slurry is prepared from a waterborne polyacrylate emulsion, a waterborne acrylic acid thickener, an additive, deionized water and ammonia water, wherein the waterborne polyacrylate emulsion is prepared from a pre-emulsion, a seed emulsion, a secondary emulsion, a 10% adipic dihydrazide aqueous solution and ammonia water. According to the present invention, diacetone acrylamide (DAAM) is introduced into the system, and the adipic dihydrazide (ADH) modified branch chain is introduced, such that the cross-linking sites in the system can be increased so as to improve a self-cross-linking performance of the aqueous PA and form the medium temperature self-cross-linking type base slurry; and the baking temperature can be appropriately reduced by 10-30 DEG C so as to save energy sources.

Owner:长兴三伟热熔胶有限公司

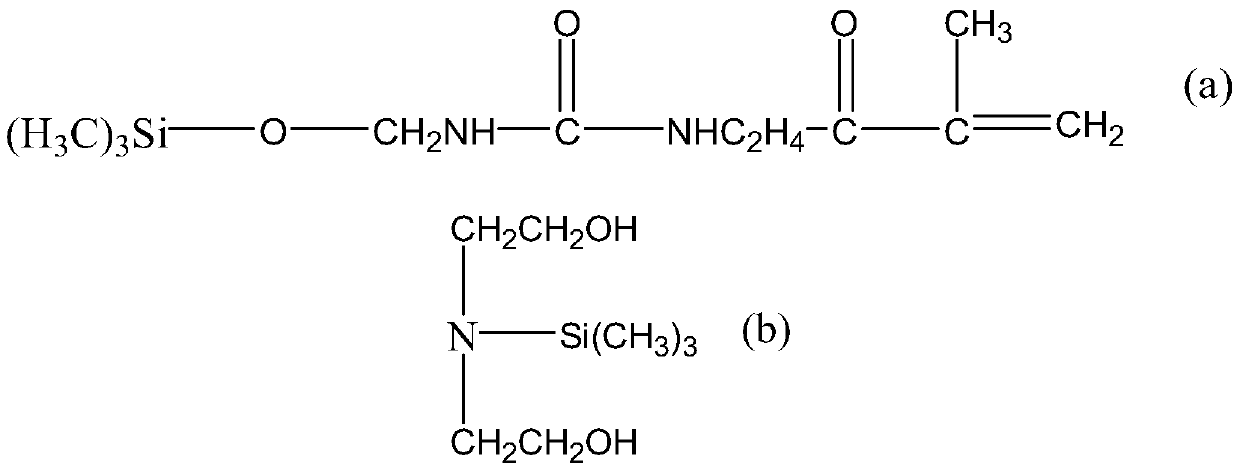

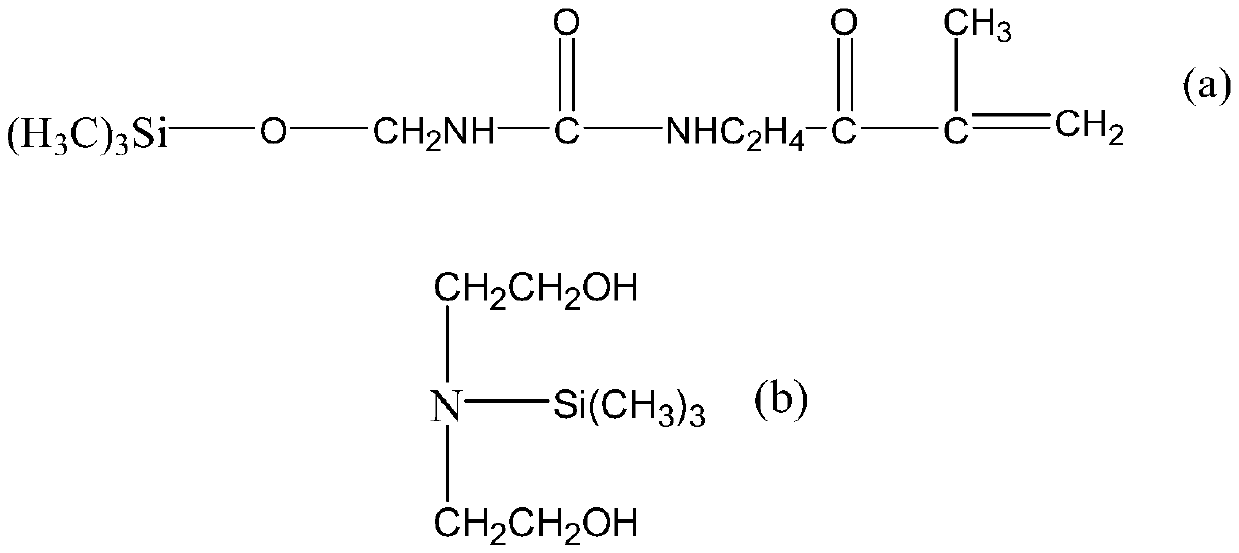

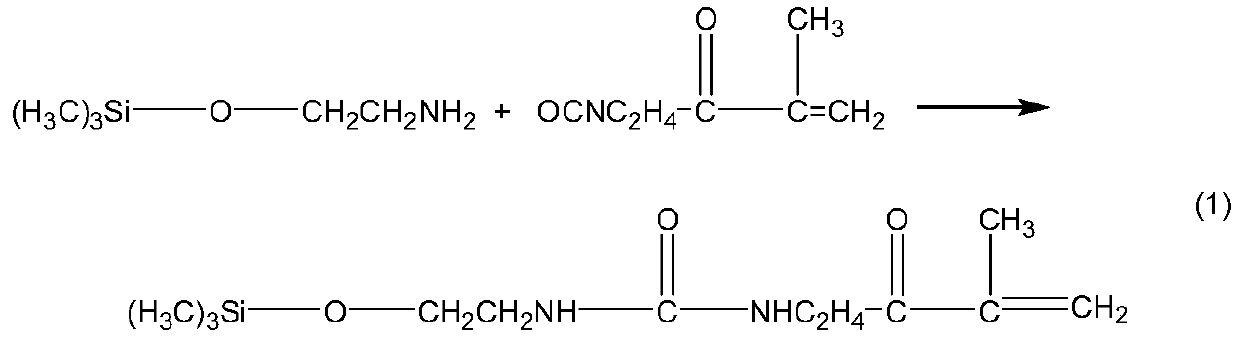

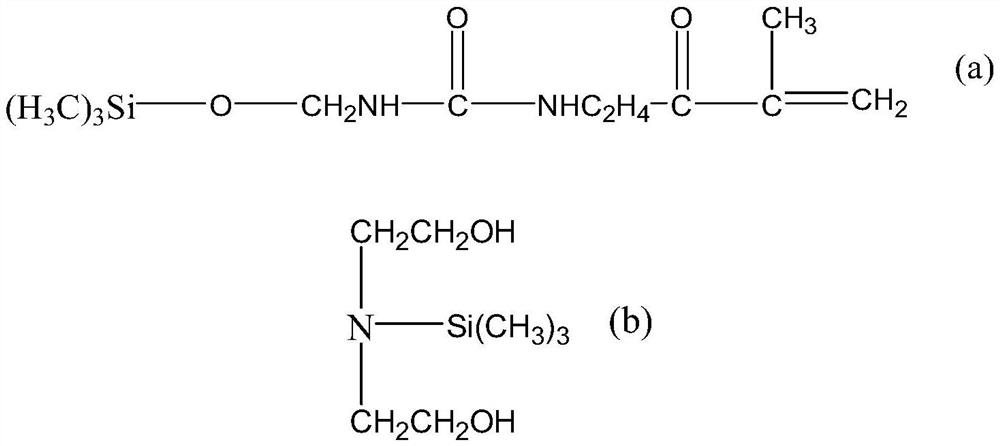

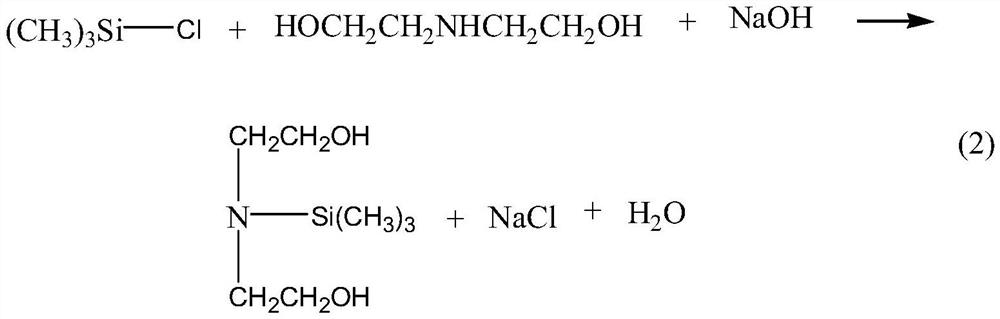

Silicon-containing water repellent finishing agent

ActiveCN109750503AIncrease steric hindranceImprove stabilityFibre treatmentFunctional monomerEmulsion

The invention discloses a silicon-containing water repellent finishing agent. The silicon-containing water repellent finishing agent is formed by blending 86-122 parts of an organosilicon modified acrylate emulsion and 72-94 parts of an organosilicon modified polyurethane emulsion. The organosilicon functional monomer using a Si(CH3)3 group is adopted, because of large steric hindrance and non-hydrolysis, the stability of emulsion polymerization is greatly improved, the content of silicon in polymer is increased, the distribution of organosilicon in a polymer molecular chain is enabled to be balanced, and the water repellency of the polymer is enhanced. Based on the complementary properties of polyurethane and polyacrylate, the two emulsions are blended and compounded to obtain the composite finishing agent with excellent water repellency. By introducing diacetone acrylamide and adipic dihydrazide into the emulsions, the crosslinking sites in the system can be increased and the self-crosslinking performance can be improved after the two emulsions are blended to form the moderate temperature self-crosslinking finishing agent, and the baking temperature can be appropriately reduced.

Owner:浙江东进新材料有限公司

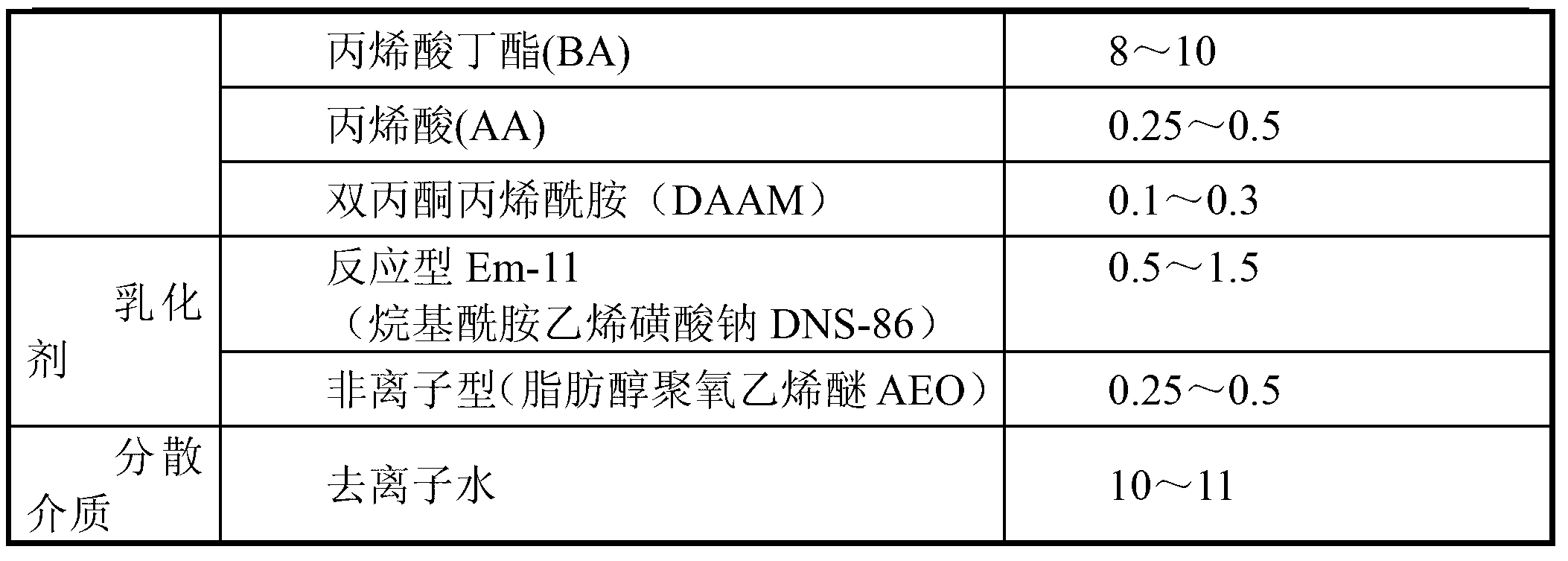

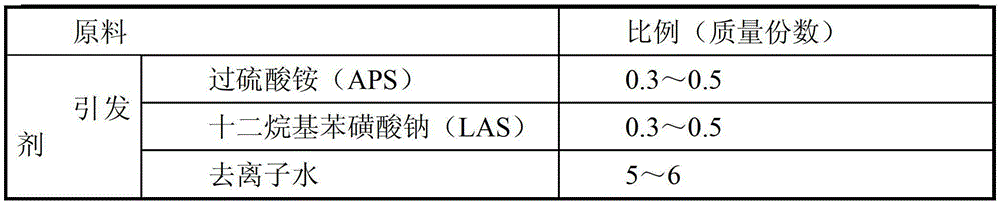

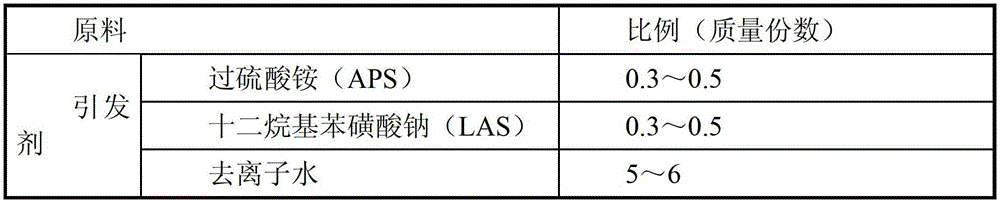

Emulsion polymerization reaction method

InactiveCN103214617AImprove self-crosslinkingGood adhesionFibre treatmentEster polymer adhesivesEmulsionEmulsion polymerization

The invention discloses an emulsion polymerization reaction method comprising the steps that: 1, a core emulsion is prepared, wherein a 3 / 4 composite initiator solution is divided into four parts; a reaction temperature is maintained at 75 DEG C; a first part of the composite initiator solution is added into a reaction kettle and is mixed with a seed emulsion; rest 3 / 4 of a pre-emulsification liquid is dropped in within 1h, wherein a second part of the composite initiator solution is supplemented with a time interval of 30min; 2, a shell emulsion is prepared, wherein an emulsification agent in a sub-emulsification liquid is added into the reaction kettle in one time; a third part of the composite initiator is supplemented, and sub-emulsification liquid monomer is dropped in; after 30min, a fourth part of the composite initiator is dropped in, and the dropping is finished 20min before the dropping of the sub-emulsification liquid monomer; the temperature is increased to 80 DEG C, and a reaction is carried out for 2h; the temperature is reduced to room temperature, and a 10% adipic dihydrazide water solution is slowly added; the pH value is neutralized to 7-8 by using ammonia water; and filtering is carried out, such that waterborne polyacrylate emulsion is prepared. According to the invention, the preparation process and the product are cleaner, such that requirements of green, environment-friendly, and healthy are satisfied. The invention keeps pace with the trend.

Owner:长兴三伟热熔胶有限公司

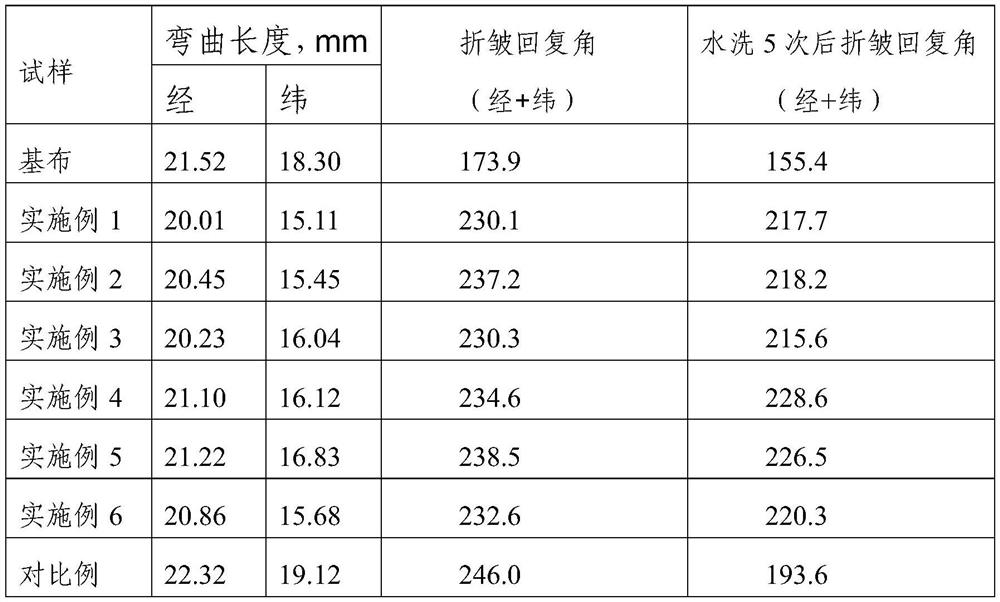

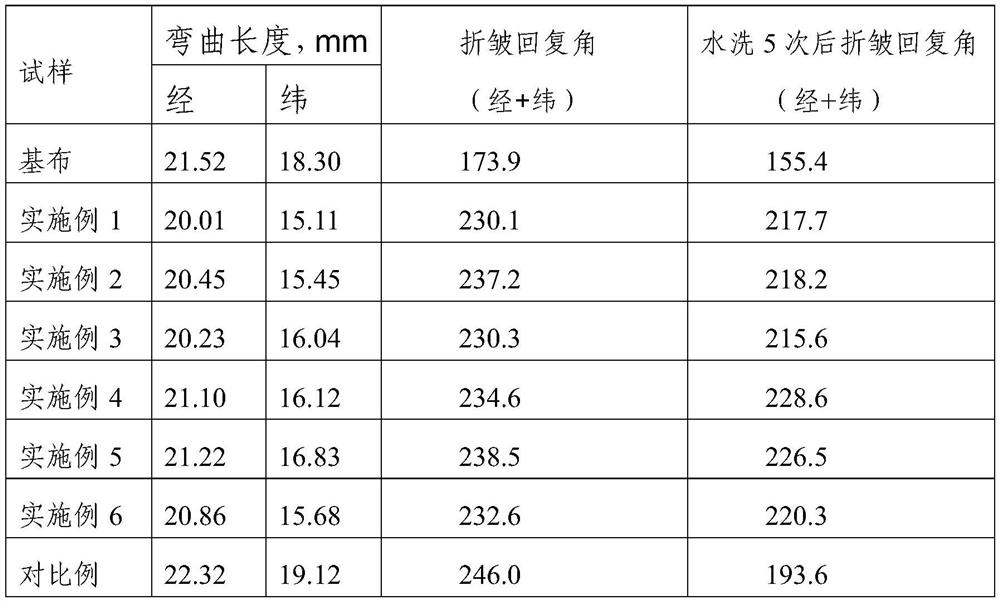

Water-based imitation coating high-elasticity-and-stiffness finishing agent and preparation method

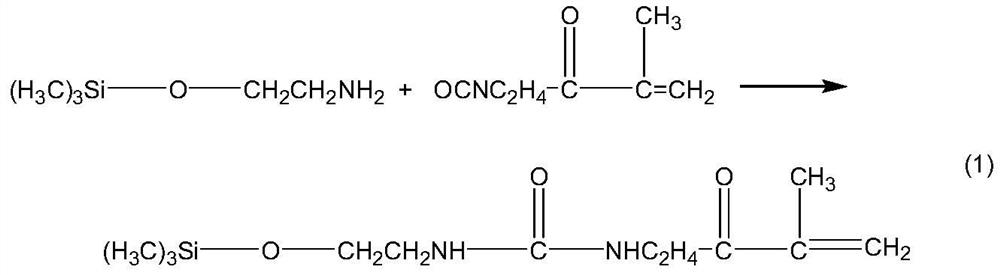

ActiveCN112593410AIncreased self-crosslinkingImprove elasticity and wrinkle resistanceWrinkle resistant fibresGrip property fibresIsocyanateOrganosilicon

The invention discloses a water-based imitation coating high-elasticity-and-stiffness finishing agent and a preparation method, and relates to the technical field of textile fabric after-finishing. The finishing agent is prepared from the following raw materials in parts by weight of 50-60 parts of an emulsion A, 100-120 parts of an emulsion B and 5-10 parts of a cationic blocked isocyanate cross-linking agent. According to the preparation method of the water-based imitation coating high-elasticity stiff and smooth finishing agent, the high-molar-mass epoxy modified polysiloxane emulsion A, the emulsion B prepared from amino polyether modified polysiloxane and a polyethyl silicate crosslinking agent and the blocked isocyanate cross-linking agent are reasonably compounded, and padding and finishing are performed on a fabric, so that the elasticity and stiffness of the fabric can be obviously improved, and the effect of a coating process is achieved. The obtained finishing agent is goodin softness, good in anti-wrinkle effect, excellent in washability, water-based and environment-friendly, and can meet environmental protection requirements of export.

Owner:LIAONING FIXED STAR FINE CHEM

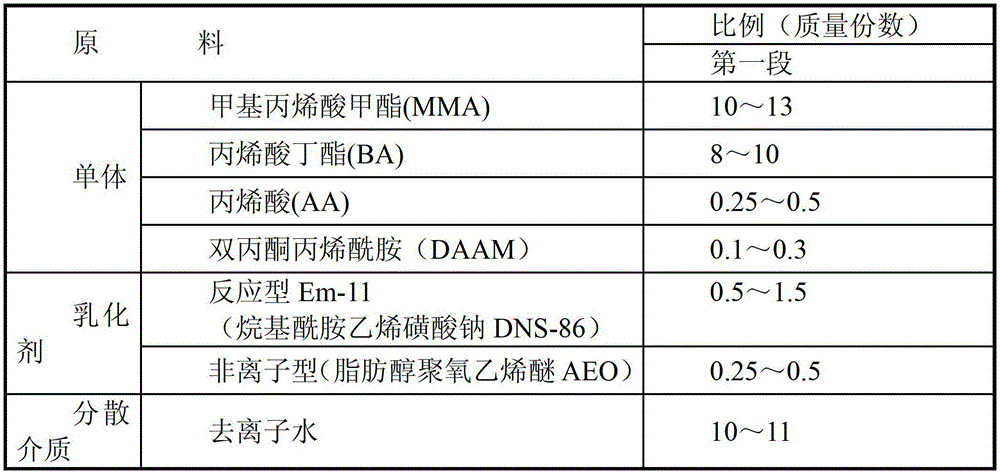

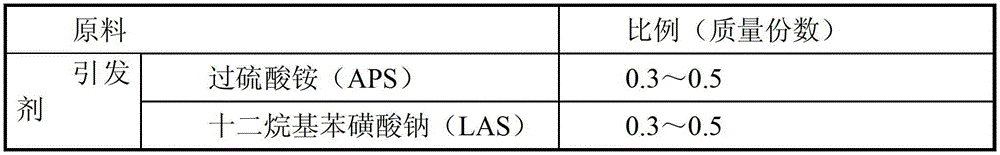

Preparation method of water-based polyacrylate emulsion

The invention discloses a preparation method of a water-based polyacrylate emulsion. The preparation method comprises the following steps: 1) preparing a pre-emulsion, namely adding components of the pre-emulsion into a pre-reaction kettle, rising the temperature to 55 DEG C, and mixing for 10 min to prepare the pre-emulsion; 2) preparing a seed emulsion, namely adding a polymeric kettle backing material into a reaction kettle at first, mixing, extracting 1 / 4 of the pre-emulsion into the reaction kettle, rising the temperature to 75 DEG C, dropwise adding 1 / 4 of compound initiator, and reacting for 30 min to prepare the seed emulsion; and 3) producing an emulsion polymerization reaction. According to the preparation method, diacetone acrylamide (DAAM) is introduced into a system and adipic dihydrazide (ADH) is introduced for modifying branch chains at the same time, and the number of cross-linked sites in the system can be increased, thereby improving the self-crosslinking performance of water-based PA (polyacrylate) and forming medium-temperature self-crosslinking base mud; and the baking temperature can be properly reduced by 10-30 DEG C, so that the energy resources can be saved.

Owner:长兴三伟热熔胶有限公司

A kind of aqueous polyacrylate emulsion

Owner:长兴三伟热熔胶有限公司

Method for preparing clothing adhesive lining from self-crosslinking water-borne polyacrylate powderless base mud

ActiveCN103183772AImprove self-crosslinkingGood adhesionEster polymer adhesivesHydrophilic monomerAdhesive

The invention discloses a method for preparing a clothing adhesive lining from self-crosslinking water-borne polyacrylate powderless base mud. The method comprises the following steps: at first, mixing water-borne polyacrylate emulsion, auxiliaries and deionized water, wherein the water-borne polyacrylate emulsion is prepared from pre-emulsion, seed emulsion, secondary emulsion, 10% adipic dihydrazide water solution and ammonia water, and the pre-emulsion is prepared from methyl methacrylate, butyl acrylate, acrylic acid, diacetone acrylamide, alkenamides sodium ethylenesulphonate, fatty alcohol-polyoxyethylene ether and deionized water; and then, adjusting the pH value of the system to be neutral with ammonia water, adding a water-borne acrylic thickener, and adjusting the viscosity to be less than 30,000. Soap-free emulsion prepared from lyophobic and hydrophilic monomers through a core-shell emulsion copolymerization technology is applied to the powderless base mud, so that the product has cleaner characteristics in preparation process and the product itself, meets green, environmental-friendly and healthy requirements, and conforms to the historical trend of the time.

Owner:长兴三伟热熔胶有限公司

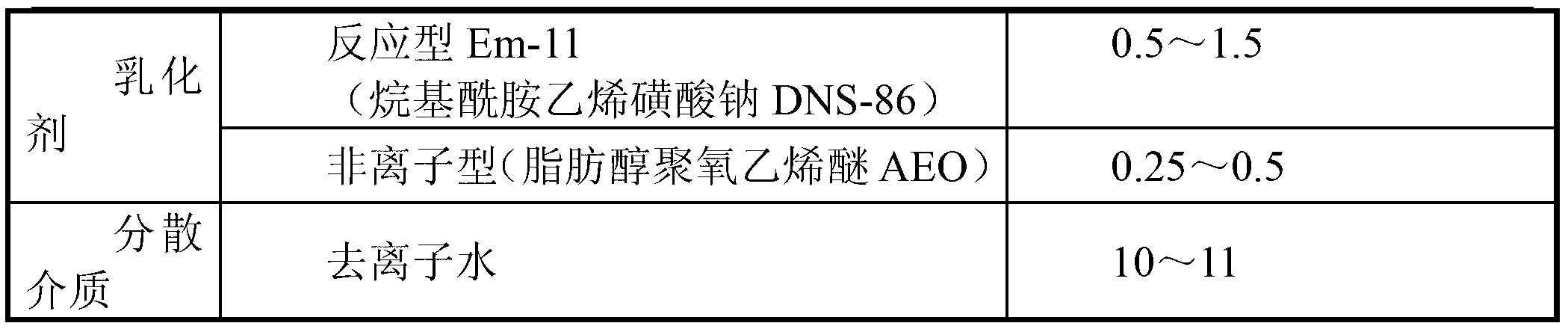

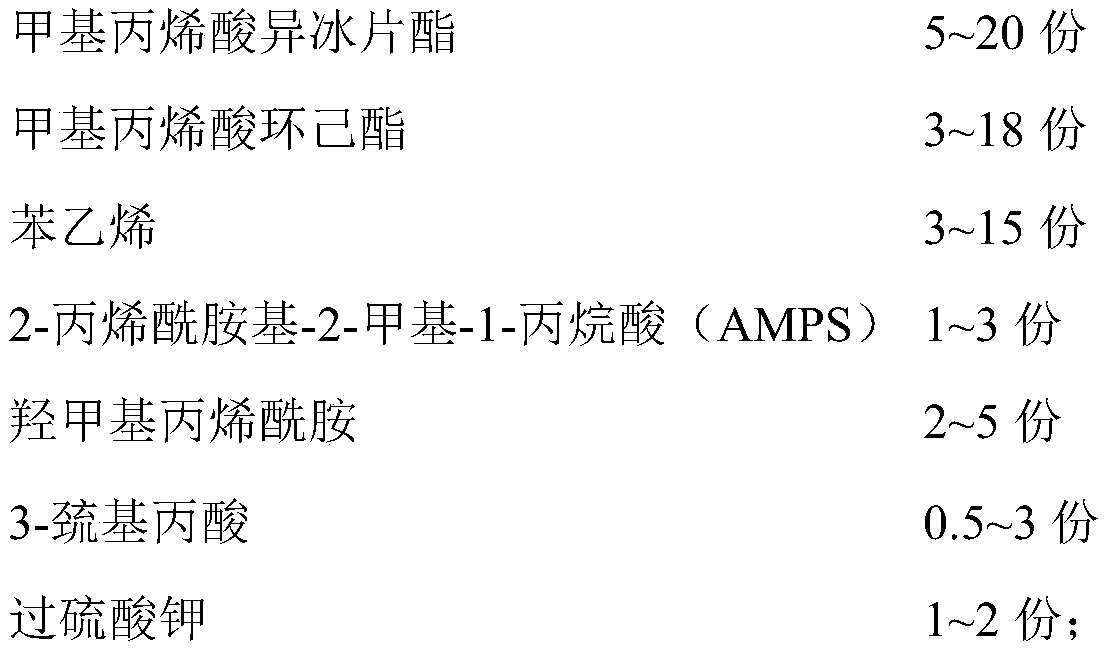

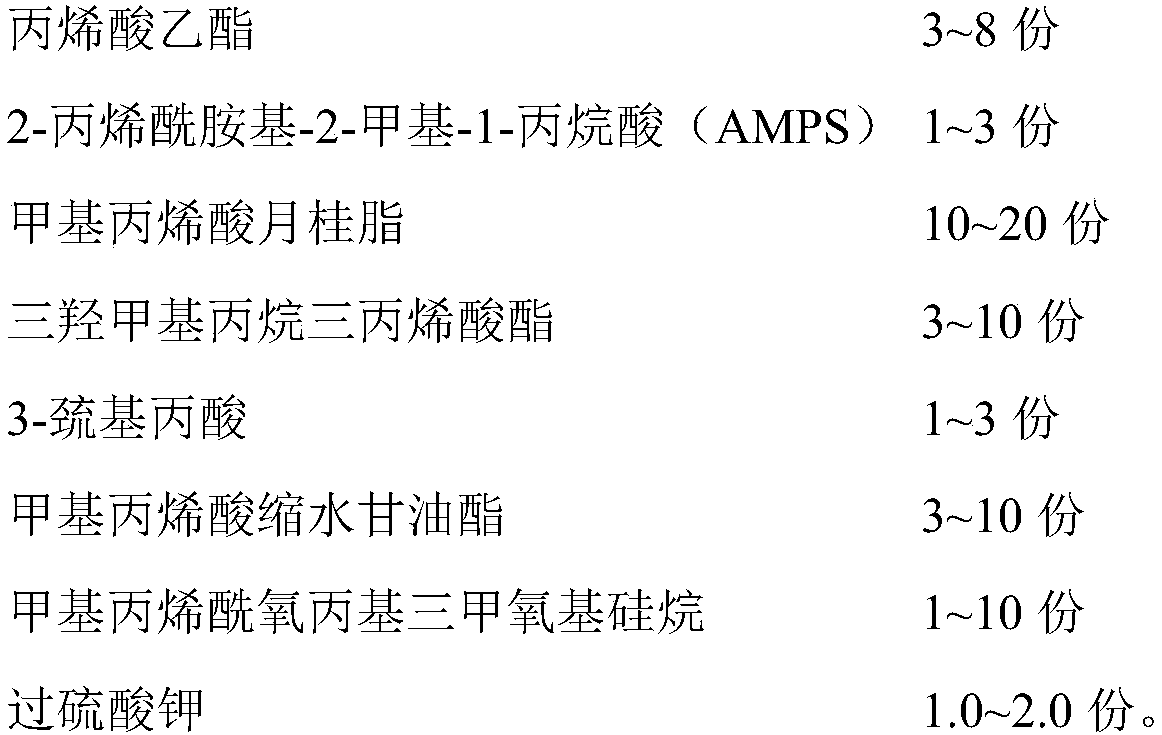

Automatic repair acrylic microgel self-emulsifying emulsion and preparation method thereof

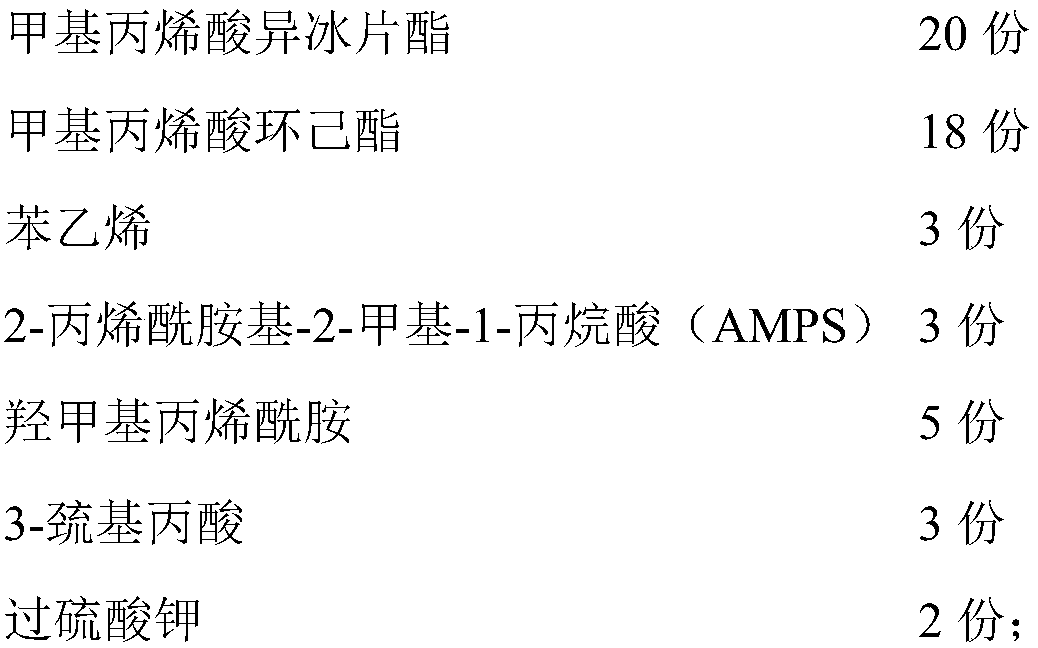

ActiveCN108794683AAvoid pollutionFacilitate continuous productionCoatingsMicroballoon preparationPotassium persulfateGlycidyl methacrylate

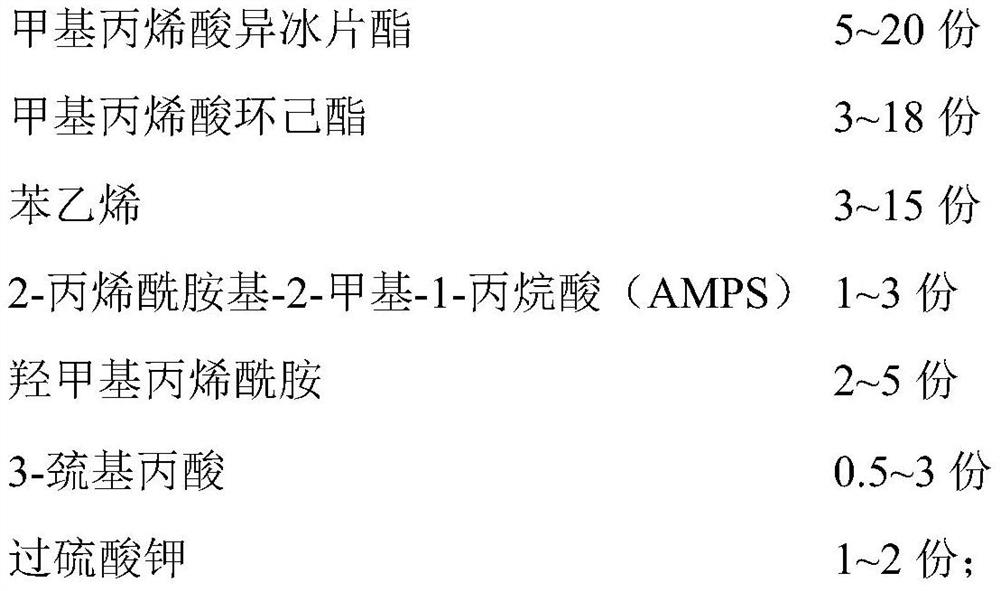

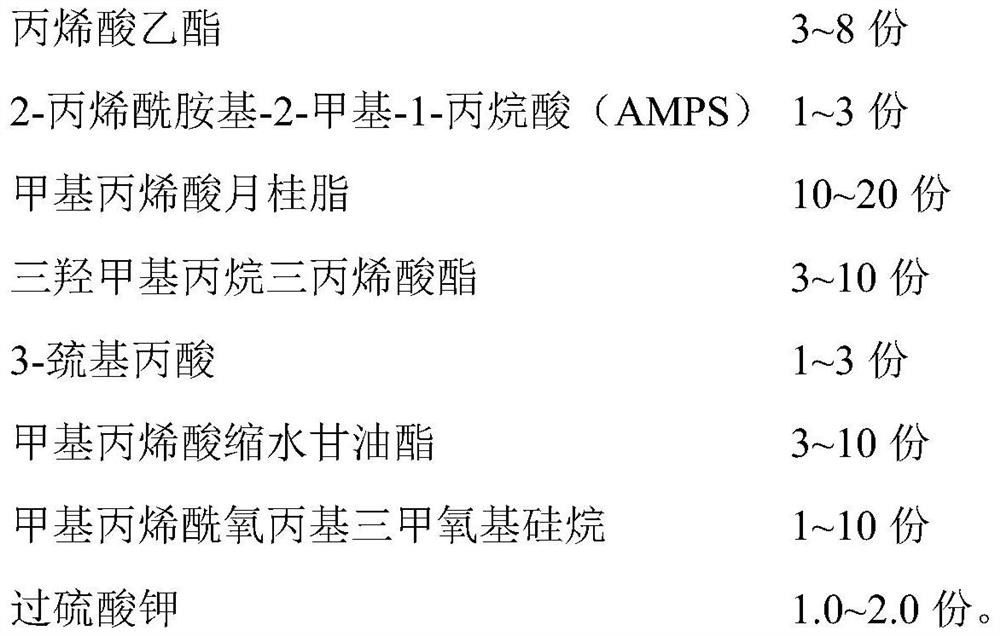

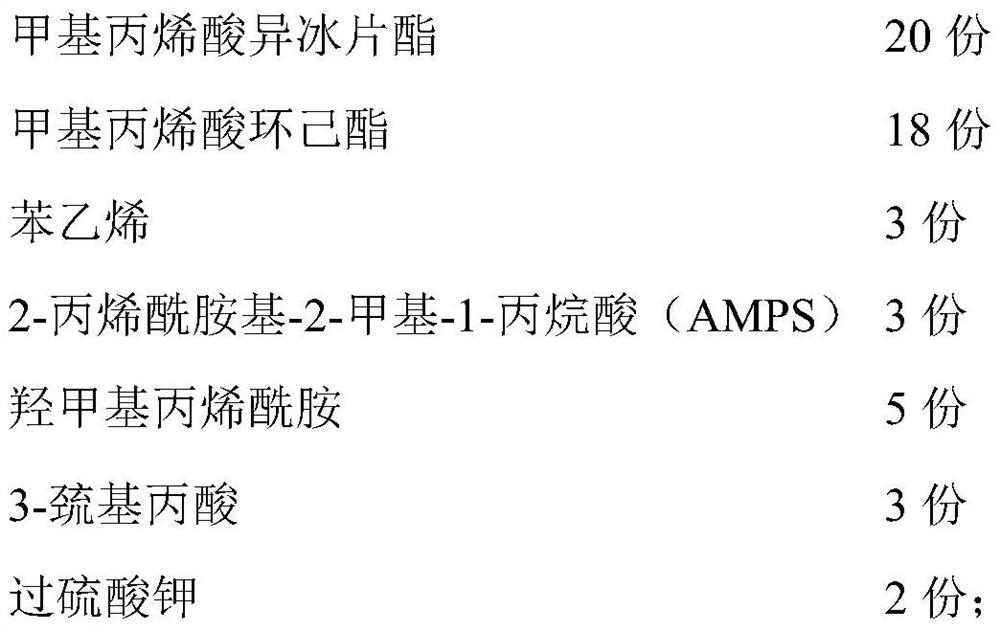

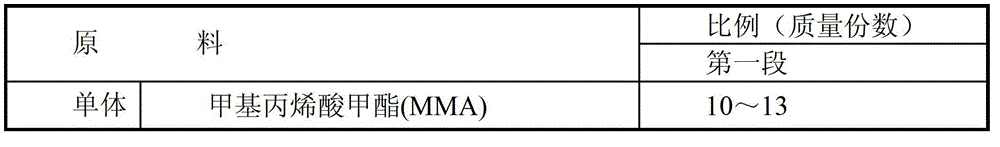

The invention discloses automatic repair acrylic microgel self-emulsifying emulsion and a preparation method thereof, belonging to the technical field of modified coatings. The acrylic microgel emulsion comprises a shell layer and a core, wherein the shell layer is prepared from isobornyl methacrylate, cyclohexyl methacrylate, 3-mercaptopropionic acid, styrene, 2-acrylamide-2-methyl-1-propanesulfonic acid (AMPS), methylol acrylamide and potassium persulfate; the core is prepared from trimethylolpropane triacrylate, 2-acrylamide-2-methyl-1-propanesulfonic acid (AMPS), lauryl methacrylate, 3-mercaptopropionic acid, ethyl acrylate, glycidyl methacrylate, methacryloxy propyl trimethoxyl silane and potassium persulfate. The emulsion provided by the invention is prepared in a water phase, and has the advantages of being good in compatibility between the shell and the core, high in repair temperature, capable of self-emulsifying, high in solid content, low in emission of volatile organic compounds (VOC) and the like.

Owner:安徽优科新材料科技有限公司

Self-crosslinking sulfonate-base epoxy ester aqueous dispersion and anti-corrosive primer thereof

ActiveCN101659740BGood storage stabilitySmall particle sizeAnti-corrosive paintsEpoxy resin coatingsEpoxySulfonate

The invention relates to a self-crosslinking sulfonate-base epoxy ester aqueous dispersion and an anti-corrosive primer thereof. The self-crosslinking sulfonate-base epoxy ester aqueous dispersion is characterized in that the aqueous dispersion is prepared by introducing a sulfonate functional monomer into epoxy resin, wherein vegetable oil or fatty acid, the epoxy resin and the functional monomer containing a sulfonate base undergo esterification reaction in the presence of a catalyst; when the acid value is qualified, a latent solvent and a neutralizing agent are added into the mixture; andfinally, the mixture is diluted by deionized water to obtain the sulfonate-base epoxy ester aqueous dispersion. An aqueous anti-corrosive primer prepared by using the epoxy ester aqueous dispersion as a base material has excellent storage stability, and waterproof and anti-corrosive properties.

Owner:SHANGHAI HUAYI FINE CHEM CO LTD

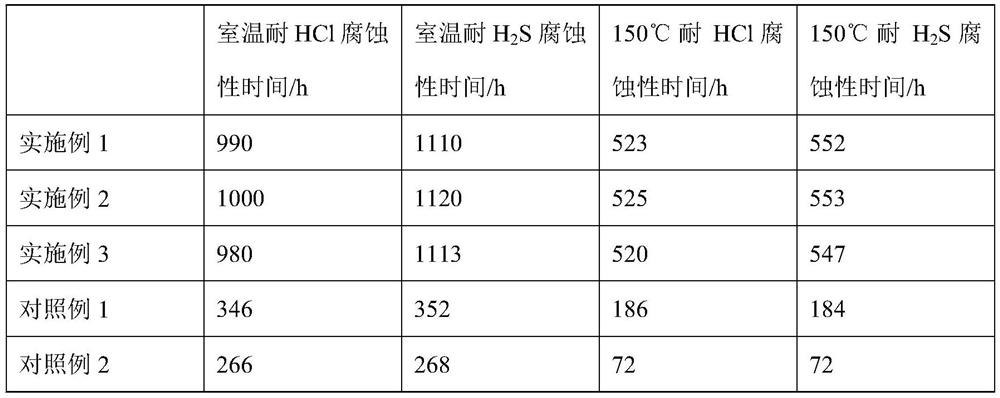

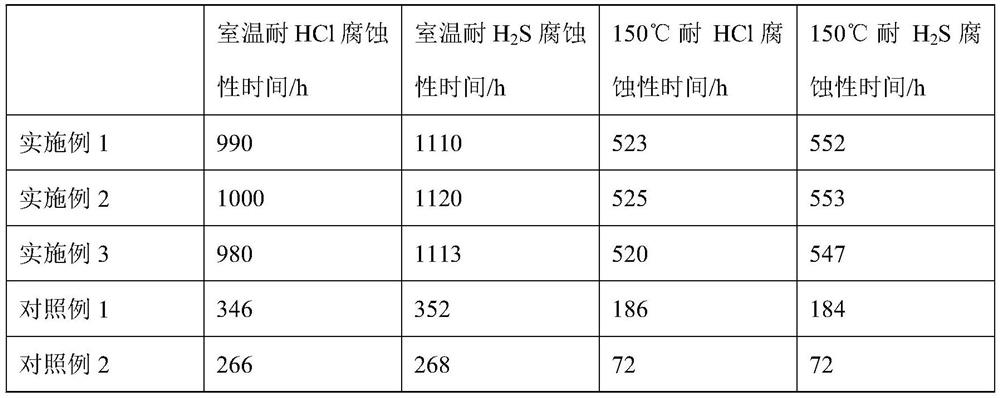

HCl-H2S corrosion-resistant and high-temperature-resistant coating and preparation method thereof

ActiveCN112812652AImprove high temperature anti-corrosion performanceImprove functionalityFireproof paintsAnti-corrosive paintsDiethylene glycol monobutyl etherMethacrylate

The invention relates to a HCl-H2S corrosion-resistant and high-temperature-resistant coating which is prepared from the following raw materials: 6-amino-2-picolinic acid, graphene nanosheets, organic resin, polyethylene polyamine, trimethylolpropane trimethacrylate, diethylene glycol monobutyl ether, organosiloxane resin, a dispersing agent, an anticorrosive filler, a flatting agent, a defoaming agent and water. The preparation method comprises the following steps: firstly, carrying out esterification reaction on 6-amino-2-picolinic acid and graphene nanosheets to obtain 6-amino-2-picolinic acid graphene ester, then carrying out reaction on organic resin, polyethylene polyamine and trimethylolpropane trimethacrylate to obtain cross-linked modified organic resin, finally, using the obtained 6-amino-2-picolinic acid graphene ester for functionalizing cross-linked modified organic resin to obtain a 6-amino-2-picolinic acid graphene ester functionalized organic resin material, and mixing and stirring the 6-amino-2-picolinic acid graphene ester functionalized organic resin material with other components to obtain the HCl-H2S corrosion resistant and high temperature resistant coating.

Owner:中环涂层技术(广东)有限公司

A kind of preparation method of aqueous polyacrylate emulsion

The invention discloses a preparation method of a water-based polyacrylate emulsion. The preparation method comprises the following steps: 1) preparing a pre-emulsion, namely adding components of the pre-emulsion into a pre-reaction kettle, rising the temperature to 55 DEG C, and mixing for 10 min to prepare the pre-emulsion; 2) preparing a seed emulsion, namely adding a polymeric kettle backing material into a reaction kettle at first, mixing, extracting 1 / 4 of the pre-emulsion into the reaction kettle, rising the temperature to 75 DEG C, dropwise adding 1 / 4 of compound initiator, and reacting for 30 min to prepare the seed emulsion; and 3) producing an emulsion polymerization reaction. According to the preparation method, diacetone acrylamide (DAAM) is introduced into a system and adipic dihydrazide (ADH) is introduced for modifying branch chains at the same time, and the number of cross-linked sites in the system can be increased, thereby improving the self-crosslinking performance of water-based PA (polyacrylate) and forming medium-temperature self-crosslinking base mud; and the baking temperature can be properly reduced by 10-30 DEG C, so that the energy resources can be saved.

Owner:长兴三伟热熔胶有限公司

A kind of self-healing acrylic microgel self-emulsifying emulsion and preparation method thereof

ActiveCN108794683BAvoid pollutionFacilitate continuous productionCoatingsMicroballoon preparationPotassium persulfatePolymer science

The invention discloses automatic repair acrylic microgel self-emulsifying emulsion and a preparation method thereof, belonging to the technical field of modified coatings. The acrylic microgel emulsion comprises a shell layer and a core, wherein the shell layer is prepared from isobornyl methacrylate, cyclohexyl methacrylate, 3-mercaptopropionic acid, styrene, 2-acrylamide-2-methyl-1-propanesulfonic acid (AMPS), methylol acrylamide and potassium persulfate; the core is prepared from trimethylolpropane triacrylate, 2-acrylamide-2-methyl-1-propanesulfonic acid (AMPS), lauryl methacrylate, 3-mercaptopropionic acid, ethyl acrylate, glycidyl methacrylate, methacryloxy propyl trimethoxyl silane and potassium persulfate. The emulsion provided by the invention is prepared in a water phase, and has the advantages of being good in compatibility between the shell and the core, high in repair temperature, capable of self-emulsifying, high in solid content, low in emission of volatile organic compounds (VOC) and the like.

Owner:安徽优科新材料科技有限公司

Self-cross-linking type waterborne polyacrylate powder-free base slurry for clothing fusible interlining

The present invention discloses a self-cross-linking type waterborne polyacrylate powder-free base slurry for a clothing fusible interlining. The self-cross-linking type waterborne polyacrylate powder-free base slurry is prepared from a waterborne polyacrylate emulsion, a waterborne acrylic acid thickener, an additive, deionized water and ammonia water, wherein the waterborne polyacrylate emulsion is prepared from a pre-emulsion, a seed emulsion, a secondary emulsion, a 10% adipic dihydrazide aqueous solution and ammonia water. According to the present invention, diacetone acrylamide (DAAM) is introduced into the system, and the adipic dihydrazide (ADH) modified branch chain is introduced, such that the cross-linking sites in the system can be increased so as to improve a self-cross-linking performance of the aqueous PA and form the medium temperature self-cross-linking type base slurry; and the baking temperature can be appropriately reduced by 10-30 DEG C so as to save energy sources.

Owner:长兴三伟热熔胶有限公司

A kind of seed emulsion preparation method

ActiveCN103183774BImprove self-crosslinkingGood adhesionEster polymer adhesivesHydrophilic monomerSulfonate

The invention discloses a method for preparing a seed emulsion for preparing a waterborne polyacrylate resin emulsion. The method for preparing the seed emulsion comprises the following steps: firstly, adding polymerization kettle bottom materials in a reaction kettle for stirring, then extracting 1 / 4 preemulsion into the reaction kettle, increasing the temperature to 75 DEG C, and then dripping 1 / 4 compound initiating agent to react for 30 minutes to obtain the seed emulsion. The preemulsion is prepared by methyl methacrylate, butyl acrylate, acrylic acid, diacetone acrylamide, sodium alkylamide ethylene sulfonate, fatty alcoholpolyoxyethylene ether and deionized water. After the soap-free emulsion prepared with hydrophobic and hydrophilic monomers by the core shell emulsion copolymerization technology is applied to the powderless base mud, the seed emulsion has the characteristic of higher cleanliness in preparation process and product itself, meets the requirements of green, environmental protection and health, and conforms to the trend of the times.

Owner:长兴三伟热熔胶有限公司

resistant to hcl-h 2 Corrosion, high temperature resistant coating and preparation method thereof

ActiveCN112812652BImprove high temperature anti-corrosion performanceImprove functionalityFireproof paintsAnti-corrosive paintsMethacrylateTrimethylolpropane

An HCl‑H resistant 2 S corrosion, high temperature resistant coatings, including the following raw materials, 6‑amino‑2‑picolinic acid, graphene nanosheets, organic resins, polyethylene polyamines, trimethylolpropane trimethacrylate, diethylene glycol butyl ether , organosiloxane resin, dispersant, anti-corrosion filler, leveling agent, defoamer, water. Wherein, 6-amino-2-picolinic acid and graphene nanosheets are first esterified to obtain 6-amino-2-picolinic acid graphene ester, and then the organic resin is mixed with polyethylene polyamine and trimethylolpropane Trimethacrylate is reacted to obtain a cross-linked modified organic resin, and finally the obtained 6-amino-2-picolinate graphene ester is functionalized to the cross-linked modified organic resin to obtain 6-amino-2-picolinate graphite Enester functionalized organic resin material, and then mixed with the rest of the components to obtain HCl‑H resistant 2 S corrosion, high temperature resistant coatings.

Owner:中环涂层技术(广东)有限公司

Monomer containing phenylimide phenylacetylene structure and high temperature self-crosslinking copolyester and preparation method thereof

ActiveCN104592094BHigh self-crosslinking flame retardant efficiencyGood flame retardantOrganic chemistryImidePolymer science

Owner:SICHUAN UNIV

Foaming material for shoes

InactiveCN102532675BNarrow molecular weight distributionIncrease elasticityFootwearElastomerFoaming agent

The invention provides a foaming material for shoes. The foaming material comprises the following raw materials in parts by weight: 20-30 parts of ethylene-vinyl acetate copolymer, 20-30 parts of polyethylene, 15-25 parts of polyolefin elastomer, 1-10 parts of filler, 2-5 parts of foaming agent and 0.1-0.5 parts of cross-linking agent. The foaming material for the shoe provided by the invention has the characteristics of high elasticity, wear resistance, bacteria removal, odor removal and environmental friendliness, and leftover materials can be reutilized.

Owner:蔡龙源

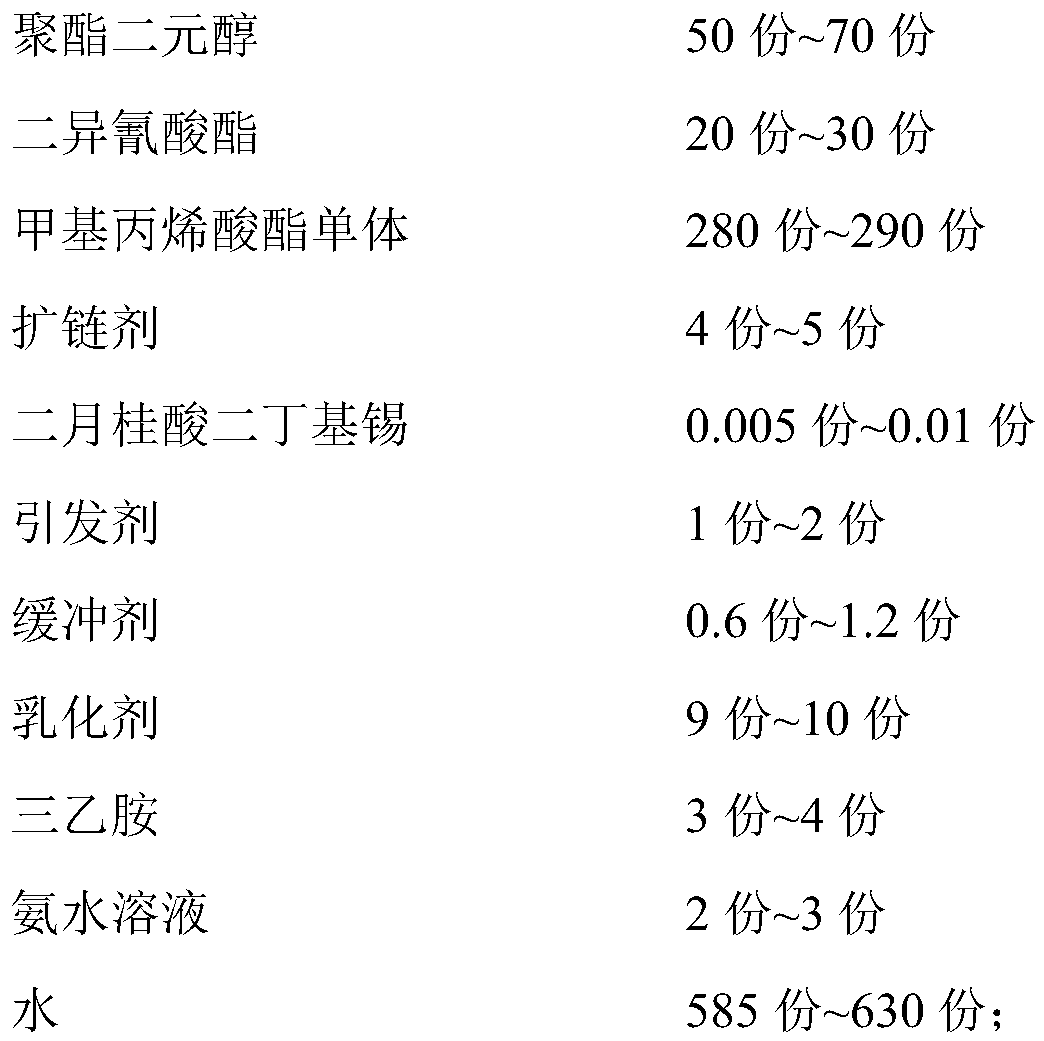

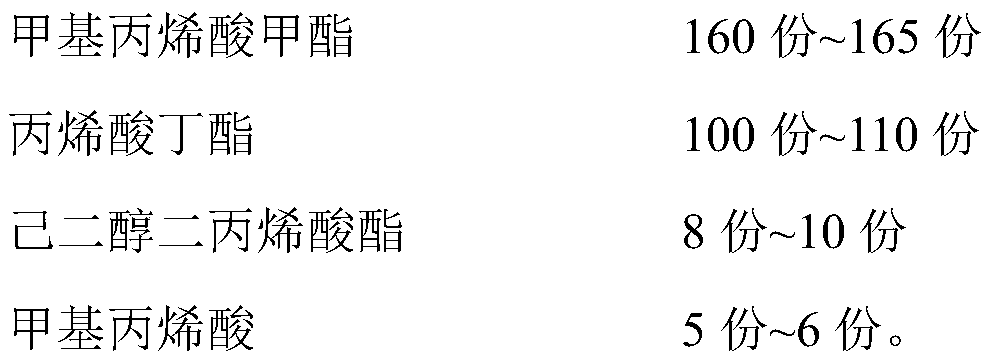

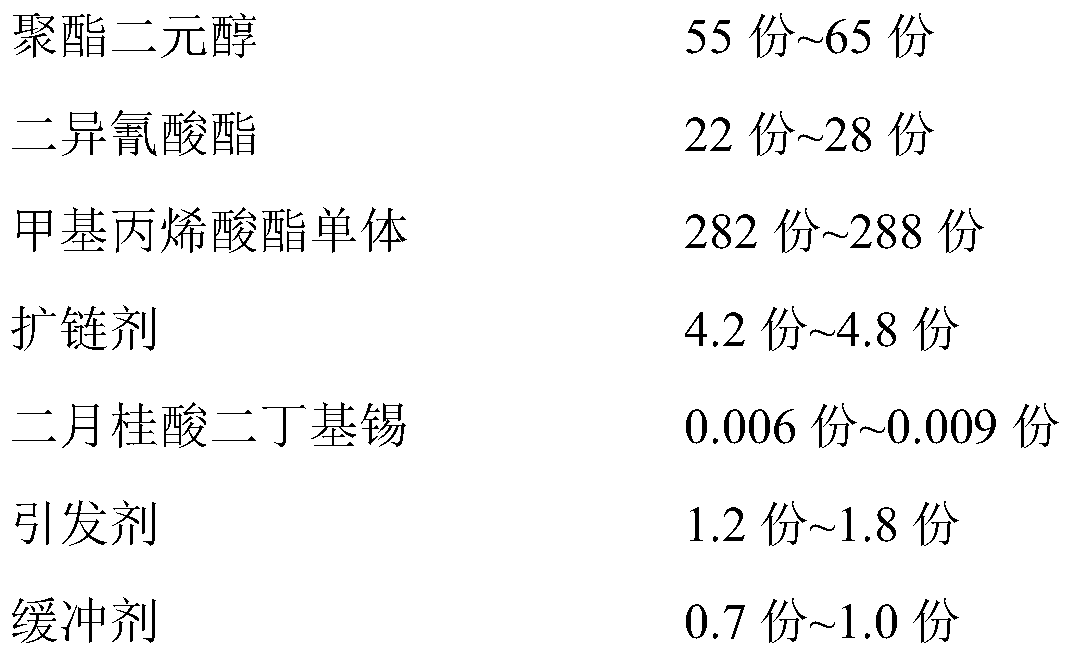

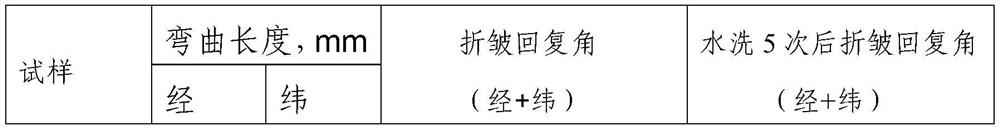

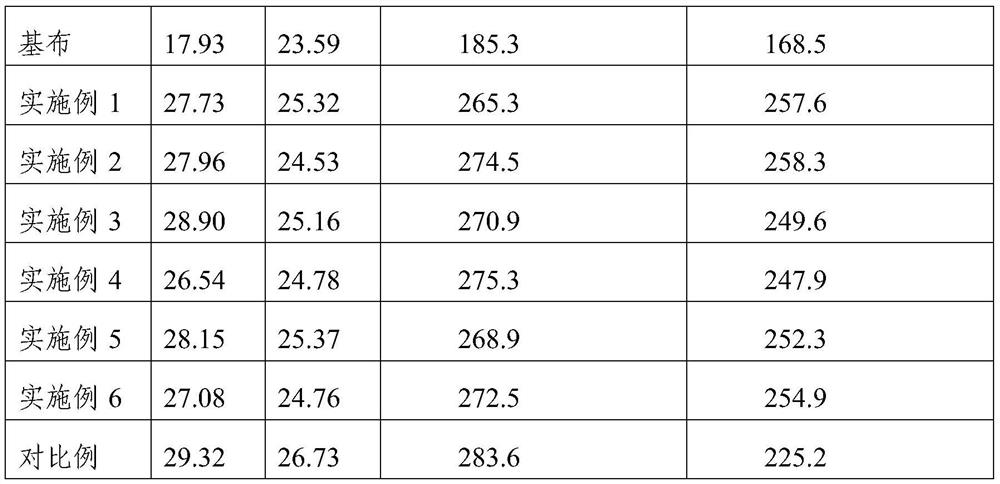

PUA emulsion having super strong ability of covering matting powder and realizing high extinction and high permeability and preparation method of PUA emulsion

ActiveCN110591489AHigh extinctionImprove permeabilityPolyurea/polyurethane coatingsWater basedPolyester

The invention relates to the technical field of coatings, and in particular relates to a PUA emulsion having super strong ability of covering matting powder and realizing high extinction and high permeability and a preparation method of the PUA emulsion. The PUA emulsion having super strong ability of covering the matting powder and realizing high extinction and high permeability includes a polyester diol, diisocyanate, a methacrylate monomer, a chain extender, dibutyltin dilaurate, an initiator, a buffer agent, an emulsifier, triethylamine, an ammonia aqueous solution and water. The PUA emulsion not only has high hardness, but also has better water and solvent resistance, and more important, the PUA emulsion has low costs and can bring higher economic benefits; the water-based polyurethane dispersion mainly plays the role of a high-efficiency dispersant and can efficiently disperse an inorganic matting agent, so that a paint film can still maintain high permeability under the condition of high extinction; and the preparation method of the PUA emulsion having super strong ability of covering the matting powder and realizing high extinction and high permeability has the characteristics of a simple process, low production costs, and suitability for large-scale production.

Owner:东莞大宝化工制品有限公司

A silicon-containing water-repellent finishing agent

ActiveCN109750503BImprove self-crosslinkingIncreased cross-linking sitesFibre treatmentDiacetonaminePolymer science

The invention discloses a silicon-containing water-repellent finishing agent. The silicon-containing water-repellent finishing agent is formed by blending a silicone-modified acrylate emulsion and a silicone-modified polyurethane emulsion, wherein the silicone-modified acrylate 86‑122 parts of emulsion, 72‑94 parts of silicone modified polyurethane emulsion; using Si(CH 3 ) 3 The organosilicon functional monomer of the group, due to its large steric hindrance and non-hydrolysis, greatly improves the stability of emulsion polymerization, increases the silicon content in the polymer, and makes the distribution of organosilicon in the polymer molecular chain even. Enhances the water repellency of polymers. Utilizing the complementary properties of polyurethane and polyacrylate, the two emulsions are blended and compounded to obtain a composite finishing agent with excellent water repellency. By introducing diacetone acrylamide and adipic hydrazide into the emulsion, after the two emulsions are blended, the crosslinking sites in the system can be increased, the self-crosslinking performance can be improved, and a medium-temperature self-crosslinking finishing agent can be formed, which can properly reduce Baking temperature.

Owner:浙江东进新材料有限公司

Method for preparing clothing adhesive lining from self-crosslinking water-borne polyacrylate powderless base mud

ActiveCN103183772BImprove self-crosslinkingGood adhesionEster polymer adhesivesHydrophilic monomerAdhesive

The invention discloses a method for preparing a clothing adhesive lining from self-crosslinking water-borne polyacrylate powderless base mud. The method comprises the following steps: at first, mixing water-borne polyacrylate emulsion, auxiliaries and deionized water, wherein the water-borne polyacrylate emulsion is prepared from pre-emulsion, seed emulsion, secondary emulsion, 10% adipic dihydrazide water solution and ammonia water, and the pre-emulsion is prepared from methyl methacrylate, butyl acrylate, acrylic acid, diacetone acrylamide, alkenamides sodium ethylenesulphonate, fatty alcohol-polyoxyethylene ether and deionized water; and then, adjusting the pH value of the system to be neutral with ammonia water, adding a water-borne acrylic thickener, and adjusting the viscosity to be less than 30,000. Soap-free emulsion prepared from lyophobic and hydrophilic monomers through a core-shell emulsion copolymerization technology is applied to the powderless base mud, so that the product has cleaner characteristics in preparation process and the product itself, meets green, environmental-friendly and healthy requirements, and conforms to the historical trend of the time.

Owner:长兴三伟热熔胶有限公司

A kind of inorganic reflective heat insulation lotus leaf coating and preparation method thereof

ActiveCN106221323BLow thermal conductivityImprove stain resistanceFireproof paintsAntifouling/underwater paintsAluminium silicateBuffering agent

The invention discloses inorganic reflective-insulation lotus leaf paint which is mainly prepared from the following raw materials: an inosilicate film forming matter, a composite reflective insulation material, rutile titanium dioxide, waterborne acrylic emulsion, an organosilicone adjuvant, a silane coupling agent, glycol, a dispersing agent, a wetting agent, a defoaming agent, a thickening agent, a buffering agent, a viscosity stabilizer and water, wherein the composite reflective insulation material is prepared from the following raw materials: thermal reflective insulation powder, kieselguhr, a compound aluminium silicate functional pigment, aedelforsite and mica powder. The inorganic reflective-insulation lotus leaf paint not only has an excellent thermal reflective insulation effect on building base materials, but also is capable of reducing indoor temperature to 20-25 DEG C in summer by virtue of optimization on the composite reflective insulation material; the reflective insulation compound material contains no organic waste gases such as formaldehyde and no APEO, is health-care and environmental-friendly, achieves a lotus leaf effect and is antifouling. The invention also discloses a preparation method of the inorganic reflective-insulation lotus leaf paint.

Owner:广东伊思曼新材料科技有限公司

A kind of water-based imitation coating high elastic stiffening finishing agent and preparation method

ActiveCN112593410BFeel smoothIncrease elasticityWrinkle resistant fibresGrip property fibresEndcappingEmulsion

The invention discloses a water-based imitation coating high-elasticity stiffening finishing agent and a preparation method, and relates to the technical field of textile fabric finishing. The finishing agent is prepared from the following raw materials in parts by weight: 50-60 parts of emulsion A, 100-120 parts of B, 5-10 parts of cationic blocked isocyanate crosslinking agent. A method for preparing a water-based imitation coating high-elasticity stiffening finishing agent. The epoxy-modified polyorganosiloxane emulsion A with high molar mass is cross-linked by amino polyether-modified polyorganosiloxane and polyethyl silicate. The reasonable compounding of the emulsion B prepared by the agent and the blocked isocyanate crosslinking agent, and the padding finishing of the fabric can significantly improve the elasticity and stiffness of the fabric, and achieve the effect of the coating process. The obtained finishing agent has good softness, good anti-wrinkle effect, excellent washing resistance, and is water-based and environmentally friendly, and can meet the export environmental protection requirements.

Owner:LIAONING FIXED STAR FINE CHEM

A PUA emulsion with super strong ability to coat matting powder and realize high matting degree and high permeability and preparation method thereof

ActiveCN110591489BHigh extinctionImprove permeabilityPolyurea/polyurethane coatingsMethacrylatePolyester

The invention relates to the technical field of coatings, and in particular relates to a PUA emulsion having super strong ability of covering matting powder and realizing high extinction and high permeability and a preparation method of the PUA emulsion. The PUA emulsion having super strong ability of covering the matting powder and realizing high extinction and high permeability includes a polyester diol, diisocyanate, a methacrylate monomer, a chain extender, dibutyltin dilaurate, an initiator, a buffer agent, an emulsifier, triethylamine, an ammonia aqueous solution and water. The PUA emulsion not only has high hardness, but also has better water and solvent resistance, and more important, the PUA emulsion has low costs and can bring higher economic benefits; the water-based polyurethane dispersion mainly plays the role of a high-efficiency dispersant and can efficiently disperse an inorganic matting agent, so that a paint film can still maintain high permeability under the condition of high extinction; and the preparation method of the PUA emulsion having super strong ability of covering the matting powder and realizing high extinction and high permeability has the characteristics of a simple process, low production costs, and suitability for large-scale production.

Owner:东莞大宝化工制品有限公司

Special coated abrasives adhesive preparation and preparation process thereof

InactiveCN106893535AImprove adhesion strengthGood miscibilityNon-macromolecular adhesive additivesChemical paints/ink removersSolubilityPolymer science

The invention discloses a special coated abrasives adhesive preparation and a preparation process thereof; the special coated abrasives adhesive preparation is prepared from, by weight, 30-35% of styrene, 30-35% of butyl acrylate, 10-15% of methyl methacrylate, 5-10% of acrylonitrile, 3-5% of paraffin, 3-5% of urea, 2-5% of glyoxal, 1-2% of a plasticizer, 1-2% of an emulsifier, and 1-2% of silane coupling agent. By introducing various functional monomers through process and formula innovations, adhesive strength and wet adhesive strength of emulsion are improved effectively, the polarity of the product is improved effectively, the properties of the product are improved, and the phenol-aldehyde mixing solubility of the product is also improved.

Owner:江苏洛法新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com