Silicon-containing water repellent finishing agent

A technology of water-repellent finishing and silicone, which is applied in the field of textiles, can solve the problems of silicone mechanical strength and poor adhesion, and achieve the effect of large silicon-oxygen bond angle, good flexibility, and large steric hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A silicon-containing water-repellent finishing agent, which is formed by blending silicone-modified acrylate emulsion and silicone-modified polyurethane emulsion, wherein, 86 parts of silicone-modified acrylate emulsion and 72 parts of silicone-modified polyurethane emulsion;

[0044] Described organosilicon modified acrylate emulsion, preparation method is as follows:

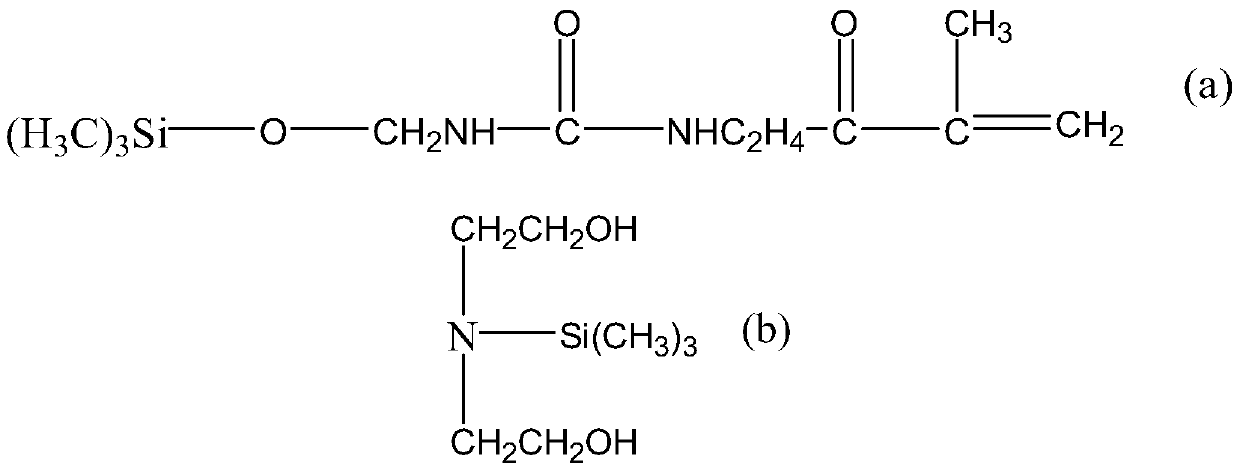

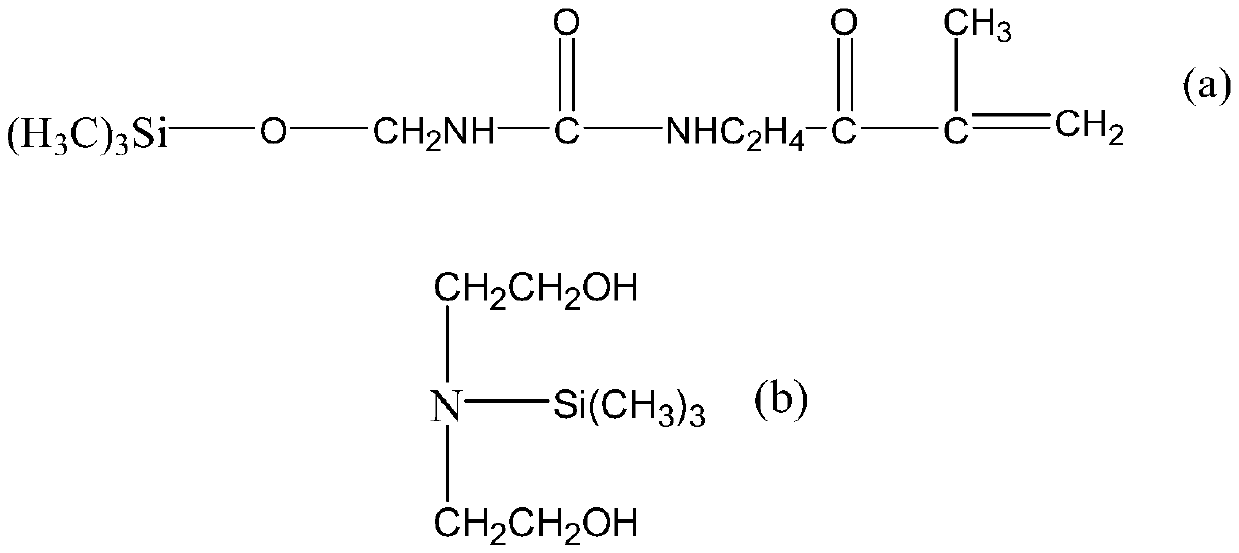

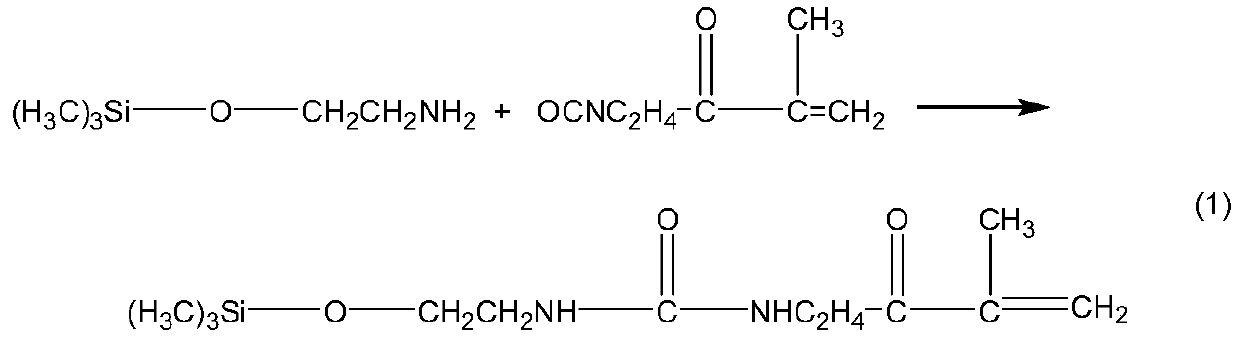

[0045] (1) Stir and dissolve 1.6 parts of AEO-9 fatty alcohol polyoxyethylene ether, 0.7 part of OP-10 alkylphenol polyoxyethylene (10) ether, 3.8 parts of SDS sodium lauryl sulfate and 124 parts of water into an aqueous solution; Add 32 parts of methyl methacrylate, 13 parts of ethyl acrylate, 45 parts of butyl acrylate, 16 parts of octadecyl acrylate, 12 parts of dicapped vinyl silicone oil, 14 parts of functional silicone monomer, 6 parts of diacetone Acrylamide, after fully mixing, emulsify with high-speed stirring to form a pre-emulsion;

[0046] (2) Add 72 parts of water, 0.8 part of AEO-9 fatty al...

Embodiment 2

[0059] A silicon-containing water-repellent finishing agent, which is formed by blending silicone-modified acrylate emulsion and silicone-modified polyurethane emulsion, wherein, 104 parts of silicone-modified acrylate emulsion and 84 parts of silicone-modified polyurethane emulsion;

[0060] Described organosilicon modified acrylate emulsion, preparation method is as follows:

[0061] (1) Stir and dissolve 1.6 parts of AEO-9 fatty alcohol polyoxyethylene ether, 0.7 part of OP-10 alkylphenol polyoxyethylene (10) ether, 3.8 parts of SDS sodium lauryl sulfate and 124 parts of water into an aqueous solution; Add 32 parts of methyl methacrylate, 13 parts of ethyl acrylate, 45 parts of butyl acrylate, 16 parts of octadecyl acrylate, 12 parts of dicapped vinyl silicone oil, 14 parts of functional silicone monomer, 6 parts of diacetone Acrylamide, after fully mixing, emulsify with high-speed stirring to form a pre-emulsion;

[0062] (2) Add 72 parts of water, 0.8 part of AEO-9 fatty...

Embodiment 3

[0075] A silicon-containing water-repellent finishing agent, which is formed by blending silicone-modified acrylate emulsion and silicone-modified polyurethane emulsion, wherein, 122 parts of silicone-modified acrylate emulsion and 94 parts of silicone-modified polyurethane emulsion;

[0076] Described organosilicon modified acrylate emulsion, preparation method is as follows:

[0077] (1) Stir and dissolve 1.6 parts of AEO-9 fatty alcohol polyoxyethylene ether, 0.7 part of OP-10 alkylphenol polyoxyethylene (10) ether, 3.8 parts of SDS sodium lauryl sulfate and 124 parts of water into an aqueous solution; Add 32 parts of methyl methacrylate, 13 parts of ethyl acrylate, 45 parts of butyl acrylate, 16 parts of octadecyl acrylate, 12 parts of dicapped vinyl silicone oil, 14 parts of functional silicone monomer, 6 parts of diacetone Acrylamide, after fully mixing, emulsify with high-speed stirring to form a pre-emulsion;

[0078] (2) Add 72 parts of water, 0.8 part of AEO-9 fatty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com