AM-DAAM-AMPS ternary polymer gel particle drive-adjusting reagent and synthesis method thereof

A technology of ternary polymers and gel particles, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of pre-crosslinked particle plugging agent difficult deep profile control, etc., to achieve enhanced molecular rigidity, good Profile control and water shutoff ability, increase the effect of temperature resistance and salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Example 1: Synthesis of Ternary Polymerized Gel Particles AM-DAAM-AMPS

[0013] Weigh 14g AM, 2g DAAM, and 4g AMPS respectively into jars, and take a certain amount of pure water to prepare an aqueous solution with a concentration of 20% of the total monomer mass. Titrate with NaOH solution to pH 7, then add initiator ammonium persulfate solution and sodium bisulfite solution (molar ratio is 1:1), the amount of initiator added is 0.4% of the total mass of monomer; add crosslinking agent MBA , the cross-linking agent addition is 0.07% of the total mass of monomers. The jar was put into a water bath at 50°C for 3 hours to react, and finally washed with absolute ethanol, pulverized, and dried to obtain AM-DAAM-AMPS ternary polymer gel particles.

Embodiment 2

[0014] Example 2: Characterization of AM-DAAM-AMPS terpolymer gel particle structure

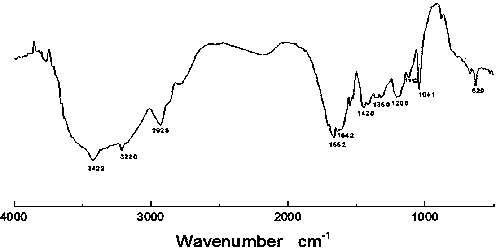

[0015] The infrared spectrogram of the terpolymer AM-DAAM-AMPS synthesized by embodiment 1 is as follows figure 1 shown; From the figure, we can see that the stretching vibration peak of C-S is located at 629cm -1 ; The characteristic absorption peak of the sulfonic acid group is located at 1041cm -1 、1208cm -1 ; The methyl absorption peak is located at 2925cm -1 、1350cm -1 and 1425cm -1 , and at 1350cm -1 and 1425cm -1 A bifurcation occurs at the place, and it can be identified that there are two gem-dimethyl groups with different chemical environments, that is, DAAM and AMPS; 1642cm -1 Be the C=O absorption peak in AM; 1662cm -1 Be the C=O absorption peak of DAAM; 3220cm -1 It is the absorption peak of -NH, 3422cm -1 for-NH 2 the absorption peak.

Embodiment 3

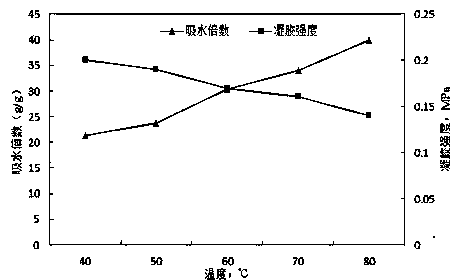

[0016] Example 3: Investigation on temperature resistance of AM-DAAM-AMPS terpolymer gelling agent particles

[0017] The gel particles synthesized in Example 1 were soaked and aged in 8000 mg / L formation water for 30 days at 40°C, 50°C, 60°C, 70°C, and 80°C to measure their water absorption and gel strength. figure 2 It can be seen that the pre-crosslinked particles aged in standard saline at 80°C for 30 days have a water absorption multiple of 40, a gel strength of 0.14 MPa, good toughness, and good temperature resistance (the determination method of strength and toughness: after absorbing water The sample of the profile control agent, after being filtered by a sieve, deformed without breaking when squeezed hard, and returned to its original shape after being loosened, indicating that the profile control agent has good toughness. The laboratory made a set of evaluation gel strength The device, pour the gel particles to be tested into the intermediate container, turn on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com