Water-soluble dispersing agent for gel ink and preparation method of water-soluble dispersing agent

A neutral ink and dispersant technology, applied in the direction of pigment paste, etc., can solve the problems of few potential points, difficult to prepare stable color paste, small steric hindrance of dispersant, etc., to improve potential density, facilitate dispersion and charge stability the effect of enhancing steric hindrance and charge repulsion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

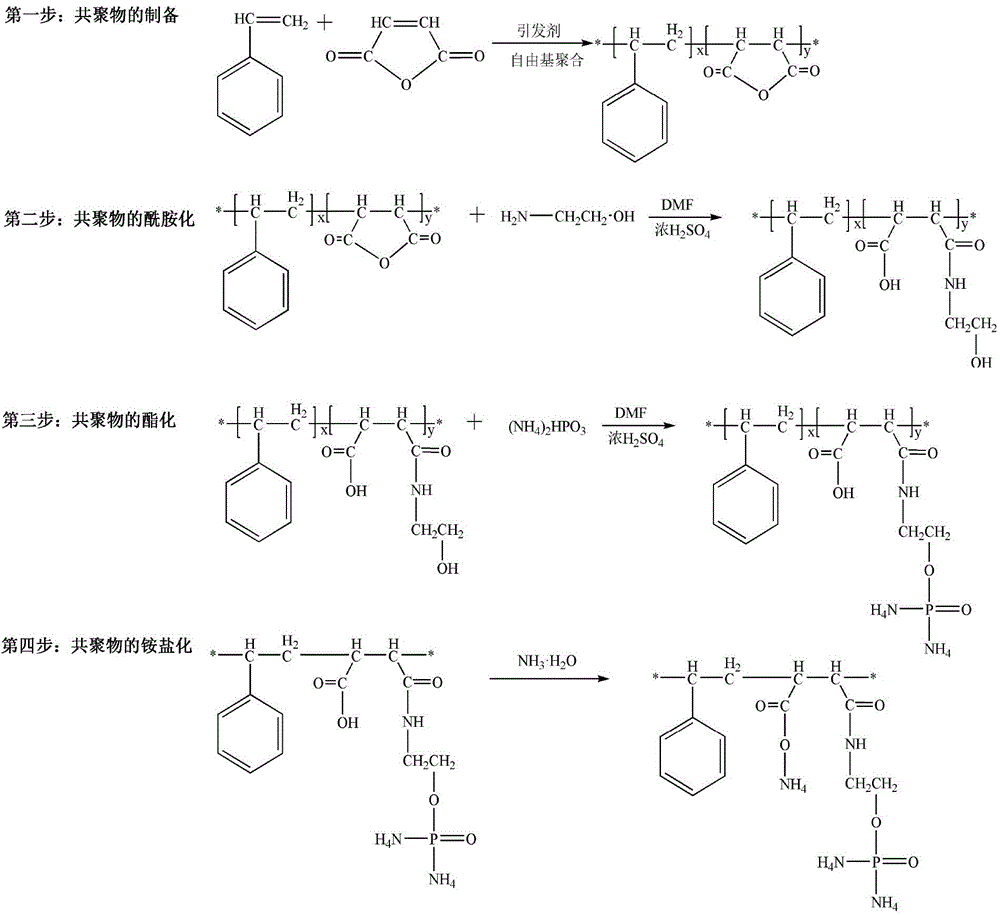

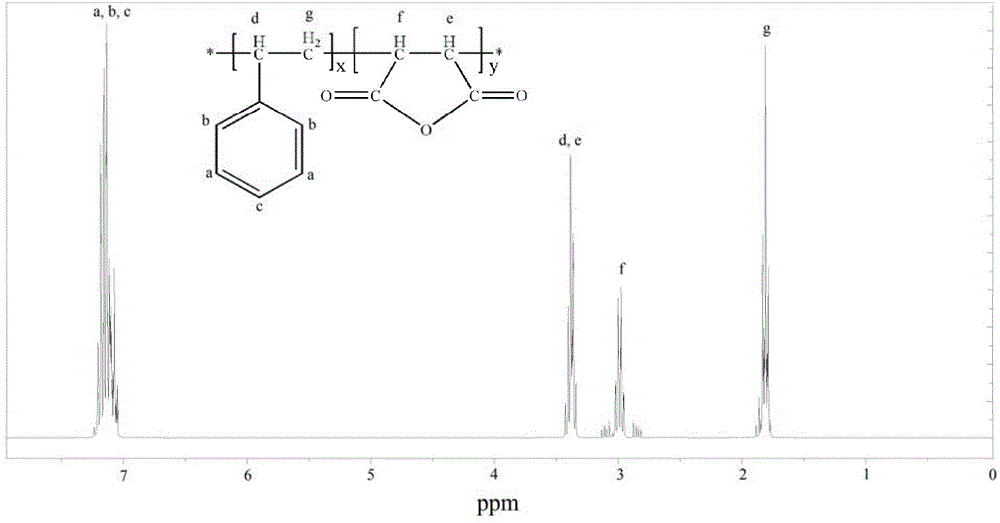

[0027] (1) The preparation of styrene-maleic anhydride copolymer: take styrene, maleic anhydride as raw material, toluene is solvent, control styrene concentration is 0.1mol / L, and the raw material molar ratio of styrene, maleic anhydride is 1:0.5, use benzoyl peroxide or azobisisobutyronitrile as the initiator, the amount of the initiator is 1:0.001 of the molar ratio of styrene to the initiator, react at 60°C for 5 hours, and pump out after the reaction Filter, use toluene as a wetting agent, and rinse three times to obtain a white powder. After vacuum drying at 60°C for 48 hours, a styrene-maleic anhydride copolymer is obtained.

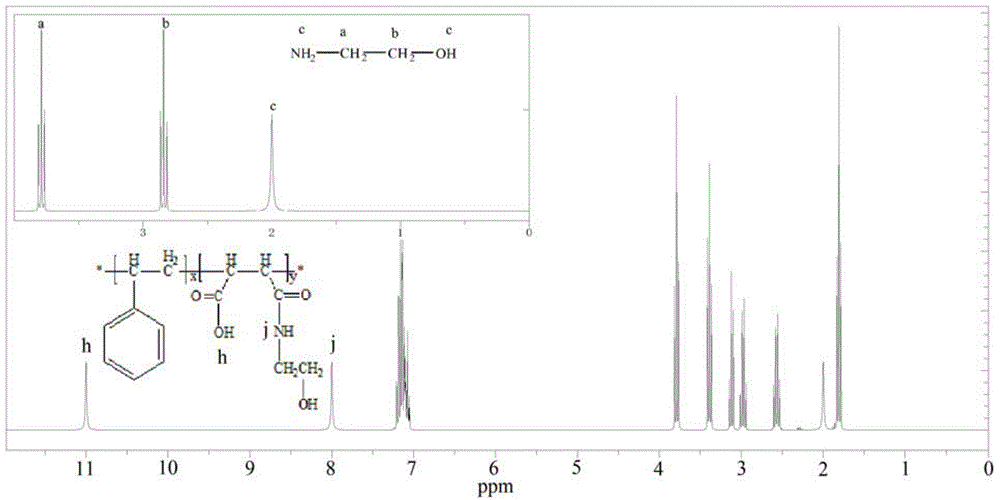

[0028] (2) Preparation of amidated styrene-maleic anhydride copolymer: with dimethylformamide (DMF) as solvent, to 0.5mol / L ethylene glycol amine in dimethylformamide, according to ethylene glycol The molar ratio of the amine to the carboxylic acid in the above-mentioned styrene-maleic anhydride copolymer is 1:0.5, add the styrene-maleic anhydride...

Embodiment 2

[0033] (1) The preparation of styrene-maleic anhydride copolymer: take styrene, maleic anhydride as raw material, toluene is solvent, control styrene concentration is 2.5mol / L, and the raw material molar ratio of styrene, maleic anhydride is 1:1.5, using benzoyl peroxide or azobisisobutyronitrile as the initiator, the amount of the initiator is 1:0.005 of the molar ratio of styrene to the initiator, reacting for 3 hours at 85°C, and pumping after the reaction Filter, use toluene as a wetting agent, and rinse three times to obtain a white powder. After vacuum drying at 40°C for 48 hours, a styrene-maleic anhydride copolymer is obtained.

[0034] (2) Preparation of amidated styrene-maleic anhydride copolymer: with dimethylformamide as solvent, to ethylene glycol amine of 1.0mol / L in dimethyl formamide, according to ethylene glycol amine and above-mentioned The molar ratio of carboxylic acid in the styrene-maleic anhydride copolymer is 1:0.5, add the above-mentioned obtained styr...

Embodiment 3

[0039] (1) The preparation of styrene-maleic anhydride copolymer: take styrene, maleic anhydride as raw material, toluene is solvent, control styrene concentration is 0.5mol / L, and the raw material molar ratio of styrene, maleic anhydride is 1:1, use benzoyl peroxide or azobisisobutyronitrile as the initiator, the amount of the initiator is 1:0.004 of the molar ratio of styrene to the initiator, react for 5 hours at 80°C, and pump out after the reaction Filter, use toluene as a wetting agent, and rinse three times to obtain a white powder. After vacuum drying at 60°C for 48 hours, a styrene-maleic anhydride copolymer is obtained.

[0040] (2) Preparation of amidated styrene-maleic anhydride copolymer: with dimethylformamide as solvent, to ethylene glycol amine of 1.0mol / L in dimethyl formamide, according to ethylene glycol amine and above-mentioned The molar ratio of carboxylic acid in the styrene-maleic anhydride copolymer is 1:0.5, add the above-mentioned obtained styrene-ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com