HCl-H2S corrosion-resistant and high-temperature-resistant coating and preparation method thereof

A high-temperature-resistant coating, hcl-h2s technology, applied in anti-corrosion coatings, polyurea/polyurethane coatings, polyester coatings, etc., can solve the safety problems of industrial enterprises, economic loss, S corrosiveness, insufficient high temperature resistance, and insufficient corrosiveness And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

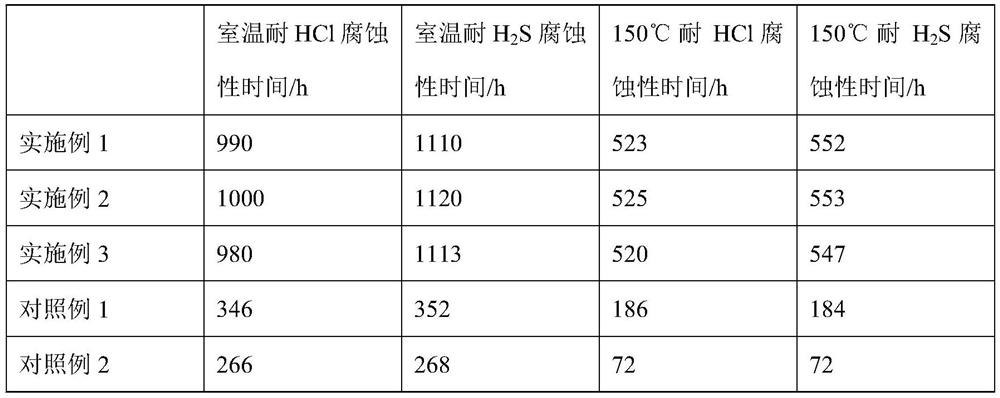

Examples

Embodiment 1

[0025] A resistant HCl-H 2 S corrosion and high temperature resistant coatings, raw materials include 6-amino-2-pyridine carboxylic acid, graphene oxide nanosheets, organic resin, polyethylene polyamine, trimethylolpropane trimethacrylate, diethylene glycol butyl ether, Organosiloxane resins, dispersants, anti-corrosion fillers, leveling agents, defoamers, water.

[0026] Firstly, the organic resin material functionalized with graphene ester of 6-amino-2-pyridinecarboxylate was prepared.

[0027] (1) Add 6-amino-2-pyridinecarboxylic acid and graphene nanosheets into the reactor according to the mass ratio of 10:2, use zinc isooctanoate as a catalyst, and react at 135°C for 12h to obtain 6-amino- Graphene 2-pyridinecarboxylate.

[0028] (2) Mix the organic resin and diethylene glycol butyl ether according to the mass ratio of 1:1, then heat up to 70°C, add polyethylene polyamine for heat preservation reaction for 1h, the molar ratio of polyethylene polyamine to organic resin ...

Embodiment 2

[0032]A resistant HCl-H 2 S corrosion and high temperature resistant coatings, raw materials include 6-amino-2-pyridine carboxylic acid, graphene oxide nanosheets, organic resin, polyethylene polyamine, trimethylolpropane trimethacrylate, diethylene glycol butyl ether, Organosiloxane resins, dispersants, anti-corrosion fillers, leveling agents, defoamers, water.

[0033] Firstly, the organic resin material functionalized with graphene ester of 6-amino-2-pyridinecarboxylate was prepared.

[0034] (1) Add 6-amino-2-pyridinecarboxylic acid and graphene oxide nanosheets into the reactor at a mass ratio of 10:3, use zinc isooctanoate as a catalyst, and react at 120°C for 13 hours to obtain 6-amino - Graphene 2-pyridinecarboxylate.

[0035] (2) Mix the organic resin and diethylene glycol butyl ether according to the mass ratio of 1:(1-2), then heat up to 80°C, add polyethylene polyamine for heat preservation reaction for 1h, polyethylene polyamine and organic The molar ratio of r...

Embodiment 3

[0040] A resistant HCl-H 2 S corrosion and high temperature resistant coatings, raw materials include 6-amino-2-pyridine carboxylic acid, graphene oxide nanosheets, organic resin, polyethylene polyamine, trimethylolpropane trimethacrylate, diethylene glycol butyl ether, Organosiloxane resins, dispersants, anti-corrosion fillers, leveling agents, defoamers, water.

[0041] Firstly, the organic resin material functionalized with graphene ester of 6-amino-2-pyridinecarboxylate was prepared.

[0042] (1) Add 6-amino-2-pyridinecarboxylic acid and graphene oxide nanosheets into the reactor at a mass ratio of 10:1, use zinc isooctanoate as a catalyst, and react at 145°C for 10 hours to obtain 6-amino - Graphene 2-pyridinecarboxylate.

[0043] (2) Mix the organic resin and diethylene glycol butyl ether according to the mass ratio of 1:2, then heat up to 75°C, add polyethylene polyamine for heat preservation reaction for 1h, the molar ratio of polyethylene polyamine to organic resin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com