Patents

Literature

710 results about "Polyethylene polyamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rosin cation asphalt emulgent

InactiveCN1861721AReduce manufacturing costGood emulsificationTransportation and packagingMixingRosinAsphalt

The invention relates to a rosin cationic bitumen emulsifier. The rosin intermediate is reacted by the rosin and the polyethylene polyamine, then to condensate with the different types of the quaternary ammonium salt to get the emulsifier. The emulsifier can be used to produce the normal cationic emulsifying asphalt or the SBR modified emulsifying asphalt for the road priming oil and the felting oil. The character of the invention is to use the nature resin rosin as the material, so the cost has decreased and it meets the environment need. The emulsifying asphalt can reach the need of the standard of the China ministry of communications and the America ASTMD2397.

Owner:DALIAN UNIV OF TECH

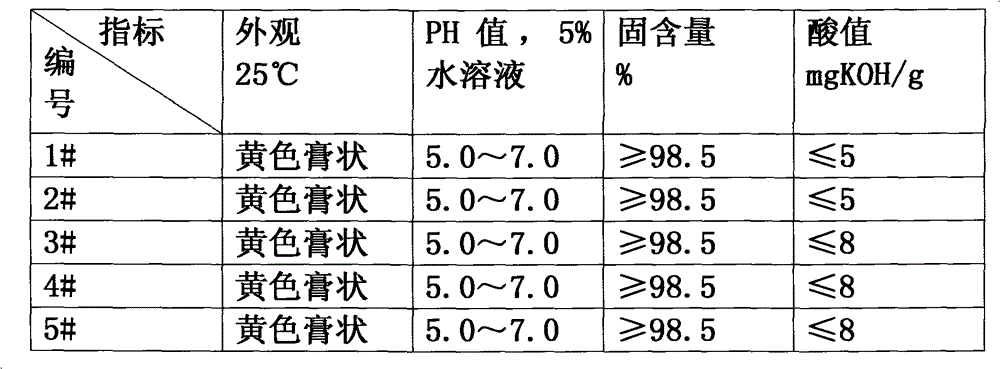

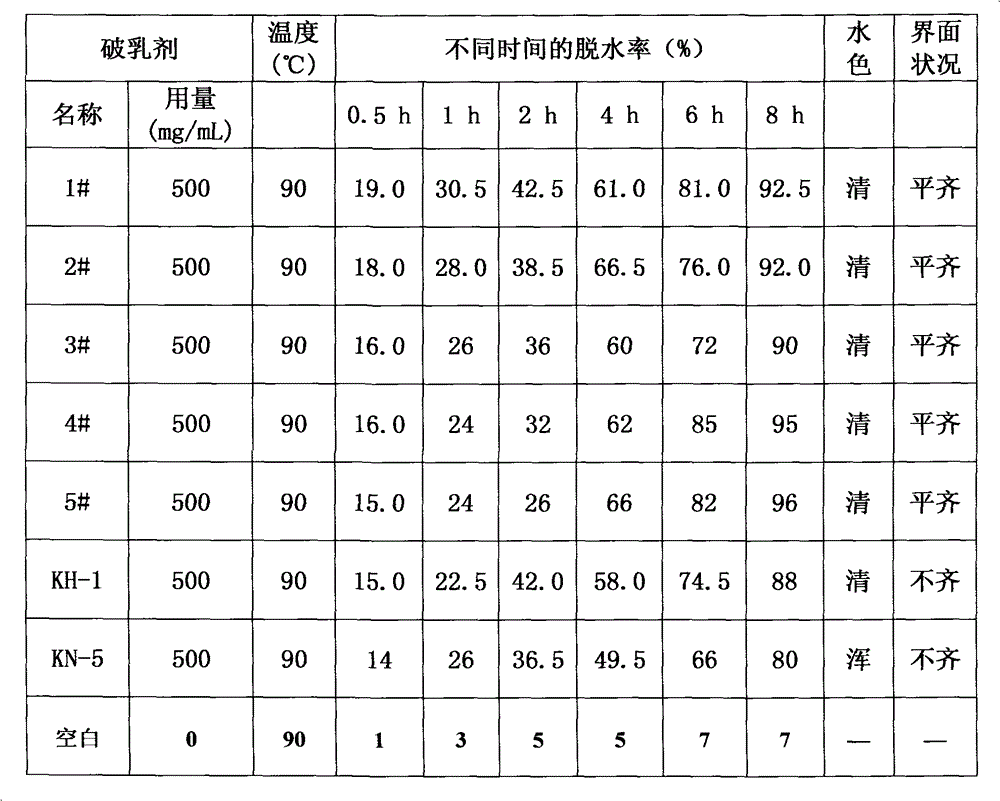

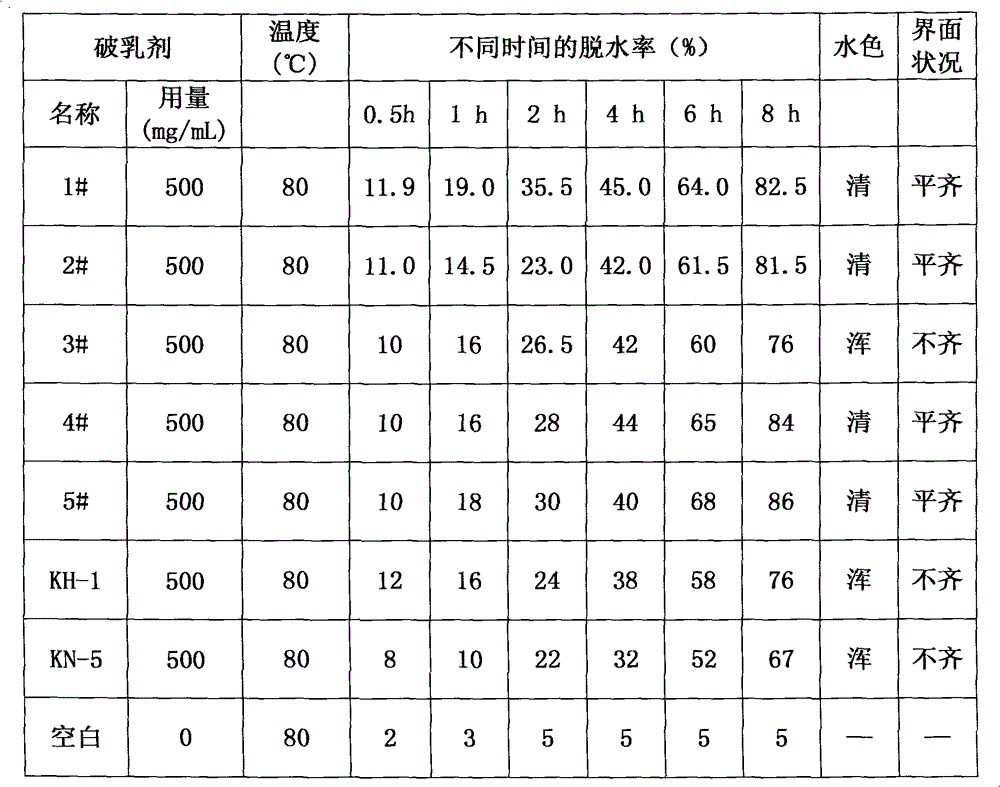

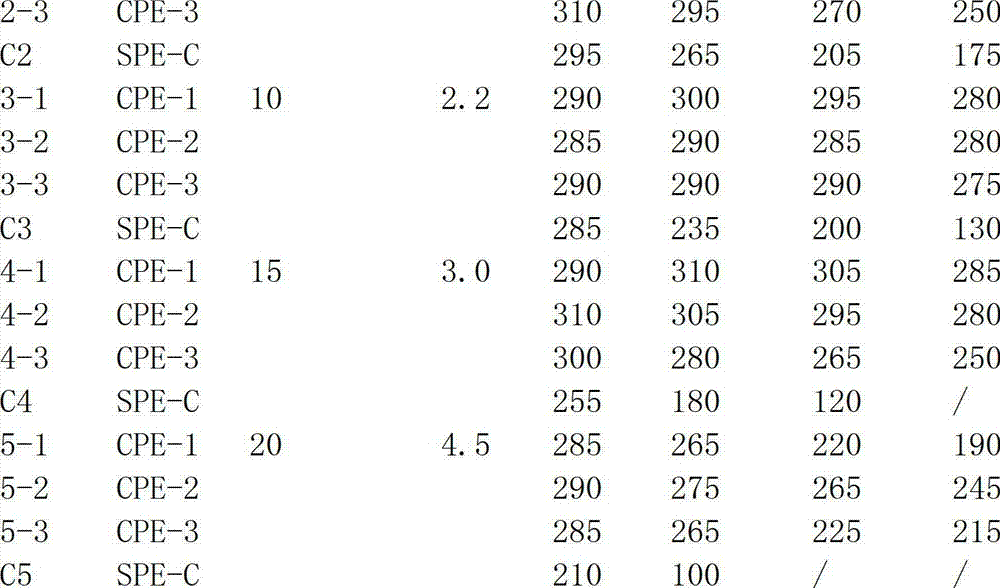

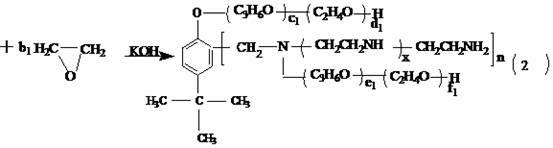

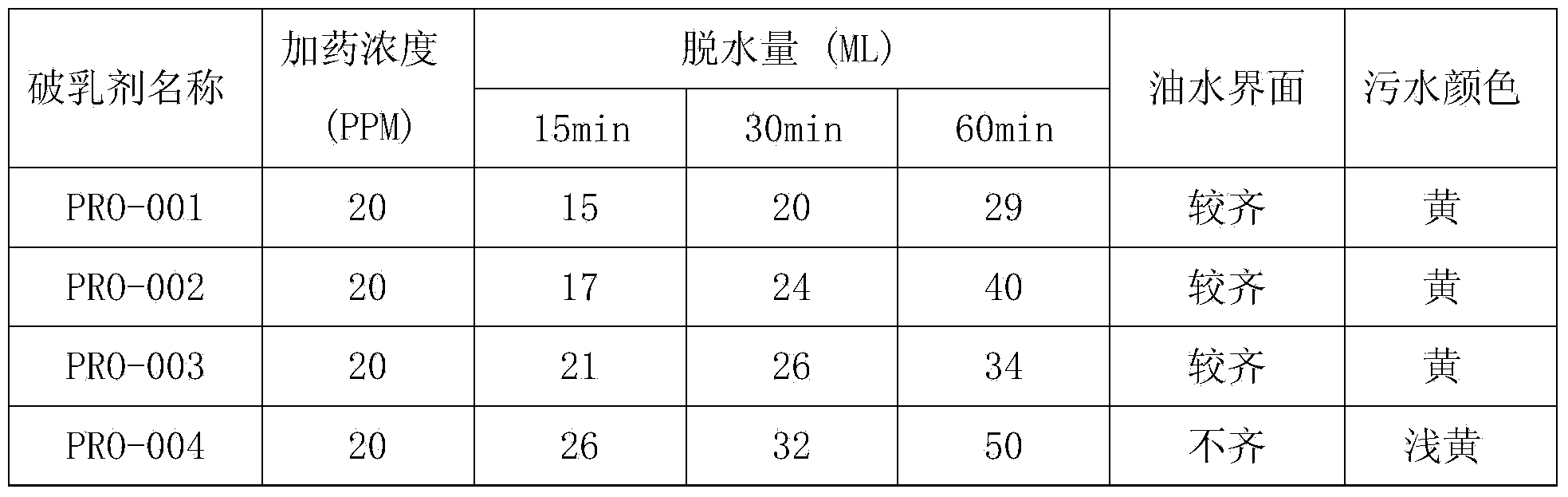

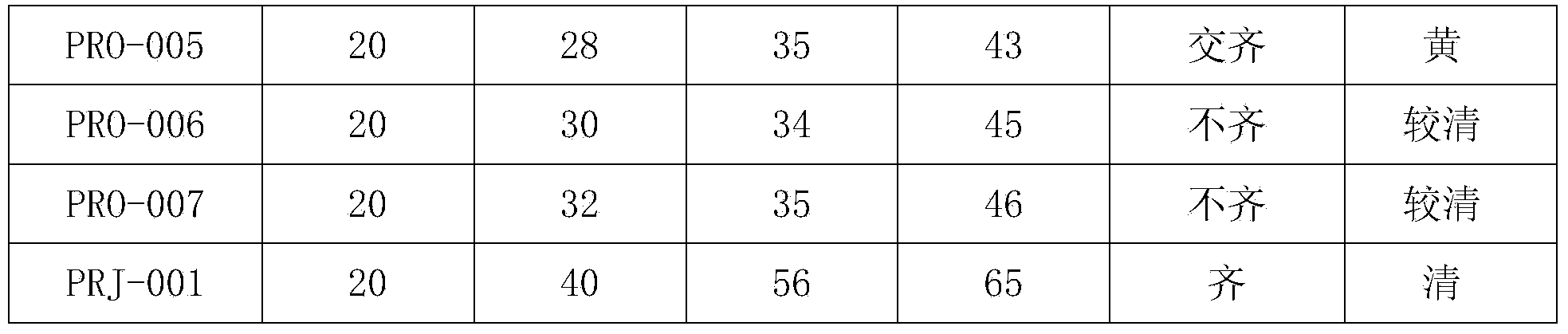

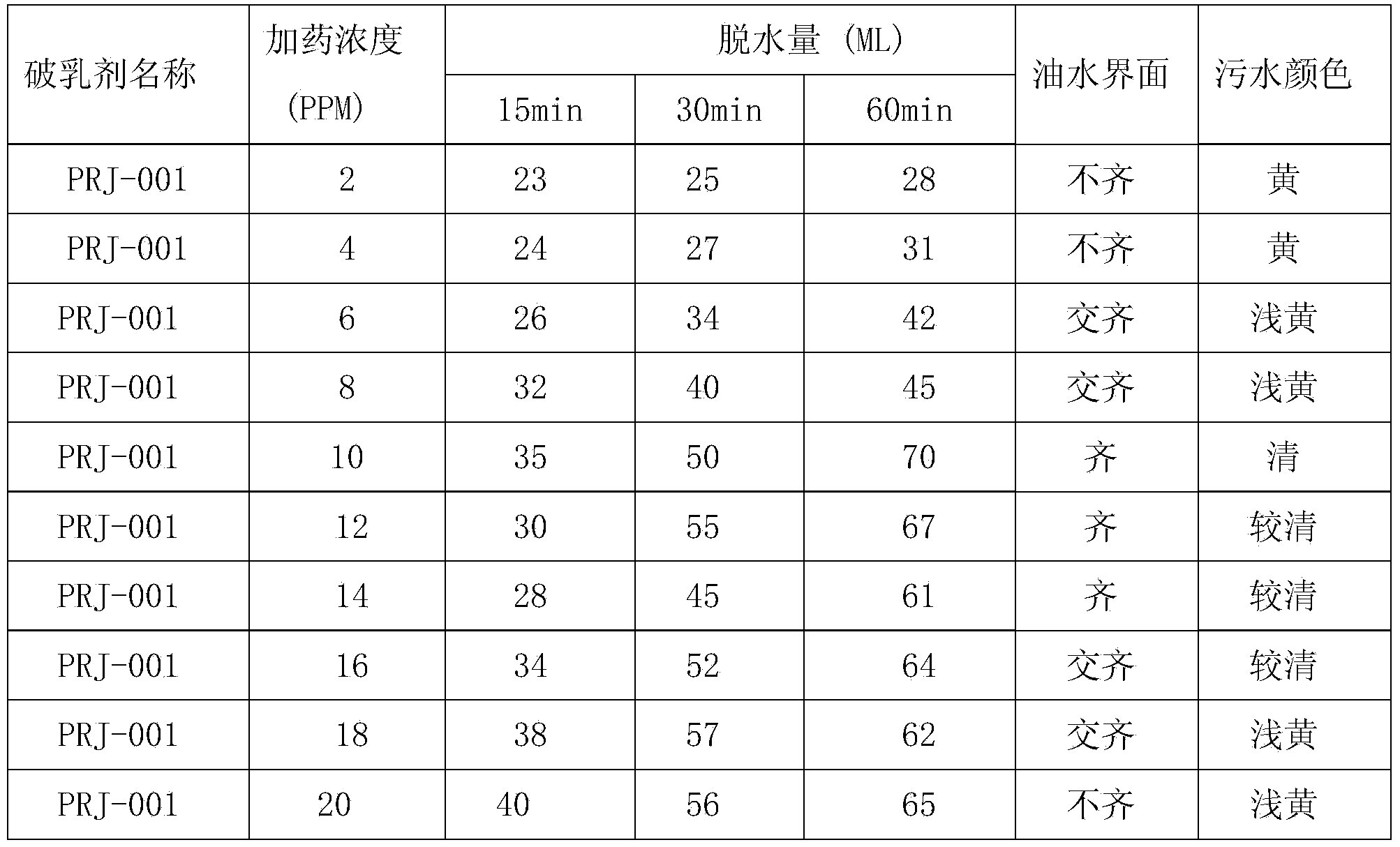

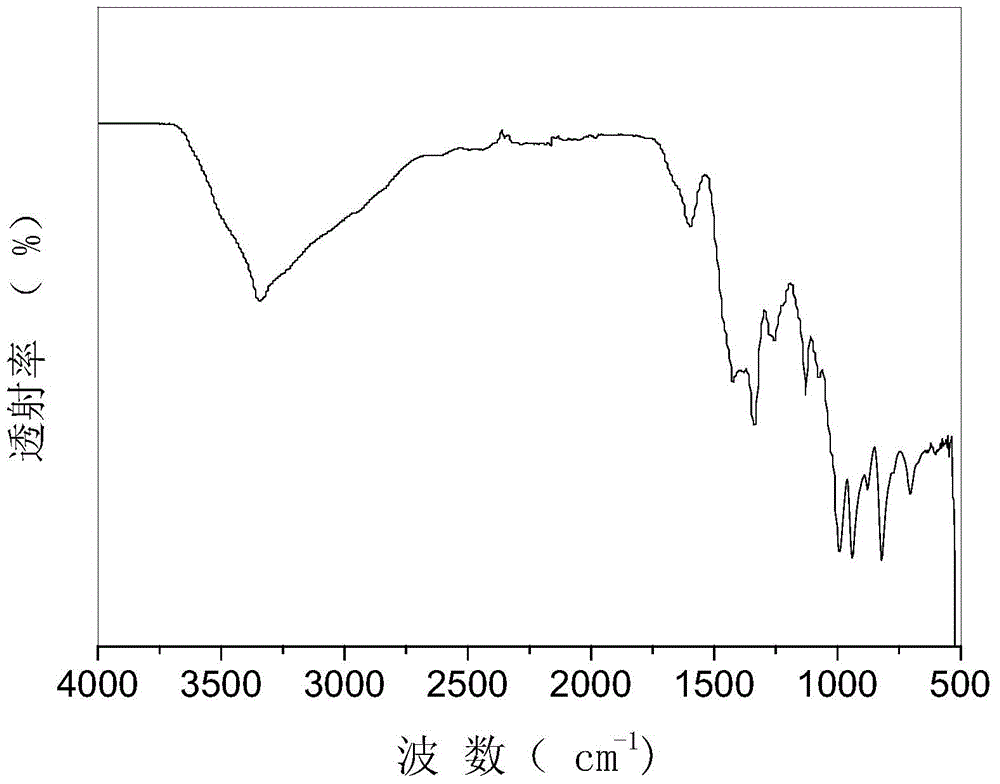

Preparation method of efficient deemulsifier for naphthenic extra heavy oil and product thereof

ActiveCN102746470AWeak elasticityReduce viscosityDewatering/demulsification with chemical meansAlkylphenolPhenol

The invention relates to a preparation method of an efficient deemulsifier for naphthenic extra heavy oil and a product thereof, belonging to the technical field of petroleum processing. The efficient deemulsifier is prepared by polymerizing alkylphenol, polyethylene polyamine and formaldehyde to obtain thermoplastic phenol-amine resin as an initiator, polymerizing the initiator with oxirane and epoxypropane to generate polyether blocked copolymer, and then esterifying the polyether blocked copolymer with acrylic acid and other unsaturated acids to generate a modified polyether product by grafting olefine acid. The product prepared by the method has the characteristics of quick dehydration and low dosage. The efficient deemulsifier of the invention is suitable for dehydrating the naphthenic extra heavy oil of Karamay oil fields, meeting the requirements of proper temperature, quick dehydration, high dehydration rate, clear water color, and tidy oil-water interface, and has high efficiency demulsification and dehydration performance.

Owner:克拉玛依市天明化工有限责任公司

Inspissated oil emulsion viscidity reducer

ActiveCN1778862AStrong resistance to mineral saltHigh emulsifying colloidDrilling compositionPhosphateOil emulsion

A thickened oil emulsifying viscosity reducer consists of anion surface activator, non-ionic-anion surface activator, demulsifier and water in proportion by 1:0.1-50:0.01-20 and water content is 0.2-5000 times of the sum of a, b and c. Anion surface activator comprises sodium salt and calcium salt of petroleum sulfoacid salt methyl condensate and sulfonated lignin; non-ionic-anion surface activator is chosen organic phosphate salt, sulfuric ester salt , carboxylate and sulfosalt of alkylphenol or fatty alcohol-polyoxyethylene ether; demulsifier is copolymer of alkyl ammonium halide cation demulsifier, polyethylene glycol polyoxytrimethylene polylol ether non-ionic demulsifier or polyethylene glycol polyoxytrimethylene polyethylene polyamines block. It has strong emulsifying ability and low thickened oil viscosity,

Owner:CHINA PETROLEUM & CHEM CORP +1

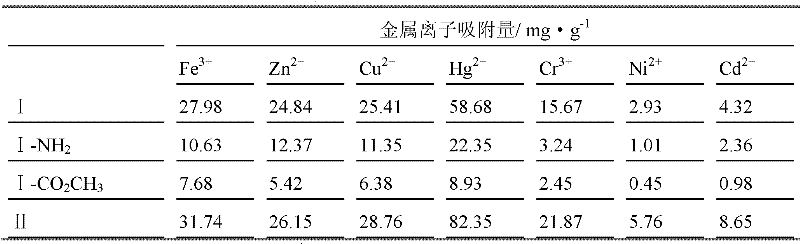

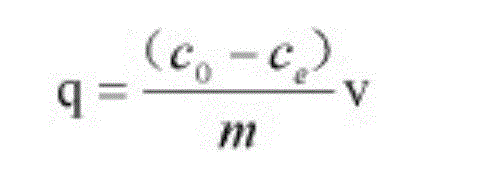

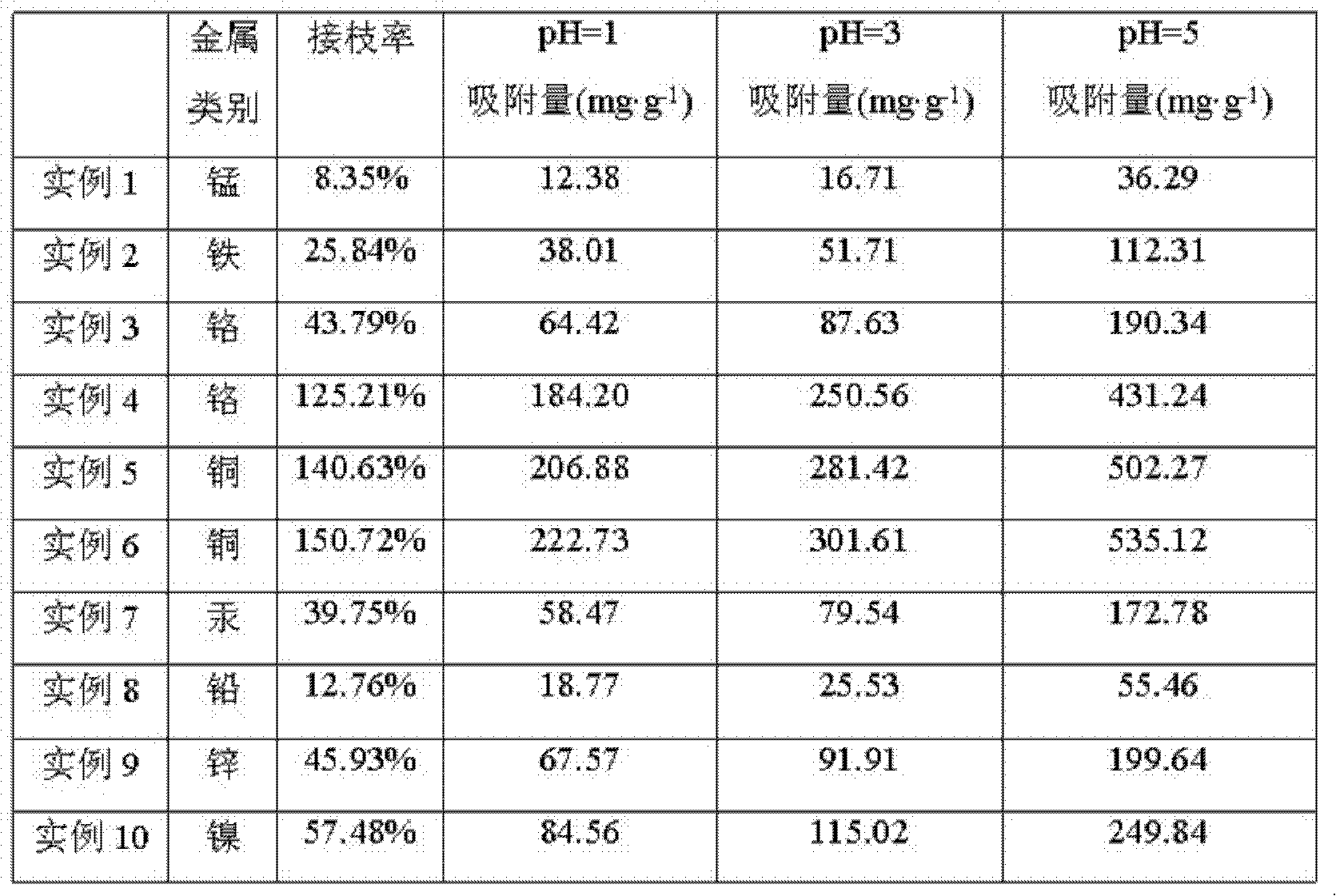

Preparation method and usage of modified attapulgite adsorption material

ActiveCN102247807AImprove adsorption capacityReduce process stepsOther chemical processesProcess efficiency improvementDistillationSolvent

The invention discloses a preparation method and usage of a modified attapulgite adsorption material. The method comprises the following steps: modifying attapulgite which has undergone purification and acid activation with an amino-silane coupling agent so as to introduce amino onto the surface of attapulgite; subjecting amino and excess acrylic acid ester to a Michael addition reaction so as tointroduce ester groups, subjecting introduced ester groups and polyethylene polyamine to a Michael addition reaction, carrying out underpressure distillation to remove a solvent and excess reactants,and carrying out vacuum drying, grinding and sieving to obtain a finished product. According to the invention, polyethylene polyamine or alcamine compounds are bonded to the surface of attapulgite through covalent bonds, thereby substantially improving adsorption performance of attapulgite to metal ions.

Owner:江苏麦阁吸附剂有限公司

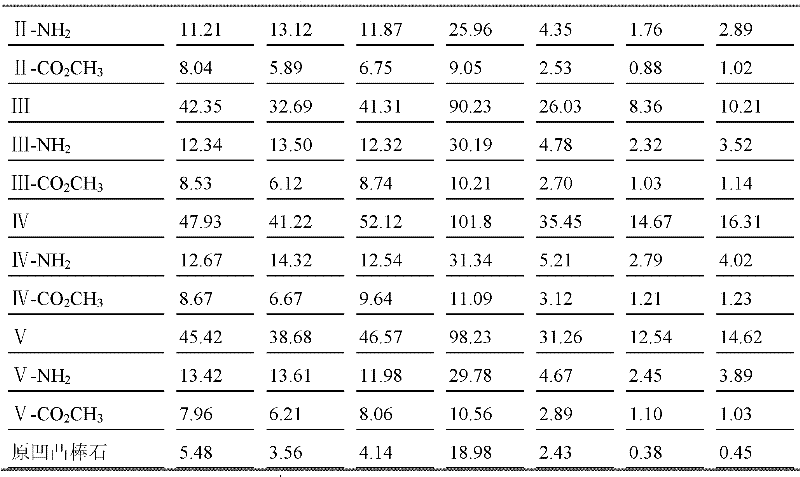

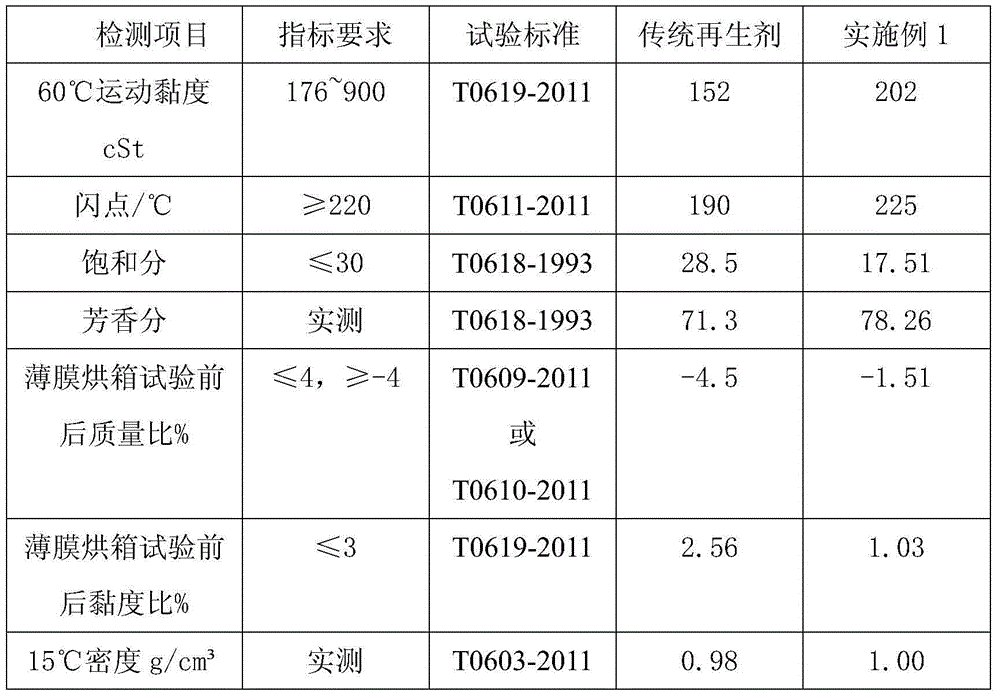

Asphalt regeneration agent as well as preparation method and application thereof

ActiveCN104610768AReduce manufacturing costAchieve reuseClimate change adaptationBuilding insulationsPlasticizerMixed materials

The invention discloses an asphalt regeneration agent which is prepared from the following raw materials in percentage by mass: 65-80% of plant asphalt, 3-5% of an interface reinforcing modifier, 15-30% of a plasticizer, 0.3-1% of a penetrating agent and 0.5-1% of an anti-aging agent, wherein the interface reinforcing modifier is one or a mixture of more than two of epoxy aliphatic polyethylene polyamine, epoxy silicon resin and epoxy resin in any ratio; the content of the epoxy group in the interface reinforcing modifier is 10-40%. In addition, the invention further provides a preparation method of the asphalt regeneration agent, an asphalt mixed material prepared from the asphalt regeneration agent, and a preparation method of the asphalt mixed material. When the asphalt mixed material is prepared from the asphalt regeneration agent, the anti-rutting performance, the anti-water damage property and the low-temperature anti-cracking property can be greatly improved, and waste resources can be recycled.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

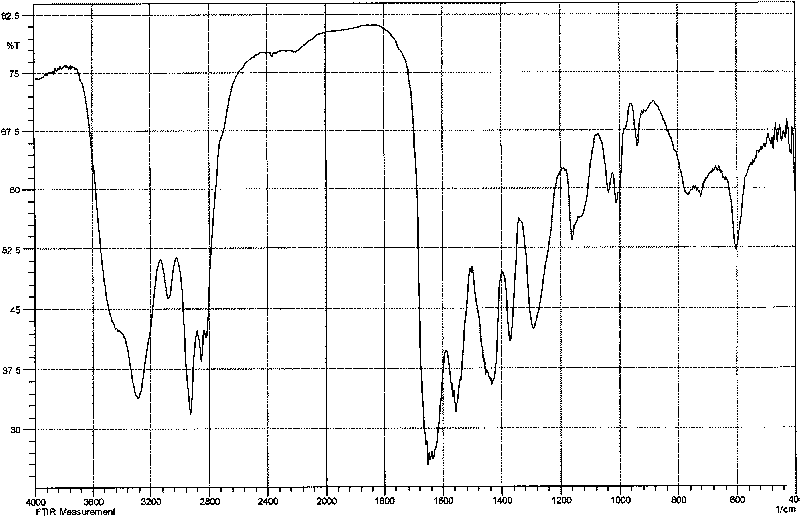

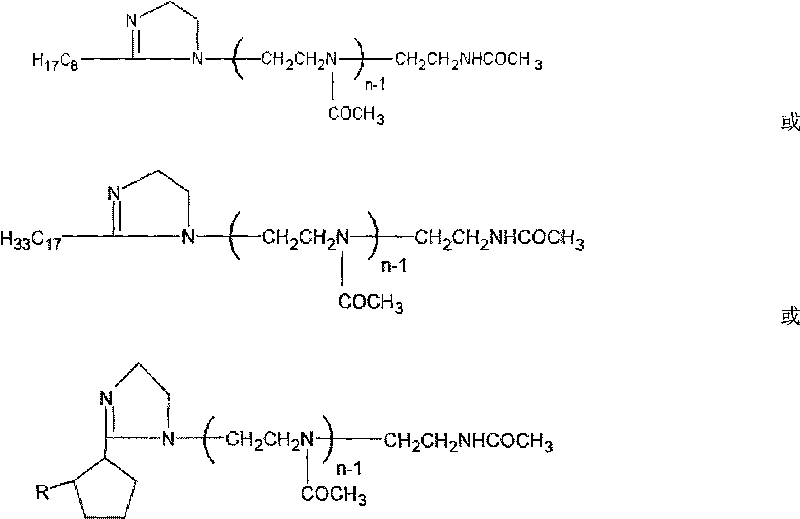

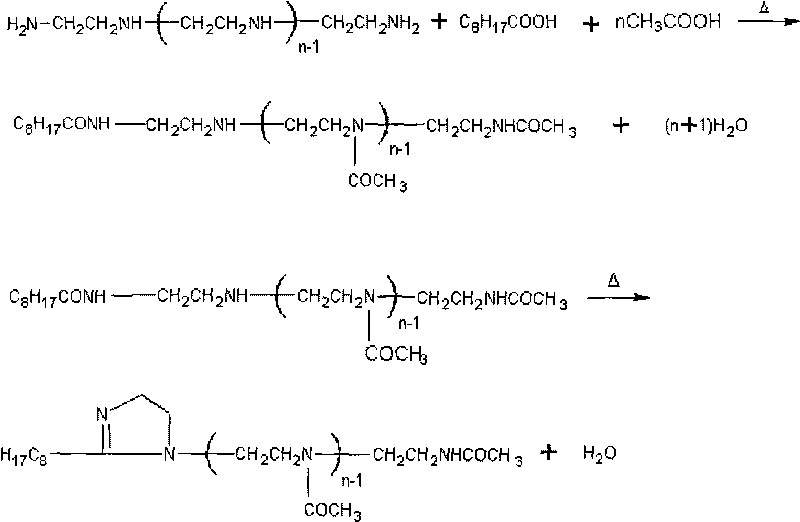

Water-soluble imidazoline amide corrosion inhibitor, preparation method thereof and using method thereof

InactiveCN101705112AEasy to useLow costOrganic chemistryTreatment apparatus corrosion/fouling inhibitionFatty acidRaw material

The invention provides a water-soluble imidazoline amide corrosion inhibitor, a preparation method thereof and a using method thereof, and belongs to the technical field of oil refining. The corrosion inhibitor consists of the following components in percentage by mass: 10 to 30 percent of water-soluble imidazoline amide, 0 to 15 percent of ethylene diamine, 0 to 20 percent of ammonia water with a mass concentration of 25 to 28 percent, 0 to 20 percent of ethanol and 40 to 90 percent of water, wherein the water-soluble imidazoline amide is prepared by the amidation reaction and the ring-closing reaction of polyethylene polyamines, glacial acetic acid and fatty acid serving as raw materials and toluene serving a solvent. When the corrosion inhibitor is continuously added to the top part of a primary distillation tower, the top part of a atmospheric distillation tower, the top part of a vacuum distillation tower or the top part of a hydrogenation fractional distillation tower of an oil refinery, the corrosion of a HCL-H2S-H2O medium on the top part of the tower is inhibited, and simultaneously, the quality of products on the top part of the tower is not affected. In the method for preparing the corrosion inhibitor, water is used as the solvent, so that the method has the advantages of being safely used, having low cost and facilitating the addition of a neutralizing agent.

Owner:SHENYANG POLYTECHNIC UNIV +1

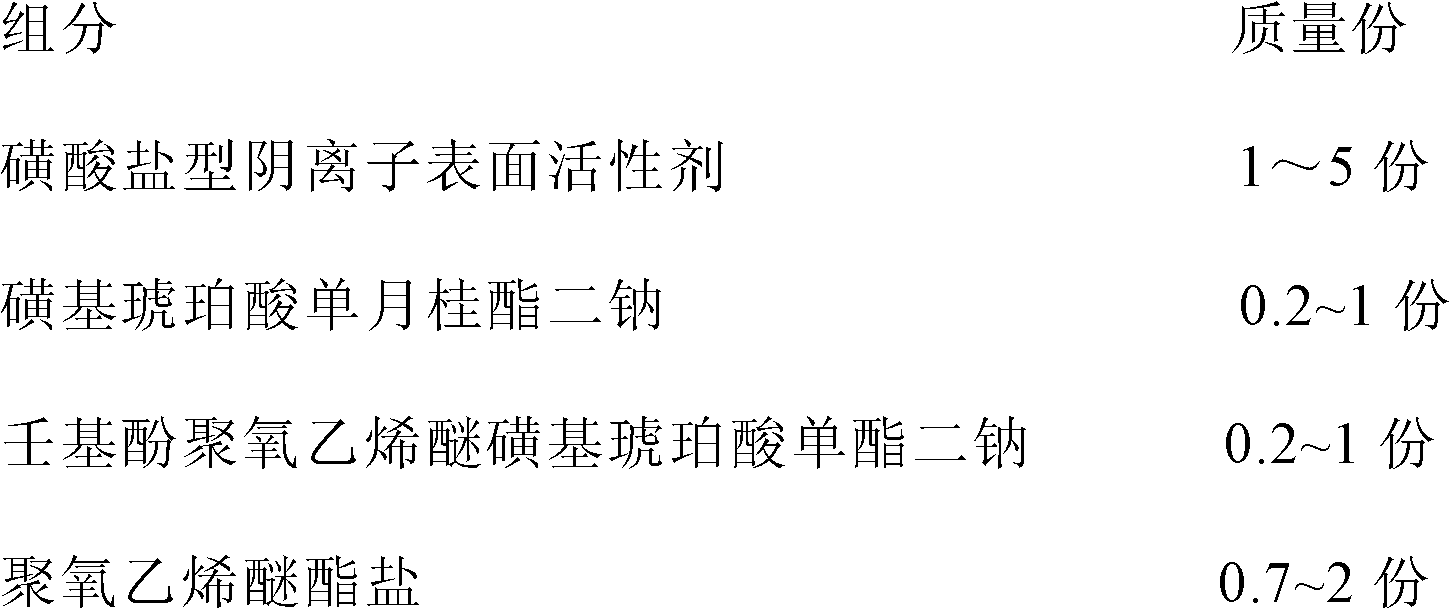

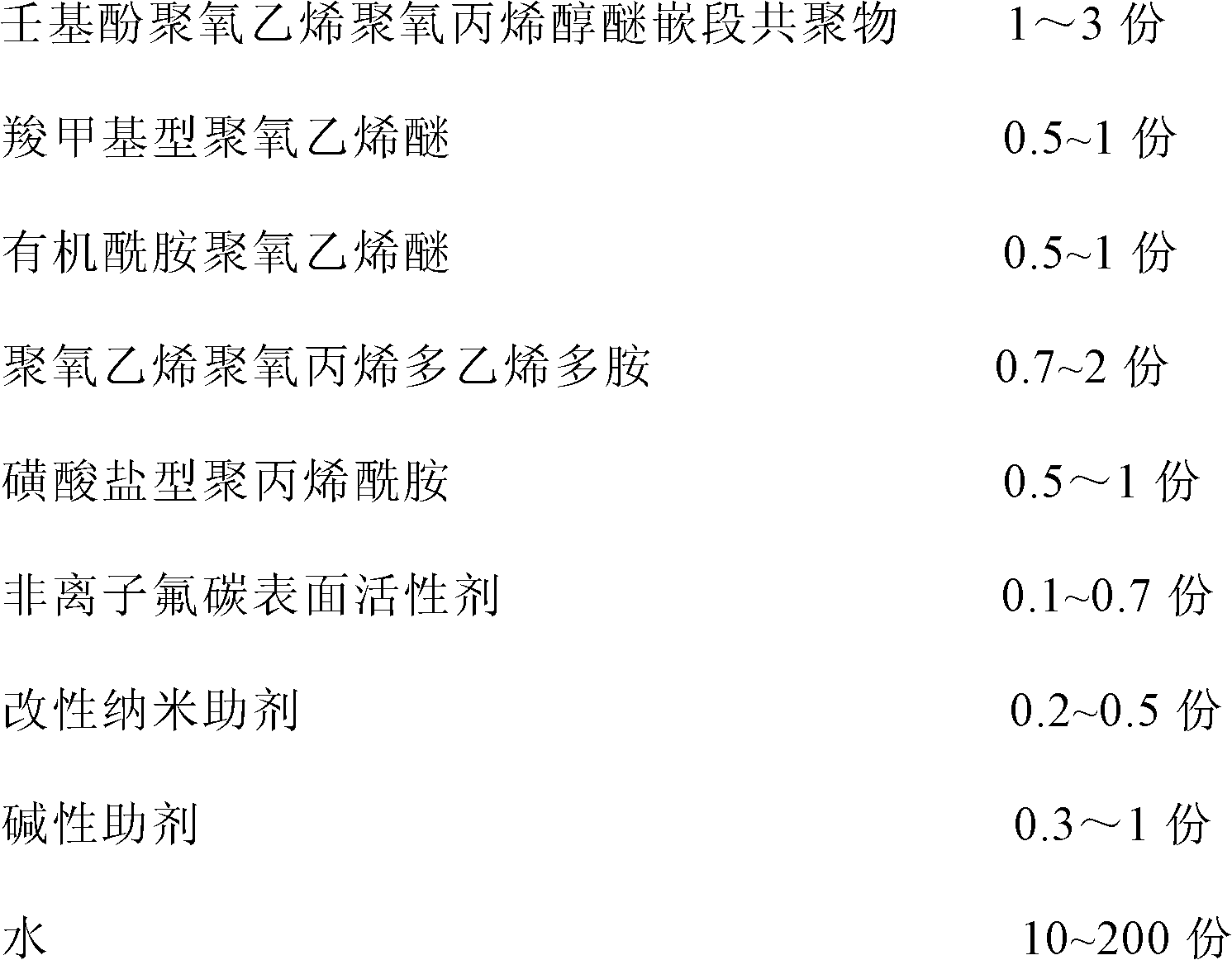

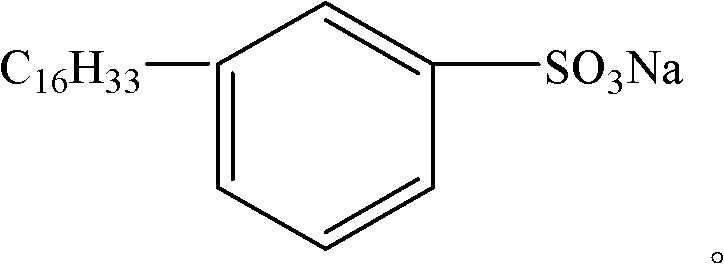

Salt- and temperature-resistant emulsification viscosity reducer for heavy oil

The invention relates to a salt- and temperature-resistant emulsification viscosity reducer for thick oil. The emulsification viscosity reducer is applied in oil fields for emulsification viscosity reduction of heavy oil and super heavy oil and is characterized by comprising the following components by mass: 1 to 5 parts of sulfonate anionic surfactant, 0.2 to 1 part of disodium monolauryl sulfosuccinate, 0.2 to 1 part of polyoxyethylene nonylphenyl ether disodium monoester sulfosuccinate, 0.7 to 2 parts of polyoxyethylene ether ester salt, 1 to 3 parts of polyoxyethylene nonylphenyl-polyoxypropylene alcohol ether block copolymer, 0.5 to 1 part of carboxymethyl polyoxyethylene ether, 0.5 to 1 part of organic amide polyoxyethylene ether, 0.7 to 2 parts of polyoxyethylene polyoxypropylene polyethylene polyamine, 0.5 to 1 part of sulfonate polyacrylamide, 0.1 to 0.7 part of nonionic fluorocarbon surfactant, 0.2 to 0.5 part of a modification nanometer auxiliary agent, 0.3 to 1 part of an alkalescence auxiliary agent and 10 to 200 parts of water. The beneficial effects of the emulsification viscosity reducer are as follows: salt resistance is up to 24*10<4> mg / L, resistance to a temperature as high as 150 DEG C is realized, and emulsification viscosity reduction of super heavy oil with a viscosity of 500 Pa.s at a temperature of 50 DEG C is realized.

Owner:PETROCHINA CO LTD

Preparation method of modified bagasse cellulose based heavy metal adsorbent

InactiveCN102716728ASolve the use problemSolve secondary pollutionOther chemical processesWater/sewage treatment by sorptionWater bathsCellulose

The invention relates to a preparation method of a modified bagasse cellulose based heavy metal adsorbent. The preparation method comprises the technological steps of: defibering natural fibers, washing with distilled water and ethanol, stirring and activating in NaOH solution, putting the fibers into dimethyl sulfoxide for water-bath heating and gelatinization, adding deionized water and initiators, feeding in nitrogen for initiation and adding acrylic acid monomers for reaction to obtain graft copolymerization products; adding polyethylene polyamine monomers for reaction, washing and drying to obtain crude cellulose based heavy metal adsorbent; and washing with deionized water, soaking and rinsing in ethanol, rewashing with deionized water, extracting by using acetone and drying to obtain the refined heavy metal adsorbent. The preparation method provided by the invention has the advantages that the method is simple, the cost is low, the environmental friendliness is good, the adsorption effect is excellent, the method is compliant with the concept of circular economy and sustainable development, the problem of secondary pollution caused by bagasse combustion is solved, the water bodies which are polluted by heavy metals are purified and the economic advantage is remarkable.

Owner:GUANGXI UNIV

Polyamine strong inhibitor for drilling fluid, and preparation method thereof

InactiveCN103087691AEnhanced inhibitory effectReduced tendency to absorb waterFlushingDrilling compositionSodium BentoniteInstability

The invention relates to a polyamine strong inhibitor for a drilling fluid. The polyamine strong inhibitor is prepared through the following step that: an amine compound and an epoxy compound are subjected to a reaction at a temperature of 90-110 DEG C in the presence of an alkali metal catalyst to synthesize the polyamine strong inhibitor for the drilling fluid, wherein the amine compound is polyether amine, alkyl amine, ether amine, tetraethylenepentamine, pentaethylenehexamine or polyethylene polyamine, and the epoxy compound is propylene oxide or ethylene oxide. According to the present invention, based on high temperature strong water sensitivity easy-instability stratum, special molecular structure design is adopted, such that the inhibitor has strong inhibition, and mud making of clay and hydration expansion of shale can be inhibited; and the inhibitor provides a stabilization effect for dynamic cutting force when the Xuanhua bentonite addition amount is up to 30%, wherein a debris rolling recovery rate can be more than 90%, a 8 h shale linear expansion rate is less than or equal to 10%, a temperature resistance performance is more than or equal to 180 DEG C, biological toxicity is low, and a LC50 value is more than 38010 mg / L.

Owner:CHINA PETROLEUM & CHEM CORP +1

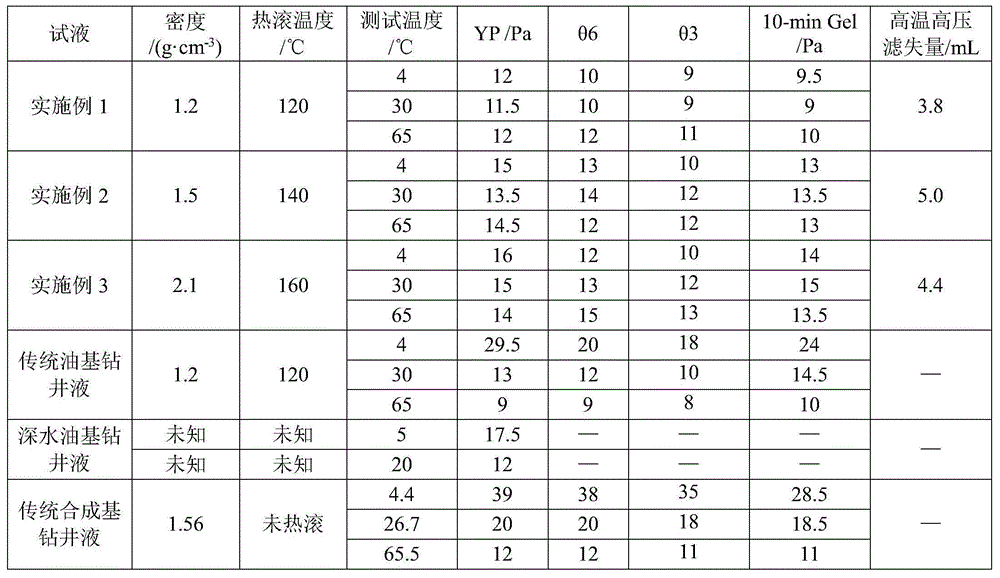

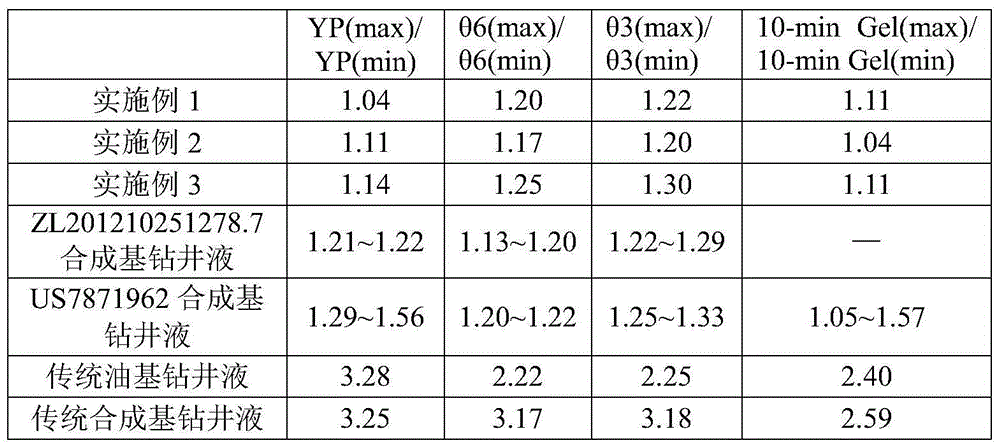

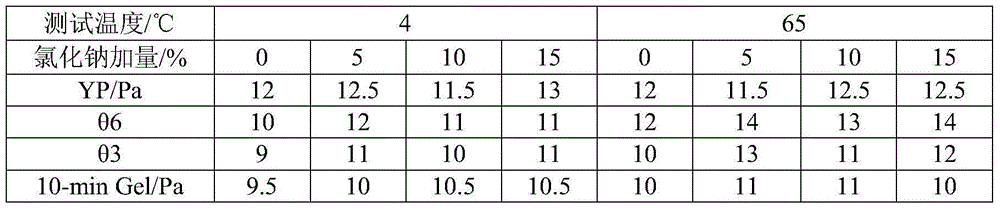

Deepwater constant-rheology oil base drilling fluid

ActiveCN104861944ARaw material requirements are relaxedLow costDrilling compositionDimer acidWhite oil

The invention discloses a deepwater constant-rheology oil base drilling fluid applicable for deep sea drilling. The deepwater constant-rheology oil base drilling fluid applicable for deep sea drilling comprises the following components in parts by weight: 70-100 parts of white oil, 0-30 parts of a calcium chloride aqueous solution, 1.5-5 parts of a fluid type conditioning agent, 1-4 parts of an emulsifying agent, 0.5-2.5 parts of a wetting agent, 1-3.5 parts of organic soil used for drilling fluid, 1.5-5 parts of a filtrate reducer, 0.2-0.6 parts of calcium oxide and 0-260 parts of a weighting agent. The fluid type conditioning agent is at least one of ethylene-propylene copolymer, polymethacrylate, trimeric acid, phenolic resin, copolymer generated from reaction of dimer acid, cholamine and polyethylene polyamine and copolymer generated from reaction of acrylamide, styrene and methacrylic acid. The movable shearing force and six-speed viscometer of the oil base drilling fluid is respectively less than 6 r / min and 3 r / min, and the 10-min static shearing force can be kept steady within 4-65 DEG C; constant eheology is realized in the temperature range of the barrel of the deepwater drilling, technical demands on sea deepwater drilling can be satisfied, requirements on base oil raw material are loose, and the cost is low.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

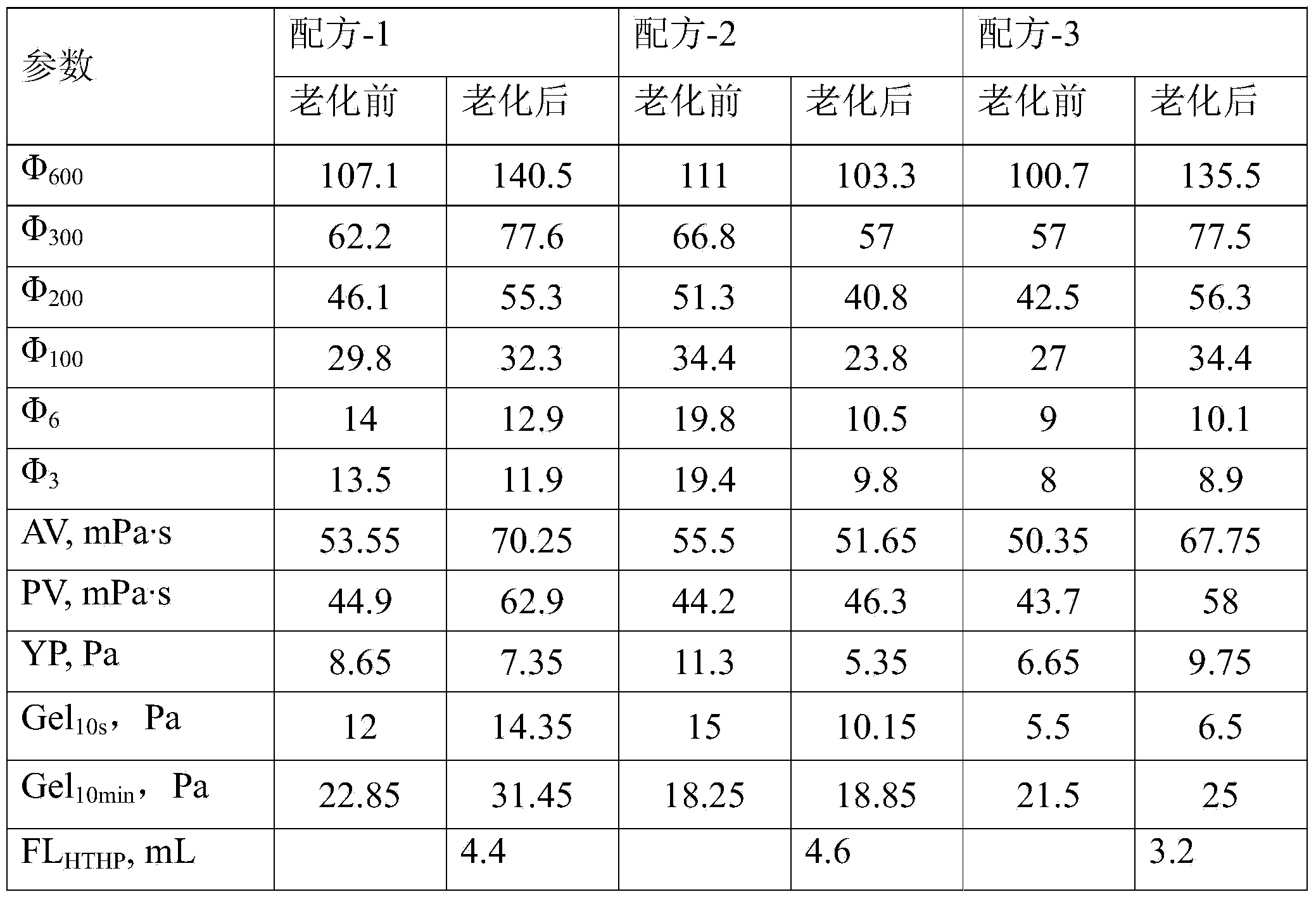

Polyamide amine flowing modifier for mineral oil based drilling fluid and preparation method of modifier

The invention discloses a polyamide amine flowing modifier for mineral oil based drilling fluid and a preparation method of the modifier. The modifier is prepared in such way that dimer fatty acid and polybasic amine are subjected to amidation reaction at 120-160 DEG C and then a reaction product is homogeneously mixed with a solvent; the content of dimer in the dimer fatty acid is greater than 78wt%; the polybasic amine is a homolog of polyethylene polyamine containing 2-5 amido groups; the molar ratio of the carboxylic groups in the dimer fatty acid to the amido groups in the polybasic amine is 1 to (0.2-1.2). The preparation process is fulfilled in a reaction vessel connected with a Dean-Stark receiver. The polyamide amine flowing modifier has high molecular weight and multiple active functional groups, can form multi-point adsorption, is hard to desorb from the surface of organic soil, and is continuously effective and stable in performance at high temperature; the preparation process is simple and reaction conditions are easy to control.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

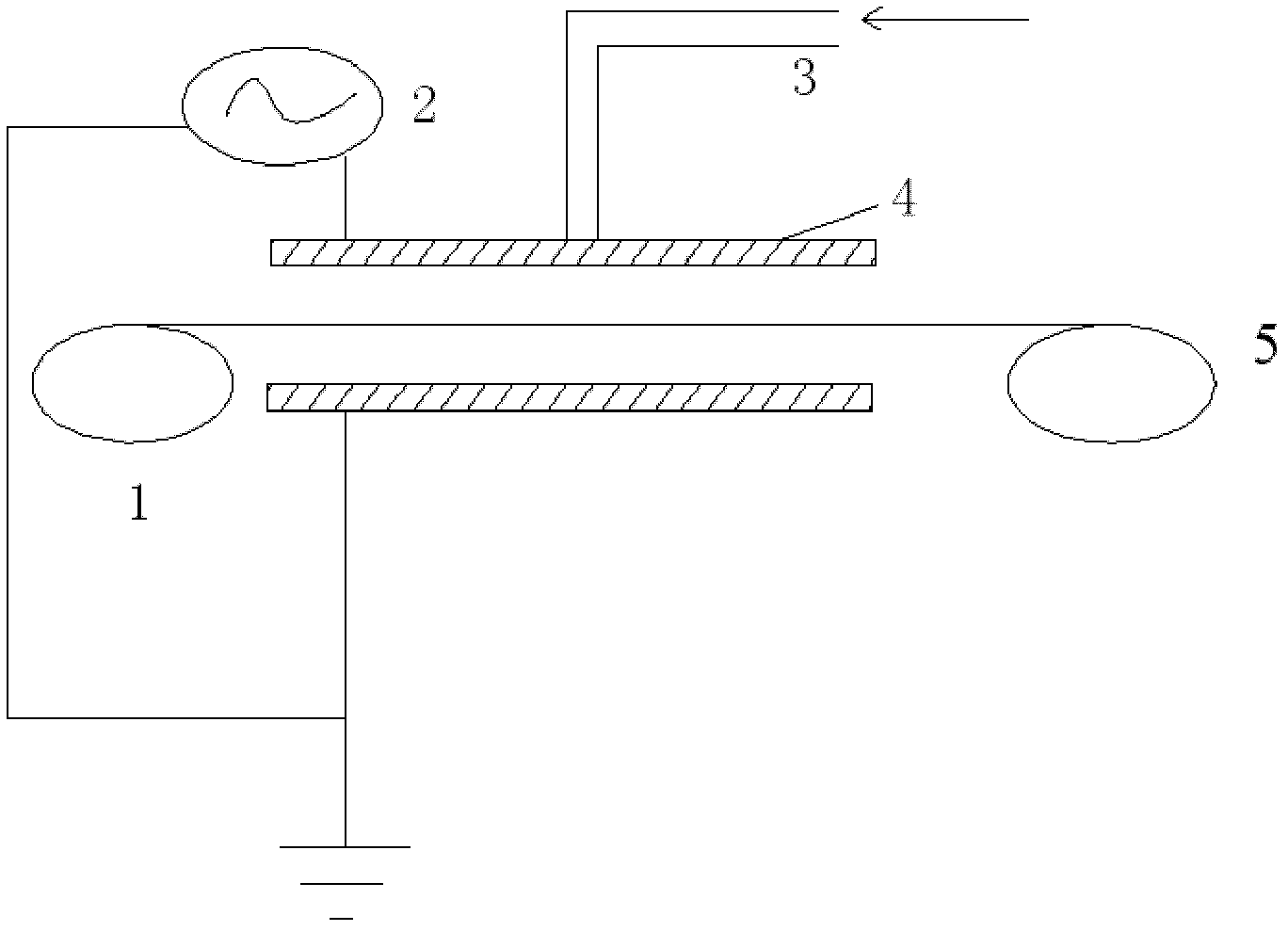

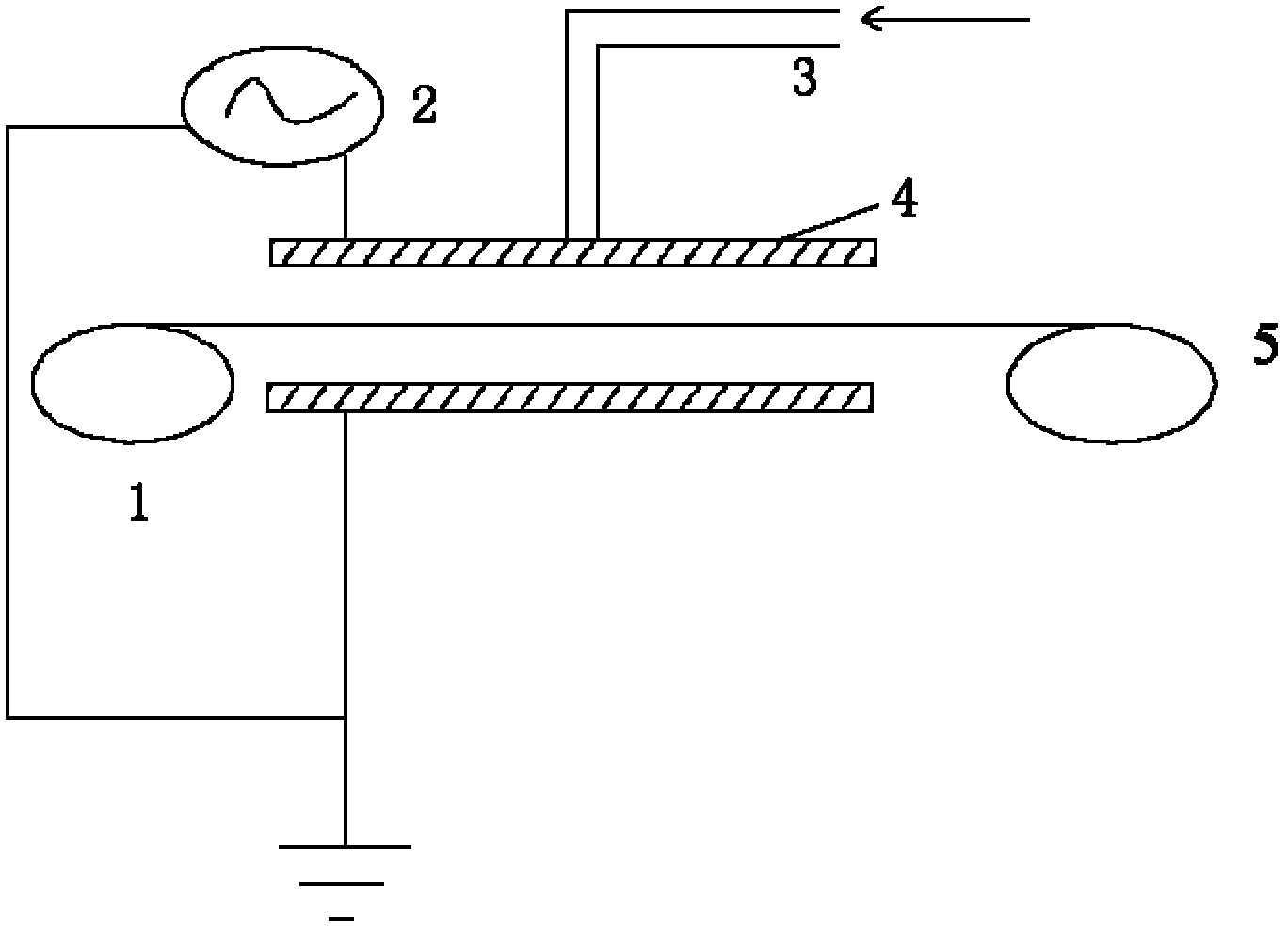

Preparation method of modified polymer film material for effectively removing trace heavy metal ions in water body

ActiveCN102634054AImprove mechanical propertiesFlexible designSemi-permeable membranesOther chemical processesUnit massTherapeutic effect

The invention discloses a preparation method of a modified polymer film material for effectively removing trace heavy metal ions in a water body, which comprises the following steps: 1) carrying out plasma treatment on a polymer film; 2) respectively preparing an initiator solution, a monomer solution, a buffer solution, an activating solution and a polyethylene polyamine water solution; 3) immerging the polymer film in the initiator solution, and carrying out surface activation by ultraviolet irradiation; 4) putting the polymer film into the monomer solution to carry out grafting reaction under ultraviolet irradiation; 5) activating the polymer film in the activating solution; and 6) putting the activated film into a polyethylene polyamine water solution to carry out coupling reaction, thereby preparing the modified film material capable of removing trace heavy metal ions in a water body. In the polymer film modifying process, carboxyl and amino groups are introduced to carry out hydrophilization and endow the modified film with complexing capacity, thereby removing the trace heavy metal ions. The invention has the advantages of simple technique, favorable treatment effect, wide application range, low cost, high unit mass adsorption capacity, time saving, high efficiency and energy saving.

Owner:NINGBO SHUIYI FILM TECH DEV CO LTD

Solidifying agent for aqueous epoxy resin, and preparation method

This invention discloses a method for preparing waterborne epoxy resin curing agent. The method comprises: condensing epoxy resin and polyester diol, performing addition modification on polyethylene polyamine, mixing with acrylonitrile at nitril / amine H mol ratio of (1.1-1.2):1.0, reacting at 65-70 deg.C for 1.5-2.0 h for end-capping, and salifying. The obtained waterborne epoxy resin curing agent has a solid content of 45-50%, an amine value of 290-500, and a viscosity of 8.0-14 ps. The curing agent has a moderate amine equivalent, and can emulsify and cure low molecular weight epoxy resin at room temperature. Besides, the curing agent has no toxicity, no harm, no volatile organic solvent, and largely reduced stimulation of modified amine to skin.

Owner:佛山市桐立新材料科技有限公司

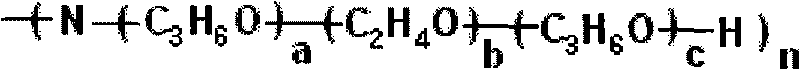

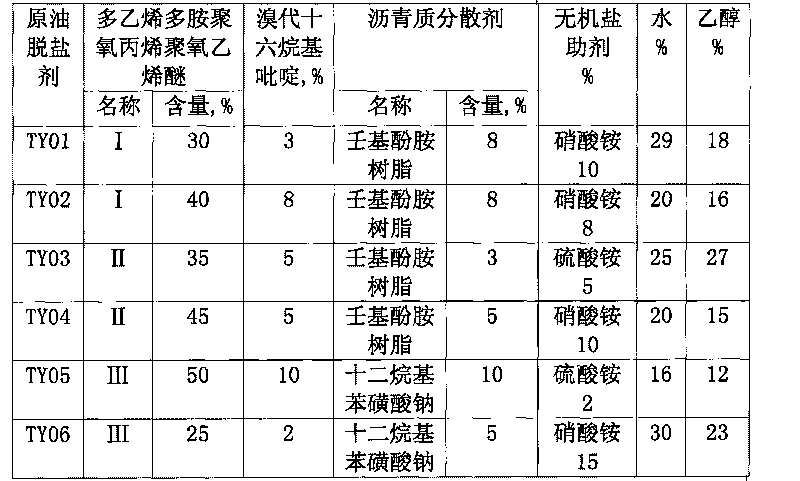

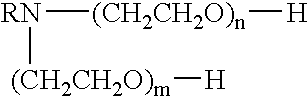

Crude oil desalting agent and preparation method thereof

ActiveCN101724438ADewatering/demulsification with chemical meansDewatering/demulsification with electric/magnetic meansDemulsifierInorganic salts

The invention relates to a crude oil desalting agent and a preparation method thereof, which are mainly used for solving the shortcomings of poor demulsification and desalination effects, over-standard salt content in crude oil after electric desalination, large using quantity of demulsifier and the like of the conventional demulsifier. The demulsifier comprises (a) 10% by weight-60% by weight of polyoxyethylene polyoxypropylene polyethylene polyamine, (b) 1% by weight-20% by weight of asphaltene dispersant, (c) 1% by weight-20% by weight of surfactant, (d) 1% by weight-20% by weight of inorganic salt additive and (e) 10% by weight-60% by weight of solvent. The use of the desalting agent can better solve the problems, and the desalting agent has good demulsification, desalination and dehydration performances, thereby being particularly applicable to demulsification, desalination and dehydration of heavy oil with high gluey content and high asphaltene content.

Owner:CHINA PETROCHEMICAL CORP +1

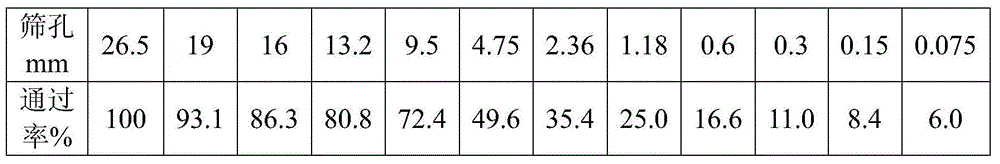

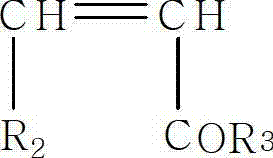

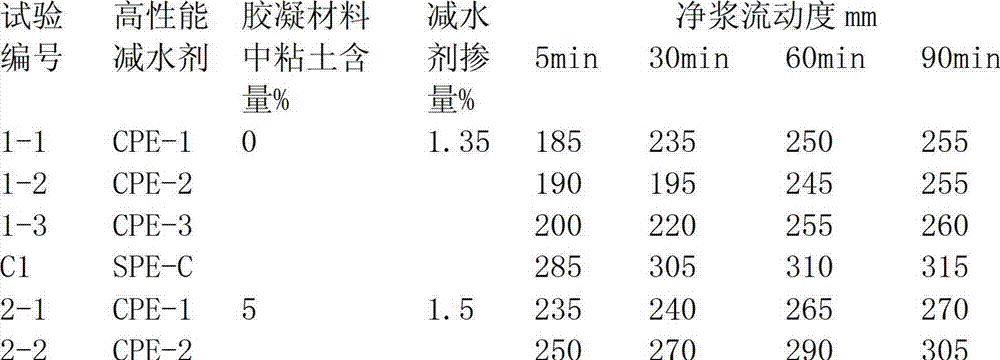

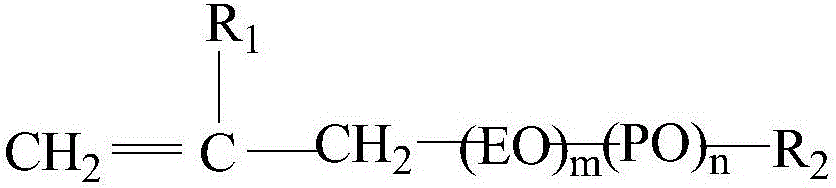

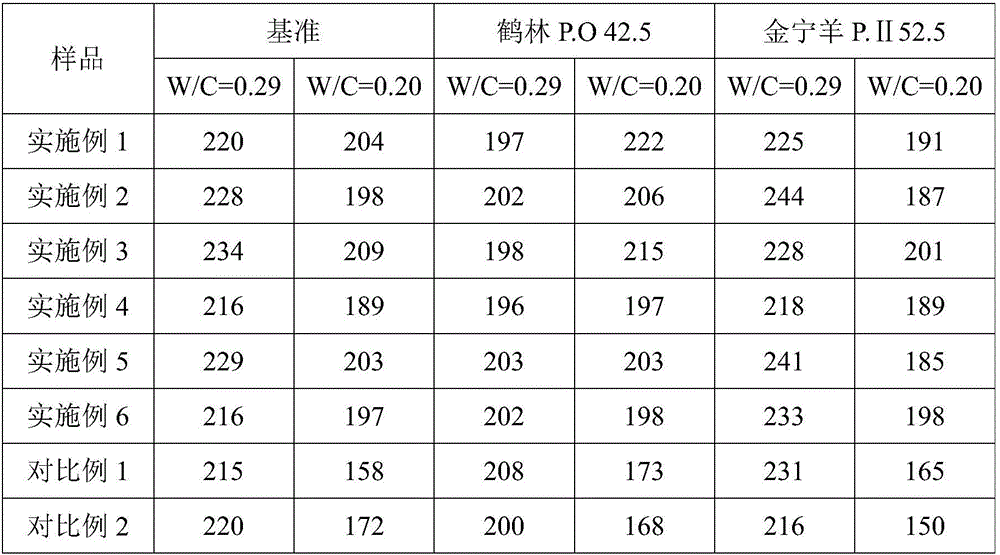

Clay-resistant polycarboxylate water reducer and preparation method thereof

The invention discloses a clay-resistant polycarboxylate water reducer and a preparation method of the clay-resistant polycarboxylate water reducer. The water reducer comprises the following components by weight: 35-45% of unsaturated polyoxyethylene ether monomer I, 40-50% of unsaturated polyoxyethylene ether monomers II, 10-20% of unsaturated monocarboxylic acid and derivative monomer of unsaturated monocarboxylic acid, 5-15% of unsaturated alkenyl sulphonate, and the like, wherein the unsaturated polyoxyethylene ether monomers I, the unsaturated polyoxyethylene ether monomers II, the unsaturated monocarboxylic acid and the derivative monomers of the unsaturated monocarboxylic acid, the unsaturated alkenyl sulphonate and the like are mixed and copolymerized, and then neutralized by polyethylene polyamine which is 0.5-2.0% of total monomer weight. The polyethylene oxide alkenyl short side chain of the water reducer can enhance the stability of the solvation water membrane layer on the surface of mineral fine powder particles in concrete; carboxyl groups and sulfonic groups generate electrostatic adsorption to prevent the adsorption and water absorption expansion rate of internal structures between clay layers; and polyethylene polyamine chains are adsorbed on the surfaces of clay particles to have shielding and scattering functions, therefore, the problem that the polycarboxylate water reducer and overlarge mud content in a concrete material are incompatible can be solved effectively.

Owner:北京榆构有限公司

Acid inhibitor compositions for metal cleaning and/or pickling

ActiveUS20090032057A1Trend downImprove protectionDetergent mixture composition preparationDetergent compounding agentsHexamethylenetetramineFatty amine

An acid inhibitor concentrate is provided which contains water, at least one polyamino-aldehyde resin such as a quaternized polyethylenepolyamine-glyoxal resin, and at least one compound selected from the group consisting of acetylenic alcohols, ethoxylated fatty amines, ethoxylated fatty amine salts, and aldehyde-releasing compounds (such as hexamethylenetetramine). Such concentrates form useful metal cleaning and pickling solutions when combined with aqueous acid, wherein such solutions, when contacted with a metal surface, are effective in removing scale, smut and other deposits from the metal surface but exhibit a reduced tendency for the aqueous acid to attack or etch the metal itself.

Owner:HENKEL KGAA

Preparation method and application of multifunctional polyamine amide for oil field

The invention relates to a preparation method of multifunctional polyamine amide for an oil field. The preparation method comprises the steps of: firstly dissolving long-chain fatty acyl polyamine prepared from long-chain fatty acid and polyethylene polyamine in an organic solvent in a container, adding a cross-linking agent to the container under stirring, stirring and heating reactants in the container, and cooling to room temperature to finally obtain a light yellow solution, namely a polyamine amide solution in the container; or evaporating the organic solvent from the light yellow solution obtained in the container to obtain light yellow waxy solid, namely polyamine amide. In application, polyamine amide is dissolved in an organic solvent to prepare a solution, the solution is added to crude oil to obtain a mixture, when the solidifying point of the crude oil is reduced by 5-25 DEG C and the viscosity of the crude oil is reduced by 30-80%, the mixture is prepared into an aqueous solution with mass concentration of 100-10000 ppm, and the corrosion inhibition of the aqueous solution is measured to obtain that the corrosion inhibition rate of the aqueous solution to the steel sheets in different concentrations of hydrochloric acid is 40-90%.

Owner:西安利奇材料科技有限公司

Preparation of polymer flooding produced fluid demulsifier

ActiveCN102676209ASolve the problems of increased difficulty in separation and high oil content in the extracted waterGood effectHydrocarbon oil dewatering/demulsificationCross-linkPolymer science

The invention provides a preparation method of a polymer flooding produced fluid demulsifier, which mainly comprises the following steps: condensing p-tert-butyl phenol, polyethylene polyamine and formaldehyde to obtain a thermoplastic phenol amine resin of which the molecular weights are within a certain range; sequentially and proportionally carrying out ring-opening polymerization on the resin, epoxyethane and propylene oxide; mixing the synthesized products with different molecular weights in a certain mass ratio, and regulating the pH value with acetic acid; and finally, cross-linking with dicarboxylic acid to obtain the final product. The invention aims to solve the problems of severe oil / water emulsification, greater difficulty in oil-water separation, high oil content in dehydrated water and the like in the polymer flooding produced fluid, and the problem that the dehydration effect of the conventional demulsifier on the produced fluid is not ideal.

Owner:DESHI ENERGY TECH GRP CO LTD

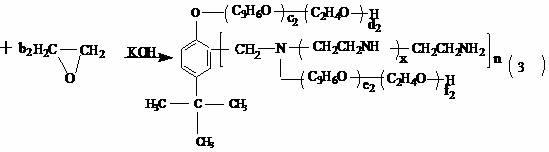

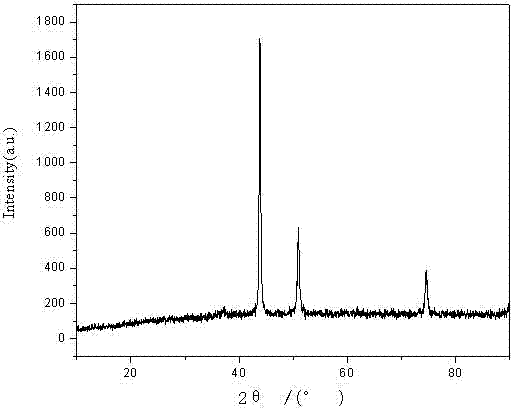

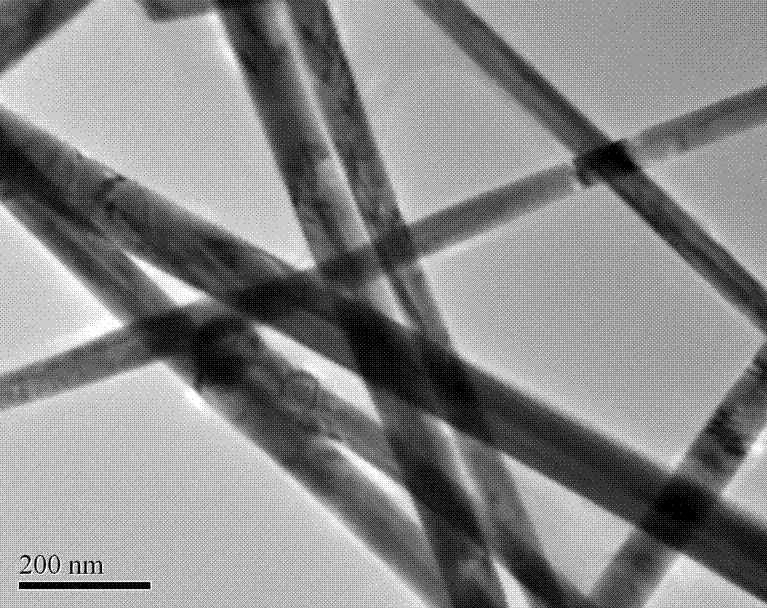

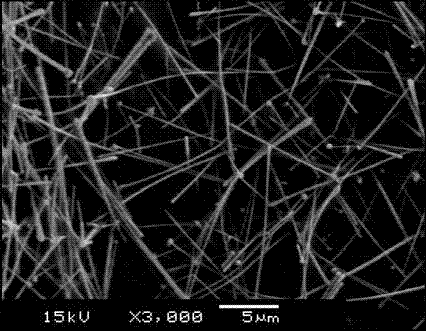

Preparation method for copper nanowire

ActiveCN103084581AEasy to removeVolatilePolycrystalline material growthFrom normal temperature solutionsHydroxylaminePotassium hydroxide

The invention belongs to the technical field of novel function nanometer material preparation, and discloses a preparation method for a copper nanowire. Reducing agent is added to copper source on the premise that morphology control agent and chemical potential control agent are exist in water solution, and the copper nanowire are obtained after separation and under the condition that reaction is carried out for at least one hour in temperature of 25 DEG C to 100 DEG C, wherein the copper source is one or combination of copper hydroxide and copper oxide, the morphology control agent is one kind or combination of more than two kinds of polyethylene polyamine, the chemical potential control agent is one or combination of sodium hydroxide and potassium hydroxide, and the reducing agent is one or combination of hydrazine hydrate and hydroxylamine. The preparation method for the copper nanowire has the advantages of being simple in technology and device, cheap and easy-getting in raw materials, low in cost, high in productivity, suitable for large-scale industrial production, and the like. Prepared copper nanometers are uniform in diameter, diameters and lengths of the copper nanometers can be controlled through changing concentration of the morphology control agent and concentration and reaction temperature of the copper resource.

Owner:HENAN UNIVERSITY

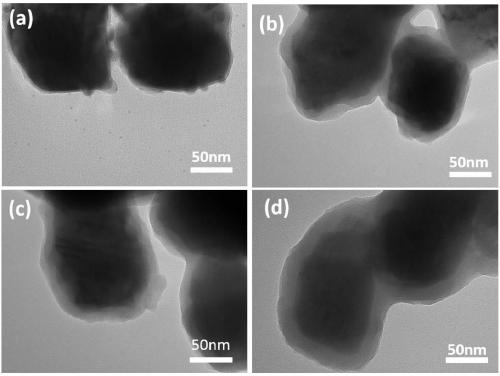

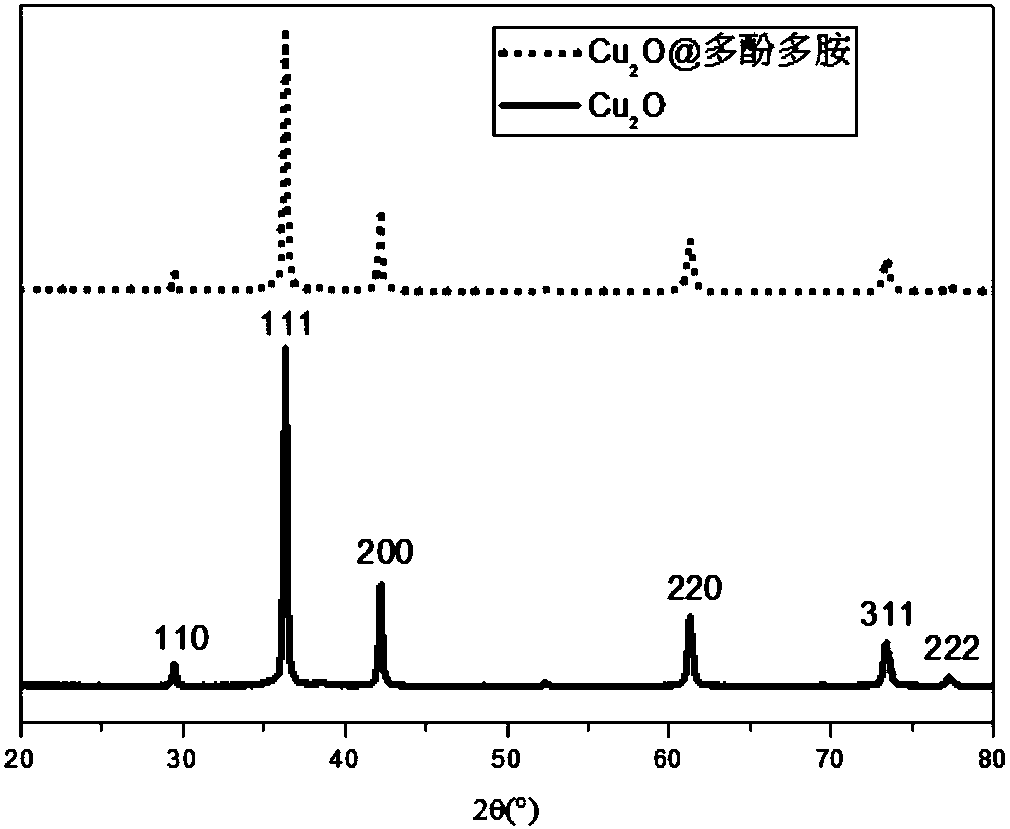

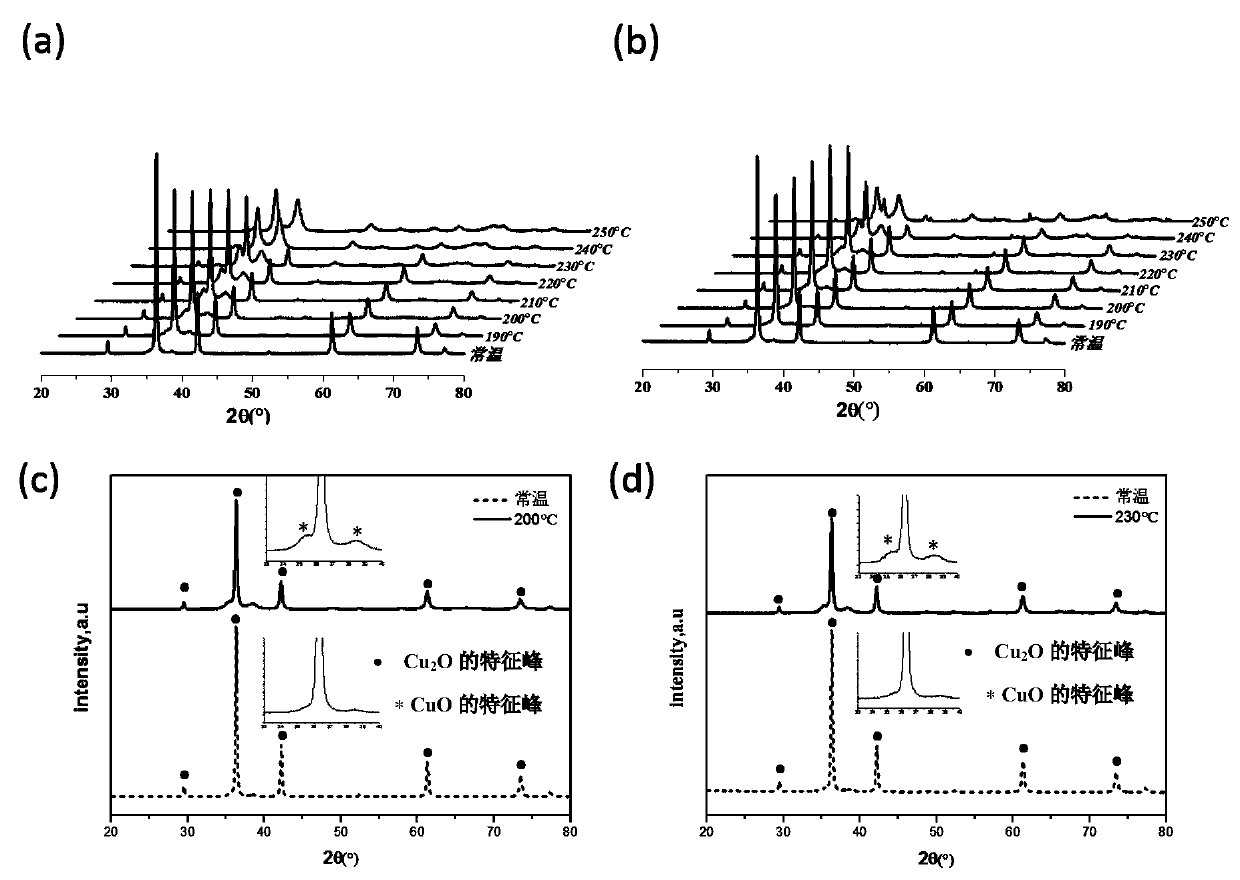

Organic-inorganic hybrid antibacterial nanomaterial, and preparation method and use thereof

The invention discloses an organic-inorganic hybrid antibacterial nanomaterial, and a preparation method and a use thereof. The antibacterial material is a core-shell structure, wherein the core is aninorganic antibacterial material, and the shell is an organic antibacterial material; the inorganic antibacterial material is one or more of Ag2O, TiO2, ZnO, CaO, MgO, CuO and Cu2O; the organic antibacterial material is a polymerization product of a polyphenol compound and a polyamine compound, and the polyphenol compound is one or more of dopamine, tannic acid, gallocatechin, catechin and catechol; and the polyamine compound is one or more of polyethylene polyamine compound. The organic-inorganic hybrid antibacterial nanomaterial has the advantages of excellent synergistic antibacterial property, good dispersibility, good interfacial properties, and facilitation of uniform dispersion of the material in a polymer material. The preparation method of the invention has the advantages of simplicity, greenness, environmental protection, and low price and low toxicity of cuprous oxide nanoparticles.

Owner:INST OF CHEM CHINESE ACAD OF SCI +1

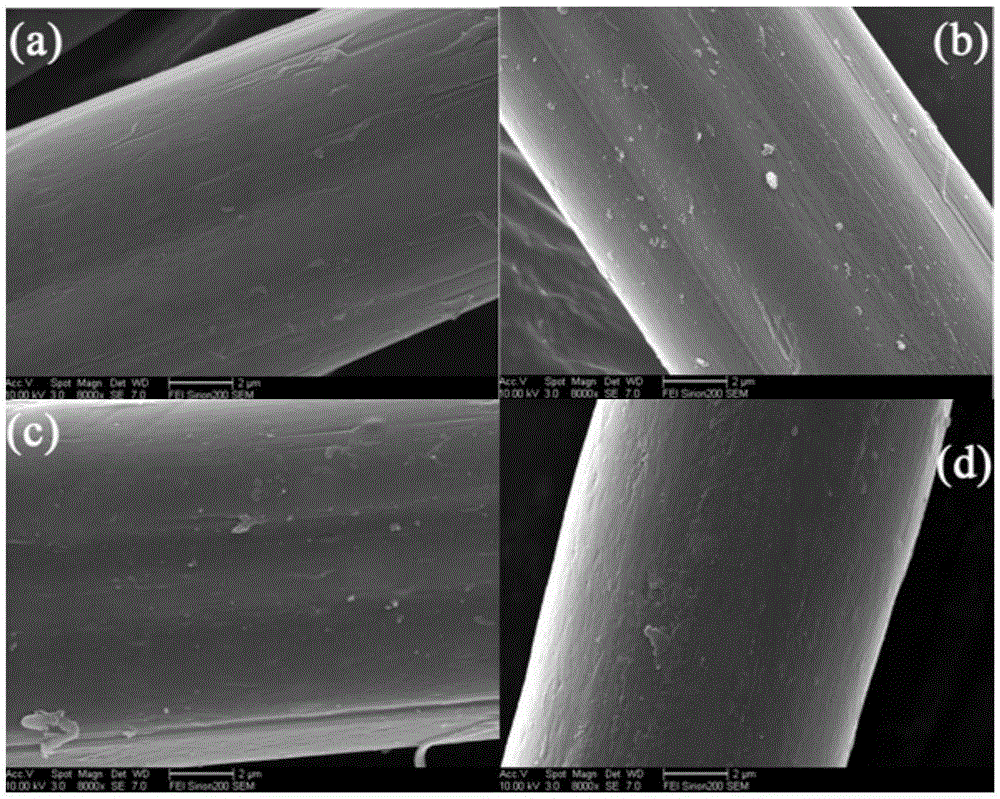

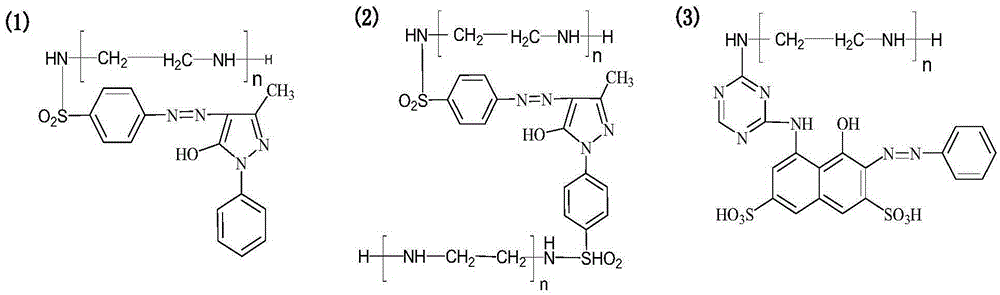

Dyeing method for calcium alginate fibers

The invention belongs to the technical field of fiber dyeing, and particularly relates to a dyeing method for calcium alginate fibers. According to the dyeing method for the calcium alginate fibers, dye containing polyethylene polyamine framework structures is adopted to dye the calcium alginate fibers; the defect that the fibers are damaged due to the fact that inorganic salt needs to be added for dyeing accelerating in the dyeing process of traditional dye is fundamentally overcome, and the strength loss of the fibers after dyeing is small; meanwhile, compared with the weaker intermolecular force and hydrogen-bond interaction between general direct dye and the fibers, the acting force between molecules of the dye and the fibers is higher, and then the advantages of being higher in dye-uptake rate and soaping fastness and the like are achieved; the dyed fibers are uniform and bright in color and meet the dyeing requirements of the calcium alginate fibers, and the dyeing method is economical in energy and environmentally friendly.

Owner:SHANDONG UNIV OF TECH

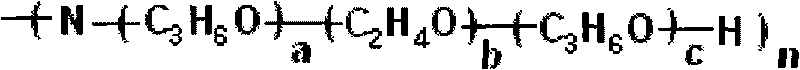

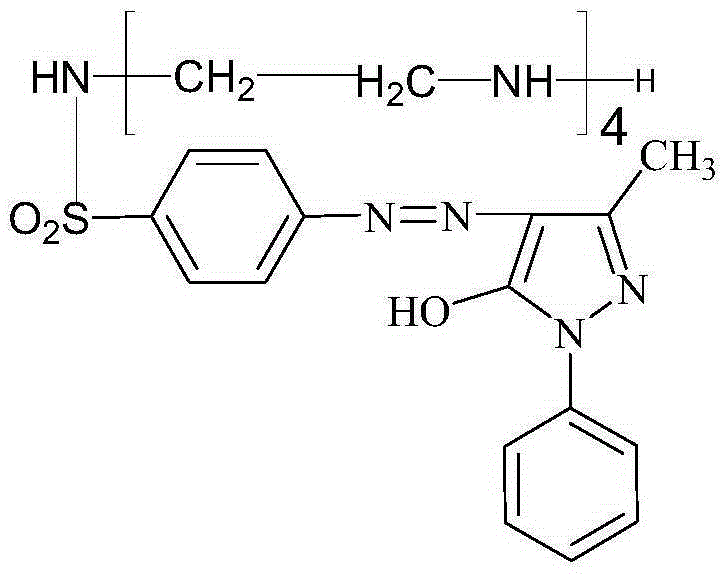

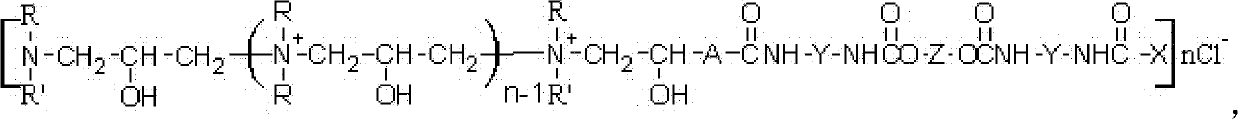

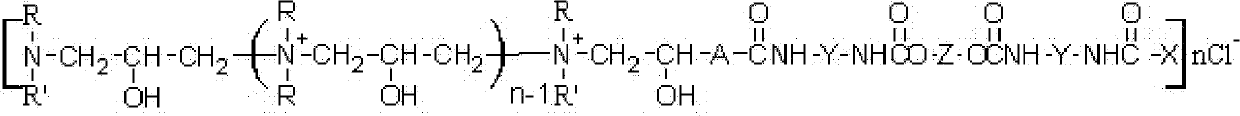

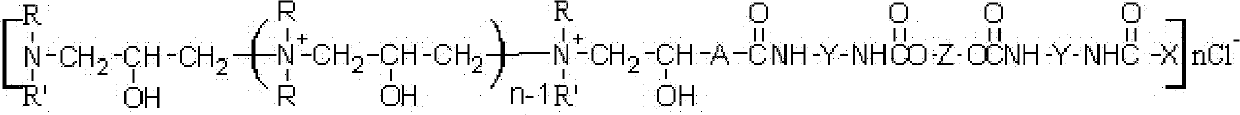

Waterborne polyurethane graft-modified polyamine color fixing agent and preparation method thereof

InactiveCN102251416AImprove color fastness to wet rubbingImprove washing fastnessDyeing processPolymer scienceSolvent

A waterborne polyurethane graft-modified polyamine color fixing agent disclosed by the invention is shown in structural formula (I); the preparation method of the color fixing agent comprises the following steps: weighing the following materials by mass: 2.51%-32.19% of amino compounds, 3.77%-52.95% of epichlorohydrin, 0.63%-1.61% of polyethylene polyamine, 2.00%-26.38% of diisocyanate, 2.70%-42.82% of polyols, 0.013%-0.135% of catalysts, 0.96%-6.28% of blocking agents, 3.22%-13.24% of organic solvent a, 3.60%-17.95% of organic solvent b, 0.13%-2.58% of acidifying reagents, and the balance ofdeionized water, preparing polyamine high molecular polymer and polyurethane prepolymer in sequence, and performing a chain extending reaction, a blocking reaction, solvent removal, and emulsification to obtain the waterborne polyurethane graft-modified polyamine color fixing agent of the invention.

Owner:XI'AN POLYTECHNIC UNIVERSITY

Anticorrosion paint for chimney of electric plant and its uses

InactiveCN101007921AExtended service lifeGood corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsBrickDiethylenetriamine

The invention belongs to anticorrosion paint field, which in detail relates to anticorrosion paint for power plant chimney and its application to protecting inner wall of chimney. It comprises: component A: drying-oil modified epoxy resin and flake glass-filled coating; component B composite curing agent: triethanolamine, calcium trisodium diethylenetriamine pentoacetate and polyethylene polyamine.Mixing component A and B according to ratio by weight of 100: 15- 30, coating it on inner wall of chimney, curing at normal temperature for 48 hours and forming hard paing film, which can protect armored concrete or brick construction from corrosion caused by temperature and smoke gas and perlong chimney life length. The product is characterized by strong adhesion force and excellent corrosion- resistance and as long as 30 years' life length.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

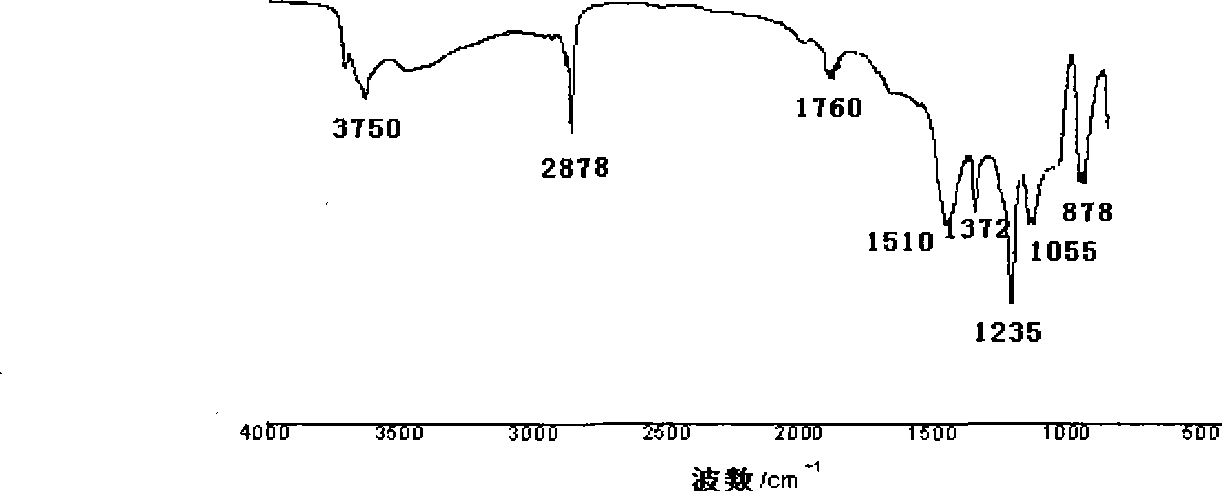

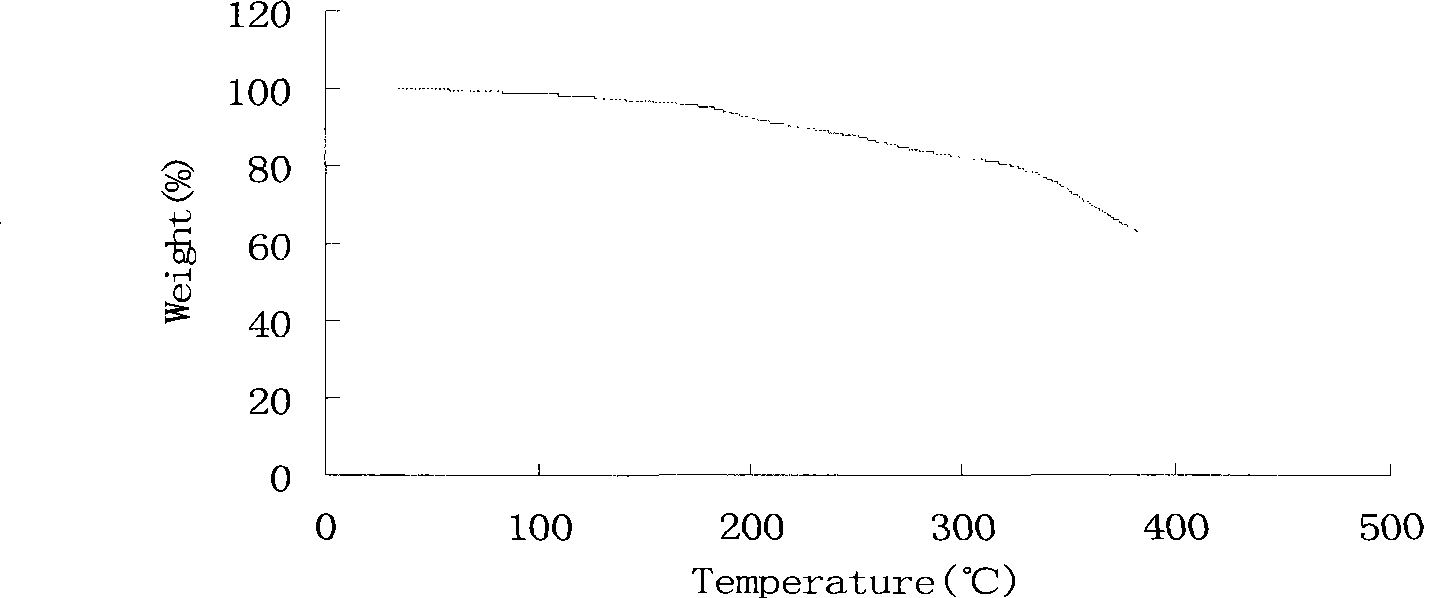

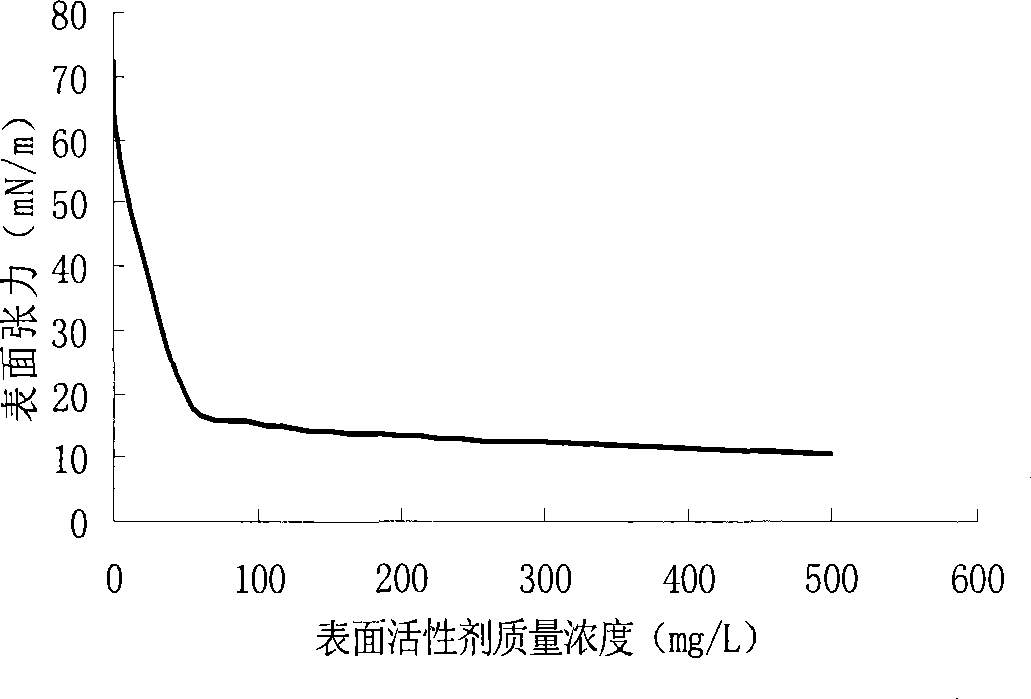

Fluorocarbon gemini surfactant as well as preparation method and application thereof

ActiveCN101502771AUse low concentrationReduce surface tensionTransportation and packagingMixingPotassium hydroxideEthyl acetate

The invention discloses a fluorine-carbon gemini surfactant for oil extraction and a preparation method thereof. The preparation method of the surfactant is as follows: 1) perfluorooctsulfunyl fluoride is dissolved in ethyl acetate, is firstly mixed with polyethylene polyamines and then reacts with potassium hydroxide after being heated to obtain diperfluoro octyl sulfamide; 2) diperfluoro octyl sulfamide is mixed with 2-chlorethanol in an organic solvent and reacts with potassium hydroxide to obtain N-N-alcohol diperfluoro octyl sulfamide; 3) N-N-alcohol diperfluoro octyl sulfamide is mixed with hydrogen peroxide and reacts with potassium hydroxide to obtain the target product. The fluorine-carbon gemini surfactant for oil extraction provided by the invention has comparatively low using concentration, can obviously reduce the surface tension of aqueous phase system, is excellent in temperature and salt resistance, can be used as a surfactant component in polymer-surfactant binary compound flooding and alkali-polymer-surfactant ternary compound flooding systems and can also be directly applied in surfactant flooding.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Polyamine slow-breaking quick-setting asphalt emulsifier and preparation method and application thereof

ActiveCN102719106AReduce exposureMeet slow cracking requirementsOrganic compound preparationCarboxylic acid amides preparationPolyethylene polyamineOrganic acid

The invention relates to a polyamine slow-breaking quick-setting asphalt emulsifier and a preparation method and an application thereof. The emulsifier is made through the method as follows: dripping formaldehyde into polyethylene polyamine, and the proportion (mole ratio) of the polyethylene polyamine to the formaldehyde is 1:(0.25 to 4); allowing reacting for 0.5 to 2 hours at room temperature, and then heating to 110 DEG C; allowing reacting for two hours, and heating to 160 to 200 DEG C; allowing reacting for 1 to 3.5 hours, and then cooling to 100 to 110 DEG C, so as to obtain an intermediate after decompressing and dehydrating; adding organic acid by the proportion (mole ratio) of the polyethylene polyamine to the organic acid of (0.5 to 4):1, using dimethylbenzene as a water-carrying agent, and heating the system to 160 to 200 DEG. C; after reaction for 5 hours, cooling to 70 to 80 DEG C, and carrying out reduced pressure distillation, so as to obtain the polyamine slow-breaking quick-setting asphalt emulsifier. Emulsified asphalt prepared through the emulsifier obtained by the invention is uniform and stable, and is proven to be a slow-breaking type through a demulsification test and to be a quick-setting type through an experiment of mixation with quartz sand. The emulsifier can satisfy the requirement of rapid traffic opening.

Owner:HEBEI UNIV OF TECH

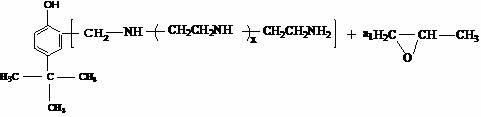

High-water-cut heavy oil demulsifier used for oil fields and preparation method thereof

ActiveCN103642518AImprove dehydration effectPromote demulsificationDewatering/demulsification with chemical meansFreeze-dryingFiltration

The invention relates to a high-water-cut heavy oil demulsifier used for oil fields and a preparation method thereof, belonging to the technical field of crude oil dehydration. The preparation method of the high-water-cut heavy oil demulsifier used for oil fields comprises the following steps: 1. synthesizing an initiator: dropwise adding a formaldehyde solution to polyethylene polyamine and bisphenol S at 30-60 DEG C, heating the materials to 100-150 DEG C to react for 1-5 hours, and freeze-drying a product; 2. synthesizing polyether: carrying out catalytic polymerization on the initiator as well as ethylene oxide and propylene oxide with KOH, neutralizing a product with acetic acid, and carrying out suction filtration and desalination; 3. synthesizing epoxy polyether: after diluting polyether with a xylene solution, reacting polyether with epoxy chloropropane to obtain epoxy polyether A; dropwise adding 2-methyl crotonate to triethylene diamine, and then reacting with epoxy chloropropane to obtain epoxy polyether B; 4. synthesizing a demulsifier: dissolving epoxy polyether A and epoxy polyether B in xylene to obtain the high-water-cut heavy oil demulsifier. The preparation method is simple in process, is convenient to operate and is accessible in raw materials and low in cost. The obtained demulsifier has the advantages of small dosage, high dehydration speed, good demulsification effect and the like.

Owner:滨州乾坤化工机械有限公司

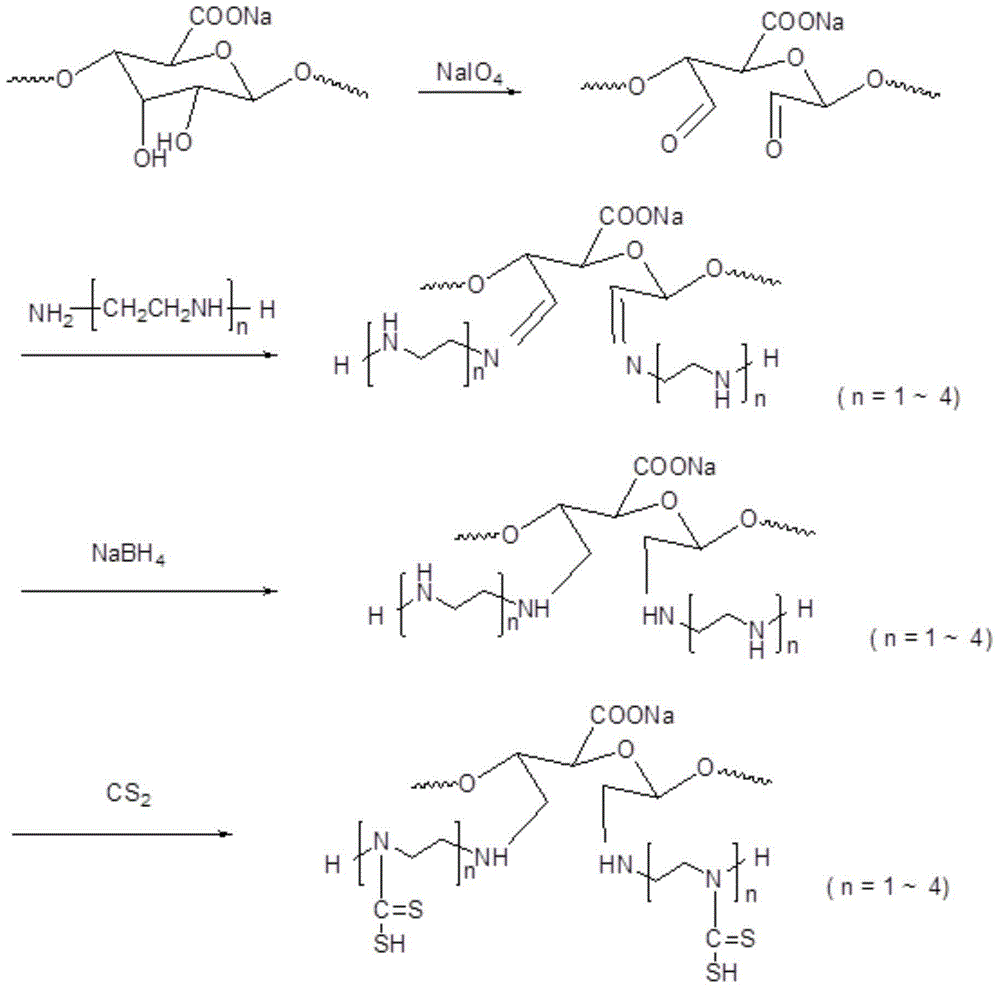

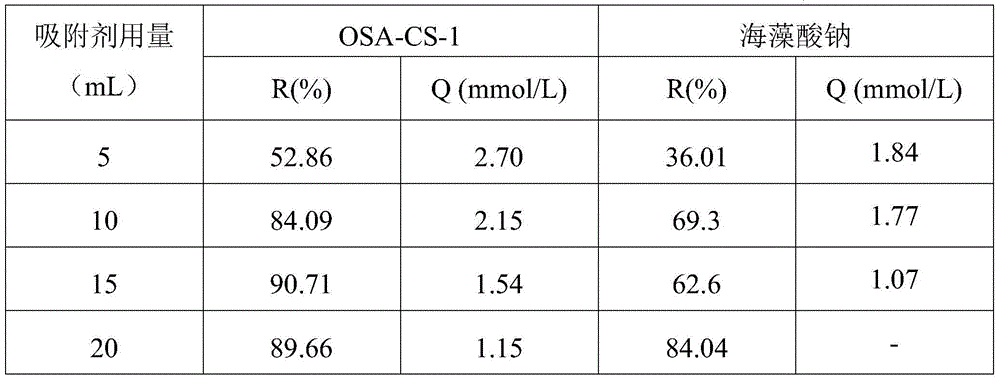

Preparation method and application of heavy metal ion absorbent

ActiveCN104907051AImprove capture abilityHigh removal rateOther chemical processesWater/sewage treatment by sorptionSorbentDesorption

The invention relates to the technical field of high-molecular material modification, and especially relates to a preparation method and an application of a heavy metal ion absorbent. The preparation method comprises the following steps: (1) aldehyde sodium alginate is prepared into a water solution; polyethylene polyamine is added and a reaction is carried out; sodium borohydride is added for reducing; and the reaction is continued, such that amino sodium alginate is obtained; (2) a mixed solution of carbon disulfide and sodium hydroxide is added into the solution obtained after the reaction in the step (1); the reaction is continued until carbon disulfide droplets in the solution are disappeared; the reaction is stopped, and an alcohol solvent is added, such that a product is precipitated; the mixture is allowed to stand and to layer; the precipitate precipitated at the bottom layer is separated; drying is carried out, such that the heavy metal absorbent is obtained. The absorbent has high absorbability upon heavy metal ions, and desorption efficiency is improved.

Owner:JIANGSU GOLDEN AUTUMN CORD CO LTD

Viscosity reducing polycarboxylate-type water reducing agent for high-performance concrete

The invention relates to a viscosity reducing polycarboxylate-type water reducing agent for high-performance concrete and a preparing method thereof, and belongs to the field of cement concrete water reducing agents. The preparing method includes the following steps that polyethylene polyamine and alkyl acrylate are used for preparing a comonomer A; the comonomer A, polyoxyethylene-polyoxypropylene comonomer B, a vinyl aromatic compound C and an unsaturated carboxylic monomer are subjected to water-phase free radical polymerization reaction under the action of initiator and a chain transferring agent, and the pH value is adjusted after the reaction is completed to prepare the viscosity reducing polycarboxylate-type water reducing agent. The viscosity reducing polycarboxylate-type water reducing agent for high-performance concrete has the advantages of being high in dispersing performance, obvious in viscosity reducing effect, high in adaptability to cement and particularly suitable for preparing high-strength and ultrahigh-strength concrete and self-compaction concrete. The viscosity reducing polycarboxylate-type water reducing agent is low in requirement for production equipment and simple in process, operation is convenient, which is beneficial for industrial production, and the product is free of chloridion, and does not corrode rebars in the concrete.

Owner:NANJING HYDRAULIC RES INST

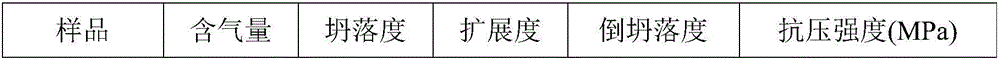

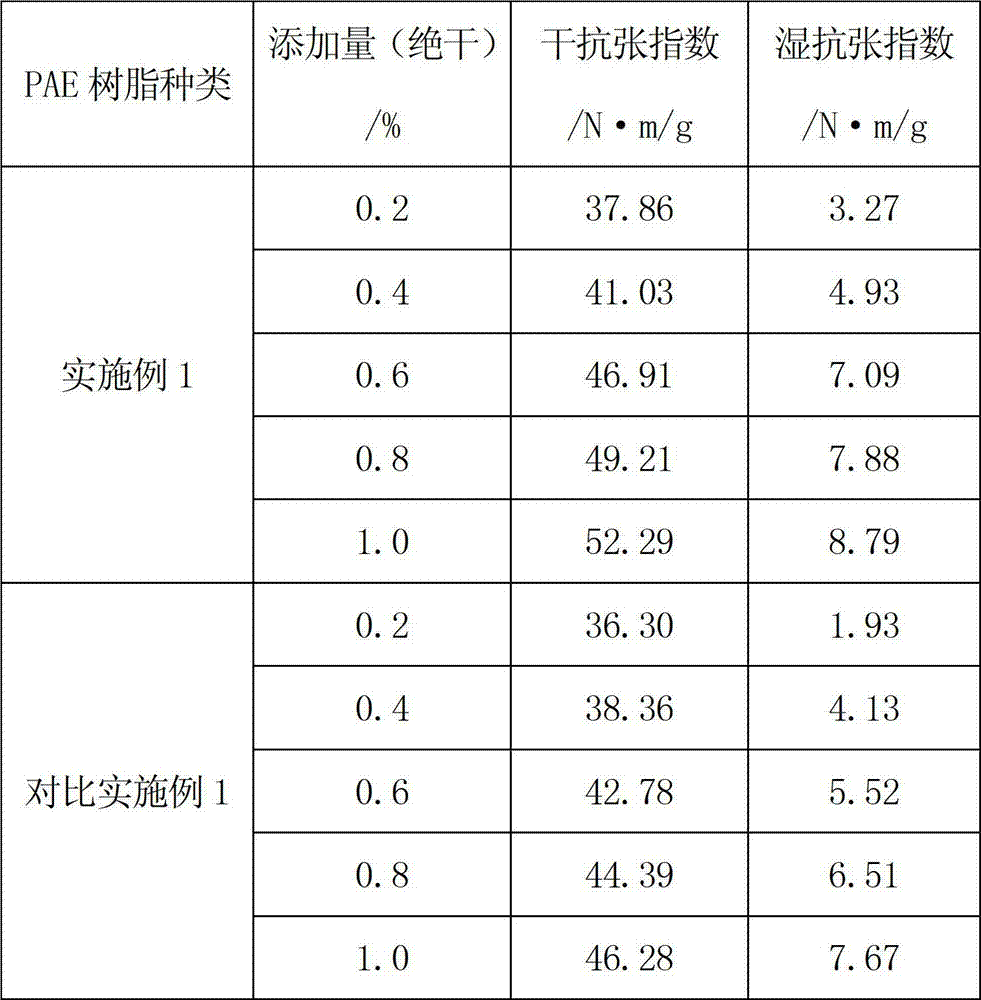

Preparation method of modified polyarylether (PAE) resin

InactiveCN102898643AAchieving charge controlImprove dry strengthReinforcing agents additionPaper/cardboardFiberPolyamine

A preparation method of modified polyarylether (PAE) resin comprises the following steps of: reacting polyethylene polyamine and binary acid under effects of a catalyst to synthesize polyamine prepolymer, adjusting a solid content of the polyamine prepolymer tobe 20-30%, adjusting a pH value to be 8-10, adding carboxyl modifier, then adding epichlorohydrin, adding hydrochloric acid after a reaction is completed, adjusting the pH value to be 3-4 and finishing the reaction to obtain the modified PAE resin. Carboxyl is introduced in a molecular structure of the PAE resin, the carboxyl is used for balancing positive electricity carried by the PAE resin, and electric charge control of the PAE resin is achieved. Simultaneously, after paper is used, the carboxyl carried by the modified resin can form hydrogen bonds between fibers, the carboxyl in a structure of the PAE resin and epoxy functional groups and the like exist simultaneously, after the carried carboxyl forms the hydrogen bonds between fibers, a distance of the epoxy functional groups and primary amine groups and the like between different PAE resins is reduced, covalent bonds are conveniently formed, time needed by curing is shortened, and accordingly, paper forming humidity and strength are improved, and a humidifying and strength performance are strengthened.

Owner:SHAANXI UNIV OF SCI & TECH

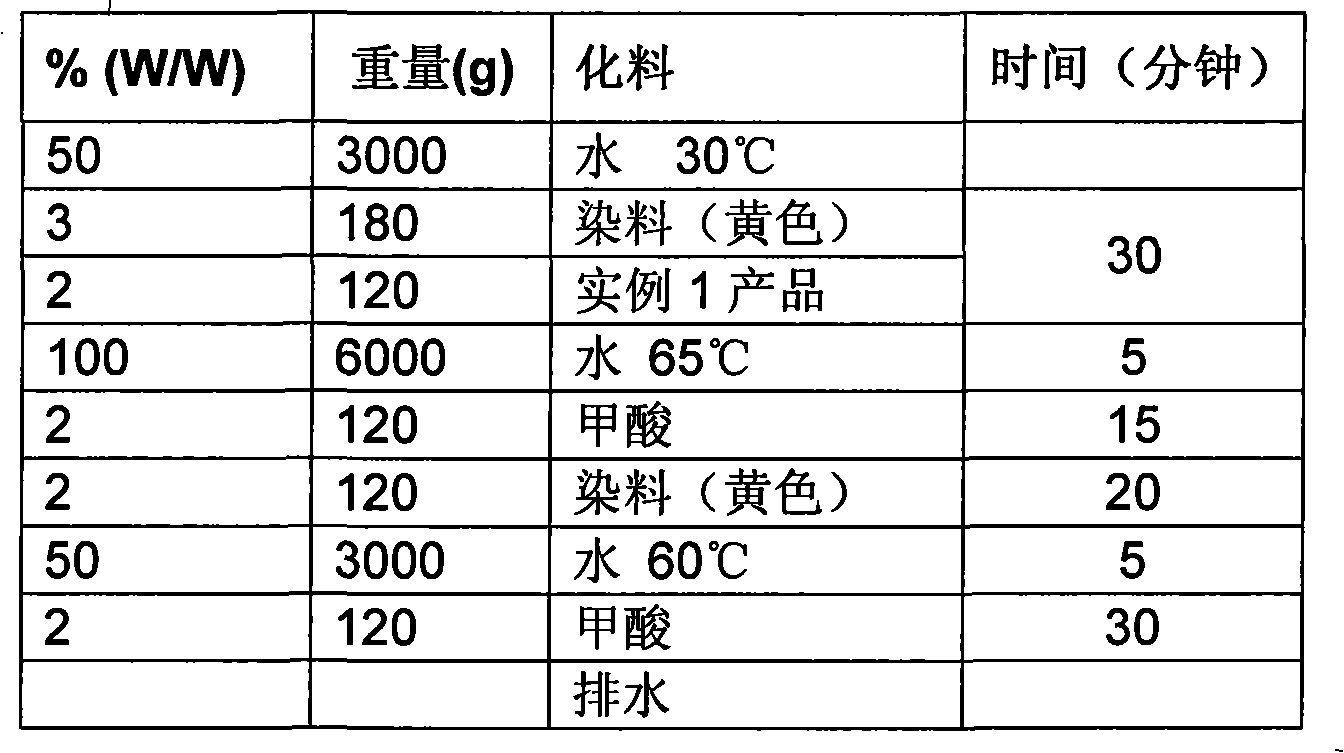

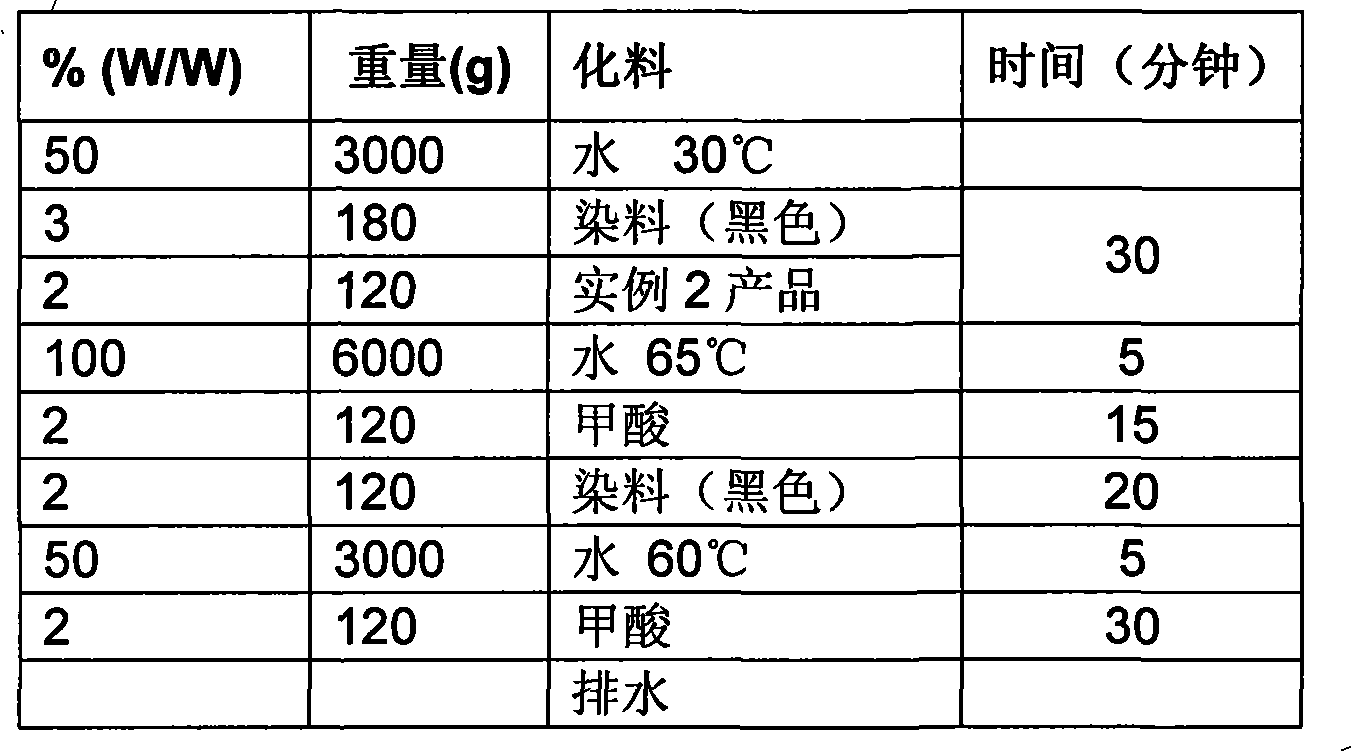

Leather dye uniformly dyeing penetrating agent and preparation method thereof

The invention discloses a leather dye uniformly dyeing penetrating agent and a preparation method thereof. The leather dye uniformly dyeing penetrating agent comprises the following components in part by weight: 0 to 100 parts of sodium lignin sulfonate, 50 to 100 parts of polyethylene polyamine, 1 to 5 parts of sodium hexametahposphate, 40 to 100 parts of sodium sulfite, 0 to 100 parts of vegetable tannin extract and 300 to 400 parts of water. The leather dye uniformly dyeing penetrating agent simultaneously has functions of a dye levelling agent and a penetrating agent, and has high uniformly dyeing performance to ensure that the surface of treated leather has uniform and bright colors; and the leather dye uniformly dyeing penetrating agent can obviously increase the permeability of a leather dye, shorten the operating time of a dyeing process, promote the absorption rate of the dye, and reduce the used amount of the dye.

Owner:SHANGHAI SINOFRA FINE CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com