Leather dye uniformly dyeing penetrating agent and preparation method thereof

A technology of penetrant and dye, which is applied in the field of leveling agent and penetrating agent for leather dyes, which can solve the problems of restricted application range and achieve the effects of reducing dosage, excellent leveling performance and promoting absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The described fatliquoring agent that improves leather intensity, its composition is as follows, is weight part:

[0020] Sodium lignosulfonate 100

[0021] Polyethylene polyamine 50

[0022] Sodium hexametaphosphate 5

[0024] water 350

[0025] Polyethylene polyamine is a mixture of equimolar ratios of ethylenediamine, diethanolamine, dimethylamine and monomethylamine;

[0026] The preparation method is:

[0027] Dissolve sodium lignosulfonate in water first, then add polyvinylpolyamine, sodium sulfite and sodium hexametaphosphate in sequence and mix well, raise the temperature of the reaction system to 120°C and pressure 0.17Mpa, react for 3.5 hours, and the obtained liquid product is sprayed The final product is obtained after drying.

[0028] The obtained product has a brownish yellow or yellowish green powder appearance and a pH value (10% aqueous solution) of 7.5.

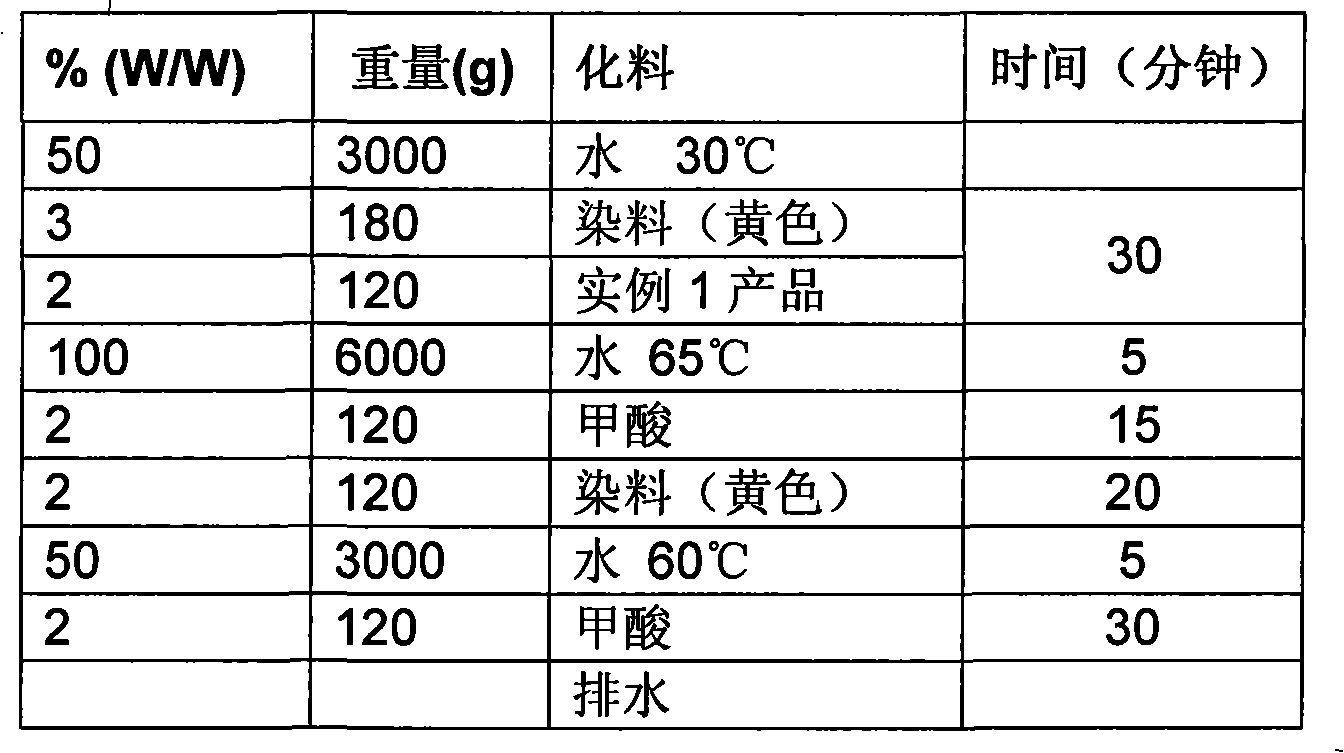

[0029] According to the following process, the product of examp...

Embodiment 2

[0036] The described fatliquoring agent that improves leather intensity, its composition is as follows, is weight part:

[0037] Tannin extract 100

[0038] Polyethylene polyamine 50

[0039] Sodium hexametaphosphate 5

[0040] Sodium sulfite 100

[0041] Water 350.

[0042] Polyethylene polyamine is a mixture of equimolar ratios of ethylenediamine, diethanolamine, dimethylamine and monomethylamine;

[0043] Tannin extract is commercially available chestnut extract.

[0044] The preparation method is:

[0045] Dissolve the tannin extract in water first, then add polyvinyl polyamine, sodium sulfite and sodium hexametaphosphate in sequence and stir to mix evenly, raise the temperature of the reaction system to 120°C, and the pressure is 0.18Mpa, and react for 5 hours, and the obtained liquid product is spray-dried get the final product.

[0046] The obtained product has a brownish-yellow or yellow-green powder appearance and a pH value (10% aqueous solution) of 8.0.

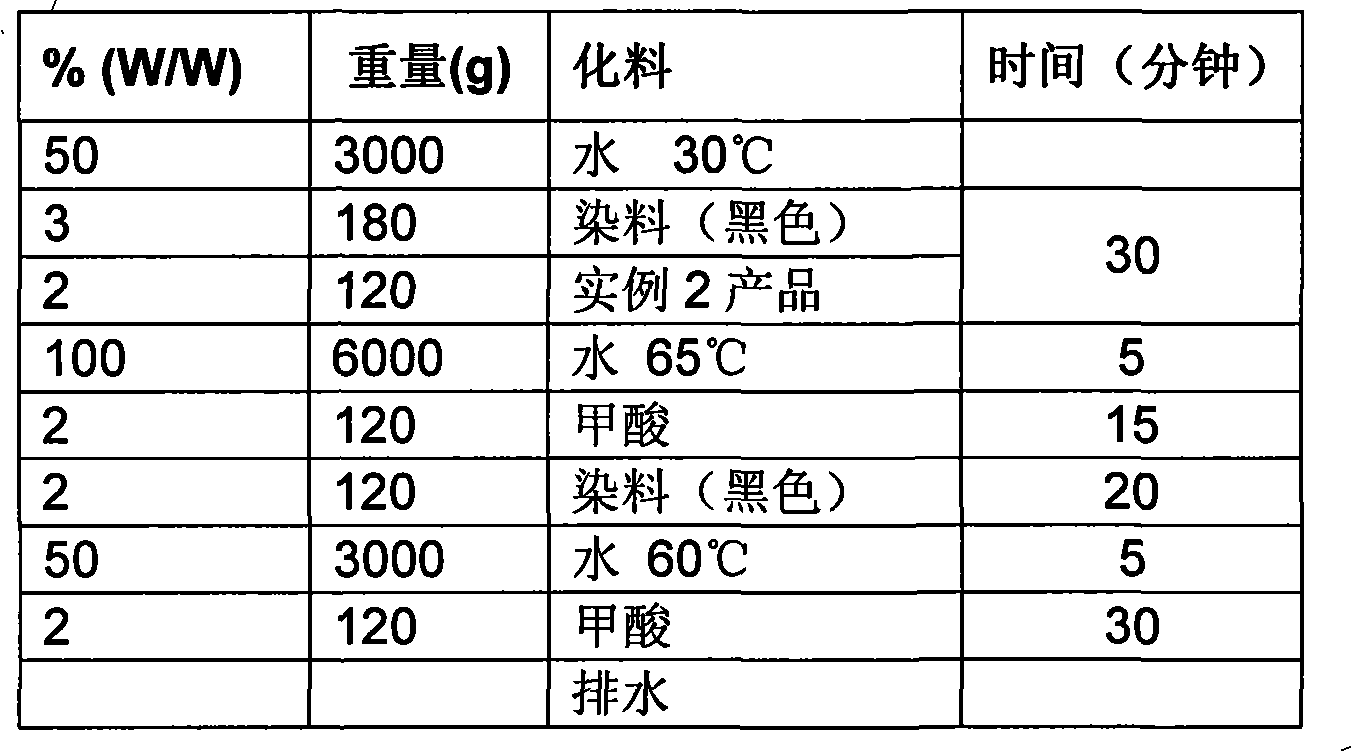

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com