Asphalt regeneration agent as well as preparation method and application thereof

A technology of asphalt regeneration agent and plant asphalt, which is used in climate change adaptation, building components, building insulation materials, etc., can solve the problems of inability to obtain a large number of applications and small dosage, and restore and improve road performance and enhance adhesion. , the effect of good infiltration and diffusion ability and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

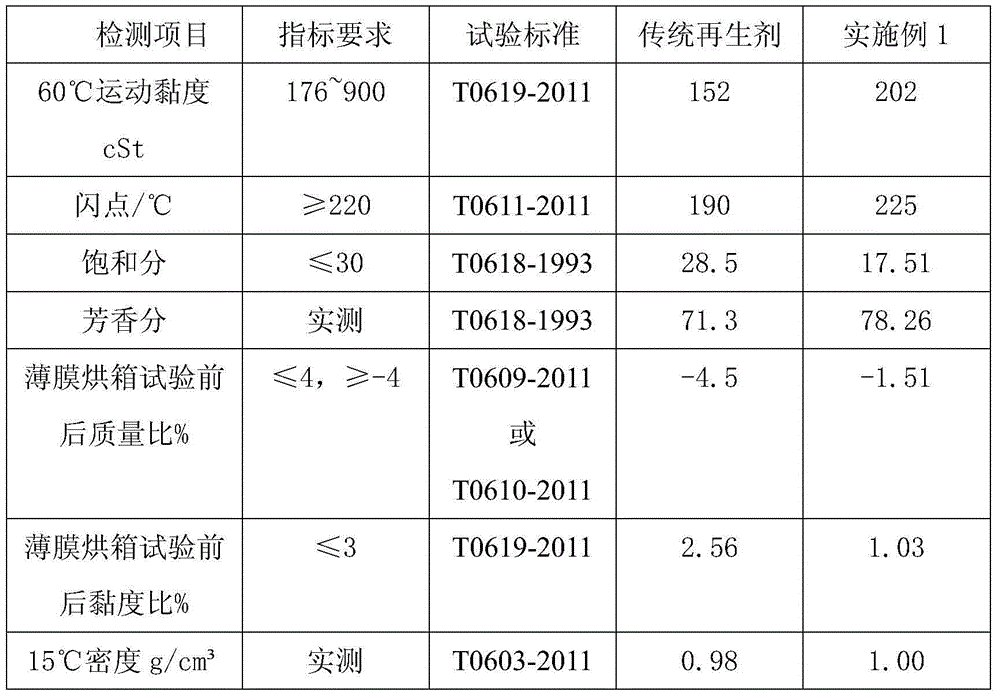

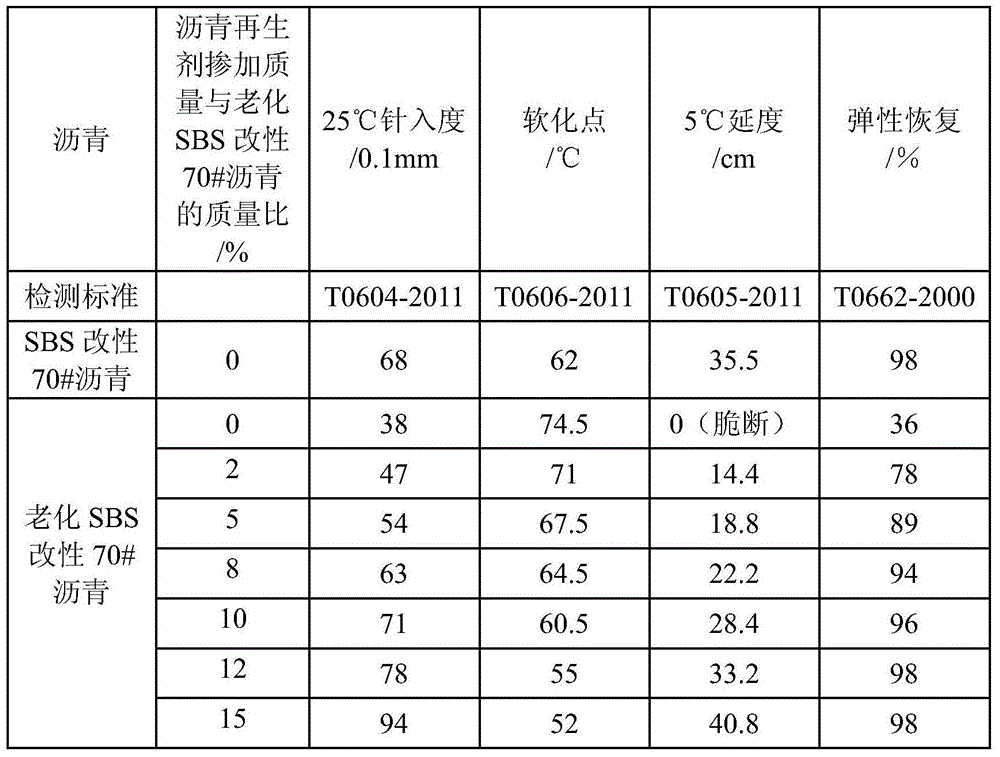

Embodiment 1

[0031] An asphalt rejuvenating agent, by mass percentage, consists of the following raw materials:

[0032] Vegetable asphalt, accounting for 70% of the total mass of asphalt rejuvenating agent;

[0033] The interface enhancement modifier adopts epoxy silicone resin, accounting for 4% of the total mass of the asphalt agent regenerant, and the content of epoxy groups in the interface enhancement modifier is 10wt%;

[0034] The plasticizer is carboxymethyl cellulose, accounting for 25% of the total mass of the asphalt regenerant;

[0035] The penetrant is n-octane, accounting for 0.5% of the total mass of the asphalt regenerant;

[0036] The anti-aging agent adopts dibutyl hydroxytoluene (BHT), accounting for 0.5% of the total mass of the asphalt regenerant;

[0037] According to the above ratio, taking the preparation of 100kg of asphalt regenerant as an example, the preparation process of the asphalt regenerant is as follows:

[0038] 75kg of vegetable pitch was heated to 1...

Embodiment 2

[0053] A kind of asphalt regeneration agent, by mass percentage, is made up of following raw materials:

[0054] Vegetable asphalt, accounting for 80% of the total mass of asphalt regenerant;

[0055] The reinforcement modifier adopts epoxy resin, which accounts for 3% of the total mass of the asphalt regenerant, and the epoxy group content in the interface reinforcement modifier is 40wt%.

[0056] The plasticizer is hydroxyethyl cellulose, accounting for 15% of the total mass of the asphalt regenerant;

[0057] The penetrating agent adopts trichlorethylene, accounting for 1% of the total mass of the asphalt regenerant;

[0058] The anti-aging agent adopts 2-hydroxy-4-methoxy-5-sulfobenzophenone (UV-284), accounting for 1% of the total mass of asphalt regenerant;

[0059] According to the above ratio, taking the preparation of 100kg asphalt rejuvenator as an example, the preparation process of asphalt rejuvenator is as follows

[0060] Take 80kg of plant asphalt and heat it...

Embodiment 3

[0075] A kind of asphalt regeneration agent, by mass percentage, is made up of following raw materials:

[0076] Vegetable asphalt, accounting for 65% of the total mass of asphalt regenerant;

[0077] The reinforcement modifier adopts epoxy aliphatic polyethylene polyamine, which accounts for 3% of the total mass of the asphalt regenerant, and the epoxy group content in the interface reinforcement modifier is 30wt%

[0078] Modified petroleum resin is used as plasticizer, accounting for 30% of the total mass of asphalt regeneration agent;

[0079] Chloroform is used as penetrating agent, accounting for 1% of the total mass of asphalt regenerant;

[0080] The anti-aging agent adopts butylated hydroxytoluene (BHT), which accounts for 1% of the total mass of the asphalt regenerant;

[0081] According to the above ratio, taking the preparation of 100kg asphalt rejuvenator as an example, the preparation process of asphalt rejuvenator is as follows:

[0082] Take 65kg of plant as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com