High-water-cut heavy oil demulsifier used for oil fields and preparation method thereof

A technology of demulsifier and heavy oil, which is applied in the field of high water content heavy oil demulsifier and its preparation in oil fields, can solve the problems of slow dehydration process of crude oil, poor demulsifier effect, high preparation cost, etc., achieve good dehydration effect, low cost, The effect of easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of demulsifier for heavy oil with high water content for oil field, the raw materials it adopts are polyethylene polyamine, bisphenol S, formaldehyde, KOH catalyst, ethylene oxide, propylene oxide, acetic acid, xylene, triethylene diamine, 2 - Methyl crotonate, epichlorohydrin, take the following process to synthesize:

[0032] 1) Synthetic initiator: Polyethylene polyamine and bisphenol S are added dropwise to formaldehyde solution at 30-60°C, the molar ratio of polyethylene polyamine, bisphenol S and formaldehyde is 1:5:4, and then the temperature is raised to 120 ℃ for 3 hours, and the product was freeze-dried to obtain a self-made phenamine-aldehyde resin starter.

[0033] 2) Synthesis of polyether: Under KOH catalysis, according to the operating conditions for preparing alkoxylation, the dosage of KOH catalyst is 0.22%-0.27%. Propylene oxide is catalyzed and polymerized by KOH, wherein the molar ratio of ethylene oxide to propylene oxide is 1:1, the product...

Embodiment 2

[0038] A kind of preparation method of high water content heavy oil demulsifier for oil field, preparation method comprises the following process steps:

[0039] 1) Synthetic initiator: Polyethylene polyamine and bisphenol S are added dropwise to formaldehyde solution at 50°C, the molar ratio of polyethylene polyamine, bisphenol S and formaldehyde is 1:7:5, and then the temperature is raised to 150°C for reaction After 3 hours, the product was freeze-dried to obtain a self-made phenamine-aldehyde resin starter.

[0040] 2) Synthesis of polyether: Under KOH catalysis, according to the operating conditions for preparing alkoxylation, the dosage of KOH catalyst is 0.25%, and under the conditions of 110°C and 0.2MPa, the initiator and ethylene oxide and propylene oxide Polymerization is catalyzed by KOH, wherein the molar ratio of ethylene oxide to propylene oxide is 2:1, the product is neutralized with acetic acid, and desalted by suction filtration to obtain polyether.

[0041]...

Embodiment 3

[0045] The dehydration effect of heavy oil with high water content is simulated in the experiment, and the evaluation method specified in the oil and gas industry standard SY-T5281-2000 crude oil demulsifier performance test method (bottle test method) is adopted in the experiment. The high water-containing heavy oil demulsifier PRJ-001 obtained in Example 2.

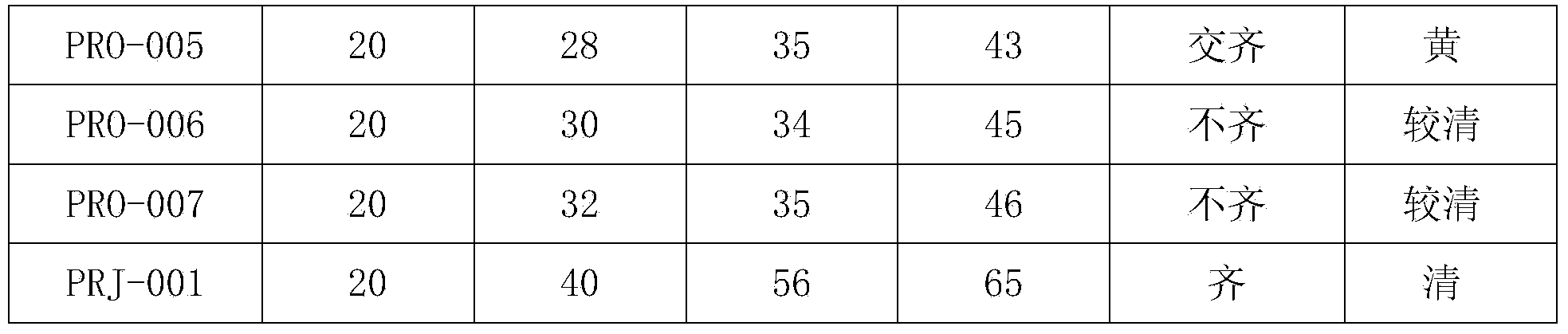

[0046] The experimental temperature is 70°C, the water content in the oil is 60.4%, and the oil-water ratio is 70:30. The experimental results are as follows:

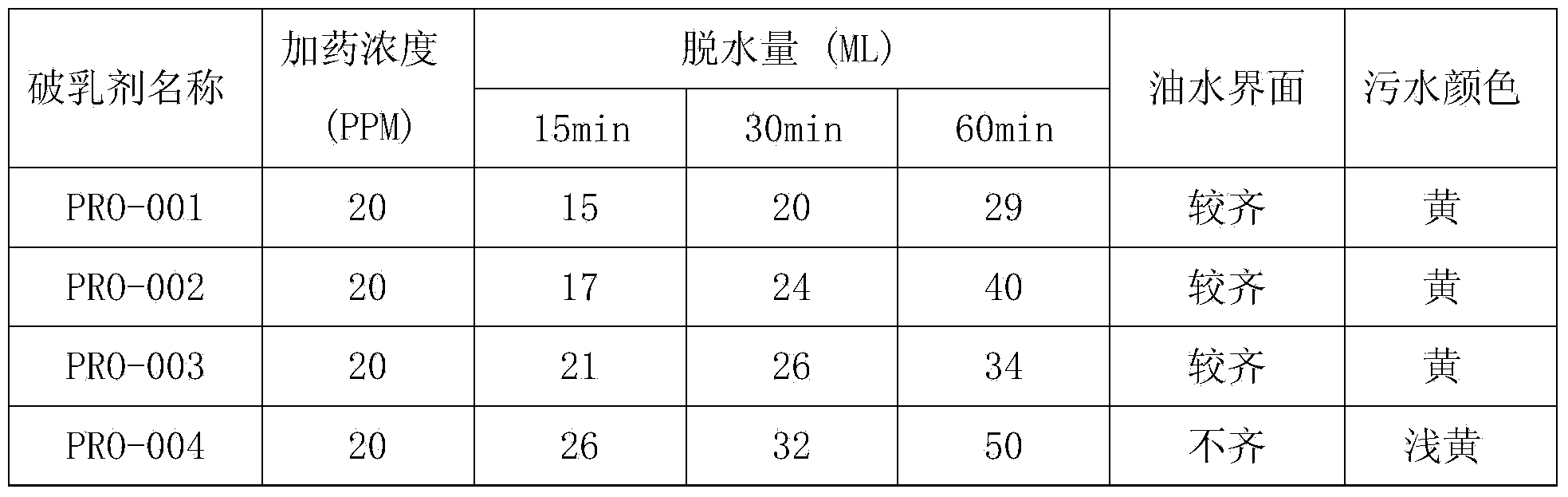

[0047] Demulsification effect of different demulsifiers in table 1

[0048]

[0049]

[0050] Among them, PRO-001--PRO-007 are demulsifiers synthesized for heavy oil with high water content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com