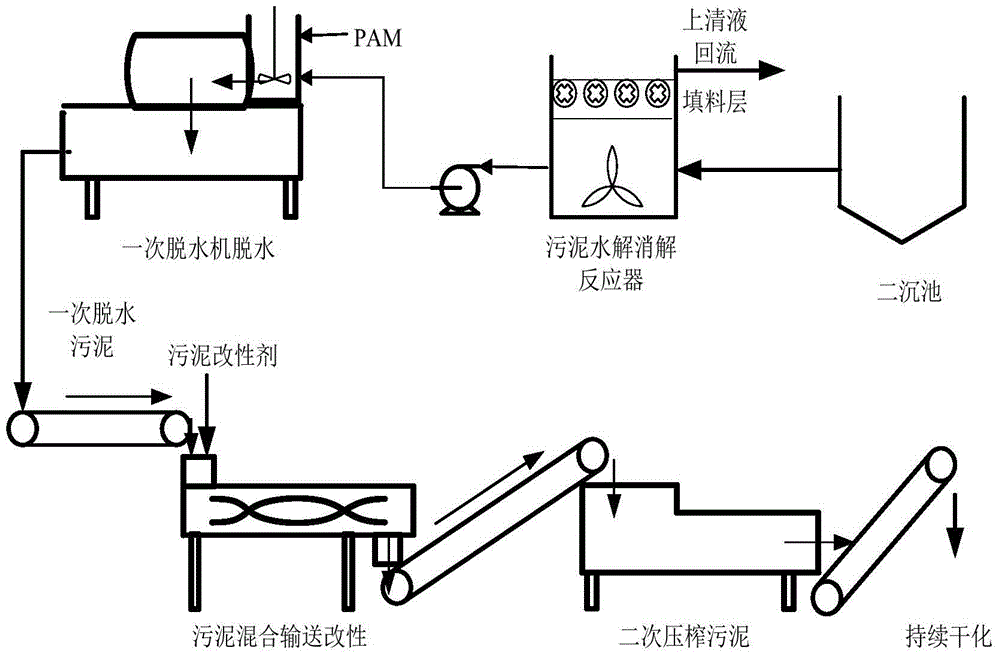

Sludge reduction and desiccation combination method

A sludge reduction and sludge drying technology, which is applied in chemical instruments and methods, sludge treatment, sludge treatment, etc., can solve the problems of large equipment footprint, inability to discharge continuously, and high moisture content of sludge , to achieve the effect of reducing operating costs, reducing affinity, and less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] An urban sewage treatment plant with a scale of 8×10 4 m 3 / d, the amount of mud output from the secondary settling tank (water content 99%) is 960 tons per day. The remaining sludge from the secondary settling tank is discharged into the hydrolysis and digestion reactor with agitator, and the amount of sludge entering is 960 tons per day. Adjust the sludge concentration in the hydrolysis and digestion reactor to 30g / L, and the known volume of the hydrolysis and digestion reactor is 1065m 3 , the hydraulic retention time of the sludge is 26.62h. The hydrolysis and digestion reactor is cylindrical, and the packing layer inside the hydrolysis and digestion reactor is a commercially available PE material cylindrical packing, fully stirred, the moisture content of the reactor sludge is 97%, and the sludge weight reduction rate is 40% , then the wet sludge output from the reactor is 192t / d.

[0033] The sludge from the hydrolysis and digestion reactor enters the sludge d...

Embodiment 2

[0040] Scale is 4×10 4 m 3 / d of the urban sewage treatment plant, the sludge output from the secondary settling tank (water content 99%) is 480 tons, and the remaining sludge from the secondary settling tank is discharged into the sludge hydrolysis and digestion reactor equipped with a mixer, and the sludge is fed every day The quantity is 480 tons. Adjust the sludge concentration in the sludge hydrolysis digester to 30g / L, and the volume of the known reactor is 500m 3 , the hydraulic retention time of the sludge is 25h. The hydrolysis and digestion reactor is cylindrical, and the packing layer inside the hydrolysis and digestion reactor is a commercially available PE material cylindrical packing, fully stirred, the moisture content of the reactor sludge is 96%, and the weight reduction rate is 45%. Then the amount of wet sludge output from the reactor is 66t / d.

[0041] The sludge from the sludge hydrolysis and digestion reactor enters the drying system for the following...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com