Oil-water slag separation device for kitchen garbage

A technology of oil-water separator and garbage oil, which is applied in the direction of liquid separation, separation method, centrifugal separation water/sewage treatment, etc. It can solve the problems affecting the oil output effect and grease adhesion, and achieve shortened treatment cycle, low power consumption, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

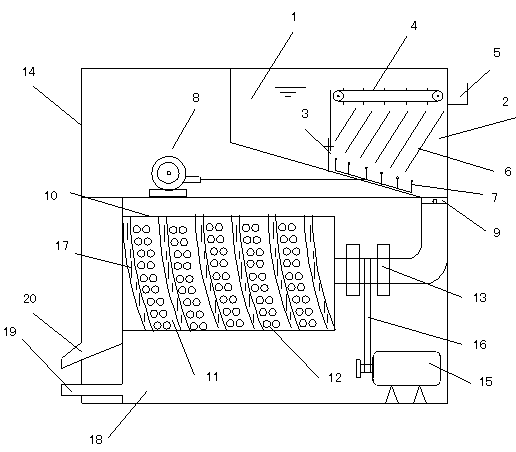

[0020] Such as figure 1 Shown is a food waste oil-water slag separator, including a feed box 1, an oil-water separator 2, a solid-liquid separation drum 10 and a closed outer box 14; the outlet of the feed box 1 and the oil-water separator The feed port of 2 is connected, and the discharge port of the oil-water separator 2 is connected with the feed port of the solid-liquid separation drum 10; the material in the feed box 1 flows into the oil-water separator 2 by its own weight, and the The material in the oil-water separator 2 flows into the solid-liquid separation drum 10 by its own gravity.

[0021] The upper part of the oil-water separator 2 is provided with a scraping oil collector 4, the middle part is provided with a sloping plate 6, and the bottom is provided with an aeration tube 7, and the sloping plate 6 is inclined against the material outflow direction; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com