Patents

Literature

2630 results about "Oil–water separator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An oil water separator (OWS) is a piece of equipment used to separate oil and water mixtures into their separate components. There are many different types of oil-water separator. Each has different oil separation capability and are used in different industries. Oil water separators are designed and selected after consideration of oil separation performance parameters and life cycle cost considerations. "Oil" can be taken to mean mineral, vegetable and animal oils, and the many different hydrocarbons.

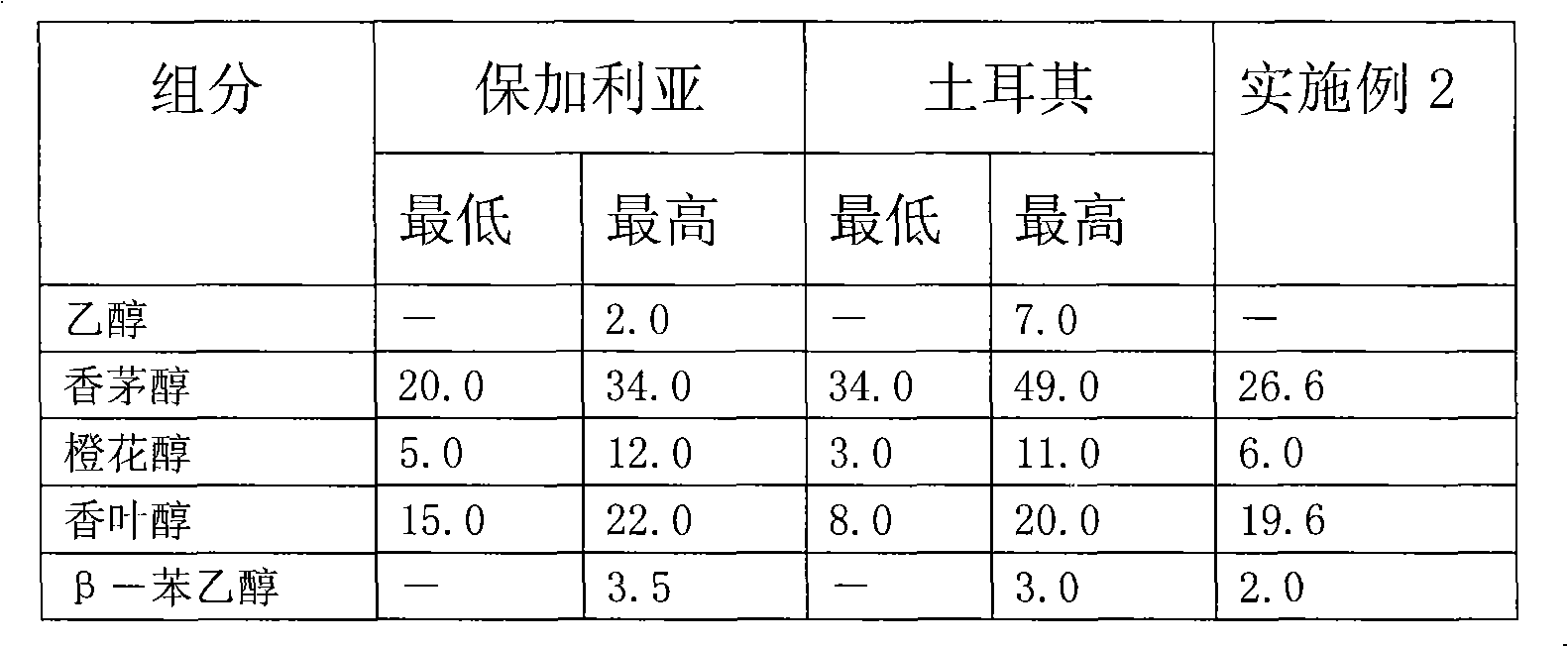

Method for extracting rose essence oil and rose absolute by water vapor water distillation technology

InactiveCN101280243AImprove stabilityImprove the yield of active ingredientsEssential-oils/perfumesFatty-oils/fats productionSlagWater vapor

The invention discloses a method of extracting rose essential oil and rose pure dew, using the distillation technique in the water vapor. The method includes the steps: (1) the roses are fed into a distillation kettle; (2) deionized water is added to the distillation kettle; (3) non-iodine salt is added to the distillation kettle; (4) the coiled pipe is opened to supply steam and heat the distillation kettle; (5) the condenser is opened to supply cooled water; the cooled oil water is mixed with steam; (6) the oil water mixture cooled by the condenser is guided into an oil water separator for the oil water separation; (7) the water layer separated by the oil water separator flows back to the distillation kettle to have repeated distillation; when the repeated distillation is finished, the repeated flow valve is closed and the collector valve is opened to collect the water layer so that the rose pure dew is obtained; (8) when the oil and water are divided into layers, the oil water separator is opened to collect the water layer so that the rose essential oil is obtained; (9) water is released and the waste slag is discharged. The method of extracting the rose essential oil and the rose pure dew has the advantages of high stability of the products, high content of the active composition, simple operation, easy mastery and low production cost.

Owner:浙江景和旅游产业发展有限公司

Equipment and method for extracting perfume plant essential oil by reduced pressure steam distillation

InactiveCN102250689AWide applicabilityEasy and flexible operationEssential-oils/perfumesWater vaporOil phase

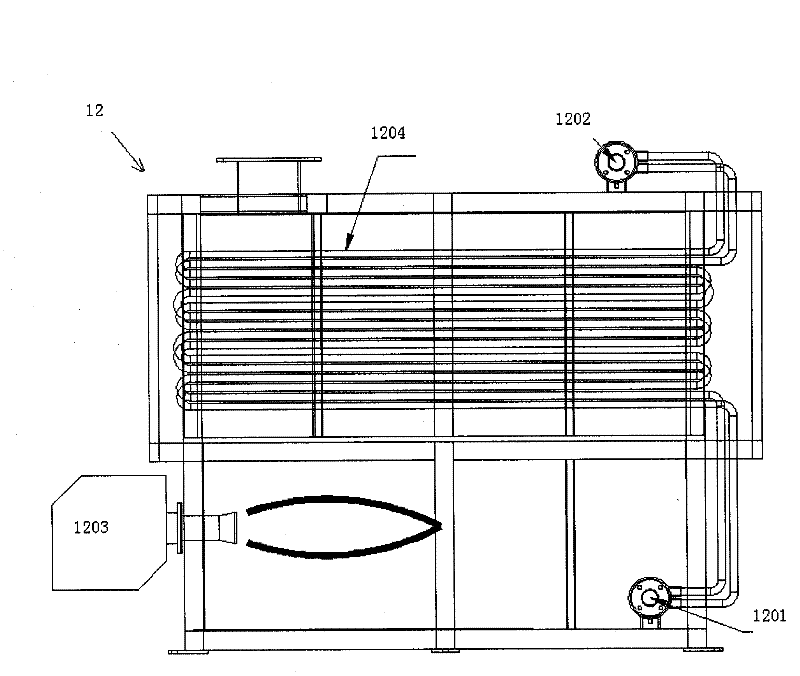

The invention provides a piece of equipment and a method for extracting volatile essential oil from natural perfume plants by using the technology of reduced pressure steam distillation extraction. The equipment provided in the invention comprises a steam distillation system and a vacuum system, wherein the steam distillation system is composed of a steam generator, a material retort, a condenser, an oil-water separator and connecting pipelines, and the vacuum system comprises a vacuum unit or a suction pump, a pressure regulator valve, connecting pipelines and the like. The method comprises the following steps that: plant raw materials to be extracted for essential oil in the material retort is controlled to be at a certain temperature and under certain pressure so as to reduce changes of aroma components in perfume plants in the process of extraction as much as possible; extracted volatile components of essential oil is mixed with steam to form mixed steam of water and oil; the mixed steam enters into the condenser for condensation and then enters into the oil-water separator for separation; an oil phase is collected after separation and the oil phase is plant essential oil; the separated water phase is flower water. The essential oil and flower water obtained by the extraction method have pure aroma, suffer little loss for head volatile thereof, and are applicable to the industries of perfumes, essence, cosmetics, daily chemicals, etc.

Owner:XINJIANG UNIVERSITY +2

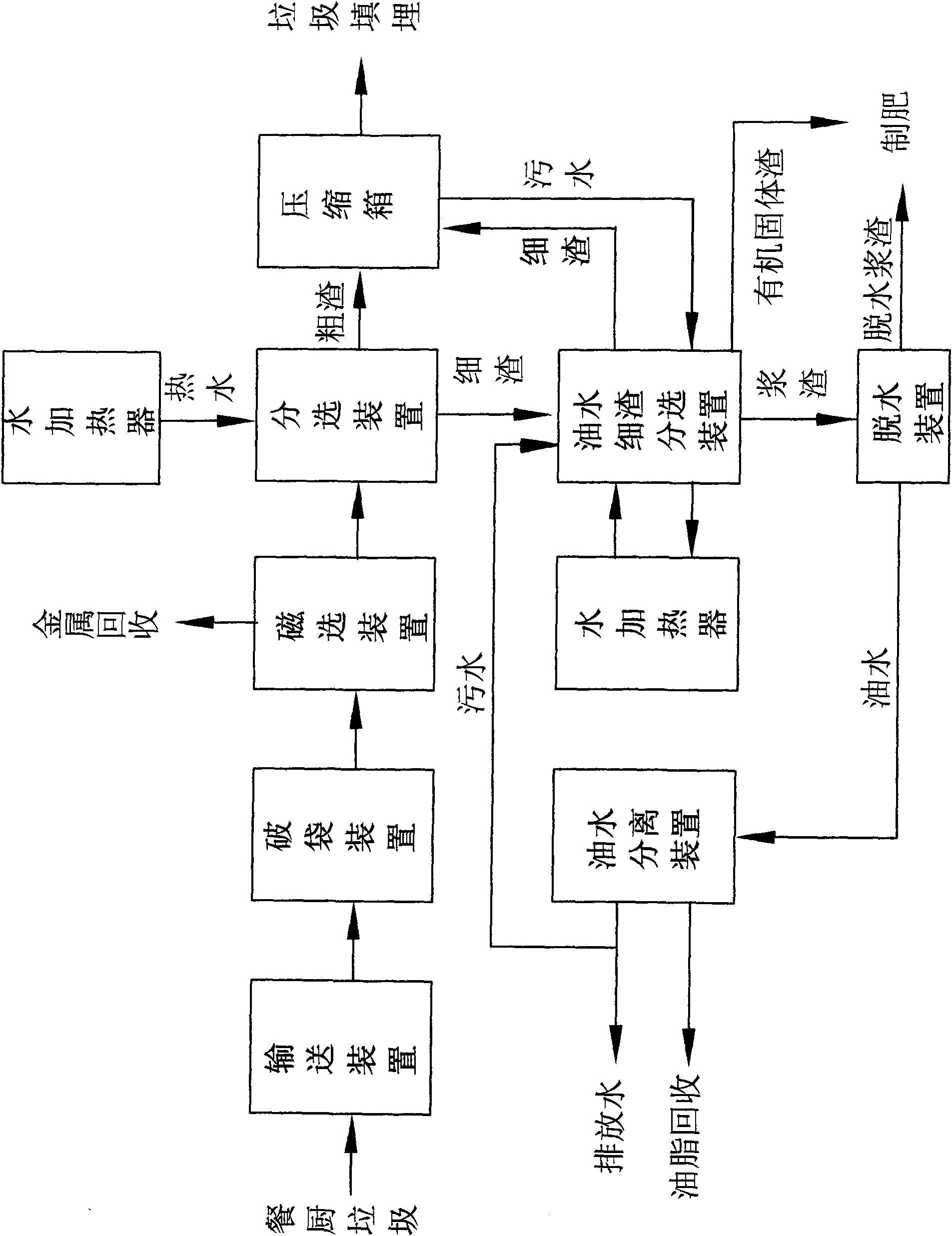

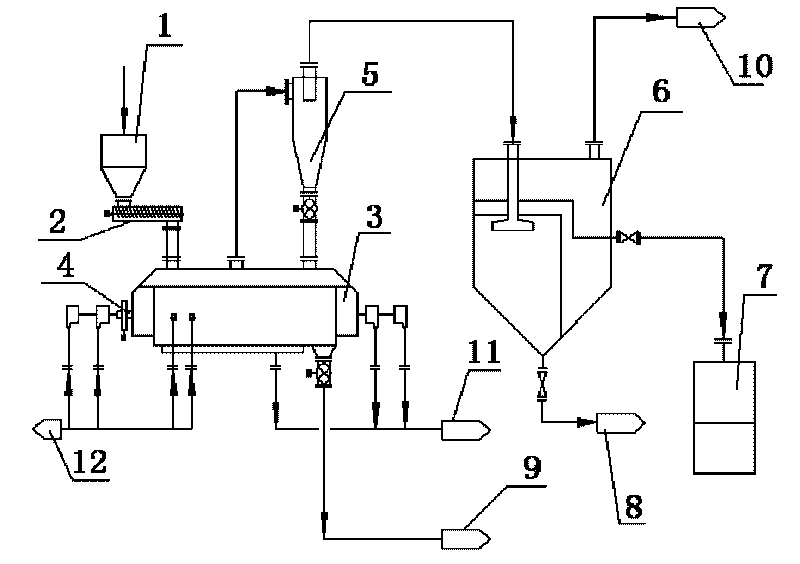

Treating technical method for food wastes and treating equipment

InactiveCN101524700AHarmlessReduce consumptionSolid waste disposalMagnetic separatorEnvironmental engineering

The invention discloses a treating technical method for food wastes and treating equipment, which relate to the technical field of screening and oil water separation in food waste treatment; the technique method comprises the following steps: the food waste is recycled by bag crushing, magnetic separation, coarse residue screening, hot water washing, solid-liquid separation of fine residue and secondary oil water separation with water in a separator of oil, water and fine residue. The treating equipment of food wastes for realizing the technique method mainly comprises a charging part, a conveying part, a bag-crushing device, a magnetic separator, a coarse residue separating part, a solid-liquid separator, a dehydrating unit, an oil water separator and the like. The invention can carry out grading screening, solid-liquid separation, oil water separation and resource recycling on food wastes, has continuous operation in use, thorough treatment and high efficiency and can protect environment.

Owner:BEIJING CENTURY GREEN ENVIRONMENTAL ENG &TECH +1

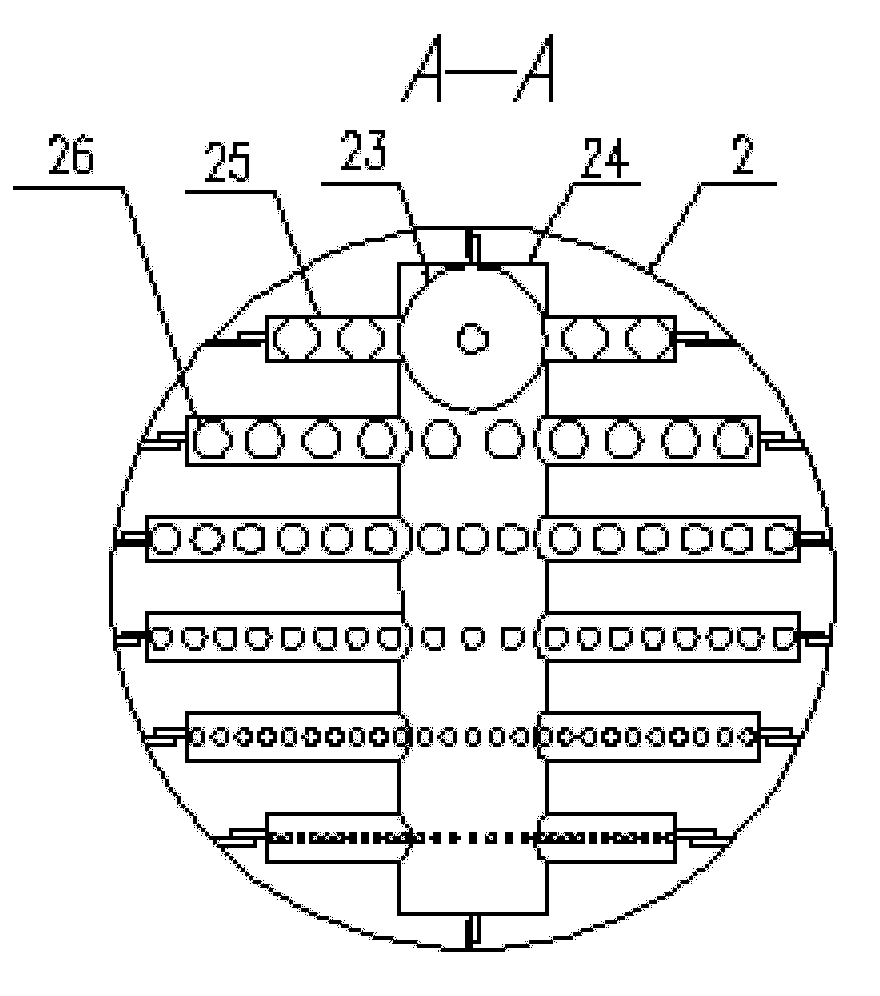

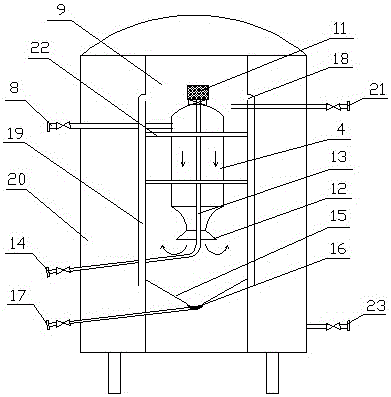

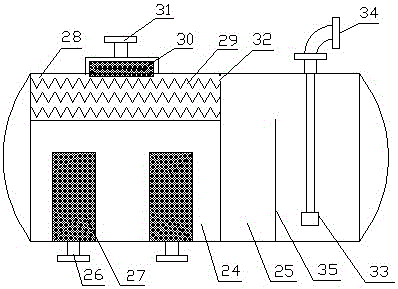

Oil-water separating device and method

ActiveCN101972559AWith deep separationAchieve deep separationNon-miscible liquid separationOil waterPolypropylene

The invention discloses oil-water separating device and method. The oil-water separating device comprises a swirler and a horizontal type agglutinating oil-water separator, wherein a bottom flow pipe of the swirler is in a U shape; the horizontal type agglutinating oil-water separator has the liquid uniform distributing function; an inlet liquid distributor, a rectifying sieve plate, a stainless steel plate ripple filler, a polypropylene gauze ripple filler, an outlet liquid collector, and the like are sequentially arranged in the horizontal type agglutinating oil-water separator, and the stainless steel plate ripple filler and the polypropylene gauze ripple filler are fixed by a limit grid plate; the U-shaped bottom flow pipe of the swirler and a filter screen arranged in the swirler can filter a small number of solid impurities contained in liquid so as to prevent the blockage of agglutinated fillers; the inlet liquid distributor and the outlet liquid collector ensure that the liquid is uniformly distributed; the rectifying sieve plate reduces the flow rate of the liquid to form lamellar flow; the stainless steel plate ripple filler provides a place for agglutinating and separating oil drops; and the polypropylene gauze ripple filler with an air floating device can further agglutinate and separate residual fine oil drops. The combination simultaneously has the effects of whirl, agglutination and air floatation and can realize the deep separation of oil and water.

Owner:TIANJIN UNIV

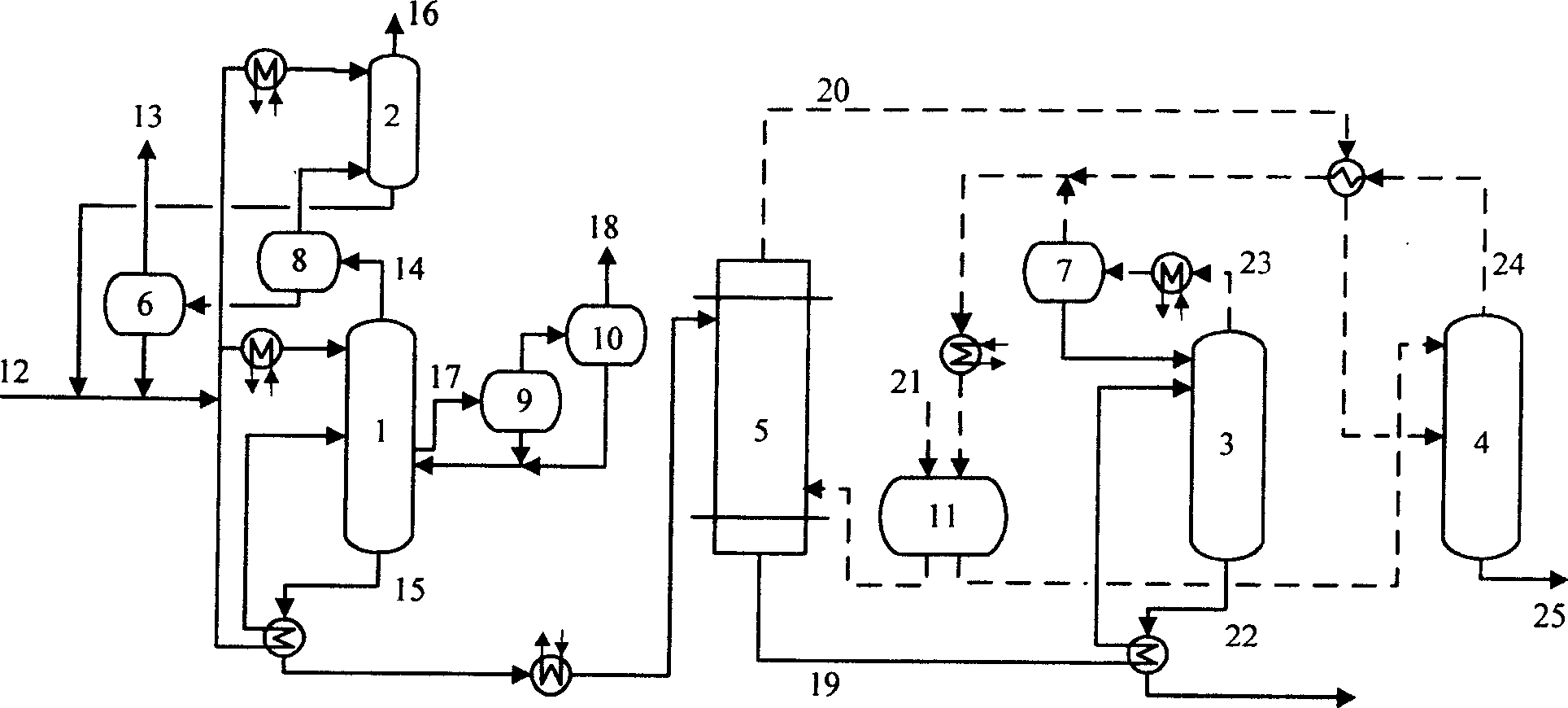

Method for treating coal gasification wastewater by single-tower pressurization stripping and device therefor

InactiveCN1884150AHigh removal rateReduce crystallizationFatty/oily/floating substances removal devicesMultistage water/sewage treatmentCoal gasification wastewaterOrganic solvent

The invention discloses a gasification wastewater disposing method and device through single-tower pressurizing stripping, which comprises the following steps: entering the extracted of acid gas or ammonia gas of cold and hot coal gasification wastewater from band lateral line in the stripping tower from top and upper top; blending gas; dividing phases; washing; separating light oil and acid gas; preparing liquid ammonia through two-grade concreting and refining; separating crude phenol and organic solvent from bottom of tower through inversed-extracting autoclave liquid and organic solvent; recycling organic solvent through stripping. The gasification disposing device contains oil acid gas / ammonia stripping tower, extracting tower, acid gas washing tower, solvent stripping tower, solvent recycling tower, oil-water separator, dephlegmator, pump and reservoir.

Owner:SOUTH CHINA UNIV OF TECH

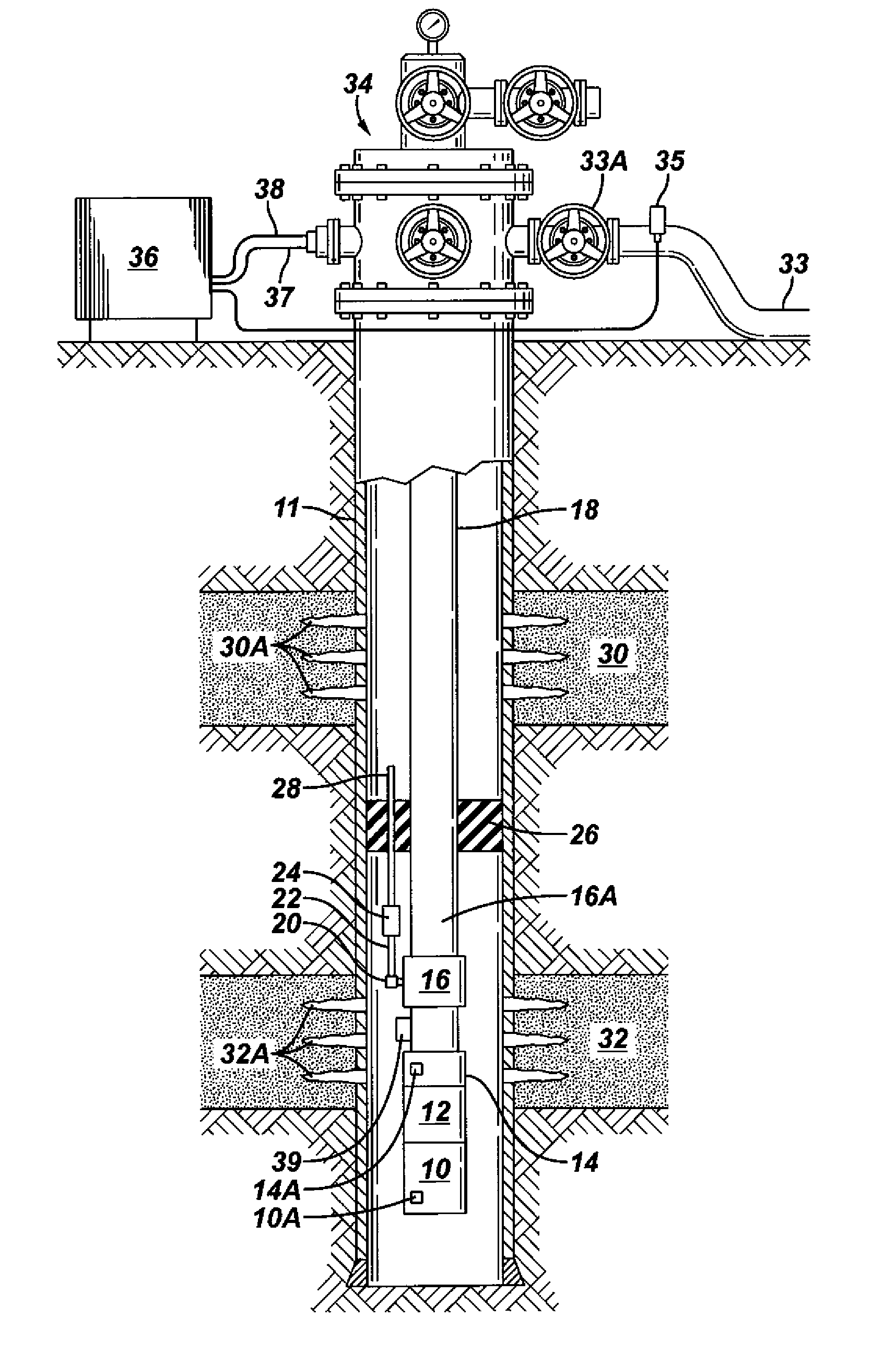

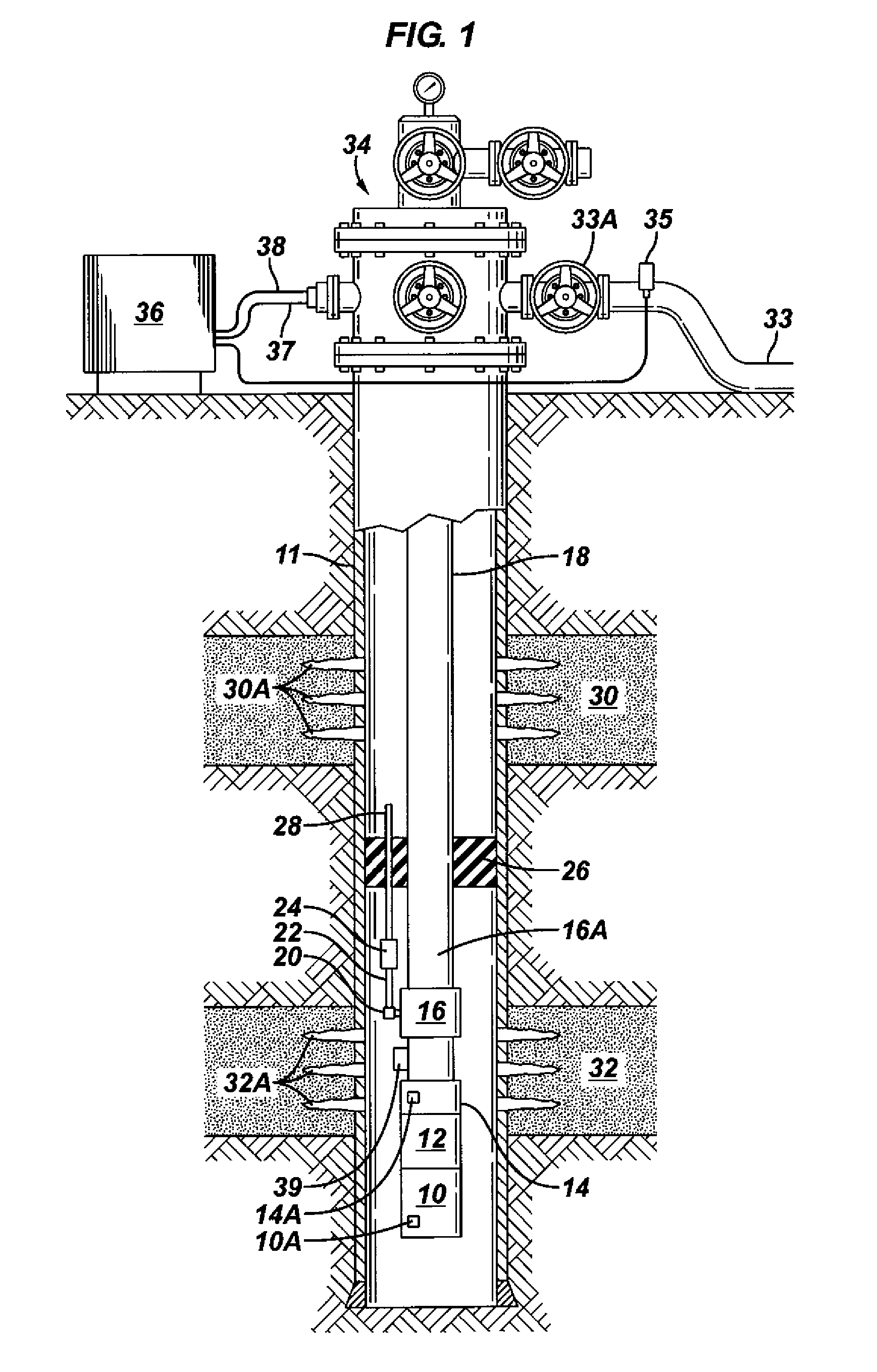

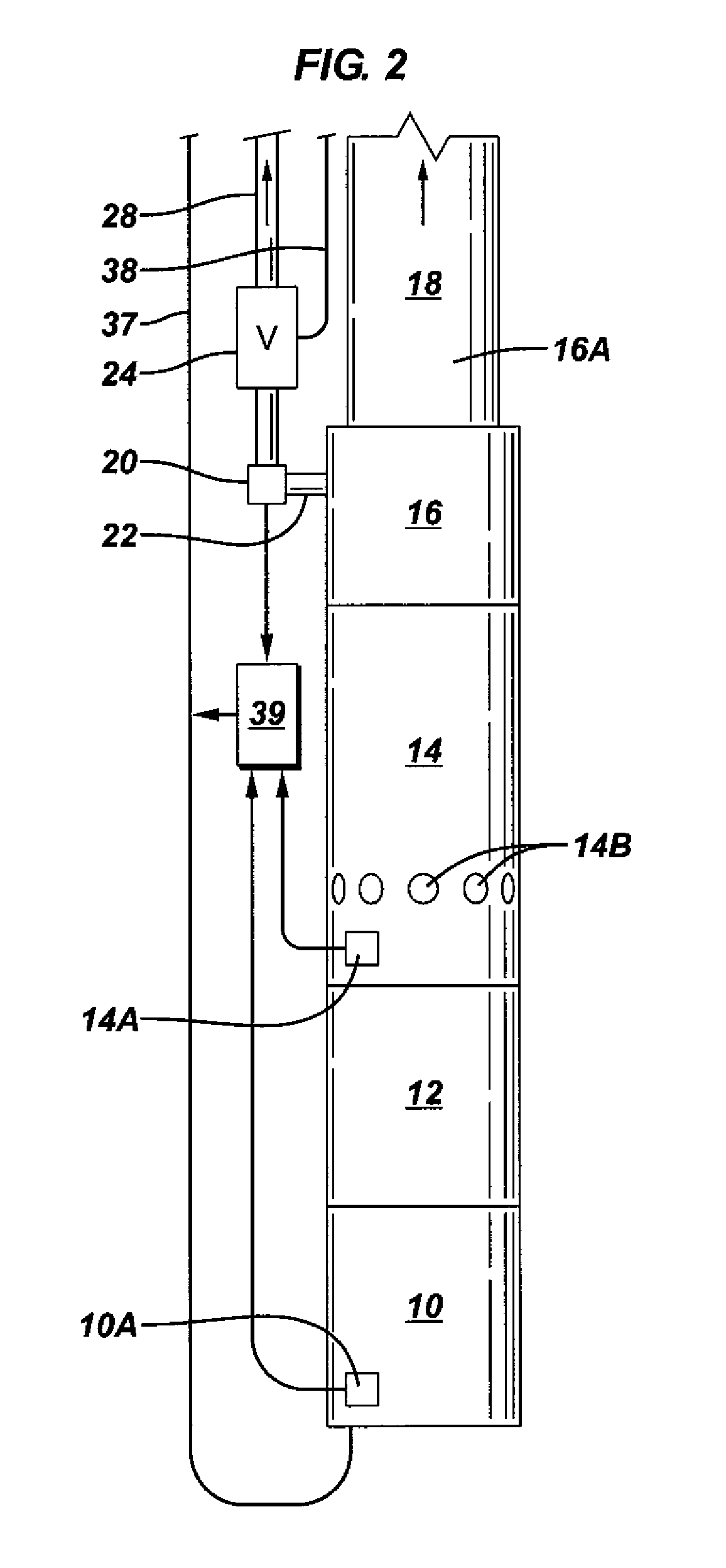

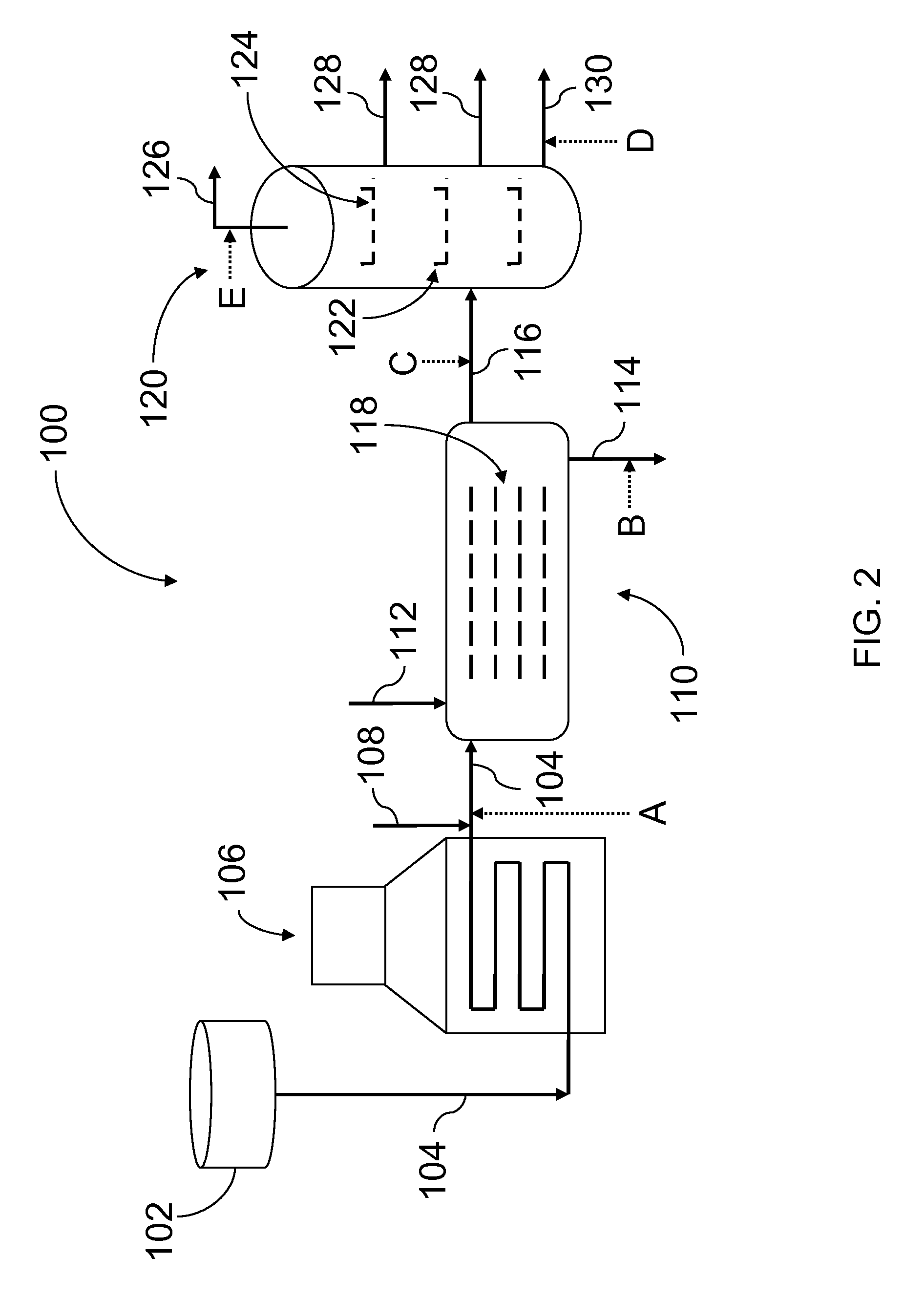

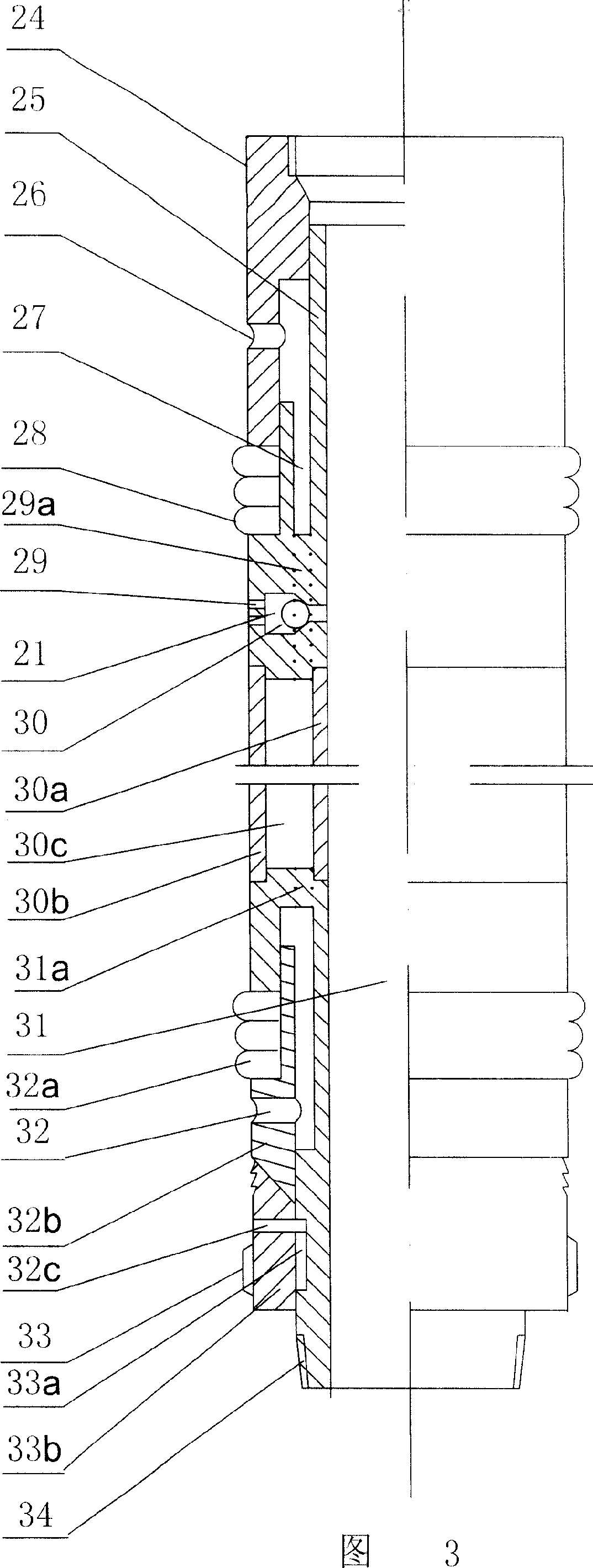

Monitoring and automatic control of operating parameters for a downhole oil/water separation system

A method for operating a downhole oil water separator and electric submersible pump includes measuring fluid pressure proximate one of the pump intake, separator intake and a bottom of a wellbore. At least one of flow rate and pressure is measured at the separator water outlet. Pump and a water outlet restriction are controlled to maintain an optimum fluid pumping rate and an optimum injection rate of separated water. A flow control system includes a controllable valve disposed in a water outlet of the separator. At least one of a pressure sensor and a flowmeter is operatively coupled to the water outlet. A controller is in signal communication with the at least one of a pressure sensor and flowmeter and in operative communication with the valve. The controller operates the valve to maintain at a selected pressure and / or a selected flow rate through the water outlet.

Owner:SCHLUMBERGER TECH CORP

Treatment method and treatment apparatus of oily sludge

InactiveCN102503055AHigh recovery rateReduce moisture contentSludge treatment by thermal conditioningSludgeLiquid state

The invention provides a treatment method of oily sludge, which comprises the steps of: introducing overheated vapor into a high temperature treatment groove to roast the oily sludge so as to evaporate the liquid containing oil and water in the oily sludge to gas; separating the solid granules from the oily sludge and contained in the gas in a gas-solid separator, and conveying the solid granules to a drying machine to be dried and burnt so as to be discharged; condensing the gas separated from the gas-solid separator to liquid state oil and water, separating the liquid state oil and water in an oil-water separator to be respectively recycled, wherein the oily sludge is introduced into the high temperature treatment groove in a pumping manner, the overheated vapor is introduced into the high temperature treatment groove by supersonic jet flow and is vertically collided with the oily sludge. The invention further provides a treatment apparatus of oily sludge for executing the method; the treatment method and treatment apparatus provided by the invention have the advantages of guaranteeing high crude oil recovery, and small water content and oil content of finally generated dry residues.

Owner:河北海清大地环保科技有限公司

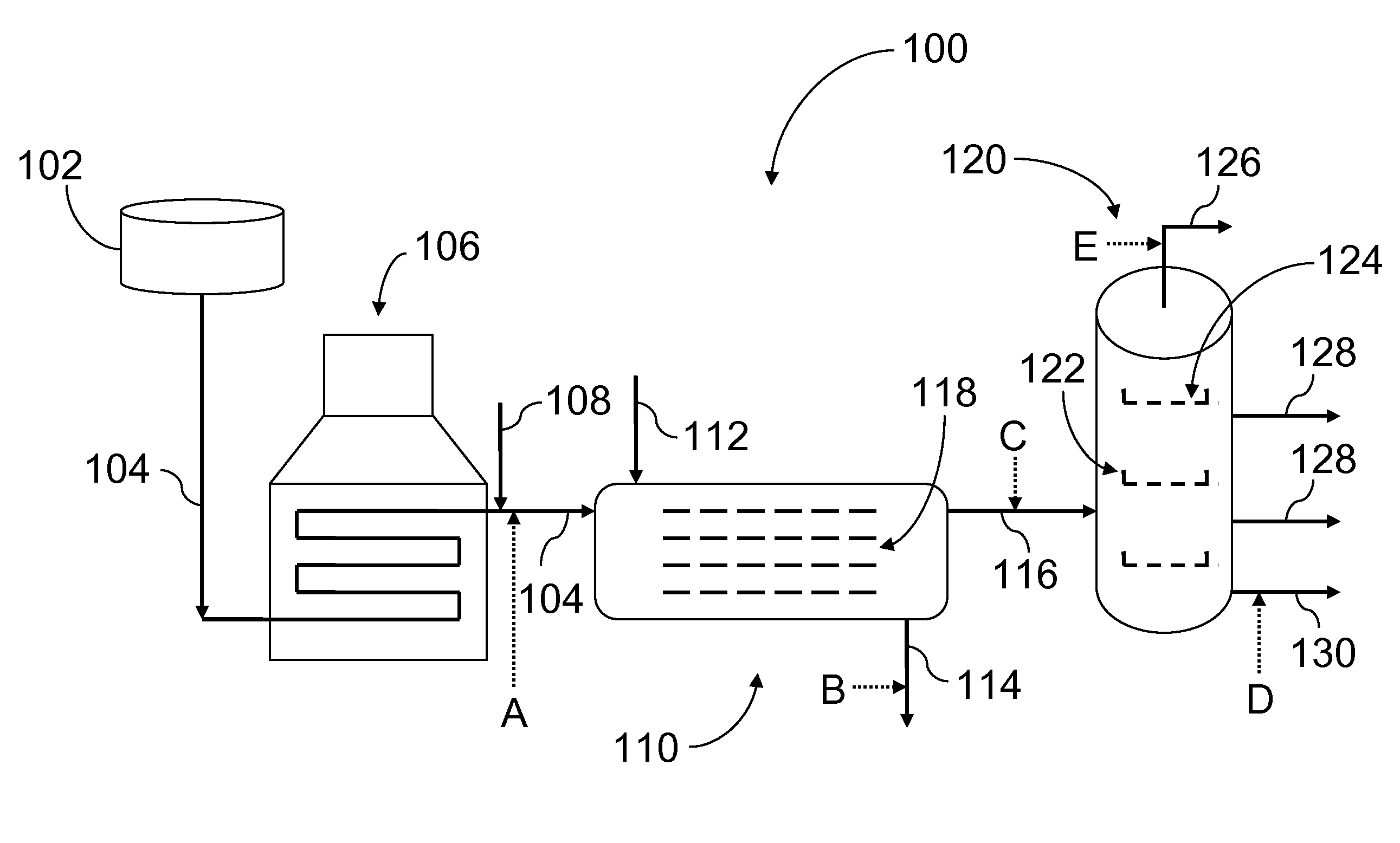

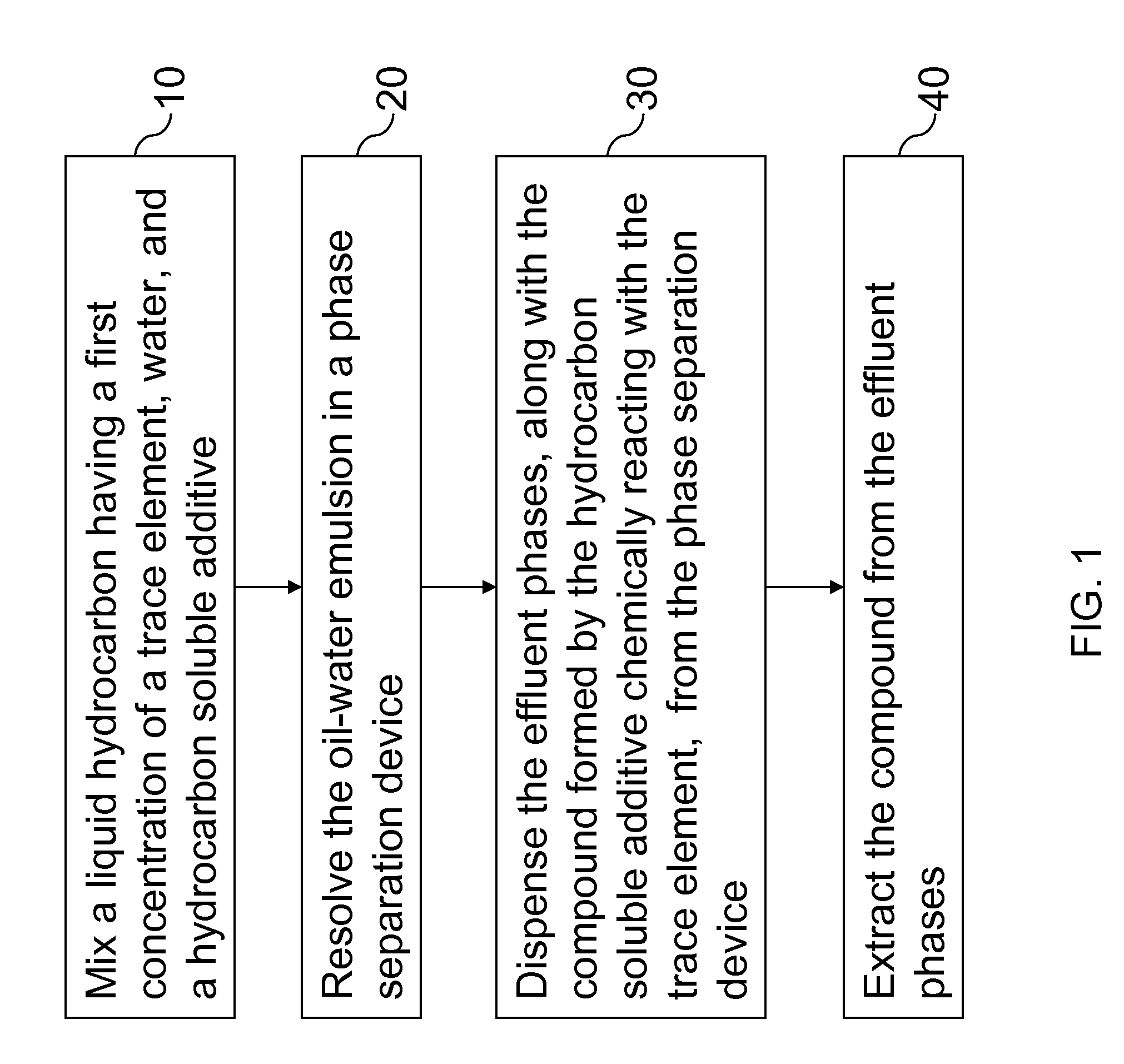

System and method for separating a trace element from a liquid hydrocarbon feed

InactiveUS20100000910A1Easy to removeEasy to separateTransportation and packagingRefining by water treatmentChemical reactionTrace element

The present invention is generally directed to removing a trace element from a liquid hydrocarbon feed. The liquid hydrocarbon feed, containing the trace element, is mixed with the water along with a hydrocarbon-soluble additive. While being mixed, a compound, which in some cases is preferably insoluble, is formed by the hydrocarbon-soluble additive chemically reacting with the trace element. A phase separation device, such as a desalter or an oil-water separator, receives the oil-water emulsion containing the compound and resolves the mixture to produce the compound, effluent brine, and effluent liquid hydrocarbon with a reduced concentration of the trace element as compared to the liquid hydrocarbon feed. In some embodiments, the present invention is directed to removing elemental mercury from a liquid hydrocarbon feed. A hydrocarbon-soluble sulfur-containing additive, typically an organic polysulfide, is mixed with the liquid hydrocarbon feed and water. The hydrocarbon-soluble, sulfur-containing additive reacts with the mercury, rapidly forming an agglomeration of mercuric sulfide which is then dispensed with the effluent brine or the effluent liquid hydrocarbon.

Owner:CHEVROU USA INC

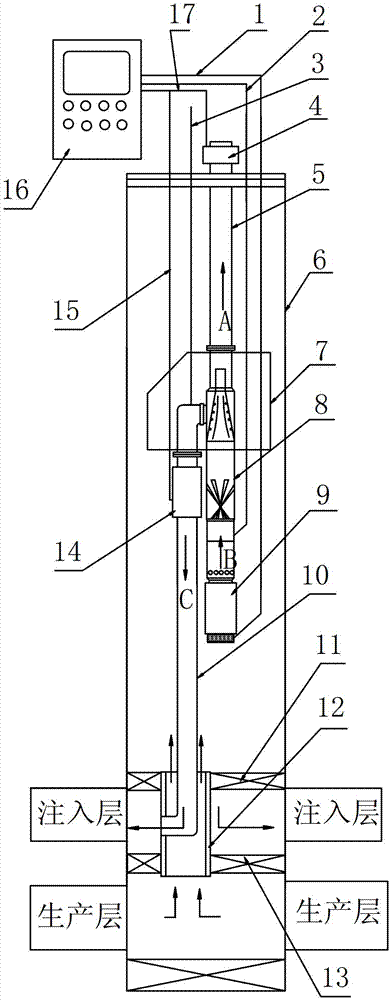

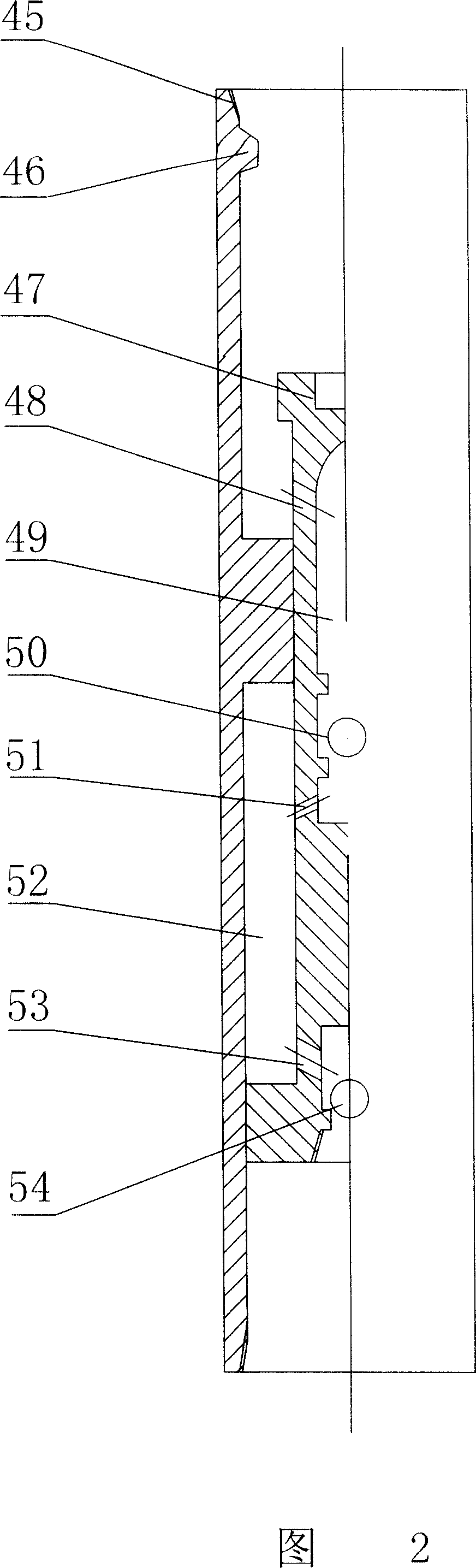

Real-time adjustable and controllable hanging type underground oil and water separating system

ActiveCN102828736AImprove work efficiencyImprove job stabilitySurveyFluid removalStreamflowInstrumentation

The invention discloses a real-time adjustable and controllable hanging type underground oil and water separating system, which comprises an underground sleeve pipe, a water injection oil pipe, an oil extracting oil pipe and a flow rate control valve, wherein the flow rate control valve is arranged at the wellhead part, the aboveground ground is provided with a visual control device, a hanging type three-way joint connected with the oil extracting oil pipe, an oil and water separator and the water injection oil pipe is arranged in the sleeve, the oil and water separator is connected with an electric submersible pump unit, a water injection pressure regulating device is arranged on the water injection oil pipe, a flow rate and pressure monitoring instrument is arranged in the electric submersible pump unit, a flow rate and pressure monitoring instrument and a regulating valve are arranged in the flow rate control valve, monitoring instrument cables and signal transmission cables are respectively connected among the electric submersible pump unit, the water injection pressure regulating device, the flow rate control valve and the visual control device, the visual control device converts received real-time flow rate and pressure signals into visual data to be output, and the work of the whole system is regulated and controlled. The hanging type underground oil and water separating system has the advantages that the stability is high, the treatment capability is high, and the hanging type underground oil and water separating system can be widely applied to an oilfield same-well production injection process.

Owner:CNOOC ENERGY TECH & SERVICES

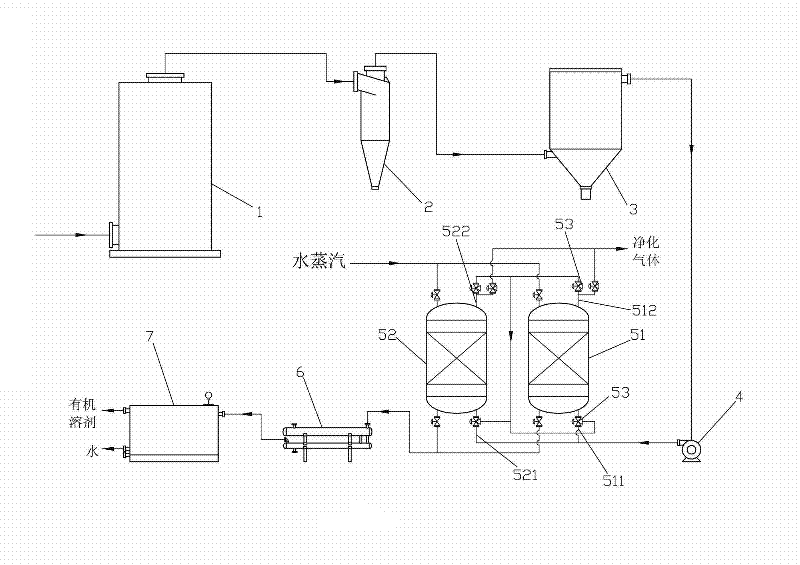

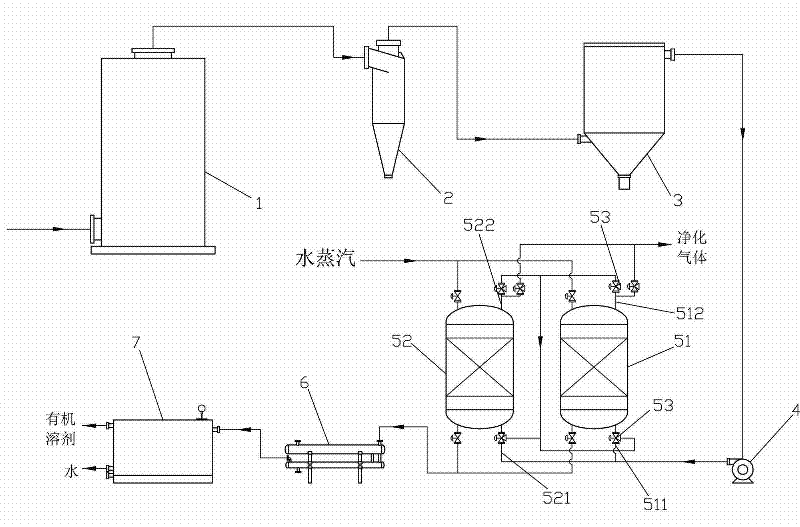

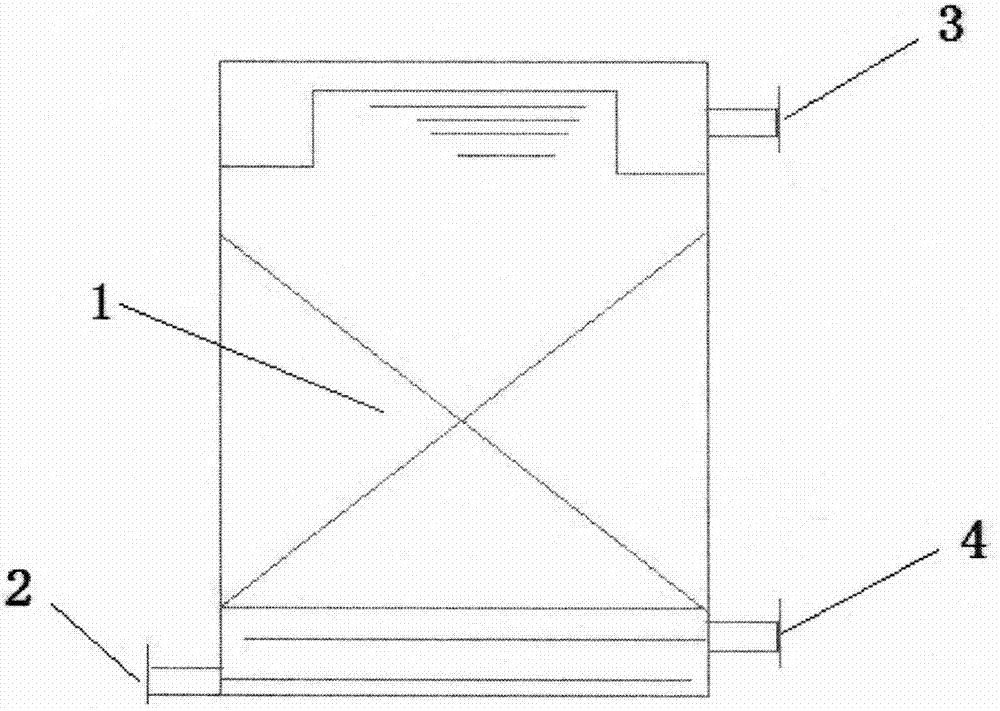

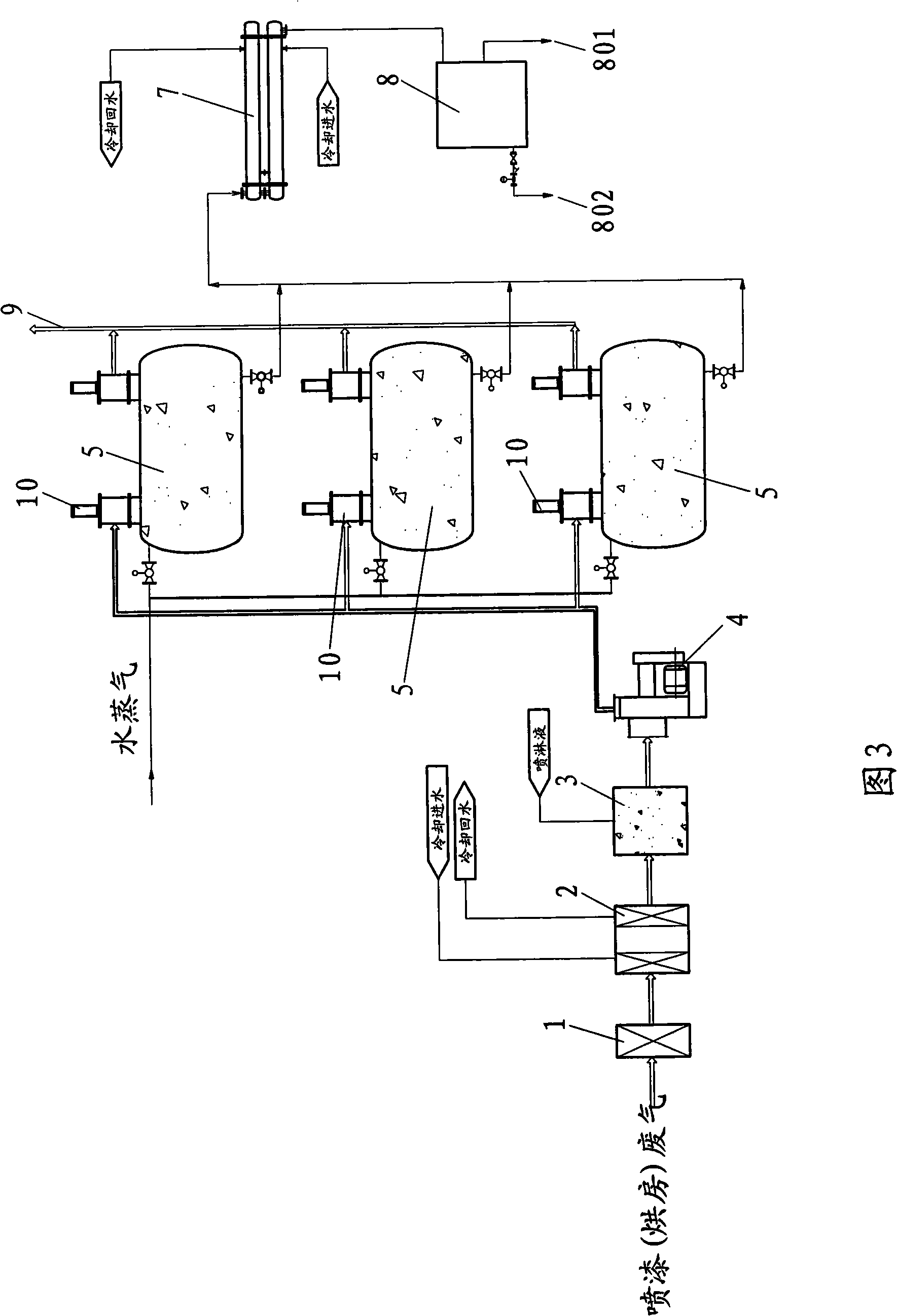

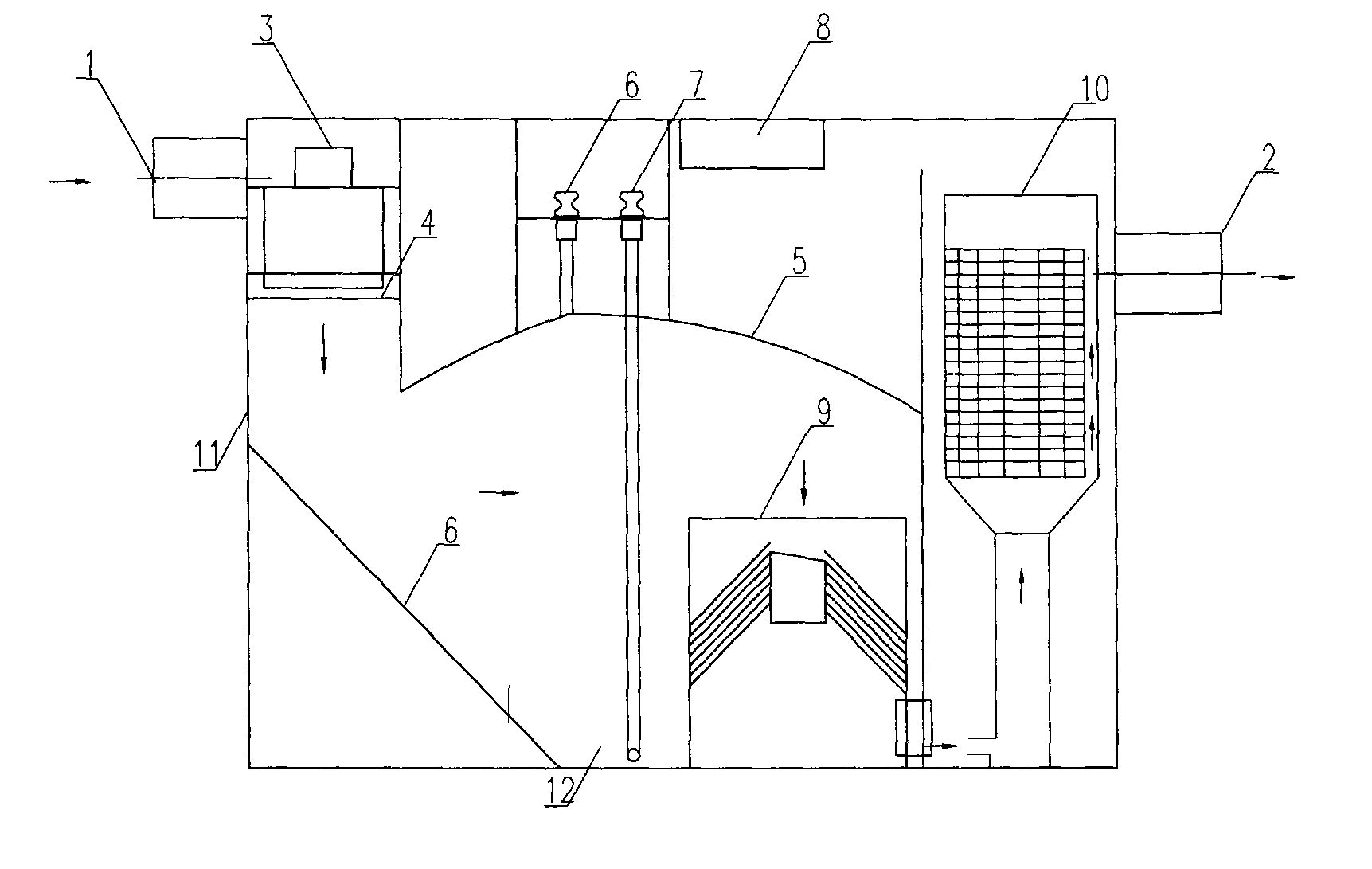

Recycling device for exhaust gas of painted organic solvent and method for recycling organic solvent

The invention discloses a recycling device for an exhaust gas of a painted organic solvent. The recycling device comprises a painting fog removing device, a fan, an absorbing jar, a condenser and an oil-water separator which are connected in turn, wherein the painting fog removing device comprises a gas collecting tank, a cyclone dust collector and a bag type dust collector; the gas collecting tank is used for temporarily storing the exhaust gas of the organic solvent; and the gas collecting tank, the cyclone dust collector and the bag type dust collector are connected in turn. All componentsof the recycling device are reasonably and compactly jointed; collection efficiency is high; and the painting fog is efficiently removed while a trouble in frequently exchanging filter cotton is avoided. The invention also discloses a method for utilizing the recycling device for the exhaust gas of the painted organic solvent to recycle the organic solvent. The method comprises the following steps: removing the painting fog; absorbing; desorbing steam; condensing; and separating oil from water, wherein the step of removing the painting fog is carried out by changing the painting fog into painting powder and then efficiently removing the painting fog. Compared with a traditional process, the method is more reasonable, compact and labor-saving.

Owner:中科天龙(厦门)环保股份有限公司

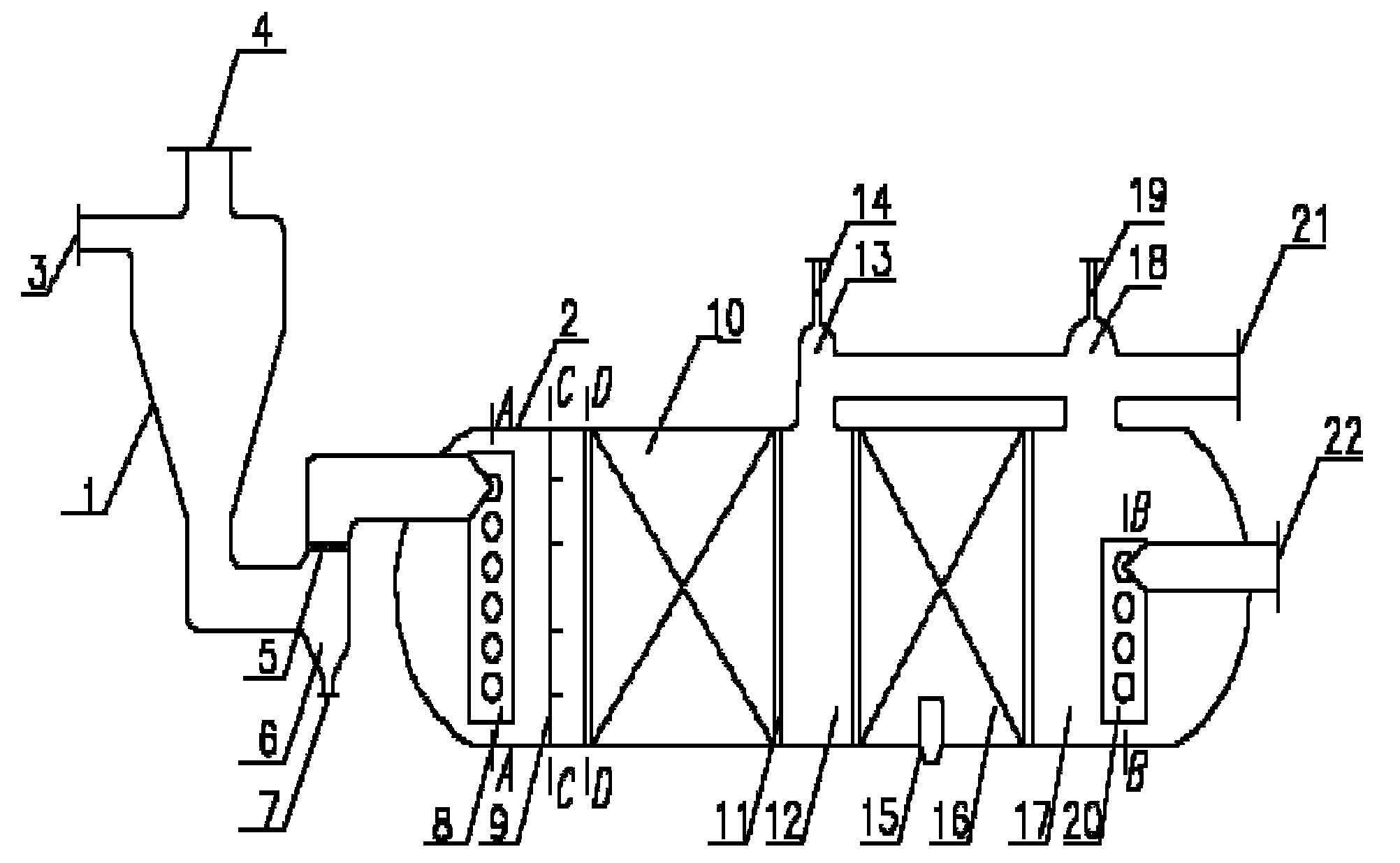

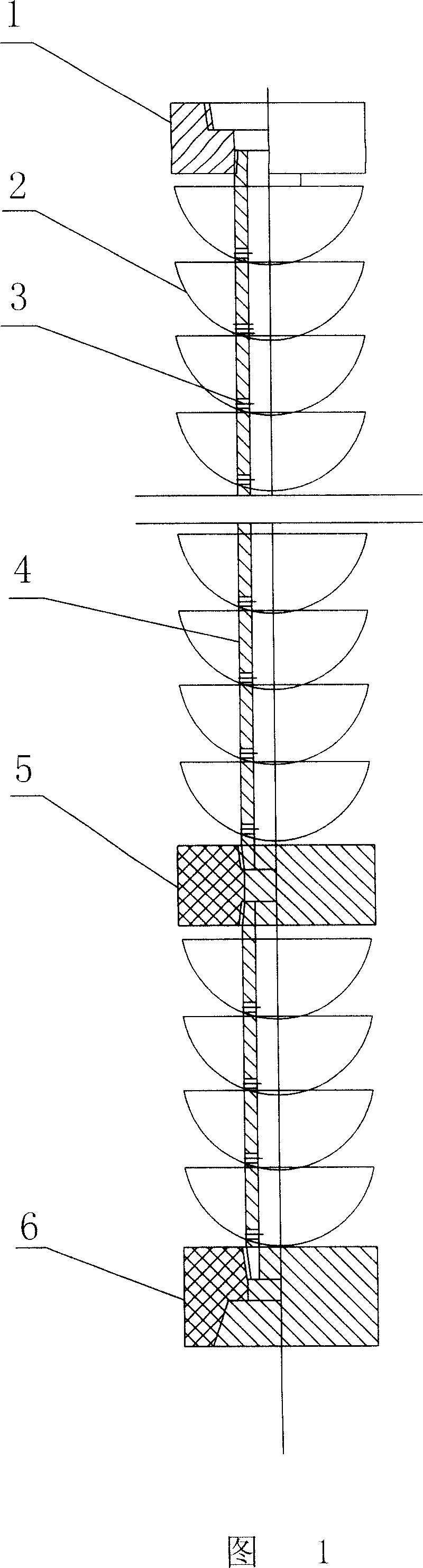

Method for realizing high-water containing same-well injection-production by multi-cup equi-flow type down-hole oil-water separator

The invention is a method for implementing high-water content well same-well injection production by multi-cup uniform-flux underground oil-water separator, characterized in: using multi-cup uniform-flux underground oil-water separator to make the produced liquid from the extracted bed automatically deposit when underground flowing through the separator, after the oil and water are separated from each other, using two lifters to lift and reinject through the respective independent flow channels and the two lifter are respectively called extraction pump and injection pump, the produced liquid with low water content is lifted by the extraction pump through the flow channel of the extraction pump up to the ground and the produced liquid with higher water content is reinjected by the injection pump through the flow channel of the injection pump into the injection bed. And it can perfectly complete underground separation of oil and water, implement economic and effective extraction for high-water content wells and implement water injection for other oil beds in the same well site at the same time.

Owner:DAQING OILFIELD CO LTD +1

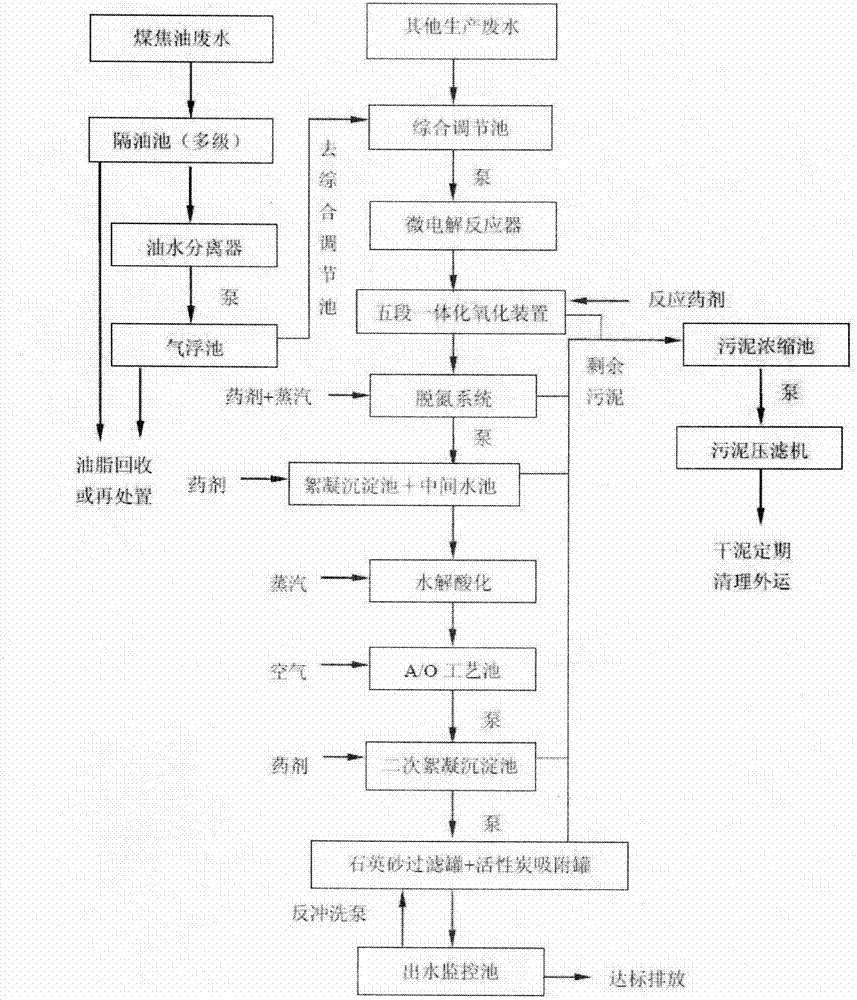

Complete equipment and process for processing coal tar wastewater

InactiveCN103113003AEasy to handleCreate economic valueMultistage water/sewage treatmentChemical oxygen demandElectrolysis

The invention provides complete equipment and process for processing coal tar wastewater, and belongs to the technical field of environmental conservation. The process comprises the following steps of: adopting different removal principles according to different physicochemical properties of heavy oil, light oil and emulsified oil; scientifically and orderly removing the heavy oil, light oil and emulsified oil through three sets of environmental conservation equipment such as a multi-stage oil separator, an oil-water separator and an air floating tank gradually; combining a micro electrolysis reactor with a five-section integrated oxidization device; and firstly destroying a benzene ring by microelectrolysis, and then strongly oxidizing various organic matters through an oxidant, so that the COD (chemical oxygen demand) and the chromaticity are greatly reduced. Ammonia nitrogen can be efficiently removed by a denitrification system; the denitrification system is low on requirements of pH value and temperature, and low in operation cost; the denitrification system is arranged behind the five-section integrated oxidization device; the reaction change of power of hydrogen is fully considered; and the complete equipment complies with the scientific principle, and can be used for reducing feeding of acid and alkali, and lowering the operation cost.

Owner:NANJING ZIDU ENVIRONMENTAL PROTECTION SCI & TECH

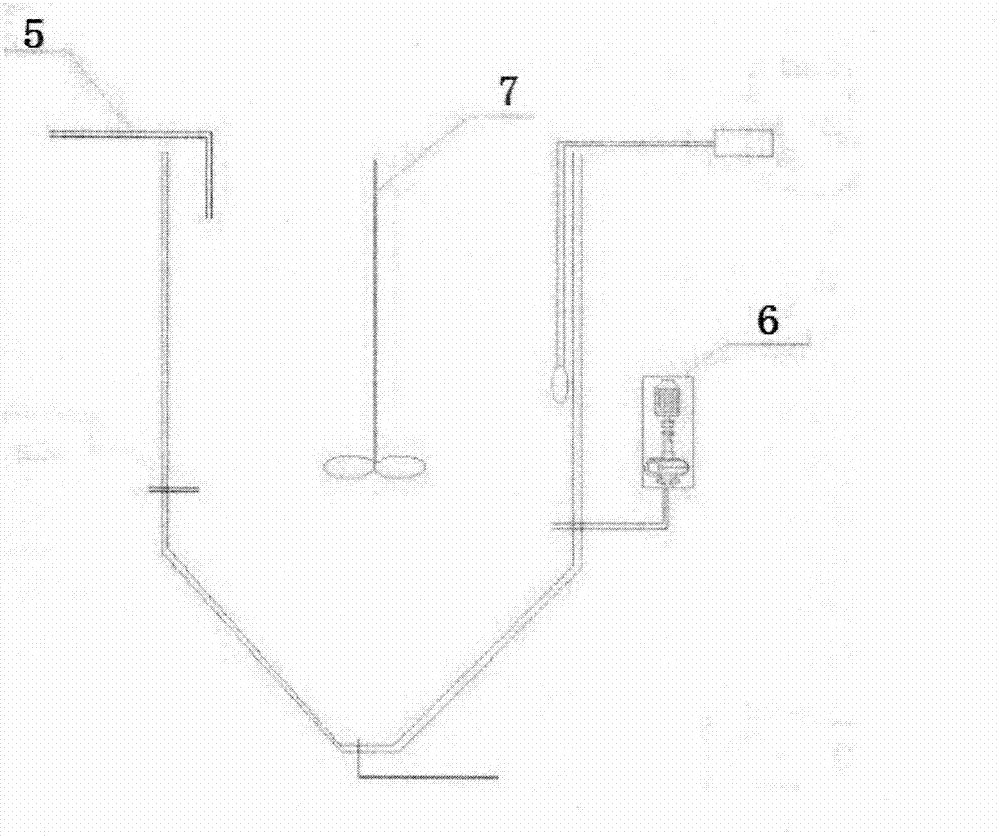

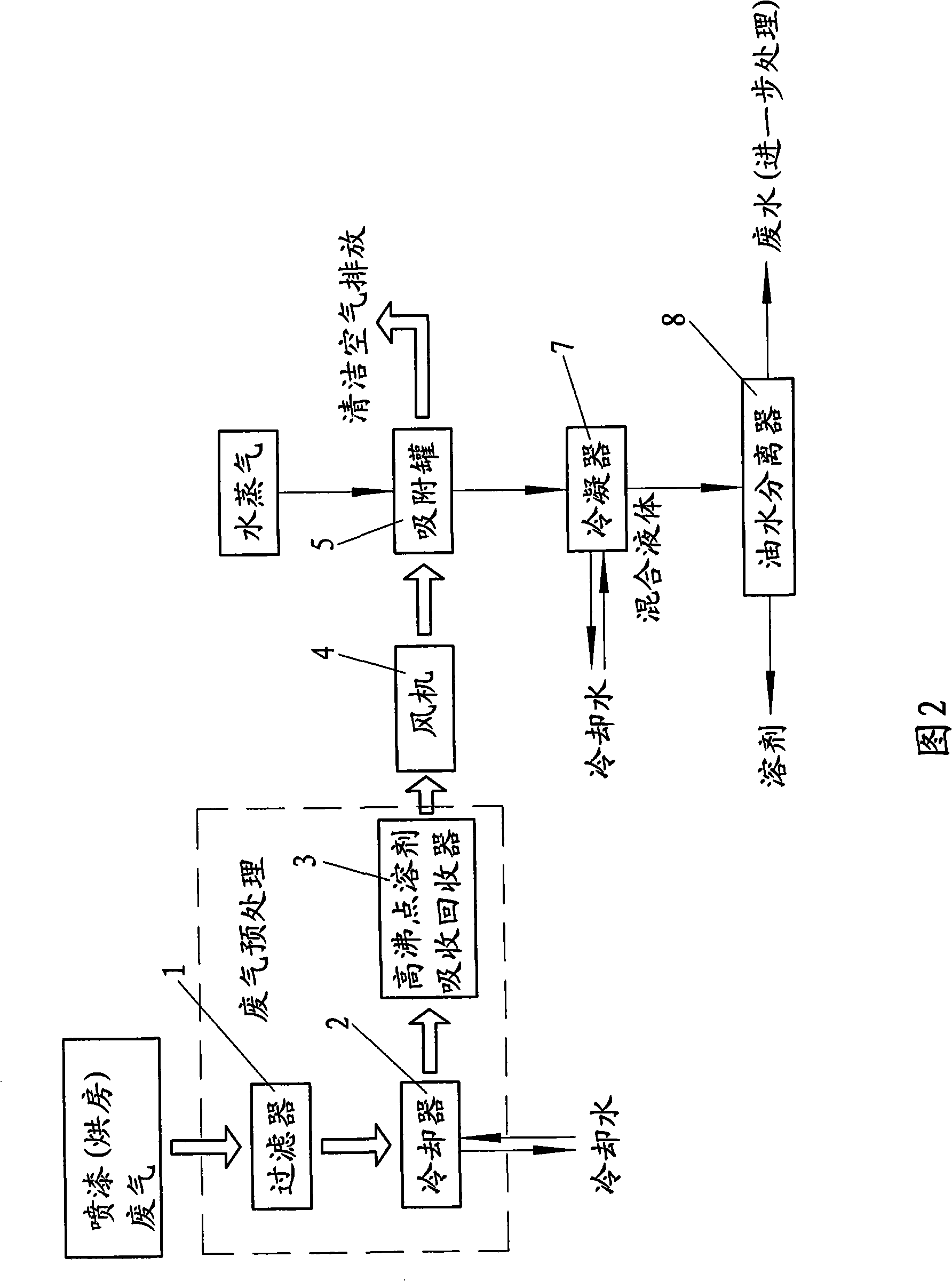

Method for cleaning, recovering and treating painted lacquer exhaust organic gas and device

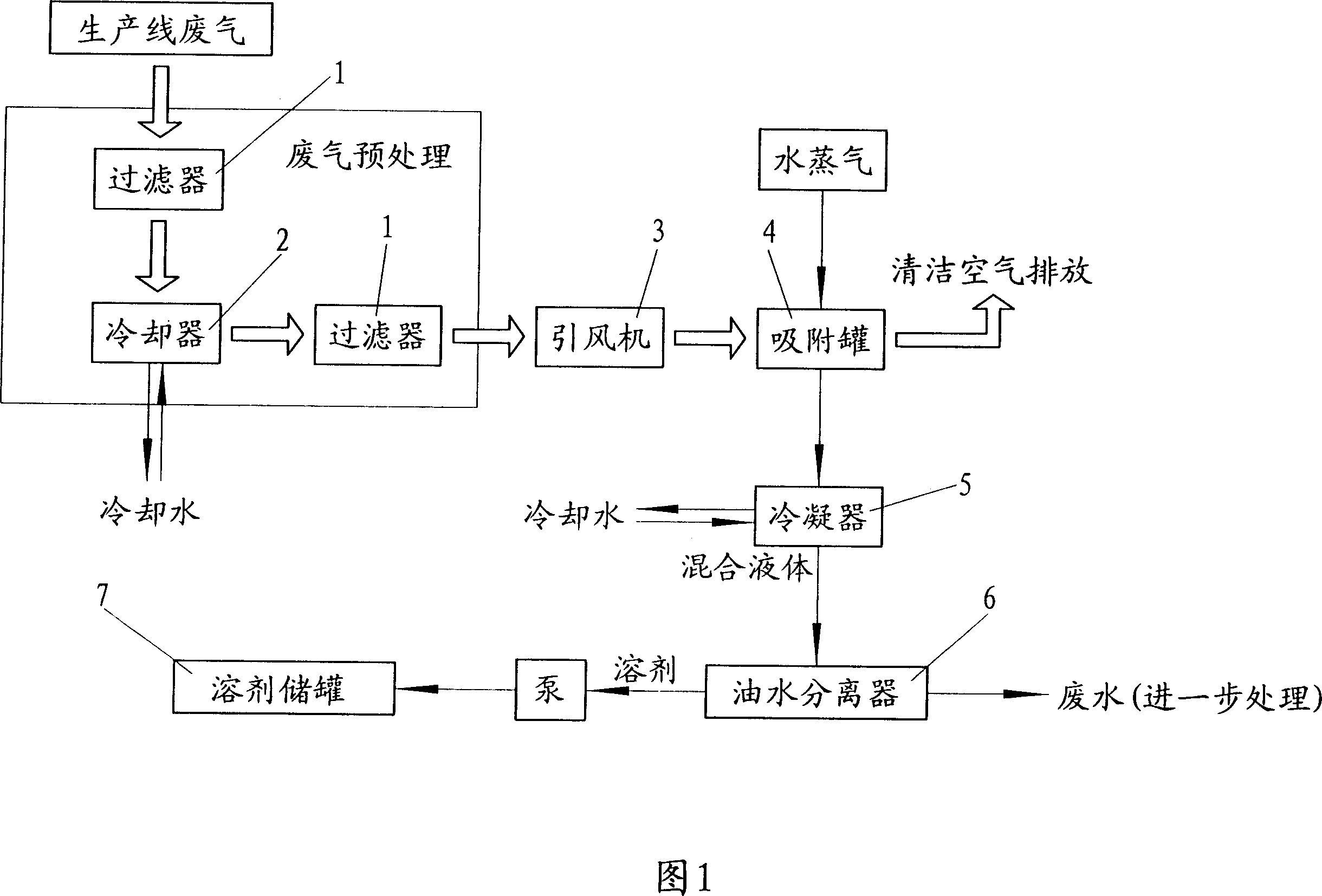

ActiveCN101274150AGuaranteed uptimeDisplay and monitor working status in real timeDispersed particle separationVapor condensationFiltrationLacquer

The invention discloses a spraying paint organic exhaust gas purification recovery disposal method and a device. The method has the steps as follows: (1) the dust and paint mist of the spraying paint organic exhaust gas are removed by filtration, and high boiling point organic solvent component with the boiling point more than 110 DEG C is condensed; (2) a high boiling point solvent absorption recoverer is used for recovering the high boiling point organic solvent; (3) residual organic exhaust gas is sent into an adsorption tank, the organic solvent component in the exhaust gas is adsorbed, and the exhaust gas is exhausted after being adsorbed by the adsorption tank; (4) by adopting a vapour desorption method, the organic solvent adsorbed by the adsorption tank is desorbed; (5) the desorbed solvent steam and vapour are condensed as liquid; (6) the condensed mixed liquid is separated by the oil and water separator, the separated organic solvent can be used again, and the separated wastewater can be disposed separately. Therefore, precious resources can be recovered, secondary pollution can be reduced, the recovered solvent can be used again, and the consumption of energy source can be reduced.

Owner:蔡志煌

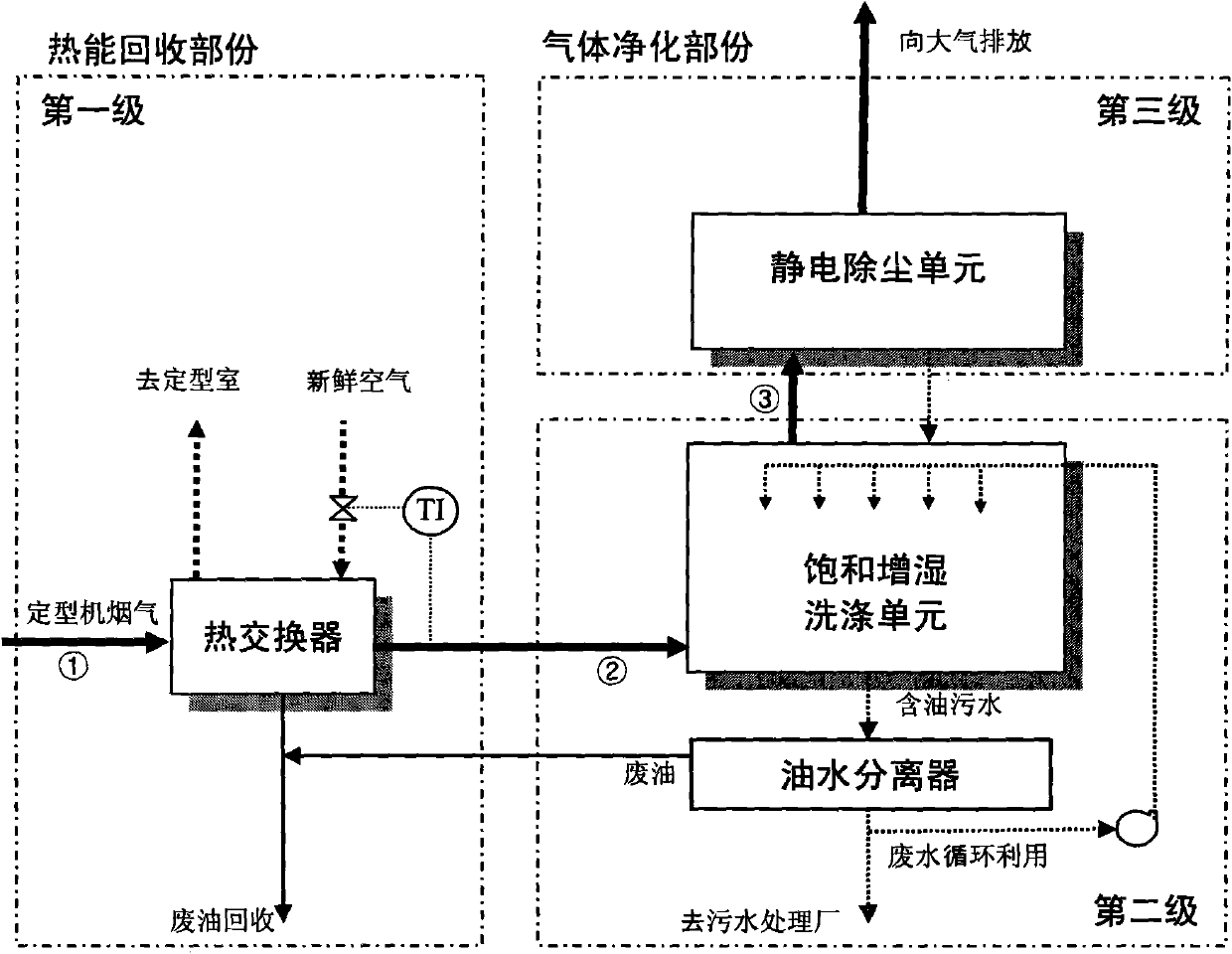

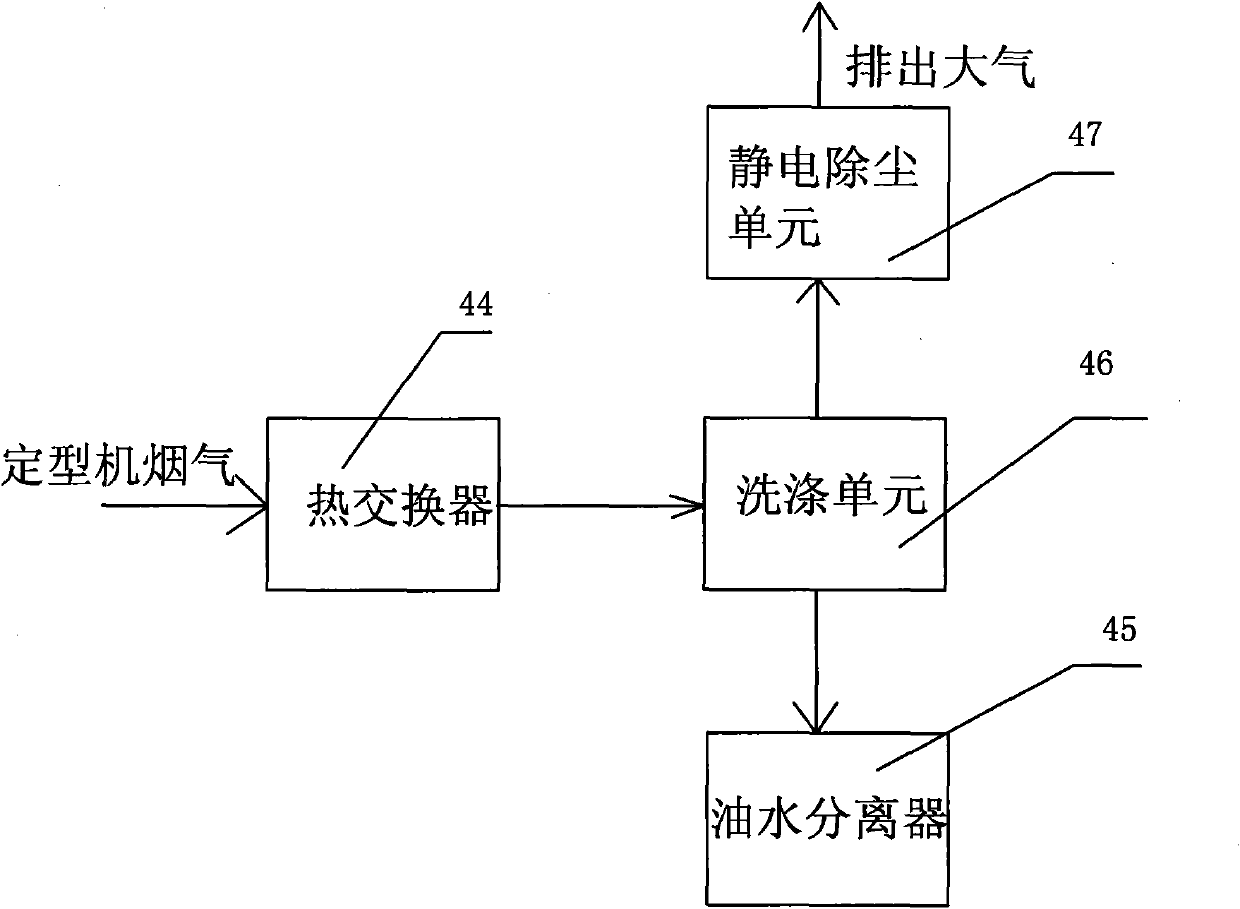

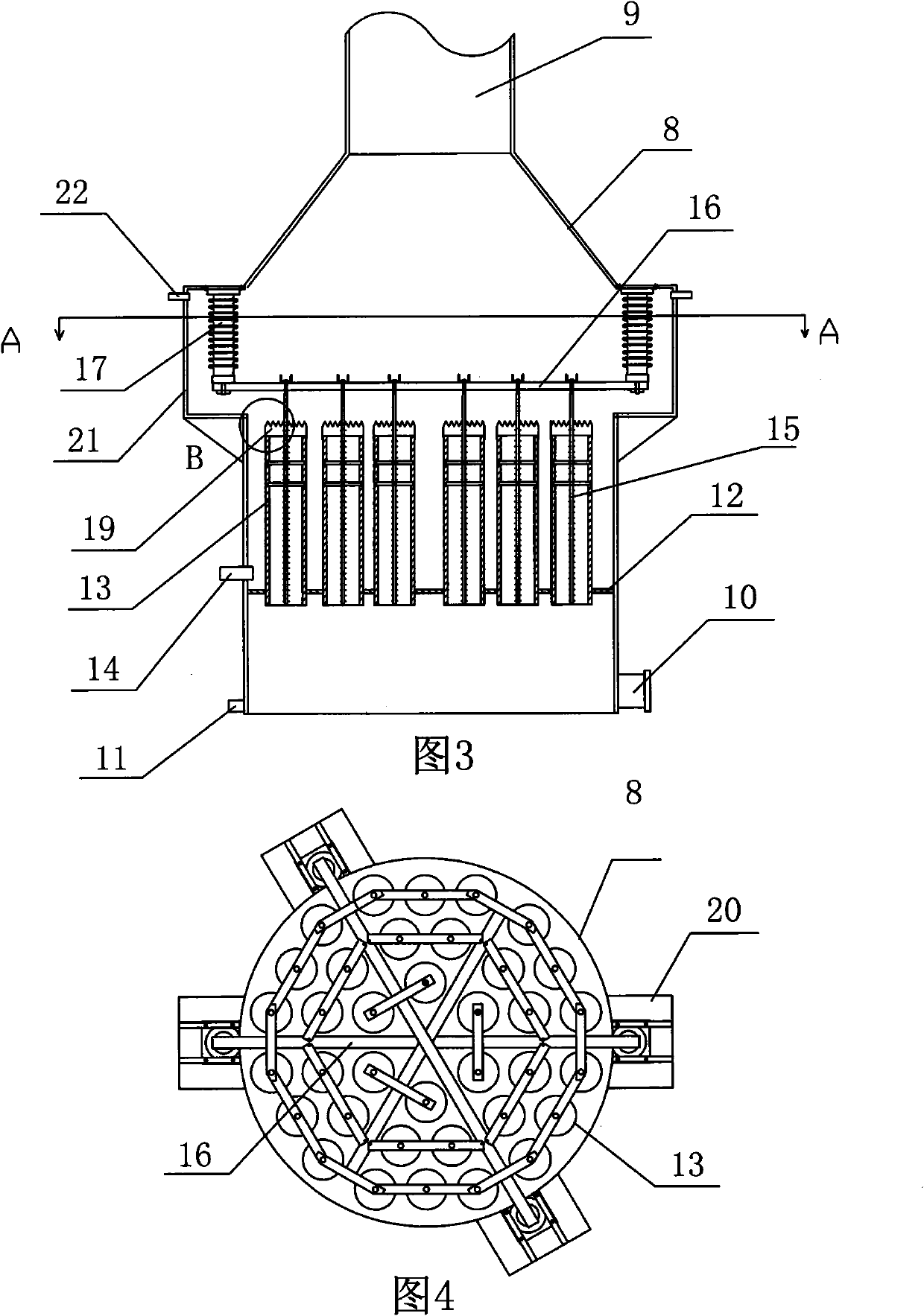

Method for treating flue gas of dyeing and finishing setter

InactiveCN101766943ASave energyReduce the amount of sewageCombination devicesParticulatesHigh density

The invention discloses a method for treating flue gas of a dyeing and finishing setter. The rear end of the setter is provided with a heat exchanger, a washing unit, an oil-water separator and an electrostatic dedusting unit. In the method, (1) the counterflow heat exchange is carried out between the flue gas of the setter and the air by the heat exchanger, the waste heat is recovered, and the energy is saved; (2) the flue gas treated by the heat exchanger enters from the bottom of the washing unit and is sprayed and washed by the spraying liquid in the washing unit, and the flue gas is in counterflow contact with the spraying liquid, so as to remove most soot grains with the grain diameter being more than 1mum; and (3) the flue gas treated by the washing unit is dedusted by the wet-type electrostatic dedusting unit, most soot grains with grain diameter being less than 1mum are attached by electrons with high density, the charged grains move to the wall of a condensation pipe directionally and are collected and captured by the wall of the pipe, and the liquid film on the inner wall of the condensation pipe is updated continuously, thereby achieving the self-cleaning function of the inner wall of the condensation pipe.

Owner:NINGBO UNIV

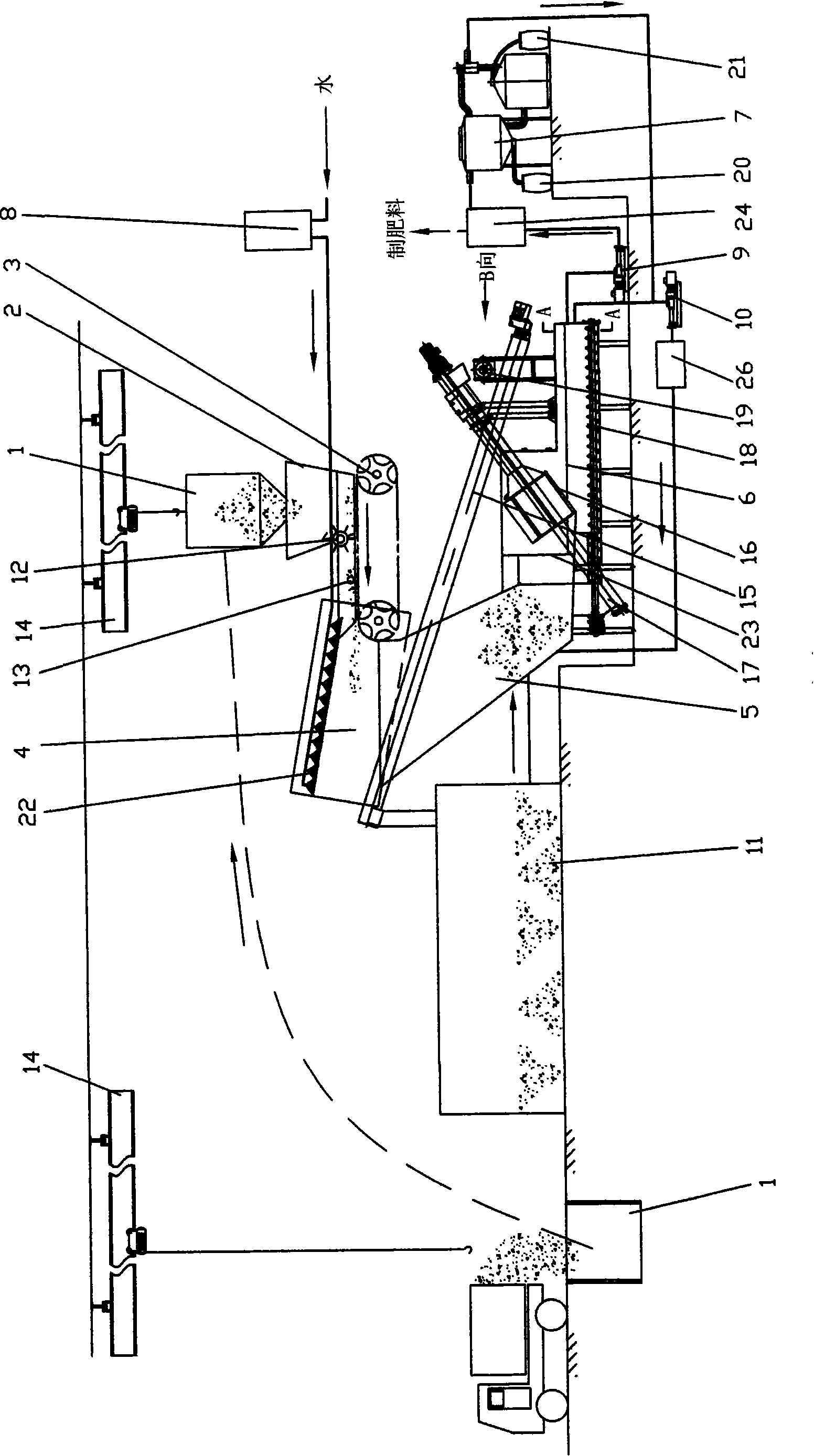

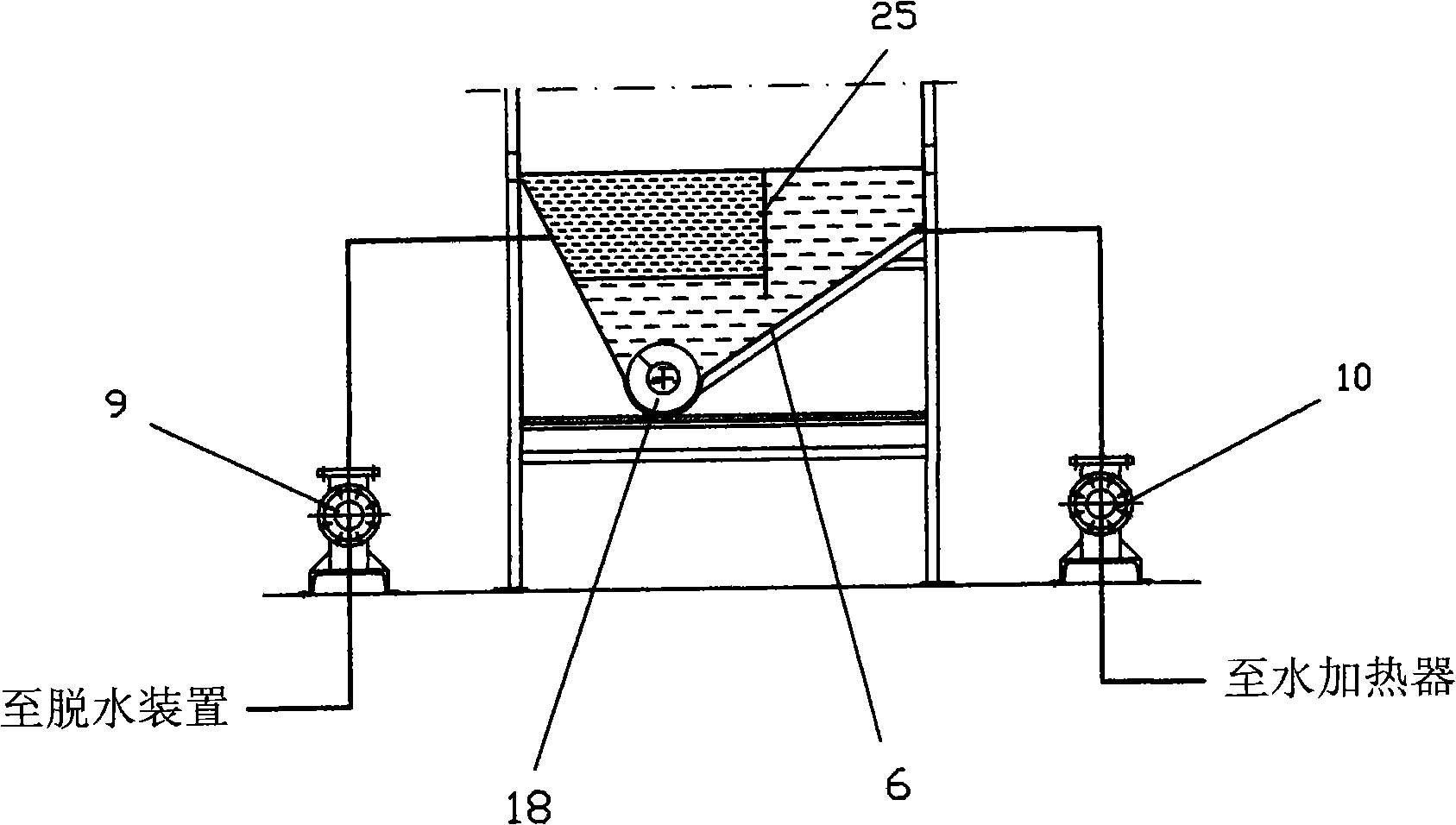

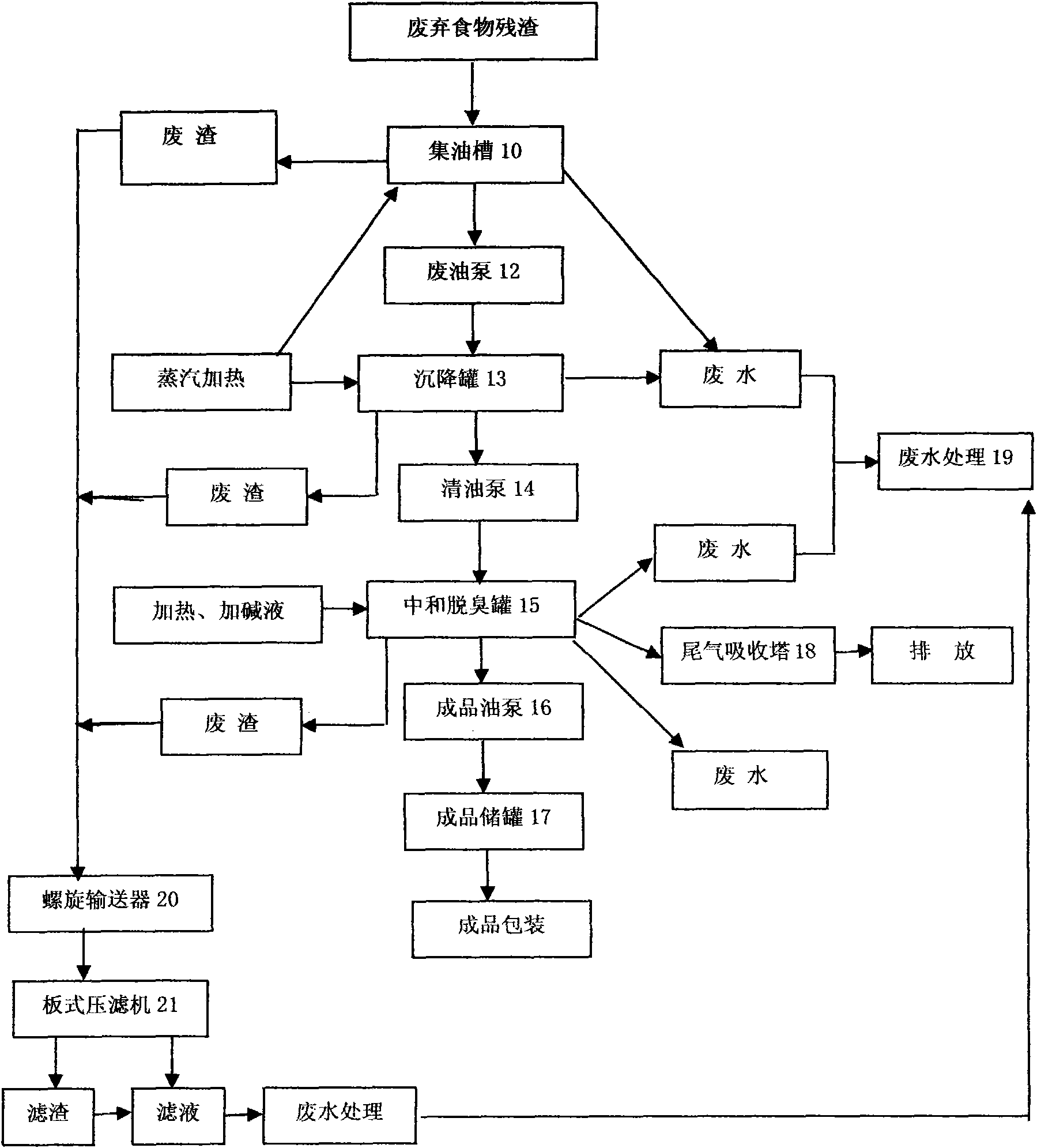

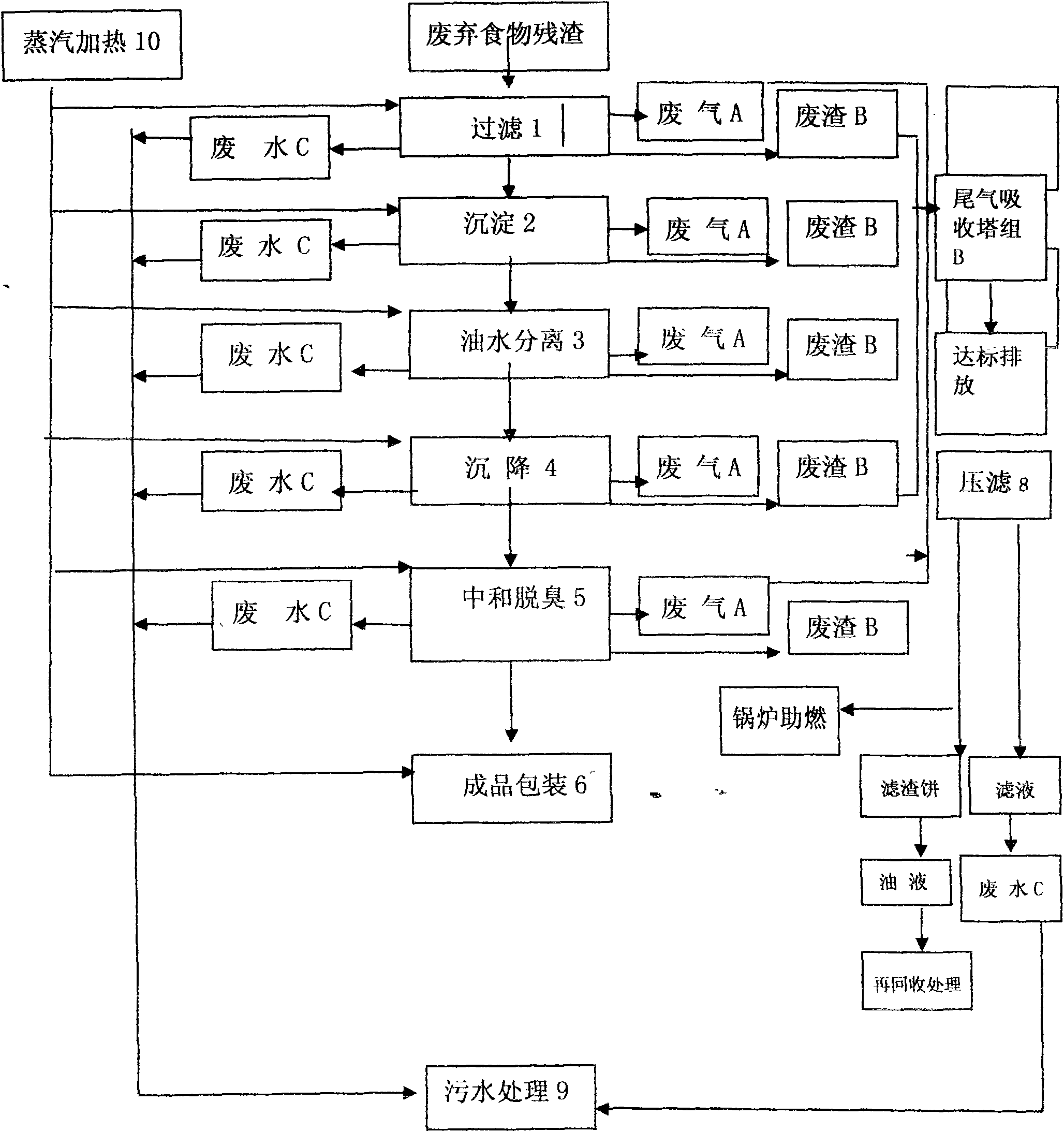

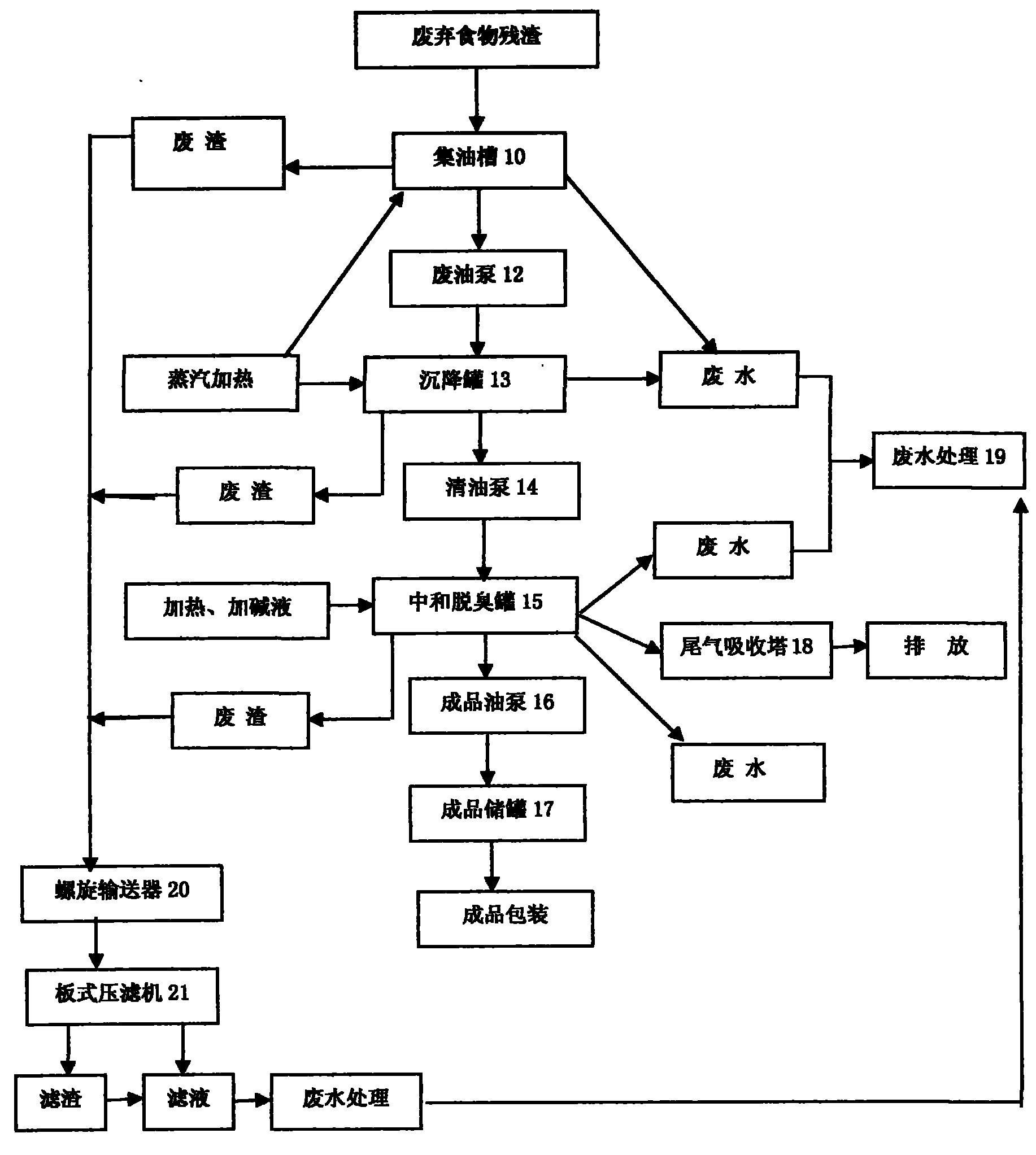

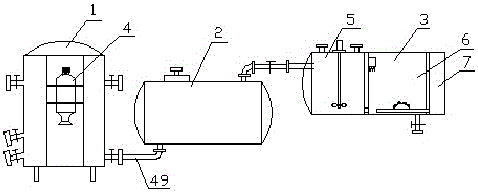

Industrialized treatment facility and method for catering wastes

InactiveCN102051267AAvoid secondary pollutionRealize recycling of resourcesFatty oils/acids recovery from wasteFatty/oily/floating substances removal devicesChemical treatmentBiodiesel

The invention discloses an industrialized treatment facility and method for catering wastes. The facility is composed of a filter, an oil-water separator, an oil sump, a sedimentation tank, a neutralization and deodorization tank, a storage tank, a tail gas absorption system, a waste water treatment system and a waste residue treatment system, wherein the filter and the oil-water separator are arranged in the oil sump, the oil sump, the sedimentation tank, the neutralization and deodorization tank and the storage tank are sequentially communicated; a waste water pump is arranged between the oil sump and the sedimentation tank, and a boiled oil pump is arranged between the sedimentation tank and the neutralization deodorization tank; and the tail gas absorption system is respectively communicated with the filter, the oil-water separator, the sedimentation tank and the neutralization and deodorization tank. The production process in the invention comprises six procedures of solid-residue separation, oil-water separation, neutralization and deodorization, tail gas purification, sewage treatment and waste residue treatment. In the invention, catering wastes are subjected to physical and chemical treatment under the close condition, and no waste gas, waste residue or waste water is discharged; separation, deodorization, decolourization and other technologies are utilized to separate waste oil from the catering wastes, and the waste oil is used for producing industrial production raw materials of biodiesel, lubricating grease and the like; and 'three wastes' produced in the production process are recycled by adopting chemical and physical methods, thus biomass fuel, reuse water for life and purified air are obtained. The invention thoroughly avoids secondary pollution in waste oil refining and separating process and realizes recycling of waste water, waste gas and waste residue.

Owner:XIAN ZHONGRUN ENVIRONMENTAL PROTECTION TECH

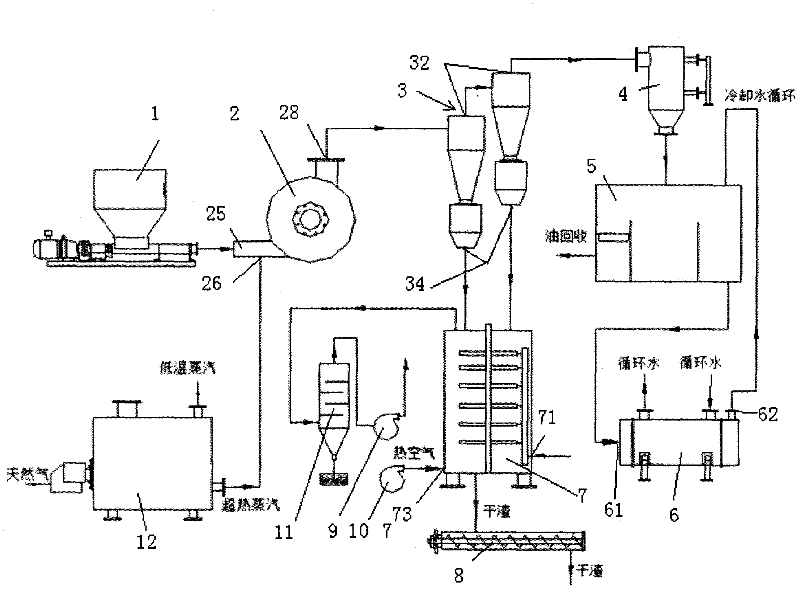

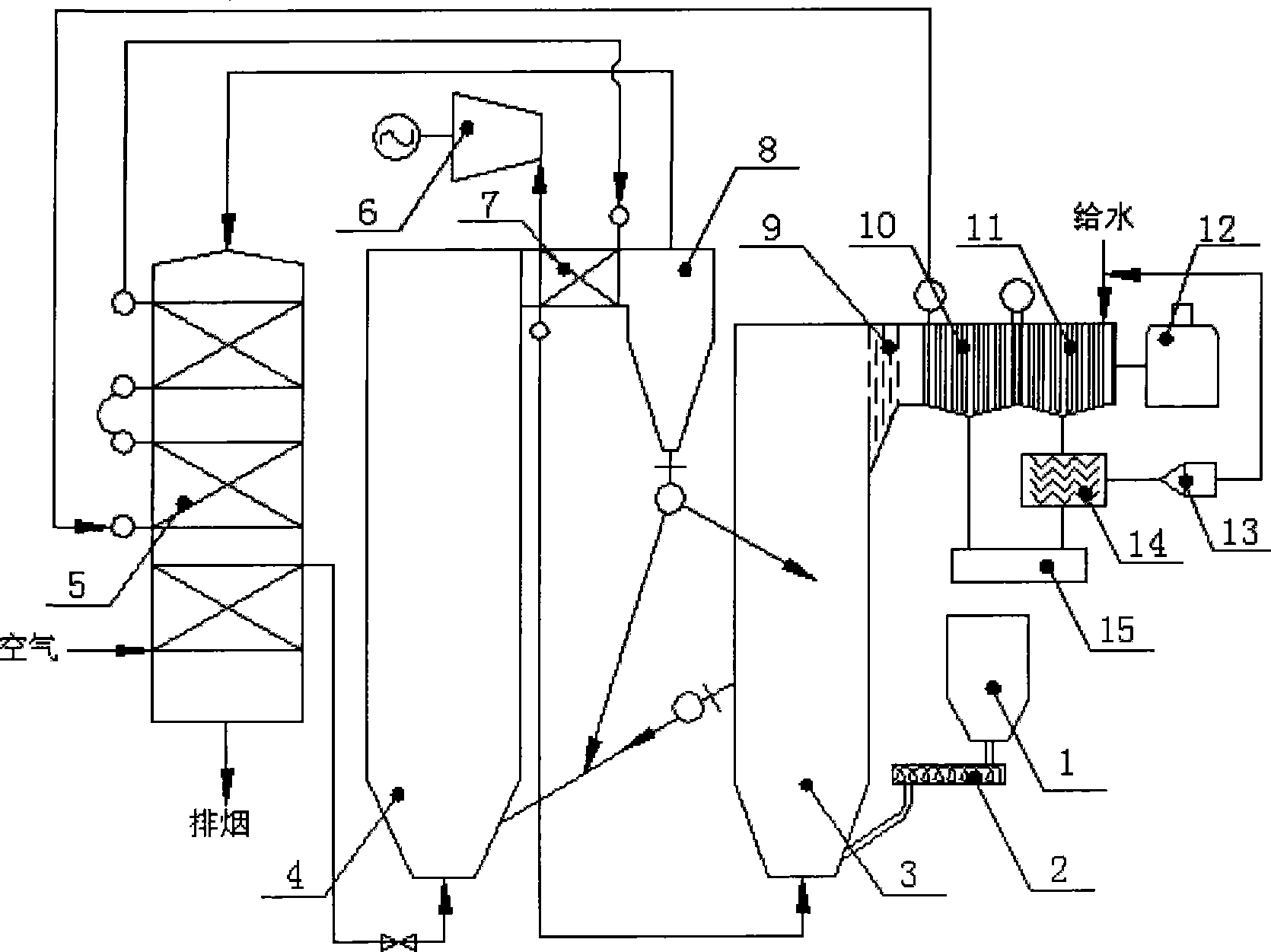

Oil shale fluidized bed dry distillation system

InactiveCN101440293ARealize scientific utilizationImprove heat transfer efficiencySpecial form destructive distillationWater vaporOil shale gas

The invention relates to a carbonization system of an oil shale fluidized bed. Oil shale with high oil content and low pyrolysis temperature is used as a carbonization material; high-temperature steam-gas and circulating hot ash are utilized to fluidize and heat the oil shale in a carbonization chamber of the fluidized bed; after ash removal, mixed airflow of generated shale oil and noncondensable gas and vapour in the carbonization chamber of the fluidized bed enters a cooler; the condensed oil-water mixture is divided into shale oil and water through the oil-water separator; the shale oil is transported to a shale oil storage tank; the water is purified and is conducted to the cooler; and noncondensable gas which is not condensed through the cooler is transported to a fuel gas storage tank. Oil shale carbocoal produced through the carbonization chamber of the fluidized bed is directly transported to a boiler of an oil shale carbocoal circulating fluidized bed, is burned and discharges heat; one part of the produced steam-gas is used as fluidized wind of the carbonization chamber of the fluidized bed; the residual steam-gas is conducted to a steam turbine-dynamo system, applies work and generates electricity; and part of circulating ash in the boiler is used as a heat source of the carbonization chamber of the fluidized bed. The carbonization system can realize high-efficient, clean and economic comprehensive utilization of the oil shale.

Owner:SHANGHAI JIAO TONG UNIV

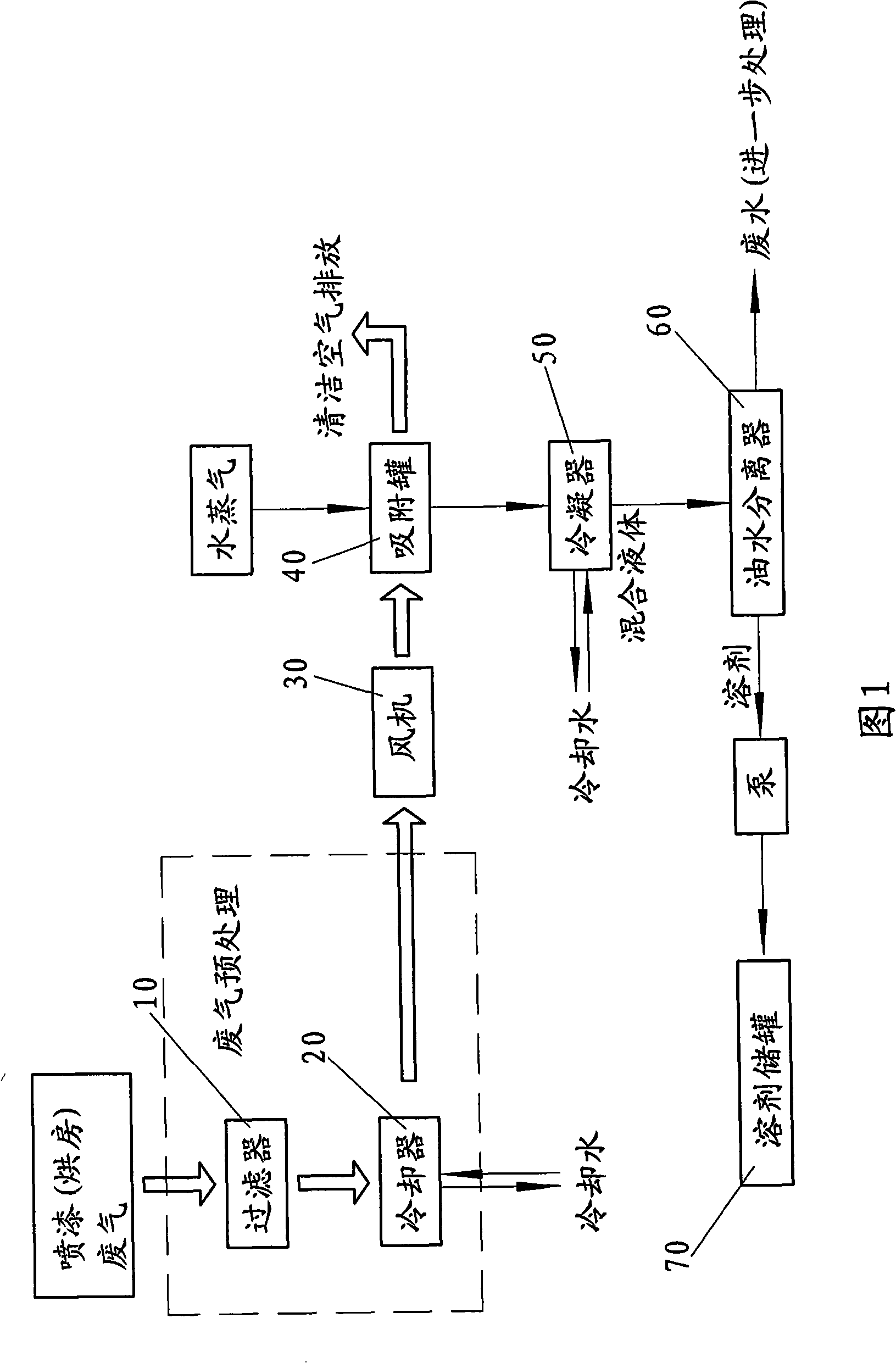

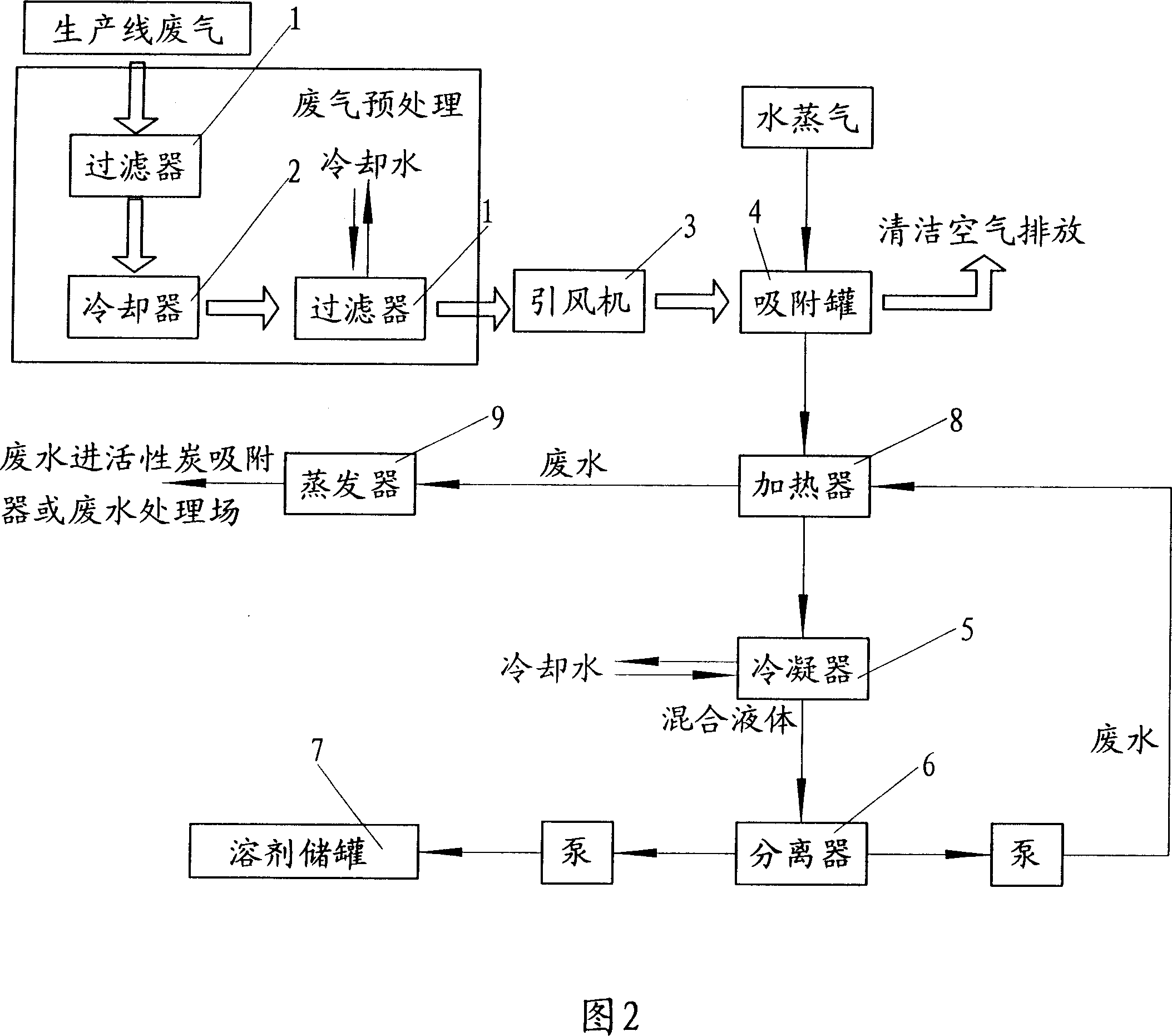

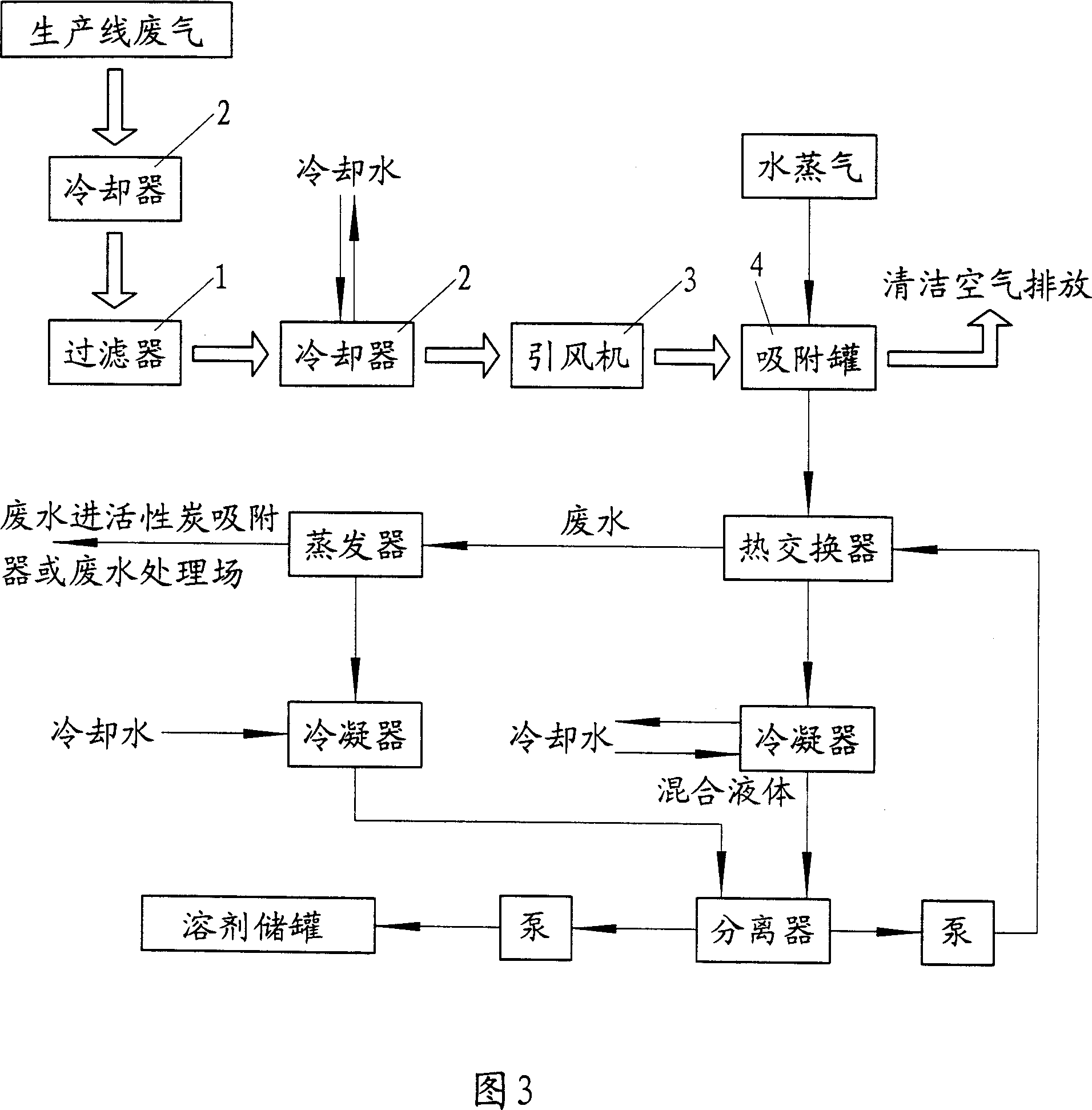

Method for recovering organic waste gas

InactiveCN101125274AReduce reprocessing costsImprove recycling efficiencyDispersed particle separationVapor condensationRecovery methodWater vapor

The present invention discloses a recovery method of the organic waste gas, which comprises the following steps: firstly, the organic waste gas is pretreated in a strainer and a cooler; secondly, adsorbed by an adsorption tank, then desorbed by the water vapor after having a saturated adsorption, the desorbed mixed gas is condensed by the condenser again, then came into an oil-water separator, separating the solvent and the waste water; a dividing wall type heat exchange waste water heater is added between the adsorption tank and the condenser; the waste water separated from the oil-water separator is sent to the waste water heater, utilizing the excess heat of the water vapor desorbed from the adsorption tank, heated by the dividing wall type heat exchange, vaporizing the remnants solvent of the waste water; the solvent after vaporizing has a recycle treatment, the rest waste water after vaporizing comes into another active carbon absorber or sewerage station, adsorbing the micro-solvent of the sewerage until coming up to the standards, then being drained. The present invention utilizes the most of the excess heat of the water vapor desorbed from the adsorption tank to heat the sewerage, reduces the organic solvent content of the sewerage, enhances the recovery efficiency, reduces the reprocessing cost of the sewerage, and reduces the secondary pollution.

Owner:蔡志煌

Oil-water separator

ActiveCN103663851ASolve environmental problemsReduce processing linksFatty/oily/floating substances removal devicesMultistage water/sewage treatmentSlagSludge

The invention discloses an oil-water separator comprising a water inlet, a water outlet, a container, a movable filter residue bucket, a fixed filter net, an oil storage area, a vortex shallow filter, a sludge bucket, an electronic integration controller, an oil suction port, a slag suction port and a biological filter disc, wherein the fixed filter net finely filters the wastewater; an oil drop of which the diameter is 10-100 microns is separated and ascended to the oil storage area in the vortex shallow filter; the sludge bucket concentrates the waste residue; the waste residue descends to the bottom of the sludge bucket to be gathered under the effect of gravity after participating on the sludge bucket; the oil suction port is used for absorbing oil; the slag suction port is used for absorbing the slag; the biological filter disc is used for discharging the residual sewage. By adopting the oil-water separator, the environment-friendly problem of emission of restaurant waste water is solved, so that the discharged water achieves the corresponding national emission standards, the congestion problems of drainage pipelines caused by waste oil wall built-up are solved, separated excessive oil impurities are solved, and the processing link of restaurant waste oil in specified use is reduced.

Owner:CLEAR SUZHOU ENVIRONMENTAL TECH CO LTD

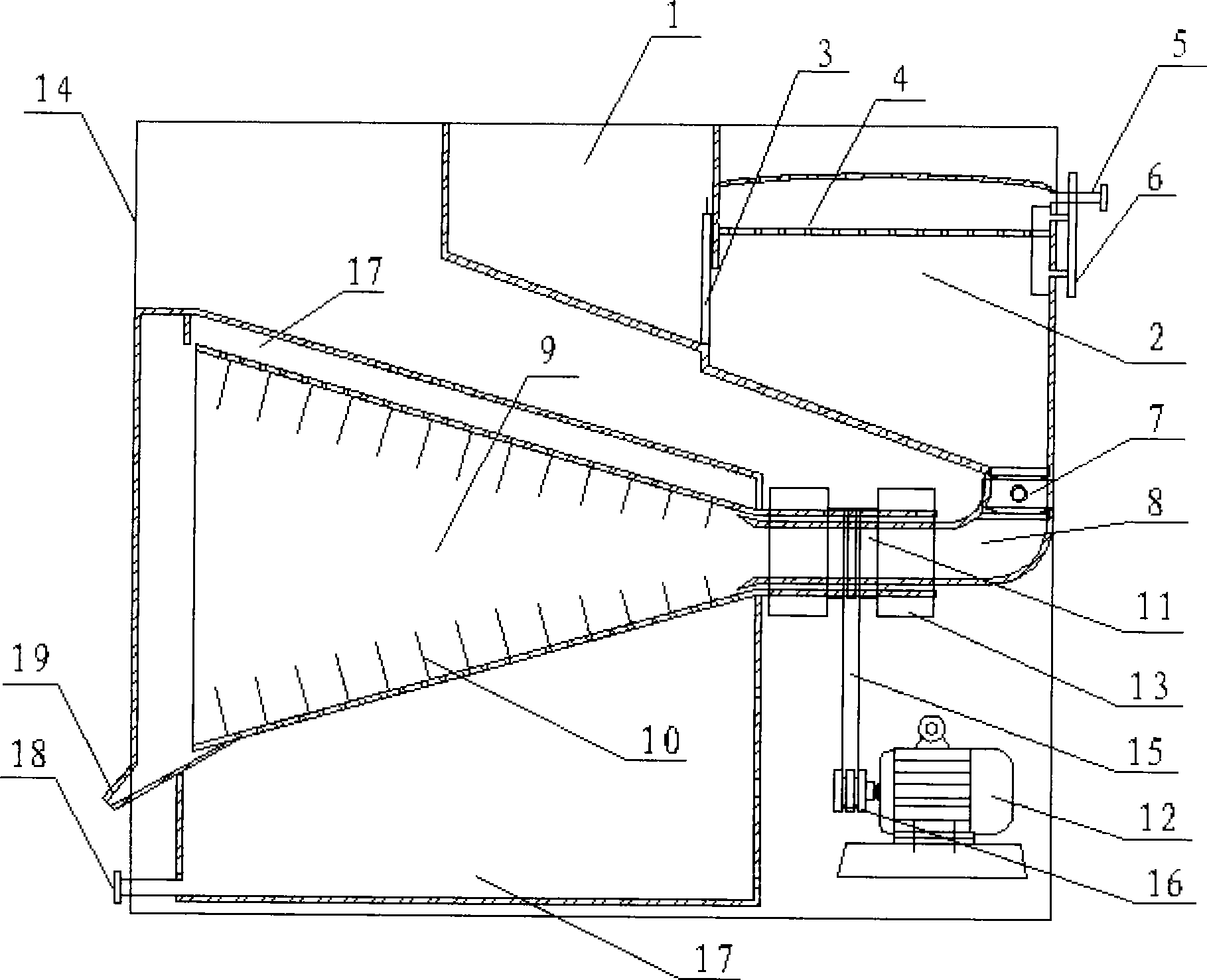

Solid-liquid separator suitable for kitchen waste

InactiveCN101480541AAchieve moderate dehydrationShort stayRotary centrifugesLiquid separationResource utilizationLiquid storage tank

The invention discloses a solid-liquid separating device for kitchen wastes, which is used for the preliminary treatment of the resource utilization of the kitchen wastes. The invention can effectively separate the kitchen wastes into oil, water and solid matters and can further carry out separate treatment and decrement transportation to shorten the dwell time of the kitchen wastes from production to collection, transportation and treatment, control contamination at a source, reduce the loss of raw materials caused by rottenness and deterioration, and reduce the environmental pollution. The solid-liquid separating device for the kitchen wastes is of a totally sealed structure; and a main component comprises a feeding cylinder, an oil-water separator, a solid-liquid separator, a liquid storage tank, a transmission device, and the like. The invention has the advantages of simple structure, convenient operation, little power consumption, and the like, can effectively achieve the intermediate dehydration and the oil removal of raw materials of the kitchen wastes, and satisfies the demands on the post-treatment and the utilization of solid materials, thereby effectively improving the efficiency of the further resource utilization of the kitchen wastes.

Owner:北京青龙河技术开发有限公司

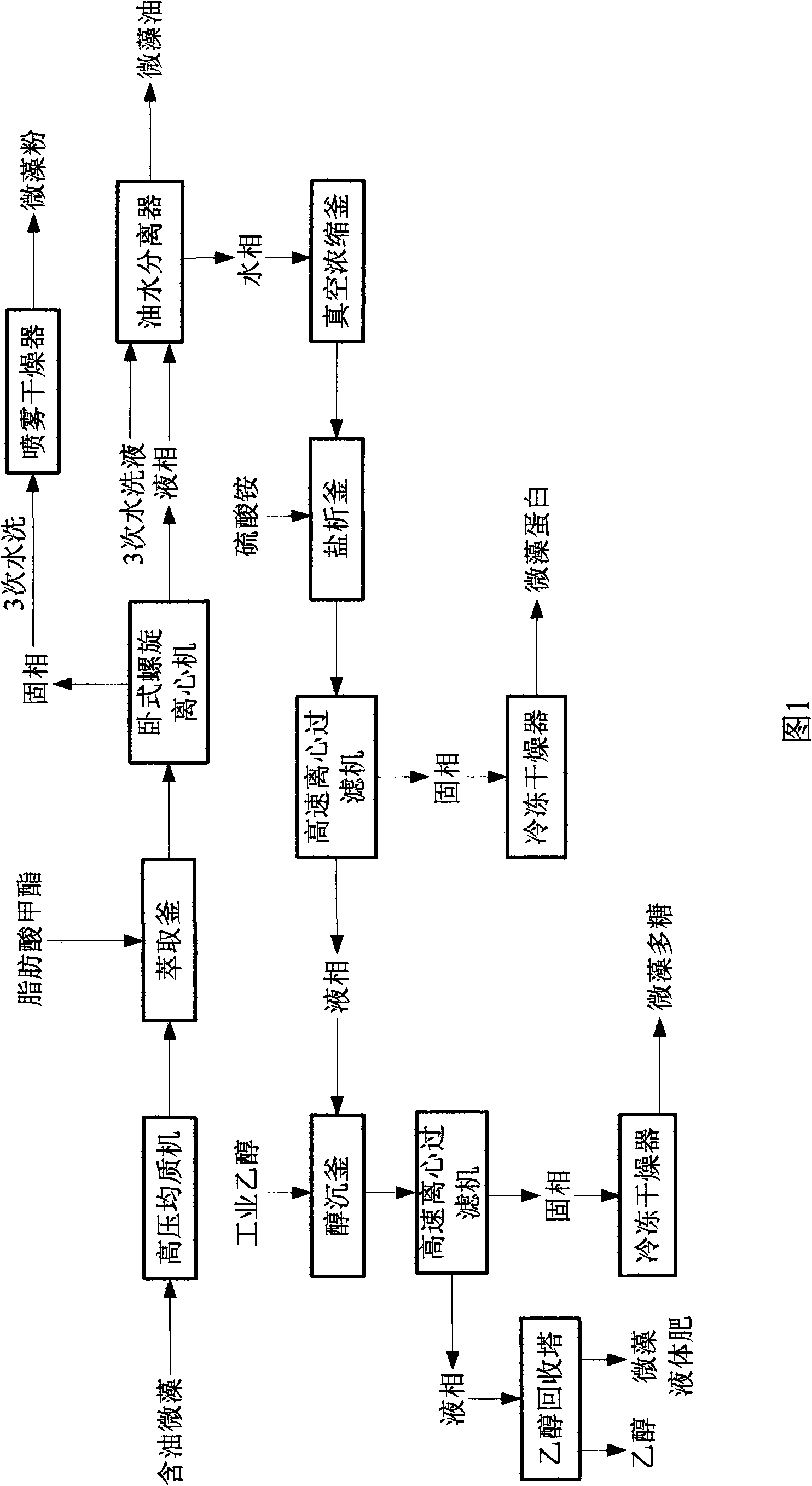

Production method for fully using oil-containing micro-algae

InactiveCN101352249AImprove broken rateSimple production equipmentPeptidesLiquid hydrocarbon mixture productionOil phaseHigh pressure

The invention relates to the filed of microalgae utilization engineering, in particular to a production method for fully utilizing oleaginous microalgae. The method is characterized in that the wall of the microalgae is broken by a high-pressure homogenization method, and the solid phase and liquid phase are separated out by an extraction kettle and a horizontal spiral centrifuge, and microalgae powder is made from the solid phase by a spray dryer. An oil phase and a water phase are separated from the liquid phase by an oil-water separator, and the oil phase is microalgae oil. A solid phase and a liquid phase are separated from the water phase by a vacuum concentration kettle, a salting-out kettle and a high-speed centrifugal filter, and microalgae protein is made from the solid phase by a freeze dryer or a spray dryer. A solid phase and a liquid phase are separated from the liquid phase by an alcohol precipitation kettle and the high-speed centrifugal filter, and microalgae polysaccharide is made from the solid phase by the freeze dryer or the spray dryer, and ethanol and microalgae liquid fertilizer are made from the liquid phase by an ethanol recovery tower. The invention is a good production method which requires low investment, has simple operation and can comprehensively use microalgae on a large scale, and can produce semi-finished products with high added value, such as the microalgae oil, the microalgae powder, the microalgae protein, microalgae polysaccharide, the microalgae liquid fertilizer, etc.

Owner:云南圣草峰生物科技有限公司

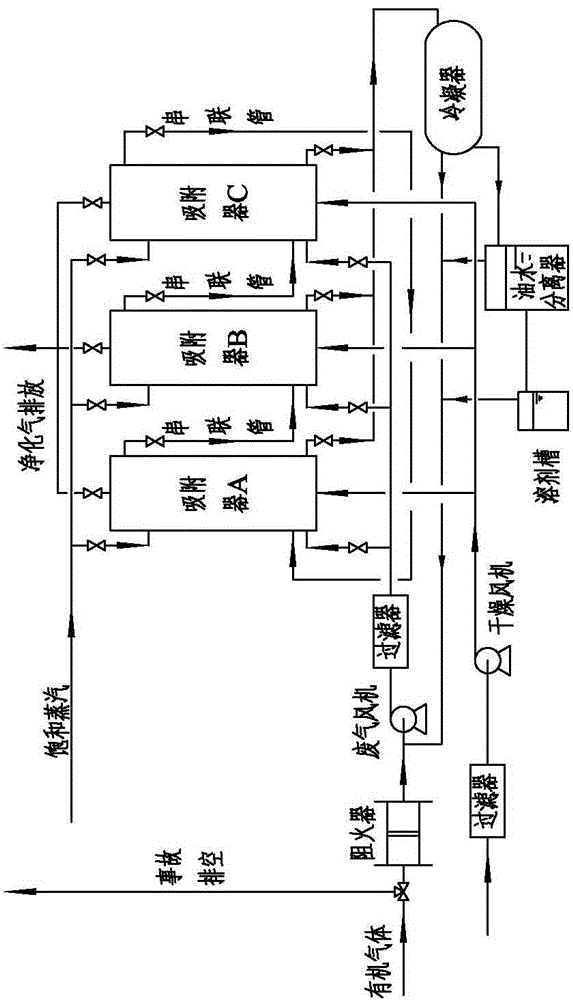

Method for multistage adsorption and recovery of organic gases through active carbon fiber

InactiveCN104906917AGuaranteed emission standardsFlexible operationDispersed particle separationFiberOrganic solvent

The invention provides a method for multistage adsorption and recovery of organic gases through active carbon fiber. All adsorbers can operate the organic gases in a series-parallel manner through series tubes arranged between every adjacent adsorbers to realize multistage adsorption of the organic gases, the highest adsorption grade can reach (N-1) grade (N is the quantity of the adsorbers contained in a system), and the opening or closure of the series tubes can be controlled to switch the adsorption grade between 1 and (N-1). After the adsorbers are saturated, saturated steam is used to desorb the adsorbers, desorbed steam is processed through a condenser and an oil-water separator, and an organic solvent is recovered. The desorbed adsorbers are dried and regenerated by air or an inert gas, then enter an adsorption process, and respectively work according to the above flow in a circulating manner, and the last stage adsorption in the adsorption process is desorption of the regenerated adsorbers. Compared with present multistage adsorption technologies, the method has the advantages of agile operation, low running cost, small device investment, high adsorption grade and obvious investment saving.

Owner:北京日新达能技术有限公司

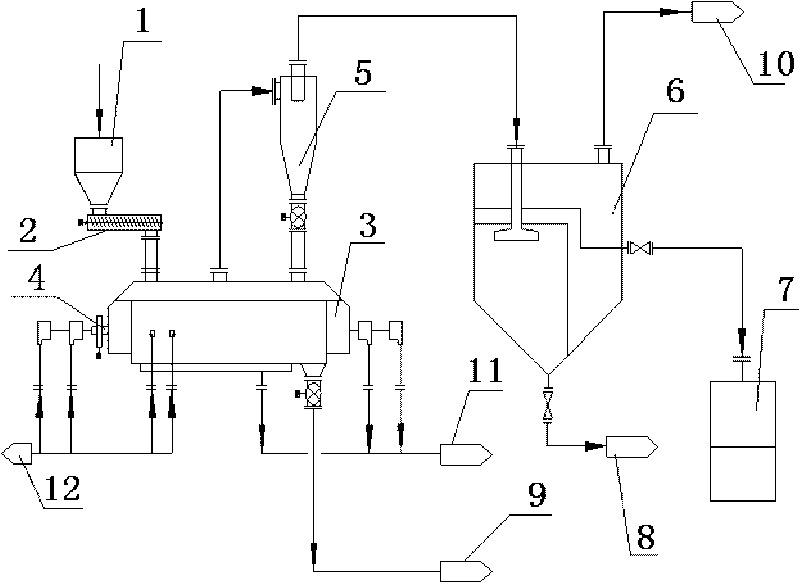

Oil field oil sludge drying treatment combined device and oil sludge drying treatment technique

ActiveCN101759344ARealize resourcesAchieve reductionSludge treatment by de-watering/drying/thickeningOil fieldOil sludge

The invention relates to an oil field oil sludge drying treatment method, in particular to an oil field oil sludge drying treatment combined device and an oil sludge drying treatment technique, being technically characterized in that oil sludge with the moisture content of about 80% is firstly added into a sludge hopper from an oil sludge inlet, and the wet sludge is sent into a paddle dryer by the sludge hopper through a lower screw conveyer; a hollow shaft of the paddle dryer as well as a hollow blade and a dimple jacket which are arranged on the hollow shaft are internally communicated with a high temperature heating medium, so that the sludge can be treated by drying; oil-water mixed steam with moisture evaporated out from the paddle dryer enters the cyclone separator, and trace sludge dust enters the cyclone separator, so that gas-solid separation can be carried out; the trace sludge dust returns back into the paddle dryer, and the purified moisture enters an oil-water separator for cooling and separating oil and gas; and the oil is recovered into an oil storage tank. The oil field oil sludge drying treatment combined device and the oil sludge drying treatment technique have the advantages of shrinkage, harmlessness and reclamation.

Owner:XIAN CHANGQING TECH ENG

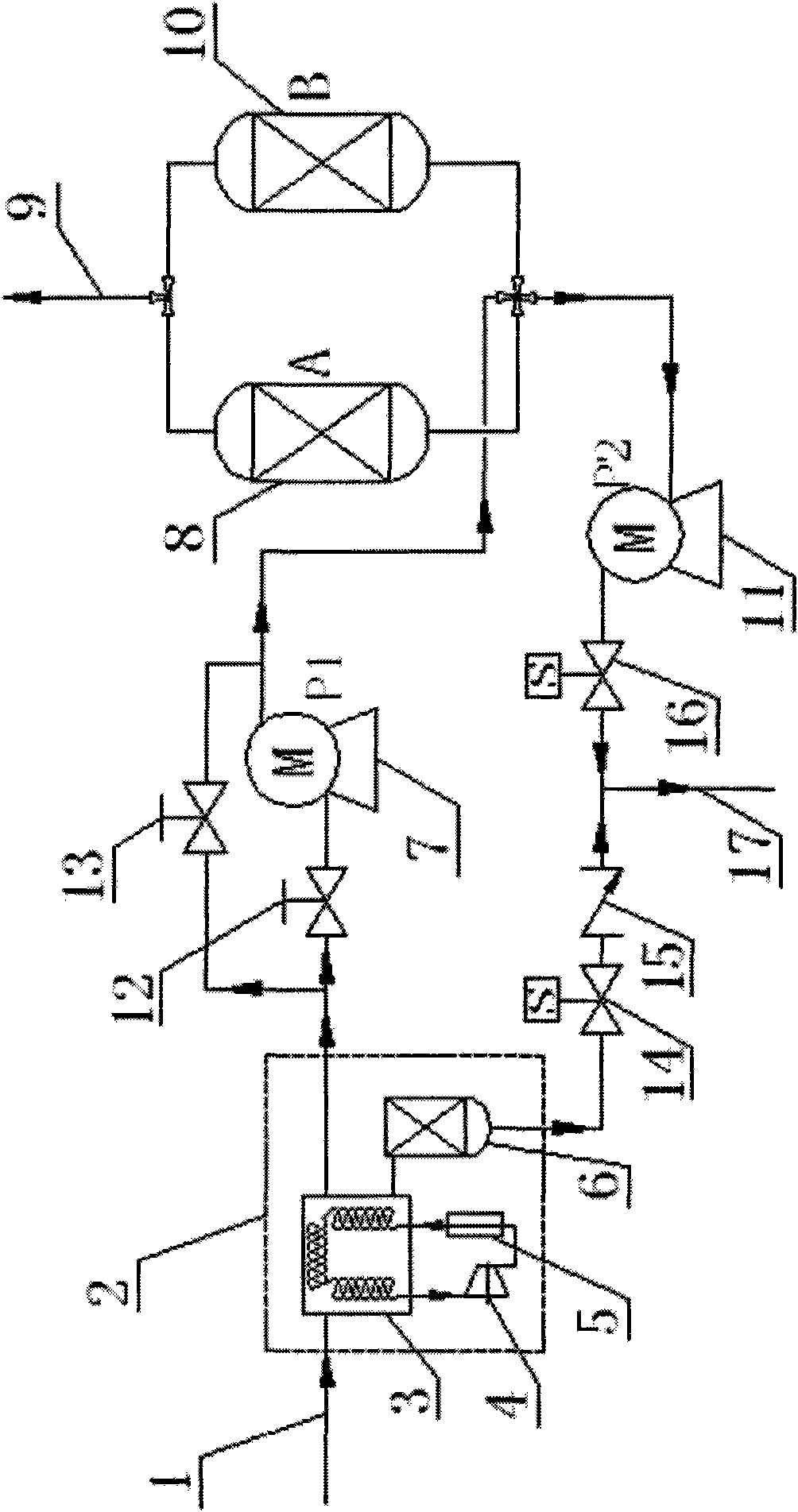

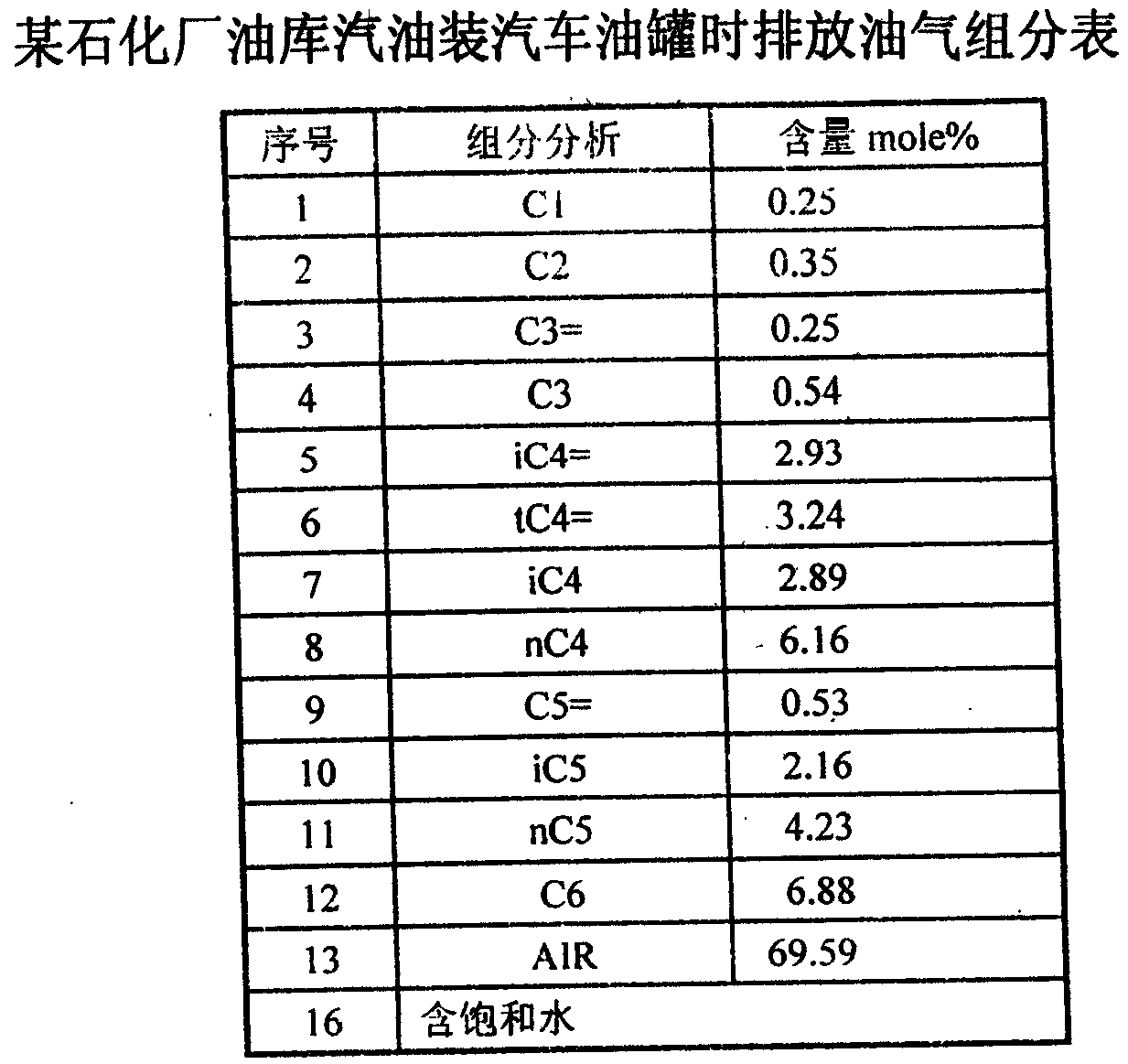

Device and method for recovering oil gas by condensation-adsorption combined technology

InactiveCN101579596ARelieve pressureReduce trafficDispersed particle separationVapor condensationGas collecting tubeAtmospheric air

The invention relates to a device and a method for recovering oil gas by adopting a condensation-adsorption combined technology. The whole technical proposal is characterized in that a mixed gas of various oil gases and air generated during various storage and transportation processes enters a condensing unit with an integrative structure which consists of an evaporator, a compressor, a condenser and an oil water separator through a gas collecting tube; when being condensed to the temperature of about minus 5-5 DEG C, most of components over C5 are condensed and liquefied, and are delivered to a storage tank through a valve and an oil return pipe, or used directly; the rest small part of oil gas mixture passes through the valve and is delivered to an adsorption system by a vacuum pump P1 for further adsorption treatment; after being adsorbed and analyzed alternately by an adsorber A and an adsorber B, stripping gas containing oil gas is delivered to the storage tank by a vacuum pump 2 and the valve, or used directly; the effluent gas with the oil gas approximate to zero enters the atmosphere through an emptying pipe; the sorbent used by the two adsorbers is a phi3 cylindrical-shaped active carbon which is specially researched and used for the recovery of oil gas, and carry out vacuum desorption alternately under the action of the vacuum pump p2; and the desorption time is set to 15-20 minutes. The recovery rate of oil gas by utilizing the device and the method can reach over 98 percent, and the device and the method have the advantages of low cost and being beneficial to environmental protection.

Owner:江苏三星化工有限公司

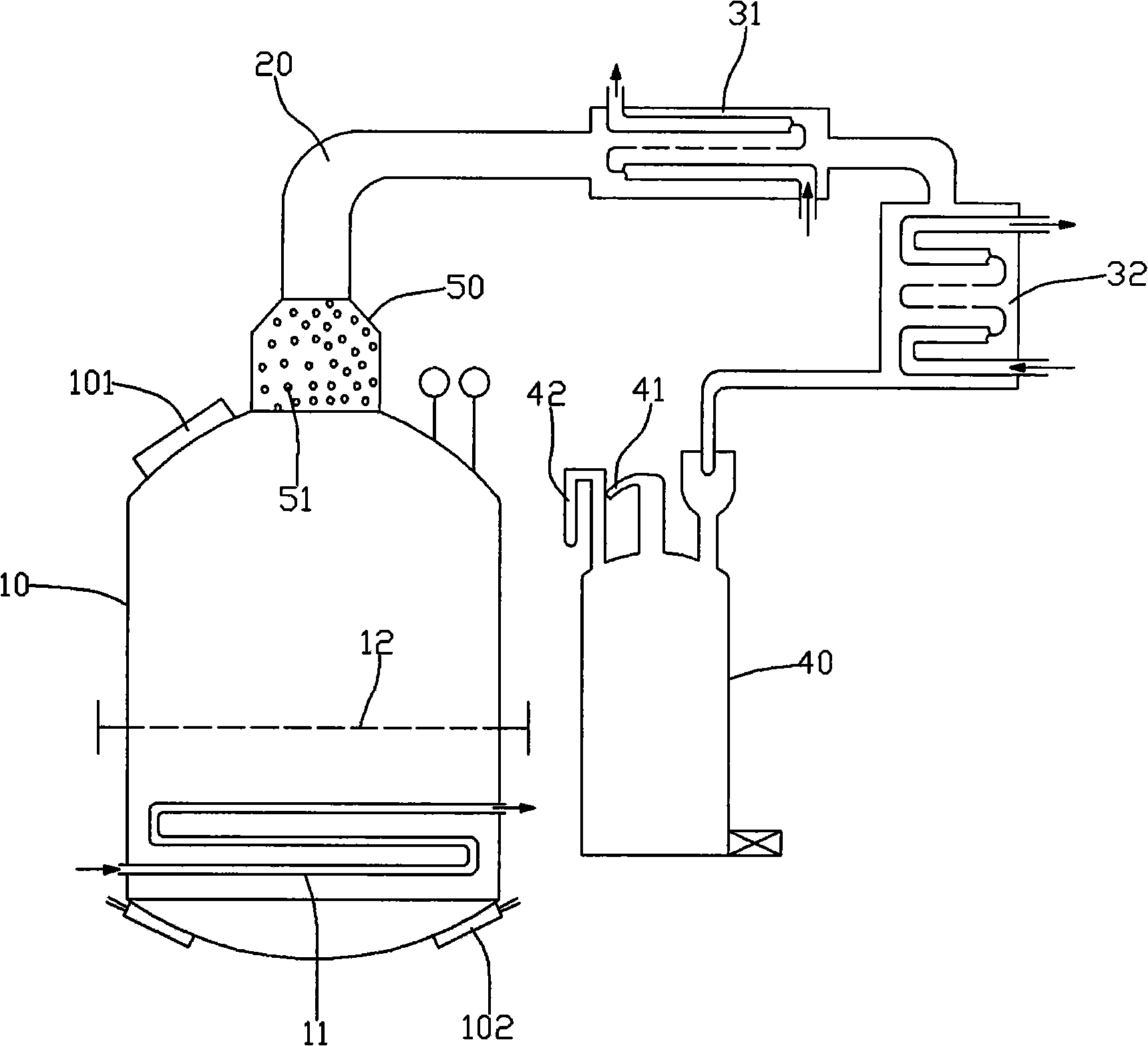

Rose essential oil and rose pure dew extraction equipment

InactiveCN101353611AAvoid direct accessInhibition of dissolutionEssential-oils/perfumesDistillationEngineering

The invention discloses extraction equipment for rose essential oil and rose hydrosol which mainly includes a distillation still, a steam conduit, a condenser and an oil-water separator, wherein, the distillation still is connected with the oil-water separator by the steam conduit and the condenser; the lower end of the interior of the distillation still is provided with a steam heating coil; and the upper part of the steam heating coil is provided with a transverse plate sieve which can be opened freely. An adsorption plant is arranged between the top of the distillation still and the steam conduit and internally filled with active ceramic rings serving as an absorbent. The extraction equipment of the invention has the advantages of simple operation, convenient use and high production efficiency, and can greatly enhance the quality of the rose essential oil and the rose hydrosol.

Owner:许向梅

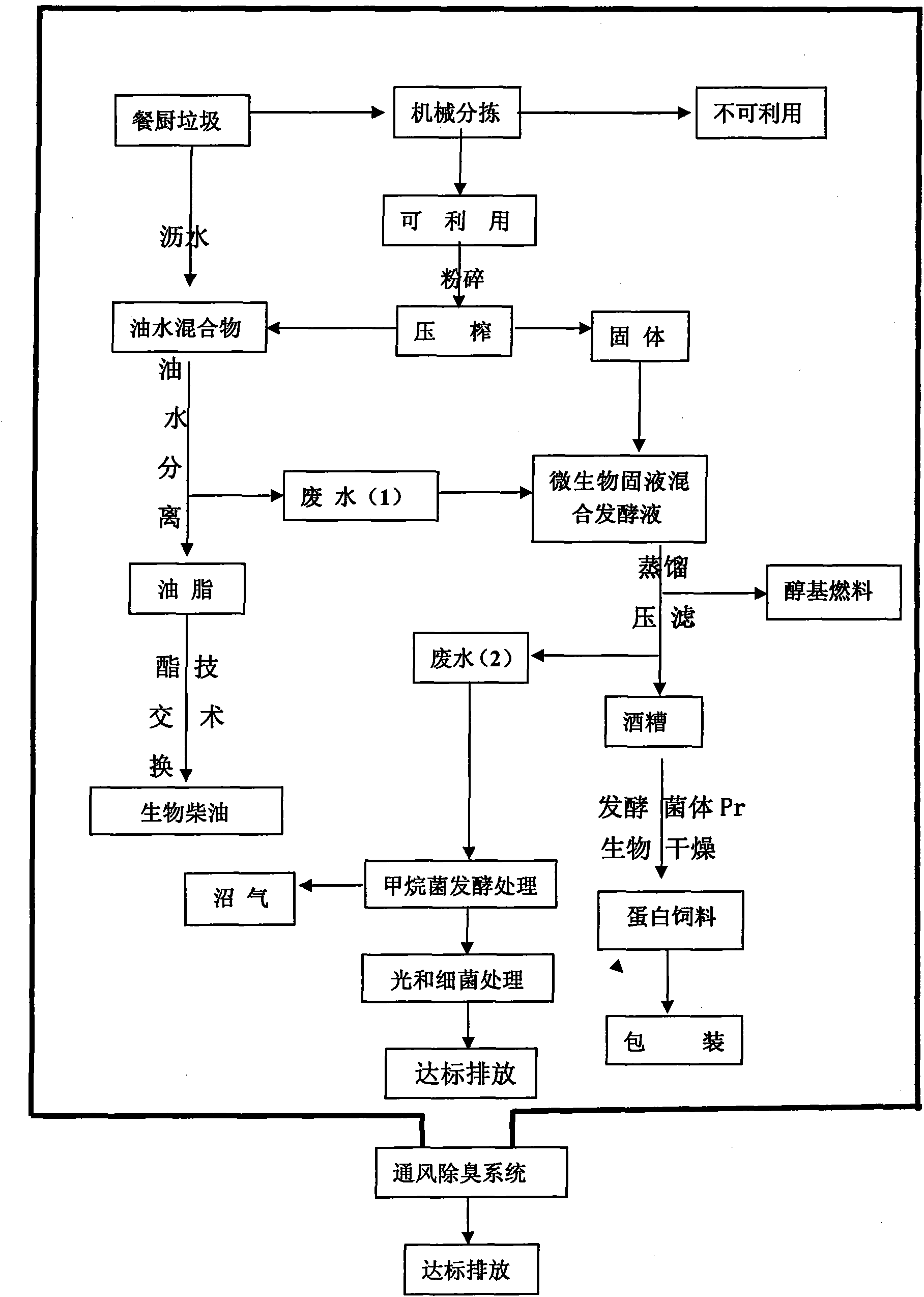

Process for preparing bio-fuel and protein feed from food waste by means of microbial fermentation

The process has the steps that food wastes are filter-pressed in a filter press for solid-liquid separation; oil and water are naturally separated through an oil-water separator; the separated oil is used for preparing biodiesel; solid residuals are added with glucoamyLase and microbial strains for saccharification together with fermentation after being liquefied and sterilized; the product from the fermentation process can be distilled so as to obtain alcohol base fuel and high-protein feed and can also be extracted and fermented together with microorganisms by means of biodiesel to prepare alcohol base fuel; and the base solution in a distillation kettle can reach the national emission standards after being processed with photosynthetic bacteria. The process has the characteristics that nutrients and residual liquid in food waste are fully recycled, and differences between ingredients in the food waste are utilized to regenerate various products, thereby lowering product cost and meeting the requirements for the development of circular economy.

Owner:HUAZHONG AGRI UNIV +1

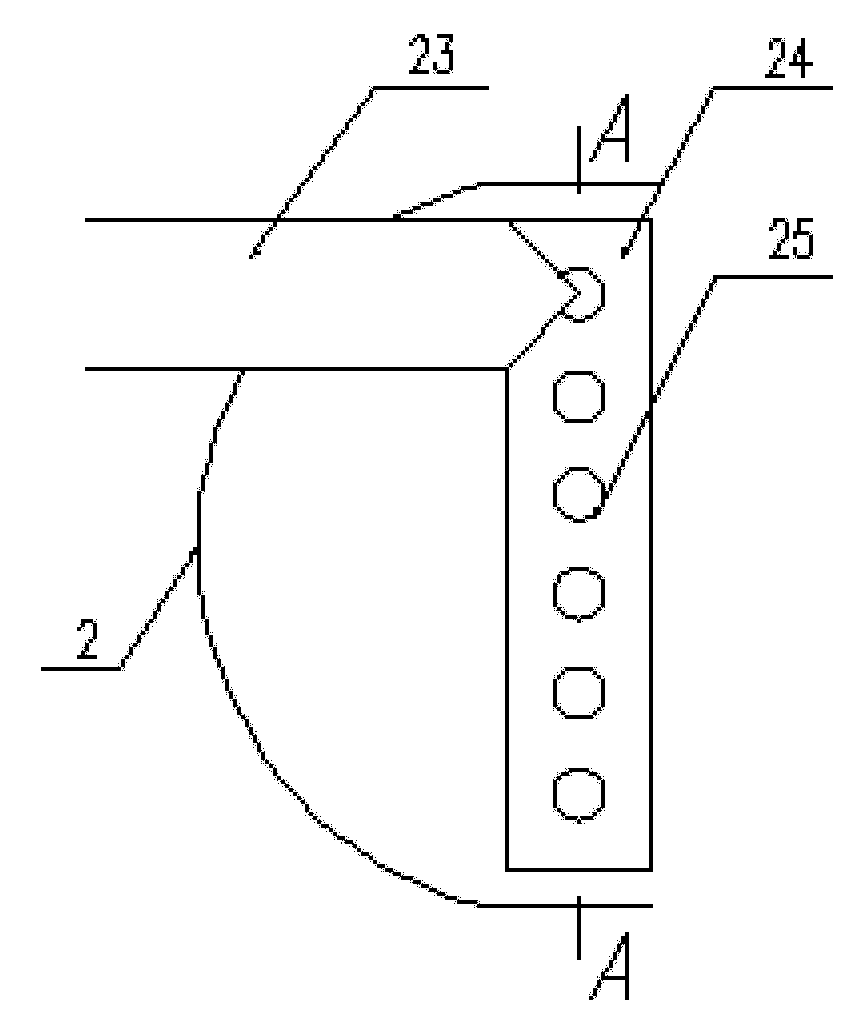

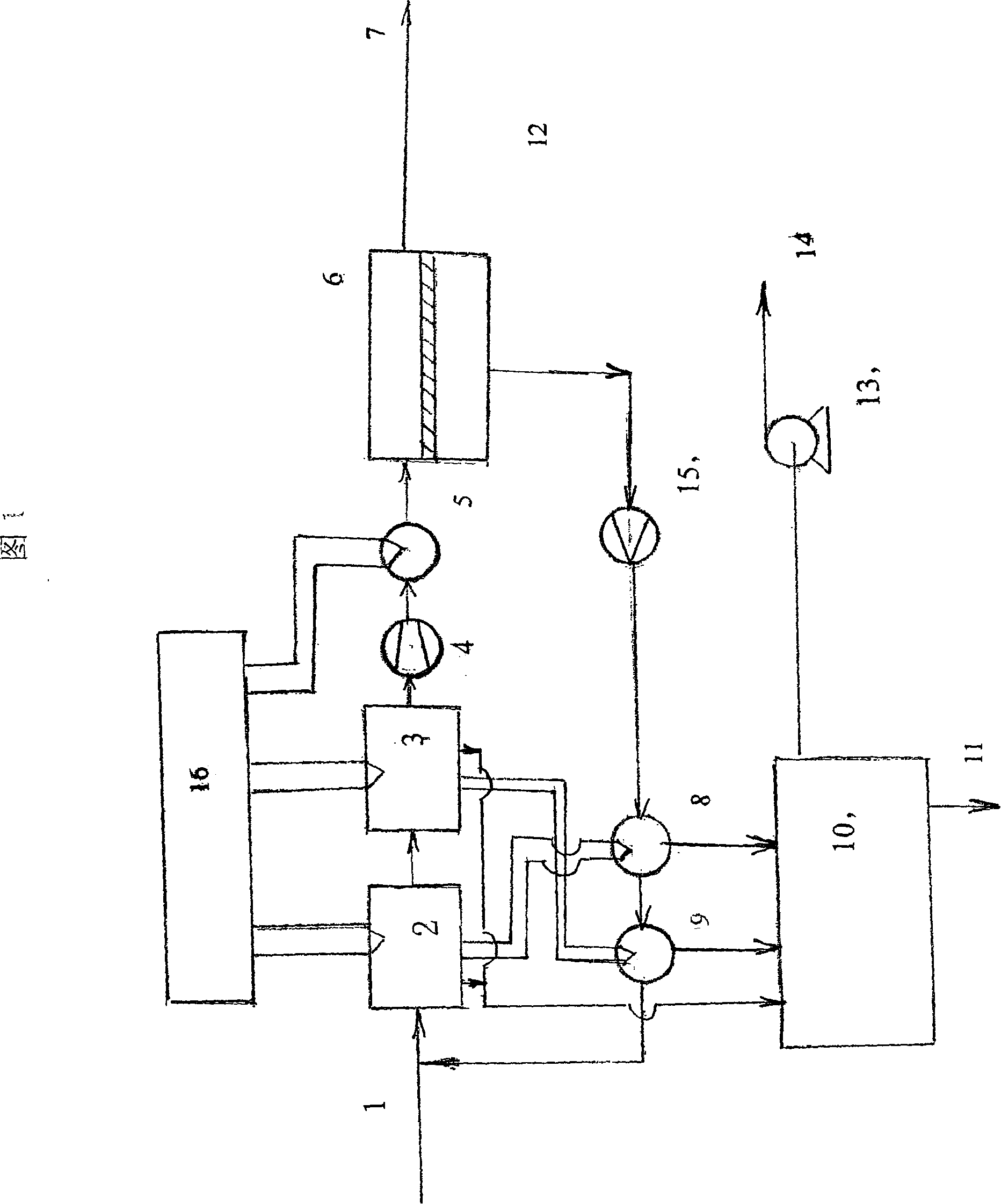

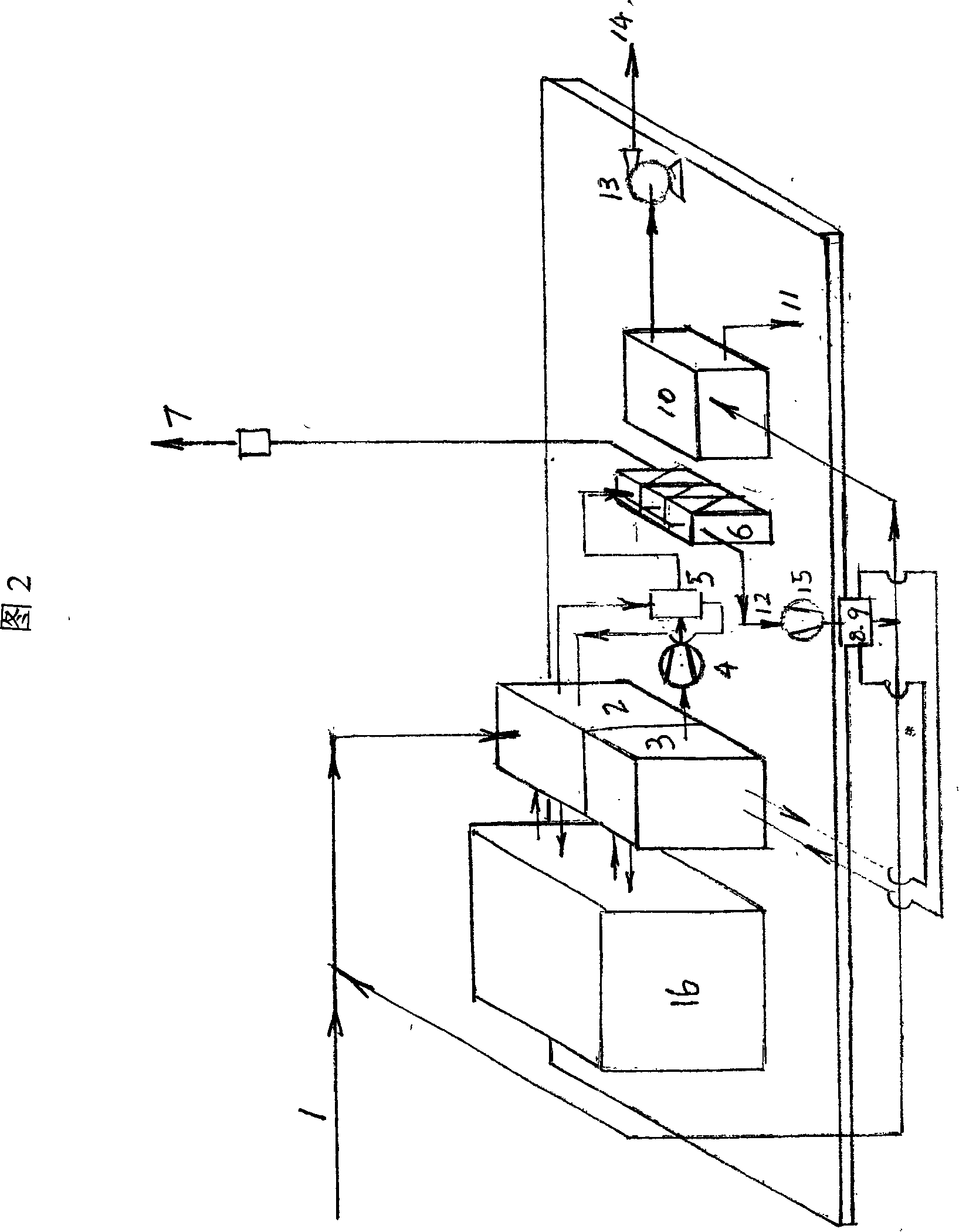

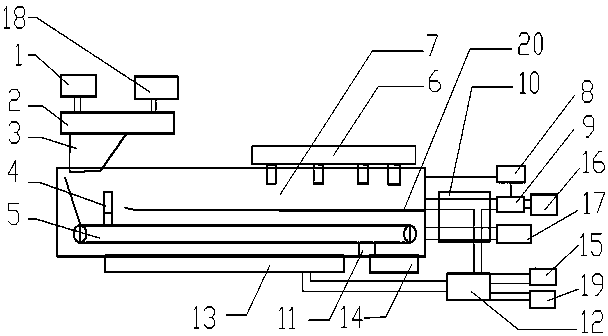

Condensing and membrane separation combined type oil gas reclaiming technical technology

InactiveCN101161590ALiquid hydrocarbon mixture recoveryVapor condensationSeparation technologyCombined method

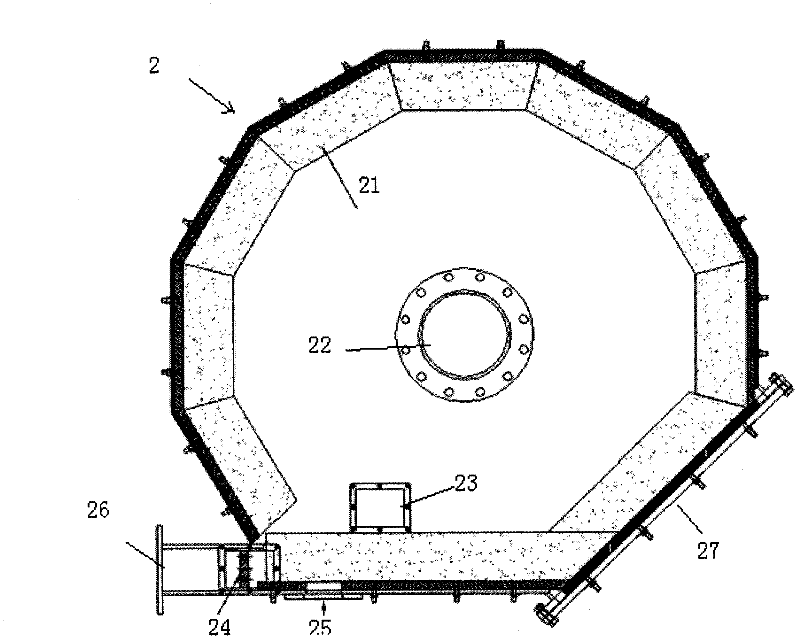

The invention relates to a condensation and film separation combination type oil gas recycling art technique which is an improvement of condensation type oil gas art technique. The invention adopts the combined method of condensation technique and film separating technique to reach discharging standards. The problem that the temperature of single condensation type oil gas recycling reaches lowers than 95 DEG C below zero is overcome. The invention belongs to the oil gas recycling technical field, and is mainly used for the oil gas recycling of oil house, city transfer oil house, gasoline and light weight oil loading and unloading process. The invention consists of a refrigeration machine set 16, a pre-cooling box 2, a middle cooling box 3, a liquid ring type compressor 4, a switch 5, a membrane module 6, a vacuum pump 15, a switch 8, a switch 9, an oil water separator 10 and an oil pump 13. According to the art flow sequence in the attached drawing 1, the refrigeration machine set 16, the pre-cooling box 2, the middle cooling box 3, the liquid ring type compressor 4, the switch 5, the membrane module 6, the vacuum pump 15, the switch 8, the switch 9, the oil water separator 10 and the oil pump 13 are connected together and are arranged on a base crowing. The construction is shown in the attached drawing 2. The three-dimensional graph of the modular structure is shown in the attached drawing 2.

Owner:王建基 +1

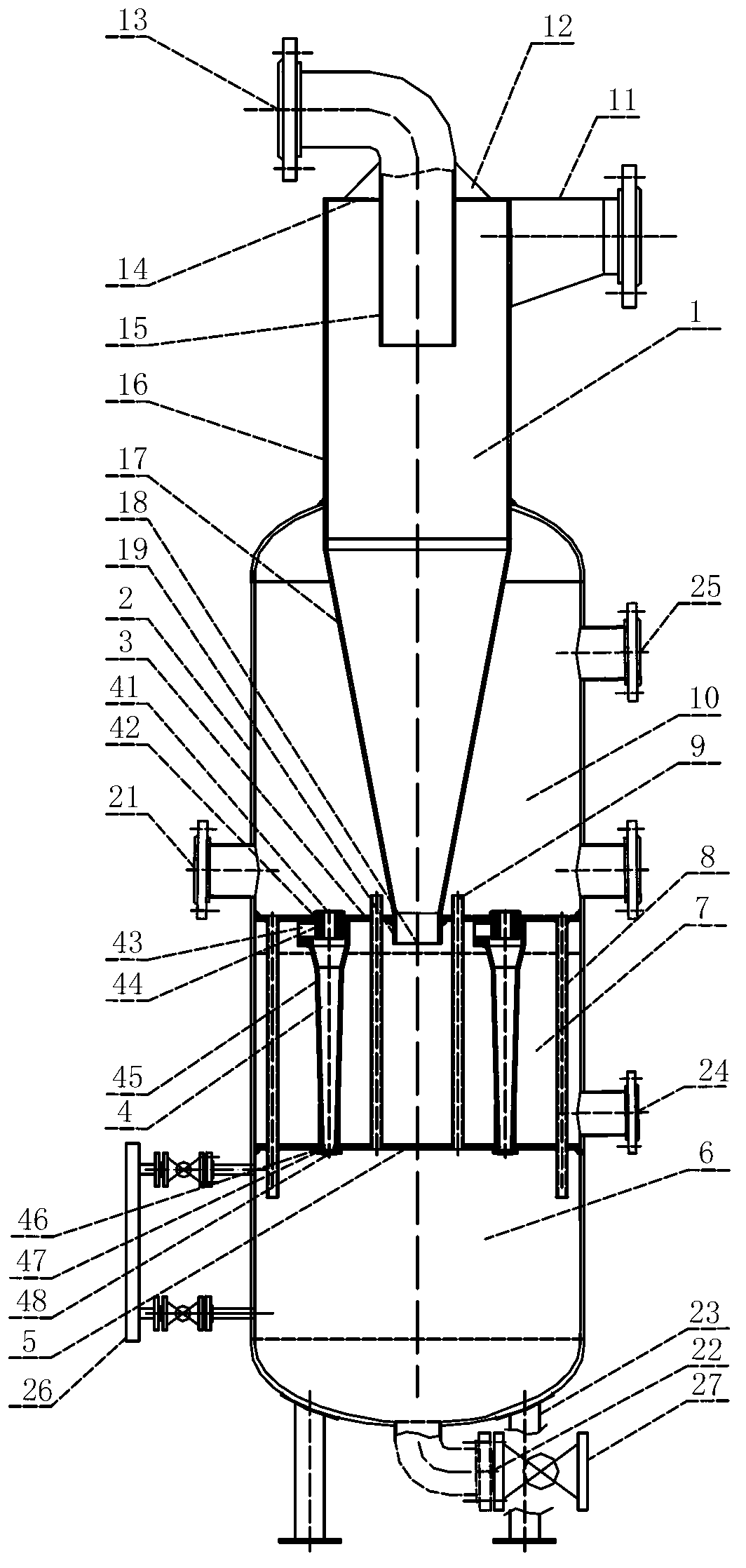

Oil-gas-water three-phase hypergravity separator

ActiveCN102794033AReduce volumeSmall footprintLiquid degasificationLiquid separationVapor–liquid separatorHypergravity

The present invention relates to an oil-gas-water three-phase hypergravity separator, including a housing, one or more swirling hypergravity gas-liquid separators, one or more swirling hypergravity oil-water separators, a group of water return pipe, a group of oil return pipe, an oil-water interface controller and a solenoid valve. The housing is divided into a water-collection chamber, an oil-water chamber and an oil-collection chamber from bottom to top by a lower separation plate and an upper separation plate. The gas-liquid separator is inserted from the top of the housing, penetrated through the oil collection chamber and not communicated with the oil collection chamber. The inlet pipe and the exhaust port of the gas-liquid separator are located outside of the housing. The liquid discharge port of gas-liquid separator is communicated with the oil-water chamber. The oil-water separator is arranged in the oil-water chamber. The oil-water inlet of the oil-water separator is communicated with the oil-water chamber. The oil discharge outlet is communicated with the oil collection chamber. The water outlet is communicated with the water collection chamber. The oil collection chamber and the water collection chamber are communicated through the water return pipe and the oil return pipe. The oil-water interface controller and the solenoid valve control the water discharging. The oil-gas-water three-phase hypergravity separator solves the problem of large volume and large floor area of conventional three-phase separators.

Owner:广东蓝水能源有限公司

Consecutive reaction apparatus for moisture sludge through anhydration and pyrolysis under microwave irradiation as well as method thereof

ActiveCN104163555AGood heating selectivityRapid pyrolysisSludge treatment by pyrolysisByproduct vaporizationRadiation lossNitrogen generator

The invention discloses a consecutive reaction apparatus for moisture sludge through anhydration and pyrolysis under microwave irradiation as well as a method thereof. The condensation comprises a sludge warehouse, a stirrer, a hopper feeder, a sludge-shaped controller, a belt sender, a power control microwave irradiation device, a microwave pyrolysis reaction chamber, a pressure sensing controller, a blower fan, a condensation heat exchanger, a scraper plate separator, an oil-water separating device, a liquid dredging groove, a coke storage tank, a product oil tank, a product gas tank, a nitrogen generator, a coke crusher, a sludge water pot and a gas shunting plate. According to the invention, microwave material internal heating characteristic can be fully used for reducing heat radiation loss, moisture sludge is directly performed with anhydration and pyrolysis to obtain the cracking oil, combustible gas and solid coke; heat recovery of the product gas and auxiliary microwave heating characteristic of the products residue are fully used for reducing the operation cost, and sludge pyrolysis efficiency and products quality can be increased. The apparatus has the advantages of simple structure, small volume, reasonable design and convenient market popularization, and is suitable for industrial application of microwave sludge continuous pyrolysis.

Owner:ZHEJIANG UNIV

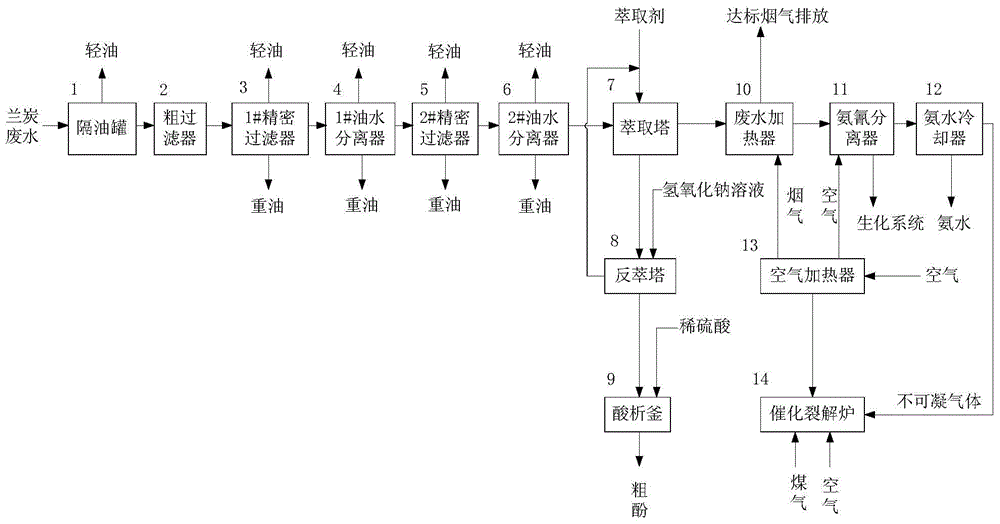

Technological method and device for semi-coke production wastewater resource utilization

ActiveCN104445815AImprove biodegradabilityImprove economic competitivenessOrganic chemistryOrganic compound preparationResource utilizationCoking wastewater

The invention discloses a technological method and device for semi-coke production wastewater resource utilization. The technological method comprises three steps, namely deep oil-water separation, high-efficiency complexing extraction dephenolization and ammonia stilling, to be specific, firstly, separating and recycling a part of coal tar from wastewater when the wastewater passes through an oil partitioning tank, recycling coal tar in a precision filter and an oil-water separator in sequence after discharged water passes through a coarse filter; feeding the oil-removed semi-coke wastewater and an extraction agent into an extraction tower for extraction and dephenolization, feeding the extract phase and a sodium hydroxide solution into a reverse extraction tower for countercurrent contact reverse extraction, feeding an obtained sodium phenolate solution into an acidification kettle, and adding sulfuric acid for acidification to obtain crude phenol; feeding dephenolized wastewater discharged from the bottom of the extraction tower into a wastewater heater, feeding into an ammonia cyanogen separator to be mixed with hot air from an air heater to remove ammonia after being heated by fume from the air heater, and feeding an ammonia-containing mixed gas discharged from the top of the ammonia-cyanogen separator into an ammonia water cooler for cooling to obtain ammonia water. By adopting the method and the device, precious resources such as coal tar, phenol and ammonia can be recycled from the semi-coke production wastewater resource, and the biodegradability of the semi-coke wastewater is improved.

Owner:陕西华祥能源科技集团有限公司

Oil removing pretreatment technology for petroleum oil refining wastewater

ActiveCN106007209AStructural scienceSimple processFatty/oily/floating substances removal devicesTreatment involving filtrationCycloneWater based

The invention discloses an oil removing pretreatment technology for petroleum oil refining wastewater. According to the oil removing pretreatment technology, a water collecting tank with gratings is used for separating sand and sludge; a three-phase cyclone liquid separation floating oil collecting and discharging adjusting tank is used for achieving separation of water, oil and residues; a cyclone oil coarse graining polymerization oil-water separator is used for removing fine oil grains; a dissolved air flotation device is used for demulsification and flocculation reaction, wherein air bubbles and suspended solids in wastewater make contact for adhesion and float upwards, and the standard is met through residue scraping. The technology is simple, the structure is scientific, the three-phase cyclone liquid separation floating oil collecting and discharging adjusting tank, the cyclone liquid coarse graining polymerization oil-water separator and the dissolved air flotation device jointly serve as the core treatment scheme, oily wastewater is pretreated through the density difference of oil and water based on the fluid dynamics principle, a physical method and a chemical method act jointly, and the oil content in the pretreated oily wastewater is smaller than or equal to 20 mg / L and reaches the standard. The oil removing pretreatment technology is large in daily treatment amount, high in oil removing efficiency, remarkable in oil collecting effect and considerable in economic benefit, and the water content of the recycled waste oil is 5% or lower.

Owner:江苏中嘉华新环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com