Oil-water separator

A technology of oil-water separator and sewage, applied in the direction of liquid separation, separation methods, chemical instruments and methods, etc., can solve the problems of low oil-water separation efficiency, waste oil collection and theft, and difficulty in supervision, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

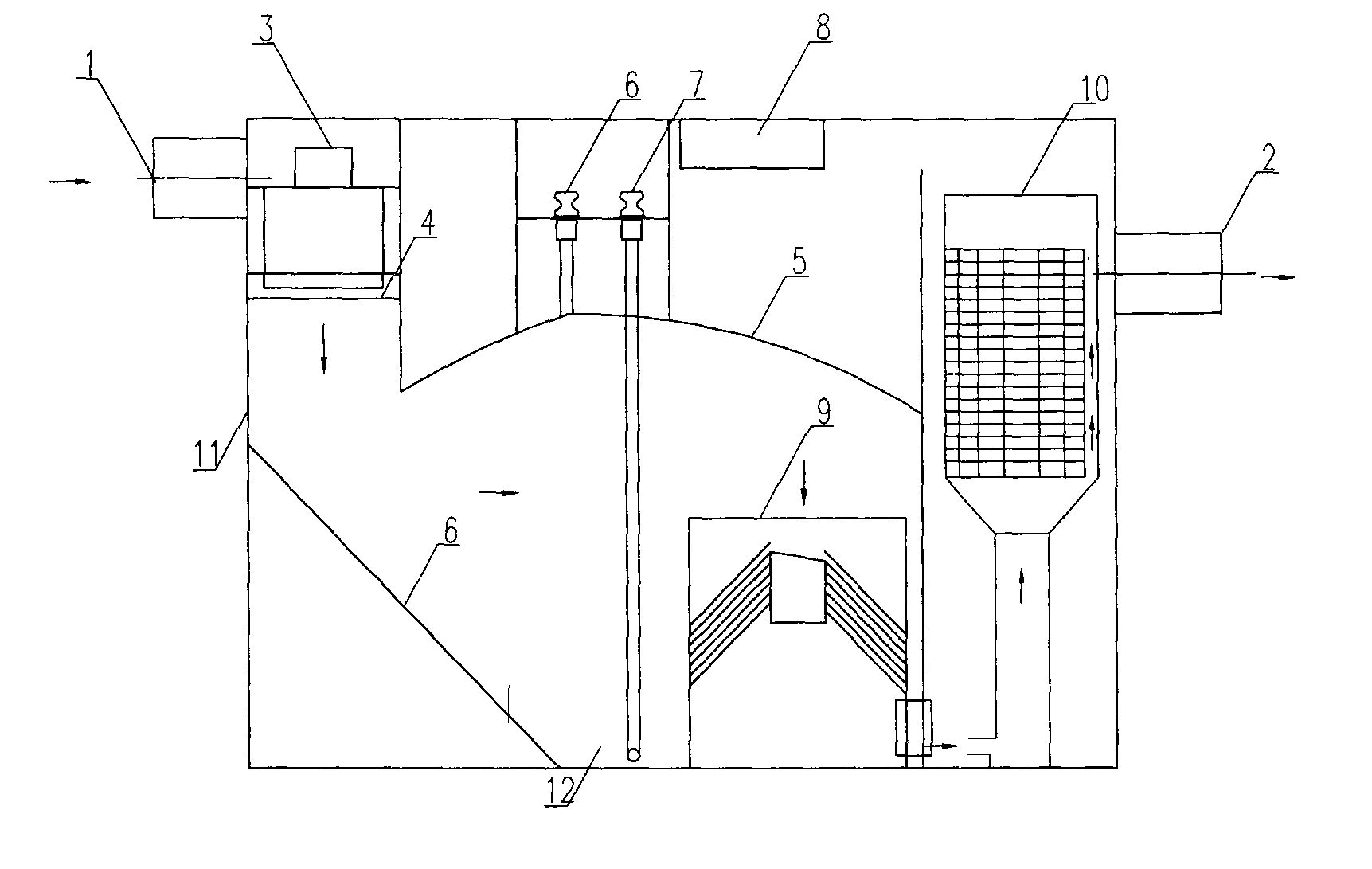

[0020] The present invention will be further described in detail below in conjunction with the drawings.

[0021] An oil-water separator is composed of at least a water inlet 1, a water outlet 2, and a container 11. The main material of the container is PE and has a long corrosion resistance life. The oil-water separator also includes coarse filtration of catering wastewater, which is The filter residue hopper 3 intercepted by large-particle waste residues, the filter residue hopper 3 is movable; the fixed filter screen 4 for fine filtration of waste water; the oil storage area 5, the sewage has some particles in the oil-water separator. The large oil is separated by the principle of gravity stratification when passing through the area below the oil storage area 5, and rises to the oil storage area 5; the cyclone shallow filter 9, oil droplets with a diameter between 10 microns and 100 microns It is separated in the cyclone shallow filter 9 and rises to the oil storage area 5; th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com