Preparation method of lightweight water-resistant paperbacked gypsum board

A paper-faced gypsum board, light-weight technology, applied in the field of board processing, can solve problems such as waste of resources, deterioration of the site environment, etc., achieve the effects of reducing weight, solving environmental problems, and improving water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

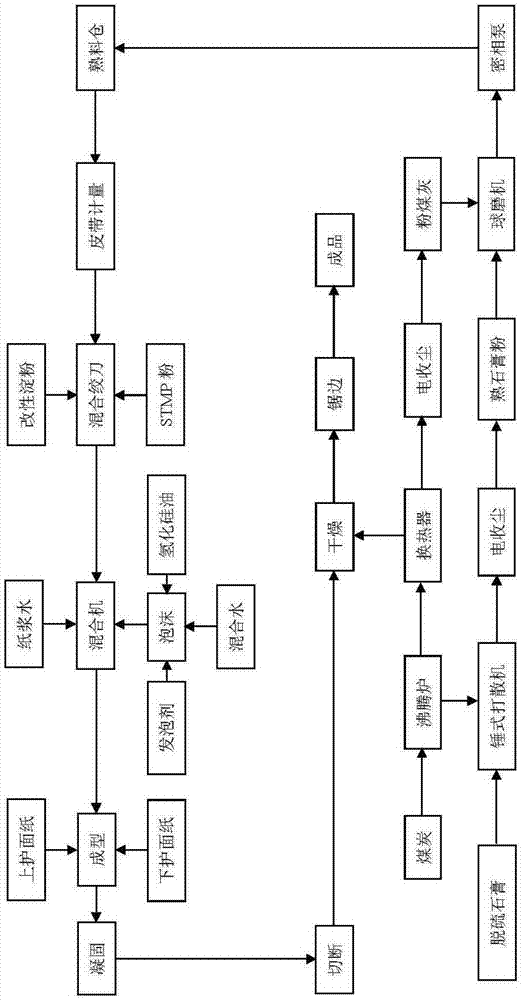

[0025] The present invention provides as attached figure 1 Shown is a kind of preparation method of lightweight water-resistant gypsum board, at least comprising the following steps:

[0026] a) Dispersing and frying the desulfurized gypsum to make mature gypsum powder;

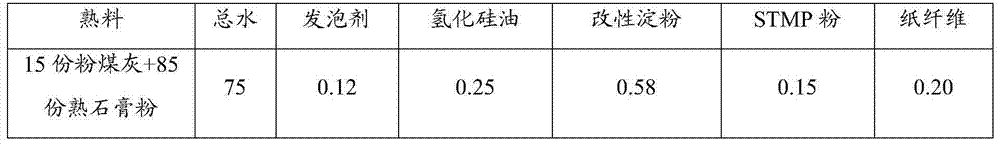

[0027] b) fully mixing fly ash and plaster powder, and performing grinding modification to obtain clinker;

[0028] c) The clinker is mixed with water, foaming agent, hydrogenated silicone oil, modified starch, STMP powder, and paper fiber, and fully stirred to obtain a uniform slurry;

[0029] d) The slurry is poured continuously between two layers of protective paper, and is extruded to obtain a wet gypsum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com