Method for extracting rose essence oil and rose absolute by water vapor water distillation technology

A technology of water distillation and rose essential oil, which is applied in the production of essential oils/spice, fat oil/fat, and fat production, can solve the problems of high production equipment requirements, high consumption of organic solvents, and high production costs, and achieves high production equipment requirements. The effect of high yield of active ingredients and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for extracting rose essential oil and rose pure dew by steam water distillation technology, specifically comprising the following technical steps:

[0036] (1) 360kg Damascus No. 1 roses are dropped into the distillation still;

[0037] (2) Add deionized water to the still; By weight, water: flowers are 2.0: 1;

[0038] (3) add salt in still still; Adding salt can reduce the solubility of rose oil composition in water in still still, can obviously improve the oil yield of rose; By weight, salt: water is 2.5: 100;

[0039] (4) Open the coil to access steam, heat the still, and control the rate of evaporation in the still by adjusting the steam pressure of the access coil; the heating time is 6 hours;

[0040] From the initial heating to before boiling, the vapor pressure is 0.25Mpa; within 0.5 hours after boiling, the pressure is controlled at 0.05MPa; within 0.5 hours after boiling, it is advisable to control at 0.08MPa; within 3 hours after boiling, it is con...

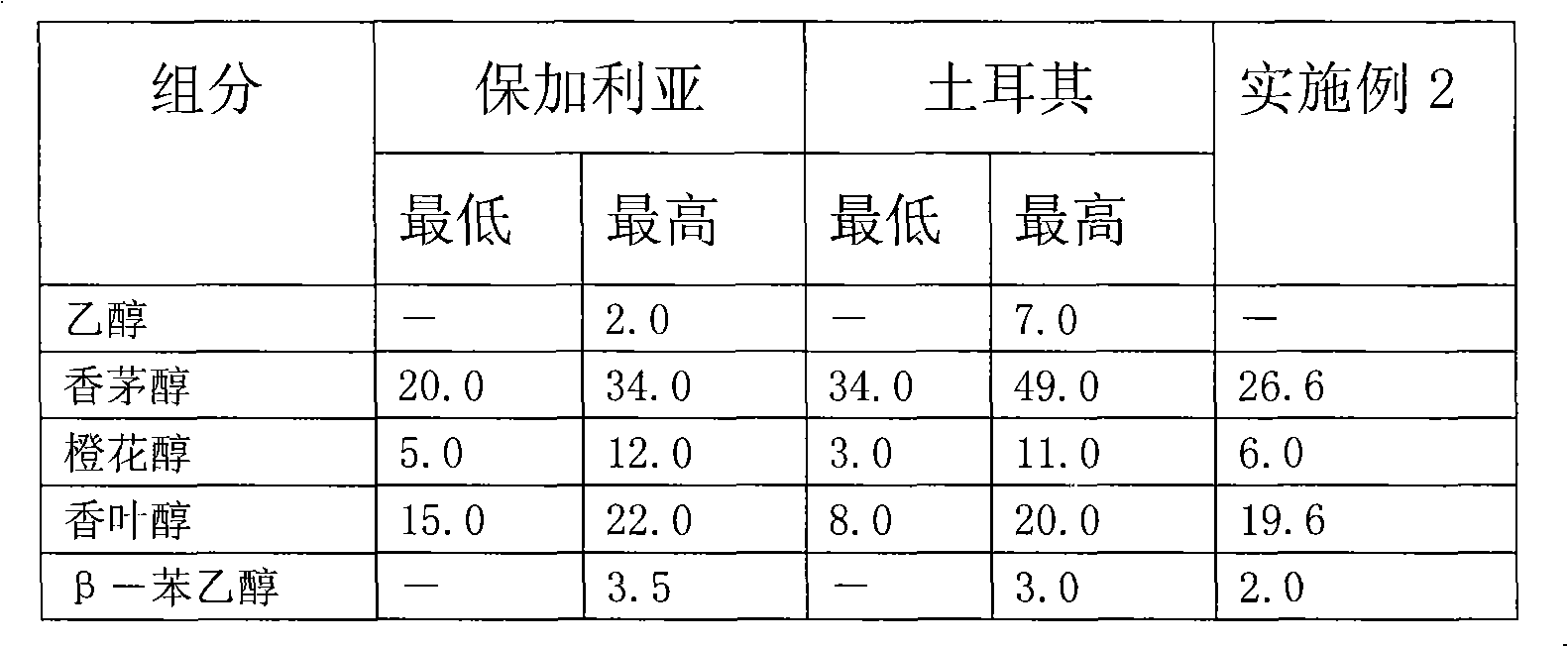

Embodiment 2

[0050] A method for extracting rose essential oil and rose pure dew by steam water distillation technology, specifically comprising the following technical steps:

[0051] (1) 420kg Damascus No. 1 roses are dropped into the distillation still;

[0052] (2) Add deionized water to the still; By weight, water: flowers are 2.5: 1;

[0053] (3) add salt in still still; Adding salt can reduce the solubility of rose oil composition in water in still still, can obviously improve the oil yield of rose; By weight, salt: water is 4: 100;

[0054] (4) Open the coil to access steam, heat the still, and control the rate of evaporation in the still by regulating the steam pressure of the access coil; the heating time is 7 hours;

[0055] From initial heating to before boiling, the vapor pressure is 0.30Mpa; within 0.5 hours after boiling, the pressure is controlled to 0.07MPa; within 2 hours after boiling, it is advisable to control at 0.09MPa; within 4 hours after boiling, it is controlled...

Embodiment 3

[0065] A method for extracting rose essential oil and rose pure dew by steam water distillation technology, specifically comprising the following technical steps:

[0066] (1) 500kg Damascus No. 1 roses are dropped into the distillation still;

[0067] (2) Add deionized water to the still; By weight, water: flowers are 3.0: 1;

[0068] (3) add salt in still still; Adding salt can reduce the solubility of rose oil composition in water in still still, can obviously improve the oil yield of rose; By weight, salt: water is 5: 100;

[0069] (4) Open the coil to access the steam, heat the distillation still, and control the evaporation rate in the still by adjusting the steam pressure of the access coil; the heating time is 8 hours;

[0070] From the initial heating to before boiling, the vapor pressure is 0.35Mpa; within 0.5 hours after boiling, the pressure is controlled to 0.08MPa; within 3 hours after boiling, the pressure is controlled at 0.1MPa; within 5 hours after boiling, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com