Process for preparing bio-fuel and protein feed from food waste by means of microbial fermentation

A technology for microbial fermentation and food waste, applied in the direction of biofuels, microbial-based methods, biochemical equipment and methods, etc., can solve the problem of single products and achieve good economic results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

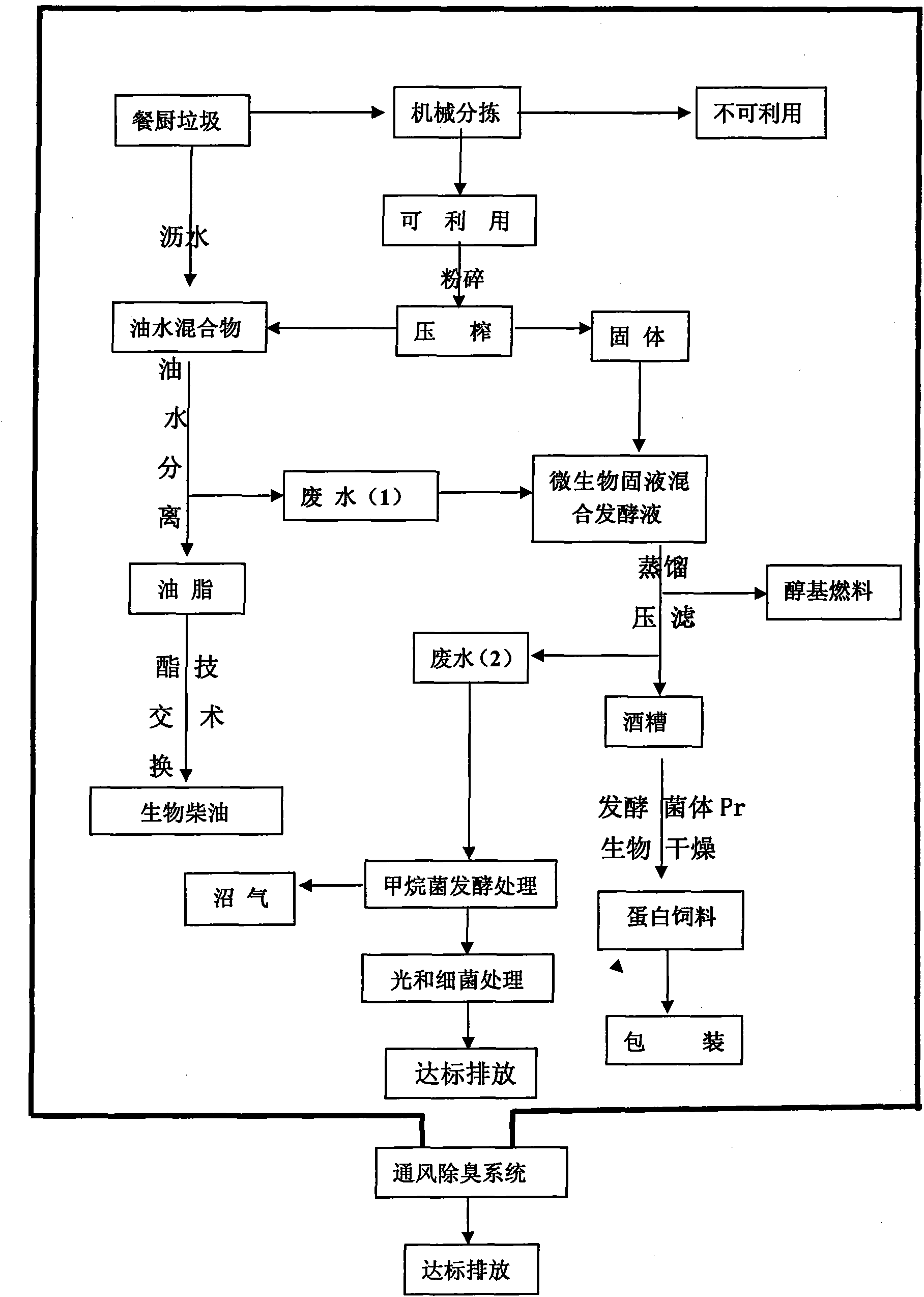

[0010] Example 1: Biodiesel, alcohol-based fuel, and protein feed were prepared by collecting leftovers from canteens.

[0011] Add water to 1000g of leftover rice and leftovers mixture to obtain coarse solid material and oil-water mixture, and the solid part is pulverized by a tissue grinder and then filtered by a filter press to obtain fine solid material and oil-water mixture. The two parts of the oil-water mixture are mixed and then pass through the unpowered oil-water separator (attached figure 1 ) to obtain oil and waste water containing a large amount of organic matter, after the separation, obtain 86g of oil separation and extraction of oil, and obtain 81g of biodiesel by esterification and transesterification two-step method; the solid-liquid ratio of the waste water after the above separation and the press filtration is 1:1.5, add 2% amylase, 2% glucoamylase and 1% Saccharomyces cerevisiae for mixed fermentation. Afterwards, ethanol was obtained by distillation at 8...

Embodiment 2

[0012] Example 2: Collecting swill from food stalls to prepare biodiesel, alcohol-based fuel, and protein feed

[0013] 1000g of swill is filtered to obtain coarse solid and oil-water mixture, and the solid part is pulverized by a tissue grinder and then press-filtered to obtain fine solid and oil-water mixture. The two parts of the oil-water mixture are mixed and then passed through the unpowered oil-water separator to obtain grease and waste water containing a large amount of organic matter. After separation, 120g of grease is obtained by separating and extracting grease, and 103g of biodiesel is obtained by two-step esterification and transesterification; Add amylase, glucoamylase, and Saccharomyces cerevisiae to the waste water and the fine solid material after press filtration, and then distill to obtain ethanol to produce 67.2g of ethanol; The mixed residue is passed through pressure filtration again to obtain residue solids and waste water, then add water-absorbing biom...

Embodiment 3

[0014] Example 3: Collecting swill from hotels to prepare biodiesel, alcohol-based fuel, and protein feed

[0015] Separation of 1000g of swill to obtain crude solids and oil-water mixture, the oil-water mixture is then passed through a non-powered oil-water separator to obtain oil and waste water, after separation, 88g of oil is obtained by separating and extracting oil, and 73g of biodiesel is obtained by two-step esterification and transesterification; the above separation After the waste water and the fine solid material after press filtration adjust the solid-liquid ratio to be 1: 10, add Clostridium acetobutylicum after sterilization and prepare butanol 43.1g by anaerobic fermentation; Wastewater, then add water-absorbing biomass such as bran to the residue solid material, then dry and pulverize, make protein feed to obtain 207g protein feed, the protein content is 42.0% after determination; waste water is fermented to obtain about 260L of methane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com