Patents

Literature

320 results about "Gas collecting tube" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The characterization gas collecting tube describes an oblong gas-tight container with one valve at either end. Usually such a container has a gauged volume, has a cylindrical shape and is made of glass. Gas collecting tubes are used for science-related purposes; for taking samples of gases.

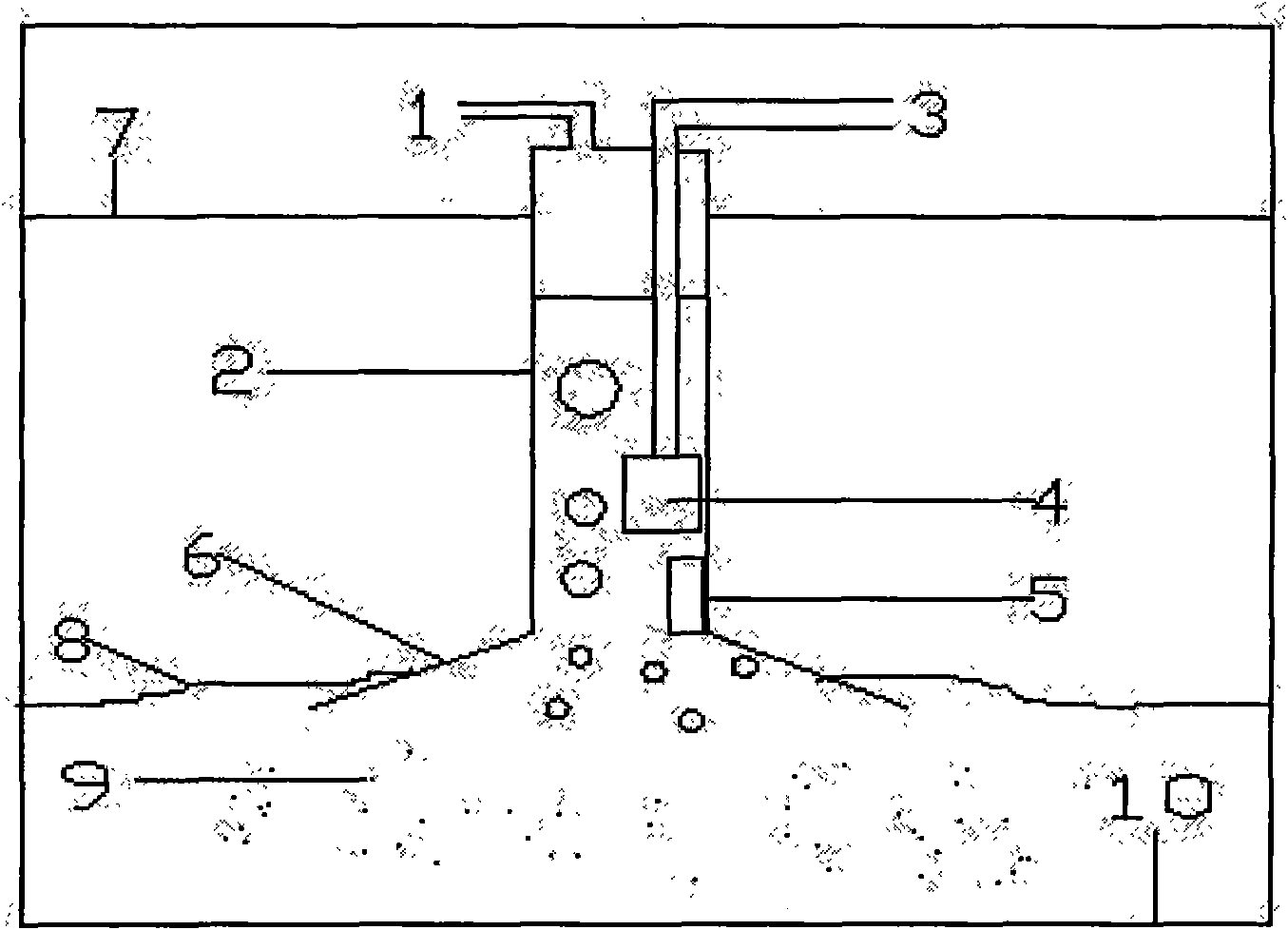

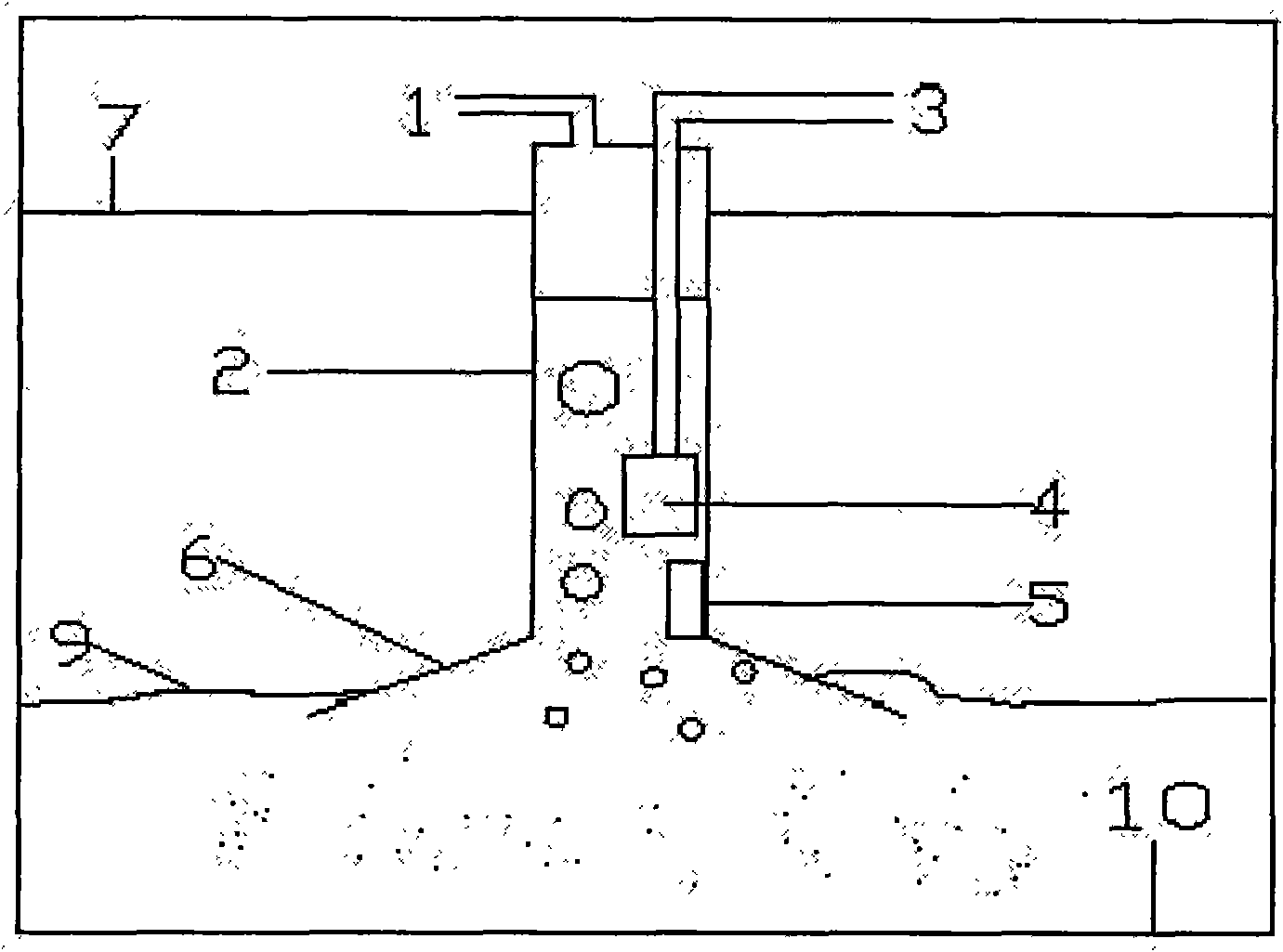

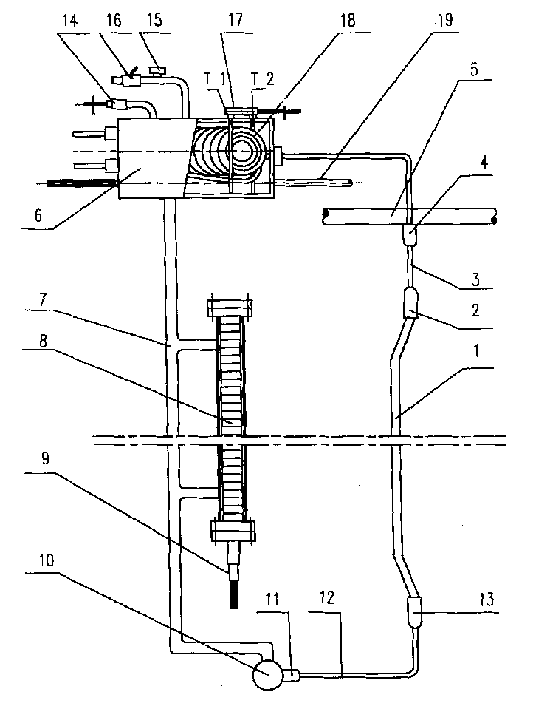

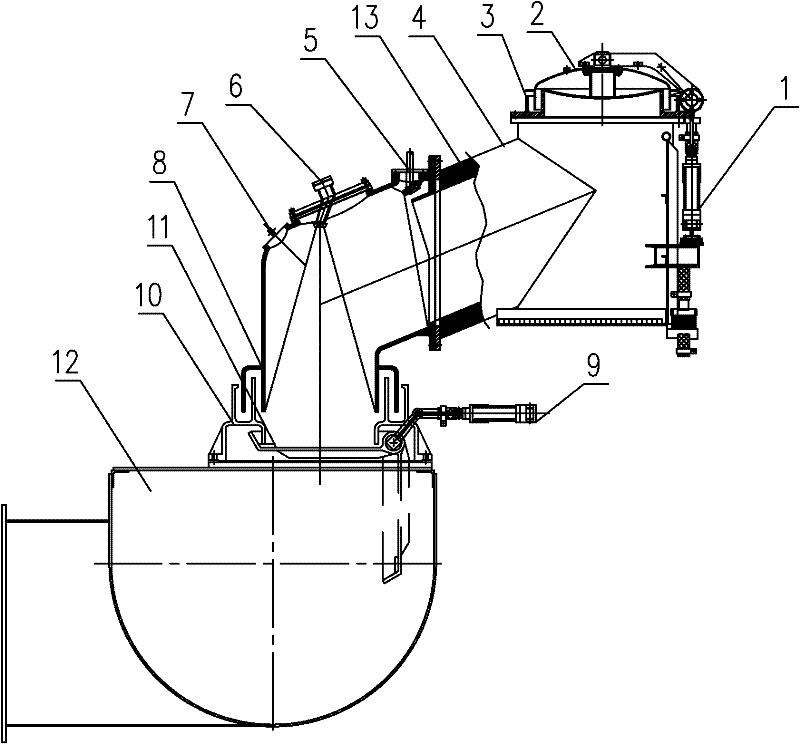

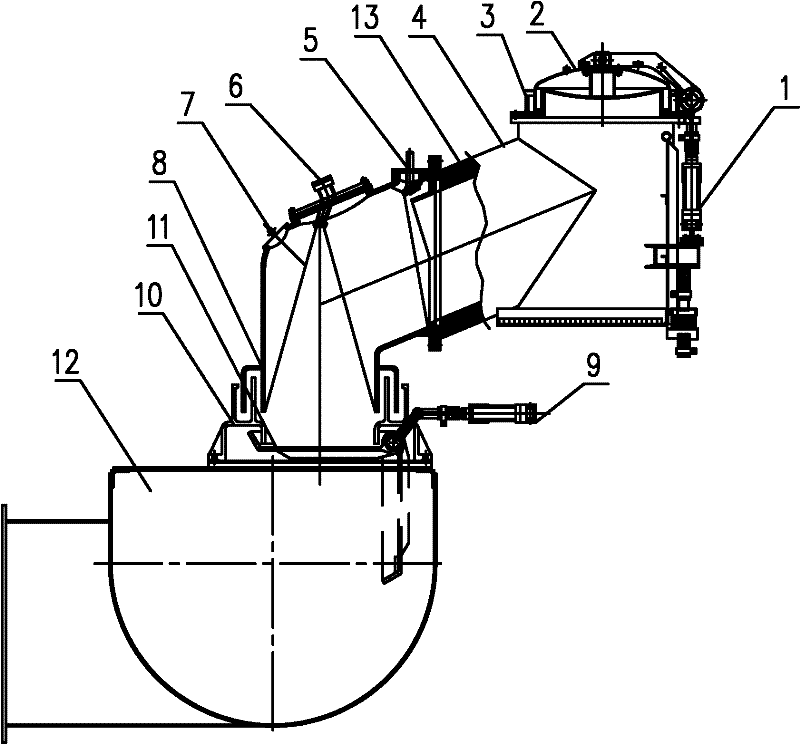

Extraction device for undersea gas hydrate and extraction method thereof

ActiveCN101555797AAchieve miningMining technology is simpleConstructionsMineral miningGas collecting tubeEngineering

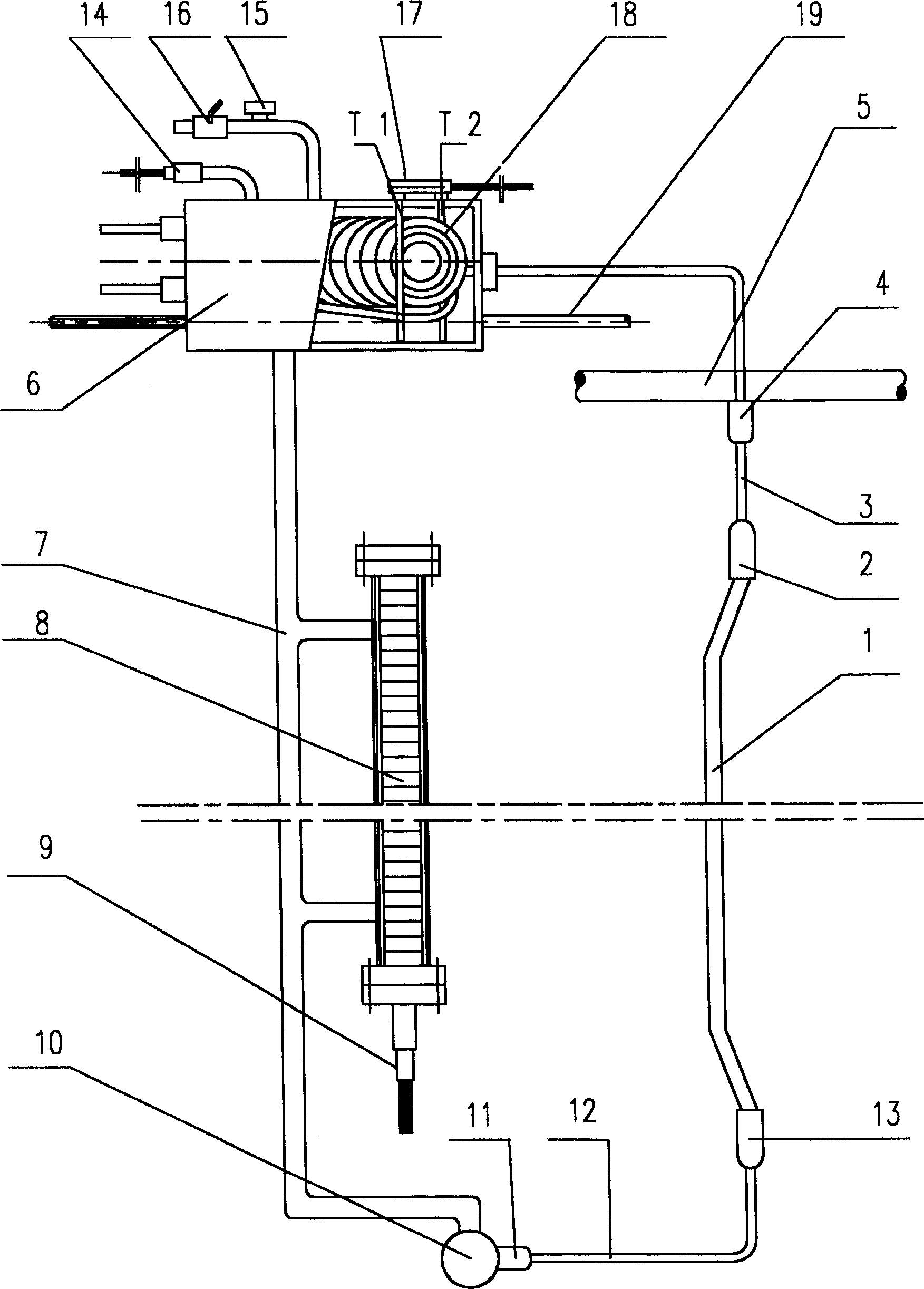

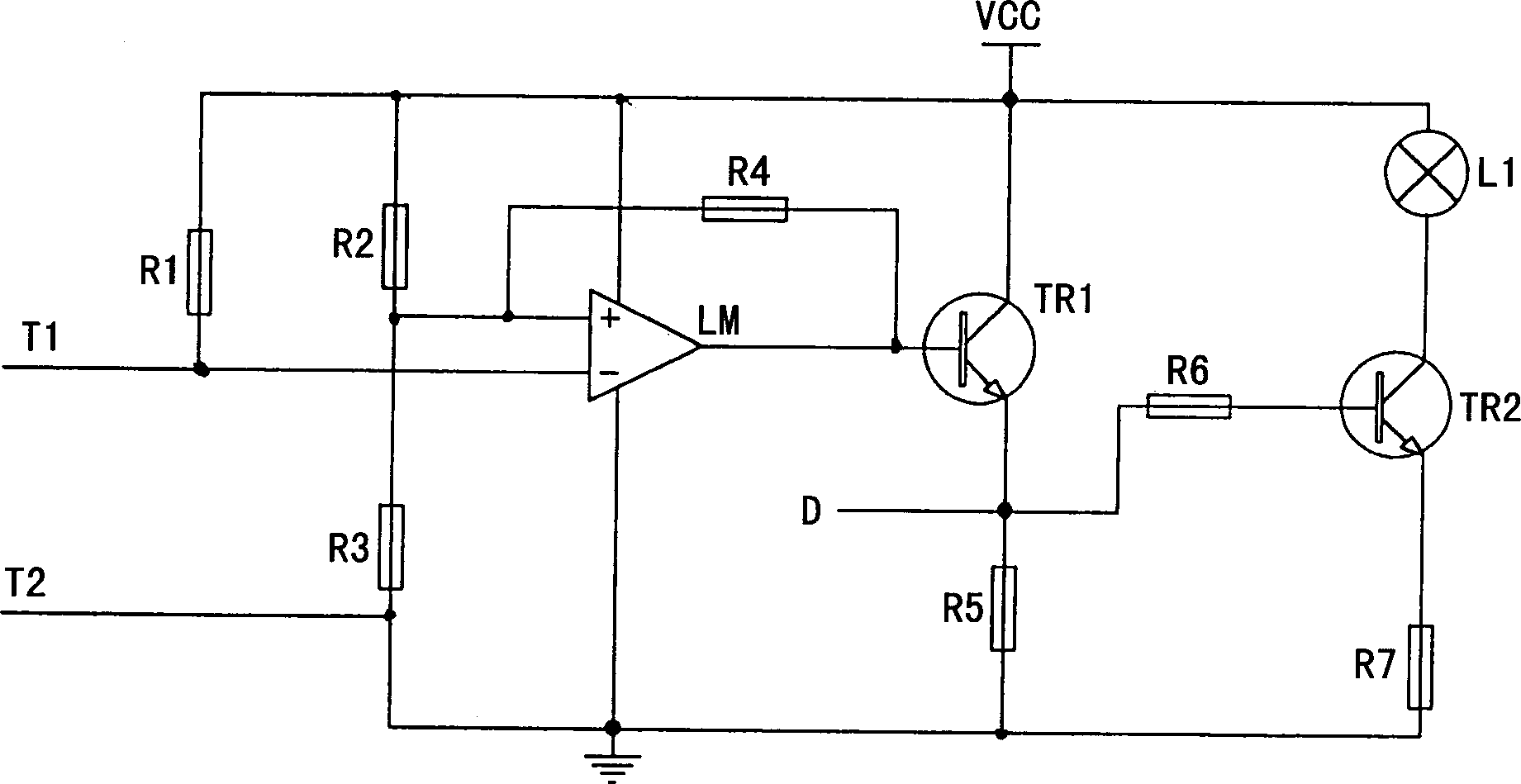

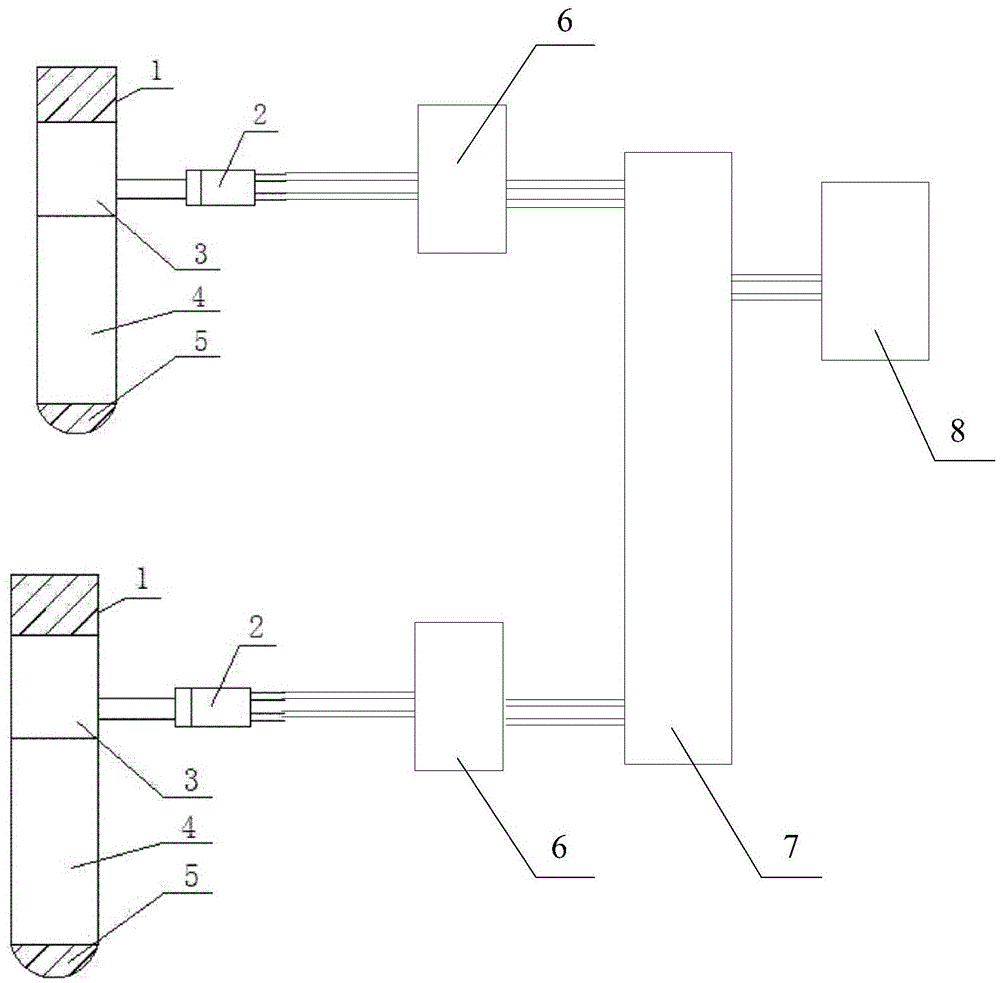

The invention discloses an extraction device for undersea gas hydrate and an extraction method thereof, which is characterized in that the device is directly communicated with undersea (10) gas hydrate layer (9) through a hollow rigid body (2); or the hollow rigid body is communicated with undersea (10) gas hydrate layer (9) through layers of sand and clay (8) or impermeable bed (11); a water pump (4) and a test and supervisory equipment (5) are provided on one side of the hollow rigid body, the water pump is connected with a drain pipe (3) which is above the sea level (7) through a pipe, the test and supervisory system is connected with an image pickup system and a pressure testing system, and a gas collecting pipe (1) is arranged on the top of the inside of the hollow rigid body. The extraction method comprises the following steps: 1) a hollow rigid body is built on the sea separated with water, and the hollow rigid body is communicated with undersea gas hydrate layer; 2) water in the hollow rigid body is drained out via a water pump to lower the water height in the hollow rigid body and reduce the pressure acting on the gas hydrate layer and the gas hydrate is decomposed into gas and water when the pressure acting on the gas hydrate layer is less than the balance pressure; 3) the decomposed gas escapes upward, is discharged through the gas collecting pipe and is collected.

Owner:SICHUAN UNIV

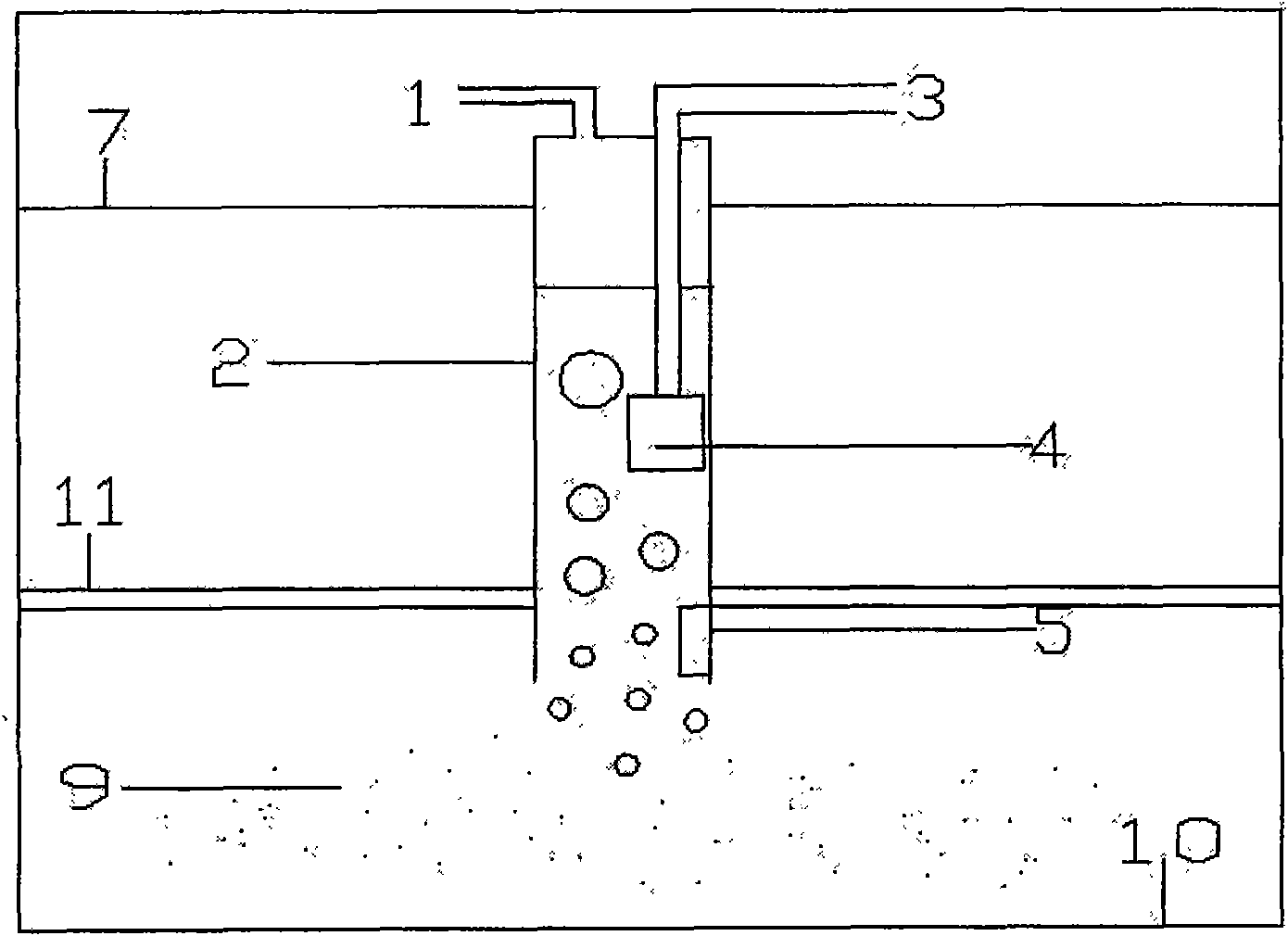

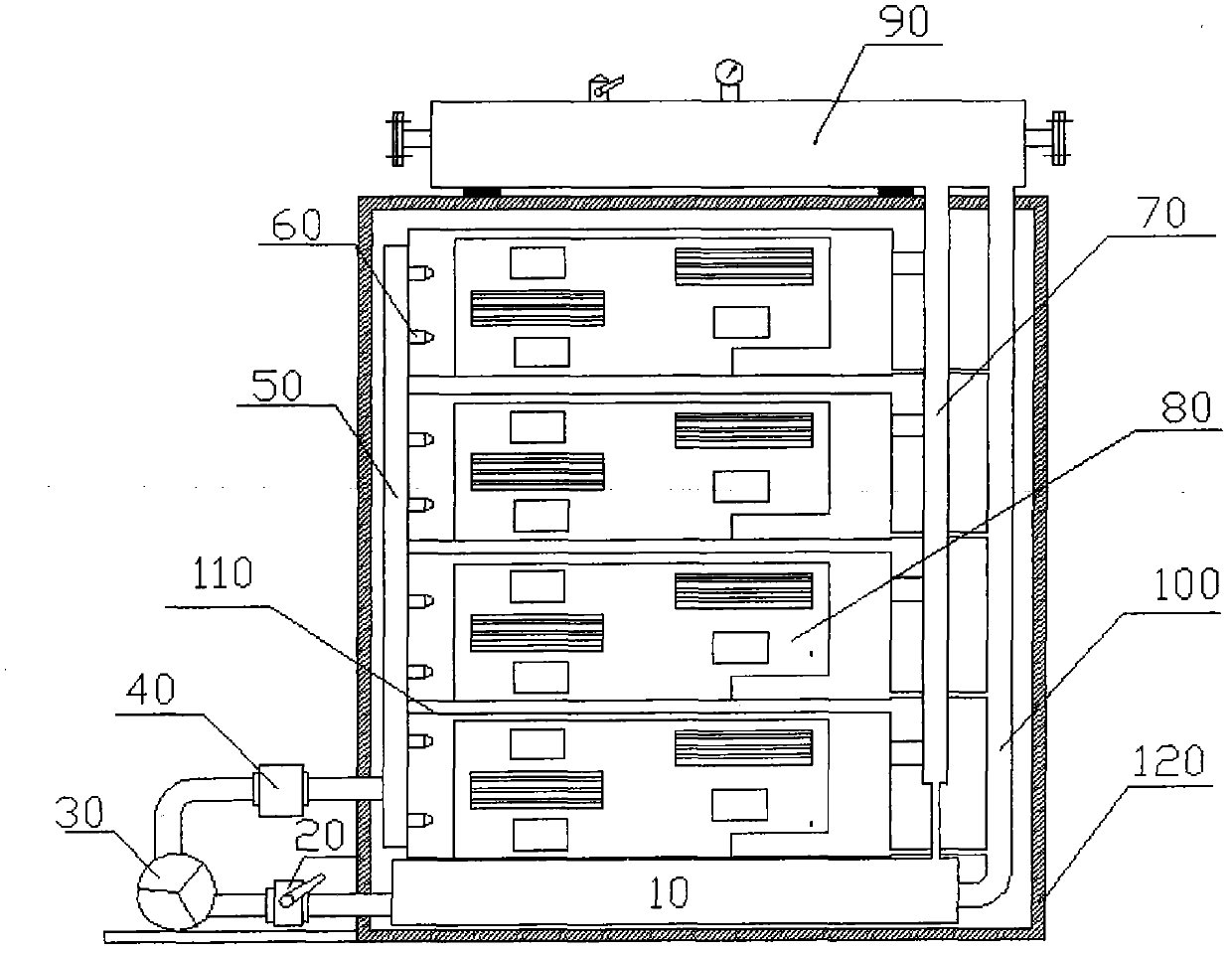

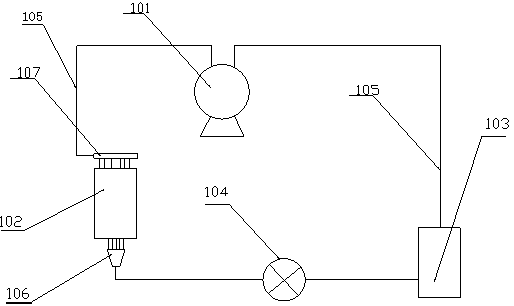

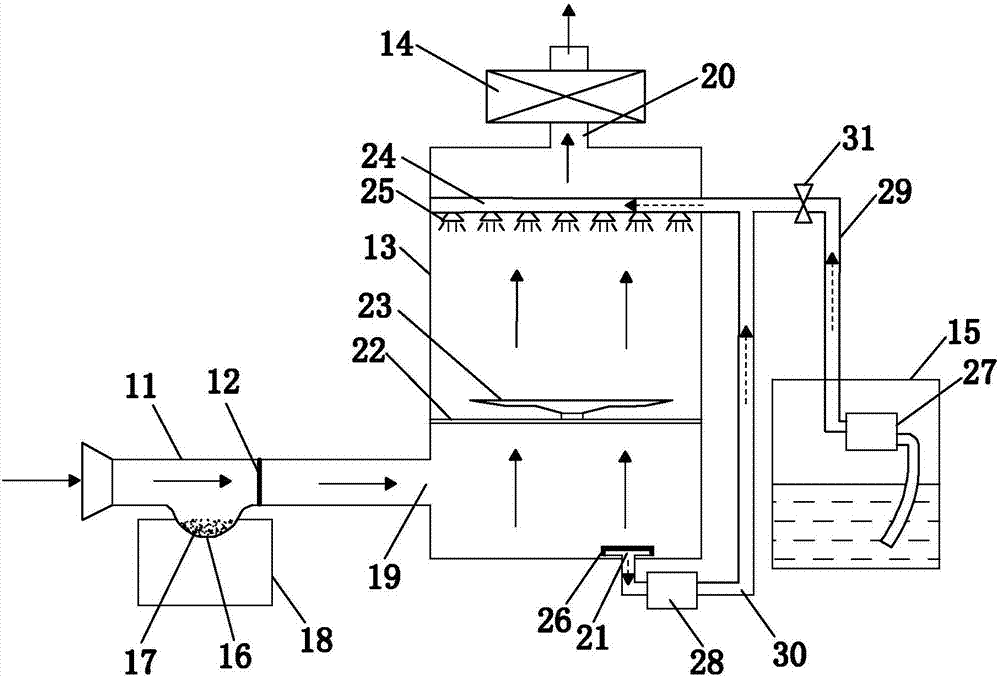

Spray-type evaporative cooling and circulating system of heating device

InactiveCN102573385AReduce dosageLayout restrictionsDigital data processing detailsCooling/ventilation/heating modificationsGas collecting tubeLiquid storage tank

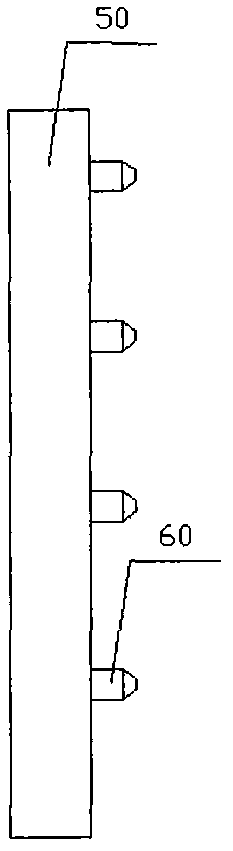

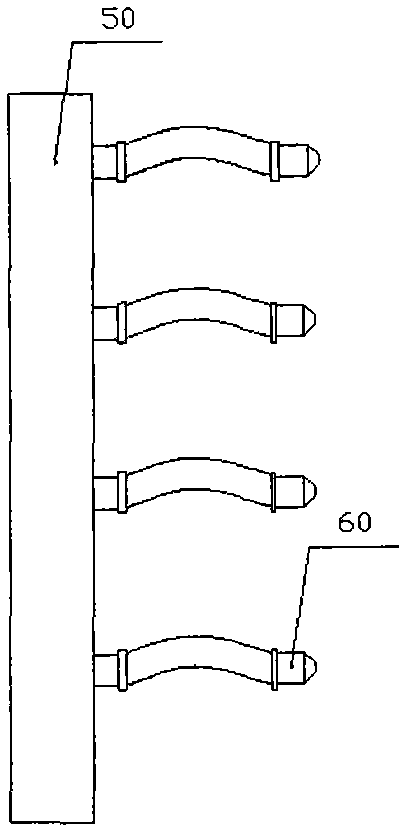

The invention provides a spray-type evaporative cooling and circulating system of a heating device. A plurality of element seal boxes (110) are arranged in a heating device cabinet (120), a control valve (20) is arranged between a liquid storage tank (10) and a circulating pump (30), a filter (40) is arranged on the front end of a liquid distributor (50), the liquid distributor (50) is arrange on any position in the heating device cabinet (120), a plurality of nozzles (60) are installed on the liquid distributor (50), and one end of a gas collecting tube (70) is connected with the element seal boxes (110). After an evaporative cooling medium atomized by the nozzles (60) exchanges heat with a heating unit (80), the liquid part in the evaporative cooling medium returns to the liquid storage tank (10) through a liquid return tube (100), the evaporated evaporative cooling medium rises to a condenser (90) through the gas collecting tube (70), is condensed by the condenser (90) to become liquid, and returns to the liquid storage tank (10) through the liquid return tube (100).

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

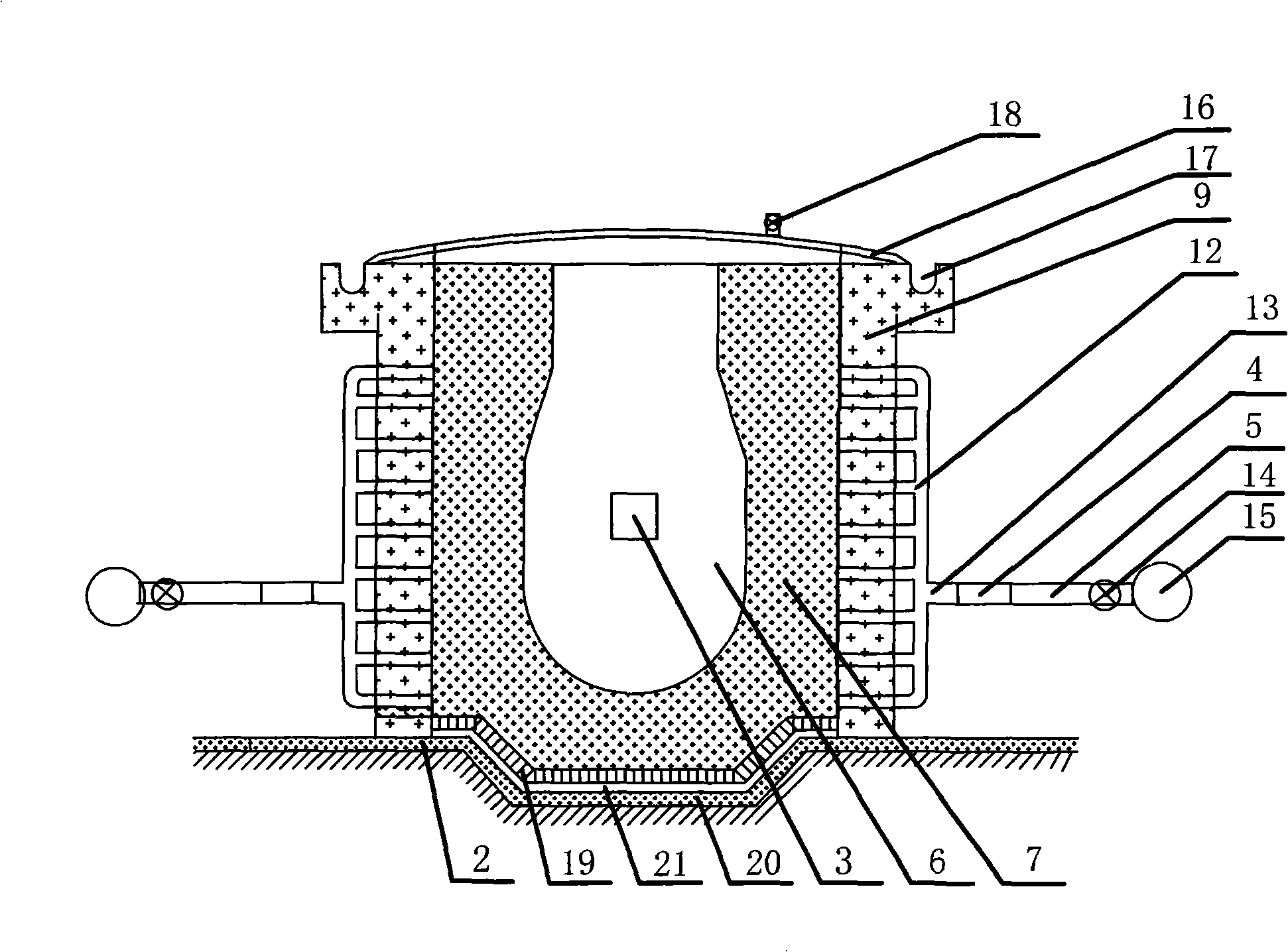

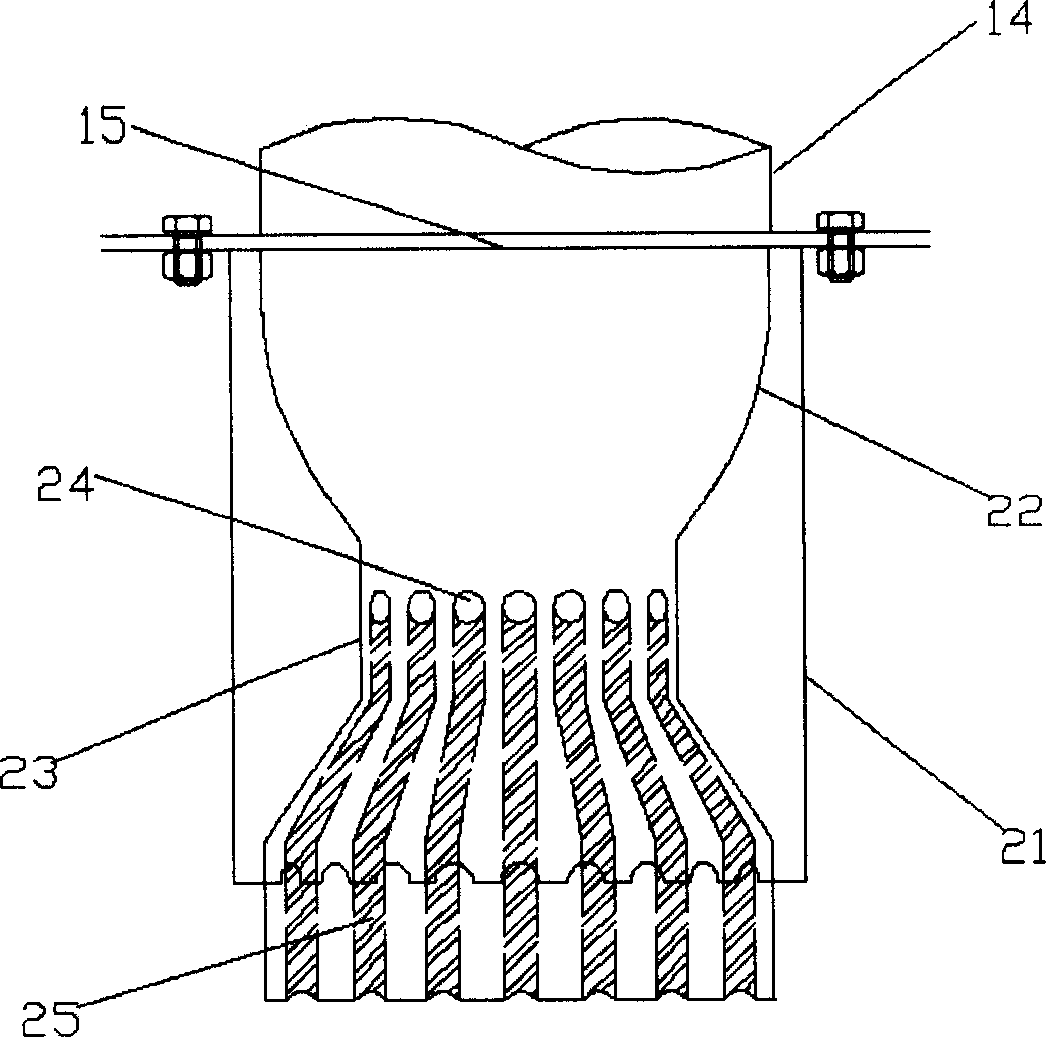

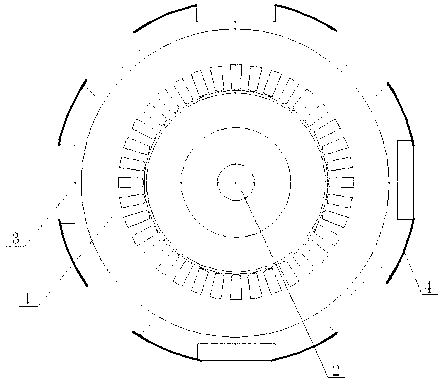

Evaporative cooling equipment of stator winding of hydraulic generator

InactiveCN1416202AImprove cooling effectExtended service lifeCooling/ventillation arrangementGas collecting tubeElectrical conductor

The cooling system is the enclosed self-loop system with the cooling medium being filled inside. The stator winding of the generator is composed of the hollow conductor and the solid conductor combined. The upper and lower ends of the stator winding throug hthe electrolyte separation joints at the upper and lower ends are connected to the upper insulation draft tube and the lower insulation draft tube. The upper insulation draft tube through the gas collecting tube is connected to the condensation space. The lower insulation draft tube through the liquid collecting tube is connected to the lower end of the liquid returning tube. The upper end of the liquid returning tube is connected to the condensation space. The looping pipe connects multiple condensers in parallel.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

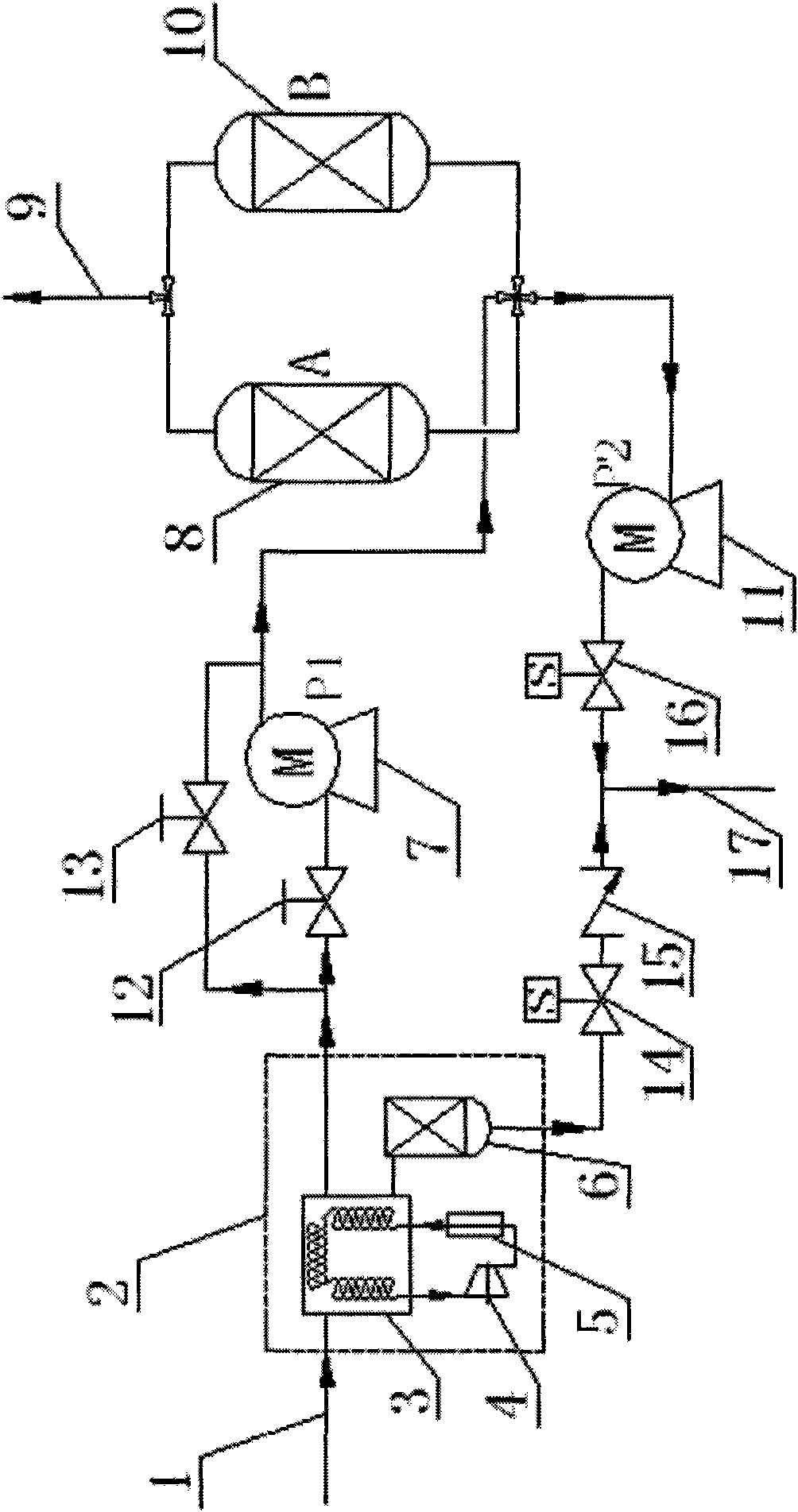

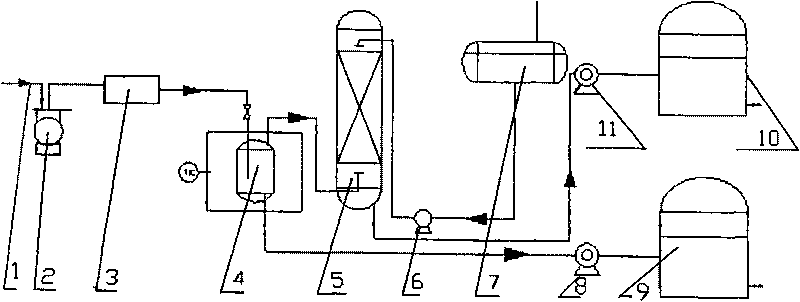

Device and method for recovering oil gas by condensation-adsorption combined technology

InactiveCN101579596ARelieve pressureReduce trafficDispersed particle separationVapor condensationGas collecting tubeAtmospheric air

The invention relates to a device and a method for recovering oil gas by adopting a condensation-adsorption combined technology. The whole technical proposal is characterized in that a mixed gas of various oil gases and air generated during various storage and transportation processes enters a condensing unit with an integrative structure which consists of an evaporator, a compressor, a condenser and an oil water separator through a gas collecting tube; when being condensed to the temperature of about minus 5-5 DEG C, most of components over C5 are condensed and liquefied, and are delivered to a storage tank through a valve and an oil return pipe, or used directly; the rest small part of oil gas mixture passes through the valve and is delivered to an adsorption system by a vacuum pump P1 for further adsorption treatment; after being adsorbed and analyzed alternately by an adsorber A and an adsorber B, stripping gas containing oil gas is delivered to the storage tank by a vacuum pump 2 and the valve, or used directly; the effluent gas with the oil gas approximate to zero enters the atmosphere through an emptying pipe; the sorbent used by the two adsorbers is a phi3 cylindrical-shaped active carbon which is specially researched and used for the recovery of oil gas, and carry out vacuum desorption alternately under the action of the vacuum pump p2; and the desorption time is set to 15-20 minutes. The recovery rate of oil gas by utilizing the device and the method can reach over 98 percent, and the device and the method have the advantages of low cost and being beneficial to environmental protection.

Owner:江苏三星化工有限公司

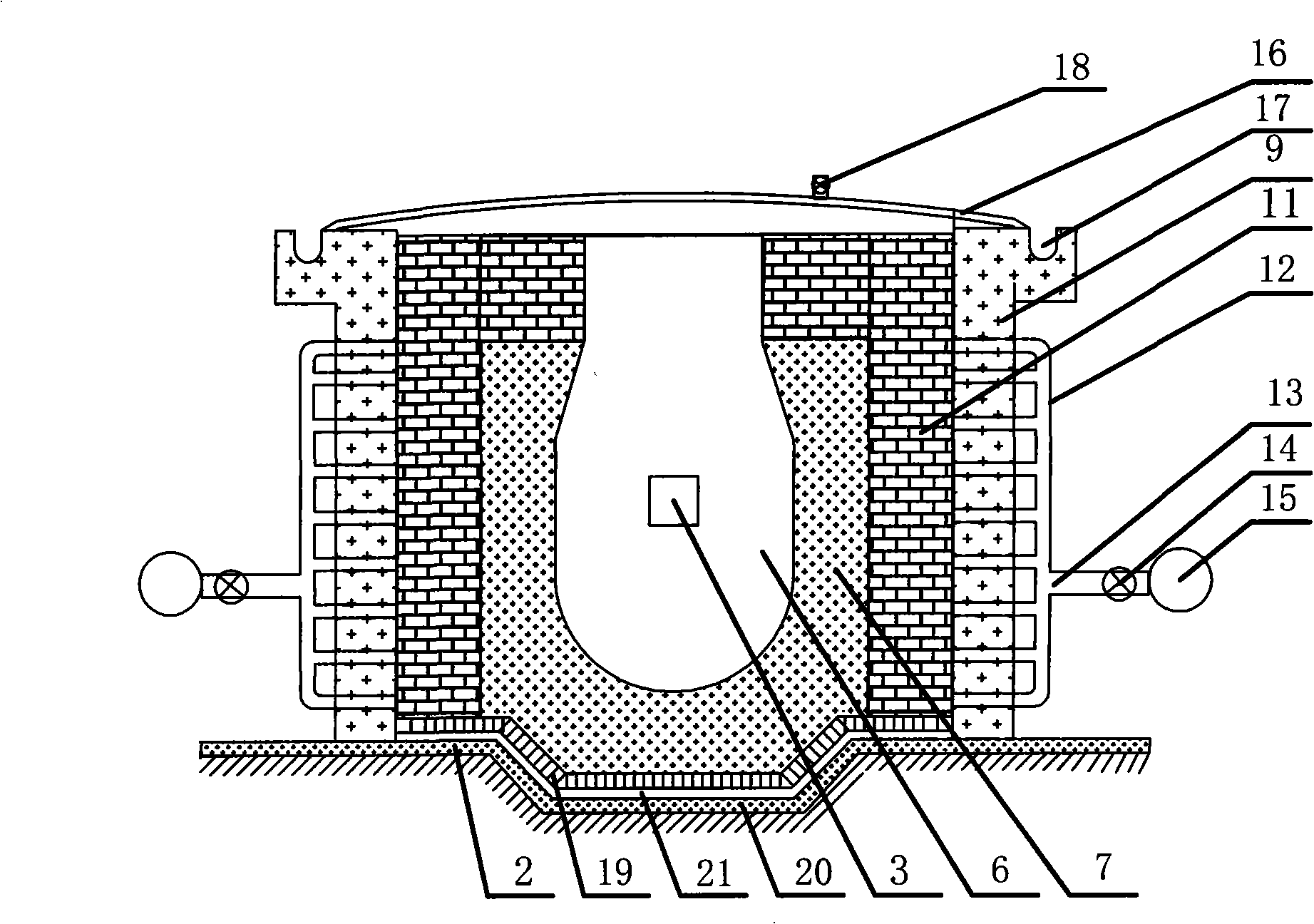

Refining furnace of silicon carbide for recovering smelting waste gases

The invention provides a silicon carbide smelting furnace which can recycle a waste smelting gas, and solves the shortcomings that the combustible waste gas produced in the production process of the conventional smelting furnace structure is directly discharged along the gap of the furnace body, and burns on the surface of the furnace, thus resulting in great energy resource waste without recycling. The silicon carbide smelting furnace is as follows: airproof furnace walls are arranged on the two sides of a furnace body; the furnace walls, a furnace end and a furnace bottom form a straight groove shape; a furnace cover is arranged on the top of the straight shape; the furnace end, the furnace bottom, the furnace walls and the furnace cover form an enclosed space inside the furnace body; a plurality of gas collecting tubes are arranged to communicate the inside with the outside of the furnace body, thus achieving the purpose of collecting, discharging and utilizing the waste smelting gas. The silicon carbide smelting furnace has the advantages of simple manufacture and obvious waste gas recycling effect, and can effectively utilize energy resource and reduce smelting production cost.

Owner:贾玉东

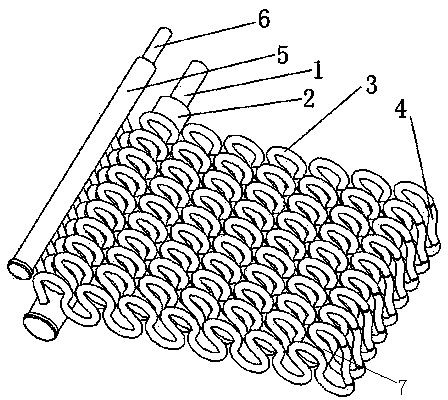

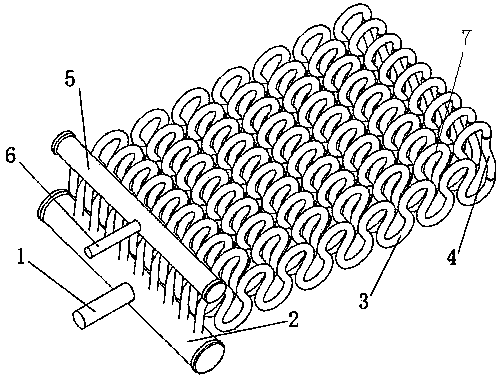

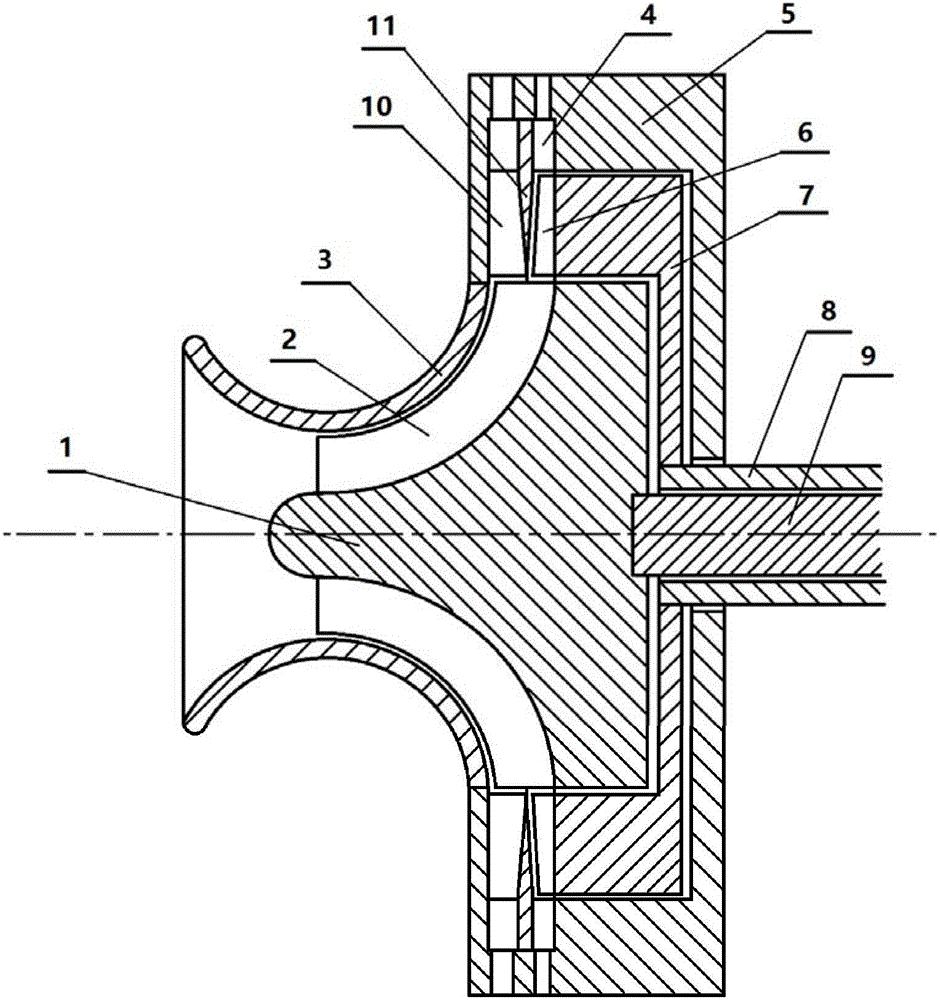

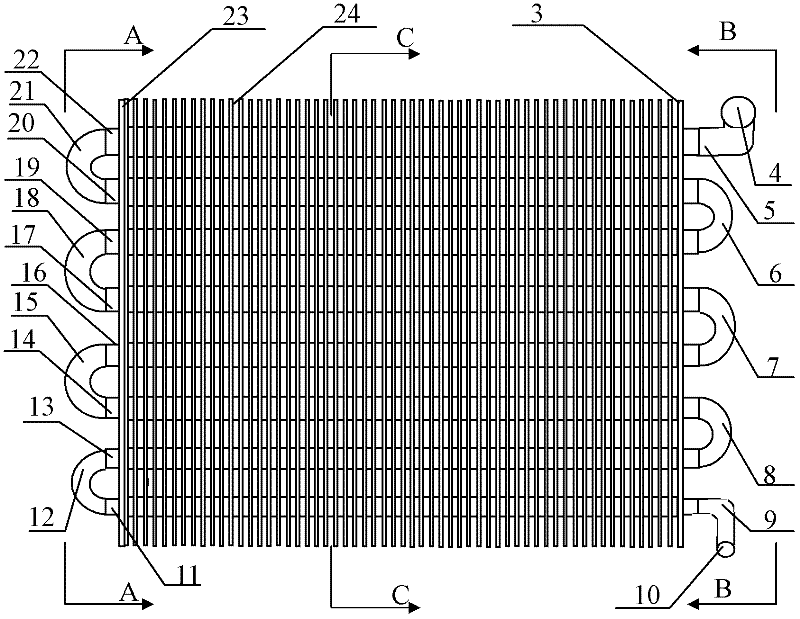

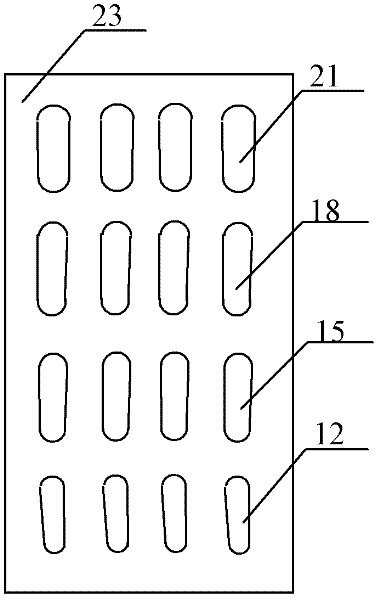

Efficient heat exchange tube and evaporative condenser

ActiveCN103808185AEvenly distributedReduce resistanceEvaporators/condensersTubular elementsGas collecting tubeCondenser (heat transfer)

The invention discloses an efficient heat exchange tube. The efficient heat exchange tube comprises a gas collecting tube and a liquid collecting tube. A plurality of heat exchange tube units are communicated between the gas collecting tube and the liquid collecting tube. Each heat exchange tube unit comprises a first heat exchange tube, a second heat exchange tube and a corner elbow. The inlets of the first heat exchange tubes are communicated with the gas collecting tube. The outlets of the second heat exchange tubes are communicated with the liquid collecting tube. The second heat exchange tubes are vertically layered and arranged in a staggered mode relative to the first heat exchange tubes. The corner elbows are arranged between the first heat exchange tubes and the second heat exchange tubes. The outlets of the first heat exchange tubes are communicated with the inlets of the second heat exchange tubes. The efficient heat exchange tube solves the problems that in the prior art, the heat exchange tubes of an evaporative condenser are low in inner side heat exchange coefficient and large in outer side wind resistance, and is good in heat conduction performance and small in tube diameter; the evaporative condenser is good in heat transfer performance, high in pressure resistance, compact in structure and small in occupied space.

Owner:HANGZHOU SHENSHI ENERGY CONSERVATION TECH

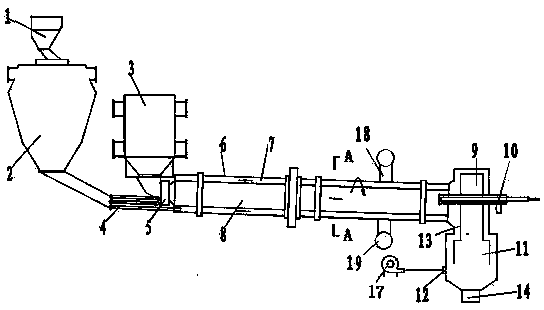

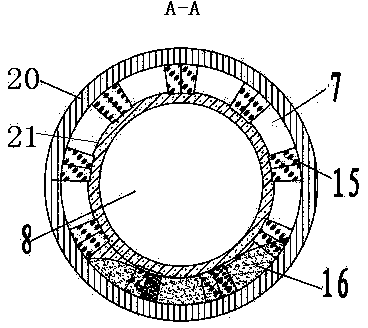

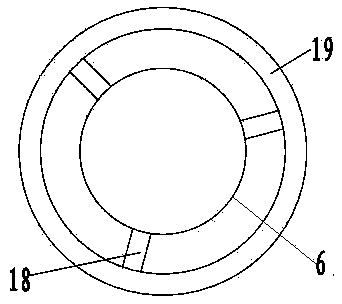

Rotary kiln with power generation device

ActiveCN104016596AReduce energy consumptionAvoid direct contactLime productionGas collecting tubeFlue gas

The invention relates to a rotary kiln with a power generation device. The rotary kiln comprises a power generation device, a material loading device, a material bin, a kiln body, a kiln end cover, a cooler and a cooling fan. A kiln head is provided with a burner; the kiln body is composed of an inner cylinder and an outer cylinder structure, a kiln chamber is in the middle of the inner cylinder, an annular space formed between the inner cylinder and the outer cylinder is a material chamber, and the annular space is provided with a support column; the rotary kiln is provided with a screw conveyor, a discharge passage and a gas collecting tube; the material loading device is connected with the material bin, the material bin is connected with the annular space through the screw conveyor, and the annular space through the discharge passage is connected with the cooler; and the lower part of the cooler is connected with a discharge hatch, the upper part of the cooler through the kiln head is connected with the kiln chamber, and the kiln chamber is connected with the power device. Through the kiln body with the inner cylinder and outer cylinder structure, limestone in the annular space is heated through flue gas dividing wall, so as to avoid direct contact of the flue gas with the material and benefit utilization and recovery of decomposed carbon dioxide gas; and at the same time, and waste heat of flue gas is utilized for power generation, so as to reduce the energy consumption of the rotary kiln.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

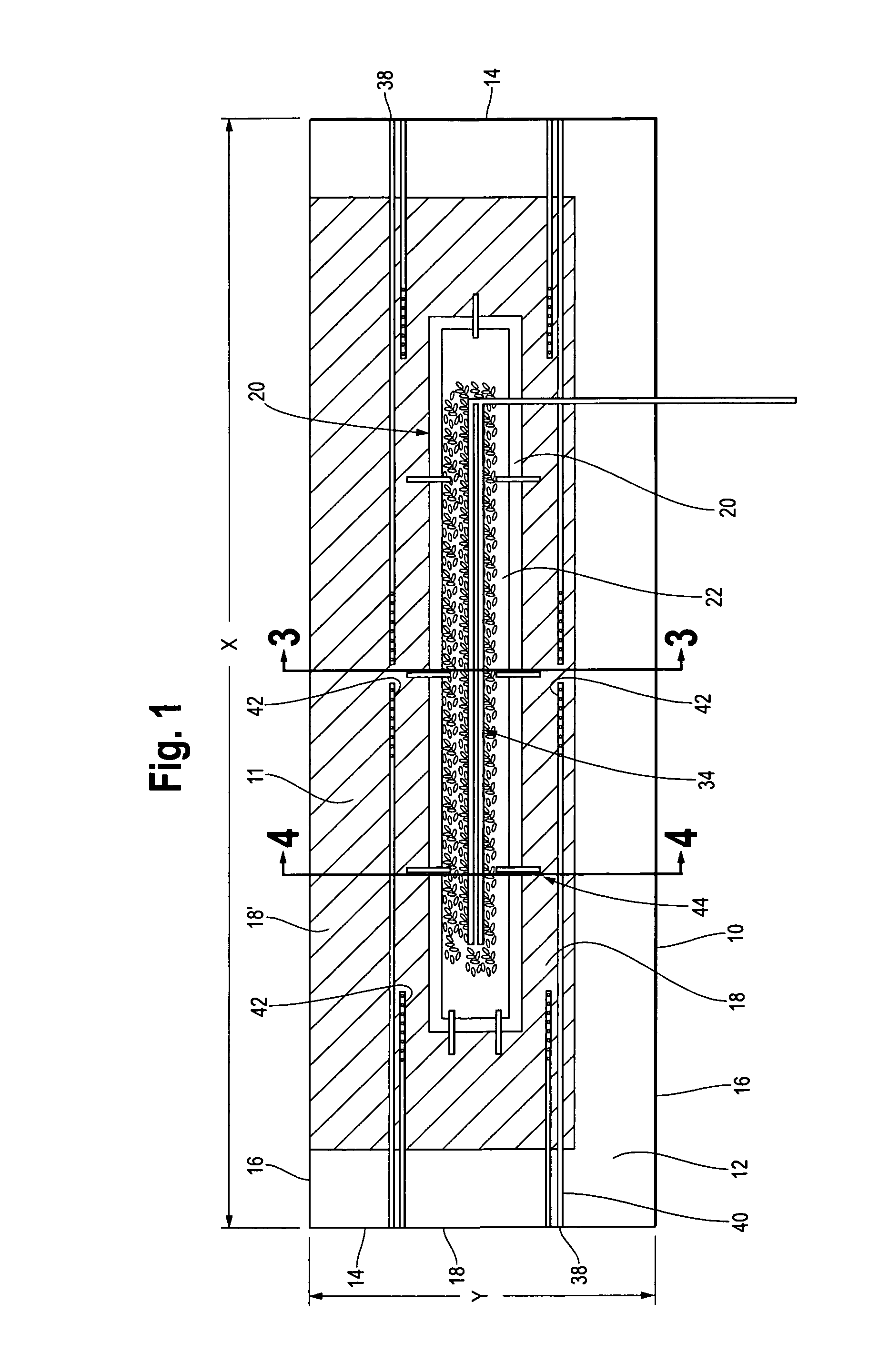

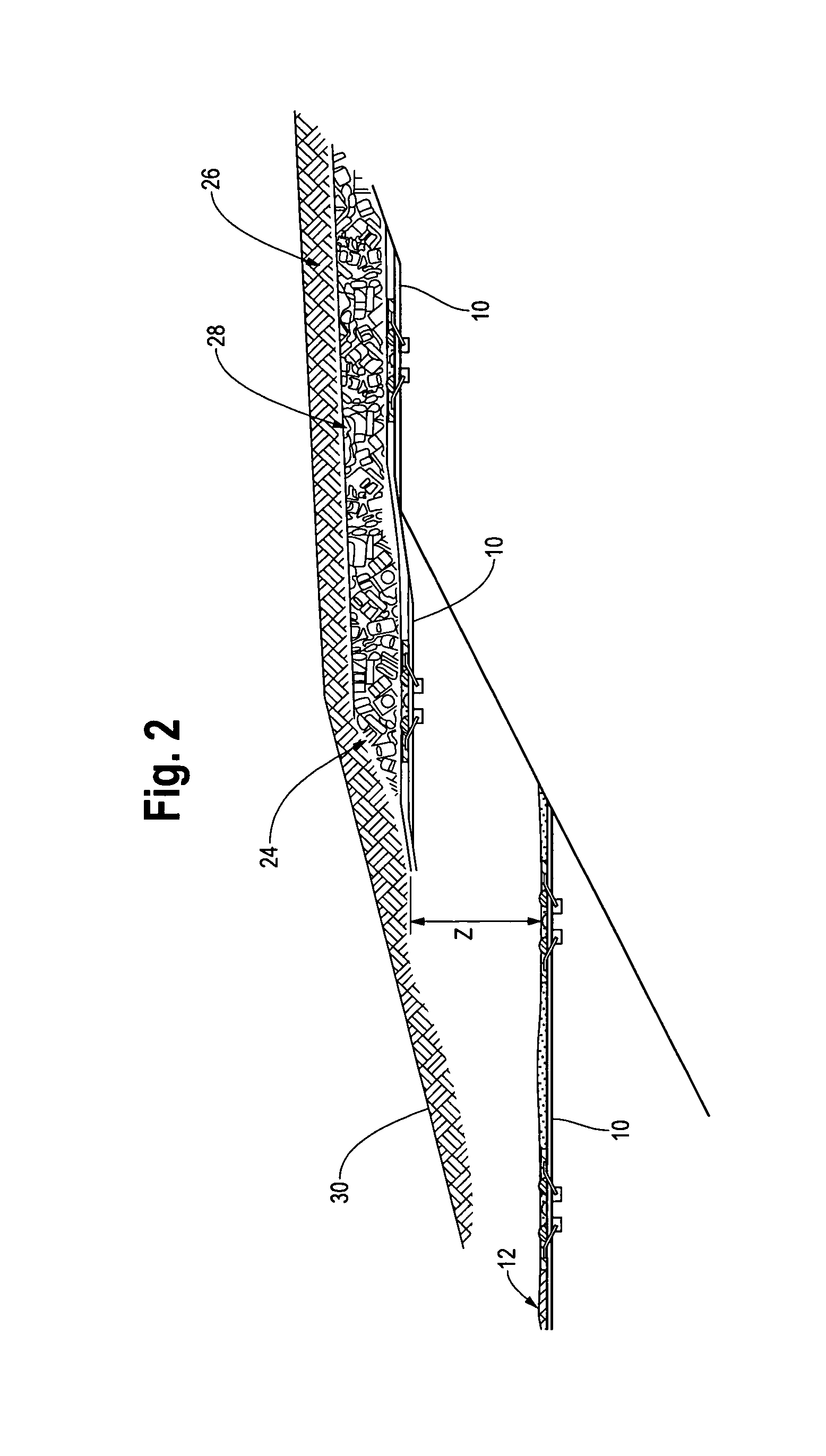

Multi-planar gas recovery bioreactor

Owner:WM INTPROP HLDG L L C

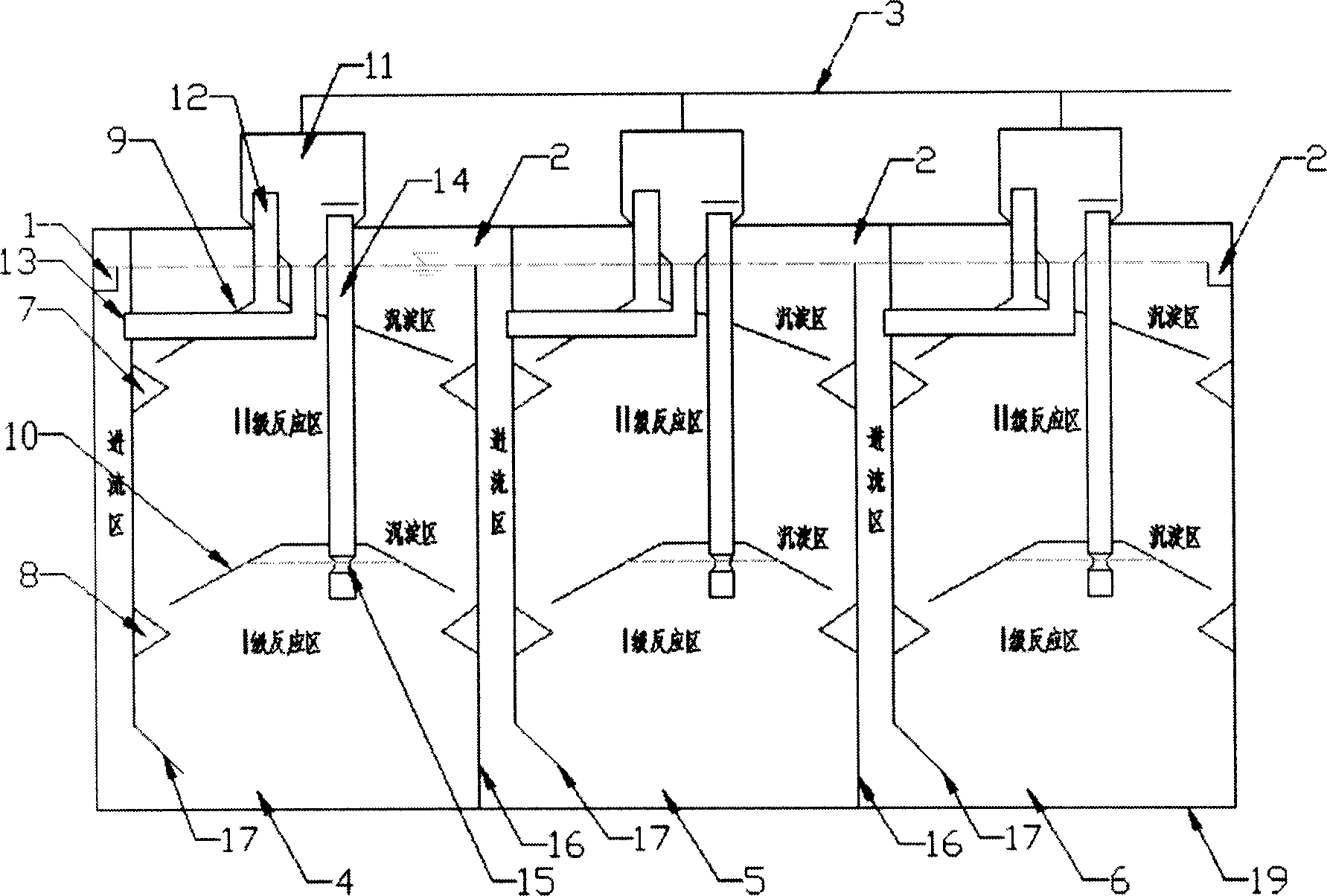

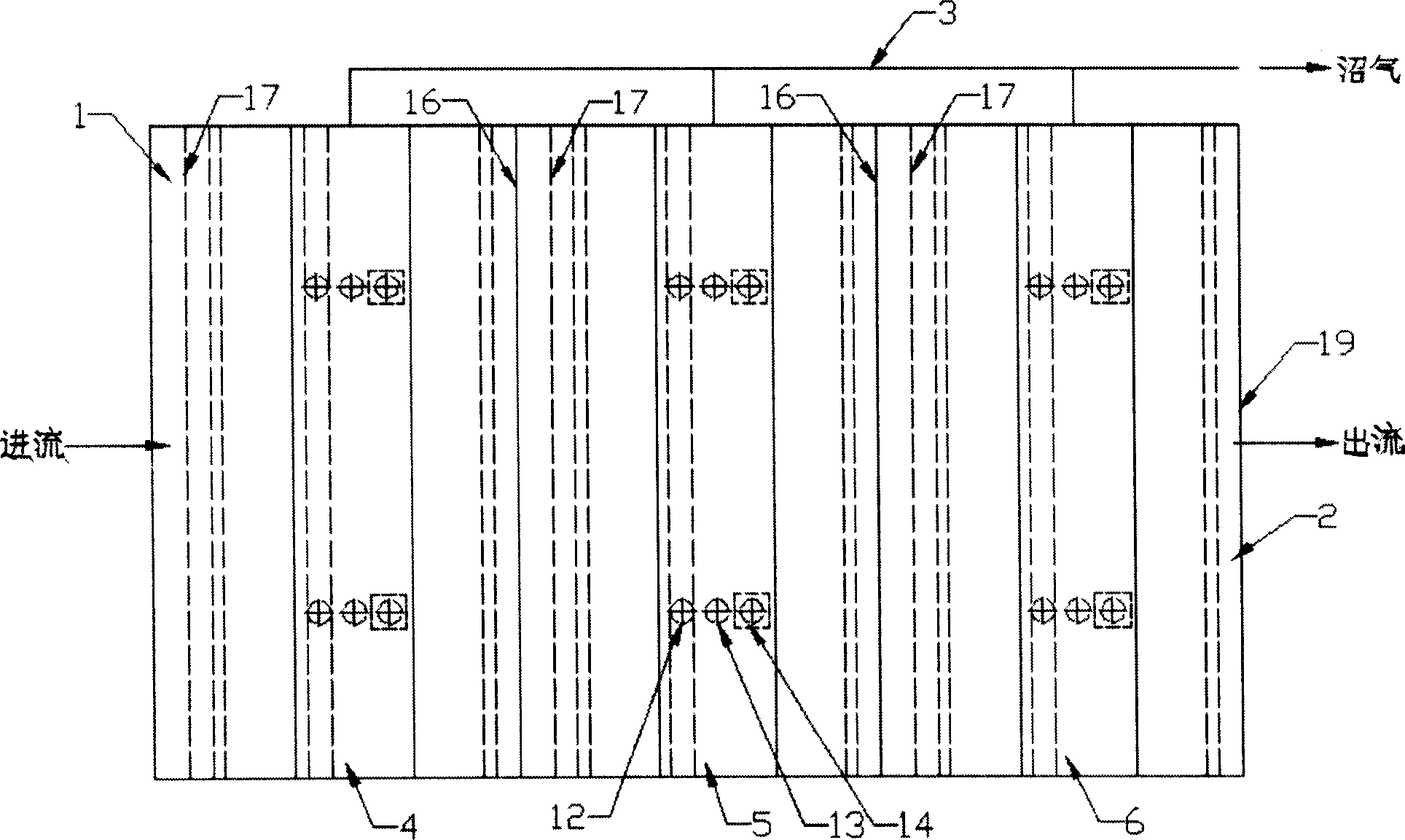

Multi-phase internal circulating anaerobic reactor

InactiveCN1803668AImproved separation propertiesHigh activityWater contaminantsWaste based fuelSeparated stateGas collecting tube

The disclosed multiphase inner cycle anaerobic reactor comprises: at least two gas-sealed inner cycle anaerobic reaction chambers separated by separator and connected in series and contained a two-stage reaction zone, an opposite gas-lift tube, a gas collecting tube, a backflow tube, gas-liquid separators parallel on one gas exhaust pipe or output respectively, and a three-phase separator; and arranging a water guide plate on the inlet of reaction chamber and a gas stripping device on bottom of the air-lift. This invention has well flow pattern, mixed liquid, well microbe separated state, and other advantages.

Owner:林知谚

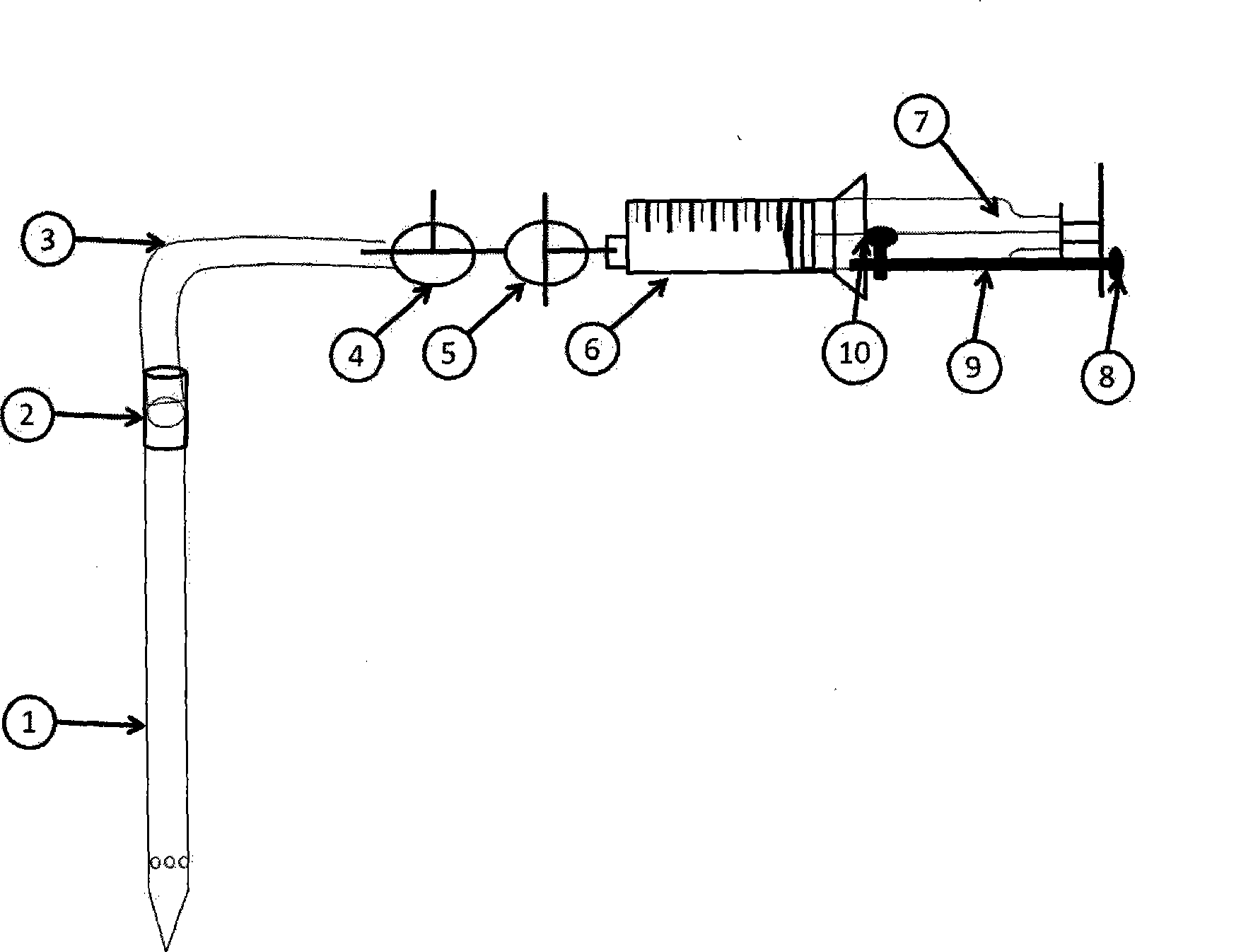

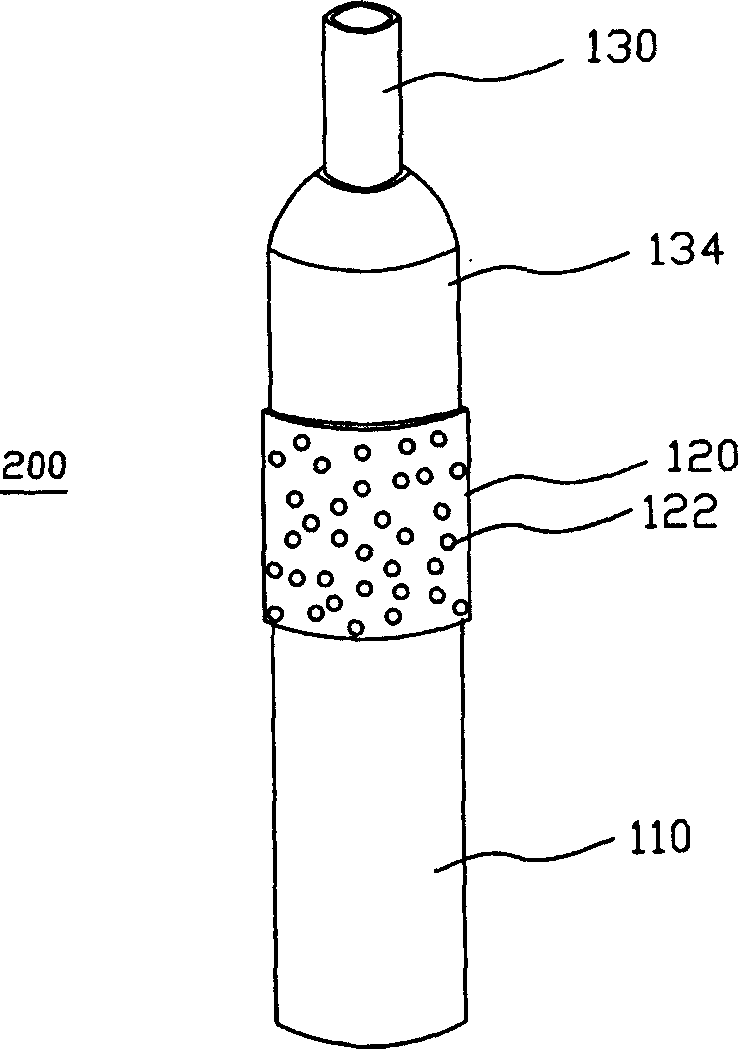

Collecting device of different depth soil gas

The invention relates to a collector for collecting gas at different depths soil, which has a structure that the top end of a gas collecting tube is tip-shaped and closed with a plurality of pores arranged around the tip of the gas collecting tube which is connected with a connecting tube, the other end of the connecting tube is connected with a tee the other end of which is connected with the front end of an injector. The invention solves the defect existed in the prior soil gas collecting box and gas collecting bag. The invention, which can adapt different climate condition and meet the requirement of extensively collecting gas at different depths soil, reduces disturbance to soil, has the advantages of unnecessary of preembedding and additional power, simple structure, convenient operation, low cost, time saving and labor saving, and adaptability for simultaneously multi-point observation.

Owner:YANGZHOU UNIV

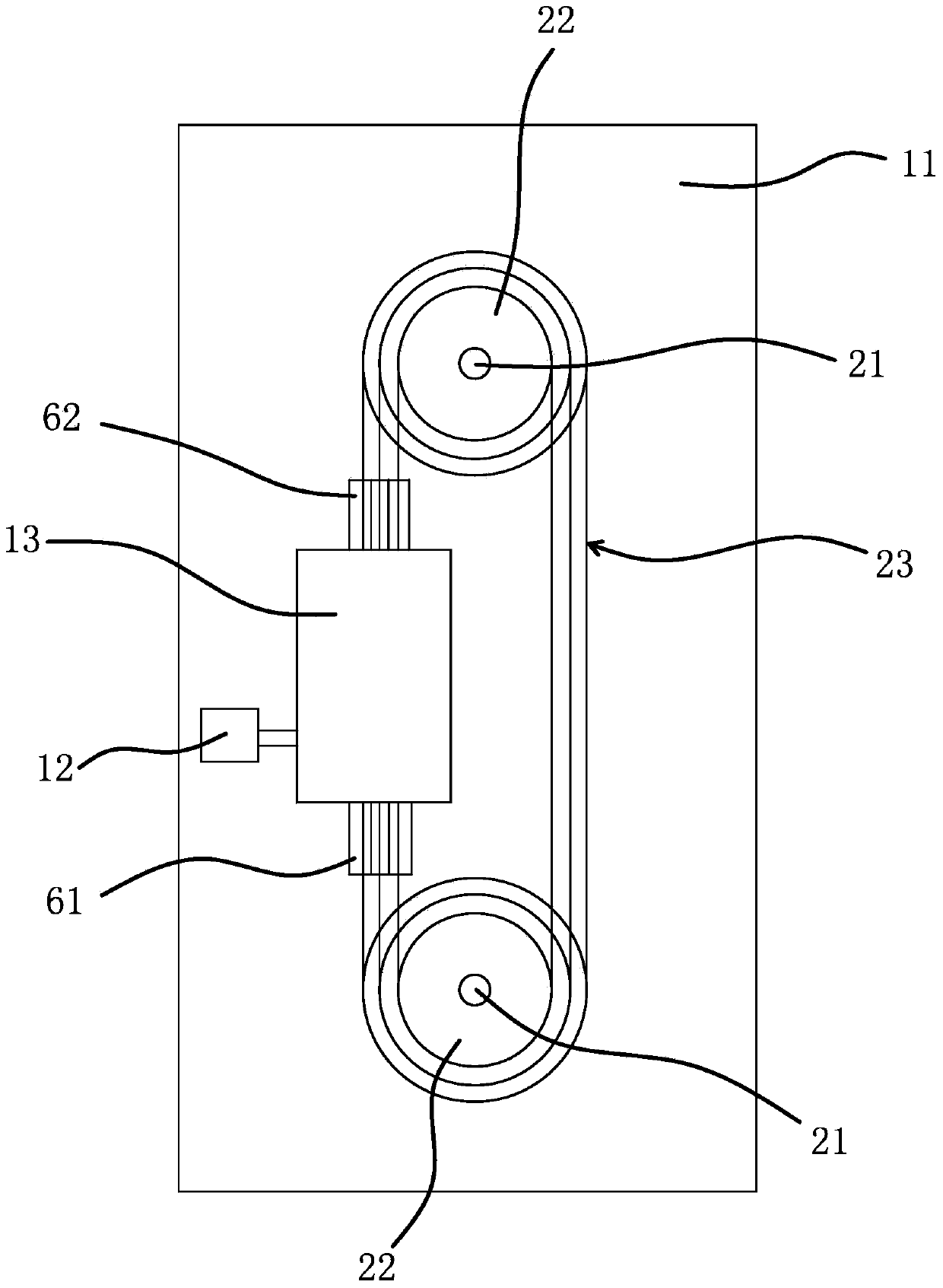

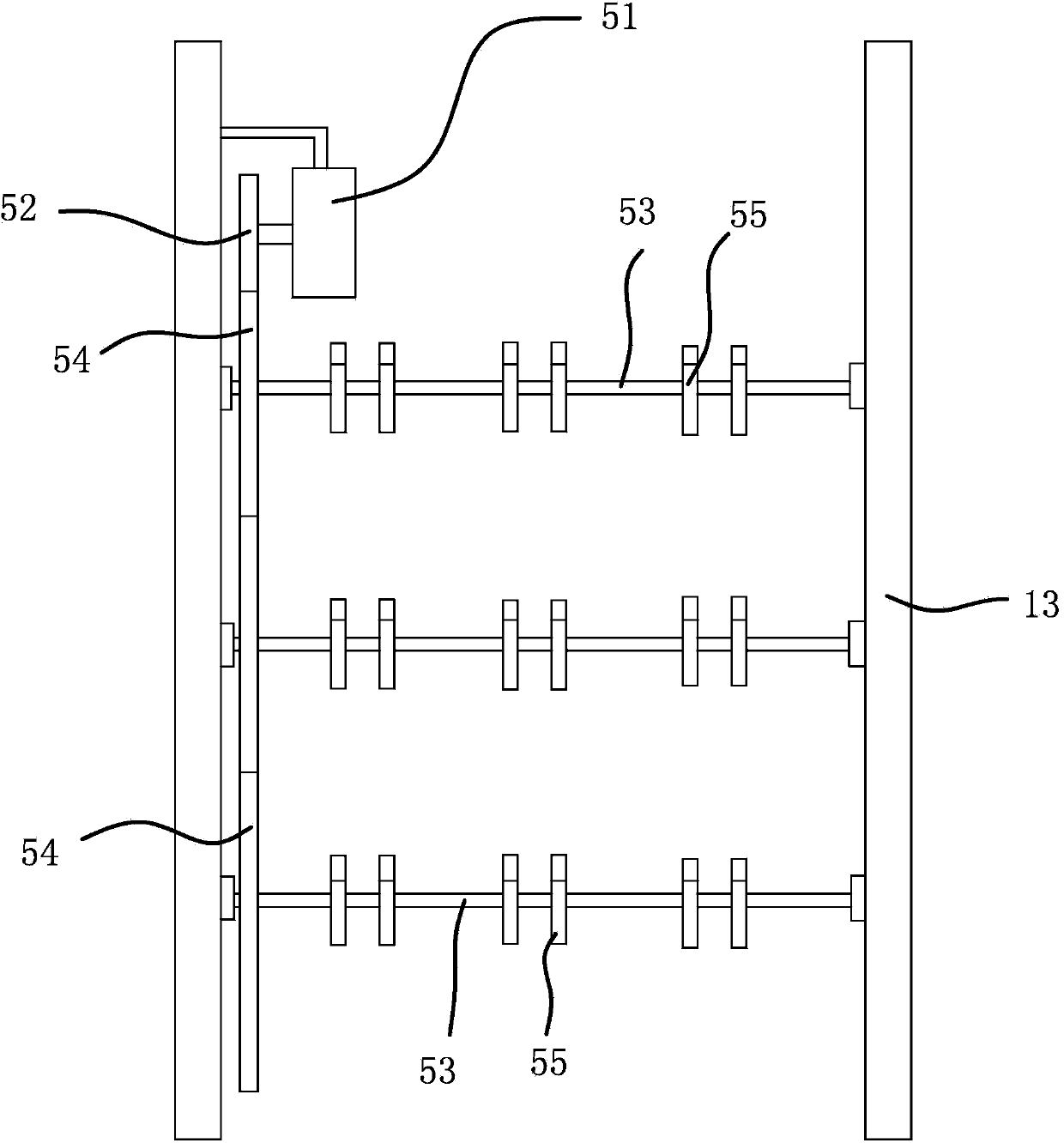

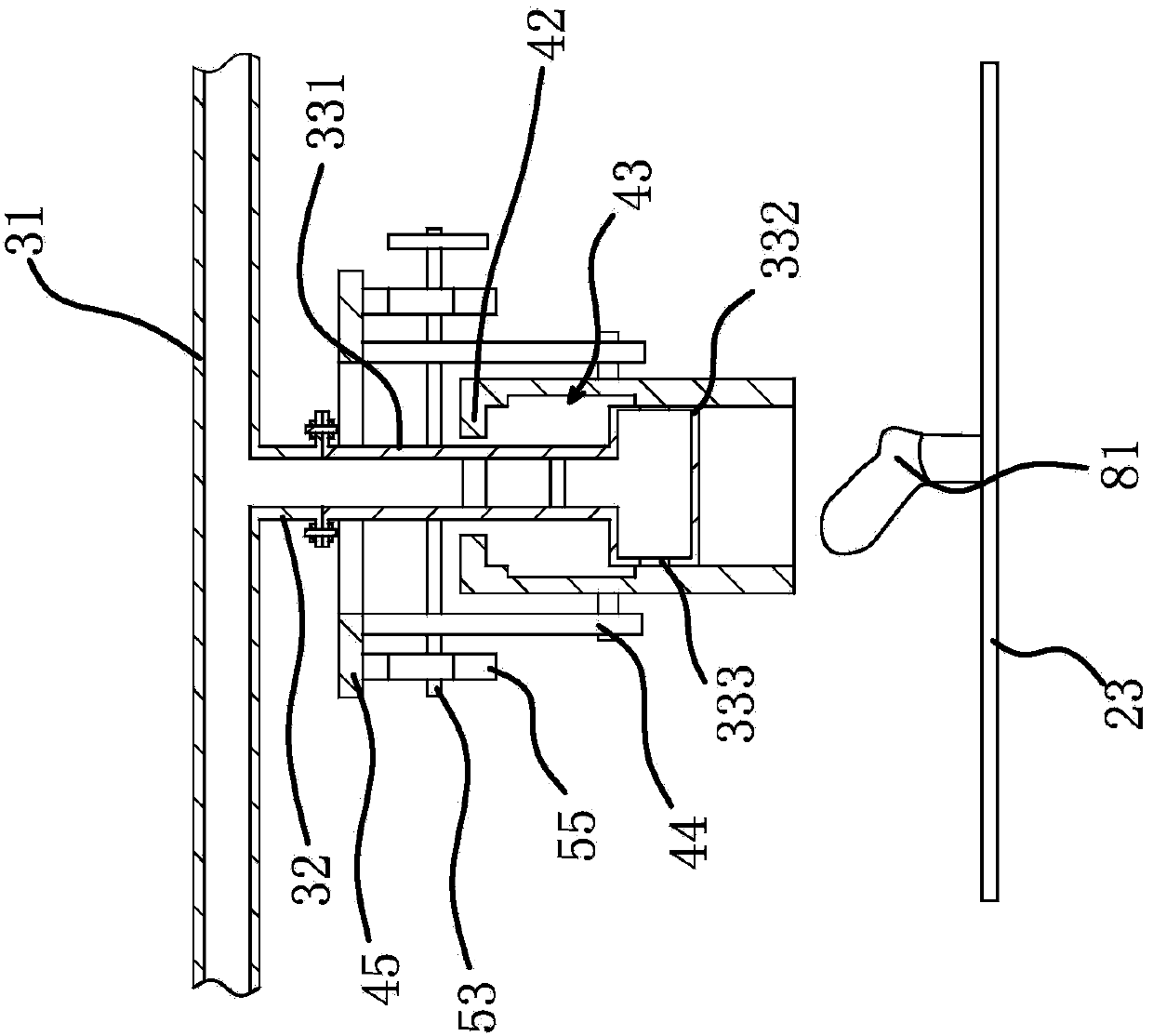

Steam sock setting machine

ActiveCN103726249AImprove styling efficiencyMobile unificationHeating/cooling textile fabricsShaping/stretching tubular fabricsSOCKSGas collecting tube

Owner:浙江汉保利罗针织股份有限公司

A method for exporting raw coke oven gas

ActiveCN102268269ANo backflowGuaranteed smooth productionCharging devicesDistillation gas withdrawalGas collecting tubeCoke oven

The invention relates to a method for drawing raw coal gas out of coke oven. A device used comprises a riser water seal cover opening and closing control device on a coke oven side or coke side, a riser water seal cover, a riser lead-out device, a cooled low-pressure ammonia water spraying device, a high-pressure ammonia water spraying device, a bridge tube, a water seal valve body, a water seal valve disk, a water seal valve disk opening and closing control device and a gas collecting tube, and is characterized in that: the method adopts a downward inclined riser lead-out device for preventing ammonia water from flowing back, and the two sides of the riser lead-out device are connected with the bridge tube and a riser water seal seat respectively. The device has the advantages that: raw coal gas generated in production in coke oven can be led into the gas collecting tube smoothly without returning ammonia water; the drawback that sealing material in the valve disk is washed out of the socket of the valve disk when the U-shaped valve disk is washed by high-pressure ammonia water is overcome; and the operation is flexible, the overhaul is convenient, the structural arrangement is reasonable, and the energy-saving and environment-protection effects are obvious, and the like.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

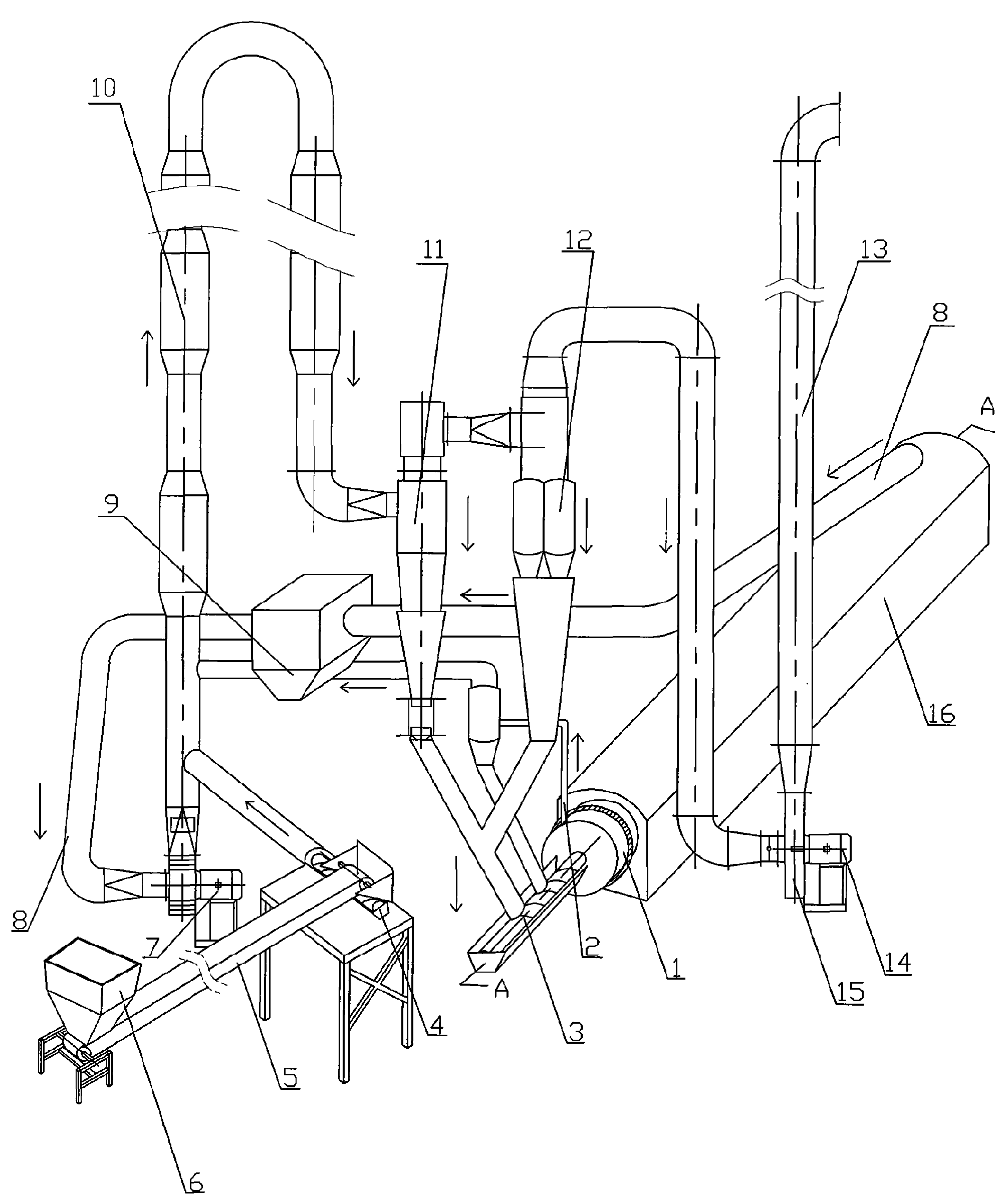

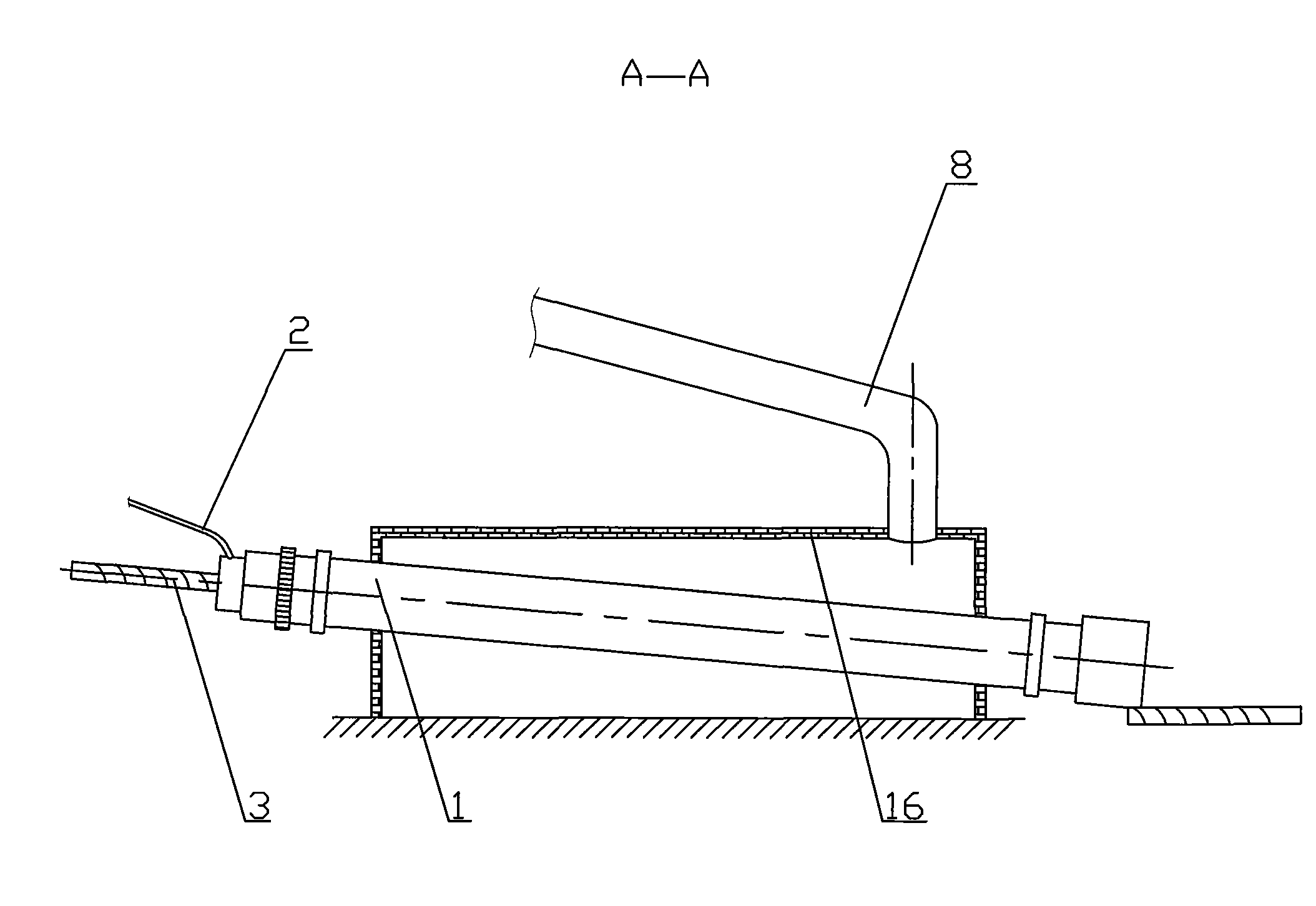

Energy-saving environment protection apparatus for drying and producing chemical gypsum powder by using tail gas

The present invention relates to an energy-saving environment protection apparatus for drying and producing chemical gypsum powder by using tail gas, including a circumversion frying pan (1) and a hearth box (16), wherein the circumversion frying pan is provided with a packing auger feeder (3), characterized in that a tail gas collecting tube (8) is connected with one end of a impulse drying tube (10), the other end of the impulse drying tube (10) is connected with a cyclonic collector (11), a feed end of the cyclonic collector (11) is connected with the packing auger feeder (3), and an exhaust end of the cyclonic collector (11) is connected with a draught fan (14). The beneficial effect of the apparatus is that the gypsum raw material is dried by using the high-temperature tail gas and aqueous vapour generated by the circumversion frying pan. The gas drying contact area is large, and the thermal efficiency is high. The tail gas contains microparticle flue dust which may play a function of the activated carbon to remove yellow, so that the white content of the gypsum powder is improved. The tail gas and the aqueous vapour is purified by a dedusting environment protection apparatus, thus the pollutant will be not discharged outside, and the environment protection effect is good.

Owner:蚌埠百佳新型建材有限公司

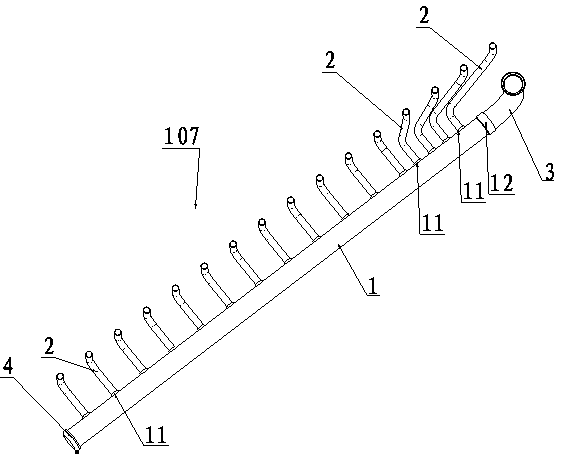

System and method for pyrolyzing coal

ActiveCN105567267AEasy to handleImprove qualitySpecial form destructive distillationGas collecting tubeTar

The invention discloses a system and method for pyrolyzing coal. The system comprises a moving bed pyrolysis reactor and a spray tower; the reactor comprises a coal material inlet, a semicoke outlet, regenerative radiant tubes, oil gas exporting pipelines, a stirring device and gas collecting tubes; the regenerative radiant tubes are arranged in the reactor in the height direction of the reactor for multiple layers, and multiple regenerative radiant tubes which are parallel to one another in the horizontal direction are arranged on each layer; through holes are formed in the pipe walls of the oil gas exporting pipelines; the stirring device comprises a stirring shaft and multiple stirring rods connected to the stirring shaft; the gas collecting tubes comprise the gas collecting header tube and the gas collecting branch tubes, and the gas collecting header tube is connected with the spray tower. According to the system, powdered coal can be effectively treated, and the treatment efficiency is high; meanwhile, oil gas resources generated through pyrolysis can be quickly exported, secondary reactions are few, the tar oil quality is high, and the content of light components in tar oil is high; in addition, due to the fact that the regenerative radiant tubes are adopted in the pyrolysis reactor and rotatable inner elements are arranged in the regenerative radiant tubes, heat transfer among particles and between the particles and the radiant tubes is increased, and the heat transfer efficiency is high.

Owner:SHENWU TECH GRP CO LTD

Soil moisture detecting apparatus

The invention discloses a soil moisture detecting apparatus, including controllers, a display screen, a plurality of vertically-arranged moisture sensors, piezoresistance sensors corresponding to the moisture sensors, gas collecting tubes, plastic tubes, pottery clay heads, and rubber plugs. One end of each gas collecting tube communicates with one end of each corresponding plastic tube, the other end of the gas collecting tube is provided with one rubber plug, and the other end of the plastic tube is provided with one pottery clay head. A side wall of one gas collecting tube communicates with a measurement end of each corresponding moisture sensor, which communicates with each corresponding piezoresistance sensor, and the piezoresistance sensor is in electric connection with a sensor circuit. The controllers control the moisture sensors to output monitored results on the display screen. The provided soil moisture detecting apparatus can monitor moister situations of soil with different depth, the controllers receive the monitored results of the moisture sensors, and the monitored results are output on the display screen.

Owner:CHONGQING DUOBANG TECH DEV

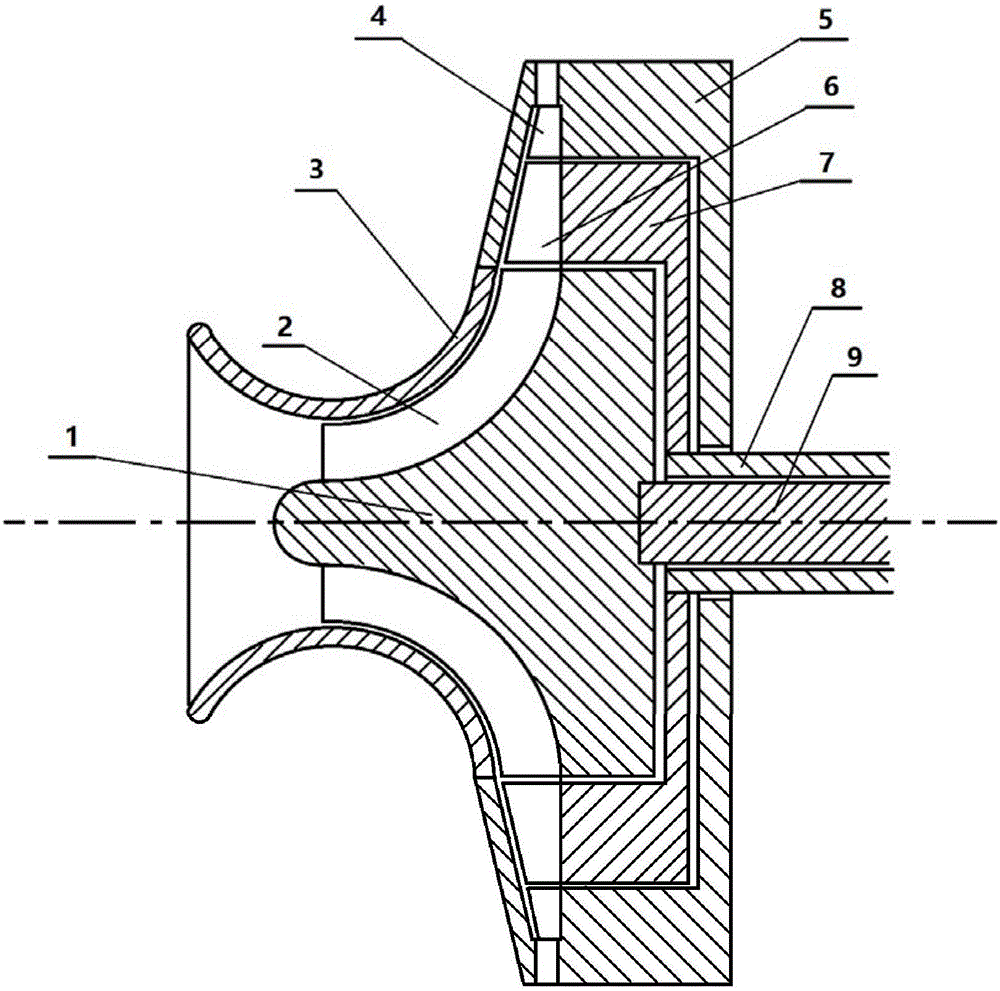

Centrifugal contra-rotating ram compressor

The invention belongs to the technical field of gas supercharging and relates to a centrifugal contra-rotating ram compressor which comprises a gas inlet system, a transmission device, an impeller and a housing, wherein a punching wheel which reversely rotates along with the impeller is arranged on a position, at the radial outer side of the impeller, between the impeller and a pressure expander or between the impeller and a gas collecting tube; and the punching wheel and the impeller are separately connected with a power device through the transmission device. According to the centrifugal contra-rotating ram compressor, the punching wheel is arranged in a gas flow channel for further supercharging gas, so that gas pressure higher than that of an existing centrifugal compressor can be obtained, and therefore, a pressure ratio is effectively increased, efficiency of the compressor is improved, and the range of application of the compressor is expanded.

Owner:SHENZHEN FUSTAR POWER TECH CO LTD

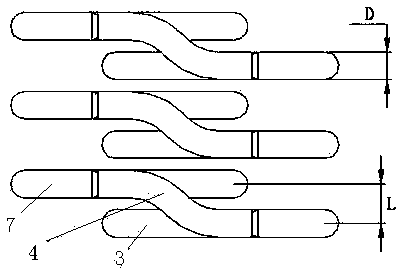

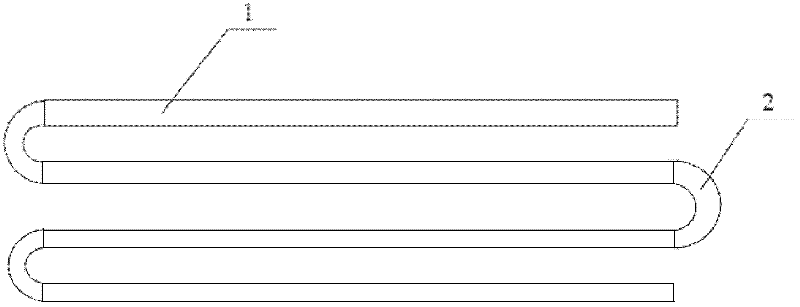

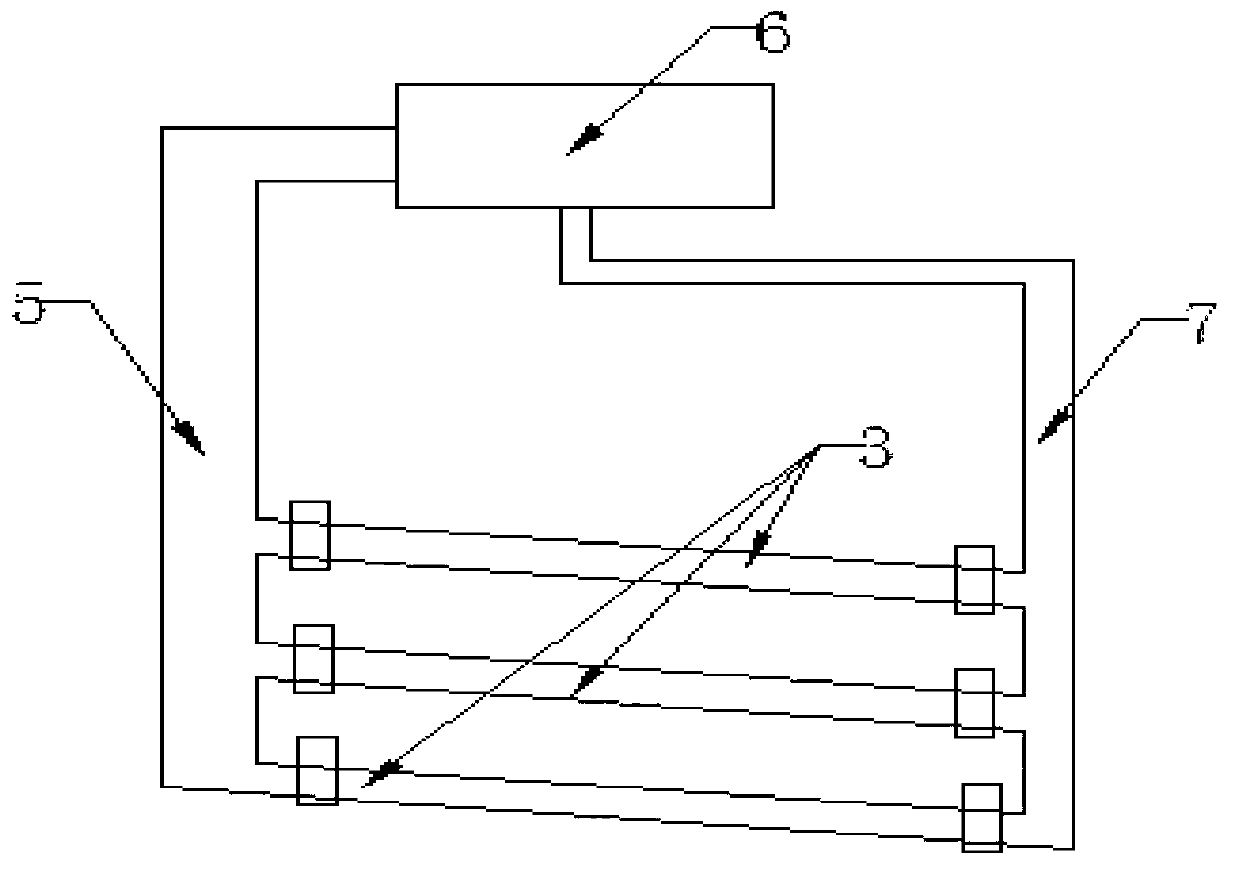

Heat exchange tube unit, finned tube air-cooled condenser and cooling air evaporator

InactiveCN102445100AReduce consumptionImprove performanceEvaporators/condensersTubular elementsGas collecting tubeSpecific volume

The invention discloses a heat exchange tube unit, a finned tube air-cooled condenser and a cooling air evaporator, and aims to provide the heat exchange tube unit in which heat exchange tube monomers and connecting elbows change as the change of the specific volume of a refrigerant in the heat exchange tube, the air-cooled condenser and the cooling air evaporator. The heat exchange tube unit comprises a plurality of heat exchange tube monomers which are parallelly arranged, wherein the heat exchange tube monomers are connected end to end to form a heat exchange medium channel through the elbows, the diameters of the heat exchange tube monomers which are adjacently arranged along the direction in which the specific volume of gas increases gradually increase, and the elbows are gradually diameter-changing elbows. The diameters of the heat exchange tube monomers which are adjacently arranged along the direction from a gas inlet tube to a liquid collecting tube in the air-cooled evaporator gradually decrease, and the elbows are gradually reducing elbows. The diameters of the heat exchange tube monomers which are adjacently arranged along the direction from a liquid distributing tube to a gas collecting tube in the air-cooled evaporator gradually increase, and the elbows are gradually diameter-expanding elbows. For the condenser, the metal consumption can be reduced. For the evaporator, the flow losses can be reduced.

Owner:TIANJIN UNIV OF COMMERCE

Integrated pyrolysis and reduction system and garbage disposal method

ActiveCN103438461AExpand application spaceEasy to handleIncinerator apparatusAnaerobic decompositionGas collecting tube

The invention discloses an integrated pyrolysis and reduction system and a garbage disposal method. The integrated pyrolysis and reduction system comprises an anaerobic carbonization kettle, wherein the anaerobic carbonization kettle is provided with an extrusion feeding device which is used for feeding materials and blocking a material port; a heating chamber is arranged below the anaerobic carbonization kettle, the other side of the anaerobic carbonization kettle is communicated with an anaerobic decomposition kettle, the anaerobic decomposition kettle is respectively communicated with a thermal chemical reaction kettle and a waste residue oxidation chamber through a heating pipe, the thermal chemical reaction kettle is located above the waste residue oxidation chamber, a water seal type ash discharging port is formed below the waste residue oxidation chamber, a plurality of gas collecting pipes are arranged above the anaerobic carbonization kettle and the anaerobic decomposition kettle, and the gas collecting pipes are communicated with the thermal chemical reaction kettle. By the adoption of the anaerobic carbonization kettle, the extrusion feeding device, the anaerobic decomposition kettle, the thermal chemical reaction kettle, the waste residue oxidation chamber and the like, application space of garbage disposal is expanded, and generation conditions of pollutants of dioxins are controlled from sources.

Owner:徐浩

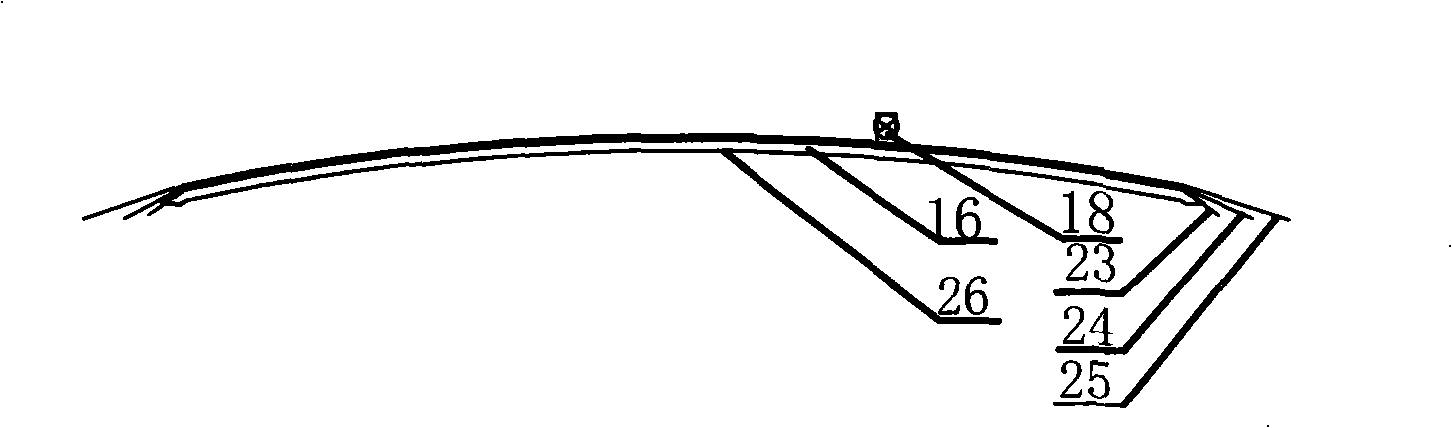

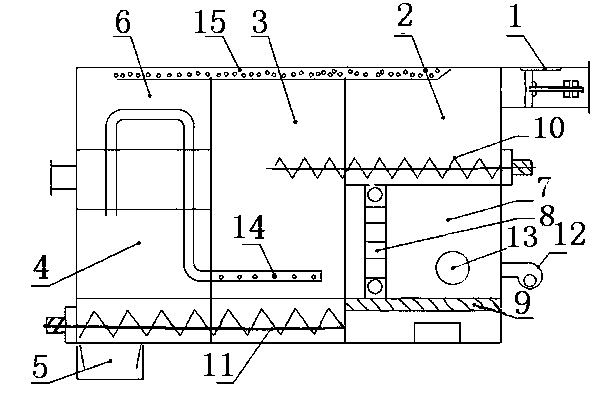

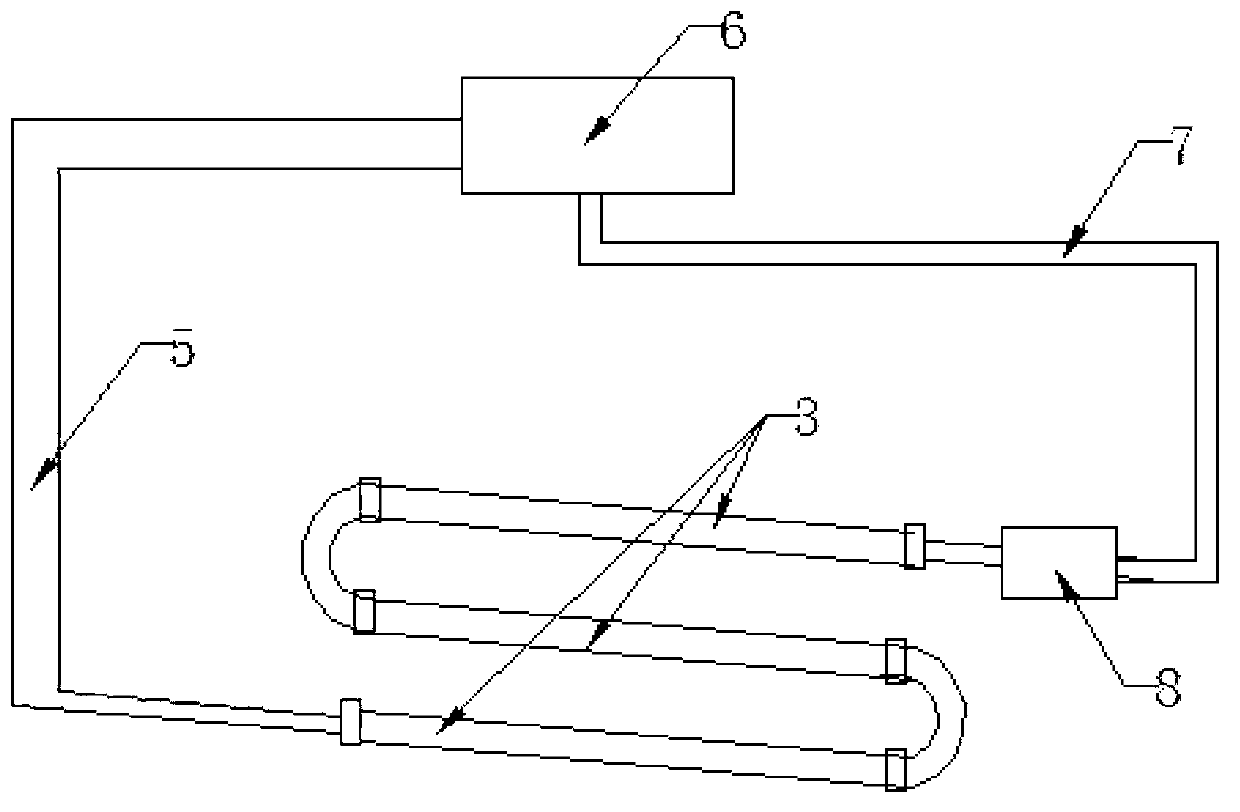

Enclosure pipeline-type stator evaporating and cooling device

InactiveCN103280928AImprove insulation performanceNon-flammable and non-explosiveCooling/ventillation arrangementSupports/enclosures/casingsGas collecting tubeEngineering

The invention discloses an enclosure pipeline-type stator evaporating and cooling device, which comprises a cooling pipeline (3), a gas collecting tube (5), a condenser (6) and a liquid returning tube (7), wherein the condenser (6) is installed above a motor; one end of the gas collecting tube (5) is connected with the outlet of the cooing pipeline (3); the other end of the gas collecting tube (5) is communicated with the condenser (6); one end of the liquid returning tube (7) is connected with the condenser (6); the other end of the liquid returning tube (7) is connected with the inlet of the cooing pipeline (3); secondary cooing medium is introduced into the condenser (6); the above components form a self-circulation evaporating and cooling loop; a pump (8) is connected between the liquid returning tube (7) and the cooling pipeline (3) to form a forced circulating evaporating and cooling loop; the cooling pipeline (3) is formed by connecting a plurality of cooling pipelines in parallel or series; the cooling pipeline (3) is arranged on the inner wall of a motor enclosure (4) or the outer wall of the motor enclosure (4); the cooling pipeline (3) can be arranged on the rectangular notch of the outer circumstance of a stator (1); and the outer cross section of the cooling pipeline (3) on the notch is rectangular.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

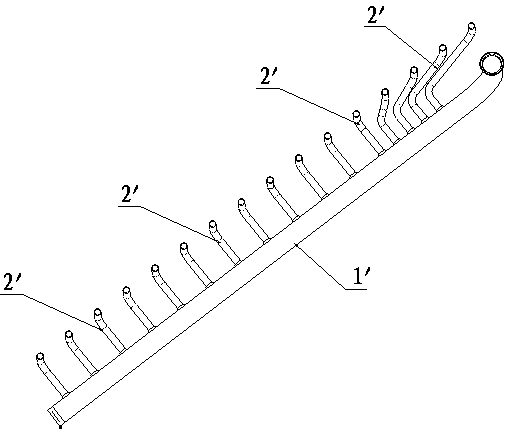

Method for manufacturing gas collecting tube component and air-conditioning system

InactiveCN102848137ALow costImprove reliabilitySoldering apparatusSpace heating and ventilation detailsGas collecting tubeProcess engineering

The invention relates to a method for manufacturing a gas collecting tube component. The method comprises the following steps of: 1) preparing a main gas collecting tube made of a stainless steel material; 2) preparing a plurality of gas collecting branch tubes made of carbon steel materials; 3) fixing the main gas collecting tube, the gas collecting branch tubes and a tube orifice sealing cap obtained in the steps 1 and 2 through interference or transition fit; and 4) welding the assembled parts to form the gas collecting tube component. The invention also provides an air-conditioning system. The material manufacturing cost can be greatly reduced; and meanwhile, according to novel materials, a novel method for manufacturing the gas collecting tube component is adopted, the airtight reliability and corrosion resistance of the product are improved, the process is simplified, the pickling step is canceled, and the environmental pollution can be avoided through the pickling process.

Owner:ZHEJIANG SANHUA CLIMATE & APPLIANCE CONTROLS GRP CO LTD

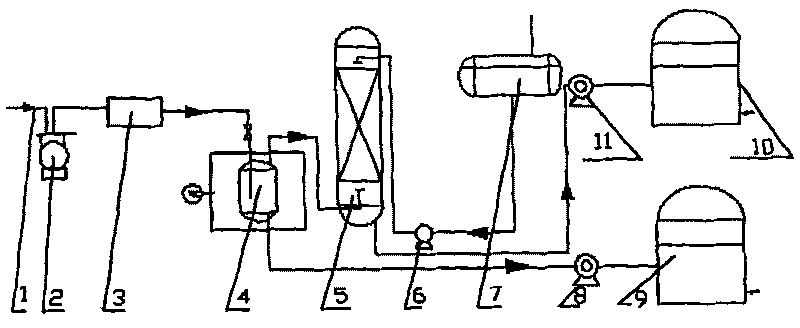

Device for collecting and recovering oil gas by condensation and absorption

InactiveCN101703841AEfficient recyclingRecycling is even more effectiveDispersed particle separationVapor condensationSocial benefitsGas collecting tube

A device for collecting and recovering oil gas by condensation and absorption relates to a chemical engineering device and comprises a gas collecting tube, an oil gas storing vessel, a precooler, a deep condenser, an absorption tower, a lean oil pump, an absorbent storing vessel, an oil storing vessel and a rich oil pump; the precooler and the deep condenser together construct a condensation system; the precooler is composed of built-in conduits; the oil gas storing vessel is connected to the left end of the precooler, the right end of the precooler is connected to the top of the deep condenser, the top of the deep condenser is connected to the bottom of the absorption tower, the bottom of the deep condenser is connected to the inlet of a centrifugal pump, the outlet of the centrifugal pump is connected to the oil storing vessel, the absorbent storing vessel is connected to the inlet of the lean oil pump and the outlet of the lean oil pump is connected to the top of the absorption tower. The invention has over 99% oil gas recovery rate, has good economic, environmental and social benefits, and can be applied to aspects of oil gas storage and transport, etc.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

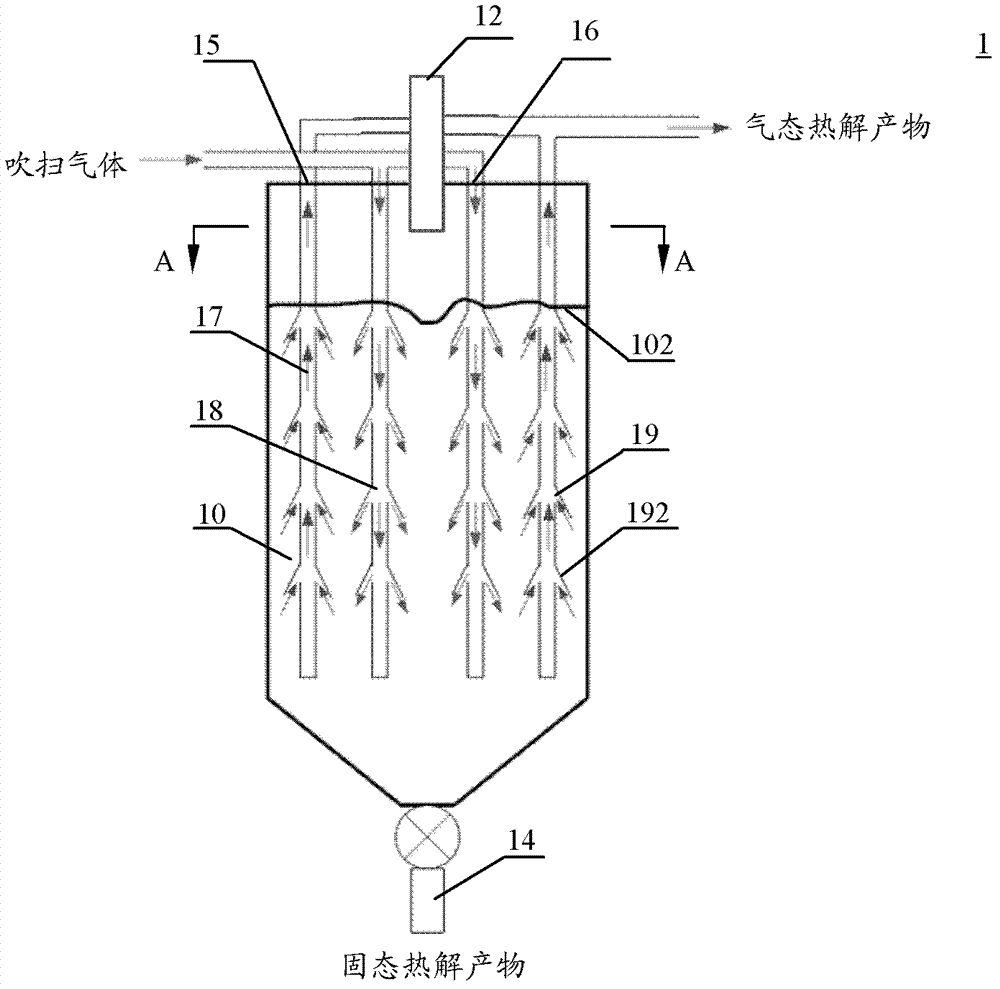

Carbon material pyrolysis device

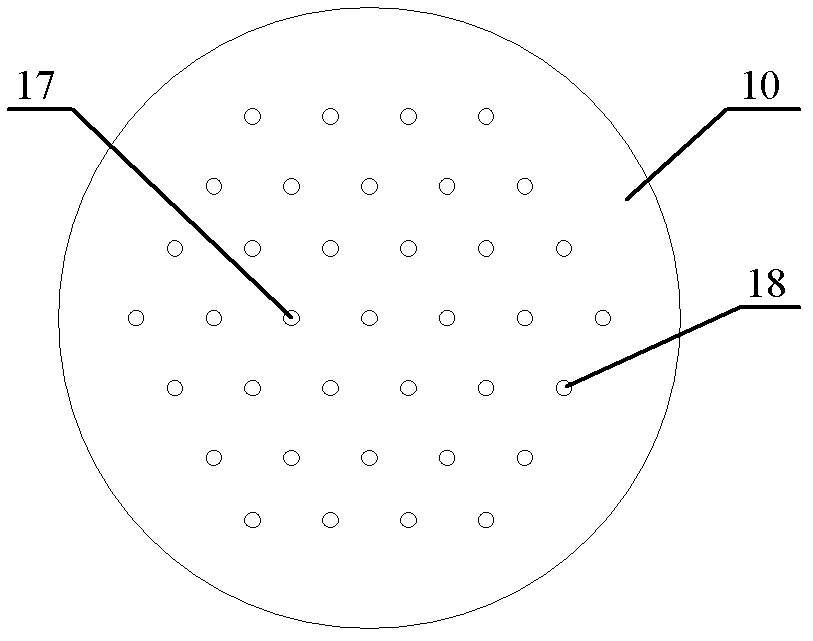

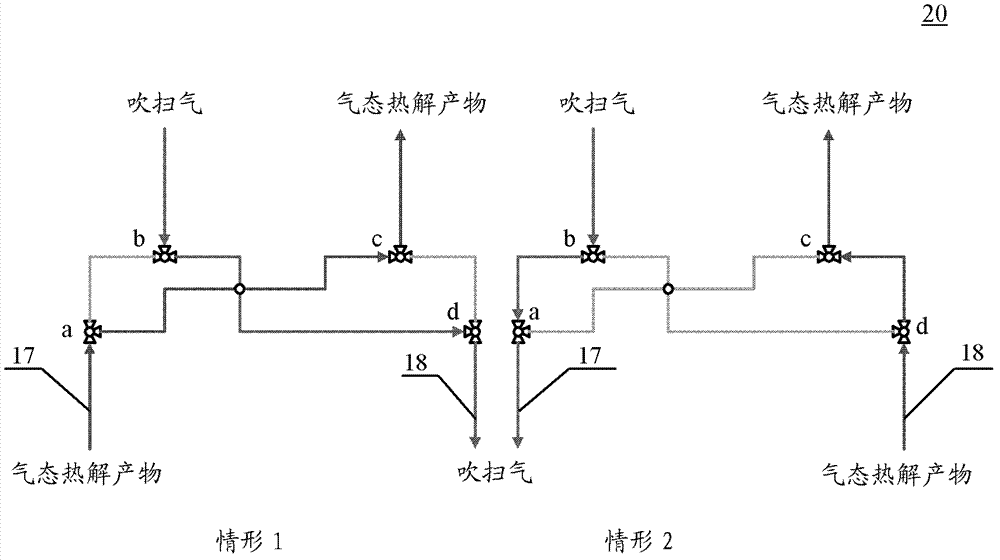

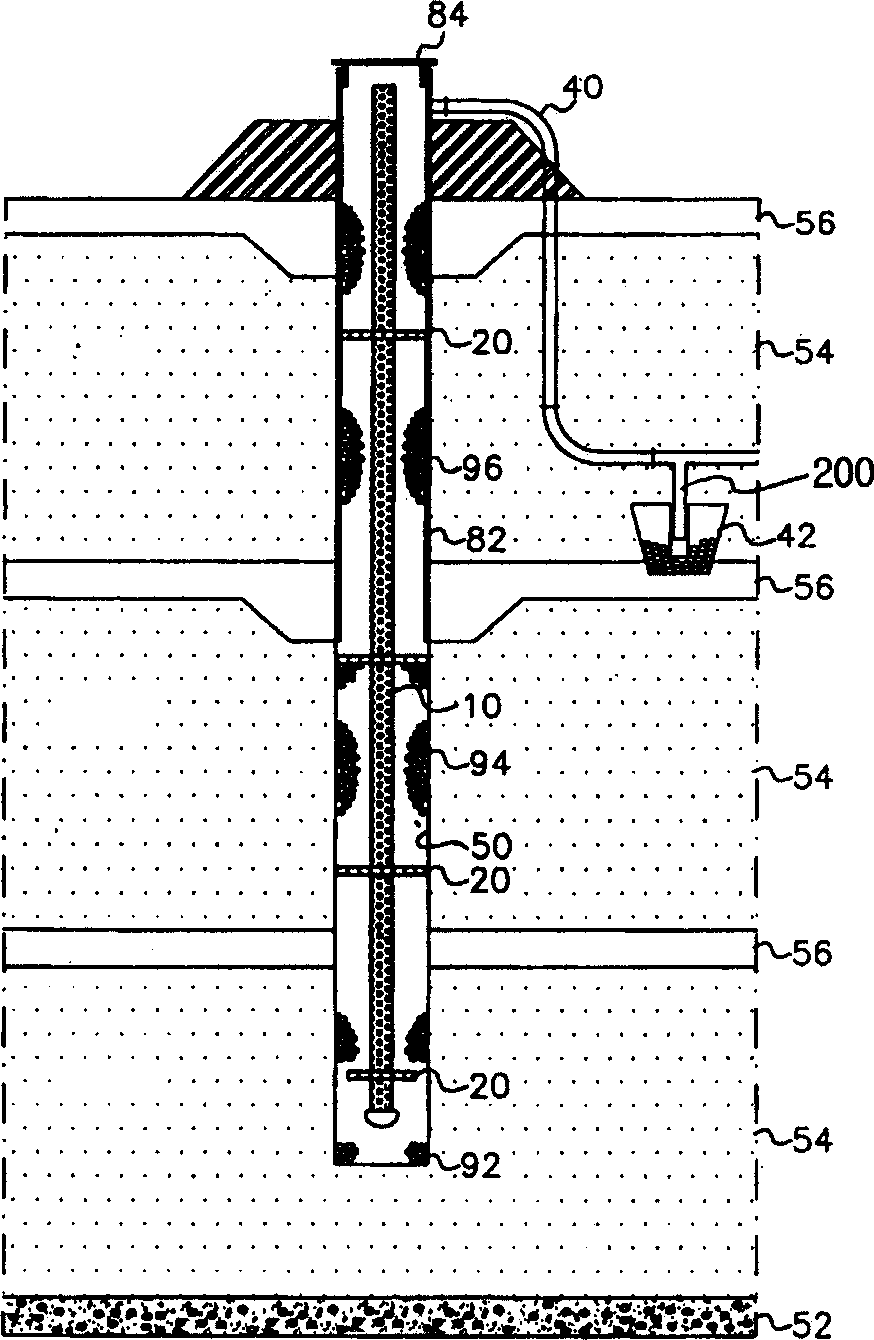

The invention discloses a carbon material pyrolysis device which can be used to greatly raise the yield of liquid pyrolysis products. The device provided by the invention comprises a pyrolyzing furnace which is used for pyrolyzing a carbon material therein and is a moving bed, fixed bed or vibration bed pyrolyzing furnace, at least a gas collecting tube and at least an air blowpipe which are positioned inside the pyrolyzing furnace, wherein walls of the gas collecting tube and the air blowpipe are respectively provided with at least one gas channel which passes through the wall and is used for communicating the gas collecting tube and the air blowpipe. A gas pyrolysis product generated in the pyrolyzing furnace passes through the gas collecting tube and is rapidly discharged out of the pyrolyzing furnace; a sweeping gas from the outside of the pyrolyzing furnace passes through the air blowpipe and is conveyed into the pyrolyzing furnace; and the gas pyrolysis product in the pyrolyzing furnace is swept into the gas collecting tube.

Owner:NAT INST OF CLEAN AND LOW CARBON ENERGY

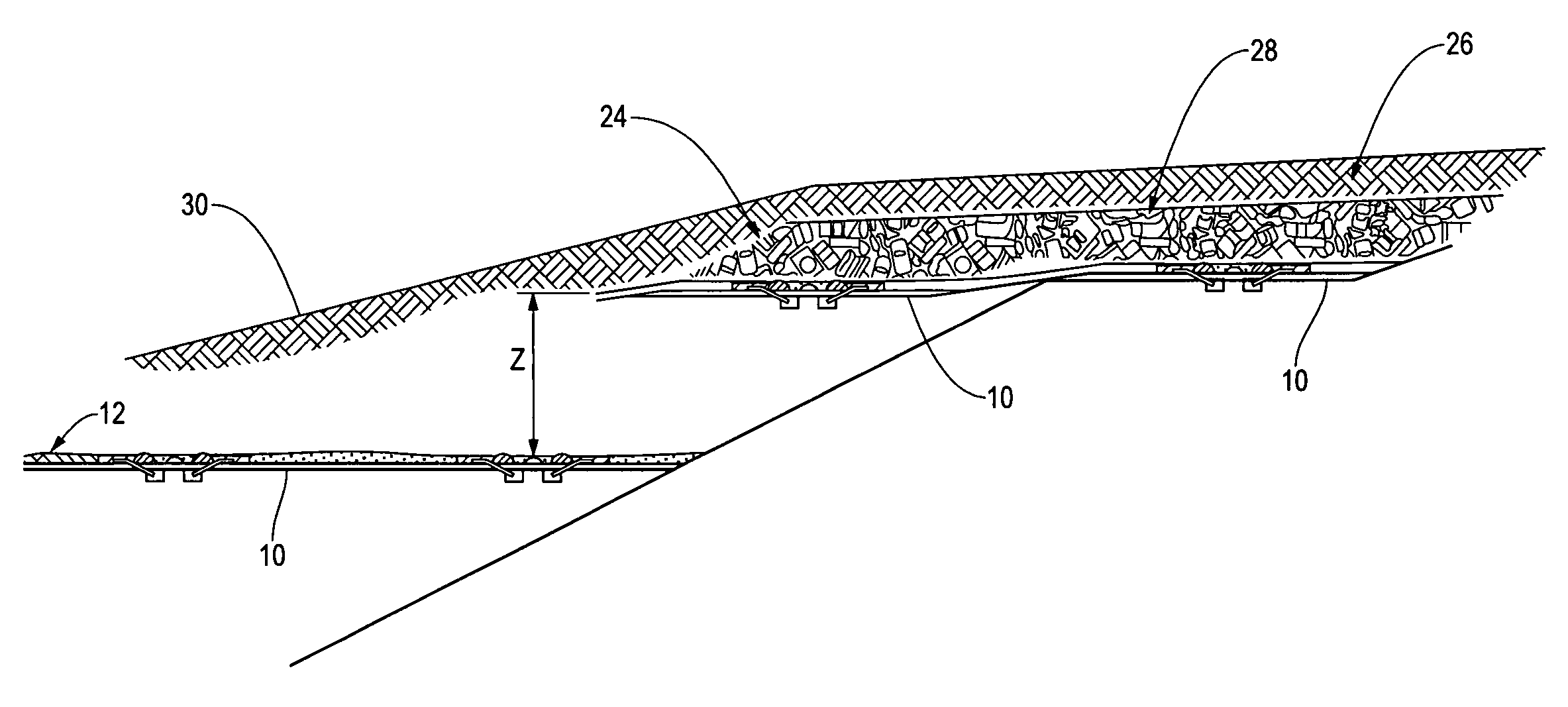

Gas discharging apparatus for waste reclaimed land

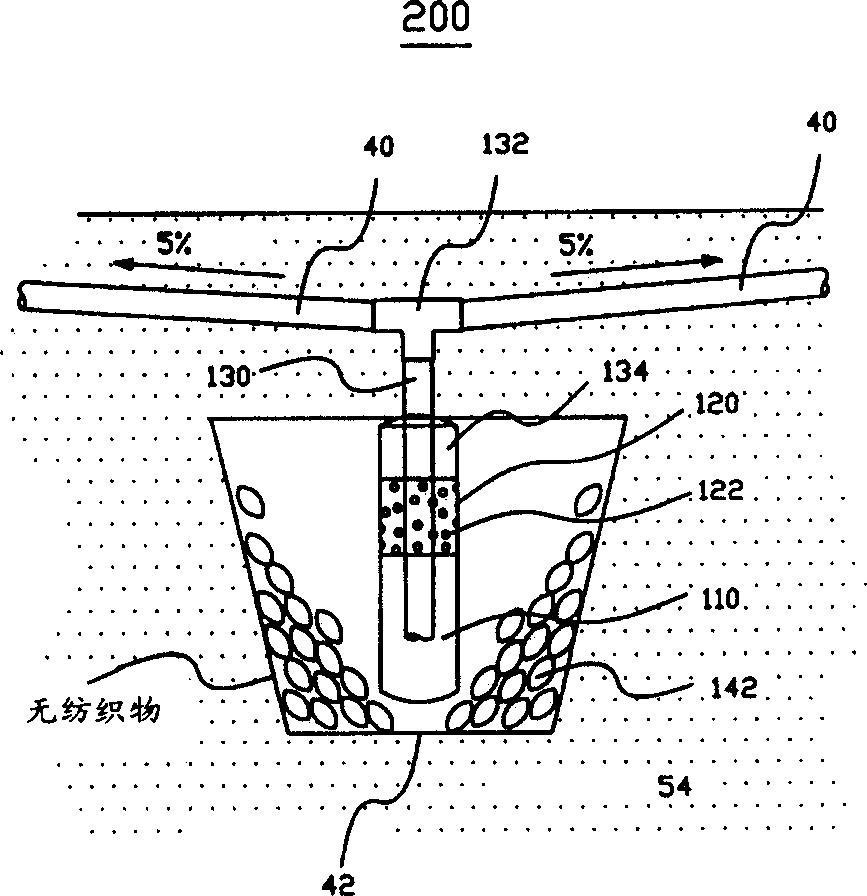

A gas discharge device for a landfill site is disclosed having a condensate drain for removing condensate from hazardous and explosive gases generated in the landfill site. The gas discharge device at this landfill site includes: a gas collection pipe, located inside the garbage layer, to collect the gas generated by the garbage layer; a gas delivery pipe, connected to the upper part of the gas collection pipe, and to discharge the gas collected in the gas collection pipe ; and a condensate drain connected to the gas collecting pipe and separating the condensate from said gas by gravity, wherein the condensate drain comprises: a waterproof pipe having an opening in its upper portion; a porous pipe with the opening of the waterproof pipe and having a plurality of drainage holes in its side; and a connecting piece connecting the porous tube to the gas delivery tube in such a way that water can flow.

Owner:SUDOKWON LANDFILL SITE MANAGEMENT CORP

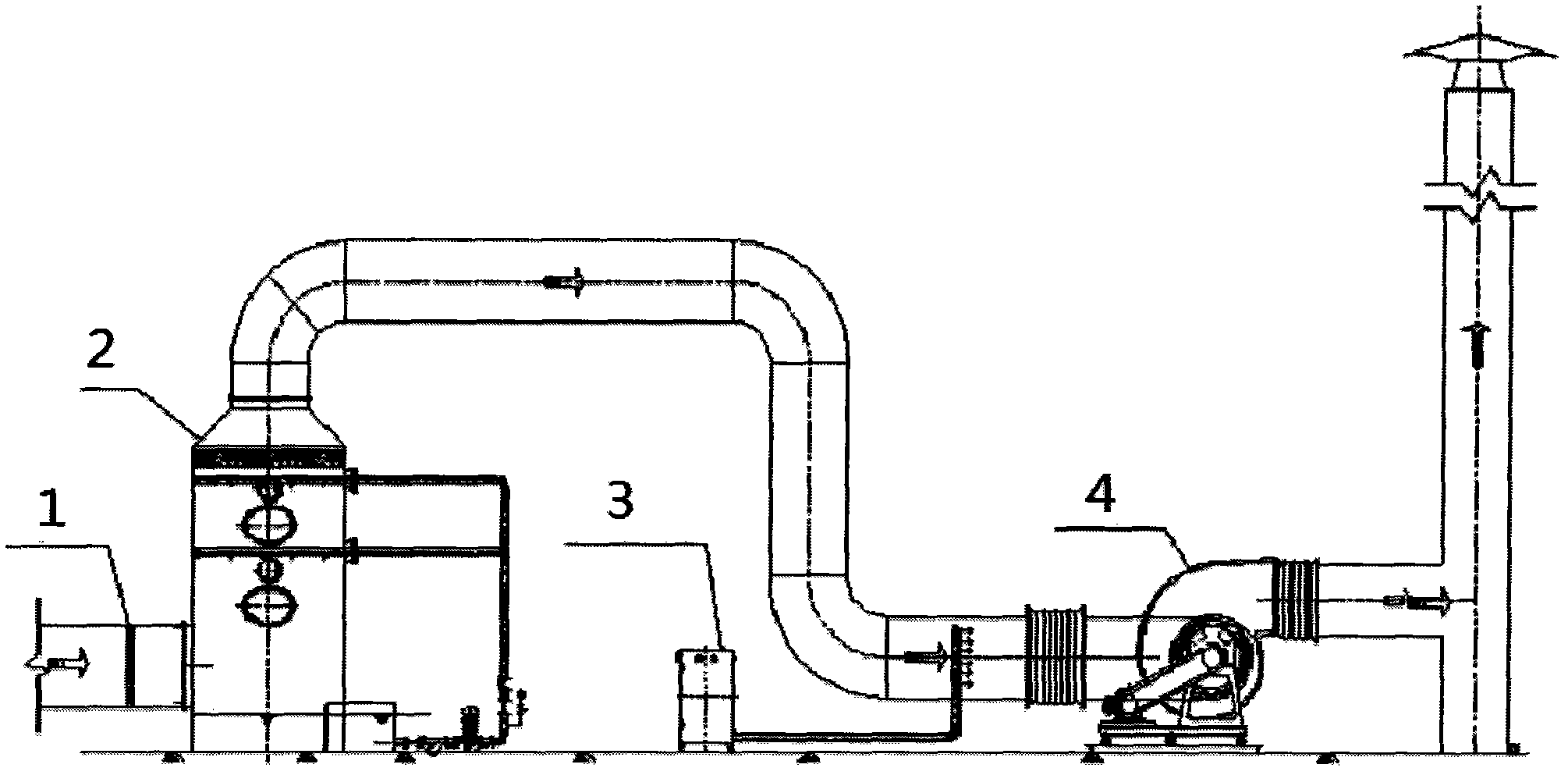

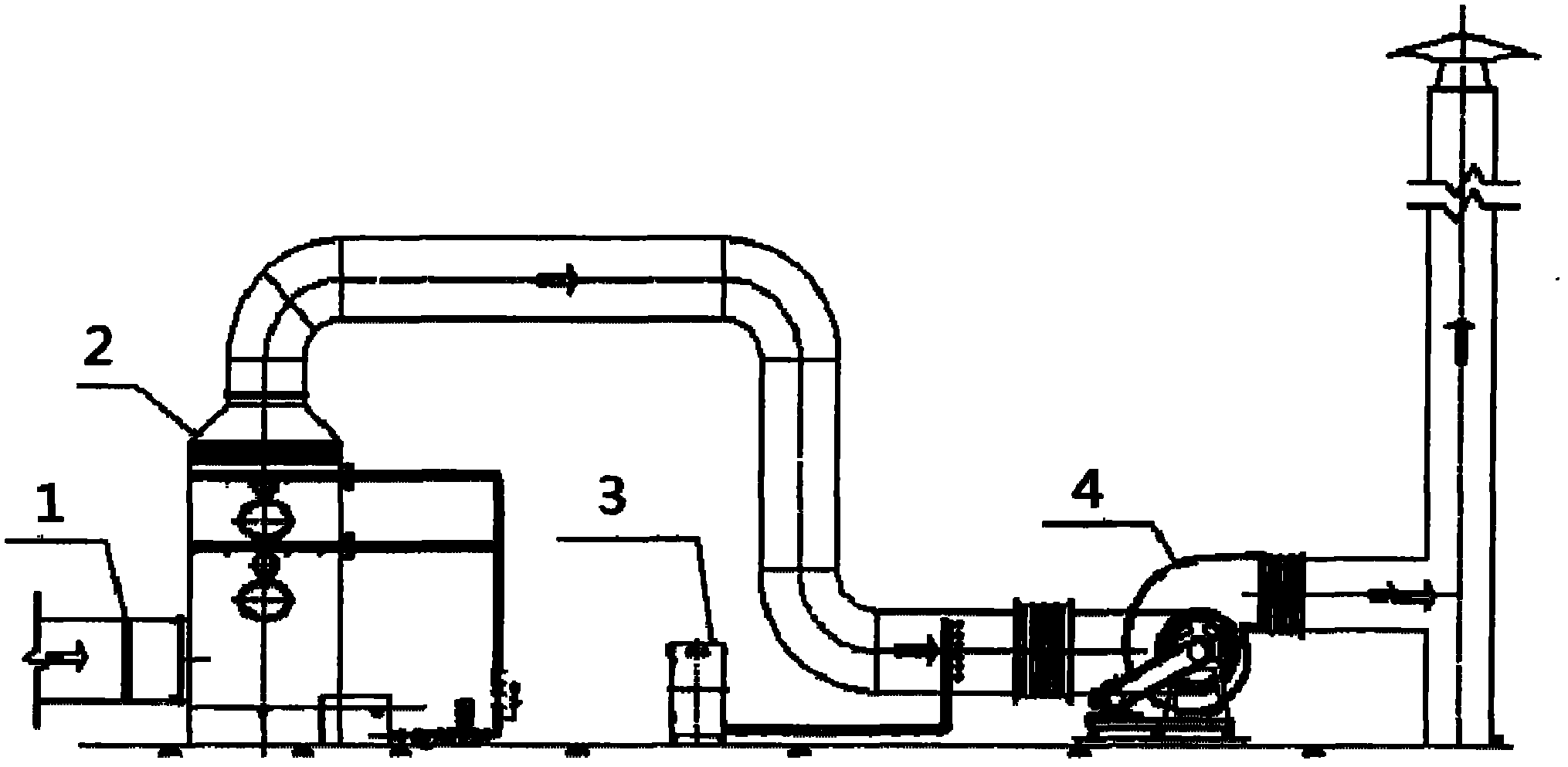

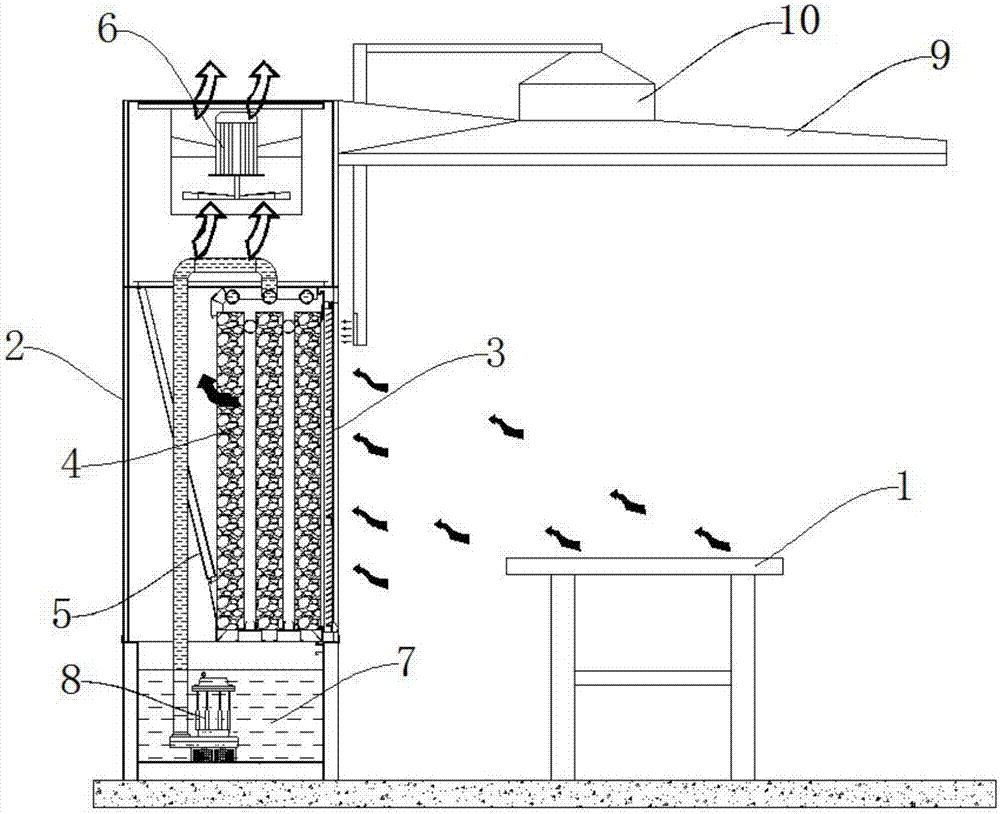

Device and method for processing gases with offensive odor by utilization of biofiltration-active carbon combination method

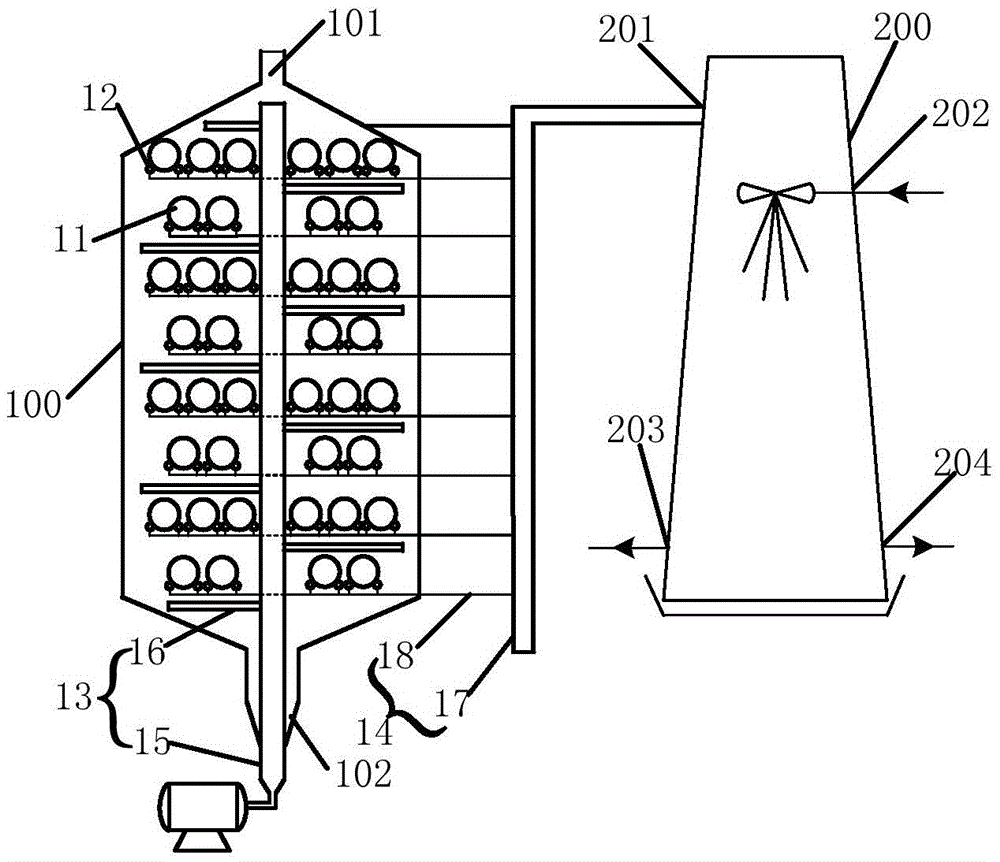

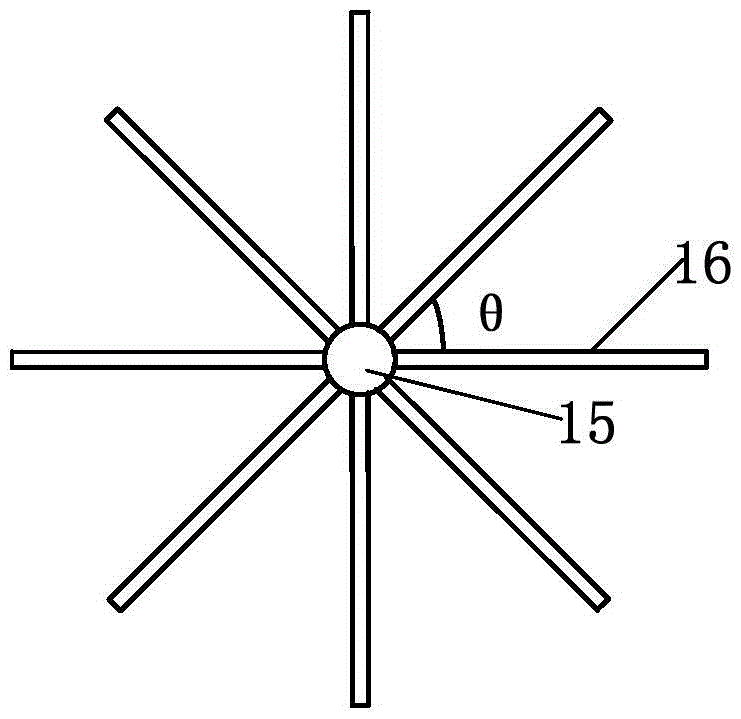

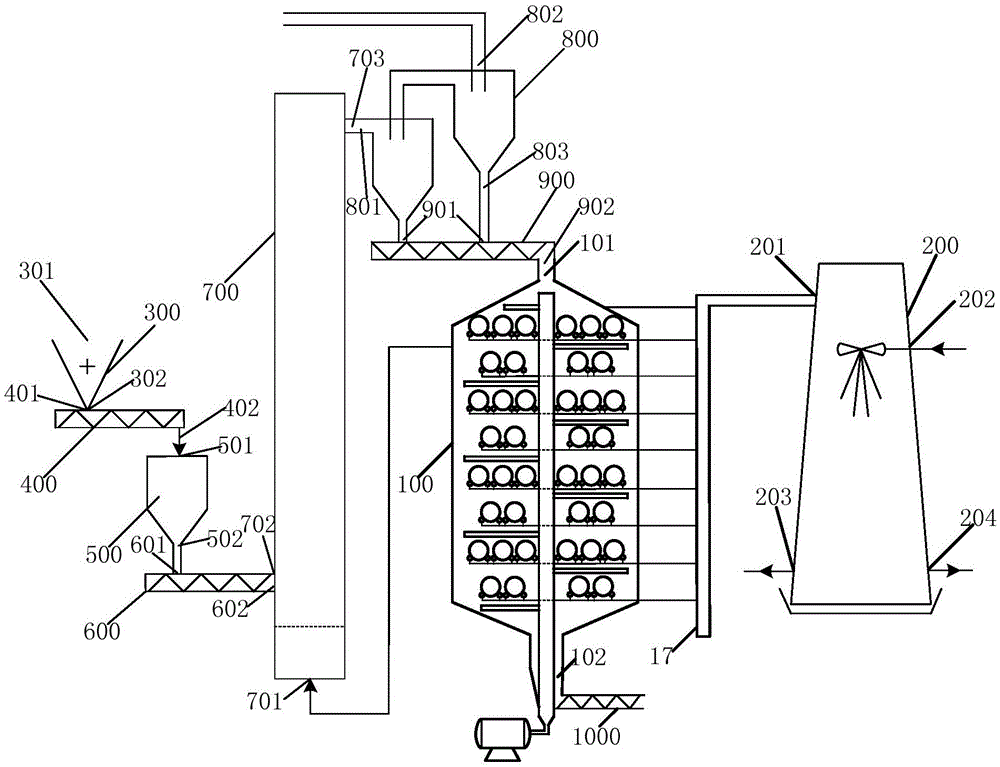

ActiveCN104147921ACompletely degradedCompact structureDispersed particle separationAir quality improvementActivated carbonGas collecting tube

The invention belongs to the waste gas treatment technology field, and especially relates to a device and method for processing gases with offensive odor by utilization of a biofiltration-active carbon combination method. The device is composed of a negative pressure collection unit, a gas collection pipe, a blower fan, a biofiltration unit and an active carbon adsorption unit. A gas distribution device is arranged at the bottom of the biofiltration unit. The biofiltration unit is filled with light active biological filling materials. A nutrient solution and spraying liquid inlet is arranged in the side wall and a pipe connected with a spray thrower is installed on the side wall. The active carbon adsorption unit is loaded with composite active carbon adsorption filling materials. Gases with offensive odor of a generation source are collected by utilization of the negative pressure collection unit, and go into the biofiltration unit through a gas inlet pipe, most pollutants in the gases with offensive odor are degraded by bacteria and fungus microorganisms on the filling materials, the pollutants, which are not degraded, with low concentrations go into the active carbon adsorption unit through a gas conveying pipe, and are absorbed by the filled active carbon adsorbing agents and purification is achieved. The purified gases are discharged into the atmosphere from a discharging hole.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

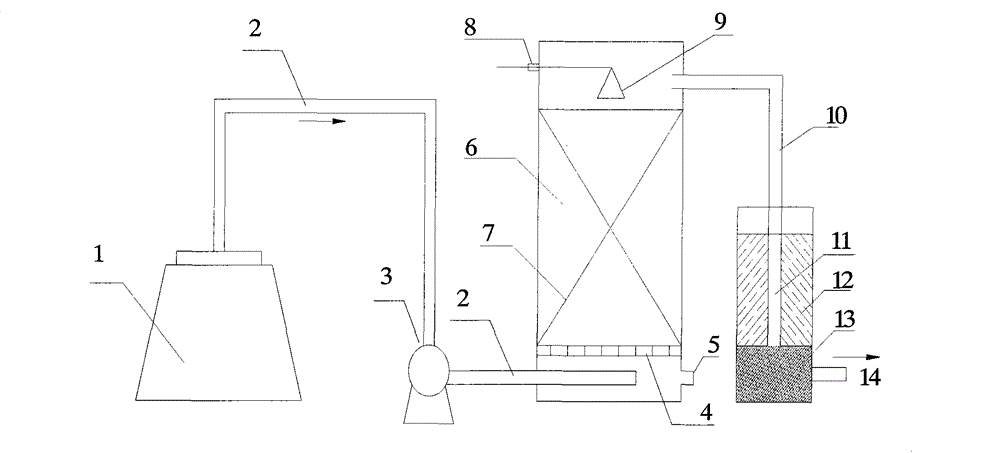

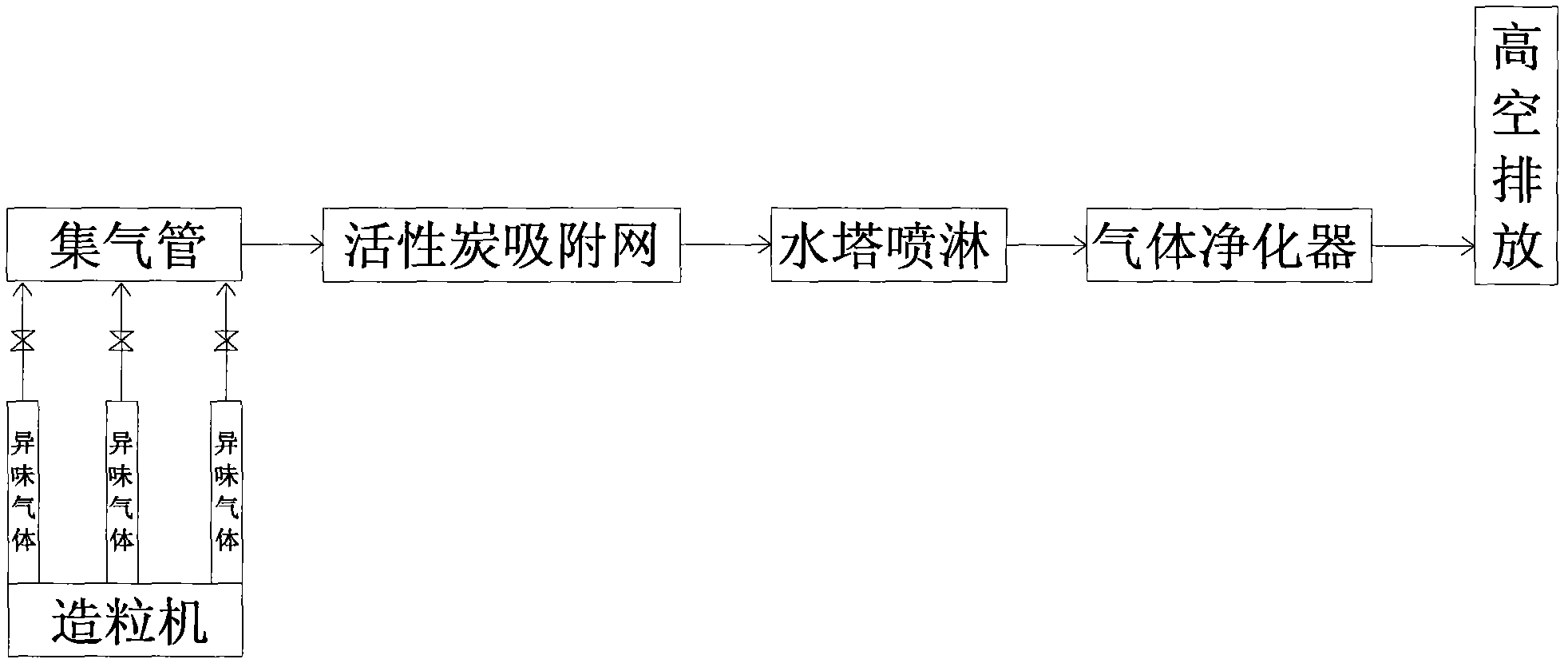

Equipment and method for treating odor of high density polyethylene (HDPE) plastic pipeline production line

InactiveCN101912719AImprove production environmentAchieve the purpose of governanceCombination devicesGaseous substancesLow-density polyethyleneGas collecting tube

The invention provides equipment and a method for treating odor of a high density polyethylene (HDPE) plastic pipeline production line. The equipment comprises a gas collecting tube which is connected to the tail end of a pipeline collecting system of the HDPE plastic pipeline production line; and an adsorption net, a spraying water tower and gas purification equipment are arranged on the gas collecting tube in turn. The odor treated by an active carbon adsorption net passes through the spraying water tower into which a deodorant is added, and water vapor and small-volume particles in the odor are removed. The odor passing through the spraying water tower is deodorized by a deodorant which is released by a deodorization diaphragm inside the gas purification equipment, and then is added into an air duct, and the treated gas is raised and exhausted by a centrifugal fan. Therefore, the aim of treating odor of HDPE reclaimed material extrusion granulation is fulfilled.

Owner:GUANGDONG LIANSU TECH INDAL

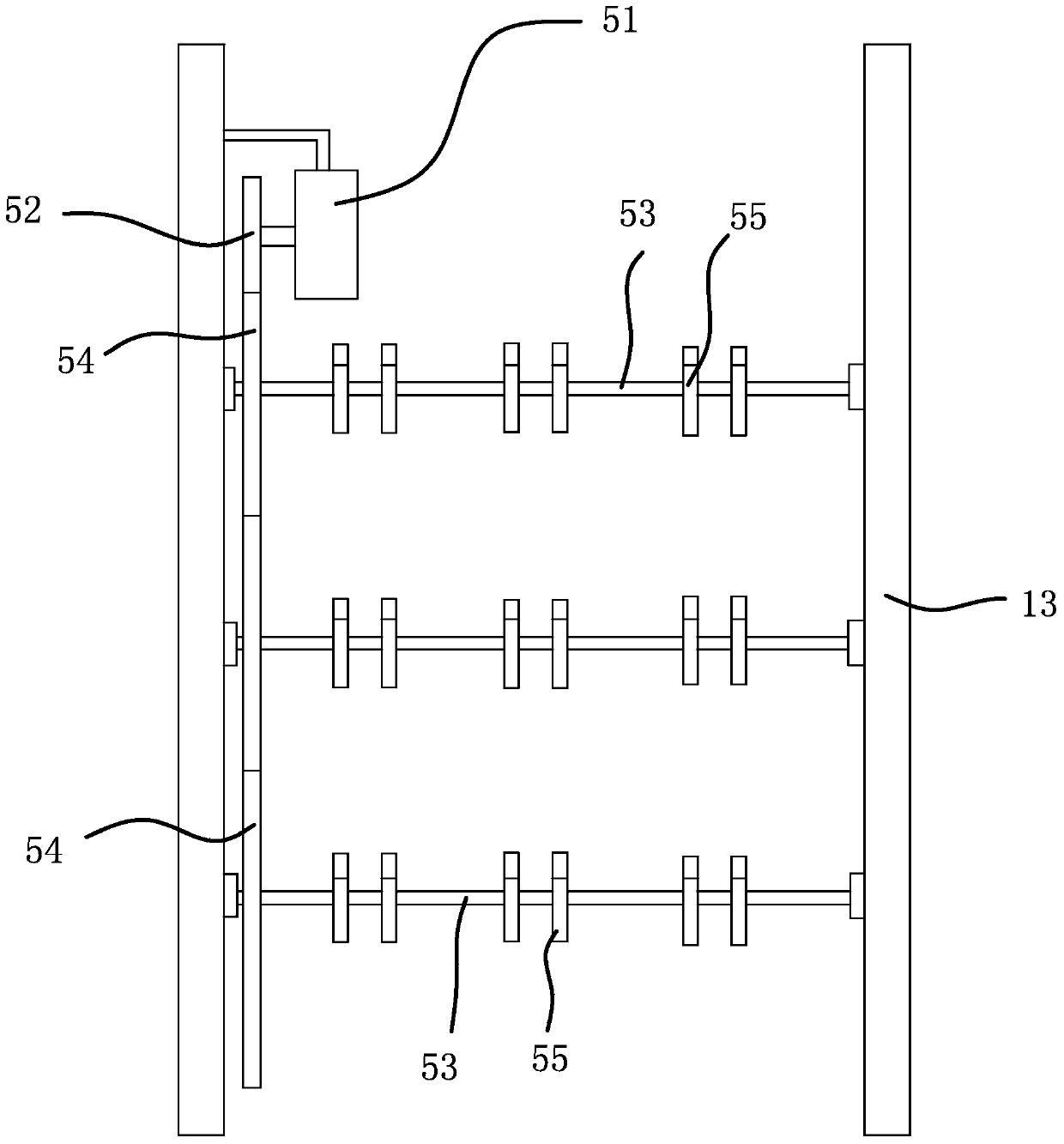

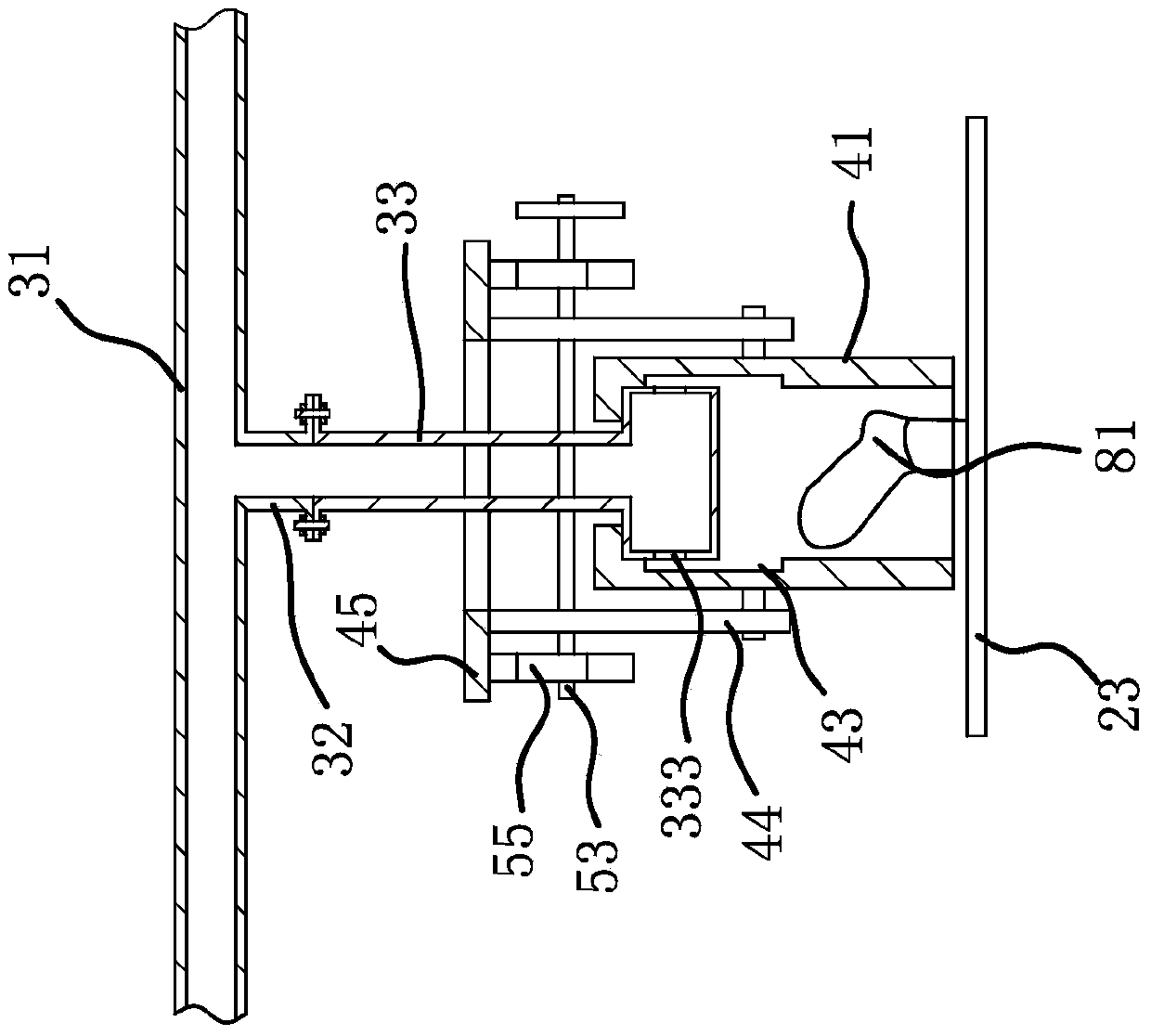

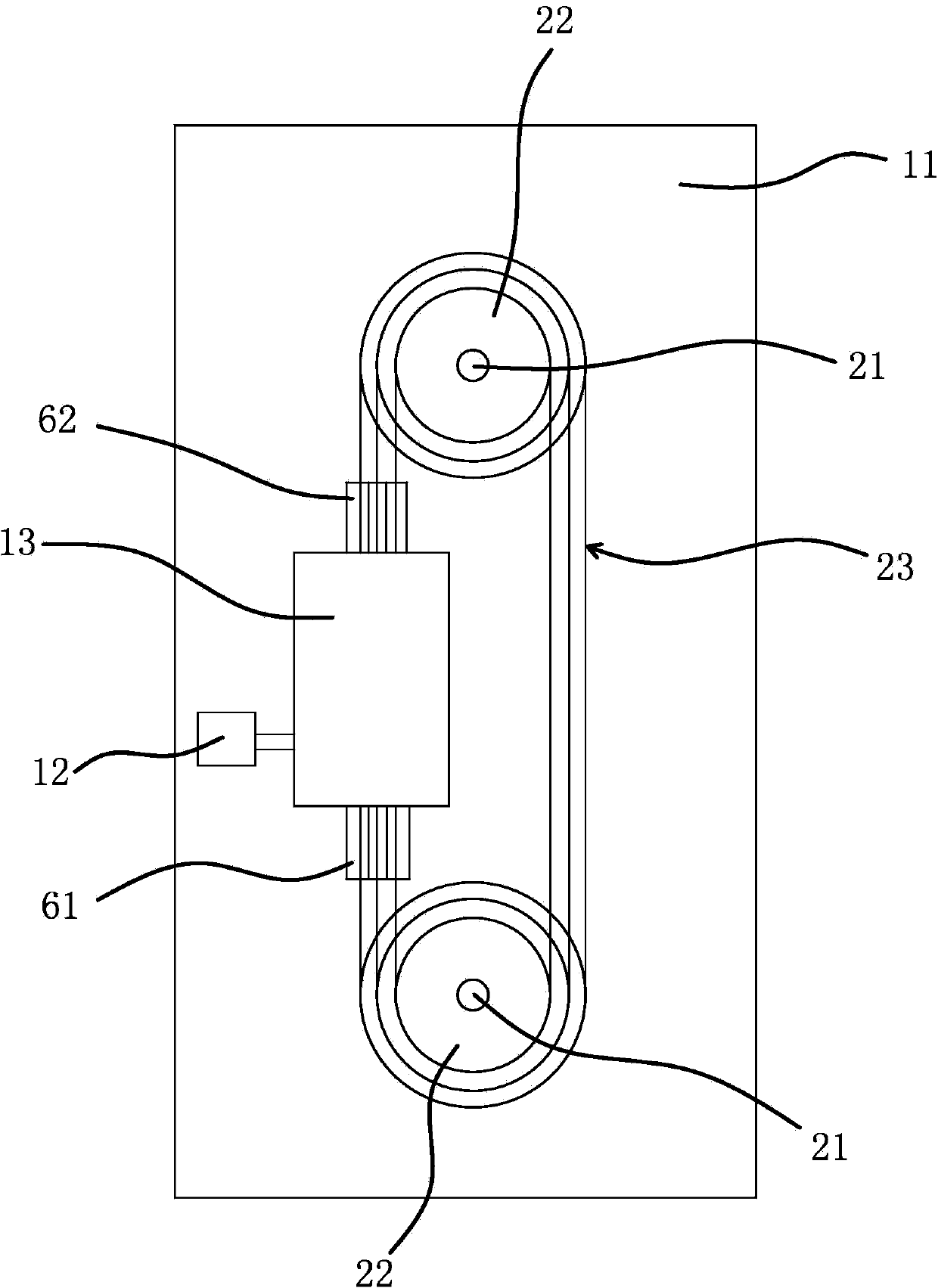

Steam setting device of steam sock setting machine

InactiveCN103726250AQuality assuranceReduce dosageShaping/stretching tubular fabricsLiquid/gas/vapor textile treatmentSOCKSGas collecting tube

The invention provides a steam setting device of a steam sock setting machine, belongs to the technical field of machinery and aims to solve the technical problem of setting deficiency and the like of the conventional steam sock setting machine. The steam setting device of the sock steam setting machine comprises steam pipelines and gas collecting tubes, wherein the steam pipelines are fixed in a steam setting chamber and in one-to-one correspondence with driving chain wheels; a plurality of steam sub-pipelines are arranged at the lower ends of the steam pipelines and all fixedly communicated with a connecting pipe; an air outlet part is sleeved with the gas collecting tubes; a control mechanism is arranged between the gas collecting tubes and the steam setting chamber, and can drive the gas collecting tubes to slide up and down to enable the gas collecting tubes to open an air outlet and cover sock sleeve plates or to close the air outlet and enable the gas collecting tubes to be positioned above the sock sleeve plates. The steam setting device has the advantages that a uniform steam sock setting effect is achieved, and the quality of socks is ensured.

Owner:张金英

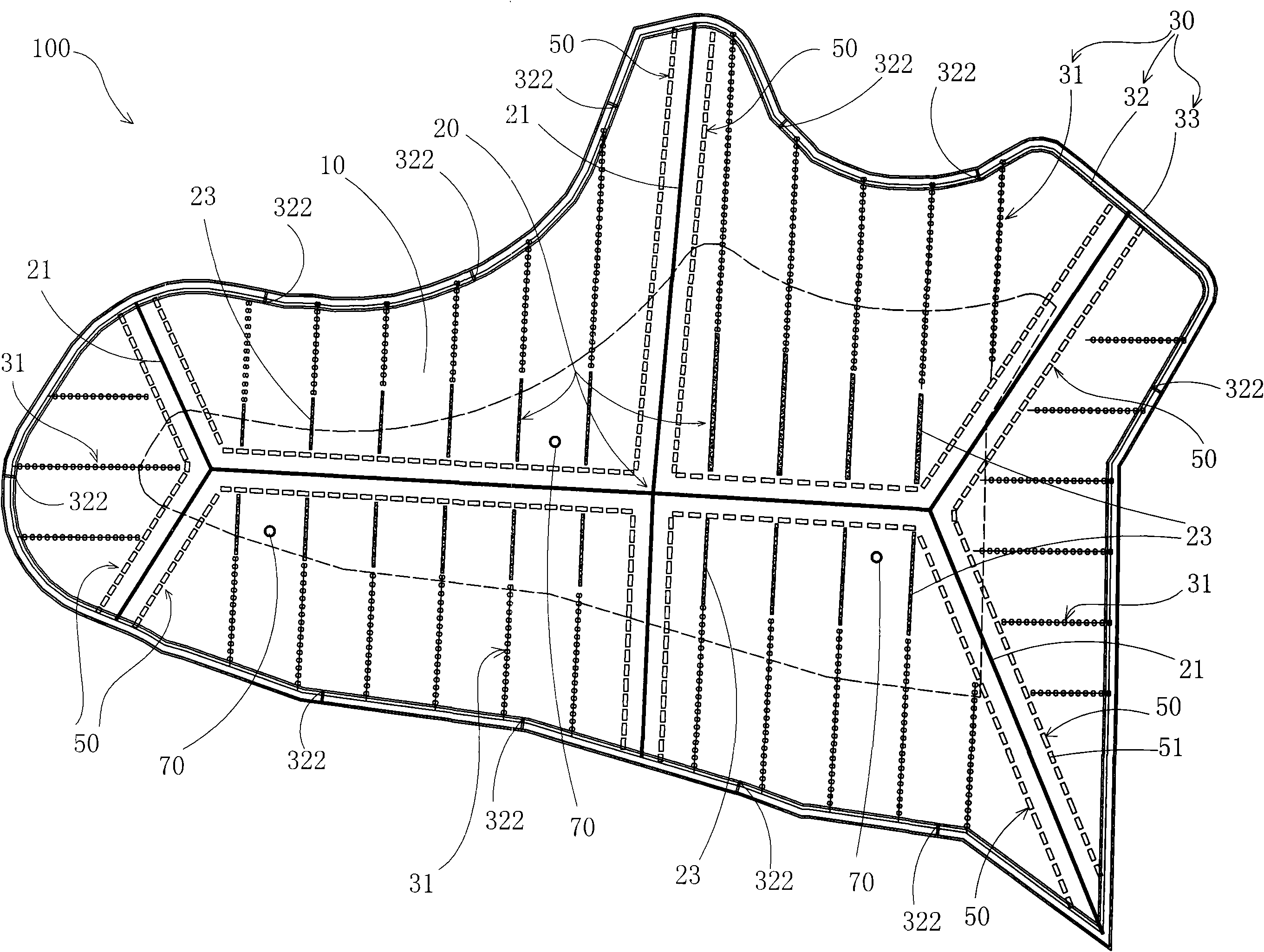

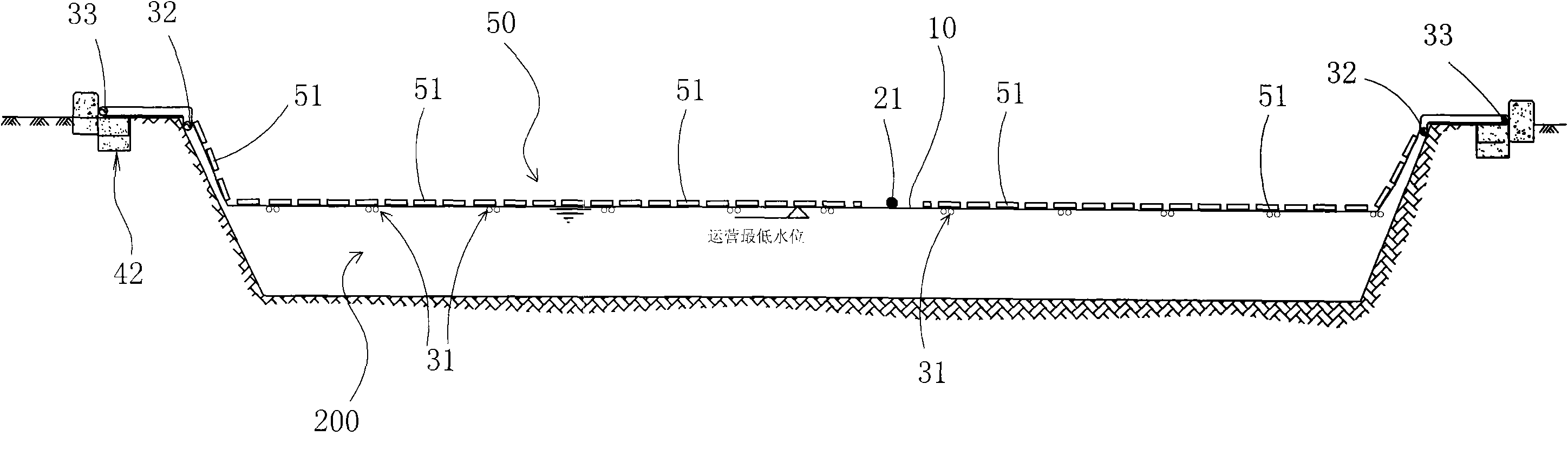

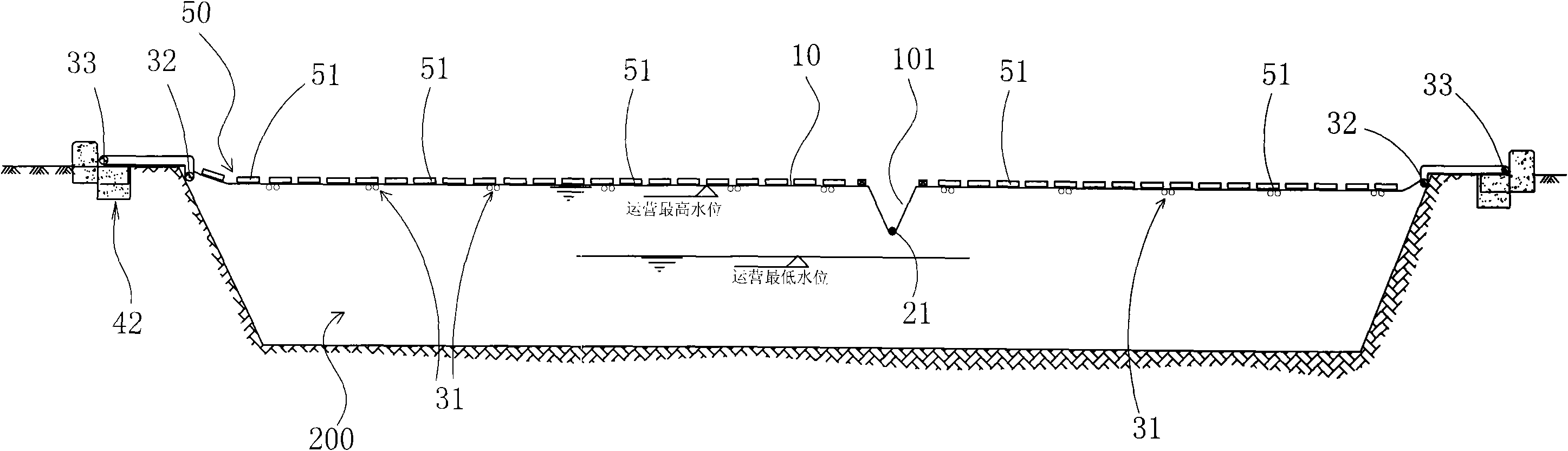

Wet construction method for coverage system of refuse landfill sewage adjusting tank

ActiveCN102079549AReduce wrinklesNot easy to damageWater/sewage treatmentGas collecting tubeEngineering

The invention discloses a wet construction method which is used for constructing and building an anticorrosion coverage system of a flexible floating coverage film on a refuse landfill sewage adjusting tank filled with sewage, wherein the anticorrosion coverage system can prevent the bad smell of the adjusting tank from diffusing, prevent rain and sewage from mixing, conveniently collect methane and conveniently extract and discharge rain. The construction procedures are as follows: cleaning impurities on the surface of sewage in the tank; installing a gas collecting tube; building an overwater working platform (floating bridge device); cutting, overlaying, anchoring, welding and detecting a floating coverage film; installing a floating ball string device, a pedestrian path and a maintenance hole device; moving the working platform; repeatedly installing the floating coverage film, the pedestrian path on the film and the floating ball string device below the film; removing the workingplatform; installing a gravity ballasting system; and installing a gas delivery tube. On the floating bridge device, the performance of the welding line of the floating coverage film can be detected until the welding line is qualified, and the pedestrian path, the floating ball string device and the maintenance hole device can be installed; after one section is finished, the floating bridge device can be moved for the construction of the next section; and thus, wet construction is realized.

Owner:中城建胜义(深圳)环境科技有限公司

Novel grinding dust treatment equipment

InactiveCN106955553APrevent slipping awayGood purification and dust removalCombination devicesGrinding/polishing safety devicesGas collecting tubeSpray tower

The invention relates to novel grinding dust treatment equipment and aims to provide novel grinding dust treatment equipment which is good in dedusting effect, simple to operate and long in service life. The novel grinding dust treatment equipment provided by the invention comprises a grinding workbench, first dust treatment equipment and second dust treatment equipment. The first dust equipment comprises a suction box and a dust absorption shed. The suction box is arranged on one side, opposite to staff, of the grinding worktable; second dust treatment equipment is arranged between the suction box and the grinding worktable; an air-inlet grille is arranged on one side, close to the second dust treatment equipment, of the suction box. The second dust treatment equipment also comprises a gas collecting tube, a dust filter screen, a spray tower, a filter and a liquid filter box. The air inlet of the gas collecting pipe is aligned to the grinding worktable, the gas outlet of the spray tower is aligned to the filter plate in the first dusts treatment equipment, an air inlet and an air outlet are formed in the spraying tower, a spraying tube is mounted on the upper portion of the spraying tower, and a plurality of nozzles are formed in the bottom of the spraying tube.

Owner:中环盛达环保科技集团(庆云)有限公司

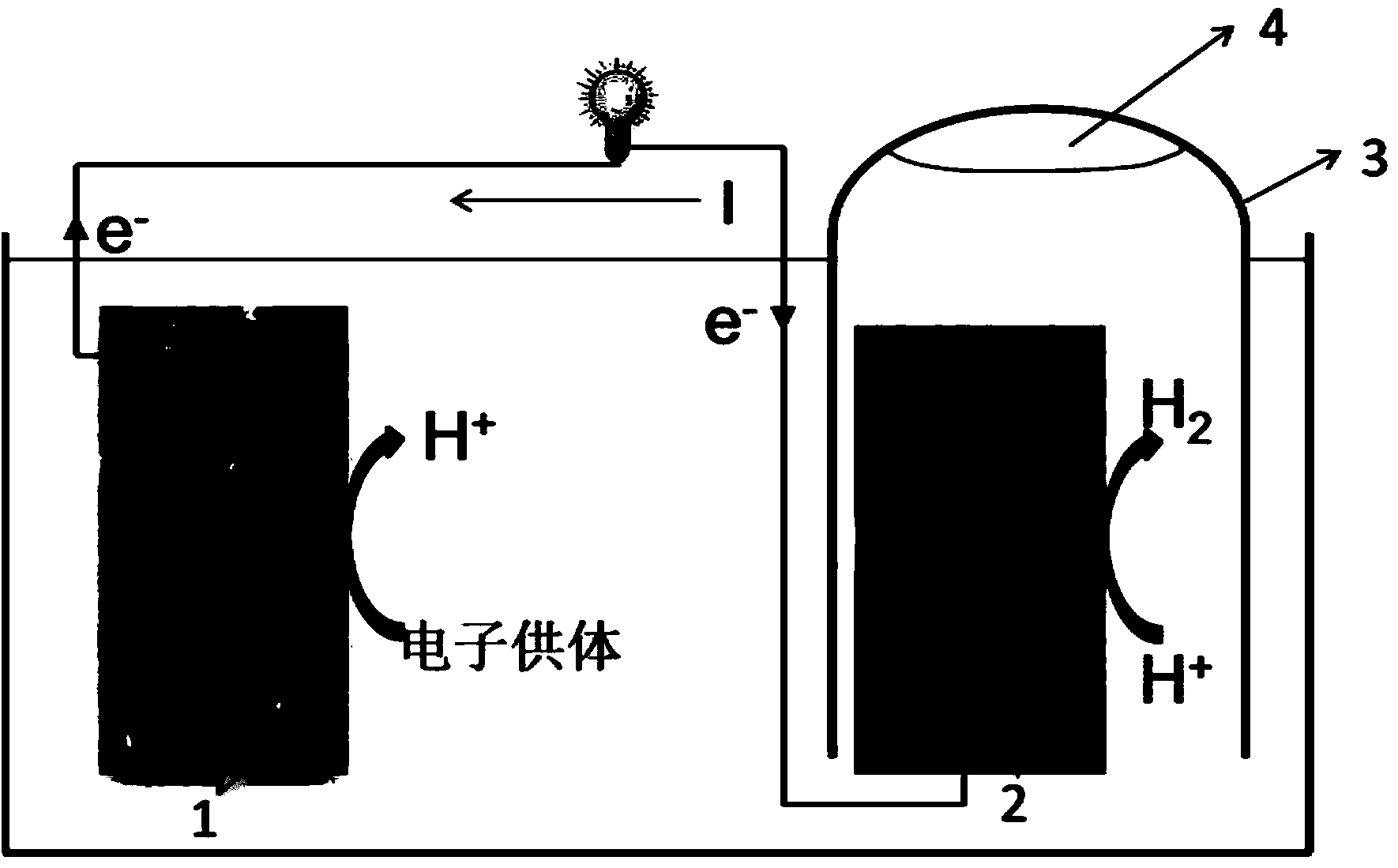

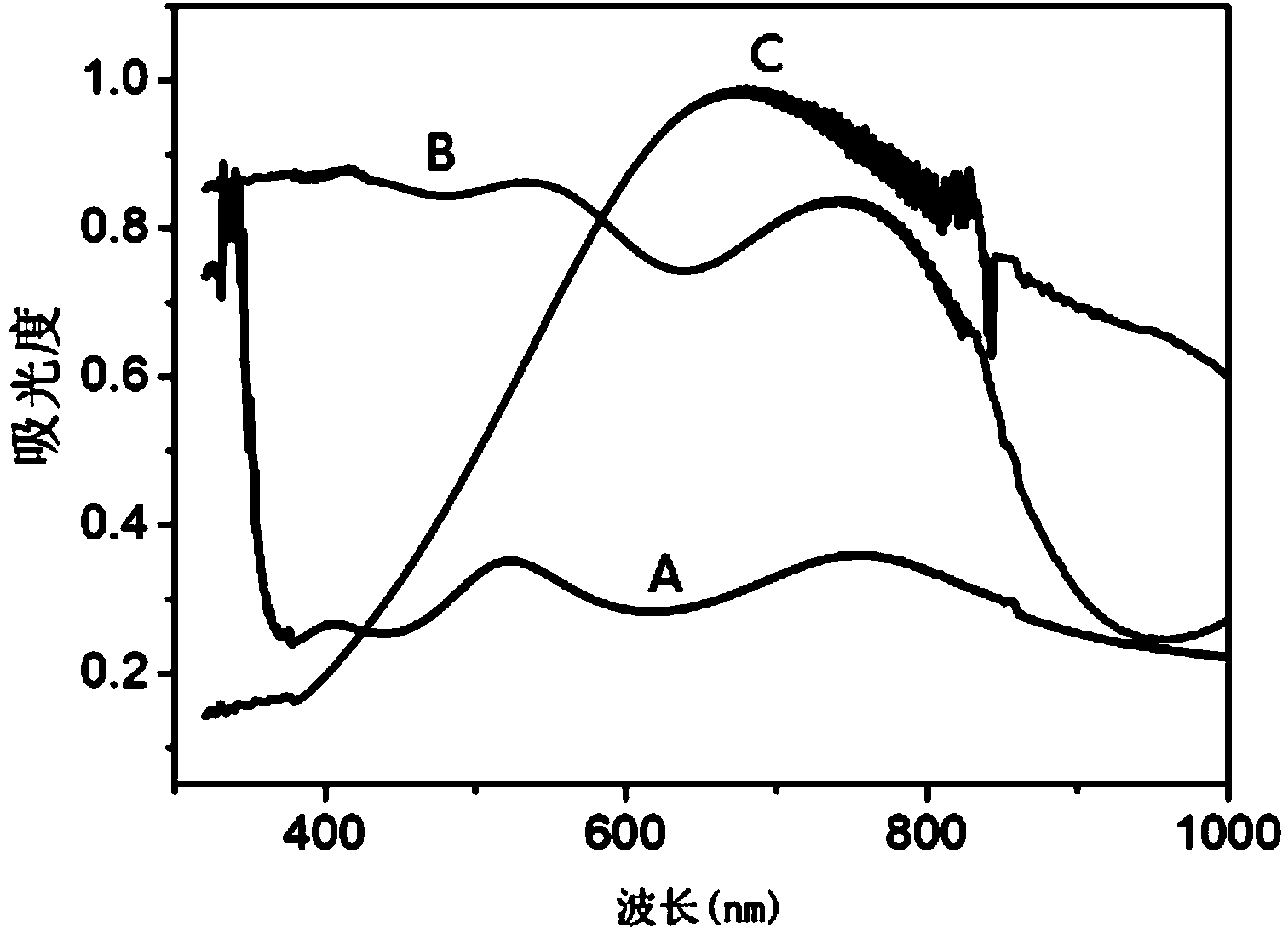

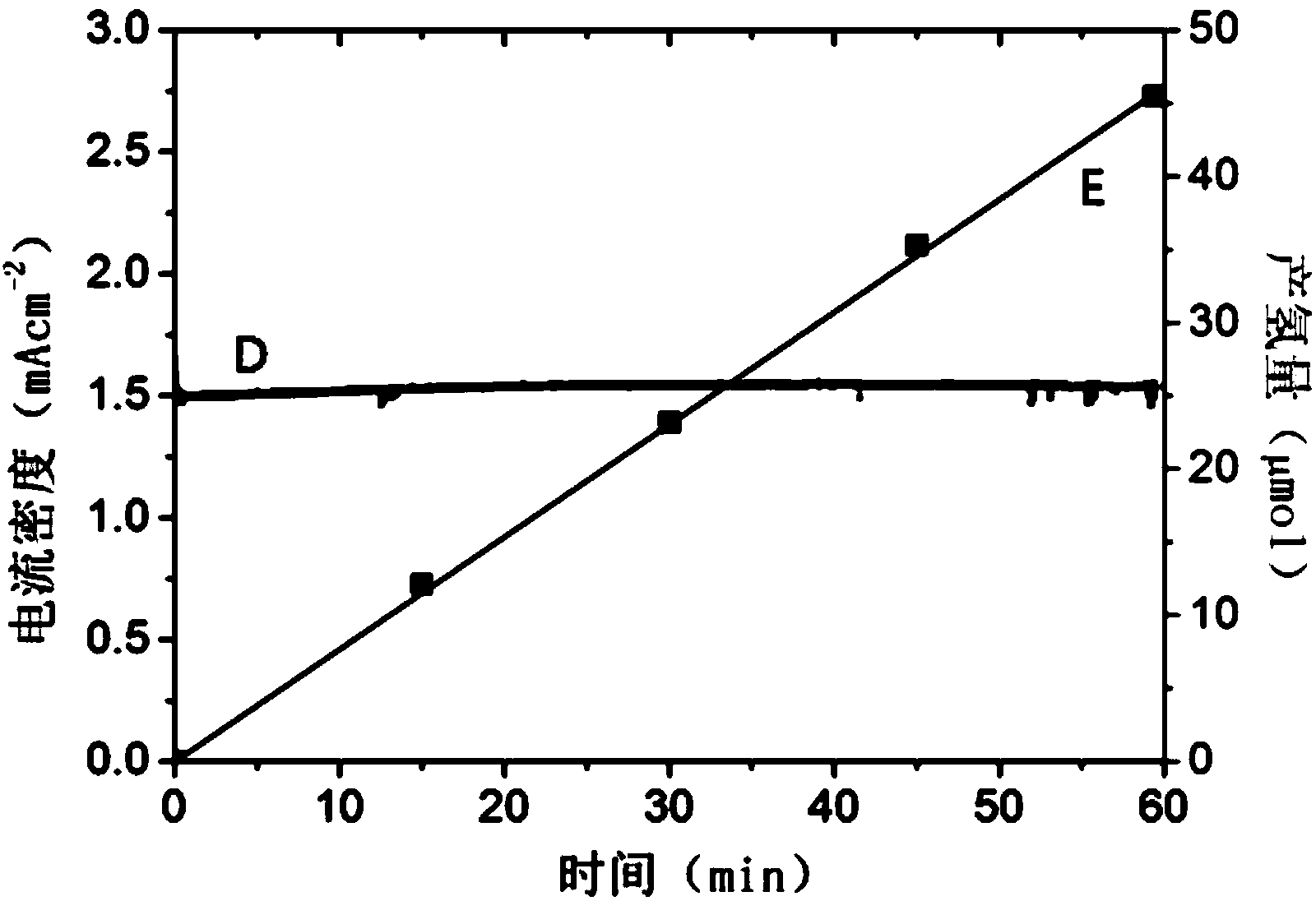

Visible-light response type automatic-bias photoelectrical catalytic water decomposition hydrogen production and electricity generation system

InactiveCN104009123AImprove stabilityGood technical effectFinal product manufactureFuel cellsGas collecting tubeTio2 nanotube

The invention provides a visible-light response type automatic-bias photoelectrical catalytic water decomposition hydrogen production and electricity generation system. The visible-light response type automatic-bias photoelectrical catalytic water decomposition hydrogen production and electricity generation system comprises a visible-light response type Bi2S3 sensitized TiO2 nanotube array film photo-anode, a visible-light response type silicon cell photo-cathode decorated with platinum, an electrolyte, a visible-light source, a quartz reaction tank and a quartz gas collecting tube. The materials of the photo-anode and the materials of the photo-cathode are both high in visible-light absorption performance. The photo-anode and the photo-cathode are inserted into a 0.1-0.5 M Na2S electrolyte solution at the same time and are connected through an external circuit. The visible-light source is switched on to irradiate the photo-anode and the photo-cathode, the photo-anode and the photo-cathode respectively generate an electrode reaction and then form a loop through the external circuit, and therefore automatic-bias photoelectrical catalytic hydrogen production and electricity generation are achieved. The invention further discloses a preparation method of the visible-light response type automatic-bias photoelectrical catalytic water decomposition hydrogen production and electricity generation system. The visible-light response type automatic-bias photoelectrical catalytic water decomposition hydrogen production and electricity generation system can be applied to solar hydrogen production and electricity generation at the same time and has the advantages of visible-light response, efficient hydrogen production and electricity generation, good stability and low cost. The visible-light response type automatic-bias photoelectrical catalytic water decomposition hydrogen production and electricity generation system and the preparation method of the system have an important significance in developing the solar hydrogen production and electricity generation technology.

Owner:SHANGHAI JIAO TONG UNIV

Large-ratio lean coal coking method

The invention provides a large-ratio lean coal coking method which comprises the following steps: uniformly mixing the following coal: 50-60wt% of coal of which Rmax is 1.5-1.7%, 10-15wt% of coal of which Rmax is 0.6-0.9%, 15-25wt% of coal of which Rmax is 0.9-1.2% and 10-25wt% of coal of which Rmax is 1.2-1.5%; transferring into a stamp-charging coke oven; and under the conditions that the machine side temperature is 1315-1325 DEG C, the coke side temperature is 1325-1335 DEG C, the coke cake center temperature is 970-1000 DEG C, the observation hole pressure is 5-10 pa, the gas collecting tube pressure is 100-120 pa and the branch gas flue suction force is 235-245 pa, coking for 25-28 hours to obtain coke meeting the requirements of blast furnace ironmaking. Thus, the invention effectively solves the problems that the coke quality is poor due to lean coal large-ratio coking and coke in the coke oven is difficult to push in the coking process, reduces the coke pushing current by 50 Amperes, effectively lowers the coal blending cost and solves the problem on shortage of coal resources.

Owner:YUNNAN COAL & ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com