Method for manufacturing gas collecting tube component and air-conditioning system

A manufacturing method and a gas collecting pipe technology, which are applied in the field of air conditioning systems, can solve the problems of large mutual thermal influence, difficult air tightness control, poor surface quality, etc., to simplify the process, improve the air tightness reliability and corrosion resistance, reduce the The effect of material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technology of the present invention will be described below in conjunction with specific embodiments.

[0045] In order to facilitate the description of the technical solution of the present invention, the same numbers are used for the same parts of the present invention and the prior art.

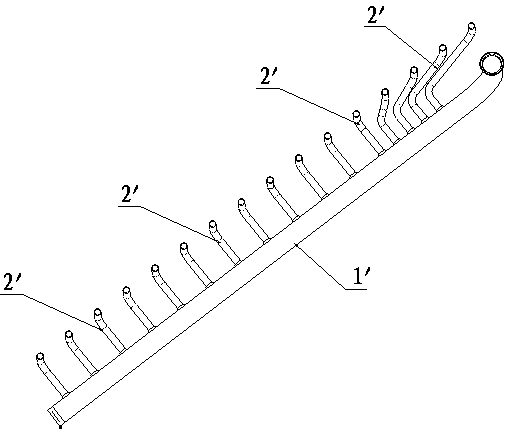

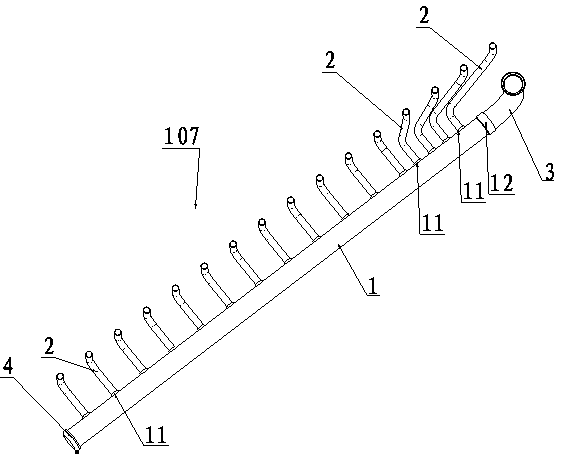

[0046] Please refer to image 3 , Figure 4 , image 3 A schematic structural view of the gas collecting pipe assembly provided by the present invention, Figure 4 A schematic cross-sectional view of the main air collecting pipe provided by the present invention;

[0047] The air collecting pipe assembly 107 is composed of the main air collecting pipe 1 as the main structure. The main air collecting pipe 1 is generally in the shape of a hollow round rod, and several stepped flanges 11 are processed on the pipe wall. The main air collecting pipe 1 can be a straight pipe as shown in the figure. According to the connection requirements, a bend can be provided at one or both end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com