Patents

Literature

219 results about "Manufactured gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The history of gaseous fuel, important for lighting, heating, and cooking purposes throughout most of the 19th century and the first half of the 20th century, began with the development of analytical and pneumatic chemistry in the 18th century. The manufacturing process for "synthetic fuel gases" (also known as "manufactured fuel gas", "manufactured gas" or simply "gas") typically consisted of ...

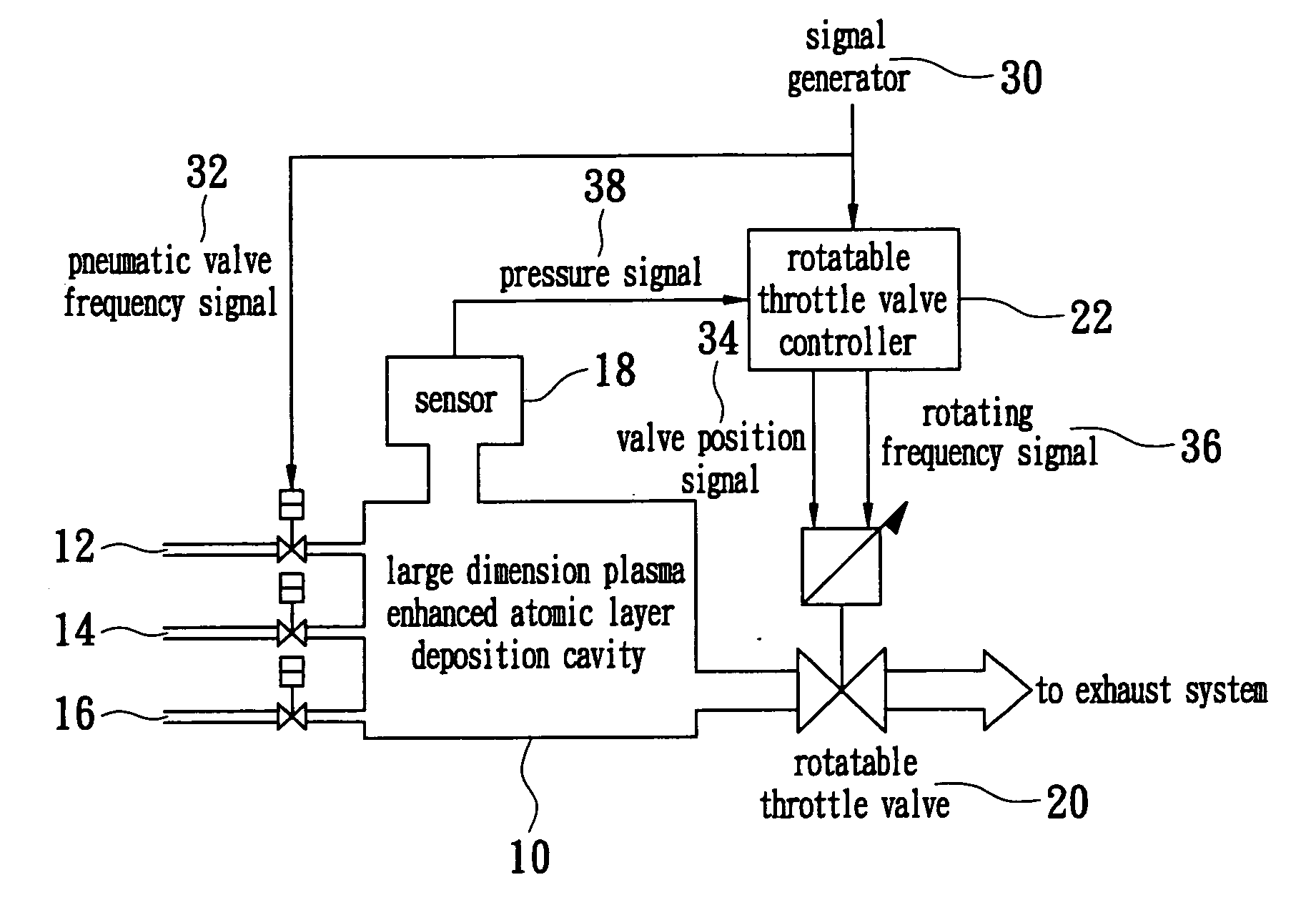

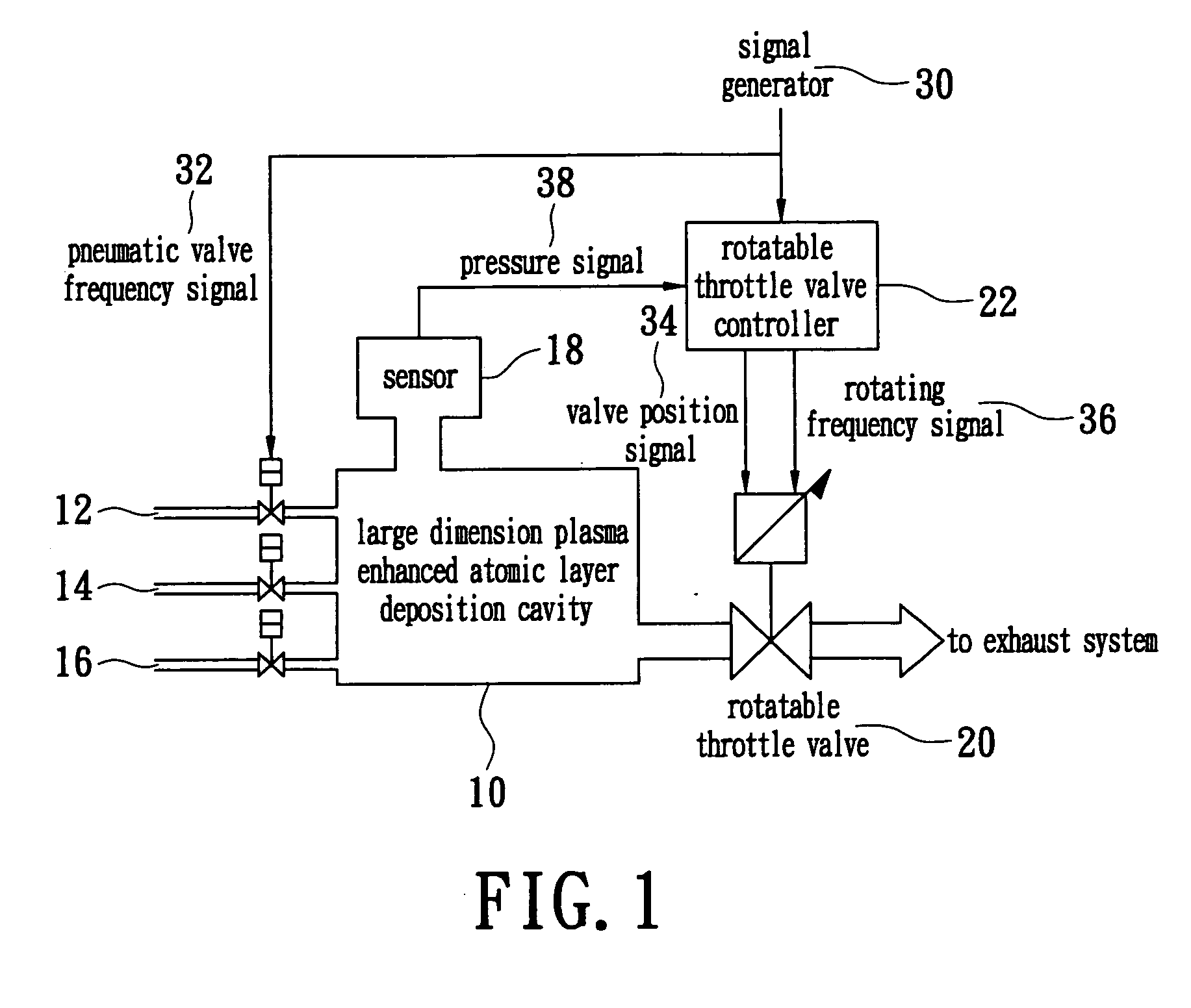

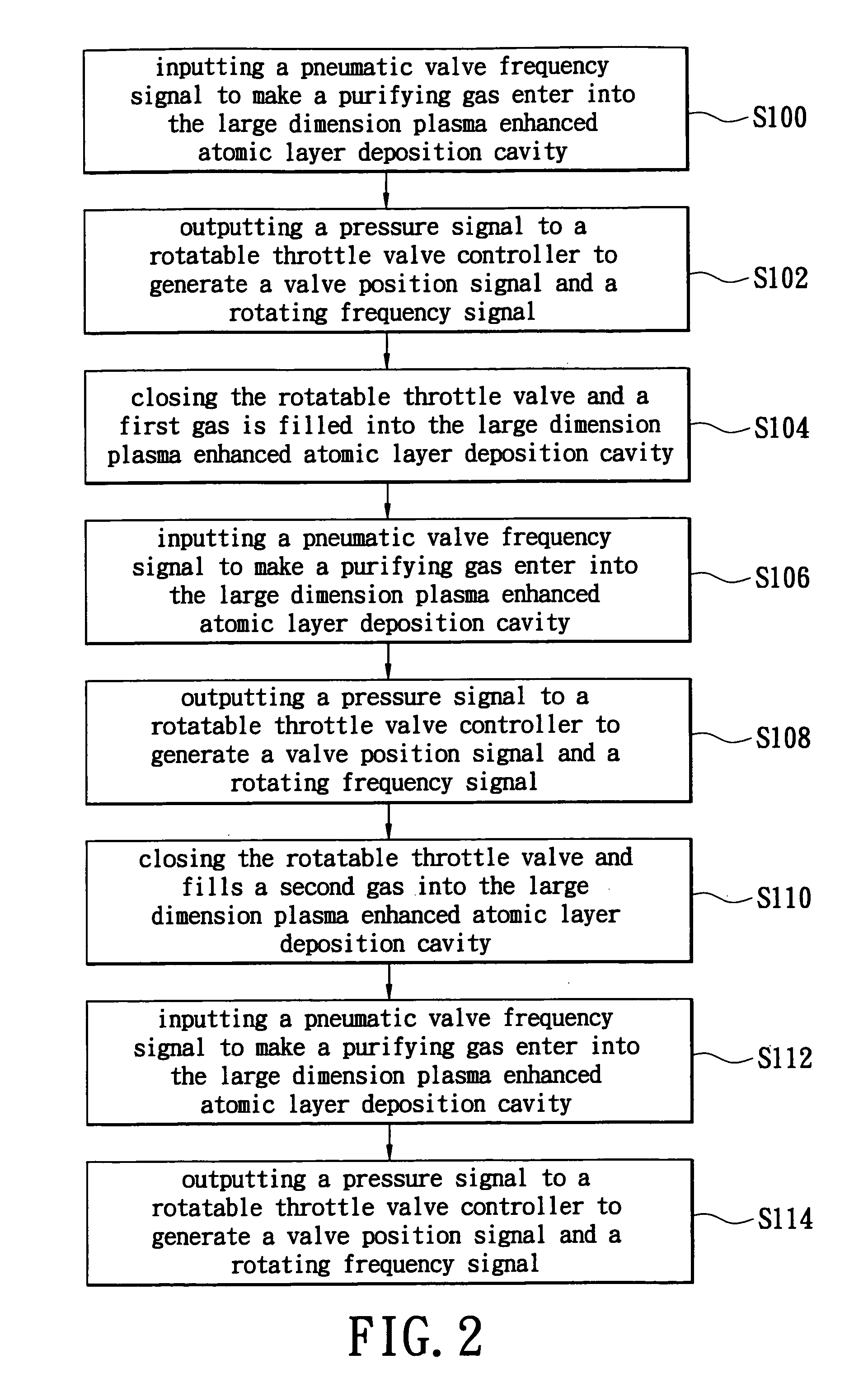

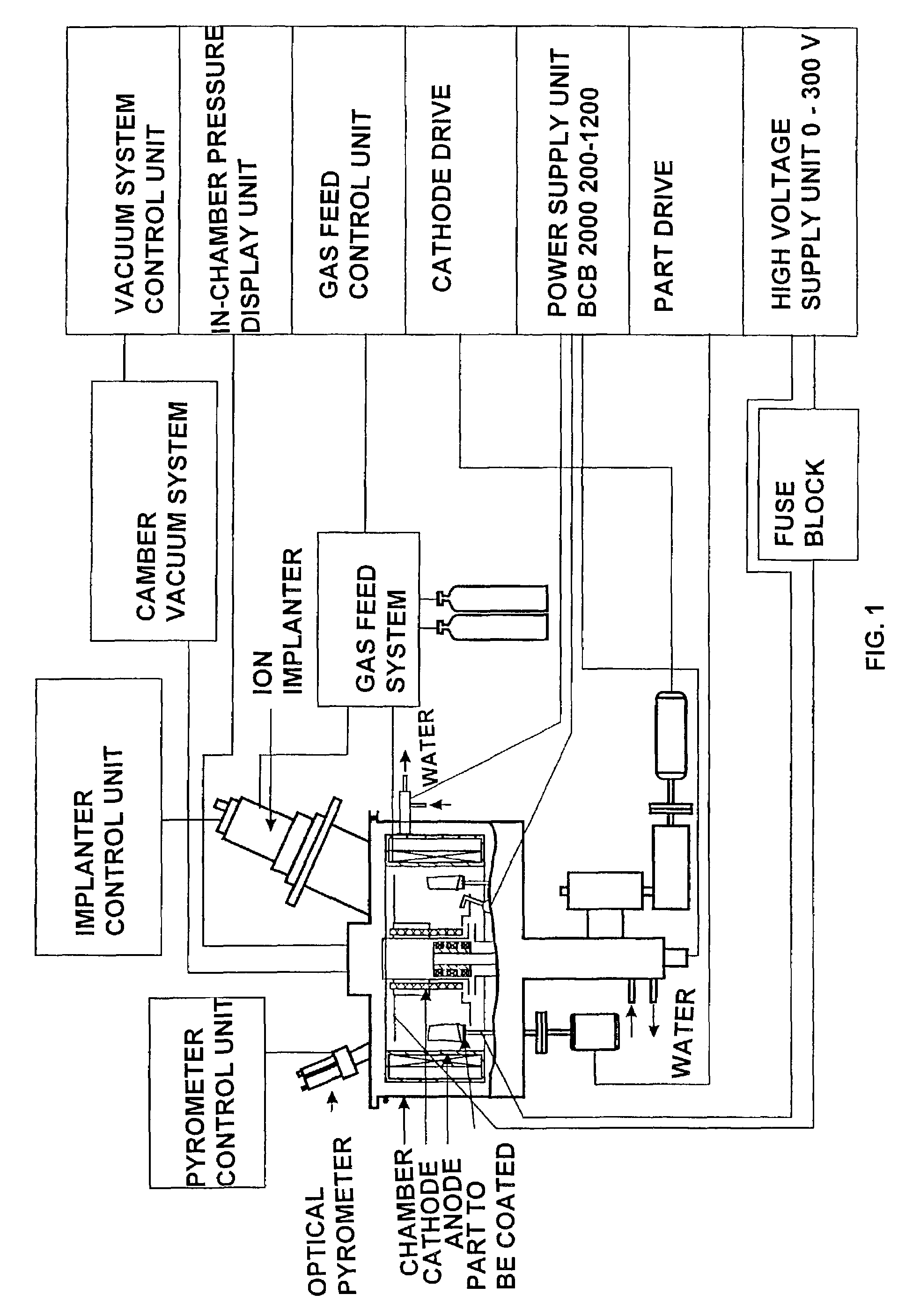

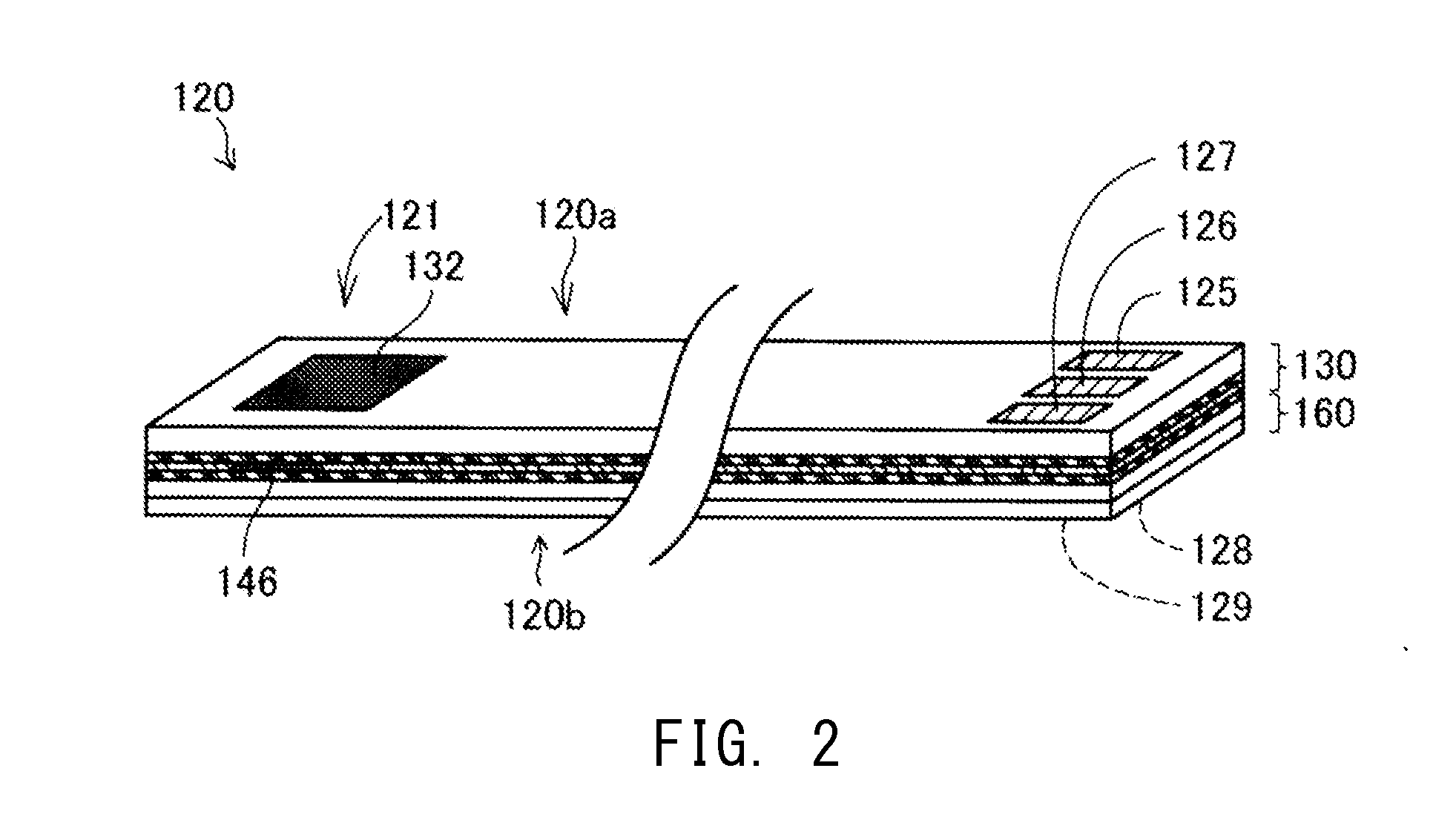

Operating method for a large dimension plasma enhanced atomic layer deposition cavity and an apparatus thereof

ActiveUS20070026162A1Effectively control pressureIncrease airflowSemiconductor/solid-state device manufacturingChemical vapor deposition coatingManufacturing cost reductionEngineering

An operating method for a large dimension plasma enhanced atomic layer deposition cavity and an apparatus thereof are provided. The present invention reduces the time needed for filling the manufacturing gas into the large volume manufacturing cavity. Therefore, the plasma enhanced atomic layer deposition apparatus can switch the precursors rapidly to increase the thin film deposition rate, reduce the manufacturing gas consumption and lower the manufacturing cost.

Owner:CHINA STAR OPTOELECTRONICS INT HK

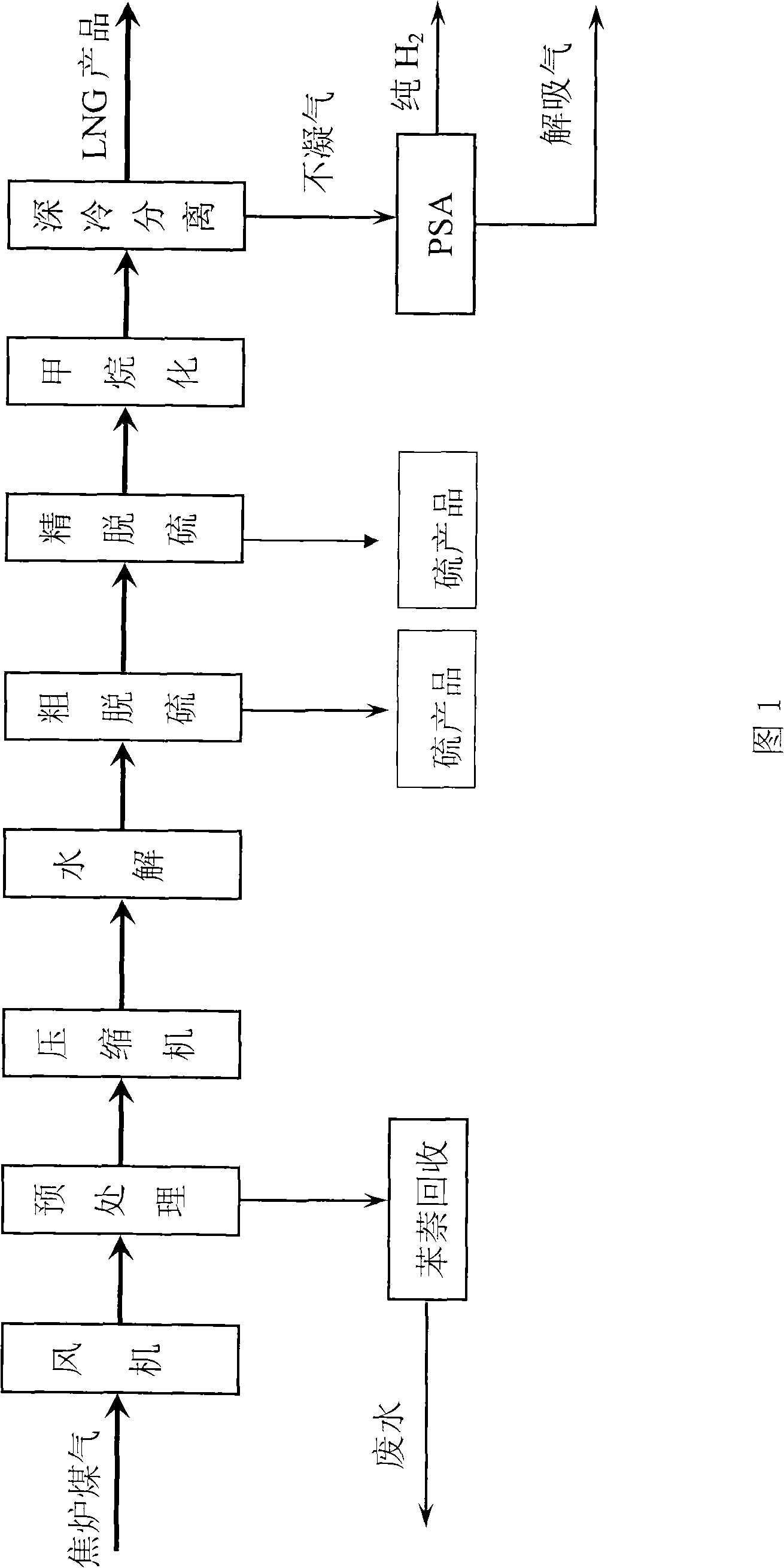

Method for preparing liquefied natural gas from coke oven gas

InactiveCN101280235ATo achieve coordinated developmentReasonable process combinationCombustible gas chemical modificationChemical industryMethanationImpurity

Disclosed is a method which uses coke-oven gas as the raw material to produce liquefied natural gas; the method includes that the coke-oven gas is pretreated firstly to enable the tar, naphthalene and benzene impurities contained in the coke-oven gas to be purified deeply; and the purified coke-oven gas is processed with methanation reaction after compression and desulfurization; the liquefied natural gas product which contains CH4 with the content of more than 85% through the cryogenic separation process; the residual non-condensable gas is prepared to obtain the hydrogen with the purity of 99% through the PSA separation technique; the residual desorbed gas can be used as manufactured gas. The method which uses the coke-oven gas as the raw material to produce liquefied natural gas has the advantages of making full use of the compositions, saving energy, water and the investment, simple process and realizing the trinity coordinated development of economy, environment and energy sources.

Owner:SHENGHE RESOURCES HLDG CO LTD

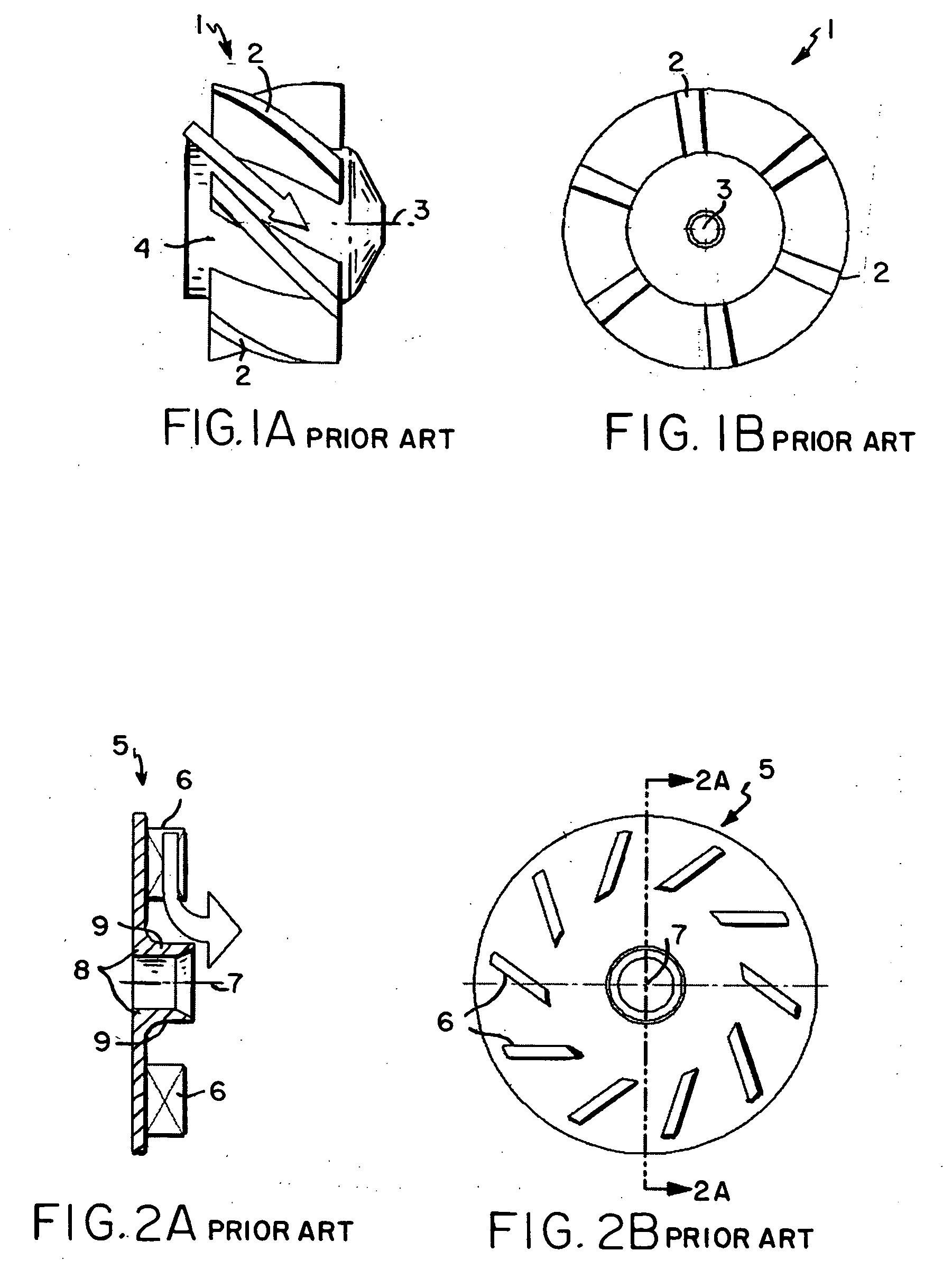

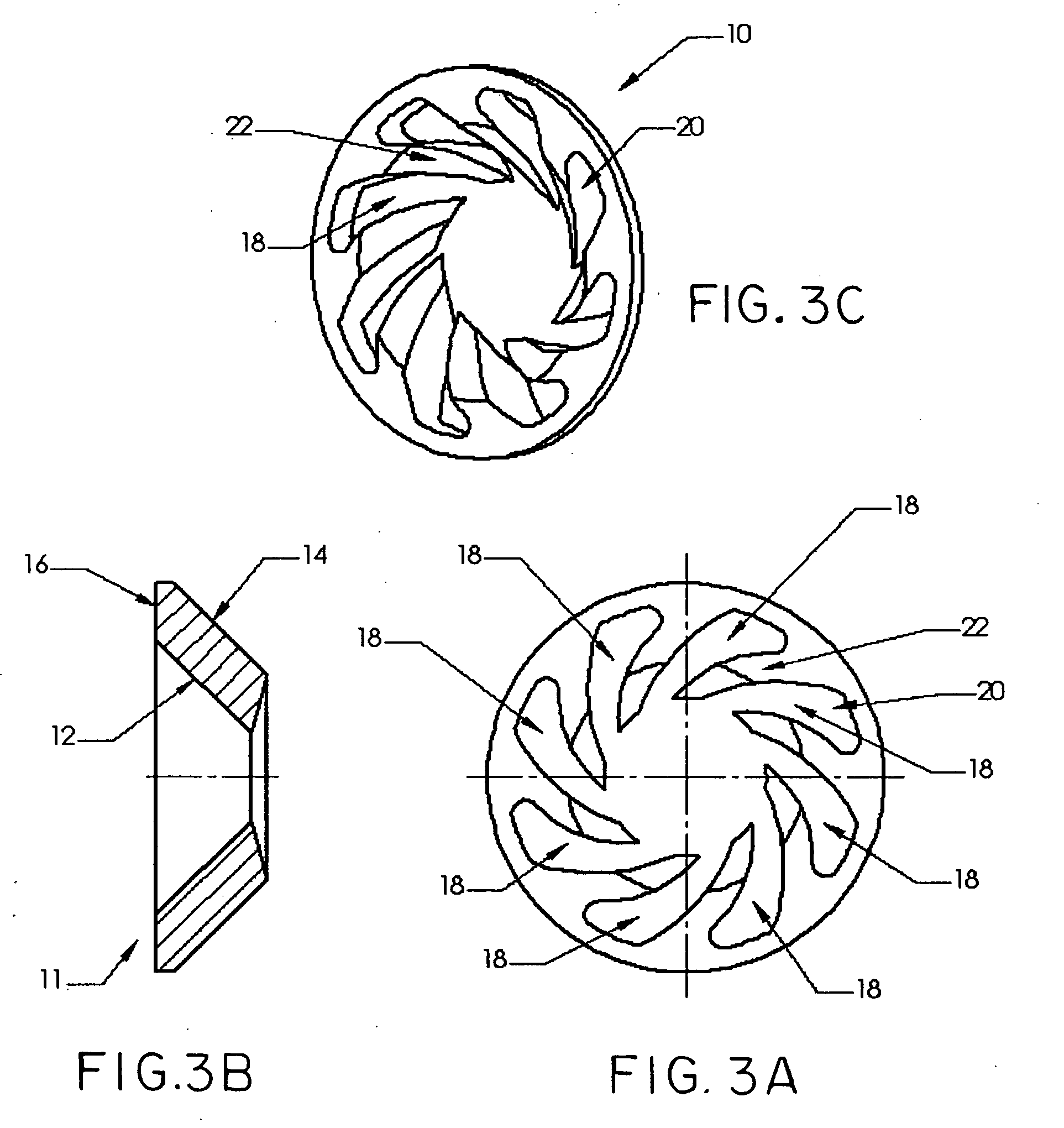

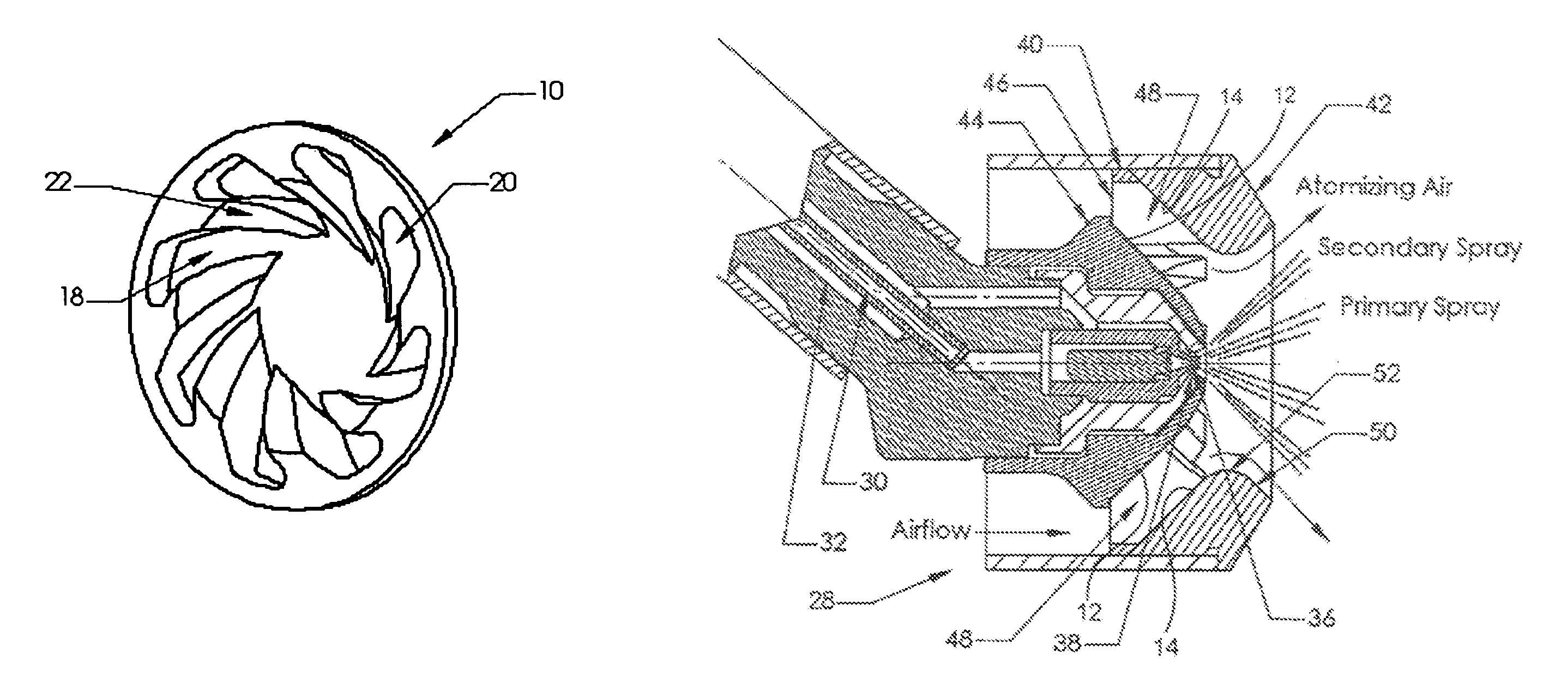

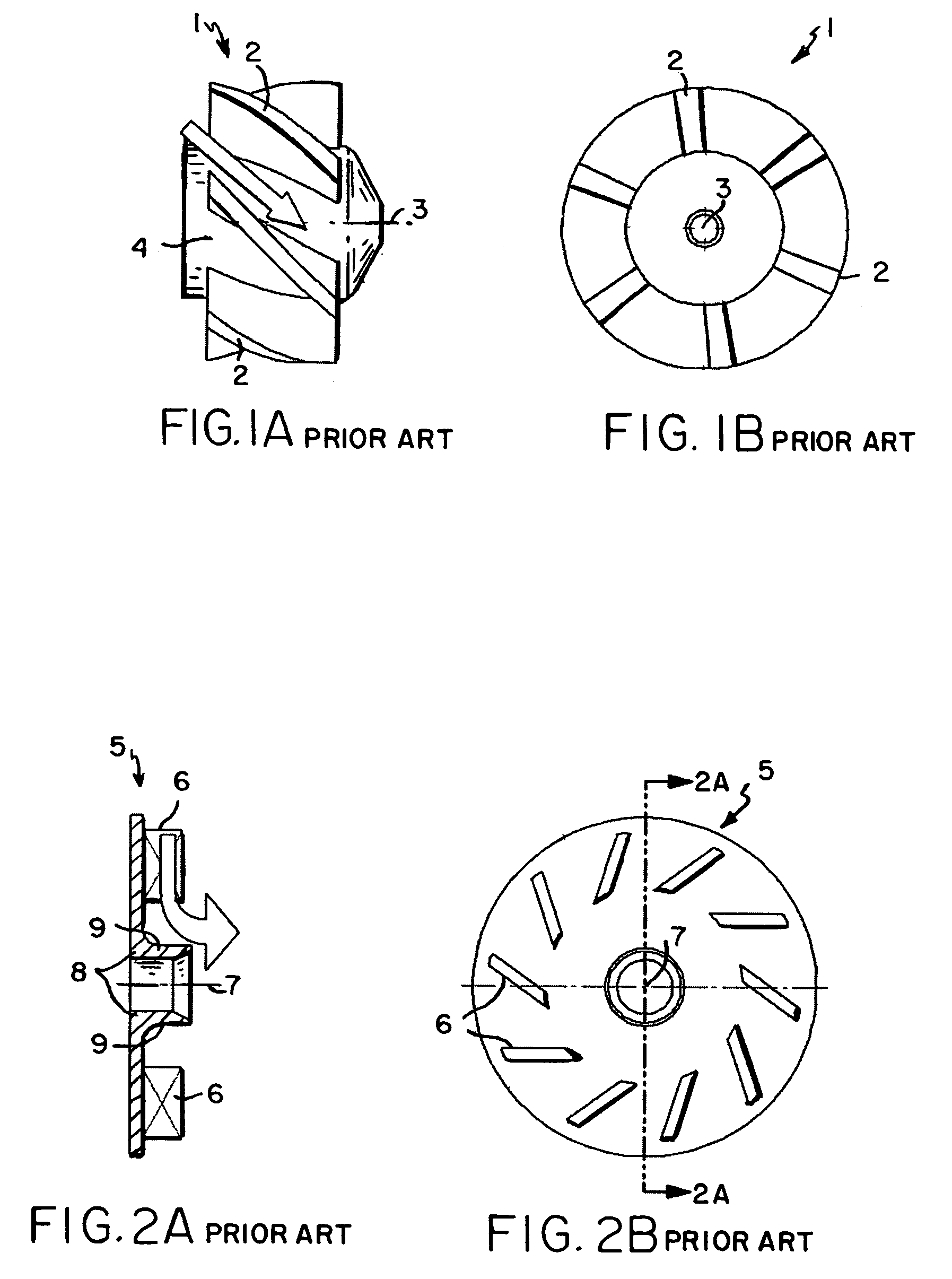

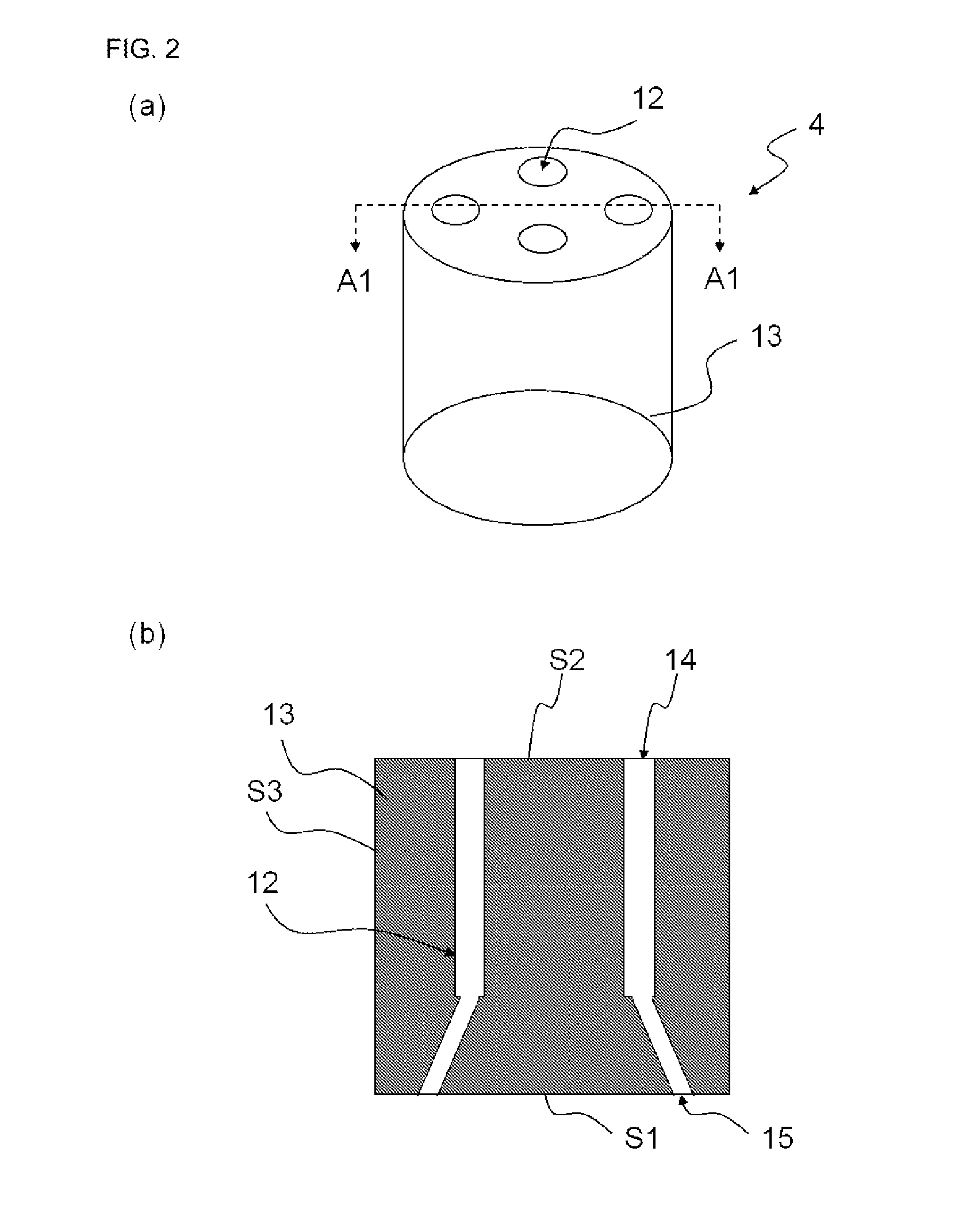

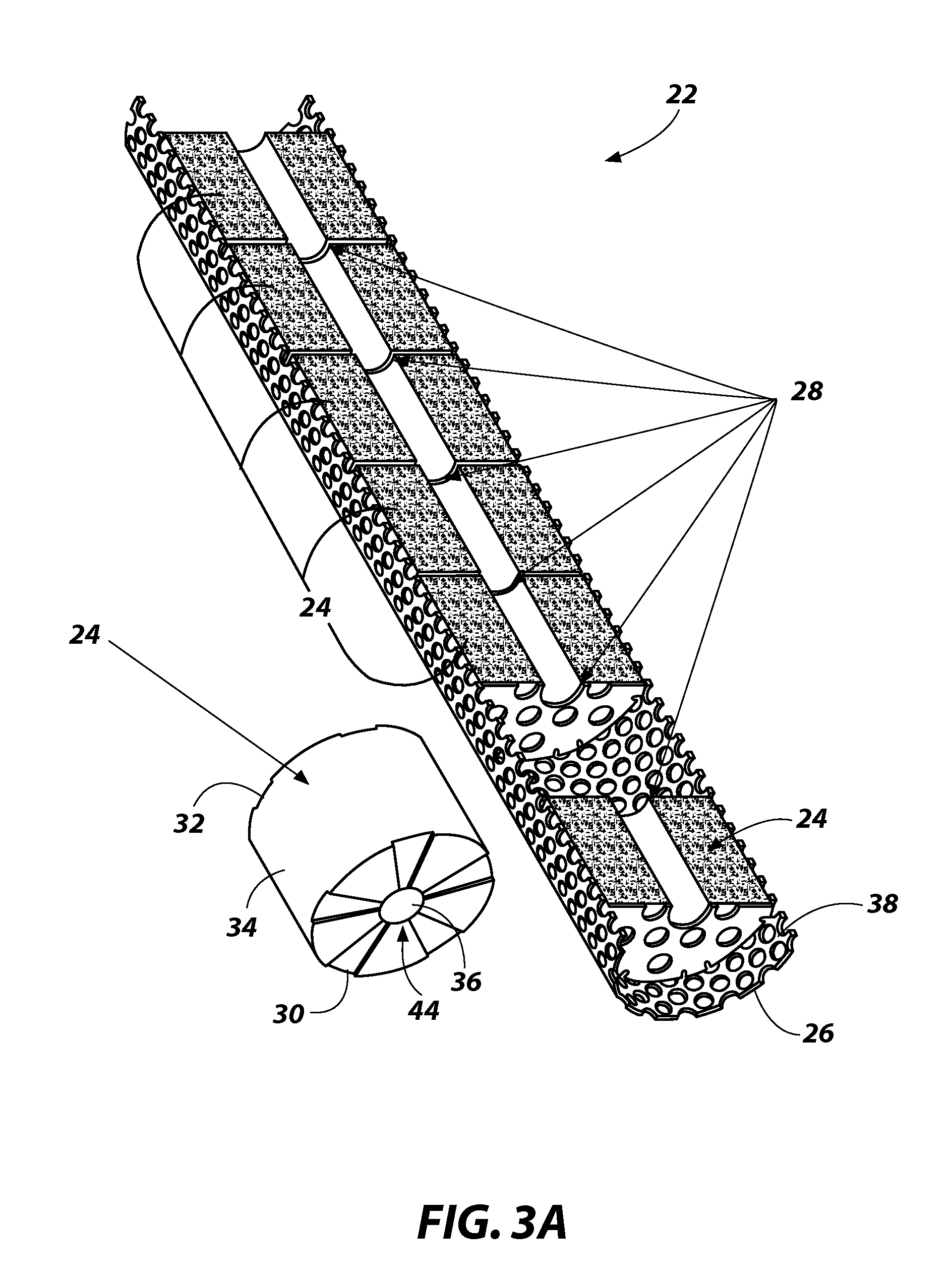

Conical swirler for fuel injectors and combustor domes and methods of manufacturing the same

ActiveUS20050279862A1Area minimizationReduced frontal surface areaContinuous combustion chamberSpray nozzlesCombustorCombustion chamber

A method of manufacturing gas and / or fuel swirlers for fuel injectors and combustor domes and cone-shaped swirlers so manufactured are disclosed. The disclosed conical swirlers feature cut-through slots on a cone-shaped body. The contour and spacing of the slots are configured and arranged to accommodate a wide range of requirements for fluid flow areas and swirl strengths. Preferably, the cone-shaped swirlers can be manufactured by wire EDM processing. More preferably, multiple cone-shaped swirlers can be manufactured simultaneously by nesting swirler blanks in a stack and wire EDM processing the stack as a unit. The cone-shaped pinwheel swirler fits well into various fuel injector heads, enabling the injectors to reduce the frontal surface area and flat area for minimal potential of carbon formation.

Owner:COLLINS ENGINE NOZZLES INC

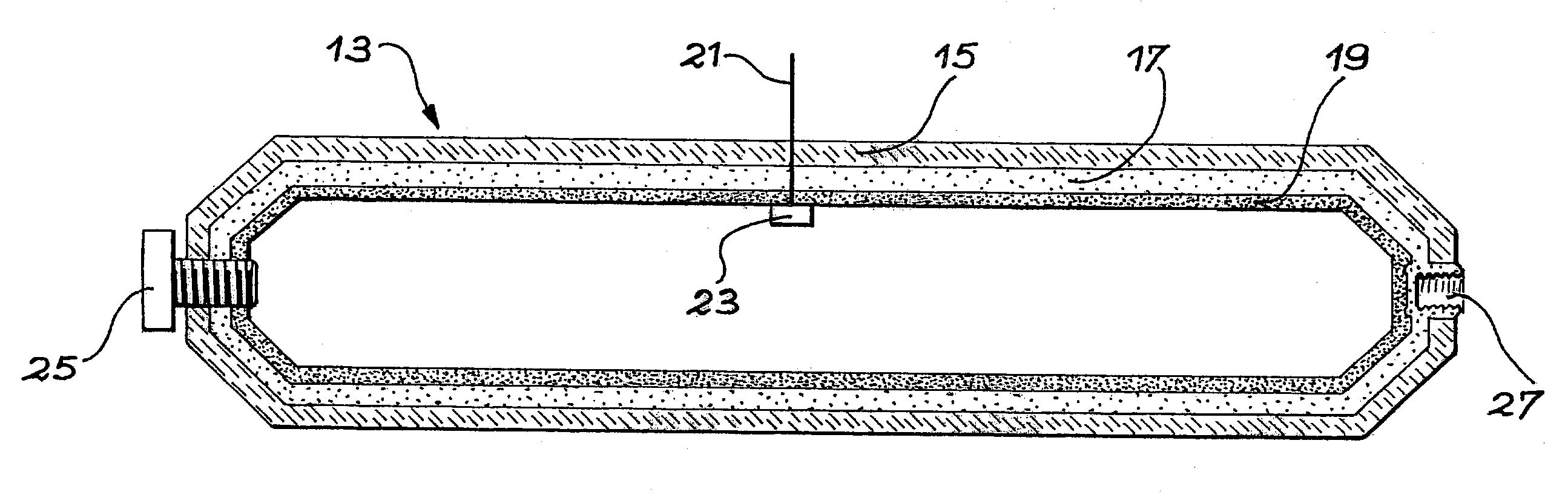

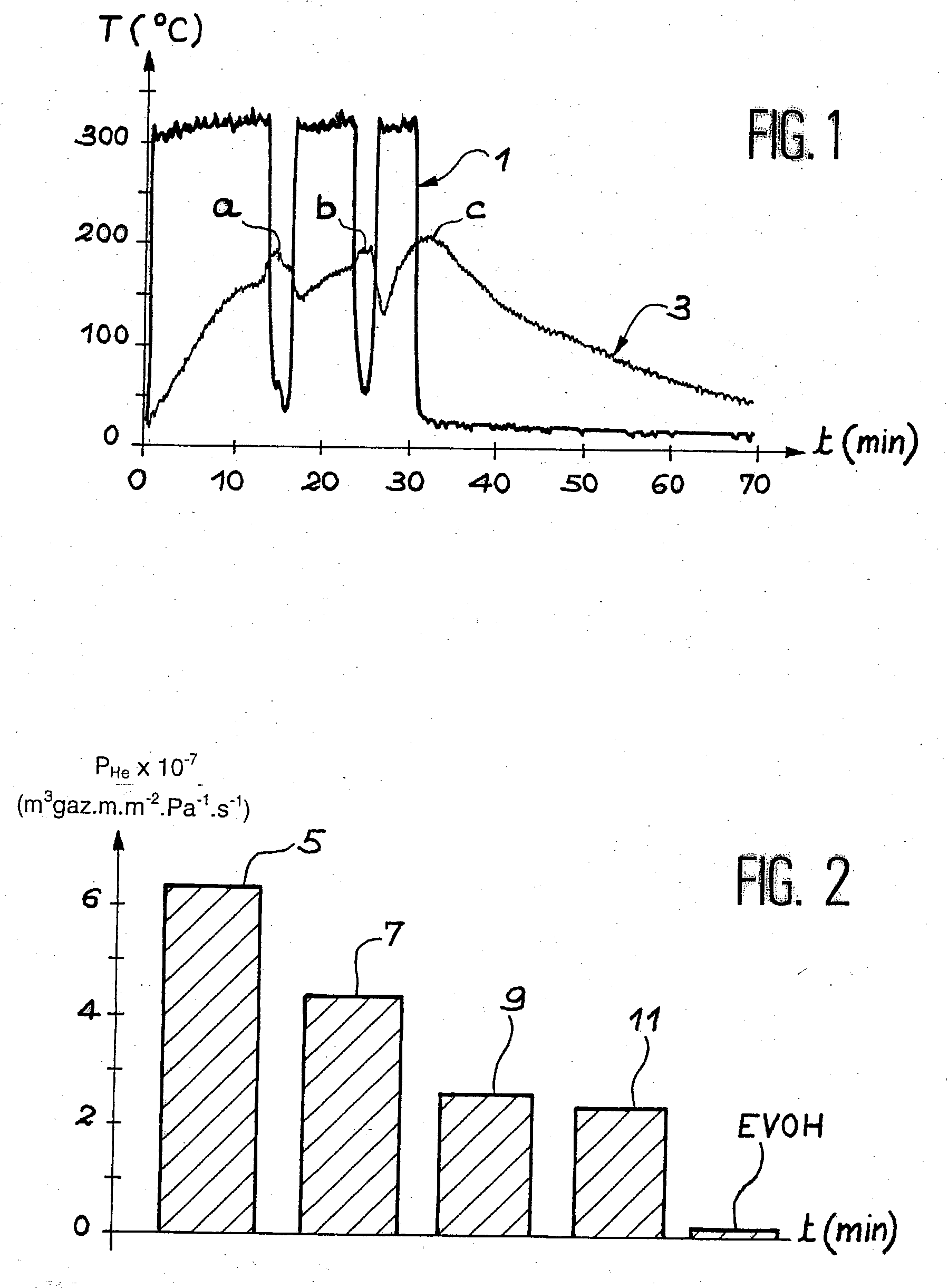

Mulitlayer thermoplastic structure for gas tank

InactiveUS20030175457A1Avoid the needControlling the riskUnderstructuresRecord information storageThermoplasticMelt flow index

This invention relates to a multiple layer thermoplastic structure, use of the said structure for manufacturing a tank, and a tank comprising the said structure. Multi-layer thermoplastic structure of the said invention comprising at least one layer composed of an ethylene-vinyl alcohol copolymer with a density of between 0.94 and 1.4, and a melt flow index of between 1.3 and 4.2 g / 10 minutes at a temperature between 170 and 240° C. It is used for manufacturing gas tanks.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

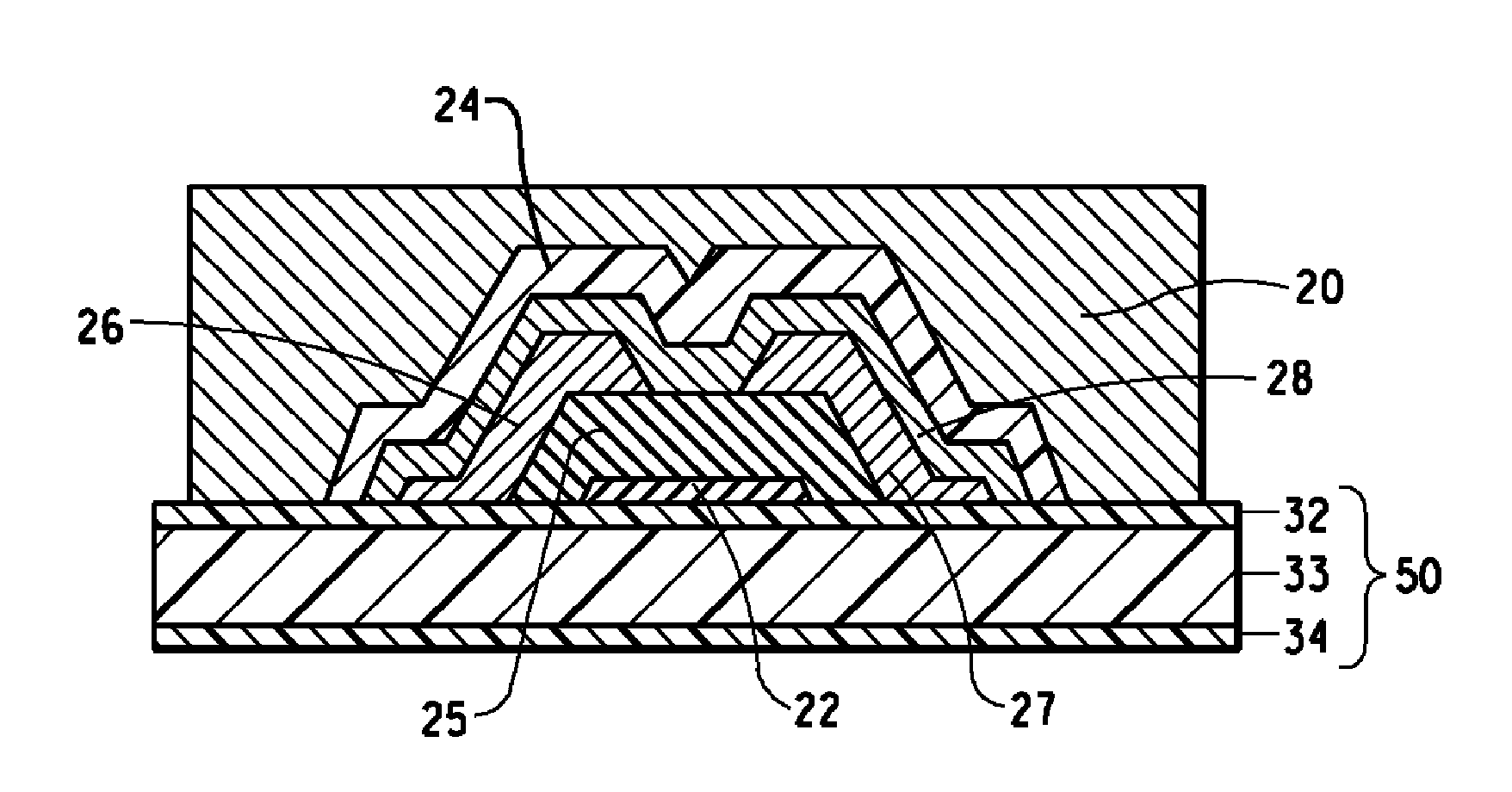

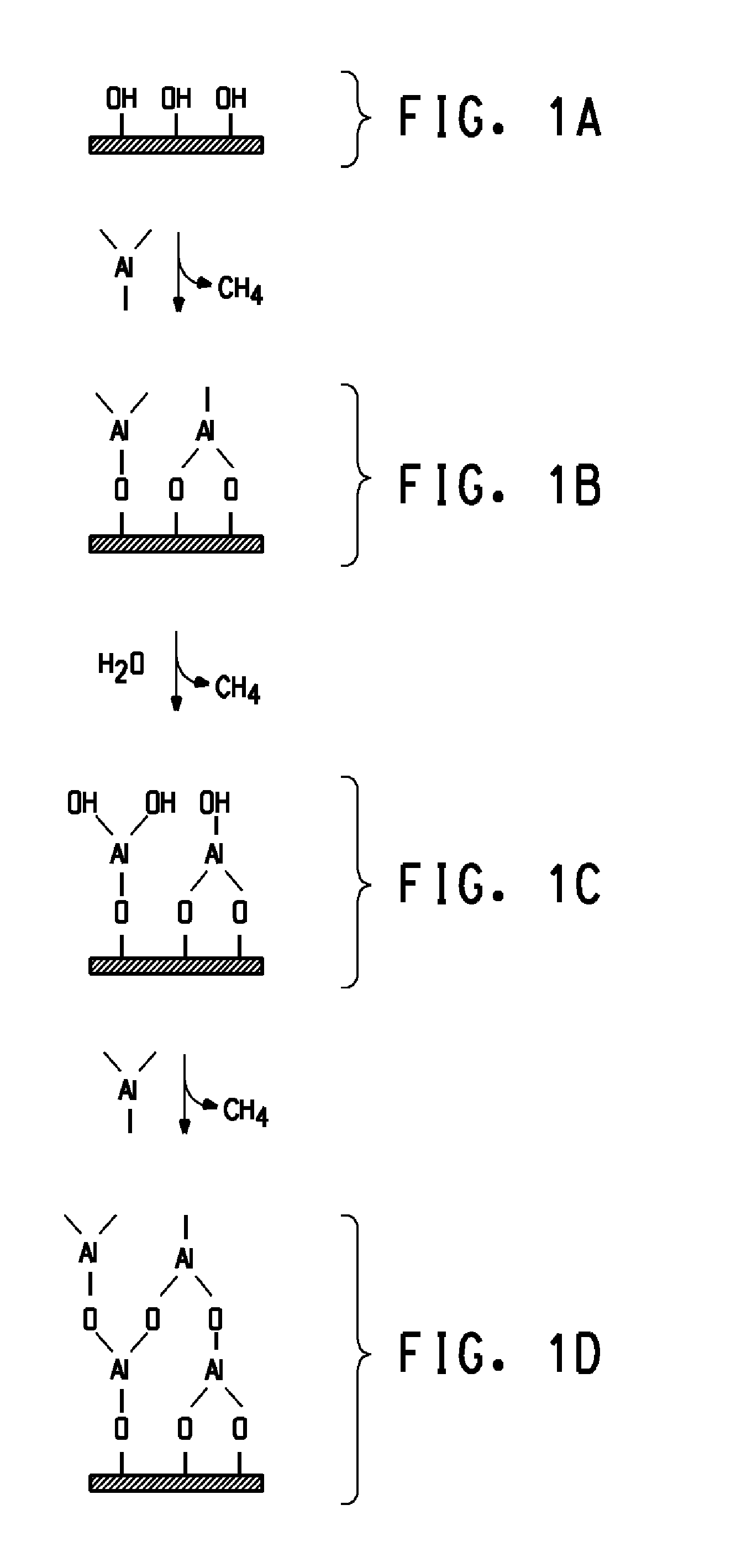

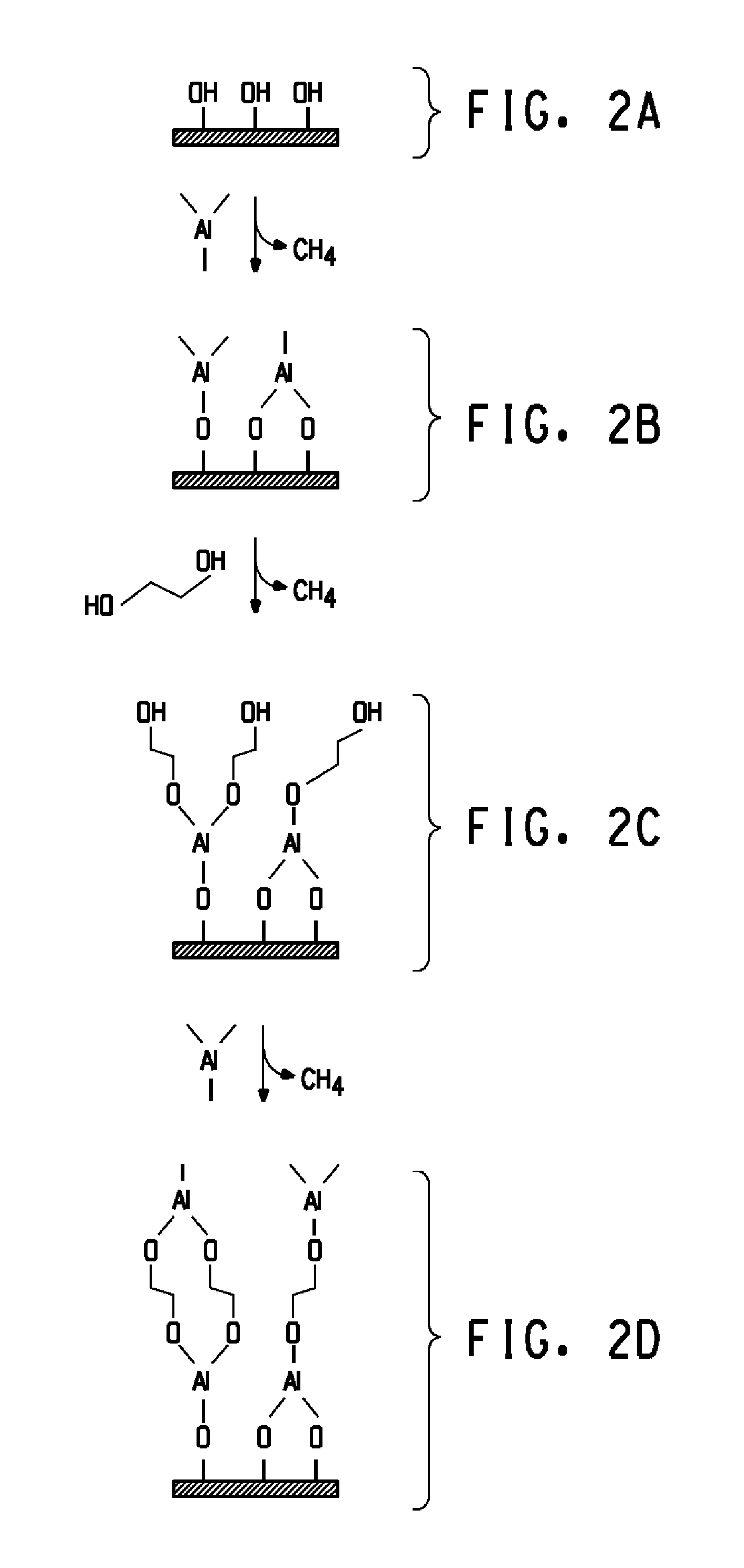

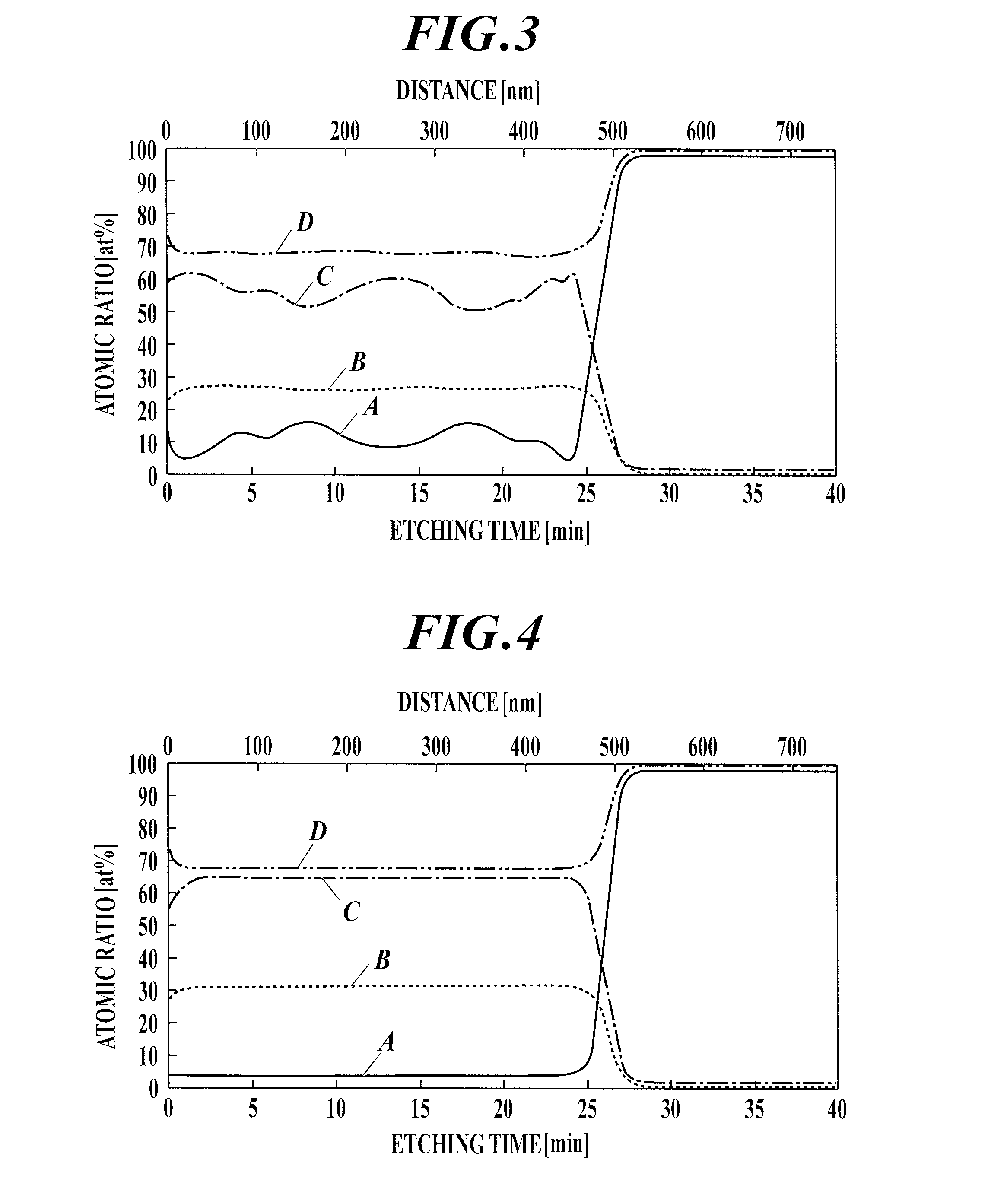

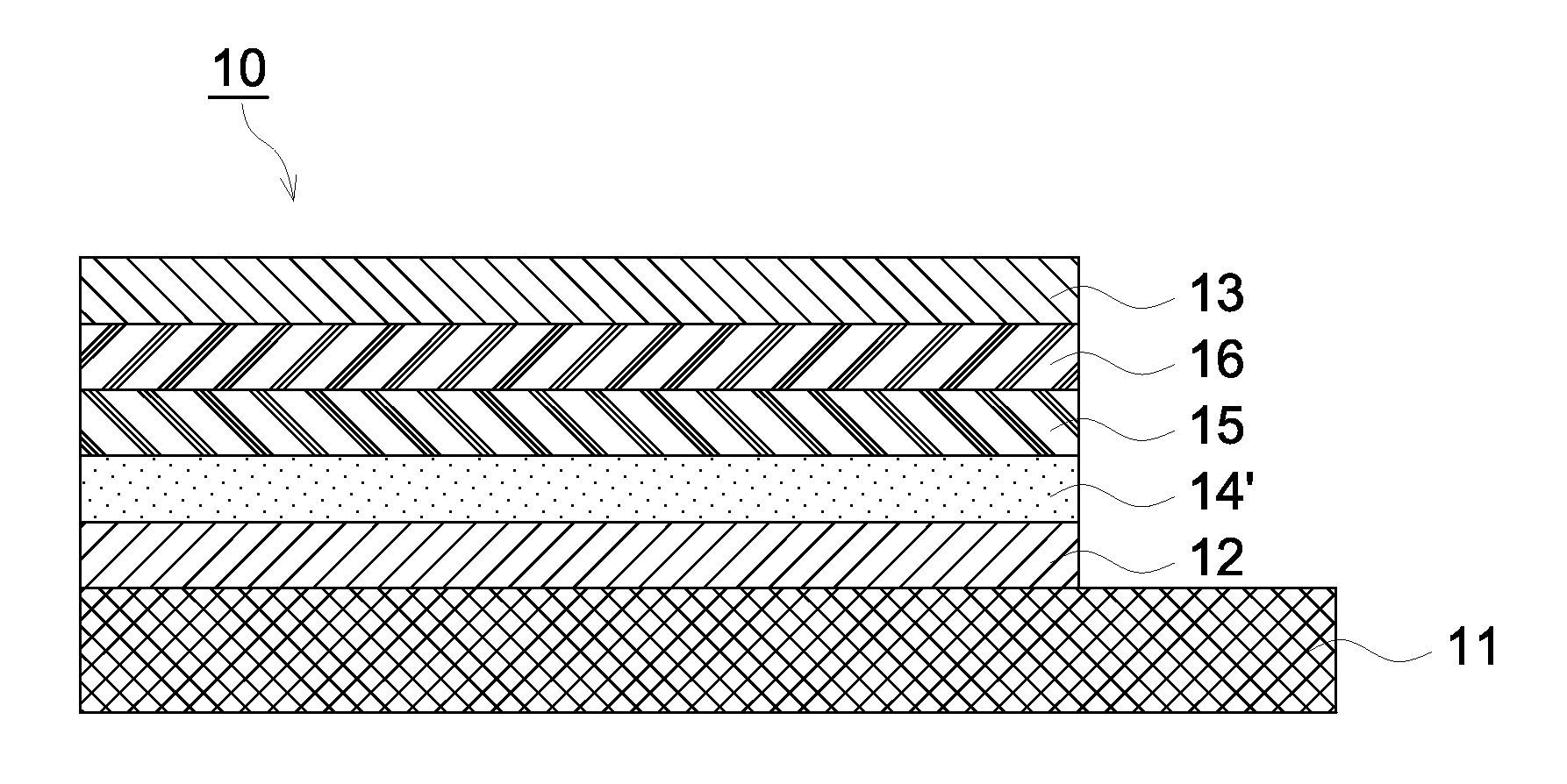

Process for manufacturing gas permeation barrier material and structure

Hybrid inorganic-organic, polymeric alloys are prepared by combining atomic layer deposition and molecular layer deposition techniques provide barrier protection against intrusion of atmospheric gases such as oxygen and water vapor. The alloy may be formed either directly on objects to be protected, or on a carrier substrate to form a barrier structure that subsequently may be employed to protect an object. The alloy thus formed is beneficially employed in constructing electronic devices such as photovoltaic cell arrays, organic light-emitting devices, and other optoelectronic devices.

Owner:EI DU PONT DE NEMOURS & CO

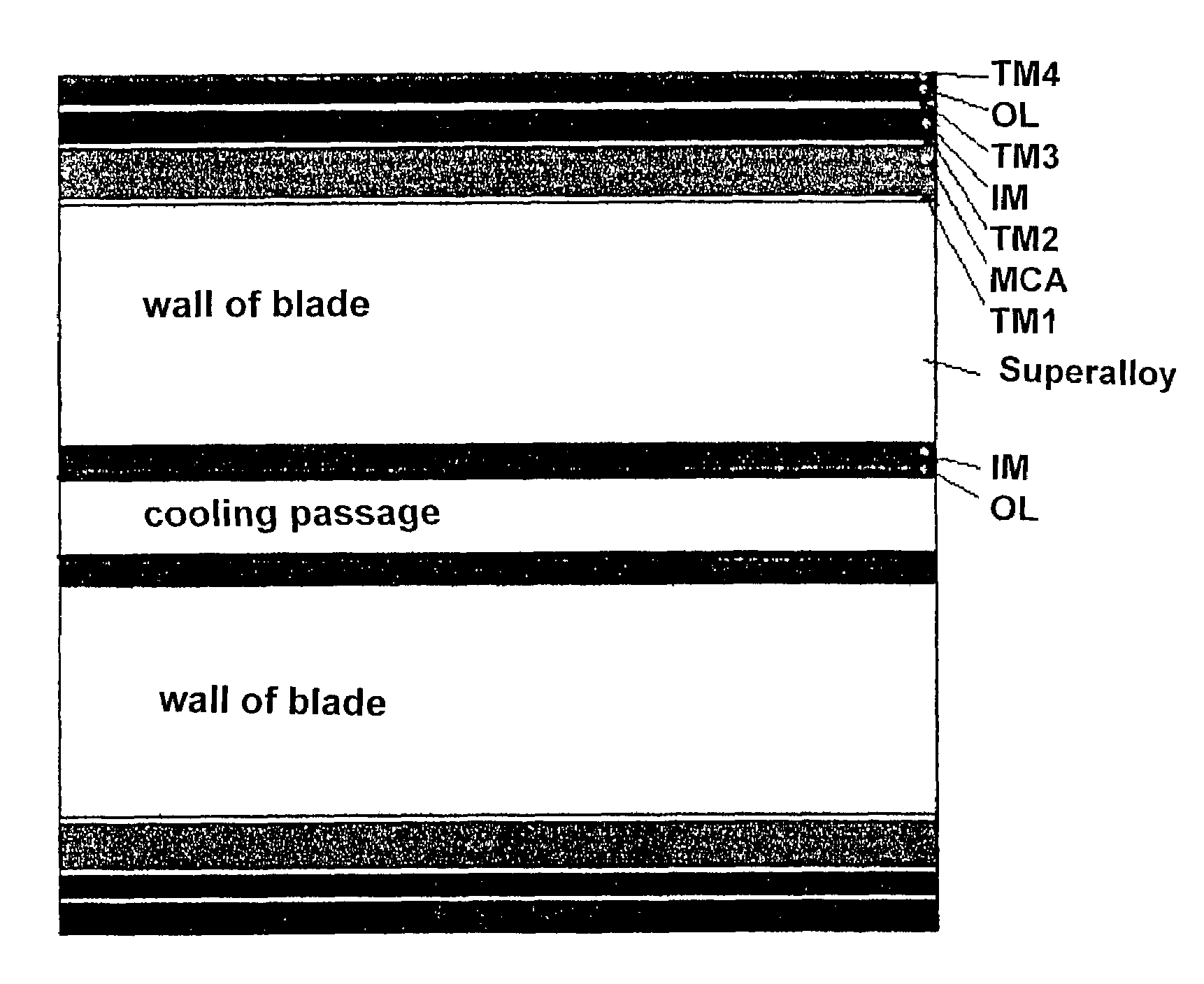

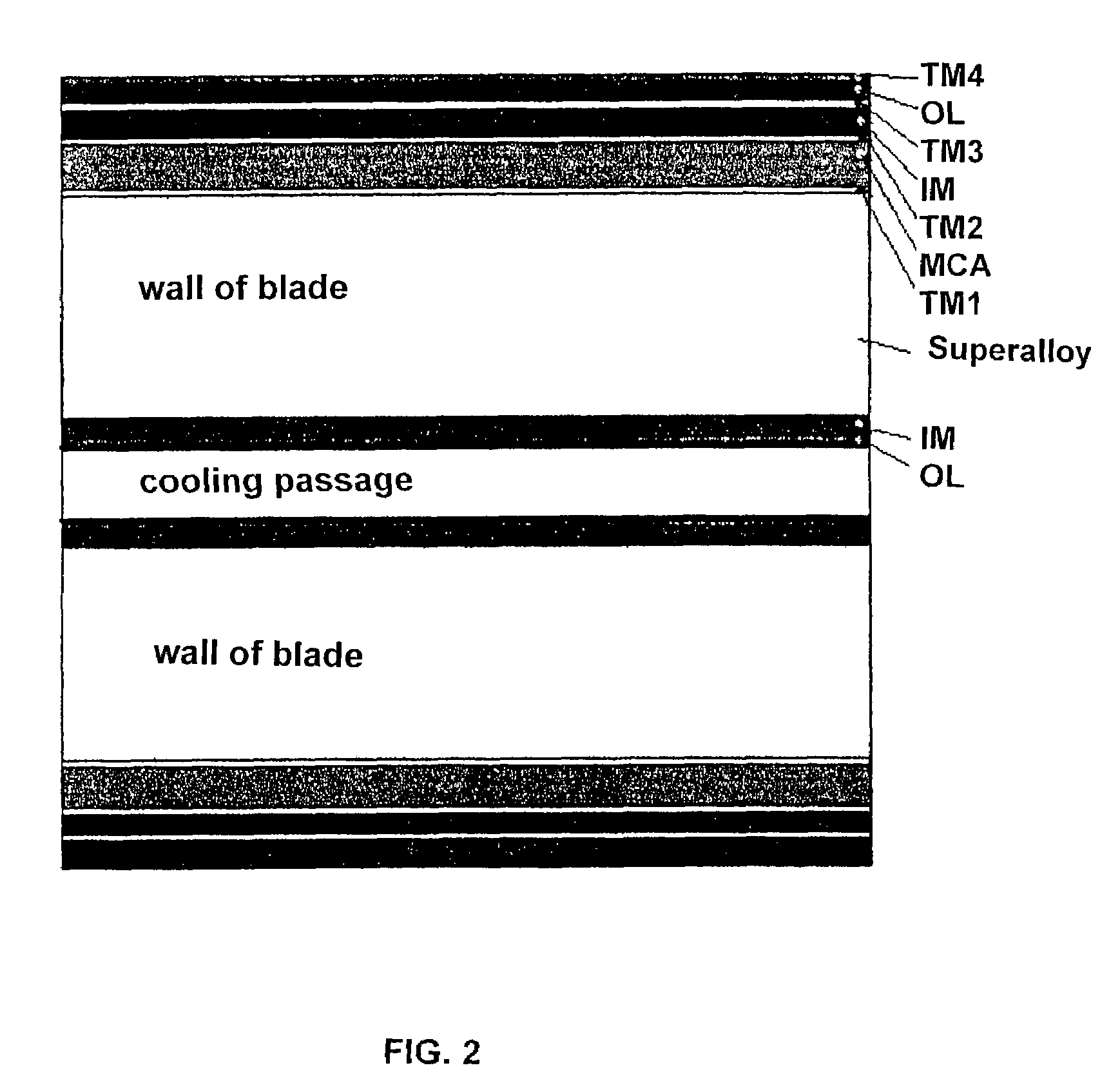

Protective coating method for pieces made of heat resistant alloys

InactiveUS7229675B1Improve featuresGood adhesionVacuum evaporation coatingPretreated surfacesContinuous useEvaporation

The invention relates to metallurgy and mechanical engineering, in particular to the development of methods for providing metallic pieces with protective coatings with a view to improving the performance characteristics thereof. In accordance with the inventive method, a multilayer coating is formed by combining and simultaneously or consecutively using of various technologies including ion-plasma evaporation diffusive metallization and controlled atmosphere thermal treatment. The obtained coatings possess superior characteristics with respect to overall properties and are used for gas turbine construction, in particular, for manufacturing gas turbine vanes of aircraft engines.

Owner:PADEROV ANATOLY NIKOLAEVICH +1

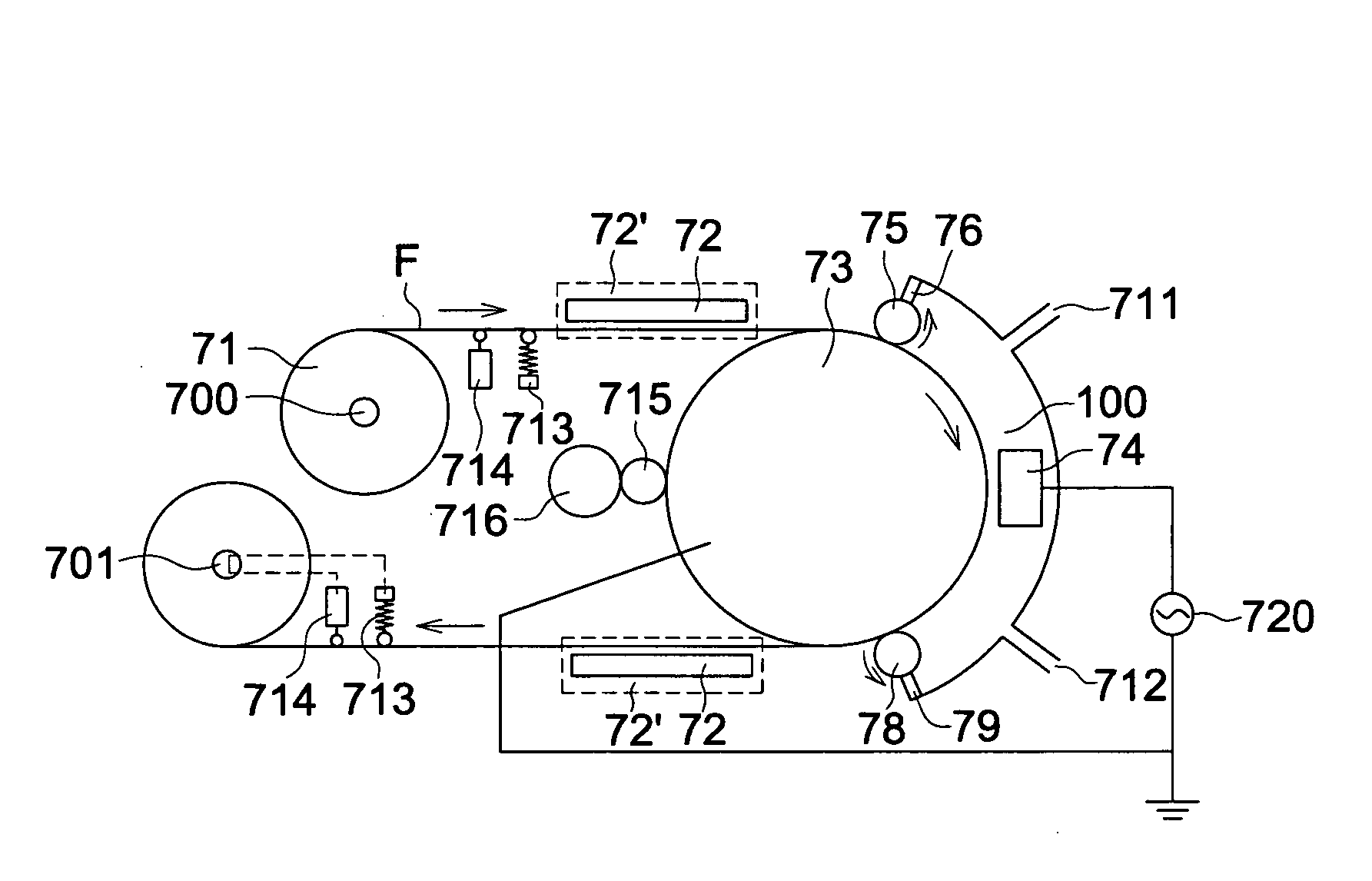

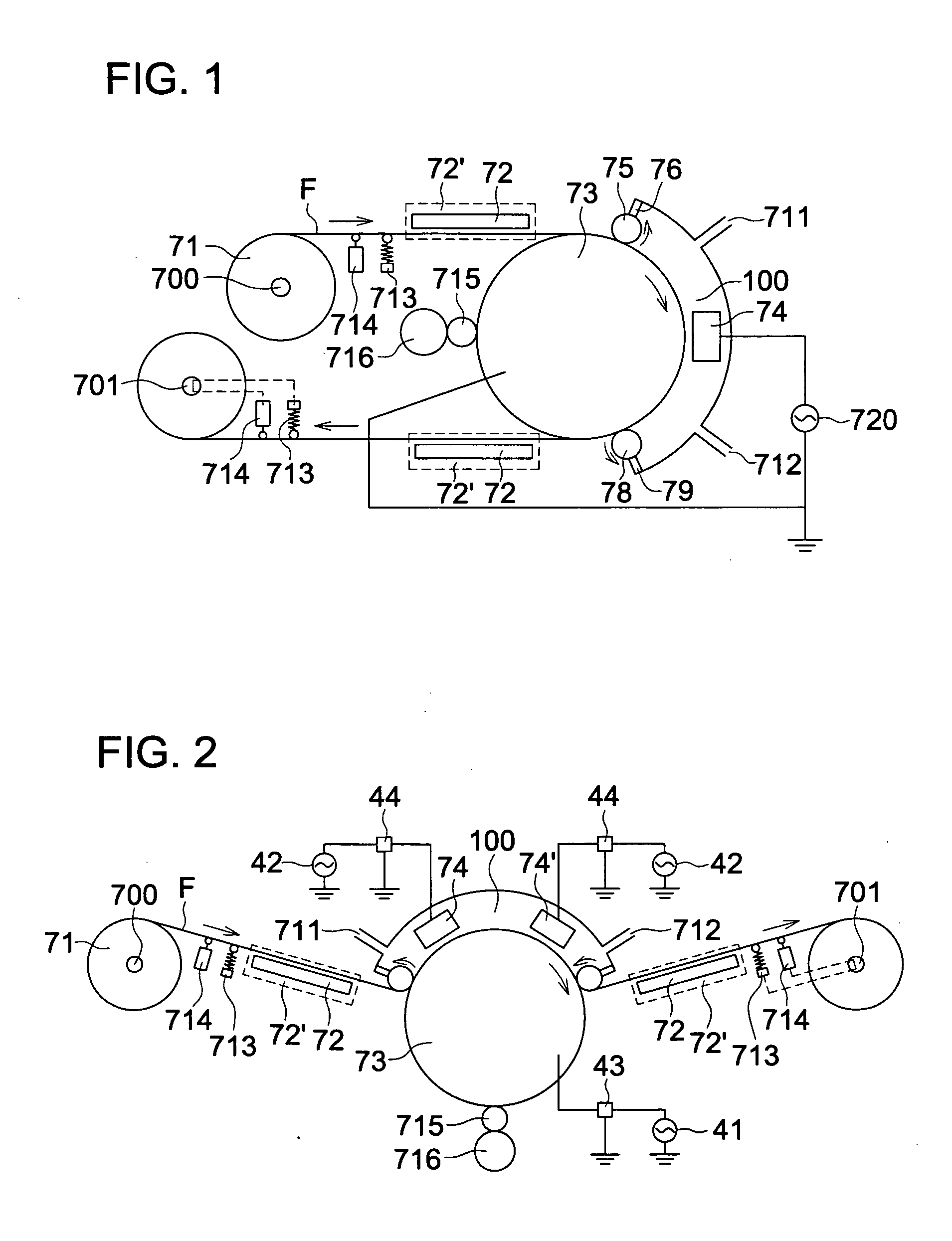

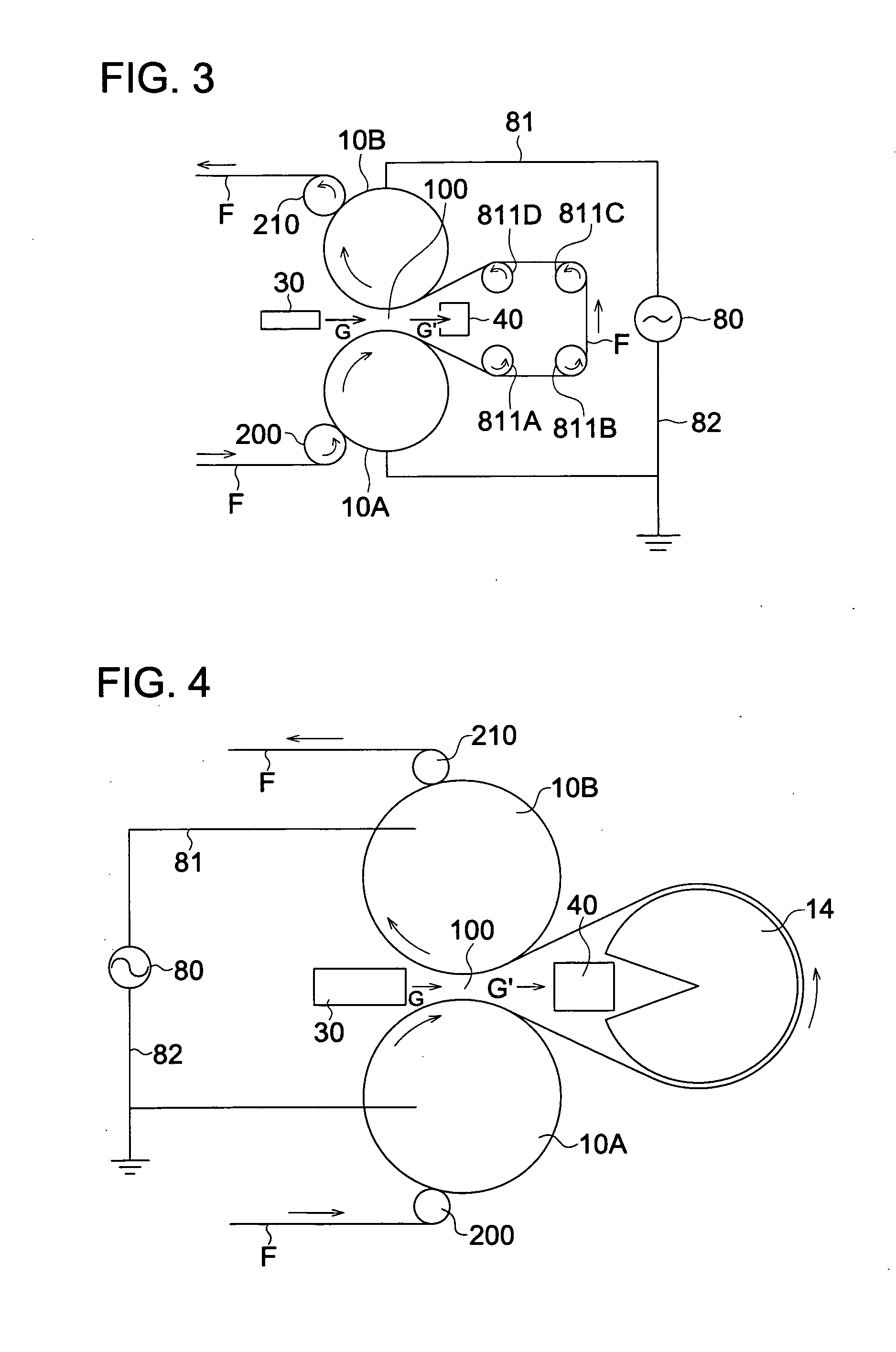

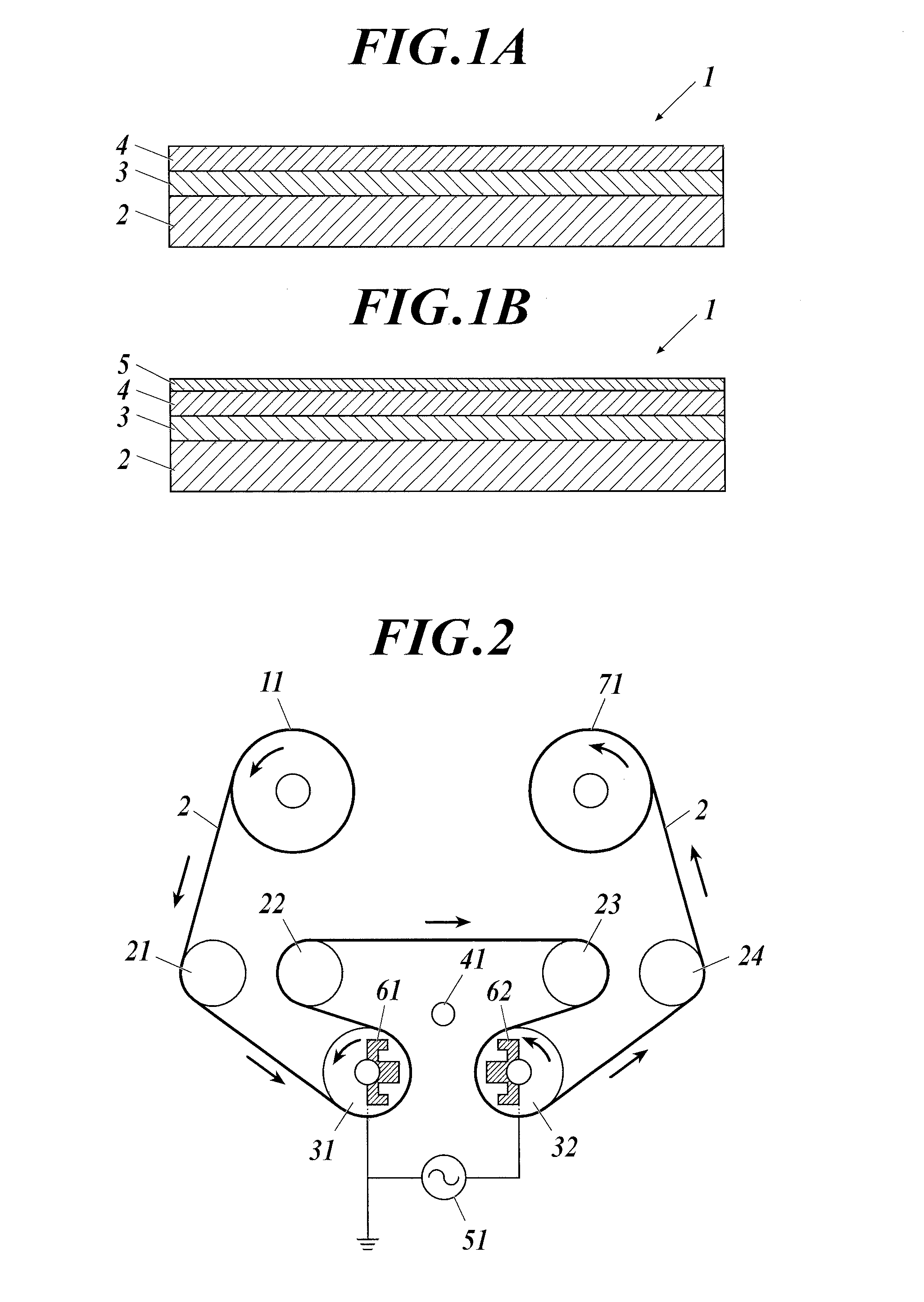

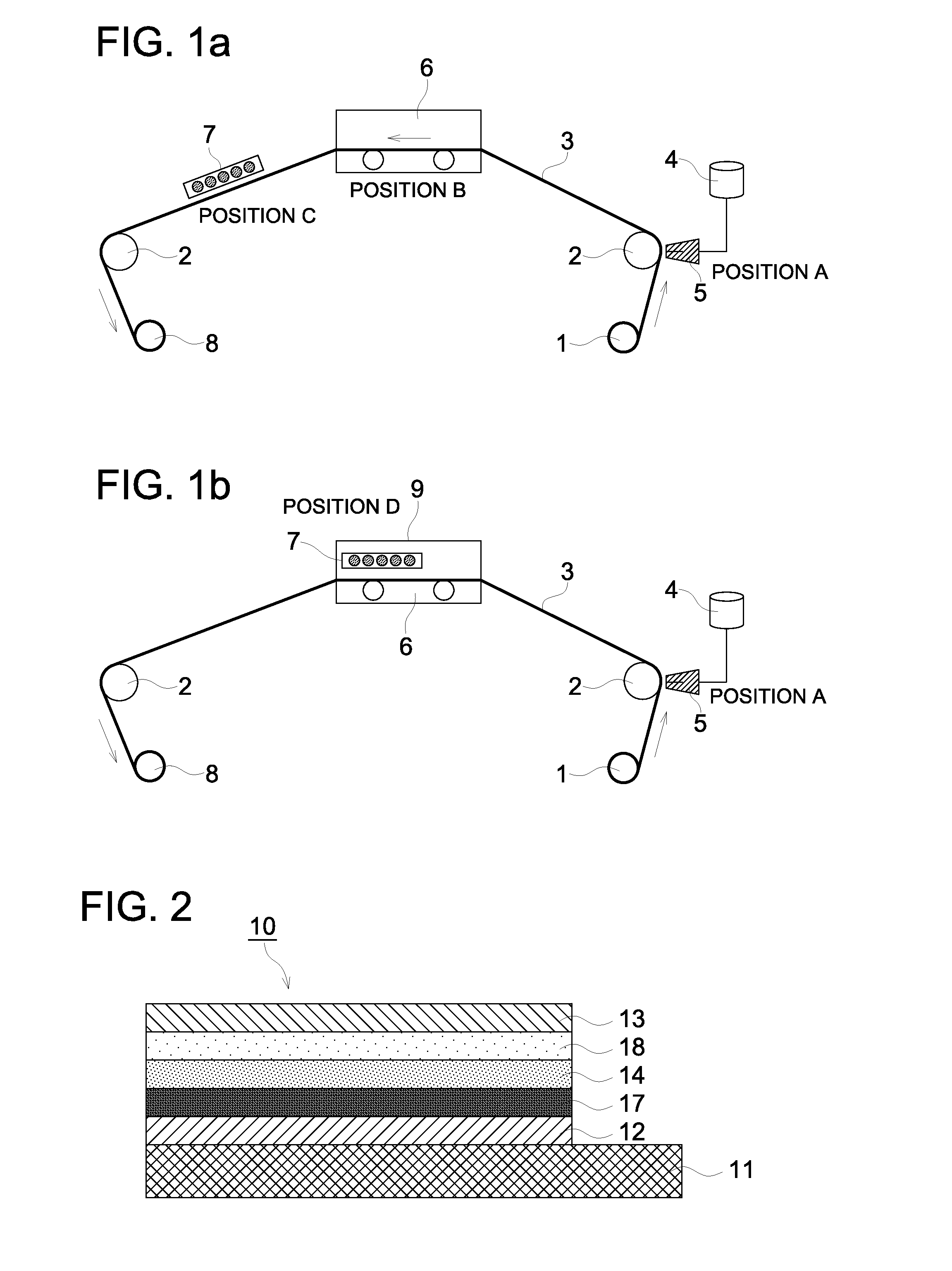

Plasma discharge treatment apparatus, and method of manufacturing gas barrier film

InactiveUS20090252893A1Increase productionMinimal numberElectric discharge tubesChemical vapor deposition coatingThin layerOptoelectronics

Provide is a method of preparing a highly-functional film capable of reducing surface failure and of improving the yield, and a manufacturing apparatus thereof. This is a plasma discharge treatment apparatus to plasma-discharge-treat for the surface of a substrate conveyed between a winder and an unwinder at atmospheric pressure or approximately atmospheric pressure, and is a plasma discharge treatment apparatus by which the substrate is conveyed with no contact by only nip roller separating the discharge section from outside. Provided is a method of preparing a gas barrier film exhibiting high gas barrier, together with reduction of surface failure (crack failure) during gas barrier thin layer formation. The surface on the gas barrier thin layer side of the gas barrier film has a curvature radius of at least 75 mm during conveyance, and the surface on the opposite side has a curvature radius of at least 37.5 mm.

Owner:KONICA MINOLTA INC

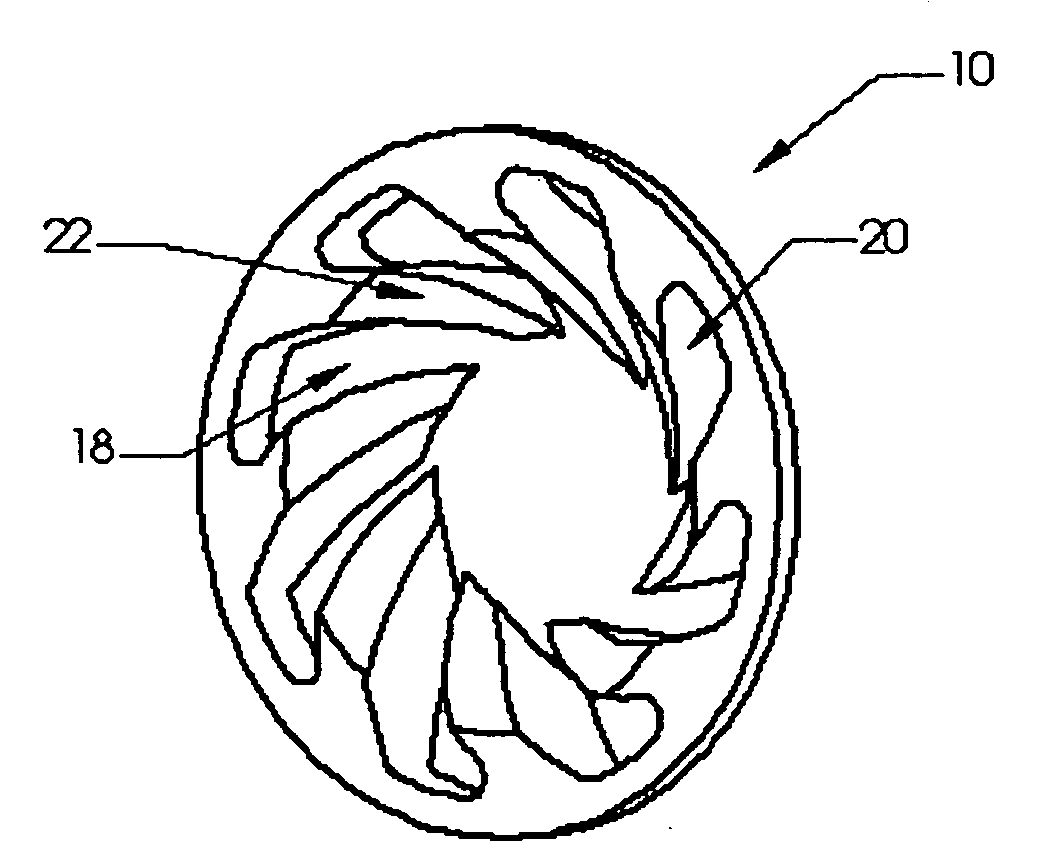

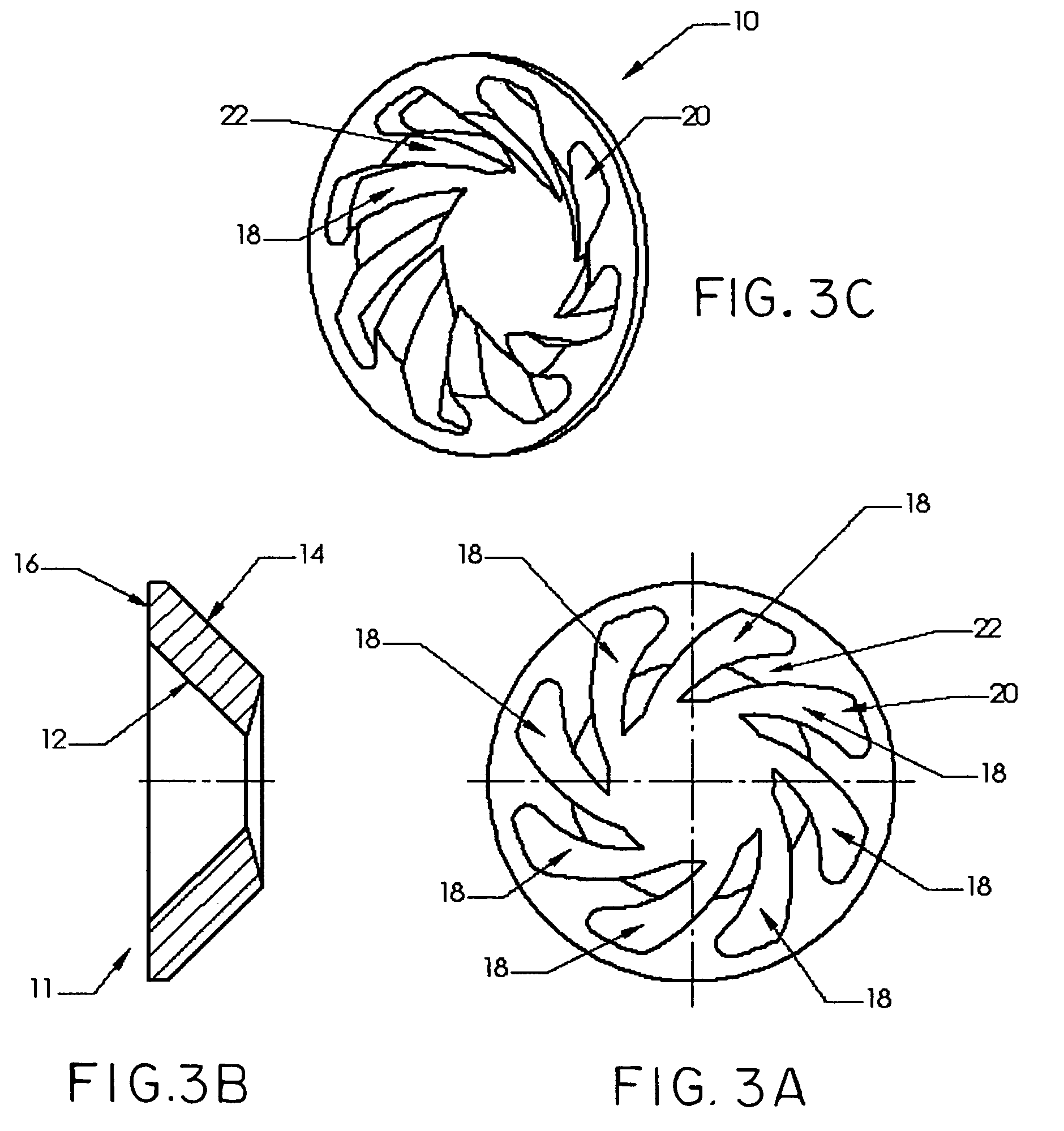

Conical swirler for fuel injectors and combustor domes and methods of manufacturing the same

ActiveUS8348180B2Area minimizationReduce areaContinuous combustion chamberSpray nozzlesCombustorUltimate tensile strength

Owner:COLLINS ENGINE NOZZLES INC

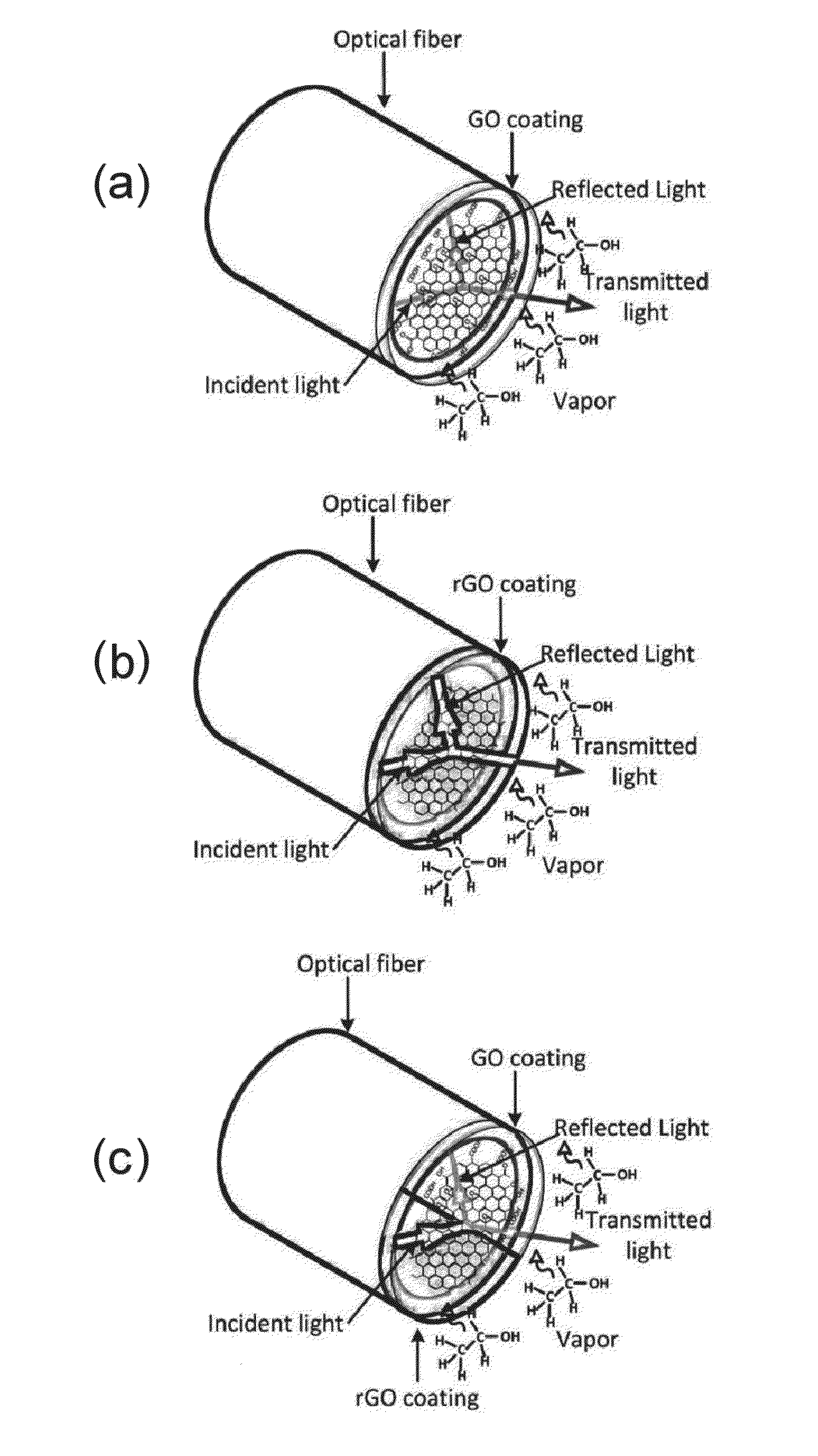

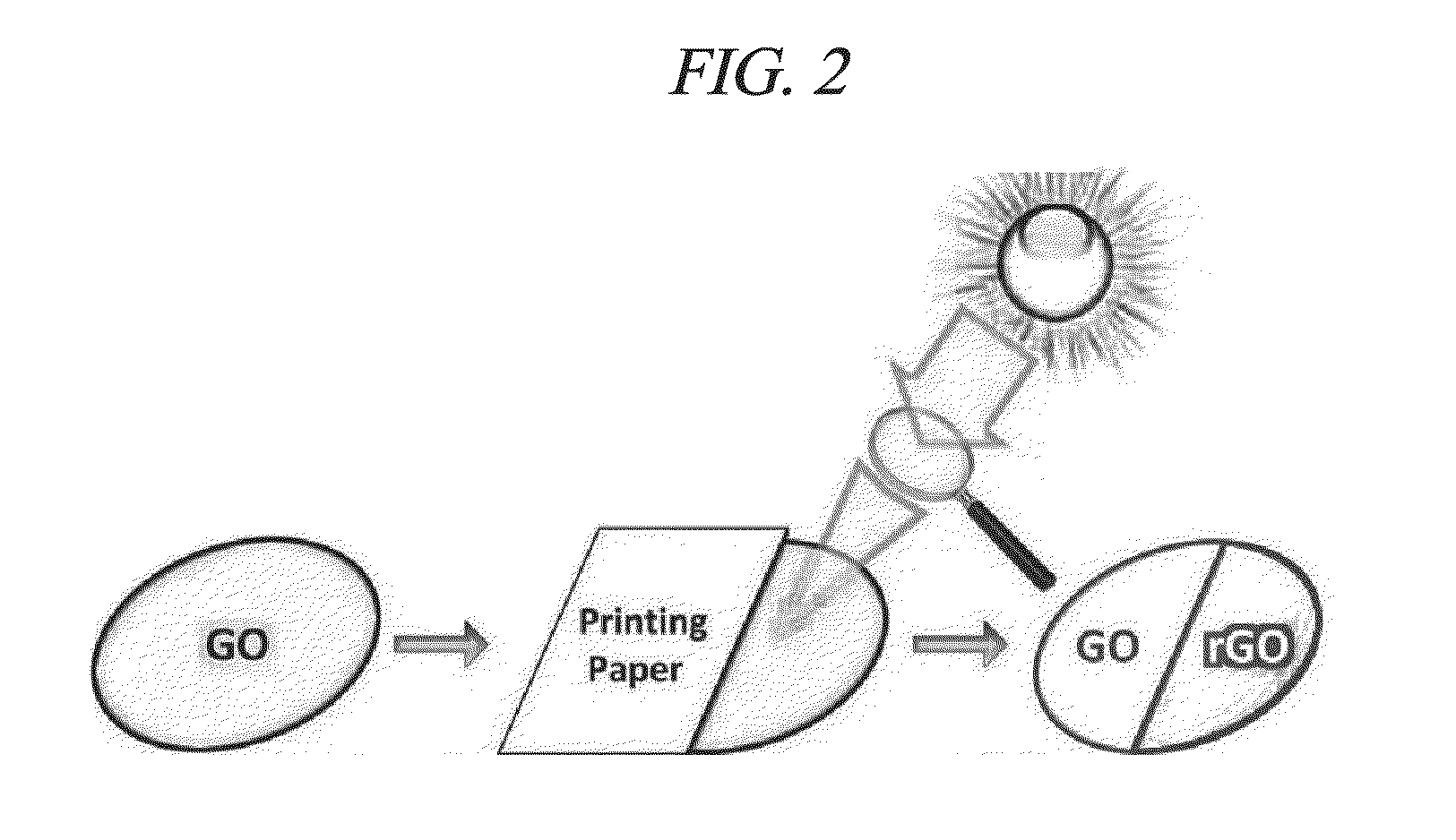

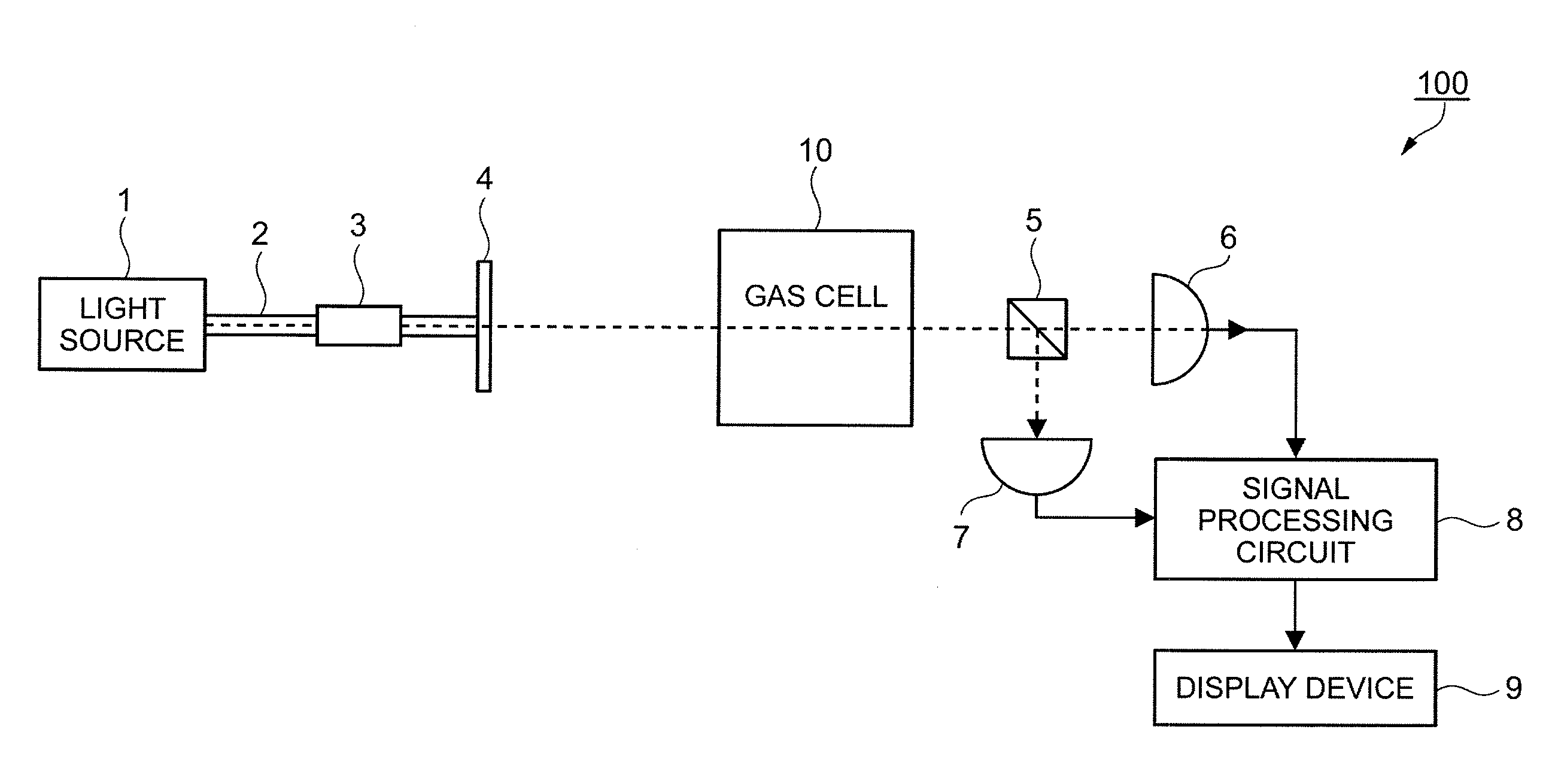

Optical fiber containing graphene oxide and reduced graphene oxide, and method for manufacturing gas sensor containing the same

An optical fiber includes a graphene oxide and a reduced graphene oxide and a gas sensor includes the optical fiber. A method for manufacturing the optical fiber includes coating a graphene oxide layer and reducing a part of the graphene oxide layer, and a method for manufacturing the gas sensor includes coating a graphene oxide layer and reducing a part of the graphene oxide layer.

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV

Method of manufacturing gas diffusion electrodes

ActiveCN1880508AHigh gradientIncrease or decrease property rangeFinal product manufactureElectrode collector coatingDiffusionPowder mixture

The invention describes a process for the manufacture of a gas diffusion electrode involving preparing a powder mixture containing at least a catalyst and a binder, applying the powder mixture to an electrically conducting support, and pressing the powder mixture with the electrically conducting support.

Owner:COVESTRO DEUTSCHLAND AG

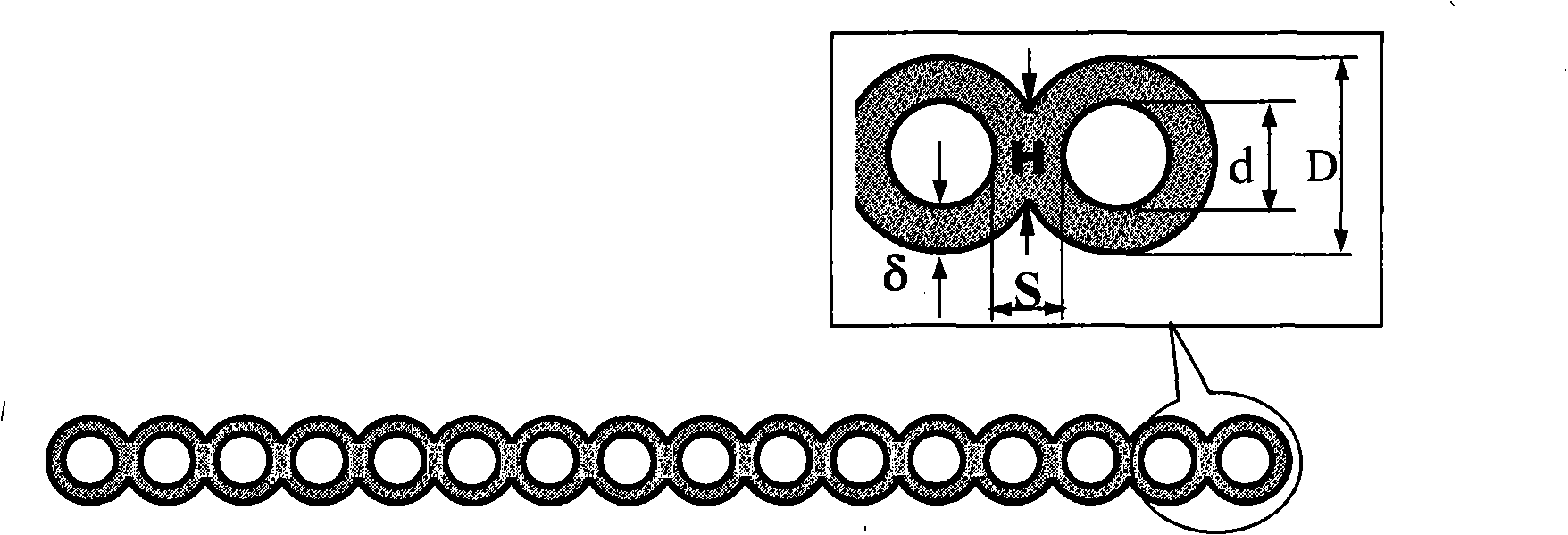

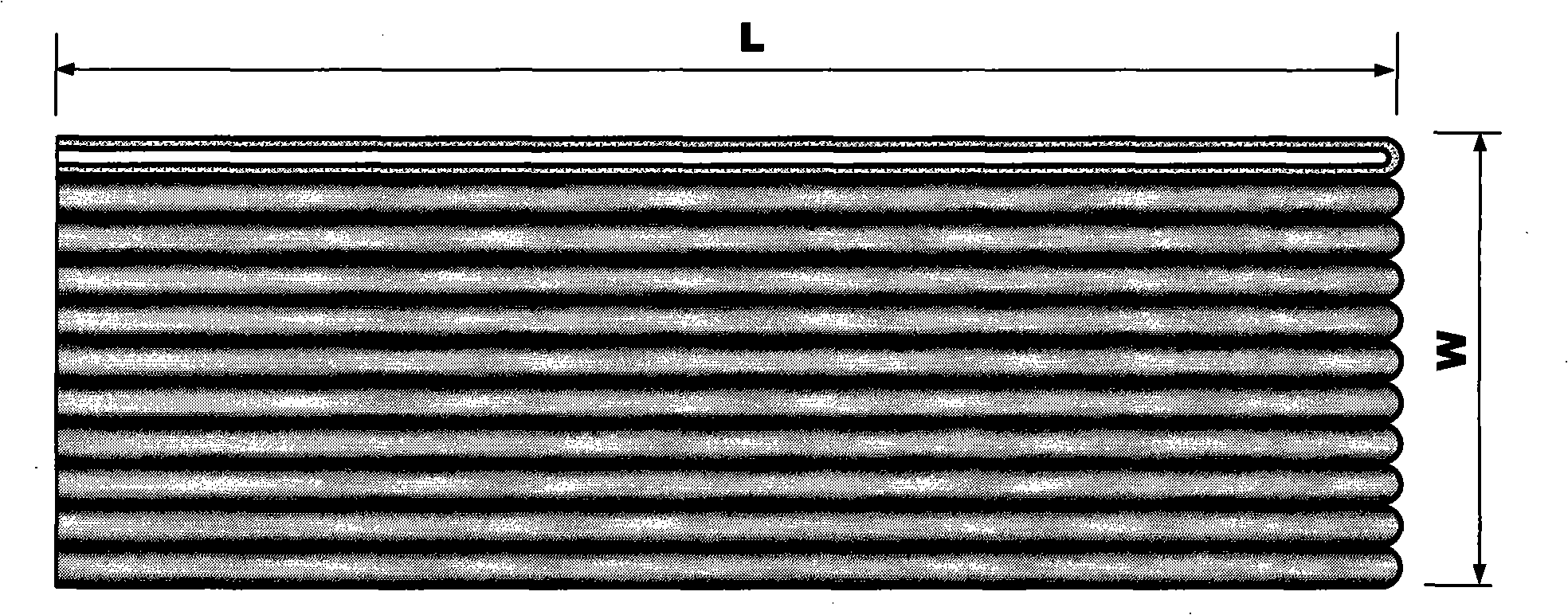

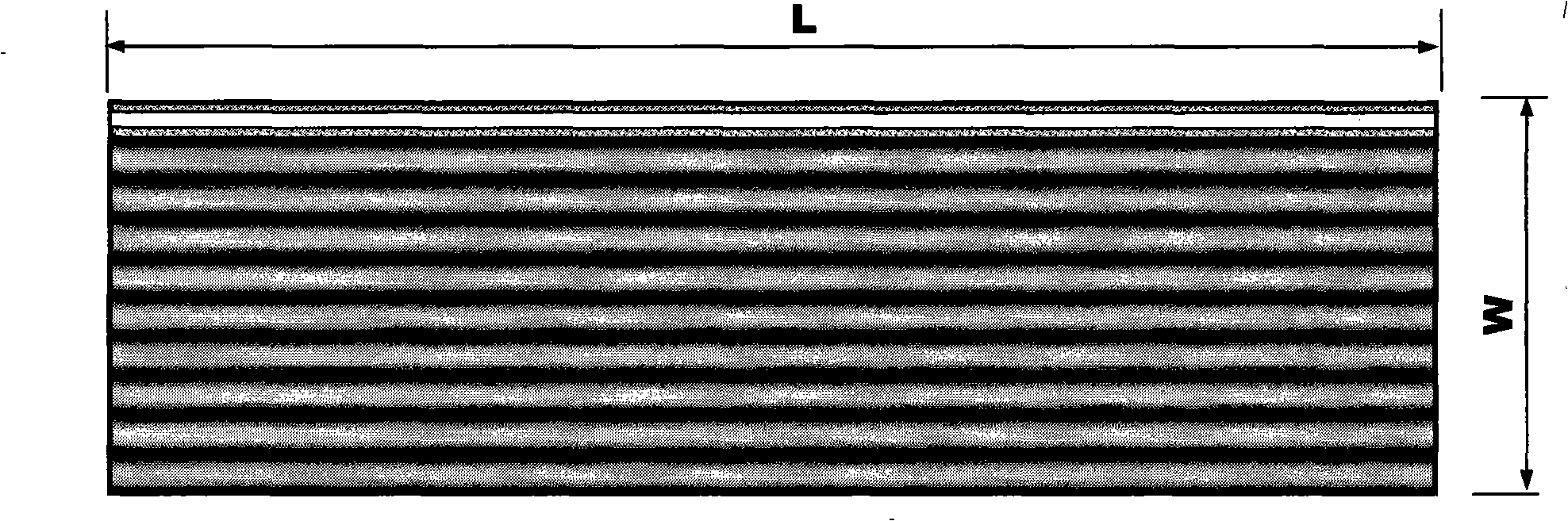

Plate shaped ceramic film composed of multiple hollow fiber ceramic films by parallel connection and preparation thereof

InactiveCN101318106AIncrease packing densityImprove manufacturing yieldSemi-permeable membranesHollow fibreDispersity

The invention discloses a tabular hollow fiber ceramic membrane element formed by connecting a plurality of hollow fiber ceramic membranes in parallel and a preparation method thereof. The invention is characterized in that a plurality of hollow fiber ceramic membrane green bodies, one end of which is open and the other end of which is closed or both ends of which are open are sintered at the temperature ranging from 900 to 1600 DEG C for 5 to 20 hours in a state of mutual close contact by aligning both ends and driving single layer to stand side by side; or the tabular hollow fiber ceramic membrane green bodies, which are prepared by a single layered parallel connection of hollow fiber ceramic membranes using extrusion, are sintered at a high temperature ranging from 900 and 1600 DEG C for 5 to 20 hours after being dried. Compared with a single fiber hollow ceramic membrane element, the mechanical strength of the tabular hollow fiber ceramic membrane element is significantly enhanced, thus being beneficial to preparing large-size membrane elements, enhancing the reliability and the service life of the ceramic membrane; moreover, owing to the decrease of the assembly dispersity, the packing density of the membrane components is further enhanced far from being lowered. The tabular hollow fiber ceramic membrane element can be used for manufacturing gas or liquid separation and purification device or high temperature heat exchanger.

Owner:UNIV OF SCI & TECH OF CHINA

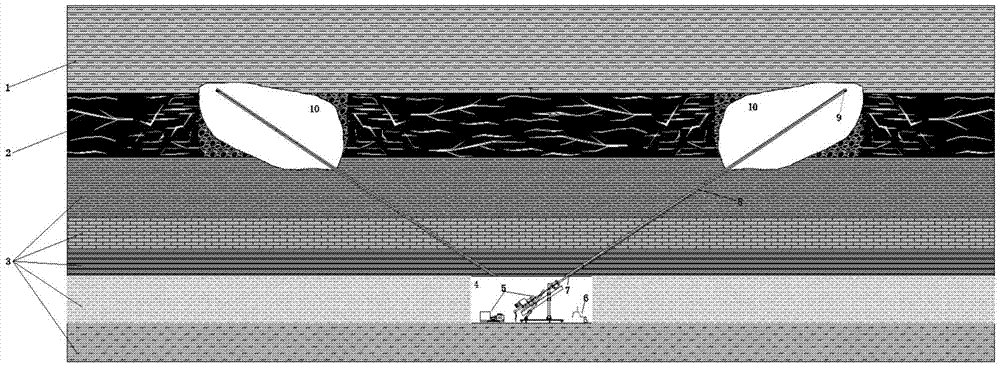

Method for extracting high-pressure hydraulic cave-manufacturing gas from rock roadway crossing hole

InactiveCN104763462AIncrease the exposed areaImprove permeabilityGas removalPunchingHydraulic fracturing

The invention discloses a method for extracting high-pressure hydraulic cave-manufacturing gas from a rock roadway crossing hole and belongs to the field of a soft high outburst seam gas extracting method. The method is characterized in that upward or downward large-diameter crossing holes are constructed into the coal seam roof or the coal seam floor by drilling and stamping integration equipment in the rock roadway of the soft high outburst seam; the cave is manufactured hydraulically by combining hydraulic fracturing with hydraulic jetting punching; a great cave is established in the coal seam and a fracture expansion region is formed around the cave, so that the coal ground stress is reduced, the bare area of the coal seam is increased, and the permeability of the coal seam, the gas extracting efficiency and the gas extracting quantity are improved. The method has the advantages that the large cave is established in the soft high outburst seam and a huge fracture expansion mesh is formed around the cave, so that the coal ground stress is reduced, the bare area of the coal seam is increased, and the permeability of the coal seam is improved; besides wide space is provided to convey and extract the gas, the gas extracting efficiency and gas extracting quality in the soft high outburst seam can be effectively improved, and a new way to treat the gas in the soft high outburst seam is provided.

Owner:CHINA UNIV OF MINING & TECH

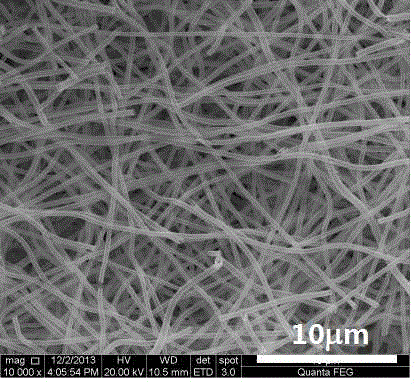

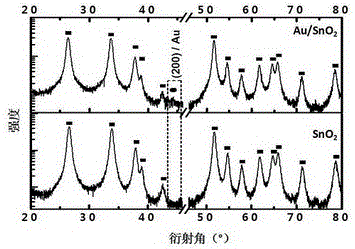

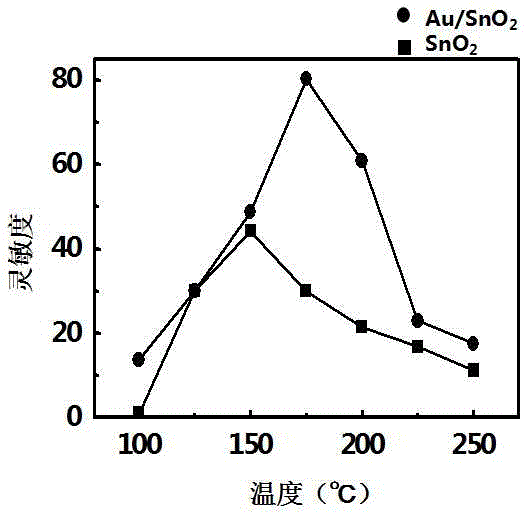

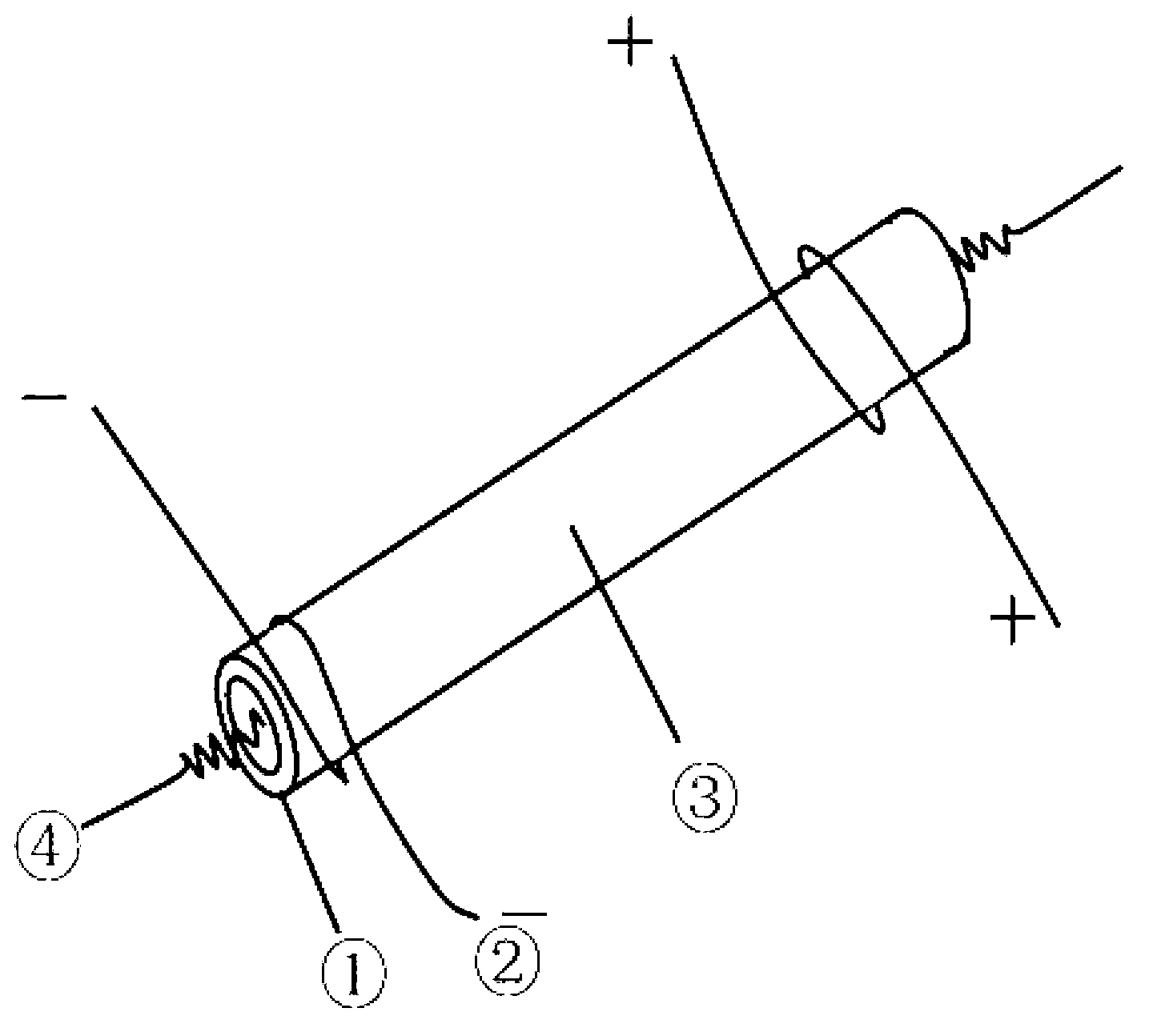

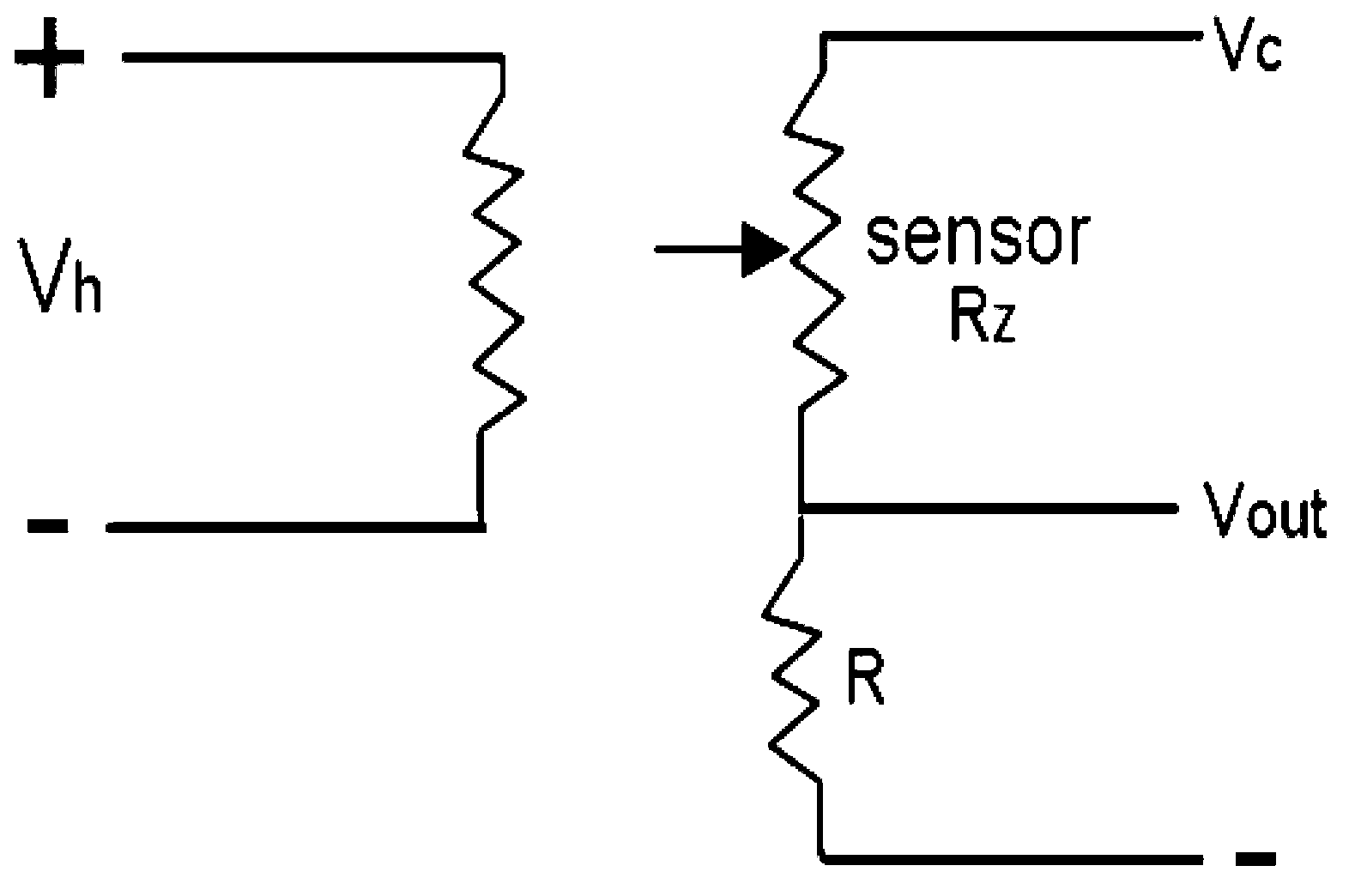

Gas-sensitive material for detecting NO2 and method for manufacturing gas-sensitive element made of gas-sensitive material

InactiveCN105606660AEasy transferSmall sizeMaterial nanotechnologyMaterial resistanceNanostructureRutile

The invention discloses a gas-sensitive material for detecting NO2 and a method for manufacturing a gas-sensitive element made of the gas-sensitive material. The gas-sensitive material is prepared into a SnO2 nano-fiber with a rough surface and a hollow tubular structure by adopting an electrospinning method and high-temperature processing, the hollow SnO2 nano-fiber is of a rutile structure, the SnO2 nano-fiber diameter is about 250-300nm, and the thickness of a particle layer is about 40nm. Au particle modification is performed on the surface of SnO2 in an in-situ reduction manner without changing the crystal structure of SnO2. The specific surface area of the material is increased by the one-dimensional hollow nano-structure characteristic of the gas-sensitive material, the gas-sensitive performance of SnO2 is obviously improved by precious metal modification, and higher sensitivity to NO2 and a larger measurement range are presented. The obtained material is applied to the surface of a ceramic tube, annealing is performed, and a calcined ceramic tube core and a nickel-chromium heating wire are welded to a base, accordingly, the gas-sensitive element is manufactured.

Owner:NORTHEAST NORMAL UNIVERSITY

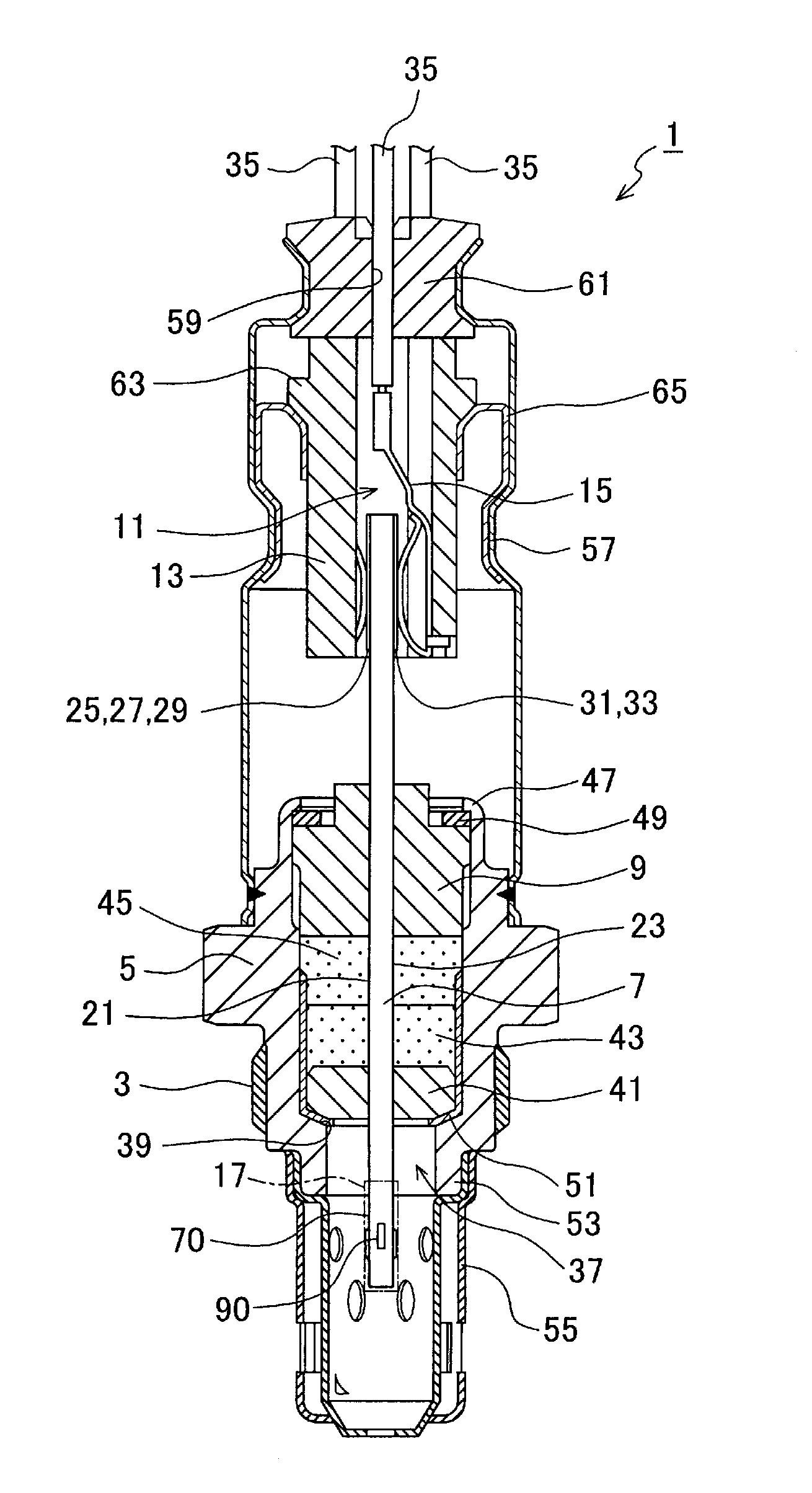

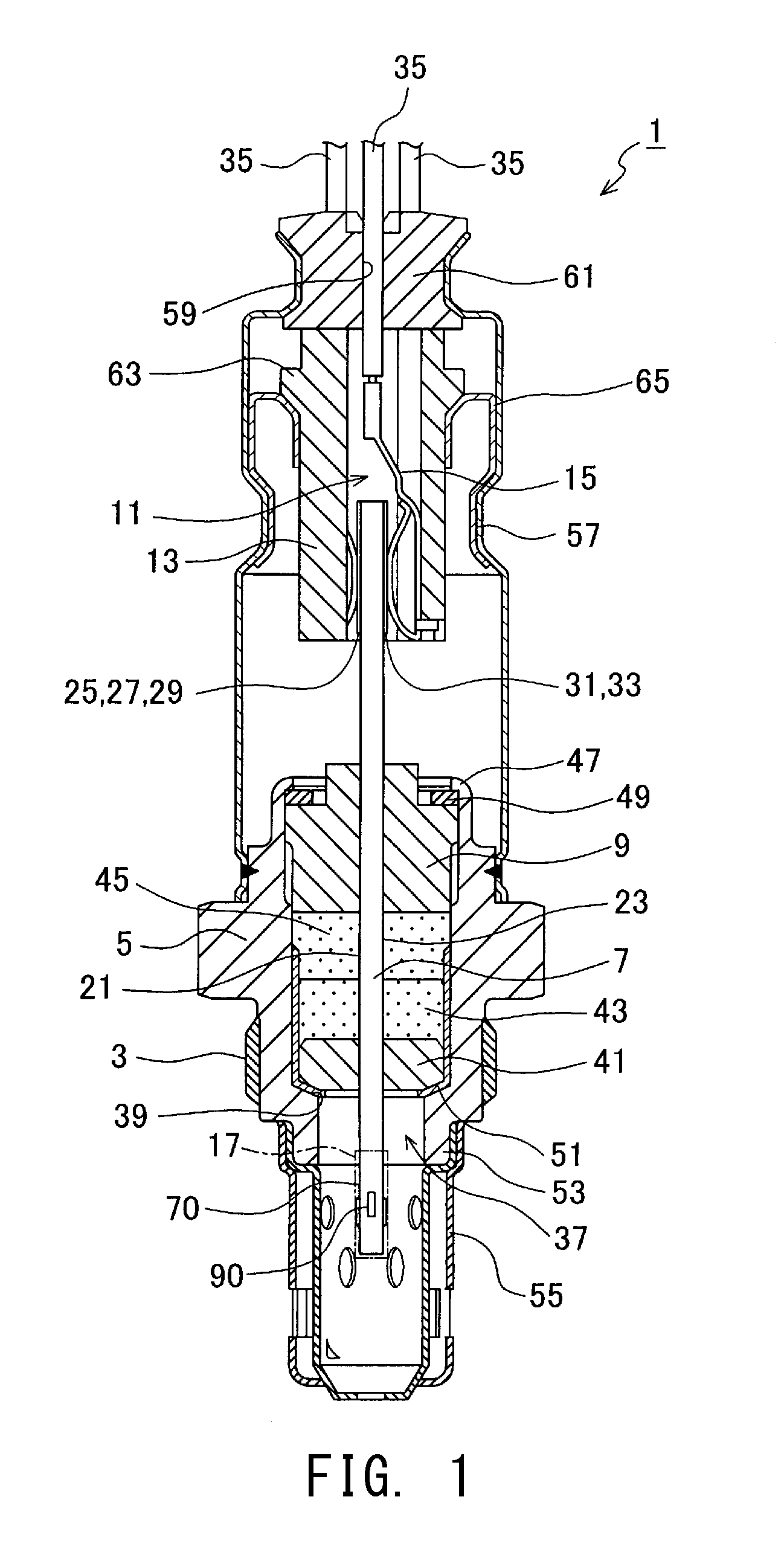

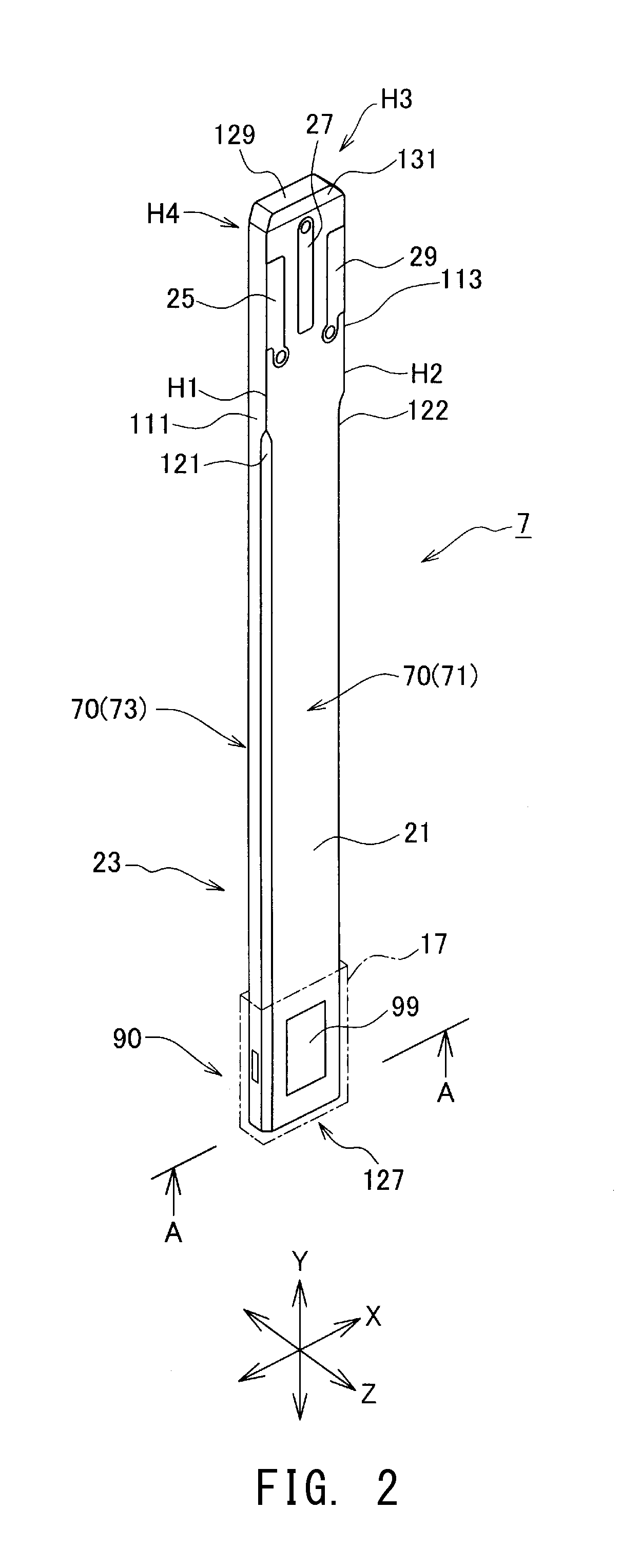

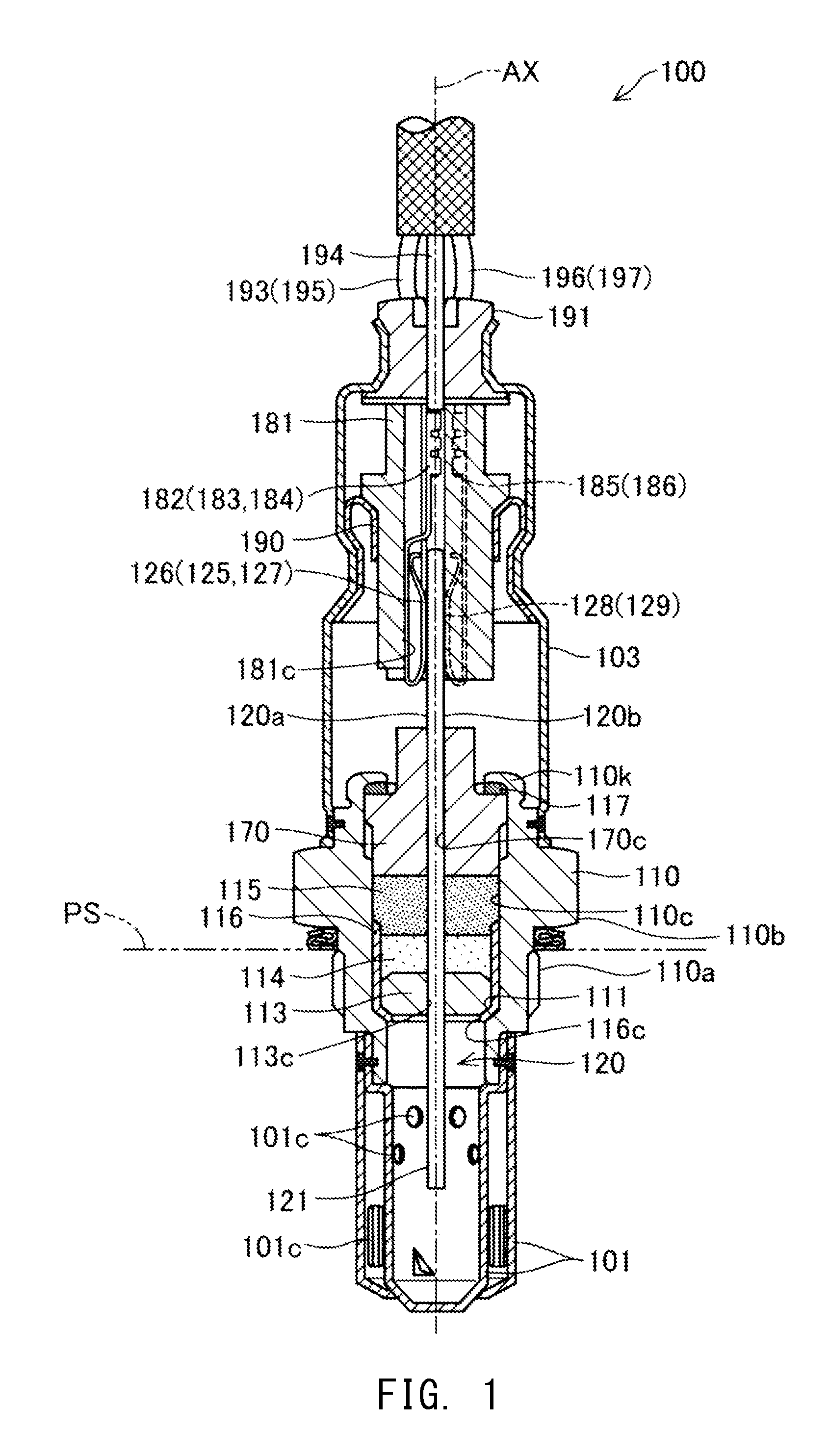

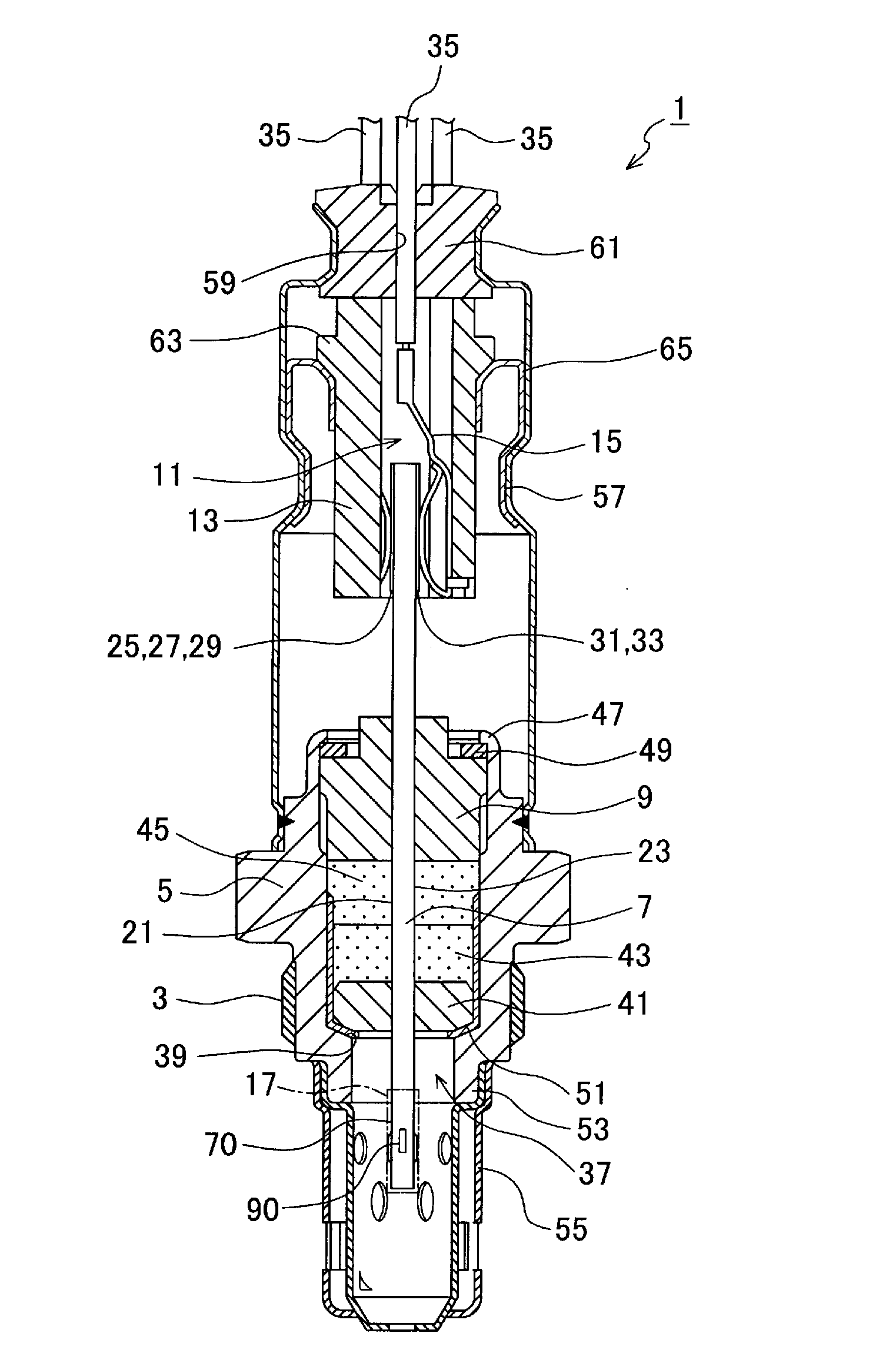

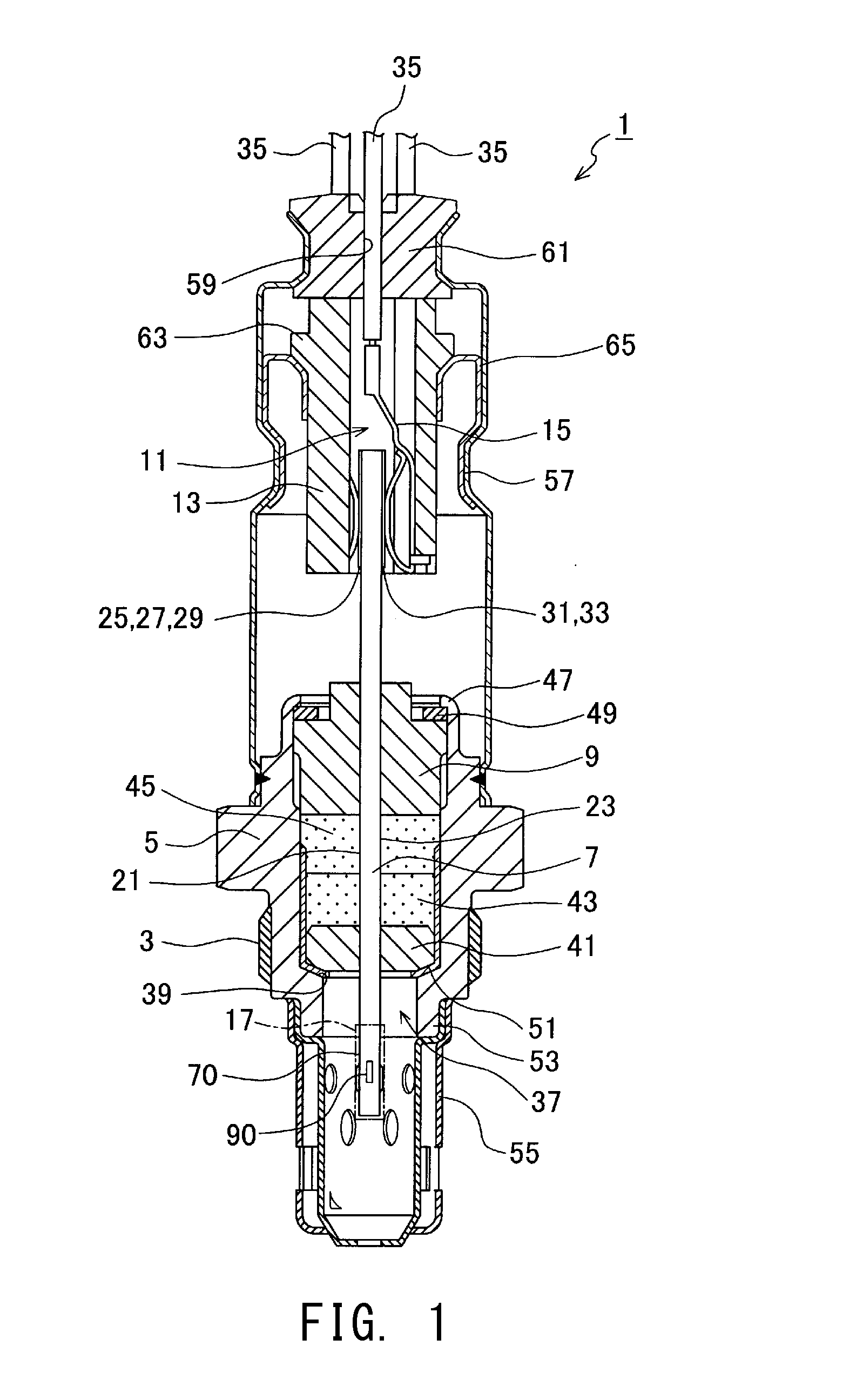

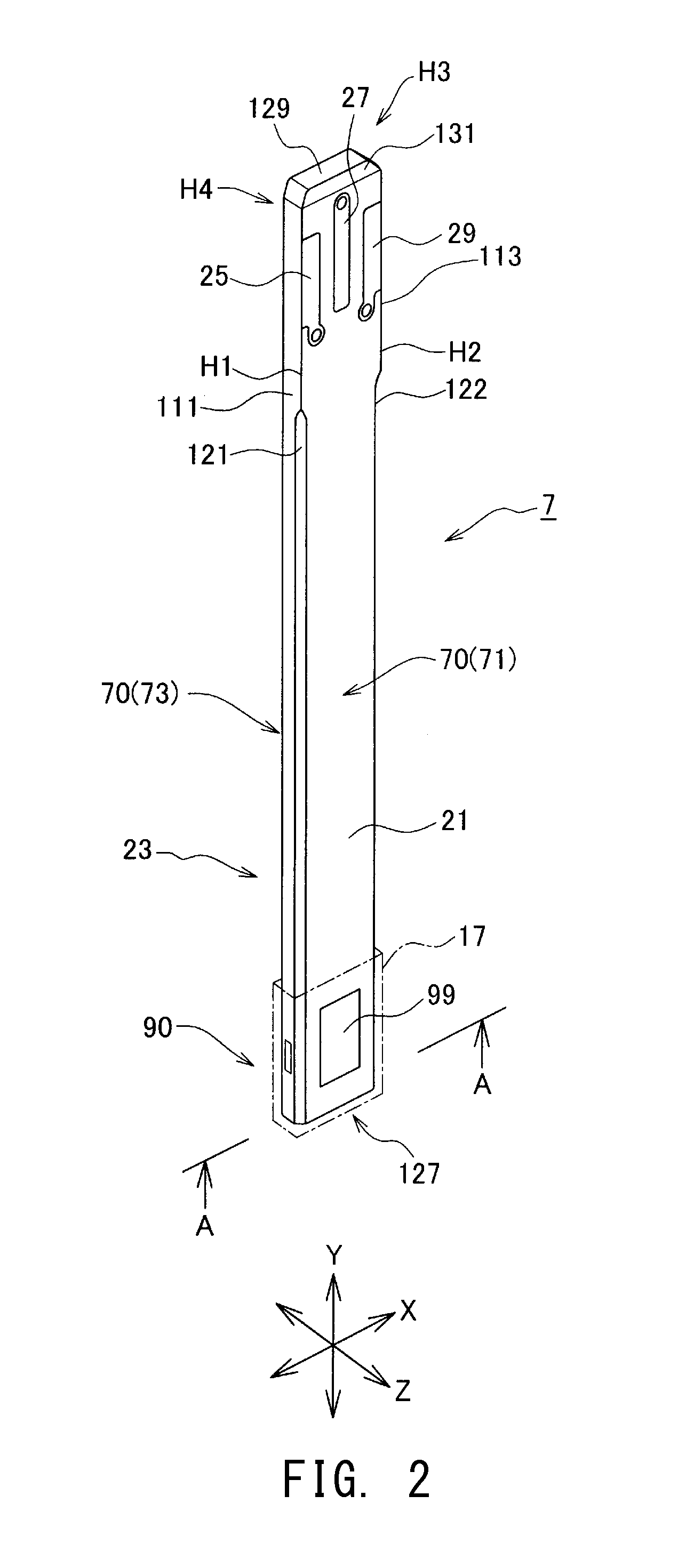

Gas sensor element, gas sensor, and method of manufacturing gas sensor element

ActiveUS20150114085A1Small heat capacityMaterial analysis by electric/magnetic meansPretreated surfacesProduct gasEngineering

A gas sensor element has a protection layer smaller in heat capacity than a conventional protection layer formed by a dipping process. A gas sensor includes the gas sensor element. The gas sensor element is manufactured by a method of manufacturing. The gas sensor element includes at least one space formed between a protection layer and an element body. The space is positioned over at least one of four vertexes of a forward end of the element body at a location at which the thickness of the protection layer is likely to become small. Therefore, it is possible to restrain breakage of the vertexes of the forward end of the element body which could otherwise result from thermal shock stemming from adhesion of water. The protection layer of the gas sensor element can be reduced in thickness and thus in heat capacity as compared with a conventional protection layer.

Owner:NGK SPARK PLUG CO LTD

Gas sensors and methods of manufacture

Disclosed herein is a gas sensor that comprises a sensor cell, a sensing side support layer, and a reference side support layer. The sensor cell comprises an electrolyte layer, a sensing electrode and a reference electrode, wherein the sensing electrode is disposed on a sensing side of the electrolyte layer, and the reference electrode is disposed on a reference side of the electrolyte layer. The reference side has a reference thickness of about 40% to about 160% of a sensing thickness of the sensing side. Methods for manufacturing gas sensors are also disclosed.

Owner:DELPHI TECH INC

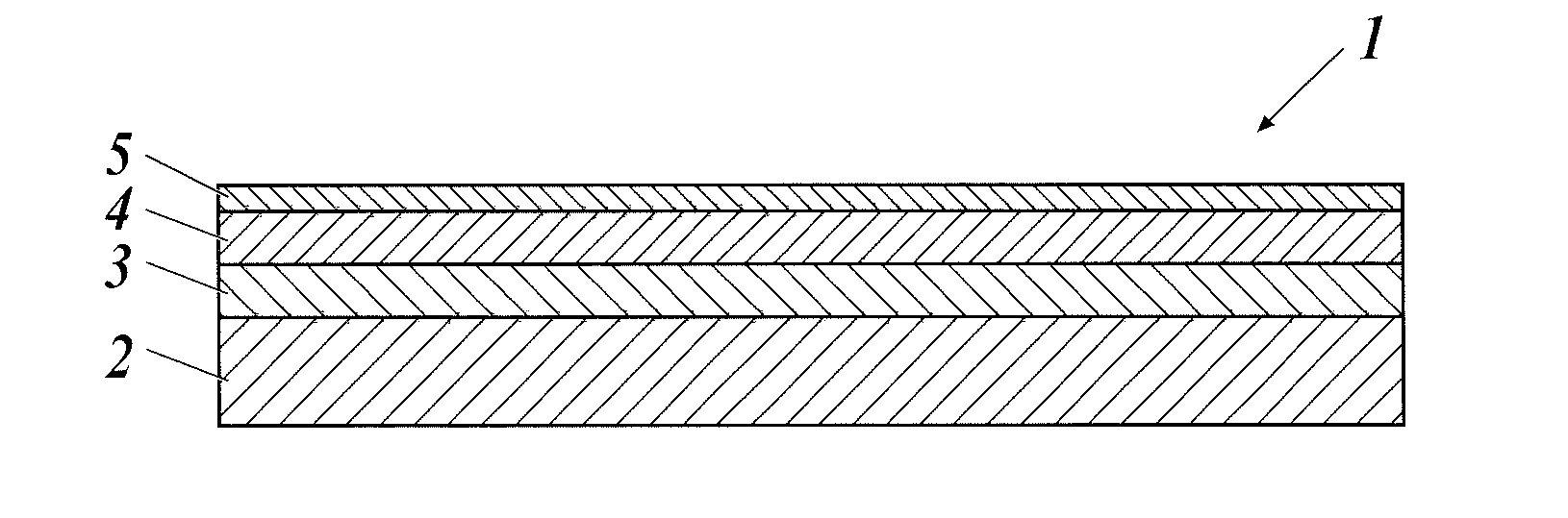

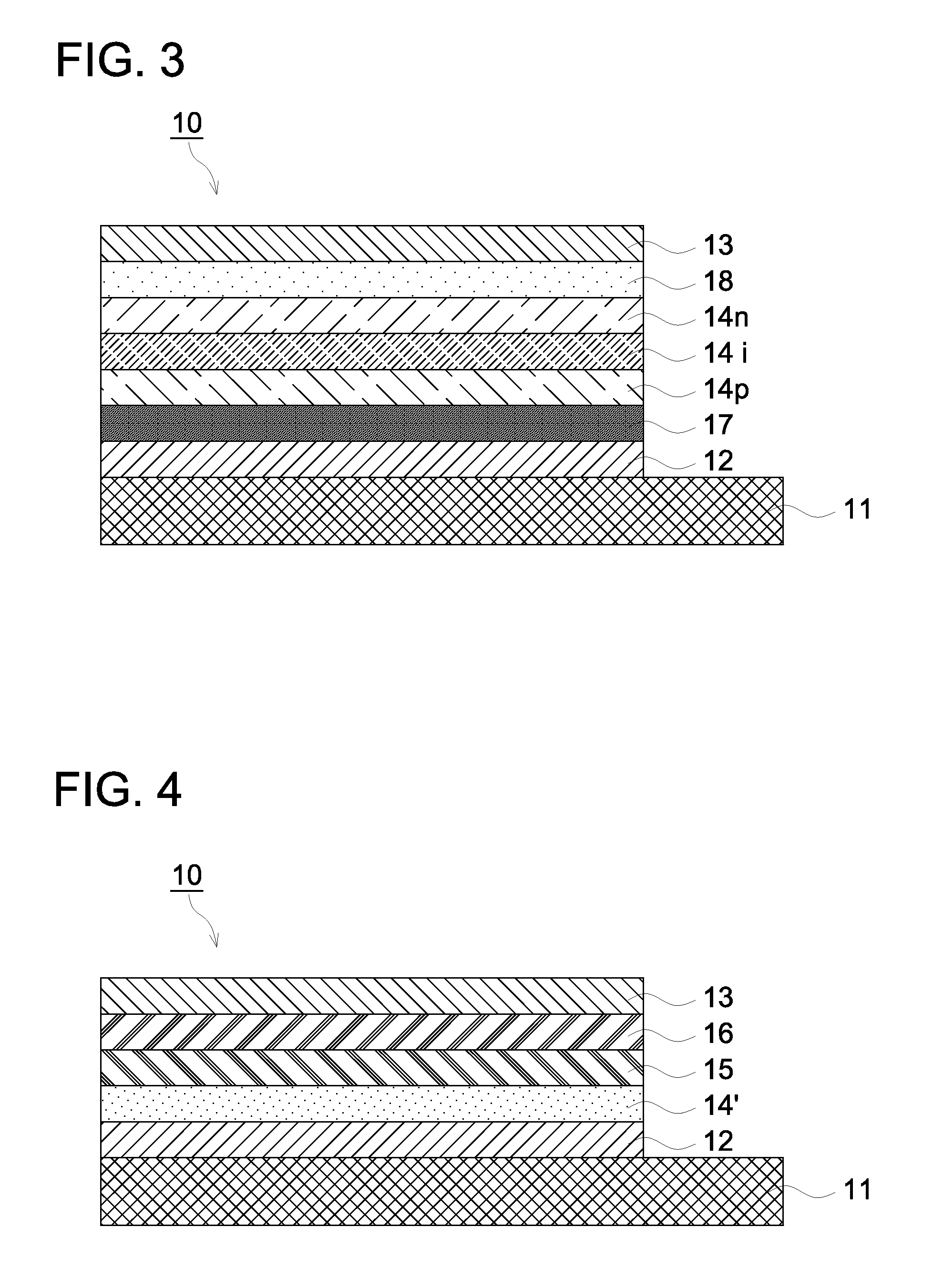

Method for manufacturing gas barrier film, gas barrier film and electronic device

InactiveUS20160049609A1Improve adhesionIncrease flexibilitySolid-state devicesSemiconductor/solid-state device manufacturingFree energiesChemical vapor deposition

A method for producing a gas barrier film includes forming a smoothing layer on one surface of a resin substrate; and forming a gas barrier layer containing a carbon atom, a silicon atom and an oxygen atom on a surface of the smoothing layer. The surface of the smoothing layer is controlled to have a dispersion component of a surface free energy in the range of 30 to 40 mN / m at an environment of 23° C. and 50% RH. The gas barrier layer is formed employing a raw material gas containing an organic silicon compound and an oxygen gas with a discharge plasma chemical vapor deposition method having a discharge space between rollers applied with a magnetic field.

Owner:KONICA MINOLTA INC

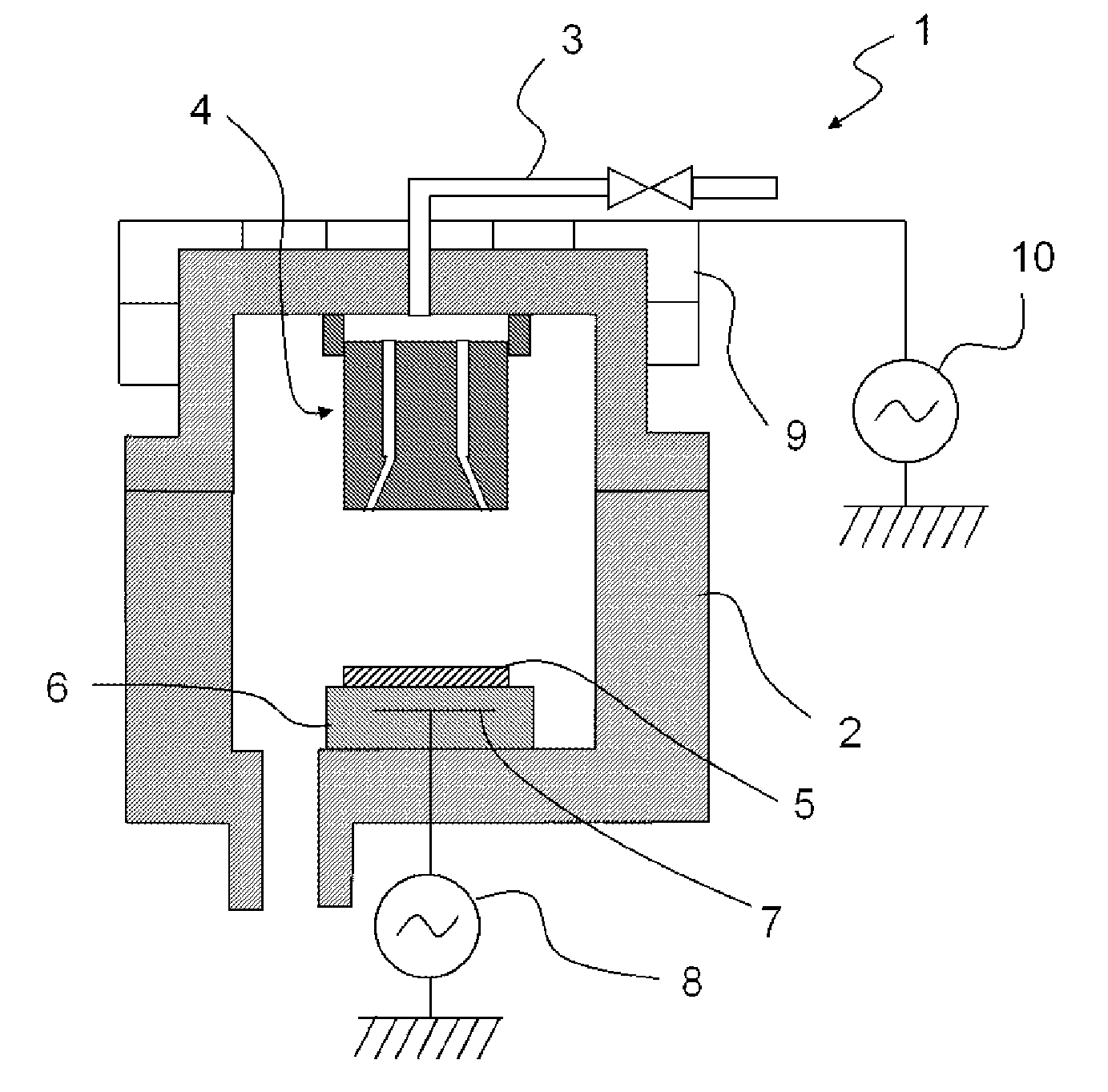

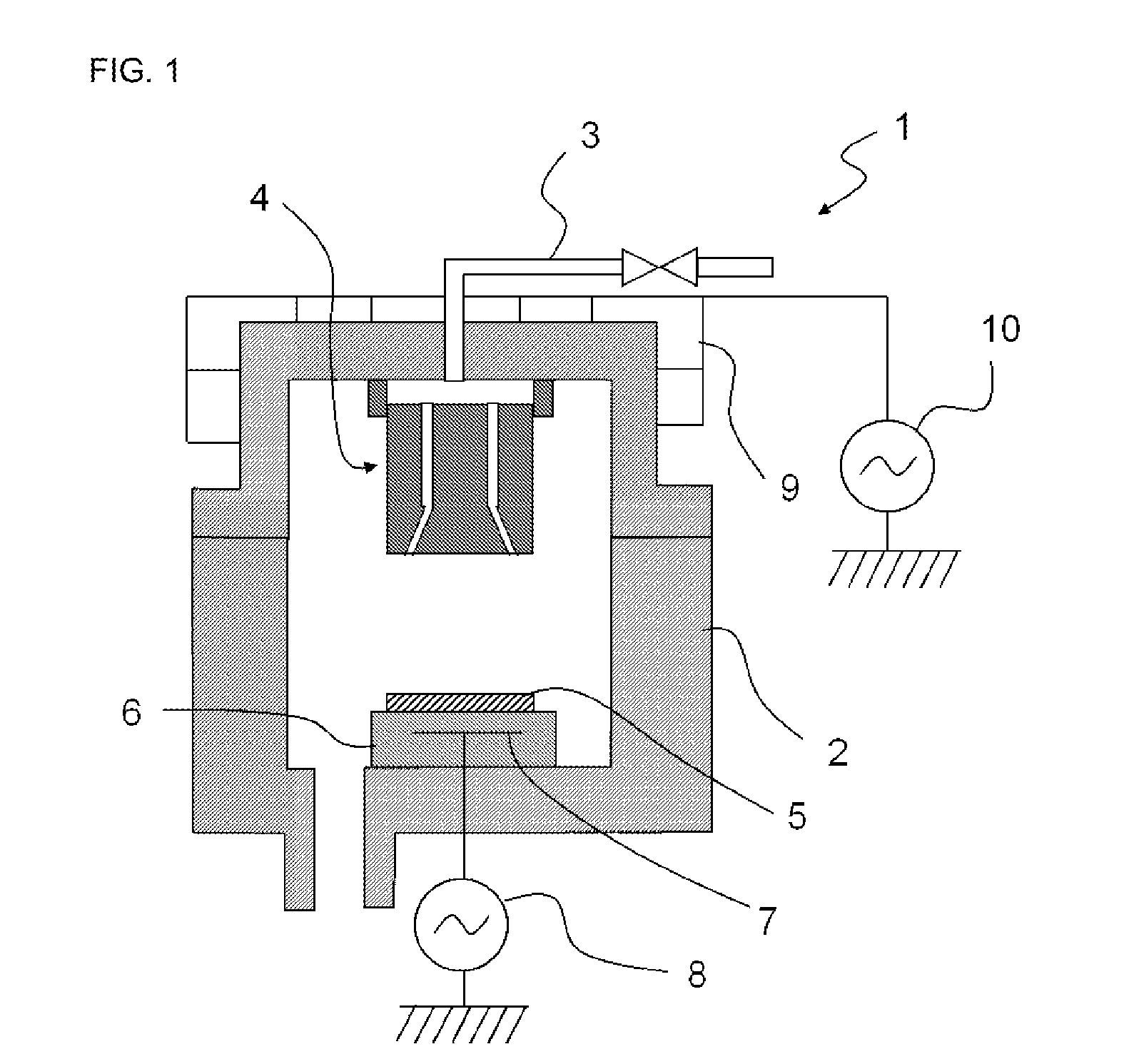

Gas nozzle, plasma apparatus using the same, and method for manufacturing gas nozzle

ActiveUS20140283995A1Suppress fallSuppresses fallElectric discharge tubesDust removalCeramic sinteringManufactured gas

[Object] To provide a gas nozzle which meets a requirement to suppress the fall of particles.[Solution] A gas nozzle 4 according to an aspect of the present invention includes a columnar main body 13 formed of a ceramic sintered body provided with a through-hole 12 formed therein through which a gas flows, an exhaust port 15 of the through-hole 12 for the gas is formed in one end surface S1 of the main body 13, and the mean width of the profile elements (Rsm) of the one end surface S1 is 5 times or more the average crystalline grain diameter of the ceramic sintered body.

Owner:KYOCERA CORP

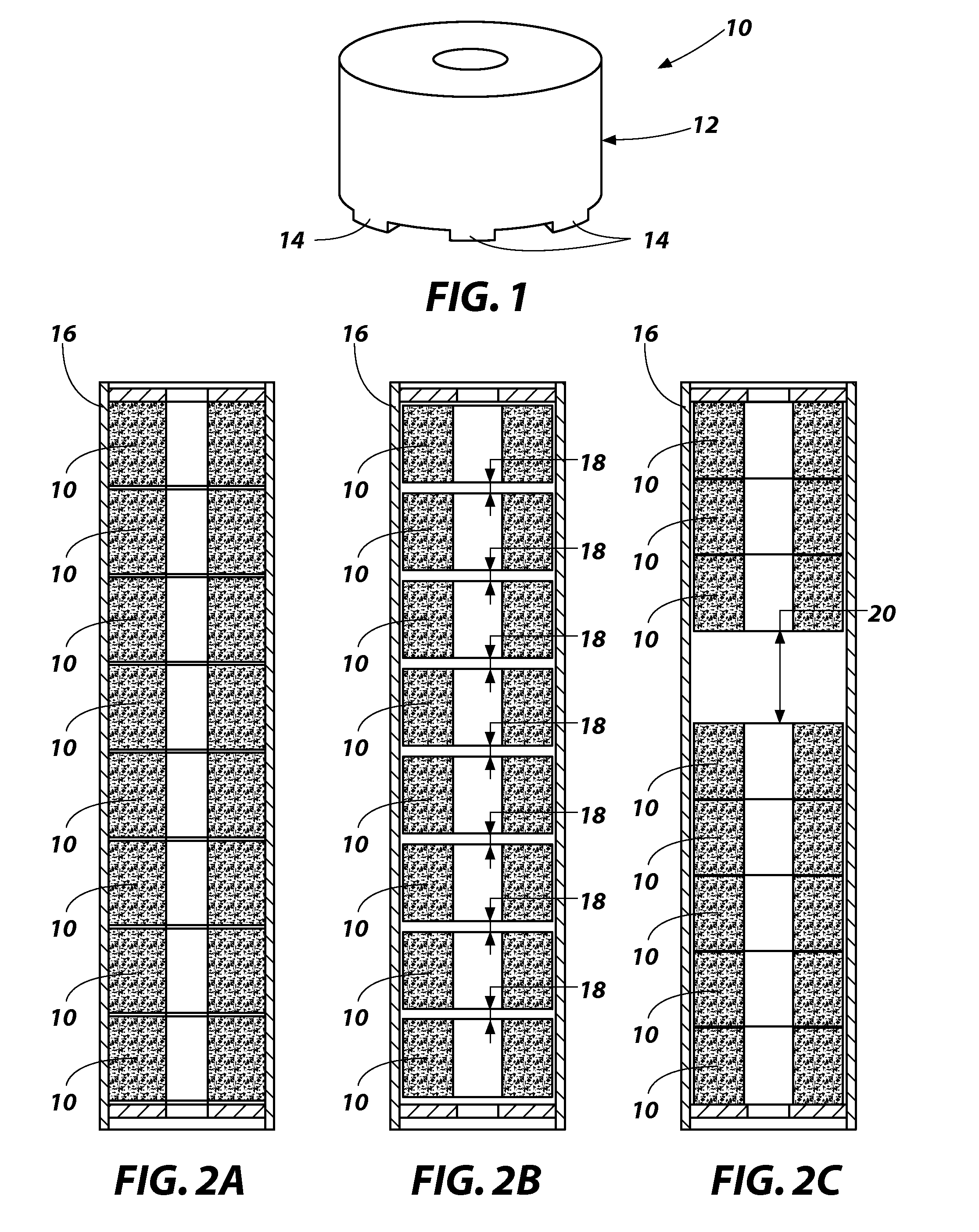

Gas-generating devices with grain-retention structures and related methods and systems

ActiveUS20100307775A1Restricts lateral movementPedestrian/occupant safety arrangementBlasting cartridgesEngineeringManufactured gas

Owner:NORTHROP GRUMMAN INNOVATION SYST INC

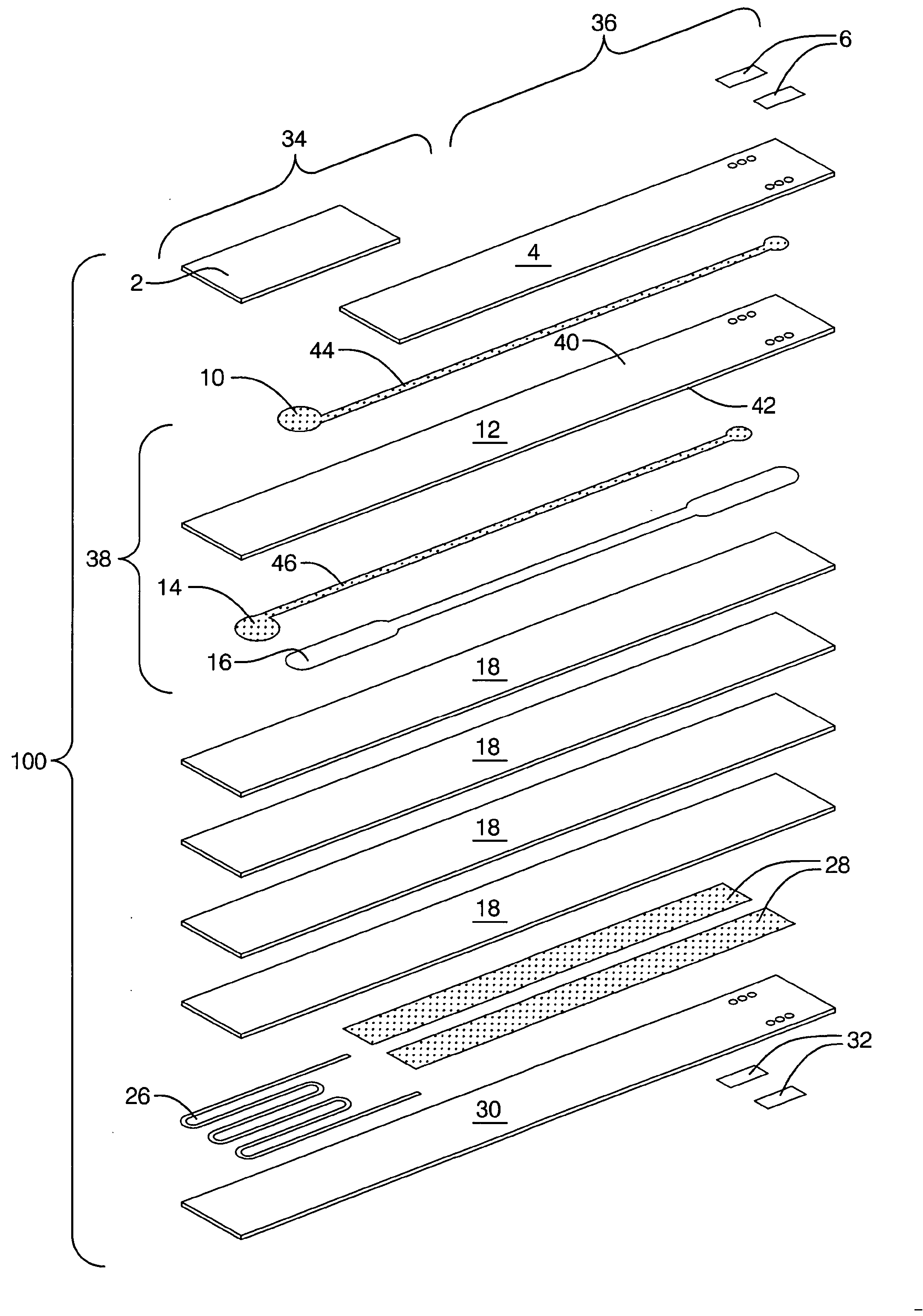

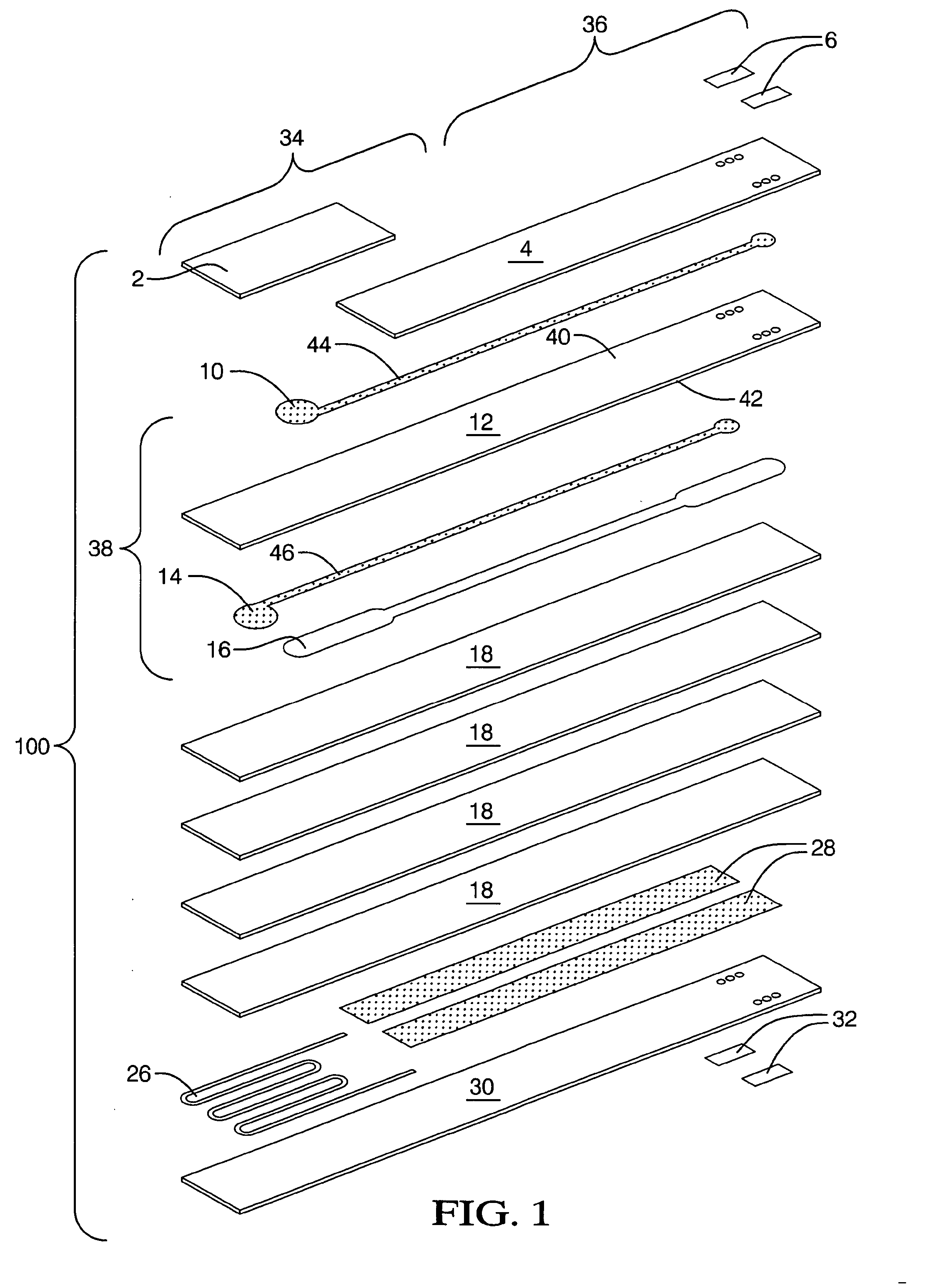

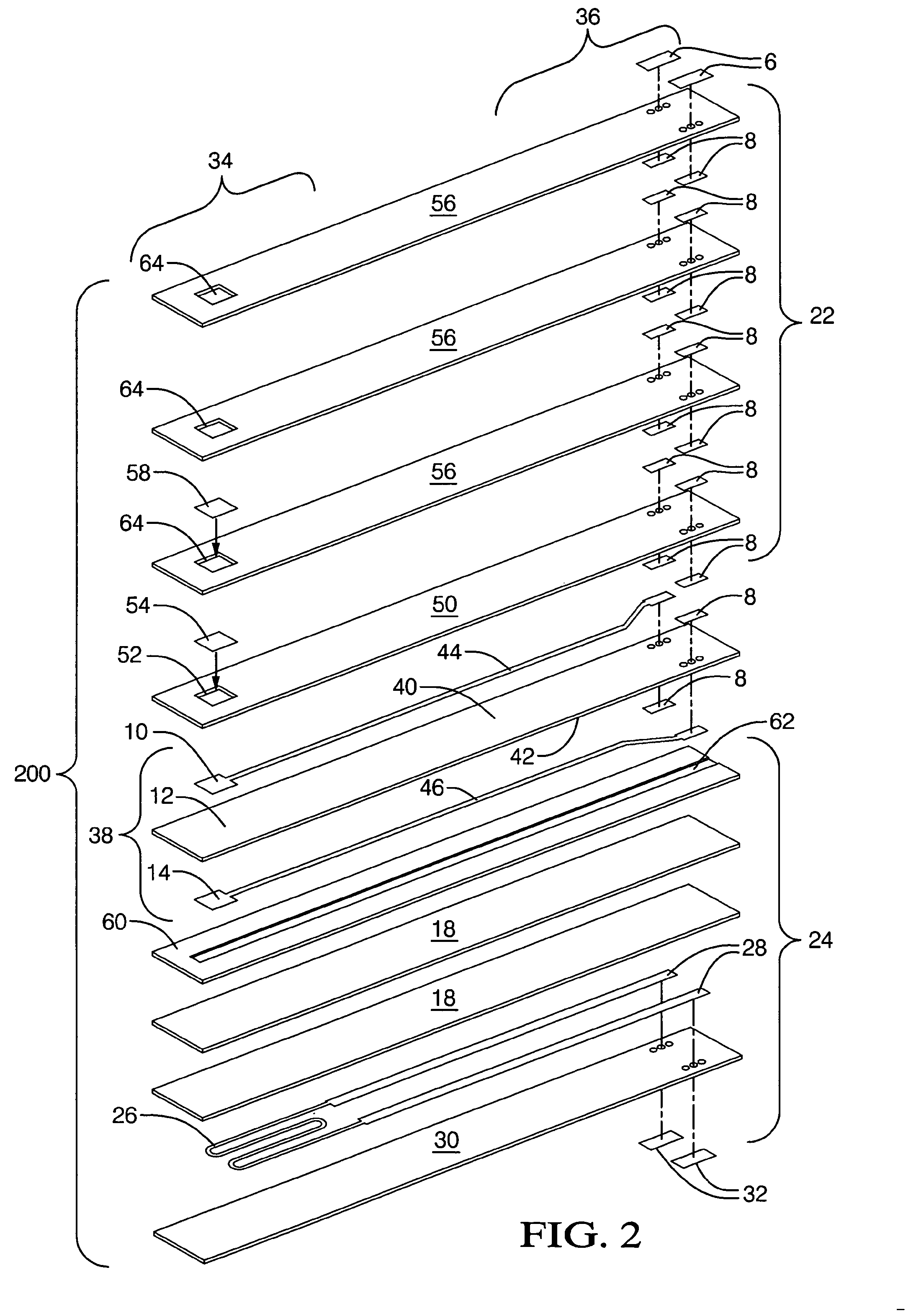

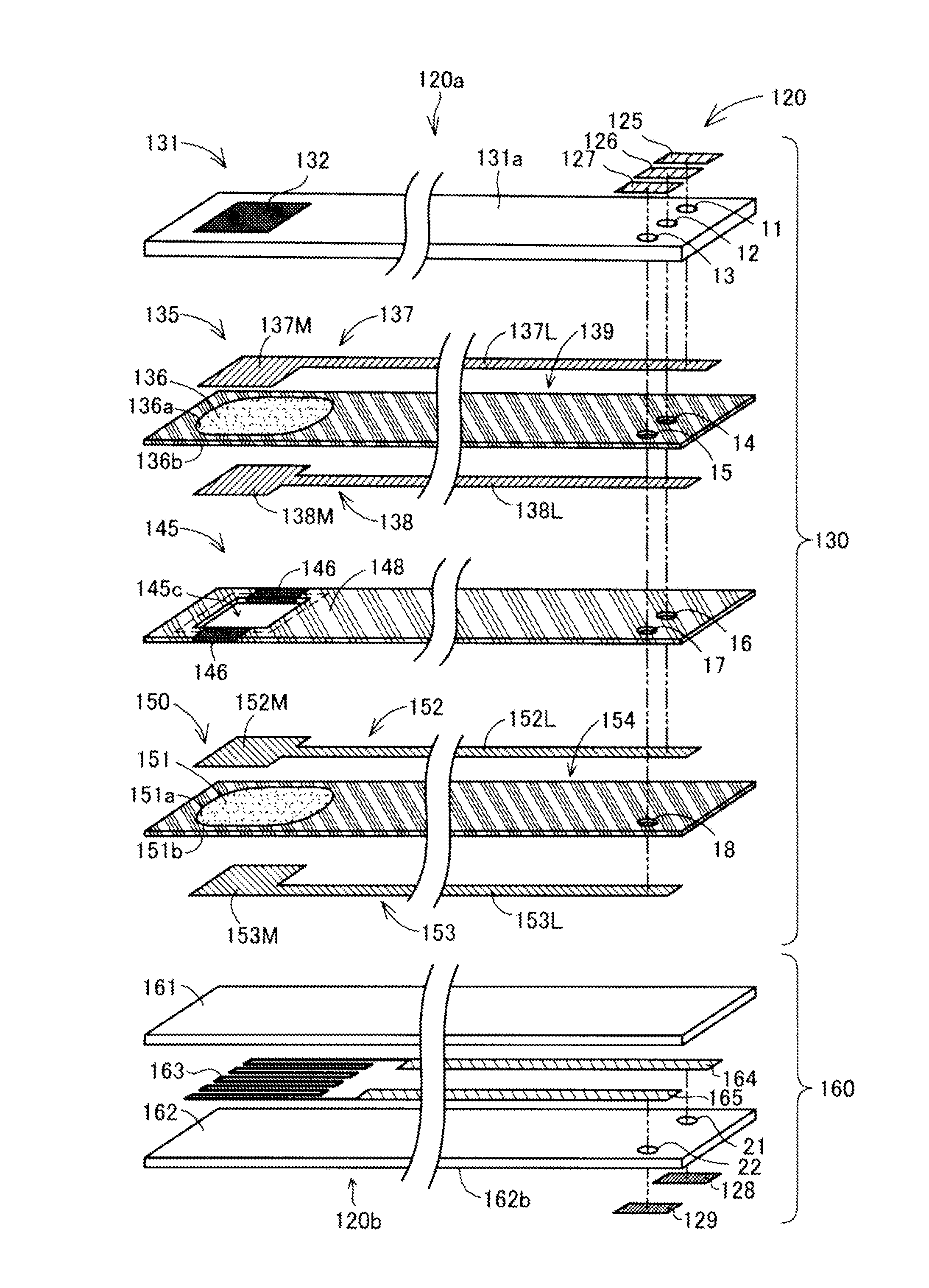

Laminated gas sensor element, gas sensor, and method of manufacturing gas sensor element

InactiveUS20150212037A1Inhibit deteriorationImprove stress conditionMaterial analysis by electric/magnetic meansPretreated surfacesArcuate shapeBiomedical engineering

A laminated gas sensor element includes a plurality of laminated plate-shaped members, including a plate-shaped insulating member in which a solid electrolyte body is embedded and which has four sides. The solid electrolyte body is formed such that, as viewed in a plane orthogonal to a thickness direction of the insulating member including the solid electrolyte body, a portion of the contour of the solid electrolyte body facing at least one side of the four sides of the insulating member has an arcuate shape projecting toward the one side.

Owner:NGK SPARK PLUG CO LTD

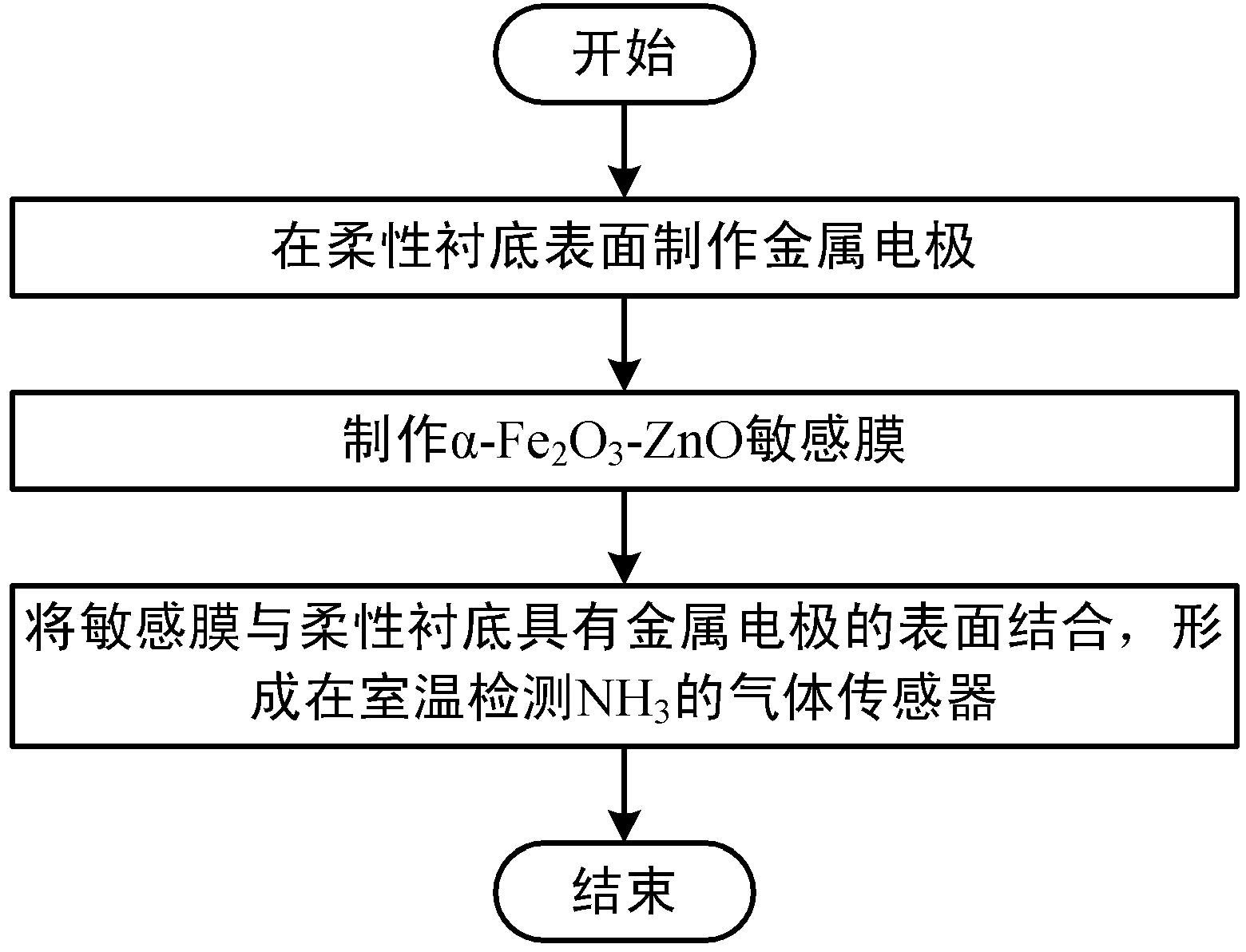

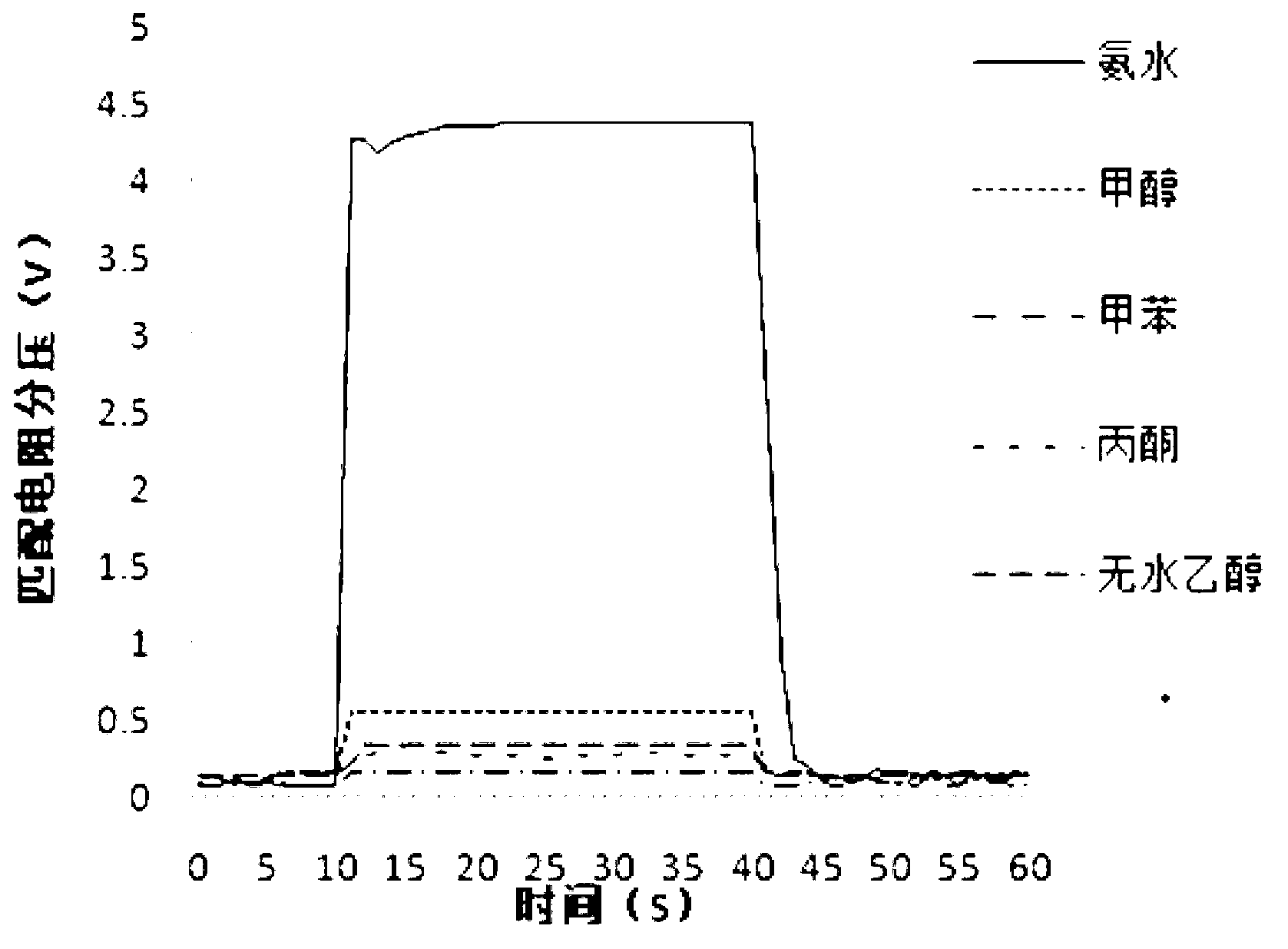

Method for manufacturing gas sensor for detecting NH3 at room temperature

InactiveCN103308560AAvoid high temperature operationMaterial analysis by electric/magnetic meansSilver pasteRoom temperature

The invention discloses a method for manufacturing a gas sensor for detecting NH3 at room temperature. The method comprises the following steps of: manufacturing a metal electrode on the surface of a flexible substrate; manufacturing a sensitive membrane Alpha-Fe2O3-ZnO; and combining the sensitive membrane Alpha-Fe2O3-ZnO and the surface, which is provided with the metal electrode, of the flexible substrate to form the gas sensor for detecting the NH3 at the room temperature. According to the method, the sensitive membrane material is combined with the flexible substrate by an indirect method, so that high-temperature operation on the flexible substrate in a sensitive membrane preparation process is avoided; the sensitive membrane Alpha-Fe2O3-ZnO is coated on the SiO2 substrate; then the lower SiO2 is etched off by HF acid, and the sensitive membrane is separated from the substrate; and finally a layer of conductive silver paste is coated on the electrode surface of the flexible substrate, so that the sensitive membrane can be combined with the flexible substrate.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Method of manufacturing gas barrier film and organic photoelectric conversion element

InactiveUS20130146860A1Improve productivityExcellent gas barrier performanceFinal product manufactureElectroluminescent light sourcesProduction rateCoated surface

The present invention provides: a method of manufacturing a gas barrier film, which is manufactured at high productivity, and has extremely high gas barrier performance and stability thereof with time, excellent surface smoothness and bending resistance, and high durability; a gas barrier film obtained using the method; and an organic photoelectric conversion element using the gas barrier film. In the method, after forming a coated layer by applying a coating liquid containing polysilazane to a substrate, a gas barrier layer is formed by applying vacuum ultraviolet light to the coated layer surface thus formed. The method is characterized in that the coated layer is irradiated with the vacuum ultraviolet light, while drying the solvent in the e coated layer.

Owner:KONICA MINOLTA INC

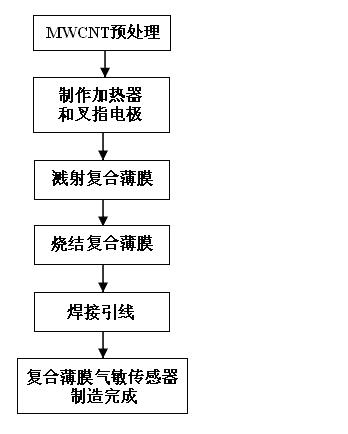

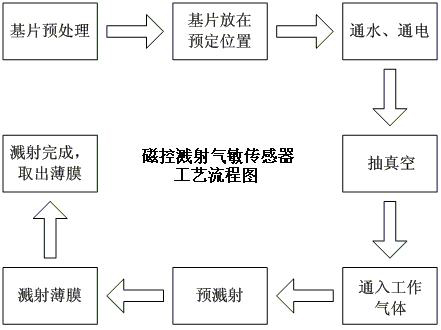

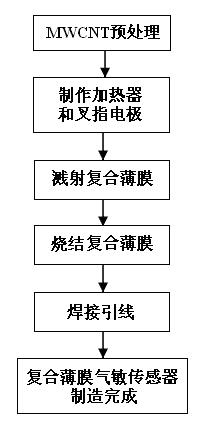

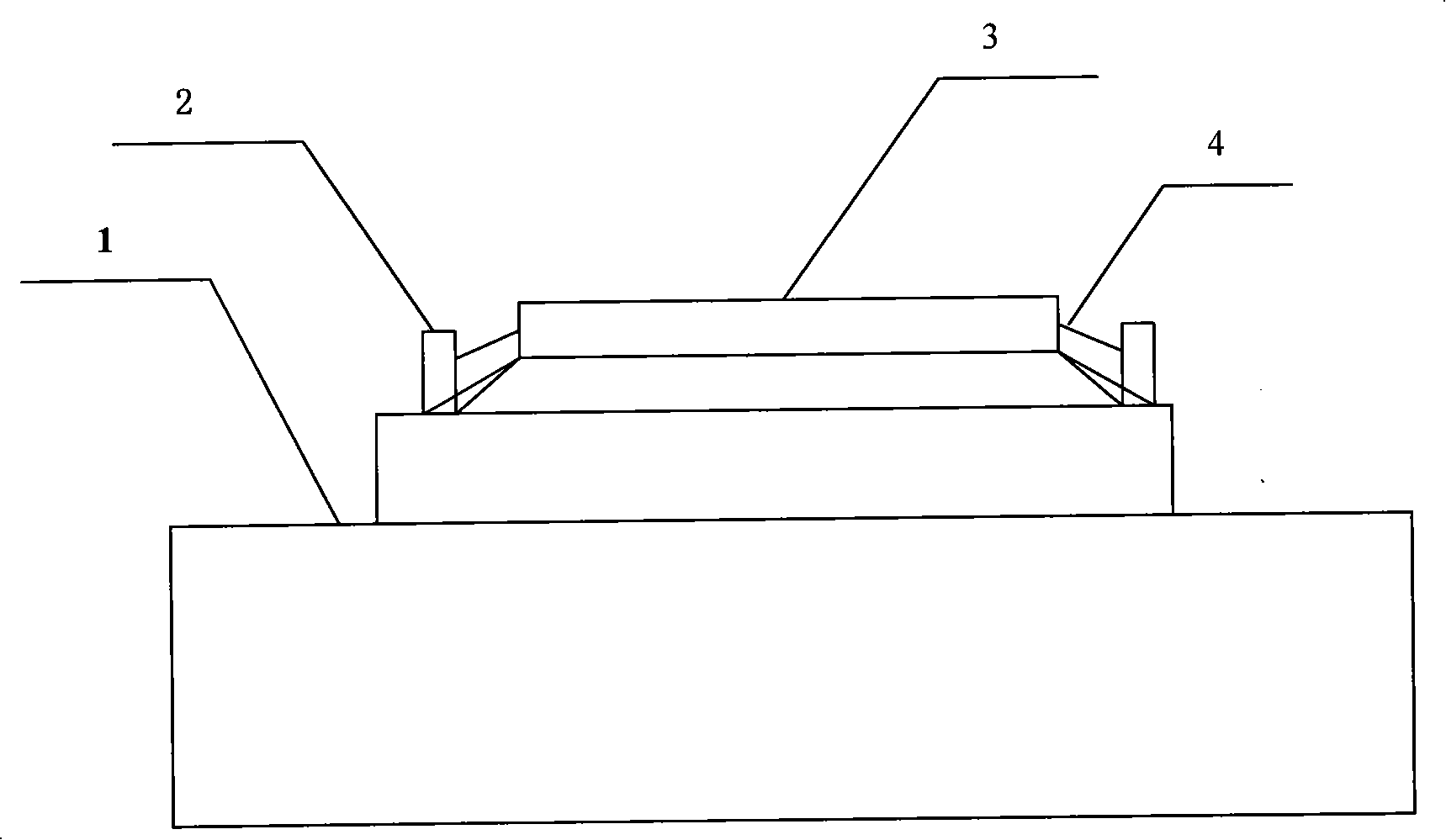

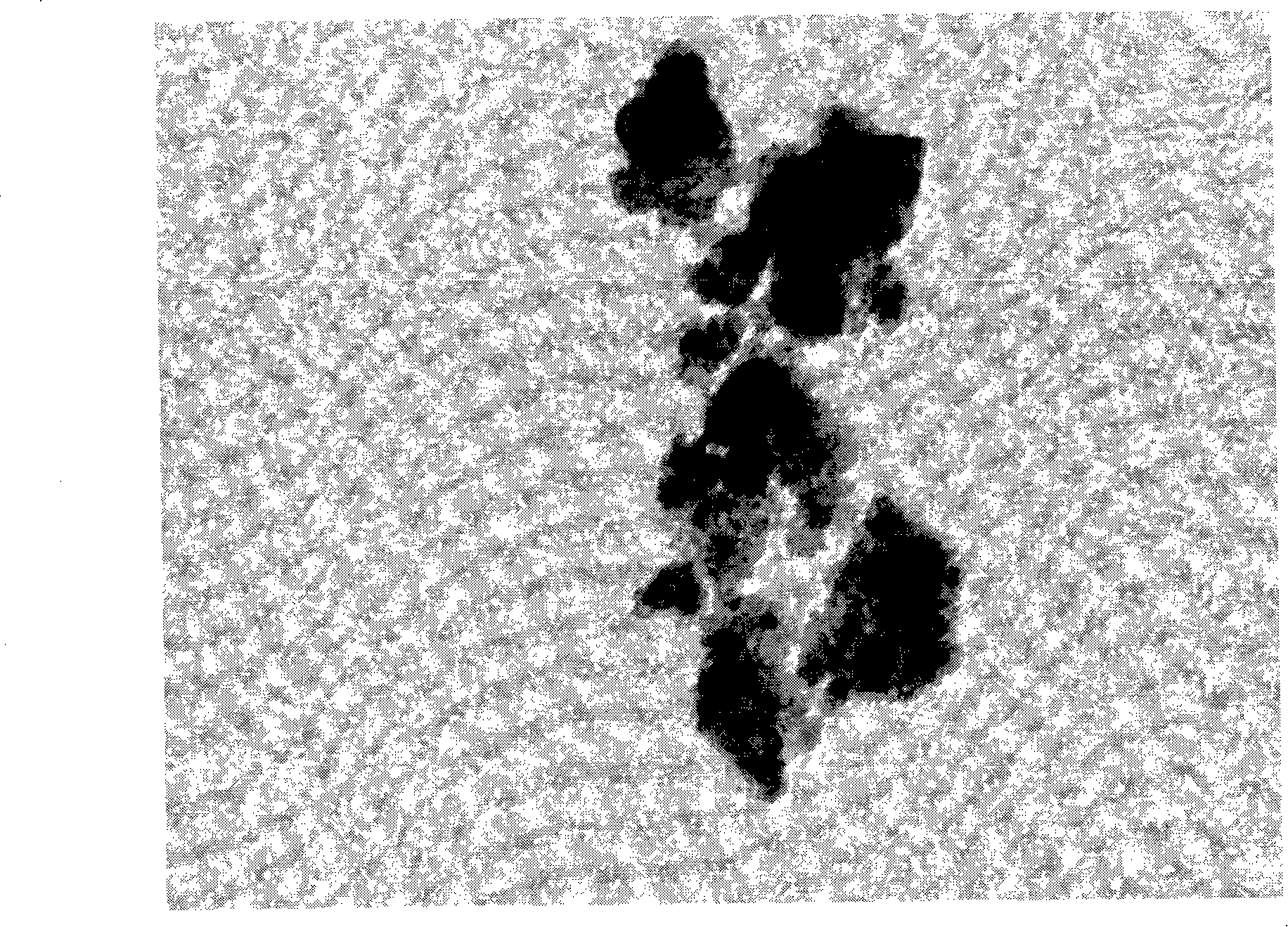

Method for manufacturing composite film gas sensor

InactiveCN101824603AImprove physical propertiesGood chemical propertiesVacuum evaporation coatingMaterial analysis by electric/magnetic meansPlatinumComposite film

The invention relates to the technical field of manufacturing gas sensors, in particular to a method for manufacturing a composite film gas sensor. The method is characterized by comprising the following steps of: 1, performing acid treatment on MWCNT, then adding and dispersing the MWCNT into an organic solvent, treating the mixture to obtain a fully-mixed suspension, and spin-coating the suspension to a tin target and a tungsten target of a radio frequency reaction magnetron sputtering device respectively; 2, manufacturing a heater and an interdigital electrode of the sensor on a silicon chip or a ceramic tube; 3, using a radio frequency reaction magnetron sputtering technique to sputter a layer of SnO2-MWCNT film on the area of the interdigital electrode, and sputter a layer of WO3-MWCNT film on the SnO2-MWCNT film to form a composite film; 4, sintering the silicon chip or the ceramic tube attached with the film in a high-temperature furnace; and 5, welding a platinum wire between the heater of the silicon chip or the ceramic tube and an outer leading wire post of the sensor and welding a platinum wire between the electrode of the silicon chip or the ceramic tube and the outer leading wire post of the sensor respectively. The SnO2-WO3-MWCNT composite film gas sensor manufactured by the method has a high gas-sensing property and a good using effect.

Owner:FUZHOU UNIV

Method for manufacturing gas sensor for testing hydrogen

InactiveCN101251508AHigh sensitivityHigh selectivityMaterial analysis by electric/magnetic meansHydrogenCoprecipitation

The invention relates to a preparation method for a gas sensor for detecting hydrogen, wherein, ultrasonic wave and low-temperature aging technologies are applied in the complex effect of zinc salts and stannum salts and chemical coprecipitation for preparation of nano ZnSnO3. The invention prepares the novel PdO-ZnSnO3 heater type semiconductor gas sensor by isomerisation of noble metal salts PdCl2, adhesives (ethyl orthosilicate) and deionized water through technologies like grinding, ultrasonic vibration, coating, sintering, etc. on the basis of the nano ZnSnO3, wherein, nano ZnSnO3 bases are prepared by adoption of an improved coprecipitation method. The preparation method for the gas sensor for detecting hydrogen has the advantages of high sensitivity of gas sensitive materials, strong selectivity, low operation temperature, simple preparation technology and so on.

Owner:CHONGQING UNIV

Copper oxide doped tin dioxide base ammonia gas sensitive sensor manufacturing method

InactiveCN102978578AHigh sensitivityResponse recovery time is shortVacuum evaporation coatingSputtering coatingTin dioxideVacuum pumping

The present invention discloses a copper oxide doped tin dioxide base ammonia gas sensitive sensor manufacturing method. The method comprises the following steps: sequentially placing a Cu target material with a purity of 99.99% and a Sn target material with a purity of 99.99% on two radio frequency sputtering targets, and placing a Al2O3 ceramic tube on a sample holder; carrying out vacuum pumping on the system before sputtering until air pressure of the system achieves 10<-3>-10<-5> Pa; opening gas path valves of oxygen gas and argon gas, wherein the air pressure is maintained to 6*10<0>-3*10<-1> Pa; carrying out pre-sputtering for 10 min, then removing a blocking disc, concurrently adjusting a power of the Sn target to 60-80 W, adjusting a power of the Cu target to 20-60 W, and sputtering for 45 min; opening the vacuum chamber to take the sample when the air pressure is 10<5> Pa; and carrying out annealing for 1-3 h at a temperature of 300-500 DEG C in a muffle furnace to obtain the finished product. The manufactured gas sensitive element provides good selectivity for ammonia gas, can quickly and effectively detect ammonia gas from a lot of mixing gas, and has characteristics of high sensitivity and short response recovery time.

Owner:HEBEI UNIV OF TECH

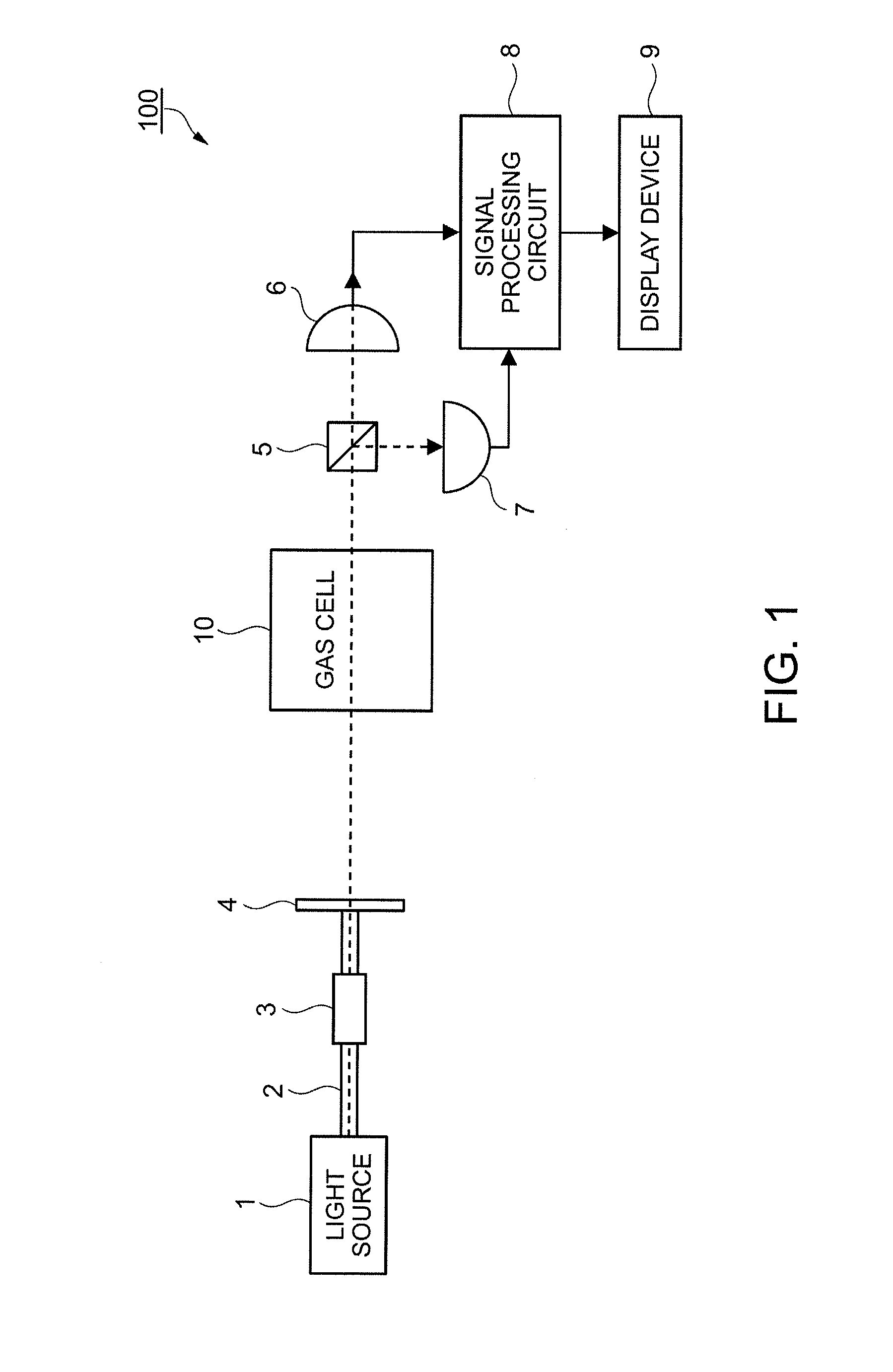

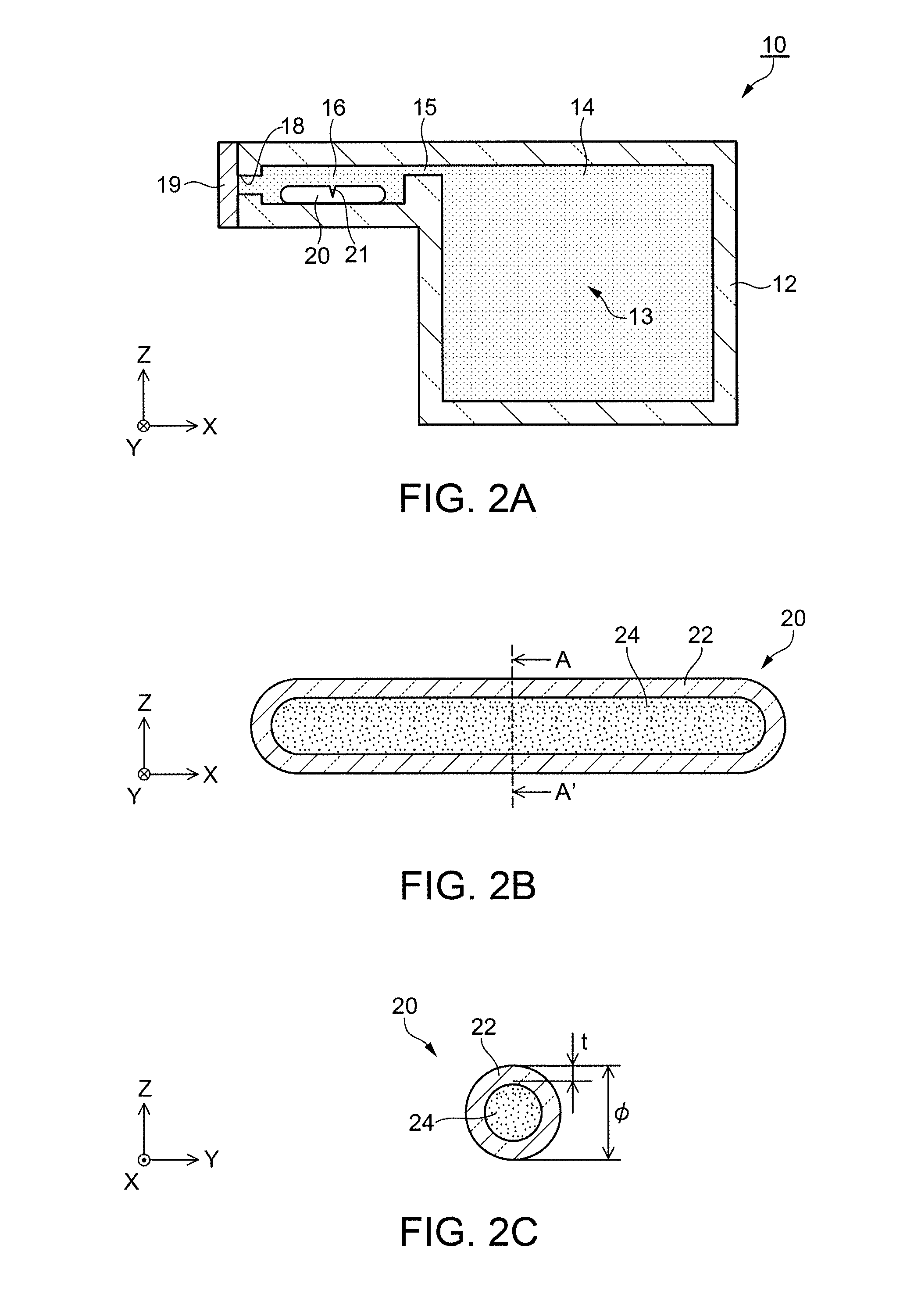

Method for manufacturing magnetism measurement device, method for manufacturing gas cell, magnetism measurement device, and gas cell

InactiveUS20160097824A1Improve abilitiesWave amplification devicesMagnetic field measurement using magneto-optic devicesMeasurement deviceOptoelectronics

A method for manufacturing a magnetism measurement device which measures a magnetic field generated from a living body, includes: arranging an ampoule made of borosilicate glass and having a hollow part filled with a solid alkali metal, in a void in a cell section made of quartz glass, and then sealing the cell section; and casting a pulse laser beam on the ampoule through the cell section and thus forming a penetration hole in the ampoule. The pulse laser beam has an energy of 20 μJ / pulse to 200 μJ / pulse. The absorption coefficient of quarts glass for the pulse laser beam is lower than the absorption coefficient of borosilicate glass for the pulse laser beam.

Owner:SEIKO EPSON CORP

Oxygen-removal method of oxygen-containing coal-bed gas

The invention provides an oxygen-removal method of oxygen-containing coal-bed gas. The oxygen-removal method is characterized in that oxygen-containing coal-bed gas and manufactured gas are fed into a reactor with a catalyst; and carbon monoxide and hydrogen in the manufactured gas react with oxygen in the oxygen-containing coal-bed gas in the presence of the catalyst to produce carbon dioxide and water so that oxygen removal is realized.

Owner:DALIAN TIANYUAN GAS TECH

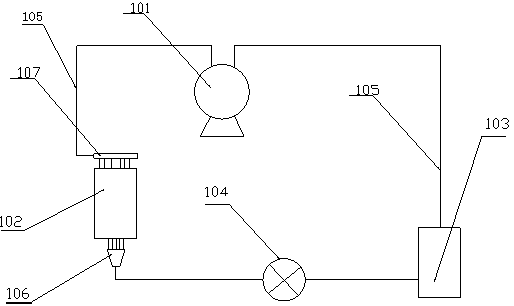

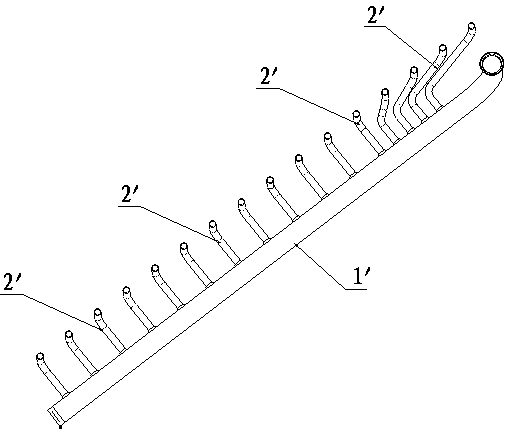

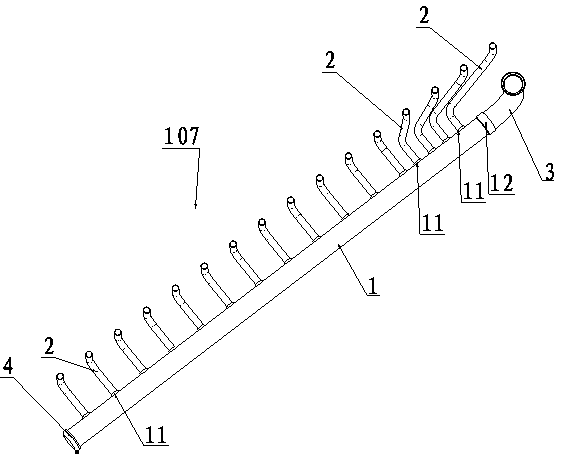

Method for manufacturing gas collecting tube component and air-conditioning system

InactiveCN102848137ALow costImprove reliabilitySoldering apparatusSpace heating and ventilation detailsGas collecting tubeProcess engineering

The invention relates to a method for manufacturing a gas collecting tube component. The method comprises the following steps of: 1) preparing a main gas collecting tube made of a stainless steel material; 2) preparing a plurality of gas collecting branch tubes made of carbon steel materials; 3) fixing the main gas collecting tube, the gas collecting branch tubes and a tube orifice sealing cap obtained in the steps 1 and 2 through interference or transition fit; and 4) welding the assembled parts to form the gas collecting tube component. The invention also provides an air-conditioning system. The material manufacturing cost can be greatly reduced; and meanwhile, according to novel materials, a novel method for manufacturing the gas collecting tube component is adopted, the airtight reliability and corrosion resistance of the product are improved, the process is simplified, the pickling step is canceled, and the environmental pollution can be avoided through the pickling process.

Owner:ZHEJIANG SANHUA CLIMATE & APPLIANCE CONTROLS GRP CO LTD

Gas sensor element, gas sensor, and method of manufacturing gas sensor element

ActiveUS20150114102A1Small heat capacityInternal-combustion engine testingMaterial analysis by electric/magnetic meansEngineeringProtection layer

A gas sensor element in an air / fuel ratio sensor includes an element body and a protection layer having two layers (a first layer and a second layer). The gas sensor element has at least one separation portion in the form of a space between the first layer and the second layer. The gas sensor element can temporarily accumulate, in the at least one separation portion, water which adheres to the surface of the protection layer and penetrates into the protection layer. Thus, as compared with a protection layer which is identical in thickness to the protection layer, but does not have separation portions, water adhering to the protection layer is less likely to reach the element body. Therefore, there can be restrained breakage of an end of the element body which could otherwise result from thermal shock stemming from adhesion of water.

Owner:NGK SPARK PLUG CO LTD

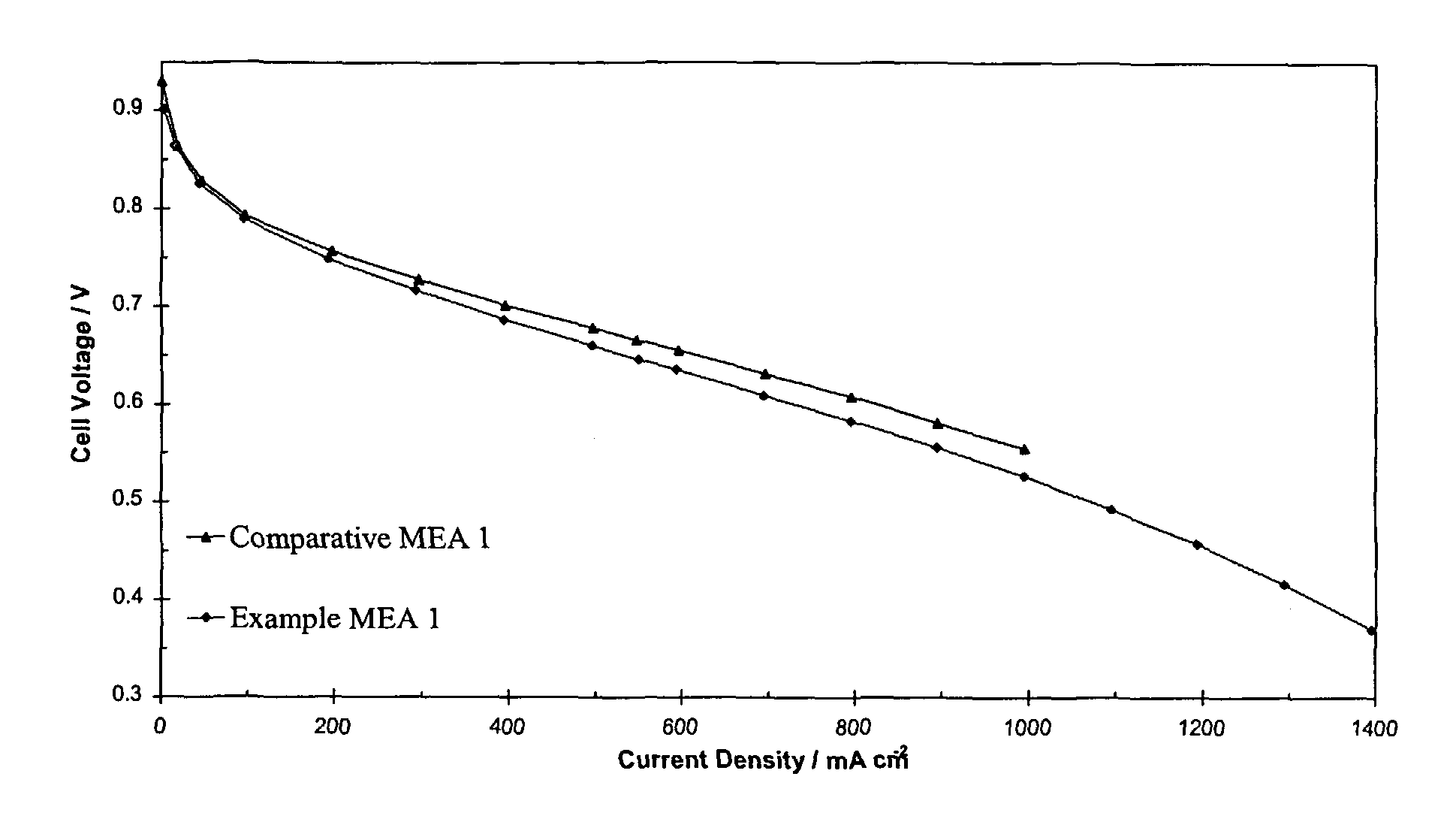

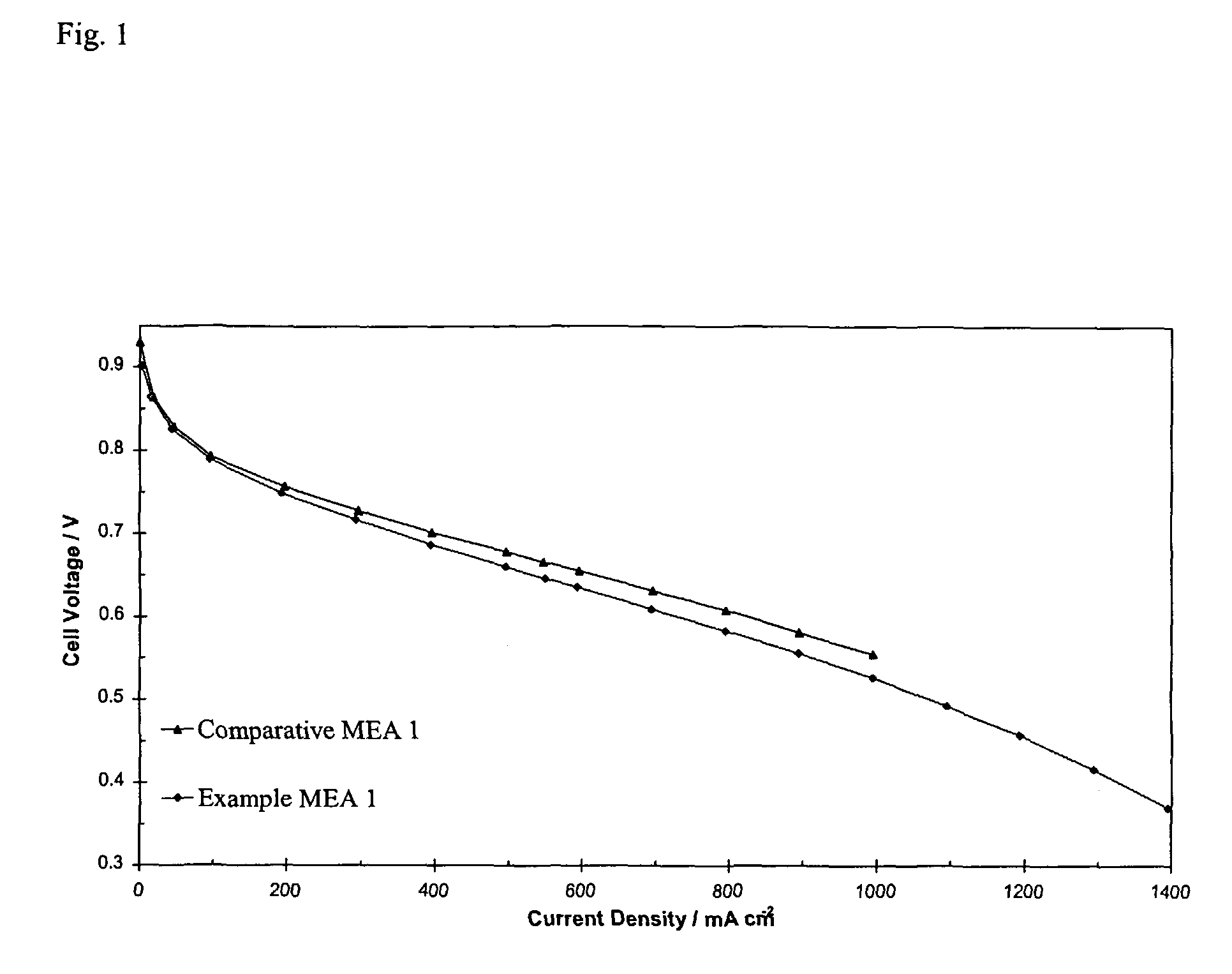

Gas diffusion substrate

ActiveUS8133306B2Improve conductivitySuitable conductivityFinal product manufactureFuel cell auxillariesFiberDiffusion

A gas diffusion substrate includes a non-woven network of carbon fibres, the carbon fibres are graphitised but the non-woven network has not been subjected to a graphitisation process. A mixture of graphitic particles and hydrophobic polymer is disposed within the network. The longest dimension of at least 90% of the graphitic particles is less than 100 μm. A process for manufacturing gas diffusion substrates includes depositing a slurry of graphitised carbon fibres onto a porous bed forming a wet fibre network, preparing a suspension of graphitic particles and hydrophobic polymer, applying onto, and pulling the suspension into, the network, and drying and firing the network. Another process includes mixing a first slurry of graphitic particles and hydrophobic polymer with a second slurry of graphitised carbon fibres and liquid forming a third slurry, depositing the third slurry onto a porous bed forming a fibre-containing layer, and drying and firing the layer.

Owner:TECHN FIBER PRODS

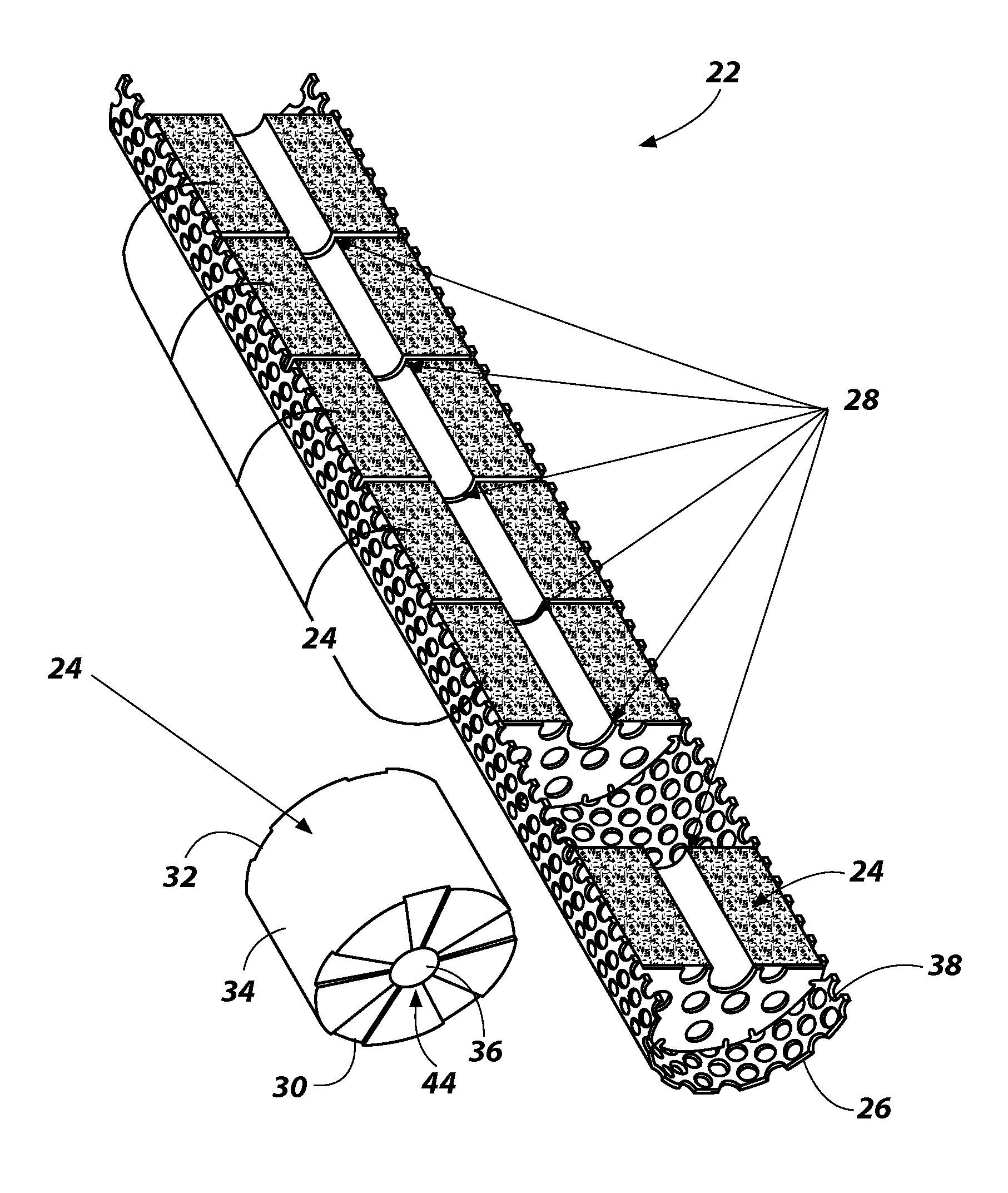

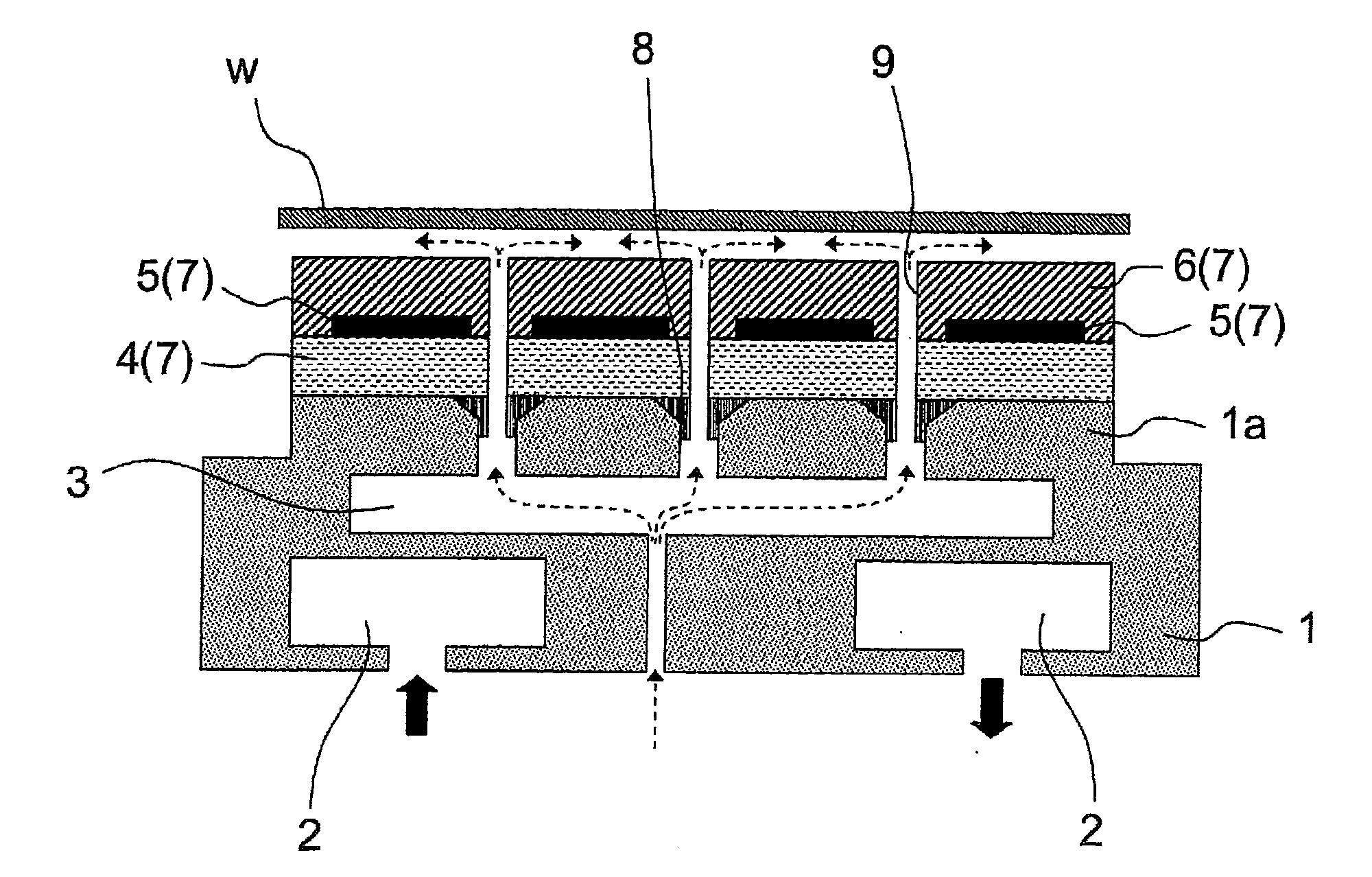

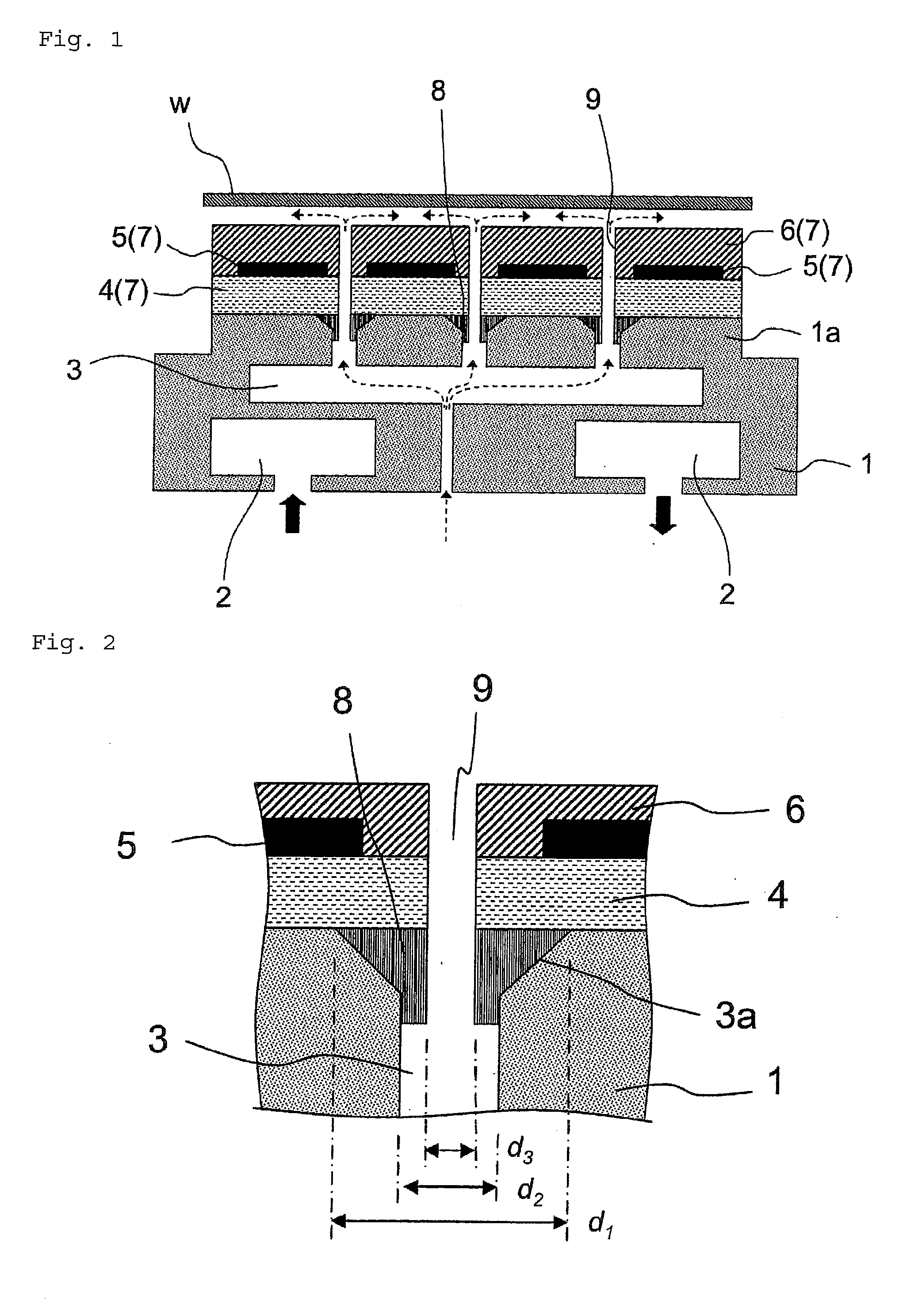

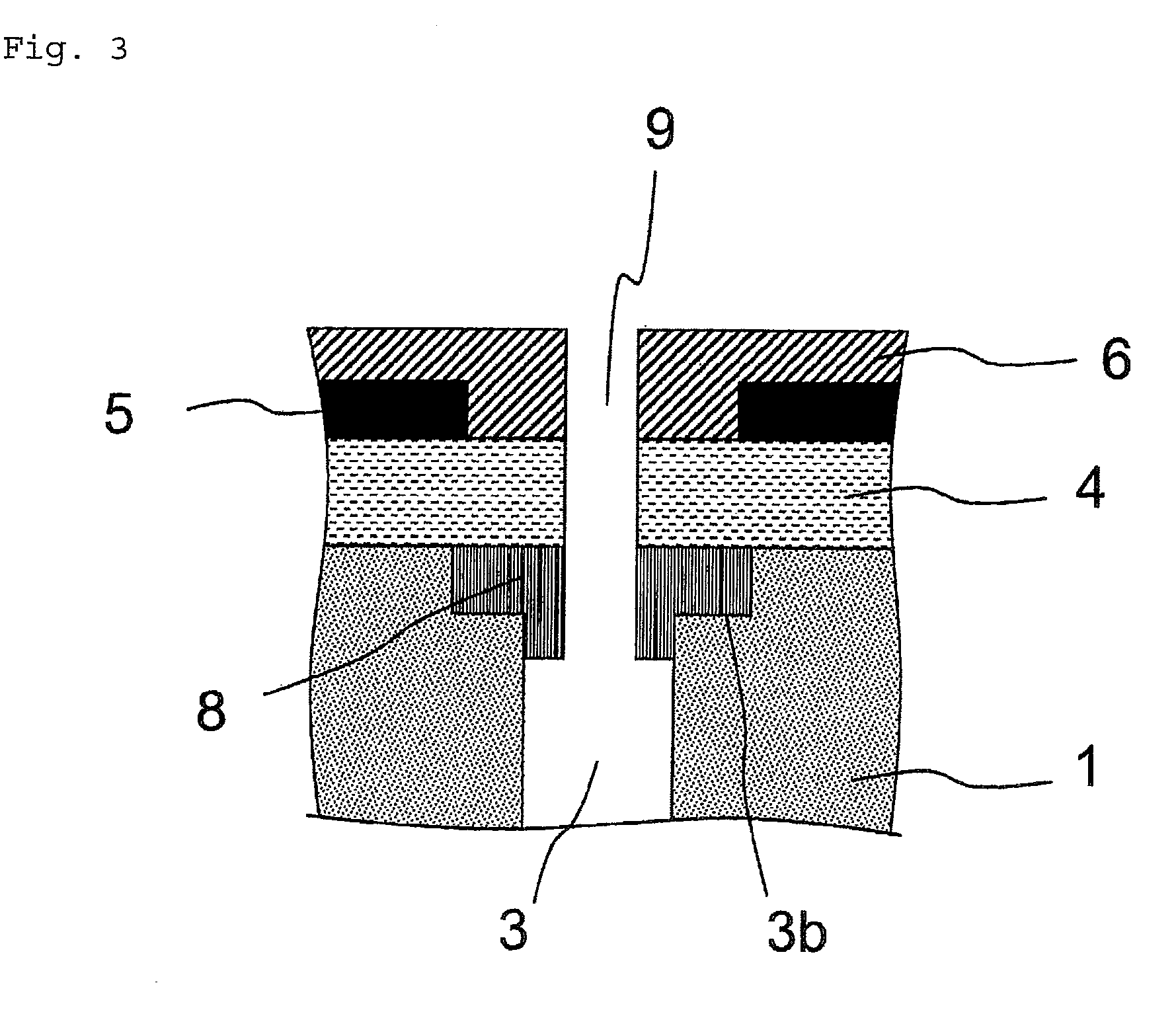

Method for manufacturing gas supply structure in electrostatic chuck apparatus, gas supply structure in electrostatic chuck apparatus, and electrostatic chuck apparatus

ActiveUS20100254064A1Increased durabilityPreventing amountPrinted circuit assemblingPipe supportsThermal sprayingAdhesive

Provided is a method of manufacturing a gas supply structure for use in an electrostatic chuck apparatus having an electrostatic chuck on the upper surface side of a metal base (1), the gas supply structure being capable of eliminating contamination due to nonuniform cooling gas jetting quantities and deposition of a thermally spraying material and the like. The method of manufacturing the gas supply structure for supplying a cooling gas supplied from the lower surface side of the metal base (1) to the back surface of a substrate (W) attracted to an upper insulating layer (6) side, through a gas supply path (3) provided on the metal base (1), the method including: prior to a step of forming a lower insulating layer (4) by thermally spraying a ceramic powder on the upper surface side of the metal base (1), a step of forming an attracting electrode (5), and a step of forming the upper insulating layer (6), a step of blocking a gas supply path outlet (3a) on the upper surface side of the metal base (1) with an adhesive (8), the adhesive containing a filler made of the same material as that of the ceramic powder that is used for forming the lower insulating layer (4); and a step of opening a hole toward the gas supply path outlet (3a) of the metal base (1) after forming the upper insulating layer (6), to thereby form a through hole (9) reaching the gas supply path (3).

Owner:CREATIVE TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com