Method for manufacturing gas sensor for detecting NH3 at room temperature

A technology of gas sensor and manufacturing method, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., and can solve the problems of uneven film formation of inorganic sensitive films, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

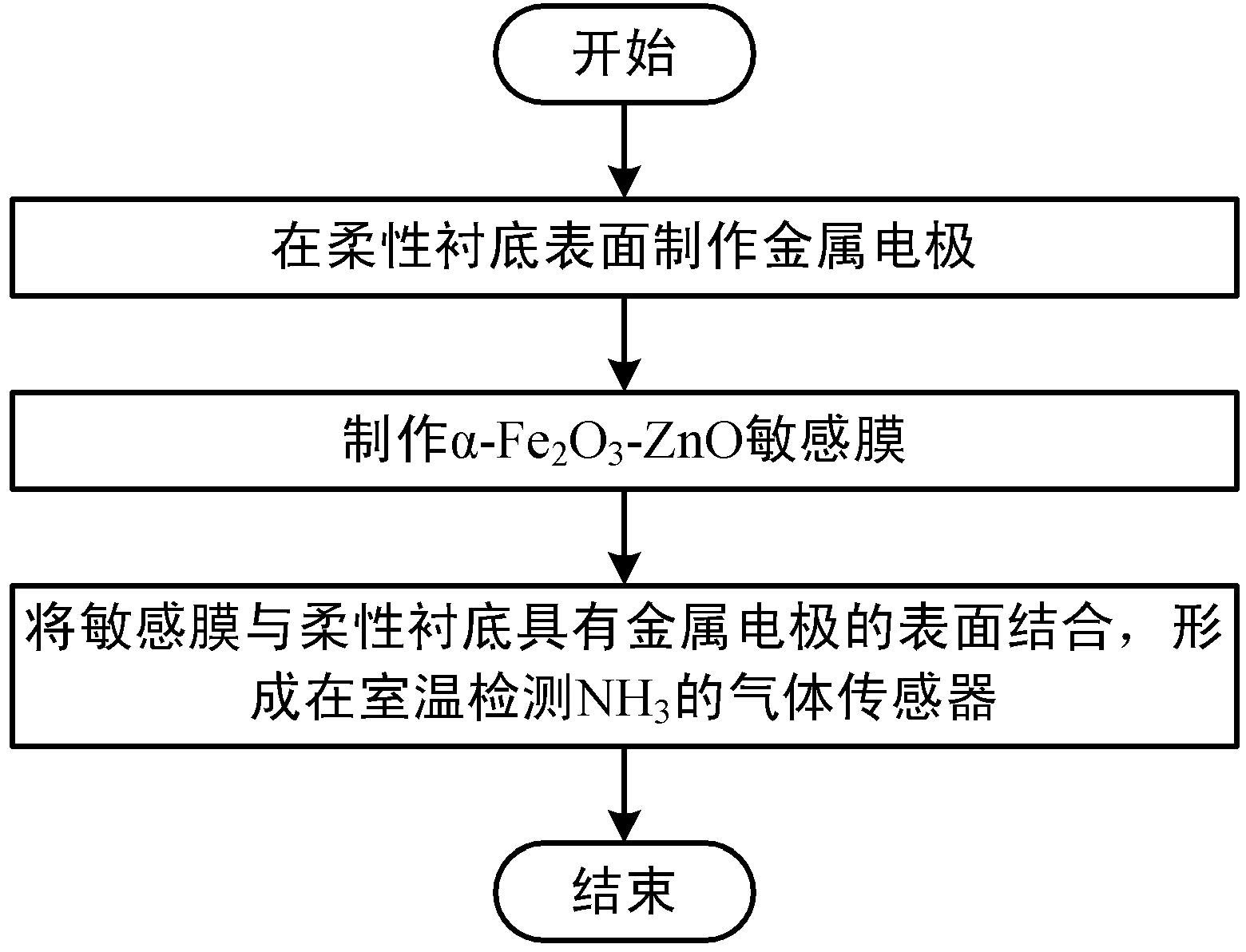

[0032] like figure 1 as shown, figure 1 It is the production room temperature detection NH provided by the present invention 3 The method flowchart of the gas sensor, the method comprises the following steps:

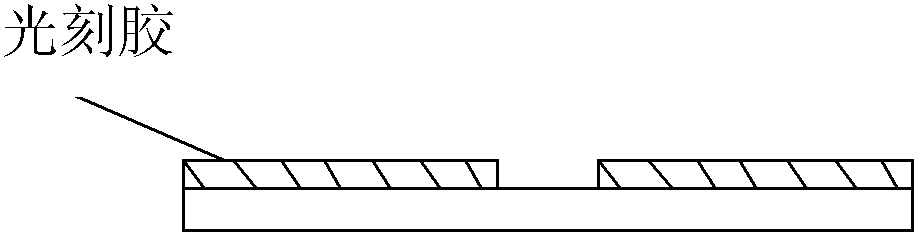

[0033] Step 1: Fabricate metal electrodes on the surface of the flexible substrate; this step specifically includes: cleaning the flexible substrate, coating a photoresist on the surface of the flexible substrate, and performing photolithography on the photoresist to carve off the surface of the flexible substrate It is used to form the photoresist at the metal electrode, and form an electrode pattern on the surface of the flexible substrate; then use electron beam evaporation to sequentially deposit Cr film and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com