Ladle automatic casting system and method

A casting system and ladle technology, applied in casting equipment, casting molten material containers, manufacturing tools, etc., can solve the problems of low service life, low production efficiency, harsh site environment, etc., to avoid high temperature operation, high positioning accuracy, and use Long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

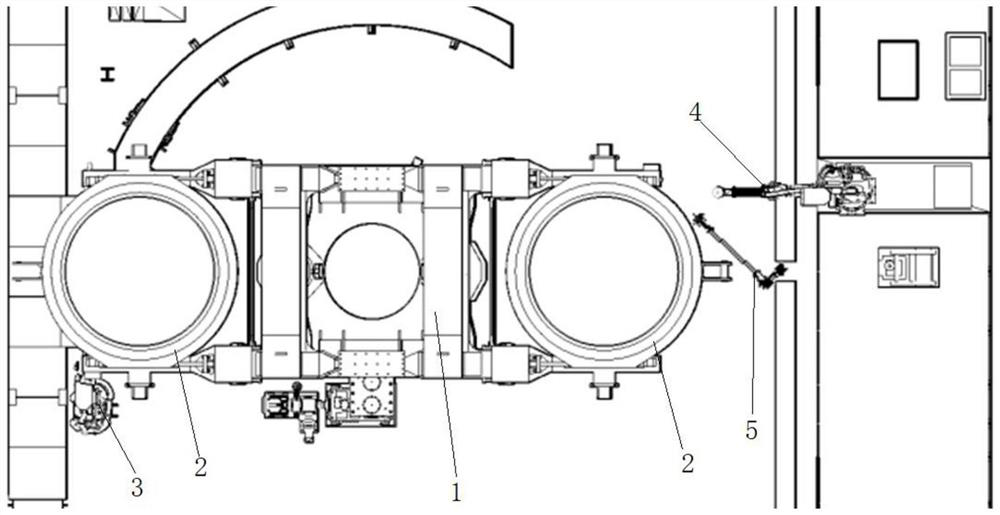

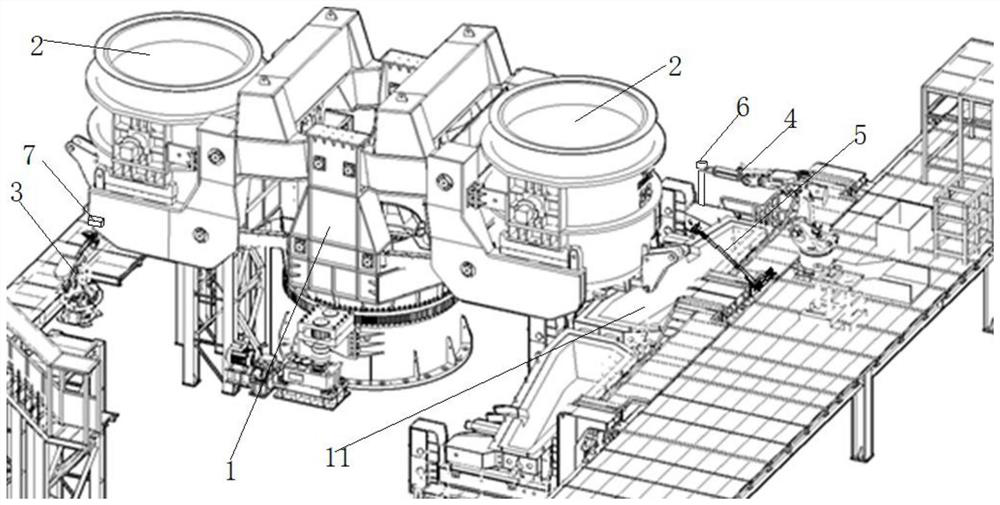

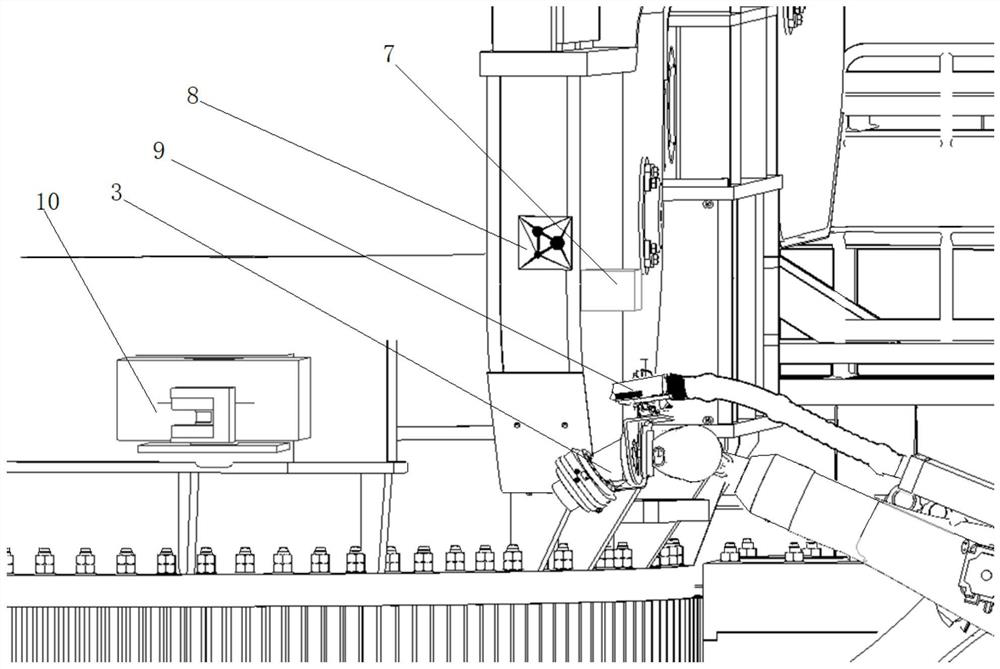

[0024] Such as Figure 1 to Figure 4 As shown, a ladle automatic casting system includes a positioning plate 8 fixed on the yoke of the turntable 1, a water inlet cylinder 7 placed on the yoke of the turntable 1, a steel pick-up robot 3 near the pick-up position, and a The casting position robot 4 and the collaborative manipulator 5 near the casting position are equipped with 3D scanners 9 on the steel position robot 3 and the casting position robot 4, and the collaborative manipulator arm 5 is driven up and down by the lifting device; the steel position robot 3 can drive the 3D scanner 9 to scan to obtain the coordinates of the positioning plate 8 and the nozzle mechanism 10 at the steel connection position and obtain the relative positional relationship between the two. The steel connection robot 3 can drive the 3D scanner 9 to scan to obtain the nozzle at the steel c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com