Spliced wood formwork for building construction and preparation method thereof

A technology for building construction and wood formwork, which is applied to the on-site preparation of building components, construction, building structure, etc. The effect of short time, simple construction and high turnover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A kind of preparation method of splicing type wooden formwork of the present invention, comprises the following steps:

[0034] S1. After drying a plurality of veneers, apply an adhesive to assemble blanks, and obtain slabs after hot pressing;

[0035] S2. Sanding the surface of the slab, repairing and leveling it, and veneering it to obtain a semi-finished wood formwork unit;

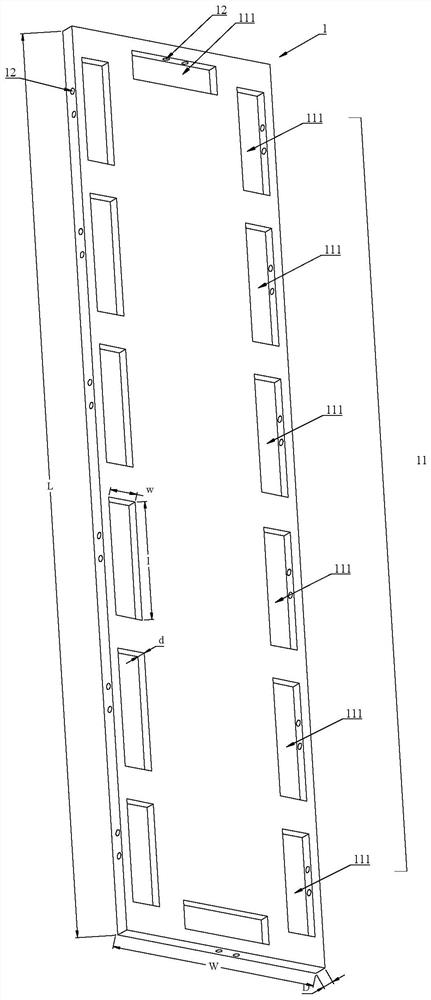

[0036] S3. Use an engraving machine to hollow out the hollow groove 11 on the back of the semi-finished wood formwork unit according to the preset requirements, and drill out the connecting holes 12 to obtain the wood formwork unit 1;

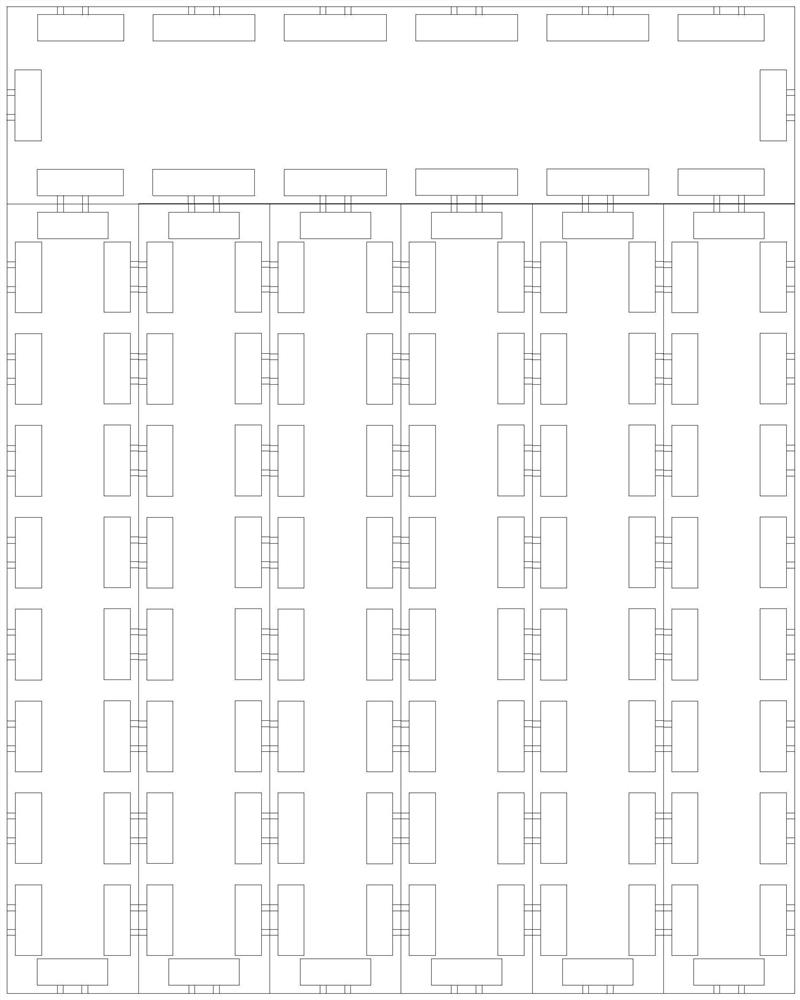

[0037] S4. Splicing the wooden formwork unit 1 into a wooden formwork according to preset requirements to obtain a spliced wooden formwork.

[0038] In the preparation method of the present invention, a plurality of wooden formwork units are hollowed out by an engraving machine to get out the hollow grooves 11, and the connection holes 12 are drilled out and t...

Embodiment 1

[0040] The preparation method of the spliced wooden formwork of this embodiment: first make a slab of 43 mm, sand the slab to 40 mm, repair the bottom of the surface with putty, and then paste glass fiber or coated paper again to produce a semi-finished product of 40 mm. The semi-finished product is partially hollowed out by the engraving machine and then drilled on four sides to produce a template unit of the required size, which specifically includes the following steps:

[0041] A. Drying of the veneer: the thickness of the veneer is 1.5-1.7mm (the thickness of this embodiment is 1.6mm), and the drying temperature is 60-80°C;

[0042] B. Blank assembly: The number of structural layers is 31 layers. Starting from the bottom plate, one layer of horizontal veneer and one layer of vertical veneer are arranged alternately. The way of laying glue is to alternately set one layer without glue and one layer of glue. The solid content is 45- 50% phenolic resin glue, cloth glue amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com