Claw replacement mechanism automatically correcting transverse deviations and mechanical hand equipment

A horizontal deviation and automatic technology, which is applied in the field of mechanical devices, can solve the problem of short loading and unloading of manipulator equipment, and achieve the effects of short loading and unloading time, high applicability, and low control precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

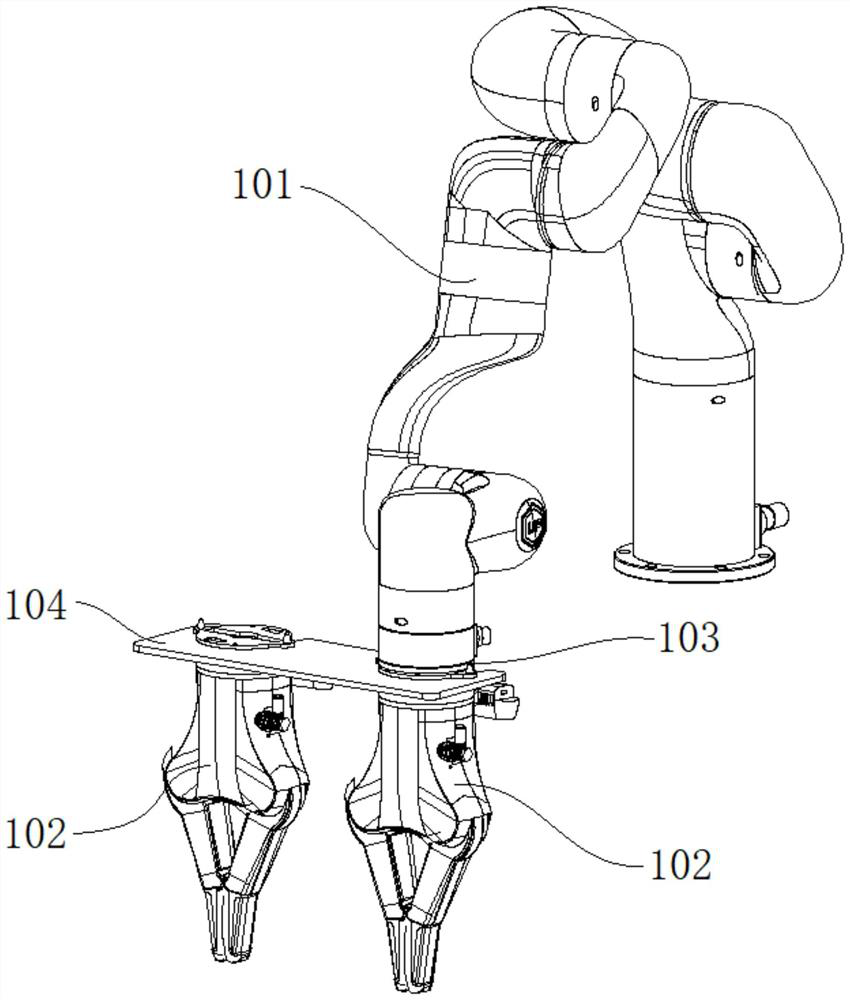

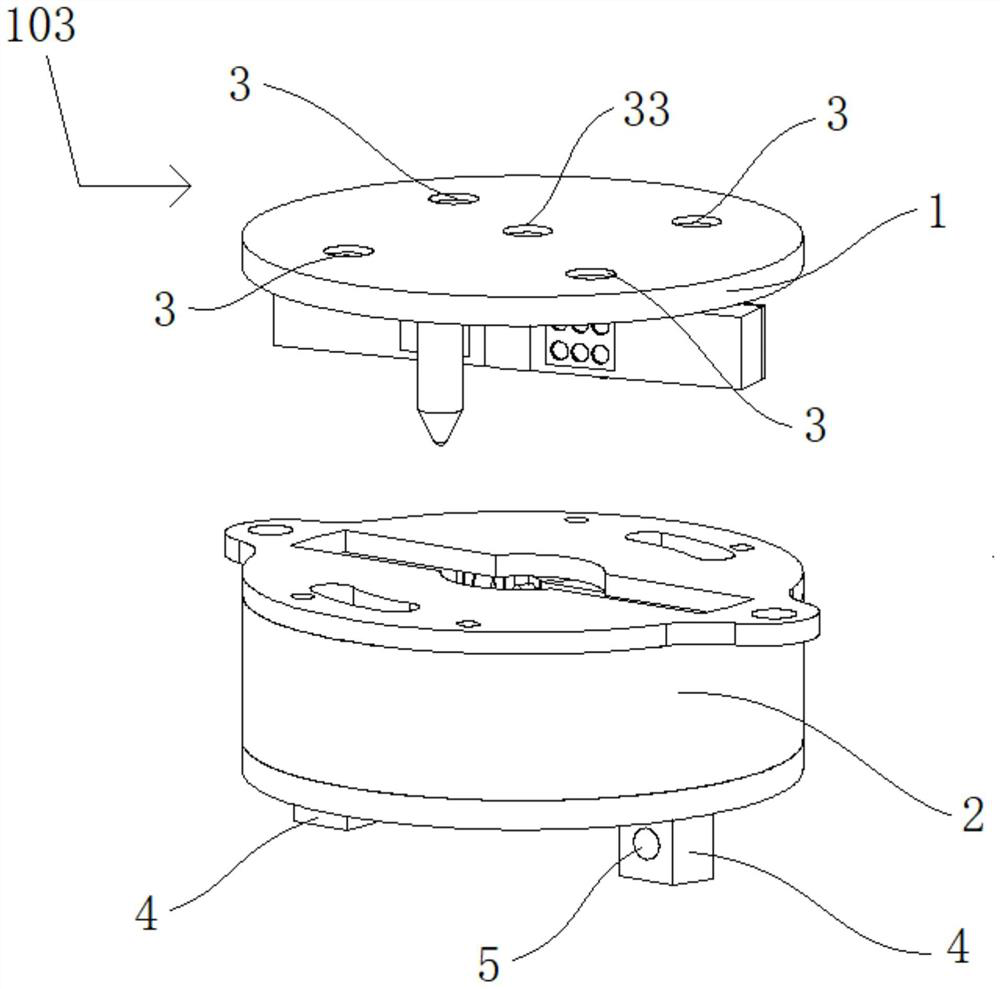

[0033] Robotic equipment such as figure 1 As shown, it includes a robotic arm 101 and a robotic claw 102 for grasping objects. The robotic claw 102 to be used is mounted on the robotic arm 101 using a claw changing mechanism 103, so that the robotic arm 101 can drive the robotic claw 102 to move, wherein the claw is changed. The mechanism 103 includes a jaw change aid 104 on which the mechanical jaws 102 not in use are placed. like figure 2 As shown, the claw changing mechanism 103 includes two connecting pieces, namely the arm connecting piece 1 and the claw connecting piece 2, wherein the arm connecting piece 1 is fixedly installed on the mechanical arm 101, and the claw connecting piece 2 is fixedly installed on the mechanical arm 101. Therefore, the arm connecting member 1 and the claw connecting member 2 are longitudinally close to each other to be assembled with each other, so that the mechanical claw 102 can be installed on the mechanical arm 101 . The specific insta...

Embodiment 2

[0043] Compared with the first embodiment, the present embodiment has the same mechanical arm 101 , the mechanical claw 102 and the claw changing auxiliary part 104 of the manipulator, but the structure of the claw changing mechanism 103 is different.

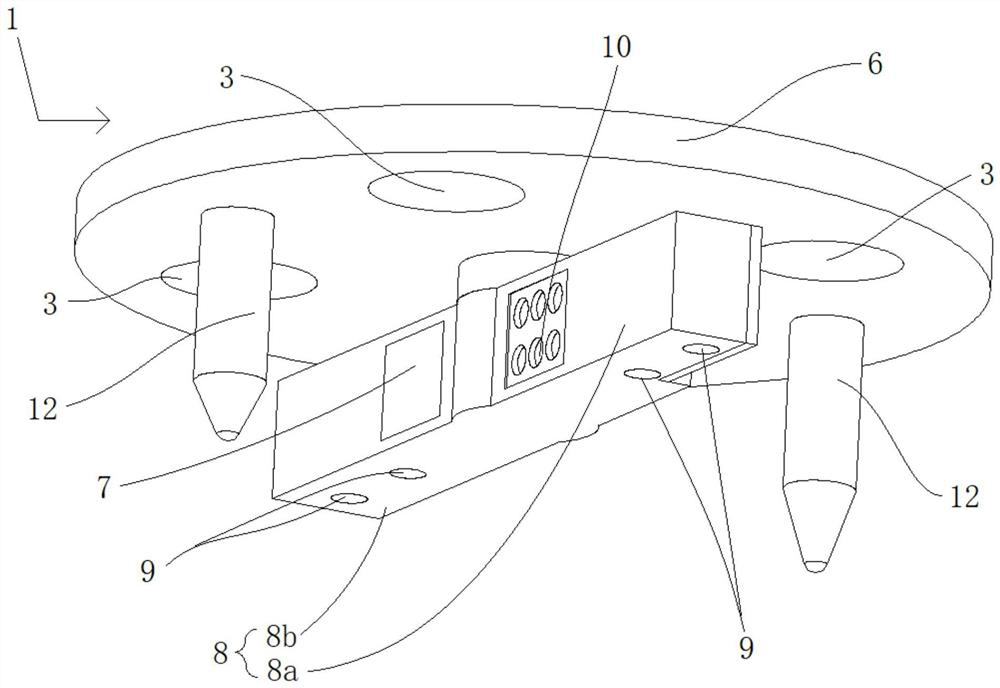

[0044] In this embodiment, the jaw changing mechanism 103 is as Figure 7 As shown, it includes an arm connector 1 and a claw connector 2, the arm connector 1 is fixedly installed on the mechanical arm 101, and the claw connector 2 is fixedly installed on the mechanical claw 102, wherein the arm connector 1 is as Figure 8 As shown, it includes a circular cover 6 and a shaft post 7 located at the center of the bottom of the cover body 6. The through hole 3 is opened on the cover body 6, and three clips protrude laterally from the side wall of the shaft post 7 near the bottom end. Connectors 26, 27, 28, these three card connectors 26, 27, 28 are distributed on the three equal positions of the shaft column 7, wherein, the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com