Bulging tooling and clamping method for large-size thin-walled cylindrical parts

A thin-walled cylinder and large-size technology, which is applied in the direction of metal processing machinery parts, clamping, manufacturing tools, etc., to achieve the effects of convenient operation, labor saving, short loading and unloading time, and simple structure

Inactive Publication Date: 2019-10-01

XIAN AERONAUTICAL UNIV

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a large-size thin-walled cylindrical part bulging tool, which solves the problem that the existing clamping tool cannot quickly and labor-savingly correct the deformed thin-walled cylindrical part blank into a cylindrical shape through clamping

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

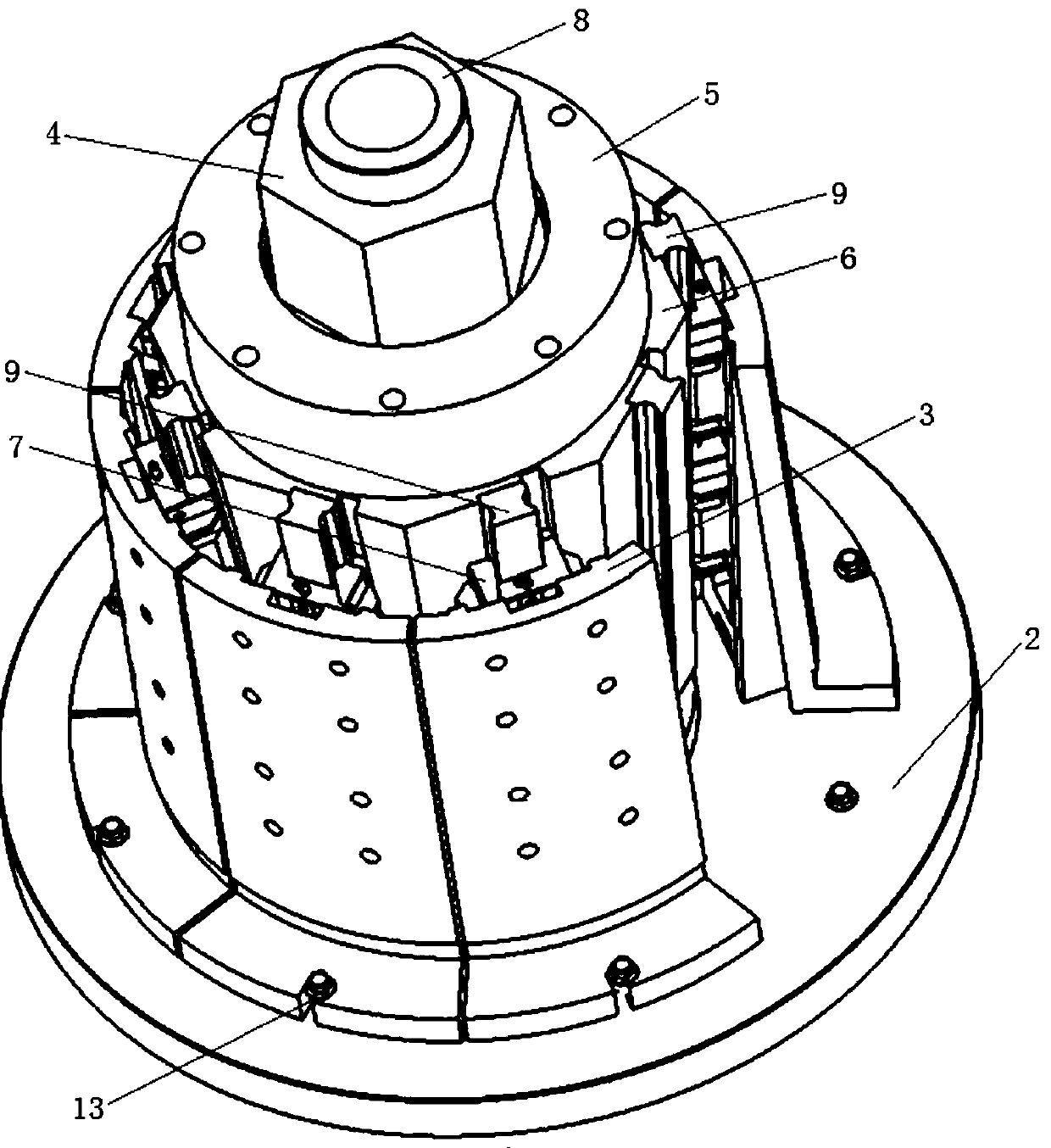

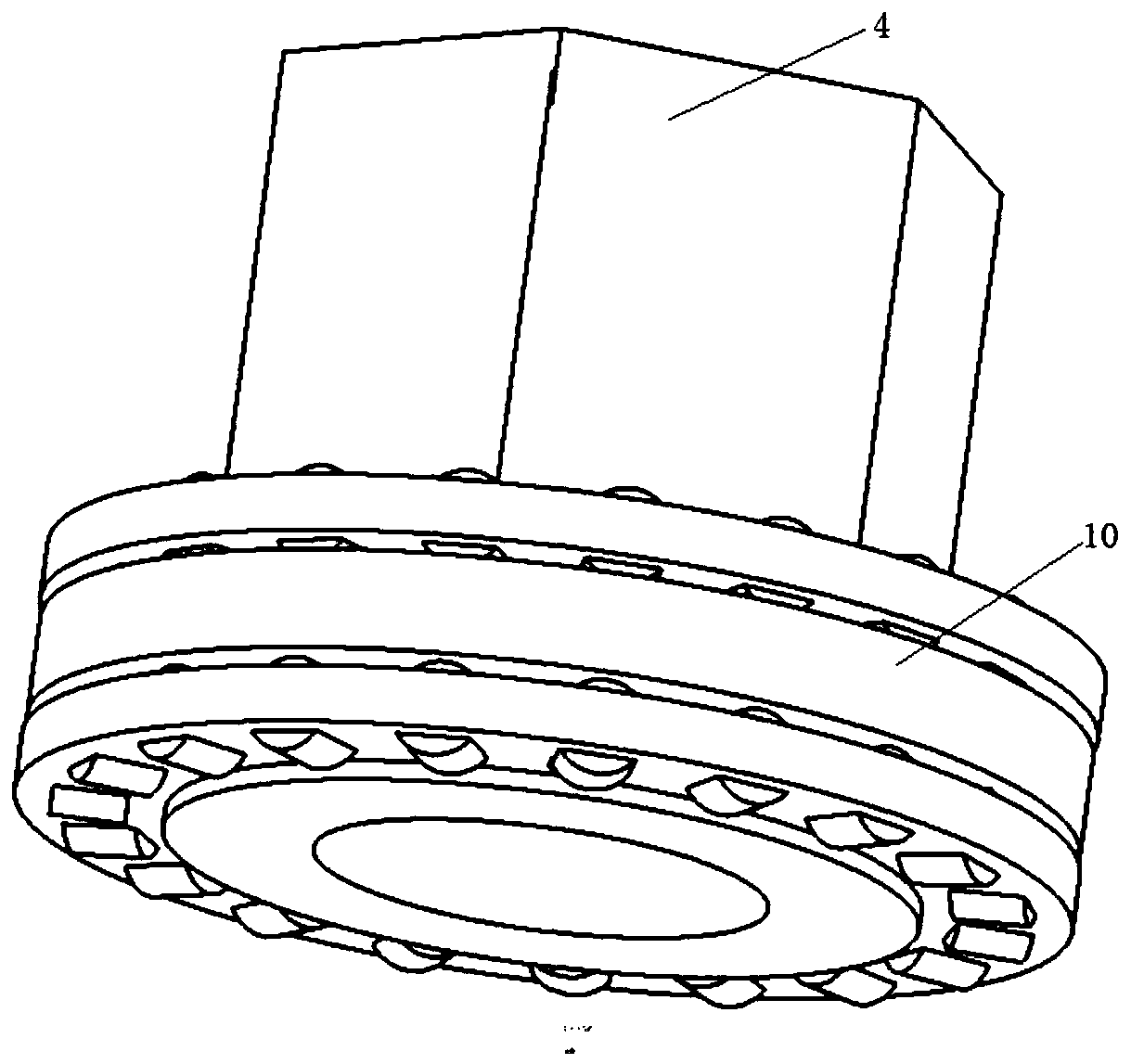

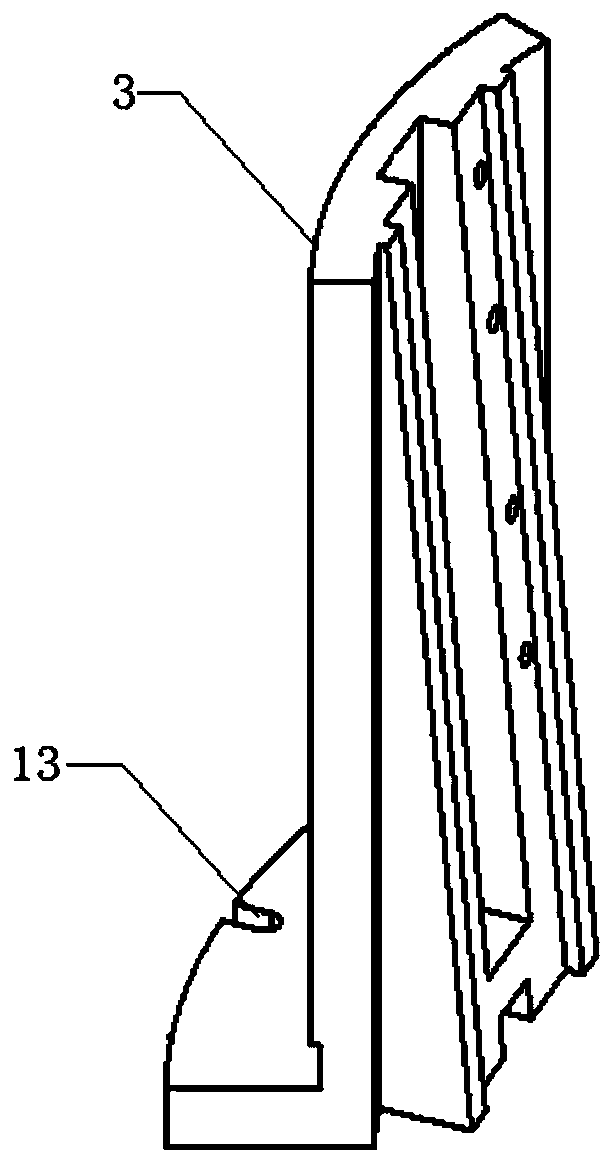

The invention discloses a large-sized thin-walled cylinder part bulging tool. The large-sized thin-walled cylinder part bulging tool comprises a base, a regularly-octagonal pyramid sleeve, eight bulging sections and a nut with a flange at the lower end. A fixed column with a thread at the upper end is vertically and fixedly arranged at the center of the base. The nut and the regularly-octagonal pyramid sleeve are embedded into the fixed column in sequence from top to bottom. A gland is fixedly connected with the regularly-octagonal pyramid sleeve. A rolling guide rail is arranged on each outercone face of the regularly-octagonal pyramid sleeve. Each bulging section is divided into a horizontal segment and a vertical segment. The horizontal segments are movably connected to the base. Sliding grooves matched with the rolling guide rails are formed the inner surfaces of the vertical segments. Sliding blocks are mounted in the sliding grooves. The invention further discloses a clamping method for the large-sized thin-walled cylinder part bulging tool. The clamping method comprises the following specific steps of mounting the tool, adjusting the regularly-octagonal pyramid sleeve to belocated on the upper portion, clamping a cylinder part, performing adjusting and measuring, performing outer circle machining and detaching the part. This large-sized thin-walled cylinder part bulging tool can efficiently and reliably clamp the large-sized thin-walled cylinder part and is high in clamping accuracy.

Description

technical field The invention belongs to the technical field of mechanical manufacturing, and in particular relates to a large-size thin-wall cylindrical part bulging tool, and also relates to a clamping method using the large-size thin-wall cylindrical part bulging tool. Background technique Large-size thin-walled cylindrical parts are one of the common parts in chemical machinery, aviation, aerospace and other products, and are often used as containers or product shells. Such parts will have requirements such as stiffness, strength, and corrosion resistance. For large-scale thin-walled cylindrical parts in aviation and aerospace, there are also requirements for weight reduction. Especially for large-sized (diameter greater than 500mm) and thin-walled (wall thickness less than 10mm) parts, the blank is usually welded or spinning, which has large deformation, poor precision, and large dispersion of deformation, which is irregular to find. The clamping method and tooling of...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23Q3/06

Inventor 郝红武

Owner XIAN AERONAUTICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com