Patents

Literature

468 results about "Collaborative robotics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

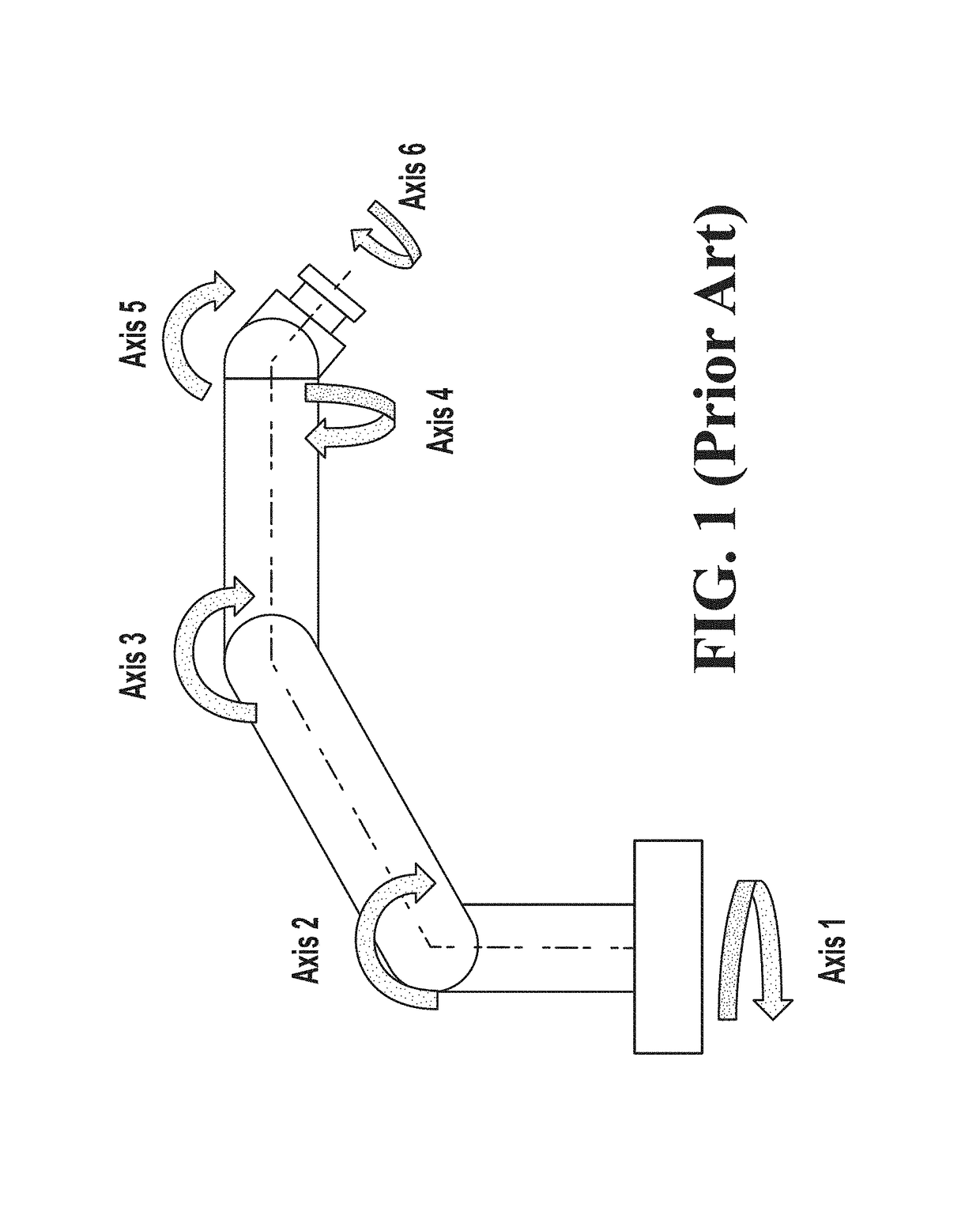

A collaborative robot is a robot designed to work in a common area with the operator on a production line. It incorporates security functions (sensors, cameras, etc.) to eliminate the installation of a grid enclosure and to make human-robot interactions more fluid. Indeed, those machines are able to work side by side with operators safely.

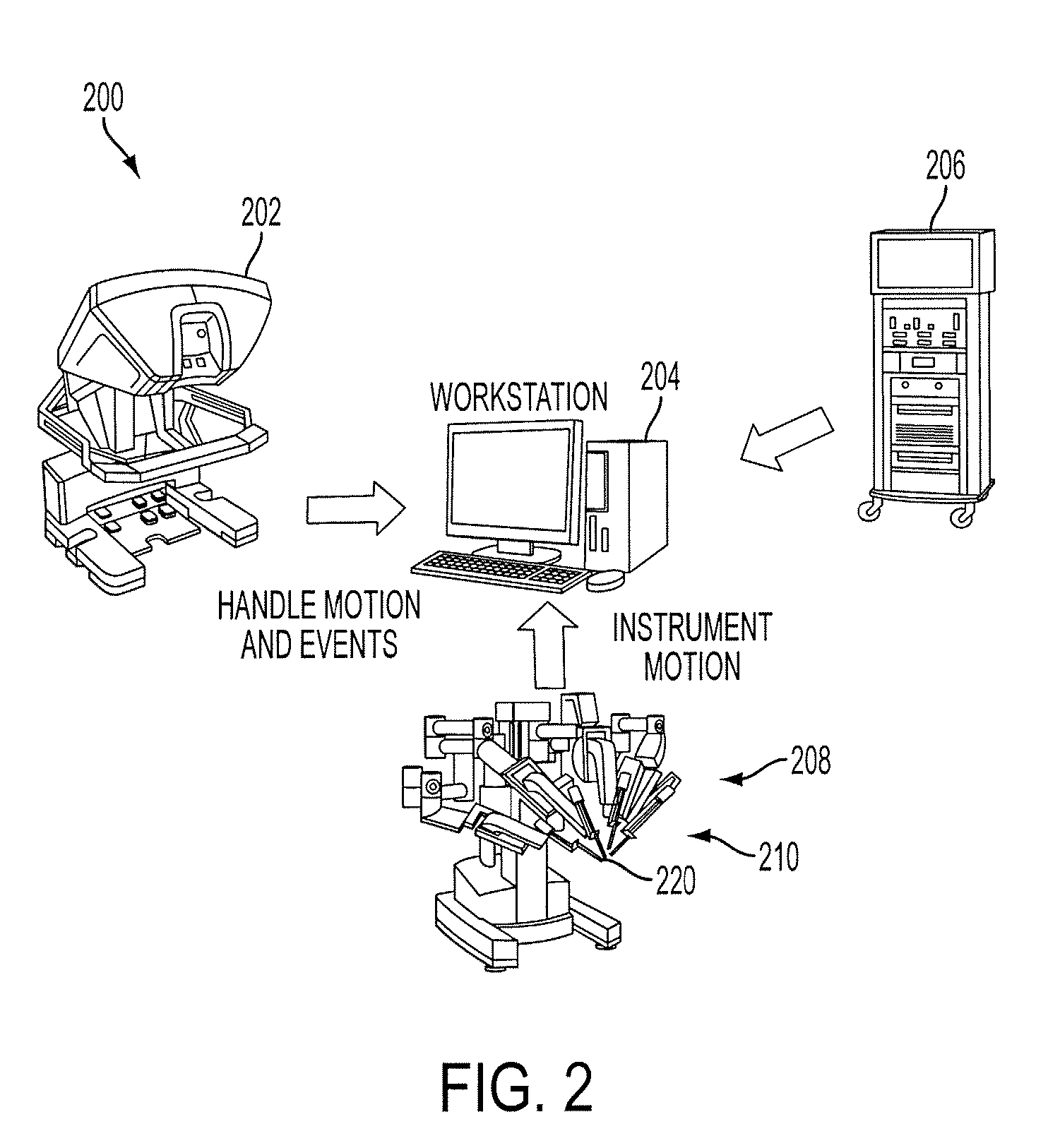

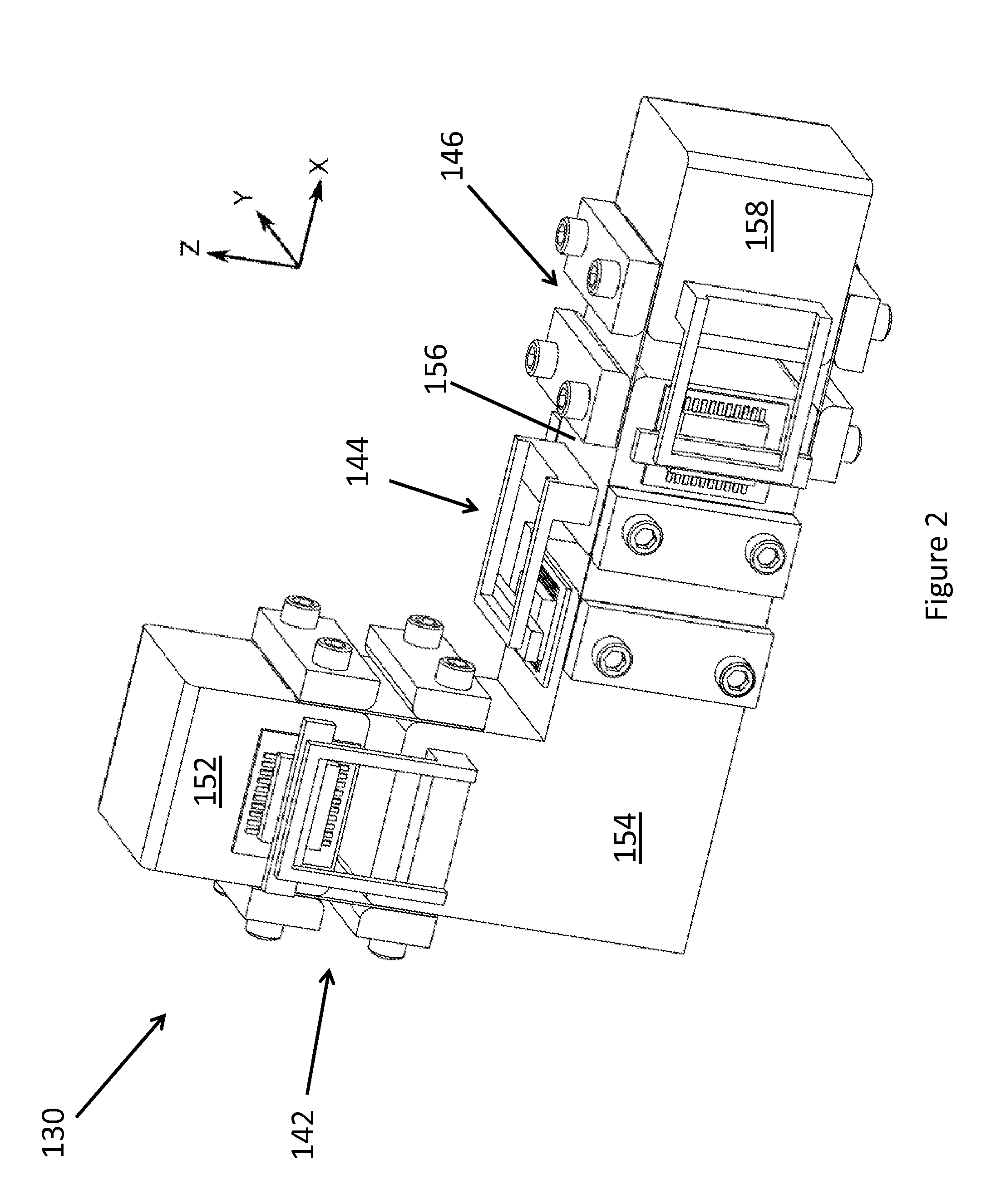

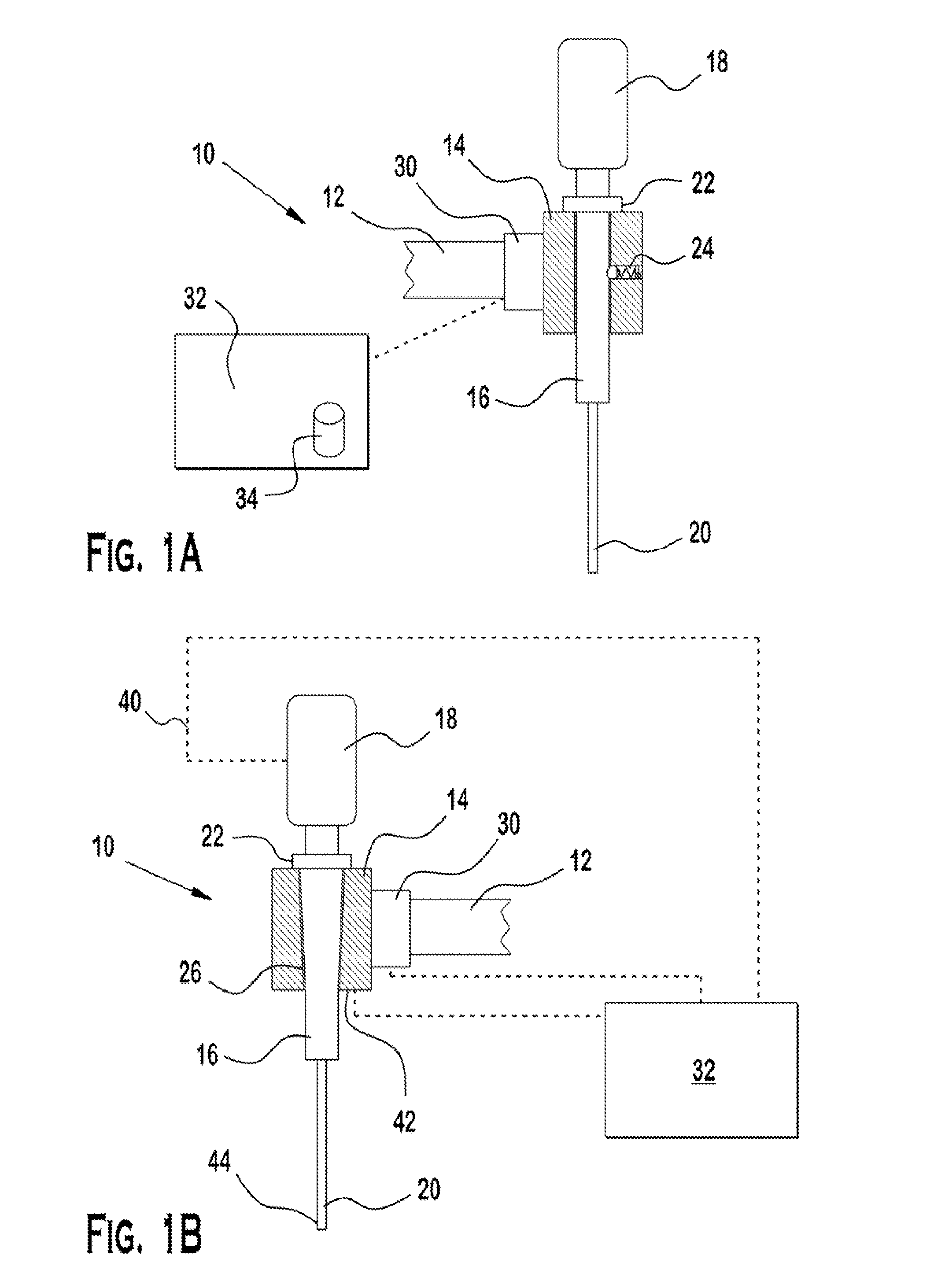

Tool exchange interface and control algorithm for cooperative surgical robots

A system and method for tool exchange during surgery for cooperatively controlled robots comprises a tool holder for receiving a surgical tool adapted to be held by a robot and a surgeon, a tool holding element for constraining downward motion of the tool while allowing low force removal of the surgical tool from the holder, a first sensor for detecting if the surgical tool is docked within the tool holder, and a selector for automatically selecting different movements or actions of the tool holder to be performed based upon information detected by the first sensor. The system and method of the present invention provides an advantage to an often slow moving cooperative robot, by increasing the speed by which the tool holder may move in the direction away from the patient.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

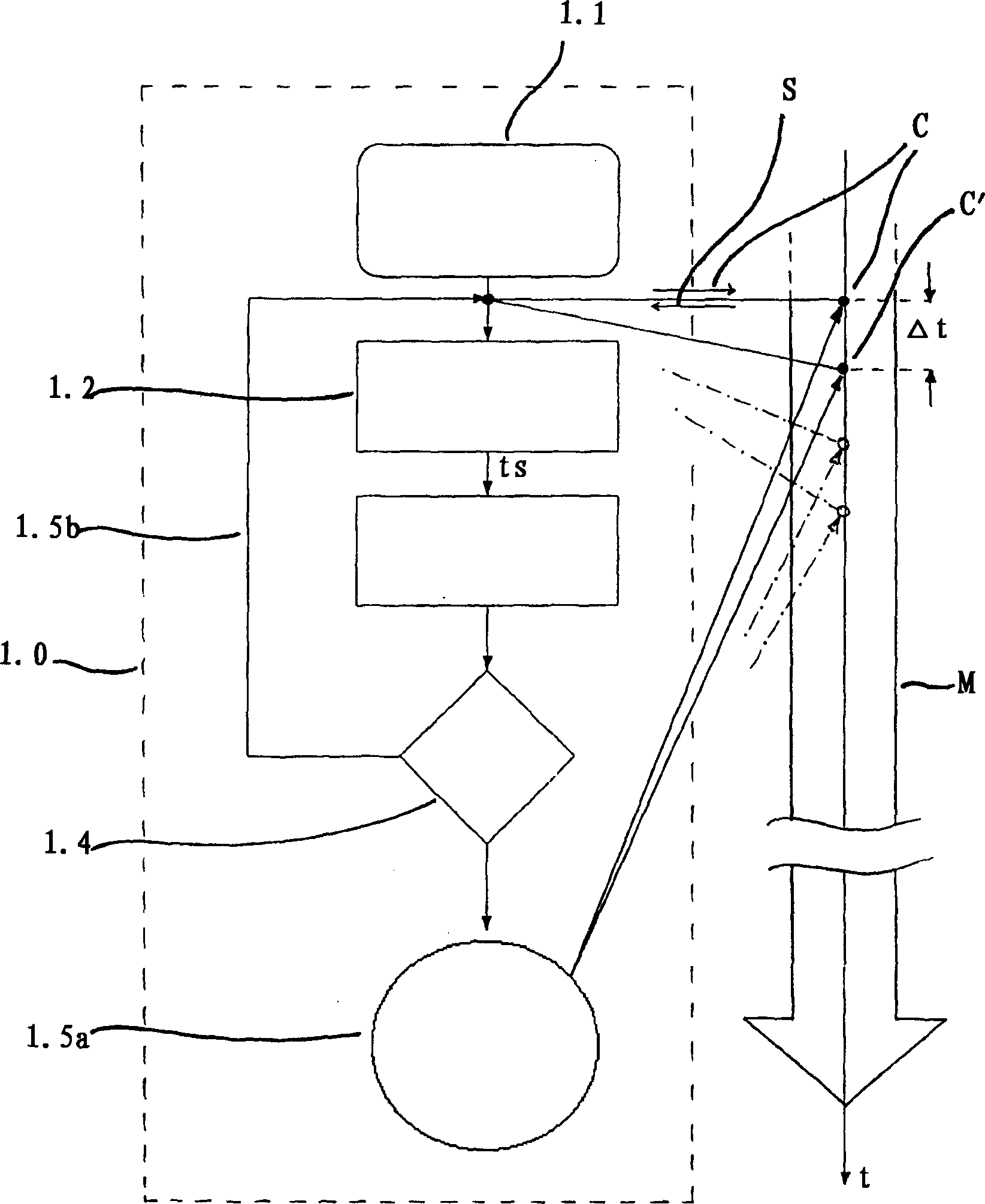

Method for preventing and device for controlling colliding between cooperated manipulators

InactiveCN1461693ASafety stopShort stop timeProgramme controlProgramme-controlled manipulatorEngineeringManipulator

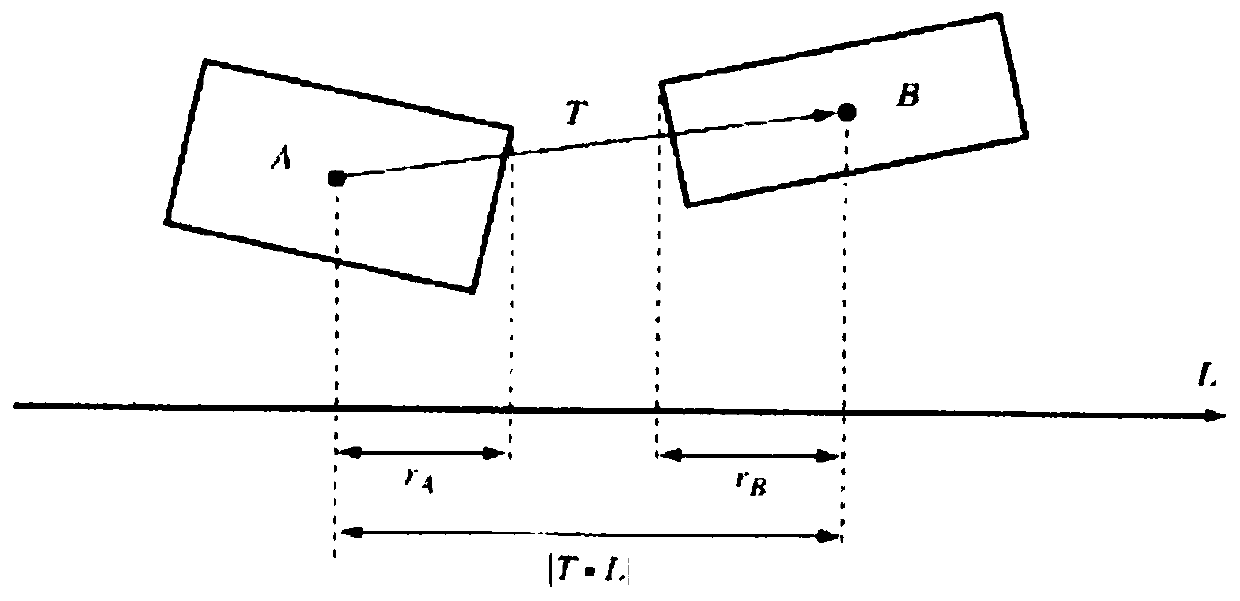

A method of avoiding collisions between a robot and at least one other object, e.g. another robot is disclosed in which the user does not need to make any provisions in a robot program for avoiding collisions, e.g. defining common work-areas. Furthermore, the inventive method allows for automatic configuration of the workcell from a collision avoidance standpoint. It determines automatically which components have potential collisions with which other components. Since the inventive method is based on predicting the configurations of the moving components over a period of time sufficient enough to allow the machines to stop safely and checks for interference, a priori knowledge of trajectories is not required. If a collision is predicted the machines are commanded to a stop on or off their paths. In this way the inventive collision avoidance method can also be used as a safeguard with other explicit methods.

Owner:KUKA ROBOTER

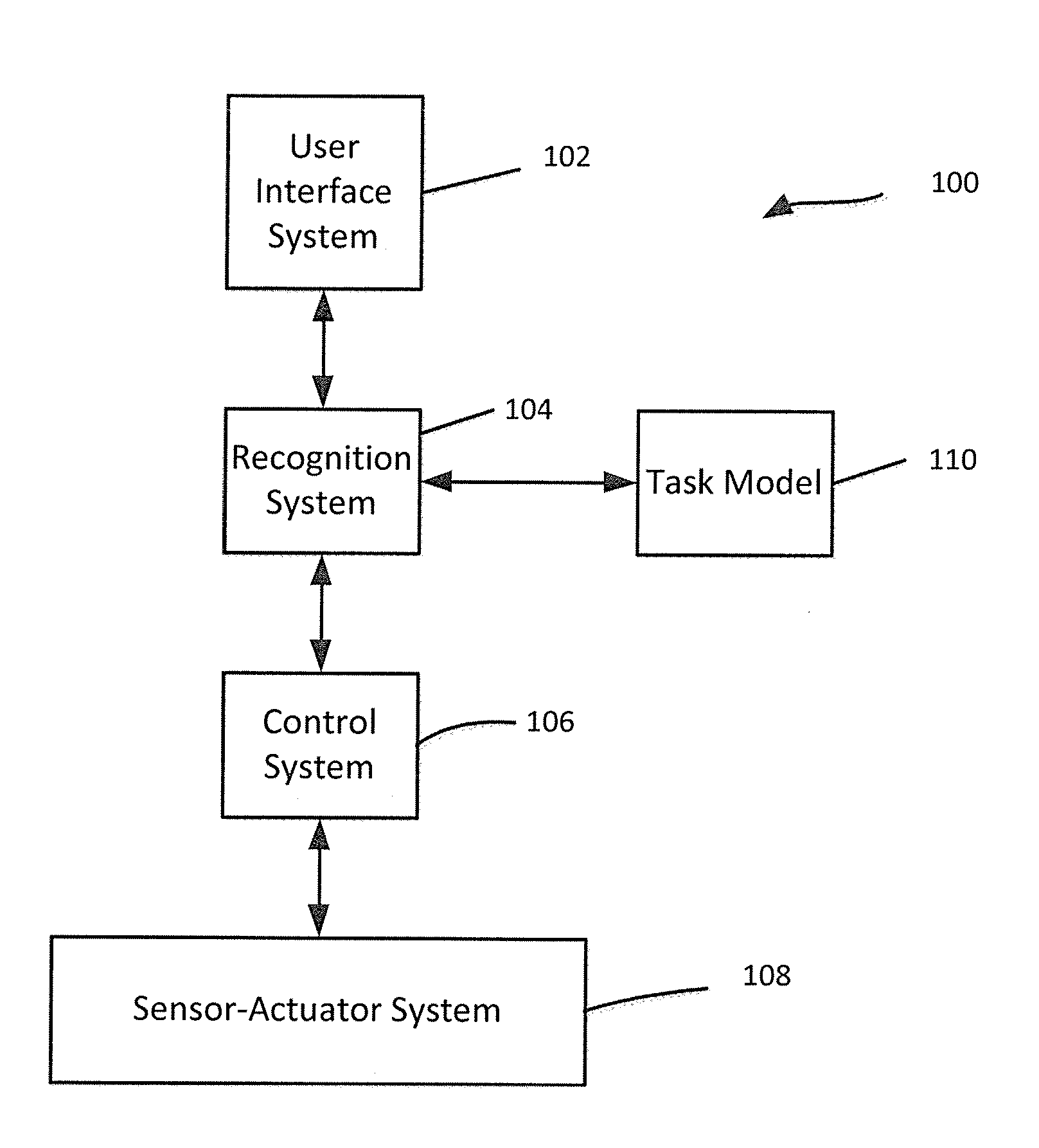

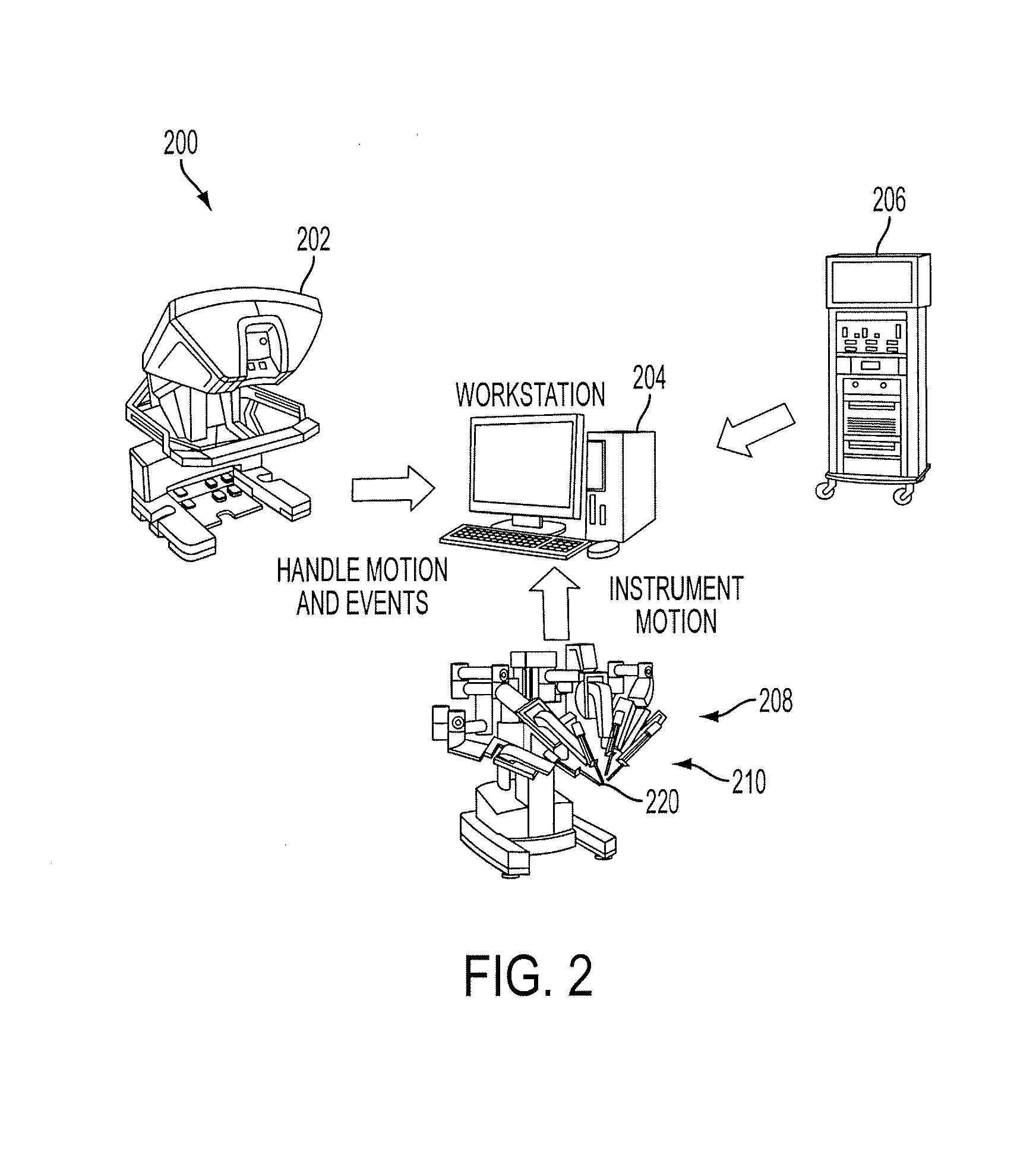

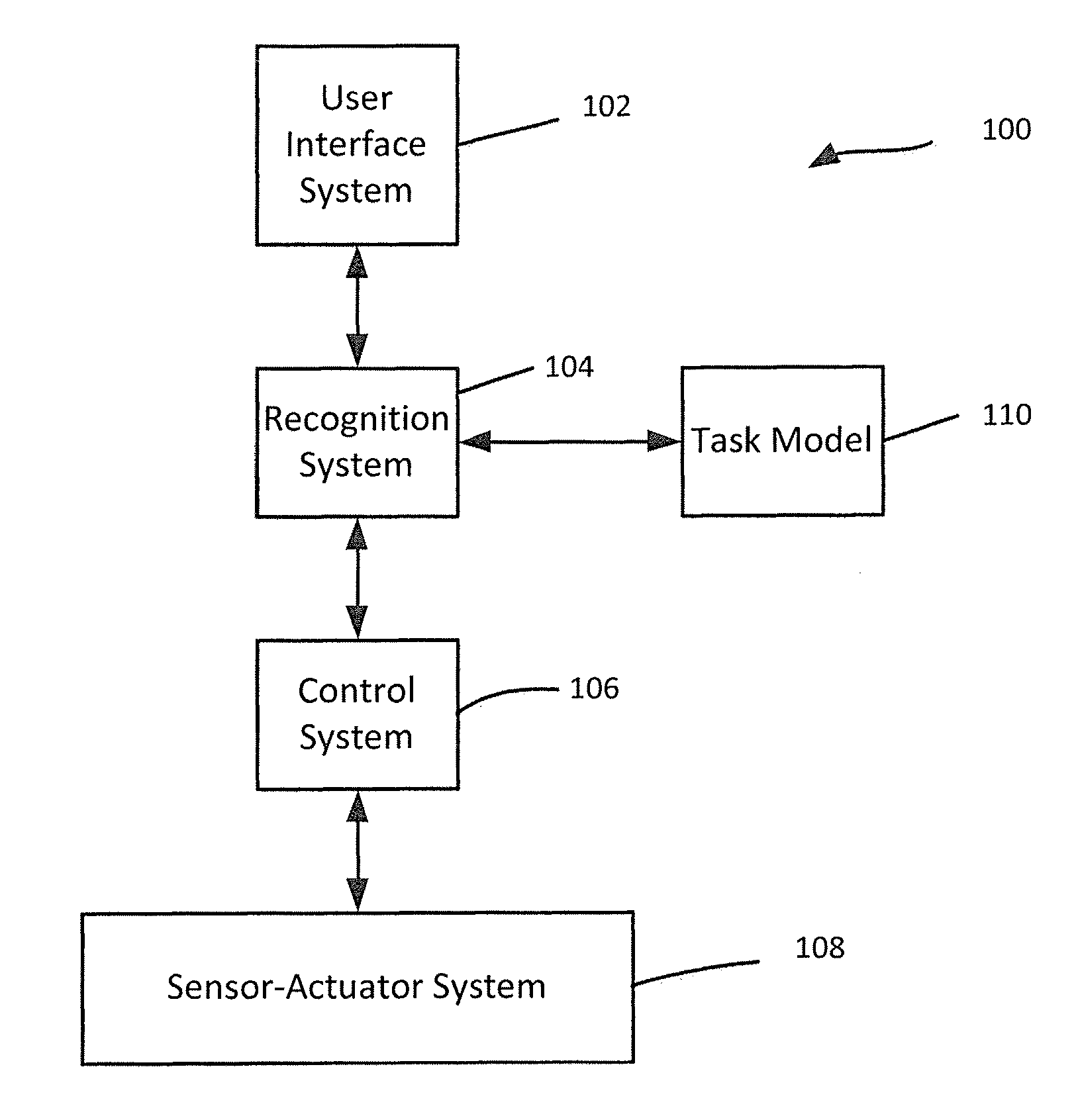

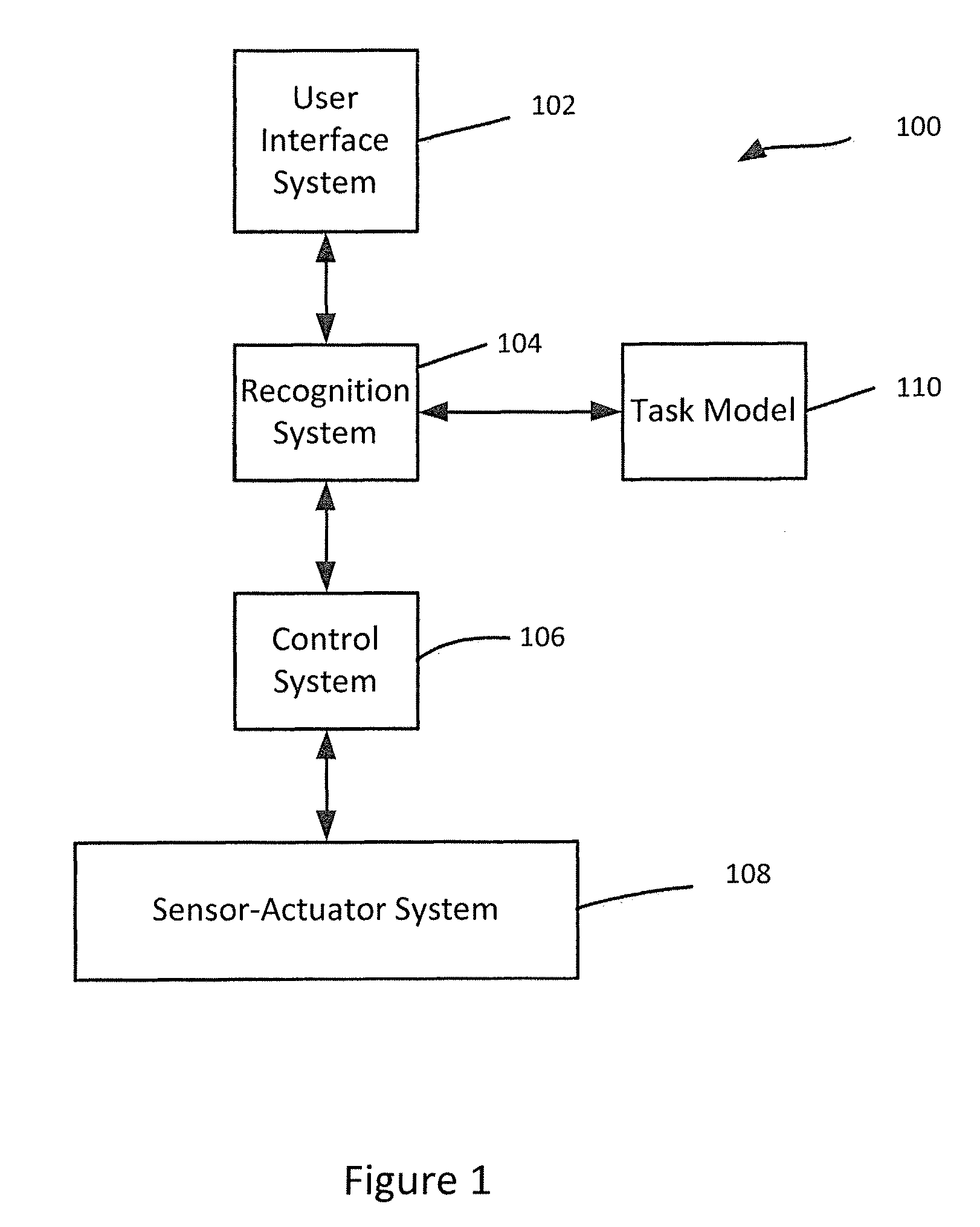

Human-machine collaborative robotic systems

ActiveUS20130218340A1Programme-controlled manipulatorMechanical/radiation/invasive therapiesRobotic systemsControl system

A semi-automatic, interactive robotic system for performing and / or simulating a multi-step task includes a user interface system, a recognition system adapted to communicate with the user interface system, a control system adapted to communicate with the recognition system, and a sensor-actuator system adapted to communicate with the control system. The recognition system is configured to recognize actions taken by a user while the user operates the user interface system and to selectively instruct the control system to cause the sensor-actuator system to perform, and / or simulate, one of an automatic step, a semi-automatic step or direct step of the multi-step task based on the recognized actions and a task model of the multi-step task.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

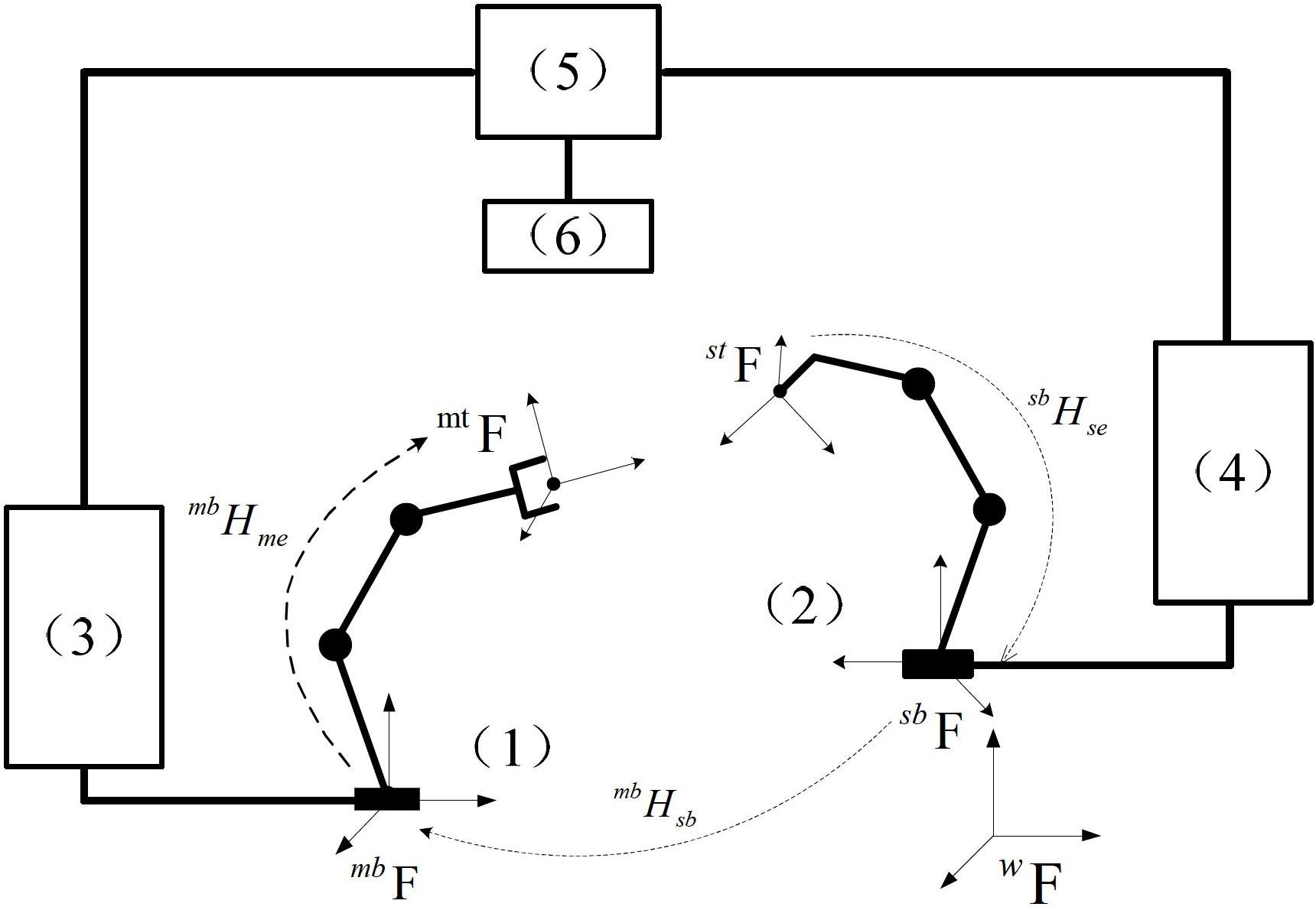

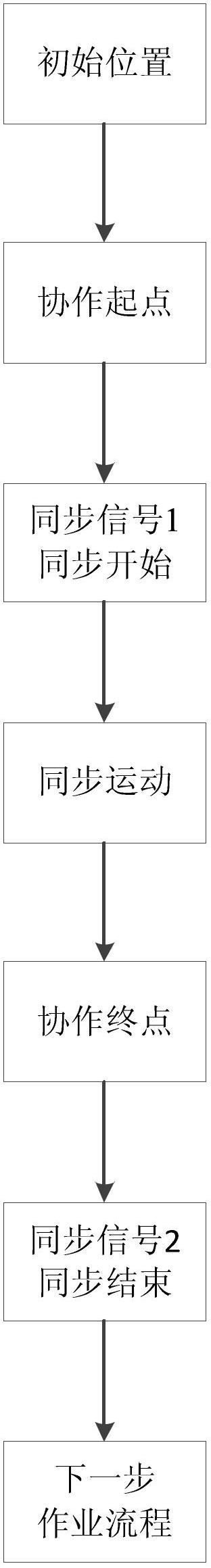

Track teaching and planning method of master-slave mode multi-robot cooperative system

InactiveCN102662350AReduce difficultyConvenient teachingNumerical controlMultirobot systemsControl engineering

The invention discloses a track teaching and planning method of a master-slave mode multi-robot cooperative system. The method comprises the steps of: classifying the cooperative movement of the multi-robot system into a coupling movement and a superposition movement according to the relative movement modes between the tail end poses of the cooperative robots, and deducing the constraint relation between the tail end poses of the robots according to the two relative movement modes; and determining the track teaching steps and teaching information of the multi-robot cooperation according to the constraint relation, and converting the cooperative movement tack planning problem of the multi-robot cooperative system into Cartesian space track planning problem of a plurality of single robots so as to finish the track teaching and planning task of the multi-robot cooperative system. The track teaching and planning method disclosed by the invention can be applied in multiple service processes meeting the movement constrain, for example, partial cooperative movement in complex assembly task, carrying of large-size workpiece and non-fixture welding process, and the like, so that the track teaching and planning method has an extensive application prospect.

Owner:SOUTHEAST UNIV

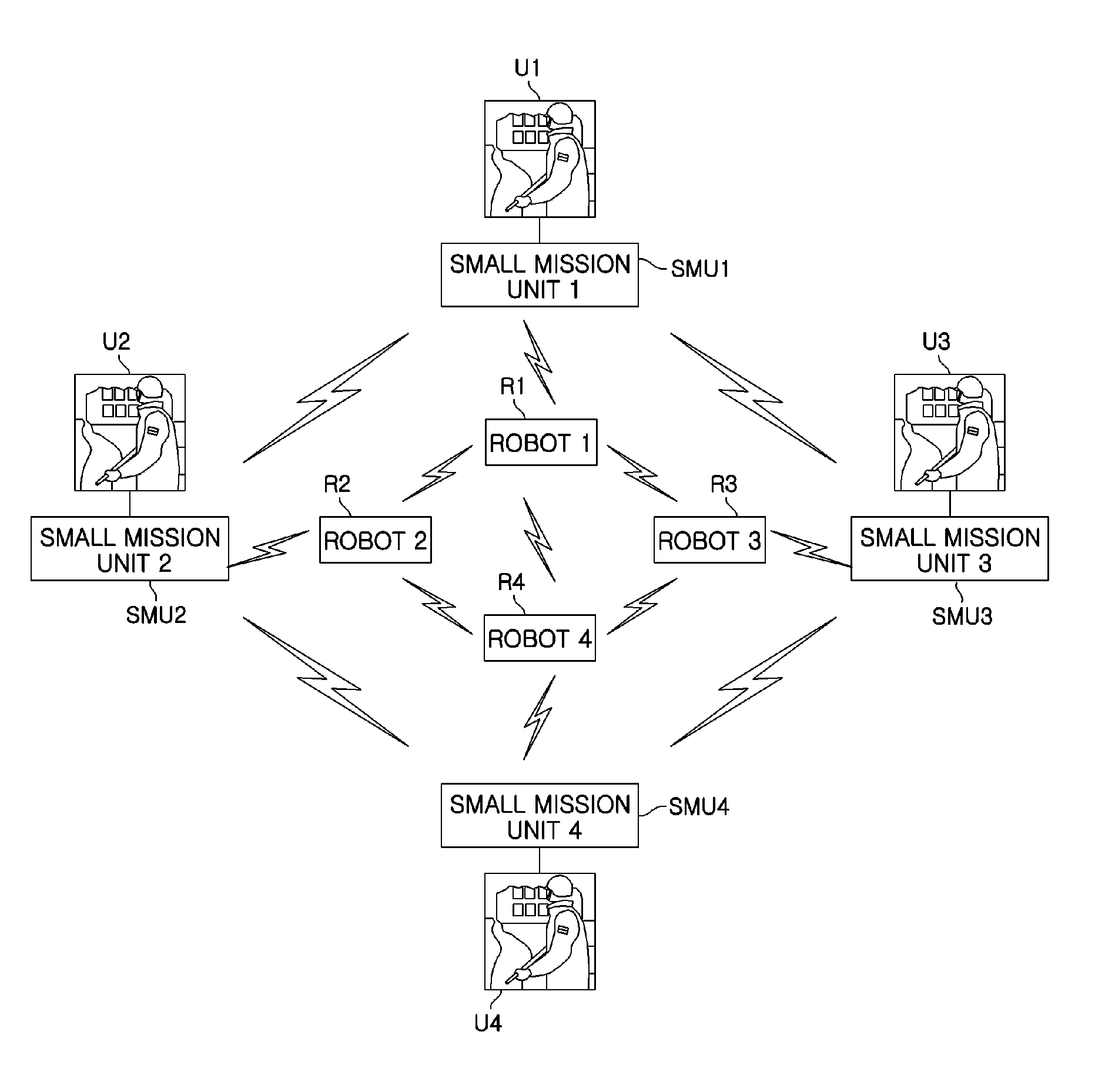

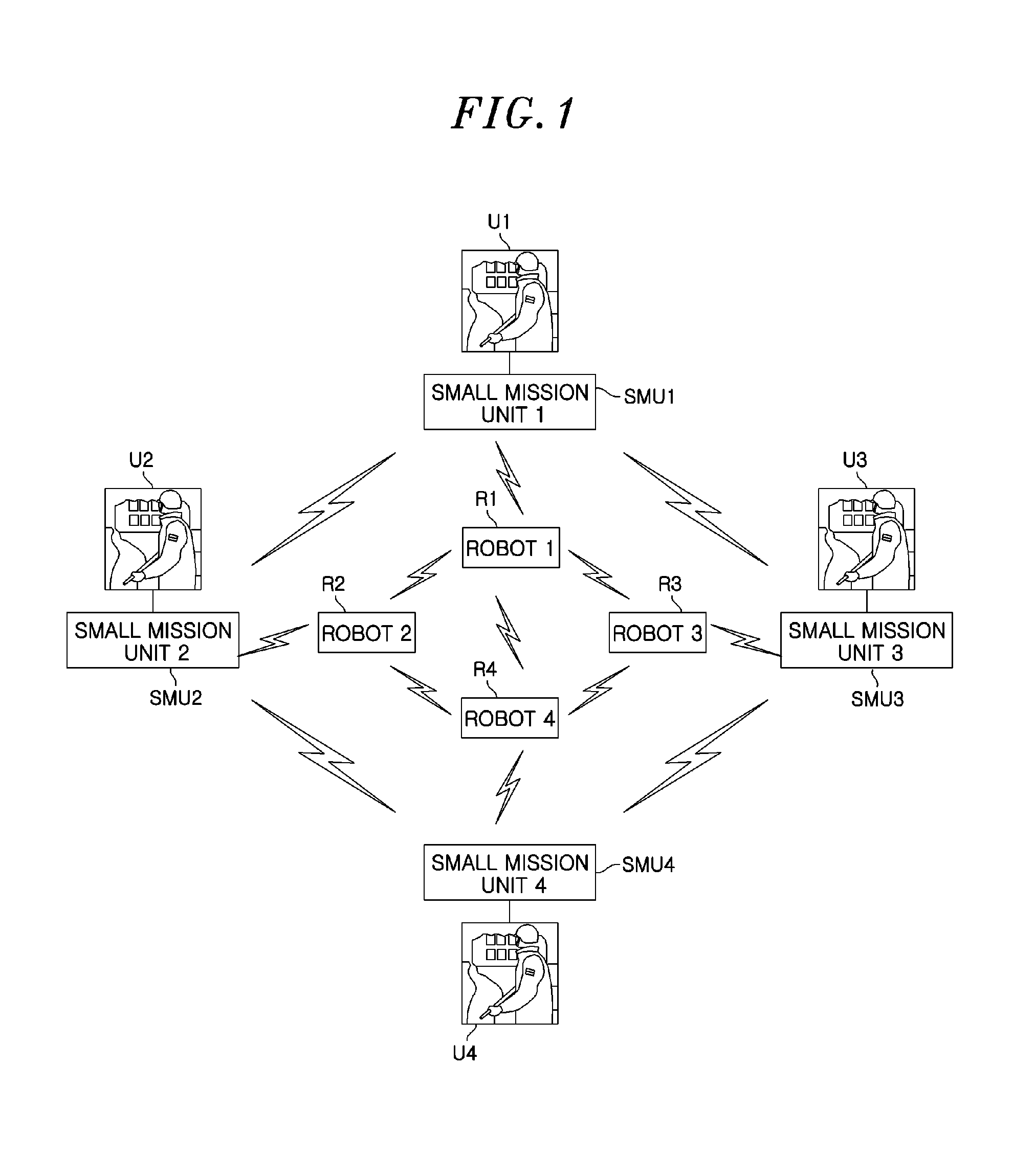

Method and system for controlling multiple small robots

InactiveUS20130123980A1Effectively fulfillProgramme-controlled manipulatorComputer controlSimulationRobot

A method for controlling multiple small robots includes generating cooperation missions to be performed through cooperation with cooperation robots according to the manipulation of a main operator, generating an operator recruiting message including mission outline information for the cooperation missions, transmitting the operator recruiting message to neighboring robot mission units. The method further includes receiving participation information including robot situation information from at least one of the neighboring robot mission units, which participates in the cooperation, assigning divided missions to operators participating in the cooperation based on the robot situation information, and transmitting the assigned divided missions to the at least one of the neighboring robot mission units participating in the cooperation.

Owner:ELECTRONICS & TELECOMM RES INST

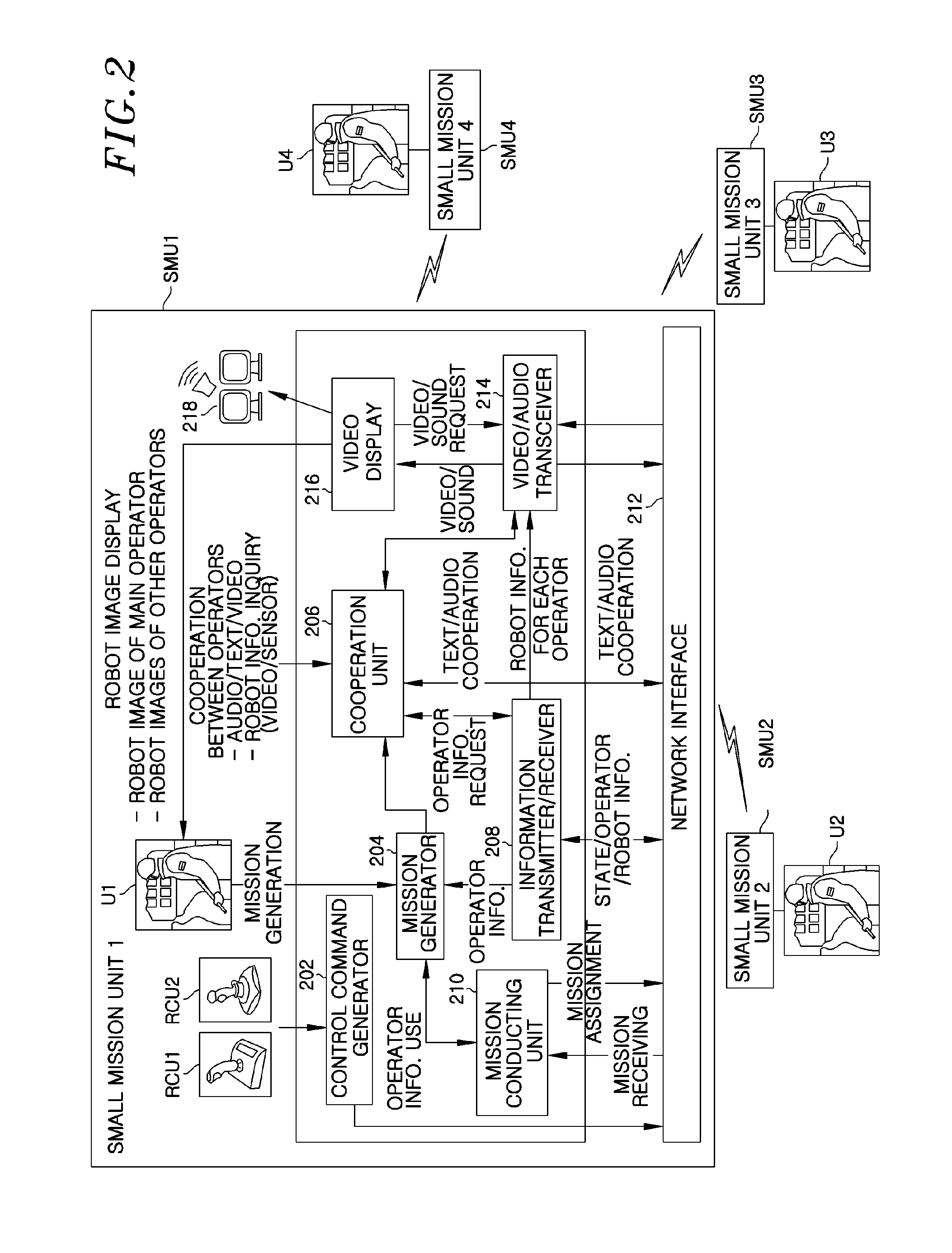

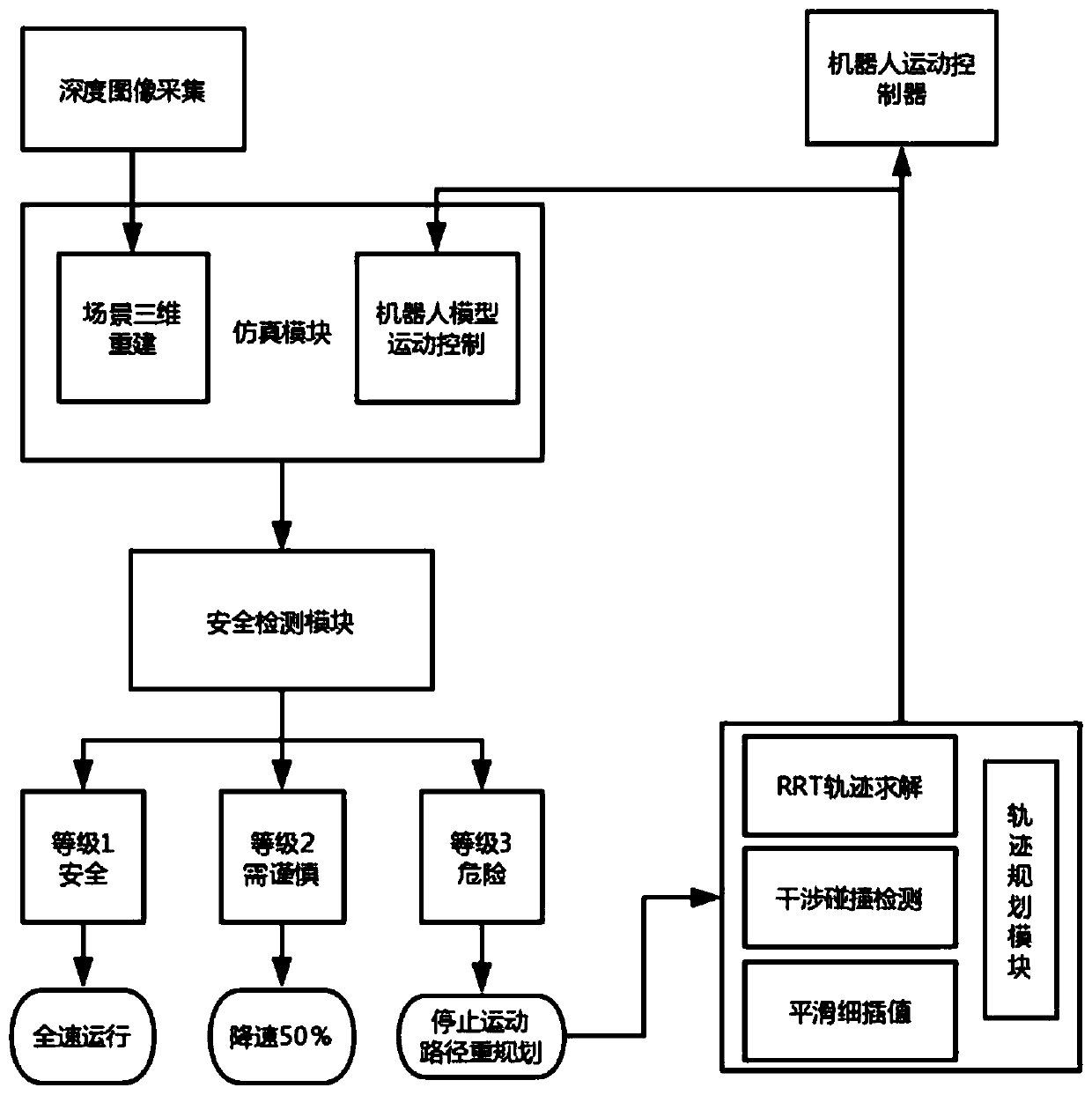

Collaborative robot safety control method based on vision

InactiveCN109822579AEnsure safetyImprove versatilityProgramme-controlled manipulatorSafety controlSimulation

The invention discloses a collaborative robot safety control method based on vision. According to the collaborative robot safety control method based on vision, a deep vision three-dimensional reconstruction technology and a trajectory planning technology are combined, real-time three-dimensional reconstruction is carried out on a man-machine collaboration scene in a simulation environment, and obstacle avoidance planning is carried out according to a self model of a robot furthermore. With the collaborative robot safety control method based on vision, the collaborative operation robot can have the ability of sensing scenes, dangerous collision in man-machine collaborative operation is avoided, and safety control over the collaborative robot is achieved.

Owner:JIANGSU ASK TECH +1

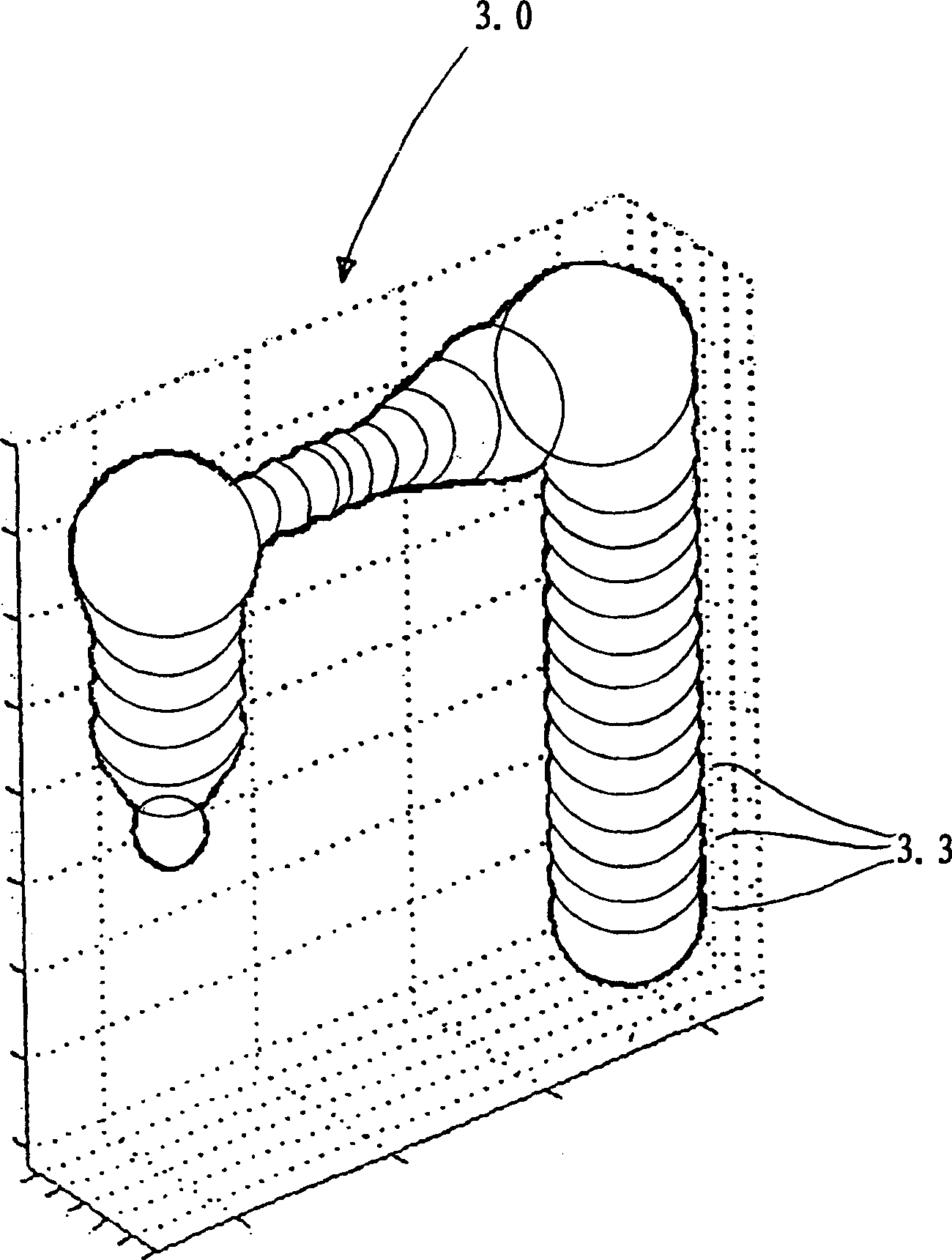

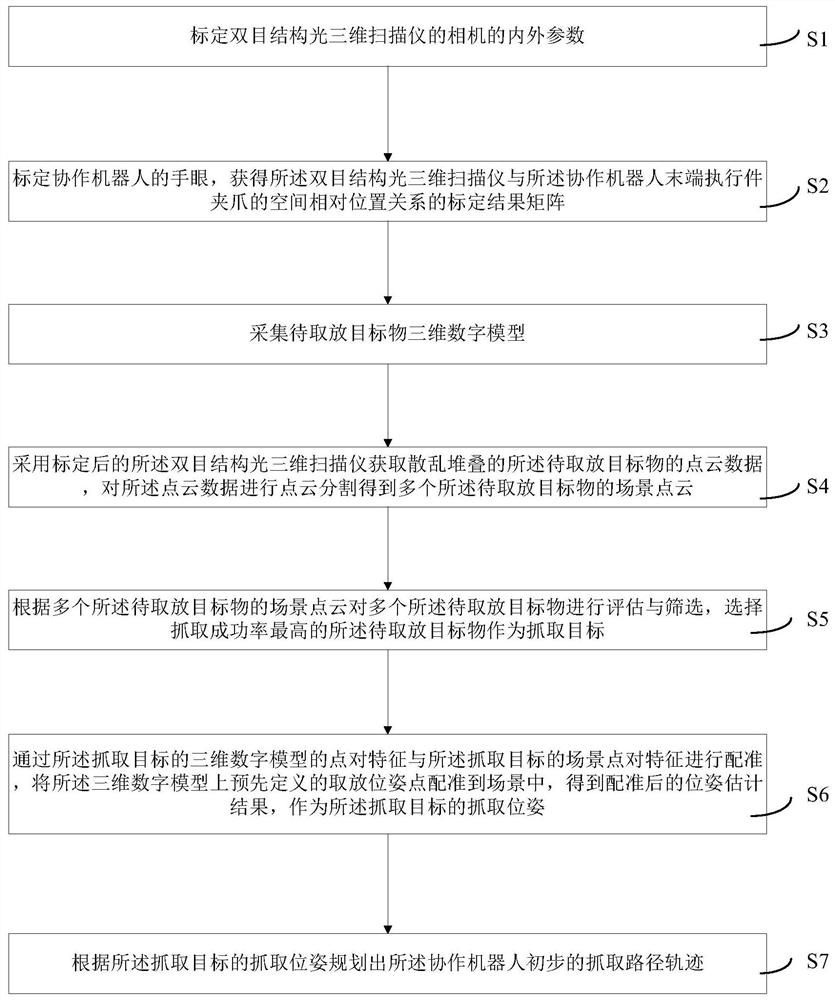

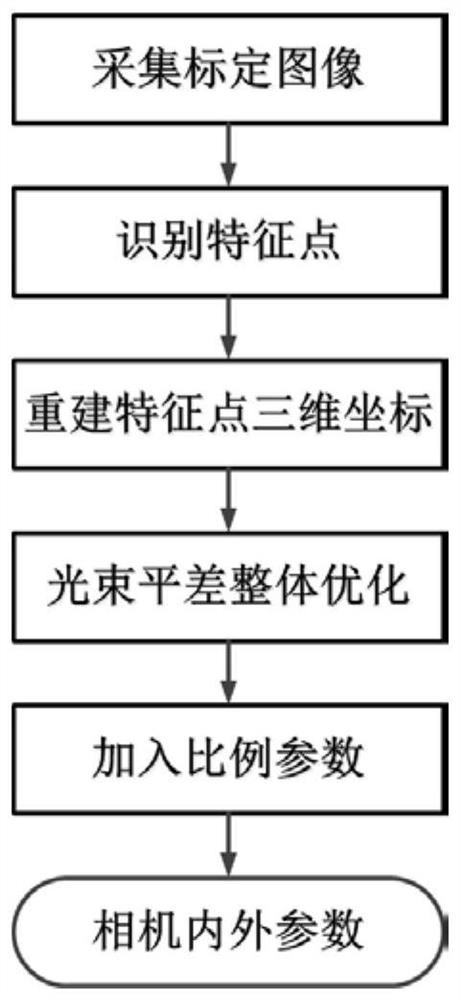

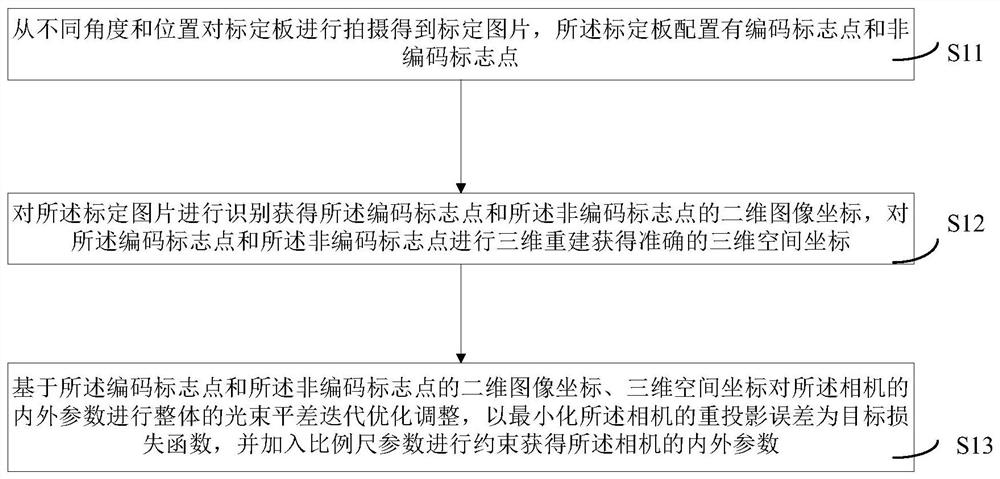

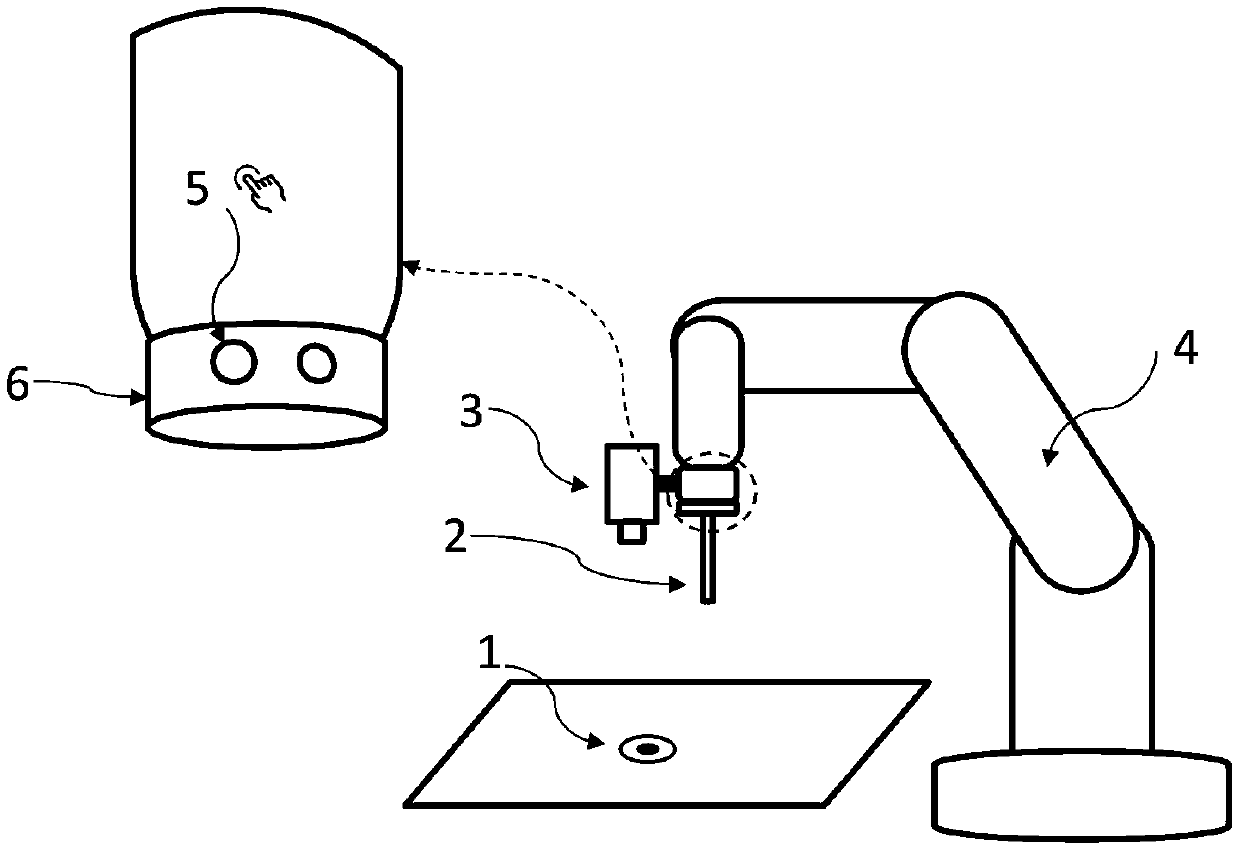

Visual 3D taking and placing method and system based on cooperative robot

ActiveCN112476434AImprove the quality of acquisitionGet fastProgramme-controlled manipulatorImage analysisPattern recognitionComputer graphics (images)

The invention provides a visual 3D taking and placing method and system based on a cooperative robot. The method comprises the steps that internal and external parameters of a camera of a binocular structured light three-dimensional scanner are calibrated; the hands and eyes of the cooperative robot are calibrated, and a calibration result matrix is obtained; a three-dimensional digital model of to-be-taken-and-placed target objects is collected; the calibrated binocular structured light three-dimensional scanner is adopted to obtain point cloud data of the to-be-taken-and-placed target objects which are stacked in a scattered mode, and the point cloud is segmented to obtain scene point clouds of the multiple to-be-taken-and-placed target objects; the to-be-taken-and-placed target object with the highest grabbing success rate is selected as a grabbing target according to the scene point clouds of the multiple to-be-taken-and-placed target objects; the three-dimensional digital model ofthe grabbing target and scene point pair features are registered, pre-defined taking and placing pose points are registered into a scene, and a registered pose estimation result is obtained and serves as a grabbing pose of the grabbing target; and a preliminary grabbing path track of the cooperative robot is planned. The target object can be accurately recognized, and the grabbing positioning precision is high.

Owner:新拓三维技术(深圳)有限公司

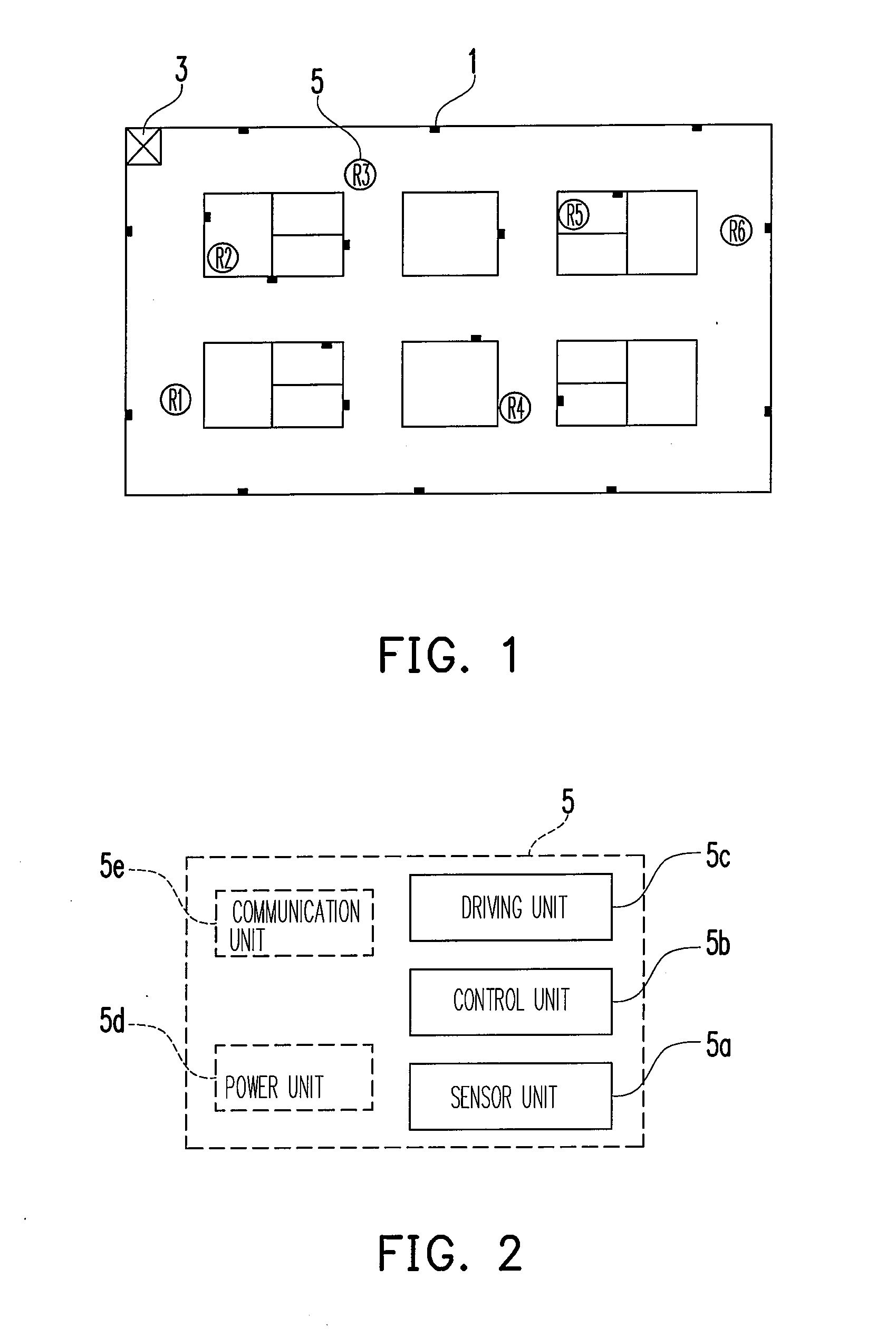

Cooperative robot system and navigation robot system

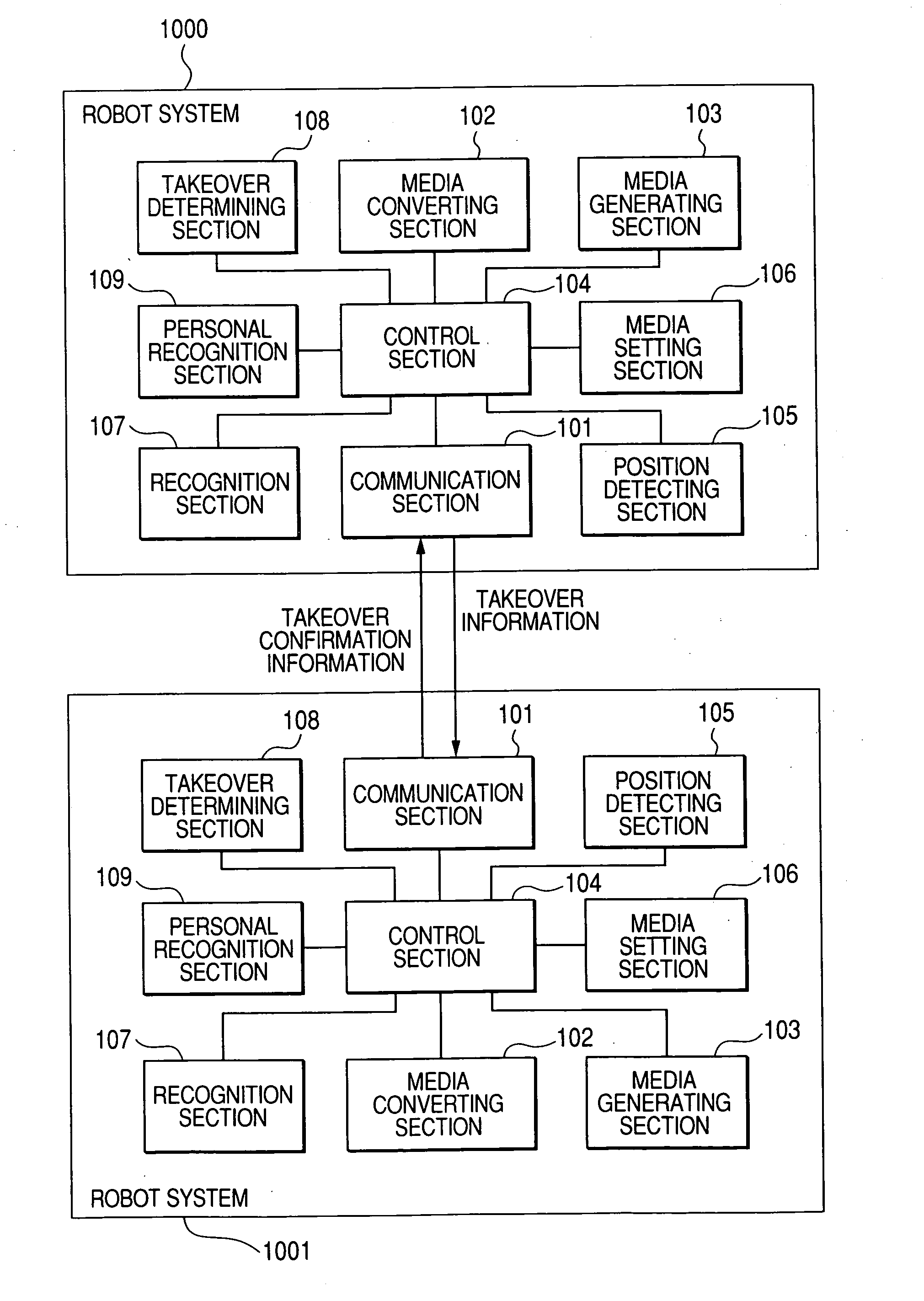

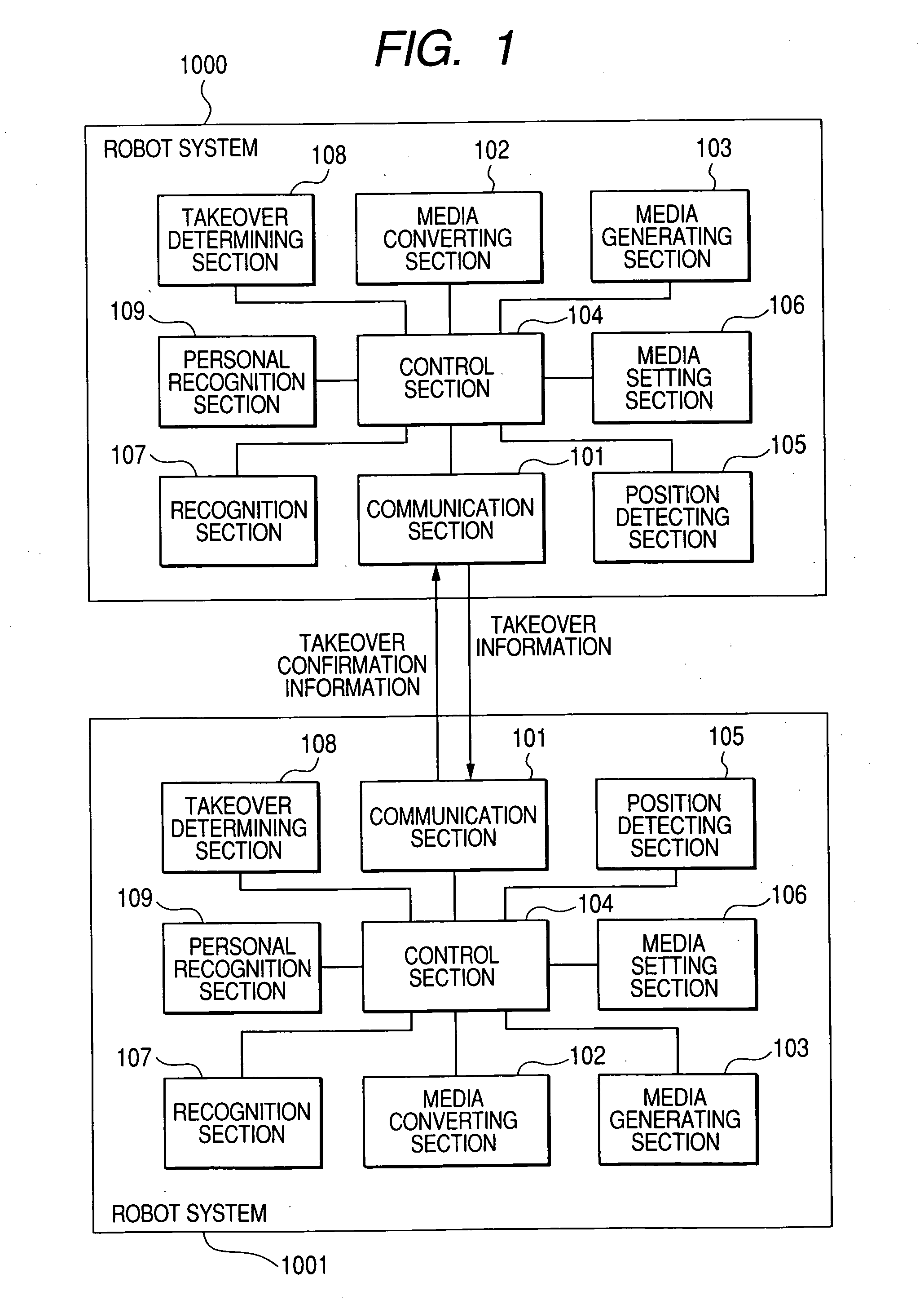

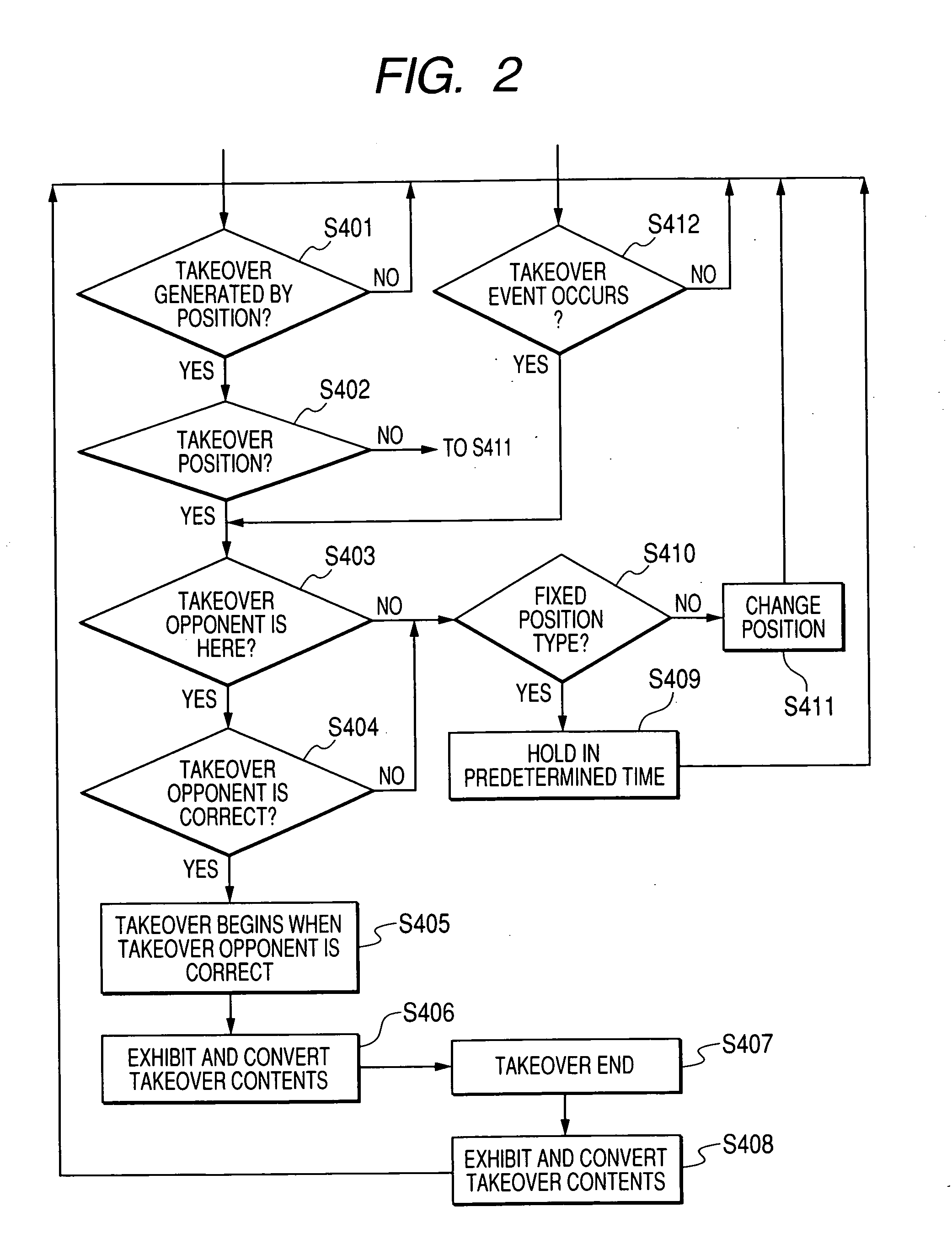

InactiveUS20050113974A1Easily take over task with safeGive safetyProgramme-controlled manipulatorData processing applicationsCo operativeMarine navigation

A cooperative robot system includes a takeover determining section which determines whether or not another robot takes over an executed task, a communication section which transmits a takeover information to the another robot when the takeover determining section determines to take over the executed task, a media converting section which converts the takeover information into at least one of linguistic expression and non-linguistic expression, a media generating section which generates control information which represents a converted result of the media converting section in the linguistic or non-linguistic expression, and a media setting section which exhibits a takeover content of the takeover information represented in at least one the linguistic expression and the non-linguistic expression.

Owner:KK TOSHIBA

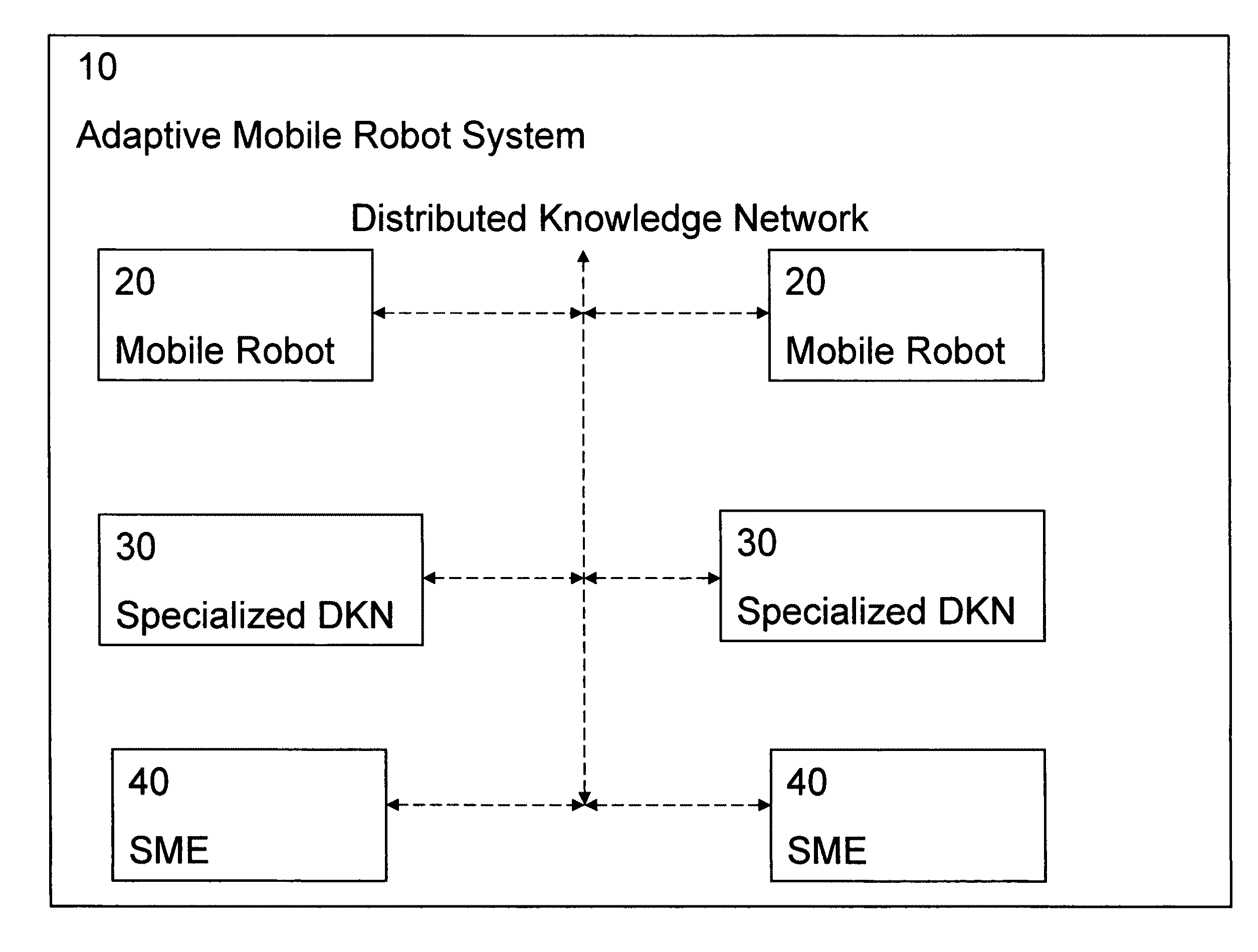

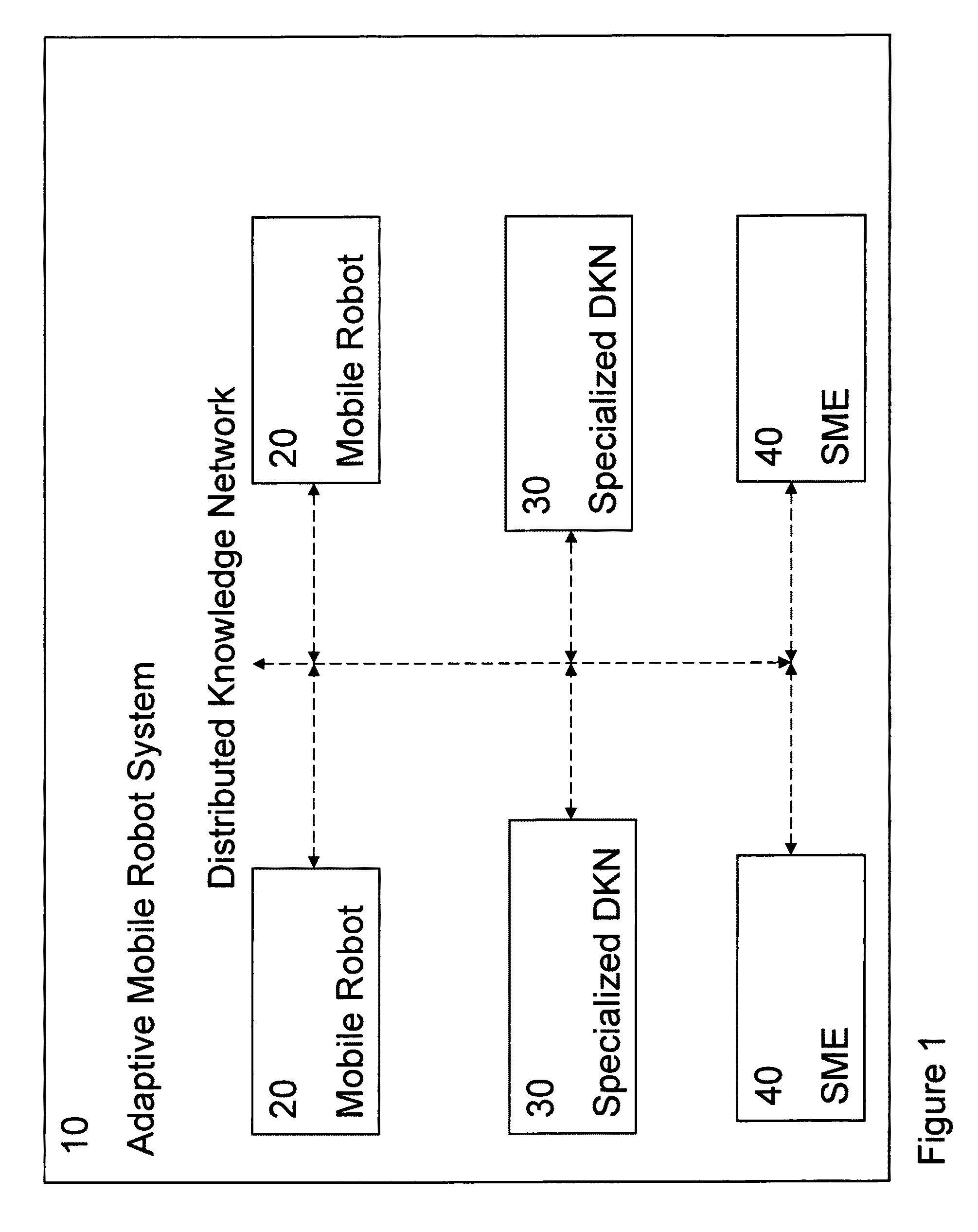

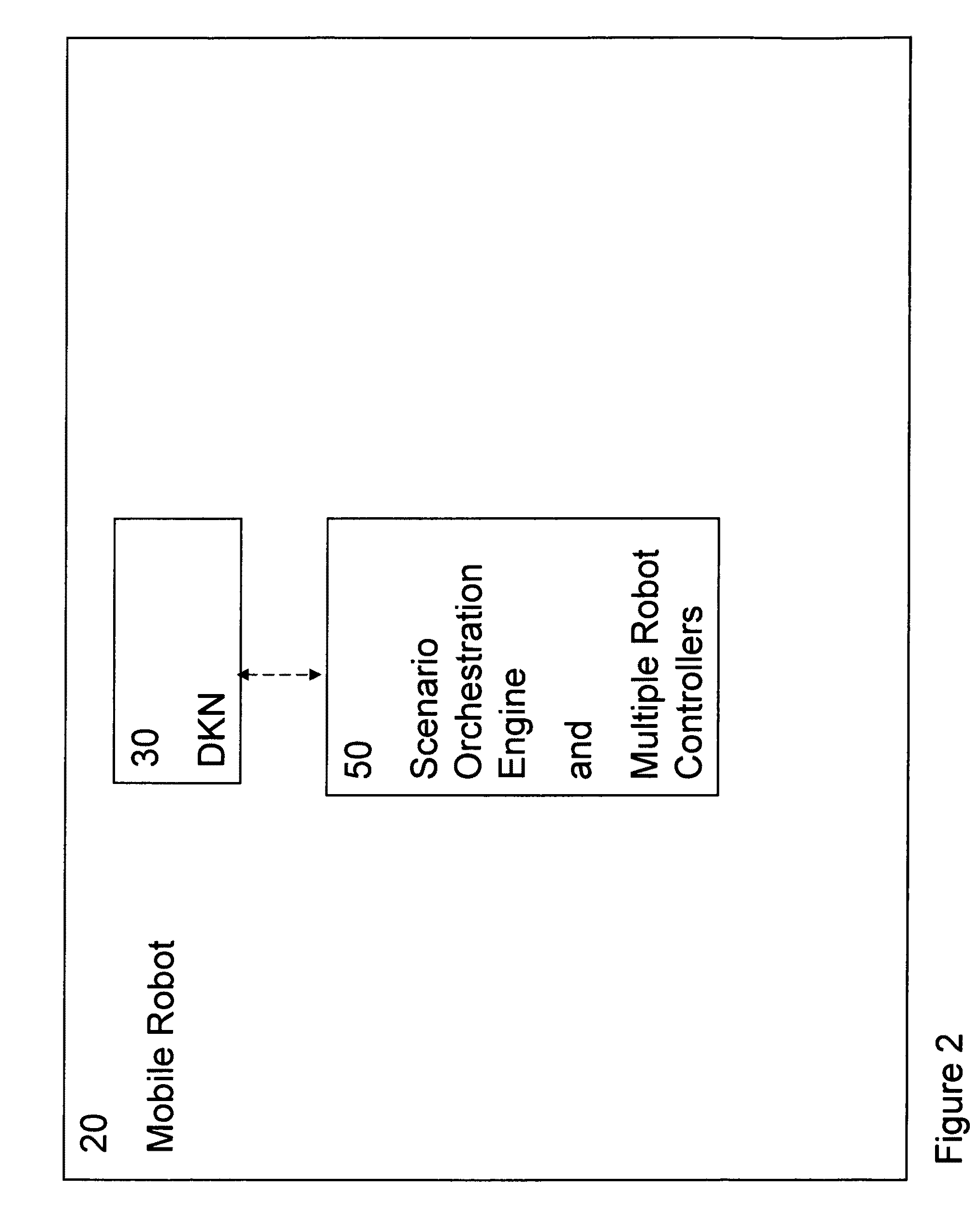

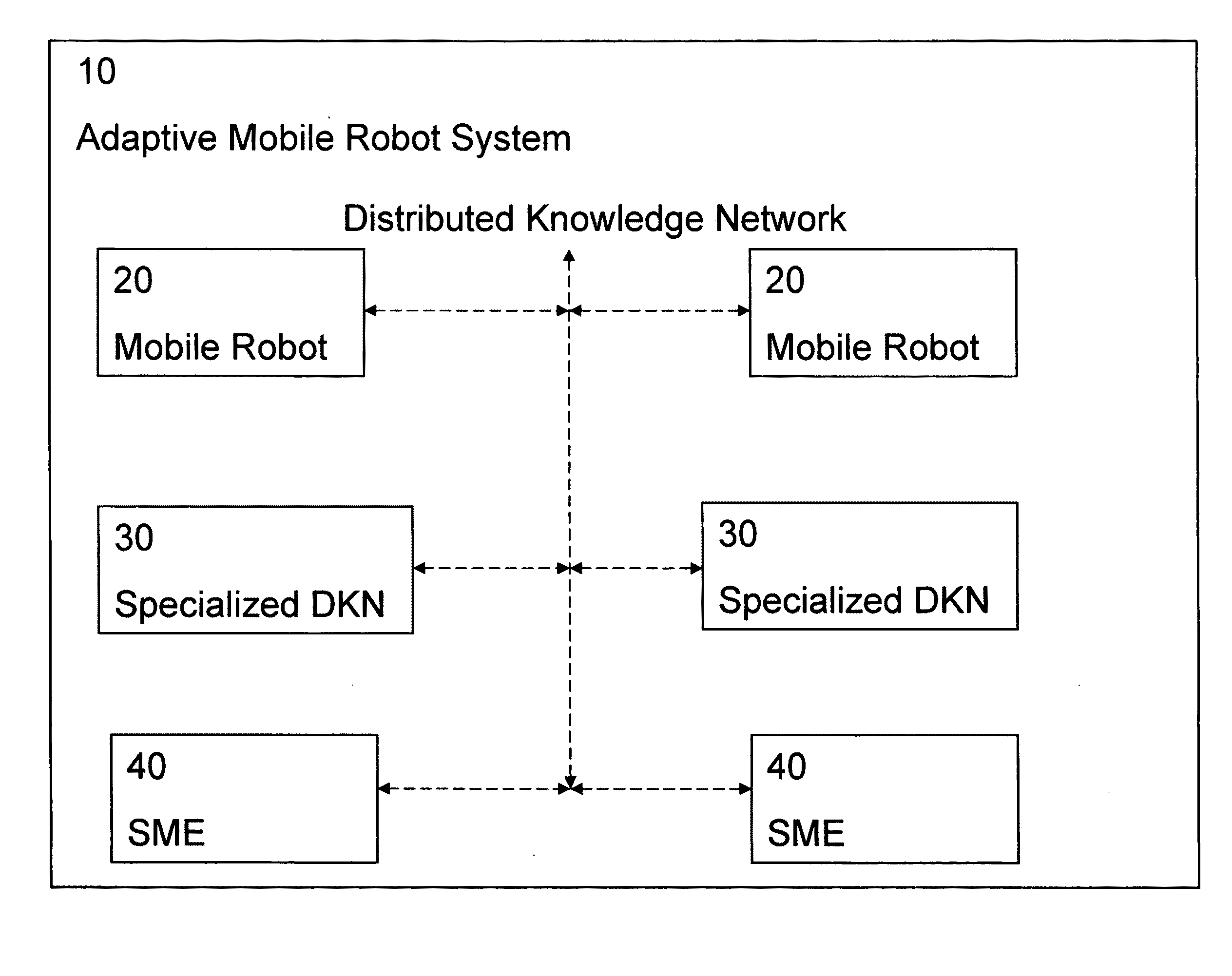

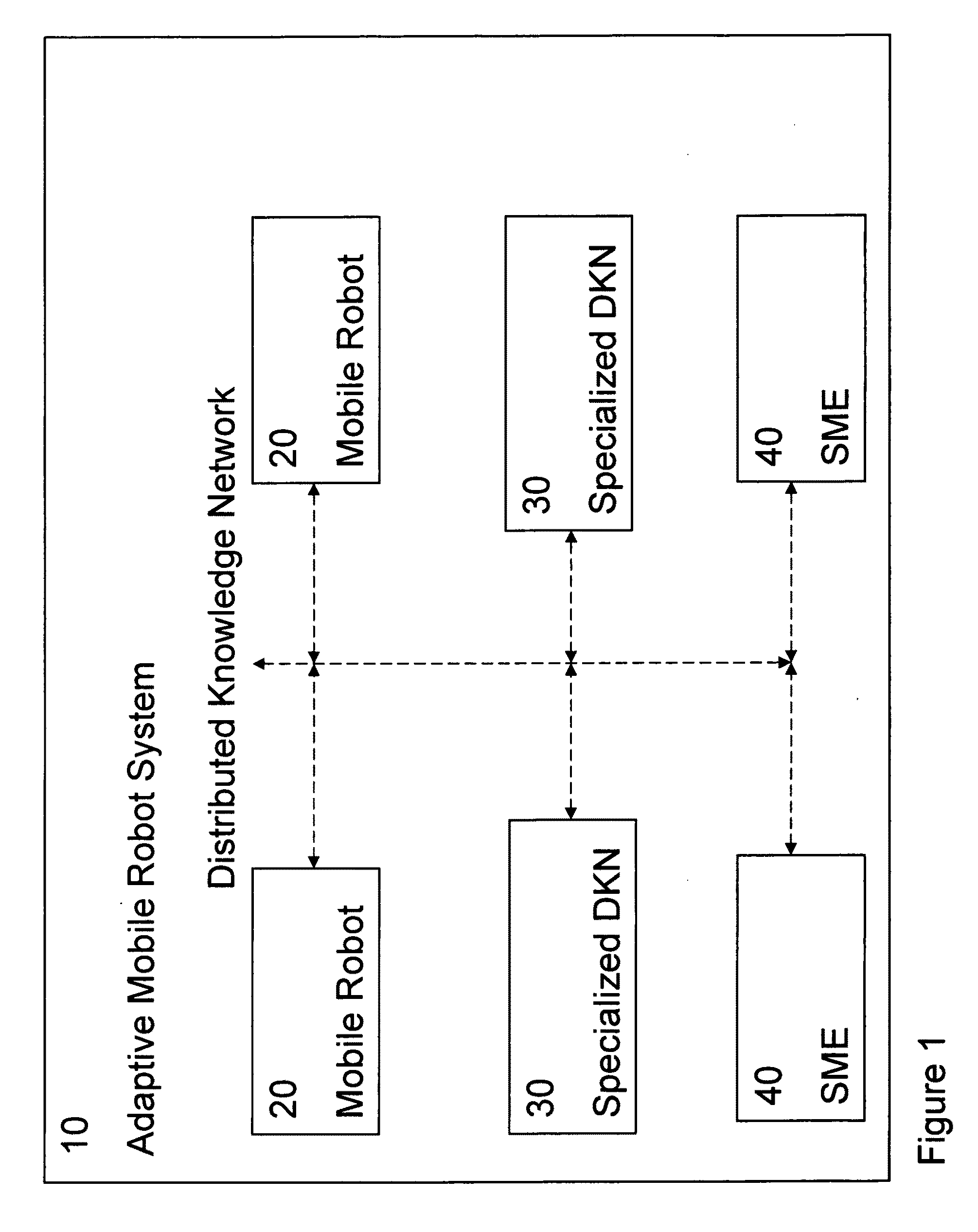

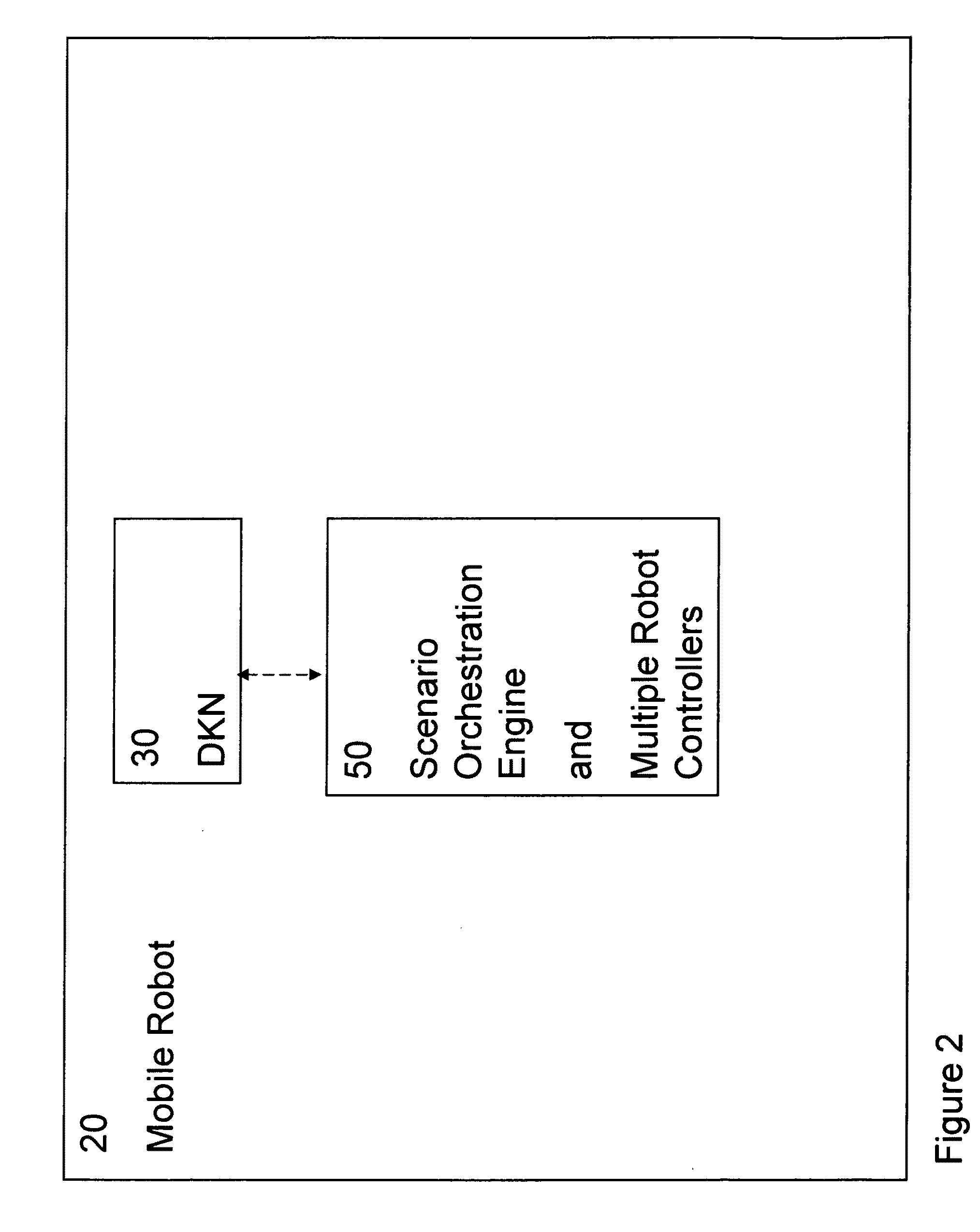

Adaptive mobile robot system with knowledge-driven architecture

Owner:ZHUK YEFIM

Collaborative robot system and method

InactiveUS20160214261A1Enhanced interactionHigh force capabilityProgramme controlProgramme-controlled manipulatorControl theoryRobot locomotion

A system for robot and human collaboration is provided. The system includes a robot having a programmed path for motion of the robot and a controller in communication with the robot. The controller has a processor and tangible, non-transitory memory on which is recorded instructions for an action to take when an unexpected contact between the robot and an object is detected. The controller is programmed to execute the instructions from the memory via the processor when the unexpected contact is detected, causing the robot to stop motion on a programmed path and to enter a push away mode. In the push away mode, the human can apply a push force having a push force direction to command the robot to move in the push force direction.

Owner:GM GLOBAL TECH OPERATIONS LLC

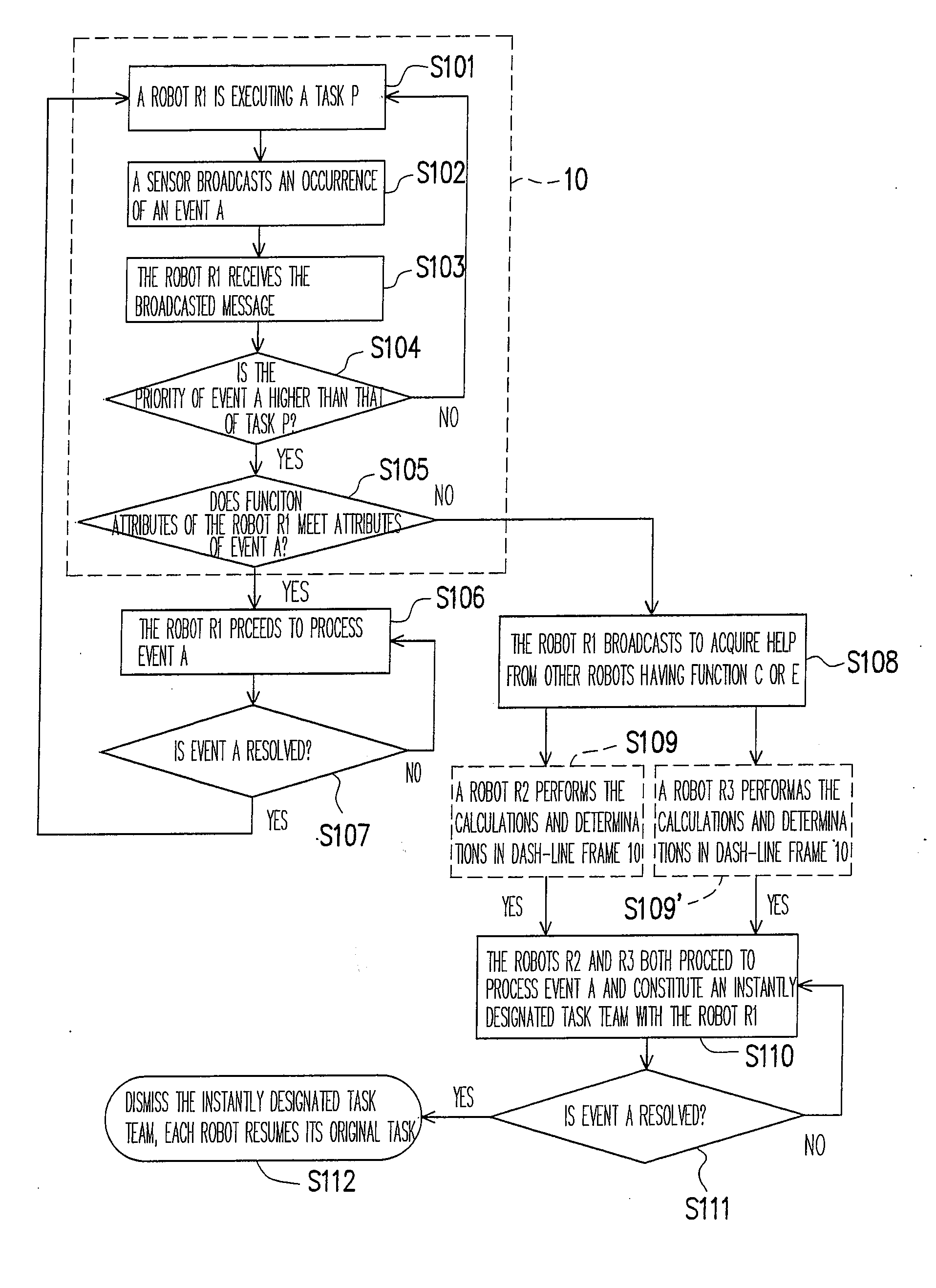

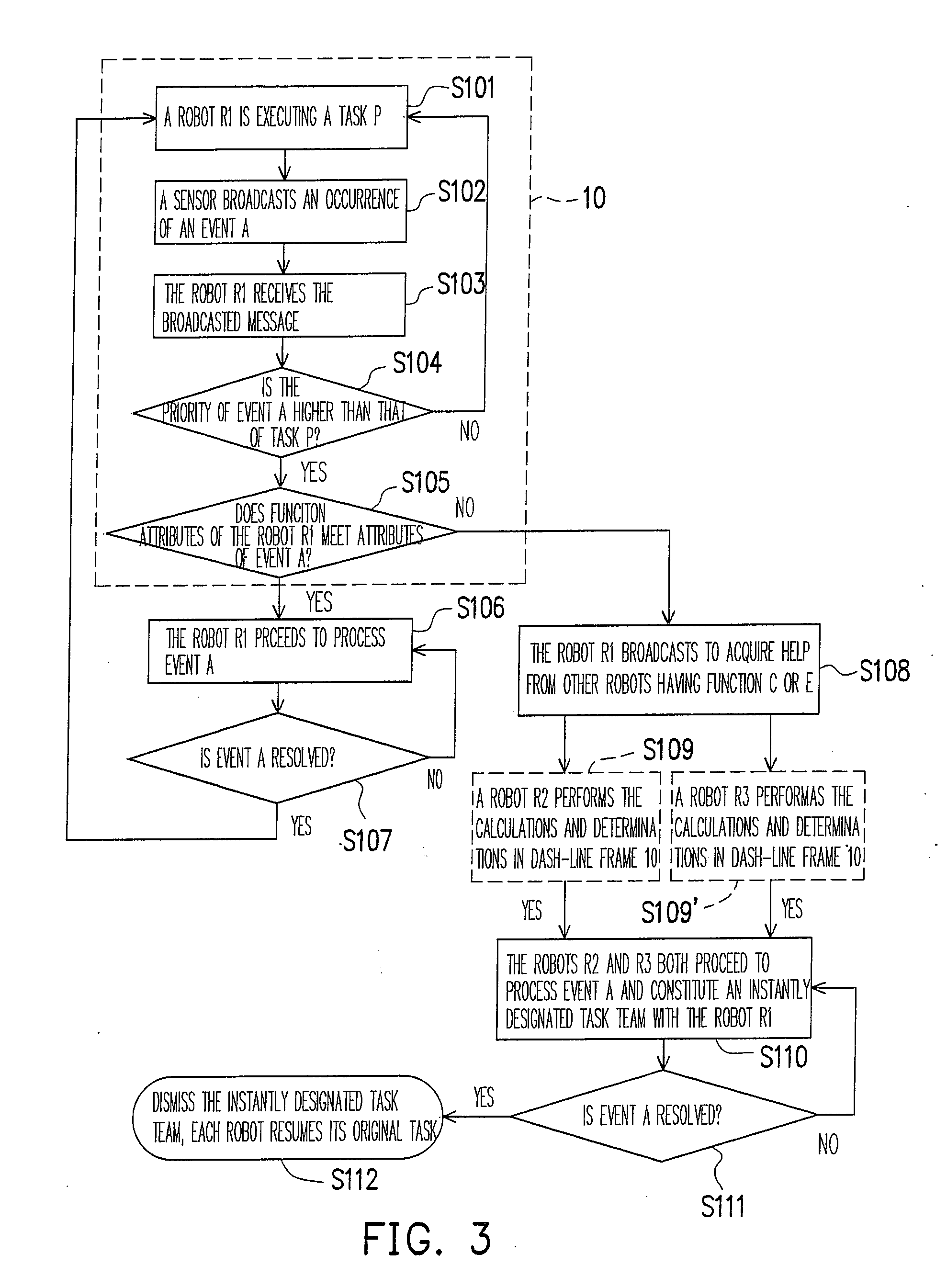

Method for coordinating cooperative robots

ActiveUS20090015404A1Avoid Task ConflictsWeight increaseProgramme-controlled manipulatorComputer controlHuman–computer interactionReal-time computing

A method for coordinating cooperative robots is provided. The method includes following steps. An abnormal event is detected by a sensor disposed in an environment or in a robot. The abnormal event is broadcasted to the cooperative robots. Each robot determines whether the priority of the abnormal event is higher than that of its currently executing task. If the answer is “yes,” whether function attributes of the robot meet attributes of the abnormal event is then determined. If the function attributes of the cooperative robot do not meet the attributes of the abnormal event, the robot broadcasts to acquire help from other robots, thereby constituting an instantly designated task team. The instantly designated task team goes to where the abnormal event takes place to process the abnormal event. After the abnormal event has been eliminated, the instantly designated task team is dismissed and these robots resume their original tasks.

Owner:IND TECH RES INST

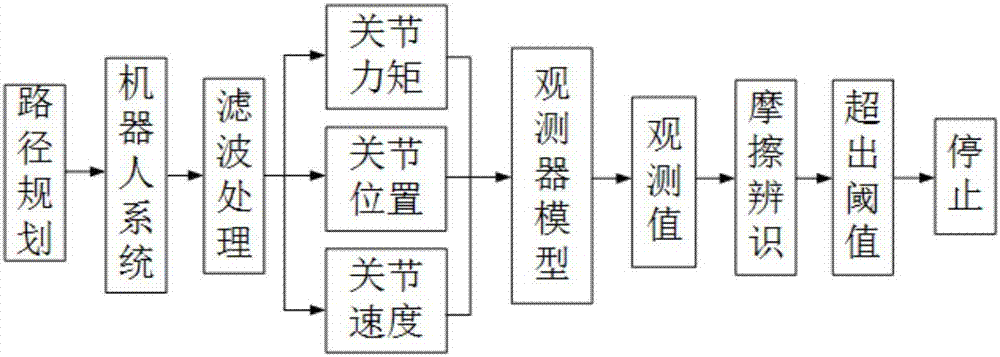

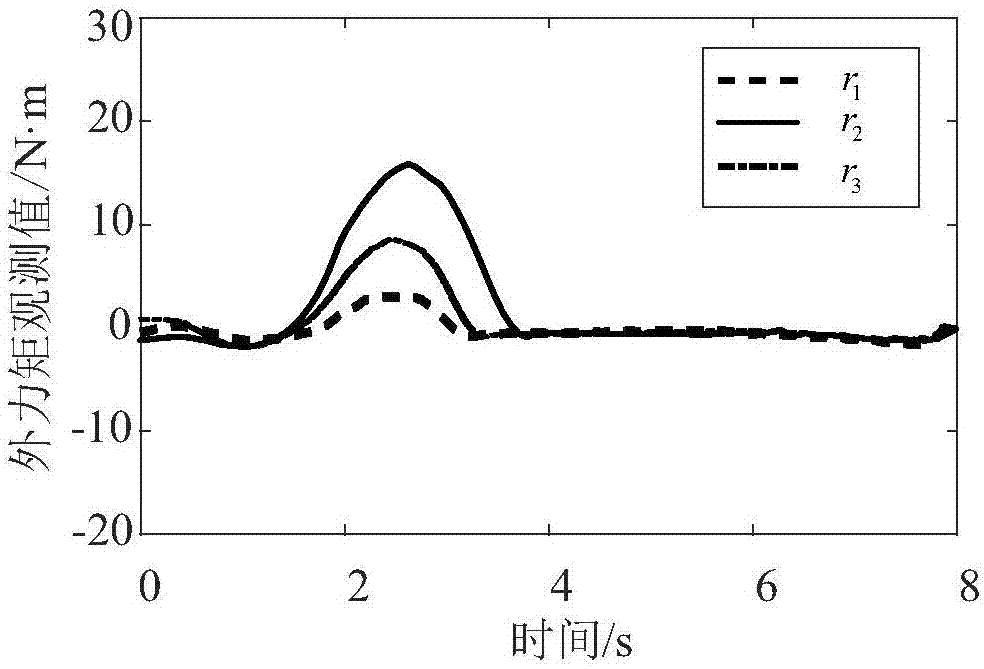

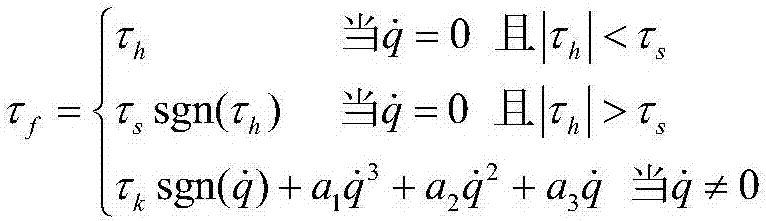

Collision detection method for sensor-less type cooperative robot

InactiveCN108000521ASecure CollaborationFlexible and convenient settingProgramme controlProgramme-controlled manipulatorMomentumCollision detection

The invention discloses a collision detection method for a sensor-less type cooperative robot. Based on a method for constructing a joint external force moment observer of cooperative robot through generalized momentum, the real time observation of the moment of the external impact force and friction force applied to the joint is achieved. A joint friction moment model is solved through an observation value of the normal operation of a robot, so that the observation value is affected only by the impact force. The robot is considered to collide with others when the observation value exceeds thepreset threshold, and the robot stops running at once, so that the injury towards human in the process of human-machine cooperation is avoided. Without the need for installing an additional sensor outside the robot, and a joint driving moment, a joint position and a joint angle of the robot is got through a robot control system, so that the collision detection function is realized, the complexityof increasing robot structure and the increase of manufacturing cost are avoided. The sensitivity of the collision detection is changed by setting the threshold. Therefore, the safety of the human-machine cooperation is guaranteed.

Owner:TIANJIN UNIV

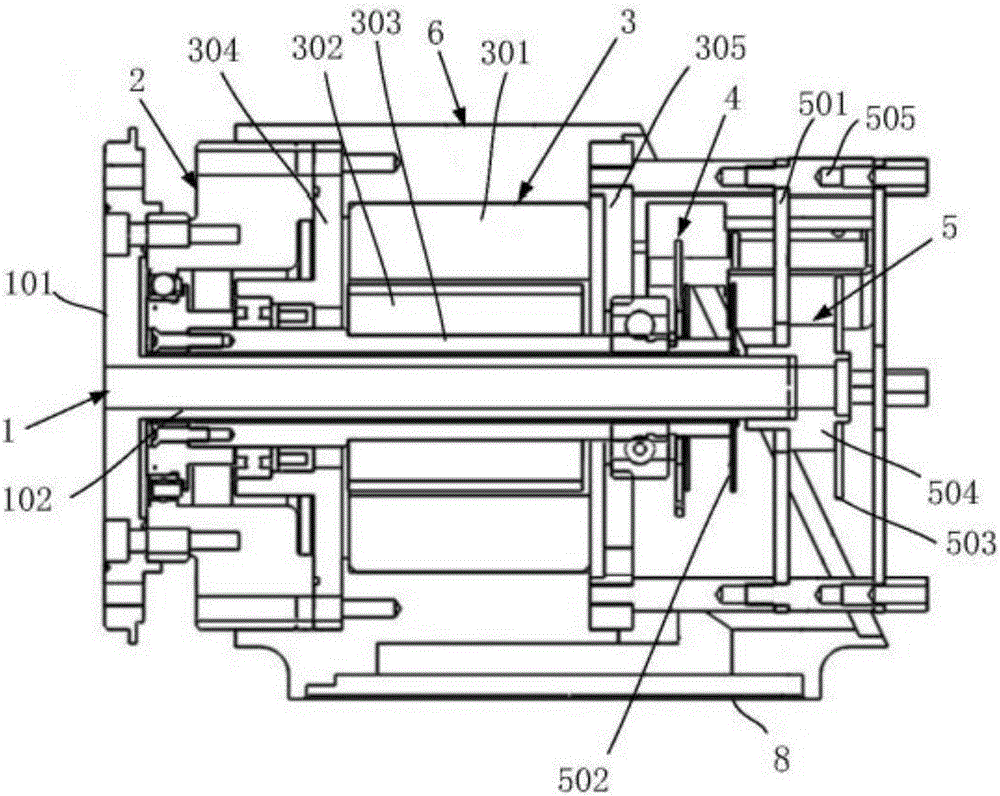

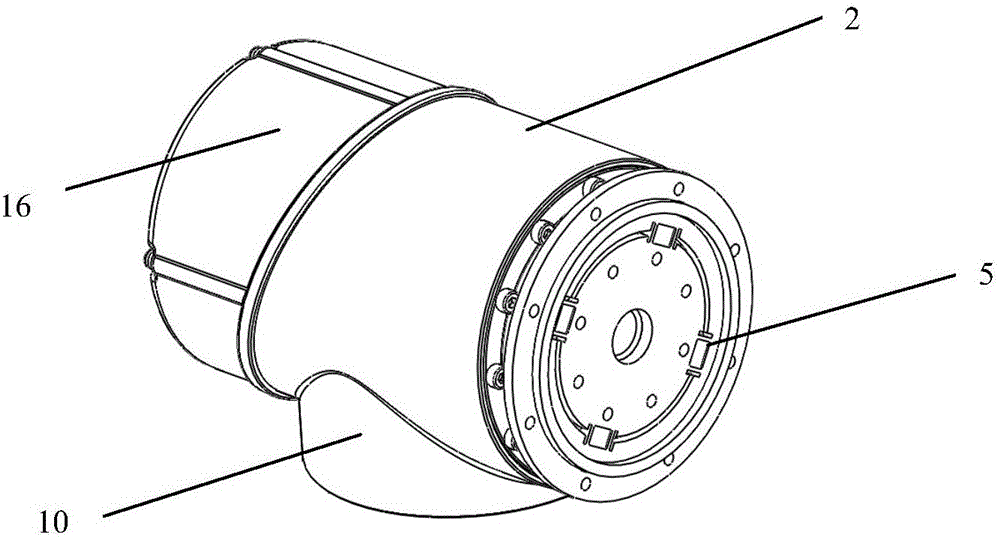

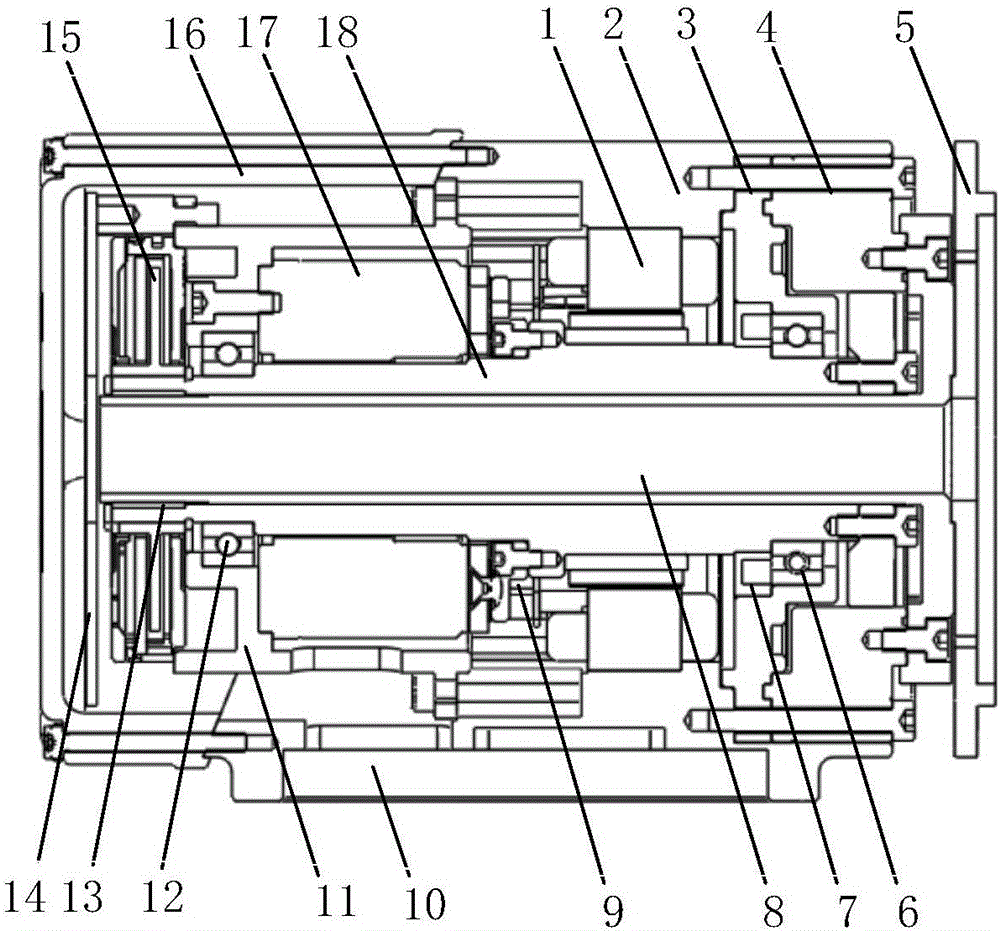

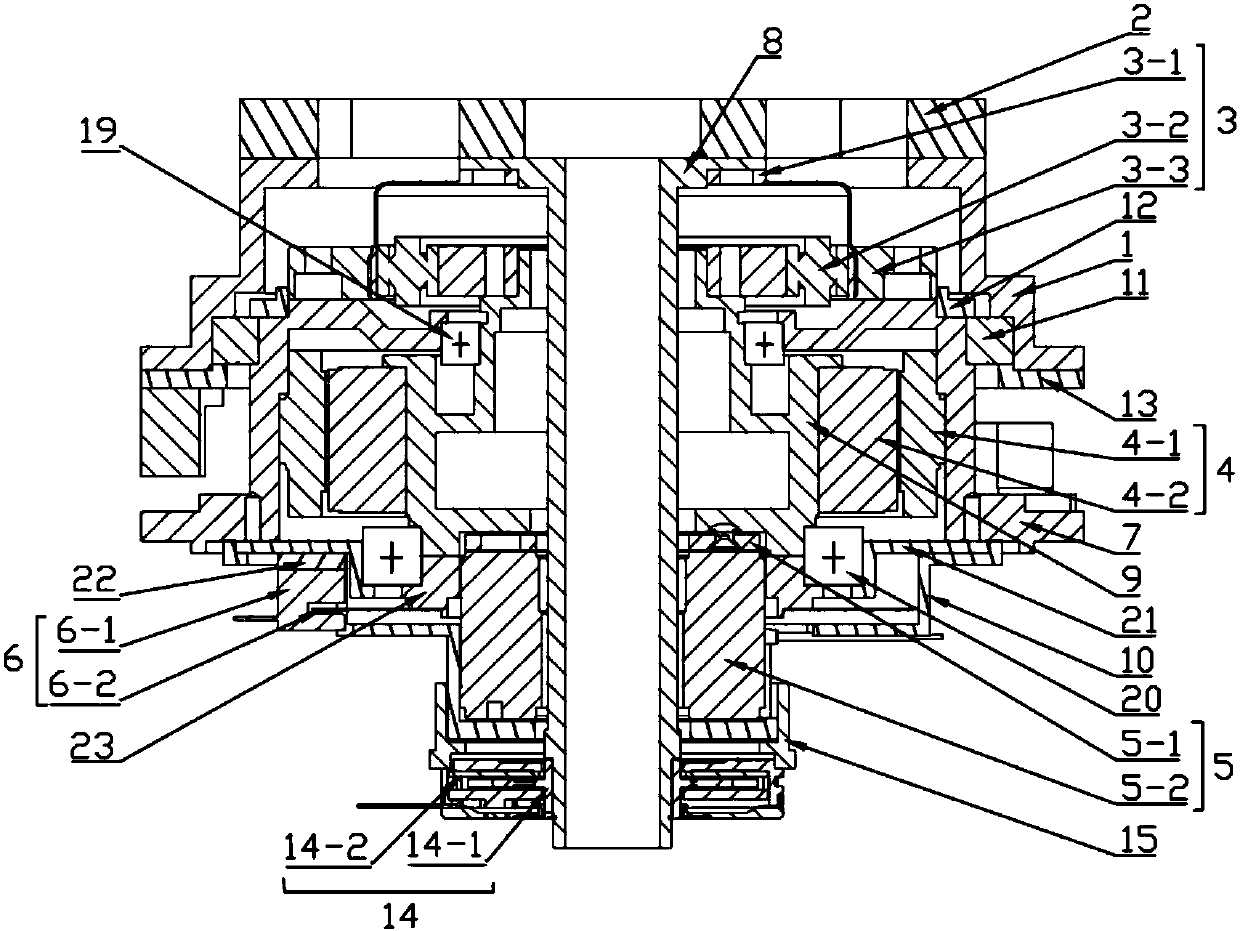

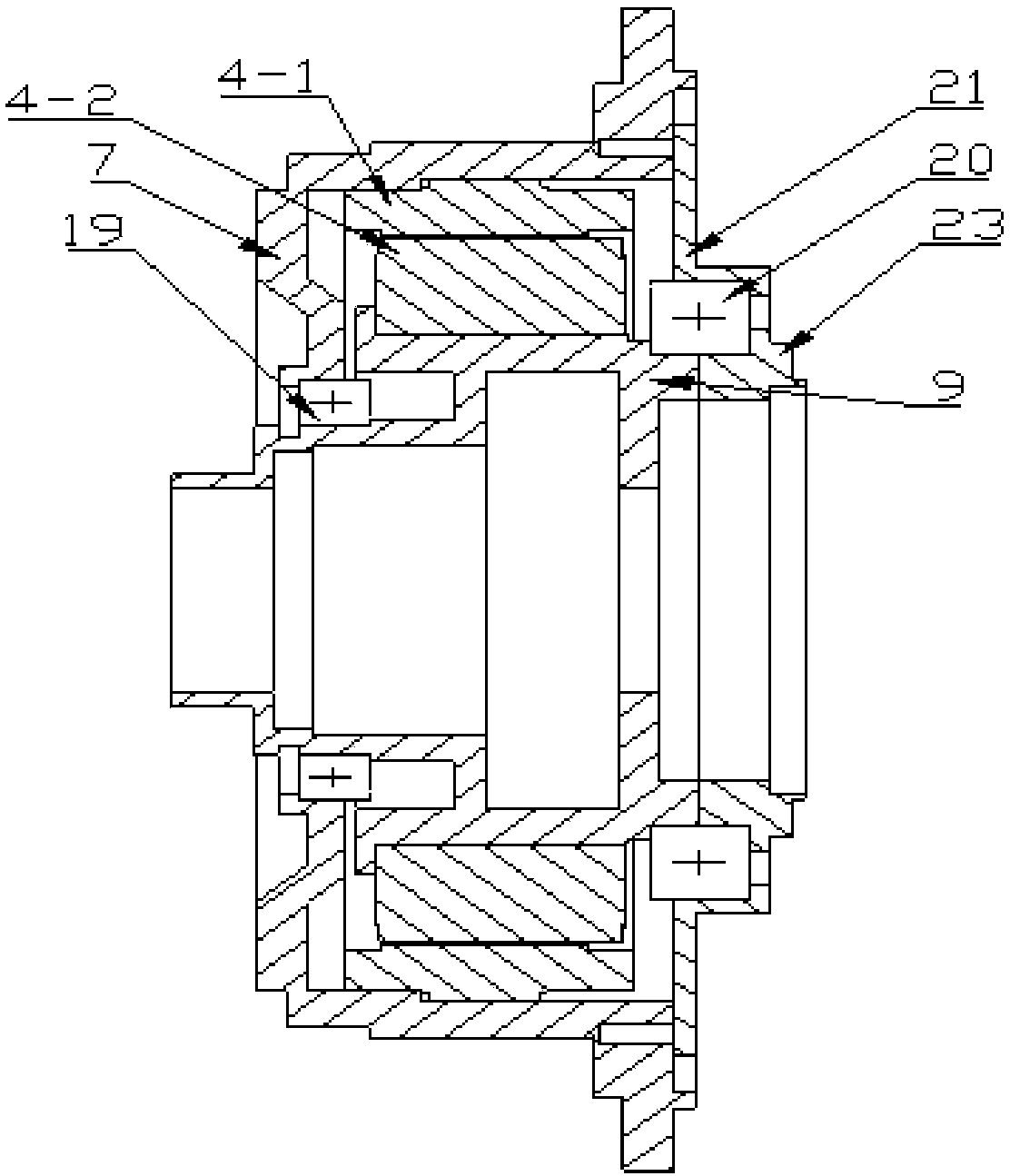

Modularized series joint of collaborative robot

The invention relates to a modularized series joint of a collaborative robot. The modularized series joint comprises a joint shell as well as a hollow motor, a harmonic reducer, an input shaft, an output shaft, a torque sensor, a brake, an absolute value encoder and a driver which are arranged in the joint shell, wherein the harmonic reducer, the hollow motor, the brake, the absolute value encoder and the driver are sequentially connected to the input shaft in series. A joint structure disclosed by the invention is more compact in structure, low in cost, higher in safety and reliability, ingenious, modularized and integrated; a brake structure is simple, convenient to install, reliable in brake performance, and stable; a force feedback system is sensitive in performance, stable, and high in reliability; and in addition, central hole wiring is used for wiring and arrangement, so that wire arrangement is more reasonable, and the wiring is more convenient.

Owner:SUZHOU XINYOUHUA INVESTMENT ADVISOR CO LTD

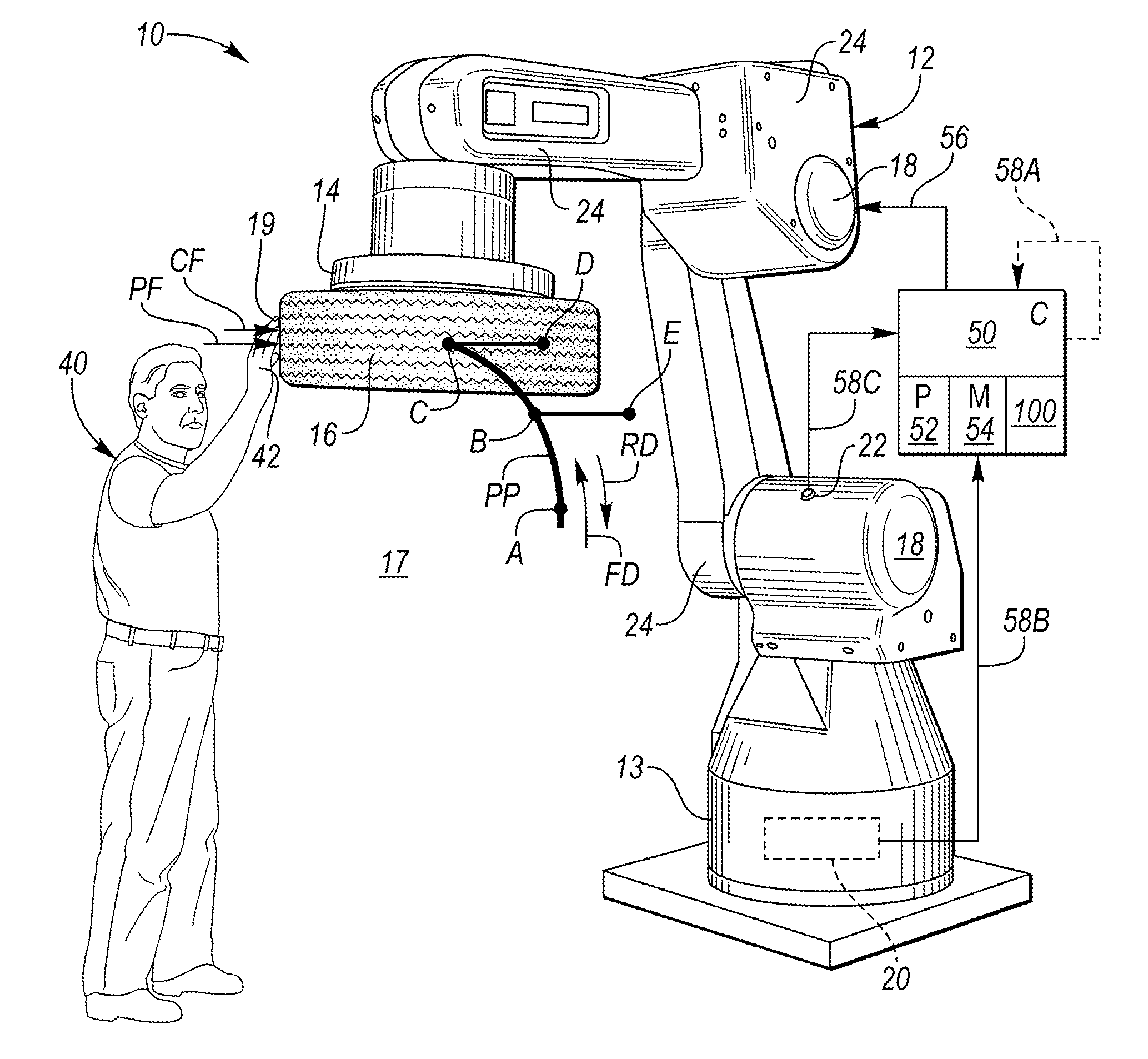

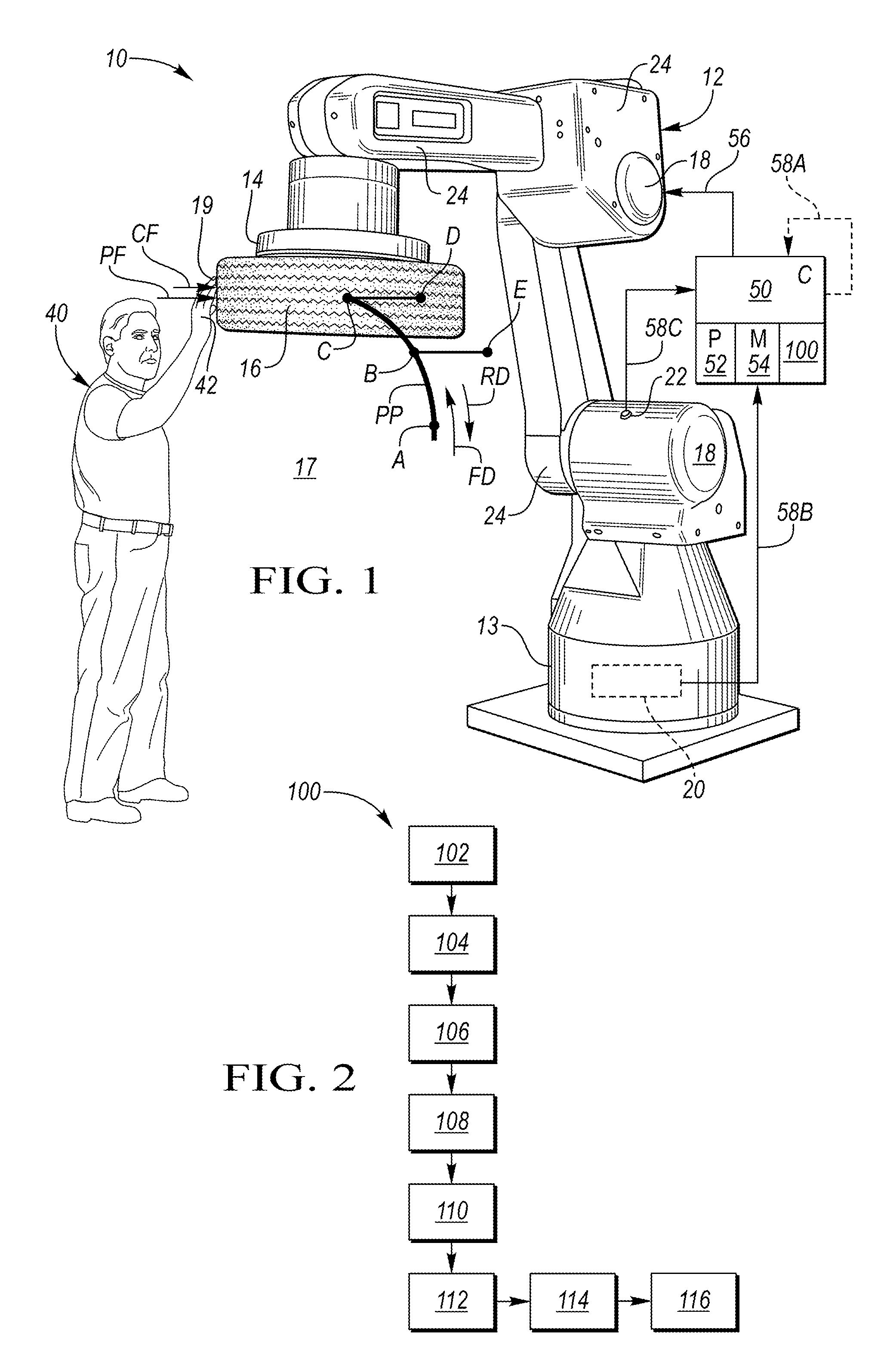

Human-machine collaborative robotic systems

ActiveUS9283675B2Programme-controlled manipulatorMechanical/radiation/invasive therapiesRobotic systemsControl system

A semi-automatic, interactive robotic system for performing and / or simulating a multi-step task includes a user interface system, a recognition system adapted to communicate with the user interface system, a control system adapted to communicate with the recognition system, and a sensor-actuator system adapted to communicate with the control system. The recognition system is configured to recognize actions taken by a user while the user operates the user interface system and to selectively instruct the control system to cause the sensor-actuator system to perform, and / or simulate, one of an automatic step, a semi-automatic step or direct step of the multi-step task based on the recognized actions and a task model of the multi-step task.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Adaptive Mobile Robot System with Knowledge-Driven Architecture

Owner:ZHUK YEFIM

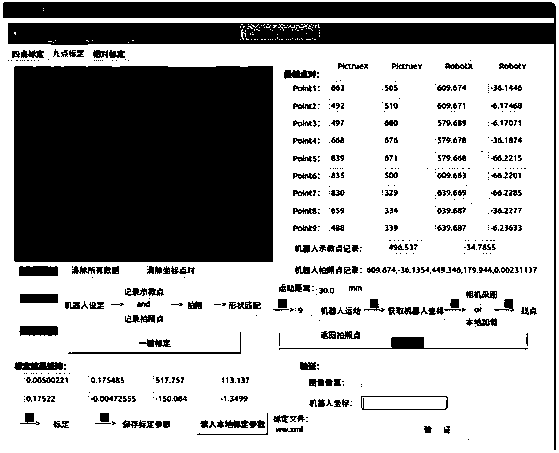

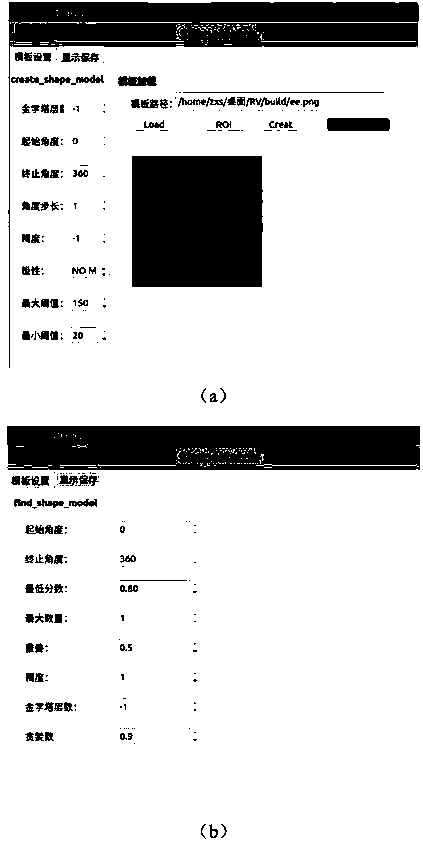

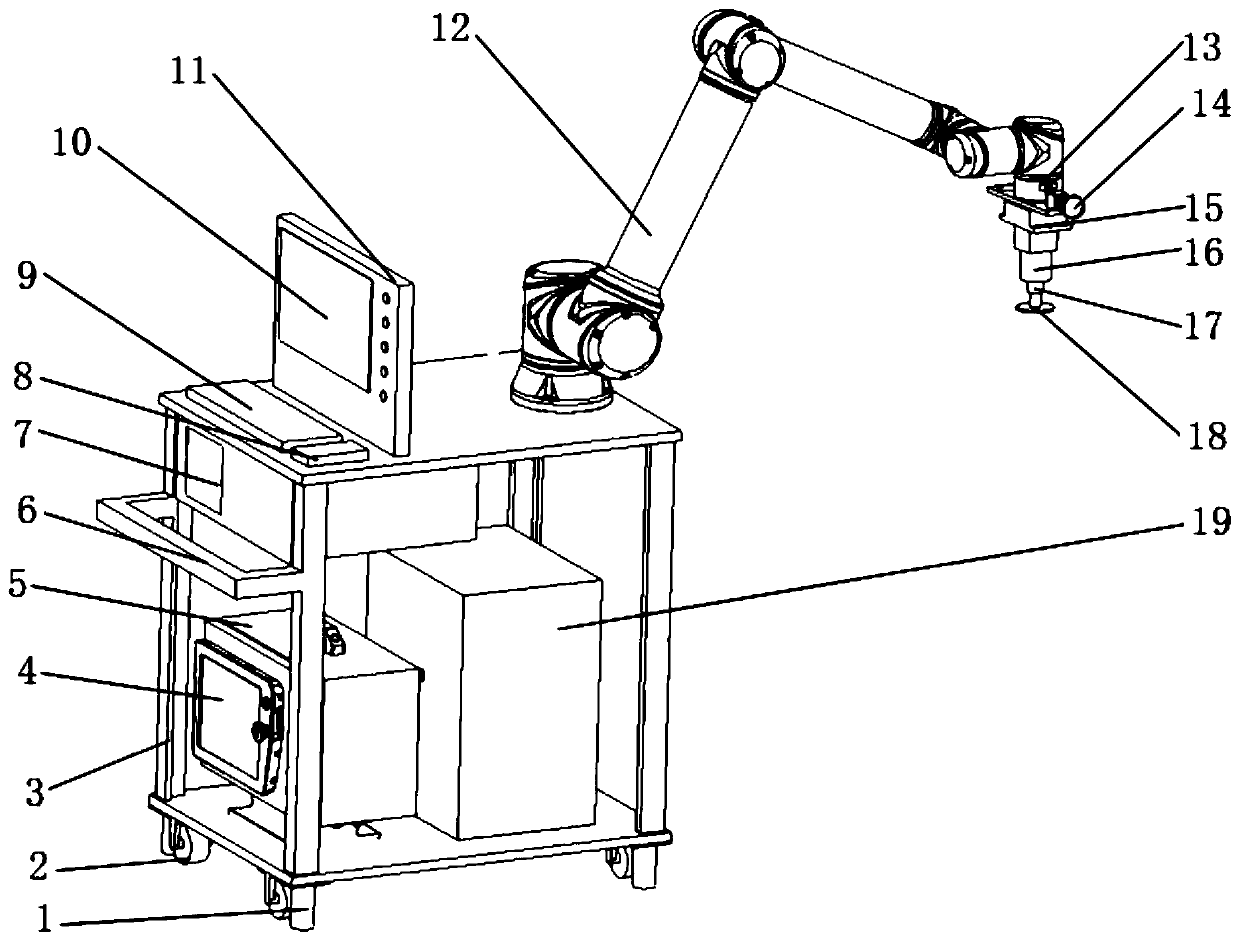

Collaborative robot hand-eye relation automatic calibration device and method

ActiveCN110497386AImprove calibration efficiencySimplify the calibration processProgramme-controlled manipulatorRobot handComputer graphics (images)

The invention provides a collaborative robot hand-eye relation automatic calibration device and method. The calibration device comprises a collaborative robot force control pulling teaching button, acalibration probe, a calibration plate with a marker and a calibration system, wherein the calibration system is mainly used for controlling the robot button to move according to a preset track; target points in the preset track automatically acquire pixel coordinates of the center point of the marker and coordinate dot pairs of a robot; and calibration parameters are calculated according to the obtained multiple dot pairs. The calibration method comprises the steps of placing the calibration plate; pulling the collaborative robot to a teaching point and recording coordinates of the robot; pulling the collaborative robot to an initial photographing point, recording the coordinates of the robot and configuring a matched template; controlling the robot to continuously change the photographing point and acquiring the coordinates of the robot and the pixel coordinate dot pairs of the marker; and calculating the calibration parameters. Through the collaborative robot hand-eye relation automatic calibration device and method, the hand-eye relation of the collaborative robot can be conveniently and quickly calibrated, the calibration precision is high, and the collaborative robot hand-eyerelation automatic calibration device and method have the important significance in industrial grabbing and application of the collaborative robot.

Owner:SIASUN CO LTD

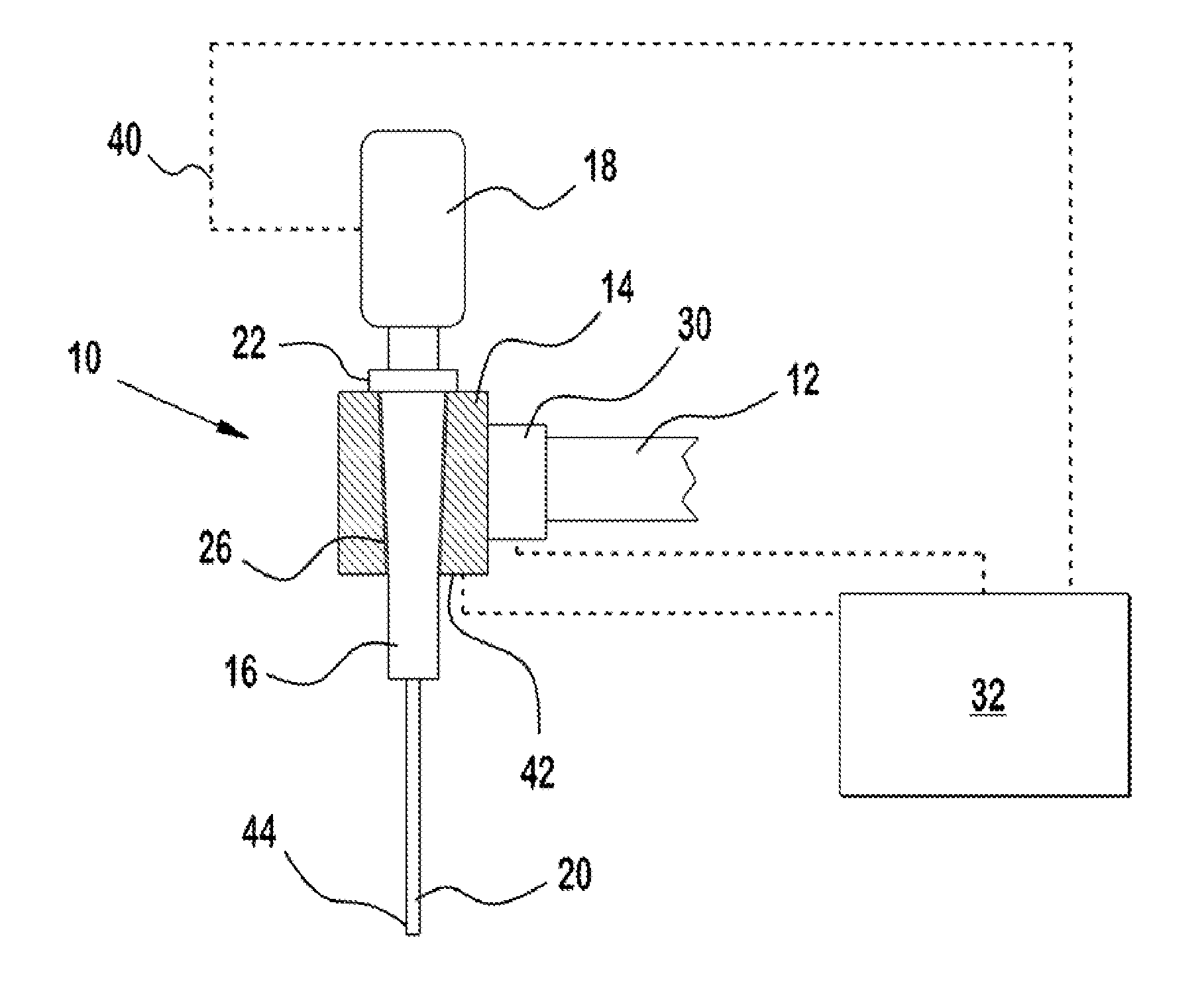

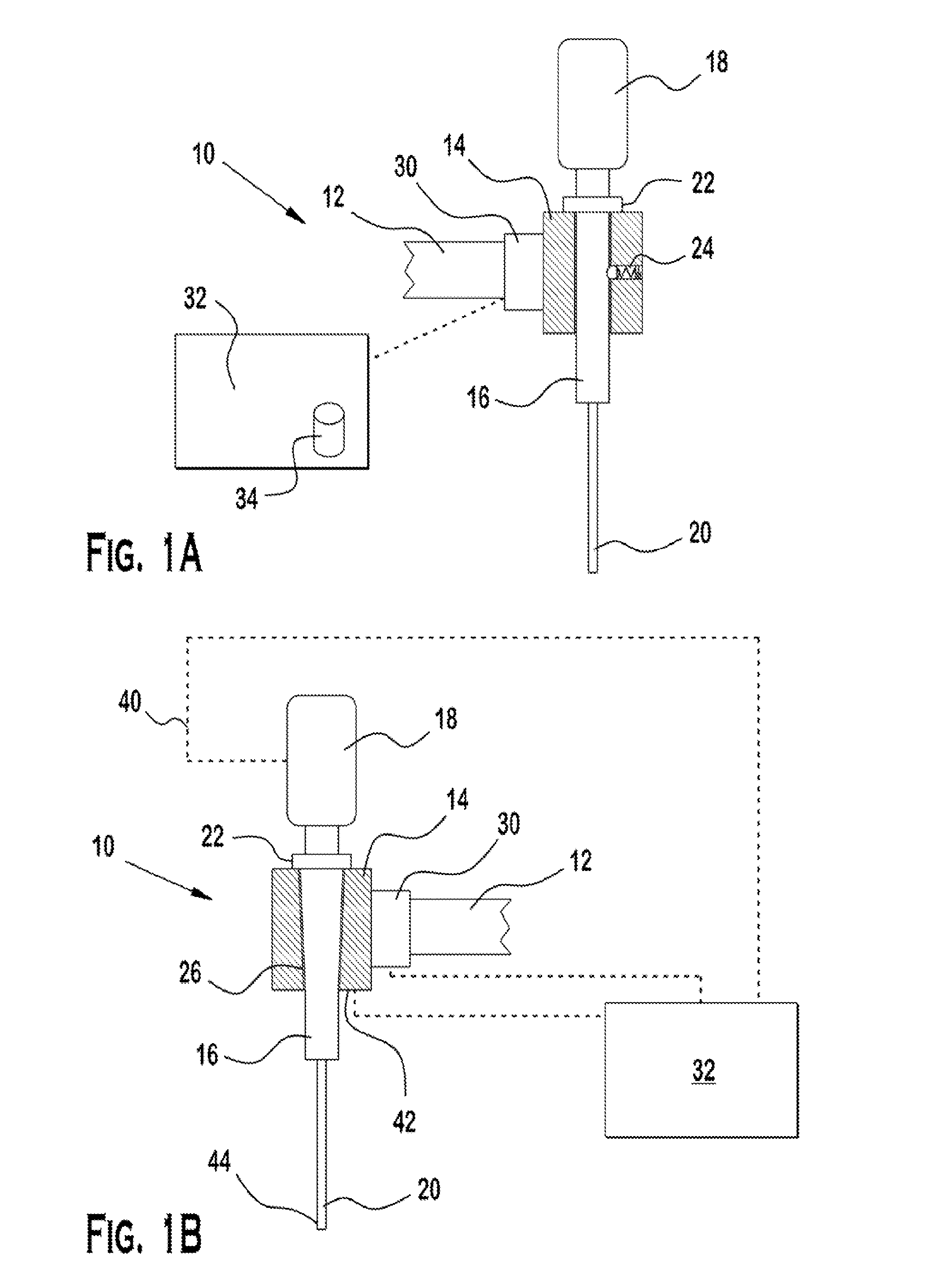

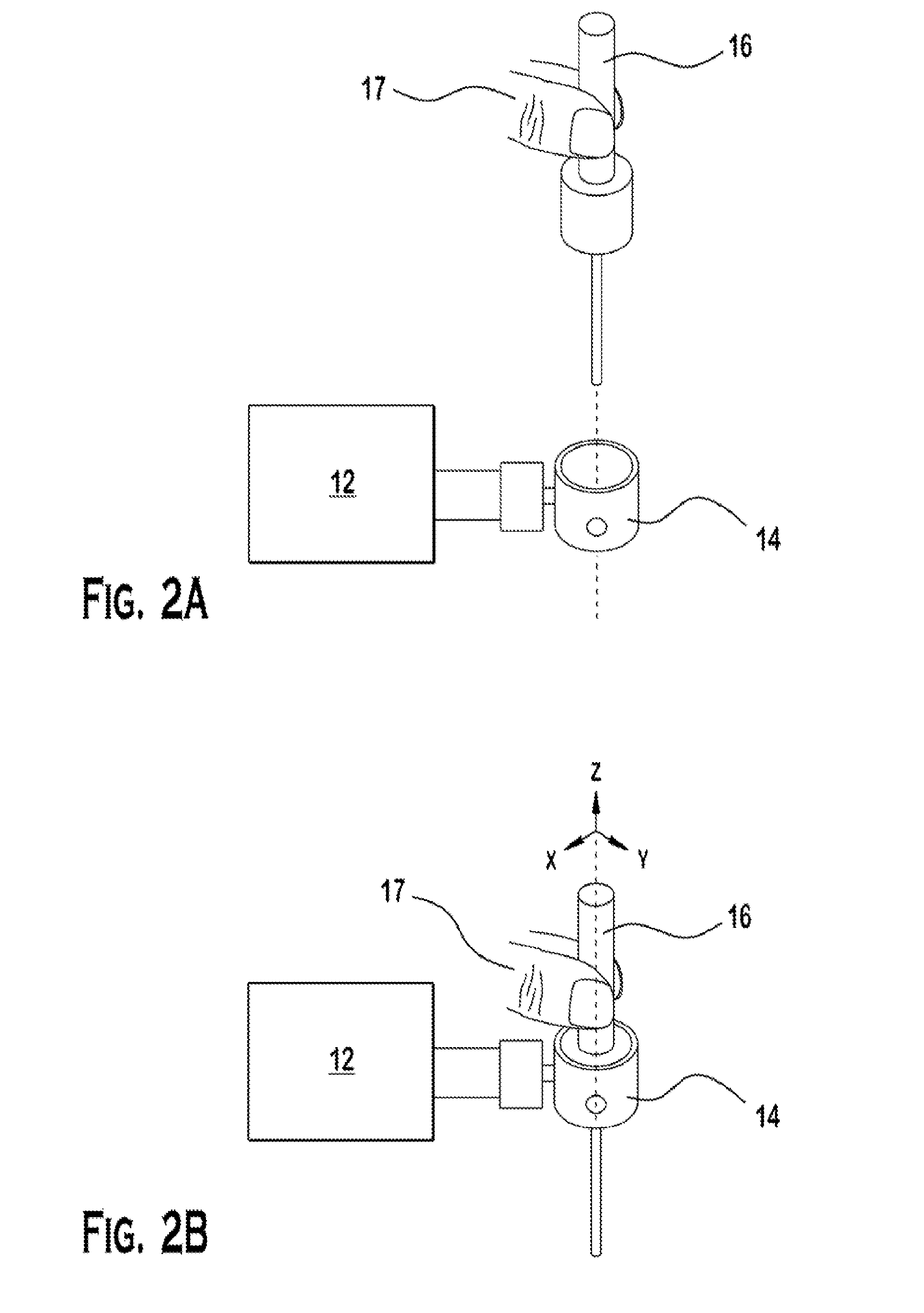

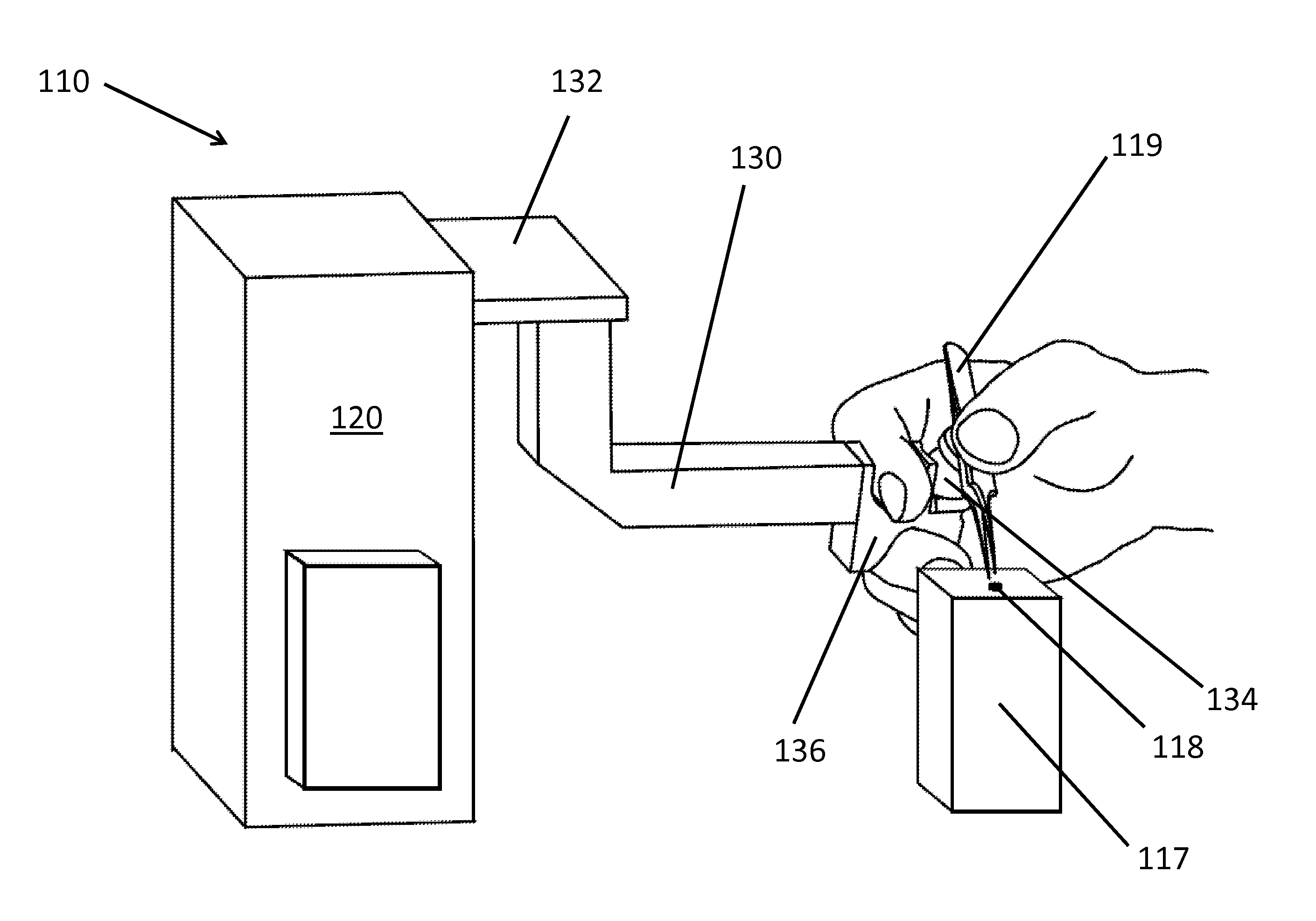

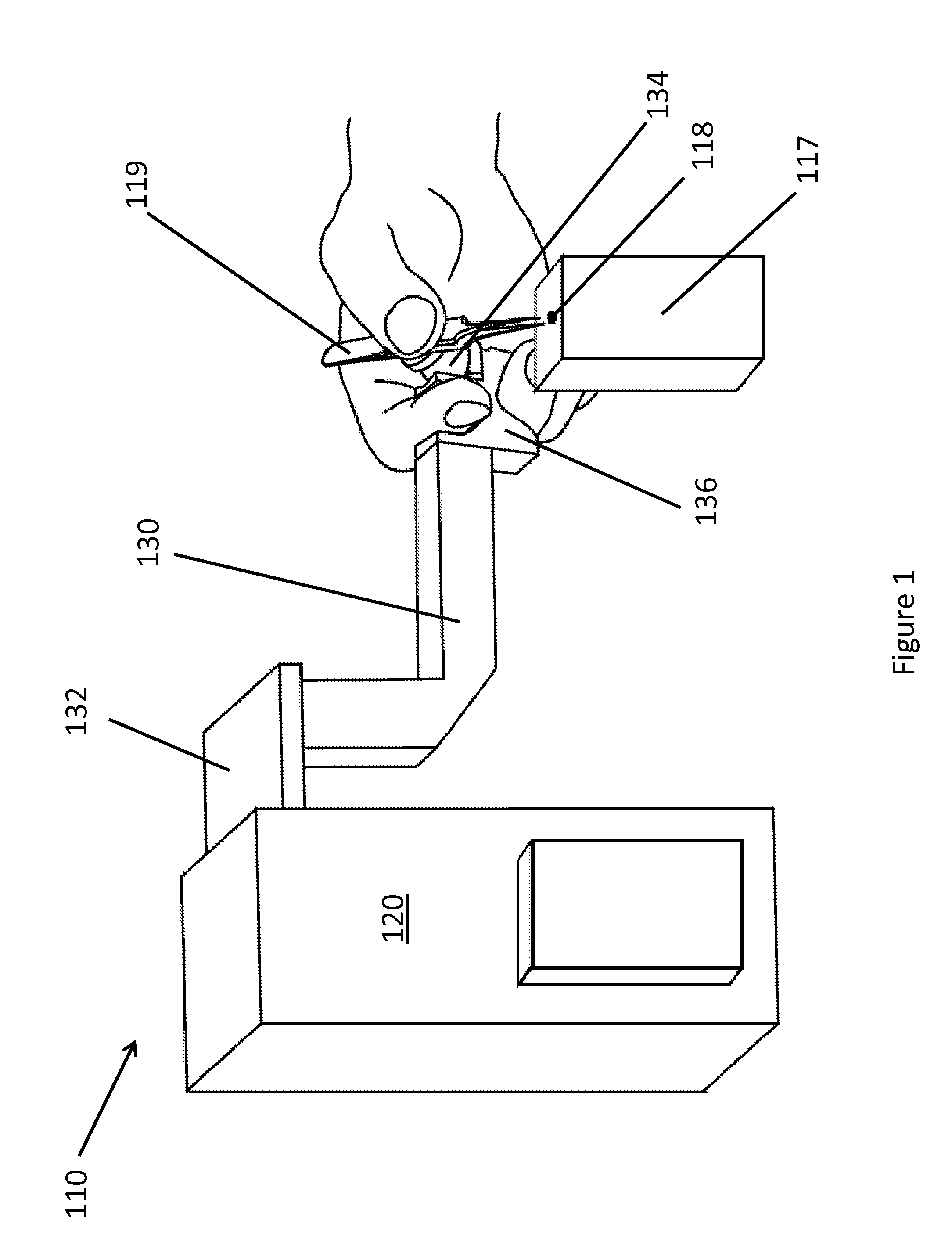

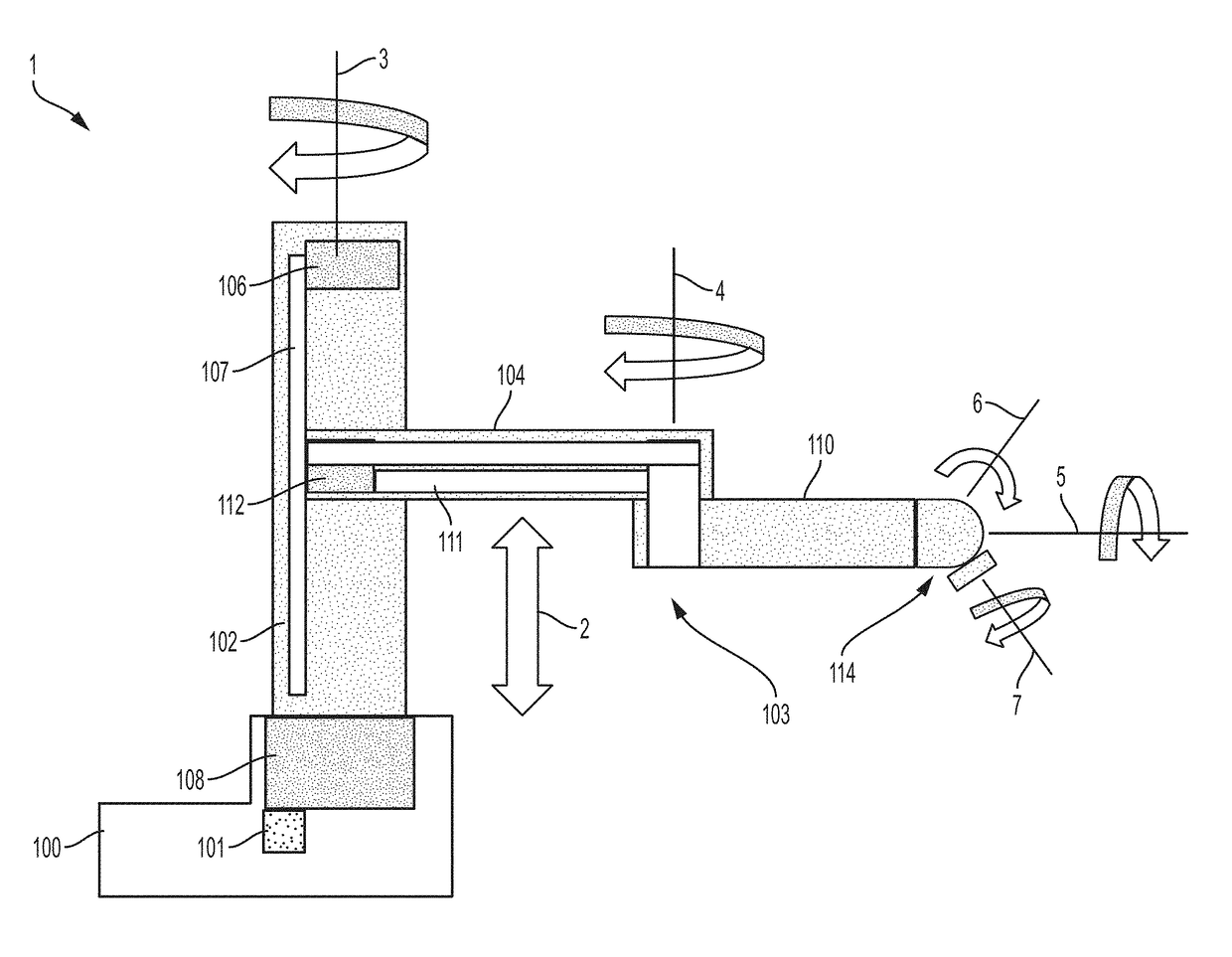

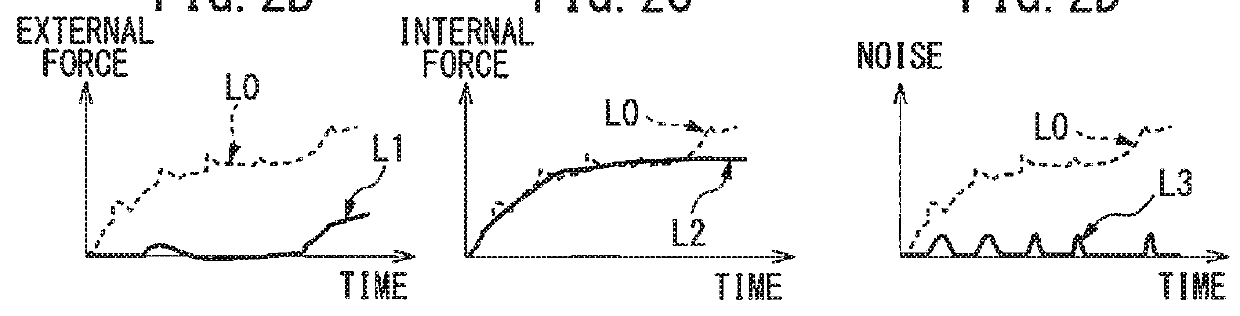

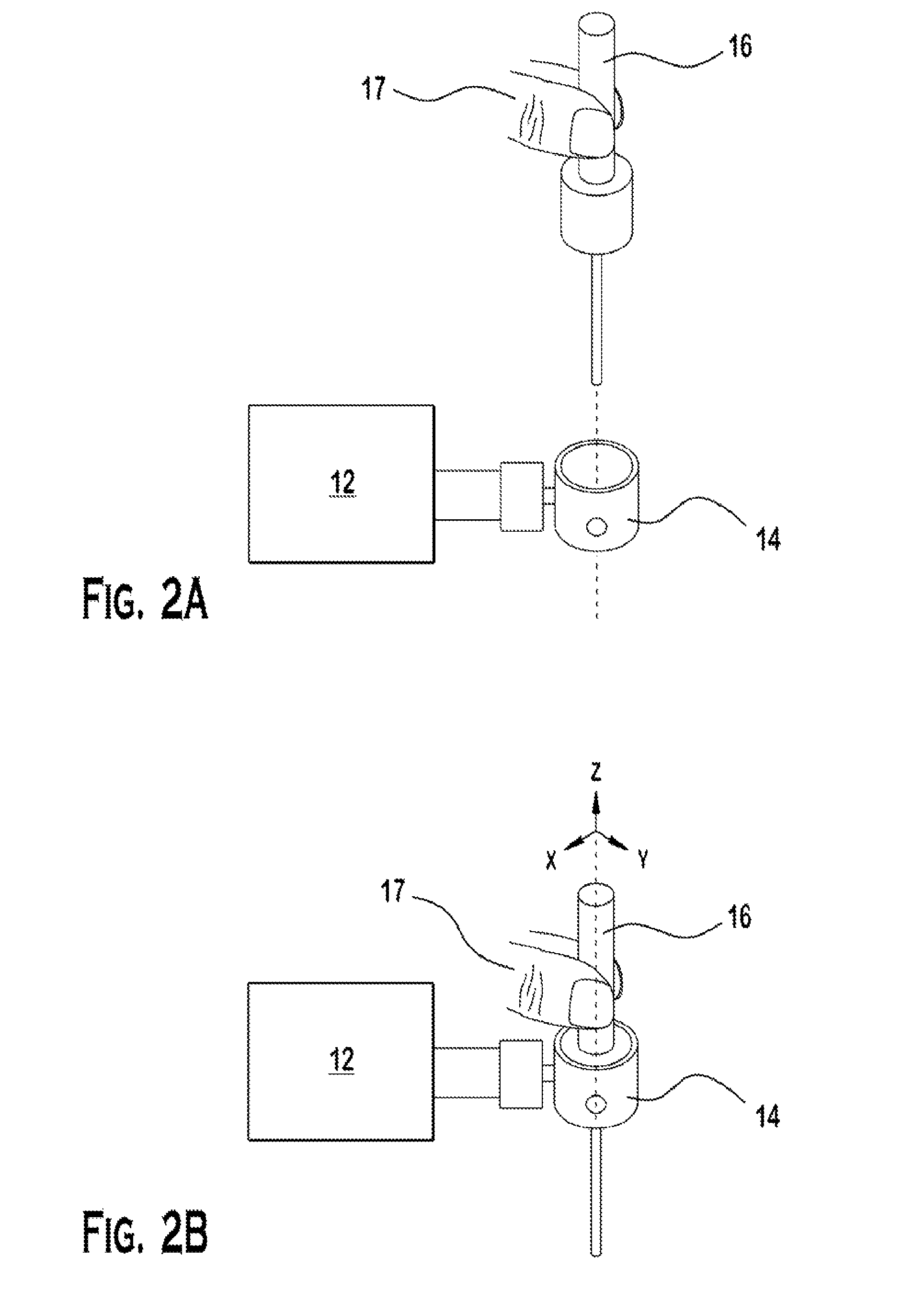

Device and Method for Controlled Motion of a Tool

ActiveUS20140277740A1Avoid relative motionProgramme controlProgramme-controlled manipulatorEngineeringCollaborative robotics

The present invention relates to devices and methods for controlled motion of a tool. In one embodiment, the device can support a tool needed to perform an activity requiring a highly-precise, stable motion, while also accommodating a person's hand for the purposes of moving the tool. In another embodiment, the device of the present invention allows for rotational motion of a tool independently of the directive motion of the tool. In yet another embodiment, the present invention relates to the design of a force transducer useful in a cooperative robot. The device and methods of the present invention are particularly useful for microsurgery or other tasks that are typically performed using cooperative robotics.

Owner:ELYTRA TECH

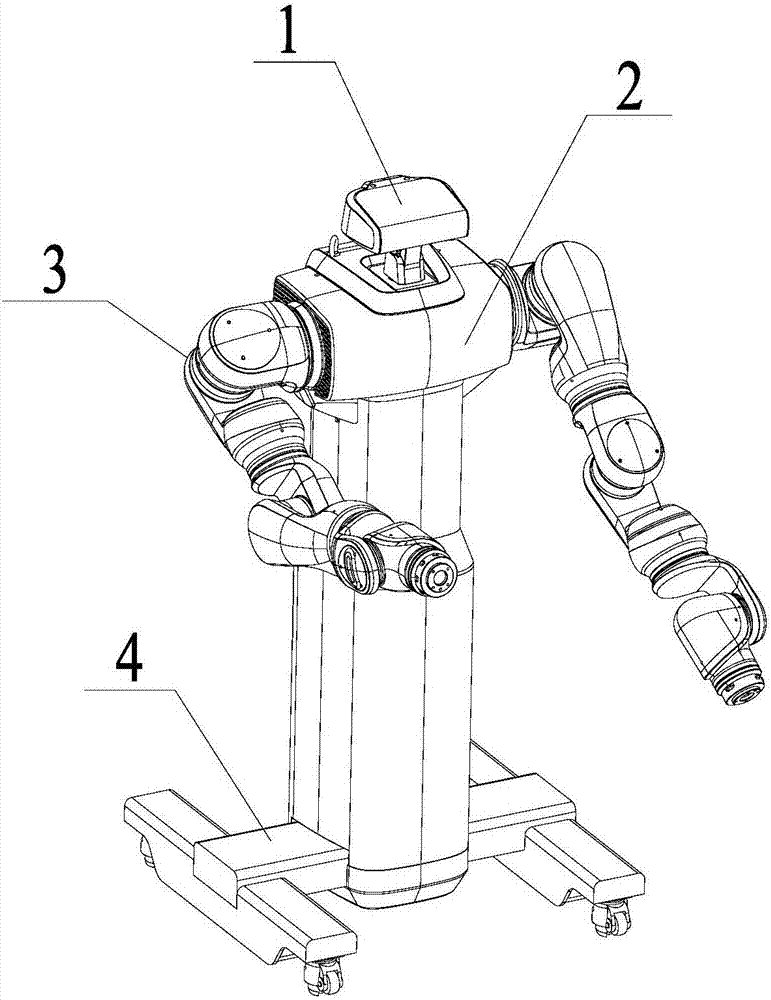

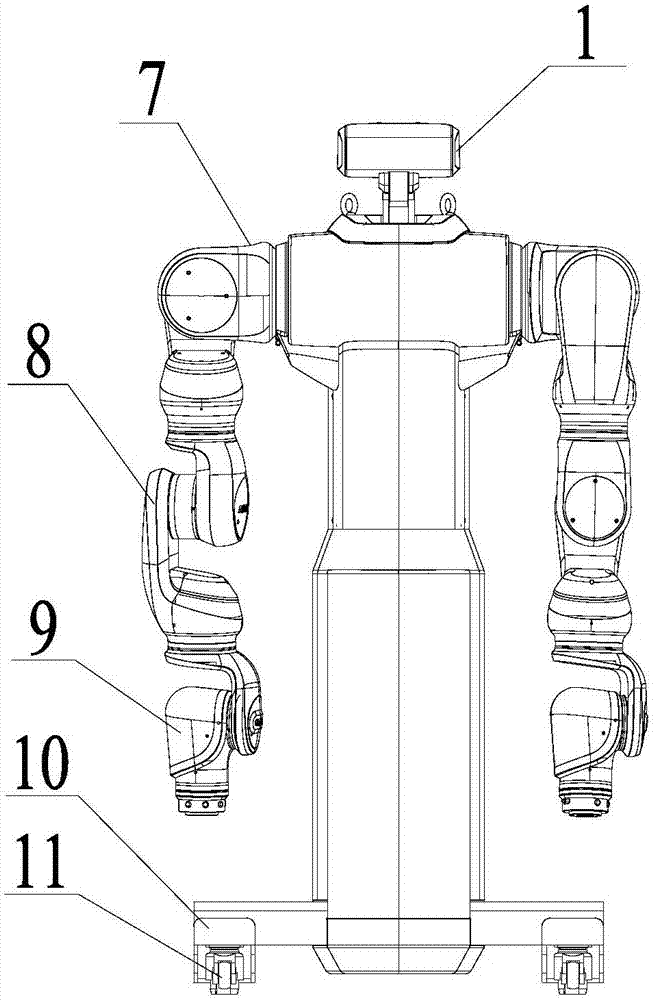

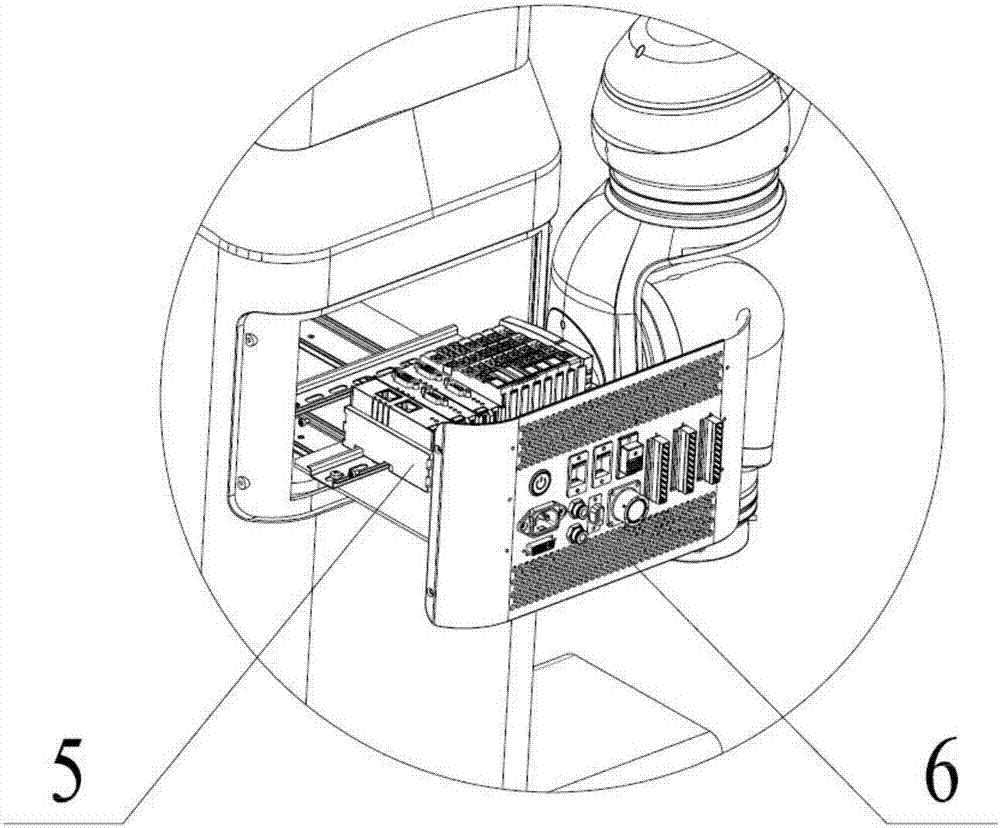

Double-arm-cooperative robot

ActiveCN106985141AAccurateImprove performanceProgramme-controlled manipulatorComputer moduleEngineering

The invention relates to the technical field of a robot, and in particular to a double-arm-cooperative robot. The double-arm-cooperative robot comprises a binocular vision component, an integrated control cabinet, a double-arm component and a movable platform; a power module, a control module, a communication module, a brake module, a main board and a rigid disc are arranged inside the integrated control cabinet; the binocular vision component comprises at least two cameras which are used for acquiring image information; the cameras are connected with a head vision board card; and the head vision board card is connected with the main board and is used for acquiring the image information and calculating three-dimensional geometrical information. The double-arm-cooperative robot provided by the invention is high in acquisition speed, accurate in location, simple and convenient to operate by virtue of more-anthropopathic setting and capable of improving the accuracy and flexibility of the action of double arms and greatly improving the performances of the robot.

Owner:SIASUN CO LTD

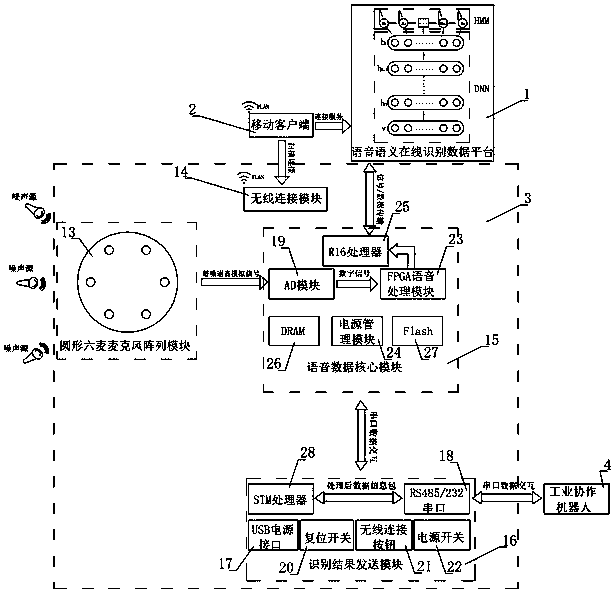

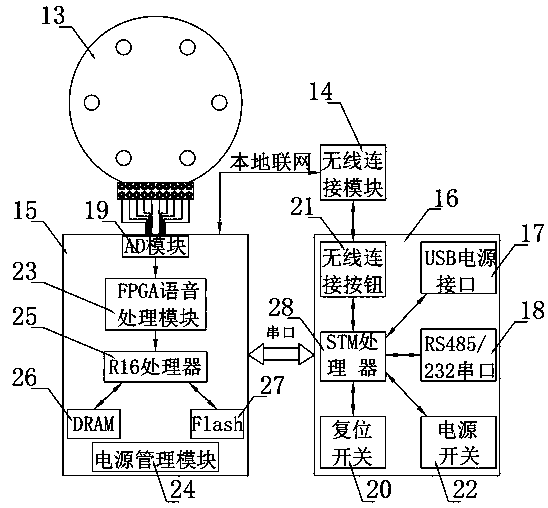

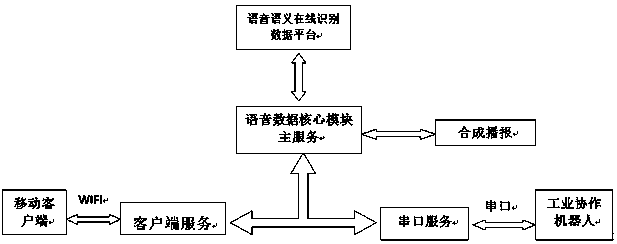

Robot voice control system in noisy condition environment

ActiveCN108447479AImprove robustnessDeepen the degree of intelligenceSpeech recognitionData platformNoise reduction

The invention discloses a robot voice control system in the noisy condition environment and relates to the industrial robot voice control technology field. In the noisy condition environment, throughcombination of local noise reduction processing and online voice identification, man-machine collaboration is accomplished. The system comprises an online voice meaning identification data platform, amobile client, a local voice control device and an industrial collaboration robot, wherein system networking is realized through the mobile client, the local voice control device is integrated with amicrophone array module to effectively overcome the noisy industrial environment, a voice signal is acquired and transmitted to a voice data core module, after noise reduction, the signal is transmitted to the online voice meaning identification data platform based on depth learning, online voice identification is realized, identification data is returned to the local voice control device, data processing is carried out, the data result is transmitted to the industrial collaboration robot, analysis is carried out through the robot, and instruction motion is further carried out. The system isadvantaged in that the noisy condition environment can be overcome, outstanding use performance is realized, and the application scope is wide.

Owner:SHANGHAI UNIV

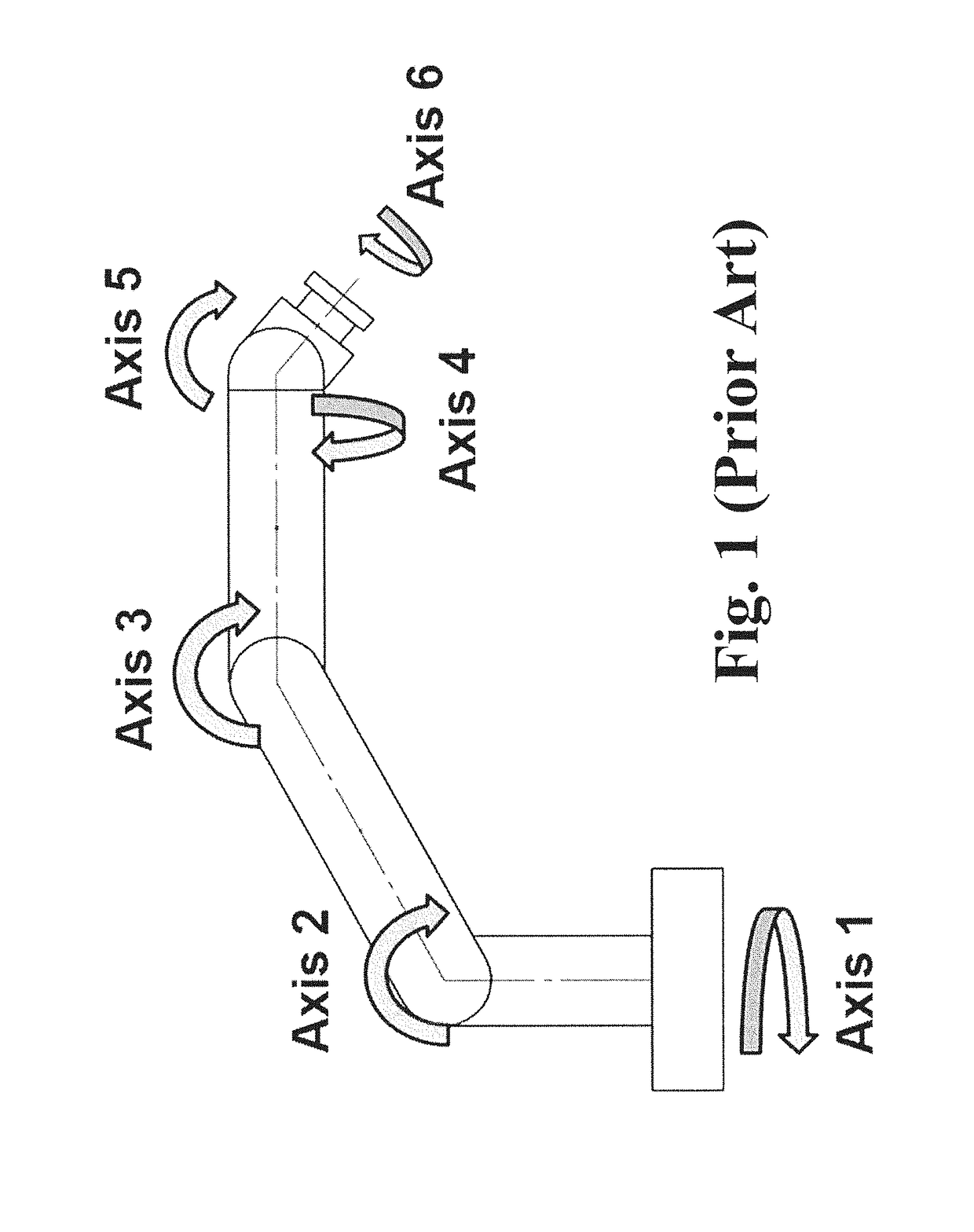

Collaborative robot

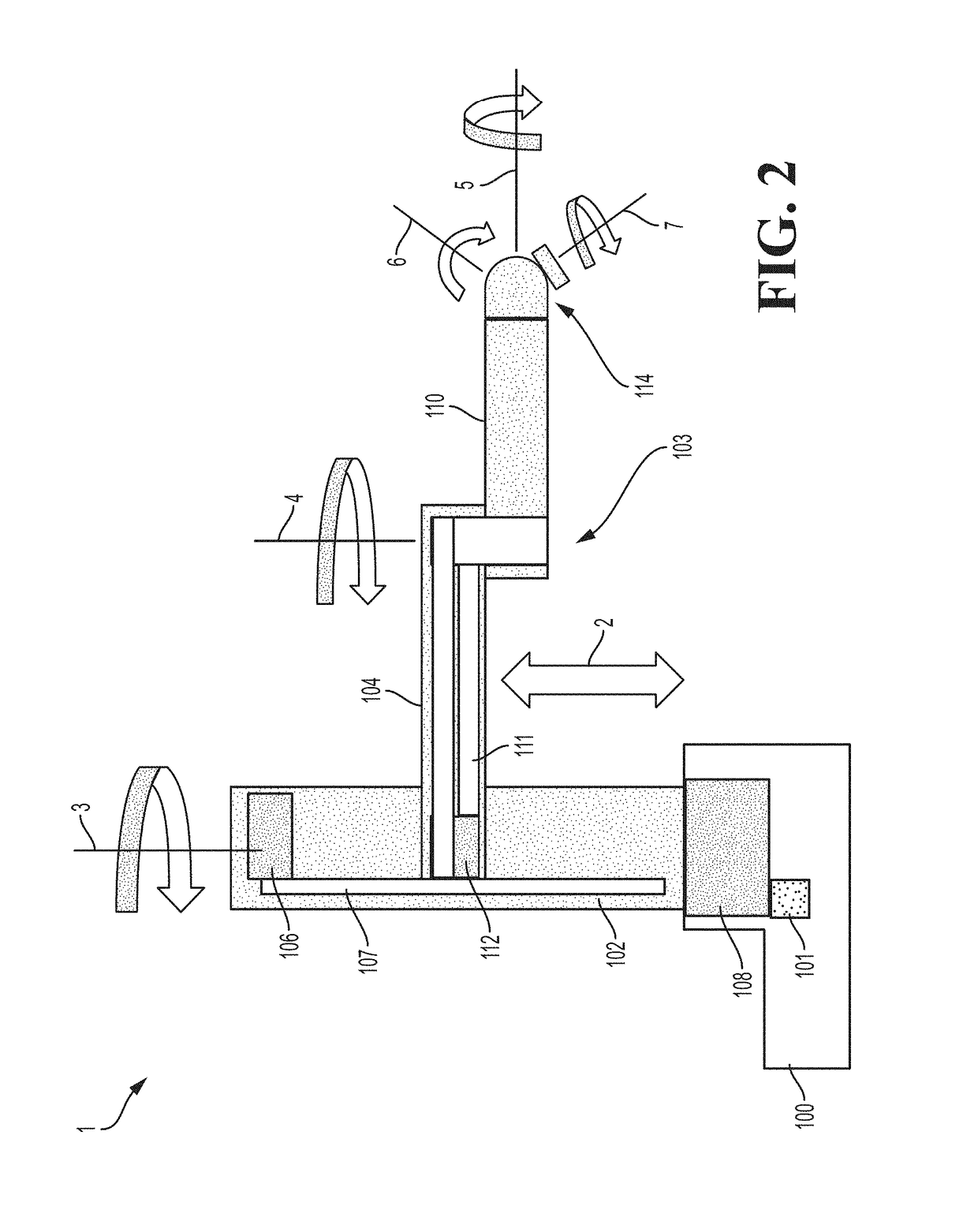

ActiveUS10029369B1Increase speedReduced reflected inertiaProgramme-controlled manipulatorProgramme control in sequence/logic controllersFeedback controlVertical axis

A collaborative robot employs low ratio drives for three or more axes of movement, such as three primary axes. An arm assembly may be mounted to a support for movement along a vertical linear axis, and the arm assembly may include first and second arm links that are each rotatable about vertical axes, e.g., such that the arm links move in a horizontal plane. Low ratio drives may be used for movement along the vertical linear axis and the rotary axes for the first and second arm links. Feedforward and feedback control may be employed to control the movement of the arm assembly and arm links, and feedback torque components may be limited to 25% or less of the maximum drive torque.

Owner:PRECISE AUTOMATION INC +2

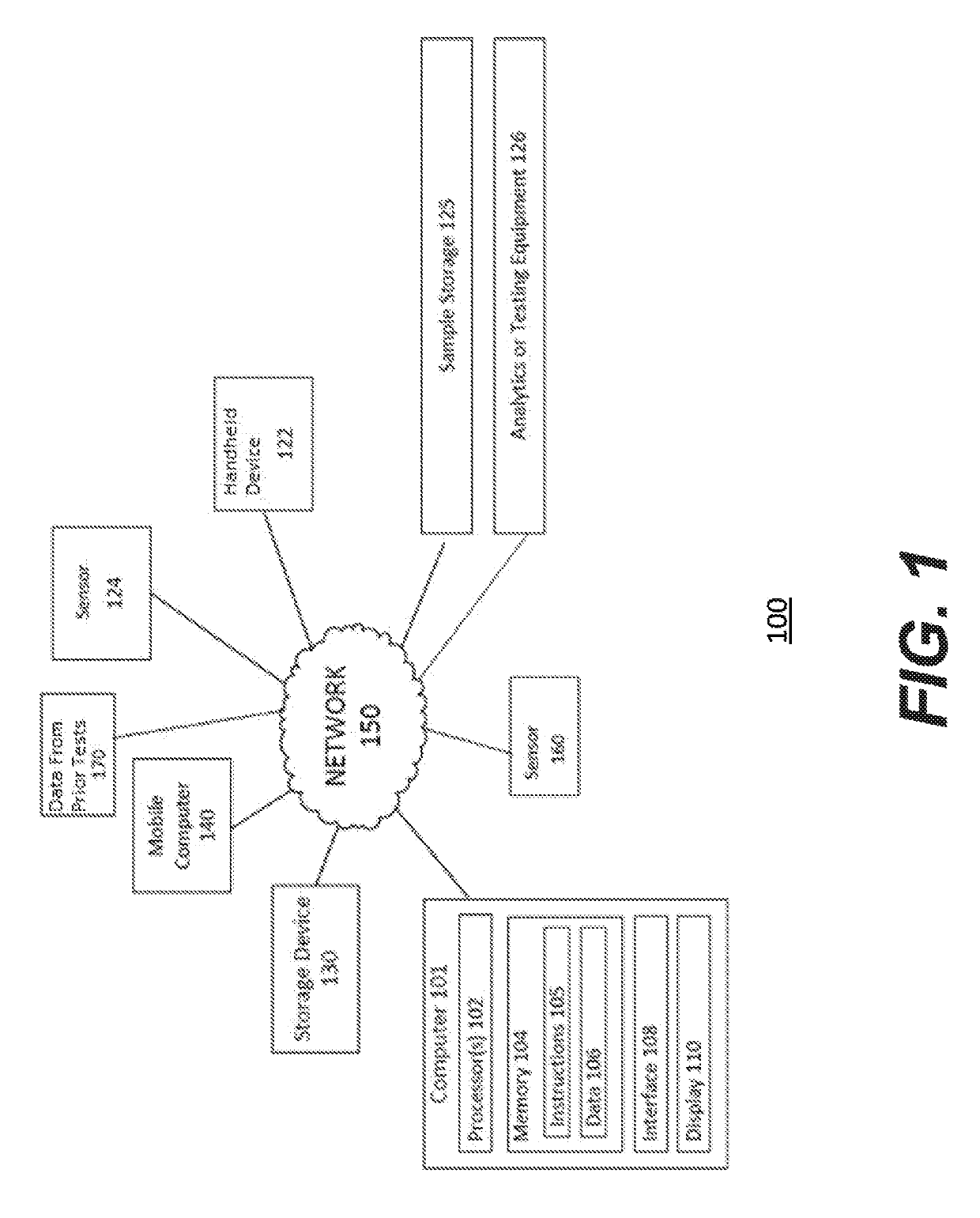

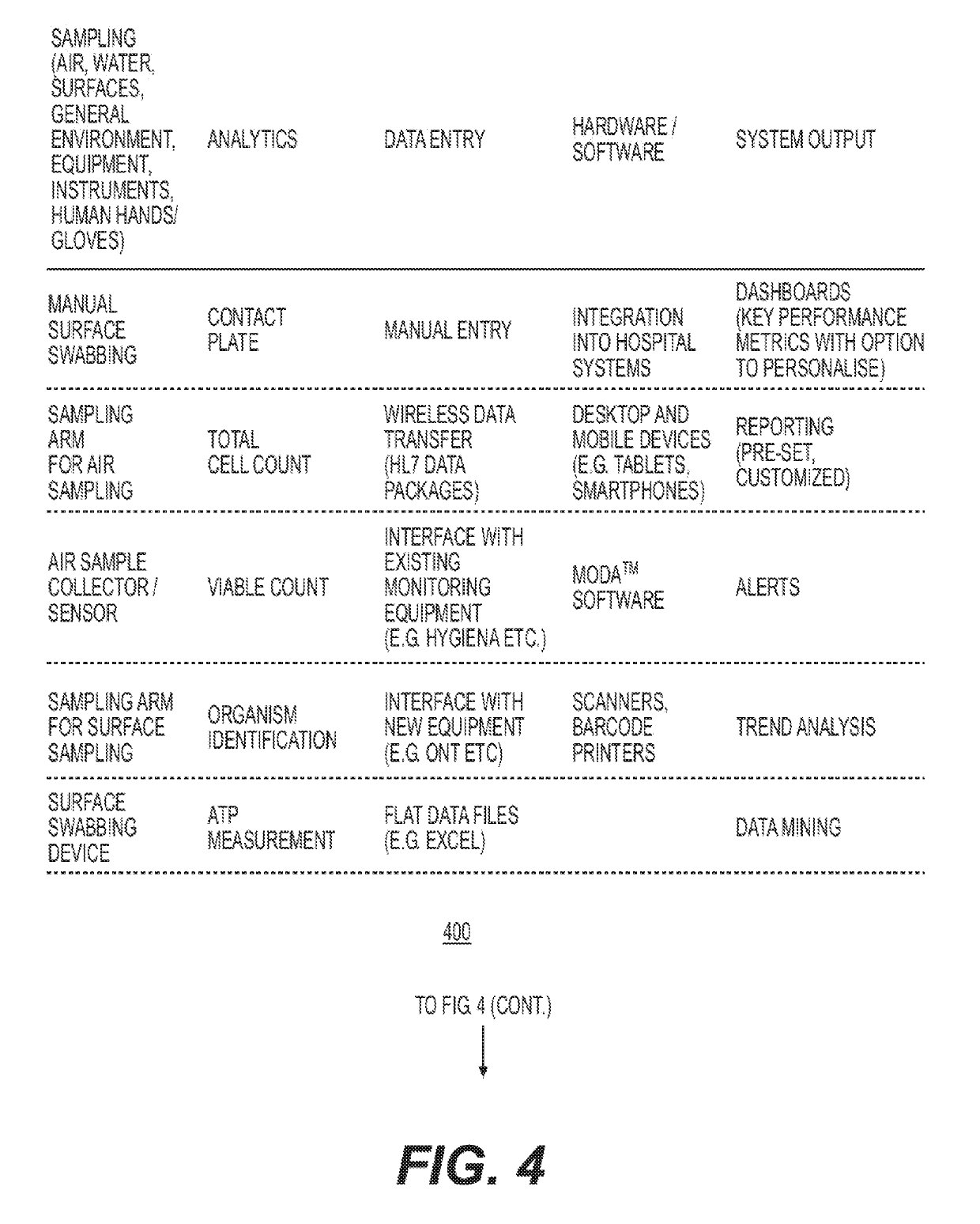

System and Method for Environmental Monitoring

InactiveUS20190331701A1Withdrawing sample devicesHealthcare resources and facilitiesMedical recordEnvironmental resource management

A system and method for monitoring an environment and performing analysis of collected samples are provided. The samples can be collected by personnel, a robot or a cobot, and the system may receive results of the monitoring / analysis and output information (e.g., alerts, reports, trends, forecasts) to environmental services, infection prevention personnel, and / or an electronic health / medical record system. If a contaminant is detected in the environment, appropriate personnel may automatically be alerted so that the contaminant can be eliminated / contained. The system may dynamically schedule the monitoring based on needs and ongoing changes in the environment, provide routing and work instructions to personnel, robots and / or cobots, and manage, maintain, and organize all information associated with the environmental monitoring so that information can be accessed, analyzed, and, if necessary, responded to, in real-time and / or in a timely manner, or where corrective actions need to be initiated as part of overall improvement plans.

Owner:LONZA SOLUTIONS AG

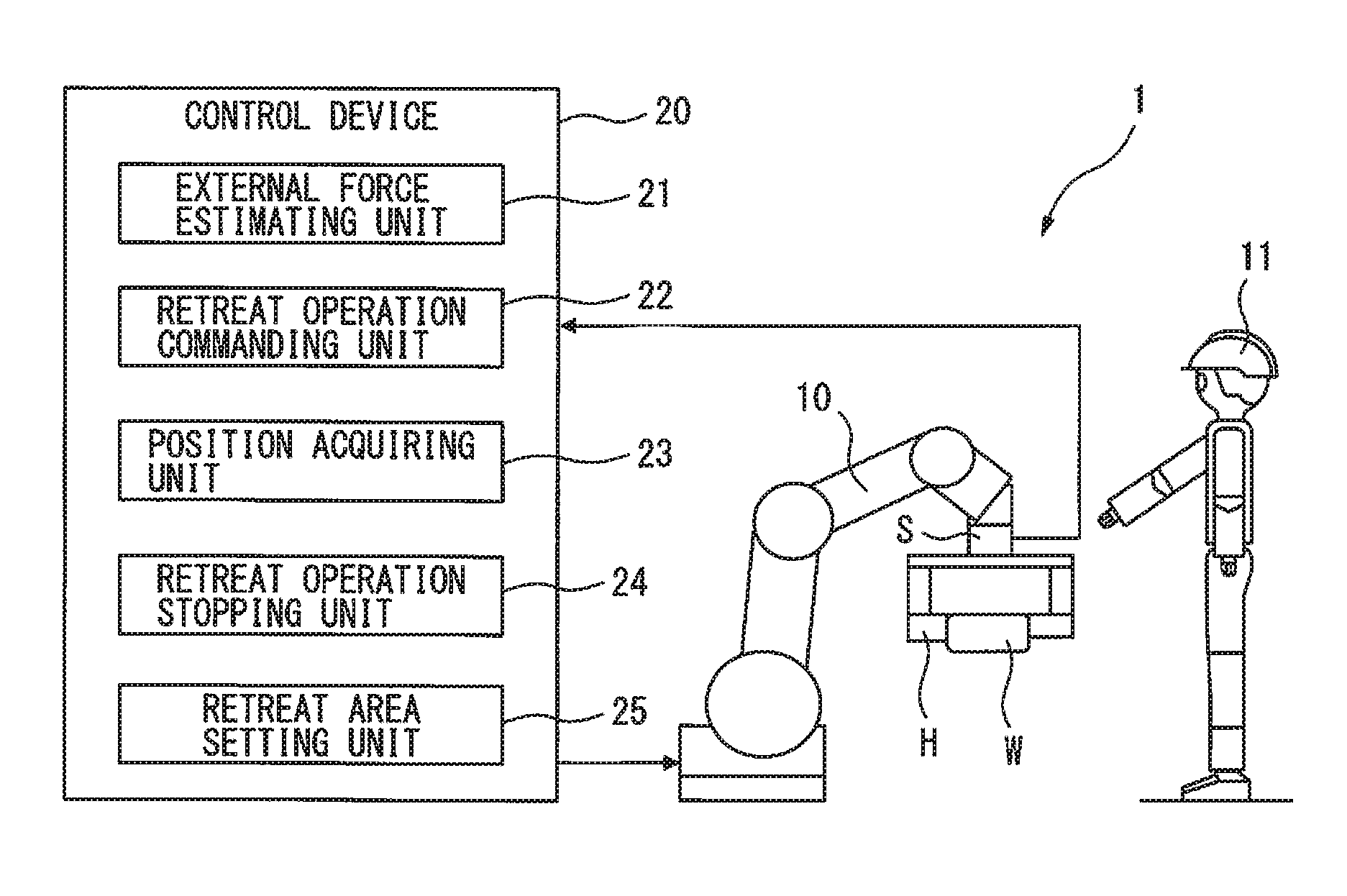

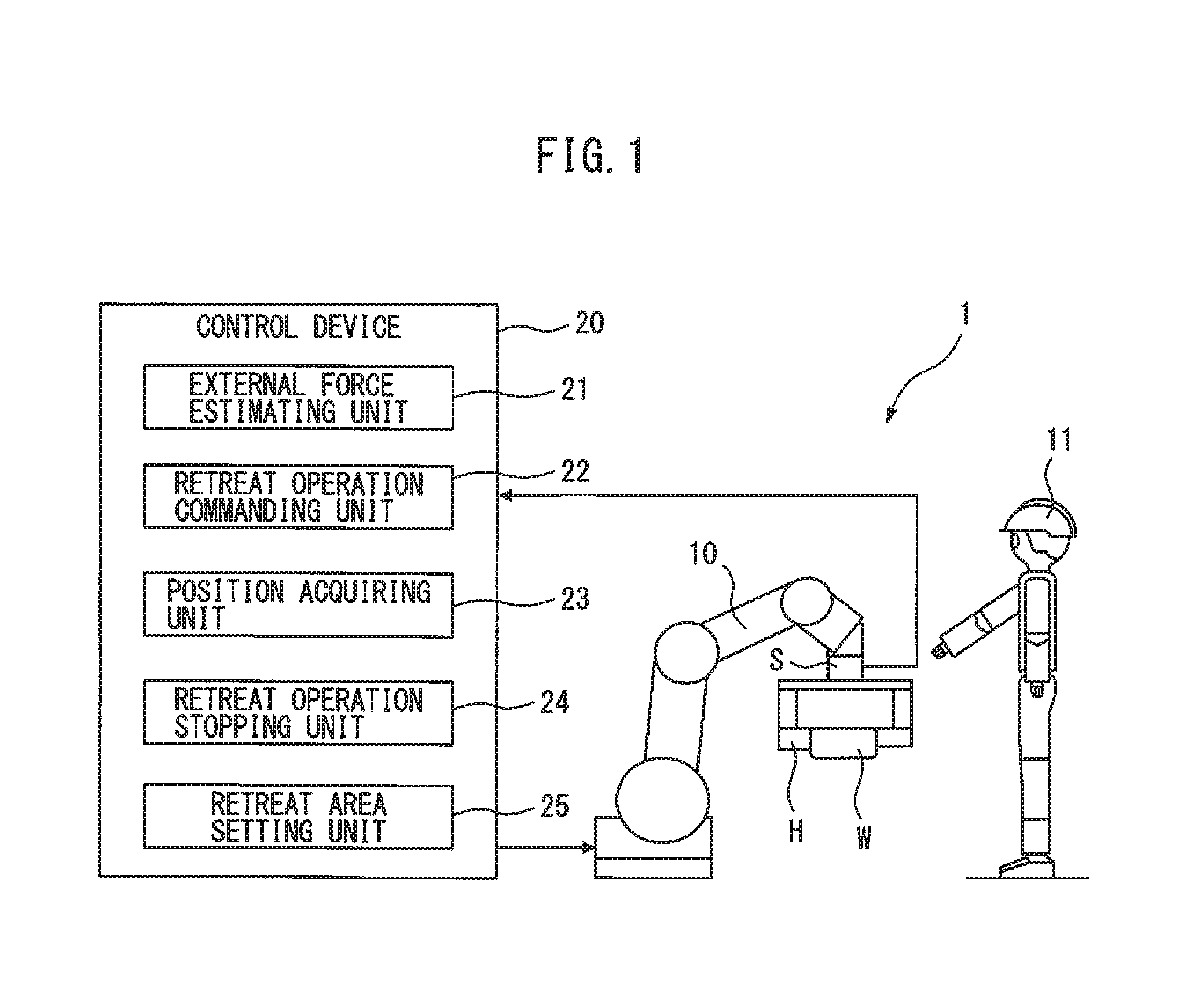

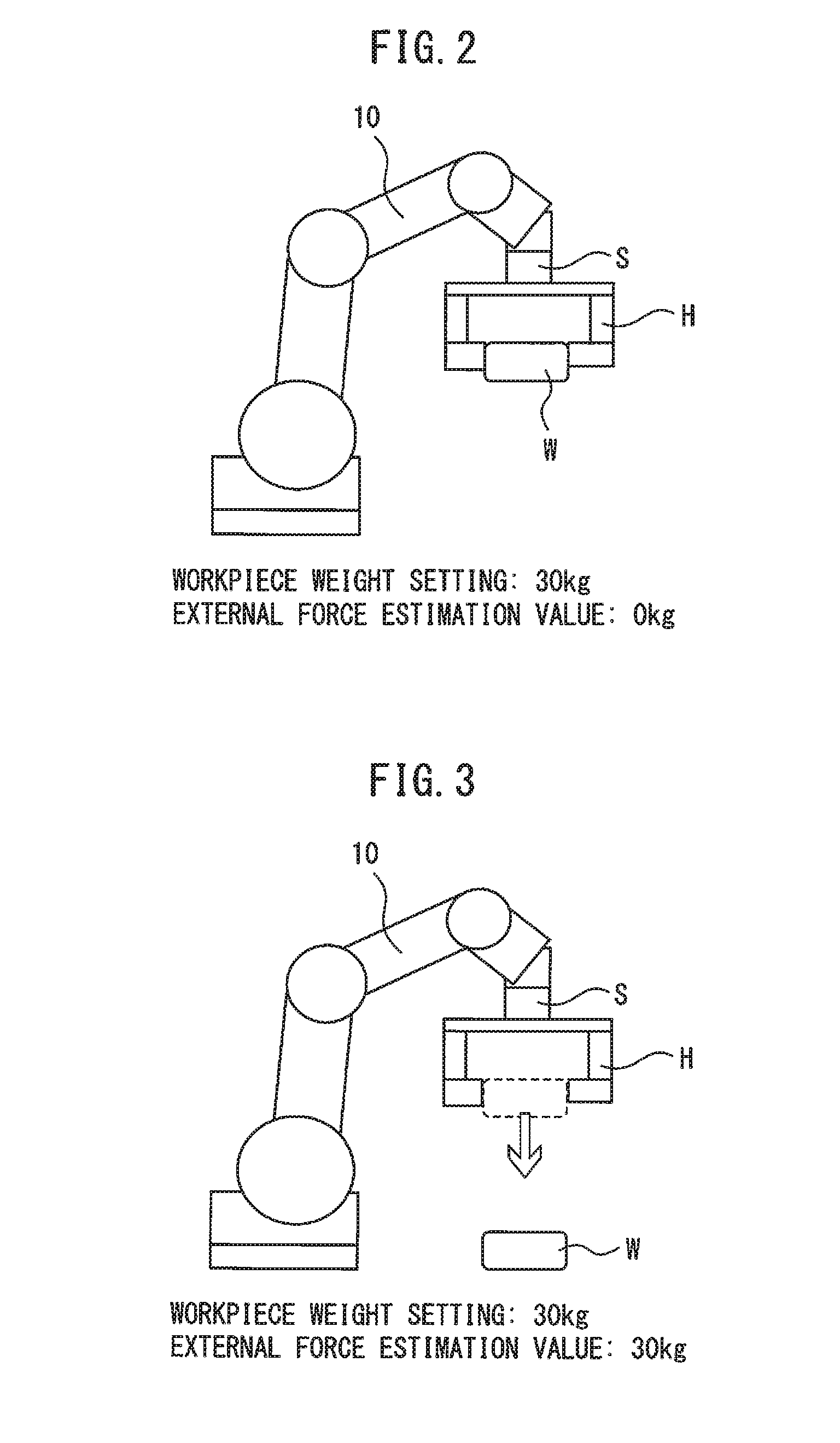

Human cooperation robot system in which robot is caused to perform retreat operation

ActiveUS20160243700A1Avoid it happening againStop retreat operationProgramme controlProgramme-controlled manipulatorRobotic systemsSimulation

A human cooperation robot system includes: an external force detecting unit that detects an external force acting on a robot; a retreat operation commanding unit that commands a retreat operation for causing the robot to be moved in a direction such that the external force is decreased when the external force detected by the external force detecting unit is larger than a first threshold value; a position acquiring unit that a current position of the robot; and a retreat operation stopping unit that stops the retreat operation when the current position of the robot acquired by the position acquiring unit departs from a retreat area.

Owner:FANUC LTD

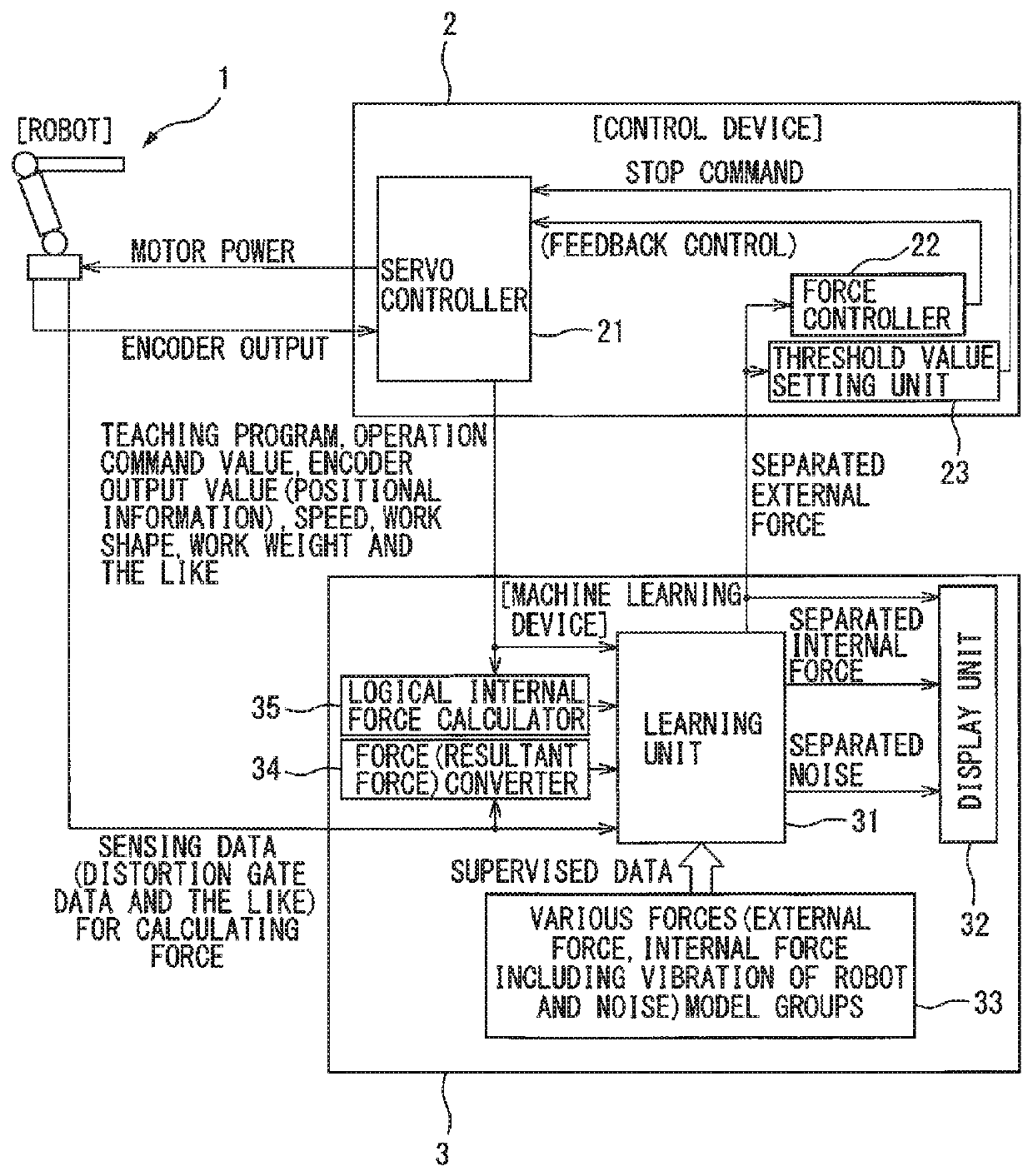

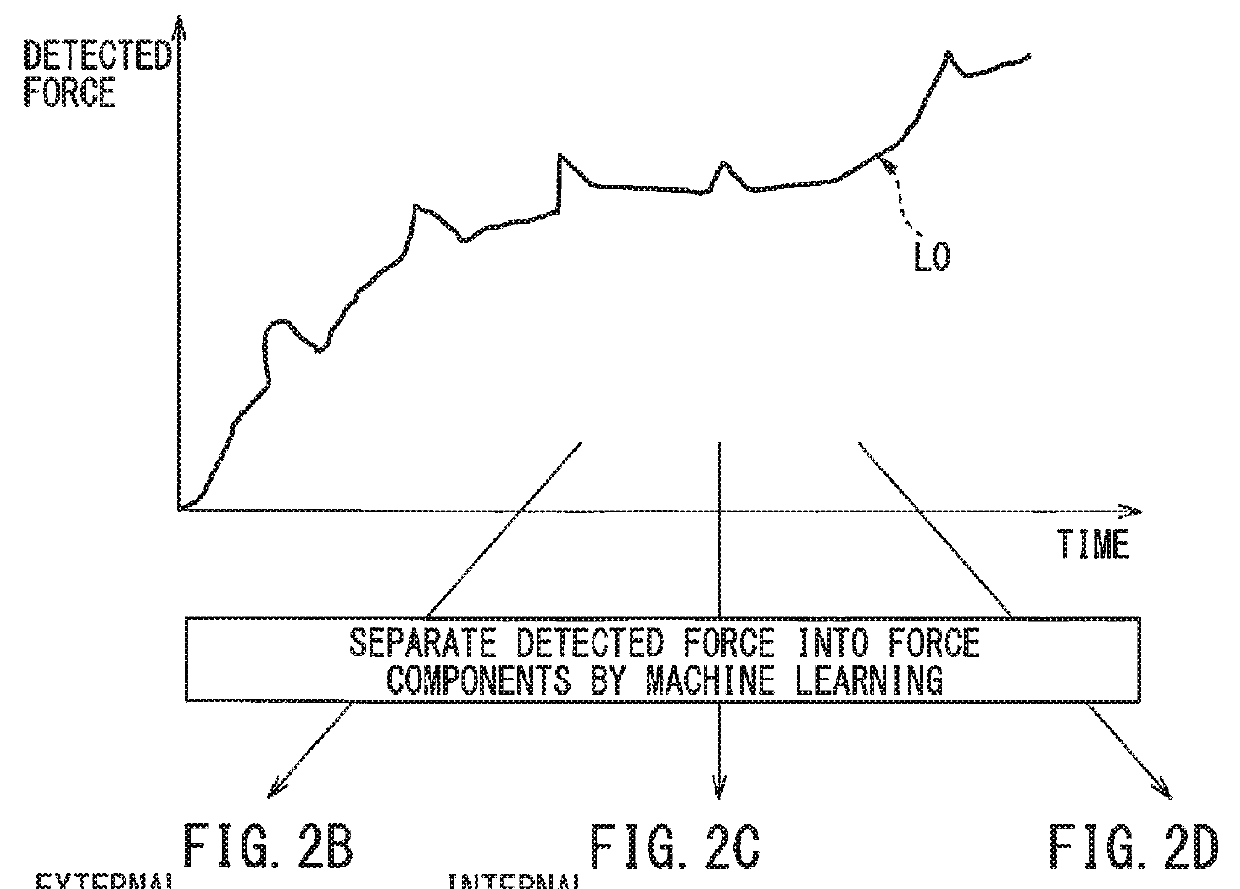

Human collaborative robot system having improved external force detection accuracy by machine learning

ActiveUS20180107174A1Programme controlProgramme-controlled manipulatorPattern recognitionSensing data

A human collaborative robot system having a function of detecting a force includes a human collaborative robot and a learning unit into which sensing data, internal data, and calculation data are input. The learning unit outputs a first force component applied to the human collaborative robot from outside, a second force component occurring in an operation of the human collaborative robot, and a third force component categorized as noise; and performs learning using supervised data in which inputs and correct labels obtained in advance are collected in pairs, wherein the correct labels of the supervised data are obtained by exerting a force on the human collaborative robot from outside, operating the human collaborative robot over a plurality of paths, and applying noise to the human collaborative robot, and the operation of the human collaborative robot is controlled based on the first force component output from the learning unit.

Owner:FANUC LTD

Tool exchange interface and control algorithm for cooperative surgical robots

A system and method for tool exchange during surgery for cooperatively controlled robots comprises a tool holder for receiving a surgical tool adapted to be held by a robot and a surgeon, a tool holding element for constraining downward motion of the tool while allowing low force removal of the surgical tool from the holder, a first sensor for detecting if the surgical tool is docked within the tool holder, and a selector for automatically selecting different movements or actions of the tool holder to be performed based upon information detected by the first sensor. The system and method of the present invention provides an advantage to an often slow moving cooperative robot, by increasing the speed by which the tool holder may move in the direction away from the patient.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

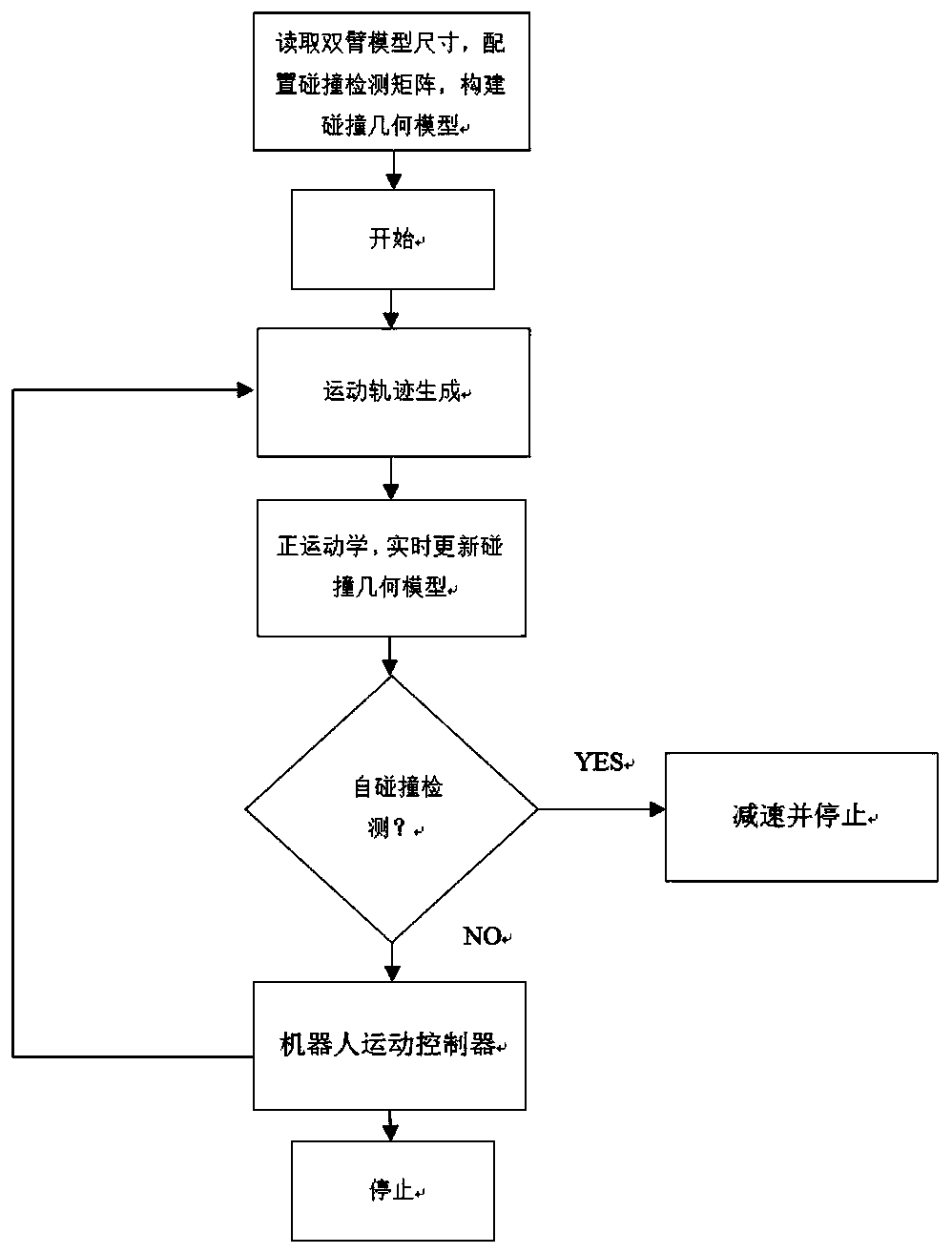

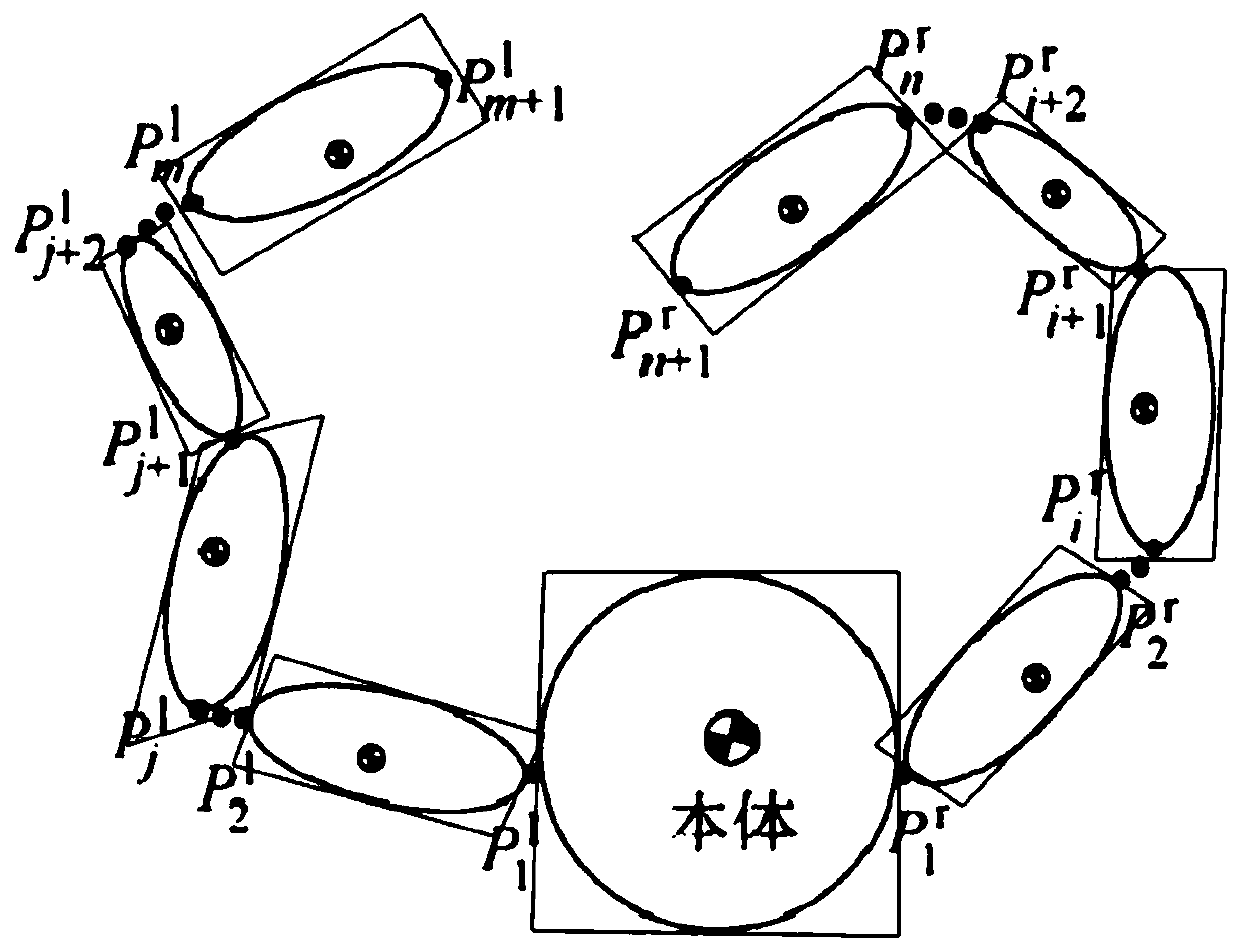

Double-arm self-collision detecting method and computer readable storage medium

ActiveCN111360824ACollision detection optimizationCollision detection is accurateProgramme-controlled manipulatorCollision detectionSimulation

The invention provides a double-arm self-collision detecting method and a computer readable storage medium. The double-arm self-collision detecting method utilizes a bundling box to perform rough collision detection, utilizes a network to perform precise collision detection, gives a task-stage motion plan for a double-arm collaborative robot, detects a collision condition among a left arm, a leftarm, a right arm and a body or among a right arm, a right arm and a body in a motion planning process of double arms; and a robot controller timely responses according to a collision feedback signal.The double-arm self-collision detecting method has the beneficial technical effect of enabling collision detection to be more optimized and more accurate.

Owner:SIASUN CO LTD

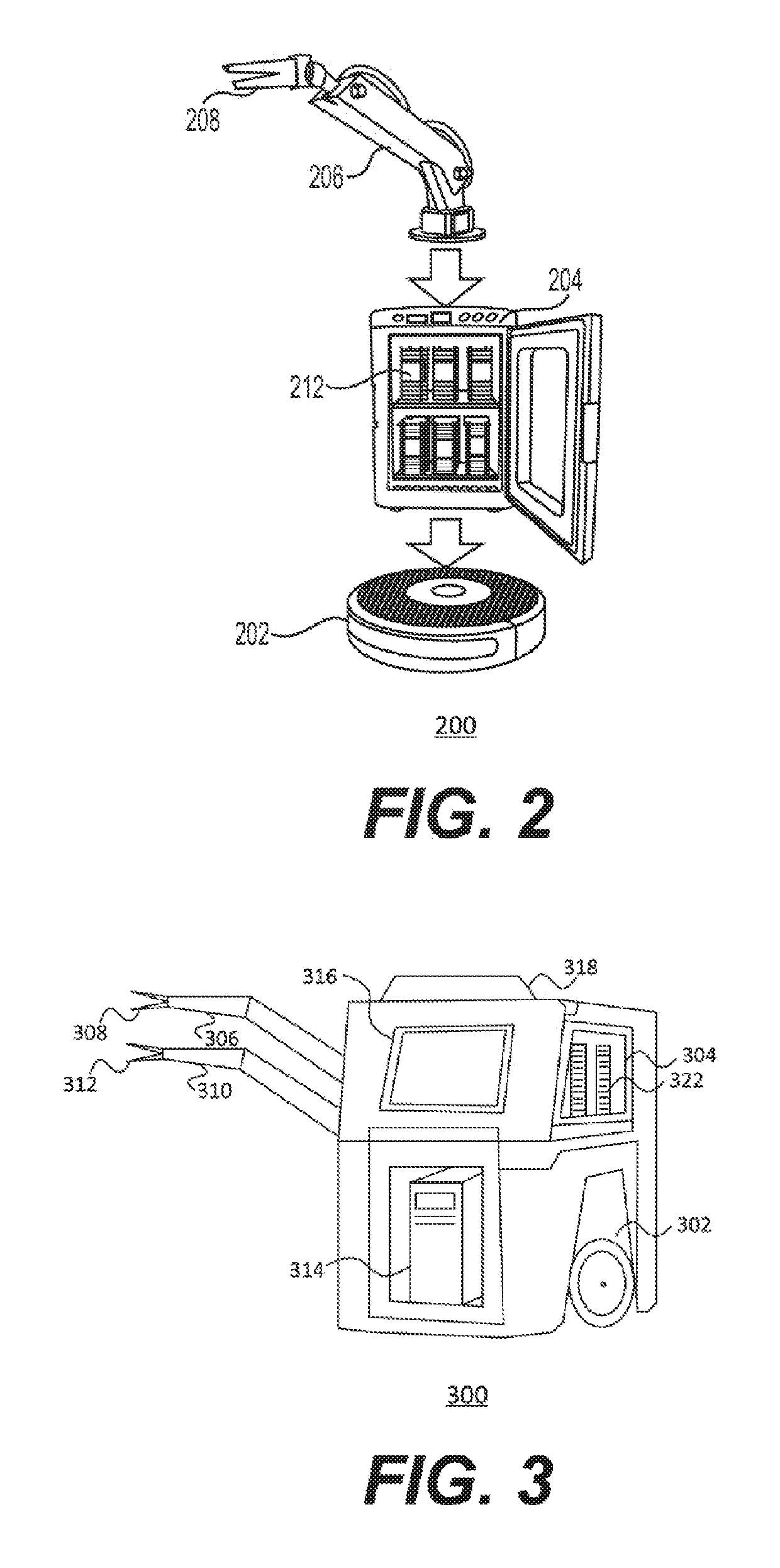

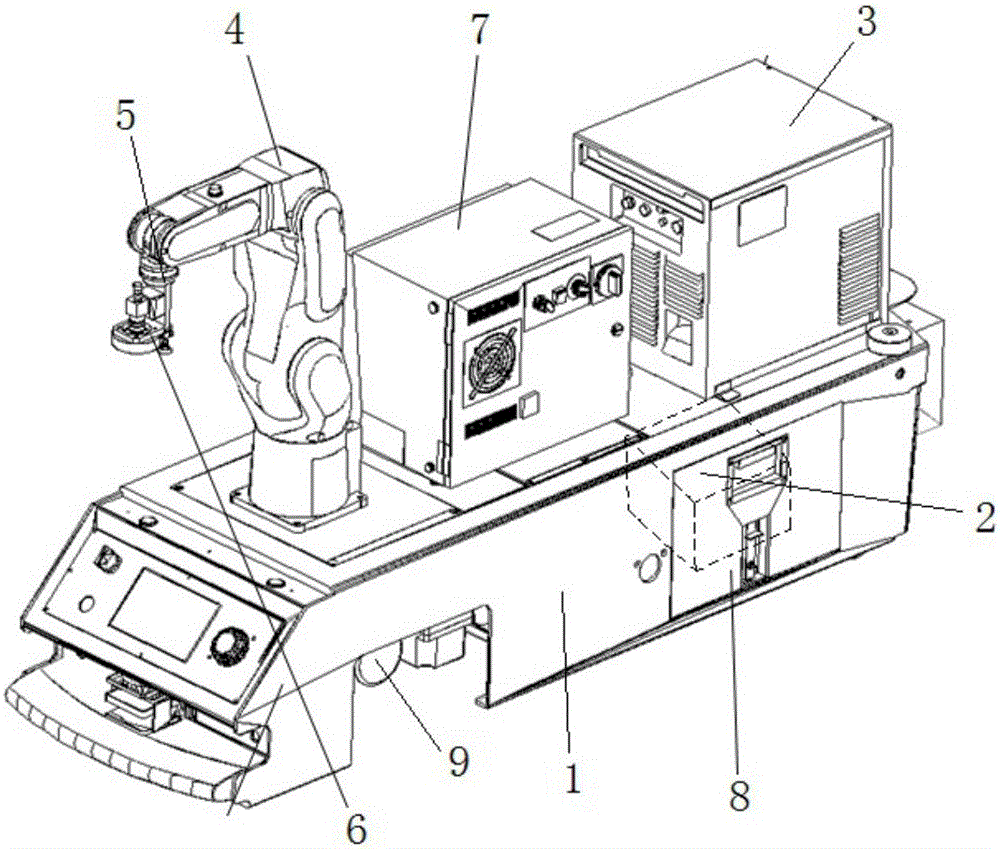

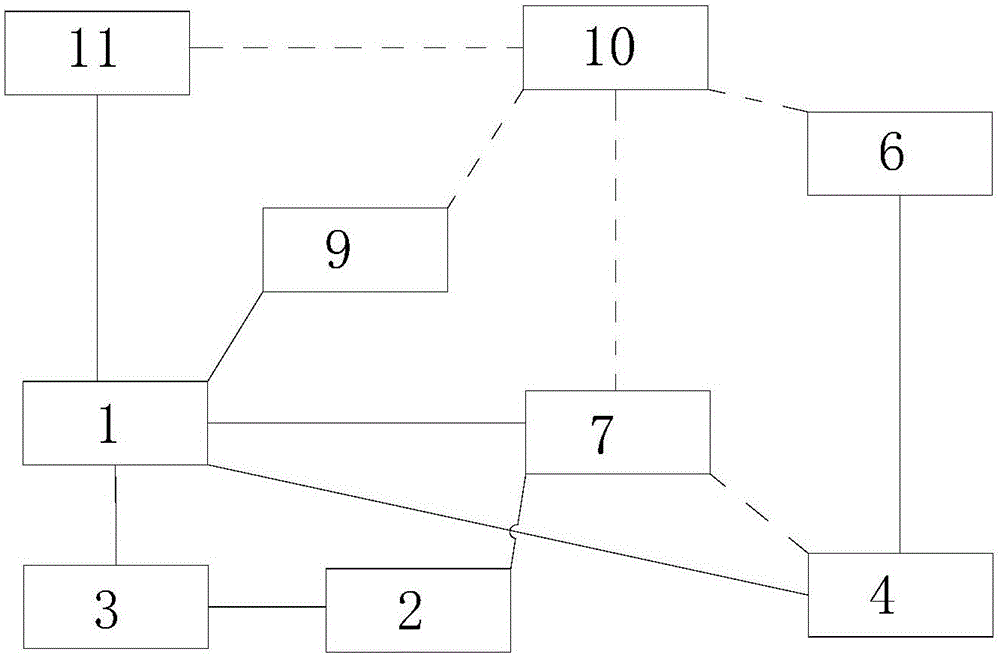

Collaborative robot with area moving capacity and working method of collaborative robot

InactiveCN105835029AAvoid personal safety hazardsHigh precisionProgramme-controlled manipulatorElectricityPower inverter

The invention discloses a collaborative robot with the area moving capacity and a working method of the collaborative robot. A battery and a power inverter for power inversion are arranged in an area moving trolley, and an industrial camera is mounted on a paw of a robot arm; the power inverter inverts a direct-current power source output by the battery into an alternating-current power source and transmits the alternating-current power source to a robot control cabinet; through the battery and the power inverter, the problem that in the running process of the trolley, continuous direct-current electricity and alternating-current electricity needed by robot motion need to be provided is solved; through an optical automatic guide device, the driving path of the trolley is guided, and the hidden danger of the trolley under the unmanned condition to personal safety of workers is avoided; due to use of the collaborative robot, the threads of the moving process of the robot to the personal injury are removed, and safety of the workers is ensured; and finally, through photographing of the industrial camera to an object to be grabbed, the deviation value between the grabbed to-be-grabbed object and the original position of the object is calculated, and the precision of relocating grabbing and carrying of the trolley is improved.

Owner:SHANGHAI FANUC ROBOTICS

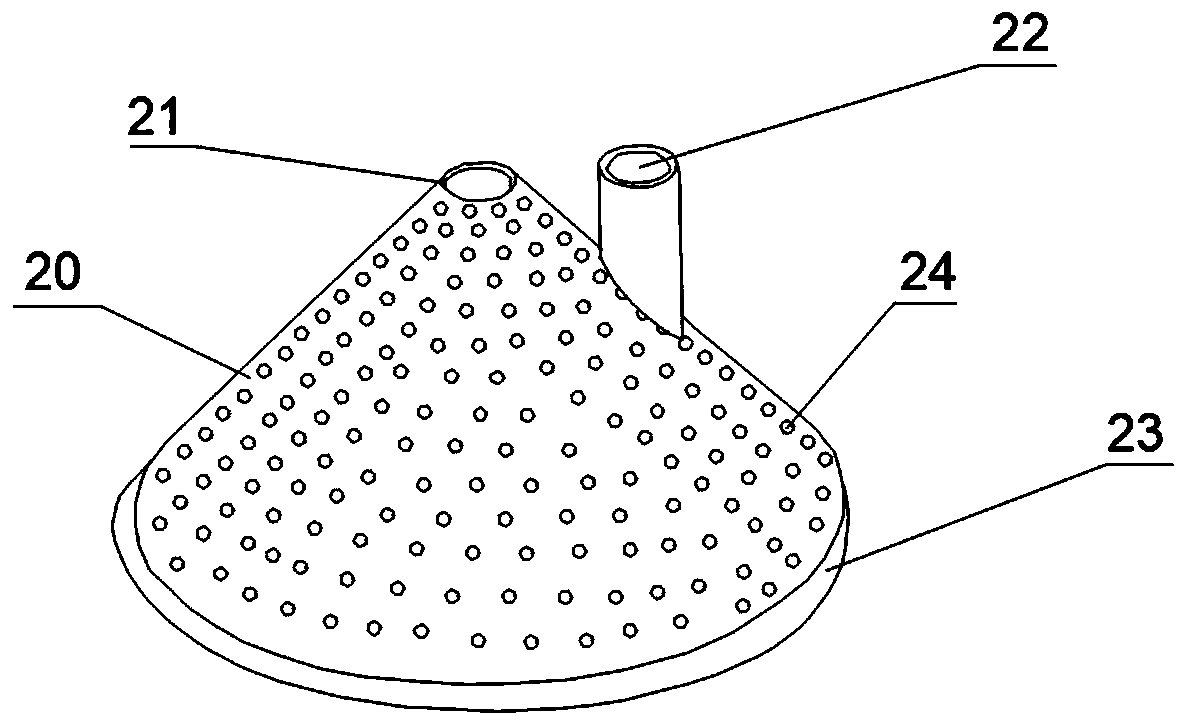

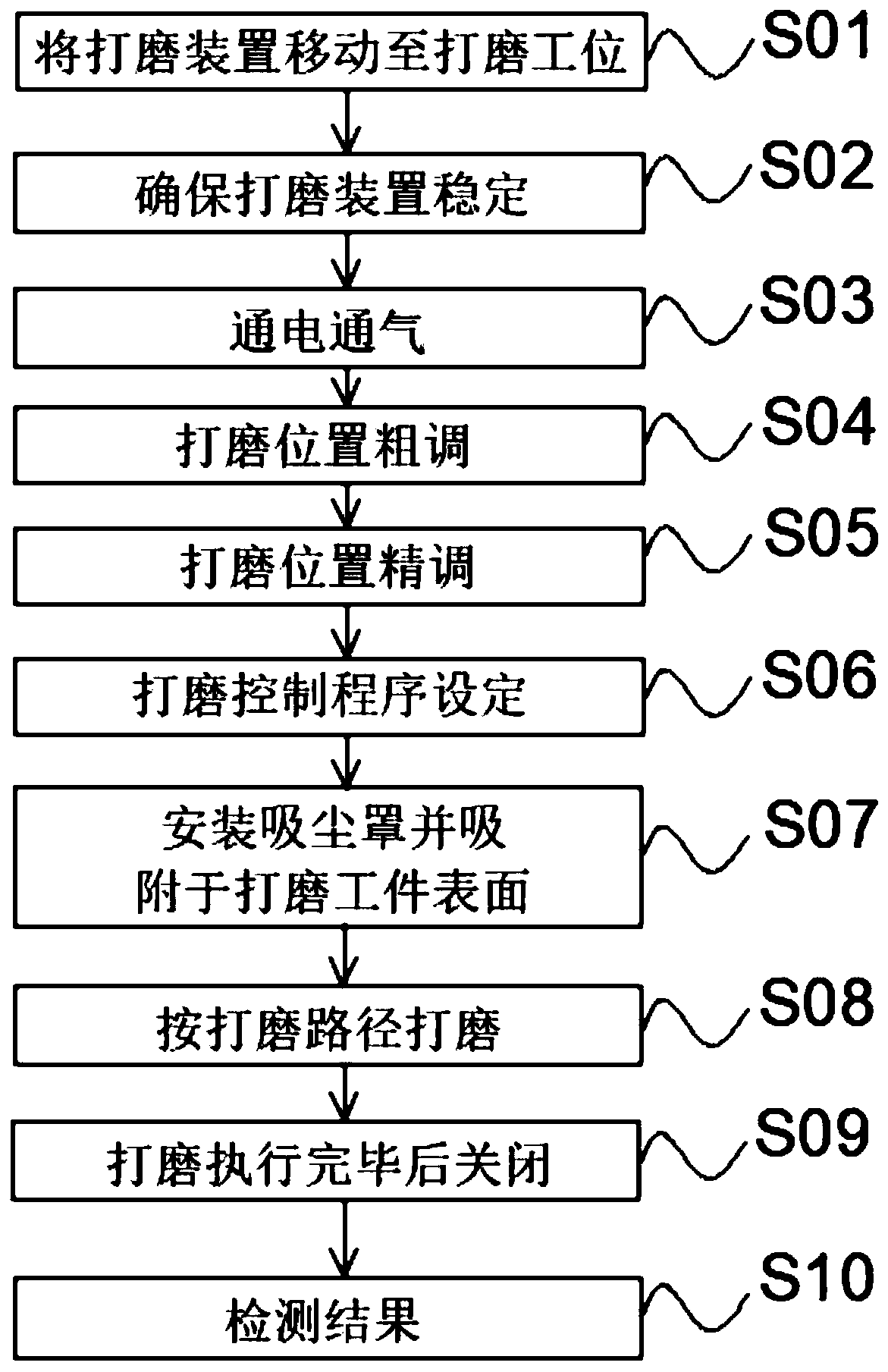

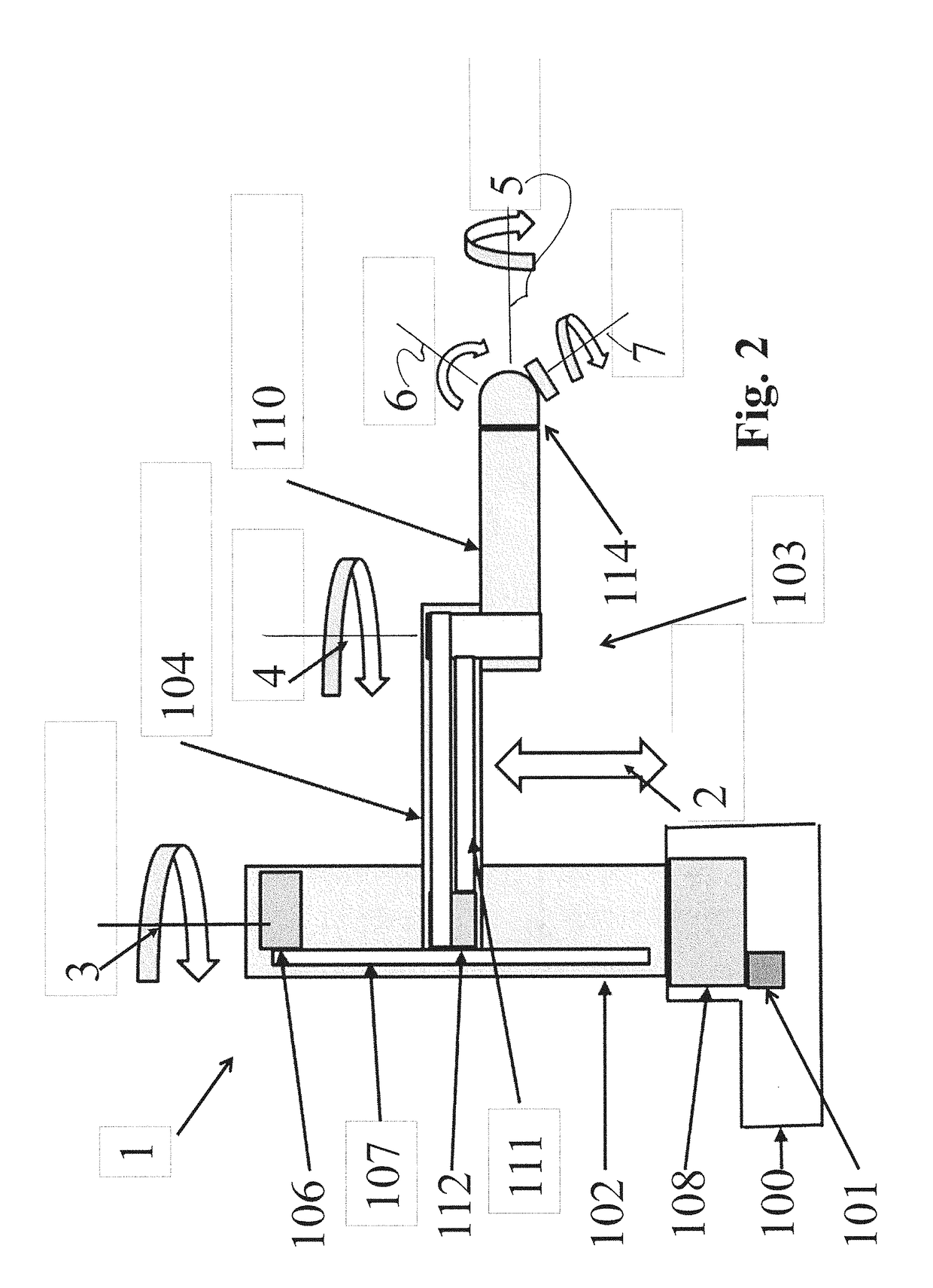

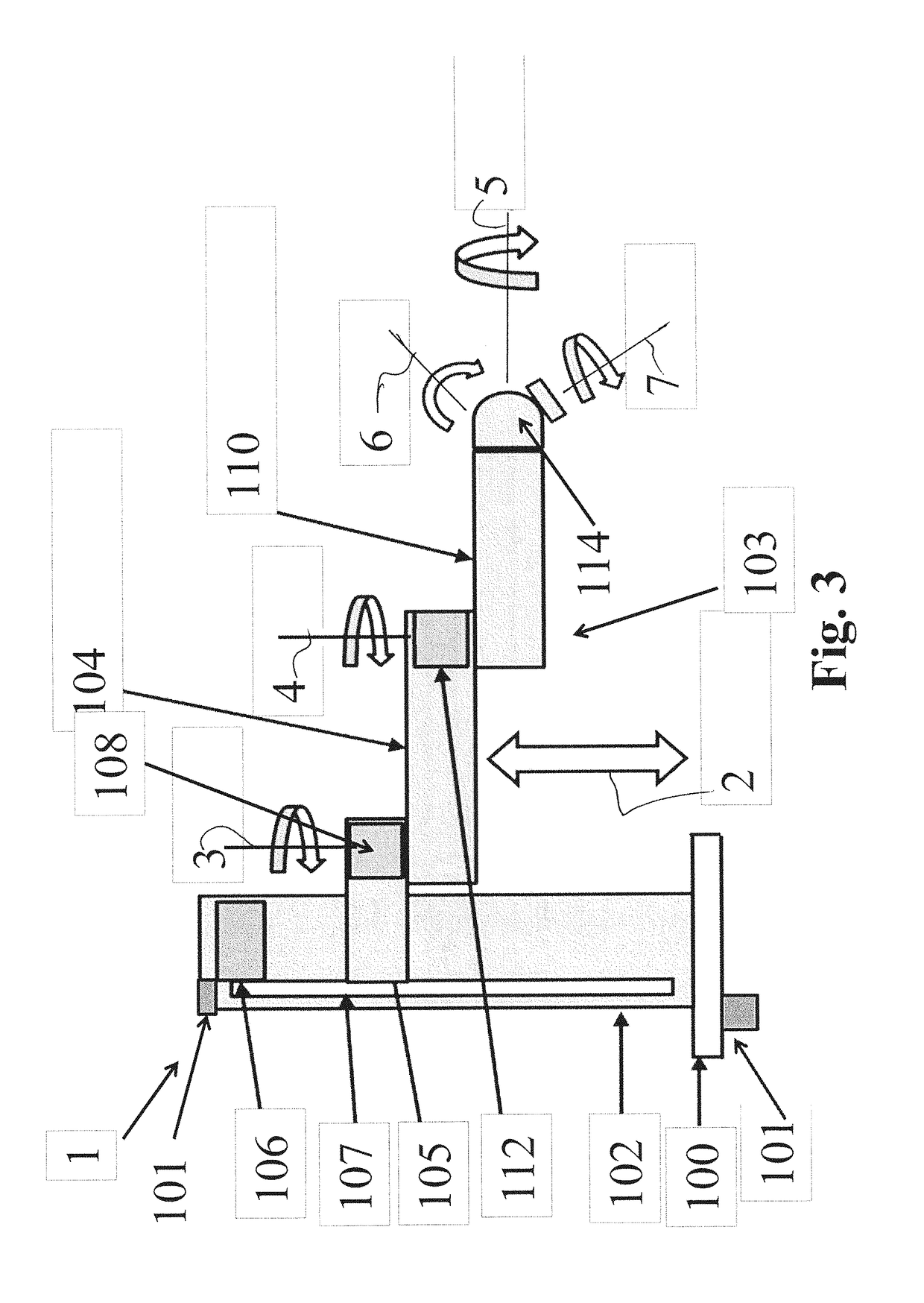

Aircraft repairing composite flexible automatic grinding device and grinding method

PendingCN111037415ASemi-automaticFully automatedGrinding feed controlGrinding machinesStructural engineeringPlastic film

The invention discloses an aircraft repairing composite flexible automatic grinding device and a grinding method, and relates to the technical field of composite grinding. The aircraft repairing composite flexible automatic grinding device comprises a movable platform, a collaborative robot, a floating force sensitive grinding head mechanism, a dust suction device and a control assembly. The collaborative robot comprises a six-axis light mechanical arm, a six-dimensional force sensor, a robot controller and a demonstrator. The floating force sensitive grinding head mechanism comprises a floating constant-force device, an air control main shaft, an automatic changing tool installing interface, and a tool handle with a grinding wheel and abrasive paper. The dust suction device comprises a dust suction host and a dust suction cover installed at the tail end of the six-axis light mechanical arm. The dust suction cover is of an umbrella-shaped transparent plastic thin film elastic structure. One-way air guide holes from outside to inside are evenly distributed in the outer surface of the dust suction cover. A rubber suction strip is arranged on the edge of the cover mouth of the dust suction cover. By means of the aircraft repairing composite flexible automatic grinding device, the semi-automatic or automatic grinding, excavating, polishing and other operation processes related to the composite repairing are realized, the manual operation intensity is reduced, the occupational health hazards are relieved, and the repairing quality is improved.

Owner:SHANGHAI HANGYI HI TECH DEV RES INST CO LTD

Collaborative robot

ActiveUS20180354135A1Increase speedReduced reflected inertiaProgramme controlProgramme-controlled manipulatorRotational axisFeedback control

A collaborative robot employs low ratio drives for three or more axes of movement, such as three primary axes. An arm assembly may be mounted to a support for movement along a vertical linear axis, and the arm assembly may include first and second arm links that are each rotatable about vertical axes, e.g., such that the arm links move in a horizontal plane. Low ratio drives may be used for movement along the vertical linear axis and the rotary axes for the first and second arm links. Feedforward and feedback control may be employed to control the movement of the arm assembly and arm links, and feedback torque components may be limited to 25% or less of the maximum drive torque.

Owner:BOOKS AUTOMATION US LLC +2

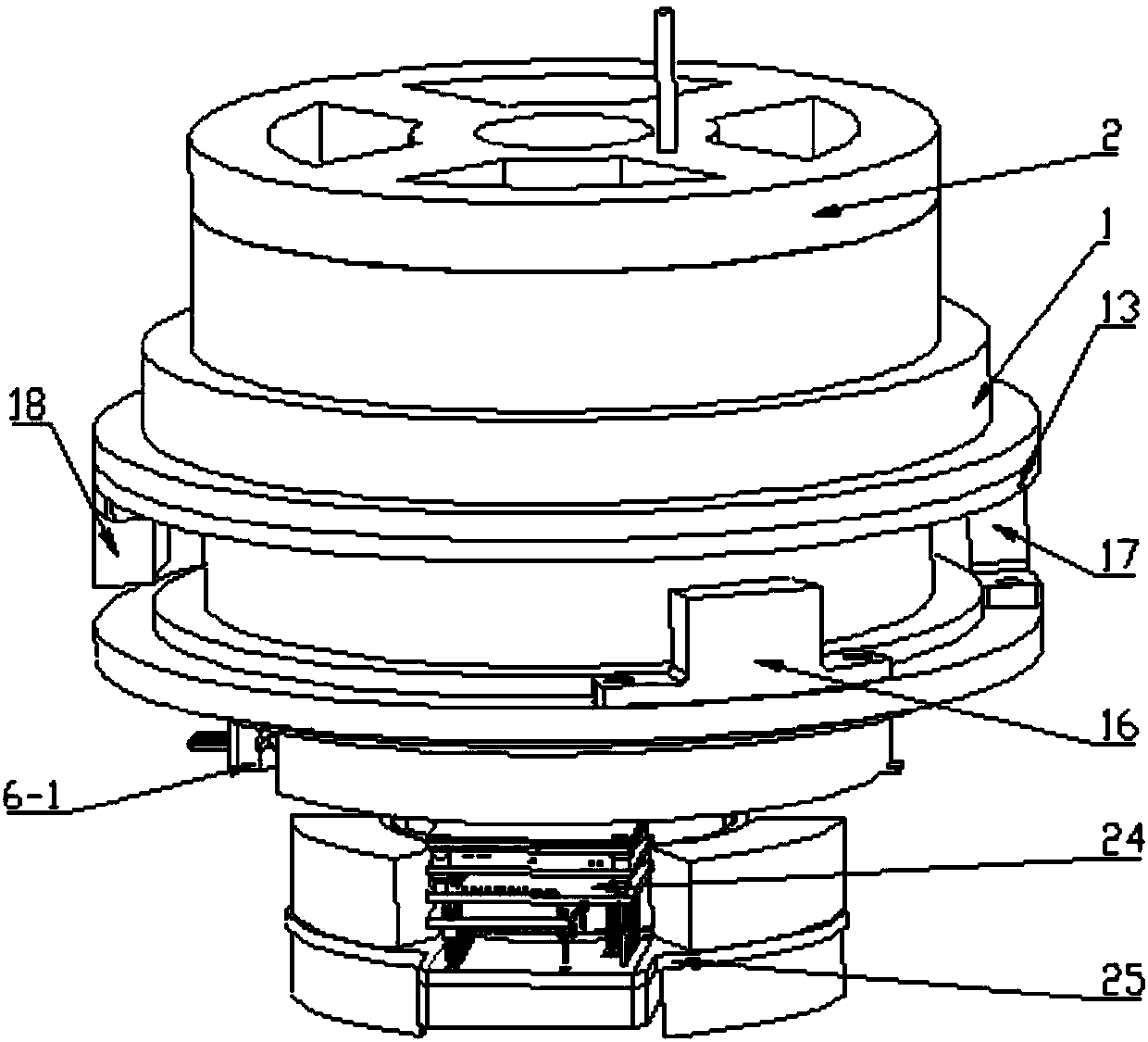

Collaborative robot joint with force perceiving function

The invention belongs to the technical field of robots, and particularly relates to a collaborative robot joint with a force perceiving function. An output flange, a torque sensor, a harmonic speed reducer, a frameless direct drive torque motor, an input flange and a wire penetrating pipe are included. The harmonic speed reducer and the frameless direct drive torque motor are contained in a cavityformed by the output flange and the input flange. The output flange and the input flange can oppositely rotate, and the harmonic speed reducer and the frameless direct drive torque motor sleeve the wire penetrating pipe. The output end of the frameless direct drive torque motor is connected with the wire penetrating pipe through the harmonic speed reducer, and the wire penetrating pipe is connected with the output flange through the torque sensor. The collaborative robot joint has the force perceiving function, a collaborative robot composed of the collaborative robot joint can work in cooperation with people in the half structure environment, and the collaborative robot joint has the advantages that the high-precision force perceiving function is achieved, the structure is compact, rigidity is high, and expandability is good.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

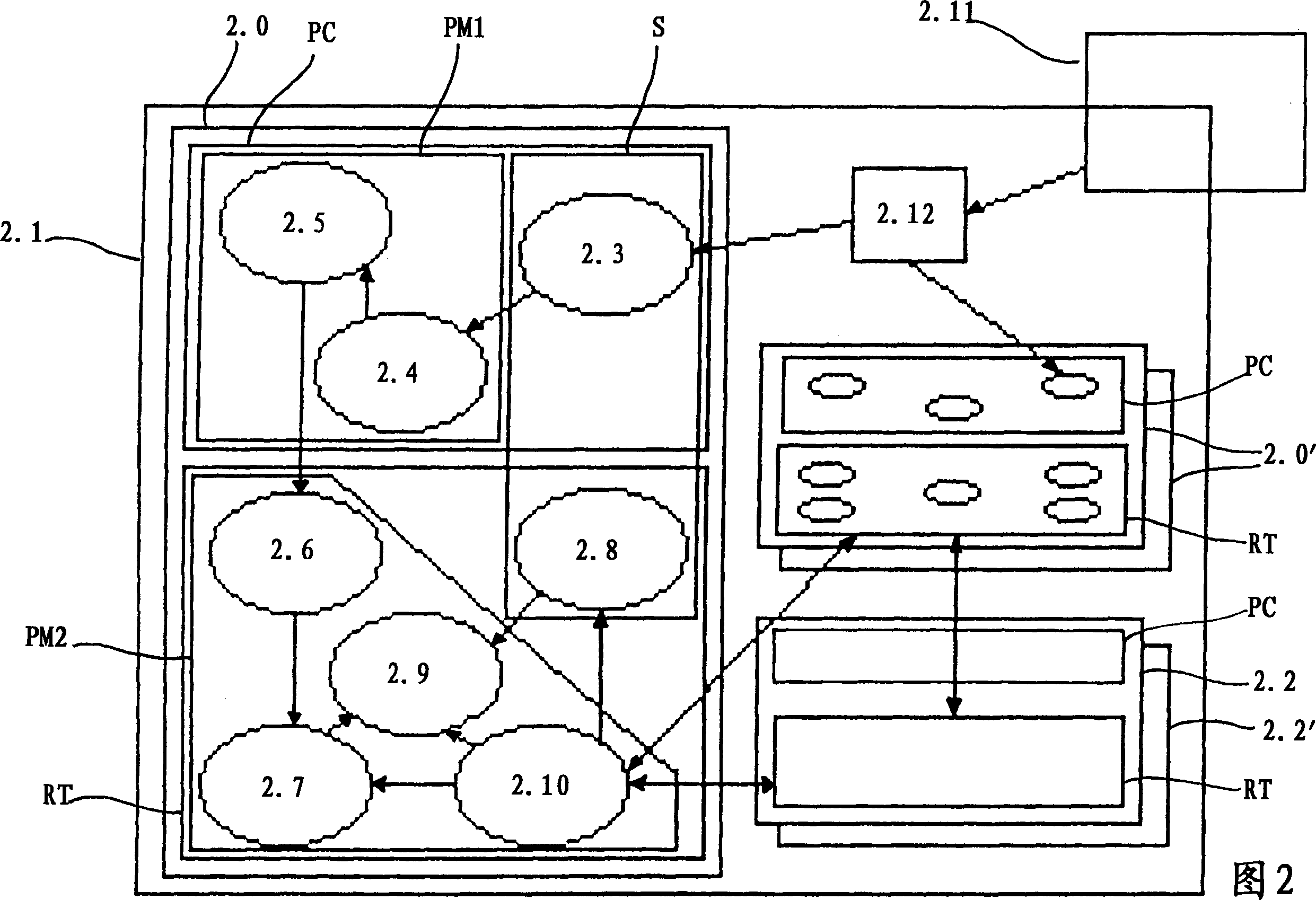

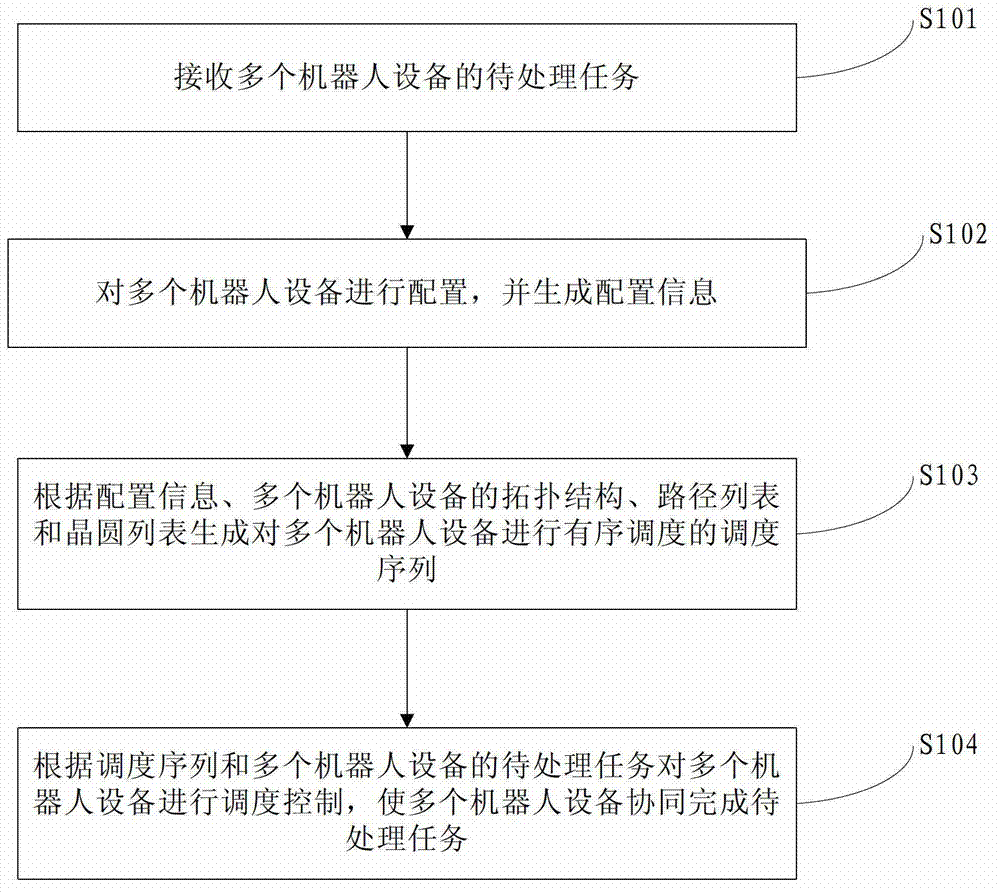

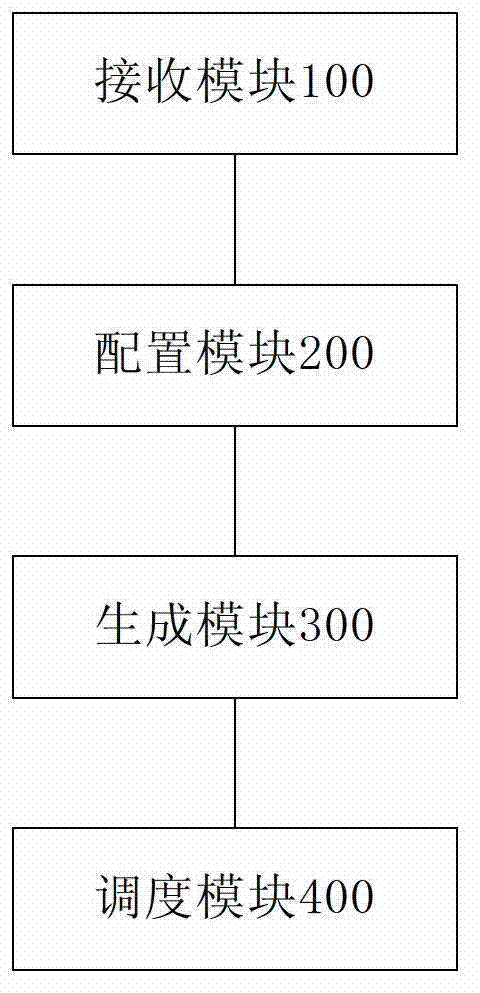

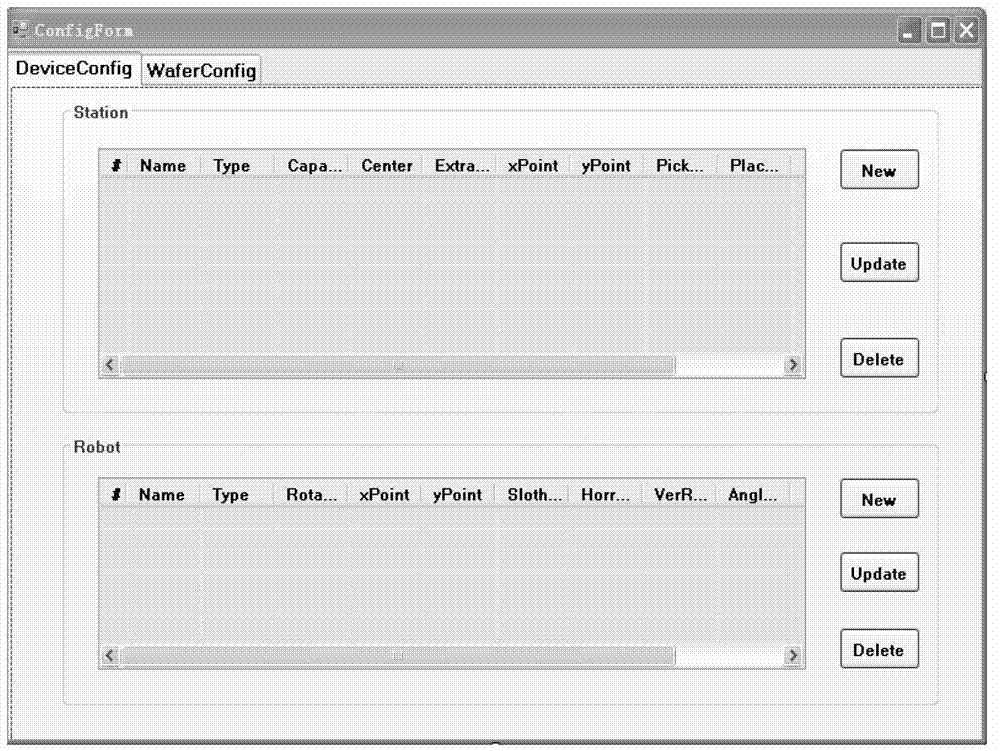

Method and system for scheduling multiple robot equipment cooperated for transferring wafers

ActiveCN103399543AFlexible configurationImprove work efficiencyTotal factory controlProgramme total factory controlSimulationCollaborative robotics

The invention provides a method and a system for scheduling multiple robot equipment cooperated by transferring wafers. The method comprises the following steps of receiving tasks to be processed of the multiple robot equipment; configuring the multiple robot equipment and generating configuration information; generating a scheduling sequence for sequentially scheduling the multiple robot equipment according to the configuration information, a topological structure of the multiple robot equipment, a path list and a wafer list; carrying out scheduling control on the multiple robot equipment according to the scheduling sequence and the tasks to be processed of the multiple robot equipment to enable the multiple robot equipment to cooperatively finish the tasks to be processed. According to the method in the embodiment of the invention, the flexible configuration of the characteristics and the production path of the multiple robot equipment cooperated for transferring the wafers as well as the required information for processing the wafers is realized; meanwhile, the working efficiency of the robot equipment is increased.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com